OPERATION AND PARTS MANUAL

WHISPERWATT™ SERIES

MODEL DCA150USJ3CAN

60HZ GENERATOR

(JOHN DEERE 6068HF285 DIESEL ENGINE)

PARTS LIST NO. M3874400114

Revision #1 (05/19/15)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

FUEL AND CHEMICAL EXPOSURE WARNINGS

Diesel engine exhaust and some of

its constituents are know to cause

cancer, birth defects and other

reproductive harm.

PAGE 2 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

REPORTING SAFETY DEFECTS

If you believe that your vehicle has a defect that could cause a crash or could

cause injury or death, you should immediately inform the National Highway

Traffi c Safety Administration (NHTSA) in addition to notifying Multiquip Inc. at

1-800-421-1244.

If NHTSA receives similar complaints, it may open an investigation, and if it

fi nds that a safety defect exists in a group of vehicles, it may order a recall and

remedy campaign. However, NHTSA cannot become involved in individual

problems between you, your dealer, or Multiquip Inc.

To contact NHTSA, you may either call the Vehicle Safety Hotline toll-free

at 1-888-327-4236 (TTY: 1-800-424-9153), go to http://www.safercar.gov; or

write to:

Administrator

NHTSA

400 Seventh Street, SW.,

Washington, DC 20590

You can also obtain information about motor vehicle safety from

http://www.safercar.gov.

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 3

TABLE OF CONTENTS

DCA150USJ3CAN 60 HzGenerator

Fuel And Chemical Exposure Warnings .................. 2

Reporting Safety Defects ......................................... 3

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Safety Information .............................................. 6-11

Specifications ........................................................ 12

Dimensions ............................................................ 13

Installation ........................................................ 14-15

General Information ............................................... 16

Major Components ................................................ 17

Diagnostic Display ............................................ 18-34

Generator Control Panel ........................................ 35

Engine Operating Panel....................................36-37

Output Terminal Panel Familiarization .............. 38-40

Load Application .................................................... 41

Generator Outputs ................................................. 42

Generator Outputs/Gauge Reading ....................... 43

Output Terminal Panel Connections ................. 44-45

3Ø 600 Vac Auto Transformer Connections ........... 46

Inspection/Setup ............................................... 47-50

Generator Start-Up Procedure ........................ 51-52

Generator Shut-Down Procedures ........................ 53

Maintenance ..................................................... 54-57

Trailer Maintenance .......................................... 58-62

Trailer Wiring Diagram ........................................... 63

Generator Wiring Diagram ..................................... 64

3Ø 600 VAC Auto Transformer Wiring Diagram ..... 65

Engine Wiring Diagram .......................................... 66

Battery Charger Wiring Diagram ........................... 67

Heater Element Wiring Diagram ............................ 68

Troubleshooting (Generator) .................................. 69

Troubleshooting (Engine Controller) ...................... 70

Explanation of Code in Remarks Column.............. 72

Suggested Spare Parts ......................................... 73

Component Drawings

Generator Assembly ......................................... 74-75

Control Box Assembly ......................................76-79

Engine And Radiator Assembly ........................ 80-83

Output Terminal Assembly ................................ 84-87

Battery Assembly.............................................. 88-89

Muffler Assembly .............................................. 90-91

Fuel Tank Assembly .......................................... 92-93

Enclosure (1) Assembly .................................... 94-97

Enclosure (2) Assembly .................................. 98-101

Rubber Seals Assembly. ............................... 102-103

Battery Charger Assembly (Option) ............ 104-105

3Ø 600 Vac Transformer Assembly (Option) 106-07

Heating Element Assembly (Option) .......... 108-109

Nameplate And Decals Assembly ............... 110-115

Terms And Conditions Of Sale — Parts .............. 116

NOTICE

Specifications are subject to change without notice.

PAGE 4 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

PARTS ORDERING PROCEDURES

www.multiquip.com

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

parts@multiquip.

To obtain an MQ Account, contact your

Effective:

, 2006

Choose from three easy options:

January 1

st

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specification Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

and Password, E-mail us at:

com.

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 5

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Tr uck

■ Ground

■ Next Day

■ Second/Third Day

SAFETY INFORMATION

Do not operate or service the equipment before reading the

entire manual. Safety precautions should be followed at all

times when operating this equipment. Failure to read and

understand the safety messages and operating instructions

could result in injury to yourself and others.

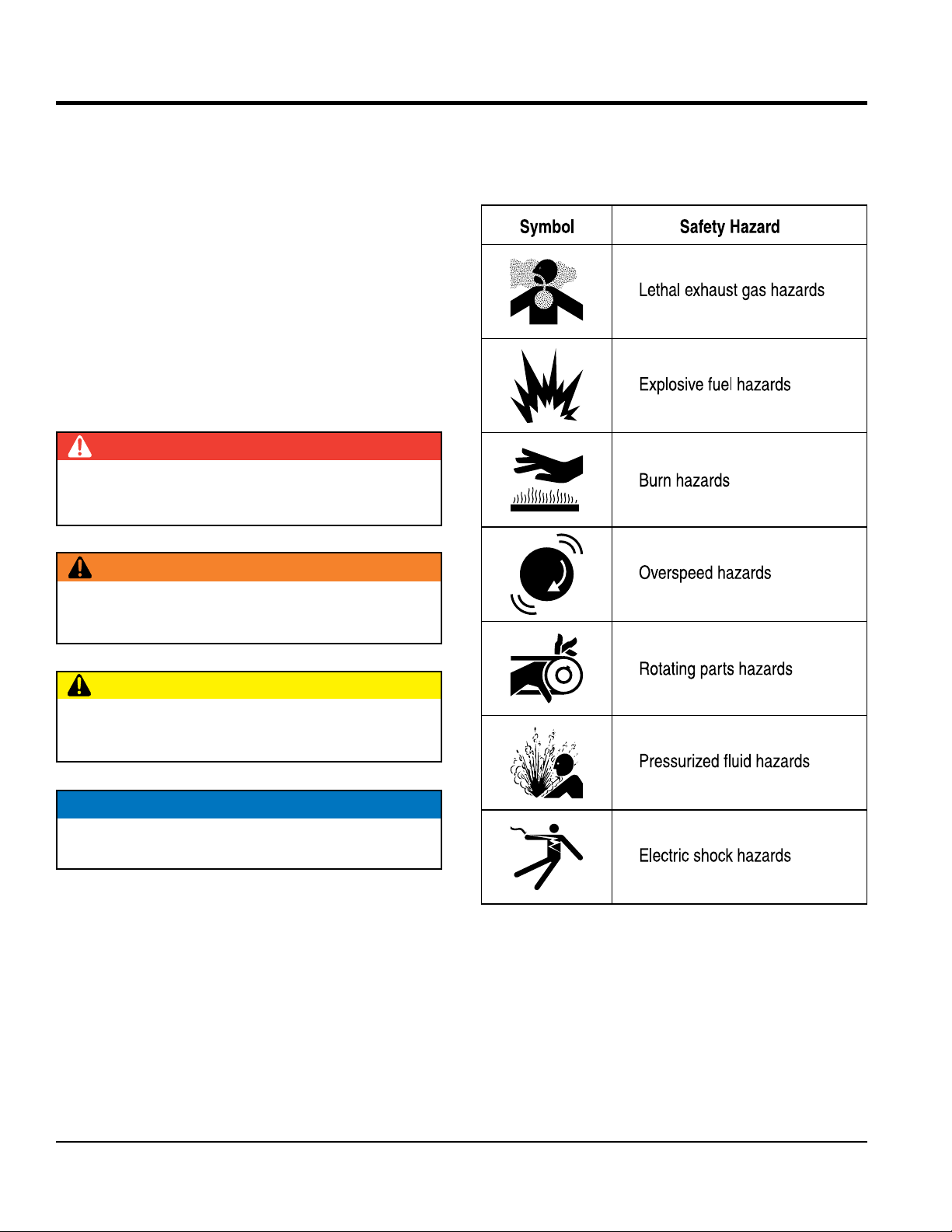

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION

SAFETY SYMBOLS

Potential hazards associated with the operation of this

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

or NOTICE.

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

PAGE 6 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

SAFETY INFORMATION

GENERAL SAFETY

NEVER use accessories or attachments that are not

recommended by MQ Power for this equipment. Damage

Also, know the

and

This information will be invaluable in

emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

lubricate components or attempt service on a

Fix damage to machine and replace any broken parts

store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the infl uence of

drugs or alcohol.

ALWAYS check the equipment for loosened threads or

bolts before starting.

DO NOT use the equipment for any purpose other than

its intended purposes or applications.

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS know the location of the nearest

phone or keep a phone on the job site.

phone numbers of the nearest ambulance, doctor

fi re department.

the case of an emergency.

GENERATOR SAFETY

DANGER

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

NOTICE

This equipment should only be operated by trained and

qualifi ed personnel 18 years of age and older.

Whenever necessary, replace nameplate, operation and

safety decals when they become diffi cult read.

Manufacturer does not assume responsibility for any

accident due to equipment modifi cations. Unauthorized

equipment modifi cation will void all warranties.

NEVER disconnect any

devices will void all warranties.

CAUTION

NEVER

running machine.

NOTICE

ALWAYS ensure generator is on level ground before use.

ALWAYS keep the machine in proper running condition.

immediately.

ALWAYS

out of the reach of children and unauthorized personnel

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 7

ENGINE SAFETY

NOTICE

run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

Wet stacking is a common problem with diesel engines

which are operated for extended periods with light or

no load applied. When a diesel engine operates without

suffi cient load (less than 40% of the rated output), it will

not operate at its optimum temperature. This will allow

unburned fuel to accumulate in the exhaust system,

which can foul the fuel injectors, engine valves and

exhaust system, including turbochargers, and reduce

it must be able to provide fuel and air in the proper ratio

and at a high enough engine temperature for the engine

Wet stacking does not usually cause any permanent

damage and can be alleviated if additional load is

applied to relieve the condition. It can reduce the system

performance and increase maintenance. Applying an

increasing load over a period of time until the excess

fuel is burned off and the system capacity is reached

usually can repair the condition. This can take several

State Health Safety Codes and Public Resources

Codes specify that in certain locations, spark arresters

must be used on internal combustion engines that use

hydrocarbon fuels. A spark arrester is a device designed

to prevent accidental discharge of sparks or fl ames

from the engine exhaust. Spark arresters are qualifi ed

and rated by the United States Forest Service for this

purpose. In order to comply with local laws regarding

spark arresters, consult the engine distributor or the

SAFETY INFORMATION

DANGER

The engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this equipment

requires an adequate free

fl ow of cooling air. NEVER

operate this equipment in

any enclosed or narrow area

where free fl ow of the air is

restricted. If the air fl ow is

restricted it will cause injury to people and property and

serious damage to the equipment or engine.

WARNING

DO NOT place hands or fingers inside engine

compartment when engine is running.

NEVER operate the engine with heat shields or

guards removed.

Keep fi ngers, hands hair and clothing away

from all moving parts to prevent injury.

NEVER

frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

the operating performance.

In order for a diesel engine to operate at peak effi ciency,

to completely burn all of the fuel.

DO NOT remove the radiator cap while the

engine is hot. High pressure boiling water

will gush out of the radiator and severely

scald any persons in the general area of

the generator.

DO NOT remove the coolant drain plug while the engine

is hot. Hot coolant will gush out of the coolant tank and

severely scald any persons in the general area of the

generator.

DO NOT remove the engine oil drain plug while the

engine is hot. Hot oil will gush out of the oil tank and

severely scald any persons in the general area of the

generator.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

hours to burn off the accumulated unburned fuel.

local Health and Safety Administrator.

PAGE 8 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

SAFETY INFORMATION

FUEL SAFETY

TOWING SAFETY

Make sure the hitch and coupling of the towing vehicle

are rated equal to, or greater than the trailer “gross

NEVER

Check the tire air pressure on both towing vehicle and

Trailer tires should be infl ated to 50 psi cold.

safety

attach trailer’s safety chains to towing

make sure the vehicle and trailer directional,

backup, brake and trailer lights are connected and

• Secure portable power cables in cable tray with tie

unless

posted otherwise. Recommended off-road towing is not to

Avoid sudden stops and starts. This can cause skidding,

or jack-knifi ng. Smooth, gradual starts and stops will

Trailer should be adjusted to a level position at all times

Raise and lock trailer wheel stand in up position when

rolling

underneath the trailer’s bumper

Use the trailer’s swivel jack to adjust the trailer height to

DANGER

DO NOT start the engine near spilled fuel or combustible

fl uids. Diesel fuel is extremely fl ammable and its vapors

can cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

ALWAYS use extreme caution when working with

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DO NOT overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

DO NOT smoke around or near the

equipment. Fire or explosion could result

from fuel vapors or if fuel is spilled on a

hot engine.

CAUTION

Check with your local county or state safety

towing regulations, in addition to meeting

Department of Transportation (DOT)

Safety Towing Regulations, before towing

your generator.

Refer to MQ Power trailer manual for additional safety

information.

In order to reduce the possibility of an accident while

transporting the generator on public roads, ALWAYS

make sure the trailer that supports the generator and

the towing vehicle are mechanically sound and in good

operating condition.

ALWAYS shutdown engine before transporting

vehicle weight rating.”

ALWAYS inspect the hitch and coupling for wear.

tow a trailer with defective hitches, couplings, chains, etc.

trailer.

Also check the tire tread wear on both vehicles.

ALWAYS make sure the trailer is equipped with a

chain.

ALWAYS properly

vehicle.

ALWAYS

working properly.

DOT Requirements include the following:

• Connect and test electric brake operation.

wraps.

The maximum speed for highway towing is 55 MPH

exceed 15 MPH or less depending on type of terrain.

improve towing.

Avoid sharp turns to prevent rolling.

when towing.

towing.

Place chock blocks underneath wheel to prevent

while parked.

Place support blocks

to prevent tipping while parked.

a level position while parked.

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 9

ELECTRICAL SAFETY

DANGER

Power Cord/Cable Safety

Make sure power cables are securely connected to the

generator’s output receptacles. Incorrect connections

may cause electrical shock and damage to the

make certain that proper power or extension

cord has been selected for the job. See Cable Selection

make sure that electrical circuits are properly

grounded to a suitable earth ground (ground rod) per

the National Electrical Code (NEC) and local codes

Severe injury or death by

can result from operating an ungrounded

drop the battery. There is a possibility that the

keep the battery charged. If the battery is not

recharge the battery in a well-ventilated

environment to avoid the risk of a dangerous concentration

DO NOT touch output terminals during

operation. Contact with output terminals

during operation can cause electrocution,

electrical shock or burn.

The electrical voltage required to

operate the generator can cause severe

injury or even death through physical contact with live

circuits. Turn generator and all circuit breakers OFF

before performing maintenance on the generator or

making contact with output terminals.

NEVER insert any objects into the output

receptacles during operation. This is

extremely dangerous. The possibility exists

of electrical shock, electrocution or

death.

Backfeed to a utility system can cause

electrocution and/or property damage.

NEVER connect the generator to a

building’s electrical system without

a transfer switch or other approved

device. All installations should be

performed by a licensed electrician in accordance with

all applicable laws and electrical codes. Failure to do so

could result in electrical shock or burn, causing serious

injury or even death.

SAFETY INFORMATION

generator.

NOTICE

ALWAYS

Chart in this manual.

Grounding Safety

DANGER

ALWAYS

before operating generator.

electrocution

generator.

NEVER use gas piping as an electrical ground.

BATTERY SAFETY

DANGER

DO NOT

battery will explode.

DO NOT expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

DANGER

NEVER let power cords or cables lay in water.

NEVER stand in water while AC power from the

generator is being transferred to a load.

NEVER use damaged or worn cables or cords when

connecting equipment to generator. Inspect for cuts in

the insulation.

NEVER grab or touch a live power

cord or cable with wet hands. The

possibility exists of electrical shock,

electrocution or death.

PAGE 10 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

WARNING

ALWAYS wear safety glasses when

handling the battery to avoid eye irritation.

The battery contains acids that can cause

injury to the eyes and skin.

Use well-insulated gloves when picking up the battery.

ALWAYS

charged, combustible gas will build up.

ALWAYS

of combustible gasses.

If the battery liquid (dilute sulfuric acid) comes into

contact with clothing or skin, rinse skin or clothing

ENVIRONMENTAL SAFETY/

Decommissioning is a controlled process used to safely

retire a piece of equipment that is no longer serviceable.

If the equipment poses an unacceptable and unrepairable

safety risk due to wear or damage or is no longer cost

effective to maintain (beyond life-cycle reliability) and is to

be decommissioned (demolition and dismantlement),be

sure to follow rules below.

EMISSIONS INFORMATION

The diesel engine used in this equipment has been

designed to reduce harmful levels of carbon monoxide

(CO), hydrocarbons (HC) and nitrogen oxides (NOx)

This engine has been certifi ed to meet US EPA Evaporative

Attempting to modify or make adjustments to the engine

emission system by unauthorized personnel without proper

training could damage the equipment or create an unsafe

Additionally, modifying the fuel system may adversely affect

evaporative emissions, resulting in fi nes or other penalties.

The emission control label is an integral part of the emission

If a replacement emission label is needed, please contact

immediately with plenty of water.

If the battery liquid (dilute sulfuric acid) comes into

contact with eyes, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

seek medical attention.

SAFETY INFORMATION

NOTICE

contained in diesel exhaust emissions.

CAUTION

ALWAYS disconnect the NEGATIVE battery terminal

before performing service on the generator.

ALWAYS keep battery cables in good working condition.

Repair or replace all worn cables.

NOTICE

DECOMMISSIONING

DO NOT pour waste or oil directly onto the ground, down

a drain or into any water source.

Contact your country's Department of

Public Works or recycling agency in your

area and arrange for proper disposal of

any electrical components, waste or oil

associated with this equipment.

emissions requirements in the installed confi guration.

condition.

Emission Control Label

system and is strictly controlled by regulations.

The label must remain with the engine for its entire life.

your authorized engine distributor.

When the life cycle of this equipment is over, remove

battery and bring to appropriate facility for lead

reclamation. Use safety precautions when handling

batteries that contain sulfuric acid.

When the life cycle of this equipment is over, it is

recommended that the trowel frame and all other metal

parts be sent to a recycling center.

Metal recycling involves the collection of metal from

discarded products and its transformation into raw

materials to use in manufacturing a new product.

Recyclers and manufacturers alike promote the process

of recycling metal. Using a metal recycling center

promotes energy cost savings.

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 11

Table 1. Generator Specifications

Model

Type

Armature Connection Star with Neutral Zigzag

Phase

Standby Output

Prime Output

3Ø/1Ø Voltage (L-L/L-N)

Voltage Selector Switch at 3Ø 240/139

3Ø/1Ø Voltage (L-L/L-N)

Voltage Selector Switch at 3Ø 480/277

1Ø Voltage (L-L/L-N)

Voltage Selector Switch at 1Ø 240/120

Power Factor

Frequency

Speed

Aux. AC Power

Aux. Voltage/Output

Dry Weight

Wet Weight

Table 2. Engine Specifications

Model

Type

No. of Cylinders

Bore x Stroke

Displacement

Rated Output

Starting

Coolant Capacity

Lube Oil Capacity

Fuel Type

Fuel Tank Capacity

Fuel Leak Warning Capacity

Fuel Consumption

Battery

SPECIFICATIONS

DCA150USJ3CAN

Revolving field, self ventilated,

open protected type synchronous generator

3 Single

132 KW (165 kVA) 95.7 KW

120 KW (150 kVA) 87 KW

208Y/120, 220Y/127,

240Y/139

416Y/240, 440Y/254,

480Y/277

N/A 240/120

0.8 1.0

60 Hz

1800 rpm

Single Phase, 60 Hz

4.8 Kw (2.4 kW x 2)

7,099 lbs. (3,220 kg.)

8,719 lbs. (3,955kg.)

John Deere 6068HF285 Tier 3

4 cycle, water-cooled, direct injection, turbo-charged

air to air intercooled

6 cylinders

4.19 in. x 5.00 in. (106 mm x 127 mm)

415 cu. in. (22,928 cc)

180 HP @ 1800 rpm

Electric

5.8 gal. (22.0 liters)

8.19 gal. (31.0 liter)

#2 Diesel Fuel

214 gal. (810 liters)

47.3 gal. (179 liters)

8.6 gal. (32.6 L)/hr at full load 6.9 gal. (26.3 L)/hr at 3/4 load

5.2 gal. (19.5 L)/hr at 1/2 load 2.9 gal. (11.1 L)/hr at 1/4 load

4D (CCA O F 925A) x 1

N/A

N/A

PAGE 12 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

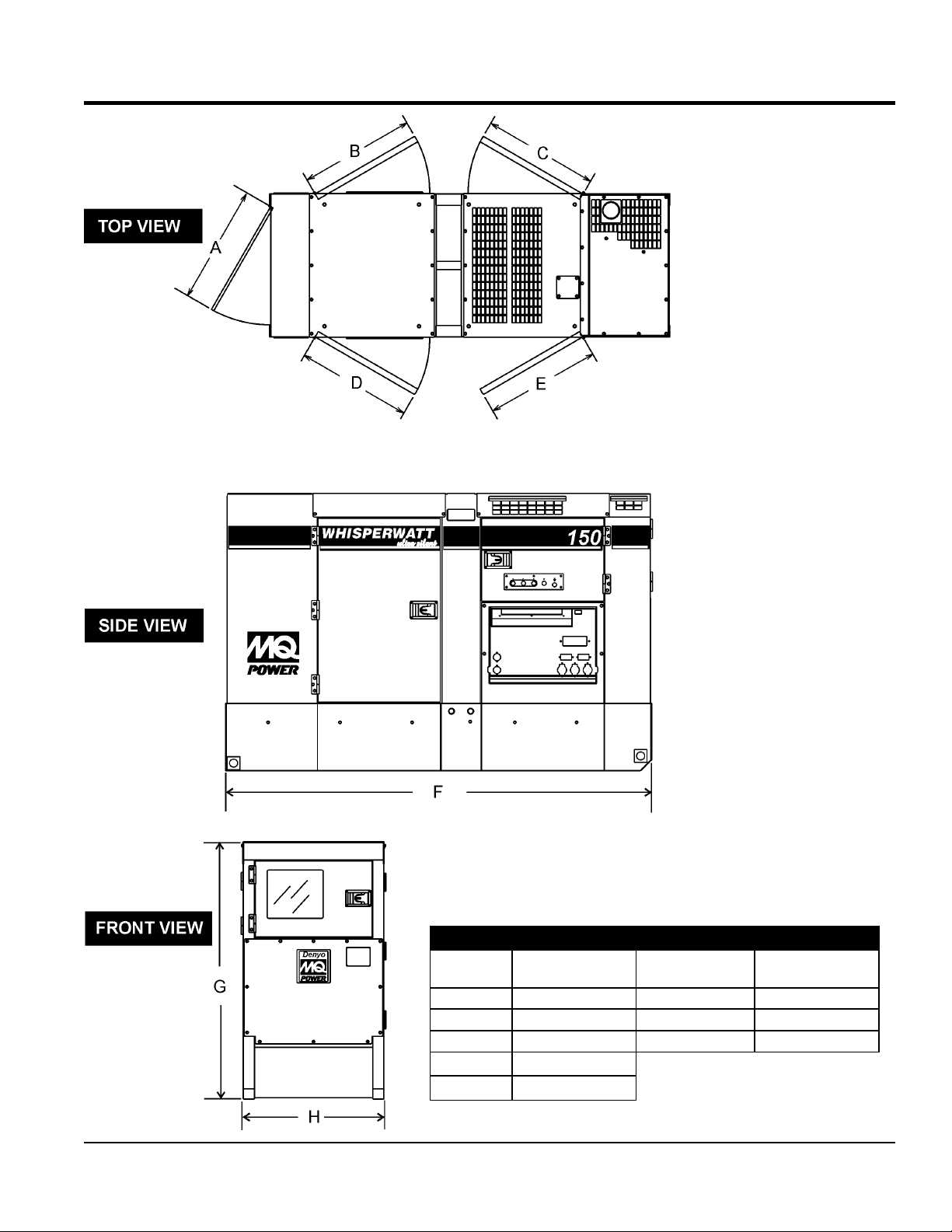

DIMENSIONS

Figure 1. Dimensions

Table 3. Dimensions

Reference

Letter

A 42.50 in. (1080 mm.) F 128.00 in. (3,250 mm.)

B 40.20 in. (1020 mm.) G 75.00 in. (1,905 mm.)

C 40.90 in. (1040 mm.) H 48.80 in. (1240 mm.)

D 40.20 in. (1020 mm.)

E 40.90 in. (1040 mm.)

Dimension in. (mm) Reference Letter Dimension in. (mm)

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 13

GENERATOR

./2.4 M (MINIMUM)

GROUND LUG

GROUND CABLE

INSTALLATION

GROUND ROD FOR

EARTH GROUND.

CONNECT TO BUILDING

GROUND IF APPLICABLE

REFERENCE

NEC 250-83 (C)

8 FT

Figure 2. Typical Generator Grounding Application

PAGE 14 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

INSTALLATION

OUTDOOR INSTALLATION

Install the generator in a area that is free of debris,

bystanders, and overhead obstructions. Make sure the

generator is on secure level ground so that it cannot slide

or shift around. Also install the generator in a manner so

that the exhaust will not be discharged in the direction of

nearby homes.

The installation site must be relatively free from moisture

and dust. All electrical equipment should be protected from

excessive moisture. Failure to do will result in deterioration

of the insulation and will result in short circuits and

grounding.

Foreign materials such as dust, sand, lint and abrasive

materials have a tendency to cause excessive wear to

engine and alternator parts.

CAUTION

Pay close attention to ventilation when operating the

generator inside tunnels and caves. The engine exhaust

contains noxious elements. Engine exhaust must be

routed to a ventilated area.

GENERATOR GROUNDING

To guard against electrical shock and possible damage to

the equipment, it is important to provide a good EARTH

ground.

Article 250 (Grounding) of the National Electrical Code

(NEC) provides guide lines for proper grounding and

specifies that the cable ground shall be connected to the

grounding system of the building as close to the point of

cable entry as practical.

NEC articles 250-64(b) and 250-66 set the following

grounding requirements:

1. Use one of the following wire types to connect the

generator to earth ground.

a. Copper - 8 AWG (5.3 mm2) or larger.

b. Aluminum - 6 AWG (8.4 mm2) or larger.

2. When grounding the generator (Figure 2) connect the

ground cable between the lock washer and the nut on

the generator and tighten the nut fully. Connect the

other end of the ground cable to earth ground.

INDOOR INSTALLATION

Exhaust gases from diesel engines are extremely

poisonous. Whenever an engine is installed indoors the

exhaust fumes must be vented to the outside. The engine

should be installed at least two feet from any outside wall.

Using an exhaust pipe which is too long or too small can

cause excessive back pressure which will cause the engine

to heat excessively and possibly burn the valves.

MOUNTING

The generator must be mounted on a solid foundation (such

as concrete) and set firmly on the foundation to isolate

vibration of the generator when it is running. The generator

must set at least 6 inches above the floor or grade level (in

accordance to NFPA 110, Chapter 5-4.1). DO NOT remove

the metal skids on the bottom of the generator. They are

to resist damage to the bottom of the generator and to

maintain alignment.

3. NEC article 250-52(c) specifies that the earth ground rod

should be buried a minimum of 8 ft. into the ground.

NOTICE

When connecting the generator to any buildings

electrical system ALWAYS consult with a licensed

electrician.

NOTICE

This generator has a permanent bonding conductor

between the generator stator windings and the frame.

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 15

GENERAL INFORMATION

GENERATOR

This MQ Power generator (Figure 3) is a high quality

portable (requires a trailer for transport) power source for

telecom sites, lighting facilities, power tools, submersible

pumps and other industrial and construction machinery.

ENGINE OPERATING PANEL

The “Engine Operating Panel” is provided with the following:

Tachometer

Water Temperature Gauge

Oil Pressure Gauge

Charging Ammeter Gauge

Fuel Level Gauge

Panel Light/Panel Light Switch

ECU Controller

Engine Speed Switch

Emergency Stop Button

Emergency Stop Lamp

Warning Lamp

Pre-Heat Lamp

Fuel Leak Detected Alarm Lamp

Diagnostic Gauge

GENERATOR CONTROL PANEL

The “Generator Control Panel” is provided with the following:

Frequency Meter (Hz)

AC Ammeter (Amps)

AC Voltmeter (Volts)

Ammeter Change-Over Switch

Voltmeter Change-Over Switch

Voltage Regulator

3-Pole, 400 amp Main Circuit Breaker

“Control Box” (located behind the Gen. Control Panel)

• Automatic Voltage Regulator

• Current Transformer

• Over-Current Relay

• Starter Relay

• Voltage Selector Switch

OUTPUT TERMINAL PANEL

The “Output Terminal Panel” is provided with the following:

Three 120/240V output receptacles (CS-6369), 50A

Three auxiliary circuit breakers, 50A

Two 120V output receptacles (GFCI), 20A

Two GFCI circuit breakers, 20A

Five output terminal lugs (3Ø power)

OPEN DELTA EXCITATION SYSTEM

This generator is equipped with the state of the art “OpenDelta” excitation system. The open delta system consist

of an electrically independent winding wound among

stationary windings of the AC output section.

There are four connections of the open delta A, B, C and

D. During steady state loads, the power from the voltage

regulator is supplied from the parallel connections of A to

B, A to D, and C to D. These three phases of the voltage

input to the voltage regulator are then rectified and are the

excitation current for the exciter section.

When a heavy load, such as a motor starting or a short

circuit occurs, the automatic voltage regulator (AVR)

switches the configuration of the open delta to the series

connection of B to C. This has the effect of adding the

voltages of each phase to provide higher excitation to the

exciter section and thus better voltage response during the

application of heavy loads.

The connections of the AVR to the AC output windings are

for sensing only. No power is required from these windings.

The open-delta design provides virtually unlimited excitation

current, offering maximum motor starting capabilities. The

excitation does not have a “fixed ceiling” and responds

according the demands of the required load.

ENGINE

This generator unit incorporates an John Deere 6068HF285

diesel engine. This engine is designed to meet every

performance requirement for the generator. Reference

Table 2 for engine specifications.

In keeping with MQ Power’s policy of constantly improving

its products, the specifications quoted herein are subject

to change without prior notice.

ELECTRIC GOVERNOR SYSTEM

The electric governor system controls the RPMs of the engine.

When the engine demand increases or decreases, the

governor system regulates the frequency variation to ±.25%.

EXTENSION CABLES

When electric power is to be provided to various tools or

loads at some distance from the generator, extension cords

are normally used. Cables should be sized to allow for

distance in length and amperage so that the voltage drop

between the generator and point of use (load) is held to

a minimum. Use the cable selection chart (Table 6) as a

guide for selecting proper extension cable size.

PAGE 16 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

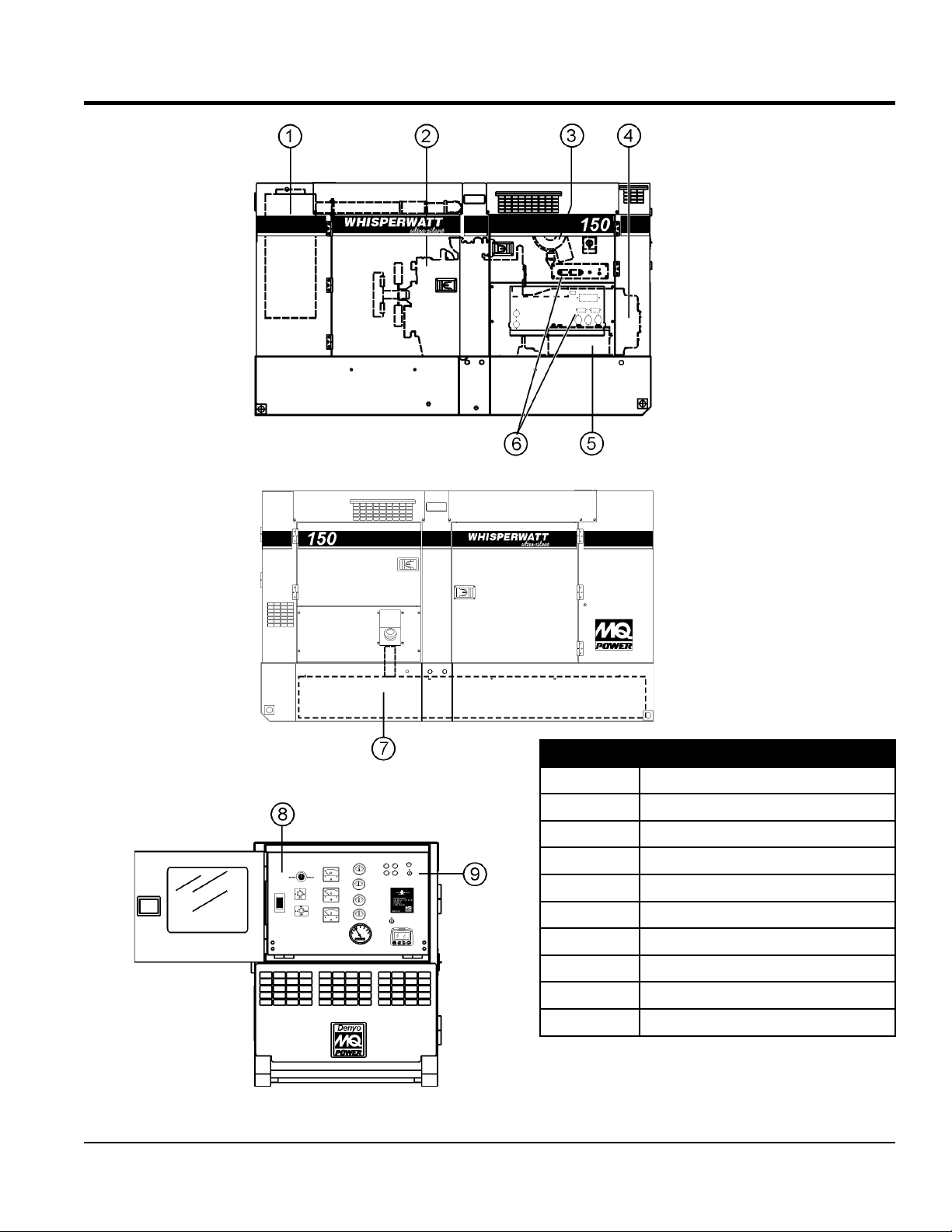

MAJOR COMPONENTS

Table 4. Generator Major Components

ITEM NO. DESCRIPTION

1 Muffler Assembly

2 Engine Assembly

3 Air Filter Assembly

4 Generator Assembly

5 Battery Assembly

6 Output Terminal Assembly

7 Fuel Tank Assembly

8 Generator Control Panel Assembly

9 Engine Operating Panel Assembly

Figure 3. Major Components

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 17

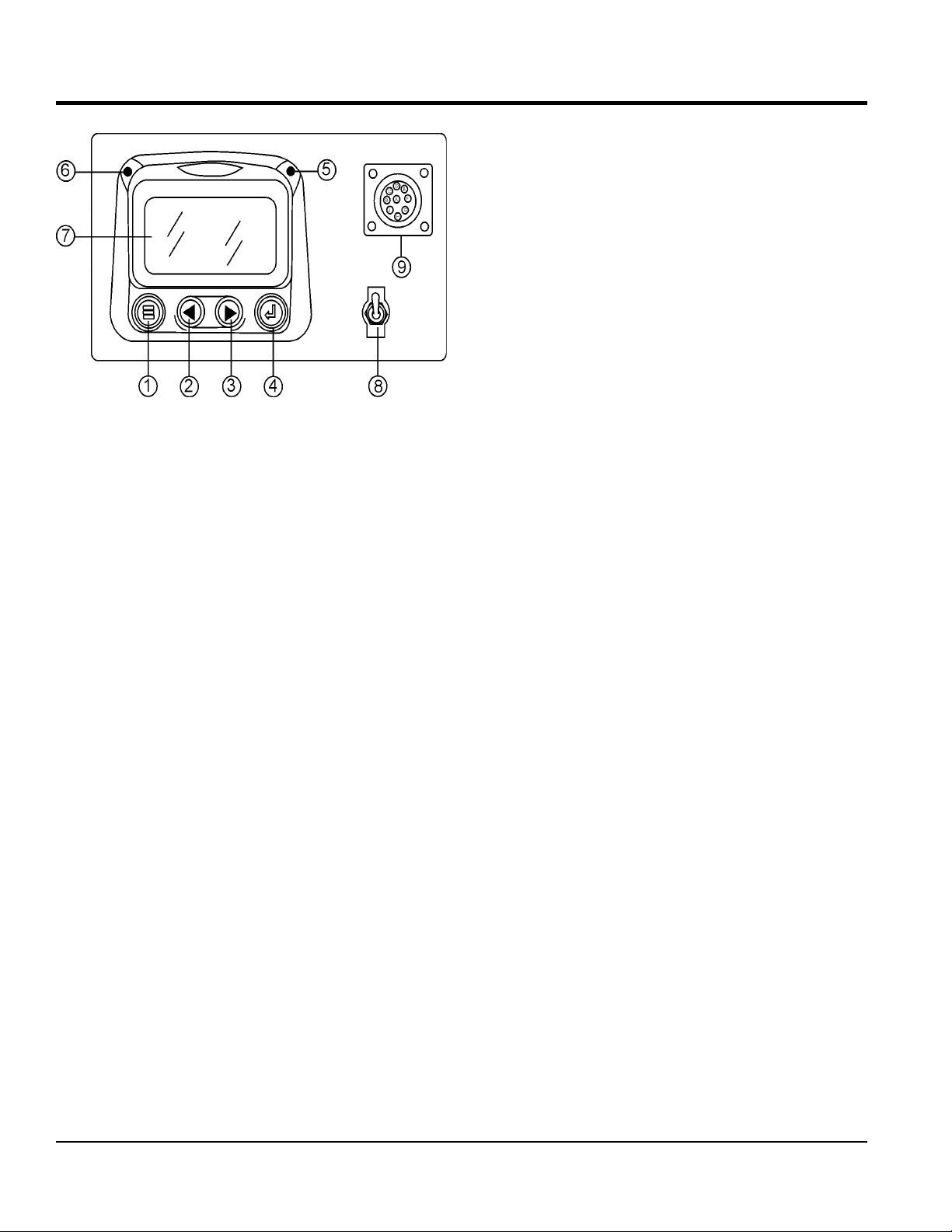

Figure 4. Diagnostic Display

The diagnostic display panel located inside the control

box on the generator (Figure 4) is designed to meet the

needs for instrumentation and control of electronically

controlled engine communication using the SAEJ1939

Controller Area Network (CAN). This diagnostic display is

a multifunction tool that enables equipment operators to

view many different engine parameters and service codes.

The keypad on the diagnostic display panel is a capacitive

touch sensing system. There are no mechanical switches

to wear or stick. This keypad (display unit) will operate in

extreme hot or cold weather conditions.

Other components in the system are microprocessor-based

components for displaying critical engine data broadcast

by an electronic engine or transmission’s Engine Control

Unit (ECU): engine RPM, oil pressure, coolant temperature,

system voltage, etc., and a combination audible alarm and

relay unit for warning and shutdown annunciation.

The Engine Control Unit (ECU) used with this generator

diagnosis engine faults that arise with the the engine

control system and the engine itself. Engine faults can

be determined by viewing the Diagnostic Trouble Codes

(Active Fault Codes) which are displayed on the Diagnostic

Display Panel. See the John Deere Engine Operator’s

Manual for a complete listing of active fault codes and

countermeasures.

The following definitions describe the controls and functions

of the Diagnostic Display Panel (Figure 4).

1. Menu Button – Press this button to enter or exit menu

screens.

DIAGNOSTIC DISPLAY

2. Left Arrow Button – Press this button to scroll through

the screen either moving the parameter selection

toward the left or upward.

3. Right Arrow Button – Press this button to scroll

through the screen either moving the parameter

selection toward the right or downward.

4. Enter Key Button – Press this button to select the

parameter that is highlighted on the screen.

5. Emergency Stop LED – When lit (RED) indicates a

major fault has occured. This condition will shudown

the generator.

6. Warning LED – When lit (AMBER), indicates a engine

parameter has exceeded its limits (minor fault). The

generator will still run in this condition.

7. Display Screen – Graphical backlight LCD screen.

Back lighting is controlled via menu or external

dimmer potentiometer. The display can show either a

single parameter or a quadrant display showing four

parameters simultaneously.

8. Diagnostic Switch – When placed in the ON position,

will activate the diagnostic display panel.

9. CAN Diagnostic Connector – Controller Area

Network connector. This connector outputs diagnostic

error codes. Connect a scanner or similar device into

this connector to read error codes.

Display Parameters

The following are some of the engine and transmission

parameters displayed on the diagnostic disply panel.

Engine RPM’s

Engine Hours

System Voltage

% Engine Load at current RPM

Coolant Temperature

Oil Pressure

Fuel Economy

Current Fuel Consumption

Throttle Position

Engine Manifold Air Temperature

Active Service Codes

Set Units for Display (English or Metric)

English Configuration Parameters.

PAGE 18 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

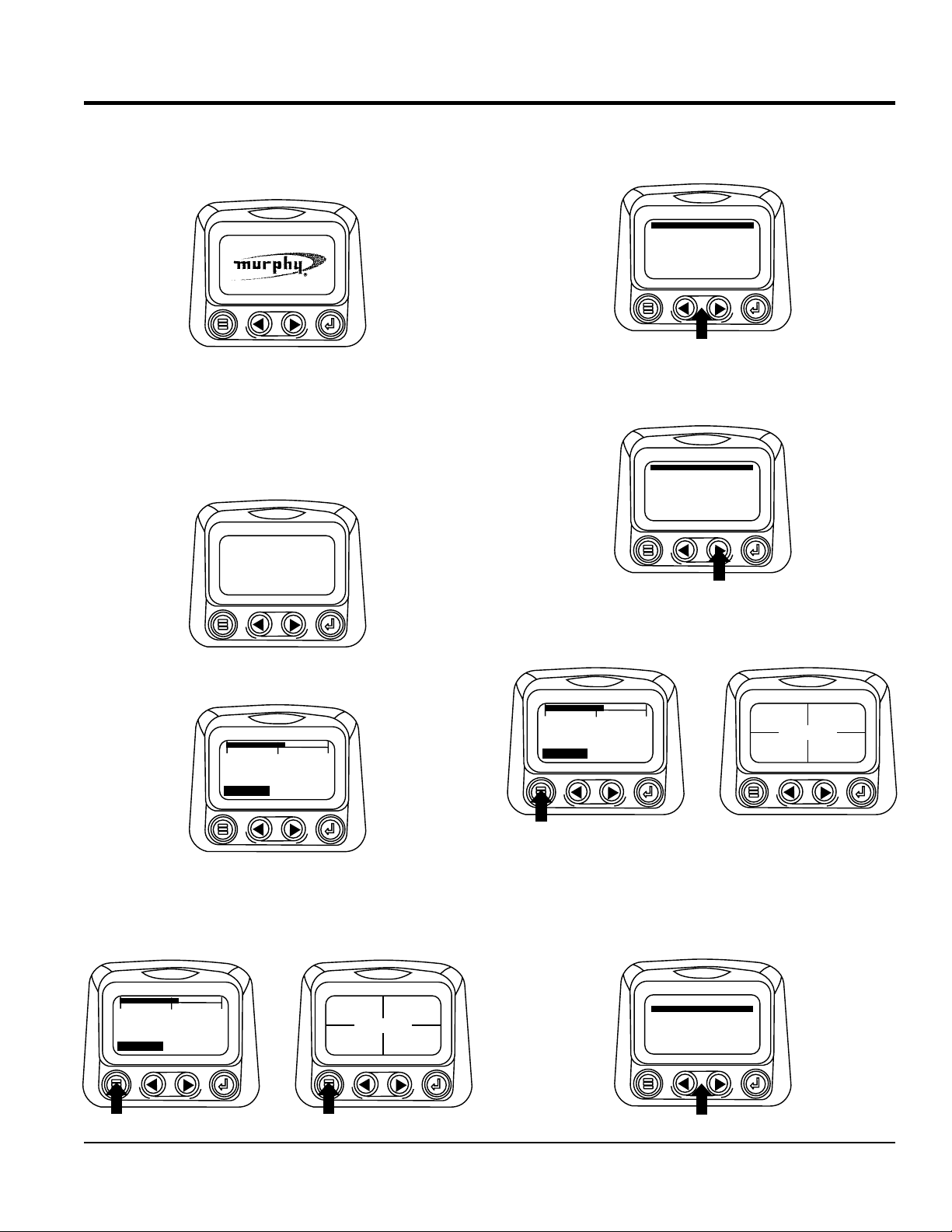

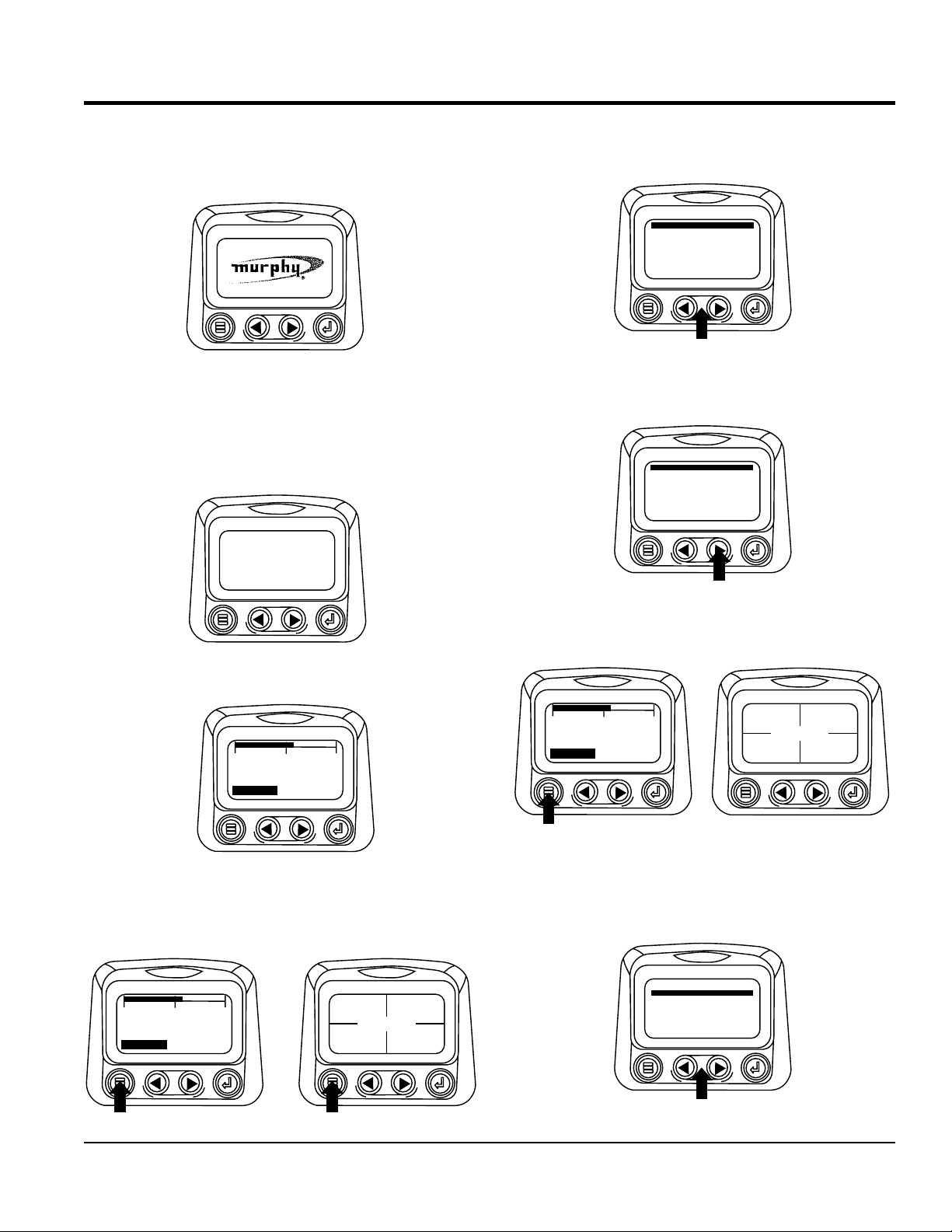

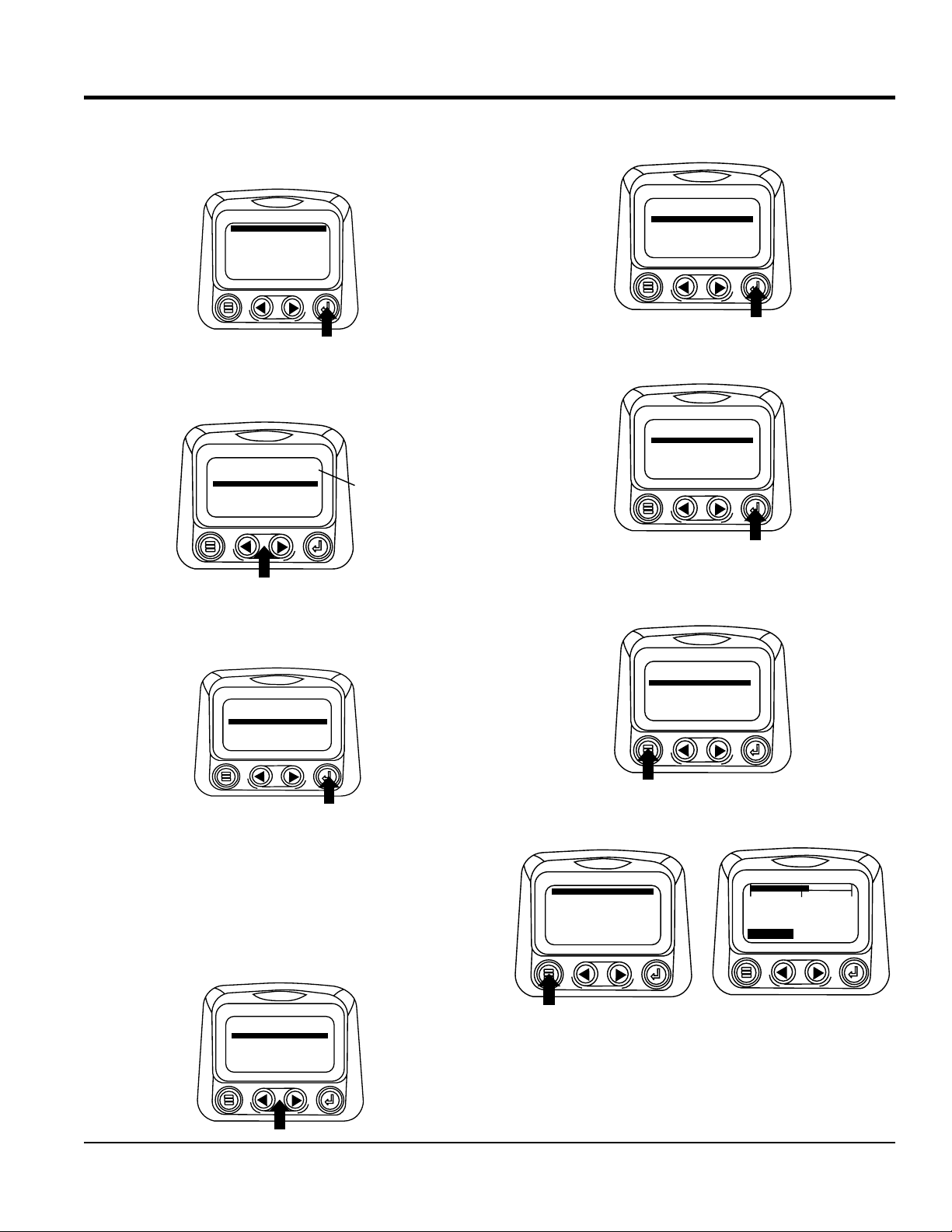

DIAGNOSTIC DISPLAY

First Time Start Up

1. When power is first applied to the diagnostic display,

the “Logo” is displayed.

2. The “Wait to Start” message will be displayed for

engines with a pre-startup sequence. Once the “Wait

to Start” message is no longer displayed the operator

may start the engine. Note: Displays only when SAE

J1939 message is supported by engine manufacture.

WAIT TO

START

PREHEAT

2. The first seven items of the “Main Menu” will be

displayed. Touching the “Arrow Buttons” will scroll

through the menu selection.

GO TO 1-UP DISPLAY

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

G

3. Touching the right arrow button will scroll down to reveal

the last items of “Main Menu” screen highlighting the

next item down.

ADJUST BACKLIGHT

ADJUST CONTRAST

UTILITIES

3. Once the engine has started the single engine

parameter is displayed.

0

3000

1500

1800 RPM

TEMP

ENG RPM

COOL

Main Menu Navigation

1. Starting at the single or four engine parameter display,

touch “Menu”.

1000 RPM

0

1500

1800 RPM

ENG RPM

COOL

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

ENG RPM

57 PSI

OIL PRES

4. Touch the Arrows” to scroll to the desired menu item

or touch “Menu” to exit the Main menu and return to

the engine parameter display.

0

1500

1800 RPM

ENG RPM

COOL

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

ENG RPM

57 PSI

OIL PRES

1000 RPM

Selecting a Language

1. Starting at the main menu display use the “Arrows to

scroll to the “Language” menu and once highlighted

touch the “Enter” button.

GO TO 1-UP DISPLAY

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

G

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 19

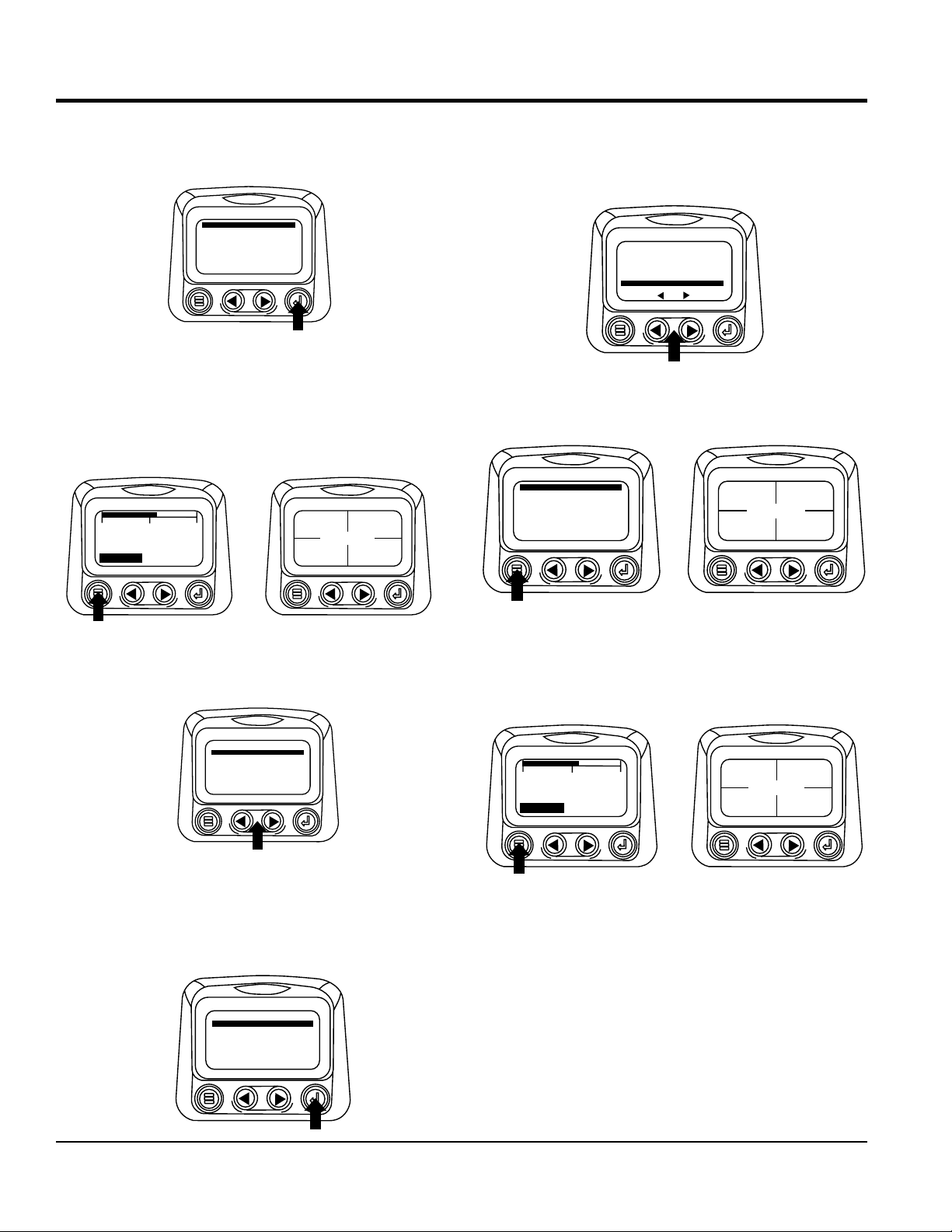

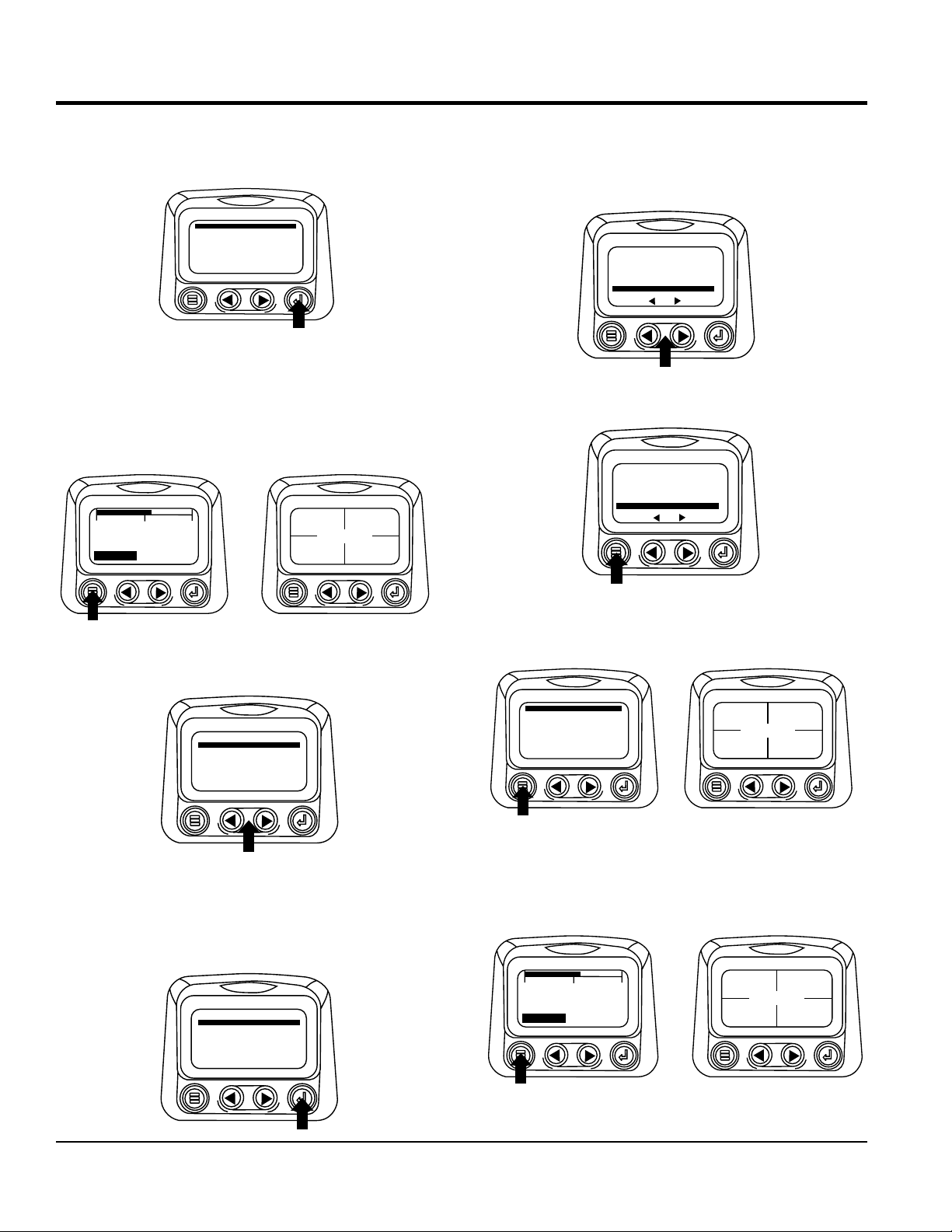

DIAGNOSTIC DISPLAY

2. The language choices will be displayed. Use the

“Arrow” buttons to scroll through the selections and

touch “Enter” to make a selection.

ENGLISH

ESPANOL

FRANCAIS

DEUTSCH

3. Now that you have selected the language, touch the

“Menu” button to return to the main menu display.

Stored Fault Codes

1. Starting at the single or the four engine parameter

display touch the “Menu button.”.

1000 RPM

0

1500

1800 RPM

COOL

ENG RPM

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

ENG RPM

57 PSI

OILPRES

4. If the word “MORE” appears above the “Arrow Buttons”

there are more stored fault codes that may be viewed.

Use the “Arrow Buttons” to scroll to the next Stored

Diagnostic Code.

1ofx

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

5. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

2. The main menu will pop up on the display. Use the

“Arrow Buttons” to scroll through the menu until the

Stored Fault Codes is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

G

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

3. Once the “Stored Fault Codes” menu item has been

highlighted touch the “Enter Button” to view the “Stored

Fault Codes” (when applicable, consult engine or

transmission manufacturer for SAE J1939 supported

parameters).

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

Engine Configuration Data

1. Starting at the single or four engine parameter display

touch the “Menu Button”. First Time Start Up

1000 RPM

0

1500

1800 RPM

COOL

ENG RPM

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

ENG RPM

57 PSI

OIL PRES

PAGE 20 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

DIAGNOSTIC DISPLAY

First Time Start-Up

1. When power is first applied to the diagnostic display,

the “Logo” is displayed.

2. The “Wait to Start” message will be displayed for

engines with a pre-startup sequence. Once the “Wait

to Start” message is no longer displayed the operator

may start the engine. Note: Displays only when SAE

J1939 message is supported by engine manufacturrg.

WAIT TO

START

PREHEAT

2. The The first seven items of the “Main Menu” will be

displayed. Touching the “Arrow Buttons” will scroll

through thr menu selection.

GO TO 1-UP DISPLAY

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

G

3. Touching the right arrow button will scroll down to reveal

the last items of “Main Menu” screen highlighting the

next item down.

ADJUST BACKLIGHT

ADJUST CONTRAST

UTILITIES

3. Once the engine has started the single engine

parameter is displayed.

0

3000

1500

1800 RPM

TEMP

ENG RPM

COOL

Main Menu Navigation

1. Starting at the single or four engine parameter display,

touch “Menu”.

0

1500

1800 RPM

COOL

ENG RPM

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

4. Touch the Arrows” to scroll to the desired menu item

or touch “Menu” to exit the Main menu and return to

the engine parameter display.

0

1500

1800 RPM

ENG RPM

COOL

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

ENG RPM

57 PSI

OIL PRES

1000 RPM

Selecting a Language

1. Starting at the main menu display use the “Arrows to

scroll to the “Language” menu and once highlighted

touch the “Enter” button.

GO TO 1-UP DISPLAY

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

G

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 21

ENGLISH

ESPANOL

FRANCAIS

DEUTSCH

DIAGNOSTIC DISPLAY

2. The language choices will be displayed. Use the

“Arrow” buttons to scroll through the selections and

touch “Enter” to make a selection.

3. Now that you have selected the language, touch the

“Menu” button to return to the main menu display.

Stored Fault Codes

1. Starting at the single or the four engine parameter

display touch the “Menu button”.

1000 RPM

0

1500

1800 RPM

COOL

ENG RPM

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

ENG RPM

57 PSI

OIL PRES

4. f the word “MORE” appears above the “Arrow Buttons”

there are more stored fault codes that may be viewed.

Use the “Arrow Buttons” to scroll to the next Stored

Diagnostic Code.).

1ofx

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

5. Touch the “Menu Button to return to the main menu.

1ofx

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

2. The main menu will pop up on the display. Use the

“Arrow Buttons” to scroll through the menu until the

Stored Fault Codes is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

3. Once the “Stored Fault Codes” menu item has been

highlighted touch the “Enter Button” to view the “Stored

Fault Codes” (when applicable, consult engine or

transmission manufacturer for SAE J1939 supported

parameters

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

6. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

G

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

LOAD RPM

BATTVOLT

98%

14.2

1000 RPM

ENG RPM

57 PSI

OIL PRES

Engine Configuration Data

1. Starting at the single or four engine parameter display

touch the “Menu Button”.

1000 RPM

0

1500

1800 RPM

ENG RPM

COOL

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

ENG RPM

57 PSI

OIL PRES

PAGE 22 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

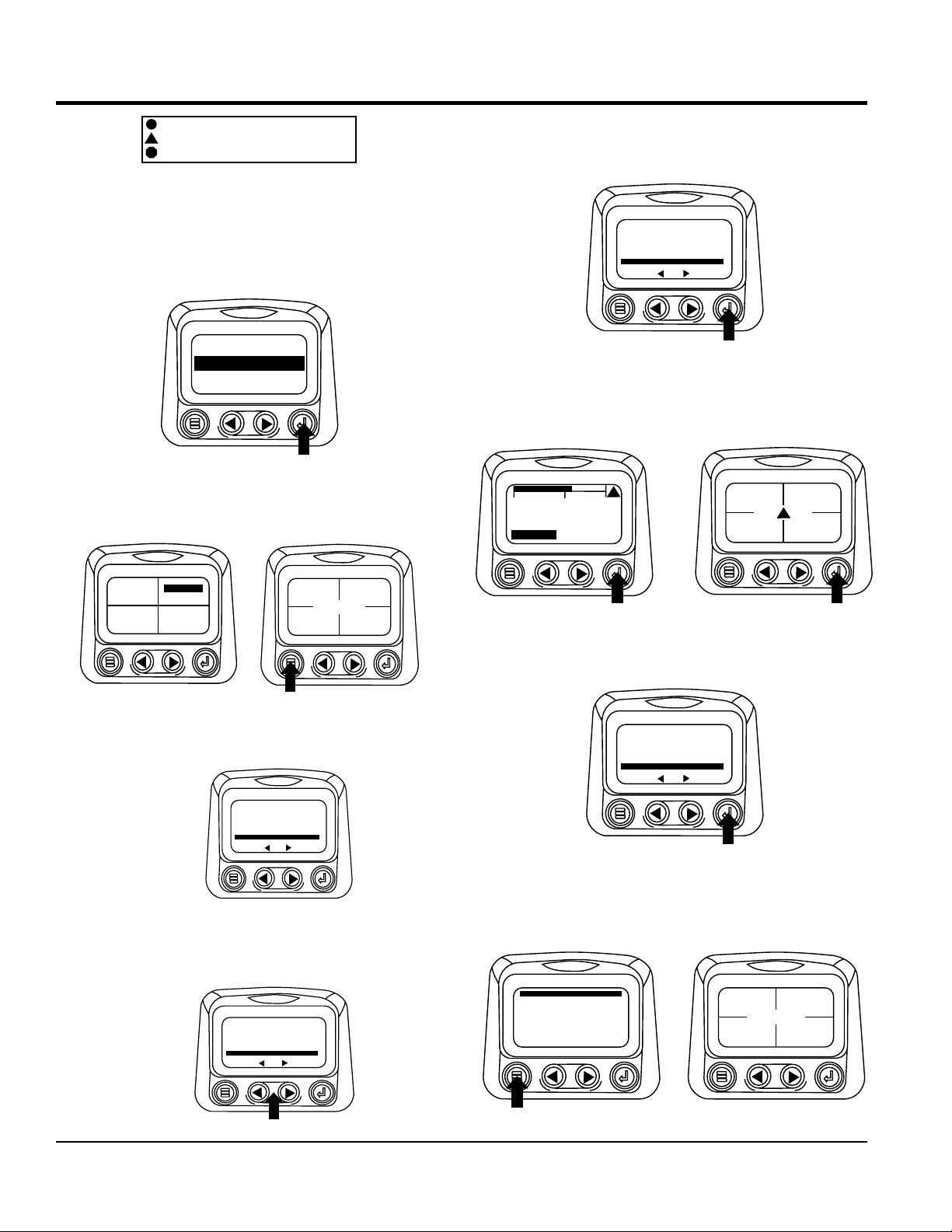

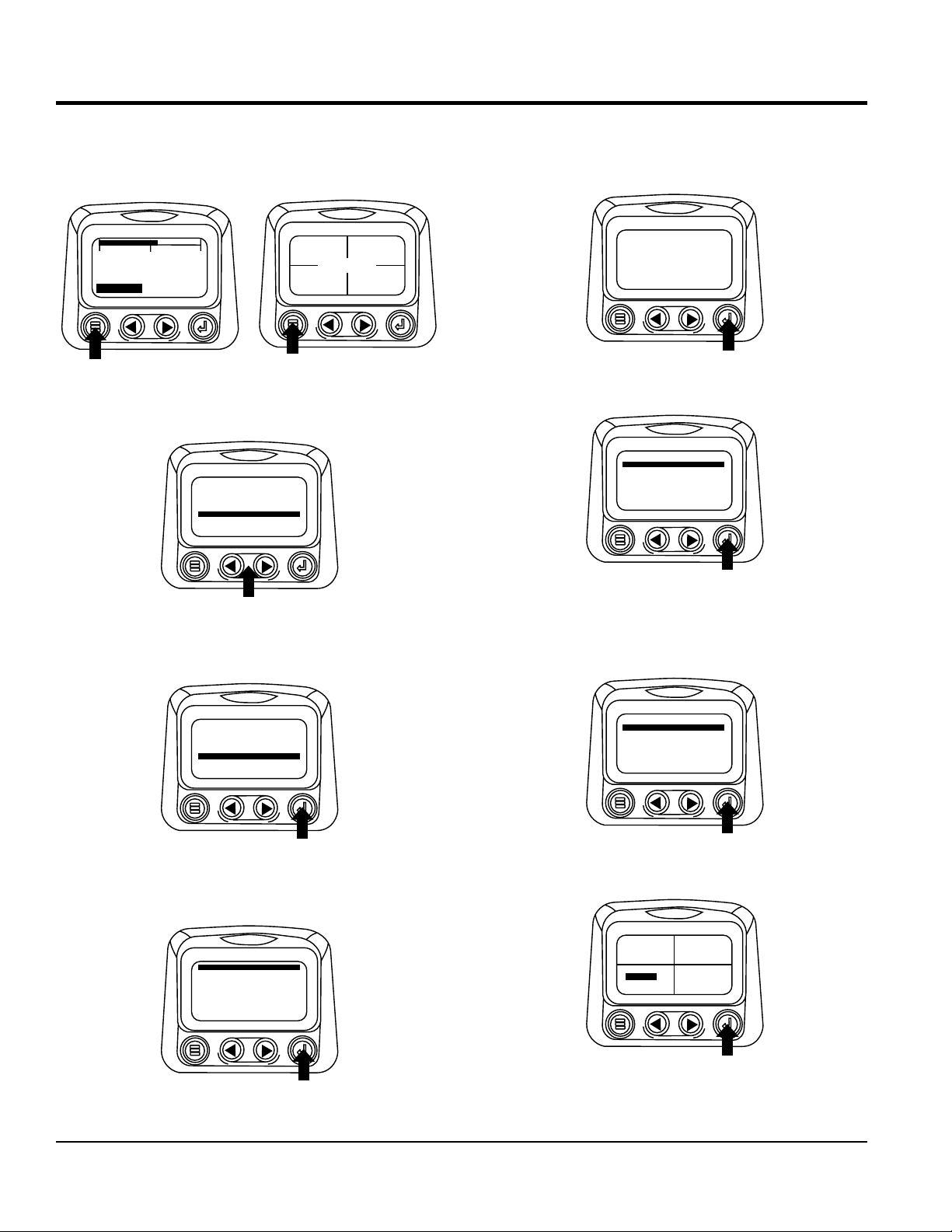

COOL

1800 RPM

0

1500

3000

TEMP

ENG RPM

98%

14.2

57 PSI

1000 RPM

LOAD RPM

BATTVOLT

ENG RPM

OILPRES

ENGINE OIL PRESSURE

GAGE NOT RESPONDING

1ofx

HIDE

DIAGNOSTIC DISPLAY

2. The main menu will pop up on the display. Use the

“Arrow Buttons” to scroll through the menu until the

“Engine Configuration” menu item has been highlighted

.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

3. Once the “Engine Configuration” menu item has been

highlighted touch the “Enter Button” to view the engine

configuration data.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

FAULTS AND WARNING

Auxiliary Gage Fault

1. During normal operation the single or four parameter

screen will be displayed.

2. The PVA Series of auxiliary gages can be attached to

the PowerView. These auxiliary gages communicate

with the Modbus master PowerView via a daisy-chained

RS-485 port. If at any time during system initialization

or normal operation an auxiliary gage should fail, the

single or four parameter screen will be replaced with

the “MLink Gage Fault” message.

4. Use the “Arrow Buttons” to scroll through the engine

configuration data.

ENGINE SPEED PT 1

1800 RPM

MORE

5. Touch the “Menu Button” to return to the main menu.

ENGINE SPEED PT 1

1800 RPM

MORE

6. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

3. To acknowledge and “Hide” the fault and return to the

single or four parameter display, touch the “Enter

Button.

1ofx

ENGINE OIL PRESSURE

GAGE NOT RESPONDING

HIDE

4. The display will return to the single or four parameter

screen.

0

1500

1800 RPM

ENG RPM

COOL

3000

TEMP!

!

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

!

57 PSI

OIL PRES

!

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 23

!

98%

14.2

57 PSI

1000 RPM

LOAD RPM

BATTVOLT

ENG RPM

OIL PRES

125°F

COOL TEMP

143°F

OIL TEMP

57 PSI

1000 RPM

ENG RPM

OILPRES

SPN110 FMI10

HIGH COOLANT TEMP

WARNING

1ofx

MORE

HIDE

SPN110 FMI10

HIGH COOLANT TEMP

1ofx

MORE

HIDE

Indicates Auxiliary Gage Fault

!

Indicates Fault Warning

!

Indicates Derate or Shutdown Condition Fault

5. Touching the “Enter Button” will redisplay the hidden

fault. Touching the “Enter Button” once again will hide

the fault and return the screen to the single or four

parameter display. NOTE: The fault can only be cleared

by correcting the cause of the fault condition.

1ofx

ENGINE OIL PRESSURE

GAGE NOT RESPONDING

HIDE

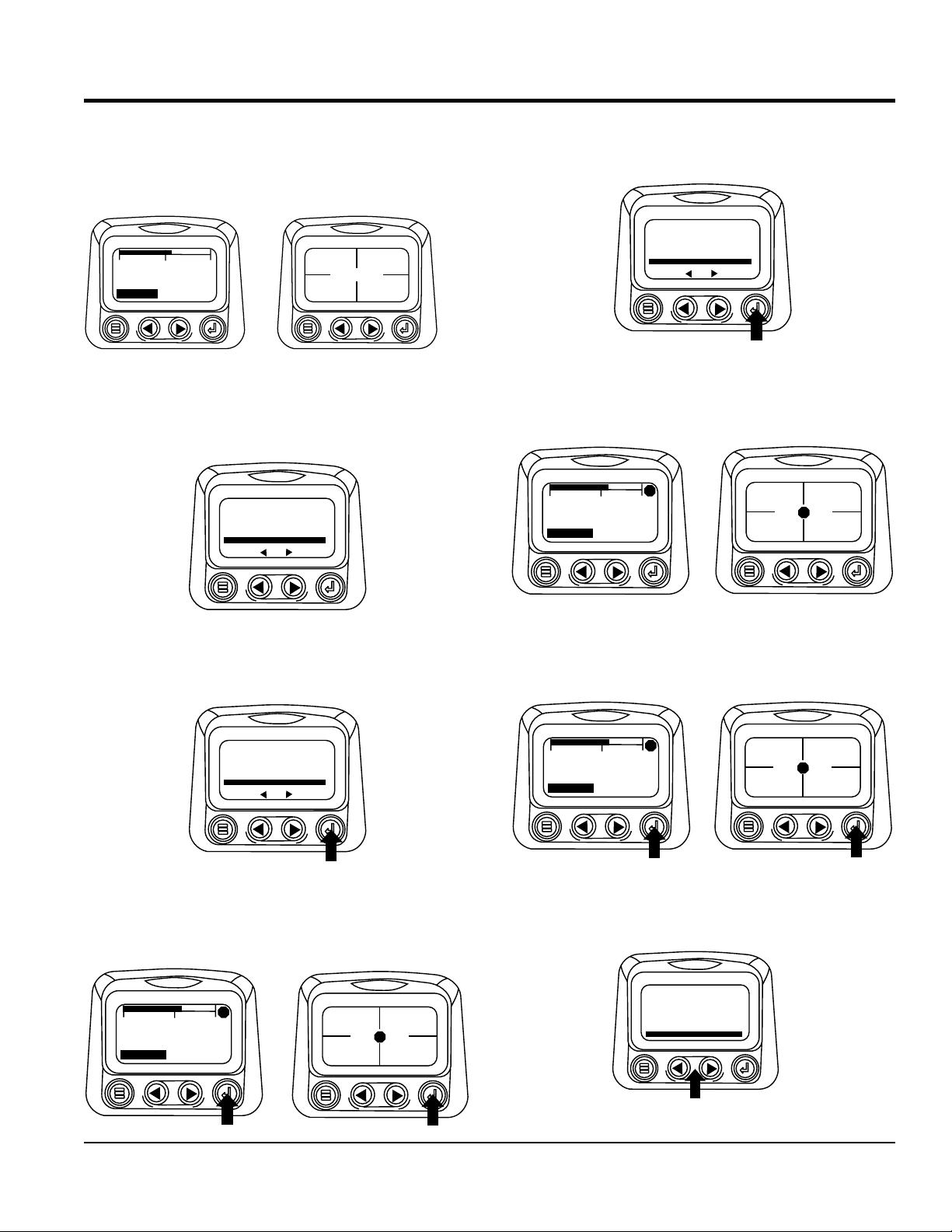

DIAGNOSTIC DISPLAY

4. To acknowledge and “Hide” the fault and return to the

single or four parameter display touch the “Enter

Button”.

1ofx

SPN110 FMI10

HIGH COOLANT TEMP

MORE

5. The display will return to the single or four parameter

display but the display will contain the “Active Fault”

warning icon. Touching the “Enter Button” will redisplay

the hidden fault.

HIDE

Active Fault Codes

1. During normal operation the single or four parameter

screen will be displayed

2. When the PowerView receives a fault code from an

engine control unit the single or four parameter screen

will be replaced with the “Active Fault Codes” message.

3. If the word “MORE” appears above the “Arrow Buttons”,

there are more active fault codes that may be viewed.

Use the “Arrow Buttons” to scroll to the next “Active

Fault Code”.

1000 RPM

0

1500

1800 RPM

ENG RPM

COOL

3000

TEMP!

!

98%

LOAD RPM

14.2

BATTVOLT

!

ENG RPM

57 PSI

OIL PRES

!

6. Touching the “Enter Button” once again will hide the

fault and return the screen to the single or four

parameter display.

1ofx

WARNING

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

7. The Single or Four parameter screen will display the

fault icon until the fault condition is corrected. NOTE:

Ignoring active fault codes could result in severe engine

damage.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

PAGE 24 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

DIAGNOSTIC DISPLAY

Shutdown Codes

1. During normal operation the single or four parameter

screen will be displayed

1000 RPM

0

1500

1800 RPM

COOL

ENG RPM

3000

TEMP

98%

LOAD RPM

14.2

BATTVOLT

2. When the diagnostic display receives a severe fault

code from an engine control unit the single or four

parameter screen will be replaced with the “Shutdown”

message.

1ofx

SHUTDOWN

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

ENG RPM

57 PSI

OILPRES

5. Touching the “Enter Button” once again will hide the

fault and return the screen to the single or four

parameter display.

1ofx

SHUTDOWN

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

6. The Single or Four parameter screen will display the

fault icon until the fault condition is corrected. NOTE:

Ignoring active fault codes could result in severe engine

damage.

0

1500

1800 RPM

ENG RPM

COOL

3000

TEMP!

!

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

!

57 PSI

OIL PRES

!

3. To acknowledge and “Hide” the fault and return to the

single or four parameter display touch the “Enter

Button”.

1ofx

SHUTDOWN

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

4. The display will return to the single or four parameter

display, but the display will contain the “Shut Down”

icon. Touching the “Enter Button” will redisplay the

hidden fault.

0

1500

1800 RPM

COOL

ENG RPM

3000

TEMP!

!

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

!

57 PSI

OIL PRES

Backlight Adjustment

1. Starting at the single or four engine parameter display

touch the “Menu Button”.

0

1500

1800 RPM

ENG RPM

COOL

3000

TEMP!

!

98%

LOAD RPM

14.2

BATTVOLT

2. The main menu will pop up on the display. Use the

“Arrow Buttons” to scroll through the menu until the

“Adjust Backlight” is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

GENGINECONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

1000 RPM

ENG RPM

!

57 PSI

OIL PRES

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 25

DIAGNOSTIC DISPLAY

3. Once the “Adjust Backlight” menu item has been

highlighted touch the “Enter Button” to activate the

“Adjust Backlight” function

GO TO 1-UP DISPLAY

STORED CODES

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

GENGINE CONF

4. Use the “Arrow Buttons” to select the desired backlight

intensity.

ADJUST BACKLIGHT

CONTRAST ADJUSTMENT

1. Starting at the single or four engine parameter display,

touch the “Menu Button”.

98%

0

1500

1800 RPM

ENG RPM

COOL

3000

TEMP

LOAD RPM

14.2

BATTVOLT

2. The main menu will pop up on the display. Use the

“Arrow Buttons” to scroll through the menu until “Adjust

Contrast” is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

1000 RPM

ENG RPM

57 PSI

OIL PRES

5. Touch the “Menu Button” to return to the main menu.

ADJUST BACKLIGHT

6. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

LOAD RPM

14.2

BATTVOLT

98%

1000 RPM

ENG RPM

57 PSI

OIL PRES

3. Once the “Adjust Contrast” menu item has been

highlighted touch the “Enter Button” to activate the

“Adjust Contrast” function.

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

ADJUST CONTRAST

G

4. Use the “Arrow Buttons” to select the desired contrast

intensity.

ADJUST CONTRAST

5. Touching the “Menu Button” will take you back through

the menus.

PAGE 26 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

DIAGNOSTIC DISPLAY

Select Units

1. Starting at the single or four engine parameter display

touch the “Menu Button”.

1000 RPM

98%

0

1500

1800 RPM

COOL

ENG RPM

3000

TEMP

LOAD RPM

14.2

BATTVOLT

2. The main menu will pop up on the display. Use the

arrow buttons to scroll through the menu until the

“Select Units” is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

ENG RPM

57 PSI

OIL PRES

5. Touch the “Enter Button” to select the highlighted units.

ENGLISH

METRIC KPA

METRIC BAR

6. Touch the “Menu Button” to return to the “Main Menu”.

ENGLISH

METRIC KPA

METRIC BAR

*

7. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

3. Once the “Select Units” menu item has been highlighted

touch the “Enter Button” to access the “Select Units”

function.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

4. Use the arrows to highlight the desired units. “English”

for imperial units i.e. PSI,”F or Metric kPa, Metric Bar

for IS units i.e. kPa, Bar, “C".

ENGLISH

ESPANOL

FRANCAIS

DEUTSCH

GO TO 1-UP DISPLAY

STORED CODES

G

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OILPRES

SETUP 1-UP DISPLAY

1. Starting at the single engine parameter display, touch

the “Menu Button”.

1000 RPM

98%

0

1500

1800 RPM

COOL

ENG RPM

3000

TEMP

LOAD RPM

14.2

BATTVOLT

2. The main menu will pop up on the display. Use the

“Arrow Buttons” to scroll through the menu until the

“Setup 1-up Display” is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

G

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

ENG RPM

57 PSI

OILPRES

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 27

DIAGNOSTIC DISPLAY

the

3. Once the “Setup 1-up Display” menu icon has been

highlighted touch the “Enter Button” to access the

“Setup 1-up display” function.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

4. Three options are available for modification of the

1-Up display.

a. Use Defaults — This option contains a set of engine

parameters: Engine Hours, Engine RPM. System

Voltage, Battery Voltage, % Engine Load at Current

RPM, Coolant Temperature, Oil Pressure.

b. Custom Setup — This option allows for the

modification of what parameter, the number of

parameters, and the order in which the parameters

are being displayed.

7. A message indicating the “Single Engine” parameter

display parameters are reset to the factory defaults will

be displayed, then the display will return to the “Custom

Setup” menu.

RESTORED TO

DEFAULTS

8. Custom Setup- To perform a custom setup of the 1-Up

Display, use the arrow buttons to scroll to and highlight

“Custom Setup” on the display.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

c. Automatic Scan — Selecting the scan function

will cause the 1-Up Display to scroll through

the selected set of parameters one at a time,

momentarily pausing at each.

5. Use Defaults- To select “Use Defaults” use the arrow

buttons to scroll to and highlight “Use Defaults” in the

menu display.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

6. Touch the “Enter Button” to activate the “Use Defaults”

function.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

9. Touching the “Enter Button” will display a list of engine

parameters.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

10. Use the “Arrow Buttons” to scroll to and highlight a

selected parameter (parameter with a # symbol to right

of it).

ENGINE SPEED

PERCENT LOAD AT CURRENT RPM

ENGINE OIL PRESSURE

ENGINE COOLANT TEMPERATURE

1

3

2

This number indicates

the order of display for

parameters and that the

parameter is selected

for display.

PAGE 28 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

DIAGNOSTIC DISPLAY

ENGINE SPEED

PERCENT LOAD AT CURRENT RPM

ENGINE OIL PRESSURE

ENGINE COOLANT TEMPERATURE

1

3

2

ENGINE SPEED

PERCENT LOAD AT CURRENT RPM

ENGINE OIL PRESSURE

ENGINE COOLANT TEMPERATURE

2

1

3

11. Touch the “Enter Button” to deselect the selected

parameter removing it from the list of parameters being

displayed on the 1-up display.

12. Use the “Arrow Button” to scroll and highlight the

desired parameter that has not been selected for

display.

ENGINE SPEED

PERCENT LOAD AT CURRENT RPM

ENGINE OIL PRESSURE

ENGINE COOLANT TEMPERATURE

2

1

Note that the numbers

now indicatethe new order

of display for the parameters.

13. Touch the “Enter Button” to select the highlighted

parameter for inclusion in the Single Engine Parameter

Display.

16. Touching the “Enter Button” toggles the “Automatic

Scan” function on.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN ON

17. Touching the “Enter Button” again toggles the

“Automatic Scan” function off.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

18. Once the “Use Defaults”, “Custom Setup” and

“Automatic Scan” functions have been set touch the

“Menu Button” to return to the main menu.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN ON

14. Continue to scroll and select additional parameters for

the custom 1-up Display. Touch the “Menu Button” at

any time to return to the “Custom Setup” menu.

15. Automatic Scan- Selecting the scan function will cause

the 1-Up Display to scroll through the selected set of

parameters one at a time. Use the “Arrow Buttons” to

scroll to the “Automatic Scan” function.

DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15) — PAGE 29

19. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

G

0

1500

1800 RPM

ENG RPM

COOL

3000

TEMP

DIAGNOSTIC DISPLAY

Setup 4-Up Display

1. From the single or four engine parameter display touch

the “Menu Button

98%

0

1500

1800 RPM

ENG RPM

COOL

3000

TEMP

LOAD RPM

14.2

BATTVOLT

2. The main menu will pop up on the display. Use the

“Arrow Buttons” to scroll through the menu until the

“Setup 4-Up Display” is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

1000 RPM

ENG RPM

57 PSI

OIL PRES

5. The “Use Defaults” screen will be displayed during the

resetting period then will automatically return to the

“Setup 4- Up Display” menu.

RESTORED TO

DEFAULTS

6. Select the “4-Up Custom Setup” from the “4-Up Setup”

menu.

USE DEFAULTS

CUSTOM SETUP

3. Once the “Setup 4-Up Display” menu item has been

highlighted touch the “Enter Button” to activate the

“Setup 4- Up Display” menu.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

4. Touch the “Enter Button” to activate the “Use Defaults”

function. This action will reset the unit to the factory

default.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

7. The quadrant with the backlit parameter value is the

current selected parameter. Use the “Arrow Buttons”

to highlight the parameter value in the quadrant you

wish to place a new parameter.

USE DEFAULTS

CUSTOM SETUP

8. Touch the “Enter Button” and a list of parameters will

appear.

125°F

COOL TEMP

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

PAGE 30 — DCA150USJ3CAN 60 HZ GENERATOR • OPERATION AND PARTS MANUAL — REV. #1 (05/19/15)

Loading...

Loading...