Page 1

OPERATION MANUAL

SERIES

STX RIDE-ON POWER TROWELSTX RIDE-ON POWER TROWEL

STX RIDE-ON POWER TROWEL

STX RIDE-ON POWER TROWELSTX RIDE-ON POWER TROWEL

STX55Y6STX55Y6

STX55Y6

STX55Y6STX55Y6

(YANMAR DIESEL ENGINE)

Revision #0 (03/15/06)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

P/N 21901

Page 2

Page 3

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials can generate

dust, mists and fumes containing chemicals known to cause serious or fatal injury or

illness, such as respiratory disease, cancer, birth defects or other reproductive harm.

If you are unfamiliar with the risks associated with the particular process and/or

material being cut or the composition of the tool being used, review the material

safety data sheet and/or consult your employer, the material manufacturer/supplier,

governmental agencies such as OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for instance, have published lists of

substances known to cause cancer, reproductive toxicity, or other harmful effects.

Control dust, mist and fumes at the source where possible. In this regard use good

work practices and follow the recommendations of the manufacturers/suppliers,

OSHA/NIOSH, and occupational and trade associations. Water should be used for

dust suppression when wet cutting is feasible. When the hazards from inhalation of

dust, mists and fumes cannot be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for the materials being used.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in

their composition may give off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and numerous other minerals

and rocks. Repeated and/or substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including silicosis. In addition, California

and some other authorities have listed respirable crystalline silica as a substance

known to cause cancer. When cutting such materials, always follow the respiratory

precautions mentioned above.

Page 4

NOTE PAGE

Page 5

STX-SERIES — HERE'S HOW TO GET HELP

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER

MULTIQUIP CORPORATE OFFICE

18910 Wilmington Ave. 800-421-1244

Carson, CA 90746

Email: mq@multiquip.com

Internet: www.multiquip.com

PARTS DEPARTMENT

800-427-1244

310-537-3700

MAYCO PARTS

800-306-2926

310-537-3700

SERVICE DEPARTMENT

800-421-1244

310-537-3700

TECHNICAL ASSISTANCE

800-478-1244

WARRANTY DEPARTMENT

800-421-1244,

310-537-3700,

ON-HAND

EXT.

279

EXT.

279

WHEN CALLING

FAX:

310-537-3927

FAX:

800-672-7877

FAX:

310-637-3284

FAX:

800-672-7877

FAX:

310-637-3284

FAX:

310-537-4259

FAX:

310-631-5032

FAX:

310-537-1173

© COPYRIGHT 2006, MULTIQUIP INC.

Multiquip Inc, the MQ logo and the Whiteman logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or

altered without written permission. All other trademarks are the property of their respective owners and are used with permission.

This manual

remain with the unit if resold.

The information and specifications included in this publication were in effect at the time of approval for printing. Illustrations are

based on the

manual are for guidance only and may not be considered as binding. Multiquip Inc. reserves the right to discontinue or change

specifications, design or the information published in this publication at any time without notice and without incurring any obligations.

MUST accompany the equipment at all times. This manual is considered a permanent part of the equipment and should

MQWhiteman Series STX Ride-On Trowel.

Illustrations, descriptions, references and technical data contained in this

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 5

/02) — PAGE 5

Page 6

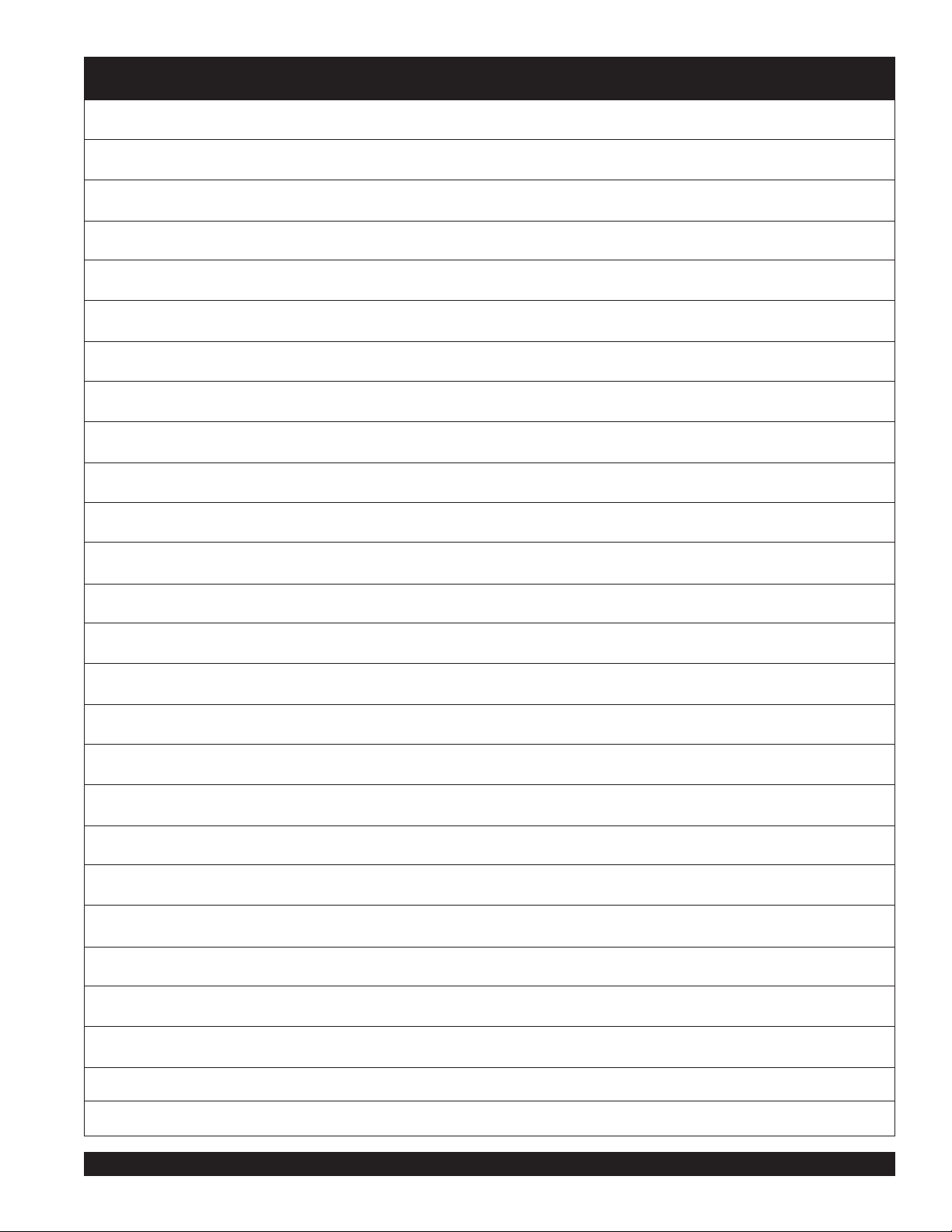

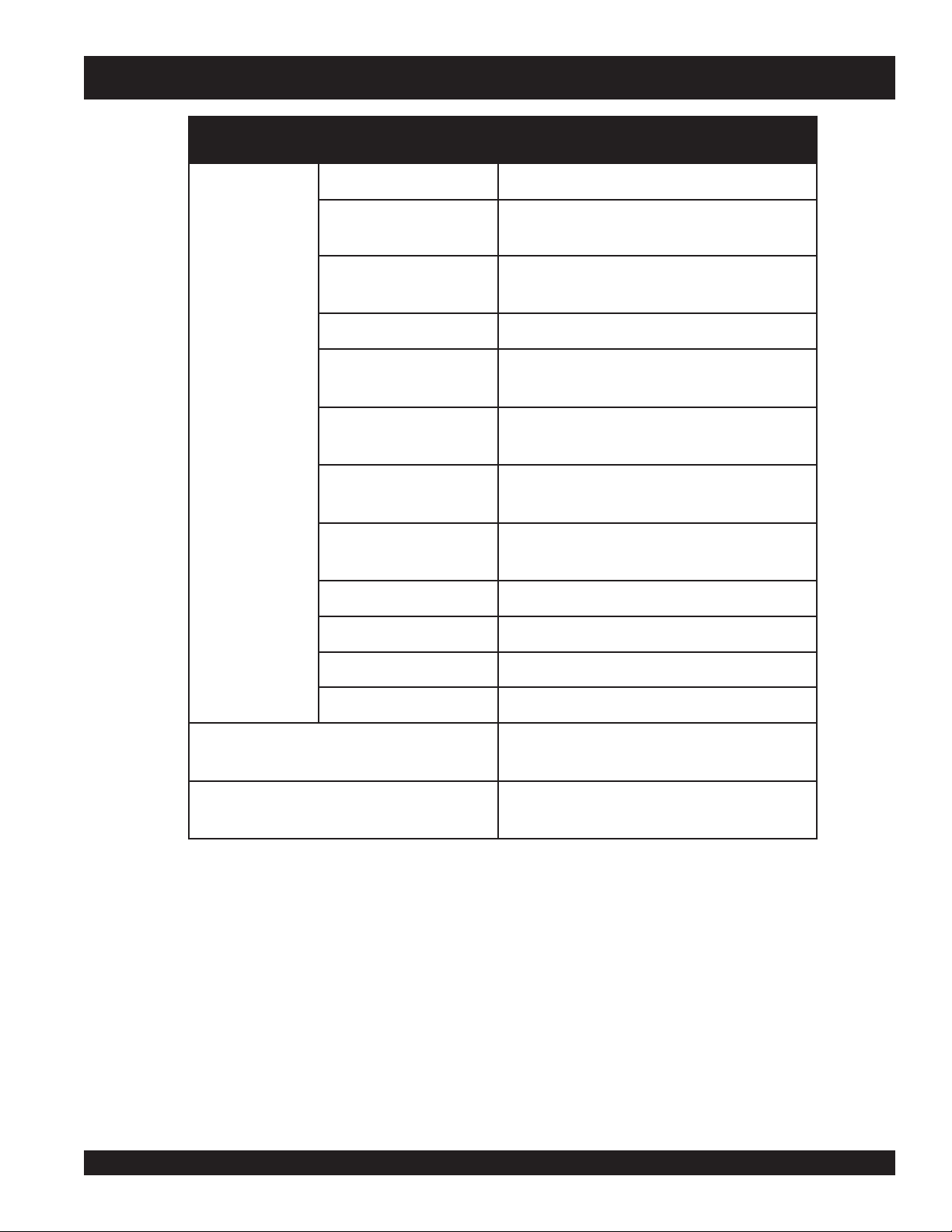

STX-SERIES — TABLE OF CONTENTS

Technical Assistance ............................................... 5

Table of Contents .................................................... 6

Parts Ordering......................................................... 7

Dimensions ............................................................. 8

Specifications .......................................................... 9

Training Checklist .................................................. 10

Daily Pre-Operation Checklist ............................... 11

Safety Message Alert Symbols ........................ 12-13

Rules For Safe Operation ................................ 14-17

Intended Use and General Information ................ 18

Operation And Safety Decals ................................ 19

MQ WHITEMAN — STX-SERIES

RIDE-ON POWER TROWEL

(YANMAR ENGINE)

Controls and Indicators .................................... 20-21

Basic Engine Information ...................................... 22

Trowel Set-Up........................................................ 23

Pre-Inspection ....................................................... 24

Initial Start-Up .................................................. 25-26

Operation ......................................................... 27-29

Maintenance .................................................... 30-43

Troubleshooting ............................................... 44-45

Terms and Conditions of Sale ............................... 47

NOTE

PAGE 6 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

Specifications are subject to

change without notice.

)

Page 7

Effective: June 1st, 2005

Ordering parts has never been easier!

PARTS ORDERING PROCEDURES

Choose from three easy options:

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■

View Parts Diagrams

■

Order Parts

■

Print Specification Information

Goto www.multiquip.com and click on

Order Par ts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

If you have an MQ Account, to obtain a

Username and Password, E-mail us at:

parts@multiquip.com.

To obtain an MQ Account, contact your

District Sales Manager for more information.

Use the

internet

on

Standard orders

complete part numbers.*

Fax

your order in and qualify for a 3% Discount

on

Standard orders

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

and qualify for a 5% Discount

for all orders which include

for all orders which include

International Customers

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

should contact

When ordering parts, please supply:

❒❒

❒

Dealer Account Number

❒❒

❒❒

❒

Dealer Name and Address

❒❒

❒❒

❒

Shipping Address (if different than billing address)

❒❒

❒❒

❒

Return Fax Number

❒❒

❒❒

❒

Applicable Model Number

❒❒

❒❒

❒

Quantity, Part Number and Description of Each Part

❒❒

NOTE

www.multiquip.com

Unless otherwise indicated by customer, all orders are treated as

within 24 hours. We will make every effort to ship

if received prior to 2PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 7

❒❒

❒

Specify Preferred Method of Shipment:

❒❒

✓

Fed Ex/UPS

■

■

■

■

Stock Orders

✓ DHL

Priority One

Ground

Next Day

Second/Third Day

✓

Tr u ck

Standard Orders

Air Shipments

must be noted on fax or web order form.

the same day the order is received,

and will ship

/02) — PAGE 7

Page 8

C-HEIGHT

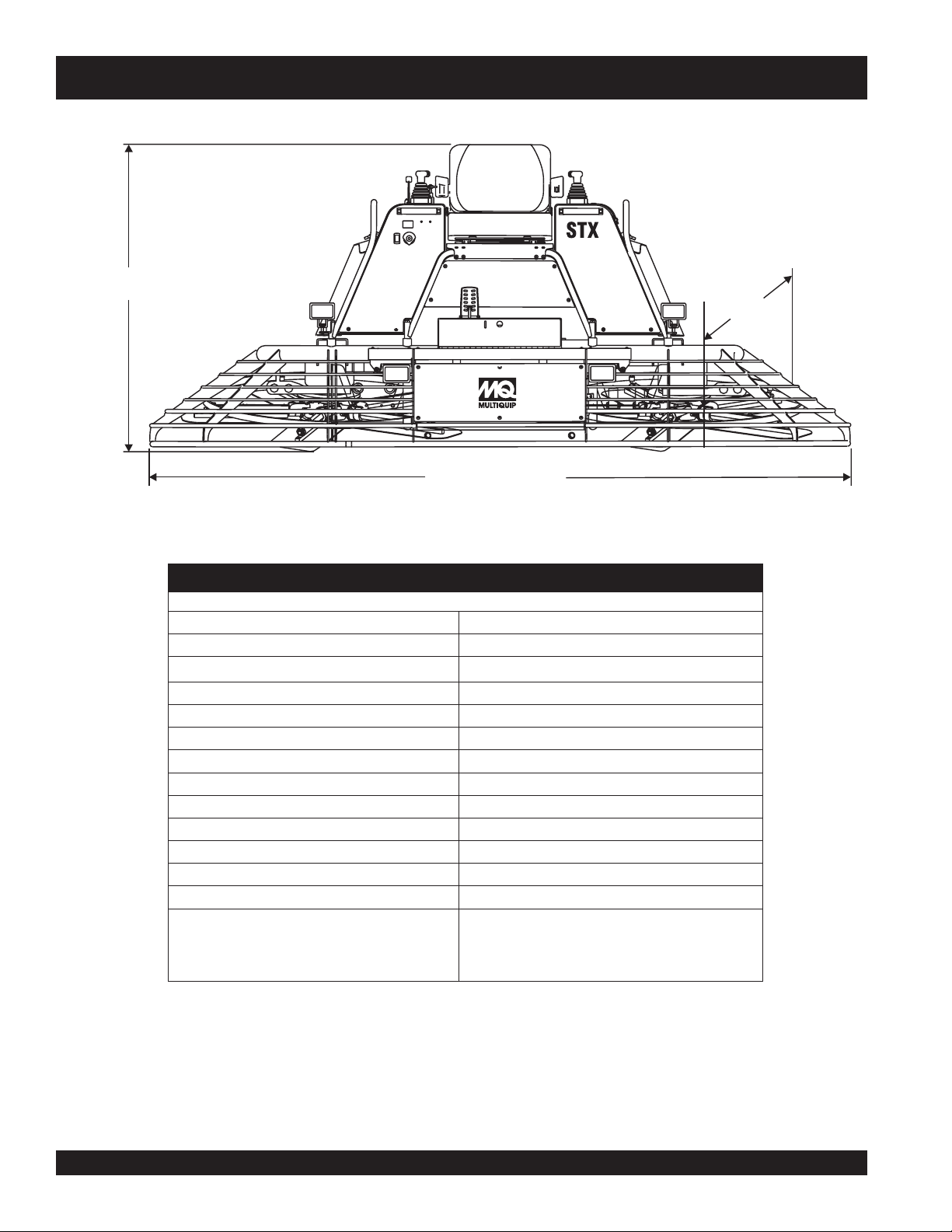

STX-SERIES — DIMENSIONS

B-WIDTH

A-LENGTH

s/tf–noitarbiV

.P.H 55

SEE NOTES NEXT PAGE

)mc(.ni–htgneL–A )813(521

)mc(.ni–htdiW–B )561(0.56

1

)mc(.ni–thgieH–C

gnitarepO).sgk(.sbl–thgieW )909(000,2

gnippihS).sgk(.sbl–thgieW )7311(0052

2

ABd–erusserPdnuoS

2

2)3

s/m(

)s/m(MPF–deepSpiTedalB )9.9(4291

enignE degrahcobruTleseiDramnaYT48VNT4

)sretil(snollag–knaTleuF )24(11

MPR–rotoR 031ot0

)mc(.ni–htdiWhtaP )792(711

4

liOciluardyH

snoitacificepS)6Y55XTS(seireS-XTS.1elbaT

)241(0.65

79

)5.2(0.8<

4

86VMWA

)rehtaewtoh04-W01(

)rehtaewdloc03-W01(

PAGE 8 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 9

STX-SERIES — SPECIFICATIONS

ledoMT48VNT4RAMNAY

)enignE(snoitacificepS.2elbaT

epyT

ekortSXeroB

degrahcobrut-detcejnitcerid

.ni5.3x.ni3.3

)mm09xmm48(

-enigneleseiddeloocretawenilnilacitreV

tnemecalpsiD)L599.1(.ni-uc7.121

1-

tuptuOxaM

enignE

yticapaCknaTleuF

leuF

nim/Wk2.14(phb55

1-

nim0123@

)sretiL46.14(

ylnOleuFleseiD

metsySgnilooC

)SP65,

snollaG.S.U11.xorppA

retaergro54rebmunleufenateC

)rotaidaR(deloocretaW

)05/05oitarezeerfitna-retaW(

metsySgnitacirbuLpmupdiohcorthtiwnoitacirbuldecroF

yticapaCliOebuLtimilreppukcitspid)retil4.7(tqSU28.7

noitisoPO.T.PedisleehwylF

dohteMgnitratSgnitratScirtcelE

noisnemiD

)HxWxL(

thgieWteN

)gnisuoHleehwylFhtiWyrD(

NOTE:

1. This value includes the seat height.

2. Sound pressure is a weighted measure. Measured at the

operators ear position while the ride-on trowel is operating

at full throttle on concrete in a manner most often

experienced in “

may vary depending upon the condition of the concrete.

Hearing protection is always recommended.

3. The vibration level indicated is the maximum RMS (Root

Mean Square) value obtained at the handle grip while

operating the ride-on trowel on curing concrete in a manner

normal

” circumstances. Sound pressure

most often experienced in “

were obtained from all three axes of motion. The values

shown represent the maximum RMS value from these

measurements.

4. “AW” stands for

viscosity

is similar to 10W-30-motor oil. It is recommended that AW

MV 68 hydraulic oil be used. If this type of hydraulic oil is

not available then use 10W-30 engine oil (cold weather)

or 10W-40 engine oil (hot weather).

.ni1.82x6.91x6.52)MV(

)mm317x5.894x946(

).gK381(sbl5.304)LC(

).gK071(sbl573)MV(

normal

anti-wear

. The 68 refers to the general viscosity range and

” circumstances. Values

and “MV” stands for

multi-

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 9

/02) — PAGE 9

Page 10

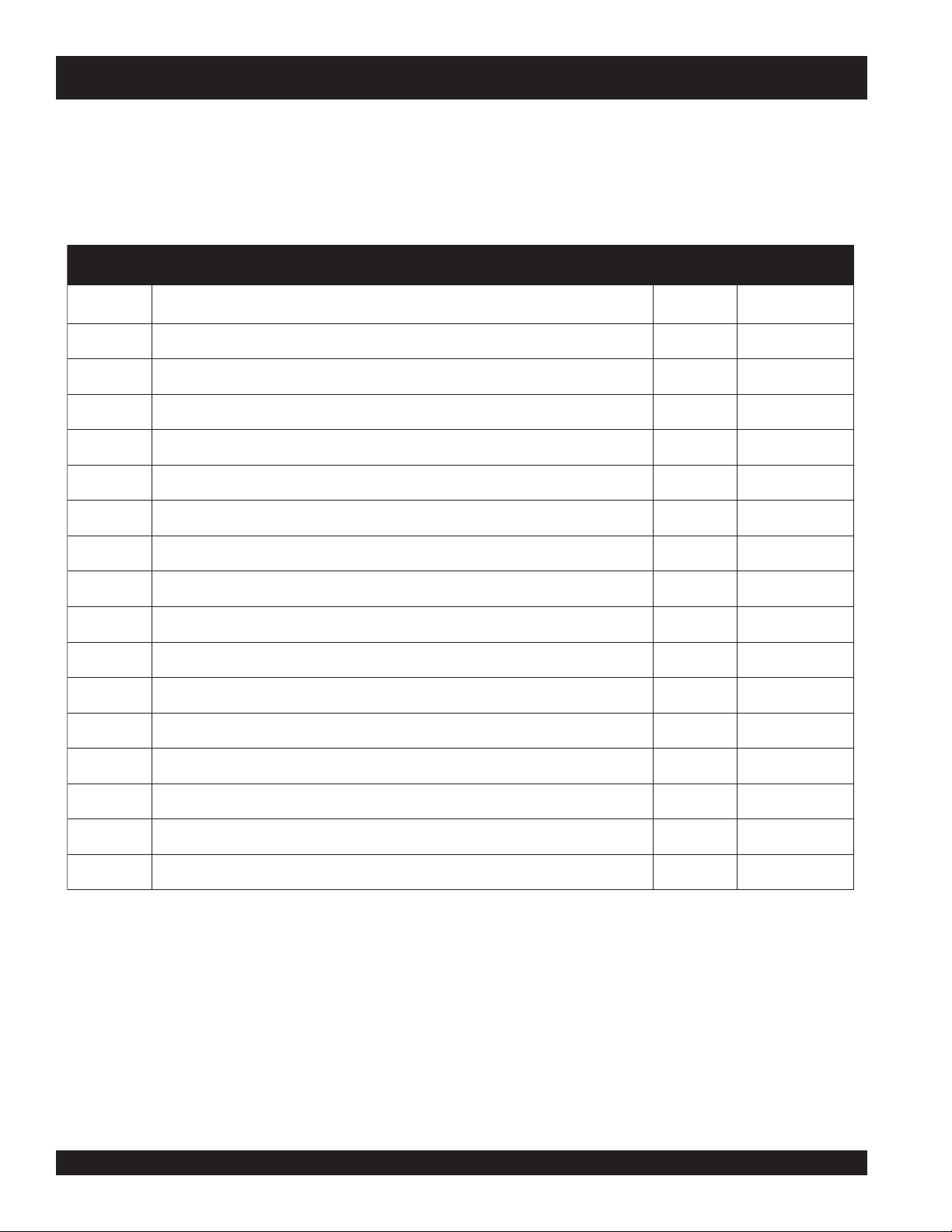

STX-SERIES — TRAINING CHECKLIST

TRAINING CHECKLIST

This checklist lists the minimum requirements for machine

maintenance and operation. Please feel free to detach it and

make copies. Use this checklist when training a new operator or

use as a review for more experienced operators.

.ON NOITPIRCSED ?KO ETAD

1 .yletelpmoclaunaMs’rotarepOdaeR

2 .slevelliociluardyhdnaenignefognikcehc,stnenopmocfonoitacol,tuoyalenihcaM

3 .erudecorpgnileufer,metsysleuF

4 .sthgildnayarpsfonoitarepO

5 .)gninnurtonenihcam(slortnocfonoitarepO

6 .noitarepohctiwspotsytefas,slortnocytefaS

TSILKCEHCGNINIART

7 .serudecorppotsycnegremE

8 .ekohcenigne,taeh-erp,enihcamfoputratS

9 .revohagniniatniaM

01 .gnirevuenaM

11 .gnihctiP

21 ™hctiP-niwT.hctipedalbgnihctaM

31 .seuqinhcetgnihsinifetercnoC

41 .enihcamfonwodtuhS

51 .)spooltfil(enihcamfognitfiL

61 .egarotsdnatropsnartenihcaM

Operator _________________________________________ Trainee __________________________________________

COMMENTS:

PAGE 10 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 11

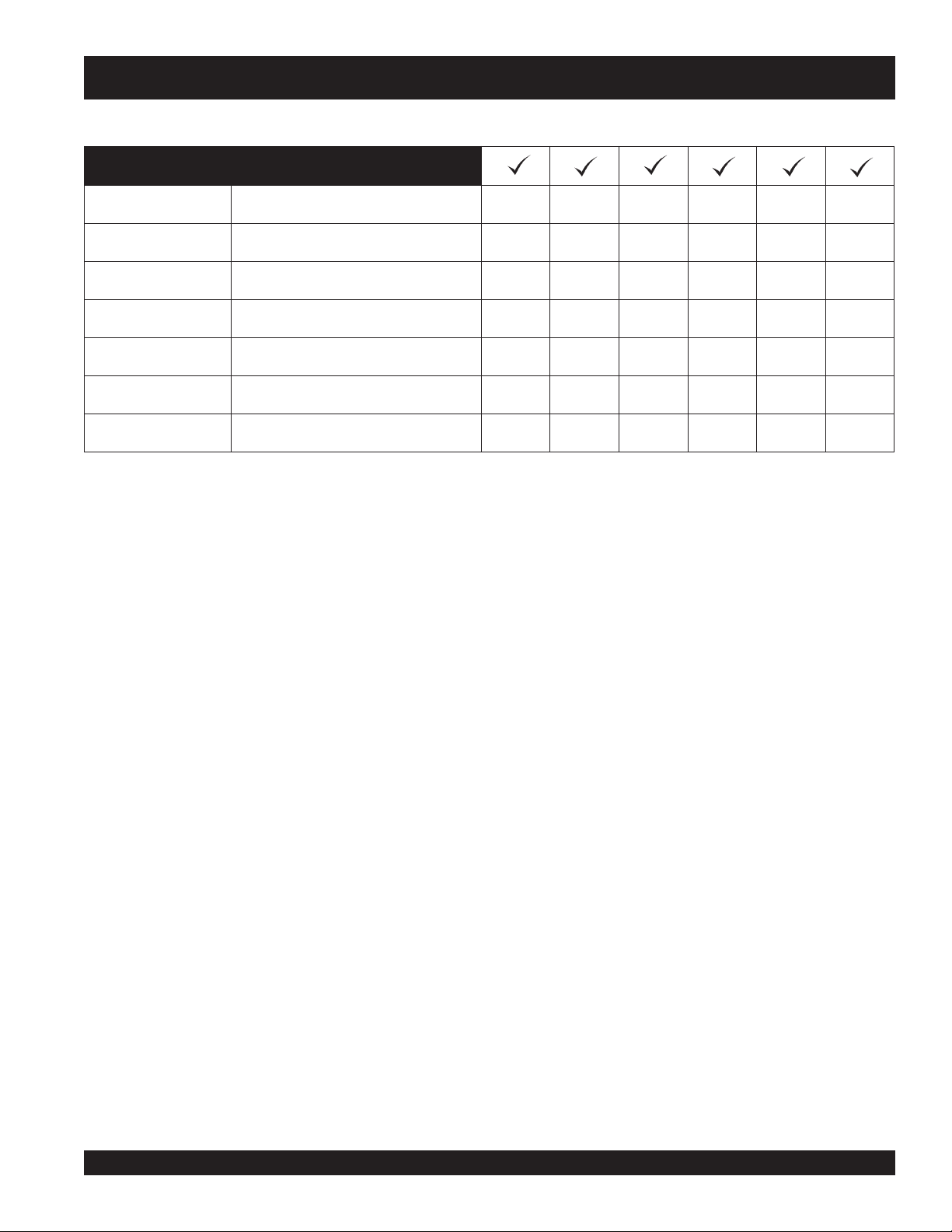

STX-SERIES — DAILY PRE-OPERATION CHECKLIST

DAILY PRE-OPERATION CHECKLIST

1 .levellioenignE

2 .levelliociluardyH

3 .leveltnaloocrotaidaR

4 .sedalbfonoitidnoC

5 pohctipedalBnoitare.

TSILKCEHCNOITAREPO-ERPYLIAD

6 efaS

7 .noitarepolortnocgnireetS

COMMENTS:

t

.noitarepohctiwSpotSy

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 11

/02) — PAGE 11

Page 12

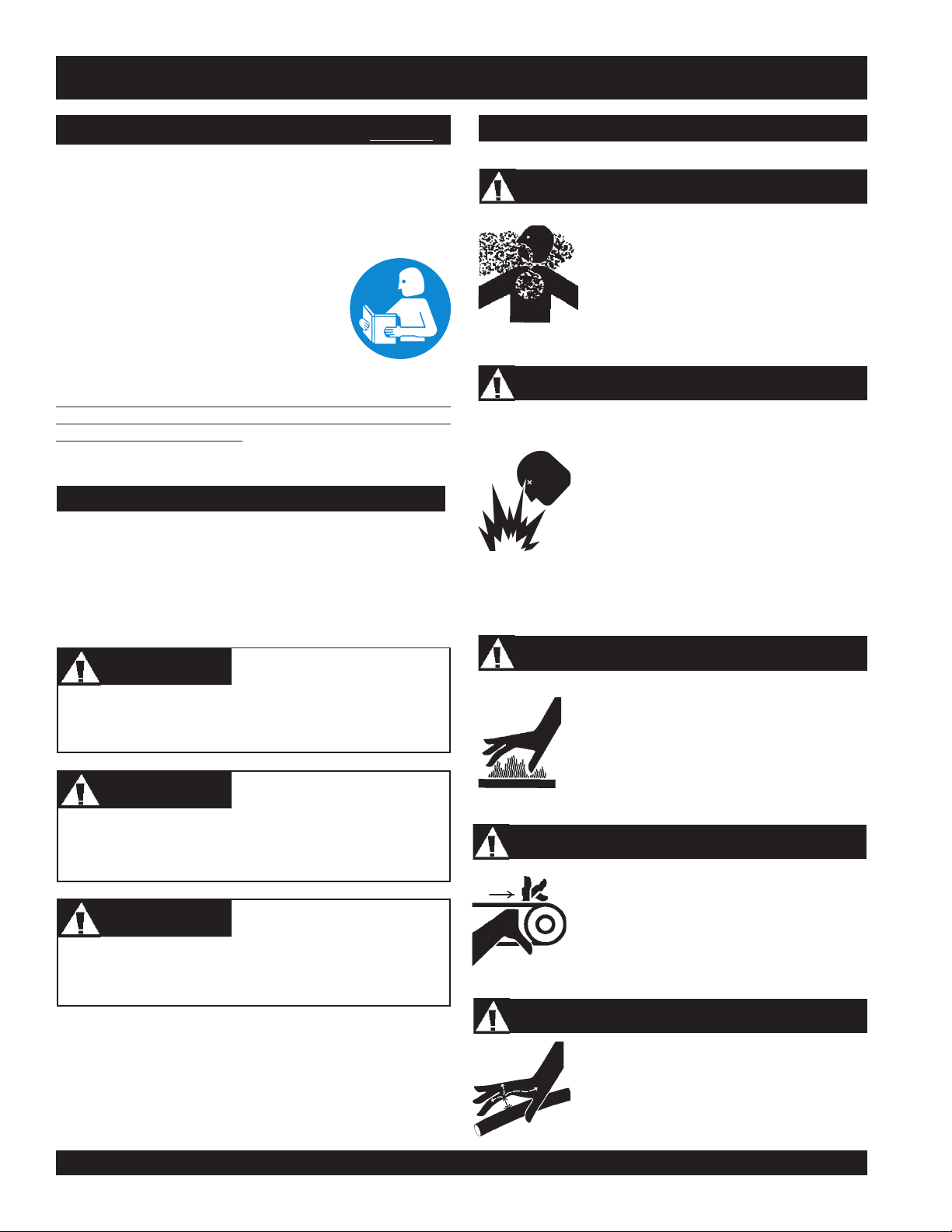

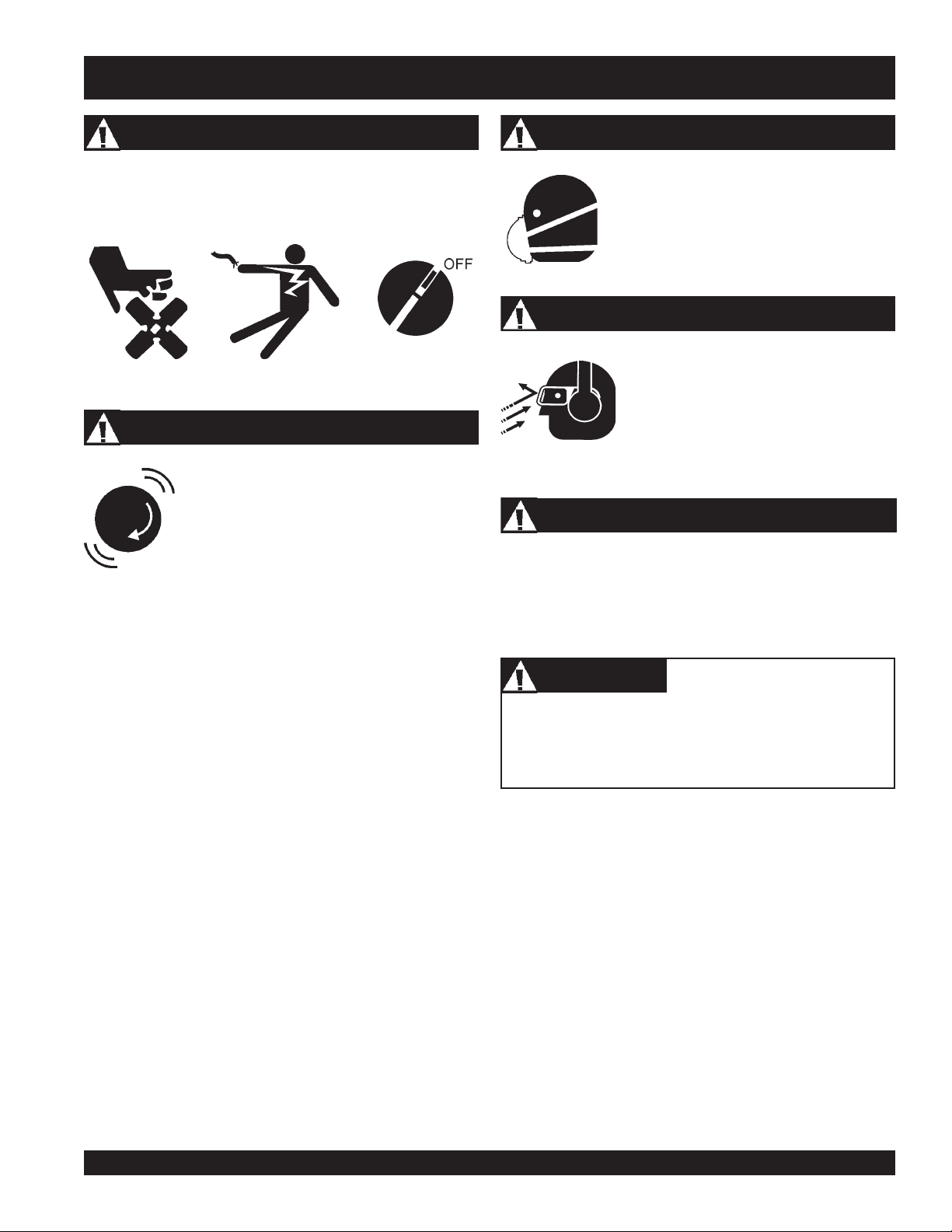

STX-SERIES — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when

operating this equipment. Failure to read, understand and

comply with the Safety Messages and Operating Instructions

could result in injury to yourself and others.

This Operation Manual has been

developed to provide instructions for the

safe and efficient operation of the Whiteman

Series STX Ride-On Trowel. For engine

maintenance information, please refer to the

engine manufacturer's instructions for data

relative to its safe operation.

Before using this Ride-On Trowel, ensure that the operating

individual has read, understands, and complies with all

instructions in this manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

HAZARD SYMBOLS

Lethal Exhaust Gases

Engine exhaust gases contain poisonous

carbon monoxide. This gas is colorless and

odorless, and can cause death if inhaled.

NEVER operate this equipment in a confined

area or enclosed structure that does not

provide ample free flow air.

Explosive Fuel

Diesel fuel is flammable, and its vapors can

cause an explosion if ignited. DO NOT start

the engine near spilled fuel or combustible

fluids. DO NOT fill the fuel tank while the

engine is running or hot. DO NOT overfill

tank, since spilled fuel could ignite if it comes

into contact with hot engine parts or sparks

from the ignition system. Store fuel in

approved containers, in well-ventilated areas

and away from sparks and flames. NEVER

use fuel as a cleaning agent.

DANGERDANGER

DANGER

DANGERDANGER

You WILL be

if you DO NOT follow these directions.

WARNINGWARNING

WARNING

WARNINGWARNING

You CAN be KILLED or

you DO NOT follow these directions.

CAUTICAUTI

CAUTION

CAUTICAUTI

You CAN be

these directions.

Potential hazards associated with trowel operation will be

referenced with Hazard Symbols which appear throughout this

manual, and will be referenced in conjunction with Safety

Message Alert Symbols.

KILLED

INJURED

or

SERIOUSLY INJURED

SERIOUSLY INJURED

if you DO NOT follow

if

Burn Hazards

Engine components can generate extreme heat.

To prevent burns, DO NOT touch these areas

while the engine is running or immediately after

operations. NEVER operate the engine with

heat shields or heat guards removed.

Rotating Parts

NEVER operate equipment with covers, or

guards removed. Keep

and

clothing

prevent injury.

Skin Injection Hazard

NEVER use your hand to find hydraulic leaks.

Use a piece of wood or cardboard. Hydraulic

fluid injected into the skin must be treated by

a knowledgable physician immediately or

severe injury or death can occur.

away from all moving parts to

fingers, hands, hair

PAGE 12 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 13

STX-SERIES — SAFETY MESSAGE ALERT SYMBOLS

Accidental Starting Respiratory Hazard

Accidental starts can cause severe injury or death. ALWAYS

place the ON/OFF switch in the OFF position. Disconnect and

ground spark plug lead and disconnect negative battery cable

from battery before servicing.

Over Speed Conditions

NEVER tamper with the factory settings of the

engine governor or settings. Personal injury

and damage to the engine or equipment can

result if operating in speed ranges above

maximum allowable.

Other important messages are provided throughout this manual

to help prevent damage to your trowel, other property, or the

surrounding environment.

ALWAYS wear approved respiratory

protection.

Sight and Hearing hazard

ALWAYS wear approved eye and hearing

protection.

Equipment Damage Messages

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

This

Ride-On trowel

surrounding environment could be damaged if you do

not follow instructions.

, other property, or the

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 13

/02) — PAGE 13

Page 14

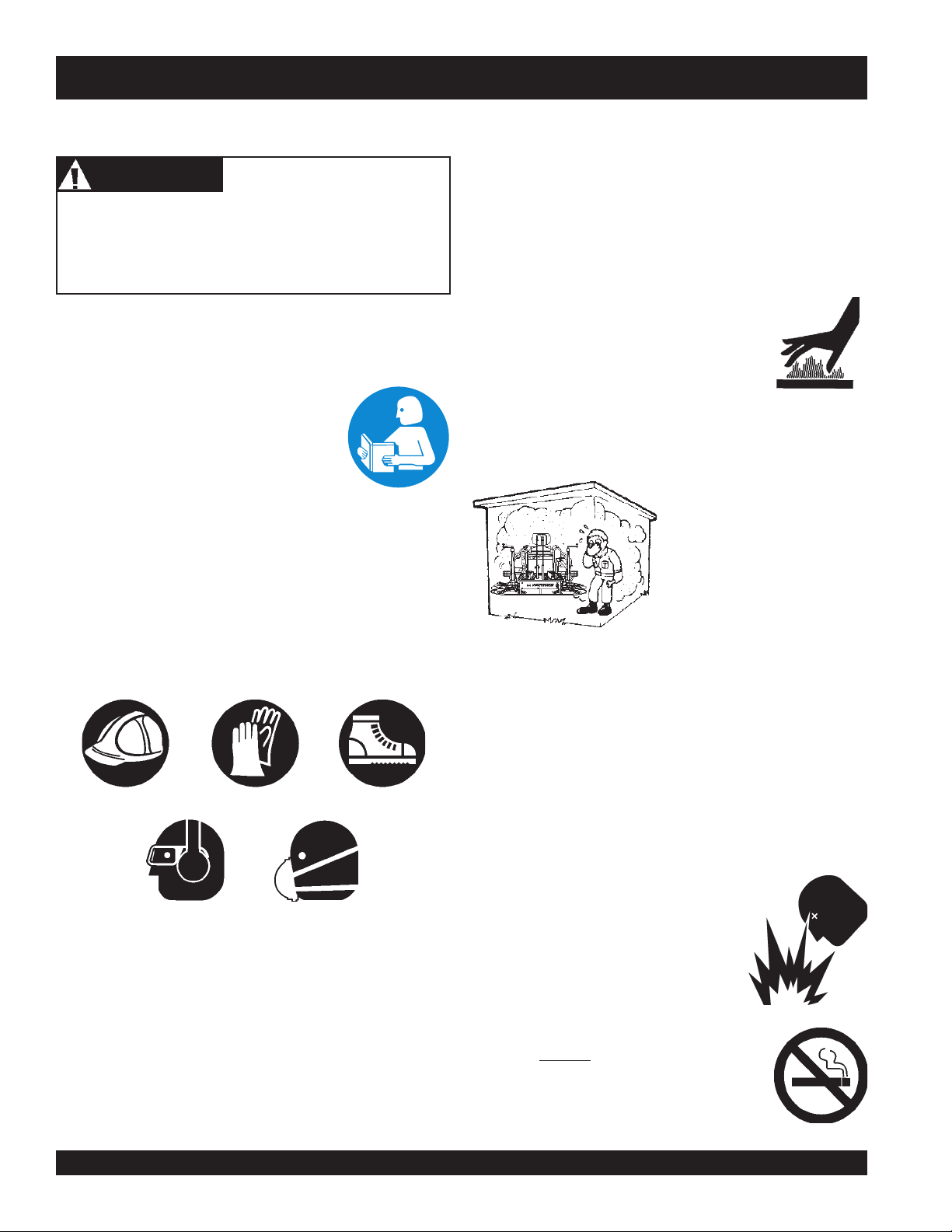

STX-SERIES — RULES FOR SAFE OPERATION

■

RULES FOR SAFE OPERATION

WARNINGWARNING

WARNING

WARNINGWARNING

Failure to follow instructions in this manual may lead to serious

injury or even death! This equipment is to be operated by

trained and qualified personnel only! This equipment is for

industrial use only.

The following safety guidelines should always be used when

operating the STX-SERIES Ride-On Trowel.

SAFETY

■

DO NOT operate or service this

equipment before you read, understand,

and comply with all safety messages in

this manual. The manual must be kept

available and accessible to the operator.

■

This equipment should not be operated by persons under the

minimum statutory age limit.

■

NEVER use this machine for any purpose other than those

described in this manual.

■

NEVER operate the trowel without proper protective clothing,

shatterproof glasses, steel-toed boots and other protective

devices required for the job.

NEVER operate this equipment when not feeling well due to

fatigue, illness or taking medicine.

■

NEVER operate the trowel under the influence of drugs or

alcohol.

■

Replace nameplate, operation and safety decals when they

become difficult to read.

■

ALWAYS check the trowel for loosened hardware such as

nuts and bolts before starting.

■

NEVER touch the hot exhaust manifold, muffler

or cylinder. Allow these parts to cool before

servicing the trowel. Contact with

components can cause serious burns.

■

The engine of this trowel requires an adequate free flow of

cooling air. NEVER operate the trowel in any enclosed or

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

hot!

narrow area where free flow of

the air is restricted. If the air flow

is restricted it will cause serious

damage to the engine and may

cause injury to people.

Remember the engine gives off

DEADLY

gas.

carbon monoxide

■

■

■

■

■

NEVER use accessories or attachments which are not

recommended by the manufacturer for this equipment.

Damage to the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications. Unauthorized equipment

modification will void all warranties. Any modification which

could lead to a change in the original characteristics of the

machine should be made only by the manufacturer who shall

confirm that the machine is in conformity with appropriate

safety regulations.

PAGE 14 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

■

Topping-off to filler port is dangerous, as it tends to spill fuel.

NEVER use fuel as a cleaning agent.

ALWAYS use extreme caution when working with flammable

liquids. When refueling, STOP the engine. Allow the engine

to cool before adding fuel or performing service and

maintenance functions.

NEVER operate the trowel in an

explosive atmosphere where fumes

are present, or near combustible

materials. An explosion or fire could

result in severe

death.

NEVER

Fire or explosion could result from

vapors

smoke

, or if fuel is spilled on a

bodily harm or even

around or near the machine.

fuel

hot!

engine.

)

Page 15

STX-SERIES — RULES FOR SAFE OPERATION

■

NEVER run engine without air filter. Severe engine damage

may occur. Service air filter frequently to prevent carburetor

malfunction.

■

NEVER place your

while starting or operating this equipment.

■

AVOID wearing jewelry or loose fitting clothing that may snag

on the controls or moving parts as this can cause a serious

injury.

■

ALWAYS keep clear of

operating the trowel.

■

Moving Parts – Shut down the engine before performing

service or maintenance functions. Contact with moving parts

can cause serious injury.

■

ALWAYS check to make sure that the operating area is clear

before starting the engine.

■

NEVER leave the machine

■

ALWAYS be sure the operator is familiar with proper safety

precautions and operations techniques before using trowel.

feet

or

rotating

hands

inside the guard rings

or

moving parts

unattended

while running.

while

Additional Safety Information

A handy safety manual for operating and maintenance personnel

of concrete power trowels produced by the Association of

Equipment Manufacturers (AEM)

can be obtained for a fee by

ordering through their website at

www.aem.org.

Order FORM PT-160.

DANGERDANGER

DANGER

DANGERDANGER

Pay close attention to ventilation when

operating the trowel in confined spaces

such as tunnels, buildings or similar areas.

The engine exhaust contains harmful

elements. Ensure proper air flow to move

engine exhaust away from the operator.

■

ALWAYS keep the work area well organized.

■

ALWAYS clear the work area of any debris, tools, etc. that

would constitute a hazard while the trowel is in operation.

WARNINGWARNING

WARNING

WARNINGWARNING

ALWAYS check to make sure that the operating area is

clear before starting the engine.

■

No one other than the operator is to be in the working area

when the trowel is in operation.

■

NEVER allow passengers or riders on the trowel during

operation.

■

Always observe all applicable compulsory regulations

relevant to environmental protection, especially, fuel storage,

the handling of hazardous substances, and the wearing of

protective clothing and equipment. Instruct the user as

necessary, or as the user, request this information and

training.

■

ALWAYS store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of

the reach of children.

Lifting the Ride-On Trowel

The STX-SERIES Ride-On Power Trowel is designed to be

moved and handled several ways.

The easiest way to lift the trowel is to utilize the lift loops that are

welded to the frame. These lift loops are located to the left and

right sides of the operator’s seat.

A strap or chain can be attached to these lift loops, allowing a

forklift or crane to lift the trowel up onto and off of a slab of concrete.

The strap or chain should have a minimum 2,000 pounds (1000kg) lifting capacity and the lifting gear must be capable of lifting

at least this amount.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

heavy

This ride-on trowel is very

around. Use proper heavy lifting procedures and DO NOT

attempt to lift the ride-on trowel by the guard rings.

DANGERDANGER

DANGER

DANGERDANGER

and awkward to move

NEVER stand under or allow anyone

else to stand under the trowel while it

is being lifted.

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 15

/02) — PAGE 15

Page 16

STX-SERIES — RULES FOR SAFE OPERATION

Transporting

■

ALWAYS shutdown engine before transporting.

■

Tighten fuel tank cap securely and close fuel petcock to

prevent fuel from spilling.

■

Drain fuel when transporting trowel for long distances or over

bad roads.

■

When placing the trowel on a truck-bed for transport,

tie-down the trowel.

■

If the trowel is being transported via a trailer, make sure the

trailer complies with all local and state safety transportation

laws. Refer to the following "

for basic towing techniques.

Towing Safety Precautions"

always

■

■

■

■

■

■

■

Use chock-blocks at each wheel when parked to prevent

trailer from rolling.

Use the trailer's swivel jack to adjust the trailer height to a

level position while parked.

Avoid sudden stops and starts. This can cause the trailer to

skid or jack-knife. Smooth, gradual starts and stops will

improve towing.

Avoid sharp turns.

Trailer should be adjusted to a level position at all times

when towing.

Raise and lock trailer wheel stand in the "UP" position when

transporting.

DOT requirements include the following:

Towing Safety Precautions

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Conform to

Towing Regulations

roads.

To reduce the possibility of an accident while transporting the

trowel on public roads, always make sure the trailer that supports

the trowel and the towing vehicle are in good operating condition

and both units are mechanically sound.

The following list of suggestions should be used when towing

your trowel:

■

Make sure the hitch and coupling of the towing vehicle are

rated equal to, or greater than the trailer "gross vehicle weight

rating" (GVWR) of 6,000 lbs.

■

ALWAYS inspect the hitch and coupling for wear. NEVER

tow a trailer with defective hitches, couplings, chains, etc.

■

Check the tire air pressure on both towing vehicle and trailer.

Trailer tires should be inflated to 50 psi cold

the tire tread wear on both vehicles.

■

ALWAYS make sure the trailer is equipped with "Safety

Chains ".

■

ALWAYS attach trailer's safety chains to towing vehicle

properly.

■

ALWAYS make sure the vehicle and trailer directional,

backup, brake, and trailer lights are connected and working

■

DO NOT exceed the recommended highway speed when

towing. Unless posted otherwise, do not exceed 45 MPH

highway, and 10 MPH off-road.

Department of Transportation (DOT) Safety

before transporting trowel on public

. Also check

Connect and test electric brake operation.

Secure portable power cables in cable tray with tie wraps.

Battery

The battery contains acids that can cause injury to the eyes and

skin. To avoid eye irritation,

shielding. Use well insulated gloves when picking the battery

up. Use the following guidelines when handling the battery.

■

DO NOT drop the battery. Any impact to

the battery may cause it to explode.

■

DO NOT expose the battery to open flames,

sparks, lit cigarettes etc. The battery

contains combustible gases and liquids. If

these gases and liquids come in contact

with a flame or spark an explosion can occur.

■

ALWAYS keep the battery charged. If the

battery is not charged a buildup of combustible gas will occur.

■

ALWAYS keep battery cables in good working condition.

Repair or replace all worn cables.

■

ALWAYS disconnect the

performing service on the trowel.

■

ALWAYS recharge the battery in a vented air environment

to avoid risk of a dangerous concentration of combustible

gases.

■

In case the battery liquid, (dilute sulfuric acid), comes in contact

with

with plenty of water.

■

In case the battery liquid, (dilute sulfuric acid), comes in contact

with your

then contact the nearest doctor or hospital and seek medical

attention.

always

clothing or skin

eyes

, rinse eyes immediately with plenty of water,

, rinse skin or clothing immediately

wear safety glasses or face

negative battery terminal

before

PAGE 16 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 17

STX-SERIES — RULES FOR SAFE OPERATION

Maintenance Safety

■

ALWAYS shut down the engine and disconnect battery before

performing service or maintenance functions. Contact with

moving parts can cause serious injury.

■

Securely support any trowel components that must be raised.

■

NEVER lubricate components or attempt service on a running

trowel.

■

ALWAYS allow the trowel a proper amount of time to cool

before servicing.

■

Keep the trowel in proper running condition.

■

Make sure that there is no buildup of concrete, grease, oil or

debris on the machine.

■

Repair damage to the trowel immediately and always replace

broken parts.

■

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

■

DO NOT use plastic food containers to dispose of hazardous

waste.

■

DO NOT pour waste oil or fuel directly onto the ground, down

a drain or into any water source.

Emergencies

■

■

■

ALWAYS know the location of

the nearest

ALWAYS know the location of the

nearest

Know the phone numbers of the nearest

ambulance, doctor

that a phone or radio is readily available at the

jobsite. If this is not possible, know the location of

the nearest phone. This information will be

invaluable in the event of an emergency.

fire extinguisher

first aid kit

.

and

.

fire department

. Ensure

■

NEVER store trowel with fuel in the tank for any extended

period of time. Always clean up spilled fuel immediately.

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 17

/02) — PAGE 17

Page 18

STX-SERIES — INTENDED USE AND GENERAL INFORMATION

Intended Use

Operate the STX-Series Trowel, tools and components in

accordance with the manufacturer's instructions. Use of any

other tools for stated operation is considered contrary to

designated use. The risk of such use lies entirely with the user.

The manufacturer cannot be held liable for damages as a result

of misuse.

STX- SERIES Ride-On Power Trowel Familiarization

The STX-SERIES Ride-On Power Trowel is designed for the

floating and finishing of concrete slabs.

Take a walk around your trowel. Take notice of all the major

components (see Figures 2 and 3, pages 20 and 21) like the

engine, blades, air cleaner, fuel system, fuel shut-off valve,

ignition switch etc. Check that there is always a proper level of

oil in the engine and a proper level of hydraulic oil in the hydraulic

oil reservoir.

Read all the safety instructions carefully. Safety instructions will

be found throughout this manual and on the machine. Keep all

safety information in good, readable condition. Operators should

be well trained on the operation and maintenance of the trowel.

Before using your trowel, test it on a flat watered down section of

finished concrete. This trial test run will increase your confidence

in using the trowel and at the same time it will familiarize you

with the trowel’s controls and indicators. In addition you will

understand how the trowel will handle under actual conditions.

Figures 2 and 3 show the location of the controls, indicators and

general maintenance parts. Each control may perform more than

one function. The functions of the controls or indicators are on

pages 20 and 21.

Hydraulic Motor

Independent hydrostatic drive motors are coupled to the enginepowered hydrostatci pumps. Each motor drives a spider assembly.

Hydraulic Steering

Dual palm grip joystick controls located to the left and right of the

operator are provided for steering the STX Ride-On Trowel. The

joysticks are linked to three hydraulic steering cylinders located

within the frame of the machine. Detailed explanation of how the

joystick controls affect the steering of the trowel can be found in

the Operation section of this manual.

Hydraulic Pump

The hydraulic pump delivers controlled flow of hydraulic fluid to

the hydraullic motors.

Training

For training, please use the “TRAINING CHECKLIST” located

in the front of this manual (Page 10). This checklist is not intended

to be a substitute for proper training but will provide an outline

for an experienced operator to provide training to a new operator.

Engine

This trowel is equipped with an liquid cooled 55 HP Yanmar

diesel engine. Refer to the engine owner’s manual for specific

instructions regarding engine operation. This manual is included

with the trowel at the time of shipping. Please contact the Multiquip

parts department if a replacement manual is required.

Blades

The blades of the trowel finish the concrete as they are swirled

around the surface. Blades are classified as combination (10 or

8 inches wide) and finish (6 inches wide). This trowel is equipped

with six blades per rotor equally spaced in a radial pattern and

attached to a vertical rotating shaft by means of a

spider

assembly.

PAGE 18 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 19

STX-SERIES — OPERATION AND SAFETY DECALS

P/N35168

Inhaling exhaust fumes can result

in

severe injury or death.

Machine Safety Decals

The STX-SERIES Ride-On Power Trowel is equipped with a number of operation and safety decals. These decals are provided for

operator safety and maintenance information. Should any of these decals become unreadable, replacements can be obtained from

your dealer.

WARNING

To avoid injury,

you MUST read

and understand

operator’s manual

before using this

machine.

This machine to

be operated by

qualified

personnel only.

Ask for training

as needed.

P/N 35137

P/N35137

P/N 21579

P/N 21589 BLACK 4.76 X 21.87

WARNING

Inhaling exhaust fumes can result

in severe injury or death.

Only operate machine in wellventilated areas.

DO NOT inhale exhaust fumes.

DANGEROUS

Only qualified personnel should

install, use, or service this equipment.

FUMES

P/N36090

P/N 30690

BELT DRIVE

GEAR DRIVE

CLOCKWISE

GEAR DRIVE

P/N: 13118

P/N 21590

P/N 2814 (WHITE)

MODEL

SERIAL NO.

CONTACT

SERVICE

DEPARTMENT

P/N: 21455

LEFT

PITCH

ONLY

P/N: 21169

WARNING

ROTATING BLADE

HAZARD

Keep hands

and feet clear

of guard rings.

Stop engine

before servicing.

P/N 35168

MORE PITCH

LESS PITCH

P/N35168

TWIN

PITCH

WARNING

HOT COOLANT can

cause severe burns.

DO NOT remove cap if

radiator is hot.

P/N 30691

WARNING

DIESEL FUEL can cause

fire or explosion.

Stop engine before fueling

Keep cigarettes, sparks

and flame away.

P/N 30692

P/N 36099 (ISO Blue)

P/N36091

P/N36092

CHECK

HOT

LUBRICATION

LUBRICATION

P/N: 11246

P/N: 20486

CHECK

COUNTER

CLOCKWISE

LIFTING POINTLIFTING POINT

LUBRICATION

LUBRICATION

WARNING

Avoid injury.

Do NOToperate with

guards removed.

Replace guard before

operating machine.

P/N: 21665

P/N21665

P/N 20936

P/N 20872

Engine exhaust and some of

itsconstituents, and somedust created

by power sanding, sawing, grinding,

drillingandother constructionactivities

contains chemicals known tothe State

of California to cause cancer, birth

defects and other reproductive harm.

Someexamples of thesechemicals are:

Leadfromlead-based paints.

Crystallinesilica frombricks.

Cementandother masonryproducts.

Arsenicandchromium fromchemically

treatedlumber.

Yourrisk from these exposures varies,

dependingon howoftenyoudo thistype

of work.To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masksthat are specially designed

to filterout microscopic particles.

P/N 20525

P/N 20953

DECAL ENGINE

SPEED PLATE

E

HIGH

N

G

I

N

E

S

P/N 11712

P

E

E

D

LOW

DIESEL FUEL

P/N: 11811

Figure 1. STX-SERIES Decals

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 19

/02) — PAGE 19

Page 20

STX-SERIES — CONTROLS AND INDICATORS

4

2

5

6

3

1

13

14

15

7

16

8

9

10

12

Figure 2. STX-SERIES Controls and Components (Front)

11

17

12

18

10

19

Figures 2 and 3 (pages 20 and 21) show the location of the

controls, indicators and general maintenance parts. The function

of each control, indicator or maintenance part is explained below:

1. Seat – Place for operator to sit. Trowel blades will not

rotate unless operator is seated. Seat is adjustable.

2. Trowel Speed Limiter Control – Used to adjust the

maximum trowel speed that can be obtained when the foot

pedal is fully depressed.

3. Hour Meter – Indicates number of hours machine has

been used.

4. Throttle Control Lever – Controls the speed of the engine.

Move the hand lever forward to increase engine speed

(high), backwards to decrease engine speed (low).

5. Operator Gauges – Allows operator to monitor engine,

hydraulic and electrical functions.

6. Ignition Switch – With key inserted turn clockwise to start

engine.

7. Light Switch – When activated, turns on six halogen lights.

Lights offer better visibility when working indoors.

8. Lights – Six low voltage halogen lights are provided with

this unit.

9. Toolbox Compartment – Storage for tools.

10. Spray Nozzles – Spray nozzle for retardant. Two spray

nozzles are supplied with this unit.

11. Foot Pedal – Controls blade speed. Slow blade speed is

accomplished by slightly depressing the foot pedal.

Maximum blade speed is accomplished by fully depressing

the foot pedal.

12. Removable Steps (left & right) – Provides for safe footing

for mounting and dismounting trowel. When removed,

provides access to spider and blade assemblies.

13. Retardant Spray Control Buttons (left & right) – When

pressed allows retardant spray to flow through the spray

nozzle located at the front of the machine.

14. Hand Holds – Use to assist safe mounting and dismounting

trowel.

15. Lift Loops – Located on both the left and right sides of the

main frame. Used when the trowel must be lifted onto a

concrete slab.

16. Pitch Block – (Behind grill guard.) Measure and adjust

pitch pressure at the pitch block.

17. Fuel Gauge/Filler Cap – Indicates the amount of fuel in

the fuel tank. Remove this cap to add fuel.

18. Overflow Bottle – (Behind grill guard.) Supplies water or

coolant to the radiator when radiator water or coolant level

is low. Fill to indicated level as shown on bottle.

19. Hydraulic Reservoir – Part of frame. Holds hydraulic oil

necessary for pump operation.

PAGE 20 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 21

STX-SERIES — CONTROLS AND INDICATORS

Figure 3. STX-SERIES Controls and Components (Rear)

20. Documentation Box – Storage for documentation and

other information regarding the trowel.

21. Battery – Provides +12V DC power to the electrical system.

22. Hydraulic Oil Sight Glass – Indicates the level of the

hydraulic oil in the reservoir.

23. Hydraulic Suction Filter – Filters hydraulic fluid prior to

entering the system. (10 Micron absolute synthetic media.)

24. Hydraulic Oil Expansion Tank – Accommodates

expanding hydraulic oil as it gets hot. The oil gravity flows

back to the reservoir as it cools down, therefore NEVER

open the the Hydraulic Oil Filler Cap (Item 30) when the

system is warm and the oil has expanded.

25. Steering Control (left side) – Allows the unit to move in a

forward or reverse direction only.

26. Blade Pitch Control Switch (left side) – Adjusts the left

27. Blade Pitch Control (Twin Pitch) – Adjusts the blade

28. Steering Control (right side) – Allows the unit to move in

29. Grill Guards (left & right) – Protects operator from moving

30. Hydraulic Oil Filler Cap – Remove this cap to add

31. Retardant Spray Tank – Holds 5 gallons of retardant,

side blade pitch independently of the right side.

pitches simultaneously.

either a forward, reverse left or right direction.

components. Remove for maintenance access.

hydraulic oil. Open ONLY when system is cooled down

and all expanded oil has returned to the reservoir.

water, or other liquid.

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 21

/02) — PAGE 21

Page 22

STX-SERIES — BASIC ENGINE INFORMATION

11

10

9

19

12

18

17

12

1

2

16

13

3

4

5

6

Figure 4. Basic Engine Components

8

7

14

15

Basic Engine Components

The following refer to basic engine components and their functions

that an operator may need to reference . The manufacturer's engine

manual provides further instructions and details of operation and

servicing. The engine shown in Figure 4 is a Yanmar engine.

1. Fuel Filter – Removes dirt and water from the engine fuel.

2. Governor Lever – This lever restricts engine speed (high

idle and low idle) through a speed control device linked to

the accelerator system.

3. Oil Dip Stick – Remove to check amount and condition of

oil in crankcase.

4. Oil Filter – Spin-on type, filters oil for contaminants.

5. Oil Drain Plug – Remove plug to drain crankcase oil.

6. Oil Filler Port – Remove to add fresh crankcase oil.

7. Crankshaft V-Pulley – Check fan V-belt between V-Pulley

and alternator to determine proper belt tension.

8. Cooling Fan – Driven by the V-belt, the cooling fan cools

the engine by cooling water/antifreeze mixture that

circulates through the engine block and cylinder head.

9. V-belt Tension Adjustment – This bolt provides means

to adjust the V-belt tension at the alternator bracket.

10. V-belt (Fan belt) – Driven by the engine crank during

operation, drives the water pump/fan as well as the aternator.

11. Fuel Return Hose – Provides fuel to the fuel injection

pump.

12. Lifting Eye – Two lifting eyes are provided if the removal/

installation of the engine becomes necessary.

13. Alternator – Provides current to the electrical system and

charges the battery. Driven by means of a crankshaft/V-belt

pulley system.

14. Starter – Starts engine when ignition key is rotated to the

"START" position.

15. Flywheel – Main power is taken off from the flywheel end.

16. Air Intake Port – Provides air from the air cleaner to the

turbocharger unit.

17. Turbocharger – Provides pressurized intake air to the

cylinder by means of a turbine energized by exhaust gas

that rotates the blower.

PAGE 22 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 23

STX-SERIES — TROWEL SETUP

Trowel Setup

The purpose of this section is to assist the user in setting up a

NEW

trowel. If your trowel is already assembled, (seat, handles,

knobs and battery), this section can be skipped.

The new trowel cannot be put into

service until the pre-setup

NOTE

Before packaging and shipping, this STX SERIES Ride-On

Power Trowel was run and tested at the factory. If there are

problems, please let us know.

installation instructions are

completed. These pre-setup

instructions only need to be

performed at the time of unpacking

NEW

a

trowel.

Seat Assembly

The seat is not installed on the trowel for shipping purposes. To

attach the seat perform the following:

The STX trowels have a seat that

NOTE

1. Remove the seat from the protective wrapping.

2. Remove the bolts on the bottom of the seat, and place seat

on the seat mounting plate, then insert the bolts through

the holes or slots on the seat mounting plate and tighten.

Battery Setup

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

is mounted on tracks, similar to an

automobile seat. This seat can be

adjusted fore and aft via the control

lever under the front of the seat.

To install the battery on the trowel, make sure that the battery is

well seated in the battery box. Connect the positive cable to the

positive terminal on the battery first, then connect the negative

cable to the negative terminal. Close the plastic battery box cover

and secure the battery box.

Figure 5. Battery and Battery Box

Use all safety precautions specified by the battery

manufacturer when working with the battery. See further

specific safety information on page 16 of this manual.

This trowel was shipped with a wet charged battery. This battery

may need to be charged for a brief period of time as per the

manufacturer instructions.

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 23

/02) — PAGE 23

Page 24

STX-SERIES — PRE-INSPECTION

PRE-INSPECTION

The following sections are

intended to assist the operator with

NOTE

use the trowel in the field. DO NOT use your Ride-On Power

Trowel until these sections are thoroughly understood.

WARNINGWARNING

WARNING

WARNINGWARNING

Failure to understand the operation of the STX-SERIES RideOn Power Trowel could result in severe damage to the trowel

or personal injury.

See Figures 2 and 3 (Pages 20 and 21) for the location of controls

and indicators referenced in this manual.

Engine Oil

pre-inspection and the initial startup of the STX-SERIES Ride-On

Power Trowel. It is extremely

important that these sections are

read carefully before attempting to

1. When checking or adding oil, place the machine so the

engine is level.

2. Pull the engine oil dipstick from its holder (item 1 Fig 6).

3. Determine if engine oil is low (item 4). Oil should be

between the upper limit and lower limit (add oil) lines.

4. If oil is below the "Add Engine Oil" line add oil up to upper

limit on the dipstick. Allow enough time for any added oil to

make its way to the oil pan before rechecking.

DO NOT overfill the oil pan with engine oil. Always keep the

engine oil level between the upper and lower limit lines on

the dipstick.

Hydraulic Oil

Determine if the hydraulic oil is low by observing the level of oil

in the hydraulic Oil Sight Glass (Figure 7). The hydraulic tank

has an elevated overflow bottle. DO NOT remove the fill cap

when the oil is hot or spillage will occur.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

1

1

2

3

4

F

L

Figure 3. Check and Fill Engine Oil

PAGE 24 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

5

1. Engine Oil Dipstick

2. Engine Oil Filler Cap

3. Dipstick Oil Level Indicator

4. "Add Oil" Line

5. Upper Oil Level Line

2

3

1. Hydraulic Oil Level Sight Glass

2. Normal Level

3. Low Level

Figure 7. Hydraulic Oil Sight Glass

)

Page 25

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Hydraulic oil can get HOT!

STX-SERIES — INITIAL START-UP

INITIAL START-UP

WARNINGWARNING

WARNING

WARNINGWARNING

ALWAYS allow hydraulic oil to cool

before removing fill cap.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Removal of the fill cap when oil fills

the sight glass will cause hydraulic

oil to spill. Clean up hydraulic oil

spills immediately.

To add hydraulic oil, remove fill cap on the hydraulic tank. Fill to

overflow with hydraulic system cool. Use Chevron AW / MV ISO

68 or equivalent.

Fuel

Determine if the engine fuel is low (Figure 8). If

fuel level is low, remove the fuel filler cap and

fill with diesel fuel. Handle fuel safely. Motor

fuels are highly flammable and can be

dangerous if mishandled. DO NOT smoke while

refueling. DO NOT attempt to refuel the ride-on

trowel if the engine is hot or running.

NEVER operate the trowel in a confined

area or enclosed area structure that does

not provide ample free flow of air.

ALWAYS wear approved eye and hearing

protection before operating the ride-on

power trowel.

NEVER place hands or feet inside the

guard rings while the engine is running.

ALWAYS shut the engine down before

performing any kind of maintenance

service on the trowel.

Starting the Engine

1. With one foot on the ground and the other foot placed on

the trowel’s platform, grasp the grab handles lifting yourself

onto the trowel. Then sit down in the operator’s seat.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

DO NOT grab hold of the joysticks to lift yourself onto the

trowel. Pulling on the joysticks repeatedly will weaken the

units. ALWAYS use the grab handles to lift yourself on the

trowel.

Figure 8. Fuel Gauge

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

DO NOT store the Ride-On Power Trowel with fuel in the

tank for an extended period of time. Completely drain the

fuel system (tank, lines, etc.) if the unit is to be put into long

term storage. For shorter or intermediate periods of time the

tank should be filled to avoid condensation that could cause

corrosion or contamination of the fuel.

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 25

/02) — PAGE 25

2. The STX Ride-On Power Trowel is equipped with a

Stop Switch

is sitting in the seat. While the engine can be started or

continue to run with the operator off the seat, the rotors will

not rotate. The weight of an operator activates a switch

within the seat allowing the rotors to turn.

Safety

. The trowel will not move unless an operator

Page 26

WARNINGWARNING

WARNING

WARNINGWARNING

STX-SERIES — INITIAL START-UP

6. Turn the ignition key clockwise to the (start) position. The

oil

and charge indicator lights (Figure 11) should be on.

NEVER disable or disconnect the

provided for the operators’ safety and injury may result if it is

disabled, disconnected or improperly maintained.

3. It is recommended that the operation of the

Switch

operations. Doing this will verify that the switch is working

properly contributing to safe operation of the machine.

4. Place the

position.

is checked prior to performing any troweling

engine throttle lever (

Safety Stop Switch

Figure 9) in the

HIGH

LOW

. It is

Safety Stop

LOW

Figure 11. Oil and Charge Indicator Lights

cold

weather turn and hold the

NOTE

In

ignition key counter clockwise to the

preheat position, wait until the

preheat indicator goes off before

turning the ignition key clockwise to

the start position. Two or three

preheat cycles may be necessary in

very cold weather.

Figure 9. Engine Throttle Control Lever (Low)

5. Insert the

ignition key

Figure 10. Ignition Switch and Key

into the ignition switch (Figure 10).

7. Turn ignition key fully clockwise and listen for engine to

start. Once engine has started release ignition key. Let

engine warm for a few minutes.

8. Place the

position.

9. The engine should be running at full RPM.

10. Repeat this section a few times to get fully acquainted with

the engine starting procedure.

engine throttle lever

LOW

(Figure 12) in the

HIGH

Figure 12. Engine Throttle Control Lever (High)

PAGE 26 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 27

STX-SERIES — OPERATION

gninoitisoPlanoitceriDkcitsyoJ.3elbaT

NOITCERID&KCITSYOJ STLUSER

evoM TFEL kcitsyoJ

drawroF

ehtylnosesuaC

ehtfoedistfel

otlewortno-edir

.drawrofevom

evoM TFEL kcitsyoJ

drawkcaB

ehtylnosesuaC

ehtfoedistfel

otlewortno-edir

.drawkcabevom

evoM THGIR kcitsyoJ

drawroF

ehtylnosesuaC

ehtfoedisthgir

otlewortno-edir

.drawrofevom

evoM THGIR kcitsyoJ

drawkcaB

ehtylnosesuaC

ehtfoedisthgir

otlewortno-edir

.drawkcabevom

evoM HTOB skcitsyoJ

drawroF

lewortno-edirehtsesuaC

nidrawrofevomot

.enilthgiartsa

evoM HTOB skcitsyoJ

drawkcaB

lewortno-edirehtsesuaC

drawkcabevomot

.enilthgiartsani

evoM THGIR kcitsyoJ

thgiRehtot

lewortno-edirehtsesuaC

.thgirehtotevomot

evoM THGIR kcitsyoJ

tfeLehtot

lewortno-edirehtsesuaC

tfelehtotevomot

OPERATION

The following section is intended

as a basic guide to the Ride-On

NOTE

Power Trowel operation, and is not

to be considered a complete guide

to concrete finishing. It is strongly

suggested that all operators

(experienced and novice) read

Slabs on Grade

“

” published by the American Concrete Institute,

Detroit Michigan.

Steering

Two joysticks (Figures 13 and 14) located to the left and right of

the operator’s seat provide directional control for the STXSERIES Ride-On Power Trowel. Table 3 illustrates the various

directional positions of the joysticks and their effect on the rideon trowel.

See Table 3 for steering and directional relationship to Joystick

Control movement.

2

3

1

4

5

1. Palm Handle 2. Left

3. Forward 4. Right

5. Reverse

Figure 14. Right Joystick Control

NOTE

All directional references with

respect to the joysticks are from

the

operator’s

1

3

1. Palm Handle

2. Forward

3. Reverse

Figure 13. Left Joystick Control

seat position.

2

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 27

/02) — PAGE 27

Page 28

STX-SERIES — OPERATION

1. The foot pedal (Figure 15) solely controls blade speed.

The position of the foot pedal determines the blade speed.

Slow blade speed is obtained by slightly depressing the

pedal. Maximum blade speed is obtained by fully

depressing the pedal.

5. Practice maneuvering the Ride-on Power Trowel using the

information listed in Table 3. Try to practice controlled

motions as if you were finishing a slab of concrete. Practice

edging and covering a large area

6. Try adjusting the pitch of the blades. This can be done with

the ride-on trowel stopped or while the trowel is moving,

whatever feels comfortable. Test the operation of optional

equipment like retardant spray and lights if equipped.

7. Pull both the left and right joysticks backward (Figure 17)

and repeat steps 3 through 6 while substituting the word

reverse for forward.

Figure 15. Blade Speed Control Foot Pedal

2. Push both the left and right joysticks forward (Figure 16).

3

3

1

1

2

3

3

2

Figure 17. Joystick Control Reverse Direction

1. Left Joystick Control

2. Right Joystick Control

3. Pull Back Forward

Figure 16. Joystick Control Forward Direction

3. With your right foot, slowly depress the right foot pedal

halfway. Notice that the ride-on power trowel begins to move

in a forward direction. Release both joystick controls to

stop forward movement then remove your right foot from

the foot pedal.

4. Practice holding the machine in one place as you increase

blade speed. When about 75% of maximum blade speed

has been reached, the blade will be moving at proper

finishing speed. The machine may be difficult to keep in

one place. Trying to keep the ride-on trowel stationary is a

good practice for operation.

Trowel Speed Limiter Control

The speed limiter control located on the control panel (Figure

18) can be used to adjust the maximum trowel speed that can be

obtained when the foot pedal is fully depressed. Pull up to reduce

the maximum speed and push down to return to full speed. For

fine adjustments, rotate the knob clockwise or counter-clockwise.

E

A

S

1. Left Joystick Control

2. Right Joystick Control

3. Pull Back Reverse

D

L

E

O

H

D

L

O

H

LOW

Figure 18. Trowel Speed Limiter Control

PAGE 28 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 29

STX-SERIES — OPERATION

Blade Pitch Control

The trowel blades can be pitched for various finishing operations

with the two rocker switches located on the left control panel

Engine Shut-Down

1. Return the speed control lever (Figure 21) to low idle, and

allow the engine to idle for 5 minutes .

next to the left joystick control (Figure 19).

Figure 19. Blade Pitch Control

The right switch pitches both blades at the same time while the

left switch will pitch only the left blade. Moving the switches

forward increases the pitch while moving them backward

decreases the pitch, (Figure 20).

NOTE

HIGH

LOW

Figure 21. Blade Pitch Control

Failure to allow the engine to idle

for 5 minutes before shutting

OFF

engine

may lead to

turbocharger damage.

LEFT

PITCH

ONLY

MORE PITCH

LESS PITCH

TWIN

PITCH

BLADES TO BE FLAT

WITH FLOAT PANS

Figure 20. Blade Pitch Rocker Switches

Important! To get the blades absolutely flat for using float

pans follow these steps:

1. TWIN PITCH all the way DOWN.

2. LEFT PITCH up a little ways.

3. TWIN PITCH all the way DOWN, again.

4. LEFT PITCH all the way DOWN.

2. Turn the ignition key counter-clockwise to the "

switch contact

" position, then remove the key.

starter

3. Clean and remove any foreign debris from the trowel.

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 29

/02) — PAGE 29

Page 30

STX-SERIES — MAINTENANCE

MAINTENANCE

When performing maintenance on the trowel or engine, follow

all safety messages and rules for safe operation stated at the

beginning of this manual.

See the engine manual supplied with your machine for appropriate

engine maintenance schedule and troubleshooting guide for

problems.

WARNING

Accidental starts can cause severe injury

or death.

ALWAYS place the ON/OFF switch in the

OFF position.

Disconnect and

ground spark plug leads and

disconnect negative battery cable

from battery before servicing.

ALWAYS allow the engine to cool before

servicing. NEVER attempt any

maintenance work on a hot! (muffler,

radiator, etc.) trowel.

6

11

1

2

3

4

12

5

18

13

14

Figure 22. Engine Service Areas

6

17

7

18

9

10

8

16

15

Maintenance Schedule

Change

the

hydraulic oil

and

filter

after the first 100 hours of

use, then change every 250 hours.

Daily (8-10 Hours)

1. Check fluid levels in engine and reservoir; fill as necessary.

Weekly (30-40 Hours)

2. Relube arms, thrust collar and clutch.

3. Replace blades if necessary.

4. Check, clean, or replace the engine air filter as necessary.

5. Replace engine oil and filter as necessary, see engine

manual.

Monthly (100-125 Hours)

Remove, clean, reinstall and relube the arms and thrust collar.

Adjust the blade arms.

Yearly (500-600 Hours)

1. Check and replace if necessary the arm bushings, and

thrust collar bushings.

2. Adjust blade speed.

3. Replace hydraulic fluid and hydraulic filter.

1. Fuel Filter

2. Governor Lever

3. Dipstick (engine oil)

4. Engine Oil Filter

5. Drain Plug (engine oil)

6. Filler Port (engine oil)

7. Crank Shaft V-pulley

8. Cooling Fan

9. Adjustment bolt (V-belt tension)

10. V-belt

11. Rocker Arm Cover

12. Fuel Injection Pump

13. Alternator

14. Starter motor

15. Flywheel

16. Air Intake Port (from air cleaner)

17. Turbocharger

18. Lifting Eyelet

PAGE 30 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 31

STX-SERIES — MAINTENANCE

WARNINGWARNING

WARNING

WARNINGWARNING

NOTE

Certain maintenance operations or machine adjustments

require specialized knowledge and skill. Attempting to

perform maintenance operations or adjustments without

the proper knowledge, skills or training could result in

equipment damage or injury to personnel. If in doubt,

consult your dealer.

Air Cleaner (Daily)

NOTE

The Yanmar 55 hp engine is equipped with a replaceable, highdensity paper air cleaner element. Most are also equipped with

an oiled-foam precleaner which surrounds the paper element.

Check the air cleaner daily or before starting the engine. Check

for and correct heavy buildup of dirt and debris along with loose

or damaged components.

Change

filter

then change every 250 hours.

the

hydraulic oil

after the first 100 hours of use,

and

7

Precleaner Service

Wear protective equipment such as

approved safety glasses or face

shields and dust masks or respirators

when cleaning air filters with

compressed air.

If so equipped, wash and re-oil the precleaner every 25 hours of

operation (more often under extremely dusty or dirty conditions).

To service the precleaner perform the following steps, refer to

Figure 23:

1. Release the latches located on either side of the air cleaner

dust pan (item 6, Figure 23), and remove the dust pan.

2. Remove the air cleaner element.

3. Blow low pressure air from the inside of the element to

dislodge the dust and dirt. Do not use excessive air pressure

or the element will be damaged and will need to be replaced.

4. Replace the element if it is damaged or excessively dirty.

WARNINGWARNING

WARNING

WARNINGWARNING

Operating the engine with loose or

damaged air cleaner components

could allow unfiltered air into the

engine causing premature wear

and failure.

5. Clean the inside of the dust pan.

2

3

1

6

4

1. Air Cleaner Case

2. Inner Element (Option)

3. Main Element

4. Dust Pan

5. Latch

6. Arrow Mark (Dust Pan)

7. Arrow Mark (Case)

Figure 23. Air Cleaner Components

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 31

5

/02) — PAGE 31

Page 32

STX-SERIES — MAINTENANCE

6. Reinstall the element or if equipped, the precleaner over

Table 4. Recommended Viscosity Grades

the paper air cleaner element.

7. Reinstall the air cleaner dust pan and secure the latches.

5W-20, 5W-30

Make sure the correct depth air

-20

NOTE

cleaner element and rubber seal

are used for the engine

F

C

-30

TEMPERATURE RANGE EXPECTED BEFORE NEXT OIL CHANGE

specification involved.

Fuel Filter (200 Hours)

■

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Do not run the engine with the air cleaner removed or without

Replace the engine fuel filter (Figure 25) every 500 hours.

Refer to your engine manual for specific details to perform

this operation.

an element.

Changing Engine Oil And Filter

1. Change the engine oil after the first 5 hours of use, then

change every 6 months or 100 hours.

-20

10W-30, 10W-40

0

-10

32 40 60 80 100

20

0

10

20 30 40

2. Remove the oil filler cap (Figure 22, Item 6), and fill engine

crankcase with recommended type oil as listed in Table 4.

Fill to the upper limit of dipstick.

3. Crankcase oil capacity with oil filter replacement is 6.72

qts. (7.4 liters).

Oil/Water Separator

If the Oil/Water Separator has collected a significant amount of

Oil Filter (100 Hours)

water at the bottom of the cup it should be drained off. Refer to

your engine manual for specific details to perform this operation.

1. Replace the engine oil filter (Figure 24) every oil change

or 100 hours. Refer to your engine manual for specific

details to perform this operation.

Oil And Fuel Lines

■

Check the oil and fuel lines and connections regularly for

leaks or damage. Repair or replace as necessary.

■

Replace the oil and fuel lines every two years to maintain the

line's performance and flexibility.

Figure 24. Oil Filter

Figure 25. Fuel Filter Removal

2. Be sure to coat the

seal

engine oil.

PAGE 32 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

of the new oil filter with clean

)

Page 33

STX-SERIES — MAINTENANCE

Radiator/Cooling System

WARNINGWARNING

WARNING

WARNINGWARNING

Hot coolant can cause severe burns.

DO NOT remove cap if radiator is

HOT.

1. Check and clean radiator fins.

2. Check cooling water.

3. Check radiator hoses for fatigue or cracking.

4. Check radiator cap seal.

Refer to your engine manual for additional information.

Battery/Charging System

WARNINGWARNING

WARNING

WARNINGWARNING

3. Never attempt to charge a battery that is frozen. The battery

can explode unless first allowed to thaw.

4. Disconnect the negative terminal ( - ) of the battery during

storage. If unit will be stored where ambient temperature

will drop to -15

warm, dry place.

Long Term Storage

■

Remove the battery.

■

Drain fuel from fuel tank, fuel line and carburetor.

■

Remove spark plug and pour a few drops of motor oil into

cylinder. Crank engine 3 to 4 times so that oil reaches all

internal parts.

■

Clean exterior with a cloth soaked in clean oil.

■

Store unit covered with plastic sheet in moisture and dustfree location out of direct sunlight.

o

C or less, remove and store battery in a

Flammable, explosive gas. (produces

hydrogen gas while charging or during

operation). Keep area around battery

well ventilated and keep from any fire

source.

Battery electrolyte contains corrosive,

toxic chemical. (dilute sulfuric acid).

Avoid contact with eyes and skin.

Shock or Fire due to electric shortcircuit. Disconnect battery cables

before inspecting electrical system

and never "spark" battery terminals

to test for charge.

1. Check and clean battery terminals for corrosion.

2. Check and keep battery electrolyte between upper and

lower limits indicated on the battery. Never operate or

recharge without sufficient fluid in the battery.

Never store the ride-on trowel with fuel in the tank for any

extended period of time. Always clean up spilled fuel

immediately.

Engine Tune-Up

■

See your engine manual for specific information on tuning

up your engine.

NOTE

At the front of the book (Page 11) there is a “Daily Pre-Operation

Checklist”. Make copies of this checklist and use it on a daily

basis.

ALWAYS disconnect battery cables before attempting any service

or maintenance on the ride-on trowel.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

See the engine manual supplied

with your machine for appropriate

engine maintenance schedule

and troubleshooting guide for

problems.

STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06) — PAGE 33

/02) — PAGE 33

Page 34

STX-SERIES — MAINTENANCE

MAINTENANCE PROCEDURES

Checking/Adjusting Trowel Speed

Because the two hydraulic drive motors operate independent of

each other, the trowel speed between them may vary. If the unit’s

steering is difficult to control, or if one spider is spinning noticeably

faster or slower than the other, the trowel speed may need to be

checked. It is also recommended that the trowel speed be

checked at least once a year.

Trowel speed adjustment is a two-step process. First, the left

side should be checked and/or adjusted. Second, the right side

should be adjusted to match the left.

Left Side Trowel Speed Adjustment

The left side trowel speed is adjusted by the set bolt located

under the operator's platform (Item A, Figure 26) and accessed

by opening the storage panel door. Backing the set screw out

decreases the left side trowel speed; screwing it inward increases

the speed.

Figure 27. Pump Connecting Rod & Levers

This rod is basically a turnbuckle (Figure 28). Rotating it in one

direction increases the length and corresponding trowel speed.

Rotating it the opposite direction decreases the length and trowel

speed. The right side trowel speed should be within 3 rpm of the

left.

1. Pump Actuation Levers

2. Connecting Rod

1

2

A

Figure 26. Trowel Speed Control

Right Side Trowel Speed Adjustment

The right side trowel speed is adjusted by changing the length

of the connecting rod on the pump actuation levers (Figure 27).

1

Figure 28. Turnbuckle & Adjustment Nuts

A good starting point in the adjustment process is to adjust the

rod such that both trowels begin to rotate at the same time when

the foot pedal is slowly depressed. This will, generally, get the

speeds fairly close; close enough for use if instrumentation is

unavailable (i.e. on the job site). From this point on, some form of

instrumentation is required to verify that the trowel speeds are

within tolerance. A strobe or magnetic pickup type speed indicator

is recommended to verify the speeds.

The trowel speeds should be adjusted on a dry concrete floor

with the blades pitched flat. Units with the Yanmar turbocharged

engine should be set at 130-135 RPM with the engine at full

speed.

3

4

1. Hydraulic Pump (Top View)

2. Pump Actuation Levers

3. Adjustment Nuts

4. Turnbuckle Assembly

2

PAGE 34 — STX-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (03/15/06)

)

Page 35

STX-SERIES — MAINTENANCE

Matching Blade Pitch for Both Sets of Blades

Sometimes it may be necessary to match blade pitch between

Adjustments are made by tightening or loosening the blade pitch

adjustment bolt (Figure 30).

the left and right sets of blades. There are some signs that this

may be necessary. For example, the differences in pitch can

cause a noticeable difference in finish quality between the left

and right sets of blades. The difference in blade pitch can also

make the machine difficult to control. This is due to the surface

area in contact with the concrete (the blade set with the greater

contact area tends to stick to the concrete more).

To synchronize pitch on both sides, the left blade assembly can

be pitched by itself. By using the electric blade pitch rocker

switches, (Figure 29) the pitch can be syncronized on the left

and the right sides.

Figure 30. Blade Pitch Adjustment Bolt

LEFT

MORE PITCH

PITCH

ONLY

LESS PITCH

BLADES TO BE FLAT

WITH FLOAT PANS

Figure 29. Blade Pitch Rocker Switches

TWIN

PITCH

The easiest and most consistent way to make this adjustment is

to use the Trowel Arm Adjustment Fixture (P.N. 9177) that is

manufactured by Whiteman Industries. This fixture will allow

consistent adjustment of the trowel arm fingers. It comes with all

the hardware necessary to properly accomplish this maintenance

and instructions on how to properly utilize this tool. Adjusting the

Blade Pitch Adjustment Procedure

The maintenance adjustment of blade pitch is an adjustment

that is made by a bolt (Figure 30) on the arm of the trowel blade

finger. This bolt is the contact point of the trowel arm to the lower