Page 1

PARTS AND OPERATION MANUAL

Tandem Vibratory Roller

T16

© COPYRIGHT 2001, MULTIQUIP INC.

Revision #2 (03/12/01)

MULTIQUIP INC

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-631-5032

E-mail:mq@multiquip.com • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

..

. PARTS DEPARTMENT:

..

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE:

Page 2

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

Asphalt Roller: T16 — PARTS & OPERATION MANUAL — REV. #0 (05/07/99) — PAGE 3

Page 4

PARTS ORDERING PROCEDURES

n

Dealer account number

n

Dealer name and address

n

Shipping address (if different than billing address)

n

Return fax number

n

Applicable model number

n

Quantity, part number and description of each part

n

Specify preferred method of shipment:

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

•

Express account number)*

Airborne Express*

•

Truck or parcel post

•

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete part numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Get special freight allowances

when you order 10 or more

line items via FAX!**

n

UPS Ground Service at no charge for freight

n

PS Third Day Service at one-half of actual freight cost

No other allowances on freight shipped by any other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

Now! Direct TOLL-FREE access

Extra Fax DiscountExtra Fax Discount

Extra Fax Discount

Extra Fax DiscountExtra Fax Discount

for Domestic USAfor Domestic USA

for Domestic USA

for Domestic USAfor Domestic USA

Dealers OnlyDealers Only

Dealers Only

Dealers OnlyDealers Only

to our Parts Department!

Toll-free nationwide:

800-421-1244

Toll-free FAX:

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

PAGE 4 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

800/6-PARTS-7 • 800-672-7877

Page 5

TABLE OF CONTENTS

Here's how to get help ................................................... 3

Parts ordering procedures ............................................. 4

Table of contents ........................................................... 5

TANDEM ROLLER: T16

Technical Data ................................................................6

Specifications ................................................................. 7

Explanation of codes in remarks column........................8

Suggested Spare Parts ..................................................9

Operations Manual .......................................................10

Safety Instructions .................................................. 11-14

General Layout ........................................................ 15-16

Operation .................................................................17-23

Tow Preparation, To Tow & To Lift .................................. 24

Hood Information ..........................................................25

Maintenance Schedule & Tightening Torque ................. 26

Frost Warning, Scrapers & Fuses ................................. 27

Electric Components ....................................................28

Main Components ........................................................ 29

Check and Adjust Pressures ................................... 30-31

Maintenance & Repair - Yanmar Engine .......................32

Hydraulic System ......................................................... 33

Hydraulic System - Vibration Switch Off Rear .............. 34

Electrical Diagram ................................................... 35-36

Drum Traveling ......................................................... 38-39

Drum Support .......................................................... 40-41

Drum Vibration ......................................................... 42-43

Scraper Chassis Front ............................................. 44-45

Scraper Chassis Rear ............................................. 46-47

Sprinkler Pump ........................................................ 48-49

Sprinkler Pipes ........................................................ 50-51

Chassis Front .......................................................... 52-53

Engine Hood ............................................................ 54-55

Chassis Rear ........................................................... 56-57

Operator Platform .................................................... 58-61

Water Tank Seat ...................................................... 62-63

Stabilizer Bar ........................................................... 64-65

Articulating Joint ..................................................... 66-67

Steering Cylinder ..................................................... 68-69

Engine ..................................................................... 70-71

Engine - Radiator ..................................................... 72-73

Engine Service Parts............................................... 74-75

Engine Electric Comp. ............................................. 76-77

Pump .......................................................................78-79

Vibration Pump ........................................................ 80-81

Components ............................................................ 82-83

Hoses Drive ............................................................. 84-85

Suction Leak Pipe .................................................... 86-87

Steering and Radiator ............................................... 88-89

Hoses Brake ............................................................. 90-91

Hoses Vibration ........................................................ 92-93

Hoses Various .......................................................... 94-95

Reversing .................................................................96-97

Sprinkler, Vibration Valve .......................................... 98-99

Engine, Ignition Switch ......................................... 100-101

Engine Battery ...................................................... 102-103

Instrument Panel .................................................. 104-107

Decals .................................................................. 108-109

Brake Release Valve ............................................ 110-111

Vibration Cut-Off Rear .......................................... 112-113

Working Frequencies ............................................ 114-115

Cover ....................................................................116-117

Lighting System ................................................... 118-119

Back-Up Signal..................................................... 120-121

Automatic Vibration .............................................. 122-123

Interval Sprinkling ................................................. 124-125

Lockable Tank Cap ............................................... 126-127

Special Sprinkler .................................................. 128-129

Battery Disconnection Switch .............................. 130-131

Tiltable ROPS ...................................................... 132-133

Roof for ROPS .....................................................134-135

Lock Pin ...............................................................136-137

Machine In Line ....................................................138-139

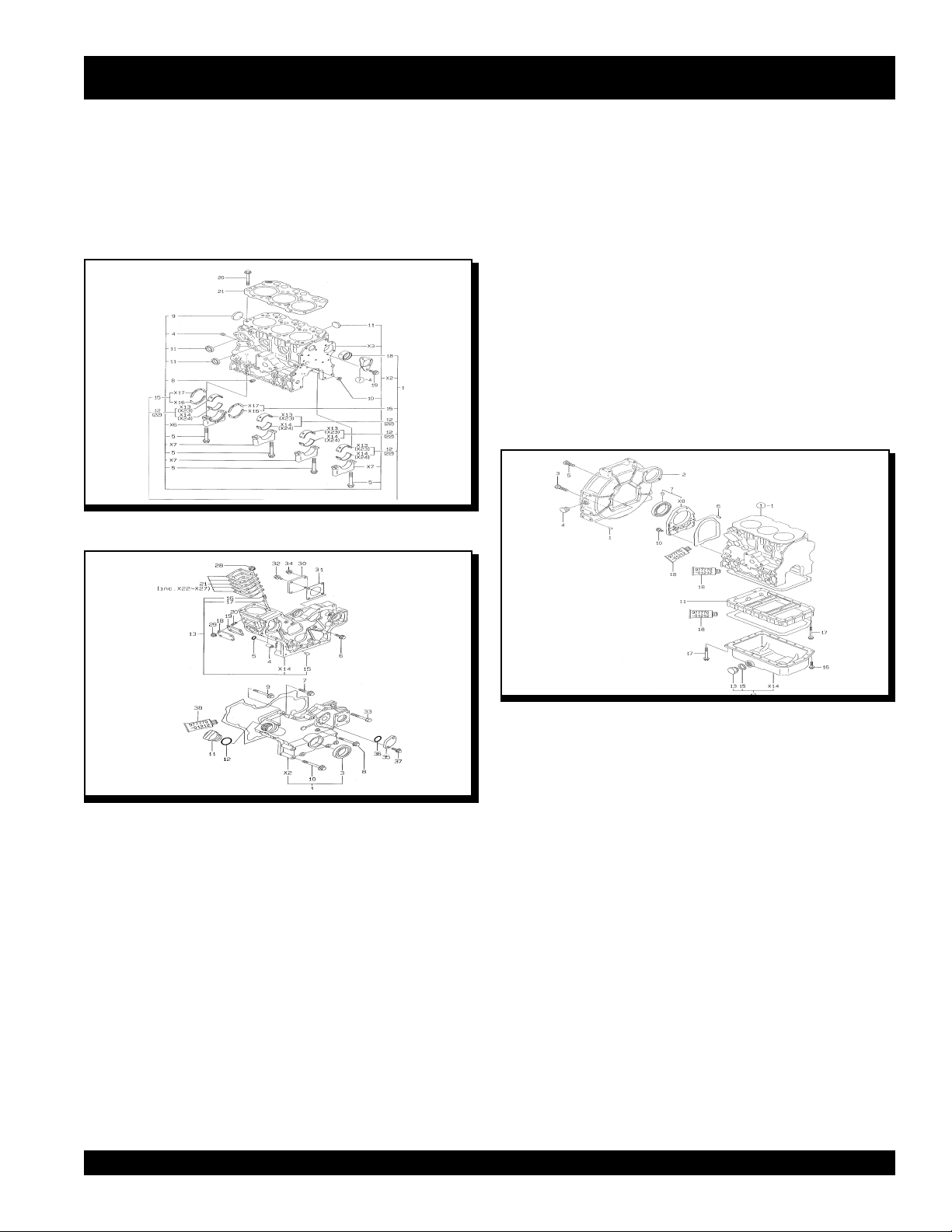

YANMAR 3TNE74AMM ENGINE

Cylinder Block ...................................................... 140-141

Gear Housing........................................................ 142-143

Flywheel Housing & Oil Sump ..............................144-145

Cylinder Head & Bonnet ....................................... 146-147

Suction Manifold & Air Cleaner............................. 148-149

Exhaust Manifold & Silencer ................................150-151

Camshaft & Drive Gear ........................................ 152-153

Crankshaft & Piston ............................................. 154-155

Lub. Oil System ....................................................156-157

Cooling Water System .......................................... 158-159

Fuel Injection Pump ............................................. 160-161

Governor ............................................................... 162-164

Fuel Injection Valve .............................................. 166-167

Fuel Line ...............................................................168-169

Starting Motor ...................................................... 170-171

Generator .............................................................. 172-173

Gasket Set ........................................................... 174-175

Terms and Conditions of Sale — Parts ................. 176

NOTE: Specification and part number are subject to change without notice.

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 5

Page 6

ECECot.ccathgiewgnitarepO )gk0071(.sbl947,3

)renni(suidargninruT )mm0671(.ni3.96

enigneleseiD MMA47ENT3-RAMNAY

B0726NIDotrewoP )wk9.41(PH02-)wk2.31(PH81

snoituloveR 0072/0042

deepsenihcaM )hpk01-0(hpm2.6-0

TECHNICAL DATA

61T—ataDlacinhceT61T—ataDlacinhceT

61T—ataDlacinhceT61T—ataDlacinhceT

61T—ataDlacinhceT

tuohtiw/htiwytilibagnibmilC

noitarbiv

egnargnireetS °43±

egnargnitallicsO °5±

fnoitarbiV:ycneuqer

edutilpmA )mm24.0(.ni610.0

:murdrepecroflagufirtneC

knatretaW )L59(lag52

yticapacknatliociluardyH )L53(lag2.9

knatleufleseiD )L62(lag9.6

esacknarcenignE )L4.2(lag6.0

)raes'revirdta(levelesioN bd5.97

)sretem7(levelesioN bd6.56

%04/03

mpr0042

mpr0072

mpr0042

mpr0072

)zH75(0243

)zH56(0093

)gk9241(.sbl0513

)gk7381(.sbl0504

PAGE 6 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 7

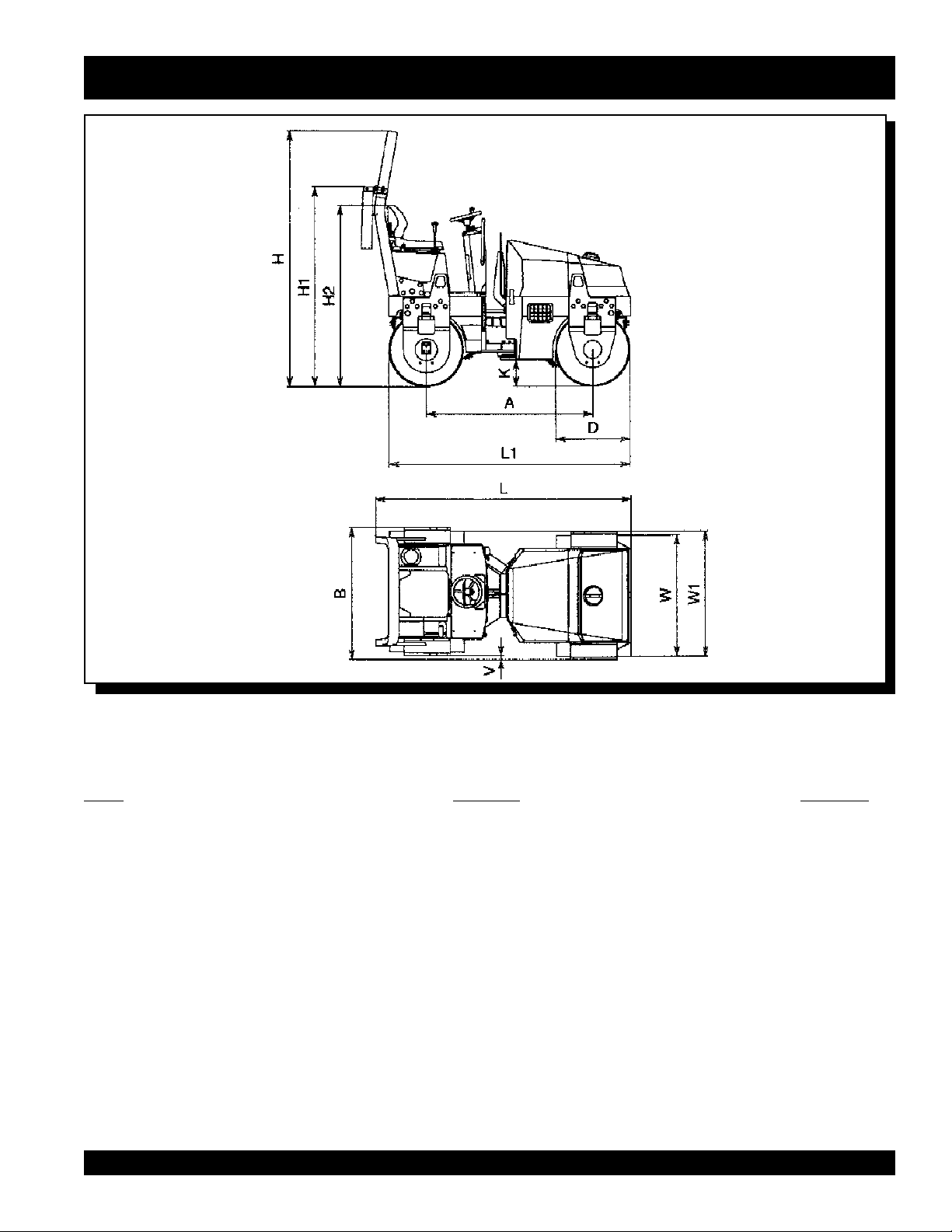

SPECIFICATIONS

T16 metric inches

L ................................................................................... 2140 mm ................................................................. 84.3"

L1 .................................................................................1965 mm ................................................................. 77.4"

B/W1 ............................................................................950 mm ................................................................... 37.4"

W .................................................................................. 900 mm ...................................................................35.4"

H...................................................................................2250 mm ................................................................. 88.6"

H1 .................................................................................1850 mm ................................................................. 72.8"

H2 .................................................................................1560 mm ................................................................. 61.4"

D...................................................................................575 mm ................................................................... 22.6"

A ................................................................................... 1390 mm ................................................................. 54.7"

K ................................................................................... 230 mm ...................................................................9.1"

V ................................................................................... 50 mm ..................................................................... 2"

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 7

Page 8

EXPLANATION OF CODE IN REMARK COLUMN

How to read the marks and remarks used in this parts

book.

Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Items Found In the “Items Number” Column

All parts with same symbol in the number column,

■

, belong to the same assembly or kit

EXPLANATION OF CODE IN REMARKS COLUMN

, #, +, %, or

*

NOTE

If more than one of the same reference number is

listed, the last one listed indicates newest (or latest)

part available.

NOTE

The contents of this catalog are

subject to change without notice

.

PAGE 8 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 9

T16 w/YANMAR 3TNE74 DIESEL ENGINE

1 to 3 Units

Qty. P/N Description

5 ............ AVL14607 ............. KEY IGNITION SWITCH

5 ............ AVL922975 ........... KEY FUEL CAP

6 ............ 12142212570 ........ FILTER AIR INNER

6 ............ 12142012511 ........ FILTER AIR OUTER

6 ............ 11966035150 ........ FILTER OIL

6 ............ 12455055700 ........ FILTER FUEL

3 ............ AVL921198 ........... FILTER SUCTION

Part number on this Suggested

Spare Parts List may super cede/

replace the P/N shown in the text

pages of this book.

SUGGESTED SPARE PARTS

NOTE

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 9

Page 10

Congratulations on your purchase of this vibration roller. The

manufacturing of this modern roller is based on many years

experience. Easy operating and excellent maintenance facilities

are two strong points of this roller. Nevertheless, in order to

avoid improper handling or maintenance, we invite you to

carefully study this operating handbook.

This operating manual includes:

■

Safety instructions

■

General machine layout

■

Machine handling

■

Maintenance

■

Diagrams

■

Error messages

■

Technical data

OPERATORS MANUAL

The following explanations are meant to familiarize the operator

with the machine in respect to use, maintenance and service. It

is, therefore, a must that the operator always has access to the

instruction manual and that before operating the machine, the

manual instructions are carefully read. By doing so, improper

handling and incorrect use, which could result in failure of the

machine, is prevented.

Service and maintenance done in accordance with the operating

manual increases reliability of the machine and its lifetime. It

reduces repair costs and guarantees less down time.

Multiquip and AMMANN rejects any responsibility should the

machine be used incorrectly.

Only spare parts in accordance with AMMANN specifications

may be used. Original AMMANN spare parts will always

guarantee correct specifications.

This operating manual should always be on the machine, at the

operator’s disposal.

PAGE 10 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 11

SAFETY INSTRUCTIONS

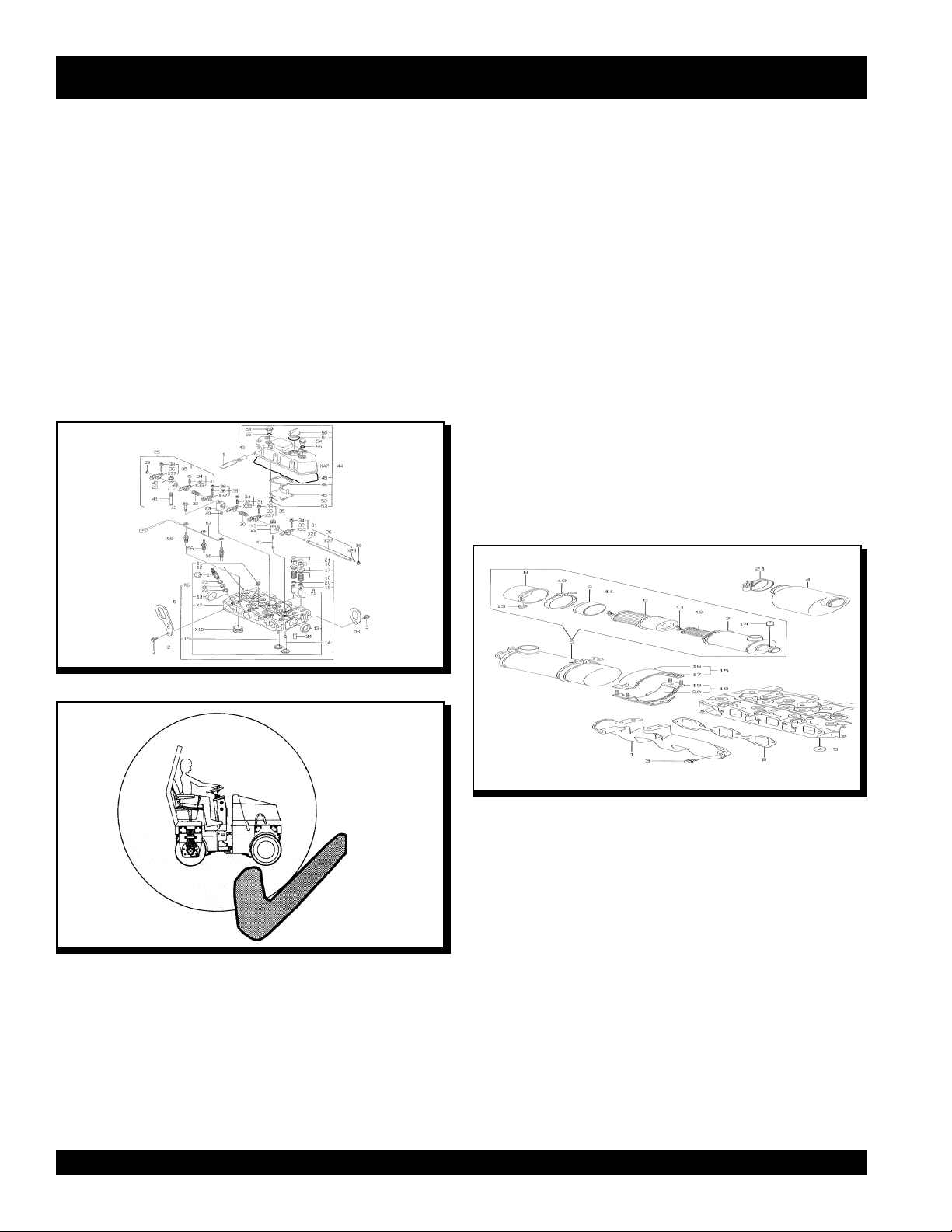

Start up the roller from the driver’s seat only (1a).

The driver must wear a seatbelt.

When the roller is being operated, there must be no one In front

or behind the roller (1b).

Any person in the vicinity of the roller (2a) while it is being

operated must maintain a minimum safety distance of 1 meter.

WARNING!

Keep your distance from side slopes and curbs! Side

slopes can slip down! Do not drive over curb!

! DANGER OF OVERTURNING !

Be aware of the hazard stated below:

1. Flat surfaces may not have uniform soil density.

2. Hollow spaces or rocks might be below the surface.

3. Clay ground can be slippery when wet.

4. The danger of sliding sidewards is higher when vibrating.

5. Sharp steering maneuvers (turns) near side slopes can

increase the danger of overturning.

6. Central articulated machines are more dangerous near side

slopes during sharp steering maneuvers (turns).

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 11

Page 12

SAFETY INSTRUCTIONS

Rollover Protection Structure (ROPS)

Please check the following:

■

The machine frame should not be bent or cracked around

the ROPS bolt on area.

■

There are no hairline cracks or open cracks.

■

All screw connections are correctly tightened (check correct

torque).

■

Bolts and nuts must be undamaged.

■

ROPS must be folded up (when tilting ROPS).

No modifications may be made on the ROPS without

authorization from the manufacturer!

Noise Level:

The following noise levels have been measured according to

the CE regulations 98/68/EWG.

■

Engine at nominal RPM

■

Microphone fixed at 1.2-meter height.

■

Measurement conditions:

■

hard ground, no snow, dry.

■

no noise reflecting objects within 20 meters.

■

wind noise must be below 10 dB(A) of the measured machine

noise values.

Noise level indications according to annex 1, Chapter 1.7.4f of

the CE machine’s specifications.

Noise at driver ear: 79,5 dB(A)

Constant noise level at 7 meters distance: 65,6 dB(A)

PAGE 12 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 13

SAFETY INSTRUCTIONS

Safety Stickers on the Machine

■

Keep safety stickers and safety plates clean and readable.

■

All instructions must be followed.

■

Damaged or incomplete stickers must be replaced

immediately.

Working Security for Rollers with Driver’s Stand

Operating the rollers

1. Only reliable qualified persons, at least 18 years of age, are

to operate rollers.

2. The manufacturer’s operation and security instruction are to

be observed.

10.Rollers may not be driven with downhill out of gear. Before

rolling downhill, the appropriate gear must be put in rollers

not equipped with a power shift transmission. Gear shifting

must not be operated while rolling downhill.

11.Especially on slopes, rollers have to be driven or parked in

such a way that they cannot overturn.

12. The driver must keep driver’s stand and treads free of

obstruction, grease, dirt, ice, etc.

13.Visibility of driving and working area must not be restricted.

Mirrors, installed for this purpose, must be adjusted and kept

clean.

14. Before leaving the driver’s stand, the parking brake must be

operated. If your roller has a hydrostatic drive, the reversing

control lever is to be put in the “0” position.

15. Before leaving the roller, the driver must turn off the engine.

The roller must be secured against unauthorized service

and against rolling.

16.Parked rollers, representing an obstacle, must be secured

by obvious measures.

17.Valid for all rollers: It is possible that the allowable sound

level of 90 dB(A) can be exceeded on the above stated rollers.

Due to the regulations for prevention of noise level accidents

(VBG 121), machine operators or persons who are in the

immediate area of the machine must wear ear protection, if

the sound level reaches or exceeds 90 dB(A).

. . . AND WITH CABINS

Running

3. Rollers are to be operated only with all the protection facilities.

4. Before starting work, steering and brakes must be checked.

The machine should not be run if any defects are noticed.

5. Before beginning a work shift, the driver must check the

effectiveness of operation and the security installation and

protection facilities.

6. If defects on security installation or any other defects are

noticed that affect safe operation of the roller, the supervisor

is to be informed immediately.

7. Operation of the roller must be stopped if defects endanger

operating security.

8. The roller may only be controlled from the driver’s stand.

9. Servicing or maintenance of the roller must be done only

while the roller is standing still and secured against rolling

away. When filling up the tank, the motor is to be switched

off.

18.While driving, the half below the doors must be closed.

Maintenance

19.Maintenance and repair work may only be done while the

machine in not in “drive.” The only exception is when repair

work cannot be carried out unless the machine is in “drive.”

20. Before working on hydraulic tubes, they must be

unpressurized.

21.Before working on electrical installation of the machine, the

battery must be disconnected. It must be isolated by covering

or removing. This is not valid for work where electrical power

is necessary.

22. After maintenance and repair work, protection facilities must

be remounted as prescribed.

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 13

Page 14

SAFETY INSTRUCTIONS

Never work under a machine which is held by a crane or by a

jack. Never stand beneath a machine that has been lifted. Always

follow the instructions given in this manual.

Signs / warnings

Danger of harmful fumes!

Never let the machine run in a closed room.

Battery gases are explosive.

Keep the battery away from fire, flames and sparks.

DANGER OF EYE INJURY!

The sulfuric acid in the electrolyte of the battery is poisonous

and aggressive. It can burn holes into clothes. A squirt of this

acid in the eyes can lead to blindness.

Re-charging safety instructions:

■

Recharge battery only in well ventilated rooms.

■

Wear eye protection and gloves.

■

Do avoid breathing in gases and fumes.

■

Refill without splashing the acid.

■

Start by means of a starter /second battery has to be done

following the instructions.

To take off the water cooler cover on a stopped engine, first

loosen the cover slightly to release the pressure. Remove the

cover only after the pressure is released.

To control the acid level of the battery, use a torch. Never check

the battery charge by connecting the two poles with a metallic

tool. Take an acid control instrument or use a voltmeter.

Always disconnect the ground (-) first and always re-connect it

last.

WARNING: Never remove the radiator cover on a

running engine!

Attention: Danger of burning

PAGE 14 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

2

Page 15

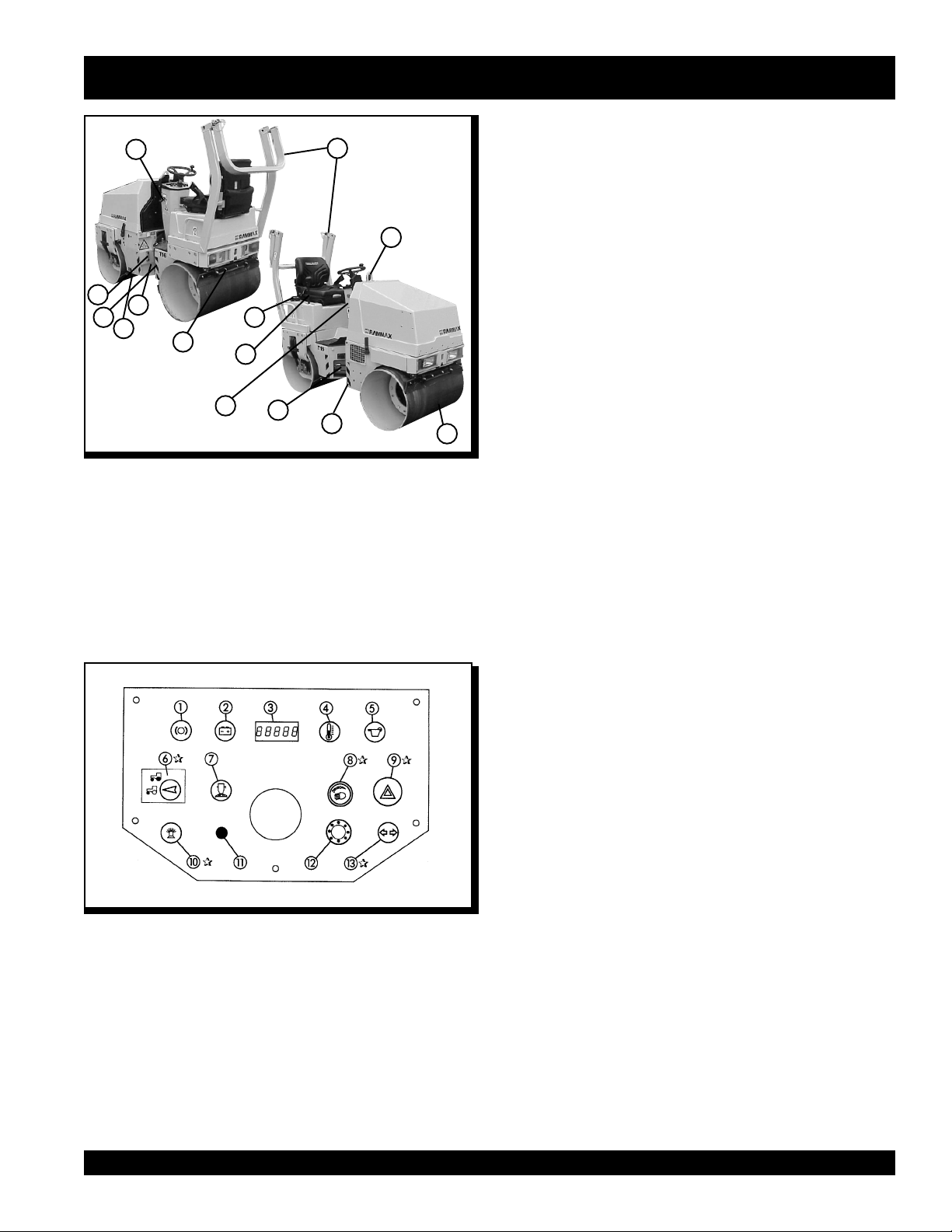

GENERAL LAYOUT

1. Hook on eye

3

12

2. Drive lever

3. Speed control lever

4. Watertank cap

1

5. Sprinkler tube

6. Fuel filter neck

9

7

1

10

5

4

2

7. Water filter

8. Articulation lock

9. Level gauge for hydraulic for oil

10. Hydraulic oil outflow

11

8

13

5

11. Switch off engine

12. ROPS

13. *Tool box

*Tool Kit for the K-Version is located under the engine hood

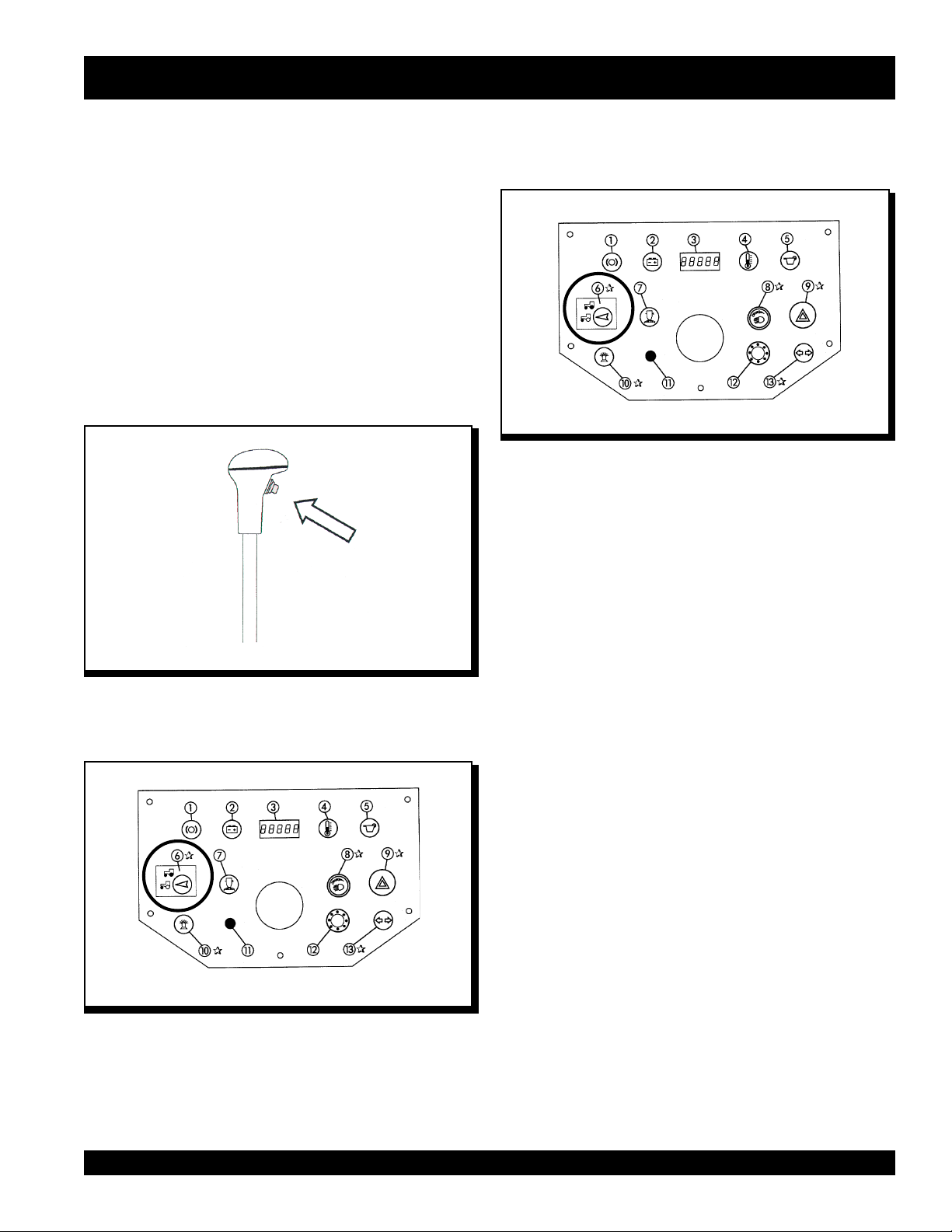

Instrument Panel

1 Control light - Brake

2 Control light - Battery

3 Display working hours

4 Control light - Cooling water

5 Control light – Oil pressure

6

✰

Vibration front – (front and rear)

7 Sprinkler system - On/Off

8

✰

Light – 0 = Off

■

1 = Parking lights

■

2 = Head lights

9

✰

Hazard warning

10

✰

Rotary warning beacon

11 (No function)

12 Horn

13

✰

Indicator – Left/Right

✰

Not included in all types

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 15

Page 16

1a

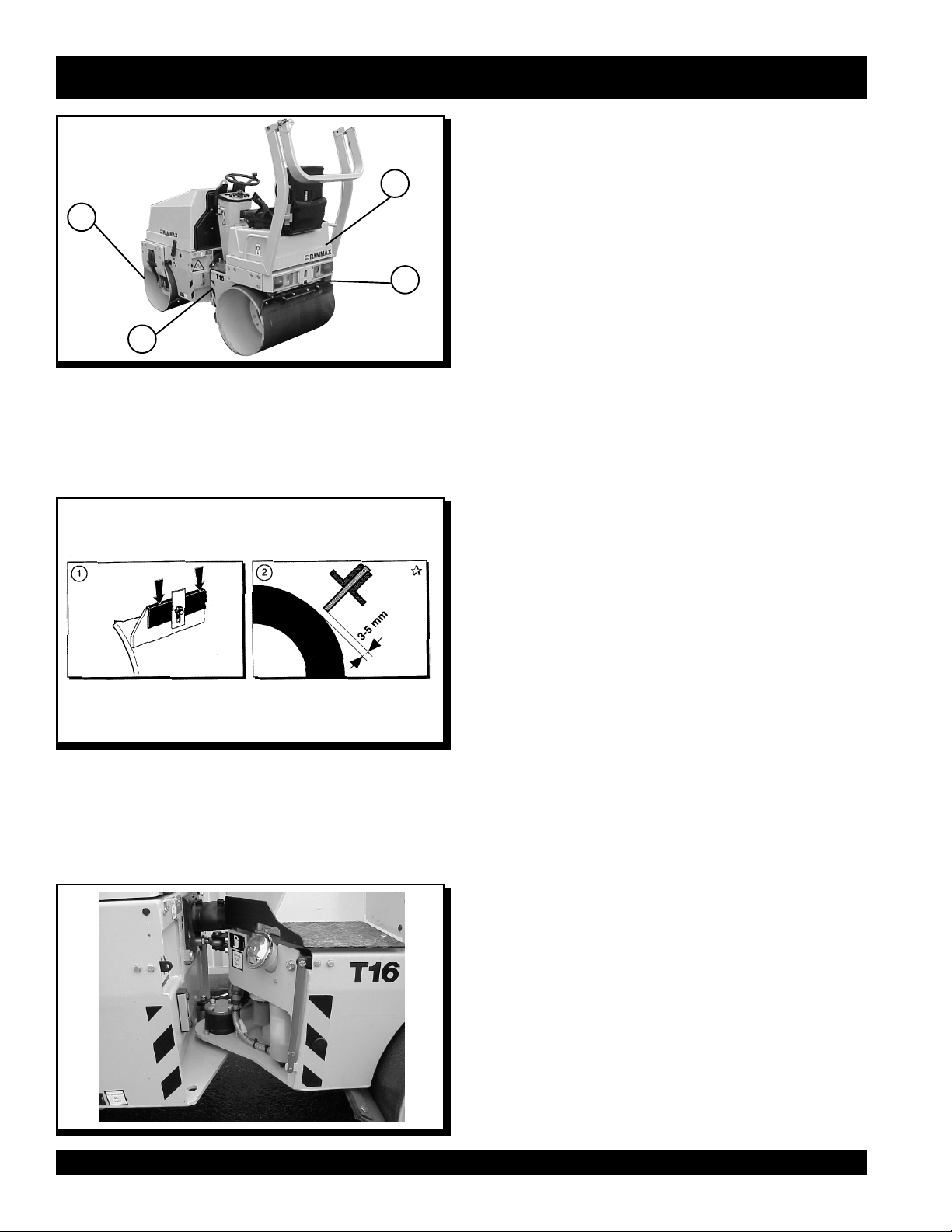

GENERAL LAYOUT

1. Cleaning

If necessary, clean water tank (1a), filter (2a) and sprinkler

tubes (3a) front and rear.

3a

2a

3a

Frost warning

In the event of frost warning completely empty sprinkling

system and take the screen filter (2a) out of the filter housing.

1. Take off filter housing.

2. Drain water

3. Switch sprinkler system on to drain remaining water

from the tubes.

SCRAPERS

1 Wheel

Lightly tighten scraper for the roller by hand.

2 Tyres

Fill scraper for the tyres with a clearance of 3-5mm.

The toolbox is located on the R.H. side, close to the articulation

joint. The toolbox of the K-Version is located under the engine

hood. The tank for the tire lubrication is located on the right side,

close to the articulation joint.

Before opening the toolbox always first put the articulation lock

in place.

PAGE 16 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 17

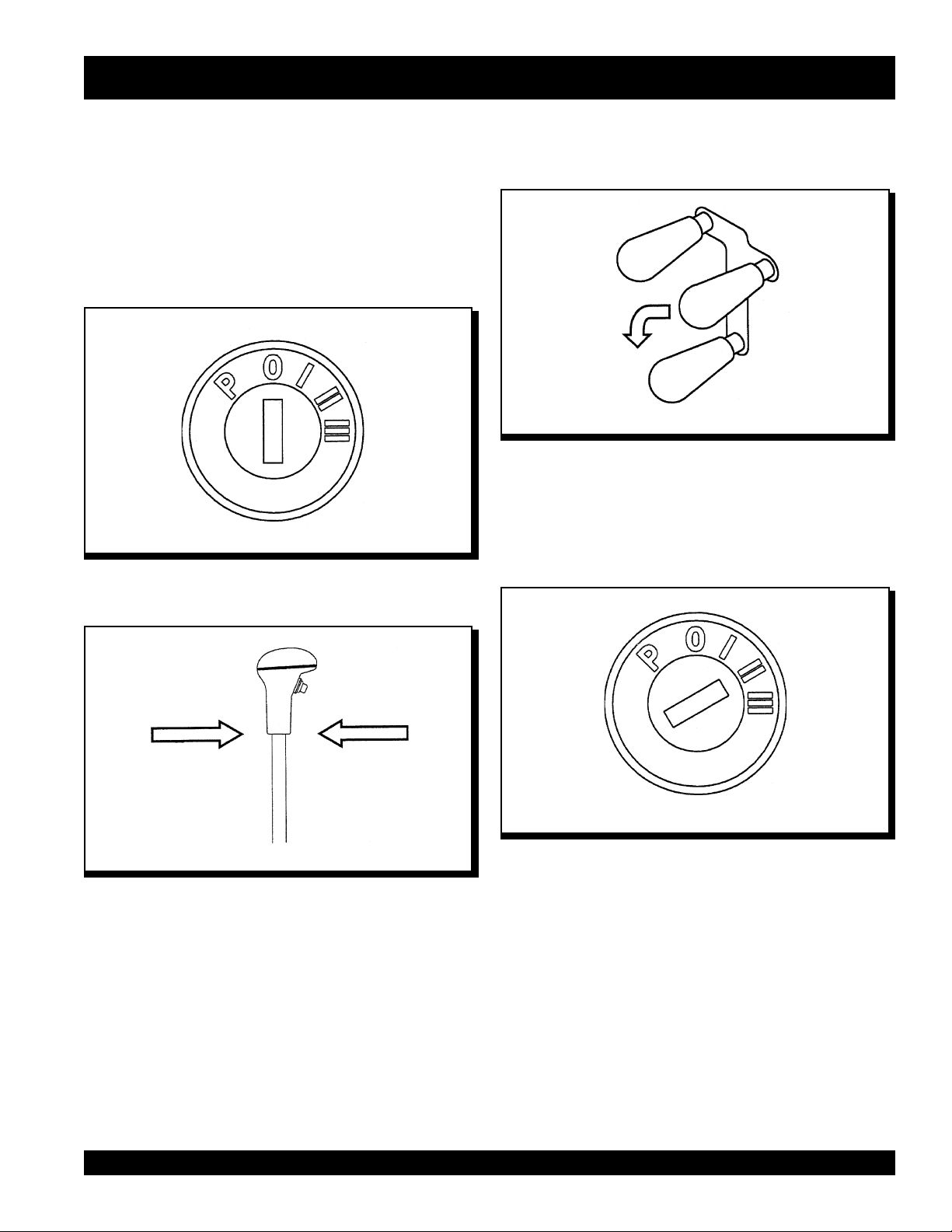

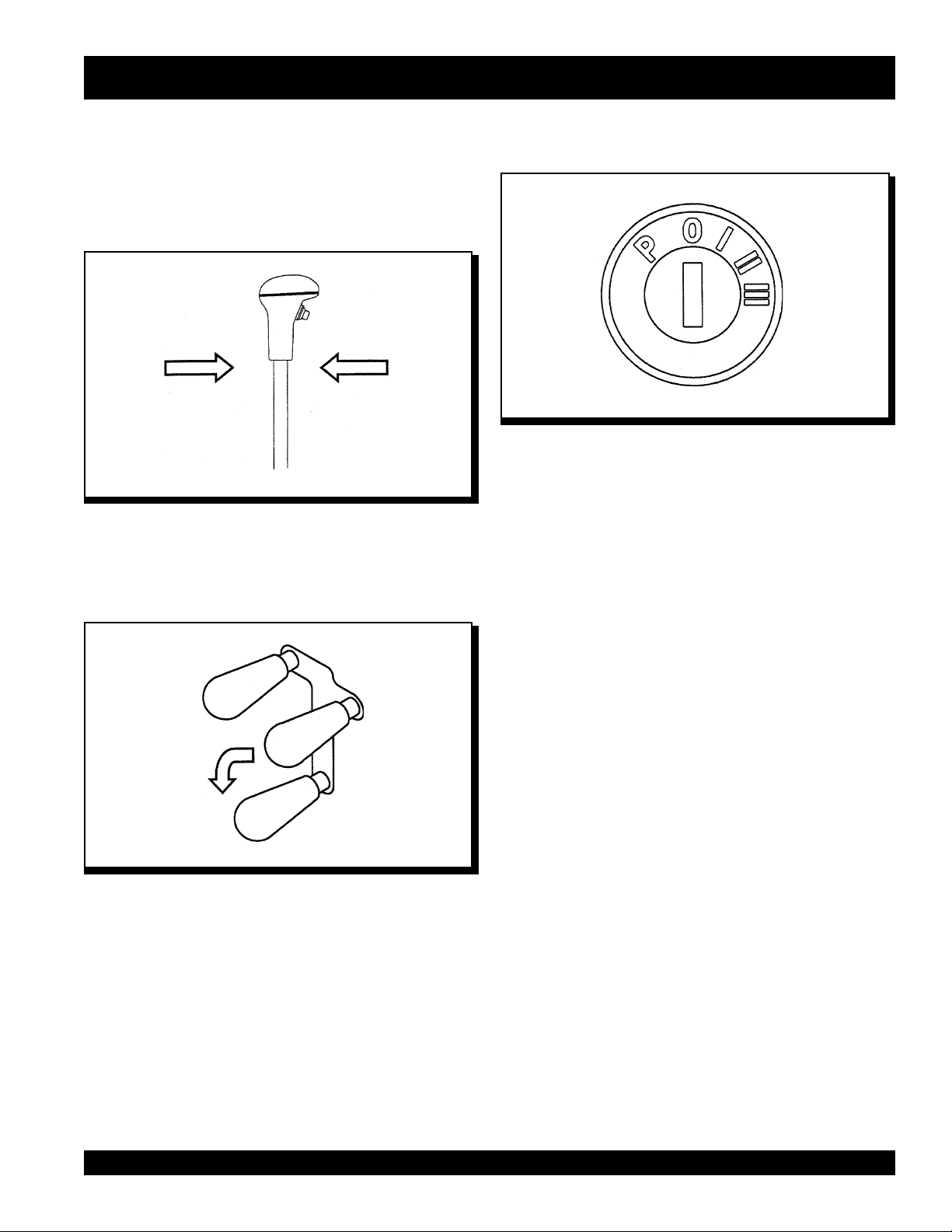

OPERATION

Engine starting

1. Ignition lock

P ...................................................................... PARK

0 ...................................................................... OFF

I. ...................................................................... Ignition

II....................................................................... Pre-heat

III. ..................................................................... Start

2. Reversing lever

3. Speed adjustment lever

Move the accelerator lever to the idle position (moving

downwards)

4. Ignition switch

Turn clockwise to position III. When the outside temperature

is below 0° C, first turn the ignition switch to position II and

wait until the preheat indicator on the instrument panel

goes off, then continue turning the switch to position III for

starting.

Bring into 0 position

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 17

Page 18

OPERATION

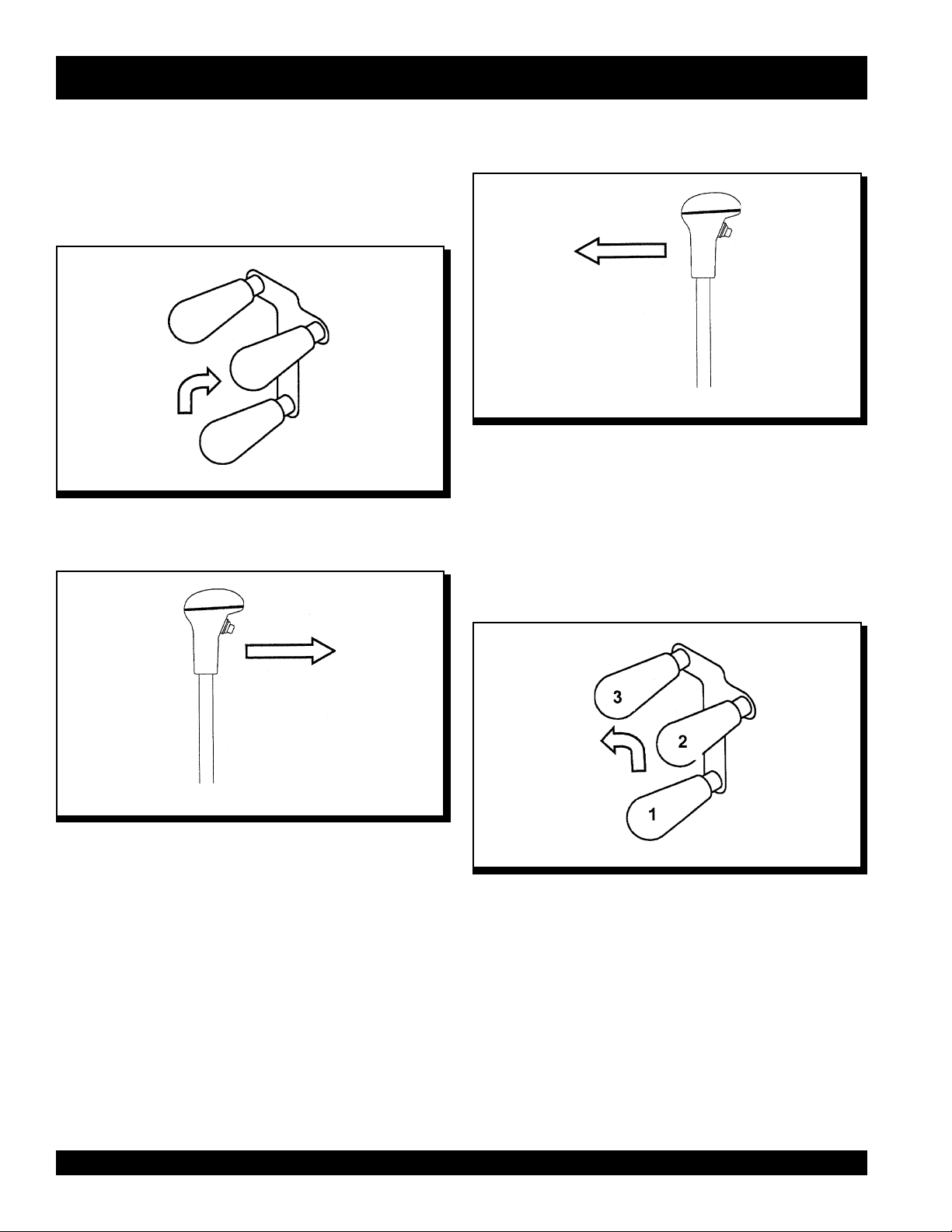

Driving / operating the machine

1. Speed adjustment lever – vibrating

Pull the lever up and then towards the driver’s seat. Lock it

in the 2400-rpm position.

2. Forward travel

Move the travel lever forward slowly.

3. Reverse travel

Move the travel lever back slowly.

4. Speed adjustment lever – travelling

To move the machine from one site to another one, put the

accelerator lever into the 2700 rpm position (pull it up and

push it forward).

1 – Idling speed

2 – Working speed (2400 rpm)

3 – Transporting speed (2700 rpm)

PAGE 18 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 19

OPERATION

Service brake / engine shut-down

Application of service brake

Move the drive lever slowly into neutral (0) position. The machine

is automatically braked by the hydrostatic transmission.

Engine shut-down

Move the drive lever slowly into neutral (0) position as shown

above.

Engine shut-down

Turn the ignition key counter-clockwise to the (0) position.

Move the accelerator lever downward to the idling position.

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 19

Page 20

OPERATION

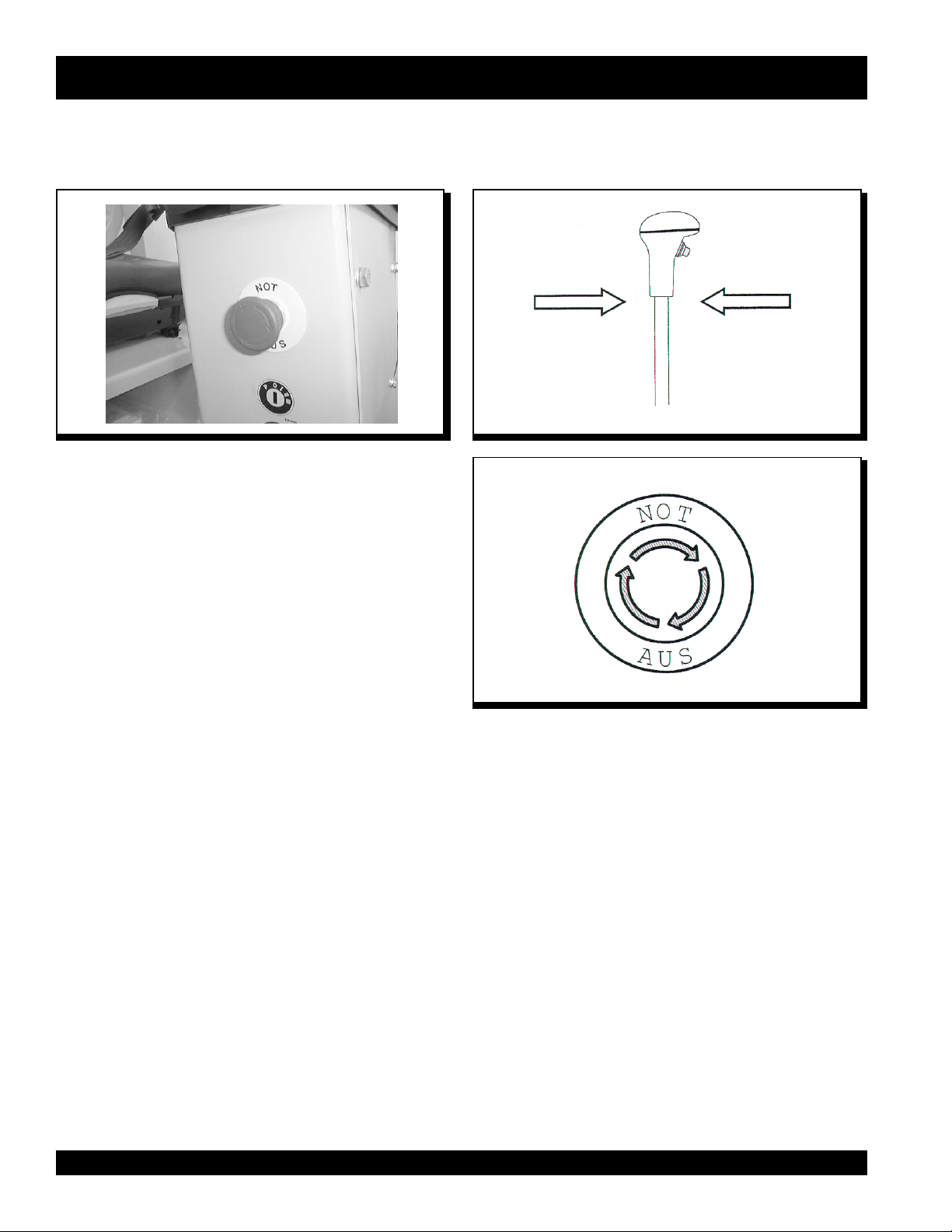

Emergency stop

In case of an emergency, bring the machine to a standstill by

pressing the EMERGENCY STOP BUTTON.

Release the emergency stop

To release the emergency stop, the drive lever has to be brought

to neutral (0) position.

Release the emergency stop

Turn the emergency stop button slightly in the direction indicated

by the arrows until it snaps out.

Indication

When the emergency stop is engaged, the vibration and the

sprinkler systems are turned off.

PAGE 20 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 21

OPERATION

Driver’s seat

1. Forward/backward adjustment

Pull the longitudinal adjustment lever outward and set the

seat to the desired position.

➜

2. Adjustment of back rest

Pull the backrest adjustment lever upwards and set the

backrest to the desired position.

3. Weight adjustment

Push the lever (1) downward to the desired weight

adjustment (9 weight steps from 50 kg to 130 kg

available). To decrease the weight adjustment, push

the lever fully to the bottom against the stop: The lever

comes back automatically to the 50 kg position.

Never pull the adjustment lever upwards!

➊

Please note!

➜

The driver seat must not be adjusted while the vehicle is in

motion: DANGER OF ACCIDENT!

This driver seat helps to minimize fatigue. Therefore appropriate

care and maintenance is recommended.

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 21

Page 22

OPERATION

Sprinkler system

1. Water tank

Fill water tank (1).

1

2. Turn sprinkler on and off

Put the sprinkler system on and off by turning the

corresponding switch.

SPRINKLER WITH FOOT OPERATED SWITCH

This function is possible if the ignition is turned on. If you need

water, push the switch (1) and the sprinkling system works. If you

release the switch (1), the sprinkling system will stop. The

sprinkler foot switch will work only if the main sprinkler switch is

turned off.

1

PAGE 22 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 23

OPERATION

Single / double vibration

1. Switch on vibration

Press the vibration switch on the drive lever handle.

2. Switch off the vibration

Again press the vibration switch on the driver

lever handle.

Attention

Only engage the vibration when the throttle lever is set to a

working speed.

Vibration at the front only

To put on the front vibration only, turn the vibration selector switch

counter-clockwise (6).

Vibration front and rear

To put on the front and rear vibration, turn the vibration selector

switch clockwise (6).

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 23

Page 24

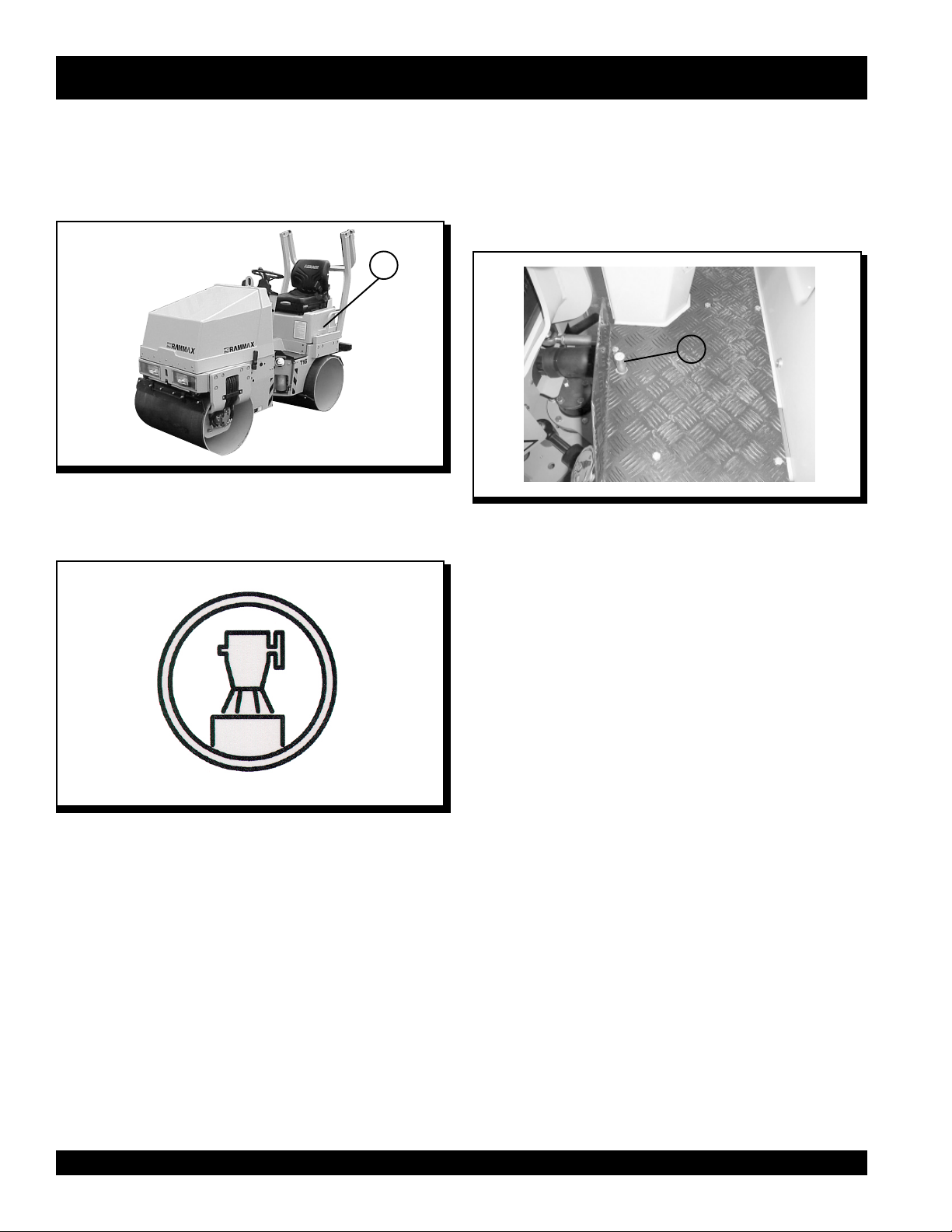

TOW PREPARATION, TO TOW & TO LIFT

Preparation

1. Remove R.H. floor panel (4).

2. Install tow lever (from the toolbox) in pos. 1.

3. Turn tow lever clockwise to pos. 2.

4. Turn the steering wheel counterclockwise (left) until the

resistance increases and the steering starts moving slightly.

5. Turn the tow lever to pos. 3.

Towing (see page “To tow”)

Reposition for drive

1. Turn tow lever back to pos. 1.

2. Remove tow lever.

3. Replace floor panel

Attention!

Diesel engine may only be started in pos. 1

Not included in all types.

Towing

Only tow the machine in case of emergency for the purpose

of moving the machine out of the hazard area (maximum of

10 meters).

Towing eye (1a)

Transport machine with lifting brackets and transporter.

1 Articulation lock

Before attaching the machine affix articulation lock.

2 Attachment to load hook

Suspend machine on crane hook.

WARNING!

Never stand under lifted machine! While loading or unloading

the machine, use only ramps. While transporting the machine, it

must be secured against rolling, sliding and tipping over.

PAGE 24 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 25

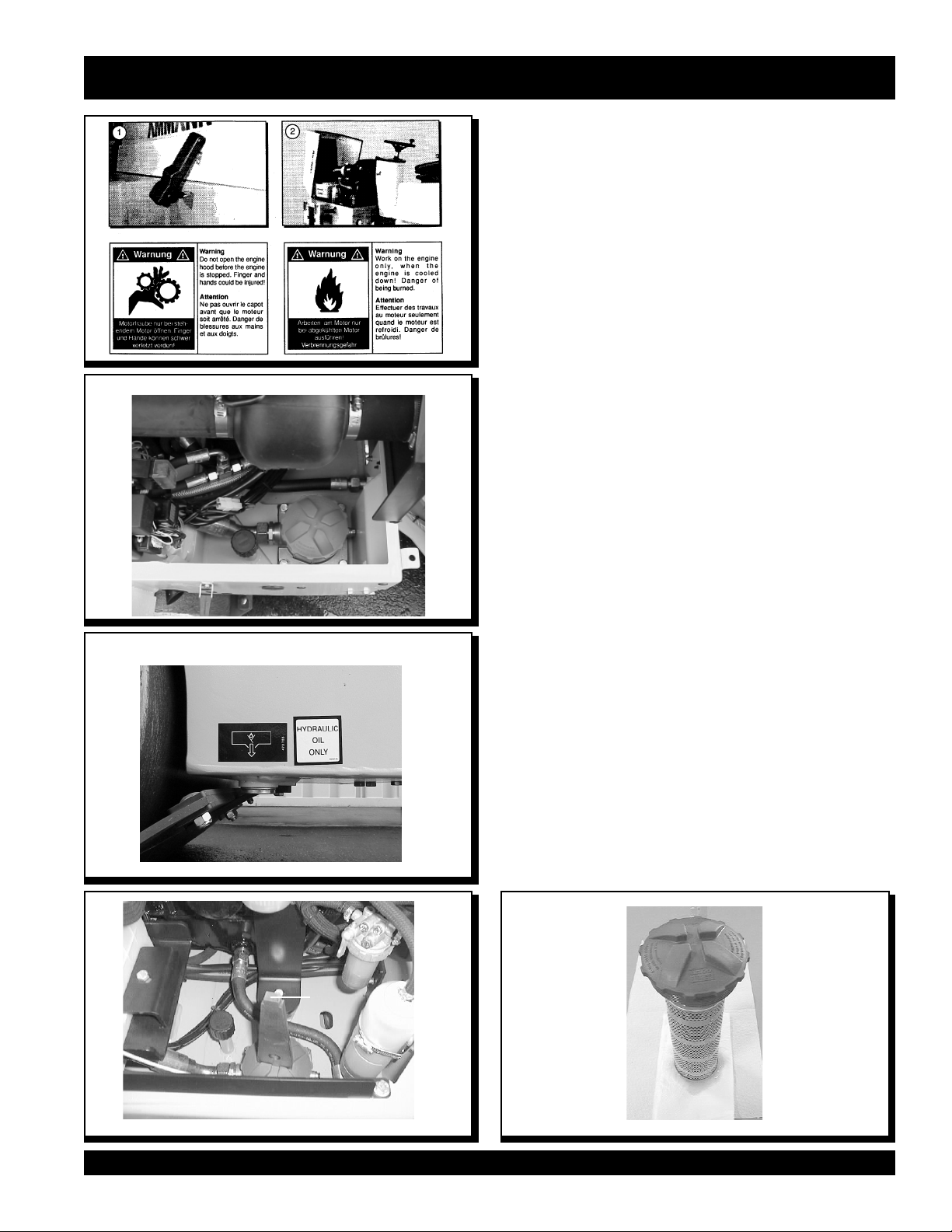

HOOD INFORMATION

1 Fastener

Release fastener on both sides.

2 Hood

Open engine hood.

Hydraulic oil change

Always change oil and oil filter at the same time. First oil change

after 500 operting hours, then every 2000 operting hours, but at

least once a year.

1. Hydraulic tank breather

2. Oil drain screw

Unscrew oil drain plug and drain oil into pan. Then screw oil

drain plug back again.

➊

3. Oil filter

Remove hydraulic oil filter.

4. Hydraulic oil

Fill in new hydraulic oil and fit a new hydraulic oil filter.

Retighten tank breather.

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 25

Page 26

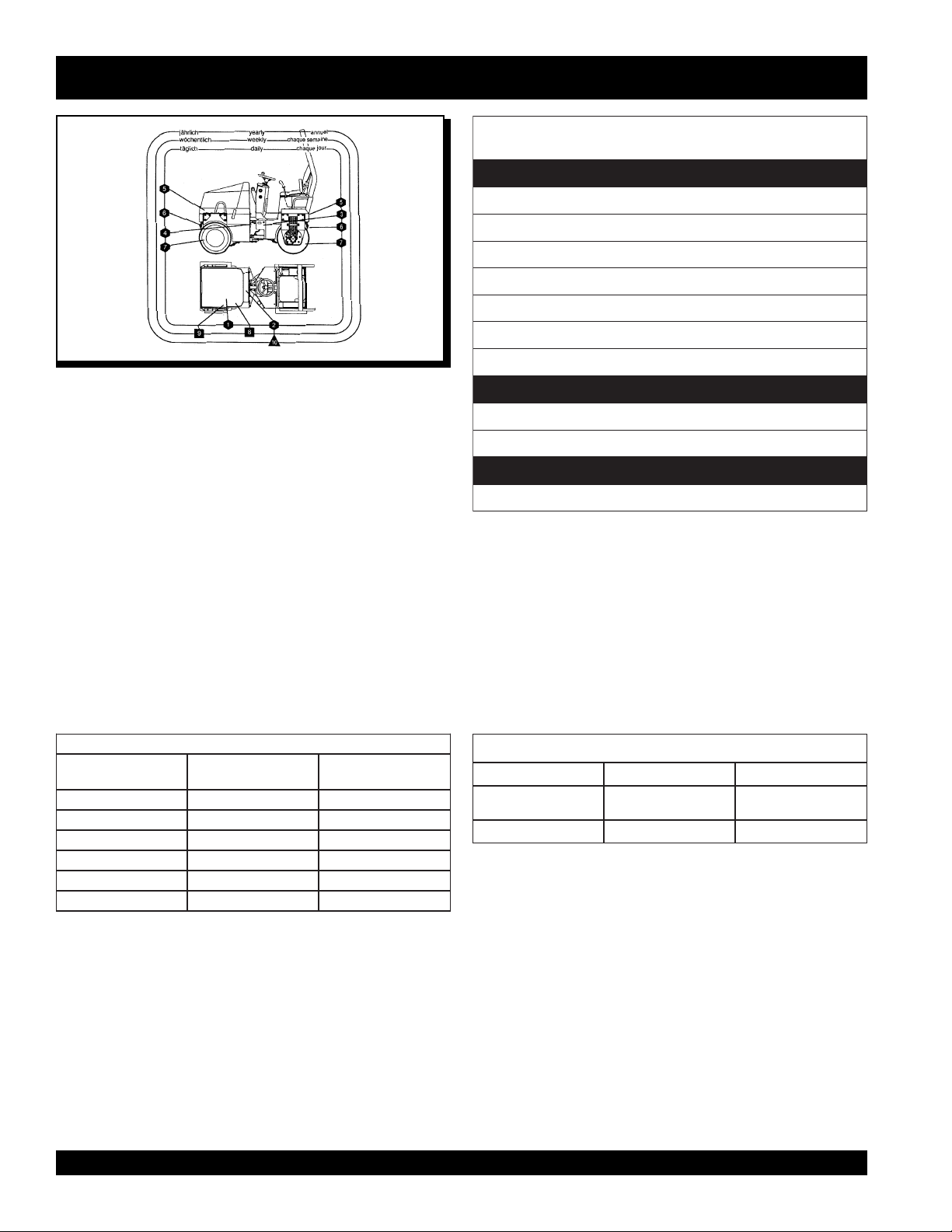

MAINTENANCE SCHEDULE & TIGHTENING TORQUE

ECNANETNIAM

ELUDEHCS

yliaD

levellioenignE

levelretawgnilooC

levelleuF

levelliociluardyH

metsysrelknirpS

reparcS

erusserperiT/smurD

ylkeeW

tnemelerenaelcriA

leveldiuqilyrettaB

ylraeY

liociluardyH

1 Check

EUQROTGNINETHGITEUQROTGNINETHGIT

EUQROTGNINETHGITEUQROTGNINETHGIT

EUQROTGNINETHGIT

wercS ytilauQ

6M 8.8 01

8M 8.8 52

01M 8.8 94

21M 8.8 68

61M 8.8 012

02M 8.8 014

2 Refill / Clean / Grease

3 Replace

Note: Not all the maintenance work is listed in this operating

manual. Please refer to the Yanmar

Engine operating manual for additional maintenance work.

ELUDEHCSTNACIRBULELUDEHCSTNACIRBUL

ELUDEHCSTNACIRBULELUDEHCSTNACIRBUL

euqrotgninethgiT

mNni

LIBOM

LLEHS

liociluardyH liociluardyH

31ETDeliboM 51ETDeliboM

23TsulleT 64TsulleT

ELUDEHCSTNACIRBUL

PAGE 26 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 27

FROST WARNING, SCRAPERS & FUSES

Fuses

The fuses (B) are located in the sterring column

*5 F5 Hazard light (10A)

*6 F6 Working light rear (10A)

*7 F7 Low beam

*8 F8 Parking light (10A)

*not included in all types

The electric components (A) are located behind the battery on

the left.

Fuses

1. F1 First solenoid (30A)

2. F2 Second solenoid (7.5A)

3. F3 Ventilator (15A)

4. F4 Seating OPTION (10A)

Solenoid

9. K31 Stop solenoid

10. K30 Timer solenoid

11. K14 Starter control solenoid (70A)

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 27

Page 28

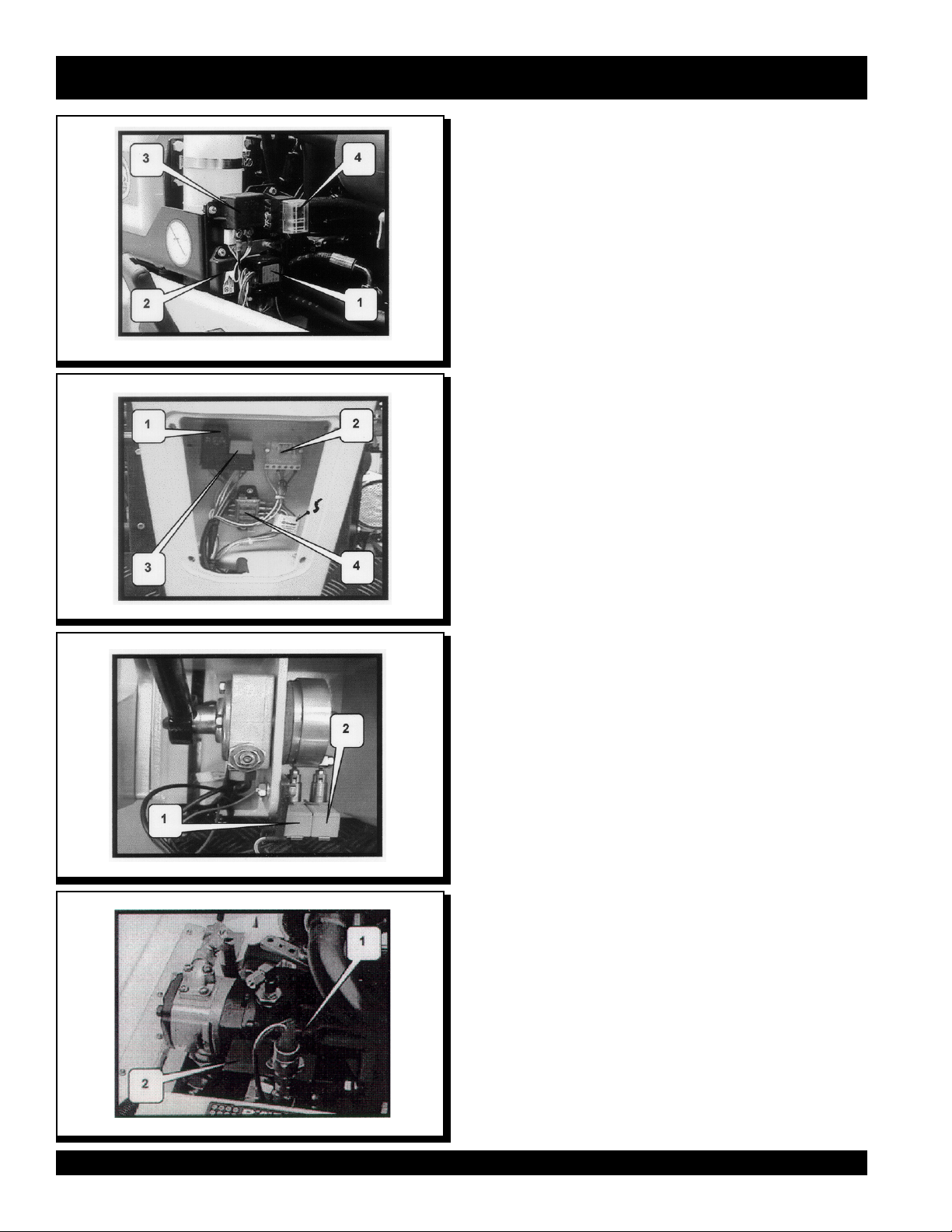

ELECTRONIC COMPONENTS

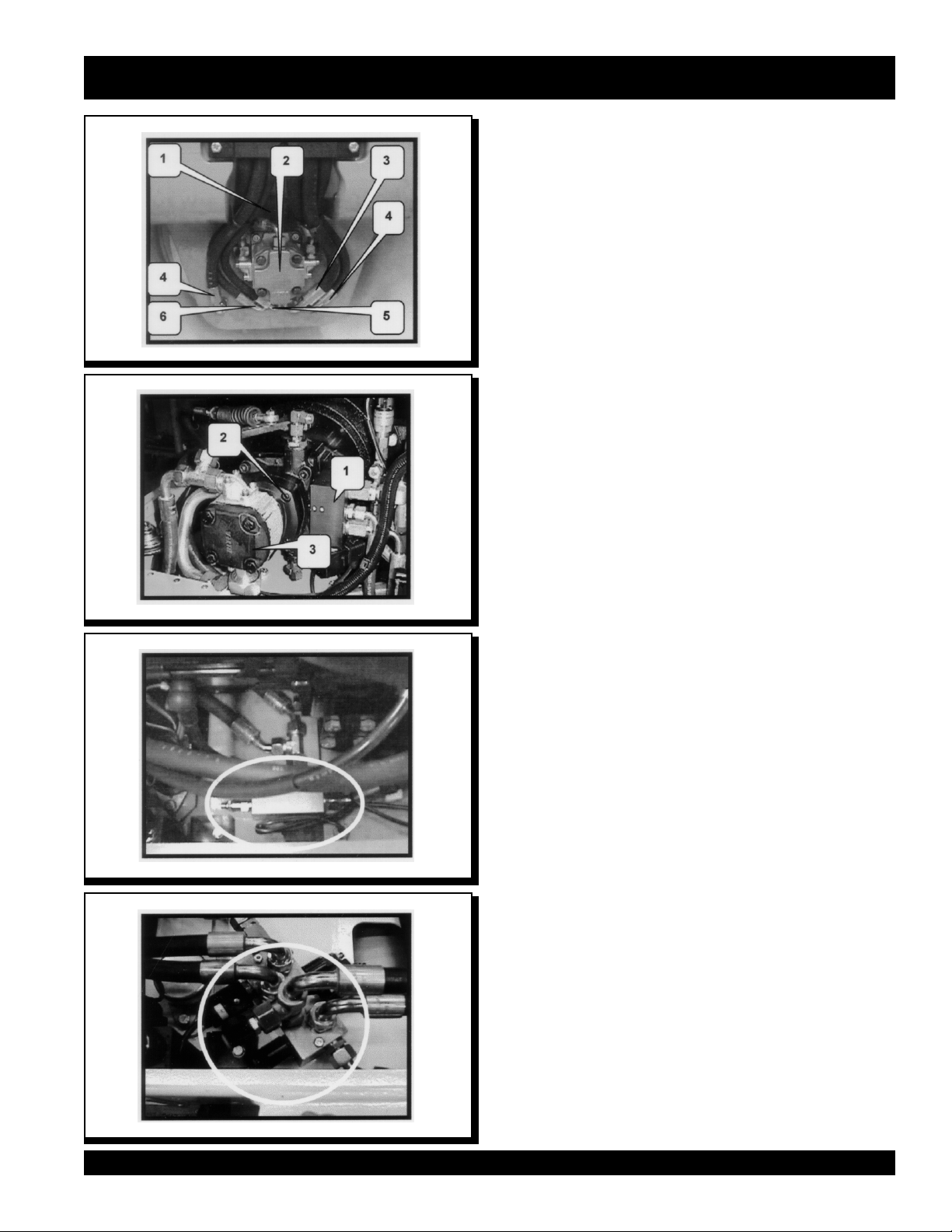

1 Relay for start - stop solenoid

2 Timer for relay of start - stop solenoid

3 Start relay

4 Fuse box

1 Relay for emergency stop

2 Relay vibration

3 Relay head lamps

4 Fuses

1 Emergency stop

2 Option

1 Brake control switch

2 Solenoid, emergency stop valve

PAGE 28 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 29

MAIN COMPONENTS

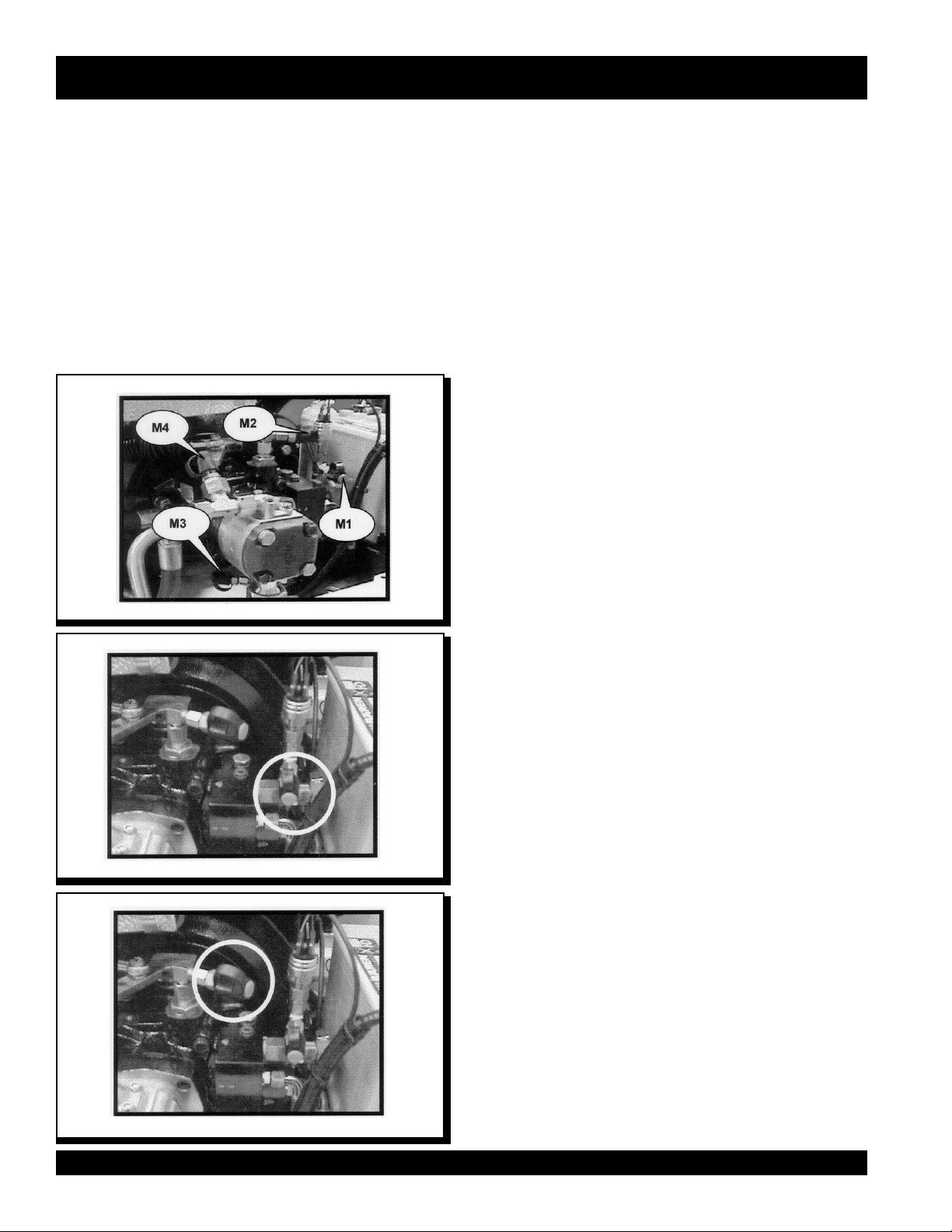

1 Drive motor

2 Vibration motor

3 Leak oil drive and vibr. motor

4 Main drive circuit A & B

5 Brake pressure hose

6 Leak oil vibrating motor

1 Emergency stop valve

2 Drive pump

3 Steering and vibration pump

Vibration valve, standard (in the engine compartment)

Vibration valve — option VAB (in the engine compartment)

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 29

Page 30

All values stated are valid at:

■

Hydraulic oil temperature of approx. 140° F and high idle

(full RPM) of Diesel engine

■

Relief valves should relase pressure for max. 5 seconds.

CHECK AND ADJUST PRESSURES

Pressure gauge measuring range:

M1 ....................................................... 900PSI

M2, M3, M4, M5 ................................... 9000PSI

M1 Charge pressure for drive pump at speed of approx. 2 Mph

■

260 ± 30 PSI (cannot be adjusted)

M1 Pressure of drive circuit forward with blocked drum

■

4350 PSI plus charge pressure = 4610 ± 220PSI

PAGE 30 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 31

CHECK AND ADJUST PRESSURES

M3 Pressure of drive circuit backward with blocked drum

■

4350 PSI plus charge pressure = 4610 ± 220 PSI

M4 Relief valve when engaging single vibration

■

1350 ± 150 PSI

M3 Pressure of drive circuit backward with blocked drum

■

4350 PSI plus charge pressure = 4610 ± 220 PSI

M5 Relief valve when changing from single to double vibration

■

1350 ± 150 PSI

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 31

Page 32

MAINTENANCE & REPAIR — YANMAR ENGINE

TRAP METI YLIAD

lliferdnalevelleufehtkcehC

knatlioleufehtniarD

partretawehtdnaretliflioleufehtkcehC

LIOLEUF

METSYS

retlifleufehtnaelC

tnemeleretlifleufehtecalpeR

evlavnoitcejnileuF

noitidnocnoitcejniehtkcehC

pmupnoitcejnileuF

gnimitnoitcejniehtkcehC

esacknarcehtnilevellioebulehtkcehC

LIOEBUL

lioebulehtecalpeR

METSYS

retliflioebulehtecalpeR

m

m

YREVE

05

.SRH

YREVE

.SRH002

YREVE

.SRH004

YREVE

0001

.SRH

m

m

m

m

●

●

m

ts

1(

)emit

m

ts

1(

)emit

m

dn

2(

dnaemit

)retfaereht

m

dn

2(

emit

dna

)retfaereht

levelretawgniloocehtkcehC

GNILOOC

RETAW

gniggolcrofsnifrotaidarehtnaelcdnakcehC

METSYS

retawgniloocehtecalpeR

m

m

m

)naelC(

m

yreve(

)raey

m

EKATNIRIA

METSYS

riA

renaelc

tnemele

naelC

ytsudni(

)snoitidnoc

ecalpeR

m

m

ytsudni(

m

)snoitidnoc

metsysknilronrevogehtniliO

ENIGNE

KCOLB

stlobehtnethgiteR

ecnaraelcevlavtsuahxe/ekatniehttsujdA

spmalgninrawllakcehC

m

sruoh05tsrifehtretfA

ylbmessa-erdnaylbmessasidhcaeretfasruoh05

●

m

LACIRTCELE

TNEMPIUQE

leveldiuqilyrettabehtkcehC

noisnettlebnafehttsujdA

m

m

PAGE 32 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 33

HYDRAULIC SYSTEM

Drive

rear

Steering

Vibration

Vibration control valve

front

Not included in all types

(Option þ Brake release valve)

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 33

All values stated are valid at:

■

hydraulic oil temperature of approximately

60ºC

■

full speed of diesel engine

Relief valves may release pressure for

maximum of 5 seconds.

Measuring of pressure with manometers:

■

M1 = 60 bars measuring ratio

■

M2 to M5 = 600 bars measuring ratio

Measuring point M2, M3

Pressure for translation 300 + 18 bars = 318 +

15 bars at blocked drums.

Measuring point M4I

Relief valve 180 + 5 bars when putting on double

vibration.

Measuring point M4

Relief valve 105 + 5 bars at full articulation.

Measuring point M1

Supply pressure translation pump psp = 18 + 2

bars at approximate speed of 3 kilometers per

hour.

IDynamic pressure means maximum pressure

with maximum value recorded.

Page 34

HYDRAULIC SYSTEM —VIBRATION SWITCH OFF REAR

English

Drive

rear

Steering

Vibration

Vibration control valve

front

Not included in all types

(Option þ Brake release valve)

PAGE 34 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

All values stated are valid at:

■

hydraulic oil temperature of approximately

60ºC.

■

full speed of diesel engine.

Relief valves may release pressure for maximum

of 5 seconds.

Measuring of pressure with manometers:

■

M1 = 60 bars measuring ratio

■

M2 to M5 = 600 bars measuring ratio

Measuring point M2, M3

Pressure for translation 300 + 18 bars = 318 +

15 bars at blocked drums.

Measuring point M4I

Relief valve 95 + 5 bars when putting on simple

vibration.

Measuring point M4

Relief valve 105 + 5 bars at full articulation.

Measuring point M1

Supply pressure translation pump psp = 18 + 2

bars at approximate speed of 3 kilometers per

hour.

Measuring point M5I

Relief valve 90 + 5 bars when putting on double

vibration.

■

Dynamic pressures mean maximum

pressure with maximum value recorded.

Page 35

ELECTRICAL DIAGRAM

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 35

Page 36

ELECTRICAL DIAGRAM

1A ecivedlortnocgnitaeherP

3B nroH

11E tfel-thgilnoitisoP

21E tfelthgilliaT

31E thgir-thgilnoitisoP

41E thgir-thgilliaT

51E tfel-pmaldaeH

61E thgir-pmaldaeH

02E tnorf-pmaldrazaH

12E raer-pmaldrazaH

1F dioneloStsriF

2F dionelosdnoceS

3F noitarbiV

4F nroH

5F thgilgninrawdrazaH

4K rotacidninoitceriDredneS

41K )A07(dioneloS

02K dionelosnoitarbiV

42K dionelospotsycnegremE

13K dionelospotS

1M rotomgnitratS

2M rotomrewolB

41M tnorf-rotompmupretaW

51M raer-rotompmupretaW

6P retemruoH

3R bluB

2S nottubretratS

6S hctiwsgninrawerusserpliO

7S hctiwserutarepmetretawgnilooC

31S nrohhctiwS

6F raerpmaldaehgnikroW

7F maebwoL

8F thgilgnikraP

1G )rotalugerhtiw(rotanretlA

2G yrettaB

1H rotanretla-thgillortnoC

2H retawgnilooc-thgillortnoC

3H erusserplio-thgillortnoC

6H tnorftfel-rotacidninoitceriD

7H raertfel-rotacidninoitceriD

8H tnorfthgir-rotacidninoitceriD

9H raerthgir-rotacidninoitceriD

91H ekarb-thgillortnoC

41S hctiwspmaldrazaH

81S hctiwsthgiL

23S ekarbciluardyhhctiwssserP

45S metsystratshctiwsytefaS

55S hctiwsrelknirpS

65S raeromaldaehgnikrowhctiwS

75S hctiwsorbiV

85S hctiwsrotacidnI

95S noitarbivhctiwsrotceleS

76S hctiwspotsycnegremE

37S hctiwspotsycnegremerelloR

08S hctiwstaeS

4Y evlavekarbycnegremE

41Y tnorf-evlavretaW

51Y raer-evlavretaW

61Y pmupnoitarbivdioneloS

71Y noitarbivraeR

12Y dionelospotS

PAGE 36 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 37

NOTE PAGE

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 37

Page 38

DRUM - TRAVELING

PAGE 38 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 39

1-0.1

DRUM - TRAVELLING

NO PART NO PART NAME QTY. REMARKS

1 AVL365032 WHEEL 1

5 AVL820478 CORE (CONNECTOR) 6

6 AVL365056 WASHER 1

6 AVL365129 WASHER 1

7 AVL365054 WASHER 1

9 AVL820488 RING 1

12 AVL341944 BELLOW 1

13 AVL922711 HOSE CLAMP 1

15 AVL494045 ISOLATION MOUNTING 12

17 AVL236498 ADDITIONAL WEIGHT 2

18 AVL820476 DISTANCE SLEEVE 1

30 AVL901893 SCREW HEX. HD 8

31 AVL901916 SCREW HEX. HD 6

32 AVL922712 PIN 8

33 AVL902263 WASHER 8

34 AVL902124 NUT HEX. 8

35 AVL902126 NUT HEX. 12

36 AVL902128 NUT HEX. 6

46 AVL901799 SCREW HEX. HD. 7

DRUM - TRAVELING

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 39

Page 40

DRUM SUPPORT

PAGE 40 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 41

1-0.2

DRUM SUPPORT

NO PART NO PART NAME QTY. REMARKS

1 AVL135523 DRUM SUPPORT 1

2 AVL390518 HYDRAULIC MOTOR 1

2 AVL390519 HYDRAULIC MOTOR 1

2.1 AVL906685 SEAL 3

2.2 AVL906689 SEAL 2

2.3 AVL944006 SEAL 1

2.4 TEXT0001 (ON REQUEST) 1

3 AVL390435 HYDRAULIC MOTOR 1

3.1 TEXT0001 (ON REQUEST) 1

4 AVL365805 CARDAN SHAFT FLEXIBLE 1

5 AVL902640 ALAN SCREW 4

6 AVL901063 REDUCER 2

7 AVL901311 REDUCER 2

8 AVL901059 REDUCER 1

9 AVL901064 REDUCER 1

10 AVL491356 FLANGE COMPLETE 2

10.1 AVL908882 ALAN SCREW 2

10.2 AVL902682 ALAN SCREW 2

10.3 AVL902323 SPRINGWASHER 4

10.4 AVL906670 SEAL 1

11 AVL901786 SCREW HEX. HEAD 8

12 AVL901889 SCREW HEX. HEAD 6

13 AVL901765 SCREW HEX. HEAD 2

14 AVL341945 STRAP 2

15 AVL365798 DISTANCE PLATE 1

DRUM SUPPORT

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 41

Page 42

DRUM VIBRATION

PAGE 42 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 43

1-0.3

DRUM - VIBRATION

NO PART NO PART NAME QTY. REMARKS

1 AVL341942 HOUSING 1

2 AVL341943 COVER 1

3 AVL365046 VIBRO SHAFT 1

4 AVL803362 RING 1

5 AVL909432 ROLLER BEARING 2

6 AVL800412 LIP SEAL 1

7 AVL906534 CAP SCREW 1

8 AVL901760 SCREW HEX. HEAD 1

9 AVL901763 SCREW HEX. HEAD 6

10 AVL901782 SCREW HEX. HEAD 6

11 AVL907870 ALAN SCREW 1

DRUM VIBRATION

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 43

Page 44

SCRAPER CHASSIS FRONT

PAGE 44 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 45

SCRAPER CHASSIS FRONT

1-2.1

SCRAPER CHASSIS FRONT

NO PART NO PART NAME QTY. REMARKS

1 AVL803568 PLATE 2

2 AVL824059 SCRAPER BRACKET 2

3 AVL455082 SCRAPER 2

4 AVL803567 PLATE 2

5 AVL901772 SCREW HEX. HEAD 4

6 AVL902206 NUT HEX. 12

7 AVL902264 WASHER 4

8 AVL921045 SAUCER-HEAD SCREW 4

9 AVL901763 SCREW HEX. HEAD 4

10 AVL820598 SCRAPER BRACKET 2

11 AVL921747 SAUCER-HEAD SCREW 8

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 45

Page 46

SCRAPER CHASSIS REAR

PAGE 46 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 47

SCRAPER CHASSIS REAR

1-2.2

SCRAPER CHASSIS REAR

NO PART NO PART NAME QTY. REMARKS

1 AVL803567 PLATE 2

2 AVL455082 SCRAPER 2

3 AVL803568 PLATE 2

4 AVL824059 SCRAPER BRACKET 2

5 AVL820598 SCRAPER BRACKET 2

6 AVL921045 SAUCER-HEAD SCREW 4

7 AVL921747 SAUCER-HEAD SCREW 8

8 AVL902206 NUT HEX. 12

9 AVL902264 WASHER 4

10 AVL901772 SCREW HEX. HEAD 4

11 AVL901763 SCREW HEX. HEAD 4

12 AVL365594 PLATE 1

13 AVL901783 SCREW HEX. HEAD 6

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 47

Page 48

SPRINKLER PUMP

PAGE 48 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 49

1-3.1

SPRINKLER PUMP

NO PART NO PART NAME QTY. REMARKS

1 AVL495062 WATER PUMP 1

3 AVL494443 FILTER 1

3.1 AVL921706 FILTER BASE 1

3.2 AVL921709 FILTER HOLDER 1

3.3 AVL921707 GLASS 1

3.4 AVL921710 ELEMENT 1

3.5 AVL921708 GASKET 1

4 AVL905413 EXTENSION 1

6 AVL908156 REDUCER 1

7 AVL906101 REDUCER 1

8 AVL909398 REDUCER 1

9 AVL901415 REDUCER 1

12 AVL908157 HOSE CLAMP 6

16 AVL921495 HALF BOWL 2

17 AVL903719 WASHER 2

18 AVL921645 ALAN SCREW 2

22 AVL901752 SCREW HEX. HEAD 4

23 AVL902261 WASHER 4

24 AVL903792 HOSE 1

26 AVL903792 HOSE 1

30 AVL824386 PROTECTION FOR WATER PUMP 1

SPRINKLER PUMP

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 49

Page 50

SPRINKLER PIPES

PAGE 50 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 51

1-3.2

SPRINKLER PIPES

NO PART NO PART NAME QTY. REMARKS

1 AVL366254 SPRINKLER PIPE 4

2 AVL491751 STRAP 8

3 AVL491752 SEAL RING 6

4 AVL923967 CHECK VALVE 6

5 AVL495061 NOZZLE 6

6 AVL491754 COUPLING NUT 6

7 AVL923408 PLUG 4

8 AVL923263 FEMALE REDUCER 2

9 AVL906101 REDUCER 2

10 AVL921534 REDUCER 1

11 AVL903726 HALF BOWL 8

12 AVL902682 ALAN SCREW 8

13 AVL903719 WASHER 8

14 AVL908157 HOSE CLAMP 5

15 AVL903792 HOSE, 0.25 m 1

16 AVL903792 HOSE, 1.77 m 1

17 AVL903792 HOSE, 0.8 m 1

SPRINKLER PIPES

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 51

Page 52

CHASSIS FRONT

PAGE 52 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 53

2-0.1

CHASSIS FRONT

NO PART NO PART NAME QTY. REMARKS

1 AVL135509 FRONT FRAME 1

2 AVL495048 OIL LEVEL GAUGE 1

3 AVL820516 PLATE 1

4 AVL820607 RUBBER PLATE 1

5 AVL901763 SCREW HEX. HEAD 4

6 AVL365495 BATTERY MOUNTING 1

7 AVL907534 ISOLATION MOUNTING 4

8 AVL908876 COUNTERSUNK SCREW 4

9 AVL341945 STRAP 2

10 AVL901756 SCREW HEX. HEAD 5

12 AVL901783 SCREW HEX. HEAD 4

13 AVL902124 NUT HEX. 4

14 AVL902287 WASHER 4

15 AVL803850 ANGLE 1

16 AVL921628 SCREW HEX. HEAD 1

17 AVL494945 RUBBER PLATE 1

18 AVL365193 TENSION BOW 2

19 AVL824073 BRACKET 1

20 AVL824060 GRID 1

21 AVL494417 PROFILED JOINT, 0.68 m 1

22 AVL922992 CHEESE HEAD SCREW 4

CHASSIS FRONT

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 53

Page 54

ENGINE HOOD

PAGE 54 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 55

2-1.1

ENGINE HOOD

NO PART NO PART NAME QTY. REMARKS

1 AVL135382 HOOD 1

1.2 AVL923542 PROFILE, 0.85m 2

1.3 AVL494417 PROFILED JOINT, 1.5m 1

2 AVL820601 BRACKET 1

3 AVL341972 HINGE 1

4 AVL922586 PNEUMATIC SPRING 1

4.1 AVL902124 NUT HEX. 1

6 AVL494880 BENT-LEVER CLOSURE 2

7 AVL901758 SCREW HEX. HEAD 10

8 AVL902262 WASHER 10

10 AVL922953 WIRE CABLE, 0.65m 1

11 AVL922952 PRESSURE CLAMP 1

12 AVL365114 PLATE 1

13 AVL820566 BRACKET 2

15 AVL902840 FLAT HEAD SCREW 6

16 AVL902839 FLAT HEAD SCREW 6

17 AVL922556 BLIND RIVETING 13

18 AVL902122 NUT HEX. 6

ENGINE HOOD

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 55

Page 56

CHASSIS REAR

PAGE 56 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 57

2-3.1

CHASSIS REAR

NO PART NO PART NAME QTY. REMARKS

1 AVL135511 REAR FRAME 1

2 AVL135377 FUEL TANK 1

3 AVL820542 BRACKET 1

4 AVL901772 SCREW HEX. HEAD 1

5 AVL341945 STRAP 2

6 AVL901763 SCREW HEX. HEAD 2

7 AVL365088 FILLER NECK 1

8 AVL922726 TANK CLOSURE 1

8.1 AVL922975 KEY 1

9 AVL820549 HOSE 1

10 AVL902780 HOSE CLAMP 2

11 AVL906102 REDUCER 2

12 AVL903772 PLUG 1

12.1 AVL906670 SEAL 1

13 AVL903807 HOSE CLAMP 2

14 AVL922332 HOSE 1.55m 2

15 AVL365496 FIXING DEVICE 1

16 AVL903664 ES BOLT 1

17 AVL901757 SCREW HEX. HEAD 2

18 AVL901763 SCREW HEX. HEAD 3

19 AVL902124 NUT HEX. 1

20 AVL591345 PLATE 1

21 AVL824073 BRACKET 1

CHASSIS REAR

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 57

Page 58

OPERATOR PLATFORM

PAGE 58 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 59

2-4.1

OPERATOR PLATFORM

NO PART NO PART NAME QTY. REMARKS

2 AVL824529 DRIVER LEVER 1

2.1 AVL495049 HANDLE 1

2.2 AVL824502 LEVER 1

2.3 AVL903225 HEXAGON ALAN PIN 1

4 AVL494814 TRANSMITTER 1

5 AVL491343 BRAKE LINER 1

6 AVL341861 BRAKE DISK 1

7 AVL803447 BRACKET 1

8 AVL491401 SWITCH 1

9 AM1648-113Z2 CABLE WIRE 1

9.1 AVL T889 BELLOW 1

9.2 AVL908922 JOINT 1

10 AVL365388 DRIVER LEVER BRACKET 1

12 AVL390469 DRIVE LEVER 1

12.1 AM1667-146DG TRANSMITTER 1

12.2 AM1667-146AZ CABLE WIRE 1

12.3 AVL922865 BALL JOINT 1

12.4 AVL923401 HANDLE 1

19 AVL902368 DISK SPRING 1

20 AVL903812 KEY 1

21 AVL922626 ALAN SCREW 2

24 AVL922643 SCREW HEX. HEAD 2

25 AVL901757 SCREW HEX. HEAD 1

26 AVL901755 SCREW HEX. HEAD 1

27 AVL906214 SCREW HEX. HEAD 3

28 AVL901764 SCREW HEX. HEAD 1

29 AVL902633 ALAN SCREW 1

33 AVL902212 NUT HEX. 1

35 AVL902262 WASHER 2

36 AVL902263 WASHER 1

OPERATOR PLATFORM

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 59

Page 60

OPERATOR PLATFORM

PAGE 60 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 61

OPERATOR PLATFORM

2-4.2

OPERATOR PLATFORM

NO PART NO PART NAME QTY. REMARKS

1 AVL236763 OPERATOR STAND 1

2 AVL472012 STEERING SHAFT 1

2.1 AVL902182 NUT HEX. 1

2.2 AVL903977 WOODRUFF KEY 1

3 AVL491410 STEERING VALVE 1

4 AVL495097 BOTTLE BRACKET 1

5 AVL491411 RELIEF VALVE 1

5.1 AVL908923 ALAN SCREW 2

5.2 AVL906695 SEAL 4

6 AVL494618 STEERING WHEEL 1

6.1 AVL922223 HANDLE 1

7 AVL494619 COVER 1

8 AVL824407 STEERING COLUMNE COVER 1

9 AVL901774 SCREW HEX. HEAD 6

10 AVL365741 PLATE 1

11 AVL365742 PLATE 1

12 AVL901762 SCREW HEX. HEAD 6

13 AVL922310 ISOLATION MOUNTING 4

14 AVL901780 SCREW HEX. HEAD 4

15 AVL902265 WASHER 2

16 AVL902126 NUT HEX. 4

17 AVL901776 SCREW HEX. HEAD 4

18 AVL901389 REDUCER 2

19 AVL901084 REDUCER 2

20 AVL902264 WASHER 6

21 AVL901787 SCREW HEX. HEAD 1

22 AVL820097 CLAMP 1

23 AVL901756 SCREW HEX. HEAD 1

24 AVL903750 GUIDE PROFILE, 0.11m 2

25 AVL908155 SOFT RUBBER PROFILE, 0.045m 1

26 AVL902839 FLAT HEAD SCREW 3

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 61

Page 62

WATER TANK, SEAT

PAGE 62 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 63

2-4.3

WATER TANK, SEAT

NO PART NO PART NAME QTY. REMARKS

1 AVL236479 WATER TANK 1

1.2 AVL922733 COVER NECK 1

1.3 AVL922734 COVER 1

1.4 AVL922857 GASKET 1

1.5 AVL922858 LACK PIN 1

1.6 C.02848.000 RAISED CHEESE HEAD SCREW 1

1.7 C.02849.000 NUT 1

2 AVL390496 DRIVER SEAT COMPLETE 1

2.01 GRA135844 PADDING FOR SEAT 1

2.02 GRA134479 PADDING FOR BACK OF SEAT 1

2.03 GRA134481 BACK OF SEAT 1

2.04 GRA134140 SEATING SURFACE 1

2.05 GRA902131 SAFETY BELT 1

2.06 GRA136015 BRACKET FOR SAFETY BELT 1

2.07 GRA133119 SHOCK ABSORBER 1

2.08 GRA133116 RUBBER SPACER 1

2.09 GRA136016 SEAT CONTACT SWITCH 1

2.10 GRA135966 CONTACT SWITCH 1

3 AVL390536 TOOL BOX 1

4 AVL903680 BLIND RIVETING 4

5 AVL341948 COVER 1

6 AVL901755 SCREW HEX. HEAD 5

7 AVL902262 WASHER 5

8 AVL901762 SCREW HEX. HEAD 4

9 AVL902638 ALAN SCREW 4

10 AVL909398 REDUCER 1

11 AVL908157 HOSE CLAMP 1

12 AVL591838 TUBE 1

WATER TANK, SEAT

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 63

Page 64

STABILIZER BAR

PAGE 64 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 65

3-0.1

STABILIZER BAR

NO PART NO PART NAME QTY. REMARKS

1 AVL341546 BRACKET 2

2 AVL820512 TUBE 1

3 AVL902645 ALAN SCREW 8

4 AVL909431 DOWEL PIN 2

5 AVL903706 JOINT ROD END 2

6 AVL902988 COUNTERSUNK SCREW 2

7 AVL902286 WASHER 10

8 AVL902125 NUT HEX. 2

9 AVL902183 NUT HEX. 1

10 AVL921370 WASHER 2

STABILIZER BAR

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 65

Page 66

ARTICULATING JOINT

PAGE 66 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 67

3-0.2

ARTICULATING JOINT

NO PART NO PART NAME QTY. REMARKS

1 AVL330239 SUPPORT 1

2 AVL474781 COVER 1

3 AVL341343 OSCILLATING STOP 1

4 AVL474784 BUSHING 1

5 AVL474785 WASHER 1

6 AVL902651 ALAN SCREW 4

7 AVL901783 SCREW HEX. HEAD 6

8 AVL901782 SCREW HEX. HEAD 4

9 AVL902374 DISK SPRING 2

10 AVL902651 ALAN SCREW 3

13 AVL494432 JOINT BEARING 1

ARTICULATING JOINT

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 67

Page 68

STEERING CYLINDER

PAGE 68 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 69

STEERING CYLINDER

3-0.3

STEERING CYLINDER

NO PART NO PART NAME QTY. REMARKS

1 AVL492435 HYDRAULIC CYLINDER 1

1.1 AVL907553 JOINT BEARING 2

1.2

1.3

1.4

1.5

1.6

1.7 AVL922716 GASKET KIT ............................................... 1 ............. INCLUDES ITEMS W/

2 AVL820624 MOUNTING 1

3 AVL820623 MOUNTING 1

4 AVL902208 NUT HEX. 2

5 AVL901800 SCREW HEX. HEAD 4

6 AVL901745 REDUCER 2

AVLK55224 PISTON PACKING 1

*

L1541007407 ROD PACKING 1

*

L2511004792 SCRAPER 1

*

AVL908917 SEAL 1

*

*

SUPPORT RING, 55x51x15 1

*

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 69

Page 70

ENGINE

PAGE 70 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 71

4-0.1

ENGINE

NO PART NO PART NAME QTY. REMARKS

1 AVL390427 DIESEL ENGINE 1

2 AVL390416 FLANGE 1

3 AVL365501 ENGINE SUPPORT RIGHT 1

4 AVL365497 ENGINE SUPPORT RIGHT 1

5 AVL365498 ENGINE SUPPORT LEFT 1

6 AVL365500 ENGINE SUPPORT LEFT 1

7 AVL820437 EXHAUST MANIFOLD 1

8 AVL824015 EXHAUST PIPE UPPER 1

9 AVL365012 BRACKET 1

10 119332-13500 MUFFLER 1

11 AVL820735 SOUND PROTECTION 1

12 AVL933954 HOSE CLIP 2

13 AVL820602 BRACKET 1

14 AVL491740 ISOLATION MOUNTING 4

15 AVL365010 EXHAUST PIPE BRACKET 1

16 AVL365482 EXHAUST PIPE 1

20 AVL901774 SCREW HEX. HEAD 6

21 AVL901772 SCREW HEX. HEAD 4

22 AVL901773 SCREW HEX. HEAD 25

23 AVL901781 SCREW HEX. HEAD 4

24 AVL901762 SCREW HEX. HEAD 6

29 AVL902264 WASHER 4

31 AVL902124 NUT HEX. 6

32 AVL923200 PIPE CLAMP 2

34 AVL901085 REDUCER 1

35 AVL922913 HOSE 1

36 AVL921685 REDUCER 1

45 124701-11911 GASKET 1

46 129107-13550 GASKET 1

48 AVL803707 CLAMP 1

ENGINE

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 71

Page 72

ENGINE - RADIATOR

PAGE 72 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 73

4-0.2

ENGINE - RADIATOR

NO PART NO PART NAME QTY. REMARKS

1 119632-44500 WATER COOLER 1

1.1 123682-44210 RADIATOR CAP 1

2 AVL236810 BRACKET 1

3 AVL365119 SUPPORT 1

4 AVL365816 SUPPORT 1

5 129150-49100 HOSE TAP 1

6 AVL922332 HOSE, 0.45m 1

7 AVL903807 HOSE CLAMP 1

8 AVL922332 HOSE, 0.24m 1

10 23000-060000 HOSE CLIP 6

11 124450-44550 STRAP 1

12 AVL903807 HOSE CLAMP 2

15 121256-44600 BRACKET 1

16 124450-44510 EXPANSIVE BOTTLE 1

17 AVL907542 ISOLATION MOUNTING 4

18 AVL365013 HOSE 1

19 121855-12060 MUFFLER 1

20 AVL901761 SCREW HEX. HEAD 4

21 AVL902263 WASHER 7

22 AVL901773 SCREW HEX. HEAD 4

25 AVL592048 HOSE 1

26 AVL922332 HOSE, 0.68m 1

27 AVL901762 SCREW HEX. HEAD 7

28 AVL820435 HOSE 1

30 AVL390423 AIR CLEANER BRACKET 1

31 119688-49010 HOSE WATER 1

32 119632-49020 HOSE WATER 1

33 23010-038000 HOSE CLIP 4

34 AVL494417 PROFILED JOINT, 0.55m 1

ENGINE - RADIATOR

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 73

Page 74

ENGINE SERVICE PARTS

PAGE 74 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 75

ENGINE SERVICE PARTS

4-0.3

ENGINE – SERVICE PARTS

NO PART NO PART NAME QTY. REMARKS

3 119656-42290 V-BELT 1

5 121521-12500 AIR CLEANER 1

5.1 121420-12511 AIR FILTER – OUTER 1

5.2 121422-12570 AIR FILTER – INNER 1

5.3 126650-12680 INDICATOR 1

6 AVL922332 HOSE, 0.3m 1

7 119660-35150 OIL FILTER 1

8 121850-55800 WATERTRAP 1

9 119620-11310 VALVE BONNET SEAL 1

11 124550-55700 FUEL FILTER 1

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 75

Page 76

ENGINE - ELECTRIC COMP.

PAGE 76 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 77

ENGINE - ELECTRIC COMP.

4-0.4

ENGINE - ELECTRIC COMP.

NO PART NO PART NAME QTY. REMARKS

2 AVL493837 RELAY 1

3 AVL494864 FUSE BOX 1

4 AVL921718 FUSE 1

5 AVL921583 FUSE 1

6 AVL922713 FUSE 1

7 AVL921584 FUSE 1

8 AVL901749 SCREW HEX. HEAD 7

9 AVL902261 WASHER 4

11 119632-77920 TIMER 1

12 119650-77100 RELAY 1

13 119836-77200 GENERATOR 1

14 119620-77011 STARTER MOTOR 1

15 119653-77950 SOLENOID 1

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 77

Page 78

PUMP

PAGE 78 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 79

4-0.5

PUMP

NO PART NO PART NAME QTY. REMARKS

1 AVL390518 VAR. DISPL. PUMP COMPLETE 1

1.4 AVLX297 EMERGENCY STOP VALVE 1

1.5 AVL906694 GASKET 2

1.6 AVL906626 GASKET 1

1.7 AVL906620 GASKET 1

3 AVL390437 CLUTCH 1

16 AVL901066 REDUCER 1

17 AVL901065 REDUCER 1

18 AVL901063 REDUCER 2

19 AVL901745 REDUCER 1

20 AVL901059 REDUCER 1

21 AVL901235 REDUCER 1

22 AVL901248 REDUCER 2

23 AVL492660 MANOMETRIC SWITCH 1

24 AVL901503 REDUCER 1

25 AVL921283 METERING CONNECTOR 1

26 AVL901058 REDUCER 2

27 AVL901208 REDUCER 2

28 AVL922862 METERING CONNECTOR 2

29 AVL902753 ALAN SCREW 3

30 AVL820438 HYDRAULIC PIPE 1

33 AVL901784 SCREW HEX. HEAD 2

34 AVL907885 WASHER 2

35 AVL902387 TENSIONER DISK 2

PUMP

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 79

Page 80

VIBRATION PUMP

PAGE 80 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 81

4-0.6

VIBRATION PUMP

NO PART NO PART NAME QTY. REMARKS

1 AVL390434 GEAR PUMP 1

1.1 TEXT0001 (ON REQUEST) 1

2 AVL491443 G – CONNECTION 1

2.1 AVL908882 ALAN SCREW 4

2.2 AVL902323 SPRING WASHER 4

2.4 AVL906672 SEAL 1

3 AVL901239 REDUCER 1

4 AVL901495 REDUCER 1

5 AVL491356 FLANGE COMPLETE 1

5.1 AVL908882 ALAN SCREW 2

5.2 AVL902682 ALAN SCREW 2

5.3 AVL902323 SPRING WASHER 4

5.4 AVL906670 SEAL 1

6 AVL901250 REDUCER 1

7 AVL921033 METERING CONNECTOR 1

8 AVL901877 SCREW HEX. HEAD 2

9 AVL902325 SPRING WASHER 2

VIBRATION PUMP

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 81

Page 82

COMPONENTS

PAGE 82 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 83

5-0.1

COMPONENTS

NO PART NO PART NAME QTY. REMARKS

1 AVL491952 SUCTION FILTER COMPLETE 1

1.01 AVL0020290 ROD 1

1.02 AVL0040182 WASHER 1

1.03 AVL0151901 THRUST SPRING 1

1.04 AVL0420601 RUBBER FUNNEL 1

1.05 AVL0425201 RUBBER FUNNEL 1

1.06 AVL0427401 RUBBER FUNNEL 1

1.07 AVL907498 SEAL 1

1.08 AVL908097 SEAL 1

1.09 AVL921198 FILTER CARTRIDGE 1

1.10 AVL921769 COVER 1

1.11 AVL921770 VALVE CONE O. FACE 1

1.12 ESO841204 RING 1

2 AVL901067 REDUCER 1

3 AVL901773 SCREW HEX. HEAD. 4

4 AVL803524 RETURN-FLOW TUBE 2

5 AVL824365 RETURN-FLOW TUBE 1

6 AVL901250 REDUCER 1

7 AVL493912 VENTILATION FILTER 1

8 AVL495045 OIL COOLER COMPLETE 1

8.1 AVL00V44 OIL COOLER 1

8.2 AVL00SG1 VENTILATOR 1

8.3 AVLM00XY HOUSING 1

9 AVL820626 BRACKET 1

10 AVL908753 SCREWED NECK 2

11 AVL901761 SCREW HEX. HEAD 2

12 AVL901763 SCREW HEX. HEAD 1

13 AVL901764 SCREW HEX. HEAD 2

14 AVL902263 WASHER 1

COMPONENTS

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 83

Page 84

HOSES DRIVE

PAGE 84 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 85

5-1.1

HOSES DRIVE

NO PART NO PART NAME QTY. REMARKS

1 AVL923726 HOSE 1

2 AVL923725 HOSE 1

3 AVL908817 HOSE 1

5 AVL923724 HOSE 1

10 AVL922906 HOSE 1

15 AVL901434 REDUCER 1

16 AVL907868 REDUCER 1

HOSES DRIVE

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 85

Page 86

SUCTION + LEAK PIPE

PAGE 86 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 87

5-2.1

SUCTION + LEAK PIPE

NO PART NO PART NAME QTY. REMARKS

1 AVL923701 HOSE 2

2 AVL923827 HOSE 1

2 AVL923828 HOSE 1

2 AVL923829 HOSE 1

3 AVL923695 HOSE 1

3 AVL923720 HOSE 1

3 AVL923732 HOSE 1

4 AVL923704 HOSE 1

5 AVL922912 HOSE 1

SUCTION + LEAK PIPE

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 87

Page 88

STEERING AND RADIATOR

PAGE 88 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 89

STEERING AND RADIATOR

5-3.1

STEERING AND RADIATOR

NO PART NO PART NAME QTY. REMARKS

1 AVL922903 HOSE 1

2 AVL922904 HOSE 1

3 AVL494969 HOSE 1

4 AVL922896 HOSE

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 89

Page 90

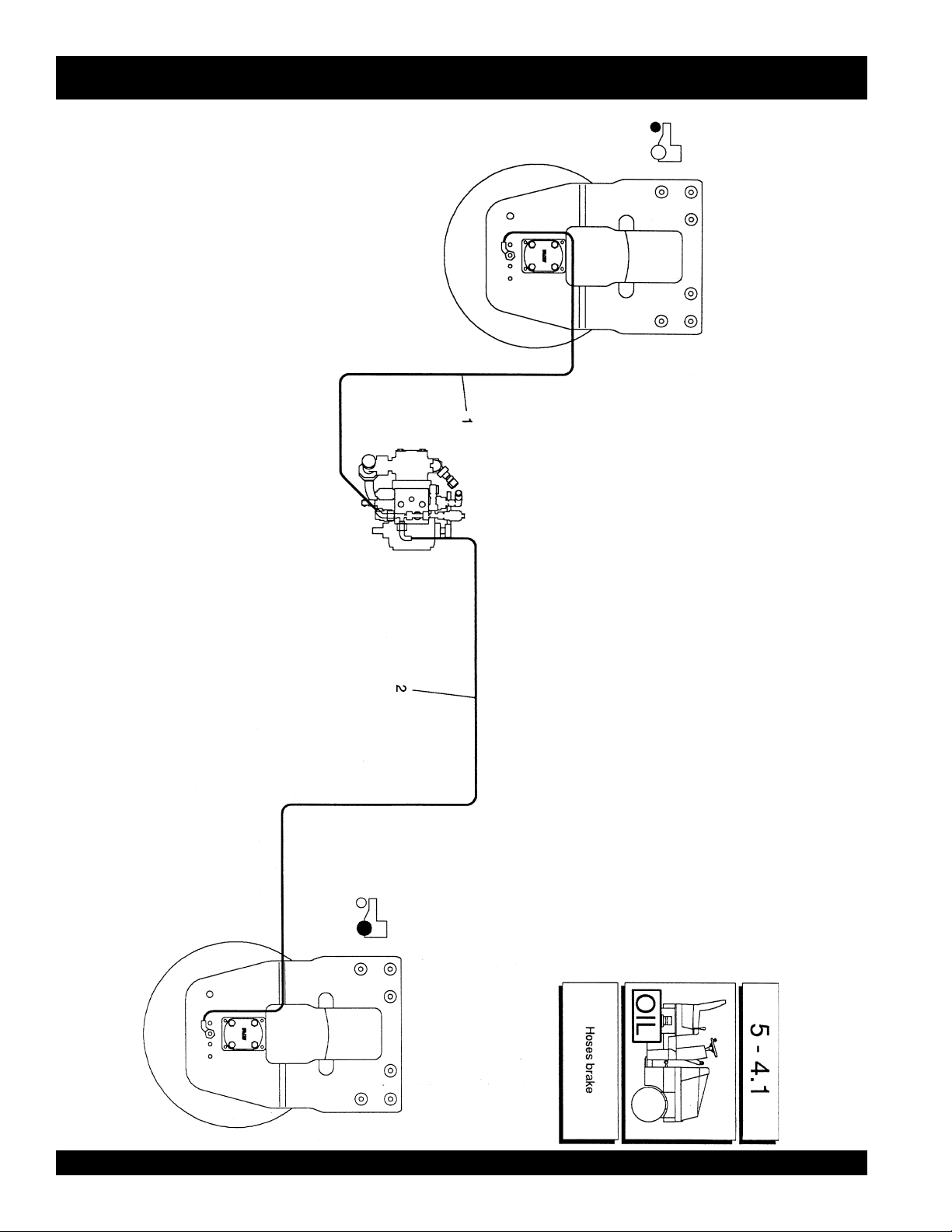

HOSES BRAKE

PAGE 90 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 91

5-4.1

HOSES BRAKE

NO PART NO PART NAME QTY. REMARKS

1 AVL923728 HOSE 1

2 AVL923727 HOSE 1

HOSES BRAKE

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 91

Page 92

HOSES VIBRATION

PAGE 92 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 93

5-5.1

HOSES VIBRATION

NO PART NO PART NAME QTY. REMARKS

1 AVL491461 VIBRATION CONTROL VALVE 1

1.1 AVL921250 MAGNET COIL 1

1.2 AVL3000100260 VALVE 1

1.3 AVL921506 WAY-VALVE 1

1.4 AVL921505 SEAL-KIT 1

1.5 AVL921504 SEAL-KIT 1

1.6 AVL921507 NUT HEX. 1

1.7 AVL921772 VALVE 1

2 AVL901064 REDUCER 2

3 AVL901250 REDUCER 1

5 AVL901863 SCREW HEX. HD 2

11 AVL495047 HOSE 1

21 AVL922926 HOSE 1

23 AVL923746 HOSE 1

24 AVL923742 HOSE 1

25 AVL923744 HOSE 1

HOSES VIBRATION

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 93

Page 94

HOSES VARIOUS

PAGE 94 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 95

5-6.1

HOSES VARIOUS

NO PART NO PART NAME QTY. REMARKS

1 AVL922913 HOSE 1

HOSES VARIOUS

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 95

Page 96

REVERSING

PAGE 96 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 97

6-0.2

REVRSING

NO PART NO PART NAME QTY. REMARKS

1 AVL491401 SWITCH 1

2 AVL824534 CONTROL PIECE GEAR 1

5 AVL901755 SCREW HEX. HEAD 2

6 AVL902794 CHEESE HEAD SCREW 2

7 AVL902262 WASHER 2

10 AVL824417 WIRING HARNESS 1

10.1 AVL912430 CONNECTOR HOUSING 1

10.2 AVL912428 CONNECTOR HOUSING 1

10.3 AVL912424 CONNECTOR HOUSING 1

REVERSING

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 97

Page 98

SPRINKLER, VIBRATION VALVE

PAGE 98 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Page 99

SPRINKLER, VIBRATION VALVE

6-0.4

SPRINKLER, VIBRATION VALVE

NO PART NO PART NAME QTY. REMARKS

1 AVL365848 WIRING HARNESS 1

1.1 AVL912431 CONNECTOR HOUSING 1

1.2 AVL912424 CONNECTOR HOUSING 2

1.3 AVL910769 CABLE BOX 5

1.4 AVL912582 DIODE 3

2 AVL803735 CONNCTION CABLE 2

2.2 AVL912428 CONNECTOR HOUSING 2

3 AVL491917 HORN 1

4 AVL910771 GASKET FOR CABLE BOX 5

5 AVL592050 HOSE 1

TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01) — PAGE 99

Page 100

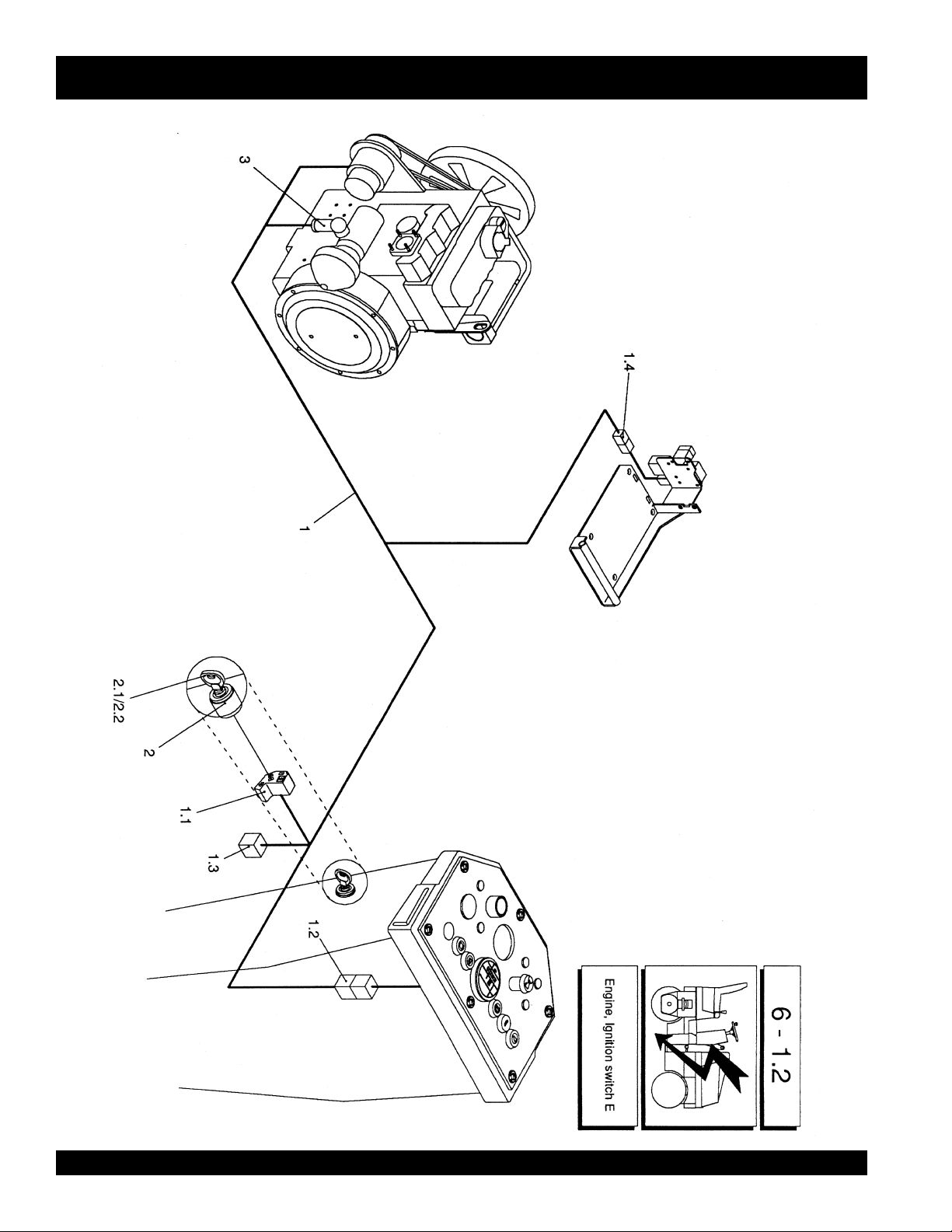

ENGINE, IGNITION SWITCH

PAGE 100 — TANDEM ROLLER: T16 — PARTS & OPERATION MANUAL — REV. #2 (03/12/01)

Loading...

Loading...