Page 1

PARTS AND OPERATION MANUAL

Tandem Vibratory Roller

T23, T26, T33

© COPYRIGHT 20001, MULTIQUIP INC.

Revision #4 (03/12/01)

MULTIQUIP INC. PARTS DEPARTMENT:

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

F AX: 310-537-3927 F AX: 310-537-4259

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

SERVICE DEPARTMENT:

Page 2

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

Asphalt Roller: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #3 (07/26/99) — PAGE 3

Page 4

PARTS ORDERING PROCEDURES

■■

■ Dealer account number

■■

■■

■ Dealer name and address

■■

■■

■ Shipping address (if different than billing address)

■■

■■

■ Return fax number

■■

■■

■ Applicable model number

■■

■■

■ Quantity, part number and description of each part

■■

■■

■ Specify preferred method of shipment:

■■

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

•

Express account number)*

Airborne Express*

•

Truck or parcel post

•

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete par t numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Get special freight allowances

when you order 10 or more

line items via FAX!**

■■

■

UPS Ground Service at no charge for freight

■■

■■

■

PS Third Day Service at one-half of actual freight cost

■■

No other allowances on freight shipped by an y other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

Extra Fax Discount

for Domestic USA

Dealers Only

Now! Direct TOLL-FREE access

to our Parts Department!

Toll-free nationwide:

800-421-1244

Toll-free FAX:

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

800/6-PARTS-7 • 800-672-7877

PAGE 4 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 5

TABLE OF CONTENTS

Here's how To Get Help .......................................... 3

Parts Ordering Procedures ..................................... 4

Table Of Contents ................................................... 5

TANDEM ROLLER: T23, T26, T33

Specifications .......................................................... 6

Explanation Of Codes In Remarks Column ............ 8

Suggested Spare Parts........................................... 9

Safety Instructions ........................................... 10-13

Operation ......................................................... 14-23

Hydraulic & Electrical ............................................ 24

Maintenance and Repair ................................. 25-38

Drum Traveling ................................................. 40-41

Vibration Drum ................................................. 42-45

Scraper Front Chassis ..................................... 46-47

Scraper Rear Chassis......................................48-49

Gravity Sprinkler .............................................. 50-51

Chassis Front ................................................... 52-55

Engine Hood .................................................... 56-57

F ront Water Tank .............................................. 58-59

Chassis Rear.................................................... 60-63

Operator Platform ............................................ 64-71

Rear W ater Tank............................................... 72-73

Driver’s Seat.....................................................74-75

Additional Weight ............................................. 76-77

Stabilizer Bar....................................................78-79

Articulating Joint .............................................. 80-81

Steering Cylinder ............................................. 82-83

Engine .............................................................. 84-87

Engine Radiator ............................................... 88-89

Engine Service Parts........................................ 90-91

Engine Electric Comp....................................... 92-93

PTO Pump........................................................ 94-97

Components...................................................98-103

Flow Divider ................................................. 104-105

Suction Leak Pipe ........................................106-107

Hydraulic Hoses ...........................................108-115

Reversing Electrical ..................................... 116-117

Sprinkler & Vibration Electrical`.................... 118-119

Ignition Switch Electrical............................... 120-121

Battery.......................................................... 122-123

Instrument Panel..........................................124-125

Instrument Panel Electrical .......................... 126-127

Decals .......................................................... 128-131

Flow Divider ................................................. 132-133

Towing Valve................................................. 134-135

Brake Release Valve .................................... 136-137

Vibration Rear .............................................. 138-139

Vibration Cut-Off Rear ................................. 140-141

Pressure Testing Connections ..................... 142-143

Cover ........................................................... 144-145

Headlights .................................................... 146-149

Strobe Light.................................................. 150-151

Back-Up Signal ............................................ 152-153

Automatic Vibration ...................................... 154-155

Pressurized Sprinkling System .................... 156-159

Interval Sprinkling ........................................ 160-161

Special Sprinkler .......................................... 162-163

Reversing Lever Left.................................... 164-165

Battery Disconnection Switch....................... 166-167

Seat Heating ................................................ 168-169

ROPS ........................................................... 170-175

Cabin............................................................ 176-177

Lock Pin ....................................................... 178-179

Tiltable Scraper............................................ 180-181

YANMAR 3TNE88 ENGINE

Cylinder Block .............................................. 182-183

Gear Housing............................................... 184-185

Flywheel Housing & Oil Sump...................... 186-187

Cylinder Head & Bonnet............................... 188-189

Suction Manifold & Air Cleaner .................... 192-193

Exhaust Manifold & Silencer ........................194-195

Camshaft & Drive Gear................................ 196-197

Crankshaft & Piston ..................................... 198-199

Lub. Oil System ............................................ 200-201

Cooling W ater System .................................. 202-204

Fuel Injection Pump .....................................206-208

Governor......................................................210-212

Fuel Injection Valve ...................................... 214-216

Fuel Strainer & Oil/Water Separator ............ 218-219

Engine Stop Device...................................... 220-221

Star ting Motor..............................................222-223

Generator (Old Style)................................... 224-225

Generator (New Style) ................................. 226-227

Gasket Set ................................................... 228-229

Te r ms and Conditions Of Sale — parts .............. 230

NOTE: Specification and part number are subject to change without notice.

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 5

Page 6

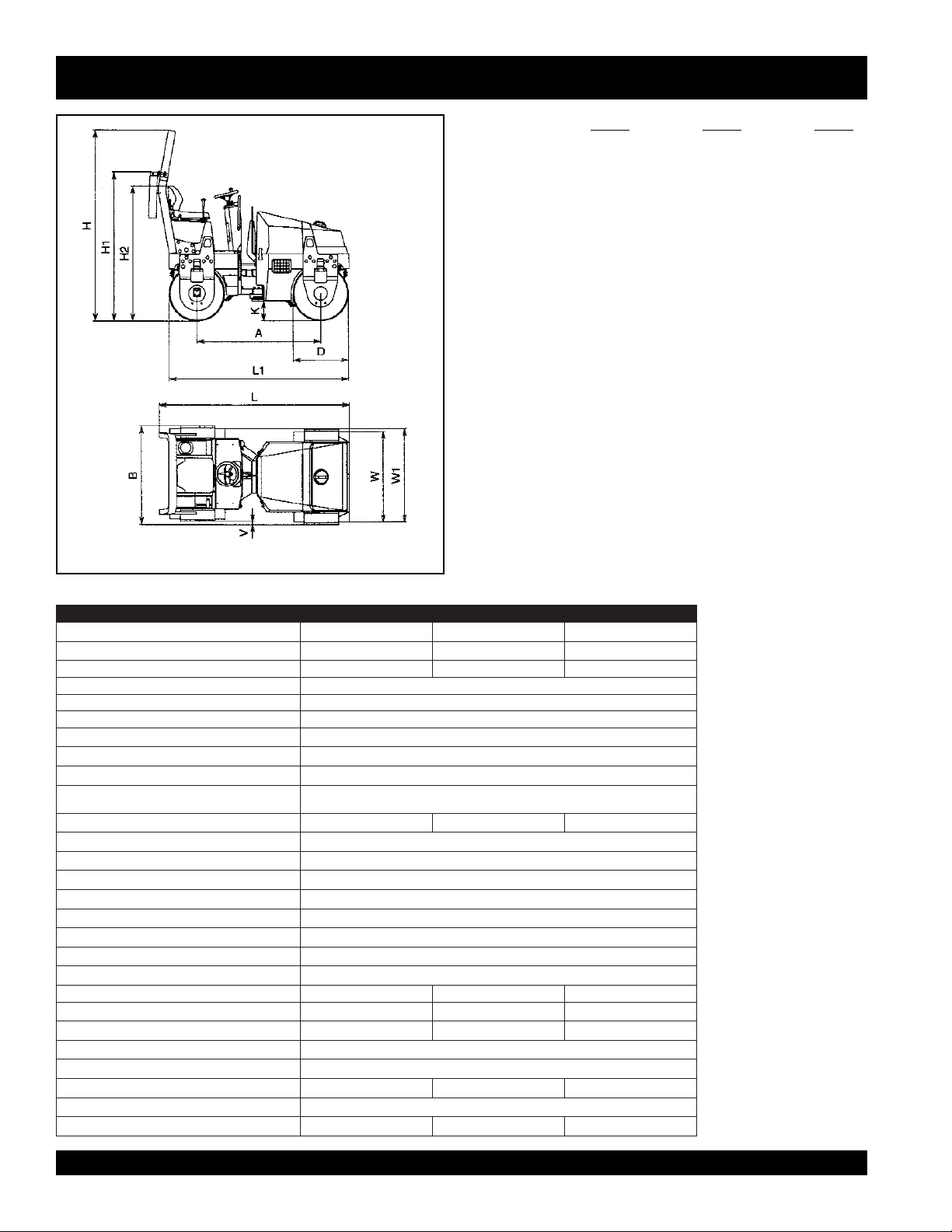

SPECIFICATIONS

T23 T26 T33

L ...................... 99.80" ...............99.80"...............99.80"

L1 .................... 94.10" ...............94.10"...............94.10"

B...................... 43.50" ...............51.58"...............55.51"

W..................... 39.37" ...............47.24"...............51.18"

W1................... 40.95"...............48.82"...............52.76"

H...................... 98.43" ...............98.43"...............98.43"

H1.................... 78.35" ...............78.35"...............78.35"

H2.................... 72.44" ...............72.44"...............72.44"

D...................... 29.13" ...............29.13"...............29.13"

A...................... 64.96" ...............64.96"...............64.96"

K...................... 10.63" ...............10.63"...............10.63"

V...................... 1.57" .................1.57".................1.57"

ledoM 32-T 62-T 33-T

ssalC

mpr0042@)gk(.sbl,ecroFlagufirtneC

mpr0072@)gk(.sbl,ecroFlagufirtneC

mpr0042@,mpv,ycneuqerF

mpr0072@,mpv,ycneuqerF

)mm(.ni,edutilpmA

)hpk(hpm,deepSlevarT

enignE

ledoMenignE

mpr;PHenignE

)mm(.ni,edisni,suidaRgninruT

%,.bivo-w/wytilibaedarG

)l(.lag,yticapaCknaTretaW

)l(.lag,yticapaCknaTleuF

)l(.lag,yticapaCknaTciluardyH

)mm(.ni,SPOR/wthgieHllarevO

)mm(.ni,SPORdedloF/wthgieHllarevO

)mm(.ni,SPOR/whtgneLllarevO

)mm(.ni,ecnaraelCdnuorG

)mm(.ni,htdiWmurD

)mm(.ni,htdiWllarevO

)mm(.ni,)tesffo(htdiWgnilloRmumixaM

)mm(.ni,tesffOmurD

)mm(.ni,retemaiDmurD

)mm(.ni,ssenkcihTmurD

)mm(.ni,ecnaraelCbruC

)gk(.sbl,thgieWgnitarepO

not5.2 not3 not4

)9212(0684 )8282(5126 )9323(9117

)9782(8236 )2073(6318 )6124(6629

0033

0873

)5.(020.

2.6ot0)01ot0(

leseiddelooc-retawrednilyc3ramnaY

MMA-88ENT3

mpr0042@PH92

mpr0072@PH33

)0532(5.29 )0522(6.88 )0022(6.68

04/03

)022(1.85

)23(5.8

)84(7.21

)0552(4.001

)0991(3.87

)0351(6.99

)572(8.01

)0001(4.93 )0021(2.74 )0031(2.15

)5111(8.34 )0231(7.15 )0241(9.55

)0401(9.04 )0421(8.84 )0431(8.25

)04(6.1

)047(1.92

)31(15.0 )41(55.0 )41(55.0

)384(91

)0632(4025 )0762(7885 )0933(5747

PAGE 6 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 7

NOTE PAGE

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 7

Page 8

EXPLANATION OF CODE IN REMARK COLUMN

How to read the marks and remarks used in this parts book.

Section 1: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Section 2: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial number

range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model number

or model number variant.

Section 3: Items Found In the “Items Number” Column

All parts with same symbol in the number column,

■

, belong to the same assembly or kit.

Note: If more than one of the same reference number is listed,

the last one listed indicates newest (or latest) part available.

If more than one of the same reference number is

listed, the last one listed indicates newest (or latest)

part available.

, #, +, %, or

*

NOTE

NOTE

The contents of this catalog are

subject to change without notice

.

PAGE 8 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 9

T23, T26, T33 w/YANMAR 3TNE88 DIESEL ENGINE

1 to 3 Units

Qty. P/N Description

5 ............AVL14607 ............. KEY IGNITION SWITCH

5 ............AVL921970 ........... KEY FUEL CAP

6 ............12142212570 ........ FILTER AIR INNER

6 ............12142012511 ........ FILTER AIR OUTER

6 ............12915035151 ........ FILTER OIL

6 ............12910055650 ........ FILTER FUEL

3 ............AVL921710 ........... FILTER WATER

3 ............AVL921198 ........... FILTER SUCTION

3 ............AVL824900 ........... SCREEN WATER TANK

Par t numbers on this Suggested

Spare Par ts List may supercede/

replace the P/N shown in the text

pages of this book.

SUGGESTED SPARE PARTS

NOTE

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 9

Page 10

SAFETY INSTRUCTIONS

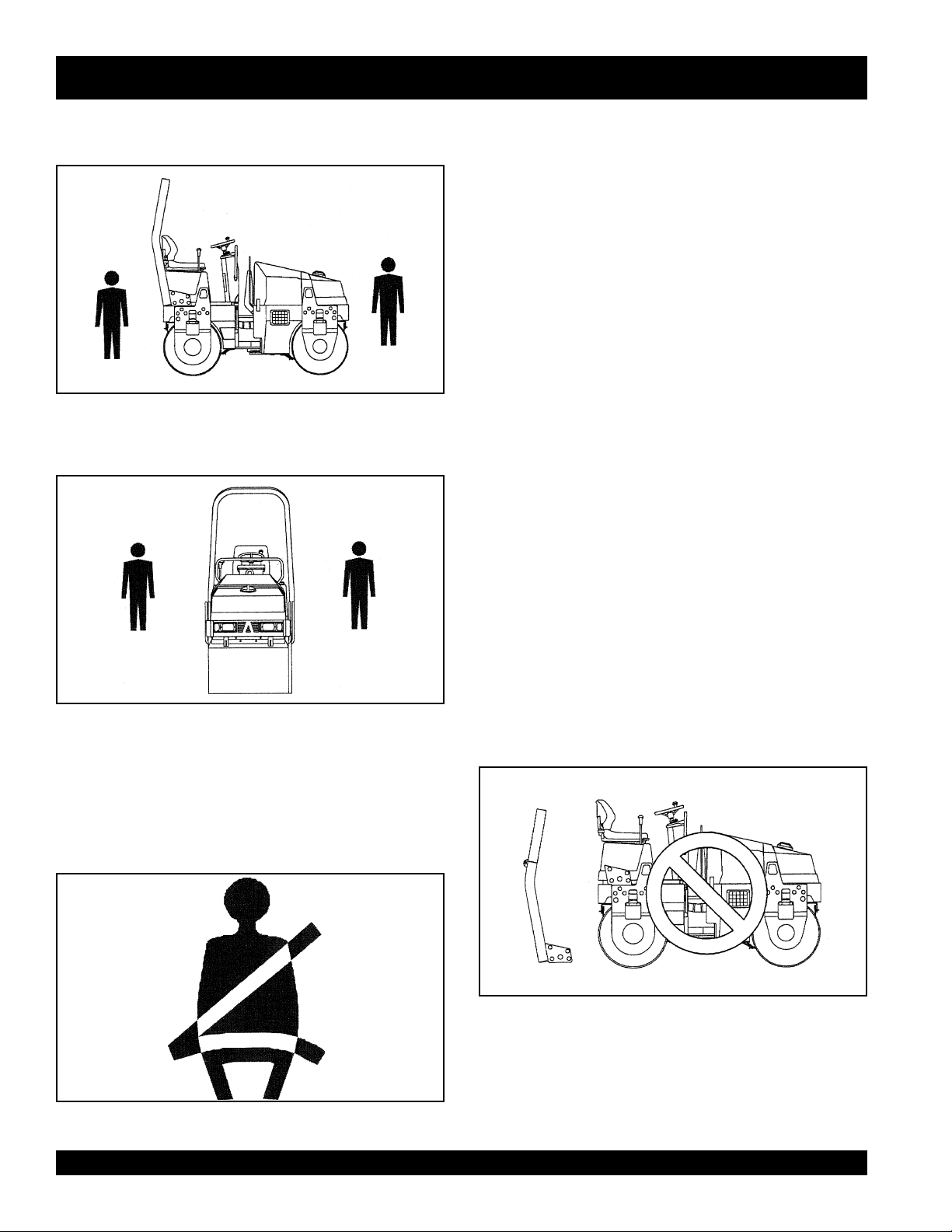

Starting the machine

Start up the roller from the driver seat only.

Operating the machine

When the roller is being operated there must be no one in

front or behind the roller.

WARNING!

KEEP YOUR DISTANCE FROM SIDE-SLOPES AND ROCKS!

THE MACHINE CAN EASILY SLIDE OFF SLOPES! DO NOT

DRIVE OVER ROCKS!

DANGER OF OVERTURNING!

Be aware of the hazards stated below:

1. Flat surfaces may not have uniform soil density

2. Hollow spaces or rocks might be below the surface

3. Clay ground can be slippery when it is wet

4. Danger of sliding sidewards is higher , when vibr ating

5. Sharp steering maneuvers (turns), near side slopes can

increase the danger of overturning

6. Central articulated machines are more dangerous near

side-slopes during sharp steering maneuvers (turns).

Rollover protection structure (R O P S)

Please check the following:

■

The machine frame should not be bent or cracked around

the ROPS bolt on area.

■

There are no hairline cracks or open cracks.

■

All screw connections are correctly tightened (check

correct torque).

■

Bolts and nuts must be undamaged.

■

Operating the machine

Any persons in the vicinity of the roller , while it is being operated,

must maintain a safe minimum distance of 3 feet (1m) for

their own safety.

Seatbelt

The driver must always wear the seatbelt.

ROPS must be folded up when operating machine.

PAGE 10 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 11

SAFETY INSTRUCTIONS

No modifications may be made on the ROPS without

authorization from the manufacturer!

Never operate the machine with the ROPS in the tilted position.

Noise level:

The following noise levels have been measured according to

the CE regulations 98/68/EWG,

■

Engine at nominal RPM

■

Microphone fixed at 1, 2m height

Measurement conditions:

■

Hard ground, no snow , dry within 20 m., no noise reflecting

objects.

■

Wind noise must be below 10dB(A) of the measured

machine noise values.

■

Noise level indications according to annex 1, Chapter

1.7.4 f of the CE machines specifications

Noise at driver’s ear: 77.5 dB(A)

Constant noise level at 7m distance: 66.1 dB(A)

Safety stickers on the machine

■

Keep safety stickers and safety plates clean and readable.

■

All instructions have to be followed.

■

Damaged or incomplete stickers must be replaced

immediately.

➜

While working on the machine or on moving parts of the

machine, never wear a scarf, tie, bracelet or loose clothing.

Should the machine catch those items, severe injuries could be

caused.

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 11

Page 12

SAFETY INSTRUCTIONS

Never work under a machine which is held by a crane or by a

jack. Never stand beneath a machine that has been lifted. Always

follow the instructions given in this manual.

Signs / warnings

Danger of intoxication!

Never let the machine run in a closed room.

Battery gases are explosive.

Keep the battery away from fire, flames and sparks.

DANGER OF EYE INJURY!

The sulfuric acid in the electrolyte of the battery is poisonous

and aggressive. It can burn holes into clothes. A squirt of this

acid in the eyes can lead to blindness.

Re-charging safety instructions:

■

Recharge battery only in well ventilated rooms.

■

Wear eye protection and gloves.

■

Do avoid breathing in gases and fumes.

■

Refill without splashing the acid.

■

Start by means of a starter /second battery has to be done

following the instructions.

To take off the water cooler cover on a stopped engine, first

loosen the cover slightly to release the pressure. Remove the

cover only after the pressure is released.

To control the acid lev el of the battery , use a torch. Ne ver check

the battery charge by connecting the two poles with a metallic

tool. Take an acid control instrument or use a voltmeter .

Always disconnect the ground (-) first and always re-connect it

last.

WARNING: Never remove the radiator cover on a

running engine!

Attention: Danger of burning

PAGE 12 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 13

SAFETY INSTRUCTIONS

Operating the rollers

1. Only reliable and qualified persons, at least 18 years old

are to operate rollers.

2. The manufacturer’ s operating and security instructions are

to be observed.

Running

3. Rollers are only to be operated with all the protection

facilities.

4. Before starting work, steering and brakes must be checked.

The machine should not be run if any defects are noticed.

5. Before beginning a working shift the driver must check the

effectiveness of operation and the security installation and

protection facilities.

6. If defects on security installations or any other defects are

noticed that affect the safe operation of the roller, the

supervisor is to be informed immediately .

7. Operating the roller must be stopped if defects endanger

operating security .

17. Valid f or all rollers: It is possib le that the allowab le sound

18. While driving, the doors must be closed.

Maintenance

19. Maintenance and repair work may only be done while the

20. Before working on hydraulic tubes and hoses, pressure in

21. Before working on electrical system of the machine, the

22. After the termination of maintenance and repair work,

level of 90 dB(A) can be exceeded on the above stated

rollers. Due to the regulations for prevention of accident

“noise” (VBG 121), machine operators, or persons who

are in immediate environment of the machine must wear

ear defenders, if the sound level reaches or exceeds an

estimated 90 dB(A). . . . AND WITH CABINS (optional)

transmission is not in operation. Only exception: if work

cannot be carried out without drive engaged.

the hydraulic system has to be released.

battery must be disconnected. It must be either removed

or covered with isolating material. This is not valid for

repairs where electrical power is necessary .

protection facilities have to be reinstalled as prescribed.

8. The roller must only be operated from the driver’ s seat.

9. Servicing or maintenance of the roller must be done only

while the roller is standing still and secured against rolling

away. When filling up the fuel tank, the motor is to be

switched off.

10. Rollers may not be driven downhill out of gear, (freewheeling) use the hydrostatic transmission to control the

speed of the roller .

11. Especially on slopes, rollers have to be driven or parked

in such a way that they cannot overturn.

12. The driver has to keep the driver’ s platform and tread steps

free of obstructions, grease, dirt, ice, etc.

13. Visibility in the driving and working area must not be

restricted.

14. Before leaving the driver’ s stand, the parking brake m ust

be engaged. If your roller has a hydrostatic drive, the

reversing control lever is to be put in “0” position.

15. Before leaving the roller , the driver has to turn off the engine.

The roller has to be secured against unauthorized

operation and against rolling off.

16. Parked rollers representing an obstacle have to be secured

by obvious measures.

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 13

Page 14

OPERATION

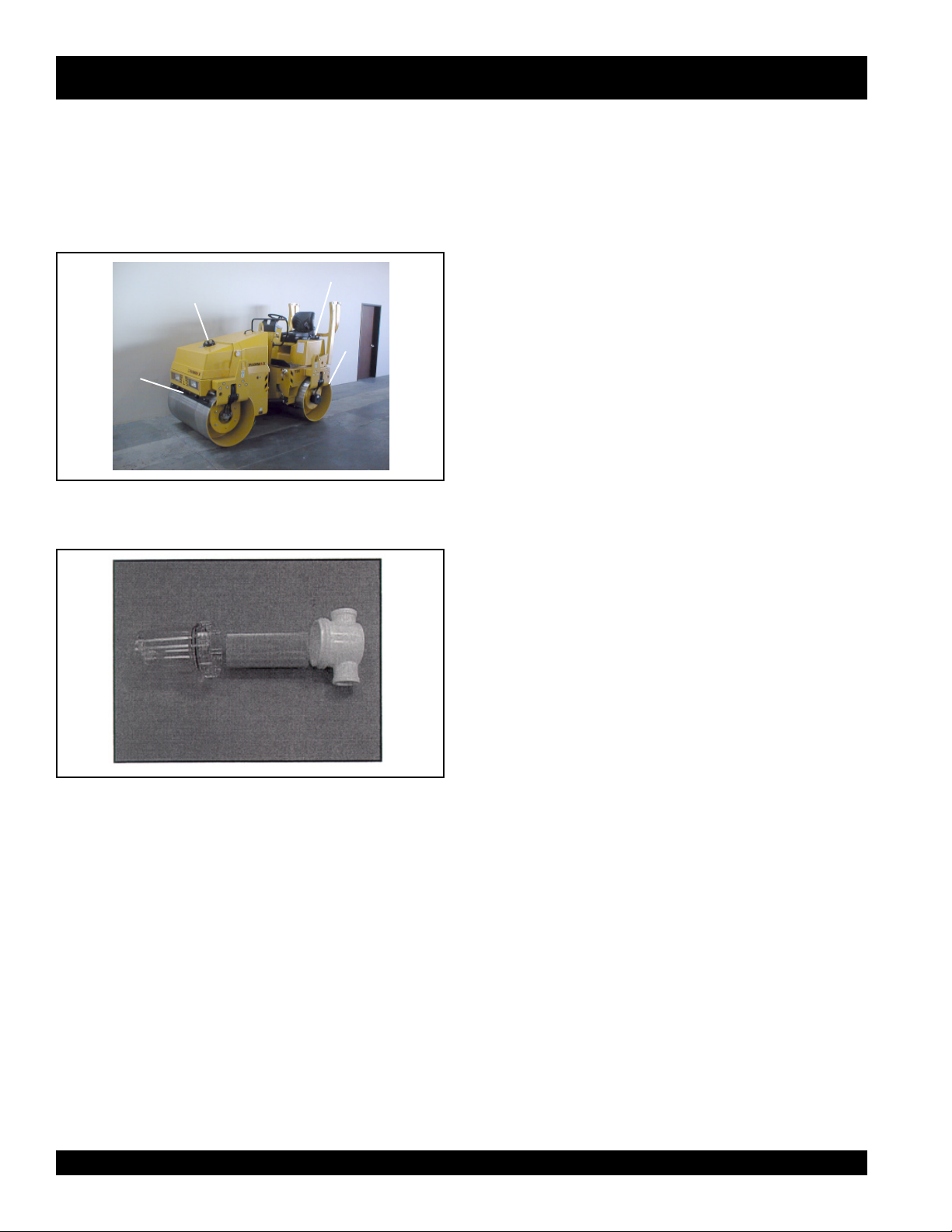

General Layout

1) Engine oil drain plug

2) Hydraulic oil drain plug

3) Fuel filler cap

4) Cap, front water tank

5) Cap, rear water tank

➍

➊

➋

1) Central lifting hook

2) Accelerator lever

3) Engine and hydraulic oil filters

4) Fuel drain plug

➎

➌

1) Drive lever

2) Articulation lock

3) Sight glass, hydraulic oil level

4) Rear sprinkler tube, scraper

5) Tool box

➎

➊

➍

➌

1) Emergency stop switch

2) Ignition switch

3) Machine plate

4) Rear water filter, sprinkling system

➋

5) Front sprinkler tube, scraper

➊

➎

➍

➋

➌

➍

➊

➋

➌

PAGE 14 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 15

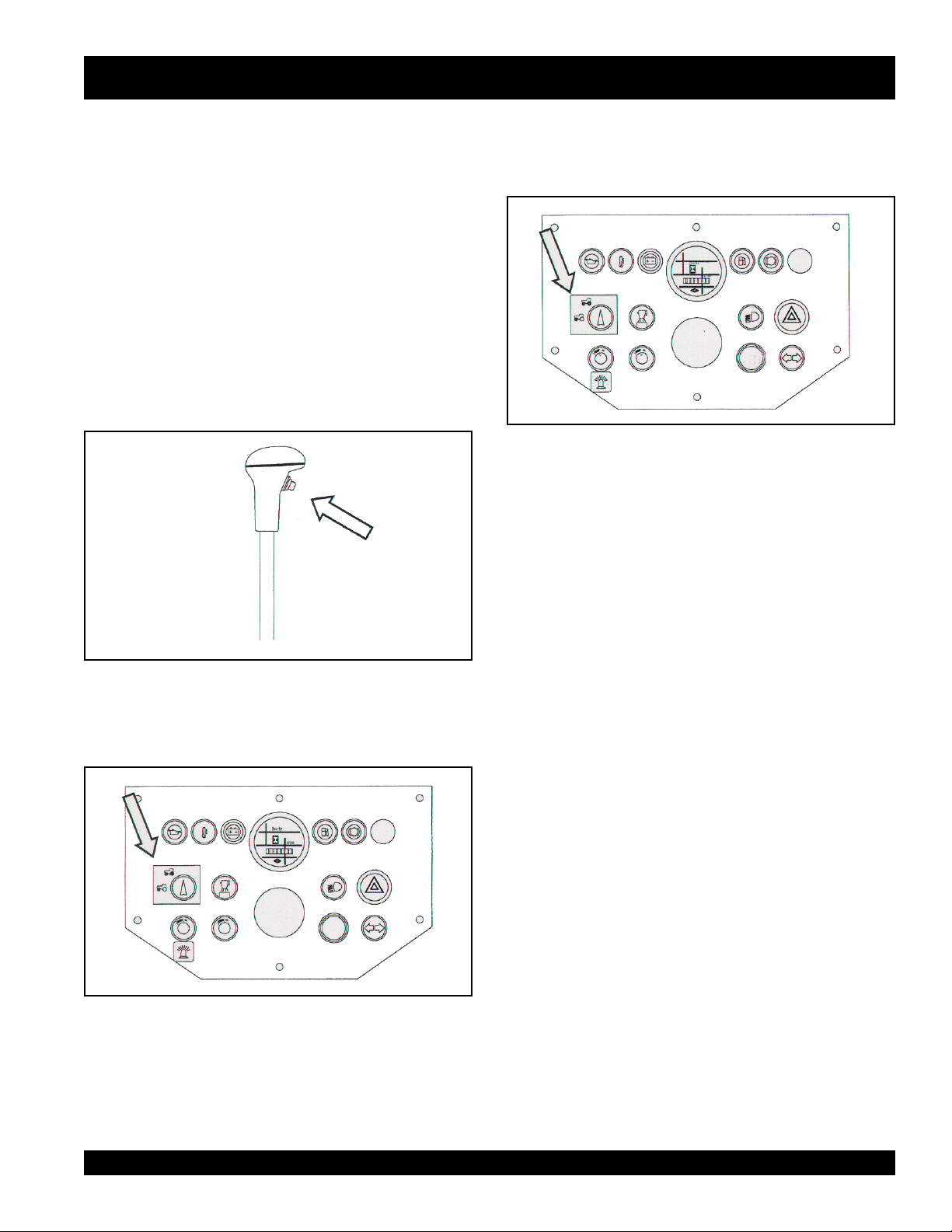

OPERATION

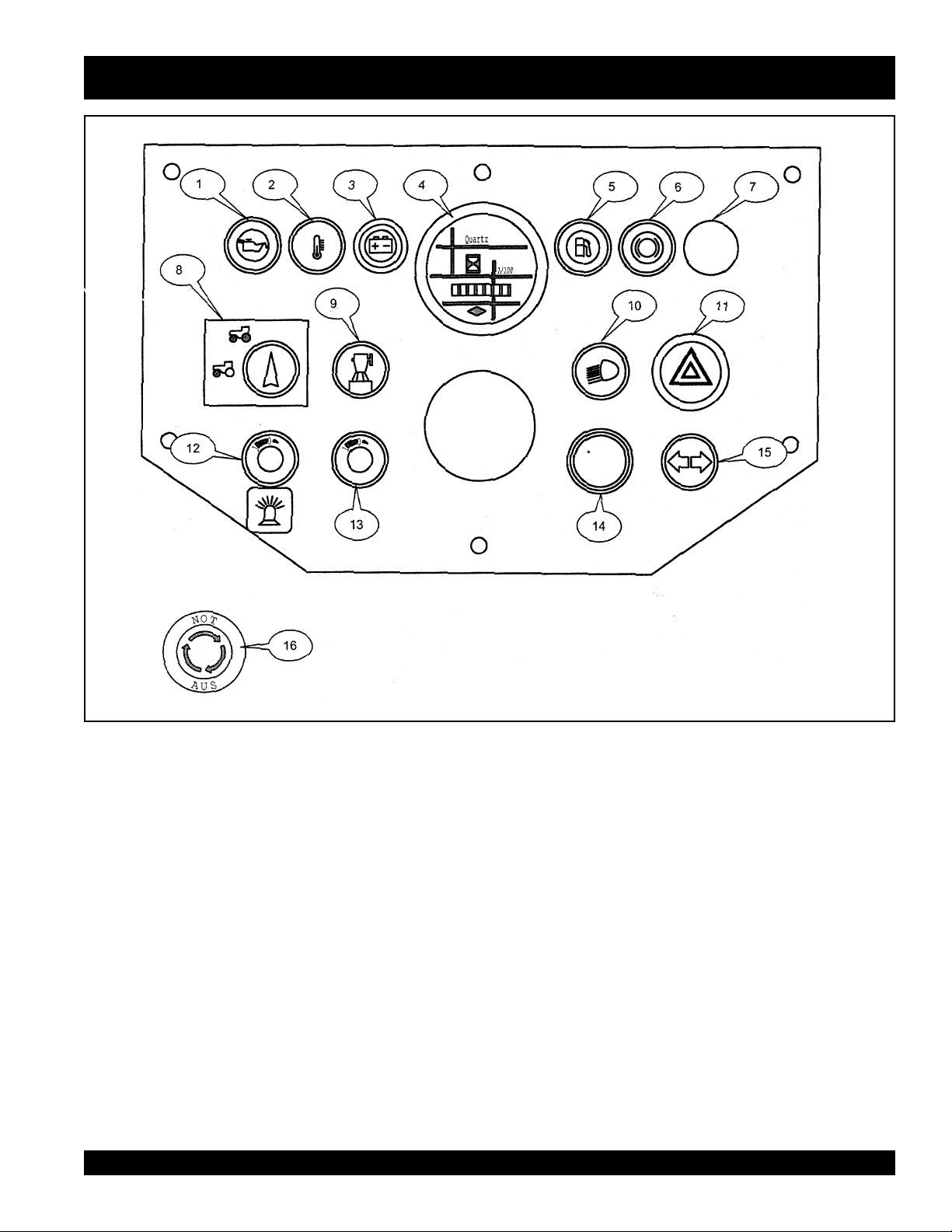

1) Warning light – engine oil pressure

2) Warning light – cooling water temperature

3) Warning light – charging system

4) Hour meter

5) Warning light – low fuel level

6) Warning light – charge / brake pressure

7) Spare

8) Selector switch – vibration front or front and back

9) Sprinkler switch

10) Light switch

0 – off

1 –parking lights

2 –head lights

11) Hazard warning button

12) Rotary warning beacon (optional equipment)

13) Working lamp (optional equipment)

14) Horn button

15) Indicator left/right (located on right side of column)

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 15

Page 16

OPERATION

16) Emergency stop switch

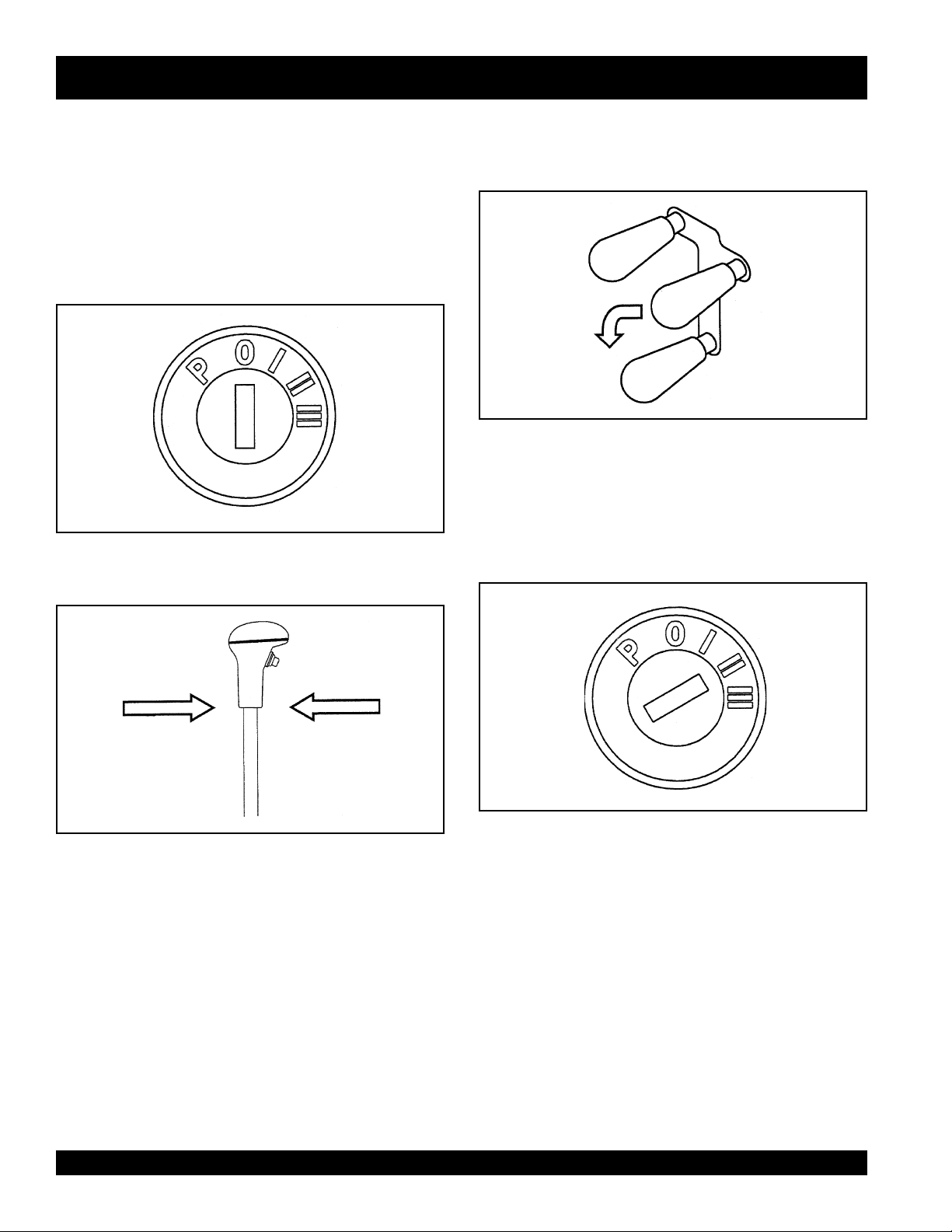

Engine starting

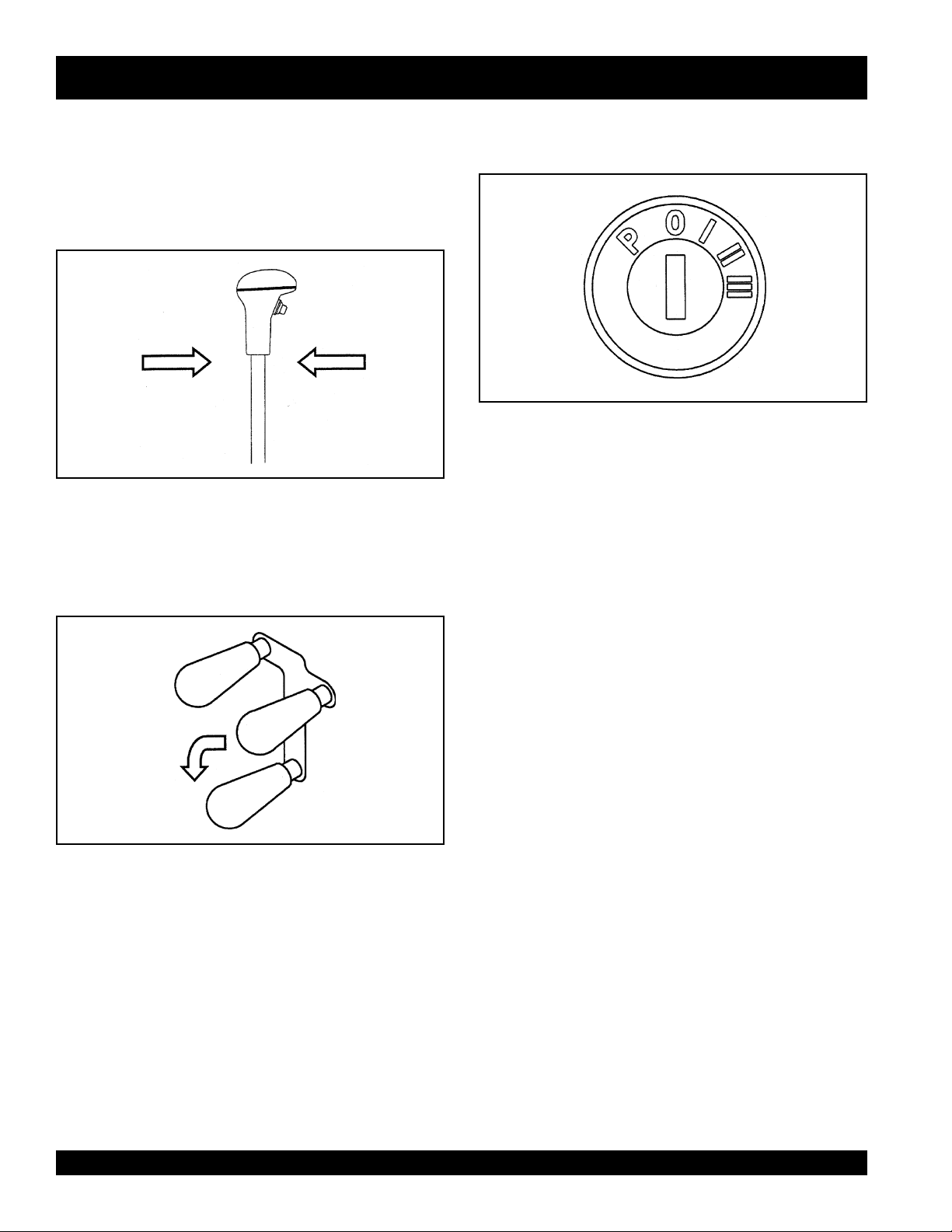

1. Ignition lock

P...................................................................... PARK

0 ...................................................................... OFF

I. ...................................................................... Ignition

I I....................................................................... Pre-heat

III...................................................................... Start

Bring into 0 position

3. Speed adjustment lever

Move the accelerator lever to the idle position (moving

downwards)

4. Ignition switch

Turn clockwise to position III. When the outside temperature

is below 0° C, first turn the ignition switch to position II and

2. Reversing lever

PAGE 16 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 17

OPERATION

wait until the preheat indicator on the instrument panel

goes off, then continue turning the switch to position III for

starting.

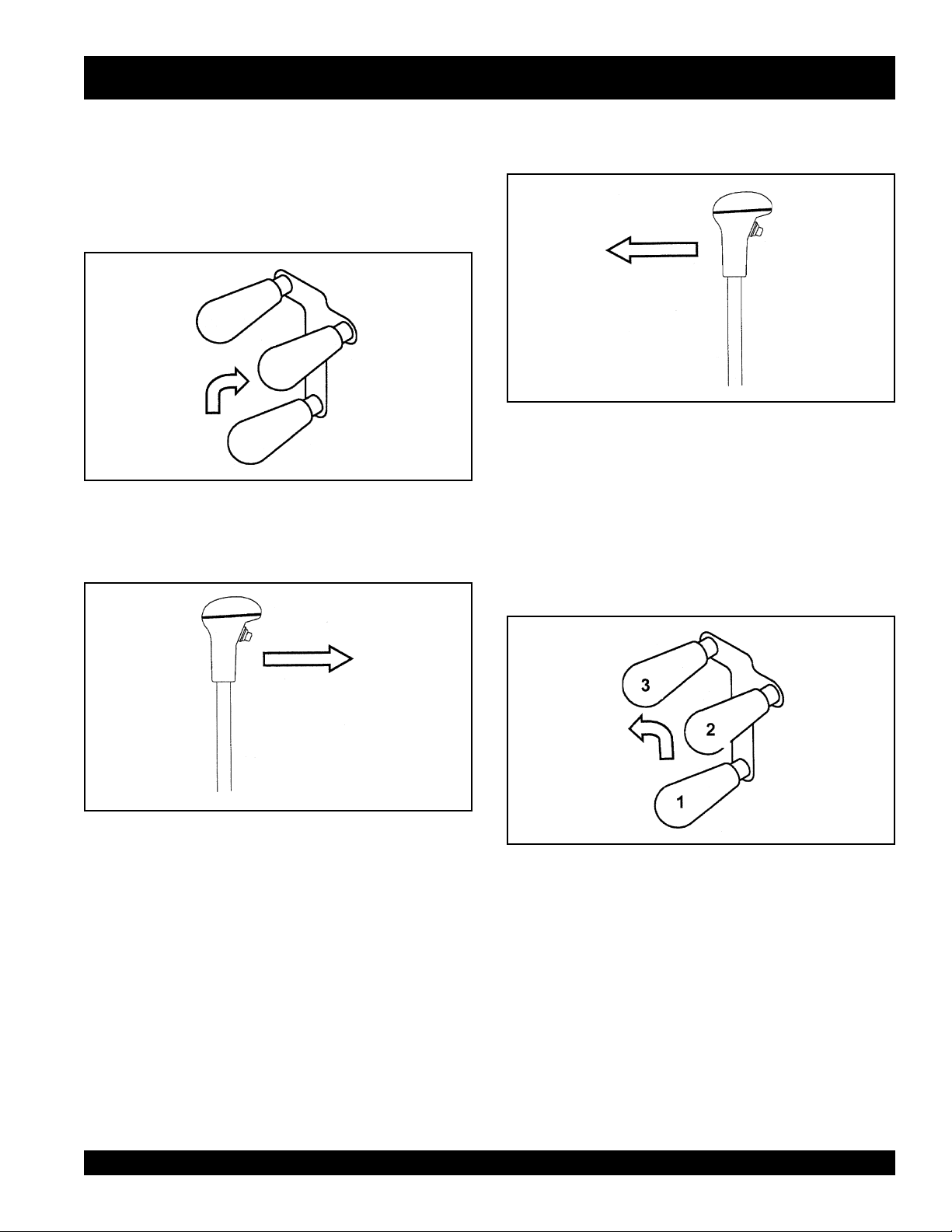

Driving / operating the machine

1. Speed adjustment lever – vibrating

Pull the lev er up and then towards the driver’ s seat. Lock it

in the 2400-rpm position.

2. Forward travel

Move the tra v el le v er f orward slo wly.

3. Reverse travel

Move the tra v el lever back slowly.

4. Speed adjustment lever – travelling

To move the machine from one site to another one , put the

accelerator lever into the 2700 rpm position (pull it up and

push it forward).

1 – Idling speed

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 17

Page 18

OPERATION

2 – Working speed (2400 rpm)

3 – Transporting speed (2700 rpm)

Service brake / engine shut-down

Application of service brake

Move the driv e lever slo wly into neutral (0) position. The machine

is automatically braked by the hydrostatic transmission.

Move the drive lever slowly into neutral (0) position as shown

above.

Engine shut-down

PAGE 18 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 19

OPERATION

Move the accelerator lever downward to the idling position.

Engine shut-down

Turn the ignition key counter-clockwise to the (0) position.

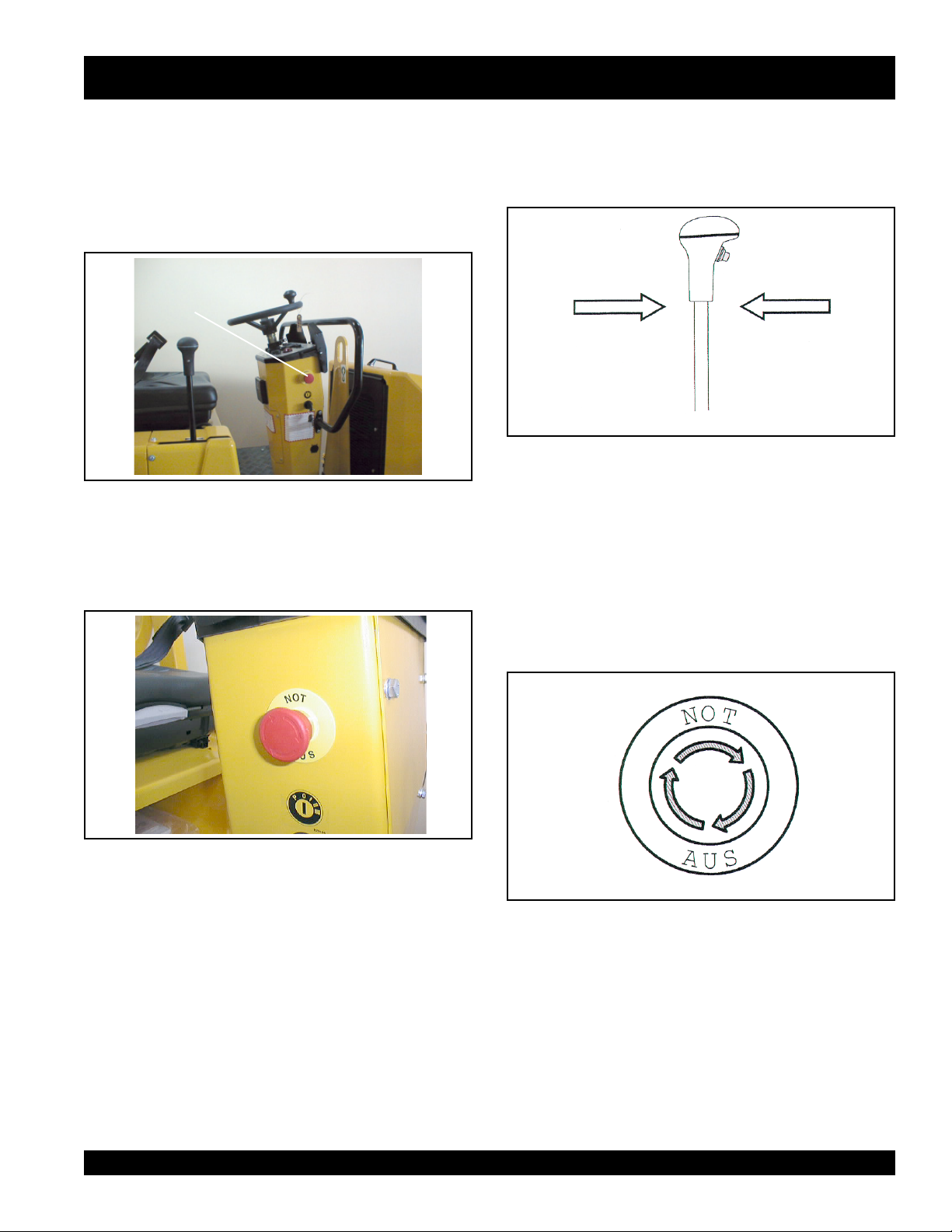

Emergency stop switch

side of the steering column.

Emergency stop

In case of an emergency, bring the machine to a standstill by

➊

pressing the EMERGENCY STOP BUTTON.

Release the emergency stop

Location of EMERGENCY STOP BUTTON

The EMERGENCY STOP BUTTON (1) is located on the R.H.

To release the emergency stop, the driv e lever has to be brought

to neutral (0) position.

Release the emergency stop

T urn the emergency stop b utton slightly in the direction indicated

by the arrows until it snaps out.

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 19

Page 20

OPERATION

Driver’s seat

1. Forward/backward adjustment

Pull the longitudinal adjustment lever outward and set the

seat to the desired position.

➜

2. Adjustment of back rest

Pull the backrest adjustment lever upwards and set the

backrest to the desired position.

3. Weight adjustment

Push the lever (1) downward to the desired weight

adjustment (9 weight steps from 50 kg to 130 kg

av ailable). To decrease the weight adjustment, push

the lever fully to the bottom against the stop: The lever

comes back automatically to the 50 kg position.

Never pull the adjustment lever upwards!

➊

Please note!

➜

The driver seat must not be adjusted while the vehicle is in

motion: DANGER OF ACCIDENT!

This driver seat helps to keep you health y . Therefore appropriate

care and maintenance is recommended.

PAGE 20 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 21

OPERATION

Sprinkler system

1. Water tank

Fill water tank (1a + 1b).

1a

2. Turn sprinkler on and off

Put the sprinkler system on and off by turning the

corresponding switch.

1b

SPRINKLER WITH FOOT OPERATED SWITCH

This function is possible if the ignition is turned on. If you need

water , push the s witch (1) and the sprinkling system works. If

you release the s witch (1), the sprinkling system will stop. The

sprinkler foot switch will work only if the main sprinkler switch is

turned off.

1

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 21

Page 22

OPERATION

Water tank, sprinkler, frost warning

Cleaning

If necessary , clean the water tanks (1) with the sie ves, the front

and rear sprinkler tubes with the sprinkler nozzles (2) and . . .

➊

➊

Frost Warning

In the event of frost warning, completely empty the sprinkling

system and remove the filter sieve from the housing. Please

proceed as follows:

1) Remove filter housing.

2) Drain water.

3) Switch on sprinkler system to drain remaining water in the

➋

➋

.....the water filters, located under the front and the back grill.

tubes.

PAGE 22 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 23

OPERATION

Single / double vibration

1. Switch on vibration

Press shortly the vibration switch on the drive lever handle.

2. Switch off the vibration

Again press shortly the vibration switch on the driver

lever handle.

Attention

Only engage the vibration when the throttle lever is set to a

working speed.

Vibration at the front only

To put on the front vibration only, turn the vibration selector

switch counter-clockwise.

Vibration front and rear

To put on the front and rear vibration, turn the vibration selector

switch clockwise.

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 23

Page 24

HYDRAULIC AND ELECTRIC

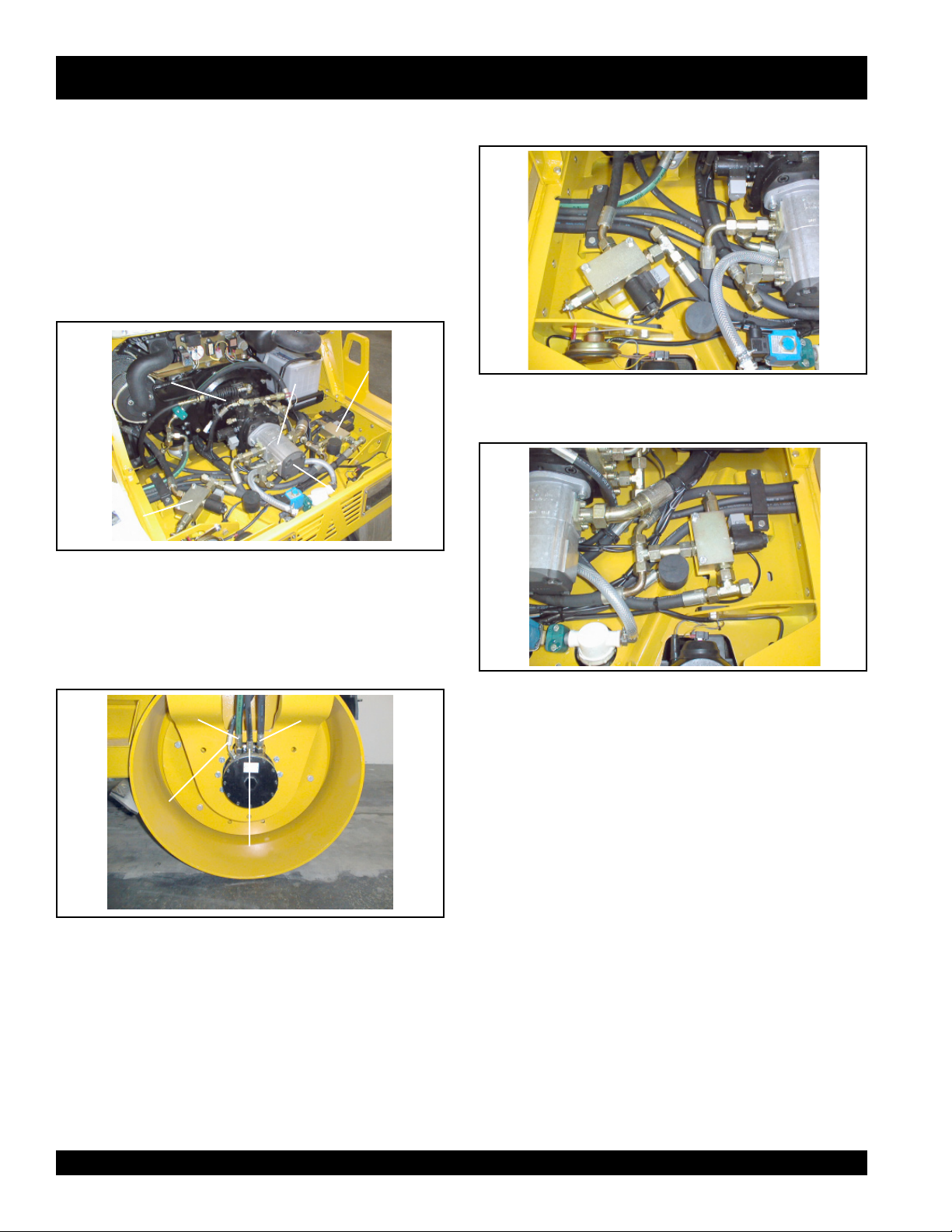

Hydraulic components

1) Vibration valve rear

2) Vibration valve front

3) Vibration pump

4) Drive pump

5) Steering and charge pump

➍

➊

➌

Vibration control valve rear

➜

➋

Vibration control valve front

➎

➜

1) Drive circuit, ports A & B

2) Leak oil hose

3) Brake pressure hose

➊

➌

➋

➊

PAGE 24 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 25

MAINTENANCE & REPAIR

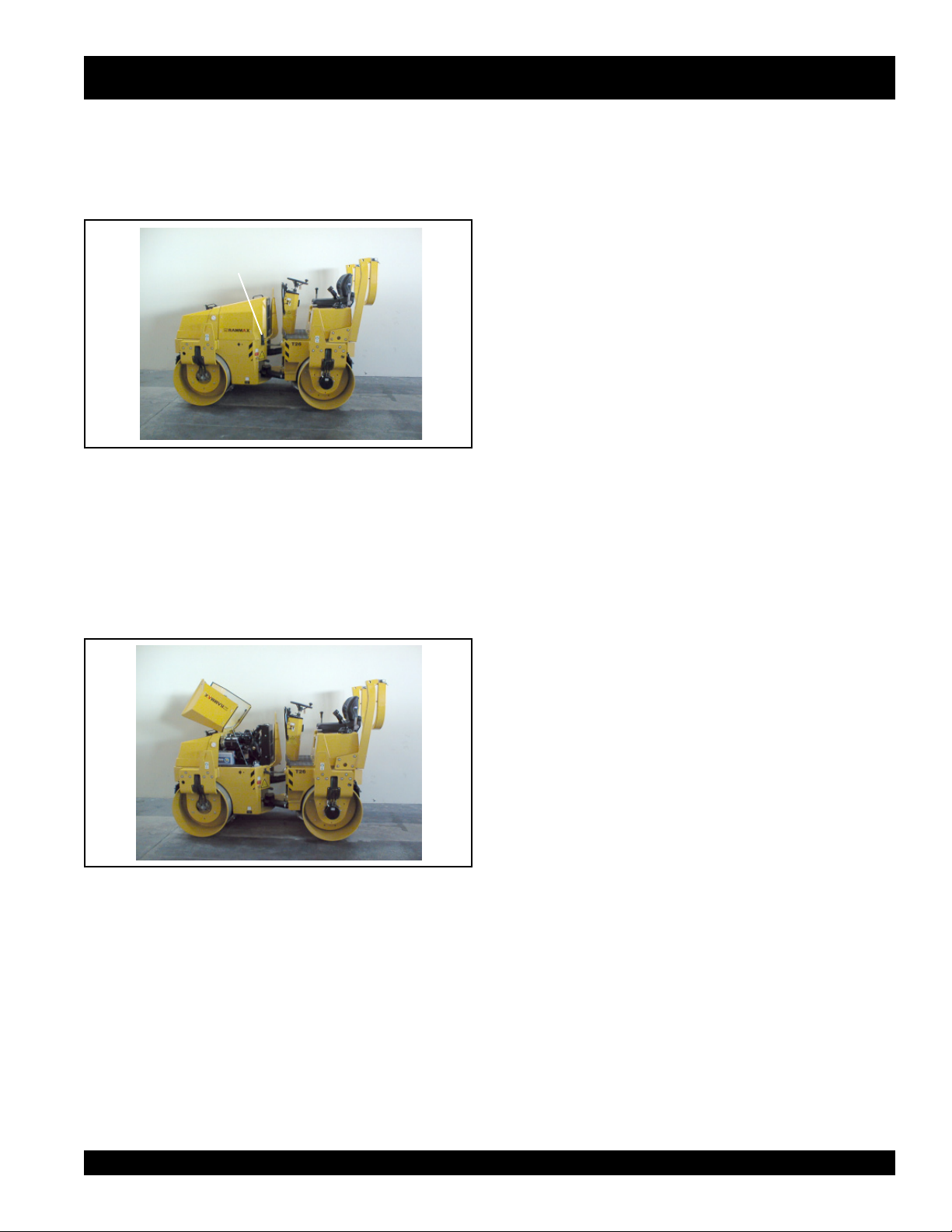

Open engine hood

1. Bonnet fastener

Release fasteners (1) on both sides of machine.

➊

2. Hood

Open engine hood.

Attention:

Warning!

Do not open the engine hood before the engine is stopped. A

Danger of injury to your hands or fingers exists!

Warning!

Work on the engine only when the engine has cooled down.

Danger of being burned!

Fuses

Guide the engine hood carefully until the retaining cable is fully

stretched. Do not slam it open.

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 25

Page 26

MAINTENANCE & REPAIR

Open front water tank

1. Pull front grill open.

➜

2. Disconnect the water hose (quick coupler).

3. Release both rubber latches.

If rubber latches are opened and the water hose is disconnected

The water tank can be lifted up and tilted back.

➜

➜

➜

PAGE 26 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 27

MAINTENANCE & REPAIR

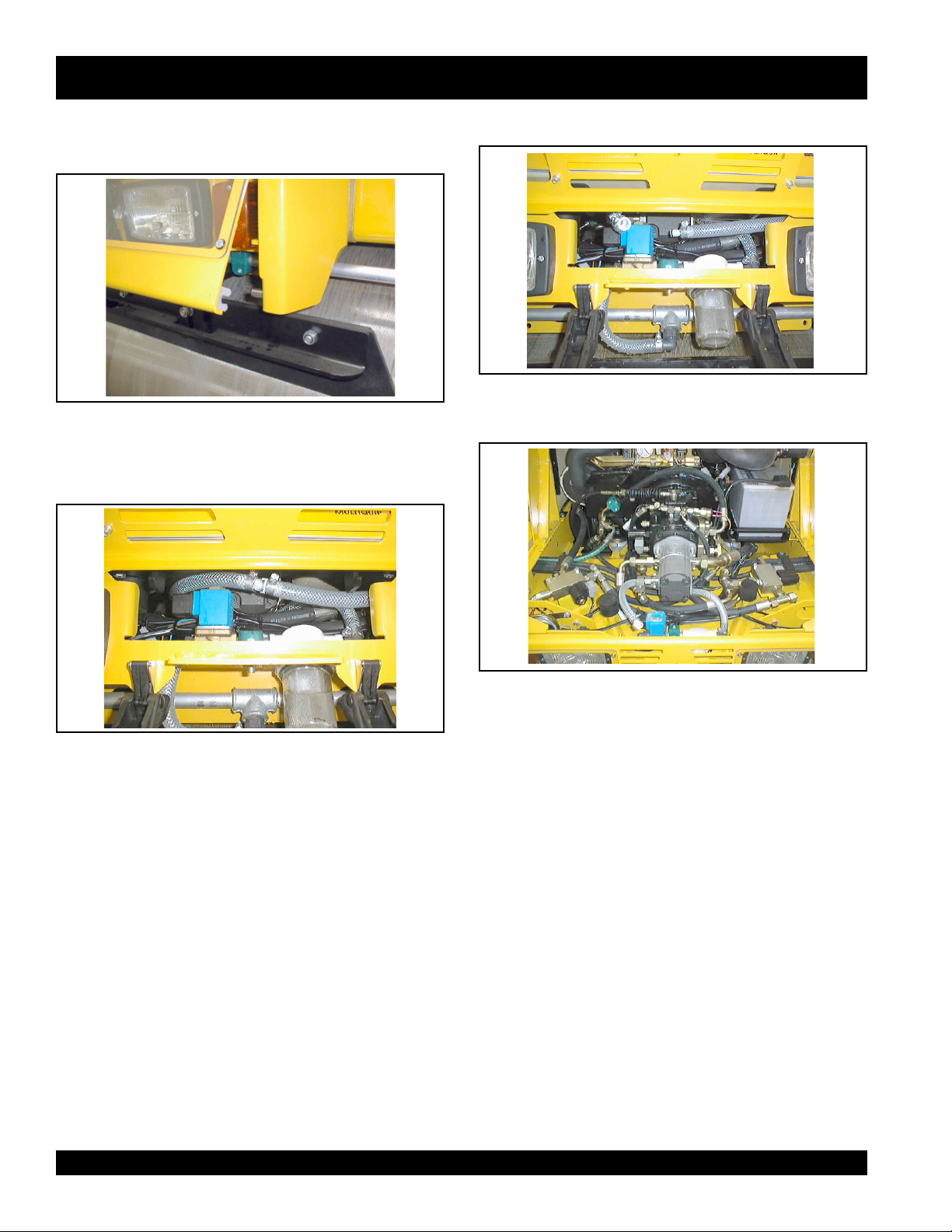

Electrical components – engine

The electrical components for the engine are located at the

front end of the engine, just above the drive pump.

1) Relay (K31), stop solenoid.

2) Timer (K30) for relay of stop solenoid.

3) Starter relay (K14), 70A.

Fuses

4 — F1, stop solenoid pulling coil (30A).

5 — F2 stop solenoid holding coil (7.5A).

6 — F3, vibration (10A).

7 — F4, horn, oil cooler fan, water pump (15A).

Electrical components lighting system

The electrical components for the lighting system are located in

➌

➋

the steering column.

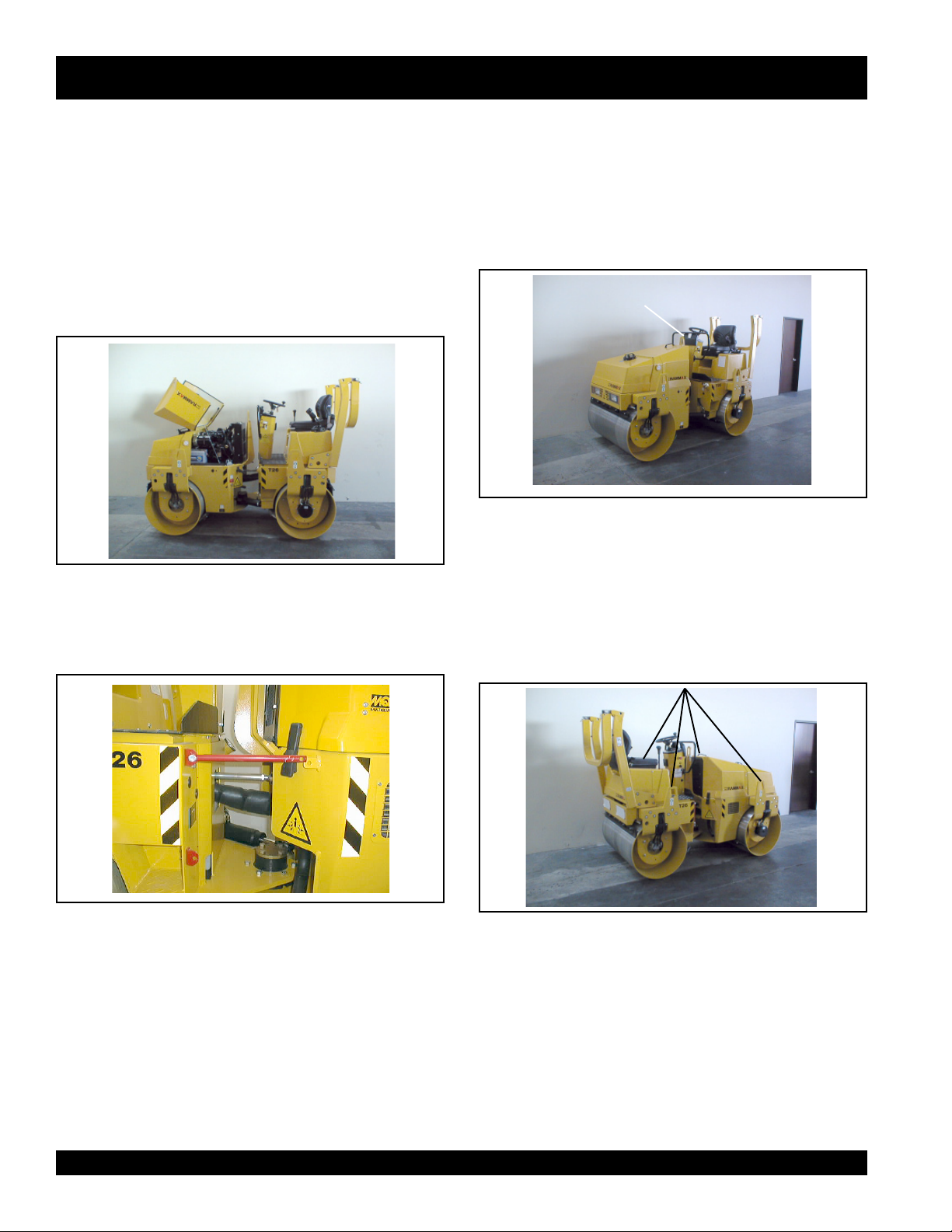

Attachment to the central loading hook

Suspend the machine on the crane hook (1).

➍

➎

➏

➊

➐

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 27

Page 28

MAINTENANCE & REPAIR

Maintenance – towing, lifting of machine

Towing

Only tow the machine in case of emergency for the purpose of

moving it out of the hazard area (max. 10 m).

Transport the machine by using a truck or low loader .

Over a longer distance, the machine may only be towed with a

tow bar (max. 500 m / 1Km/h), and the brake must be released

Max.

10 m

➜

Max.

10 m

Warning:

Never stand under lifted machine while loading or unloading it.

Use only safe ramps. While transporting the machine, it must

be secured against rolling, sliding and tipping over!

Attachment to the 4-point lifting brackets

Suspend the machine by attaching an appropriate wire rope to

➜

the 4-point lifting hooks.

Warning:

Never stand under lifted machine while loading or unloading it.

(see sheet release brake).

Articulation lock

Fix the articulation lock before lifting the machine.

Use only safe ramps. While transporting the machine, it must

be secured against rolling, sliding and tipping over!

Release brake

➊

PAGE 28 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 29

MAINTENANCE & REPAIR

Front drive motor (1)

Rear drive motor (1)

Release of spring brake

Remove plug (1).

➊

Install bolt M12X35 with washer (2) in its place.

(In pocket behind seat)

Attention!

Compared to the A4VG28 drive pump installed up to Serial

➊

➊

➋

Number 0899, this pump does no more have the possibility to

slacken the relief valve cartridges (1) to open the by-pass.

Should the machine really need to be towed away, the main

ports A and B on the drive pump would have to be connected to

each other .

After towing the machine with released brakes, braking

mode must be re-established.

Change / add hydraulic oil

➊

➊

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 29

Page 30

1) Hydraulic tank breather

Slacken the breather to release the tank pressure,

otherwise it is impossible to top up oil.

2) Oil drain plug

➊

Unscrew the oil drain plug (1) and drain the oil into a pan.

Then screw the oil drain plug back in again.

Filling capacity of hydraulic system: 48L

3) Oil filter

MAINTENANCE & REPAIR

Remove hydraulic oil filter with the special wrench (wrench

(1) with the ref.390159 is supplied with the machine) in

pocket behind seat.

4) Hydraulic oil

➊

Fit a new hydraulic oil filter onto the filter cap. Refill fresh

hydraulic oil through the filter housing and re-install filter .

Retighten tank breather.

Attention:

Never remove the filter cap before any dirt around the

neck has been cleaned off! Always change filter and oil at

the same time. First oil change after 500h, then every

2000h, but at least once a y ear.

➊

Main components

PAGE 30 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 31

MAINTENANCE & REPAIR — YANMAR ENGINE

TRAP METI YLIAD

lliferdnalevelleufehtkcehC

knatlioleufehtniarD

partretawehtdnaretliflioleufehtkcehC

LIOLEUF

METSYS

retlifleufehtnaelC

tnemeleretlifleufehtecalpeR

evlavnoitcejnileuF

noitidnocnoitcejniehtkcehC

pmupnoitcejnileuF

gnimitnoitcejniehtkcehC

esacknarcehtnilevellioebulehtkcehC

LIOEBUL

lioebulehtecalpeR

METSYS

retliflioebulehtecalpeR

m

m

YREVE

05

.SRH

YREVE

.SRH002

YREVE

.SRH004

YREVE

0001

.SRH

m

m

m

m

●

●

m

ts

1(

)emit

m

ts

1(

)emit

m

dn

2(

dnaemit

)retfaereht

m

dn

2(

emit

dna

)retfaereht

levelretawgniloocehtkcehC

GNILOOC

RETAW

gniggolcrofsnifrotaidarehtnaelcdnakcehC

METSYS

retawgniloocehtecalpeR

m

m

m

)naelC(

m

yreve(

)raey

m

EKATNITIA

METSYS

riA

renaelc

tnemele

naelC

ytsudni(

)snoitidnoc

ecalpeR

m

m

ytsudni(

m

)snoitidnoc

metsysknilronrevogehtniliO

ENIGNE

KCOLB

stlobehtnethgiteR

ecnaraelcevlavtsuahxe/ekatniehttsujdA

spmalgninrawllakcehC

m

sruoh05tsrifehtretfA

ylbmessa-erdnaylbmessasidhcaeretfasruoh05

●

m

LACIRTCELE

TNEMPIUQE

leveldiuqilyrettabehtkcehC

noisnettlebnafehttsujdA

m

m

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 31

Page 32

1) Vibration motor

2) Main drive circuit A & B

3) Leak oil vibrating motor

1) Emergency stop valve

MAINTENANCE & REPAIR

➊

➋

2) Drive pump

3) Steering and vibration pump

Check and adjust pressures

➋

➌

➋

➊

➌

PAGE 32 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 33

All values stated are valid at:

Hydraulic oil temperature of approx. 140 F and high idle

(full RPM) of diesel engine.

Relief valves should release pressure for max. 5

seconds.

M6 Relief valve when changing from single to double

M4

M2

M1

Pressure gauge measuring range:

MAINTENANCE & REPAIR

M5

M6

M3

M4 900 PSI

M1, M2, M3, M5, M6 9’000 PSI

M4 Charge pressure for drive pump at speed of approx. 2

mph

260

+ 30 PSI (cannot be adjusted)

M1 Pressure of drive circuit forward with blocked drum

4’350 PSI plus charge pressure = 4’610

+ 220 PSI

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 33

Page 34

MAINTENANCE & REPAIR

M5 Pressure of drive circuit backward with blocked drum

5’250 ± 150 PSI plus charge pressure = 5’625

M3 Steering relief valve at full articulation left and right

1’450

+ 75 PSI

+ 150 PSI

M2 Relief valve when engaging single vibration

1’750

+ 75 PSI

vibration 1’750 + 75 PSI

PAGE 34 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 35

MAINTENANCE & REPAIR

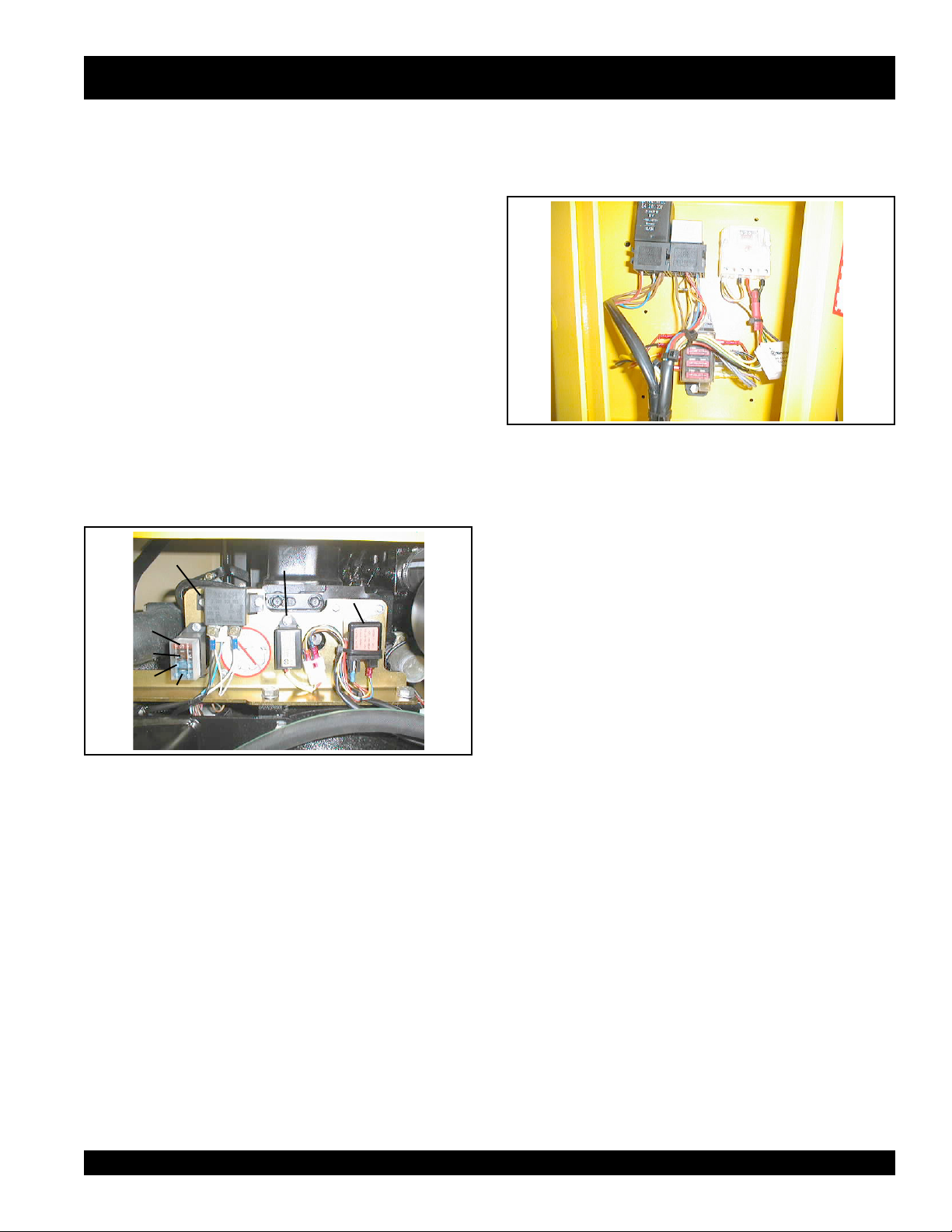

Fuses

Electrical components – engine

The electrical components for the engine are located at the

front end of the engine, just above the drive pump.

1) Relay (K31), stop solenoid.

2) Timer (K30) for relay of stop solenoid.

3) Starter relay (K14), 70A.

Fuses

4 — F1, stop solenoid pulling coil (30A).

5 — F2 stop solenoid holding coil (7.5A).

6 — F3, vibration (10A).

7 — F4, horn, oil cooler fan, water pump (15A).

1) Emergency stop

2) Back-up alarm

Air Filter Service Indicator

Filter requires service when red ring is visible

➌

➊

➋

➍

➎

➏

➐

➋

➊

1) Relay emergency stop

2) Relay vibration

3) Relay head lamps

4) Fuses

➊

➌

➋

➍

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 35

Page 36

HYDRAULIC SYSTEM

MAINTENANCE & REPAIR

PAGE 36 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 37

ELECTRICAL DIAGRAM

MAINTENANCE & REPAIR

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 37

Page 38

ELECTRICAL DIAGRAM

MAINTENANCE & REPAIR

PAGE 38 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 39

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 39

Page 40

DRUM - TRAVELING

PAGE 40 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 41

1-0.1

DRUM - TRAVELLING

NO PART NO PART NAME QTY. REMARKS

1 AVL135295 WHEEL, T23 1

1 AVL135314 WHEEL, T26 1

1 AVL135324 WHEEL 1

2 AVL341547 WASHER 1

3 AVL494805 HYDRAULIC MOTOR 1

3.1 AVL921734 NUT 5

3.2 AVL921735 WHEEL STUD 5

3.3 AVL921737 SEAL KIT 1

3.4 A VL921775 LAMELLA OUTSIDE 12

3.5 AVL921776 INSIDE LAMINA 11

4 AVL135555 DRUM SUPPORT 1

5 AVL491884 ISOLATION MOUNTING, T23/T26 5

5 AVL491884 ISOLATION MOUNTING, T33 6

6 AVL803772 STRAP 1

7 AVL824883 PLATE 1

7 AVL824884 PLATE 1

7 AVL824885 PLATE 1

8 AVL824888 DISTANCE PLATE 1

9 AVL803770 WASHER 1

10 AVL803977 ADDITIONAL WEIGHT 2

11 AVL365973 DISTANCE PLATE, T26 1

11 AVL365972 DISTANCE PLATE, T33 1

13 AVL922312 REDUCER 2

14 AVL901745 REDUCER 1

15 AVL901059 REDUCER 1

16 AVL901785 SCREW HEX. HD . 6

17 AVL901765 SCREW HEX. HD . 2

18 AVL902126 NUT HEX. 6

19 AVL901798 SCREW HEX. HD., T23/T26 6

19 AVL909746 SCREW HEX. HD., T33 8

20 AVL901901 SCREW HEX. HD., T23 6

20 AVL901911 SCREW HEX. HD., T26 6

20 AVL901915 SCREW HEX. HD., T33 6

DRUM - TRAVELING

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 41

Page 42

VIBRATION DRUM

PAGE 42 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 43

1-0.2

VIBRATION DRUM

NO PART NO PART NAME QTY. REMARKS

1 AVL135556 DRUM SUPPORT 1

2 AVL135294 FLANGE 1

3 AVL494807 HYDRAULIC MOTOR 1

3.1 AVL922226 SEAL KIT 1

4 A VL341567 HOUSING 1

5 A VL908254 V-SEAL 1

6 AVL907369 SEAL RING 1

7 A VL900426 GROO VED BALL BEARING 1

8 AVL491884 ISOLATION MOUNTING, T23/T26 4

8 AVL491884 ISOLATION MOUNTING, T33 5

9 AVL803771 STRAP 2

10 AVL824883 PLATE 1

10 AVL824884 PLATE 1

10 AVL824885 PLATE 1

11 AVL824889 DISTANCE PLATE 1

12 AVL365973 DISTANCE PLATE, T26 1

12 AVL365972 DISTANCE PLATE, T33 1

13 AVL366144 ADDITIONAL WEIGHT, T33 1

14 AVL491356 FLANGE COMPLETE 2

14.1 AVL902682 ALAN SCREW 4

14.2 AVL908882 ALAN SCREW 4

14.3 AVL902323 SPRINGWASHER 8

14.4 AVL906670 SEAL 2

15 AVL901311 REDUCER 1

16 AVL921609 KEY 1

17 AVL902640 ALAN SCREW 4

18 AVL901765 SCREW HEX. HD . 2

19 AVL901800 SCREW HEX. HD., T23/T26 4

19 AVL901807 SCREW HEX. HD., T33 5

20 AVL901901 SCREW HEX. HD., T23 6

20 AVL901911 SCREW HEX. HD., T26 6

20 AVL901915 SCREW HEX. HD., T33 6

21 AVL902267 WASHER, T26/T33 5

VIBRATION DRUM

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 43

Page 44

VIBRATION DRUM

PAGE 44 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 45

1-0.3

VIBRATION DRUM

NO PART NO PART NAME QTY. REMARKS

1 AVL236311 VIBRO SHAFT, T23 1

1 AVL236349 VIBRO SHAFT, T26 1

1 AVL236370 VIBRO SHAFT, T33 1

2 A VL341569 HOUSING 1

3 AVL341570 FLANGE 1

4 AVL493094 CLUTCH COMPLETE 1

4.1 AVLB24 PLASTIC BUSHING 1

5 A VL904014 ROLLER BEARING 2

6 AVL922670 SEAL RING 1

7 AVL922671 SEAL RING 1

8 AVL903577 RETAINING CLIP 2

9 AVL903824 KEY 1

10 AVL901774 SCREW HEX. HD . 12

11 AVL901760 SCREW HEX. HD . 1

VIBRATION DRUM

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 45

Page 46

SCRAPER CHASSIS FRONT

PAGE 46 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 47

SCRAPER CHASSIS FRONT

1-2.1

SCRAPER CHASSIS FRONT

NO PART NO PART NAME QTY. REMARKS

1 AVL824194 SCRAPER BRACKET 2

2 AVL803817 SCRAPER BRACKET 2

3 AVL449730 SCRAPER, T23 2

3 AVL465181 SCRAPER, T26 2

3 AVL803961 SCRAPER, T33 2

4 A VL236231 PLA TE, T23 2

4 A VL236232 PLA TE, T26 2

4 A VL236371 PLA TE, T33 2

5 A VL341410 PLA TE, T23 2

5 A VL341411 PLA TE, T26 2

5 A VL341710 PLA TE, T33 2

6 AVL921649 SAUCER-HEAD SCREW 8

7 AVL922555 SAUCER-HEAD SCREW 4

8 AVL902206 NUT HEX. 12

9 AVL902264 WASHER 4

10 AVL901772 SCREW HEX. HD . 4

11 AVL901773 SCREW HEX. HD . 4

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 47

Page 48

SCRAPER CHASSIS REAR

PAGE 48 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 49

SCRAPER CHASSIS REAR

1-2.2

SCRAPER CHASSIS REAR

NO PART NO PART NAME QTY. REMARKS

1 AVL824194 SCRAPER BRACKET 2

2 AVL803817 SCRAPER BRACKET 2

3 AVL449730 SCRAPER, T23 2

3 AVL465181 SCRAPER, T26 2

3 AVL803961 SCRAPER, T33 2

4 A VL236231 PLA TE, T23 2

4 A VL236232 PLA TE, T26 2

4 A VL236371 PLA TE, T33 2

5 A VL341410 PLA TE, T23 2

5 A VL341411 PLA TE, T23 2

5 A VL341710 PLA TE, T33 2

6 AVL921649 SAUCER-HEAD SCREW 8

7 AVL922555 SAUCER-HEAD SCREW 4

8 AVL902206 NUT HEX. 12

9 AVL902264 WASHER 4

10 AVL901772 SCREW HEX. HD . 4

11 AVL901773 SCREW HEX. HD . 4

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 49

Page 50

GRAVITY SPRINKLER

PAGE 50 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 51

1-3.1

GRA VITY SPRINKLER

NO PART NO PART NAME QTY. REMARKS

1 AVL341575 SPRINKLER PIPE, T23 4

1 AVL341637 SPRINKLER PIPE, T26 4

1 AVL341741 SPRINKLER PIPE, T33 4

2 AVL909418 PLUG 4

3 AVL494443 FILTER 2

3.1 AVL921706 FIL TER BASE 2

3.2 A VL921710 ELEMENT 2

3.3 AVL921709 FIL TER HOLDER 2

3.4 AVL921708 GASKET 2

3.5 AVL921707 GLASS 2

4 AVL494637 SHUT-OFF VALVE 2

4.1 AVL921739 WAY-VALVE 2

4.2 AVL921740 COIL 2

5 AVL905293 FITTING 2

6 AVL909398 REDUCER 2

7 AVL909398 REDUCER 4

8 A VL905432 NIPPLE 2

10 AVL903792 HOSE 2

11 AVL903792 HOSE 2

12 A VL908157 HOSE CLAMP 6

13 AVL903726 HALF BOWL 8

14 AVL921495 HALF BOWL 4

15 AVL902683 ALAN SCREW 8

16 AVL921645 ALAN SCREW 4

17 AVL903719 WASHER 12

GRAVITY SPRINKLER

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 51

Page 52

CHASSIS FRONT

PAGE 52 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 53

2-0.1

CHASSIS FRONT

NO PART NO PART NAME QTY. REMARKS

1 AVL135542 REAR FRAME 1

2 AVL365928 HOOD GUIDE 2

3 AVL341593 BATTERY MOUNTING 1

4 AVL803850 ANGLE 1

5 A VL366134 SUSPENSION 1

6 AVL824060 GRID 1

7 AVL494417 PROFILED JOINT 1

8 AVL366122 FRONT COVER 1

9 A VL824936 HINGE 1

10 A VL824937 HINGE 1

11 AVL820281 CORE (CONNECTOR) 2

12 AVL923617 ISOLATION MOUNTING 2

13 AVL923280 ISOLATION MOUNTING 4

14 A VL906194 CLAMP 2

15 AVL921685 REDUCER 1

16 AVL906543 CAP SCREW 1

17 AVL903769 SEAL RING 1

18 AVL906542 PLUG 1

19 AVL906943 GASKET 1

20 AVL901755 SCREW HEX. HD . 4

21 AVL901762 SCREW HEX. HD . 2

22 AVL921628 SCREW HEX. HD . 1

23 AVL901777 SCREW HEX. HD . 6

24 AVL922992 CHEESE HEAD SCREW 8

25 AVL902919 COUNTERSUNK SCREW 2

26 AVL908876 COUNTRESUNK SCREW 4

27 AVL902262 WASHER 8

28 AVL902264 WASHER 6

29 AVL902125 NUT HEX. 2

CHASSIS FRONT

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 53

Page 54

CHASSIS FRONT

PAGE 54 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 55

2-0.2

CHASSIS FRONT

NO PART NO PART NAME QTY. REMARKS

2 AVL803771 STRAP 2

3 AVL803772 STRAP 2

4 A VL495048 OIL LEVEL GAUGE 1

5 AVL494880 BENT-LEVER CLOSURE 4

6 AVL820566 BRACKET 1

7 AVL824973 RUBBER PLATE 1

8 AVL824918 PLATE 1

9 AVL493266 RUBBER PLATE 1

10 AVL903726 HALF BOWL 2

11 AVL901764 SCREW HEX. HD . 2

12 AVL901862 SCREW HEX. HD . 4

13 AVL902838 FLAT HEAD SCREW 6

14 AVL902840 FLAT HEAD SCREW 4

15 AVL902682 ALAN SCREW 2

16 AVL903719 WASHER 2

CHASSIS FRONT

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 55

Page 56

ENGINE HOOD

PAGE 56 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 57

2-1.1

ENGINE HOOD

NO PART NO PART NAME QTY. REMARKS

1 AVL236393 HOOD 1

2 A VL236741 TENSION BOW 1

3 A VL341617 HINGE 1

4 AVL236899 HOOD REINFORCEMENT 1

5 AVL236900 HOOD REINFORCEMENT 1

6 AVL824922 FENDER 1

7 AVL820566 BRACKET 1

8 AVL495063 HANDLE 1

9 AVL592048 HOSE 1

10 AVL591376 PROFILED JOINT 2

11 AVL591372 PROFILED JOINT 2

12 AVL591373 PROFILED JOINT 1

13 AVL944100 SPACER 4

14 A VL920029 HOSE CLAMP 2

15 A VL922556 BLIND RIVETING 9

16 A VL944171 BLIND RIVETING 8

17 AVL922894 SCREW HEX. HD . 4

18 AVL901756 SCREW HEX. HD . 2

19 AVL901757 SCREW HEX. HD . 9

20 AVL901765 SCREW HEX. HD . 6

21 AVL902839 FLAT HEAD SCREW 6

22 AVL902122 NUT HEX. 6

23 AVL902123 NUT HEX. 11

24 AVL902284 WASHER 9

25 AVL902300 WASHER 2

26 AVL902263 WASHER 6

27 AVL922953 WIRE CALBE 1

28 AVL922952 PRESSURE CLAMP 4

ENGINE HOOD

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 57

Page 58

FRONT WATER TANK

PAGE 58 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 59

2-2.1

FRONT WATER TANK

NO PART NO PART NAME QTY. REMARKS

1 AVL236548 WATER TANK 1

2 A VL222531 COVER NECK 1

3 A VL592433 COVER COMPLETE 1

3.1 AVL824815 GASKET 1

3.2 A VL493810 RUBBER DIAPHRAGME 1

4 AVL824900 SIEVE 1

5 AVL828021 PLATE 1

6 AVL828020 PLATE 1

7 AVL828028 LACK PIN 1

8 AVL366155 BRACKET 1

9 A VL365123 HINGE 1

10 AVL824009 REDUCER COMPLETE 1

10.1 AVL909398 REDUCER 1

10.2 AVL591838 TUBE 1

11 AVL922836 QUICK RELEASE COUPLING 1

12 AVL903792 HOSE 1

13 A VL908157 HOSE CLAMP 3

14 A VLCO3005001 GASKET 1

15 A VL922556 BLIND RIVETING 10

16 A VL944171 BLIND RIVETING 2

17 AVL901762 SCREW HEX. HD . 4

18 AVL902639 ALAN SCREW 6

19 AVL902970 COUNTERSUNK SCREW 11

20 AVL902284 WASHER 11

21 AVL902123 NUT HEX. 11

22 AVL902124 NUT HEX. 6

FRONT WATER TANK

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 59

Page 60

CHASSIS REAR

PAGE 60 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 61

2-3.1

CHASSIS REAR

NO PART NO PART NAME QTY. REMARKS

1 AVL135549 REAR FRAME 1

2 AVL135277 FUEL TANK 1

3 AVL365695 FILLER NECK 1

4 AVL824201 BRACKET 1

4.1 AVL923404 PROFILE 1

5 AVL591345 PLATE 1

6 AVL922302 TANK CLOSURE 1

6.1 AVL921970 KEY 1

7 AVL494824 FLOAT SWITCH 1

8 AVL591315 HOSE 1

9 A VL903780 HOSE CLAMP 2

10 AVL591473 HOSE 2

11 A VL903807 HOSE CLAMP 2

12 AVL906102 REDUCER 2

13 AVL906543 CAP SCREW 1

14 AVL906749 GASKET 1

15 AVL901763 SCREW HEX. HD . 2

16 AVL901772 SCREW HEX. HD . 1

17 AVL902264 WASHER 1

18 AVL495098 FUEL LEVEL CONTROL 1

CHASSIS REAR

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 61

Page 62

CHASSIS REAR

PAGE 62 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 63

2-3.2

CHASSIS REAR

NO PART NO PART NAME QTY. REMARKS

1 A VL365974 REAR COVER 1

2 A VL824936 HINGE 1

3 A VL824937 HINGE 1

4 AVL820281 CORE (CONNECTOR) 2

5 AVL803771 STRAP 2

6 AVL803772 STRAP 2

7 AVL820537 BRACKET 2

8 AVL341669 FIXING DEVICE 1

9 A VL903668 ES BOL T 1

10 A VL906194 CLAMP 2

11 AVL903726 HALF BOWL 2

12 AVL901762 SCREW HEX. HD . 2

13 AVL901763 SCREW HEX. HD . 4

14 AVL901766 SCREW HEX. HD . 4

15 AVL901784 SCREW HEX. HD . 1

16 AVL922992 CHEESE HEAD SCREW 4

17 AVL902682 ALAN SCREW 2

18 AVL902919 COUNTERSUNK SCREW 2

19 AVL903719 WASHER 2

20 AVL902262 WASHER 4

21 AVL902126 NUT HEX. 1

CHASSIS REAR

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 63

Page 64

OPERATOR PLATFORM

PAGE 64 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 65

2-4.1

OPERATOR PLATFORM

NO PART NO PART NAME QTY. REMARKS

1 AVL236852 OPERATOR STAND 1

2 AVL820467 TANK SUPPORT 2

3 AVL365588 HAND RAIL 1

4 AVL365592 PLATE 1

5 AVL365591 PLATE 1

6 AVL495097 BOTTLE BRACKET 1

7 AVL922310 ISOLATION MOUNTING 4

8 AVL901755 SCREW HEX. HD . 6

9 AVL901763 SCREW HEX. HD . 1 6

10 AVL901763 SCREW HEX. HD . 4

11 AVL901780 FLAT HEAD SCREW 3

12 AVL902126 NUT HEX 4

13 AVL902262 WASHER 6

14 AVL902263 WASHER 4

15 AVL902265 WASHER 6

OPERATOR PLATFORM

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 65

Page 66

OPERATOR PLATFORM

PAGE 66 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 67

2-4.2

OPERATOR PLATFORM

NO PART NO PART NAME QTY. REMARKS

2 AVL823429 DRIVER LEVER 1

2.1 A VL495049 HANDLE 1

2.2 AVL824502 LEVER 1

2.3 A VL903225 HEXAGON ALAN PIN 1

3 AVL494814 TRANSMITTER 1

4 AVL491343 BRAKE LINER 1

5 A VL341861 BRAKE DISK 1

6 AVL803447 BRACKET 1

7 AVL491401 SWITCH 1

8 AVL494810 CABLE WIRE 1

8.1 A VLT889 BELLOW 1

8.2 AVL908922 JOINT 1

9 AVL902368 DISK SPRING 1

10 AVL903812 KEY 1

12 AVL922643 SCREW HEX. HD . 2

13 AVL901755 SCREW HEX. HD . 2

14 AVL906214 SCREW HEX. HD . 3

15 AVL901764 SCREW HEX. HD . 1

16 AVL902633 ALAN SCREW 1

17 AVL921375 NUT HEX. 1

18 AVL902212 NUT HEX. 1

19 AVL902262 WASHER 2

20 AVL902263 WASHER 1

OPERATOR PLATFORM

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 67

Page 68

OPERATOR PLATFORM

PAGE 68 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 69

OPERATOR PLATFORM

2-4.3

OPERATOR PLATFORM

NO PART NO PART NAME QTY. REMARKS

2 AVL365504 DRIVE LEVER BRACKET 1

3 AVL390470 DRIVE LEVER 1

3.1 A VLAM1667-146DG TRANSMITTER 1

3.2 A VLAM1667-146AZ-2 CABLE WIRE 1

3.3 A VL922969 YOKE ENDS 1

3.4 A VL944072 HANDLE 1

4 A VL820105 Y OKE ENDS 1

5 AVL922735 FEET SWITCH 1

7 AVL922616 ALAN SCREW 1

8 AVL903247 HEXAGON ALAN PIN 1

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 69

Page 70

OPERATOR PLATFORM

PAGE 70 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 71

2-4.4

OPERATOR PLATFORM

NO PART NO PART NAME QTY. REMARKS

2 AVL472012 STEERING SHAFT 1

2.1 AVL902182 NUT HEX. 1

2.2 A VL903977 WOODRUFF KEY 1

3 AVL494618 STEERING WHEEL 1

3.1 A VL922223 HANDLE 1

4 AVL494619 COVER 1

5 A VL493622 STEERING V AL VE 1

6 AVL491411 RELIEF V AL VE 1

6.1 AVL906695 SEAL 4

6.2 A VL908923 ALAN SCREW 1

7 AVL901084 REDUCER 1

8 AVL901389 REDUCER 2

9 AVL901390 REDUCER 1

10 AVL901776 SCREW HEX. HEAD 4

13 A VL820097 CLAMP 1

14 AVL901756 SCREW HEX. HEAD 1

OPERATOR PLATFORM

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 71

Page 72

REAR WATER TANK

PAGE 72 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 73

2-5.1

REAR WATER T ANK

NO PART NO PART NAME QTY. REMARKS

1 AVL236501 WATER TANK 1

2 AVL365157 COVER 1

3 AVLCO2575000 COVER NECK 1

4 A VL592433 COVER COMPLETE 1

4.1 AVL824815 GASKET 1

4.2 A VL493810 RUBBER DIAPHRAGME 1

5 AVL824900 SIEVE 1

6 AVL828021 PLATE 1

7 AVL828020 PLATE 1

8 AVL828028 LACK PIN 1

9 AVL365797 SEAT CONSOLE 1

10 AVL824009 REDUCER COMPLETE 1

10.1 AVL909398 REDUCER 1

10.2 AVL591838 TUBE 1

12 A VL908157 HOSE CLAMP 1

13 A VLCO3005002 GASKET 1

14 A VL944171 BLIND RIVETING 2

15 AVL901754 SCREW HEX. HEAD 5

16 AVL901761 SCREW HEX. HEAD 4

17 AVL902639 ALAN SCREW 6

18 AVL902975 COUNTERSUNK SCREW 4

19 AVL902262 WASHER 5

20 AVL902263 WASHER 4

21 AVL922315 WASHER 4

22 AVL902124 NUT HEX. 6

REAR WATER TANK

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 73

Page 74

DRIVER’S SEAT

PAGE 74 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 75

2-6.1

DRIVER’S SEAT

NO PART NO PART NAME QTY. REMARKS

2 AVL390505 DRIVER’S SEAT 1

3 A VL390536 TOOL BOX 1

4 AVL902640 ALAN SCREW 4

5 A VL903680 BLIND RIVETING 4

DRIVER’S SEAT

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 75

Page 76

ADDITIONAL WEIGHT

PAGE 76 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 77

2-9.1

ADDITIONAL WEIGHT

NO PART NO PART NAME QTY. REMARKS

1 AVL341719 ADDITIONAL WEIGHT, T33 1

2 AVL341723 ADDITIONAL WEIGHT, T33 2

4 AVL901773 SCREW HEX. HEAD 8

5 AVL902645 ALAN SCREW 4

6 AVL902264 WASHER 12

ADDITIONAL WEIGHT

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 77

Page 78

STABILIZER BAR

PAGE 78 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 79

3-0.1

STABILIZER BAR

NO PART NO PART NAME QTY. REMARKS

1 AVL341546 BRACKET 2

2 AVL803766 TUBE 1

3 AVL902645 ALAN SCREW 8

4 A VL909431 DOWEL PIN 2

5 AVL903706 JOINT ROD END 2

6 AVL902988 COUNTERSUNK SCREW 2

7 AVL902286 WASHER 2

8 AVL902125 NUT HEX. 2

9 AVL902183 NUT HEX. 1

10 AVL921370 WASHER 2

STABILIZER BAR

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 79

Page 80

ARTICULATING JOINT

PAGE 80 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 81

3-0.2

ARTICULATING JOINT

NO PART NO PART NAME QTY. REMARKS

1 AVL341483 SUPPORT 1

2 AVL803676 WASHER 1

3 AVL341486 OSCILLATING STOP 1

4 AVL803677 RING 1

5 AVL803678 WASHER 6

6 AVL901801 SCREW HEX. HEAD 12

9 AVL902377 DISK SPRING 2

10 AVL902660 ALAN SCREW 7

13 A VL494800 JOINT BEARING 1

ARTICULATING JOINT

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 81

Page 82

STEERING CYLINDER

PAGE 82 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 83

3-0.3

STEERING CYLINDER

NO PART NO PART NAME QTY. REMARKS

1 AVL390480 HYDRAULIC CYLINDER 1

1.1 AVL923046 SEAL KIT 1

2 AVL803814 MOUNTING 1

3 AVL591046 JOURNAL COMPLETE 1

3.1 AVL803815 JOURNAL 1

5 AVL901745 REDUCER 2

7 AVL901800 SCREW HEX. HEAD 4

8 AVL901811 SCREW HEX. HEAD 1

10 AVL902128 NUT HEX. 2

12 AVL922314 WASHER 2

13 AVL922347 WASHER 1

STEERING CYLINDER

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 83

Page 84

ENGINE

PAGE 84 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 85

4-0.1

ENGINE

NO PART NO PART NAME QTY. REMARKS

1 AVL190026 DIESEL ENGINE, YANMAR 3TNE88 1

2 AVL390416 FLANGE 1

3 AVL365977 ENGINE SUPPORT 1

4 AVL365748 ENGINE SUPPORT 1

5 AVL824890 ENGINE SUPPORT 2

6 AVL820593 BRACKET 1

7 AVL803969 BRACKET 1

8 AVL366256 BRACKET 1

10 AVL491740 ISOLATION MOUNTING 4

11 AVL592048 HOSE 1

12 AVL591313 HOSE 1

13 AVL591356 HOSE 1

14 AVL591357 HOSE 1

15 AVL591358 HOSE 1

16 A VL901418 HOSE CLAMP 1

17 A VL920029 HOSE CLAMP 2

18 A VL903807 HOSE CLAMP 8

19 AVL901085 REDUCER 1

20 AVL901763 SCREW HEX. HEAD 1

21 AVL901865 SCREW HEX. HEAD 2

22 AVL901772 SCREW HEX. HEAD 4

23 AVL901773 SCREW HEX. HEAD 23

24 AVL901774 SCREW HEX. HEAD 3

25 AVL901776 SCREW HEX. HEAD 4

26 AVL901782 SCREW HEX. HEAD 4

ENGINE

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 85

Page 86

ENGINE

PAGE 86 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 87

4-0.2

ENGINE

NO PART NO PART NAME QTY. REMARKS

2 12913113520 MUFFLER 1

3 A VL34177 EXHA UST MANIFOLD 1

4 12470111911 GASKET 1

5 10395413201 GASKET 1

6 A VL236894 EXHAUST PIPE 1

7 AVL921285 PIPE CLAMP COMPLETE 2

8 AVL341794 SOUND PROTECTION 1

9 AVL820038 SOUND PROTECTION 1

10 AVL922884 HOSE CLIP 3

11 AVL901762 SCREW HEX. HEAD 4

12 AVL902263 WASHER 4

13 AVL902124 NUT HEX. 4

14 AVL902125 NUT HEX. 3

ENGINE

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 87

Page 88

ENGINE - RADIATOR

PAGE 88 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 89

4-0.3

ENGINE - RADIATOR

NO PART NO PART NAME QTY. REMARKS

1 AVL366153 BRACKET 1

2 AVL366154 BRACKET HOLDER 1

3 AVL820059 HOSE 1

4 AVL390425 HOSE 1

5 AVL591374 PROFILED JOINT 1

6 AVL907542 ISOLATION MOUNTING 4

7 12440544510 EXPANSIVE BOTTLE 1

8 12915049100 HOSE T APE 1

9 AVL591355 HOSE 1

10 AVL901761 SCREW HEX. HEAD 7

11 AVL901762 SCREW HEX. HEAD 2

12 AVL901774 SCREW HEX. HEAD 4

13 AVL902263 WASHER 4

ENGINE - RADIATOR

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 89

Page 90

ENGINE SERVICE PARTS

PAGE 90 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 91

ENGINE SERVICE PARTS

4-0.4

ENGINE SERVICE PARTS

NO PART NO PART NAME QTY. REMARKS

2 12473242290 V-BELT 1

3 12112012901 AIR CLEANER 1

4 12142212570 AIR FILTER INNER 1

5 12665012680 INDICATOR 1

6 AVL390423 AIR CLEANER BRACKET 1

7 12910055650 FUEL FILTER 1

8 12185055710 FILTER 1

9 12915035151 OIL FILTER 1

10 12185512060 MUFFLER 1

11 17135112210 HOSE 1

12 12915011310 VAL VE BONNET SEAL 1

13 A VL920029 HOSE CLAMP 2

14 AVL901763 SCREW HEX. HEAD 4

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 91

Page 92

ENGINE - ELECTRIC COMP.

PAGE 92 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 93

ENGINE - ELECTRIC COMP.

4-0.5

ENGINE – ELECTRIC COMP.

NO PART NO PART NAME QTY. REMARKS

1 AVL341823 EXHAUST PIPE BRA CKET 1

2 AVL493837 RELAY 1

3 A VL494864 FUSE BOX 1

4 AVL921718 FUSE, 7.5 AMP 1

5 AVL921584 FUSE, 15 AMP 1

6 AVL922713 FUSE, 30 AMP 1

7 AVL921584 FUSE, 15 AMP 1

8 11963277920 TIMER 1

9 12912977010 STARTER MOTOR 1

10 12977277200 ALTERNATOR 1

11 11965077100 RELAY 1

12 11964366900 DIODE 1

13 11962966800 START / ST OP SOLENOID 1

14 AVL479661 CONNECTION CABLE 1

15 AVL901751 SCREW HEX. HEAD 7

16 AVL901770 SCREW HEX. HEAD 1

17 AVL901772 SCREW HEX. HEAD 2

18 AVL902261 WASHER 7

19 AVL902264 WASHER 4

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 93

Page 94

PTO PUMP

PAGE 94 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 95

4-0.6

PTO PUMP

NO PART NO PART NAME QTY. REMARKS

1 AVL390527 V ARIABLE DISPLA CEMENT PUMP 1

1.1 A VL09447133 V ALVE HIGH PRESSURE 2

1.2 A VL09434636 VALVE LOW PRESSURE 1

1.3 A VL09609956 EMERGENCY STOP V ALVE 1

1.4 A VL09830731 SWITCH 1

2 AVL390537 CLUTCH 1

3 A VL824198 LEVER 1

4 AVL494873 FLANGE 1

4.1 A VL902648 ALAN SCREW 4

4.2 A VL902325 SPRING WASHER 4

4.3 AVL908481 SEAL 1

5 AVL476039 REDUCER 1

6 AVL492660 MANOMETRIC SWITCH 1

7 AVL922313 REDUCER 2

8 AVL908753 SCREWED NECK 1

9 AVL901430 REDUCER 2

10 AVL909785 SCREWED NECK 1

11 AVL901401 REDUCER 1

12 AVL901235 REDUCER 1

13 AVL901248 REDUCER 1

14 AVL901503 REDUCER 1

15 AVL902753 ALAN SCREW 3

PTO PUMP

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 95

Page 96

PTO PUMP

PAGE 96 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 97

4-0.7

PTO PUMP

NO PART NO PART NAME QTY. REMARKS

1 A VL494808 GEAR PUMP 1

2 A VL491354 G – CONNECTION 1

2.1 A VL908882 ALAN SCREW 4

2.2 A VL902323 SPRING WASHER 4

2.3 AVL906670 SEAL 1

3 A VL491442 G – CONNECTION COMPLETE 1

3.1 A VL908882 ALAN SCREW 4

3.2 A VL902323 SPRING WASHER 4

3.3 AVL906670 SEAL 1

4 A VL491443 G – CONNECTION 1

4.1 A VL908882 ALAN SCREW 4

4.2 A VL902323 SPRING WASHER 4

4.3 AVL906672 SEAL 1

5 AVL901210 REDUCER 1

6 AVL901250 REDUCER 1

7 AVL901236 REDUCER 1

8 AVL902646 ALAN SCREW 2

PTO PUMP

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 97

Page 98

COMPONENTS

PAGE 98 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Page 99

5-0.1

COMPONENTS

NO PART NO PART NAME QTY. REMARKS

2 AVL495101 VIBRATION CONTROL VAL VE 2

2.1 A VL922829 MAGNET COIL 2

2.2 AVL944413 VALVE 2

2.3 AVL922822 CARTRIDGE FOR WAY-VALVE 2

2.4 AVL922827 SEAL KIT 2

2.5 AVL922828 SEAL KIT 2

2.6 AVL923443 KNURLED NUT 2

3 AVL901064 REDUCER 4

4 AVL901250 REDUCER 2

5 AVL901237 REDUCER 3

6 AVL803524 RETURN-FLOW TUBE 3

7 AVL908722 REDUCER 1

8 AVL901458 REDUCER 1

9 AVL901863 SCREW HEX. HEAD 4

COMPONENTS

TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01) — PAGE 99

Page 100

COMPONENTS

PAGE 100 — TANDEM ROLLER: T23, T26, T33 — PARTS & OPERATION MANUAL — REV. #4 (03/12/01)

Loading...

Loading...