Multiquip ST2037, ST2047, ST2047B, ST2038P, ST2040T User Manual

OPERATION AND PARTS MANUAL

MODELS:

ST2037

ST2047

ST2047B

ST2038P

ST2040T

SUBMERSIBLE PUMPS

Revision #6 (09/19/19)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

ST2037, 47, 47B, 40T, 38P SERIES SUB. PUMPS — TABLE OF CONTENTS

Multiquip ST2037, ST2047,

ST2047B ST2038P and

ST2040T Submersible

Pumps

Table Of Contents ..................................................... 2

Safety Message Alert Symbols ................................. 4

Rules For Safe Operation ...................................... 5-6

Dimensions ............................................................... 7

Specifications (Pump/Control Box) ........................... 8

General Information .................................................. 9

Components............................................................10

Float Switches .........................................................11

Float Switch (Piggy-Back) .......................................12

Float Switch (Control Box) ......................................13

Operation ................................................................14

Control Box Installation ..................................... 15-16

Clean-up .................................................................17

Maintenance ........................................................... 18

Troubleshooting ...................................................... 19

Performance Curves ............................................... 20

Pump Wiring Diagram .............................................21

Explanation Of Codes In Remarks Column ............22

Suggested Spare Parts ...........................................23

Submersible Pump

Component Drawings

ST2037,ST2047, 2047B Pump Assembly ......... 24-25

ST2040T Pump Assembly ................................. 26-27

ST2038P Pump Assembly .................................. 28-29

As a continuing effort to update

NOTE

our parts book, contact the

MULTIQUIP literature department

for the latest revision of your

"Operation and Parts Manual"

PAGE 2 — ST2037,47, 47B, 38P, 40T SUB. PUMPS — OPERATION AND PARTS MANUAL — REV. #6 (09/19/19)

NOTE PAGE

ST2037,47, 47B, 38P, 40T SUB. PUMPS — OPERATION AND PARTS MANUAL — REV. #6 (09/19/19) — PAGE 3

ST2037, 47, 47B, 38P, 40T SUB. PUMP— SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when

operating this equipment. Failure to read and understand the

Safety Messages and Operating Instructions could result in

injury to yourself and others.

This Owner's Manual has been

developed to provide complete

instructions for the safe and efficient

NOTE

this manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure to

the operator, and are preceded by one of three words: DANGER,

WARNING, or CAUTION.

operation of the Multiquip

ST2037, ST2047, ST2047B,

ST2038P, and ST2040T

Submersible Pumps.

these pumps, ensure that the

operating individual has read and

understands all instructions in

Model s

Before using

HAZARD SYMBOLS

Rotating Parts

NEVER operate equipment with covers,

or guards removed. Keep fingers, hands,

hair and clothing away from all moving

parts to prevent injury.

Accidental Starting

ALWAYS place the power source circuit

breaker or ON/OFF switch in the OFF

position, when the pump is not in use.

Sight and Hearing hazard

DANGERDANGER

DANGER

DANGERDANGER

You WILL be

NOT follow directions.

You CAN be

NOT follow directions.

CAUTION

You CAN be

Potential hazards associated with the ST2037, ST2047,

ST2047B, ST2038P, and ST2040T submersible pumps

operation will be referenced with Hazard Symbols which appear

throughout this manual, and will be referenced in conjunction

with Safety Message Alert Symbols.

KILLED

WARNINGWARNING

WARNING

WARNINGWARNING

KILLED

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

INJURED

or

SERIOUSLY

or

SERIOUSLY

if you DO NOT follow directions.

injured if you DO

injured if you DO

Other important messages are provided throughout this manual

to help prevent damage to your submersible pump, other property,

or the surrounding environment.

ALWAYS wear approved eye and

hearing protection, if required.

Respiratory Hazard

ALWAYS wear approved respiratory

protection, if required.

Equipment Damage Messages

This submersible pump, other

property, or the surrounding

NOTE

environment could be damaged if

you do not follow instructions.

PAGE 4 — ST2037,47, 47B, 38P, 40T SUB. PUMPS — OPERATION AND PARTS MANUAL — REV. #6 (09/19/19)

ST2037, 47, 47B, 38P, 40T SUB. PUMP — RULES FOR SAFE OPERATION

■

NEVER use gas piping as an electrical ground.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Failure to follow instructions in this manual may lead to serious

injury or even death! This equipment is to be operated by

trained and qualified personnel only! This equipment is for

industrial use only.

The following safety guidelines should always be used when

operating the ST2037, ST2047, ST2047B, ST2038P, and

ST2040T Submersible Pump:

GENERAL SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by

persons under 18 years of age.

■

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots and other

protective devices required by the job.

■

DO NOT place hands or fingers inside pump when pump is

running.

■

ALWAYS make certain that the voltage supplied to the pump

is correct. Always read the pump's nameplate to determine

what the power requirements are. The ST2037, ST2047,

ST2038P, and ST2040T submersible pumps require 115

VAC, 60 Hz (single-phase) for normal operation.

■

DO NOT restrict the flow of the discharge hose as it may

cause overheating.

■

Be careful of discharge whipping under pressure.

■

Make sure pump installation is accordance with national

and local electrical codes.

■

ALWAYS have a qualified electrician perform the pump

wiring installation.

■

ALWAYS mount the control box in a vertical position

protected from the elements.

■

NEVER handle pump's AC power cord with

■

NEVER let an extension cord or plug connection

wet hands

lay in wate

.

r.

■

NEVER

to a power source.

■

NEVER use a pump with a defective, frayed power cord.

■

NEVER operate this equipment when not feeling

well due to fatigue, illness or taking medicine.

■

NEVER operate this equipment under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to the

equipment and/or injury to user may result.

■

Manufacture does not assume responsibility for any accident

due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and safety

decals when they become difficult read.

■

ALWAYS check the machine for loosened threads or bolts

before starting.

■

NEVER operate the submersible pump in an explosive

atmosphere or near combustible materials. An explosion or fire

could result causing severe

bodily harm or even death.

Check the power cord on the pump for cuts in the insulation.

■

NEVER use a extension cord that is frayed or damaged

where the insulation has been cut.

■

ALWAYS make certain that proper extension cord has been

selected for the job See Table 4.

■

NEVER attempt to use the power cord as a lifting or lowering

device for the submersible pump.

■

When raising or lowering of the submersible pump is

required, always attach an adequate rope or lifting device

to the correct lifting point (handle) on the pump.

■

ALWAYS place the pump in an upright position on a platform

before using. The platform will prevent the pump from

burrowing itself on soft sand or mud.

■

NEVER operate pump on its side.

■

DO NOT allow the pump to freeze in water.

■

NEVER leave an open pump chamber unattended.

■

The electrical voltage required to operate the pump can

cause severe injury or even death through physical contact

with live circuits.

from the pump before performing maintenance on the pump.

stand in water

while AC power cord is connected

ALWAYS

disconnect the electrical power

■

ALWAYS make sure submersible pump is grounded.

ST2037,47, 47B, 38P, 40T SUB. PUMPS — OPERATION AND PARTS MANUAL — REV. #6 (09/19/19) — PAGE 5

ST2037, 47, 47B, 38P, 40T SUB. PUMP

■

ALWAYS make sure that electrical circuits are properly

grounded

local codes before operating pump.

by

electrocution

pump.

.

Risk of Electric Shock -

grounding conductor and grounding-type attachment plug.

To reduce the risk of electric shock, be certain that it is

connected only to a properly grounded, grounding-type

receptacle.

Risques de chocs électriques - Risques de chocs

électriques. Cette pompe est alimentée en électricité au

moyen d’un conducteur et d’une fiche d’alimentation de terre.

Afin de réduire les risques de chocs électriques, s’assurer

que la pompe est uniquement connectée à des boîters de

protection de mise à la terre correctement enterrés.

per the

National Electrical Code

Severe injury

can result from operating an

(NEC) and

or

ungrounded

death

WARNING- Risk of Electric Shock

This pump is supplied with a

AVERTISSEMENT- Risques De Chocs Électriques

—

■

ALWAYS store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

■

ALWAYS read, understand, and follow procedures in

Operator’s Manual before attempting to operate equipment.

.

Maintenance Safety

■

NEVER lubricate components or attempt service on a running

machine.

■

ALWAYS allow the machine a proper amount of time to cool

before servicing.

■

Keep the machinery in proper running condition.

■

Fix damage to the machine immediately and always replace

broken parts

Emergencies

■

ALWAYS know the location of the nearest

RULES FOR SAFE OPERATION

fire extinguisher

.

■

NEVER use this pump to remove water from a swimming pool

people are in the water

when

■

ALWAYS be sure the operator is familiar with proper safety

precautions and operations techniques before using

submersible pump.

■

ALWAYS check pump oil level only when pump is cool.

Expansion due to heat may cause hot! oil to spray from the oil

plug when the oil plug is removed.

■

DO NOT attempt to thaw-out a frozen pump by using a torch

or other source of flame. Application of heat in this manner

may heat the oil in the seal cavity above the critical point,

causing pump damage.

■

DO NOT pump water greater than 104 degrees Fahrenheit.

Also DO NOT pump liquids containing acid or alkali.

■

ALWAYS check strainer before pumping. Make sure strainer

is not clogged. Remove any large objects, dirt or debris from

the strainer to prevent clogging.

■

■

ALWAYS use a large basket strainer when pumping

water that contain large debris.

ALWAYS flush pump after use when pumping water

concentrated with heavy debris.

water

. It is very important to always flush the pump before

turning it off to prevent clogging.

.

Flush with clean fresh

■

■

ALWAYS know the location of the nearest and

In emergencies

nearest phone or

Also know the phone numbers of the nearest

ambulance, doctor

information will be invaluable in the case of an

emergency.

always

know the location of the

keep a phone on the job site

and

fire department

first aid kit

.

. This

.

PAGE 6 — ST2037,47, 47B, 38P, 40T SUB. PUMPS — OPERATION AND PARTS MANUAL — REV. #6 (09/19/19)

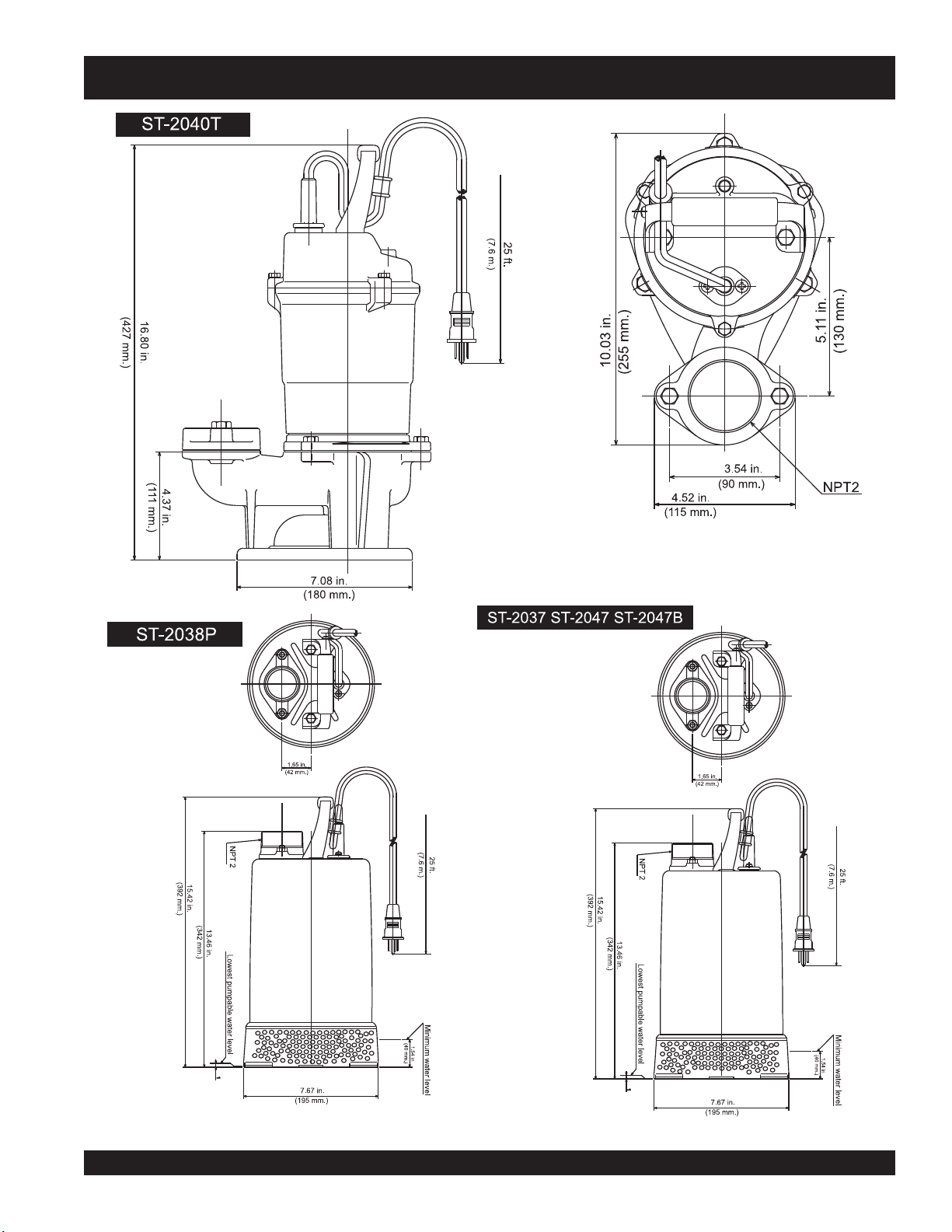

ST2037, 47, 47B, 38P, 40T SUB. PUMP — DIMENSIONS

Figure 1. Submersible Pump Dimensions

ST2037,47, 47B, 38P, 40T SUB. PUMPS — OPERATION AND PARTS MANUAL — REV. #6 (09/19/19) — PAGE 7

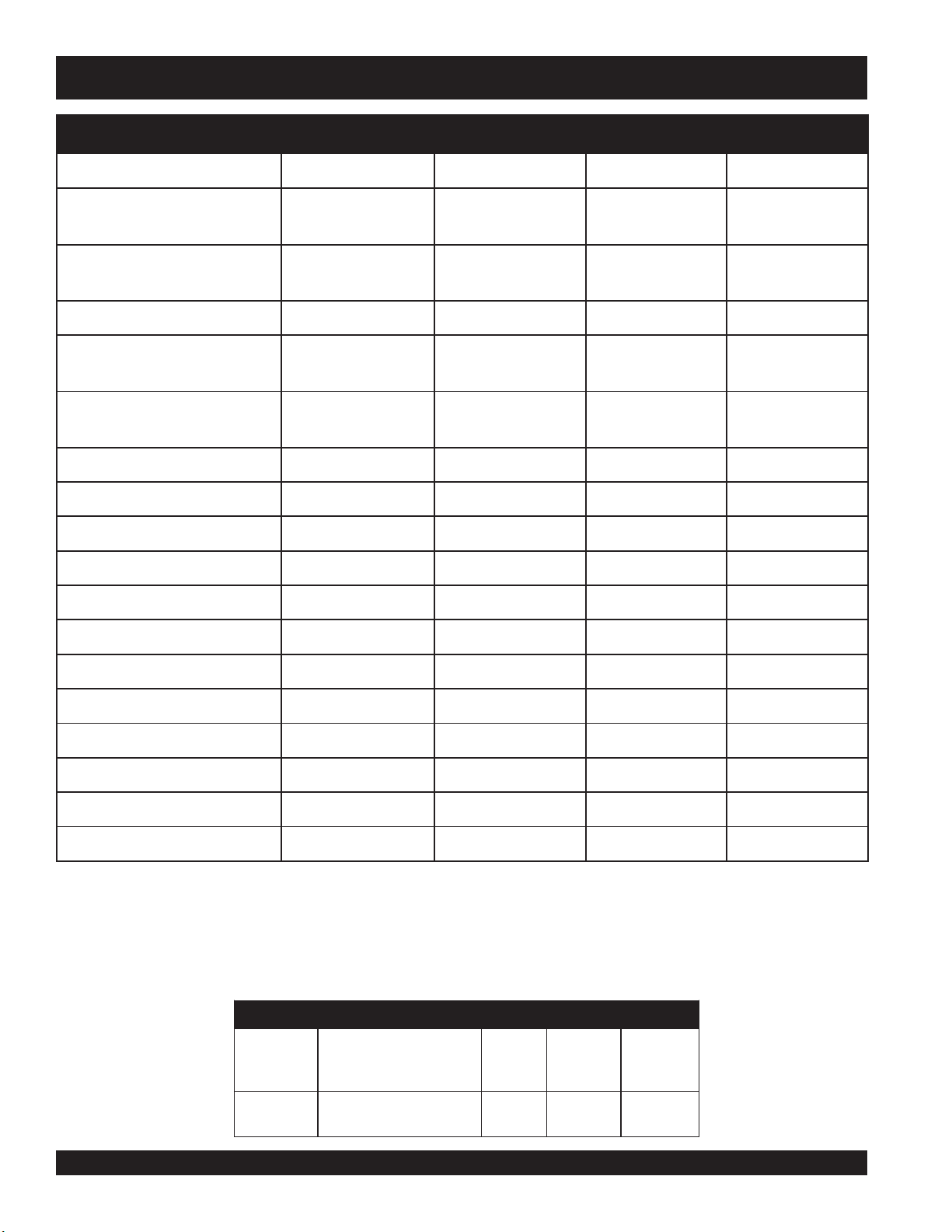

ST2037, 47, 47B, 38P, 40T SUB. PUMP — SPECIFICATIONS

SNOITACIFICEPS.1ELBAT

ledoM7302-TSB7402-TS/7402-TSP8302-TST0402-TS

epyT

rellepmI

leetS

lagufirtneC

pmuPelbisrembuS

revorebbuRelirotiN

leetS

lagufirtneC

pmuPelbisrembuS

revorebbuRelirotiN

irtneC

laguf

pmuPelbisrembuS

elirotiN

rebbuR

leetSrevo

eziSegrahcsiD&noitcuS)mm05(.ni00.2)mm05(.ni00.2)mm05(.ni00.2)mm05

yticapaCgnipmuPmumixaM

daeHxaM)sretem6.01(.tf73)sretem9.31(tf

etunim/snollag37

)etunim/sretil272(

74)sretem11(tf83

etunim/snollag78

)etunim/sretil223(

nim/snollag06

etu

)etunim/sretil722(

rewoP)wk57.0(PH1)wk57.0(PH1)wk57.0(PH1)wk57.0(PH1

esahPegatloVV511Ø1V032Ø1/V

511Ø1V511Ø1V021Ø1

spmAgnitratS525.21/525252

spmAgninnuR9.69.4/8.98.68.6

deriuqeRxoBlortnoC3etoNeeS3etoNeeS3etoNeeS3eto

noitcetorPdoalrevOlamrehTSEYSEYSEYSEY

hsarTelbisrembuS

pmuP

rebbuRelirotiN

leetSrevo

(.ni00.2

etunim/snollag97

)etunim/sretil992(

4.11(.tf04

)sretem

NeeS

noitatoR)1etoN(WCC)1etoN(WCC)1etoN(WCC)1etoN(WCC

ahceM)2etoN(.cc021)2etoN(.cc021)2etoN(.cc021)2etoN(.cc331

ycneuqerFkcehC).srh003(ylhtnoM).srh003(ylhtnoM).srh

yticapaCliOlaeSlacin

003(ylhtnoM).srh003(ylhtnoM

)deepS(MPR03-/+093303-/+052303-/+004303-/+0933

htgneLelbaCrewoP).m6.7(.TF52).m2.51

(.TF05).m6.7(.TF52).m6.7(.TF52

thgiewteNyrD)gk41(bl13)gk51(bl33)gk41(bl13)gk4.51(bl43

1. Motor Rotation – Upon start-up, the pump "

kicks

" in the opposite direction of motor rotation. The correct rotation is

counterclockwise (CCW) as viewed from the impeller end of the pump.

2. Mechanical Seal Oil – Use a good grade 10 weight non-detergent hydraulic oil (i.e. Shell Turbo 32 or equivalent). Fill oil cavity

75% to 85% full (allow air space for expansion).

3. Control Box - Control box (Table 2) may be required for certain pumping applications.

snoitacificepSxoBlortnoC.2elbaT

.oNledoMepyTegatloV

3BC

ASC/LU

detsiL

-elgniSzH06,CAV511

esahP

SEYSEYSEY

lamrehT

daolrevO

noitcetorP

taolF

hctiwS

ibapaC

ytil

PAGE 8 — ST2037,47, 47B, 38P, 40T SUB. PUMPS — OPERATION AND PARTS MANUAL — REV. #6 (09/19/19)

ST2037, 47, 47B, 38P, 40T SUB. PUMP — GENERAL INFORMATION

Introduction

The Multiquip Model ST2037, ST2047, ST2047B, ST2038P, and

ST2040T submersible pumps are designed to pump water and

is used for the draining (de-watering) of swimming pools, well

casings construction sites, cofferdams, manholes, transformer

vaults and excavations.

A Nitorile rubber over steel impeller is attached to the output

shaft of a 1HP electric motor which provides adequate power for

general purpose pumping. This submersible pump is supplied

complete with an electric power cable, and a discharge port

located at the top of the pump which accepts a 2-inch hose.

This pump is ideal for portability because of its light weight and

carrying handle. For reliability and long life, a mechanical seal

provides shaft sealing, with an oil chamber separating the pump

section from the motor.

The pump when in use, should be installed as free standing

(upright position) on its strainer base. A 2-inch discharge hose

(not supplied) should be connected to the discharge port located

on top of the pump. The discharge hose should be adequately

supported to avoid stress on the pump.

For maximum water flow, the discharge hose should be kept as

short as possible, and with minimum elevation above the pump.

Remember as the length and/or height of the discharge hose is

increased, the flow of water will be reduced. Also any reduction

in the hose size, and any fittings such as valves or outlet nozzles,

will restrict the water flow.

To avoid back-siphonage when the pump is switched off, ensure

that the end of the discharge hose is installed above the water

level at the final discharge point.

When the pump is switched off, the water remaining in the hose

will run back through the pump. This can be avoided by placing

a non-return valve in the hose nearest the pump.

If the pump was used to pump water containing mud, silt, use

clean water to flush out the pump after each use.

DO NOT allow the pump to run dry, as this will damage the

pump. During maintenance, dry running is permissible but only

for a few seconds.

NEVER lift the pump by its electrical power cord. ALWAYS lift

the pump by its carrying handle or attach a rope to the carrying

handle.

A pump fully submerged pump in liquid will not freeze, unless

the liquid freezes. DO NOT allow a partially submerged pump to

freeze. The expansion of water freezing in the volute may crack

the pump, causing expensive repairs. If there is any danger of

the pump being subjected to freezing temperatures, Lift the pump

from water and allow it to drain thoroughly.

If the pump jams or the pump rotor locks for any reason,

disconnect the pump from the power source immediately.

Allowing the pump motor to cycle ON and OFF under an overload

condition can burn out the motor.

When replacement of nuts and bolts is required, use only

recommended parts as referenced in the parts section of this

manual. This pump uses

measurement threads.

Control Box Installation Warnings

When installing the CB3 control box, the

possibility exists of

electrocution

untrained personnel perform the installation.

ALWAYS have qualified service personnel (licensed

electrician) perform the installation.

DANGERDANGER

DANGER

DANGERDANGER

and possibly

metric

threads. DO NOT use English

electrical shock

death!

NEVER have

,

NEVER use this submersible pump to pump flammable liquids

WARNINGWARNING

WARNING

or operate in a explosive or flammable environment.

Avoid using this pump in conditions where mud, grit, silt or other

debris are present. These conditions could cause blockage and

cause excessive pump wear.

DO NOT install the pump directly into an area where there is a

heavy buildup of mud, grit, silt or debris. If this condition is present,

install the pump on a platform before operating.

This pump must always be positioned on a platform in an upright

position. NEVER operate the pump by a suspended rope. To

prevent large solids from entering the pump, install a wire mesh

screen or similar barrier around the pump.

ST2037,47, 47B, 38P, 40T SUB. PUMPS — OPERATION AND PARTS MANUAL — REV. #6 (09/19/19) — PAGE 9

Failure to follow the above referenced precautions could result

in serious injury or death! Replace pump cord immediately if

cord becomes damaged or severed. This pump must be installed

in accordance with National Electric Code ANSI/NFPA 70 so as

to prevent moisture from entering or accumulating with the boxes,

conduit bodies fittings, float housing or cable.

WARNINGWARNING

Explosion or Fire Hazard exists if this

pump is used with

NOT use this pump with

liquids

hazardous locations as defined by the National Electrical

Code, ANSI/NFPA 70.

. DO NOT install this pump in

flammable liquids

flammable

. DO

ST2037, 47, 47B,38P, 40T SUB. PUMP — COMPONENTS

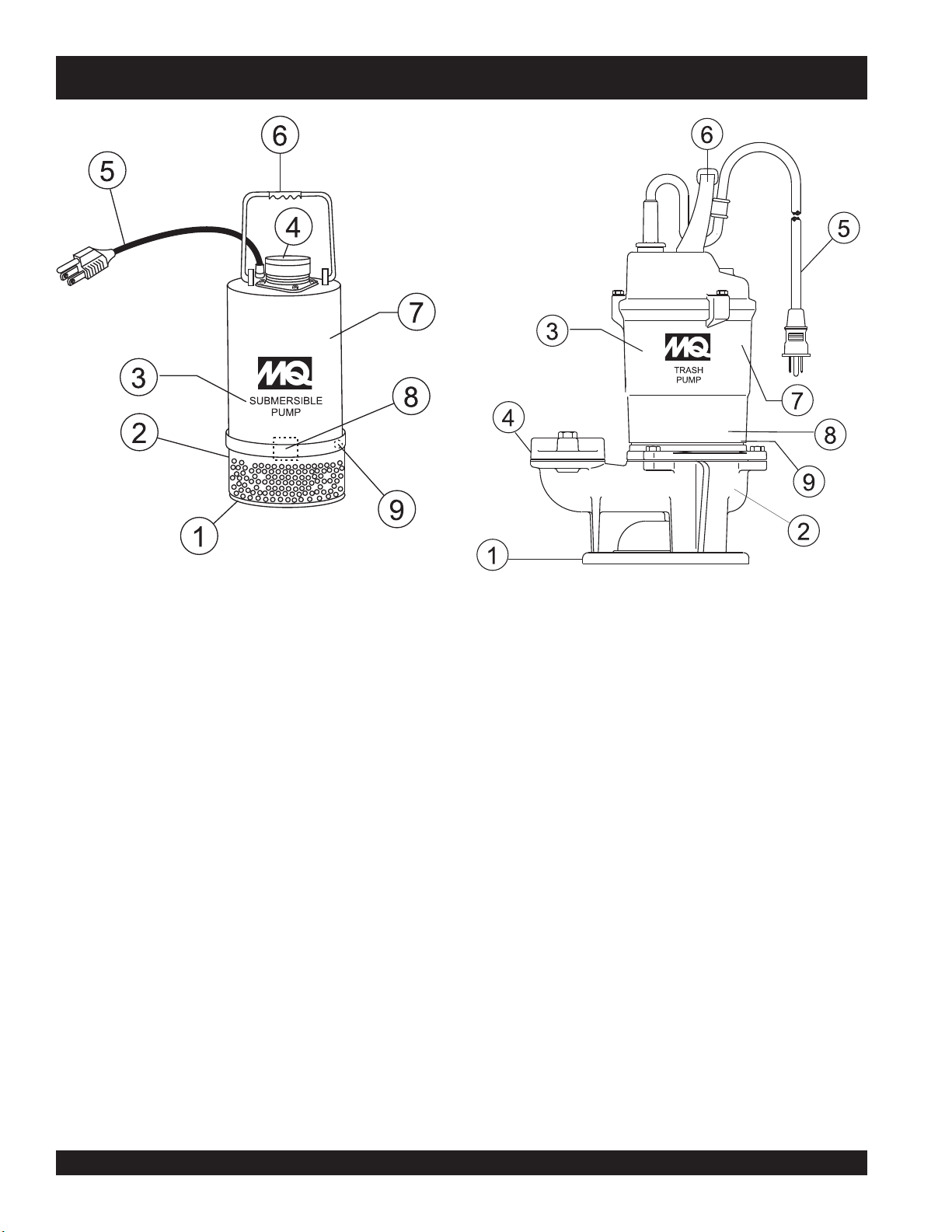

ST2037, ST2047, ST2047B ST2038P

Figure 2. Submersible Pump Components

Figures 2 shows the location of the basic components, for the

ST2037, ST2047, ST2047B, ST2038P, and ST2040T

submersible pumps. Listed below is a brief explanation of each

component.

1. Strainer Base – This strainer base is made of electrocating

steel which is resistant to hardware corrosion. DO NOT

pump large objects or debris with this pump. This pump is

for pumping water only. For de-watering purposes, always

place the strainer base on a platform.

2. Volute/Impeller – Impellers are constructed of Nitorile

Rubber to minimizes wear and prolong service life.

3. Electric Motor – These submersible pumps utilize a 60

Hz, single-phase, 115 VAC, 1 HP electric motor. Consult

licensed electrician

with a

power source. Observe all city and local safety codes.

4. Discharge Port – Connect a 2-inch hose to this port.

Remember to adequately support the discharge hose to

avoid stress on the pump.

before connecting motor to a

6. Carrying Handle – Always carry the submersible pump

by its handle. NEVER! carry the pump by its power cord.

Carrying or lifting the pump by the power cord, will cause

undue stress on the cord, and ultimately the cord will

become dislodged from the pump.

7. Thermal Overload Protection – This pump is equipped

with a thermal overload protection device that will shut down

the motor in the event of high operating temperatures. The

motor will automatically restart once the temperature returns

to an acceptable operating temperature.

8. Mechanical Seal Oil – This oil filled seal provides

lubrication when running the pump dry. NEVER! run the

pump dry. Running the pump dry will cause severe damage

to the pump.

9. Mechanical Seal Oil Plug – Remove this plug to check

and add hydraulic oil (Shell 32 or equivalent) to the oil

cavity. This oil protects the mechanical seal. Oil cavity should

be full enough to cover seal spring.

ST2040T

5. AC Power Cable – This unit is supplied with a 25 ft. (7.6

meters) or 50 ft. (15.2 meters) AC power cable. Always

check the cable for signs of wear. NEVER! use a defective

power cable. Replace the cable immediately if the cable is

worn or defective.

PAGE 10 — ST2037,47, 47B, 38P, 40T SUB. PUMPS — OPERATION AND PARTS MANUAL — REV. #6 (09/19/19)

Loading...

Loading...