Page 1

OPERATION AND PARTS MANUAL

SERIES

MODEL WBH16

(GX390RT2QTT GASOLINE ENGINE

RECOIL START)

MODEL WBH16E

(GX390RT2QNB2 GASOLINE ENGINE

ELECTRIC START)

Serial No. 110401 and ABOVE

POWER BUGGY

Revision #0 (06/14/11)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingandotherconstructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonryproducts.

Arsenicandchromiumfrom chemically

treatedlumber.

Your risk from these exposures varies,

dependingonhowoftenyoudothistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 3

TABLE OF CONTENTS

WBH16/WBH16E Power

Buggy

Proposition 65 Warning ........................................... 2

Table Of Contents .................................................... 3

Parts Ordering Procedures ...................................... 4

Safety Information ..............................................5-10

Specifications ...................................................11-12

Dimensions ............................................................ 13

General Information ............................................... 14

Components .......................................................... 15

Basic Engine .......................................................... 16

Inspection ......................................................... 17-18

Operation .......................................................... 19-23

Maintenance ..................................................... 24-25

Troubleshooting ................................................26-28

Hydraulic System Diagram .................................... 29

Explanation Of Code In Remarks Column............. 30

Suggested Spare Parts ......................................... 31

Component Drawings

Nameplate And Decals ..................................... 32-33

Hydraulic Drive Assy. ........................................ 34-35

Hydraulic Pump Assy. ....................................... 36-37

Hydraulic Dump Assy. ....................................... 38-39

Pump And Coupling Assy. ................................ 40-41

Tub Assy............................................................ 42-43

Panel Assy. ....................................................... 44-45

Brake Assy. ....................................................... 46-47

Steering Assy. ................................................... 48-49

Chassis Assy.....................................................50-51

Dump Pedal And Handle Assy. ......................... 52-53

Hydraulic Oil Tank Assy. .................................... 54-55

Battery Assy. (Electric Start) ............................. 56-57

Fuel Assy. ......................................................... 58-59

Engine Assy. ..................................................... 60-61

Terms And Conditions Of Sale — Parts ................ 62

NOTICE

Specifications and part numbers are subject to change

without notice.

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 3

Page 4

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

Effective:

PARTS ORDERING PROCEDURES

Choose from three easy options:

January 1st, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specifi cation Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

Domestic (US) Dealers Call:

1-800-427-1244

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

and Password, E-mail us at: parts@multiquip.

com.

To ob ta in an MQ Account , contac t yo ur

District Sales Manager for more information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Truck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

PAGE 4 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 5

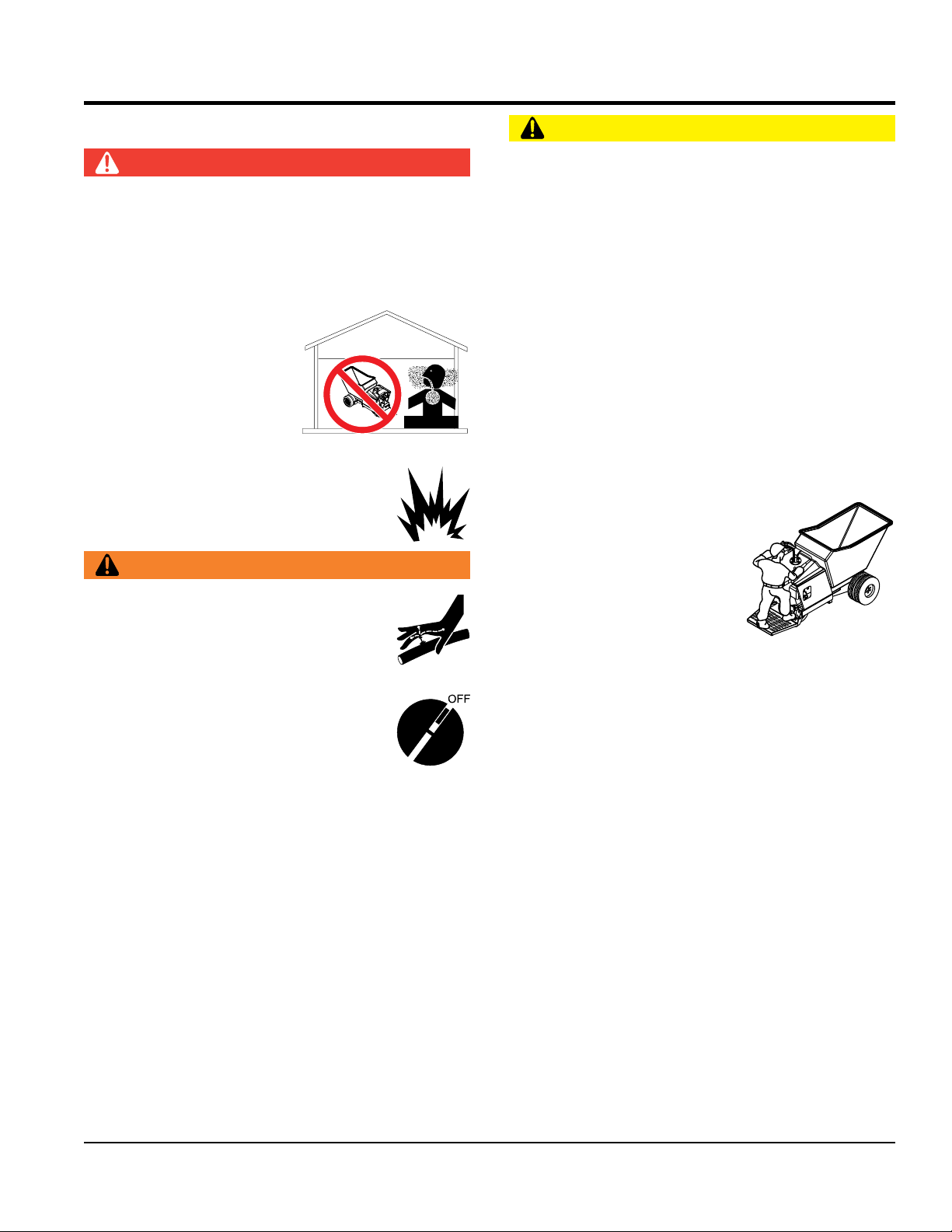

SAFETY INFORMATION

Do not operate or service the equipment before reading

Potential hazards associated with the operation of this

the entire manual. Safety precautions should be followed

at all times when operating this equipment.

Failure to read and understand the safety

messages and operating instructions could

result in injury to yourself and others.

SAFETY MESSAGES

The four safety messages shown below will inform you

about potential hazards that could injure you or others. The

safety messages specifi cally address the level of exposure

to the operator and are preceded by one of four words:

DANGER, WARNING, CAUTION or NOTICE.

SAFETY SYMBOLS

DANGER

Indicates a hazardous situation which, if not avoided,

WILL result in DEATH or SERIOUS INJURY.

WARNING

Indicates a hazardous situation which, if not avoided,

COULD result in DEATH or SERIOUS INJURY.

equipment will be referenced with hazard symbols which

may appear throughout this manual in conjunction with

safety messages.

Symbol Safety Hazard

Lethal exhaust gas hazards

Explosive fuel hazards

Burn hazards

Rotating parts hazards

CAUTION

Indicates a hazardous situation which, if not avoided,

COULD result in MINOR or MODERATE INJURY.

NOTICE

Addresses practices not related to personal injury.

Hydraulic fluid hazards

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 5

Page 6

GENERAL SAFETY

NOTICE

This equipment should only be operated by trained and

Whenever necessary, replace nameplate, operation and

accident due to equipment modifi cations. Unauthorized

recommended by Multiquip for this equipment. Damage

keep

Also, know the phone numbers

fi re department.

SAFETY INFORMATION

CAUTION

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, respiratory protection,

hearing protection, steel-toed boots and other protective

devices required by the job or city and state regulations.

Avoid wearing jewelry or loose fi tting clothes that may

snag on the controls or moving parts as this can cause

serious injury.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the

infl uence of drugs or alcohol.

ALWAYS clear the work area of any debris, tools, etc.

that would constitute a hazard while the equipment is

in operation.

qualifi ed personnel 18 years of age and older.

safety decals when they become diffi cult read.

Manufacturer does not assume responsibility for any

equipment modifi cation will void all warranties.

NEVER use accessories or attachments that are not

to the equipment and/or injury to user may result.

ALWAYS know the location of the nearest

fi re extinguisher.

ALWAYS know the location of the nearest

fi rst aid kit.

ALWAYS know the location of the nearest phone or

a phone on the job site.

of the nearest ambulance, doctor and

This information will be invaluable in the case of an

emergency.

No one other than the operator is to be in the working

area when the equipment is in operation.

DO NOT use the equipment for any purpose other than

its intended purposes or applications.

PAGE 6 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 7

SAFETY INFORMATION

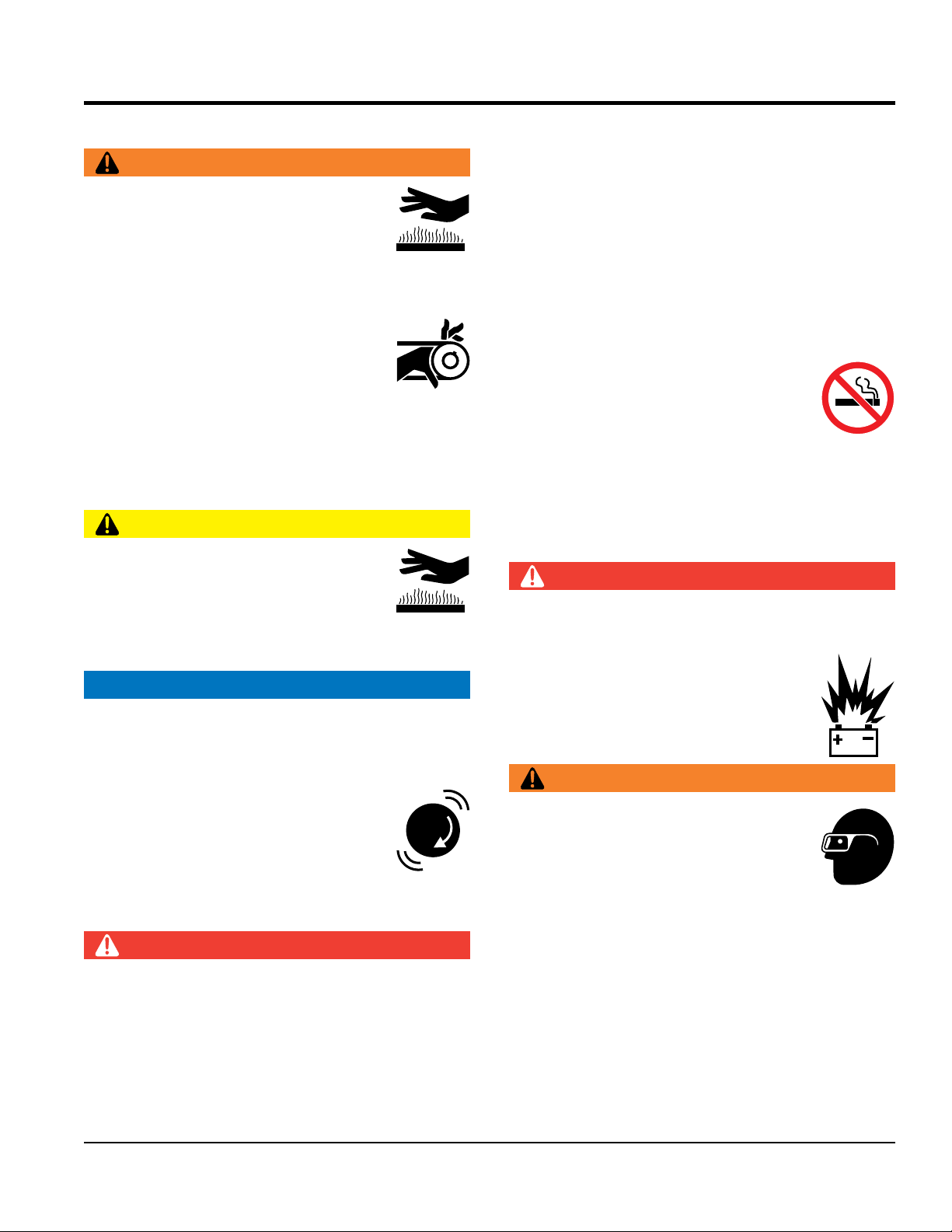

POWER BUGGY SAFETY

inspect the surface over which you will travel.

Look for holes, drop-offs and obstacles. Look for rough

and weak spots on docks, ramps or fl oor. Look for oil

spills, wet spots and slippery surfaces. Look for soft soil,

deep mud and standing water. Watch for anything that

might make you lose control or cause the power buggy

clear away trash and debris. Pick up anything

operate the power buggy on unsafe haul roads,

operate power buggy on excessive slopes with

a grade higher than 10% (6°), forward and backward or

secure the step plate (platform) in the upright

position when using the power buggy over rough terrain.

stand on the power buggy step plate (platform)

when walking in rough terrain. Walk behind the power buggy.

climb on

CAUTION

DANGER

Engine fuel exhaust gases contain poisonous carbon

monoxide. This gas is colorless and odorless, and can

cause death if inhaled.

The engine of this equipment requires an adequate free

fl ow of cooling air. NEVER operate this equipment in any

enclosed or narrow area

where free fl ow of the air is

restricted. If the air fl ow is

restricted it will cause injury

to people and property and

serio u s dama g e to th e

equipment or engine.

NEVER operate the equipment in an explosive

atmosphere or near combustible materials. An

explosion or fi re could result causing severe

bodily harm or even death.

WARNING

NEVER use your hand to fi nd hydraulic leaks.

Use a piece of wood or cardboard. Hydraulic

fl uid injected into the skin must be treated by

a knowledgeable physician immediately or

severe injury or death can occur.

Accidental starting can cause severe injury

or death. ALWAYS place the ON/OFF

switch in the OFF position.

ALWAYS

to tip over.

ALWAYS

that might puncture the tires.

ALWAYS make sure aisles, ramps, doorways and

passages are clear.

DANGEROUS

GAS FUMES

ALWAYS plan your work. Make sure you know where

you will make your pickups, dumps and turns. Before

you take a load, know where you will place it.

N EVER operate the power

buggy facing backwards. In

a ba ckwards po sition, the

opera t or cannot p r o perly

acti vate the manual brake,

emergency switch, grip the

handles or steer the machine.

ALWAYS face in the direction

of the bucket.

DO NOT

load areas, and dump areas.

DO NOT

NEVER disconnect any emergency or safety devices.

These devices are intended for operator safety.

Disconnection of these devices can cause severe injury,

bodily harm or even death. Disconnection of any of these

devices will void all warranties.

NEVER approach power lines with any part of the

buggy unless all local, state/provincial and federal

side to side.

DO NOT operate power buggy on extremely uneven

surfaces.

NEVER allow riders other than the operator on the

power buggy.

ALWAYS

(OSHA) required safety precautions have been taken.

Use extreme caution when approaching high voltage

power lines.

DO NOT

DO NOT touch, lean on or reach through the dump

mechanism or permit others to do so. NEVER

the power buggy or dump mechanism.

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 7

Page 8

SAFETY INFORMATION

DO NOT operate the power buggy at excessive speeds.

ALWAYS block the power buggy with appropriate blocks

start

Make sure that the tires are infl ated to the manufacturer’s

operate the power buggy with bad or worn tires.

make sure the hydraulic dumping mechanism

Avoid sudden stops and starts and changes in direction.

jerk the steering

keep the machine in proper running condition.

The entire power buggy (tub, step plate, shroud, wheels,

etc.) should be cleaned after every use. Make sure there

store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children and unauthorized personnel.

Reckless operation may cause accidents and severe

injury. Slow down when approaching people, wet areas,

and going up and down grades. It is the responsibility of

the operator to adjust speed, as necessary, depending

on the conditions of the road or path.

ALLOW extra time to stop when operating the power

buggy ion wet surfaces or loosely graded materials.

ONLY remove the outer tires when it is necessary to

reduce the width of the power buggy in order to access

narrow work areas. If outer tires are removed, the power

buggy must only be used on level, solid surfaces such

as concrete, asphalt, or compacted stone to prevent the

power buggy from tipping. The maximum load must also

be reduced to 1000 lb.

DO NOT dump materials that are large and chunky.

These types of material may shift causing the power

buggy to tip and throw the operator off the machine. The

power buggy is intended for dumping free-fl owing and

loose materials such as dry soil, slag, and wet concrete.

DO NOT dump materials from bucket while the power

buggy is moving.

when leaving the power buggy parked on a slope.

To prevent unexpected loss of control, DO NOT

engine on a sloping surface.

Ensure that the speed control lever works freely and

returns to the closed position. DO NOT start engine

unless speed control linkage is working properly.

recommended tire pressure.

NEVER

ALWAYS replace defective tires with new ones.

ALWAYS

of the tub is working properly.

Operate the controls smoothly. DO NOT

or any other controls.

NEVER attempt to work the control except from the

operator’s position.

NEVER drive or tow the power buggy in traffi c or on

public roads.

For walk behind operation, the operator platform must be

stowed and locked in the up position. The speed should

also be reduced to 3 mph or slower.

NOTICE

ALWAYS ensure power buggy is securely placed on

appropriate blocks or jackstands when performing

maintenance requires elevation of the buggy.

ALWAYS make sure the power buggy’s brakes are

working properly. Check brake linkage and adjust as

required. NEVER operate the power buggy with a

defective braking system.

Ensure brakes are applied when leaving or when using

on a slope.

When parking on a slope, position the power buggy at

a right angle to a slope. Ensure that the parking brake

is engaged and holds the power buggy safely in place

when parking on a slope.

ALWAYS

Fix damage to machine and replace any broken parts

immediately.

is no buildup of concrete, grease, oil or debris on the

machine.

ALWAYS

PAGE 8 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 9

ENGINE SAFETY

WARNING

ALWAYS use extreme caution when working with

overfi ll tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

leave the power buggy in the vicinity of ovens,

drop the battery. There is a possibility that the

keep the battery charged. If the battery is not

charge battery if frozen. Battery can explode.

DO NOT place hands or fingers inside

engine compartment when e ngine is

running.

SAFETY INFORMATION

fl ammable liquids.

DO NOT fi ll the fuel tank while the engine is running

or hot.

DO NOT

NEVER operate the engine with heat shields or

guards removed.

Keep fi ngers, hands hair and clothing away

from all moving parts to prevent injury.

ALWAYS shut down the engine before

performing service or maintenance.

DO NOT remove the engine oil drain plug while the

engine is hot. Hot oil will gush out of the oil tank and

severely scald any persons in the general area of the

power buggy.

CAUTION

NEVER touch the hot exhaust manifold,

muffl er or cylinder. Allow these parts to cool

before servicing equipment.

Make certain the operator knows how to and is capable

of turning the engine OFF in case of an emergency.

NOTICE

NEVER run engine without an air fi lter or with a dirty air

fi lter. Severe engine damage may occur. Service air fi lter

frequently to prevent engine malfunction.

NEVER tamper with the factory settings

of the engine or engine governor. Damage

to the engine or equipment can result

if operating in speed ranges above the

maximum allowable.

the ignition system.

Store fuel in appropriate containers, in well-ventilated

areas and away from sparks and fl ames.

NEVER use fuel as a cleaning agent.

DO NOT smoke around or near the equipment.

Fire or explosion could result from fuel vapors

or if fuel is spilled on a hot engine.

DO NOT

furnaces or radiant heaters. Heat could raise the

pressure of the fuel so that vented gas could ignite.

BATTERY SAFETY (ELECTRIC START ONLY)

DANGER

DO NOT

battery will explode.

DO NOT expose the battery to open fl ames,

sparks, cigarettes, etc. The battery contains

combustible gases and liquids. If these

gases and liquids come into contact with a

fl ame or spark, an explosion could occur.

WARNING

A LWAYS wear safety glasses when

handling the battery to avoid eye irritation.

The battery contains acids that can cause

injury to the eyes and skin.

FUEL SAFETY

DANGER

DO NOT start the engine near spilled fuel or combustible

fl uids. Fuel is extremely fl ammable and its vapors can

cause an explosion if ignited.

ALWAYS refuel in a well-ventilated area, away from

sparks and open fl ames.

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 9

Use well-insulated gloves when picking up

the battery.

ALWAYS

charged, combustible gas will build up.

DO NOT

When frozen, warm the battery to at least 61°F (16°C).

Page 10

ALWAYS recharge the battery in a well-ventilated

environment to avoid the risk of a dangerous concentration

TRANSPORTING SAFETY

When transporting of the power buggy is required, place

underneath wheel to prevent rolling.

When transporting the power buggy on a truck or trailer,

pour waste, oil or fuel directly onto the ground,

of combustible gases.

SAFETY INFORMATION

NOTICE

If the battery liquid (dilute sulfuric acid)

comes into contact with clothing or skin,

rinse skin or clothing immediately with

plenty of water.

If the battery liquid (dilute sulfuric acid) comes into

contact with eyes, rinse eyes immediately with plenty

of water and contact the nearest doctor or hospital to

seek medical attention.

CAUTION

ALWAYS disconnect the NEGATIVE battery terminal

before performing service on the equipment.

ALWAYS keep battery cables in good working condition.

Repair or replace all worn cables.

LIFTING SAFETY

CAUTION

NEVER allow any person or animal to stand underneath

the equipment while lifting.

NOTICE

When lifting of the power buggy is required, use a

properly rated forklift. Forklift pockets are provided on

the power buggy's frame. Make sure the forklift arms are

insert into the power buggy's fork lift pockets a minimum

of 24-inches.Before lifting, make sure that the lifting bale

is not damaged.

ALWAYS shutdown engine before transporting.

Tighten fuel tank cap securely and close fuel cock to

prevent fuel from spilling.

the power buggy on a fl at bed truck or equivalent and

tie down securely.

ALWAYS make sure all tie-downs and block are in

place and the bucket is completely lowered in the fl at

(horizontal) position and securely latched.

Place chock blocks

know the overall height to avoid contacting overhead

obstructions such as bridges and power lines. Check

the truck and ramp capacities.

ENVIRONMENTAL SAFETY

NOTICE

Dispose of hazardous waste properly. Examples of

potentially hazardous waste are used motor

oil, fuel and fuel fi lters.

DO NOT use food or plastic containers to

dispose of hazardous waste.

DO NOT

down a drain or into any water source.

NEVER tip the engine to extreme angles during lifting as

it may cause oil to gravitate into the cylinder head, making

the engine start diffi cult.

DO NOT lift machine to unnecessary heights.

NEVER lift the equipment while the engine is running.

ALWAYS use ramps capable of supporting the weight

of the power buggy and the operator to load and unload

the power buggy.

PAGE 10 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 11

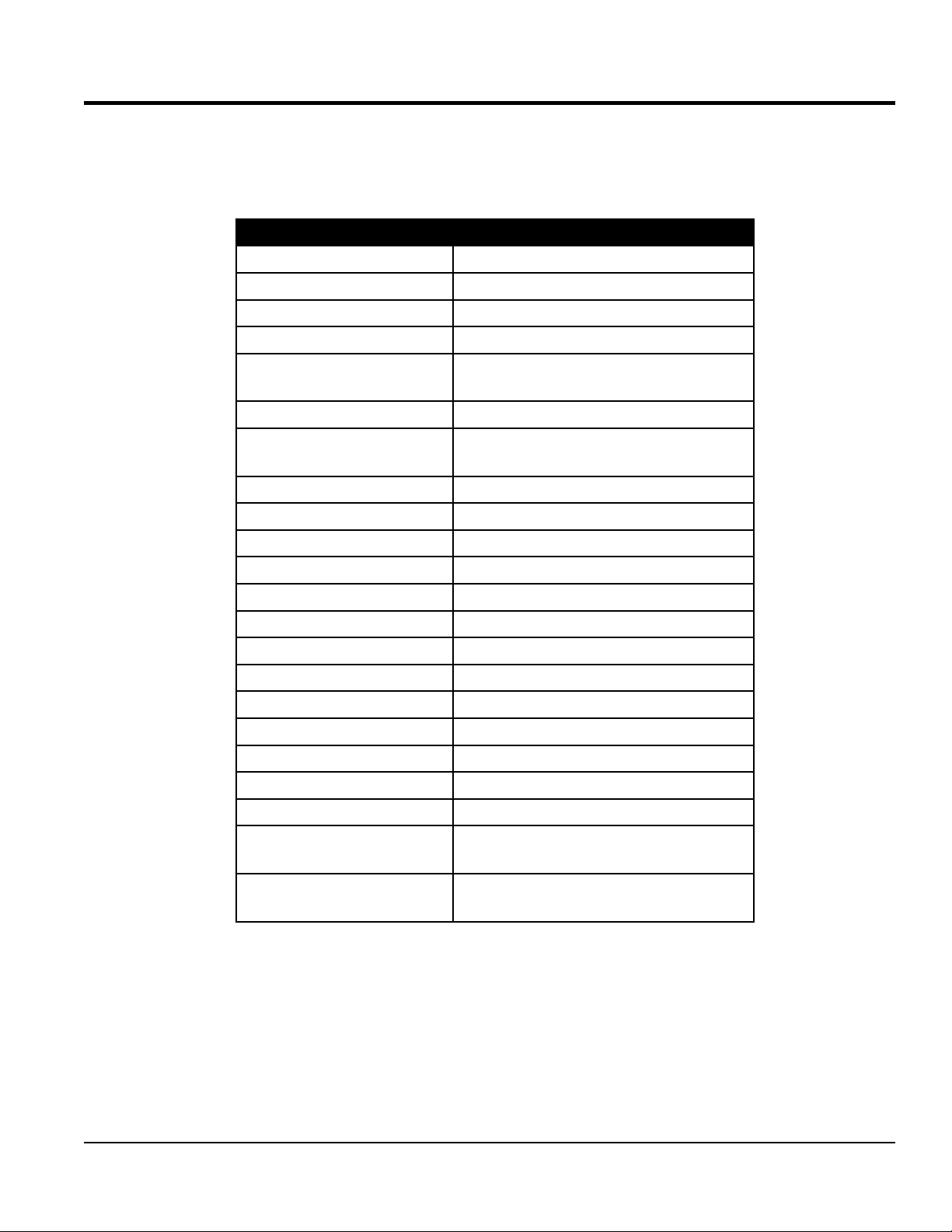

SPECIFICATIONS

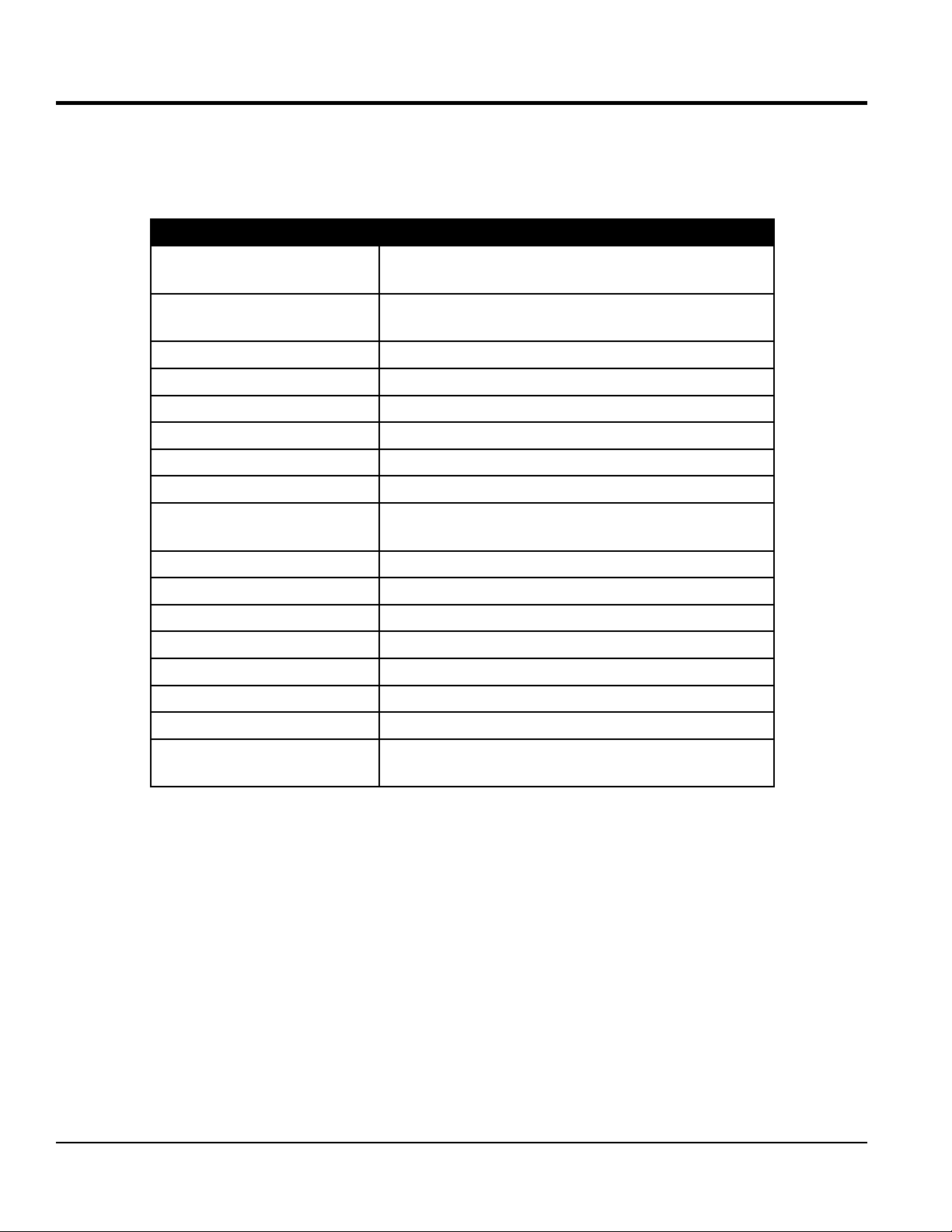

Table 1. Specifications (Power Buggy)

Models WBH16/WBH16E

Wheelbase 44 in. (1,117.6 mm)

Overall Length 103 in. (2,616.2 mm)

Overall Width- Dual Wheels 43.25 in. (1,098.6 mm)

Maximum Weight Capacity

(Dual Wheels)

Overall Width- Single Wheel 32 in. (813 mm)

Maximum Weight Capacity

(Single Wheel)

Overall Height 53 in. (1346.2 mm)

Operating Weight 1,200 lbs. (544.2 kg.)

Ship Weight Palletized 1,260 lbs. (585 kg.)

Bucket Capacity 16 cu. ft. Water Level (.59 cu. yd.)

Drive Hydrostatic

Speed Up to 7.25 mph. (11.67 km/h)

Steering Handle Bars To Rear Wheels

Brakes (Drive Wheels) Dynamic Hydrostatic

Parking Brake ( Drive Wheels) Mechanical

Dump Control Hydraulic Dump and Return

Discharge Height 6.0 in. (152 mm)

Ground Clearance 6.0 in. (152 mm)

Turning Radius 73.5 in. (1867 mm)

30.25 in. (738.65 mm) 2,500 lbs.

(1,136 kg)

1,100 lbs. (499 kg)

Tires ( Drive Wheels)

Tires (Steering)

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 11

5.70 x 8.0 x 19.0 in.

(145 x 203 x 483 mm)

4.80 x 8.0 in.

(122 x 203 mm)

Page 12

Table 2. Specifications (Engine)

SPECIFICATIONS

Model

Bore X Stroke

Displacement 389 cc

Maximum Power 11.7 hp (3,600 rpm)

Maximum Torque 19.5 ft-lbs. (2.7 kg-m) @ 2,500 rpm

Compression Ratio 8.0 : 1

Idle Speed 1,400 ± rpm

Maximum No Load RPM 3.850 ± rpm

Specific Fuel Consumption

Fuel Tank Capacity 5.5 gal. (20.81 liters)

Crankcase Oil Capacity 1.16 qts. (1.1 liters)

Ignition Timing BTDC25

Starting System Recoil/Electric

Air Cleaner Cyclone Type

Noise Level STD,OP 82.78 (S,S)

GX390RT2QTT (Recoil Start)

GX390RT2QNB2 (Electric Start)

3.46 x 2.51 in.

(88 x 64 mm.)

1 gal./hr.

(3.78 liters/hr.)

Dry Weight 68.3 lbs. (31.0 kg.)

Outside Dimensions L X W X H

PAGE 12 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

15.9 x 17.7 x 17.4

(405 X 450 X 443 mm.)

Page 13

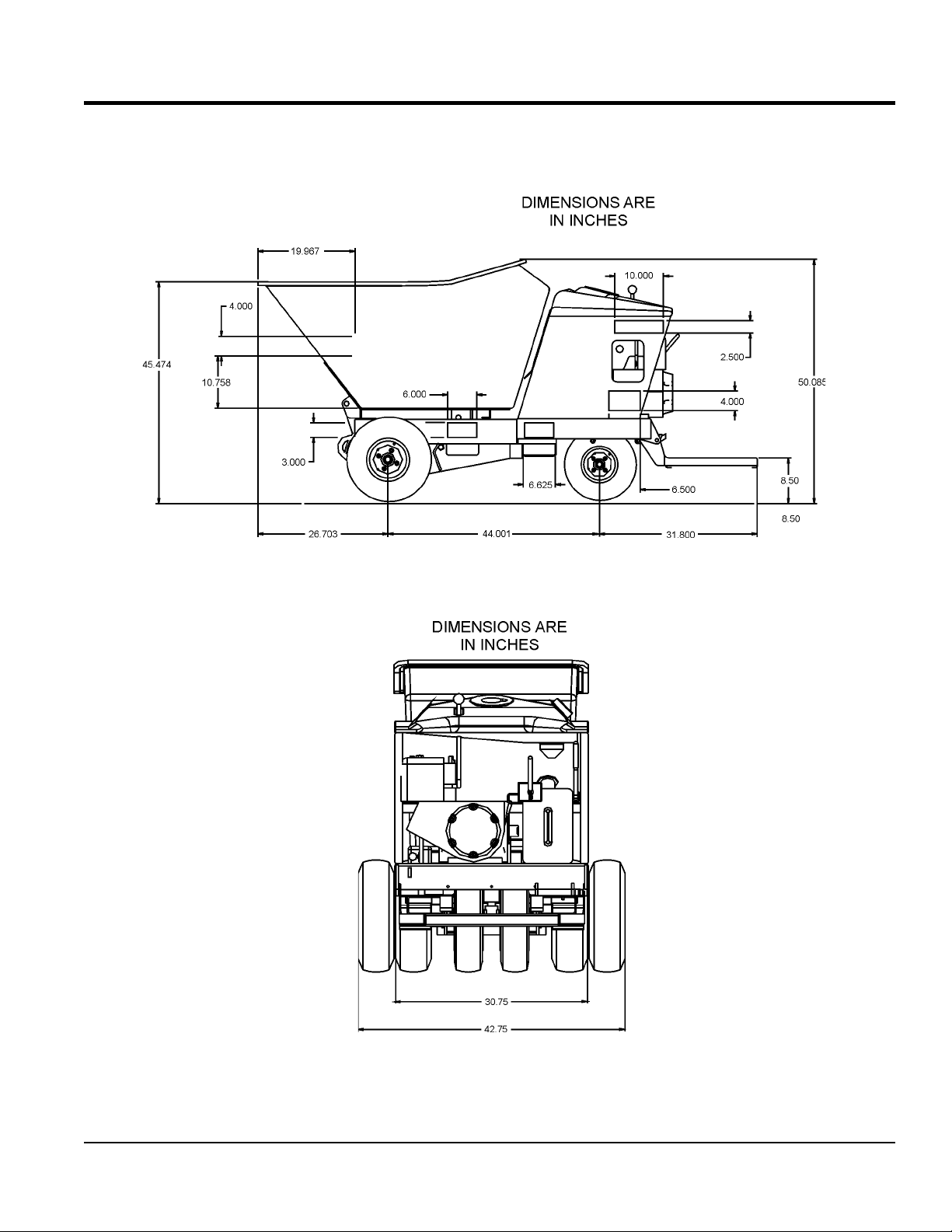

DIMENSIONS

SIDE VIEW

REAR VIEW

Figure 1. WBH16/WBH16E Dimensions

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 13

Page 14

GENERAL INFORMATION

The MQ Whiteman Power Buggy, Models WBH16 (recoil

start) and WBH16E (electric start) are intended for the

transportation of concrete, concrete spreading and spot

pouring. In addition, the WBH16/WBH16E is designed for

landscaping applications, material sub-base distribution,

job site cleanup and material transport.

The Power Buggy is equipped with a 6-inch dump height

which provides clearance and enables the operator to

maneuver over any form height. In addition, it has a unique

polyethylene tub design that reduces concrete splatter.

A low center of gravity has been incorporated into the

design which provides added safety when maneuvering

the buggy in tight areas. A 5.5-gallon fuel tank allows for

extended uninterrupted use. Maximum speed of the power

buggy is rated at 7.25 MPH.

The maximum weight capacity of the Power Buggy is 2,500

lbs. (1,136 kg). The outer wheels can be removed to allow

the buggy to pass through a 32 in. (81.28 cm.) door.

Hand and foot controls are provided for ease of dumping

and stopping of the WBH16/WBH16E. Multiple lift points

have been provided to allow for easy access of a forklift

when lifting is required.

The WBH16/WBH16E is powered by a HONDA GX390

air cooled gasoline engine rated at 11.7 HP at 3600 RPM

The engine drives a variable displacement hydrostatic

transmission which is activated by a cable controlled

hand lever. The hydraulic fluid flows to a divider valve

which directs the fluid to the forward reverse and dumping

systems.

The operator controls the forward and reverse machine

travel by manually shifting the control valve which directs

the hydraulic fluid flow to the two drive wheel motors. The

flow to the dump cylinder is also controlled by a manually

operated control valve.

This hydraulic system uses a parallel loop configuration,

operating at a maximum of 1450 PSI. The system also

features a neutral position which allows the power buggy

to be moved in the event of an emergency.

The hydraulic oil is filtered by a screen type filter located in

the hydraulic tank, then doubled filtered within the system

by a 10 micron cartridge spin-on return filter.

WARNING

All operators must have training before operating the

WBH16/WBH16E. For your safety, warnings are on

the machine and in this manual. Failure to obey these

warnings can cause severe injury or even death.

CAUTION

DO NOT attempt to operate the power

buggy until the Safety Information, General

Information, and Inspection sections of this

manual have been read and thoroughly

understood.

PAGE 14 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 15

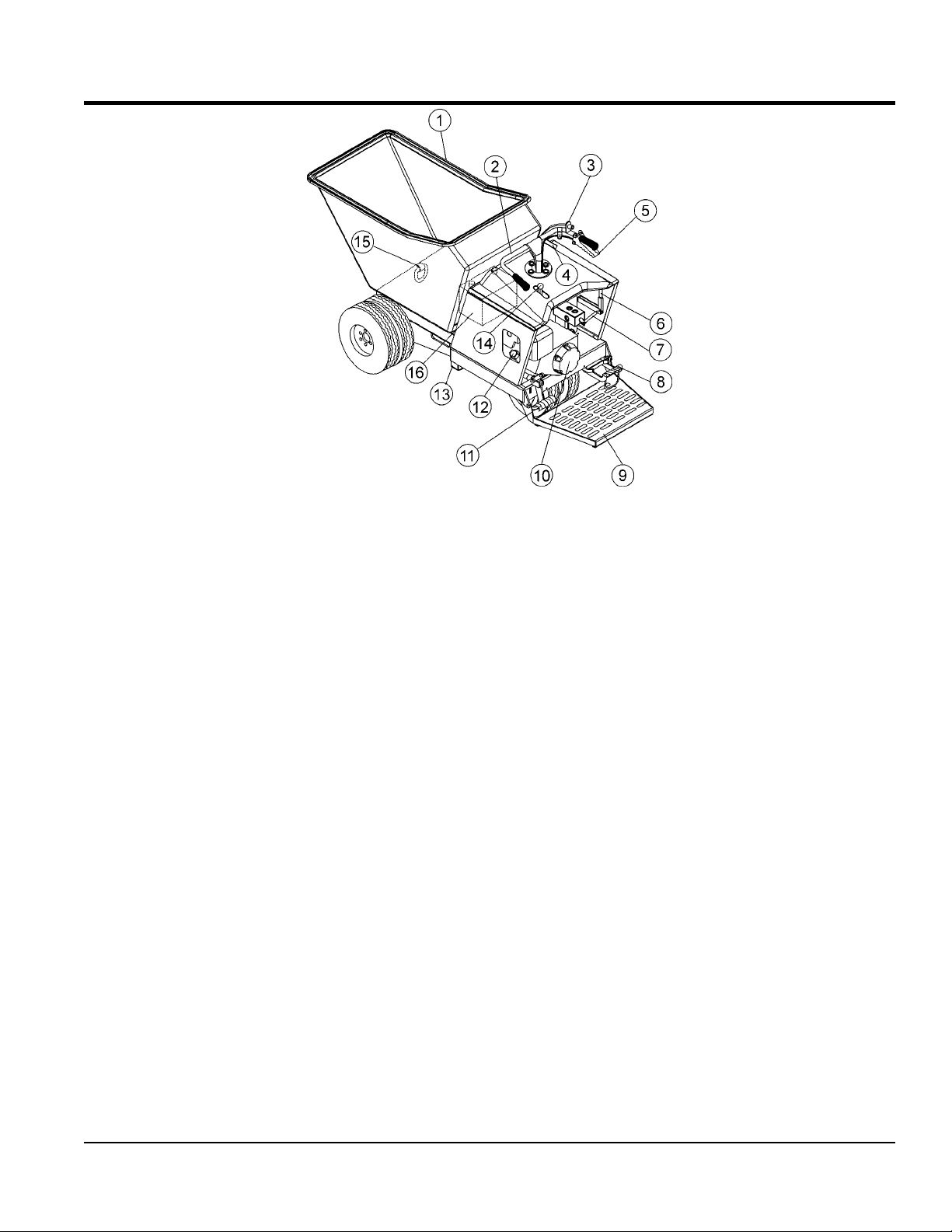

Figure 2. WBH16/WBH16E Power Buggy

Components

COMPONENTS

1. Tub or Bucket — Used for the transportation of

material. Tub holds approximately 16 cubic feet

(0.59 cubic yards) of water.

2. Handle Bar (Steering) — This handle bar is used

to steer the buggy. When driving the buggy, use both

hands and hold onto both handle bar grips.

3. Kill Switch — In the event of an emergency, press this

button to stop the engine.

4. Fuel Tank/Cap — Remove this cap to add fuel. Tank

holds approximately 5.5 U.S. gallons. Do not over fill.

5. Speed Control — Sets the power buggy's travel speed.

When fully depressed, the buggy will be at FULL speed.

When released, the buggy will STOP.

6. Parking Brake Lever — When this lever is activated

(pulled down), the parking brake will be set. To release

the brake, pull the lever upwards.

7. Travel Lever — When the travel lever is pushed

forward, the buggy will travel in the forward direction.

Placing the travel lever in the backward position will

cause the buggy to travel in the reverse direction.

Center position is neutral.

8. Brake Pedal — Press this pedal with the right foot to

stop the buggy.

10. Engine — The WBH16 uses a HONDA GX390RT2QTT

(recoil start) engine. The WBH16E uses a HONDA

GX390RT2QNB2 (electric start) engine.

11. Dump Pedal — Use this pedal to place the tub in the

dump position (vertical). Press pedal a second time to

return tub to the travel position (horizontal).

12. Hydraulic Tank/Cap — Remove this cap to add

hydraulic oil. Tank holds approximately 6.0 U.S. gallons.

DO NOT over fill.

13. Forklift Pockets — Use these fork lift pockets to lift

the power buggy with a forklift. Remember to insert the

forks of the fork lift a minimum of 24 inches into power

buggy's fork lift pockets.

14. Dump Control Lever — Use this lever forward to place

the tub in the dump position (vertical), move the lever

backward to return the tub to travel position (horizontal).

15. Towing Hook — Use this hook to tow the buggy if it

gets stuck. This hook is NOT intended for towing the

buggy on public roads at high speeds.

16. Battery — Used in the electric-start power buggy

(WBH16E) only. Always use gloves and eye protection

when handling the battery.

9. Operator Platform — When the buggy is in use, the

operator shall ALWAYS stand on this platform while

holding onto the handle bar (steering).

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 15

Page 16

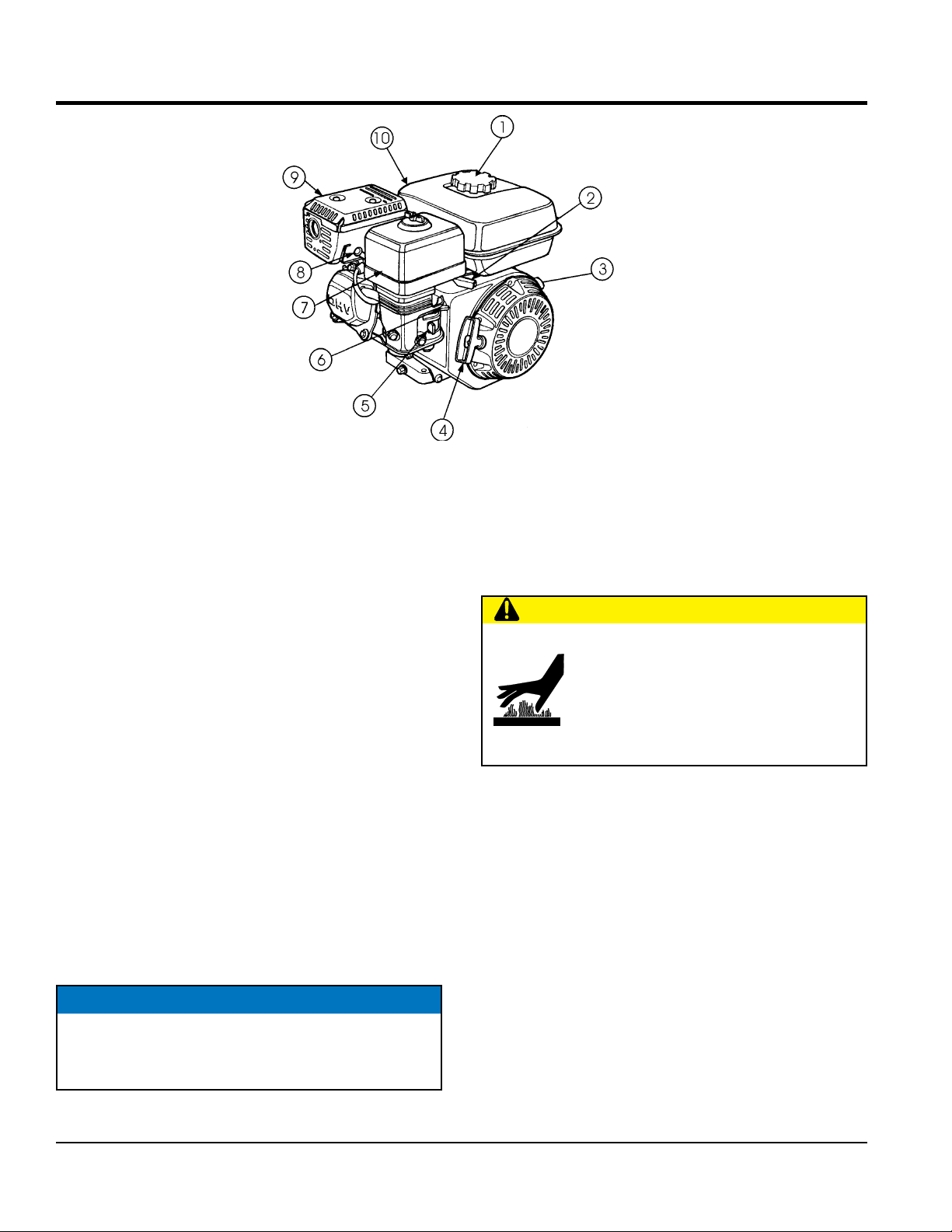

Figure 3. Honda GX390K1 Engine

BASIC ENGINE

1. Fuel Filler Cap — Remove this cap to add unleaded

gasoline to the fuel tank. Make sure cap is tightened

securely. DO NOT over fill.

2. Throttle Lever — Used to adjust engine RPM speed

(lever advanced forward - SLOW, lever back toward

operator - FAST).

3. Engine ON/OFF Switch — ON position permits engine

starting, OFF position stops engine operation.

4. Recoil Starter (pull rope) — Manual-starting method.

Pull the starter grip until resistance is felt, then pull

briskly and smoothly.

5. Fuel Valve Lever — OPEN to let fuel flow, CLOSE to

stop the flow of fuel.

6. Choke Lever — Used in the starting of a cold engine,

or in cold weather conditions. The choke enriches the

fuel mixture.

7. Air Filter — Prevents dirt and other debris from

entering the fuel system. Release the latches on

the sides of the air filter cover to gain access to filter

element.

8. Spark Plugs — Provides spark to the ignition system.

Set spark plug gap to 0.70- 0.76 mm (0.028 - 0.030 in.)

Clean spark plug once a week.

9. Muffler — Used to reduce noise and emissions.

CAUTION

Engine components can generate extreme

heat. To prevent burns, DO NOT touch

these areas while the engine is running

or immediately after operating. NEVER

op erate t he engine with the muffle r

removed.

10. Fuel Tank — Holds unleaded gasoline. For additional

information, refer to engine owner's manual.

NOTICE

Operating the engine without an air filter or with a

damaged or worn air filter will allow dirt to enter the

engine causing rapid engine wear.

PAGE 16 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 17

INSPECTION

BEFORE STARTING

1. Read safety information at the beginning of manual.

2. Clean the machine, removing dirt and dust, particularly

the engine cooling air inlet, carburetor and air cleaner.

3. Check the air filter for dirt and dust. If air filter is dirty,

replace air filter with a new one.

4. Check carburetor for external dirt and dust. Clean with

dry compressed air.

5. Check fastening nuts and bolts for tightness.

ENGINE OIL CHECK

1. To check the engine oil level, place the buggy on secure

level ground with the engine stopped.

2. Remove the filler cap/dipstick from the engine oil filler

hole (Figure 4) and wipe it clean.

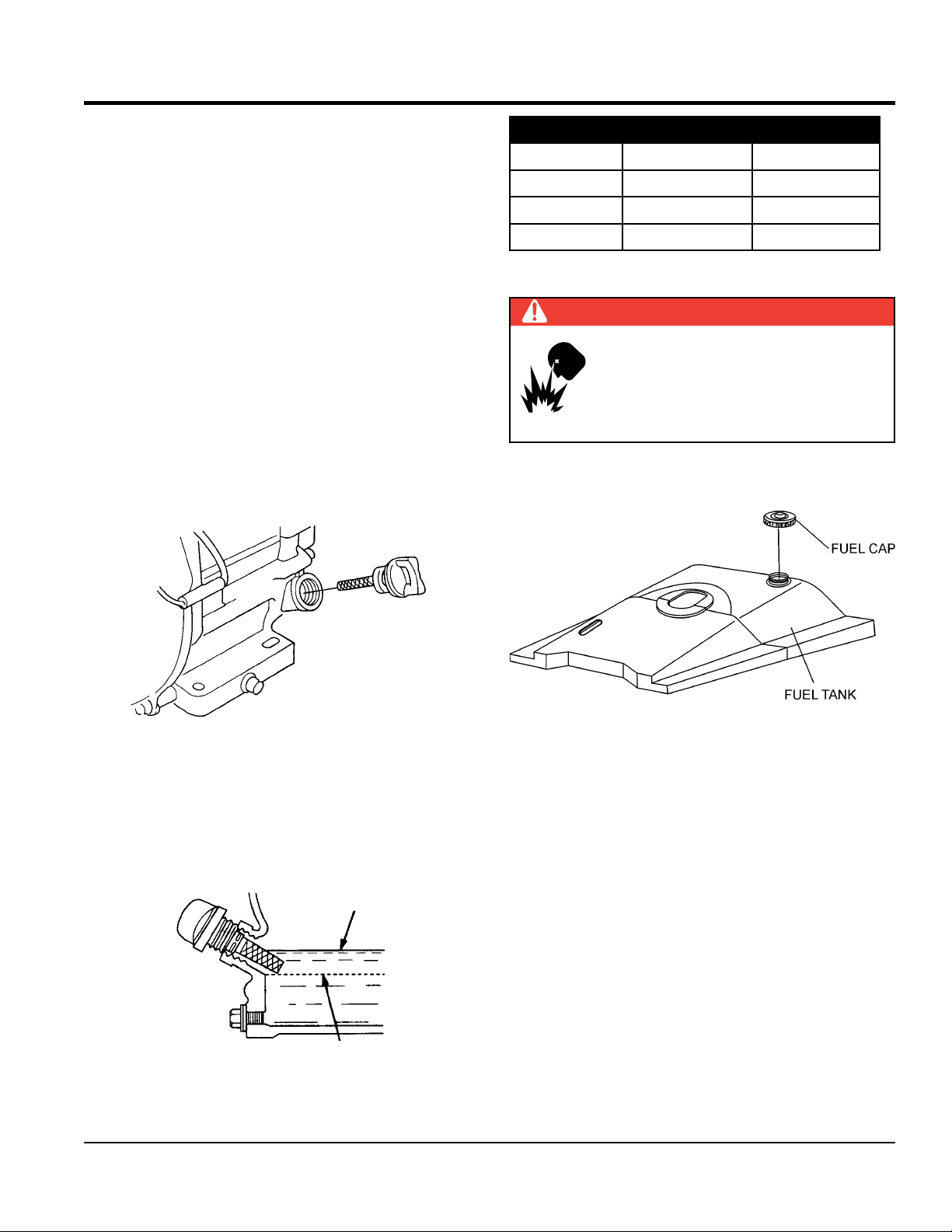

Table 3. Oil Type

Season Temperature Oil Type

Summer 25°C or Higher SAE 10W-30

Spring/Fall 25°C~10°C SAE 10W-30/20

Winter 0°C or Lower SAE 10W-10

GASOLINE CHECK

DANGER

Motor fuels are highly flammable and can

be dangerous if mishandled. DO NOT

smoke while refueling. DO NOT attempt

to refuel the pump if the engine is hot or

running.

1. Remove the gasoline cap (Figure 6) located on top

of fuel tank.

Figure 4. Engine Oil Dipstick Removal

3. Insert and remove the dipstick without screwing it into

the filler neck. Check the oil level shown on the dipstick.

4. If the oil level is low (Figure 5), fill to the edge of the

oil filler hole with the recommended oil type (Table 3).

Maximum oil capacity is 400 cc.

2. Visually inspect to see if fuel level is low. If fuel is low,

replenish with unleaded fuel.

3. When refueling, be sure to use a strainer for filtration.

Do not top-off fuel. Wipe up any spilled fuel.

Figure 6. Fuel Tank

TIRE PRESSURE CHECK

The wheels and tires of the WBH16/WBH16E are very

important in its effective operation.

1. Check the tires regularly to make certain the lugs nuts

are tight

Figure 5. Oil Level

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 17

2. Make sure tires are inflated to manufacturer's

suggested tire pressure. Do not operate the buggy

with bad or worn tires.

Page 18

PARKING BRAKE CHECK

Check the brakes as outlined in the maintenance section

of this manual.

LINKAGE CHECK

Check and make sure that all linkages within the buggy are

functioning correctly.

STEERING CHECK

1. Check and make sure that the power buggy's steering

turns freely and that there is no binding.

2. Make sure that the zerk fitting for the steering has

been lubricated.

DUMP CYLINDER CHECK

1. Check the power buggy's dump cylinder as outlined in

the operation section of this manual.

INSPECTION

2. Make sure that both zerk fittings for the dump cylinder

have been lubricated.

HYDRAULIC OIL CHECK

3. Visually read the hydraulic sight glass (Figure 7) to see

if the hydraulic oil level is low.

4. If the hydraulic oil is low, add enough hydraulic oil to

bring oil level to a normal safe operating level.

Figure 7. Hydraulic Sight Glass

PAGE 18 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 19

OPERATION

CAUTION

DO NOT attempt to operate the power

buggy until the Safety Information, General

Information, and Inspection sections of this

manual have been read and thoroughly

understood.

ELECTRIC START (WBH16E ONLY)

1. Before attempting to start the power buggy, make sure

that the safety kill switch (Figure 19) is not pushed

in. The power buggy will not start with the kill switch

engaged.

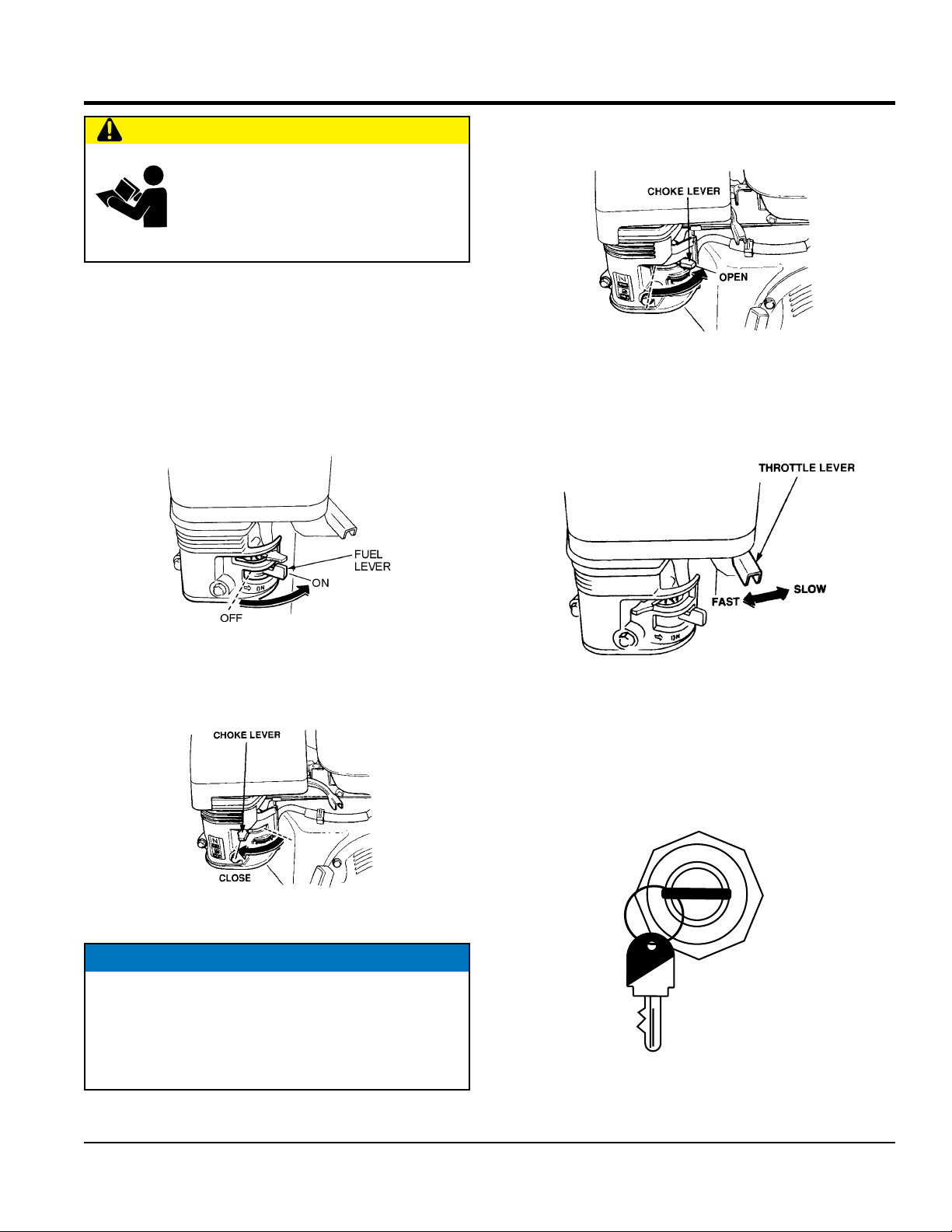

2. Place the engine fuel lever to the ON position.(Figure 8).

4. Place the choke lever (Figure 10) in the OPEN position

if starting a warm engine or the temperature is warm.

Figure 10. Engine Choke Lever (Open)

5. Move the throttle lever halfway between the FAST and

SLOW position (Figure 11) for starting.

Figure 8. Engine Fuel Lever (ON Position)

3. Place the choke lever (Figure 9) in the CLOSED

position if starting a cold engine.

Figure 9. Engine Choke Lever (Closed)

NOTICE

The CLOSED position of the choke lever enriches

the fuel mixture for starting a cold engine. The OPEN

position provides the correct fuel mixture for normal

operation after starting, and for restarting a warm

engine.

Figure 11. Throttle Lever

6. Turn the engine ON/OFF switch (Figure 12 )to the

START position and hold it until the engine starts. When

engine starts, release the key, allowing it to return to

the ON position.

F

F

O

O

N

S

T

A

R

T

Figure 12. Engine ON/OFF Switch

(Electric Start)

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 19

Page 20

OPERATION

7. Make sure the choke lever is in the OPEN position

(Figure 10) before operating the power buggy. Before

the buggy is placed into operation, run the engine for

several minutes. Check for fuel leaks, and noises that

would associate with a loose guard or cover.

RECOIL START

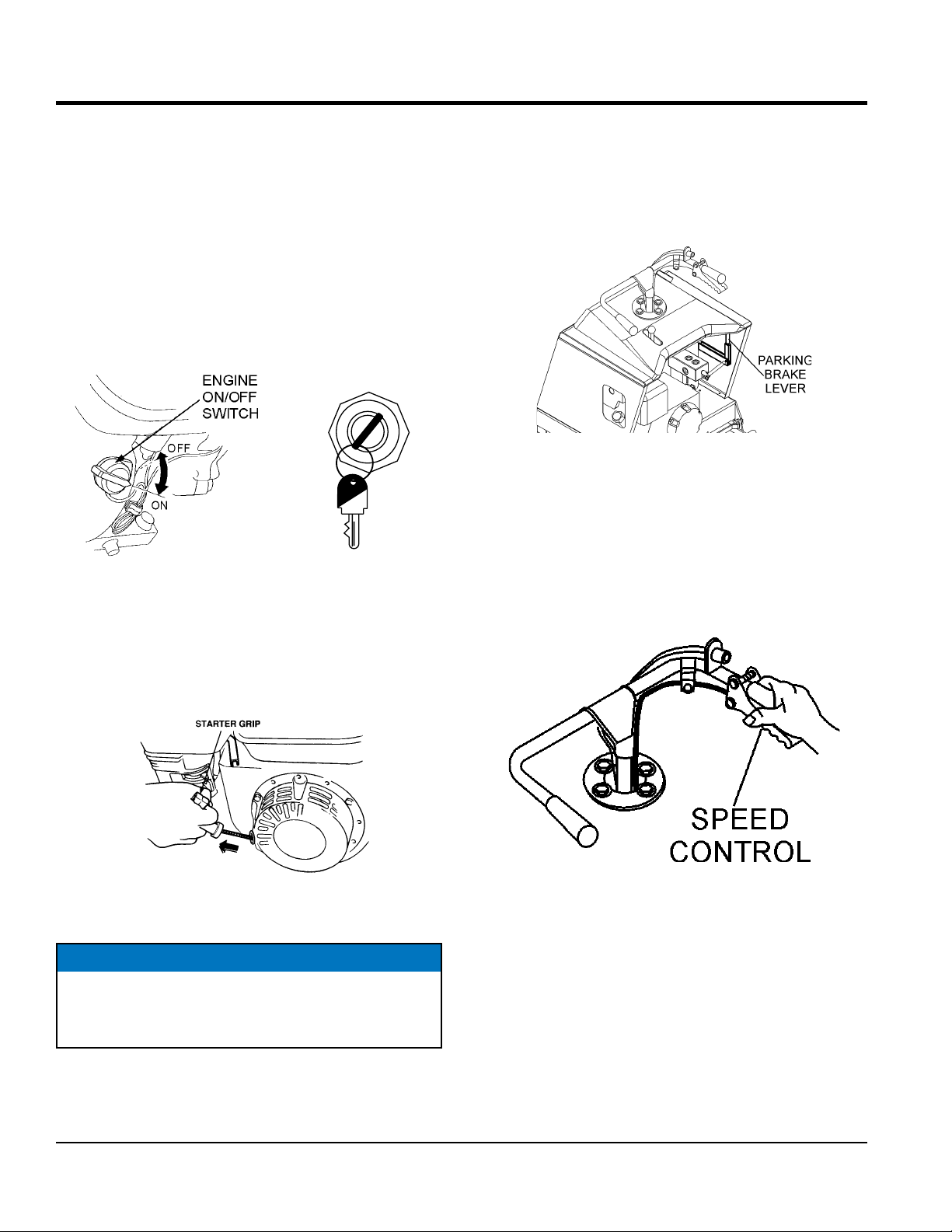

1. Follow steps 1 through 5 of the Electric Start procedure.

2. Place the Engine ON/OFF switch (Figure 13) in the

ON position.

F

F

O

O

N

S

T

A

R

T

OR

Figure 13. Engine ON/OFF Switch (Recoil Start)

3. Grasp the starter grip (Figure 14) and slowly pull it

out. The resistance becomes the hardest at a certain

position, corresponding to the compression point. Pull

the starter grip briskly and smoothly for starting.

PRE-CHECK

1. Engage the parking brake lever (Figure 15) and attempt

to rock the buggy back and forth. If the wheels turn

during the rocking motion, adjust the brakes as outlined

in the maintenance section of this manual.

Figure 15. Parking Brake Lever

2. Place the engine's throttle lever (Figure 11) in the slow

(idle) position.

3. Check the speed control lever (Figure 16) located on

the right side of the handle bar. The speed control

should work freely when squeezed by hand, and return

to the closed position when released.

Figure 14. Starter Grip

Figure 16. Speed Control Lever

NOTICE

DO NOT pull the starter rope all the way to the end.

DO NOT release the starter rope after pulling. Allow it

to rewind as soon as possible.

4. If the engine has started, slowly push the choke lever

inward to the RUN position. If the engine has not

started, repeat steps 1 through 3.

PAGE 20 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 21

OPERATION

PARKING BRAKE/DIRECTION LEVER

Before the power buggy can be put into operational use,

it is best to perform a test run to make certain that all

components are functioning properly.

1. Place the buggy on flat solid ground.

2. Engage the parking brake lever.

3. Place the engine's throttle control (Figure 11) in the

SLOW (idle) position.

4. Place the power buggy's direction lever (Figure 17) in

the forward direction.

3. When using the buggy for the first time, test the brake.

With the right foot, step up and place it on the brake

pedal (Figure 18). Gradually apply pressure to the

brake pedal until the buggy comes to rest.

Figure 17. Direction Lever

5. Slowly squeeze the speed control lever slightly

(Figure 16), for a short period of time to test the brake

holding capacity. If the buggy moves forward, adjust

the brakes as outlined in the maintenance section of

this manual.

6. If the buggy does not move forward, release the

speed control, and disengage the parking brake. If

the buggy creeps forward or reverse while the parking

brake is disengaged, the machine will require service

adjustment of the pump control lever as outlined in the

maintenance section of this manual.

TRAVELING

1. With the engine running and parking brake released,

place the direction lever (Figure 17) in the forward

direction.

2. Squeeze the speed control lever (Figure 16) slightly

until the buggy begins to move in a forward direction.

Initially, let the buggy travel at about 3 MPH.

Figure 18. Brake Pedal

4. Test the brake at different speeds until you are

comfortable with stopping the buggy. If the brakes

do not seem to stop the buggy adequately, refer to

the maintenance section of this manual for brake

adjustment instructions.

5. When starting and stopping is confirmed to be

functioning properly, the buggy is ready for operation.

SHUTDOWN (NORMAL)

Correct shutdown is important to safe operation. Follow

these general steps:

1. Come to a full stop.

2. Engage the parking brake (Figure 15).

3. Place the throttle lever (Figure 11) in the slow position.

Idle engine 3-5 minutes for gradual cooling.

4. Turn the engine on/off switch (Figure 12 or Figure 13)

to the OFF position to shut down the engine.

5. Cycle hydraulic controls to eliminate residual pressure.

6. Remove ignition key on electric start models.

7. Block wheels if on a slope or incline.

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 21

Page 22

OPERATION

EMERGENCY SHUTDOWN

The WBH16/WBH16E is equipped with a safety kill switch.

This switch is located on the right side of the handle bar.

1. Press the power buggy's kill switch (Figure 19) and

listen for the engine to stop.

Figure 19. Safety Kill Switch

2. Engage the parking brake (Figure 15).

CAUTION

DO NOT steer the buggy left or right when traveling up

or down on a grade. Travel in a straight path.

CAUTION

Avoid sudden and quick turns. When steering, turn

the handle bar slowly. Always face the controls when

traveling.

TRAVELING ON A SLOPE

1. When traveling on a slope, it is necessary to determine

the grade of the path. The WBH16/WBH16E can travel

up, down or side to side on a maximum grade of 10%

(6°). Do not travel on steeper slopes.

To determine the % grade of your path of travel, use

the formula and graph in Figure 21.

3. Turn the ignition switch (Figure 12) to the OFF position.

STEERING

To steer the buggy, use the handle bar in front of the

operator platform.

1. To turn left when traveling in the forward direction, turn

the handle bar clockwise (Figure 20).

BUGGY IS STEERED LEFT

WHEN HANDLE BAR

IS TURNED CLOCKWISE

TURN HANDLE BAR

CLOCKWISE TO STEER

BUGGY TO THE LEFT

Figure 20. Steering the Buggy

2. To turn right when traveling in the forward direction,

turn the handle bar in the counterclockwise direction.

Figure 21. Determining Grade of Slope

PAGE 22 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 23

OPERATION

2. When going up or down a slope, always travel in the

forward direction (Figure 22).

Figure 22. Slope Travel Direction

TUB (BUCKET) DUMPING

NOTICE

Releasing either one (dump control lever or pedal)

before dump is completed, will cause the tub to return

to the horizontal position.

The hydraulic dump can be controlled by hand (dump

control lever) or foot (dump pedal).

1. To activate the hydraulic dump, press down on the

dump pedal (Figure 23) or move the dump control lever

forward. The tub will move to the vertical position as

long as pressure is continuously applied to the dump

pedal or the dump control lever is held in the forward

position.

Figure 23. Dump Pedal

2. To return the tub to its horizontal position, simply

release the dump control lever or remove your foot

from the dump pedal.

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 23

Page 24

MAINTENANCE

ENGINE

Refer to the Honda engine owner’s manual for specific

information.

1. Check engine oil after every 10 hours of operation and

maintain proper levels.

2. Drain oil after every 50 hours of operation and refill

with grade of oil recommended below:

Above 40 °F. (13 °C.) - S.A.E. 30

Below 40 °F. (13 °C.) - S.A.E. 20

ADDING HYDRAULIC OIL

1. Check the hydraulic oil level in the hydraulic oil tank,

by reading the hydraulic oil sight glass mounted on the

hydraulic oil tank.

2. If the hydraulic oil level is low, fill to the proper level

with MOBIL 300, GM DEXTRON B, FORD M2C-33F,

FORD M2C41A hydraulic oil or equivalent.

3. To gain access to the hydraulic oil filler hole (Figure

24), the tub (bucket) must be put in the dump position

(vertical). Start the engine as outlined in the starting

procedure, then place the tub in the dumping position.

5. Replace hydraulic oil after every 200 hours of operation.

The hydraulic oil filter should be changed each time

the hydraulic oil is changed.

HYDRAULIC DRIVE MOTORS

The hydraulic drive motors are extremely reliable and will

not need maintenance or repair under normal conditions.

Should any problems develop with the hydraulic drive

motors, contact Multiquip's service department.

BRAKE ADJUSTMENT

Brake adjustment can be made on the brake linkage rod

located on the right-side of the buggy.

1. Place the parking brake lever in the engaged position.

The parking brake should be adjusted so that the buggy

will not move.

2. Adjustment is provided by a knob at the end of

the parking brake lever. To tighten, turn the knob

counterclockwise.

3. Adjust the knob sufficiently tight so that when the

parking brake lever is actuated, considerable pressure

is required to place it in the over center or ON position.

4. With the parking brake engaged, the buggy should not

move when the engine is started and the travel lever

pushed forward.

CHASSIS LUBRICATION

The WBH16/WBH16E is equipped with zerk fittings.

Lubricate these zerk fittings each day before operating

the buggy.

1. Lubricate with high grade chassis lubricant at all

lubricating points listed below:

Figure 24. Hydraulic Oil Tank Filler Cap

4. Use the tub support rod to support the tub, then turn the

engine OFF. Remove the hydraulic oil filler cap, and add

hydraulic oil as required. Fill to the normal operating

mark as indicated on the hydraulic oil sight gauge.

NOTICE

In climates where temperatures are below 35°F, hard

starting may occur. In these cases, the hydraulic oil

should be switched to a thinner 15 weight hydraulic fluid.

PAGE 24 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

• Dump Cylinder Pivots - two zerk fittings

• Tub Bearing Pivot Blocks (underside of tub)- four zerk

fittings.

• Steering Bearing Flange (Front side of handle bar) 0ne zerk fitting.

2. Remove rear wheel hubs and repack bearings after

every 400 hours of operation.

Page 25

MAINTENANCE

PUMP CONTROL LEVER ADJUSTMENT

If the power buggy tends to creep in the forward or reverse

direction after you release the speed control lever, the pump

control lever requires adjustment.

3. Place the machines drive wheels on jacks or blocks

free from ground contact.

4. Locate the pump control lever adjusting bolt.

5. Loosen the jam nut.

6. Start the engine and place the buggy's directional

control lever in the forward then reverse directions

while observing for wheel movement.

7. The pump lever has a very sensitive neutral position

of about 1/32" to 1/16". If the wheels are creeping,

turn the adjusting bolt in very slight increments. If

wheels are creeping in reverse, turn the adjusting bolt

counterclockwise. If wheels are creeping forward, turn

the adjusting bolt clockwise.

TIRES/WHEELS/LUG NUTS

Tires and wheels are very important an

d critical components of the buggy. When specifying or

replacing the wheels, it is important that the wheels, tires,

and axle are properly matched.

CAUTION

Table 4. Tire Wear Troubleshooting

LUG NUT TORQUE REQUIREMENTS

It is extremely important to apply and maintain proper wheel

mounting torque on the trailer. Be sure to use only the

fasteners matched to the cone angle of the wheel. Proper

procedure for attachment of the wheels is as follows:

1. Start all wheel lug nuts by hand.

2. Torque all lug nuts in sequence. See Figure 25. DO

NOT torque the wheel lug nuts all the way down.

Tighten each lug nut in 3 separate passes as defined

by Table 5.

DO NOT attempt to repair or modify a wheel. DO NOT

install an inner tube to correct a leak through the rim.

If the rim is cracked, the air pressure in the inner tube

may cause pieces of the rim to explode (break-off) with

great force and can cause serious eye or bodily injury.

TIRES WEAR/INFLATION

Tire inflation pressure is the most important factor in tire life.

1. Check tire pressure when the tires are cold before

operation.

2. Do not bleed air from tires when they are hot.

3. Check inflation pressure weekly during use to ensure

the maximum tire life and tread wear.

4. Refer to Table 4 (Tire Wear Troubleshooting) to pinpoint

the causes and solutions of tire wear problems.

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 25

Wheel Size

480 x 8 in. 20-25 35-40 50-65

3. After first road use, retorque all lug nuts in sequence

Table 5. Tire Torque Requirements

First Pass

FT-LBS

(Figure 25). Check all wheel lug nuts periodically.

Figure 25. Lug Nut Torque Sequence

Second Pass

FT-LBS

Third Pass

FT-LBS

Page 26

TROUBLESHOOTING

Troubleshooting (Power Buggy)

Symptom Possible Problem Solution

Speed control cable out of adjustment?

Loss of Power.

Loss of Travel.

System Operating Hot.

Slow Dumping.

System jerky when started.

Diffi cult to steer. Un-lubricated steering column? Lubricate steering column.

Parking brake will not hold. Brake linkage out of adjustment? Use smaller diameter hose or replace hose.

Diffi culty in stopping

Engine will not start.

.

Hydraulic oil level low.? Check hydraulic oil level. Add oil if necessary.

Contaminated hydraulic oil fi lter? Replace hydraulic oil fi lter.

Low engine RPM? Check engine speed.

Forward/Reverse lever in neutral position?

Parking brake partially engaged? Release parking brake.

Hydraulic oil level low?

Defective cooling fan? Inspect cooling fan, replace if necessary.

Low engine speed?

Dump cylinder is internally bypassing oil? Replace dump cylinder.

Speed cable out of adjustment? Adjust speed control cable.

Defective drive motors? Check drive motors, replace if necessary.

Brakes out of adjustment? Brake lining worn. Replace brake lining.

Low on fuel or fuel tank empty? Add fuel.

Defective kill switch? Check kill switch. Replace if necessary

Engine ON/OFF switch in OFF position? Set engine ON/OFF switch to ON position.

Fuel Shut-off valve CLOSED? Open Fuel shut-off valve.

Adjust speed control cable. Replace cable if

necessary

Place lever in either forward or reverse position.

Check hydraulic motors.

Check hydraulic oil level add hydraulic oil if

necessary.

Check engine speed. Adjust engine speed if

necessar.y

PAGE 26 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 27

Symptom Possible Problem Solution

Diffi cult to start, fuel is available, but no spark

at spark plug.

Diffi cult to start, fuel is available, and spark is

present at the spark plug.

Diffi cult to start, fuel is available, spark is

present and compression is normal.

Diffi cult to start, fuel is available, spark is

present and compression is low.

No fuel present at carburetor.

TROUBLESHOOTING

Troubleshooting (Engine)

Spark plug bridging? Check gap, insulation or replace spark plug.

Carbon deposit on spark plug? Clean or replace spark plug.

Short circuit due to defi cient spark plug

insulation?

Improper spark plug gap? Set to proper gap.

Fuel reaching carburetor? Check fuel line.

Water in fuel tank? Flush or replace fuel tank.

Fuel fi lter clogged? Replace fuel fi lter.

Stuck carburetor? Check fl oat mechanism.

Spark plug is red? Check transistor ignition unit.

Spark plug is bluish white?

No spark present at tip of spark plug?

No oil? Add oil as required.

Oil pressure alarm lamp blinks upon starting?

(if applicable)

ON/OFF switch is shorted? Check switch wiring, replace switch.

Ignition coil defective? Replace ignition coil.

Improper spark gap, points dirty? Set correct spark gap and clean points.

Condenser insulation worn or short circuiting? Replace condenser.

Spark plug wire broken or short circuiting? Replace defective spark plug wiring.

Wrong fuel type?

Water or dust in fuel system? Flush fuel system.

Air cleaner dirty? Clean or replace air cleaner.

Choke open? Close choke.

Suction/exhaust valve stuck or protruded? Reseat valves.

Piston ring and/or cylinder worn? Replace piston rings and/or piston.

Cylinder head and/or spark plug not tightened

properly?

Head gasket and/or spark plug gasket damaged? Replace head and spark plug gaskets.

No fuel in fuel tank? Fill with correct type of fuel.

Fuel cock does not open properly?

Fuel fi lter/lines clogged? Replace fuel fi lter.

Fuel tank cap breather hole clogged? Clean or replace fuel tank cap.

Air in fuel line? Bleed fuel line.

Check spark plug insulation, replace if worn.

If insuffi cient compression, repair or replace

engine. If injected air leaking, correct leak. If

carburetor jets clogged, clean carburetor.

Check transistor ignition unit is broken, and

replace defective unit. Check if voltage cord

cracked or broken and replace. Check if

spark plug if fouled and replace.

Check automatic shutdown circuit, "oil

sensor". (if applicable)

Flush fuel system, and replace with correct

type of fuel.

Torque cylinder head bolts and spark plug.

Apply lubricant to loosen fuel cock lever,

replace if necessary.

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 27

Page 28

Symptom Possible Problem Solution

Weak in power, compression is proper and

does not misfi re.

Weak in power, compression is proper but

misfi res.

Engine overheats.

Rotational speed fl uctuates.

Recoil starter malfunctions. (if applicable)

Starter malfunctions.

Burns too much fuel.

Exhaust color is continuously "white".

Exhaust color is continuously "black".

Will not start, no power with key "ON". (if

applicable)

TROUBLESHOOTING

Troubleshooting (Engine) - continued

Air cleaner dirty? Clean or replace air cleaner.

Improper level in carburetor? Check fl oat adjustment, rebuild carburetor.

Defective spark plug? Clean or replace spark plug.

Improper spark plug? Set to proper gap.

Water in fuel system?

Dirty spark plug? Clean or replace spark plug.

Ignition coil defective? Replace ignition coil.

Spark plug heat value incorrect? Replace with correct type of spark plug.

Wrong type of fuel? Replace with correct type of fuel.

Cooling fi ns dirty? Clean cooling fi ns.

Intake air restricted?

Oil level too low or too high? Adjust oil to proper level.

Governor adjusted incorrectly? Adjust governor.

Governor spring defective? Replace governor spring.

Fuel fl ow restricted? Check entire fuel system for leaks or clogs.

Recoil mechanism clogged with dust and

dirt?

Spiral spring loose? Replace spiral spring.

Loose, damaged wiring?

Battery insuffi ciently charged? Recharge or replace battery.

Starter damaged or internally shorted? Replace starter.

Over-accumulation of exhaust products?

Wrong spark plug?

Lubricating oil is wrong viscosity? Replace lubricating oil with correct viscosity.

Worn rings? Replace rings.

Air cleaner clogged? Clean or replace air cleaner.

Choke valve set to incorrect position? Adjust choke valve to correct position.

Carburetor defective, seal on carburetor

broken?

Poor carburetor adjustment, engine runs too

rich?

ON/OFF device not activated ON? Turn on ON/OFF device.

Battery disconnected or discharged?

Ignition switch/wiring defective? Replace ignition switch. Check wiring.

Flush fuel system and replace with correct

type of fuel.

Clear intake of dirt and debris. Replace air

cleaner elements as necessary.

Clean recoil assembly with soap and water.

Ensure tight, clean connections on battery

and starter.

Check and clean valves. Check muffl er and

replace if necessary.

Replace spark plug with manufacturer's

suggested type.

Replace carburetor or seal.

Adjust carburetor.

Check cable connections. Charge or replace

battery

PAGE 28 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 29

HYDRAULIC SYSTEM DIAGRAM

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 29

Page 30

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

PART NO. Column

QTY. Column

— Item quantity can be indicated by a

A/R (As Required) is generally used for hoses or other

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarifi ed in the “Remarks”

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

same unique symbol will be included when this item is

— Used to list an effective serial

— Indicates that the part

part is NOT used on a specifi c model or model number

available items. Examples include battery cables, shims,

— Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

Numbers Used

number, a blank entry, or A/R.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT .....................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ..........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ..1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

parts that are sold in bulk and cut to length.

Column.

REMARKS Column

to describe the item can also be shown.

Assembly/Kit — All items on the parts list with the

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specifi c Model Number Use

is used only with the specifi c model number or model

number variant listed. It can also be used to show a

variant.

Indicated by:

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarifi ed in the “Remarks” Column.

PAGE 30 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

and certain washers and nuts.

“Not Sold Separately”

for sale through Multiquip.

Page 31

SUGGESTED SPARE PARTS

WBH16/WBH16E POWER BUGGY WITH HONDA GX390RT2QTT/GX390RT2QNB2 ENGINE

1 to 3 units

Qty. P/N Description

1............508667 .................. FILTER, HYDRAULIC OIL

1............16477 .................... CAP, HYDRAULIC OIL TANK

1............18035 .................... PUMP, HYDROSTATIC

1............511719 .................. COUPLING, ENGINE SHAFT

2............18316 .................... LINING, BRAKE

1............18145 .................... ROD, BRAKE CONTROL

1............520820 .................. CAP, FUEL (EPA)

5............20763 .................... FILTER, IN-LINE FUEL

1............18025 .................... SWITCH, KILL

1............18133 .................... CABLE, THROTTLE

1............18132 .................... LEVER ,THROTTLE

1............18029 .................... WHEEL, DRIVE

1............18049 .................... WHEEL, STEERING

1............18016 .................... CABLE, PARKING BRAKE

3............9807955846 .......... SPARK PLUG

3............11078 .................... KEY, IGNITION (ELECTRIC START ONLY)

1............28462ZE3W01 ...... ROPE (RECOIL START ONLY)

3............17210ZE3010 ....... ELEMENT, AIR CLEANER

NOTICE

Part numbers on this Suggested Spare Parts list may

supersede/replace the part numbers shown in the

following parts lists.

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 31

Page 32

NAMEPLATE AND DECALS

6

18247

TRAVEL

8

BUCKET

Dump

LIFT

4

513608

LIFT

5

10

MQ WHITEMAN

SAFETYINSTRUCTIONS

OPERATEAT SAFESPEEDS ONLY

READ OPERATOR’SMANUALBEFORE STARTING

PLACE INNEUTRAL BEFORESTARTING

NO UNAUTHORIZED/UNTRAINEDOPERATORS

NO RIDERS

BE SUREALL SAFETYDEVICES AREOPERATIONAL

AND INPLACE BEFORESTARTING THEENGINE

DISCONNECTSPARK PLUG BEFORESERVICE

NEVER OPERATEINAN ENCLOSED AREA

NEVER LEAVEUNATTENDEDWHEN OPERATING

ALLOW ENGINETO COOLBEFORE ADDINGFLUIDS

18245

2

WBH16

1

11

GASOLINE ONLY

WARNING!

SURFACE AREA

7

HOT

NEUTRAL

9

12

18248

513608

LIFT

4

Return

513608

LIFT

LIFT

18245

4

5

18245

LIFT

2

5

18245

LIFT

5

PAGE 32 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

HYDRAULIC

OIL ONLY

3

985

Page 33

NAMEPLATE AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 18252 DECAL, WBH16 2

2 18251 DECAL, MQ WHITEMAN 2

3 EM985 DECAL, HYDRAULIC OIL 1

4 513608 DECAL, LIFTING HOOK 3

5 18245 DECAL, FORKLIFT LIFTING 6

6 18247 DECAL, CRUSH WARNING 1

7 18248 DECAL, HOT SURFACE WARNING 1

8 DECAL, BUCKET DUMP LEVER ......................1................NOT AVAILABLE*

9 DECAL, TRAVEL LEVER DIRECTION ..............1................NOT AVAILABLE*

10

11 DECAL, GASOLINE ONLY ................................1................NOT AVAILABLE*

12 PLATE, SERIAL NUMBER .................................1................

DECAL, WHITEMAN SAFETY INSTRUCTIONS

....1................NOT AVAILABLE*

CONTACT MULTIQUIP PARTS DEPT.

* - Imprinted on plastic cover.

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 33

Page 34

HYDRAULIC DRIVE ASSY.

VIEW FROM

OPERATOR’S

PLATFORM

SEAL

KIT

16

19

30

23

25

2

24

4

22

1

4

5

6

17

RIGHT

DRIVE MOTOR

21

20

6

18

DRIVE MOTOR

18

LEFT

17

22

19

16

13

8

26

10

15

14

9

7

12

11

8

PAGE 34 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 35

HYDRAULIC DRIVE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 18058 VALVE, DIRECTION CONTROL 1

2 18264M HOSE, DIRECTION VALVE TO DRV. MOTOR 1

4 511810 ADAPTER, ELBOW 2

5 18276M HOSE, LH HYDRAULIC MOTOR 1

6 512189 ADAPTER, T - CONNECTOR 2

7 492527 NUT, HEX 1/2-20 8

8 18029 WHEEL, DRIVE ASSY. FRONT 4

9* 511692 FLANGE, HUB 2

10* 18237 LUG BOLT/HUB FLANGE 8

11 492584 NUT, HEX 1/2-13 NYLON ..................................8................REPLACES 6109160

12 18190 SCREW, HUB STUD 1/2-13X 3 IN. 8

13 491689 KEY, COTTER 1/8 X 2 2

14 PT018038 NUT, CASTLE 1-1/8-18 2

15 18040 HUB, DRIVE 2

16 3365 ADAPTER, STRAIGHT 6

17 505718 SCREW, HHC 1/2-13 X 2-3/4 8

18 18011 MOTOR, HYDRAULIC DRIVE 2

19 PE449105 KEY, WOODRUFF 1-1/4 32 MM 2

20 492600 WASHER, FLAT 1/2 8

21 6109180 NUT, HEX 1/2" DIA 8

22 18027 HOSE, DRIVER MOTOR CROSSOVER 2

23 18275M HOSE, RH HYDRAULIC MOTOR 1

24 18265M HOSE, DIRECTION VALVE TO DRIVE MOTOR 1

25 3322 ADAPTER 2

26 516528 FLANGE HUB ASSY. .........................................1................INCLUDES ITEMS W/

30 18011K SEAL KIT, DRIVE MOTOR 1

*

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 35

Page 36

HYDRAULIC PUMP ASSY.

1

12

13

15

16

SEE

DRIVE ASSY.

DIRECTION

VALVE

SEE

HYDRAULIC

OIL TANK ASSY.

17

13

14

3

2

3

2

4

5

6

7

12

HYDRAULIC

OIL TANK

8

10

9

11

HYDRAULIC

OIL FILTER

8

SEE

DUMP CYLINDER

ASSY.

DUMP

VALVE

PAGE 36 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 37

HYDRAULIC PUMP ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 18035 PUMP, HYDRAULIC 1

2 511808 ADAPTER, STRAIGHT 2

3 3365 ADAPTER, STRAIGHT 6

4 18256M HOSE, PUMP TO DUMP VALVE 1

5 18258M HOSE, FILTER TO PUMP 1

6 18261M HOSE, PUMP TO TANK 1

7 18263M HOSE, PUMP TO DIRECTION VALVE 1

8 512190 ADAPTER, STRAIGHT 2

9 18257M HOSE, FILTER TO DUMP VALVE 1

10 508667 FILTER 1

11 508664 SUPPORT, FILTER 1

12 511799 ADAPTER, ELBOW 2

13 3322 ADAPTER, ELBOW 2

14 18058 VALVE, DIRECTION CONTROL 1

15 18262M HOSE, TANK TO PUMP 1

16 18266M HOSE, PUMP TO DIRECTION VALVE 1

17 3322 ADAPTER, ELBOW 2

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 37

Page 38

HYDRAULIC DUMP ASSY.

3

2

CONNECT

TO HYDRAULIC PUMP ASSY

ITEM 9

6 4

1

4

5

3

2

CONNECT

TO HYDRAULIC PUMP ASSY

ITEM 4

7

DUMP

VALVE

9

PAGE 38 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 39

HYDRAULIC DUMP ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 18022 CYLINDER, HYDRAULIC DUMP 1

2 491705 ZERK FITTING 2

3 511803 ADAPTER, ELBOW 2

4 18020 HOSE, DUMP VALVE TO HYD. PISTON 2

5 511804 ADAPTER, STRAIGHT 2

6 512234 ADAPTER, ELBOW 1

7 511806 ADAPTER, STRAIGHT 1

9 506191 ADAPTER, ELBOW 1

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 39

Page 40

PUMP AND COUPLING ASSY.

1

Engine

21

24

6

7

HYDRAULIC

PUMP

11

23

2

20

28

29

22

27

26

25

4

7

6

FRAME

PAGE 40 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 41

PUMP AND COUPLING ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 492472 SCREW, ALLEN HEAD 3/8-16 X 3/4 2

2 511719 COUPLING, ENGINE SHAFT 1

4 18112 FAN 1

6 492596 WASHER, FLAT 1/4" 2

7 492355 SCREW, HHC 1/4-20 X 1/2 2

11 506250 KEY, WOODRUFF 1

20 512494 FAN GUARD 1

21 512493 BRACKET, LONG 1

22 512505 BRACKET, SHORT 1

23 492373 BOLT, C/H 3/8" NC X 3/4" G5 1

24 492624 WASHER, LOCK 3/8 IN. 1

25 512367 BOLT, C/H 3/16" NC X 1/2" G2 4

26 492595 WASHER, FLAT 3/16 IN. 4

27 492621 WASHER, LOCK 3/16 IN. 4

28 492438 BOLT, C/H 5/16" NF X 1" G5 1

29 492623 WASHER, LOCK 5/16" 1

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 41

Page 42

1

TUB ASSY.

2

3

5

14

DASHED ( ) ITEMS ARE

LOCATED ON THE UNDERSIDE

OF THE BASE PLATE

6

13

9

12

10

5

11

7

4

15

15

5

5

LOCATED ON THE BACKSIDE

OF COUNTERWEIGHT

6

PAGE 42 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 43

NO. PART NO. PART NAME QTY. REMARKS

1 18004 TUB, PLASTIC 1

2 492313 SCREW, HHC 3/8-16 X 1-1/2 9

3 512193 WASHER, FLAT 3/8 LARGE 9

4 492598 WASHER, FLAT 3/8 9

5 490957 RING, SNAP 6

6 18130 PIN, HYD. PISTON CROSS 2

7 18129 PIN, TUB FRAME CROSS 1

9 492365 SCREW, HHC 5/16-18 X 1-1/4 4

10 492597 WASHER, FLAT 9.5 X 22.2 8

11 492583 NUT, NYLOC 3/4-16 9

12 492582 NUT, NYLOC 5/16-18 4

13 512279 SUPPORT, BUM STOP 2

14 18099 FRAME, TUB MOUNT 1

15 491705 ZERK GREASE FITTING 2

TUB ASSY.

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 43

Page 44

11

PANEL ASSY.

13

12

10

4

5

5

1

2

5

3

5

8

12

6

8

7

5

8

9

PAGE 44 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 45

PANEL ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 503978 POP RIVET AM-56 1

2 511474 FASTENER, ACCESS DOOR 1

3 18008 DOOR, ACCESS 1

4 492355 SCREW, 1/4 NC X 1/2 IN. G5 2

5 492597 WASHER, FLAT 9.5X22.2 26

6 18141 COVER, R/SIDE ENGINE 1

7 492364 SCREW, HHC 5/16-18X1 6

8 492582 NUT, NYLOC 5/16-18 6

9 801026 COVER, L/SIDE ENGINE 1

10 492623 WASHER, LOCK 5/16 4

11 505401 SCREW, HHC 5/16-18X 1/2 4

12 492363 SCREW, HHC 5/16 NC X 3/4 G5 6

13 23297 MANUAL HOLDER 1

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 45

Page 46

BRAKE ASSY.

PAGE 46 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 47

BRAKE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 511762 SCREW, HHC 1/2-13X8 1

2 511698 CLEVIS, ASSY. BRAKE 2

3 511761 NUT, HEX 3/8-24 NF 2

4 18111 PEDAL, BRAKE 1

5 492600 WASHER, FLAT 1/2 1

6 492584 NUT, NYLOC 1/2-13 10

7 18167 SPRING, BRAKE PEDAL 1

8* 18307 SPRING, BRAKE 2

9* 18300 BAND, BRAKE 2

10* 18316 LINING, BRAKE 2

11* 503723 RIVET, BRAKE LINING 56

12 18303 SHAFT, CRANK PIN 2

13 492395 SCREW, HHC 1/2-13X1-3/4 2

14 18302 BELL CRANK, BRAKE 2

15 18032 LINKAGE, RIGHT BRAKE 1

16 18314 LINKAGE, LEFT BRAKE 1

17 492582 NUT, NYLOC 5/16-18 2

18 492303 SCREW, HHC 5/16-18X1-14 1

19 505170 CLIP, PARK CABLE 1

20 18016 CABLE, PARK BRAKE 1

21 492367 SCREW, HHC 5/16-18X1-3/4 3

22 18015 LEVER, ASSY. PARK BRAKE 1

23 492597 WASHER, FLAT 9.5X22.2 3

24 18145 ROD, BRAKE CONTROL 1

25 512881 BRAKE BAND ASSEMBLY ................................2................INCLUDES ITEMS W/

26 492600 WASHER, FLAT 1/2 IN. 2

*

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 47

Page 48

STEERING ASSY.

37

37

PAGE 48 — WBH16/WBH16E POWER BUGGY (S/N 110401 & UP) • OPERATION AND PARTSMANUAL — REV. #0 (06/14/11)

Page 49

STEERING ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 18132 LEVER, THROTTLE 1

2 492581 NUT, NYLOC 1/4-20 1

3 492582 NUT, NYLOC 5/16-18 1

4 491030 WRAP, T1Z 1

5 504505 WRAP, T1E 1

6 18025 SWITCH, KILL 1

7 18242 HANDLE BAR 1

8 511432 GRIP, HANDLE 2

9 18181 BUSHING, CABLE 1

10 18177 SPRING 1

11 511717 KEY, WOODRUFF 1/8X5/8 1

12 18061 LEVER, CONTROL 1

13 512414 SCREW, HHC 1/4-20 X 2-1/4 1

14 492561 NUT, HEX 1/4-20 2

15 492584 NUT, NYLOC 1/2-13 1

16 492357 SCREW, HHC 1/4-20X1 1

17 18183 CONNECTOR, THROTTLE CABLE END 2

18 18176 SPRING 1

19 18182 BUSHING, CABLE 1

20 18133 CABLE, THROTTLE 1

21 492465 SCREW, ALLEN HEAD 1/4-20 X3/8 1

22 506088 SCREW, HHC 1/4-20X3/8 1

23 492369 SCREW, HHC 5/16-18X2-1/4 1

24 491723 PIN, STEERING SHAFT 1

25 18238 BUSHING, STEERING SHAFT 2

26 512186 PIN, STEERING SHAFT 1

27 18091 AXLE, STEERING 1

28 EM941306 HUB, REAR WHEEL ..........................................2................INCLUDES ITEMS W/ #

29 EM501299 WASHER, REAR WHEEL HUB 2

30 512210 NUT, CASTLE 2

31 491688 PIN, COTTER 1/8 X 1-1/2 2

32 18049 WHEEL, STEERING ASSY. REAR 2

33 8115 NUT LUG 8

34 511159 WASHER, FLAT 1 IN. 2

35# EM903113 BEARING CONE 2

36# 15191VB SEAL 1

37 512200 BUSHING, BRONZE 2

WBH16/WBH16E POWER BUGGY (S/N 110401 & UP)• OPERATION AND PARTS MANUAL — REV. #0 (06/14/11) — PAGE 49