PARTS MANUAL

StreetPro SERIES

MODELS

SP706016

SP706020

SP706026

SP706030

SP706036

PROFESSIONAL PAVEMENT SAW

(DEUTZ BF3L2011 DIESEL ENGINE)

Revision #5 (05/06/11)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

P/N 38267

PROPOSITION 65 WARNING

Engine exhaust and some of

its constituents, and some dust created

by power sanding, sawing, grinding,

drillingandotherconstructionactivities

contains chemicals known to the State

of California to cause cancer, birth

defects and other reproductive harm.

Some examples of these chemicals are:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonryproducts.

Arsenicandchromiumfrom chemically

treatedlumber.

Your risk from these exposures varies,

dependingonhowoftenyoudothistype

of work. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, such as

dust masks that are specially designed

to filter out microscopic particles.

PAGE 2 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

SILICOSIS/RESPIRATORY WARNINGS

WARNING

SILICOSIS WARNING RESPIRATORY HAZARDS

Grinding/cutting/drilling of masonry, concrete, metal and

other materials with silica in their composition may give

off dust or mists containing crystalline silica. Silica is a

basic component of sand, quartz, brick clay, granite and

numerous other minerals and rocks. Repeated and/or

substantial inhalation of airborne crystalline silica can

cause serious or fatal respiratory diseases, including

silicosis. In addition, California and some other

authorities have listed respirable crystalline silica as a

substance known to cause cancer. When cutting such

materials, always follow the respiratory precautions

mentioned above.

WARNING

Grinding/cutting/drilling of masonry, concrete, metal and

other materials can generate dust, mists and fumes

containing chemicals known to cause serious or fatal

injury or illness, such as respiratory disease, cancer,

birth defects or other reproductive harm. If you are

unfamiliar with the risks associated with the particular

process and/or material being cut or the composition of

the tool being used, review the material safety data

sheet and/or consult your employer, the material

manufacturer/supplier, governmental agencies such as

OSHA and NIOSH and other sources on hazardous

materials. California and some other authorities, for

instance, have published lists of substances known to

cause cancer, reproductive toxicity, or other harmful

effects.

Control dust, mist and fumes at the source where

possible. In this regard use good work practices and

follow the recommendations of the manufacturers or

suppliers, OSHA/NIOSH, and occupational and trade

associations. Water should be used for dust

suppression when wet cutting is feasible. When the

hazards from inhalation of dust, mists and fumes cannot

be eliminated, the operator and any bystanders should

always wear a respirator approved by NIOSH/MSHA for

the materials being used.

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 3

SP7060 StreetPro Series

Professional Pavement Saw

Proposition 65 Warning .................................................. 2

Silicosis/Respiratory Warnings ....................................... 3

Table of Contents ............................................................ 4

Parts Ordering Procedures ............................................. 5

Explanation of Code in Remarks Column ...................... 6

Suggested Spare Parts ..................................................7

Nameplates and Decals ..............................................8-9

Control Panel Decals ...............................................10-11

Electrical Control Assembly .....................................12-13

Console Mounts Assembly ......................................14-15

Rear Console Access Panel Assembly ...................16-17

Light Connector/Dash Access Assembly .................18-19

Belt and Engine Guards Assembly ..........................20-21

Depth Indicator/Stop Switch Assy. (Old Style) ......... 22-23

Depth Indicator/Stop Switch Assy. (New Style) ........24-25

F-N-R Assembly ......................................................26-27

Fuel Assembly .........................................................28-29

Battery Assembly.....................................................30-31

Stay-Level Handlebars Assembly ............................32-33

Handlebar Boot Assembly .......................................34-35

Water System Assembly ..........................................36-37

Engine Assembly .....................................................38-39

Throttle Control Assembly .......................................40-41

Engine Mounts Assembly ........................................42-43

Air Cleaner Assembly ..............................................44-45

Muffler Assembly .....................................................46-47

Lift Bail Assembly ....................................................48-49

Platform Guards/Rear Pointer Assembly .................50-51

Wheel Drive Assembly ............................................52-53

Front Axle Assembly ................................................54-55

Hydraulic System Assembly ....................................56-57

Engine Pivot Cylinder Assembly ..............................58-59

Hydraulic Hoses Assembly ......................................60-61

Hydraulic Fttings and Clamps Assembly .................62-63

Front Pointer Assembly ............................................64-65

Belt Drive Assembly ................................................66-69

Drive Pulley Assembly .............................................70-71

Bladeshaft Assembly ...............................................72-73

16", 20", 26" Bladeguard Assembly ........................74-75

30", 36" Bladeguard Assembly ...............................76-77

Optional Weight Kit Assembly ..................................78-79

TABLE OF CONTENTS

NOTICE

Specification and part number are subject to change

without notice

.

Terms and Conditions of Sale — Parts ......................... 80

PAGE 4 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

PARTS ORDERING PROCEDURES

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

Effective:

Choose from three easy options:

January 1st, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specification Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

and Password, E-mail us at: parts@multiquip.

com.

To ob tain an MQ Acc ou nt, co nt ac t yo ur

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

www.multiquip.com

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 5

When ordering parts, please supply:

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Truck

■ Ground

■ Next Day

■ Second/Third Day

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

EXPLANATION OF CODE IN REMARKS COLUMN

The following section explains the different symbols and

QTY. Column

— Item quantity can be indicated by a

A/R (As Required) is generally used for hoses or other

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

same unique symbol will be included when this item is

— Used to list an effective serial

— Indicates that the part

part is NOT used on a specific model or model number

available items. Examples include battery cables, shims,

— Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

Numbers Used

number, a blank entry, or A/R.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ......................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ...........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ...1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

parts that are sold in bulk and cut to length.

Column.

REMARKS Column

to describe the item can also be shown.

Assembly/Kit — All items on the parts list with the

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use

is used only with the specific model number or model

number variant listed. It can also be used to show a

variant.

Indicated by:

PART NO. Column

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarified in the “Remarks” Column.

PAGE 6 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

and certain washers and nuts.

“Not Sold Separately”

for sale through Multiquip.

SUGGESTED SPARE PARTS

SP7060 SAW

1 TO 3 UNITS WITH DEUTZ TURBO DIESEL ENGINE

Qty. P/N Description

1.........37094 ...................SWITCH, TOGGLE F-N-R

1.........37203 ...................SWITCH, ROLLER PLUNGER

2.........406000 .................SWITCH, ROCKER

2.........37132 ...................FRONT WHEEL ASSEMBLY

2.........37095 ...................REAR WHEEL

1.........29509 ...................CAP, FUEL TANK

2.........560017 .................GRIPS, HANDLEBAR

1.........H9406 ...................BULB, GE H9406

1.........15503 ...................KNOB, COMFORT

1.........37311 ...................BALL VALVE, WATER SYSTEM

2.........570005 .................CLAMP, MUFFLER

2.........37048 ...................SPRING, WHEEL DRIVE

2.........582012 .................BUSHING, QD

2.........915316 .................SCREW, 5/8 - 11 X 3 LH GR8

2.........915315 .................SCREW, 5/8 - 11 X 3 GR8

1.........574003 .................ROPE, POINTER

1.........37212 ...................THROTTLE ASSEMBLY

2.........200019 .................MUDFLAP, BLADEGUARD

FOR SAWS WITH 16", 20", AND 26" BLADEGUARDS

2 ........37168 ...................FLANGE, INNER 5.0"

2.........37169 ...................FLANGE ASSEMBLY, OUTER 5.0"

2.........926790 .................PIN, DOWEL

2.........362000 .................HOSE, WATER #6LP (16" BLADEGUARD)

2.........362005 .................HOSE, WATER #6LP (20" BLADEGUARD)

2.........362006 .................HOSE, WATER #6LP (26" BLADEGUARD)

ENGINE PARTS FOR DEUTZ TURBO DIESEL ENGINE

2.........1174416 ...............OIL FILTER, DEUTZ BF3L2012

2.........304010 .................FUEL FILTER, DEUTZ BF3L2011

2.........P772579 ...............PRIMARY AIR FILTER ELEMENT

2.........P775300 ...............SAFETY AIR FILTER, DEUTZ BF3L2014

2.........21004-003 ............FAN BELT, AX-35

2.........520007 .................DRIVE BELT, 5G 3VX-530

1.........406017 .................IGNITION SWITCH, W/KEY

2.........406017-1 ..............KEY, IGNITION

2.........306006 .................FILTER, TRANSMISSION

...........

FOR SAWS WITH 30" AND 36" BLADEGUARDS

2 ........37177 ...................FLANGE, INNER 6.0"

2.........37176 ...................FLANGE ASSEMBLY, OUTER 6.0"

2.........926790 .................PIN, DOWEL

2.........362007 .................HOSE, WATER #6LP (30" BLADEGUARD)

2.........362008 .................HOSE, WATER #6LP (36" BLADEGUARD)

NOTICE

Part numbers on this Suggested Spare Parts List may

supercede/replace the P/N's shown in the text pages of

this manual.

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 7

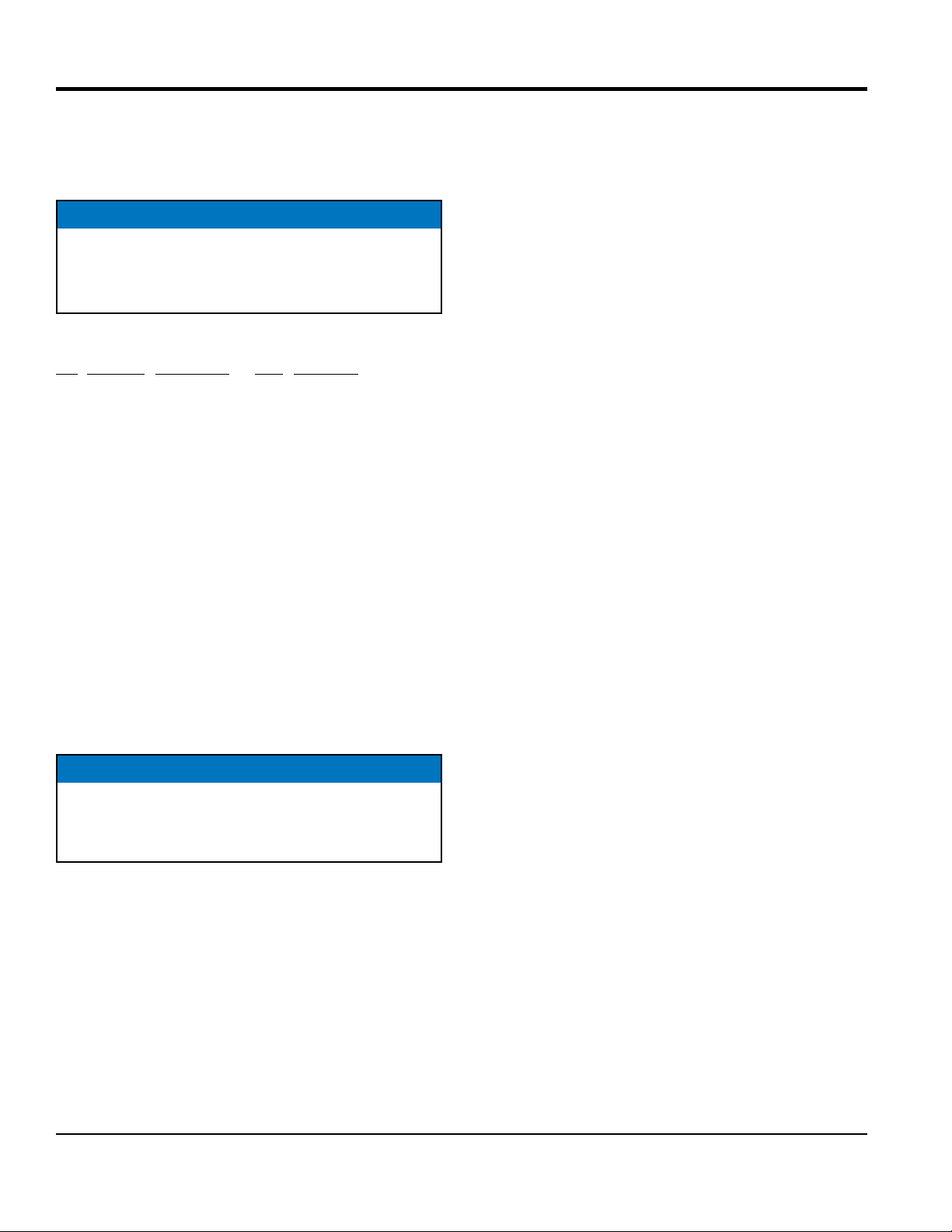

MODEL

SERIALNO.

KEEP HANDS

CLEAR

WARNING!

KEEP FEET

CLEAR

WARNING!

When Larger Bladeand Guard

is Installed, BeltDrive MUST

Be Changed toProper Size.

See Owners Manual.

S.M.I.MASONRY ANDCONCRETE

SAWMANUFACTURER’S INSTITUTE

CAUTION

FAILURETO COMPLYWITH THEC CAH

JADV EEEAV EEAOIEJGGVCBVVZ

R

O

T

A

T

I

O

N

DONOT OPERATESAW

WITHOUTPROPER TRAINING

&FULL UNDERSTANDING

OFTHE OWNERSMANUAL

HEARING

PROTECTION

KEEPALL

GUARDSIN

PLACE

EYEOR FACE

PROTECTION

HEAD

PROTECTION

RESPIRATOR

TOPREVENT SERIOUSINJURY

WHENOPERATING THISMACHINE

ALWAYSWEARSAFETY APPROVED

MASONRYAND CONCRETE

SAWMANUFACTURING INSTITUTE

SMI

WARNING

Engine exhaust and some of

itsconstituents,and somedustcreated

of California to cause cancer, birth

defects andother reproductive harm.

by power sanding, sawing, grinding,

drillingandotherconstruction activities

containschemicals knownto theState

Someexamplesof thesechemicalsare:

Leadfromlead-basedpaints.

Crystallinesilicafrombricks.

Cementandothermasonry products.

Arsenicandchromiumfromchemically

treatedlumber.

Yourrisk fromthese exposuresvaries,

dependingonhowoften youdothistype

ofwork. To reduce your exposure to

these chemicals: work in aALWAYS

well ventilated area, and work with

approved safety equipment, suchas

dustmasks thatarespecially designed

tofilter outmicroscopicparticles.

PATENT PENDING

WARNING

Onlyoperate machinein wellventilatedareas.

Onlyqualified personnelshould

install,use, orservice thisequipment.

DONOT inhaleexhaust fumes.

Inhalingexhaust fumescan result

insevere injuryor death.

DANGEROUS

FUMES

P/N36090

P/N36092

DIESELFUEL cancause

fireor explosion.

Stopengine beforefueling

Keepcigarettes, sparks

andflame away.

WARNING

P/N37161

R

O

T

A

T

I

O

N

19

21

23

24

22

1

5

6

7

8

9

10

11

25

14

18

20

13

12

17

15

16

2

3

P/N37540

API SERVICECI- 4PLUS, CI- 4,CH- 4,

CG- 4,CF- 4,CF/SL/SJ

USE 15W-40 ENGINE OIL

4

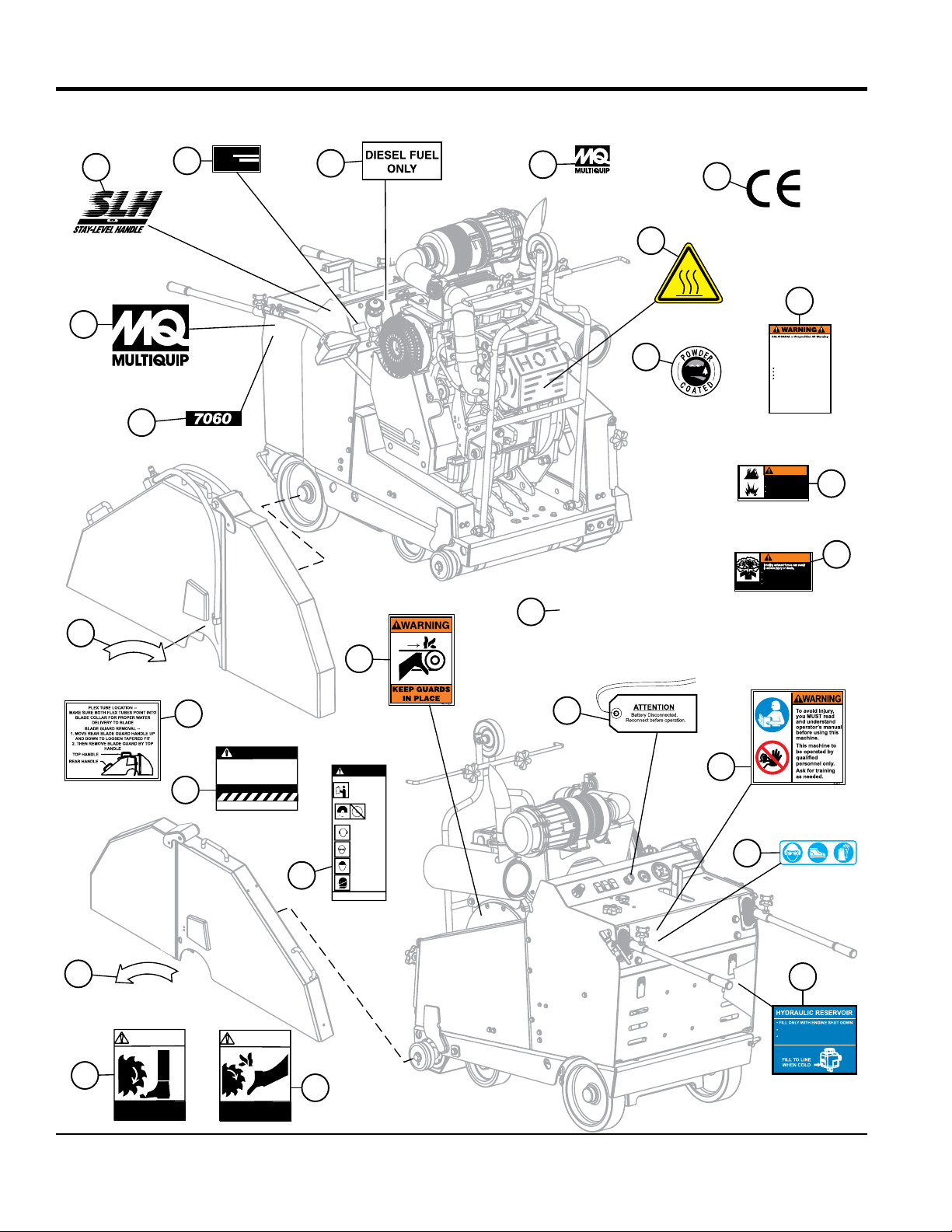

NAMEPLATES AND DECALS

PAGE 8 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

NAMEPLATES AND DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 37367 DECAL, STAY LEVEL HANDLE WHITE 2

2 38232 DECAL, MQ MULTIQUIP 5.93 X 7.45 2

3 38235 DECAL, MQ SP7060 2

4 SERIAL TAG ..............................................................1 ................... CONTACT PARTS DEPT.

5 M600002 DECAL, DIESEL FUEL ONLY 1

6 38213 DECAL, MQ LOGO 3.0 X 3.75 1

7 37161 DECAL, HOT ISO HI-TEMPERATURE .....................1 ................... SAFETY ITEM

8 13118 DECAL, POWDER COATED 1

9 20525 DECAL, WARNING "PROP 65" 3.25 X 4.25 .............1 ................... SAFETY ITEM

10 36092 DECAL, WARNING DIESEL FUEL 3.5 X 1.75 ..........1 ................... SAFETY ITEM

11 36090 DECAL, WARNING VENTILATION 2 X 4 ..................1 ................... SAFETY ITEM

12 11912 DECAL, PATENT PENDING 1

13 25282 DECAL, ATTENTION BATTERY DISCONNECTED 1

14 35137 DECAL, WARNING READ MANUAL .......................1 ................... SAFETY ITEM

15 36099 DECAL, PROTECTIVE CLOTHING ISO BLUE ........ 1 ................... SAFETY ITEM

16 37540 DECAL, HYDRAULIC RESERVOIR 1

17 21302 DECAL, WARNING KEEP GUARDS IN PLACE .......2 ................... SAFETY ITEM

18 22122-001 DECAL, WARNING RX-W ........................................2 ................... SAFETY ITEM

19 25249-001 DECAL, WARNING KEEP HANDS CLEAR ..............2 ................... SAFETY ITEM

20 25250-001 DECAL, WARNING KEEP FEET CLEAR .................2 ................... SAFETY ITEM

21 25678 DECAL, BLADE ROTATION CCW ............................1 ................... SAFETY ITEM

22 23330-001 DECAL, CAUTION BELT DRIVE 2

23 606004 DECAL, GUARD REMOVAL ..................................... 2 ................... SAFETY ITEM

24 25491 DECAL, BLADE ROTATION CW 1

25 38226 DECAL, CE 1

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 9

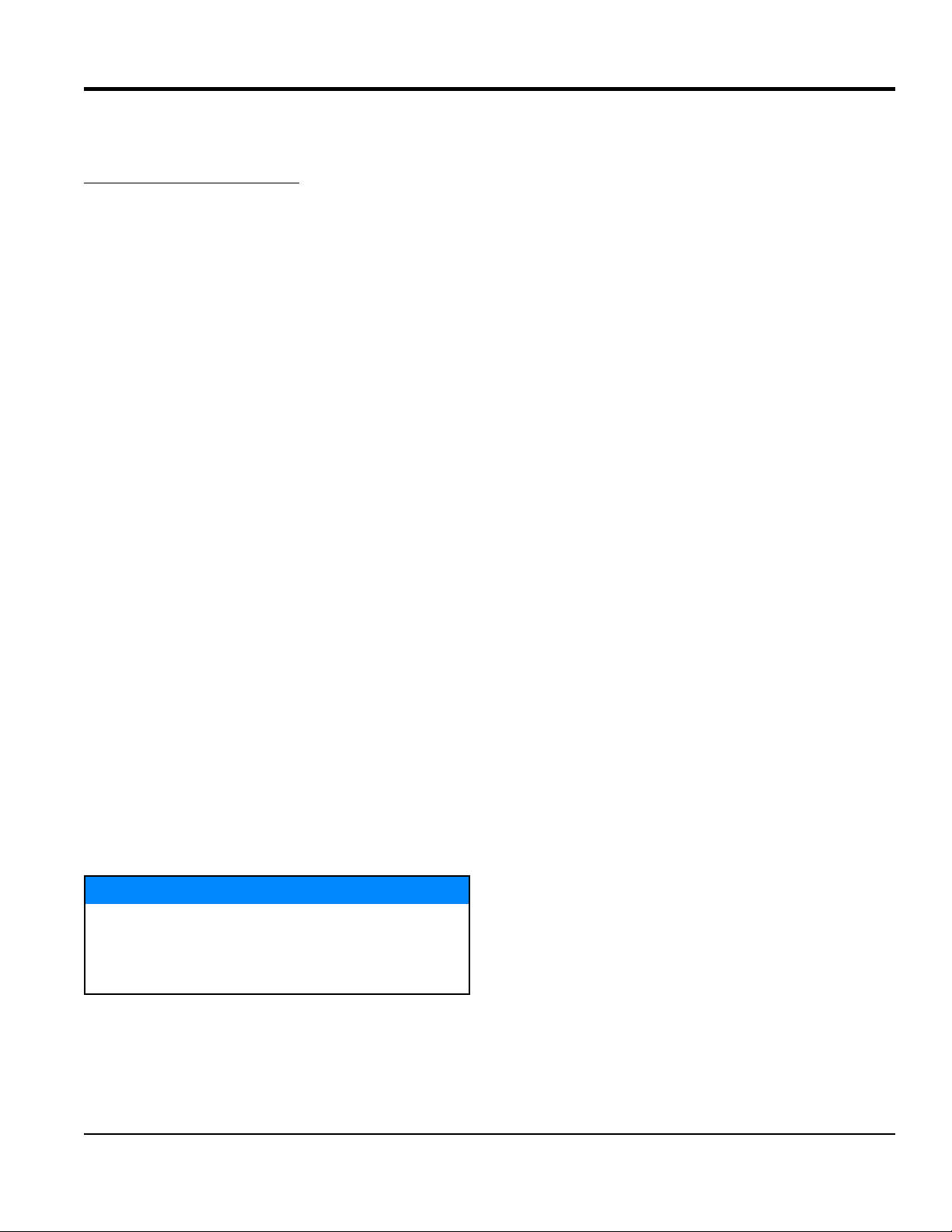

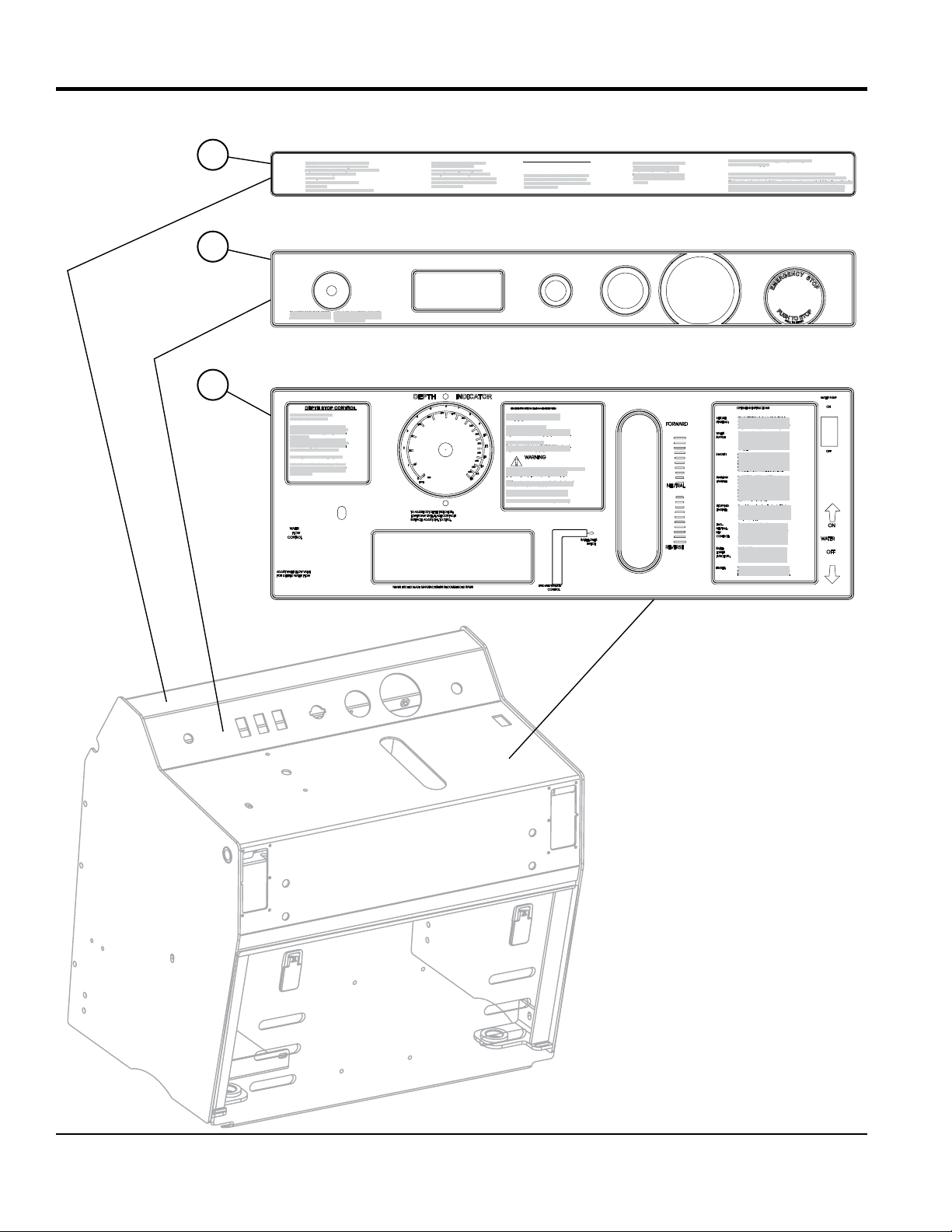

CONTROL PANEL DECALS

1

2

3

ENGINE

Airfilter: Replaceouter elementwhen theSYSTEMS

airfilter restriction lightcomes on.STATUS

Replaceinner element everyfourth outerelement.

Oil: Checkoil leveldaily, donot overfill.

SeeEngine Manual.

Oiltype:

OilService: Change oiland filterevery 125 hours

ofoperation.

Changefuel filter every250 hoursof operation.

FuelFilter:

THROTTLE

TURNKNOB COUNTERCLOCKWISE.

TOINCREASE ENGINESPEED:

TURNKNOB CLOCKWISE.

TOREDUCE ENGINESPEED:

FORQUICK THROTTLEACTION: DEPRESSRED BUTTONAND

PUSHOR PULLKNOB.

DEPTH STOPCONTROL

ToControl Depthof Cutwith Saw

Runningand BladeMounted:

Step1: Raisesaw abovedesired cuttingdepth.

Step2: Turndepth controlknob counterclockwise

untilsaw cannotbe loweredbypushing raise/lower

switchforward.

Step3: Holdraise/lower switchin thelowering

positionand rotatethe depthcontrolknob clockwise

untildesired cuttingdepth isachieved.The sawwill

repeatto thesame depthuntilre-adjusted.

ToRe-adjust forFull CuttingDepth:

Holdraise/lower switchin theloweringposition and

rotatethe depthcontrol knobclockwiseuntil sawis

fullylowered. Rotatedepthcontrol knobclockwise

additional1 turn.

WATER

FLOW

CONTROL

ADJUSTWATER FLOWVALVE

FORDESIRED WATERFLOW

HYDRAULICSYSTEM

OilLevel: Check reservoirdaily. Fillreservoir to

FULLCOLD.

linemarked

Oiltype:

15W-40premium gradeengine oil.

Changeoil and filterevery 500hours of

OilService:

operationor annually,whichever occursfirst.

Reservoir Reservoir islocated insideconsole. Remove

rearpanel foraccess.

Location:

LIGHTS

AUXILIARY

ON

ON

OFF

OFF

INDICATOR

DEPTH

6

7

5

150

175

4

125

100

3

75

2

50

25

1

0

MM

0

INCH

TOADJUST CUTDEPTH INDICATOR:

LOWERSAW UNTILBLADE CONTACTS

SURFACE,ADJUST DIALTO ZERO.

NEVEREXCEED BLADEMANUFACTURER'S RECOMMENDEDRPM'S

200

BLADESHAFT

DIS-ENGAGE

8

230

255

280

305

330

355

380

14

15

ENGAGE

9

13

MAINTENANCE INSTRUCTIONS

Note:

Wheeldrive propulsion system,lift pump,

andoil bath bladeshaftshare common

hydraulicoil reservoir,thus aremaintained

asa single system.

BLADESHAFTROTATIONDIS-ENGAGEMENT SYSTEM

Enginemust beat idlewhen engagingor

dis-engagingbladeshaft drive.

Tostop bladeshaftrotation:

Pushrocker switchlabeled BLADESHAFTforward.

Enginewill tiltforward, dis-engagingthe beltdrive.

10

Tostart bladeshaftrotation:

11

Pushrocker switchlabeled BLADESHAFTbackward.

Enginewill tiltback, engagingbelt drive.

12

WARNING

ENGINEMUST BESHUT OFF whenremoving orinstalling

bladeor bladeguardor performinganytype ofservice

tobladeshaft orany othercomponenton machine!

NEVER attempt toremove orinstallblade orbladeguard

withengine runningby dis-engagingthebelt drive!

NEVER attempt toservice anycomponentwith the

enginerunning!

NEVER leave sawunattended whileengineis running!

IGNITION SWITCH

START

ON

ENGINE

PRE-HEAT

OFF

FWD-NEUTRAL-REV

CONTROL

RAISE/LOWER

SWITCH

ENGINEPRE-HEAT

GLOWPLUG

Service:

Greaseevery 125 hrs.of operation.

Usepremium grade waterproof

Type:

EP(extreme pressure)grease.

Frontaxle pivot bearings(2), lift

Locations:

cylinderpins (2), enginetilt cylinder

pin(1).

BLADE SPEED

SYSTEMS STATUS

LUBRICATION

FORWARD

NEUTRAL

REVERSE

BeltTension:

ToAdjust

DriveBelt

Tension:

DRIVEBELTS

Bladeshaftdrive belttension is appliedhydraulically when

bladeshaftdrive isengaged.

Performfollowing procedure withsaw fullylowered.

Loosenjam nut onbelt tensionlimiting bolt.Turn belttension limitingbolt

counterclockwiseto create ½”minimum distancebetween endof boltand frame.

Startengine andengage beltdrive; increaseengine speedto fullthrottle positionfor

15seconds minimum. Slow enginespeed toidle andshut engineoff. Turn belt

tensionlimiting bolt clockwiseuntil boltlightly contactsframe. Tighten locknut.

TACHOMETER

OPERATINGINSTRUCTIONS

Checkall fluidlevels.Secure bladefirmly to

BEFORE

bladeshaft.Make sureallprotective guards

STARTING:

arein placeand properlymounted.Wear eye,

earprotection andprotective clothing.

Connectwater supplyto waterinlet.Move

WATER

waterON/OFF CONTROLto ONposition.

SUPPLY:

AdjustWATER FLOWCONTROLlever to

desiredposition. Drainwateringsystem in

coldweather toprevent damagedueto

freezing.

Alwaysfollow blademanufacturer's

BLADES:

recommendationsfor bladeselection,

speedand application.

NEVERexceed blademanufacturer's

maximumrated RPM.Seeoperator's manual

fordetailed blademounting instructions.

SetCONTROL HANDLEto NEUTRALposition.

STARTING

SetTHROTTLE toIDLE.Turn startswitch to

ENGINE:

ONposition. Waitforglow plugindicator light

togo out.Momentarilyturn switchto start

position;release switchas soonasengine

starts.Allow enginetowarm upfor several

minutesbefore increasingengine speed.Use

approveddiesel fuelonly.

Donot stopengine abruptlywhenhot! Reduce

STOPPING

THROTTLEto IDLEandallow engineto run1

ENGINE:

to2 minutesbefore turningignitionswitch off.

Damageto enginemay occurifnot allowedto

cooladequately.

Thepanel mountedhandle controls

FWD-

FORWARD,NEUTRAL andREVERSE

NEUTRAL-

operation.Neutral positionstops or holdssaw

REV

ina stationaryposition. Incremental

CONTROL:

movementin theFORWARD orREVERSE

directionwill increasespeed proportionate

toamount ofmovement.

RAISE-LOWERfunction iscontrolledby the

RAISE-

switchmounted atthe rightsideof the

LOWER

CONTROLHANDLE. Pushtoggleswitch

FUNCTION:

leverforward tolower saw.Pulltoggle switch

leverbackward toraise saw.

Thissaw isequipped withparkingbrakes.

BRAKES:

Brakesare appliedautomaticallywhen engine

isoff anddis-engaged whenengineis running.

ENGINEWILL NOTCRANK

ORSTART WHENE-STOP

BUTTONIS DEPRESSED

WATERPUMP

ON

OFF

ON

WATER

OFF

PAGE 10 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

CONTROL PANEL DECALS

NO. PART NO. PART NAME QTY. REMARKS

1 37361 DECAL, MAINTENANCE, 7000 SERIES 1

2 37354 DECAL, INSTRUMENT PANEL, 7000 SERIES 1

3 37353 DECAL, OPERATION CONSOLE PANEL 1

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 11

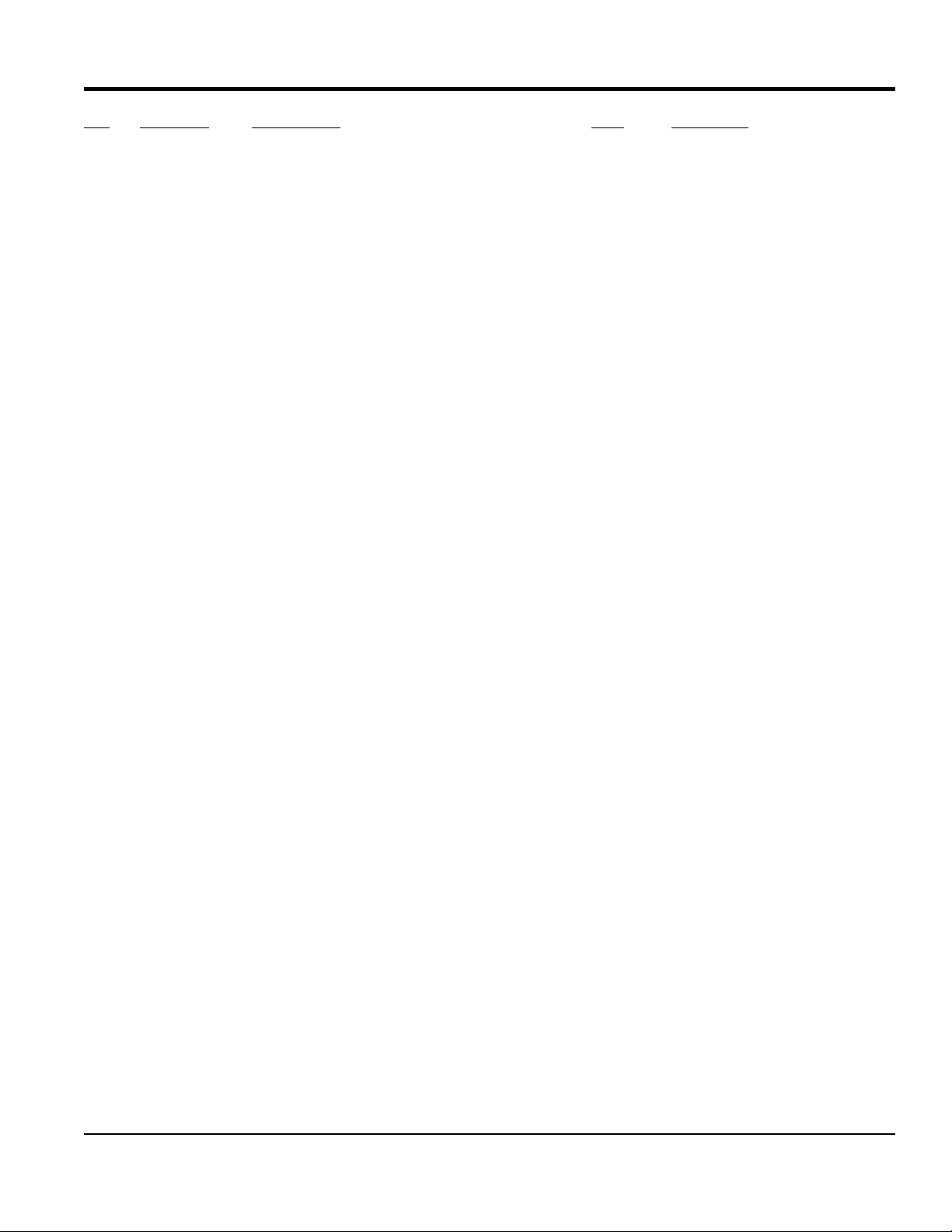

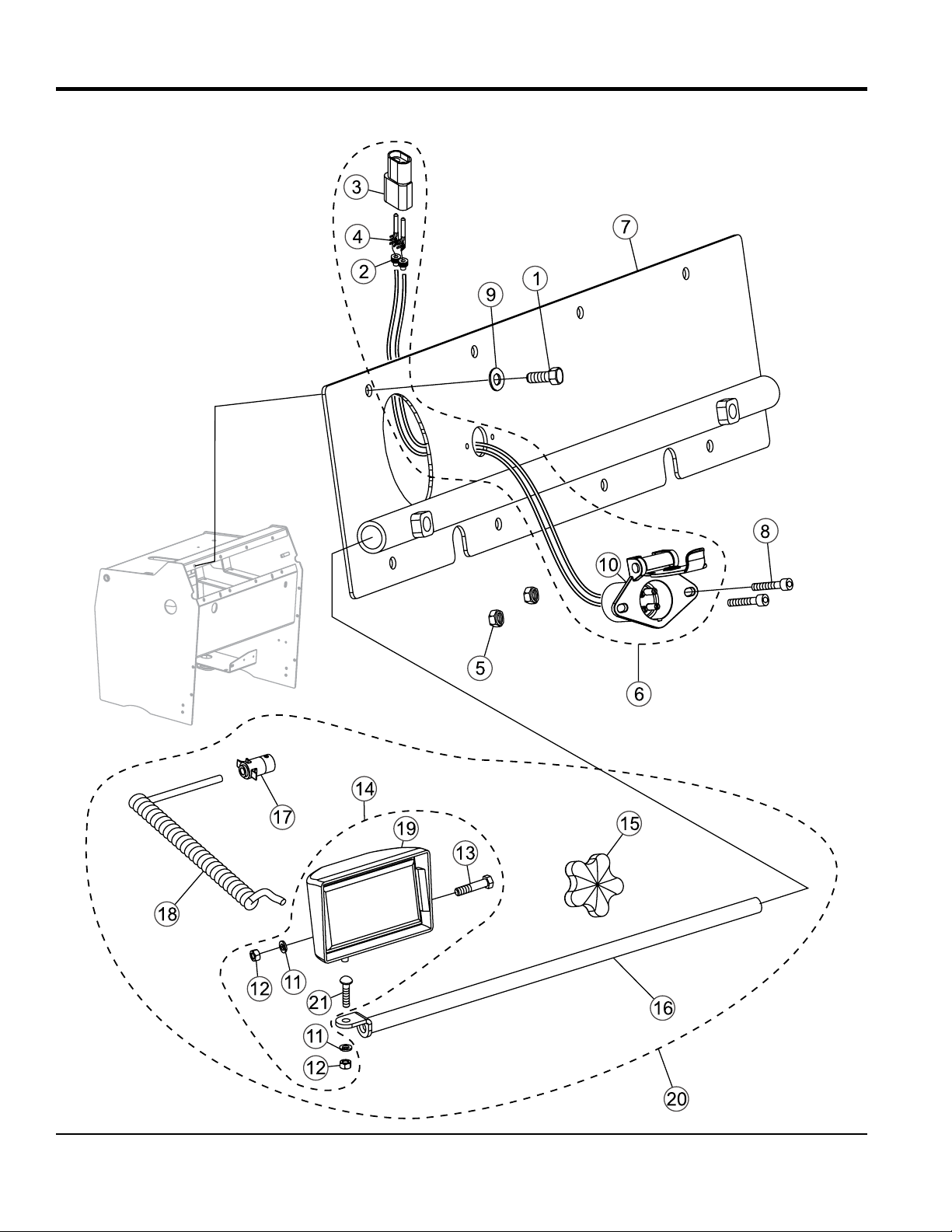

ELECTRICAL CONTROL ASSY.

PAGE 12 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

ELECTRICAL CONTROL ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 406000 SWITCH, ROCKER CH# M-58031-01 2

2 4060 17 IGNITION SWITCH, WITH KEYS .............................1 ................... INCLUDES ITEMS W/

3 37198 EMERGENCY STOP SWITCH ................................. 1 ................... SAFETY ITEM

4 37094 SWITCH, TOGGLE SPDT MOMENTARY ON-ON 1

5 37203 SWITCH, SNAP ACTION ROLLER PLUNGER 1

6 37490 HARNESS, RELAYS AND CIRCUIT BREAKERS 1

7 406021 INDICATOR, ENGINE 1

8 37243 SWITCH, ROLLER ARM 1

9 933240 WASHER, FLAT SAE 1/4 GRD 9 YZ 3

10 405000 CONNECTOR, 4-WAY SOCKET 1

11 37368 TACHOMETER, ELECTRIC 0-3000 RPM 1

12 8381 BOOT, TOGGLE SWITCH 1

13 406020 BLANK, ROCKER SWITCH 2

14 973752 SCREW, BHHC 1/4 - 20 X 5/8 SS 3

15 37325 SCREW, SHC M5 - 0.8 X 30MM 2

16 37324 NUT, NYLOC M5 - 0.8 2

17 28922-058 WASHER, M5 2

18* 406017-1 KEY, IGNITION 1

19 25628 SOLENOID, LIFT PUMP 1

*

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 13

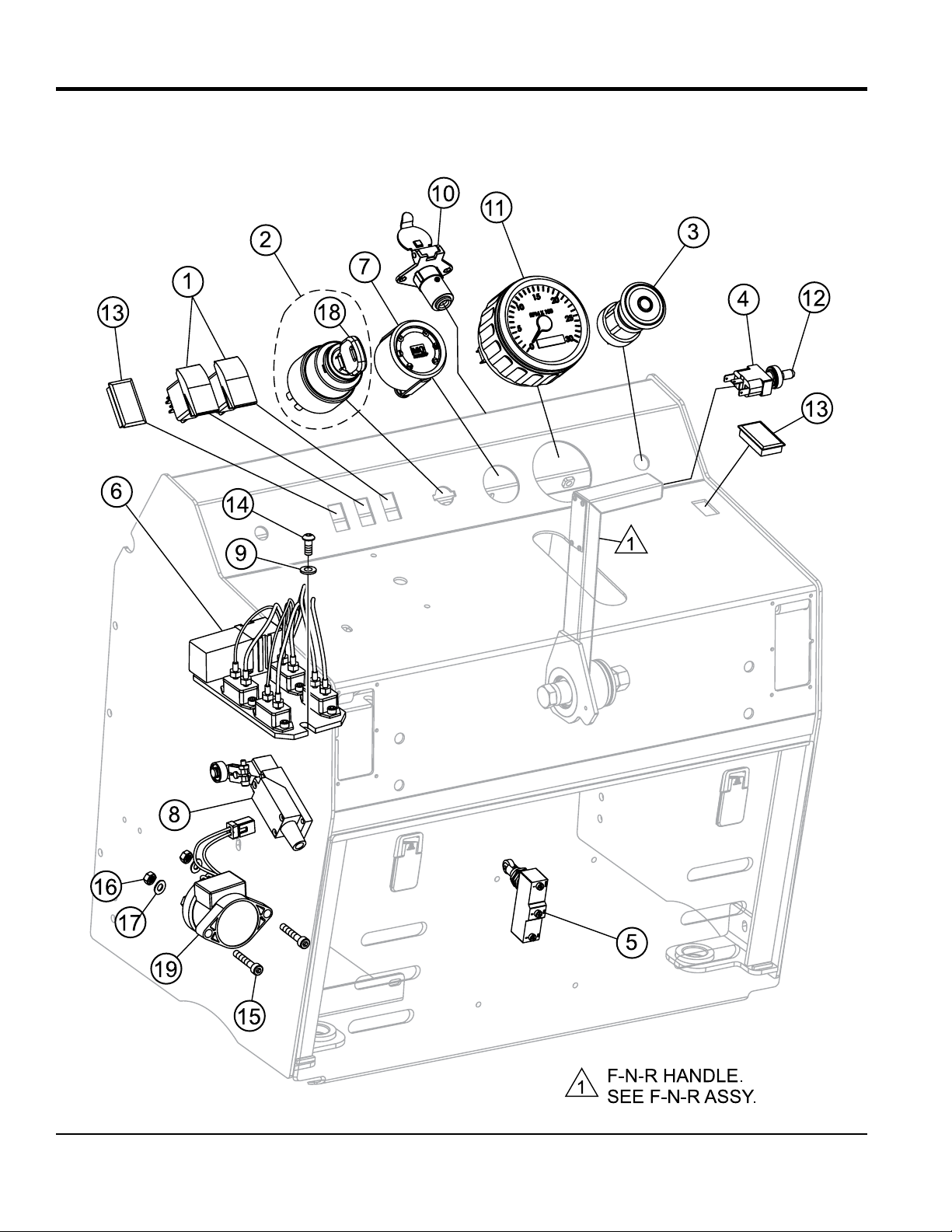

CONSOLE MOUNTS ASSY.

PAGE 14 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

CONSOLE MOUNTS ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 20742 ISOLATOR, RB2 RING/BUSHING 4

2 20743 WASHER, ISO SNUB KROFUND DYN 148099-18 4

3 575001 RUBBER ISOLATOR, TPC# 60166-1 4

4 37231-353 MOUNT, ISOLATOR FRONT 2

5 37233-353 MOUNT, ISOLATOR SIDE 2

6 37227-353 MOUNT, CONSOLE ISOLATOR FRONT 2

7 12832 WASHER, SNUBBING 4

8 06503-026 SCREW, HHC 1/2 - 13 X 3-1/4 4

9 1665 SCREW, HHC 3/8 - 16 X 2 4

10 37116-353 CONSOLE W/A 1

11 933242 WASHER, FLAT SAE 3/9 GRD 9 Y 8

12 0205 SCREW, HHC 3/8-16 X 1 8

13 TBD SCREW 4

14 TBD WASHER 4

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 15

REAR CONSOLE ACCESS PANEL ASSY.

6

5

1

8

2

3

7

9

4

PAGE 16 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

REAR CONSOLE ACCESS PANEL ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1* 10024 NUT, NYLOC 1/4 X 20 4

2* 10930 WASHER, FENDER 1/4 X 1-1/4 4

3* 12287 SCREW, THP 1/4 - 20 X 3/4 SS 4

4* 29057 DOCUMENT BOX 1

5 37219 STRIP, BACKING PLATE SAW CONSOLE 1

6 37220 STRIP, VERTICAL SAW CONSOLE 2

7* 37254-353 PANEL, REAR SAW ACCESS 1

8* 560020 LATCH, REAR SAW ACCESS PANEL 2

9 37253 PANEL ASSEMBLY, REAR SAW ACCESS ...............1 ................... INCLUDES ITEMS W/

*

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 17

LIGHT CONNECTOR/DASH ACCESS ASSY.

PAGE 18 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

LIGHT CONNECTOR/DASH ACCESS ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0655 SCREW, HHC 5/16 - 18 X 3/4 8

2* 12171 SEAL, WEATHERPACK 16-18 GA,GREEN 2

3* 12176 CONNECTOR, WEATHERPACK 2 PIN MALE 1

4* 12179 TERMINAL, WEATHERPACK MALE 14-16 GA 2

5 13287 NUT, NYLOC 8-32 2

6 25865 HARNESS, LIGHT KIT ..............................................1 ................... INCLUDES ITEMS W/

7 37234-353 COVER W/A, CONSOLE DASH ACCESS 1

8 923114 SCREW, SHC 8-32 X 1/2 2

9 933241 WASHER, FLAT SAE 5/16 GRD 9YZ 8

10* 405000 CONNECTOR, 4-WAY SOCKET CHROME 1

+# 0161 C WASHER, LOCK 5/16 MED 2

11

+# 0161 D NUT, HEX 5/16 - 18 2

12

+# 0300 A SCREW, HHC 5/16 - 18 X 2 1

13

+ 2532 LIGHT ASSEMBLY .................................................... 1 ................... INCLUDES ITEMS W/#

14

15+ 15503 KNOB, COMFORT GRIP STAR 1

+ 120206 LIGHT BAR 1

16

+ 405001 CONNECTOR PLUG, 4-PIN FEMALE 1

17

+ 405002 CORD, LIGHT EXTENDABLE 1

18

+# H9406 BULB, GE H9406 1

19

20 M18004 LIGHT KIT, SAW ....................................................... 1 ................... INCLUDES ITEMS W/

21# 11963 BOLT, CARRIAGE 5/16 - 18 X 1 1

*

+

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 19

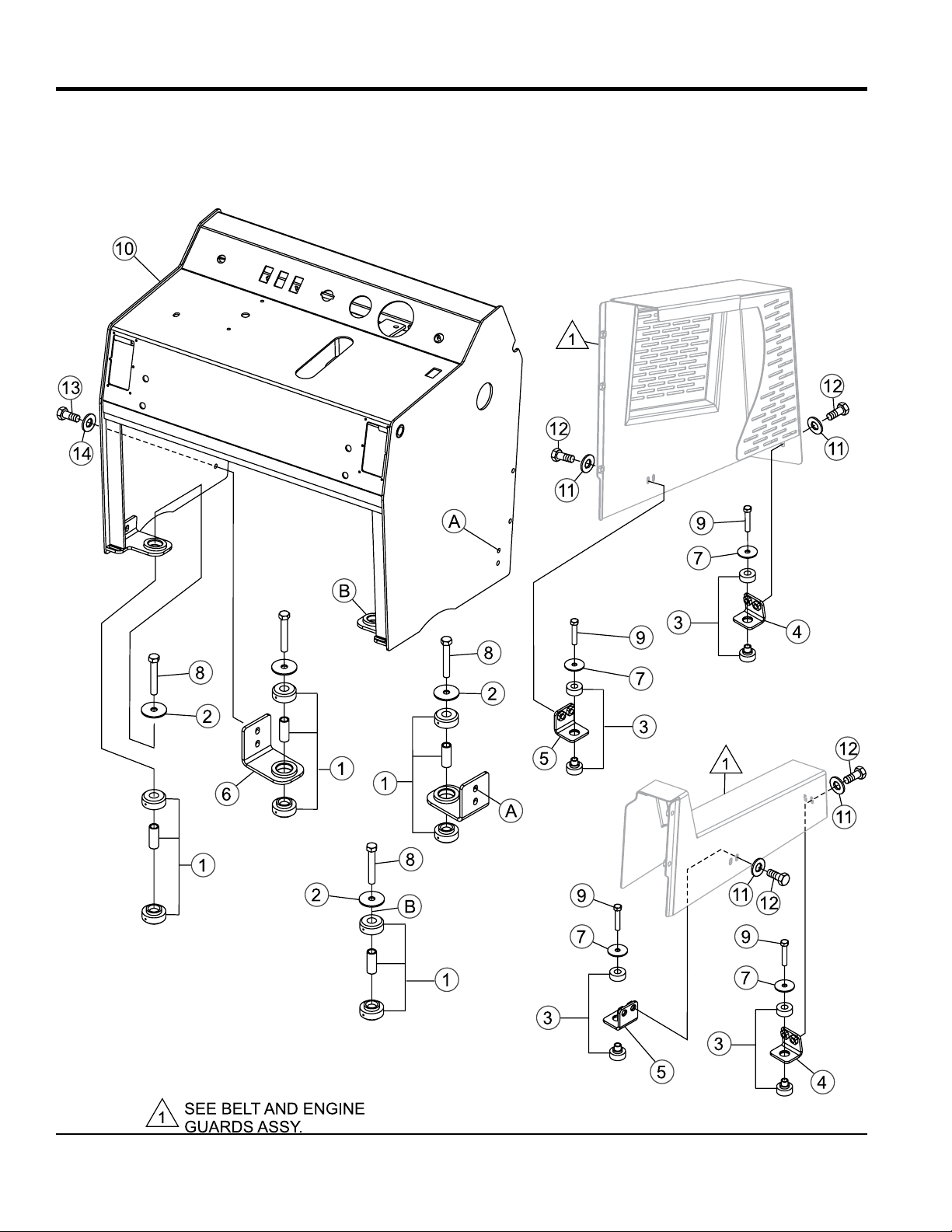

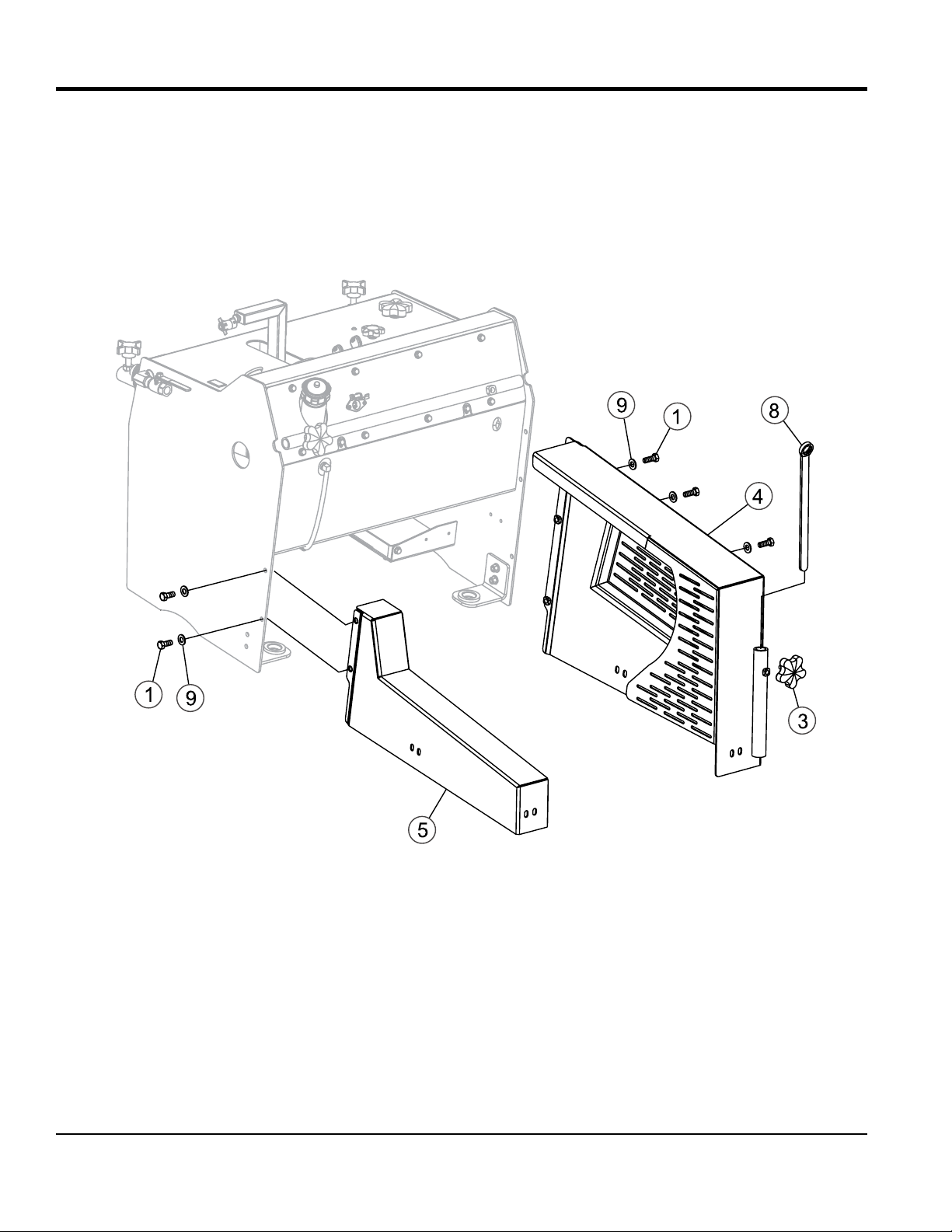

BELT AND ENGINE GUARDS ASSY.

PAGE 20 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

BELT AND ENGINE GUARDS ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0166 SCREW, HHC 3/8 - 16 X 7/8 5

3 15503 KNOB, COMFORT 1

4 37202-353 GUARD, BELT DRIVE ............................................... 1 ................... SAFETY ITEM

5 37209-353 GUARD, ENGINE ...................................................... 1 ................... SAFETY ITEM

8 584011 WRENCH, 15/16 BLADE CLOSED END 1

9 933242 WASHER, FLAT SAE 3/8 GRD 9 YZ 5

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 21

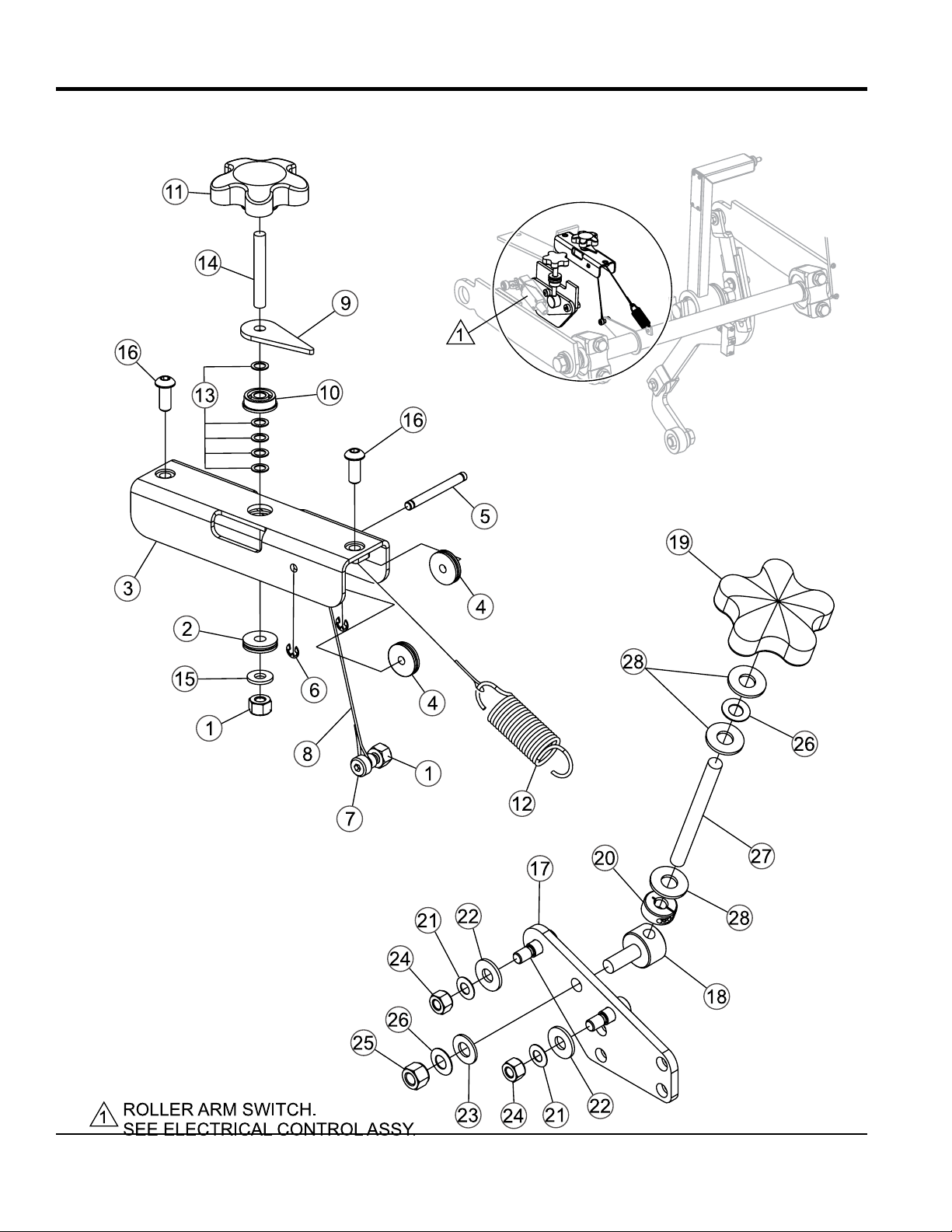

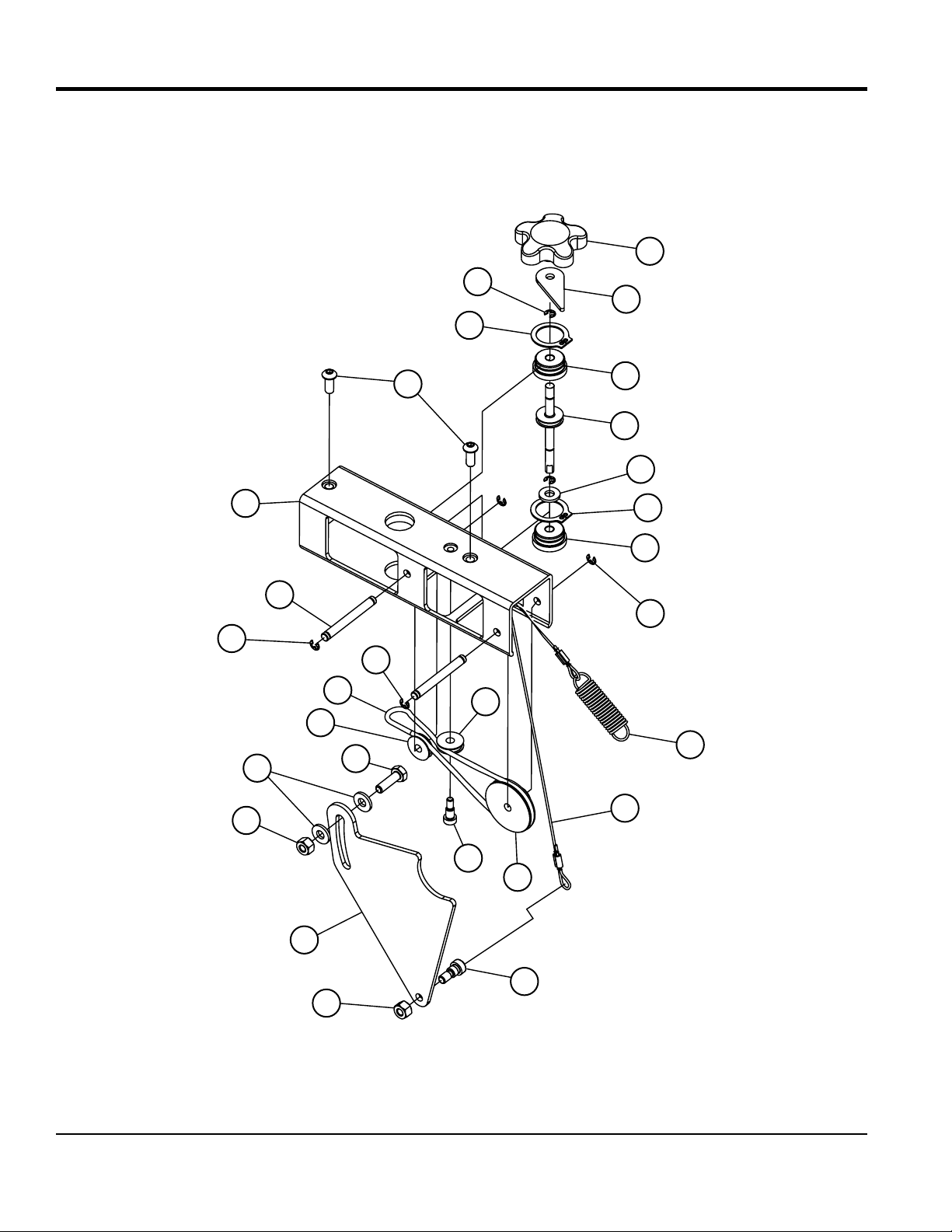

DEPTH INDICATOR/STOP SWITCH ASSY. (OLD STYLE)

PAGE 22 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

DEPTH INDICATOR/STOP SWITCH ASSY. (OLD STYLE)

NO. PART NO. PART NAME QTY. REMARKS

1 10024 NUT, NYLOC 1/4 - 20 2

2 37155 PULLEY, CABLE .75 OD 1

3 37235 BASE, SAW DEPTH INDICATOR 1

4 37240 PULLEY, CABLE .75 OD 2

5 37241 SHAFT, DEPTH INDICATOR 1

6 37332 RING, 3/16 E-STYLE EXTERNAL 2

7 37401 SCREW, SH SHLDR 1/2-20, 5/16 OD X 1/4 L 1

8 37504 CABLE, NYLON COAT SS .049 1

9 110031 POINTER, CONCRETE SAW DEPTH 1

10 460019 FLANGE, BEARING 0.25 ID X 0.75 OD 1

11 560025 KNOB, SAW DEPTH INDICATOR 1

12 565005 SPRING, EXTENSION 1

13 583059 SHIM, 0.375 OD X 0.25 ID X .020 THK 5

14 584025 STUD, 1/4 - 20 X 1-3/4 NO PLT 1

15 933240 WASHER, FLAT SAE 1/4 GRD 9 YZ 1

16 973752 SCREW, BHSC 1/4 - 20 X 5/8 SS 2

17 37248 MOUNT, SWITCH PIVOT PLATE 1

18 37246 NUT, SWIVEL DEPTH STOP 1

19 37247 KNOB, DEPTH STOP CONTROL 1

20 37249 COLLAR, SHAFT THREADED 3/8 - 16 1

21 37250 WASHER, BELLEVIEW .317 X .625 2

22 19470 WASHER, FLAT 5/16 USS 2

23 933242 WASHER, FLAT SAE 3/8 GRD 9 YZ 1

24 5283 NUT, NYLOC 5/16 - 18 2

25 10133 NUT, NYLOC 3/8 - 16 1

26 37251 WASHER, BELLEVIEW .389 X .750 2

27 37375 STUD, 3/8 - 16 X 4 1

28 4001 WASHER, FLAT USS 3/8 PLD 3

NOTICE

Parts on this page are no longer available. See Depth

Indicator/Stop Switch Assy. (New Style).

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 23

DEPTH INDICATOR/STOP SWITCH ASSY. (NEW STYLE)

6

10

5

19

10

14

17

13

3

10

8

4

9

16

4

2

1

9

19

2

10

12

20

11

7

15

18

17

PAGE 24 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

DEPTH INDICATOR/STOP SWITCH ASSY. (NEW STYLE)

NO. PART NO. PART NAME QTY. REMARKS

1 37544 SHAFT, DEPTH INDICATOR 1

2 37545 BUSHING, FLANGED 2

3 37547 SHAFT, IDLER PULLEY 2

4 37548 PULLEY, IDLER 2

5 110031 POINTER, CONCRETE SAW DEPTH 1

6 560025 KNOB, SAW DEPTH INDICATOR 1

7 37549 PULLEY, DUAL GROOVE 1

8 37550 BELT, INDICATOR DRIVE 1

9 0948 WASHER, FLAT SAE 1/4 3

10 37332 RING, 3/16 E-STYLE EXTERNAL 6

11 926149 SCREW, SHDLR 1/4D X 5/16L, 10-24 SCKT HD 1

12 37162 SPRING, EXTENSION 1

13 973752 SCREW, BHSC 1/4 - 20 X 5/8 SS 2

14 37551 HOUSING, DEPTH INDICATOR 1

15 37557 BRACKET, CABLE INDICATOR 1

16 2295 SCREW, HHC 1/4 - 20 X 7/8 1

17 10024 NUT, NYLOC 1/4 - 20 2

18 37401 SCREW, SH SHLDR 1/2-20, 5/16 OD X 1/4 L 1

19 37679 RING, SNAP SH 87 2

20 37678 CABLE ASSY., DEPTH INDICATOR 1

NOTICE

Parts on this page replace those listed on Depth Indicator/Stop Switch Assy. (Old Style)

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 25

F-N-R ASSY.

PAGE 26 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

F-N-R ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1* 576003 SNAP RING - HO-185 1

2* 460021 BEARING, ROLLER # 6204 2RS 2

3* 20842 SCREW, PAN HD 6-32 X 1/4 4

4* 579072 GROMMET, 1/2" ID 1

5* 926917 PIN, DOWEL 1/4 X 1/2 2

6* 37015 SPACER, FNR PIVOT 1

7* 37014 DISC, FNR FRICTION BRAKE 1

8* 37013 PLATE, FNR ACCESS COVER 1

9* 37022 WELDMENT, FNR HANDLE 1

10* 37016 PLATE, FNR BRAKE 1

11* 37091 SPRING, SMALLEY WAVO RW-0250 1

12* 37024 WELDMENT, FNR SPRING PLATE 1

13* 37025 NUT, HEX FINISH M20-2.5 2

14* 37026 SCREW, HHC M20 X 2.5 X 120 1

15 37021 FNR ASSEMBLY .......................................................1 ................... INCLUDES ITEMS W/

16 2153 ROD END 2

17 37136 CABLE, PUSH PULL 56" 1

18 37299 STANDOFF, PUMP CONTROL 1

19 07469-004 SCREW, SHC 10-32 X 1/2 1

20 4683 SCREW, HHC 5/16 - 18 X 5/8 1

21 933241 WASHER, FLAT SAE 5/16 GRD 9 YZ 1

22 2203 WASHER, FLAT #10 1

23 10019 NUT, NYLOC 10-32 1

24 3513 SCREW, HHC 10 - 32 X 1 1

*

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 27

FUEL ASSY.

13

15

14

12

2

5

6

3

10

2

12

11

8

8

1

7

9

4

PAGE 28 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

FUEL ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 19473 CLAMP, HOSE WORM # 2 6

2 19633 BUSHING, RUBBER FUEL DAPCO 10672 4

3 29509 CAP, FUEL TANK 2.25 DIA, ONE WAY VALVE 1

4 35022 CLAMP, LOOP CUSHIONED #8 1

5 37128 BALL VALVE, 90 W/SCREEN #6,DAPCO 12862 1

6 37191 FUEL TANK 1

7 37498 FUEL LINE 30R7 5/16 X 12 12”

8 37500 FUEL LINE 30R7 5/16 X 40.00 40”

9 37501 FUEL LINE 30R7 1/4” X 64” 64”

10 37502 TUBING, VINYL 1/4 CLEAR 1

11 37809 FILTER, DEUTZ 1178753, IN-LINE 1

12 368006 FITTING, FUEL 90 DEG. #4 X #6 BARB 3

13 37195-353 MOUNT, FUEL TANK 1

14 933242 WASHER, FLAT SAE 3/8 GRD 9 YZ 5

15 0205 SCREW, HHC 3/8 - 16 X 1.0 5

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 29

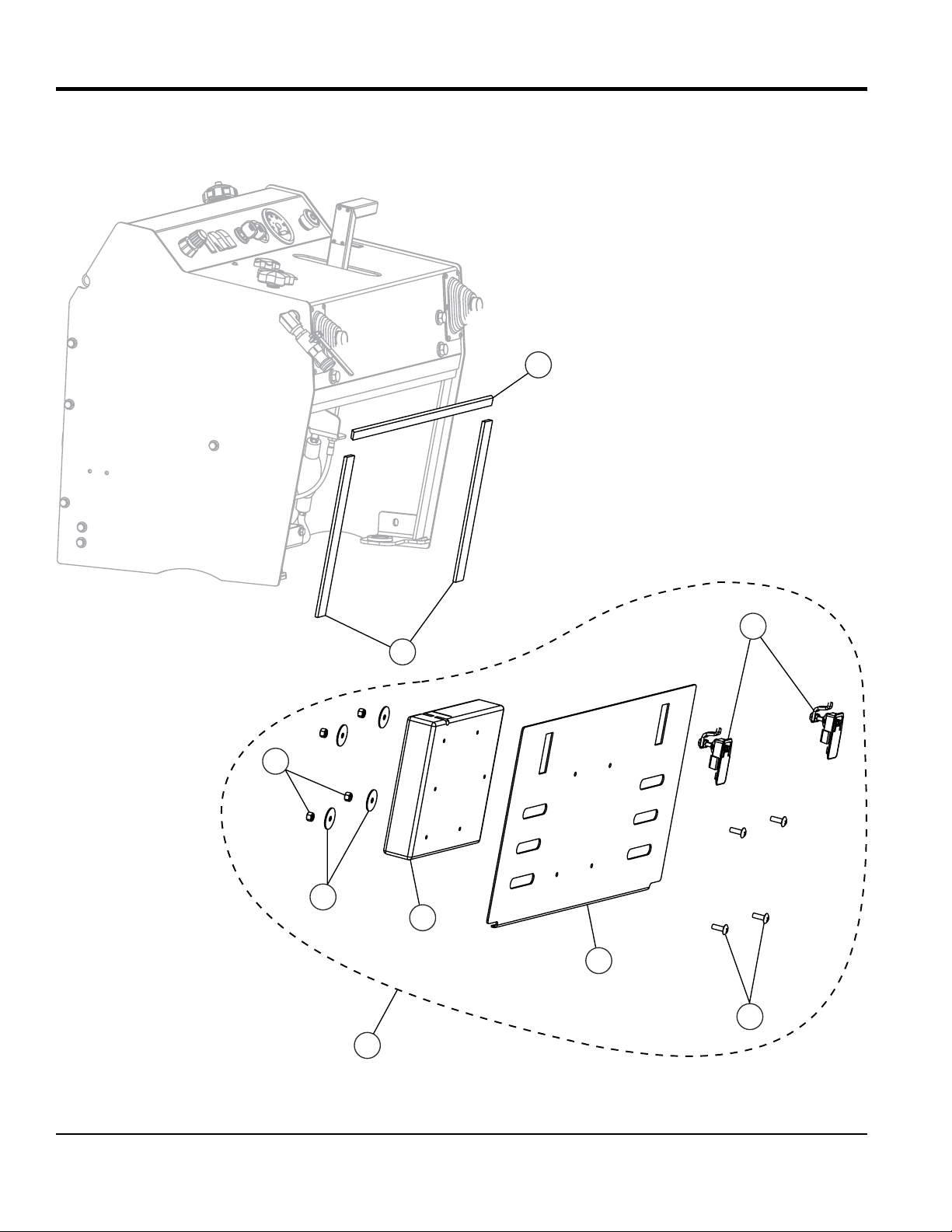

BATTERY ASSY.

PAGE 30 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

BATTERY ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 0166 SCREW, HHC 3/8 - 16 X 7/8 1

2 0655 SCREW, HHC 5/16 - 18 X 3/4 4

3 37088 BOX, BATTERY 1

4 37098 RETAINER, BATTERY HOLD-DOWN 1

5 37258-353 CLIP, BATTERY RETAINER 1

6 37284 SCREW, HHC M14 - 2.0 X 20MM GRD 8.8 PLTD 1

7 37326 CABLE, POSITIVE BATTERY STARTER 1

8 37327 CABLE, POSITIVE BATT. SOLENOID LIFT PUMP 1

9 37328 CABLE, NEGATIVE BATTERY ENGINE 1

10 37329 CABLE, NEGATIVE BATTERY LIFT PUMP 1

11 37355 CABLE, POSITIVE BATT. SOLENOID LIFT PUMP 1

12 404006 BATTERY, EXIDE ORB75DT-84 1

13 915101 SCREW, HHC 3/8 - 16 X 1/2 GRD 8 2

14 933241 WASHER, FLAT SAE 5/16 GRD 9 YZ 4

15 933245 WASHER, FLAT SAE 9/16 GRD 9 YZ 1

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 31

2

6

7

22

22

8

9

9

9

10

10

12

12

15

16

17

18

19

19

23

20

21

21

13

13

14

14

11

11

11

5

5

3

4

1

1

STAY-LEVEL HANDLEBARS ASSY.

PAGE 32 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

STAY-LEVEL HANDLEBARS ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37085 BEARING, 1.25" TAP BASE 1

2 37239 SHAFT, CROSSDRIVE SLH 1

3 37119 RECEIVER, SLH HANDLEBAR LH 1

4 37120 RECEIVER, SLH HANDLEBAR RH 1

5 37125 BEARING, PLAIN 1.0625 ULTRASERT UC200 2

6 560023 HANDLEBAR ASSY., CONCRETE SAW .................. 2 ................... INCLUDES ITEMS W/

7 37174 LINK ASSY., SLH CONTROL COUPLER ................ 1 ................... INCLUDES ITEMS W/#

8 37139 SLH CONTROL LEVER 1

9 16523 SCREW, HHC 3/4 - 10 X 1-1/2 GD 8 3

10 933245 WASHER, FLAT SAE 9/16 GRD 9 YZ 4

11 933247 WASHER, FLAT SAE 3/4 GRD 9 YZ 3

12 37284 SCREW, HHC M14-2.0 X 20MM GRD 8.8 PLTD 4

13 37312 RING, RETAINING WHM-106 2

14 19977 KNOB, CLAMP 1/2 - 13 THREAD 2

15# 37123 LINK, SLH CONTROL COUPLER LOWER 1

16# 37173 LINK, SLH CONTROL COUPLER UPPER 1

17# 37297 PLATE, SLH CLAMP 1

18# 16526 SCREW, HHC 1/2 - 13 X 1-3/4 GRD 8 2

19 4196 SCREW, HHC 3/8 - 16 X .75 2

20# 933244 WASHER, FLAT SAE 1/2 GRD 9 YZ 2

21 4001 WASHER, FLAT USS 3/8 PLD 2

22 37133 PIN, SLH COUPLER PIVOT 2

23* 560017 GRIP, HANDLEBAR 2

*

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 33

HANDLEBAR BOOT ASSY.

1

3

4

2

PAGE 34 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

HANDLEBAR BOOT ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37117 BOOT ASSY., HANDLEBAR .....................................1 ................... INCLUDES ITEMS W/

2* 37105 BOOT, SLH HANDLEBAR 1

3* 37061 PLATE, RETAINER 1

4* 5065 B SCREW, PHP 10 - 32 X 1/2 6

*

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 35

3

WATER SYSTEM ASSY.

2

5

2

1

7

3

4

6

PAGE 36 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

WATER SYSTEM ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 38313 FITTING, BRASS (F) 3/4 GHT SWIVEL 3/8 MNPT 1

2 37813 FITTING, 90 1/2MP - 3/8FP 2

3 37311 BALL VALVE, BRASS 3/8 MNPT X FNPT 2

4 37533 HOSE ASSEMBLY, WATER SYSTEM 76.5" 1

5 37397 FITTING, 8MJ X 1/2 MP 1

6 37532 FITTING, QC FEMALE 1

7 37296 HOSE ASSEMBLY, CROSSOVER 1

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 37

ENGINE ASSY.

PAGE 38 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

ENGINE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 35396 ENGINE, DEUTZ 60HP BF3L2011 TRBO DSL 1

2 2299 SCREW, HHC M8 - 1.25 X 16MM 2

3 933241 WASHER, FLAT SAE 5/16 GRD 9 YZ 2

4 10024 NUT, NYLOC 1/4 X 20 2

5 933240 WASHER, FLAT SAE 1/4 GR 9 YZ 2

6 915004 SCREW, HHC 1/4 - 20 X 7/8 2

7 37473 HEAT SHIELD ........................................................... 1 ................... SAFETY ITEM

8 37255 THROTTLE LEVER 1

9 1174696 FILTER, FUEL DEUTZ ..............................................1 ................... REPLACES 304010

10 1174416 FILTER, OIL DEUTZ .................................................1 ................... REPLACES 306012

11 21004-003 V-BELT, AX-35 1

12 37256 BRACKET, THROTTLE/FNR CABLE 1

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 39

1

THROTTLE CONTROL ASSY.

8

7

2

3

4

9

5

6

PAGE 40 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

THROTTLE CONTROL ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37212 THROTTLE 1

2 37256 BRACKET, THROTTLE/FNR CABLE 1

3 37255 LEVER, THROTTLE 1

4 933240 WASHER, FLAT SAE 1/4 GRD 9 YZ 1

5 25624 SWIVEL, CABLE END W/ WASHER 1

6 923113 SCREW, SHC 8 - 32 X 3/8 GRD 8 1

7 23942-097 WASHER, M6 2

8 12464 SCREW, HHC M6 - 1.0 X 16MM 2

9 25634 BULK HEAD ADAPTOR 1

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 41

ENGINE MOUNTS ASSY.

2

10

10

15

4

3

7

14

1

6

4

10

3

7

7

14

6

15

15

14

9

11

5

14

15

13

12

PAGE 42 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

12

10

8

ENGINE MOUNTS ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37491 MOUNT, RH ENGINE 1

2 37100 MOUNT, LH ENGINE 1

3 37099 PIN, ENGINE PIVOT 2

4 37031 BUSHING, SPHERICAL-ULTRASERT UC200 2

5 37147 PIN, UPPER ENGINE PIVOT 1

6 37313 RING, SPIRAL RETAINING WHM-200 2

7 37310 SCREW, HHC M14-2.0 X 40MM GRD 10.9 NP 6

8 37146 SCREW, HHC M14-2.0 X 35MM GRD 10.9 NP 2

9 913838 SCREW, HHC 3/4 - 10 X 4 GRD5 ZINC 1

10 933245 WASHER, FLAT SAE 9/16 GRD 9 YZ 8

11 4389 NUT, HEX 3/4 - 10 1

12 16530 SCREW, HHC 7/16 - 14 X 1 2

13 933243 WASHER, FLAT SAE 7/16 GRD 9 YZ 2

14 37037 WASHER, ENGINE PIVOT PIN 4

15 21376 SCREW, HHC 5/8 - 11 X 1-1/2 4

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 43

AIR CLEANER ASSY.

PAGE 44 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

AIR CLEANER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37151 HOSE ASSY, AIR INTAKE 1

2 10434 CLAMP, HOSE WORM # 32 1-9/16 TO 2" 1

3 35309 TUBE, AIR INTAKE BREATHER 1

4 15538 CLAMP, HOSE WORM # 6 1

5 406018 INDICATOR, ELECTRICAL SERVICE 1

6 65516 FITTING, NIPPLE 1/8" MP 1

7 29218 CLAMP, HOSE WORM # 48 2

8 933241 WASHER, FLAT SAE 5/16 GRD 9 YZ 3

9 1665 SCREW, HHC 3/8 - 16 X 2 4

10 10133 NUT, NYLOC 3/8 - 16 4

11 M940653 SCREW, HHC M6 - 1.0 X 25MM GRD 10.9 2

12 1928 SCREW, HHC M8 - 1.25 X 40MM 1

13 9182 SCREW, HHC M8 - 1.25 X 45MM 1

14 2866 SCREW, HHC M8 - 1.25 X 20MM 1

15 35399 GASKET, AIR INTAKE TUBE 1

16 37153 HOSE, 3.00 ID MOLDED 90 DEGREE 1

17 37199 AIR CLEANER ASSEMBLY 3 INCH #7VLR 1

18 37307 SPACER, AIR CLEANER MOUNT .375L 1

19 37309 SPACER, AIR CLEANER MOUNT .875L 1

20 962019 CLAMP, HOSE WORM # 44 2

21 37317 BUSHING, AIR INTAKE 2.75 X 3.00 1

22 37112 MOUNT, AIR FILTER 1

23 37761 BRACKET, AIR INTAKE BODY 2

24 P772579 PRIMARY FILTER, DEUTZ BF3L2013 1

25 P775300 SAFETY FILTER, DEUTZ BF3L2014 1

26 12832 WASHER, SNUBBING 4

27 575001 RUBBER ISOLATOR, TPC #60166-1 4

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 45

MUFFLER ASSY.

PAGE 46 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

MUFFLER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1* 285003 EXHAUST, 12" EXTENSION 1

2*# 570005 CLAMP, MUFFLER 2-1/2" 5/16 U-BOLT 2

3*# 8131 NUT, FINISH L.H. 5/16 - 24 4

4*# 933241 WASHER, FLAT SAE 5/16 GRD 9 YZ 4

5*# 280005 MUFFLER ................................................................1 ................... INCLUDES ITEMS W/%

6*#% 940693 SCREW, HHC M10 - 1.5 X 25MM GRD 10.9 NP 2

7*#% 940358 WASHER, M10 X 21MM ZINC 2

8*#$ 25592 NUT, M8 - 1.25" 3

9*#$ 25591 WASHER, M8 3

10*#$ 25642 GASKET, TURBO INLET DEUTZ 1

11*#$ 25593 STUD, M8 - 1.25 X 30MM 3

12 37143 MUFFLER ASSEMBLY COMPLETE.........................1 ................... INCLUDES ITEMS W/

13* 280002 MUFFLER AND FLEX KIT ASSEMBLY ....................1 ................... INCLUDES ITEMS W/#

14*# 280004 FLEX KIT ASSEMBLY ...............................................1 ................... INCLUDES ITEMS W/$

*

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 47

LIFT BAIL ASSY.

PAGE 48 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

LIFT BAIL ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37114 SPACER, DEUTZ ENGINE LIFTING BRACKET 1

2 37115 BRACKET, DEUTZ ENGINE LIFTING ...................... 1 ................... SEE NOTE BELOW

3 940694 SCREW, HHC M10 - 1.5 X 30MM FT 10.9 NP 1

4 37314 SCREW, HHC M12 - 1.75 X 120MM TAP BOLT 1

5 37315 SCREW, HHC M12 - 1.75 X 120MM 10.9 NP 1

6 940358 WASHER, M10 X 21MM ZINC 1

7 933244 WASHER, FLAT SAE 1/2 GRD 9 YZ 3

8 933241 WASHER, FLAT SAE 5/16 GRD 9 YZ 1

9 16083 NUT, HEX M12 - 1.75 NO PLATE 1

10 06500-007 SCREW, HHC 5/16 - 18 X 7/8 1

NOTICE

Type 2 Rope Guide System supercedes Type 1 Rope

Guide System. See Front Pointer Assy.

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 49

6

7

8

9

9

10

10

10

13

14

12

15

5

5

1

2

4

4

3

11

16

PLATFORM GUARDS/REAR POINTER ASSY.

PAGE 50 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

PLATFORM GUARDS/REAR POINTER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37185 GUARD, BLADESHAFT PULLEY ............................. 1 ................... SAFETY ITEM

2 583091 STRAP, LOWER BELT GUARD 1

3 583092 WASHER, LOWER BELT PROTECTOR 1

4 933244 WASHER, FLAT SAE 1/2 GRD 9 YZ 4

5 3214 SCREW, HHC 1/2 - 13 X 1-1/4 4

6 915105 SCREW, HHC 3/8 - 16 X 1.0 GRD 8 1

7 110020 POINTER, REAR SAW 1

8 37360 SHIELD, CONCRETE SLURRY 1

9 915105 SCREW, HHC 3/8 - 16 X 1.0 GRD 8 3

10 933242 WASHER, FLAT SAE 3/8 GRD 9 YZ 6

11 37122 PLATFORM, W/A 1

12 37450 STRIP, SLURRY CONTROL 1

13 10133 NUT, NYLOC 3/8 - 16 3

14 20982 SCREW, FHSC 3/8 - 16 X 1-1/2 PLATED 3

15 M200000 GUARD, SAW BLADE COLLAR 1

16 35030 GUARD W/A, SAW BLADE COLLAR, RH 1

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 51

WHEEL DRIVE ASSY.

PAGE 52 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

WHEEL DRIVE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37102 MOUNT, WHEEL MOTOR 1

2 37095 WHEEL, 12 X 3 TAPERED BORE 2

3 37096 BRAKE PAD 2

4 37097 BRAKE ARM 1

5 37138 CAP, WHEEL DUST 2

6 0655 SCREW, HHC 5/16 - 18 X 3/4 2

7 0205 SCREW, HHC 3/8 - 16 X 1.0 8

8 3214 SCREW, HHC 1/2 - 13 X 1-1/4 5

9 933213 WASHER, FENDER 5/16 X 1 ZINC 2

10 37048 SPRING, 1.125 X .187 X 4 W/EYELET 2

11 23858-001 EYEBOLT, 3/8 - 16 X 2.0 2

12 933242 WASHER, FLAT SAE 3/8 GRD 9 YZ 10

13 933244 WASHER, FLAT SAE 1/2 GRD 9 YZ 7

14 933247 WASHER, FLAT SAE 3/4 GRD 9 YZ 3

15 10133 NUT, NYLOC 3/8 - 16 2

16 968011 NUT, HEX FINISH 1/2 - 13 2

17 19974 PIN, CLEVIS 1/2 X 1.25 3

18 966166 PIN, CLEVIS 3/4 X 2 1

19 965105 PIN, COTTER 5/32 X 1-1/2 1

20 965103 PIN, COTTER 5/32 X 1 3

21 37322 SPRING, CREST TO CREST 4

22 1456 NUT, HEX FINISH 3/8 - 16 2

24 37923 NUT, SLOTTED 3/4-20 HEX 2

26 0126 KEY, WOODRUFF #606 3/16 X 3/4 2

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 53

FRONT AXLE ASSY.

PAGE 54 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

FRONT AXLE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37106 FRONT AXLE W/A 1

2 933246 WASHER, FLAT 5/8 SAE GRD9 YZ 2

3 06505-008 SCREW, HHC 5/8 - 11 X 1.00 2

4 37132 WHEEL ASSEMBLY, FRONT .....................................2 .................. INCLUDES ITEMS W/

5 2621 FITTING, GREASE ZERK STR 1/4 - 28 2

6 26091 SCREW, SHS 1/4 - 28 X 1/4 CUP POINT 4

7 2186 SCREW, SHC 5/16 - 18 X 2-1/4 PLTD 1

8 926064 SCREW, SQHS CUP POINT 5/16 - 24 X 5/8 1

9 5283 NUT, NYLOC 5/16 - 18 1

10 1162 A CAP, GREASE ZERK #2 YELLOW 2

11 37040 BEARING, 1.250" FLANGE 2

12 933244 WASHER, FLAT SAE 1/2 - 13 GD 8 16

13 16629 NUT, NYLOC 12 - 13 GD 8 12

14 37260 PIN, LIFT CYLINDER 1

15 915211 SCREW, HHC 1/2 - 13 X 2 GRD8 YZ 12

16 37138 CAP, WHEEL DUST 2

17* 37131 WHEEL, 8 X 3 POLYURETHANE 2

18* 460002 BEARING, BALL KOYO # 6005 SRS 4

19* 485002 SEAL, OIL CR # 28655 2

20* 576003 SNAP RING, - HO-185 2

21 37165 PLATE, BACKING 2

*

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 55

HYDRAULIC SYSTEM ASSY.

PAGE 56 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

HYDRAULIC SYSTEM ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37113 PUMP, 24V DC LIFT - HYDROGEAR 1

2 306006 FILTER, TRANSAXLE 1

3 25617 FILTER HEAD, TRANSAXLE 1

4 37121 LIFT CYLINDER ASSEMBLY 1

5 37211 CYLINDER, BRAKE 2" X 1.5" STROKE 1

6 37213 RESERVOIR, 350ML HYDROGEAR 71327 1

7 37104 PUMP, HYDROGEAR 1

8 37056 MOTOR, WHEEL - HYDROGEAR HGM-15P-7131 2

9 37162 EXTENSION SPRING, 1.8" - 8.1 LB RATE 1

10 933240 WASHER, FLAT SAE 1/4 GRD 9 YZ 4

11 1579 SCREW, HHC 1/4 - 20 X .5 2

12 4514 SCREW, HHC 1/4 - 20 X 5/8 GRD 5 2

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 57

ENGINE PIVOT CYLINDER ASSY.

PAGE 58 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

ENGINE PIVOT CYLINDER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1* 37445 VALVE, CHECK 2

2* 37446 VALVE, CARTRIDGE 4-WAY 2-POSITION 1

3* 37447 SOLENOID COIL 12VDC 1

4* 37448 PISTON, PILOT 1

5* 37449 PISTON, BACKUP RING ...................................... 2 ................S/N ZD3700241 AND BELOW

6* 37492 O-RING ................................................................. 1 ................S/N ZD3700241 AND BELOW

7* 37390 CYLINDER, HYDRAULIC 1

8 37495 CYLINDER AND VALVE ASSEMBLY .................... 1 ................INCLUDES ITEMS W/

9 37260 PIN, LIFT CYLINDER 1

10 37166 PIN, LOWER ENGINE PIVOT 1

11 933243 WASHER, FLAT SAE 7/16 GRD 9 YZ 2

12 16530 SCREW, HHC 7/16 - 14 X 1 2

*

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 59

HYDRAULIC HOSES ASSY.

PAGE 60 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

HYDRAULIC HOSES ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37475 HOSE ASSEMBLY, #4 LP 1

2 37476 HOSE ASSEMBLY, #4 LP 1

3 37477 HOSE ASSEMBLY, #4 LP 1

4 37290 HOSE ASSEMBLY, #4 HP PARFLEX 1

5 37295 HOSE ASSEMBLY, #6-8 LP 1

6 37294 HOSE ASSEMBLY, #6 LP 1

7 37347 HOSE ASSEMBLY, #6 LP ........................................ 1 .................... SEE NOTE BELOW

8 37291 HOSE ASSEMBLY, #4 PARFLEX 1

9 37292 HOSE ASSEMBLY, #4 LP 1

10 37278 HOSE ASSEMBLY, #6 PARFLEX 1

11 37279 HOSE ASSEMBLY, #6 PARFLEX 1

12 37283 HOSE ASSEMBLY, #8 LP 1

13 37281 HOSE ASSEMBLY, #6 LP 1

14 37282 HOSE ASSEMBLY, #6 LP 1

15 37293 HOSE ASSEMBLY, #4 LP 1

16 37280 HOSE ASSEMBLY, DRIVE MOTOR CROSSOVER 1

NOTICE

FOR SAWS up to S/N ZD3700238 ONLY. When Ordering

this hose (P/N 37347 item 7 on this page), also order two

(2) each fittings (P/N 11887, item 22 shown on Hydraulic

Fittings and Clamps Assy.).

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 61

22

2

11

12

15

7

13

14

4

13

12

2

22

10

10

19

18

20

10

1

8

5

9

16

3

3

17

21

3

6

23

2424

25

26

27

28

27

28

29

30

31

32

33

HYDRAULIC FITTINGS AND CLAMPS ASSY.

PAGE 62 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

HYDRAULIC FITTINGS AND CLAMPS ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 21095 FITTING, STR 4MJ - 4MO 1

2 368817 FITTING, 90 4MJ - 4MO 2

3 37407 FITTING, 4MJ X 6MO-90 4

4 15538 CLAMP, HOSE WORM #6, 7/16" TO 7/8" 2

5 37793 CLAMP ASSEMBLY, HOSE 1

6 37352 CLAMP ASSEMBLY, 5/16 HOSE 1

7 37792 CLAMP ASSEMBLY, HOSE 1

8 37433 CLAMP ASSEMBLY, HOSE 1

9 366437 FITTING, BULKHEAD #4 JIC 1

10 11721 FITTING, STR 6MJ - 6MO 4

11 12431 FITTING, 90 8MJ - 6MO 1

12 21115 FITTING, STR 6MJ - 6MO LONG 2

13 37405 FITTING, 10MO X - 6FO - ST 2

14 37406 FITTING, 6MJ X 10MO - ST 2

15 21159 FITTING, 45 4MJ - 4MO 1

16 367470 FITTING, STR 4MJ - 6MO 3

17 37788 FITTING, TEE 4MO - 4MO - 4MJ 1

18 12546 FITTING, QD 4MO DIAGN PARKER PD 341 1

19 12148 CAP, DUST DIAG PARKER PD6 - 285 1

20 35022 CLAMP, LOOP CUSHIONED #8 1

21 37493 FITTING, ORIFICE 4MJ - 4MO X .100 1

22 11887 FITTING, STR 6MJ - 4MO ........................................2 ................... SEE NOTE BELOW

23 37399 4MJ X 2MO-ST 1

24 37400 FITTING, 6MJ X 6MO-9OLL 1

25 2623 SCREW, HHC 5/16-18 X 1.25 4

26 37424 COVER PLATE, BEHRINGER STB-T2 4

27 37420 1/2" CLAMP, BEHRINGER T2050-PP 4

28 37423 STACK BOLT, BEHRINGER STB-T2 6

29 37421 5/8" CLAMP, BEHRINGER T2062-PP 2

30 37422 1/2" X 5/8" CLAMP, BEHRINGER T2050/T2062-PP 3

31 37418 TOP BOLT, 5/16X18 X 2 1

32 37417 COVER PLATE, BEHRINGER COP-O 1

33 37416 CLAMP, 5/16 1

NOTICE

FOR SAWS up to S/N ZD3700238 ONLY. When Ordering

hose (P/N 37347 item 7 on Hydraulic Hoses Assy.), also

order two (2) each fittings (P/N 11887, item 22 shown

on this page.

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 63

FRONT POINTER ASSY.

PAGE 64 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

FRONT POINTER ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37182 POINTER 1

2 582008 BUSHING, FLANGE 1.0 OD X .75 ID 4

3 500005 WHEEL, POINTER 6" X 1" 1

4 37178 AXLE, POINTER WHEEL 1

5 926006 SCREW, SQHS CP 1/4 - 20 X1/2 2

6 15503 KNOB, COMFORT GRIP STAR 1

7 110038 SAW POINTER 15" RH FRONT 1

8 1456 NUT, HEX FINISH 3/8 - 16 1

9 10133 NUT, NYLOC 3/8 - 16 ................................................ 1 ................... SEE NOTE BELOW

10 5070 B NUT, NYLOC 3/4 - 10 2

11 933247 WASHER, FLAT SAE 3/4 GRD 9 YZ 2

12 3233 WASHER, FENDER 1.50 OD X 3/8 ID 2

13 37261 PLUG, FINISHING 3/4" 2

14 544002 SHOULDER, ADAPTER ...........................................1 ................... SEE NOTE BELOW

15 125043-3 RETAINER, SAW POINTER CABLE .........................1 ................... SEE NOTE BELOW

16 540039 PULLEY, POINTER ROPE ........................................ 1 ................... SEE NOTE BELOW

17 10136 WASHER, FLAT SAE 3/8 ..........................................2 ................... SEE NOTE BELOW

18 1665 SCREW, HHC 3/8 - 16 X 2 ........................................ 1 ................... SEE NOTE BELOW

19 0205 SCREW, HHC 3/8 - 16 X 1.0 1

20 574003 ROPE, POINTER ASSY. ........................................... 1 ................... INCLUDES BALL & CRIMP

21 574002 CAM CLEAT 1

22 15173 WASHER, FLAT #8 2

23 13287 NUT, NYLOC 8 - 32 2

24 923199 SCREW, SHC 8 - 32 X 1-1/4 2

25 37112 MOUNT, AIR FILTER 1

NOTICE

These parts are used only on "Type 1" Rope Guide Systems shown in illustration on Lift Bail Assy.

Type 2 Rope Guide System supercedes Type 1 Rope

Guide System. See illustration.

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 65

BELT DRIVE ASSY.

PAGE 66 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

BELT DRIVE ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37001 PLATE, ENGINE ADAPTER-DEUTZ 1

3# SHAFT, ENGINE DRIVE-DEUTZ 1

4 37019 PLATE, PULLEY DRIVE COVER 1

5# FLANGE, ENGINE DRIVE-DEUTZ 1

6# FLANGE, PULLEY DRIVE-DEUTZ 1

7 37137 BELT TENSIONER ASSY. .........................................1 ................... INCLUDES ITEMS W/

8 37002 PULLEY, PUMP DRIVE 3.75" A-SECTION 1

9 37319 WASHER, THRUST 1.00 OD X .265 L X .265 H 1

10 37320 SCREW, SHC 10-32 X 3/4 1

11 923201 SCREW, SHC 1/4 - 20 X 1/2 8

12 37267 SPACER, BELT TENSIONER 1

13 21004-003 BELT, AX-35 1

14 37755 SHOE, LOWER BELTSIDE 1

15 460016 BUSHING, TAPER-LOCK 2517 X 1-7/8 .................... 1 ................... FITS 20", 26", 30", 36"

15 460023 BUSHING, TAPER-LOCK 2012 X 1-7/8 .................... 1 ................... FITS 16"

16 10057-061 KEY, 1/2" SQ X 3-1/2" 1

17 37269 KEY, SQUARE 1/8 X 3/4 1

18

37266 SCREW, MODIFIED HEAD 3/8 X 1-3/4 1

*

19 37218 GUARD, PUMP DRIVE ............................................. 1 ................... SAFETY ITEM

20 582012 BUSHING, QUICK DISCONNECT BLADE SHAFT 2

21 915315 SCREW, HHC 5/8 - 11 X 3 GR8 1

22 915316 SCREW, HHC 5/8 - 11 X 3 LH GR8 1

23 10138 SCREW, SHS 1/4 - 20 X 1/2 NP 1

24 926919 PIN, DOWEL 1/4 X 3/4 1

25 37268 STUD, 3/8 - 16 X 3 SELF-LOCKING 1

26 933242 WASHER, FLAT SAE 3/8 GRD 9 YZ 5

27 1456 NUT, HEX FINISH 3/8 - 16 4

28 37762 STUD, 1/2 - 13 X 1-3/4 1

29 924289 SCREW, FHSC 3/8 - 16 X 1-3/4 2

30 10133 NUT, NYLOC 3/8 - 16 2

31 939978 SCREW, FHSC M10 - 1.5 X 25MM NP 11

32 938422 SCREW, HHC M10 - 1.0 X 50MM 10.9 NP 8

33 37177 FLANGE ASSY, 6.0" OUTER BLADE ....................... 2 .............. FITS 30", 36" BELT DRIVE

33 37169 FLANGE ASSY, 5.0" OUTER BLADE ....................... 2 .............. FITS 16", 20", 26" BELT DRIVE

34 37176 FLANGE ASSY, 6.0" INNER BLADE ........................2 .............. FITS 30", 36" BELT DRIVE

34 37168 FLANGE ASSY, 5.0" INNER BLADE ........................2 .............. FITS 16", 20", 26" BELT DRIVE

35 520007 V-BELT, 5G 3 VX 530 POWERBAND 2

36 540047 PULLEY, 5.6 10G 3V X 2517 TAPER ........................1 .............. FITS 36" BELT DRIVE

36 540041 PULLEY, 5.3 10G 3V X 2517 TAPER ........................1 .............. FITS 30" BELT DRIVE

36 540040 PULLEY, 5.0 10G 3V X 2517 TAPER ........................1 .............. FITS 26" BELT DRIVE

36 540035 PULLEY, 4.75 10G 3V X 2517 TAPER ......................1 .............. FITS 20" BELT DRIVE

36 540046 PULLEY, 4.2 10G 3V X 2012 TAPER ........................1 .............. FITS 16" BELT DRIVE

*

CONTINUED NEXT PAGE

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 67

BELT DRIVE ASSY. (CONTINUED)

PAGE 68 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

BELT DRIVE ASSY. (CONTINUED)

NO. PART NO. PART NAME QTY. REMARKS

37 37134 BLADE SHAFT ASSY. 1

38 926790 PIN, DOWEL 3/8 X 1-3/4 ...................................... 2 .................. INCLUDED W/ ITEM 33

39 25992 SCREW, SHC 12 - 24 X 1/2 4

40 37735 RING, FAN MOUNT 1

41 37734 FAN, CW 8" 10 BLADE 1

42 37763 STUD, 1/2 - 13 X 5-1/2 1

43 915103 SCREW, HHC 3/8 - 16 X 3/4 GR8 YZ 2

44 37756 SHOE, UPPER BELTSIDE 1

45 37833 SPLINED DRIVE ASSY. ........................................ 1 ..................INCLUDES ITEMS W/#

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 69

DRIVE PULLEY ASSY.

PAGE 70 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

DRIVE PULLEY ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1* 37011 PULLEY, 3.3 10 3V 4.5 1A ........................................ 1 .............. FITS 26", 30", 36" BELT DRIVE

1# 37154 PULLEY, 4.1 3V 4.5 1A ............................................. 1 ..............FITS 16", 20" BELT DRIVE

2*# 37003 SUPPORT, ENGINE DRIVE BEARING 1

3*# 37028 BEARING, TAPERED ROLLER NSK #32007XJ 2

4*# 37090 SPRING, SMALLEY WAVO RW-0162 1

5*# 37017 FLANGE, ENGINE DRIVE BEARING SUPPORT 1

6*# 37092 SEAL, CR 17753 2

7*# 37035 SCREW, SHC 4-40 X 3/8 4

8*# 915004 SCREW, HHC 1/4 - 20 X 7/8 GR8 YZ 8

9*# 933240 WASHER, FLAT SAE 1/4 GRD 9 YZ 8

10 37103 DRIVE PULLEY ASSY., 3.3 10 3V 4.5 1A ................ 1 .............. FITS 26", 30", 36" BELT DRIVE

................................................................................................... INCLUDES ITEMS W.

10 37321 DRIVE PULLEY ASSY., 4.1 3V 4.5 1A ..................... 1 .............. FITS 16", 20" BELT DRIVE

................................................................................................... INCLUDES ITEMS W/#

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 71

BLADESHAFT ASSY.

PAGE 72 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

BLADESHAFT ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1* 37108 HOUSING, BLADESHAFT 1

2* 37111 BLADESHAFT, 7000 SERIES 1

3* 06502-010 SCREW, HHC 7/16 - 14 X 1-1/4 6

4* 933243 WASHER FLAT SAE 7/16 GRD 9 YZ 6

5* 421001 SENSOR, HALL EFFECT SPEED PICKUP 1

6* 583026 DRAIN PLUG, MAGNETIC 1/2 - 20 1

7* 577009 GASKET, DRAIN PLUG 1

8* 25695 WASHER, SEAL 3/4" 1

9* 25690 GEAR, SAW BLADE SHAFT SPEED PICKUP 1

10* 460010 BEARING, ROLLER KOYO # 7210BGC3 2

11* 39460011 BEARING, BALL KOYO # NU2210RC3 1

12* 480006 SEAL, OIL CR# 28655 2

13* 480007 SEAL, OIL CR- 19599 2

14* 485003 SLEEVE, BLADE SHAFT SEAL 2

15* 486001 WASHER, THRUST 6000 SERIES 2

16* 576006 SNAP RING, VITON # AS-135 2

17* 578135 O-RING, VITON # AS-135 2

18* 576007 SNAP RING, VHO-354 1

19* 10138 SCREW, SHS 1/4 - 20 X 1/2 6

20* 927048 KEY, WOODRUFF #807 1/4 X 7/8 2

21 37134 BLADESHAFT ASSEMBLY ....................................... 1 ................... INCLUDES ITEMS W/

*

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 73

16", 20", 26" BLADEGUARD ASSY.

PAGE 74 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

16", 20", 26" BLADEGUARD ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1@ 200004 BLADEGUARD W/A, 16" REAR HALF 1

1# 200008 BLADEGUARD W/A, 20" REAR HALF 1

1$ 200010 BLADEGUARD W/A, 26" REAR HALF 1

2@ 200003 BLADEGUARD W/A, 16" FRONT HALF 1

2# 200007 BLADEGUARD W/A, 20" FRONT HALF 1

2$ 200009 BLADEGUARD W/A, 26" FRONT HALF 1

3@#$ 582040 BUSHING, BLADEGUARD HINGE DELRIN 1

4@#$ 200019 FLAP,MUD BLADEGUARD ....................................... 1 ................... SAFETY ITEM

5@#$ 37394 MANIFOLD, WATER SMALL 1

6@#$ 2113 FITTING, PLUG 1/8MP HEX SKT HD 1

7@#$ 370456 FITTING, BRASS 6BARB-1/4MP 2

8@#$ 10176 NUT, NYLOC 1/2-13 1

9@#$ 10024 NUT, NYLOC 1/4-20 3

10@#$ 0131 A SCREW, HHC 1/4 - 20 X 3/4 1

11@#$ 06503-026 SCREW, HHC 1/2 - 13 X 3-1/4 1

12@#$ 26250 SCREW, HHC 1/4 - 20 X 1-3/4 2

13@#$ 10930 WASHER, FENDER 1/4 X 1-1/4 1

14@#$ 37396 3/8" QC MALE 1

15@# 37506 HOSE, WATER #6 LP, 16", 20" BLADEGUARD 2

15$ 37508 HOSE, WATER #6 LP, 26" BLADEGUARD 2

16@#$ 22129-001 PIPE STRAP 3/8 2

17@#$ 1618 NUT, NYLOC 10-24 2

18@#$ 923144 SCREW, SHC 10-24 X 1/2 2

19 BG1600 GUARD, 16" STREETPRO 3/6/7 STD FLANGE .......1 ................... SAFETY ITEM

........................................................................................................ INCLUDES ITEMS W/@

........................................................................................................ CONTACT MQ UNIT SALES

19 BG2000 GUARD, 20" STREETPRO 3/6/7 STD FLANGE .......1 ................... SAFETY ITEM

........................................................................................................ INCLUDES ITEMS W/#

........................................................................................................ CONTACT MQ UNIT SALES

19 BG2600 GUARD, 26" STREETPRO 3/6/7 STD FLANGE .......1 ................... SAFETY ITEM

........................................................................................................ INCLUDES ITEMS W/$

........................................................................................................ CONTACT MQ UNIT SALES

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 75

30", 36" BLADEGUARD ASSY.

PAGE 76 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

30", 36" BLADEGUARD ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1@ 200012 BLADEGUARD W/A, 30" REAR HALF 1

1# 200014 BLADEGUARD W/A, 36" REAR HALF 1

2* 200011 BLADEGUARD W/A, 30" FRONT HALF 1

2# 200013 BLADEGUARD W/A, 36" FRONT HALF 1

3@# 582039 BUSHING, BLADEGUARD HINGE DELRIN 1

4@# 37395 MANIFOLD, WATER LARGE 1

5@# 200019 FLAP,MUD BLADEGUARD .......................................1 ................... SAFETY ITEM

6@# 0131 A SCREW, HHC 1/4 - 20 X 3/4 1

7@# 26250 SCREW, HHC 1/4 - 20 X 1-3/4 2

8@# 06503-030 SCREW, HHC 1/2 - 13 X 3-3/4 1

9@# 10176 NUT, NYLOC 1/2-13 1

10@# 10024 NUT, NYLOC 1/4-20 3

11@# 10930 WASHER, FENDER 1/4 X 1-1/4 1

12@# 370456 FITTING, BRASS 6BARB-1/4MP 2

13@# 2113 FITTING, PLUG 1/8MP HEX SKT HD 1

14@# 37396 3/8" QC MALE 1

15@# 1618 NUT, NYLOC 10-24 2

16@# 923144 SCREW, SHC 10-24 X 1/2 2

17@# 22129-001 PIPE STRAP 3/8 2

18@ 37509 HOSE, WATER #6 LP, 30" BLADEGUARD 2

18# 37510 HOSE, WATER #6 LP, 36" BLADEGUARD 2

19 BG3000 GUARD, 30" STREETPRO 3/6/7 STD FLANGE .......1 ................... SAFETY ITEM

........................................................................................................ INCLUDES ITEMS W/@

........................................................................................................ CONTACT MQ UNIT SALES

19 BG3600 GUARD, 36" STREETPRO 3/6/7 STD FLANGE .......1 ................... SAFETY ITEM

........................................................................................................ INCLUDES ITEMS W/#

........................................................................................................ CONTACT MQ UNIT SALES

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 77

OPTIONAL WEIGHT KIT ASSY.

PAGE 78 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

OPTIONAL WEIGHT KIT ASSY.

NO. PART NO. PART NAME QTY. REMARKS

1 37829 WEIGHT KIT 1

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 79

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Parts must be in new and resalable 5.

Multiquip reserves the right to quote and

who use our products as integral parts of their

LIMITATIONS OF SELLER’S LIABILITY

connection with the sale of its products. Apart

statutory, which extend beyond the description

Terms of payment for parts are net 30 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a

signed manifest has been obtained from the

carrier, and any claim for shortage or damage

must be settled between the consignee and

the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and

credit will be allowed, subject to the following

provisions:

A Returned M aterial Authorization 1.

must be approved by Multiquip prior to

shipment.

To obtain a Return Material Authorization, 2.

a list must be provided to Multiquip

Parts Sales that defines item numbers,

quantities, and descriptions of the items

to be returned.

A copy of the Return Material Authorization 3.

must accompany the return shipment.

Freight is at the sender’s expense. All 4.

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

The parts numbers and descriptions a.

must match the current parts price

list.

The list must be typed or computer b.

generated.

The list must state the reason(s) c.

for the return.

The list must reference the sales d.

ord er(s) or in vo i ce (s) u nder

which the items were originally

purchased.

The list must include the name e.

and phone number of the person

requesting the RMA.

co nd it io n, in the original Mul ti quip

package (if any), and with Multiquip part

numbers clearly marked.

The following items are not returnable:6.

Obsolete parts. (If an item is in the a.

price book and shows as being

replace d by ano ther item, it is

obsolete.)

Any parts with a limited shelf life b.

(such as gaskets, seals, “O” rings,

and other rubber parts) that were

purchased more than six months

prior to the return date.

Any line item with an extended c.

deale r n et pr ice of less th an

$5.00.

Special order items.d.

Electrical components.e.

Paint, chemicals, and lubricants.f.

Decals and paper products.g.

Items purchased in kits.h.

The sender will be notified of any material 7.

received that is not acceptable.

Su ch m aterial will be held for five 8.

working days from notification, pending

instructions. If a reply is not received

within five days, the material will be

returned to the sender at his expense.

Credit on returned parts will be issued 9.

at dealer net price at time of the original

purch ase , l ess a 15 % restoc k in g

charge.

In cases where an item is accepted, for 10.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

Credit issued will be applied to future 11.

purchases only.

PRICING AND REBATES

Prices are subject to change without prior

notice. Price changes are effective on a

specific date and all orders received on or

after that date will be billed at the revised price.

Rebates for price declines and added charges

for price increases will not be made for stock

on hand at the time of any price change.

sell direct to Government agencies, and to

Original Equipment Manufacturer accounts

own products.

SPECIAL EXPEDITING SERVICE

A $ 35.00 surcharge will be added to the

invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

parts to the carrier.

Multiquip shall not be liable hereunder for

damages in excess of the purchase price of

the item with respect to which damages are

claimed, and in no event shall Multiquip be

liable for loss of profit or good will or for any

other special, consequential or incidental

damages.

LIMITATION OF WARRANTIES

No warr an ties, express or implied, are

made in connection with the sale of parts or

trade accessories nor as to any engine not

manufactured by Multiquip. Such warranties

made in connection with the sale of new,

complete units are made exclusively by a

statement of warranty packaged with such

units, and Multiquip neither assumes nor

authorizes any per son to ass ume for it

any other obligation or liability whatever in

from such written statement of warranty,

there are no warranties, express, implied or

of the products on the face hereof.

Effective: February 22, 2006

PAGE 80 — SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)

NOTES

SP7060 SERIES MULTIQUIP SAW — PARTS MANUAL — REV. #5 (05/06/11)— PAGE 81

PARTS MANUAL

Your Local Dealer is:

HERE’S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

UNITED STATES

Multiquip Corporate Offi ce MQ Parts Department

18910 Wilmington Ave.

Carson, CA 90746

Contact: mq@multiquip.com

Tel. (800) 421-1244

Fax (800) 537-3927

800-427-1244

310-537-3700

Fax: 800-672-7877

Fax: 310-637-3284

Service Department Warranty Department

800-421-1244

310-537-3700

Fax: 310-537-4259 800-421-1244

310-537-3700

Fax: 310-537-1173

Technical Assistance

800-478-1244 Fax: 310-943-2238

MEXICO UNITED KINGDOM

MQ Cipsa Multiquip (UK) Limited Head Offi ce

Carr. Fed. Mexico-Puebla KM 126.5

Momoxpan, Cholula, Puebla 72760 Mexico

Contact: pmastretta@cipsa.com.mx

Tel: (52) 222-225-9900

Fax: (52) 222-285-0420

Unit 2, Northpoint Industrial Estate,

Globe Lane,

Dukinfi eld, Cheshire SK16 4UJ

Contact: sales@multiquip.co.uk

Tel: 0161 339 2223

Fax: 0161 339 3226

CANADA

Multiquip

4110 Industriel Boul.

Laval, Quebec, Canada H7L 6V3

Contact: jmartin@multiquip.com

Tel: (450) 625-2244

Tel: (877) 963-4411

Fax: (450) 625-8664

© COPYRIGHT 2011, MULTIQUIP INC.

Multiquip Inc

and

the MQ logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All other trademarks are the property

of their respective owners and used with permission.

This manual MUST accompany the equipment at all times. This manual is considered a permanent part of the equipment and should remain with the unit if resold.

The information and specifications included in this publication were in effect at the time of approval for printing. Illustrations, descriptions, references and technical data contained in

this manual are for guidance only and may not be considered as binding. Multiquip Inc. reserves the right to discontinue or change specifications, design or the information published

in this publication at any time without notice and without incurring any obligations.

Loading...

Loading...