Page 1

OperatiOn and parts Manual

MOdel MB25Hd

reBar Bender

(pOrtaBle eleCtriC)

Revision #0 (04/05/10)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

Page 2

MB25Hd reBar Bender

Table of Contents ..................................................... 2

Parts Ordering Procedures ...................................... 3

Safety ...................................................................... 4

Rules and Regulations .........................................5-6

Specifications .......................................................... 7

General Information ................................................. 8

Components ............................................................ 9

Operation ..........................................................10-11

Maintenance ..................................................... 12-13

Explanation of Codes in Remarks Column ............ 14

Suggested Spare Parts ......................................... 15

COMpOnent draWinGs

Case Assembly ................................................. 16-19

Housing Assembly ............................................ 20-25

Tool Box and Tools Assembly ........................... 26-27

Wiring Diagram ...................................................... 28

taBle Of COntents

Terms and Conditions Of Sale — Parts ................. 29

Specification and part number are

subject to change without notice

PAGE 2 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

.

Page 3

parts OrderinG prOCedures

Ordering parts has never been easier!

If you have an MQ Account, to obtain a Username

Effective:

Choose from three easy options:

January 1

st

, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specification Information

Goto www.multiquip.com and click on

Order Parts

to log in and save!

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Order via Phone:

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

and Password, E-mail us at: parts@multiquip.

com.

To ob tai n an MQ Accou nt , co nta ct your

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

When ordering parts, please supply:

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Truck

■ Ground

■ Next Day

■ Second/Third Day

www.multiquip.com

WE ACCEPT ALL MAJOR CREDIT CARDS!

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 3

Page 4

safety

FOR YOUR SAFETY AND SAFETY OF OTHERS!

Safety precautions should be followed at all

times when operating this equipment. Failure

to read and understand the Safety Messages

and Operating Instructions could result in

injury to yourself and others.

This manual has been developed to

provide complete instructions for the

safe and efficient operation of this

equipment.

Before using this equipment ensure that the operating

individual has read and understood all instructions in this

manual.

SAFETY MESSAGE ALERT SYMBOLS

HAZARD SYMBOLS

Potential hazards associated with the operation of this

equipment will be referenced with Hazard Symbols which

appear throughout this manual, and will be referenced in

conjunction with Safety Message Alert Symbols.

WARNING — Respiratory Hazards

ALWAYS wear approved respirator y

protection when required.

CAUTION — Rotating Parts Hazards

NEVER operate equipment with covers or

guards removed. Keep fingers, hands, hair

and clothing away from all moving parts to

prevent injury.

The three Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure

to the operator, and are preceded by one of three words:

DANGER, WARNING, or CAUTION.

DANGER

You WILL be KILLED or SERIOUSLY INJURED if you

DO NOT follow these directions.

WARNING

You CAN be KILLED or SERIOUSLY INJURED if you

DO NOT follow these directions.

CAUTION

CAUTION — Accidental Starting Hazards

ALWAYS place the equipment ON/OFF

switch in the OFF position when the

equipment is not in use.

CAUTION — Eye and Hearing Hazards

ALWAYS wear approved eye and hearing

protection.

CAUTION — Equipment Damage Hazards

Other important messages are provided throughout

this manual to help prevent damage to your equipment,

other property, or the surrounding environment.

You CAN be INJURED if you DO NOT follow these

directions.

PAGE 4 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 5

rules and reGulatiOns

WARNING — Read This Manual

Failure to follow instructions in this manual may lead to

serious injury or even DEATH! This equipment is to be

operated by trained and qualified personnel only! This

equipment is for industrial use only.

GENERAL SAFETY

DO NOT operate or service this equipment

before reading this entire manual.

This equipment should not be operated by

persons under 18 years of age.

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots and other

protective devices required by the job.

DO NOT wear loose clothing or jewelry. Contain long hair.

Keep hair, clothing, and gloves away from moving parts.

Rotating parts can cause injury if contacted.

ALWAYS keep work area clean and free of foreign matter

and debris. Also keep work area well lit.

NEVER operate the equipment in an

explosive atmosphere or near combustible

materials. An explosion or fire could result

causing severe bodily harm or even

death.

DO NOT overreach. Keep proper footing and balance

at all times.

NEVER leave the equipment unattended. When not is

use, before servicing, and when changing accessories,

always unplug the equipment from the power source.

USE this equipment for its intended purpose only.

KEEP equipment clean for better and safer performance.

Keep handles dry, clean, and free from oil and grease.

NEVER operate this equipment when not

feeling well due to fatigue, illness or when

under medication.

NEVER operate this equipment under the

influence of drugs or alcohol.

NEVER use accessories or attachments that are not

recommended by Multiquip for this equipment. Damage

to the equipment and/or injury to user may result.

Manufacturer does not assume responsibility for any

accident due to equipment modifications. Unauthorized

equipment modification will void all warranties.

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult to read.

ALWAYS check the equipment for loosened threads or

bolts before starting.

MAINTAIN equipment is a safe operating condition at

all times.

INSPECT the equipment after each use. Replace

any damaged or worn parts immediately. Do not use

equipment if defective.

If a malfunction occurs, immediately unplug the

equipment from the power source and correct the

problem. If problem cannot be corrected, contact the

nearest MQ service center.

ALWAYS store the equipment in a clean, dry location

out of the reach of children.

EMERGENCIES

ALWAYS know the location of the nearest

fire extinguisher.

ALWAYS know the location of the nearest

first aid kit.

In emergencies, always know the location

of the nearest phone or keep a phone on the job site.

Also know the phone numbers of the nearest ambulance,

doctor and fire department. This information will be

invaluable in case of emergency.

KEEP bystanders, children, and visitors away while operating

the equipment. Distractions can cause loss of control.

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 5

Page 6

rules and reGulatiOns

noitceleSeguaGdroCnoisnetxE

erepmA

gnitaR

egnaR

stloV teeFnidroCfohtgneL

V511 .tF52 .tF05 .tF001 .tF051 .tF002 .tF052 .tF003 .tF004 .tF005

V032 .tF05 .tF001 .tF002 .tF003 .tF004 .tF005 .tF006 .tF008 .tF0001

2-0 81 81 81 61 61 41 41 21 21

3-2 81 81 61 41 41 21 21 01 01

4-3 81 81 61 41 21 21 01 01 8

5-4 81 81 41 21 21 01 01 8 8

6-5 81 61 41 21 01 01 8 8 6

8-6 81 61 21 01 01 8 6 6 6

01-8 81 41 21 01 8 8 6 6 4

21-01 61 41 01 8 8 6 6 4 4

41-21 61 21 01 8 6 6 6 4 2

61-41 61 21 01 8 6 6 4 4 2

81-61 41 21 8 8 6 4 4 2 2

02-81 41 21 8 6 6 4 4 2 2

ELECTRICAL SAFETY

ALWAYS test the POWER switch on the equipment before

operating. The purpose of this switch is to shut down the power.

NEVER use a extension cord that is frayed or damaged where

the insulation has been cut.

NEVER carry the equipment by its power cord or disconnect

it by yanking the cord from the power outlet.

ALWAYS make certain that the proper extension cord

has been selected for the job. See Extension Cord Gauge

Selection Table.

NEVER allow power cord to lay in water.

NEVER stand in water while operating the equipment.

When connecting the unit to a power receptacle, make sure

the receptacle circuit is connected to either a GFCI receptacle

or a receptacle protected by a 20 amp circuit breaker.

When plugging the unit into a power receptacle, check the

nameplate for the correct operating voltage. Operating the

rebar bender at the wrong voltage will damage the electrical

components. ALWAYS read the nameplate before applying

power.

This unit is equipped with a 3-prong male power plug. DO

NOT use a 2-prong adapter when plugging into a wall outlet.

This will defeat the purpose of the ground circuit. If the plug

does not fit into the receptacle, contact a qualified electrician

to install a 3-conductor wall receptacle (outlet).

Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electrical shock if your body is grounded.

DO NOT expose the hydraulic power unit to rain or wet

conditions. Water entering the power unit will increase the

risk of electrical shock.

When operating the unit outdoors, be sure to use the

appropriate outdoor extension cord. This type of extension

cord reduces the risk of electrical shock.

ALWAYS remove the AC power cord from the power source

before performing any service or maintenance on the unit.

This preventative safety measure reduces the possibility of

accidental starting.

When operating near an arc welder, it is important the both

the unit and the welding equipment be connected to the

same earth ground. If they are not, server damage to the

unit, par ticularly to the power cord could occur. Personal

injury may also occur.

PAGE 6 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 7

speCifiCatiOns

TABLE 1. SPECIFICATIONS

Model MB25HD

Capacity Ø6(1/4") - Ø25(1"), No.2 - No.8

Range of Bends 0° - 180°

Motor Single Phase, 115 V, 60 Hz, 15A

Standard

Equipment

Roller - 3 Allen Wrench - 2

Collar - 5 Open-End Wrench - 1

Waterproof Cover - 1 Screwdriver - 1

Tool Box - 1 Foot Switch - 1

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 7

Page 8

GENERAL INFORMATION

The MQ MB25HD Rebar Bender is designed to be used

as a portable on-site rebar bender, capable of bending

in-place rebar to approved American Concrete Institute

(ACI) radius. Labor time and injuries are greatly reduced

from manually bending rebar. The MB25HD is capable of

bends up to 180°.

The MB25HD comes standard with 3 rollers and 5 collars

which can be used in different combinations to match the

diameter of the rebar to be bent.

The MB25HD comes with a foot switch which can start

the bending procedure with a push of the pedal instead of

pressing the start button.

An emergency button is available to immediately stop the

machine when something goes wrong during bending. The

roller then returns to the starting position.

General infOrMatiOn

PAGE 8 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 9

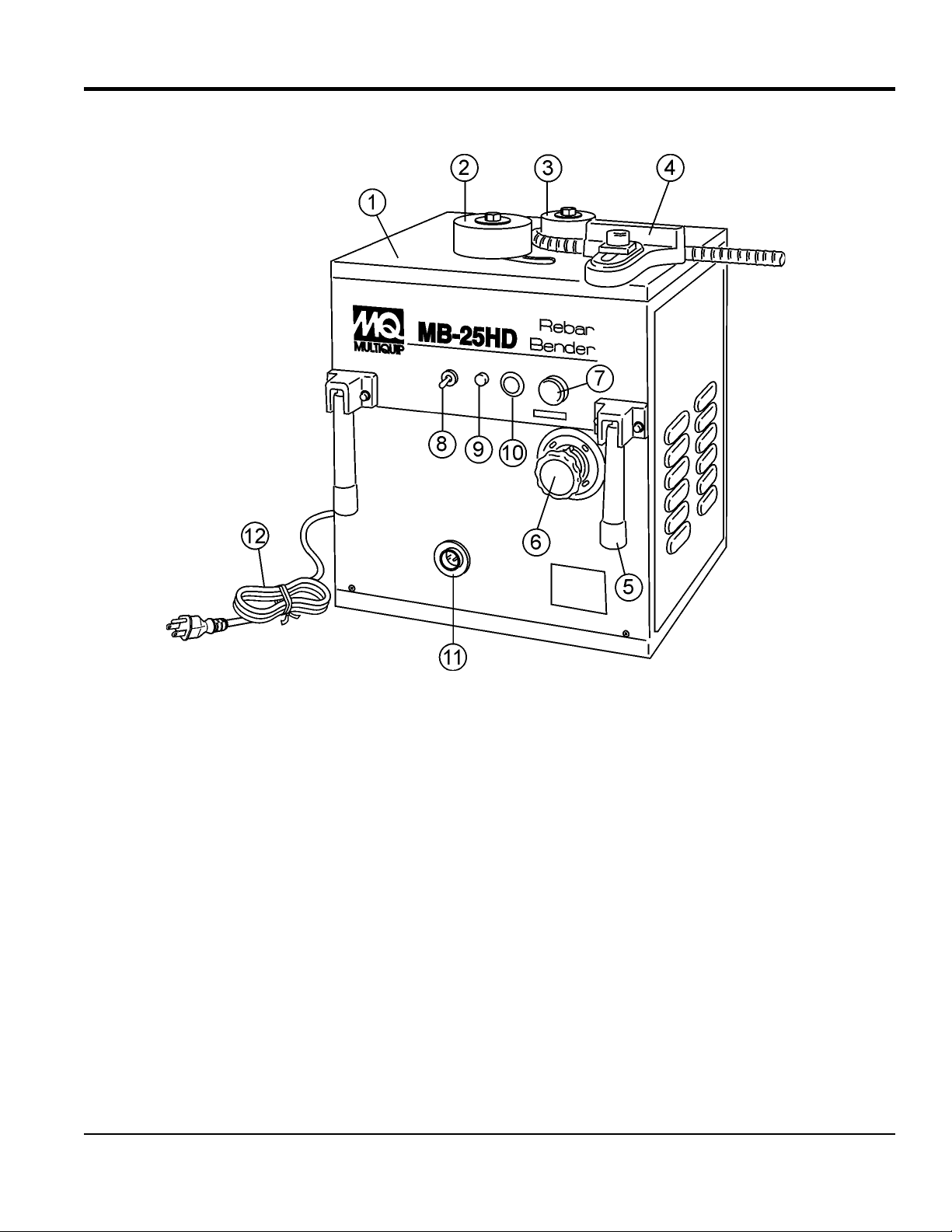

COMpOnents

Figure 1. MB25HD Components

Figure 1 shows the components of the MB25HD Rebar

Bender. These components are described below.

1. Table — Holds the roller, collar, stopper and the rebar

to be bended.

2. Roller — Works in combination with the collar

depending on the diameter of the rebar to bend.

3. Collar — Works in combination with the roller

depending on the diameter of the rebar to bend.

4. Stopper — Holds the rebar in place when bending.

5. Handle — Used to lift the rebar bender.

6. Angle Select Dial — Sets the angle that the rebar is

going to be bent.

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 9

7. Emergency Stop Switch — Stops the rebar bending

and moves the roller back to the starting position.

8. Power Switch — Turns the power of the rebar bender

on or off.

9. Pilot Lamp — Indicates rebar unit is on.

10. Start Switch — Starts the bending process.

11. Connector (for foot switch) — Connects to the foot

switch to start the machine with a push of the pedal.

12. Power Cord — Connect to a 120V, 60 Hz receptacle.

Page 10

OperatiOn

SELECTION AND INSTALLATION OF ROLLER AND

COLLAR

WARNING

Keep fingers from the bending area. Moving parts can

cause serious injury.

Do not drop anything into the machine from the bending

area as this may damage the machine.

1. Select the roller and corresponding collar to match the

diameter of the rebar to be bent. See Table 2 for the

different combinations.

2. Apply multi-purpose grease to the roller.

3. Install the collar and the roller as shown in Figure 2.

REBAR

CORRECT

STOPPER

Figure 3. Stopper Position

8. Rotate the Angle Select Dial to the desired angle that

the rebar is to be bent (Figure 4).

Figure 4. Selecting the Bending Angle

9. Plug the power cord into a proper single-phase power

source. Make sure that the rebar bender is properly

grounded.

WRONG

Figure 2. Roller and Collar Installation

4. When using a roller with a bearing, bearing must face

downward.

5. When using a collar with a bearing, bearing must face

downward.

6. To prevent the roller and the collar from coming off,

attach the washer securely with the bolt.

7. Position the stopper so that rebar to be bent is parallel

to the front of the stopper and tighten the rebar securely

in place. If the rebar is not parallel to the front, the

bending angle will be incorrect. See Figure 3.

10. Turn the power switch on.

11. Hold the rebar firmly and press the Start Switch. This

will engage the clutch and the roller to bend the rebar.

12. After the rebar is bent to the desired angle, the roller

will automatically spring back to the starting position.

PAGE 10 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 11

OperatiOn

PLUG TO CONNECTOR

ON FRONT PANEL

PUSH PEDAL

TO START BENDING

POWER

CORD

(POWER ON)

WET

HANDS

USING THE FOOT SWITCH

Instead of the Start Switch, the Foot Switch can be used

to start the bending process. See Figure 5.

Figure 5. Starting with the Foot Switch

1. Insert the plug of the foot switch to the Foot Switch

Connector on the front panel of the rebar bender.

2. Press the pedal on the foot switch to start bending.

3. When the bending angle is achieved, the roller will

automatically spring back to the start position.

WARNING

The roller goes back to start position very quickly after

bending because of the spring mechanism. Keep away

from the machine until the roller is completely back in

the start position to prevent any injury.

DANGER

During operation of this rebar bender,

there exists the possibility of electrocu-

tion, electrical shock or burn, which

can cause severe bodily harm or even

DEATH!

To avoid these hazards:

NEVER use damaged or worn cables when plugging the

rebar bender into an AC power receptacle.

NEVER grab or touch a live power

cord with wet hands.

NEVER stand in water and touch

a live power cord.

EMERGENCY STOP SWITCH

1. To stop the rebar bender immediately in case anything

goes wrong in the bending process, press the

Emergency Stop Button (Figure 6). The roller on the

rebar bender will immediately stop and return to the

start position.

Figure 6. Emergency Stop Switch

It is not necessary to press the pedal

continuously while bending. Once the pedal

is pressed bending will start and pedal can

be released.

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 11

Page 12

MaintenanCe

inch)

REMOVING STEEL DEBRIS

1. To remove steel debris from the machine, tilt it and

clear all debris from the outlet.

WARNING

Do not let debris or rust accumulate inside the machine

as this could lead to malfunction of the machine.

REPLACING CARBON BRUSHES

WARNING

Unplug unit from power source before replacing carbon

brushes.

When the carbon becomes less than 5 or 6 mm (1/4 inch)

the motor force deteriorates because of low rectification

(Figure 7). The carbon brushes need to be replaced.

1. Make sure that the power plug is not connected to the

power source.

CARBON BRUSH CAP

Figure 8. Replacing Carbon Brushes

2. Remove the rear panel and the bottom plate of the

machine so that the outer frame of the motor is visible

(Figure 8).

3. Remove the carbon brush cap of the motor outer frame

using a standard screwdriver.

4. Replace the carbon brushes with new ones.

5. Put back the cap and reinstall the rear and end panels

of the machine.

5-6 mm

(1/4

Figure 7. Carbon Brush Size

PAGE 12 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 13

WARNING

Unplug unit from power source before troubleshooting.

MOTPMYS MELBORPELBISSOP NOITULOS

MaintenanCe

GNITOOHSELBUORT.4ELBAT

dnetonlliwrableetS

hctulcfoesuaceb

.gnippils

?tcatnoc

odhctulcdnarotoM

ehtelihwkrowton

.nositnerruc

gnidnebniytiralugerrI

.selgna

?ssendrah

?demrofed

morfesionlamronbA

.rotom

?tuonrowhctulcsI .hctulcecalpeR

?pordegatlovlamronbanaerehtsI .pordegatlovlamronbafoesuackcehC

?drahootsrableetserA .ssendrahtcerrochtiwsrableetsesU

hctiwstengamnostisopedtsuderA

?tuonrowtcatnochctiwstengamsI .hctiwstengamecalpeR

?detcennocsideriwdaelsI .eriwdaeltcennoC

?evitcefedrokaewrotomcirtcelesI .rotomriaperroecalpeR

rodenoitisopylreporpmireppotsehtsI

?hguonedenethgitton

rableetsehtniytiralugerrinaerehtsI

ronekorbsenavgniloocerutamraerA

?tuonrowsgniraeberutamraerA .sgnira

.hctiwstengamhsiloP

.reppotsfossenthgitdnagninoitisoptcerroC

.ssendrahtcerrochtiwsrableetsesU

stidnaerutamraevitcefedaecalpeR

.sgniraeb

ebwenhtiwecalpeR

?ecnalabfotuoerutamrasI .erutamrawenahtiwecalpeR

?tuonrowsehsurbnobracerA .senowenhtiwecalpeR

sirotomtuptuorewoP

.tneiciffuston

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 13

?nekorbsliocfonoitalusnisI .rotomroerutamraecalpeR

?egatlovnipordaerehtsI .pordegatlovehtfoesuacehtkcehC

Page 14

explanatiOn Of COde in reMarks COluMn

The following section explains the different symbols and

QTY. Column

— Item quantity can be indicated by a

A/R (As Required) is generally used for hoses or other

A blank entry generally indicates that the item is not sold

separately. Other entries will be clarified in the “Remarks”

Some of the most common notes found in the “Remarks”

Column are listed below. Other additional notes needed

same unique symbol will be included when this item is

— Used to list an effective serial

— Indicates that the part

part is NOT used on a specific model or model number

available items. Examples include battery cables, shims,

— Indicates that an item cannot

be purchased as a separate item and is either part of an

assembly/kit that can be purchased, or is not available

remarks used in the Parts section of this manual. Use the

help numbers found on the back page of the manual if there

are any questions.

Numbers Used

number, a blank entry, or A/R.

NOTICE

The contents and part numbers listed in the parts

section are subject to change without notice. Multiquip

does not guarantee the availability of the parts listed.

SAMPLE PARTS LIST

NO. PART NO. PART NAME QTY. REMARKS

1 12345 BOLT ......................1 .....INCLUDES ITEMS W/%

2% WASHER, 1/4 IN. ...........NOT SOLD SEPARATELY

2% 12347 WASHER, 3/8 IN. ...1 .....MQ-45T ONLY

3 12348 HOSE ..................A/R ...MAKE LOCALLY

4 12349 BEARING ..............1 .....S/N 2345B AND ABOVE

NO. Column

Unique Symbols — All items with same unique

symbol

(@, #, +, %, or >) in the number column belong to the

same assembly or kit, which is indicated by a note in the

“Remarks” column.

Duplicate Item Numbers — Duplicate numbers indicate

multiple part numbers, which are in effect for the same

general item, such as different size saw blade guards in

use or a part that has been updated on newer versions

of the same machine.

NOTICE

When ordering a part that has more than one item

number listed, check the remarks column for help in

determining the proper part to order.

parts that are sold in bulk and cut to length.

Column.

REMARKS Column

to describe the item can also be shown.

Assembly/Kit — All items on the par ts list with the

purchased.

Indicated by:

“INCLUDES ITEMS W/(unique symbol)”

Serial Number Break

number range where a particular part is used.

Indicated by:

“S/N XXXXX AND BELOW”

“S/N XXXX AND ABOVE”

“S/N XXXX TO S/N XXX”

Specific Model Number Use

is used only with the specific model number or model

number variant listed. It can also be used to show a

variant.

Indicated by:

PART NO. Column

Numbers Used — Part numbers can be indicated by a

number, a blank entry, or TBD.

TBD (To Be Determined) is generally used to show a

part that has not been assigned a formal part number

at the time of publication.

A blank entry generally indicates that the item is not sold

separately or is not sold by Multiquip. Other entries will

be clarified in the “Remarks” Column.

PAGE 14 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

“XXXXX ONLY”

“NOT USED ON XXXX”

“Make/Obtain Locally” — Indicates that the part can

be purchased at any hardware shop or made out of

and certain washers and nuts.

“Not Sold Separately”

for sale through Multiquip.

Page 15

MB25HD REBAR BENDER

1 to 3 Units

Qty. P/N Description

2............M5CBC65D00 ......HOLDER CAP

2............M5CBS65D00 ....... CARBON BRUSH

suGGested spare parts

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 15

Page 16

MB25Hd — Case asseMBly

PAGE 16 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 17

MB25Hd — Case asseMBly

NO. PART NO. PART NAME QTY. REMARKS

A M5M0115V00 MOTOR ASSY., 115V ............................................ 1 ...........INCLUDES ITEMS W/#

A1# M5CBC65D00 CARBON BRUSH CAP 1

A2# M5CBS65D00 CARBON BRUSH ................................................. 1 ...........INCLUDES ITEM A7 (SET)

A3# 6070020 CARBON BRUSH HOLDER 1

A4# M5T2059400 MOTOR CASE 1

A5# M5HB0520M0 BOLT HB 5X20 4

A6# 6070020 CARBON BRUSH HOLDER 1

A7# M5CBS65D00 CARBON BRUSH ................................................. 1 ...........INCLUDES ITEM A2 (SET)

A8# M5CBC65D00 CARBON BRUSH CAP 1

A9# C5T4225600 HALF OPEN COVER 1

A10# H9XR0410M0 BOLT XR 4X6 2

A11# M5STR65D00 STATOR, 115V 1

A12# 6077110 TRIANGLE WASHER 2

A13# 6077070 FAN GUIDE 1

A14#% M5B608ZZ00 BALL BEARING 608ZZNC 1

A15#% M5T4248200 WASHER, ARMATURE 1

A16# M5AM115V00 ARMATURE, 115V ................................................ 1 ...........INCLUDES ITEMS W/%

A17#% M5B6201Z00 BALL BEARING 6201ZZNC 1

A18# M5XR051100 BOLT W/LOCK WASHER XR 5X110 4

A19 M5T4230400 MOTOR RING 1

A20 M5NM101M00 NUT NM10 4

A21 M5SW1001M0 WASHER SW10 4

A22 3300080 LINER (PILLOW BLOCK) 2

A23 M5UCF20500 PILLOW BLOCK UCF205 1

A24 M5SB1030M0 BOLT SB 10X35 4

A25 3600380 SHAFT WITH GEAR 1

A26 3701200 KEY FOR SHAFT WITH GEAR 1

A27 M5B6006Z00 BALL BEARING 6006Z 1

A28 C5HB0830M0 BOLT HB 8X30 4

A29 M5T2073300 MOTOR BASE 1

A30 H9B6080000 BALL BEARING 608 1

A31 C5T4217900 GEAR NO.2 1

A32 M5SNR20S00 STOP RING S20 1

A33 M5B6204Z00 BALL BEARING 6204Z 1

A34 M5T4329800 GEAR NO.3 1

A35 M5HB084500 BOLT HB 8X50 4

A36 C5SW0801M0 WASHER SW8 4

A37 M5T2073400 GEAR CASE 1

A38 M5K0404060 KEY FOR GEAR NO.3 1

A39 M5HB082500 BOLT HB 8X25 1

A40 C5B6202000 BALL BEARING 6202 1

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 17

Page 18

MB25Hd — Case asseMBly (COntinued)

PAGE 18 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 19

MB25Hd — Case asseMBly (COntinued)

NO. PART NO. PART NAME QTY. REMARKS

A41 7410040 STOP RING S24 1

A42 M5B6205Z00 BALL BEARING 6205Z 1

A43 3503500 COLLAR NO.1 FOR GEAR NO.5 1

A44 3601890 GEAR NO.5 1

A45 M5K0707300 KEY FOR GEAR NO.5 1

A46 3602180 GEAR NO.6 1

A47 M5B6004000 BALL BEARING 6004Z 1

A48 M5SNR47H00 STOP RING H47 1

A49 M5B6005Z00 BALL BEARING 6005Z 2

A50 M5T4330000 GEAR NO.4 1

A51 M5T4329600 COLLAR NO.2 (CLUTCH) 1

A52 M5CLMMC500 MAGNET CLUTCH (MMC-5) 1

A53 M5SRP05260 SPRING PIN SRP5530 1

A54 7513000 BOLT HB 6X10 6

A55 M5T4336300 LINER B 1

A56 M5B6004000 BALL BEARING 6004Z 1

A57 M5T2073500 GEAR CASE COVER 1

A58 3300100 LINER S (GEAR CASE COVER) 2

A59 3300090 LINER L (GEAR CASE COVER) 2

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 19

Page 20

MB25Hd — HOusinG asseMBly

PAGE 20 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 21

MB25Hd — HOusinG asseMBly

NO. PART NO. PART NAME QTY. REMARKS

B1 M5SB122000 BOLT SB12520 1

B2 M5T4273800 WASHER A 1

B3 9000850 ROLLER NO.10 (ø168) ......................................... 1 ...........OPTION

B3 9000870 ROLLER NO.13 (ø154) ......................................... 1 ...........OPTION

B3 9000840 ROLLER NO.16 (ø138) 1

B3 9000850 ROLLER NO.19 (ø92) 1

B3 9000880 ROLLER NO. 22 (ø72) ........................................... 1 ...........OPTION

B3 3150570 ROLLER NO. 25 (ø51) 1

B4 014212030 BOLT, 12X30 1

B5 012012020 BOLT, 12X20 1

B6 M5T4273800 WASHER A 1

B7 3505750 COLLAR NO.13 (ø46) 1

B7 3505740 COLLAR NO.16 (ø56) 1

B7 3505730 COLLAR NO.19 (ø95) 1

B7 3505720 COLLAR NO.22 (ø110) 1

B7 9000890 COLLAR NO.25 (ø125) 1

B8 M5T4266000 PIN 1

B9 M5HB102500 BOLT HB 10X25 6

B10 M5HB205000 BOLT HB 20X50 1

B11 M5T4267800 WASHER B 1

B12 M5T42640N1 STOPPER 1

B13 M5K1008500 KEY FOR STOPPER 1

B14 M5T4331400 TABLE 1

B15 M5NM080100 NUT NM8 1

B16 M5T4269700 SHOCK ABSORBER 1

B17 C5HB0830M0 BOLT HB8530 1

B18 M5T4273600 ATTACH PIN 1

B19 M5B6308Z00 BALL BEARING 6308Z 1

B20 C5HB0830M0 BOLT HB8530 1

B21 9000230 ARM 1

B22 M5T4331900 DUST PLATE 1

B23 M5K1208440 KEY FOR GEAR WHEEL 1

B24 M5K1208440 KEY FOR GEAR WHEEL 1

B25 M5T43289N1 OUTPUT SHAFT 1

B26 M5T4338100 BUSHING 1

B27 9000740 GEAR WHEEL 1

B28 M5SNR45S00 STOP RING S45 1

B29 M5T43308N2 SPIRAL GEAR B 1

B30 M5SNR40S00 STOP RING S40 1

B31 M5T44829N1 CHAIN FITTING COLLAR 1

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 21

Page 22

MB25Hd — HOusinG asseMBly (COntinued)

PAGE 22 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 23

MB25Hd — HOusinG asseMBly (COntinued)

NO. PART NO. PART NAME QTY. REMARKS

B32 M5HB082500 BOLT HB8525 1

B33 M5AZ714100 LIMIT SWITCH 1

B34 7538140 BOLT W/WASHER, LOCK XR4530 2

B35 M5NM120100 NUT NM12-1 4

B36 M5SW1201M0 WASHER SW12 4

B37 M5UCF20700 PILLOW BLOCK UCF-207 1

B38 7521000 BOLT HS858 2

B39 7513010 BOLT HB6512 1

B40 H9SW060100 WASHER SW6 1

B41 7651000 PLAIN WASHER M6 1

B42 M5T4464900 BEARING WASHER 1

B43 7101040 BALL BEARING 6002Z 1

B44 M5T44598N1 CHAIN ROLLER 1

B45 6600100 JOINT LINK SET 1

B46 6600100 JOINT LINK SET 1

B47 M5T4484000 RETURN SPRING C 4

B48 7700100 NUT NM12-3 1

B49 M5T4481200 RETURN SPRING FITTING A 1

B50 M5T4481300 RETURN SPRING FITTING B 1

B51 M5T4484500 ROLLER CHAIN B 1

B52 M5T4332800 PANEL B 1

B53 H9Y8411000 RUBBER BUSHING 1

B54 H9EC115V00 CORD WITH PLUG (UL) 1

B55 M5XR0410M0 BOLT W/WASHER, LOCK XR4510 6

B56 M5SW1201M0 WASHER SW12 6

B57 M5NM120100 NUT NM12 6

B58 M5SB127000 BOLT SB12570 1

B59 M5T1048000 FRAME 1

B60 8103030 TOOL BOX 1

B61 90003000 HANDLE SET 1

B62 C5HB0830M0 BOLT HB8530 2

B63 M5XR0410M0 BOLT W/WASHER, LOCK XR4510 4

B64 C5ST52K000 TOGGLE SWITCH 1

B65 M5BN564000 PILOT LAMP 1

B66 M518331N00 START SWITCH 1

B67 M518920N00 EMERGENCY STOP SWITCH 1

B68 7538000 BOLT W/WASHER, LOCK XR358 1

B69 M5HS25RC00 FOOT SWITCH CONNECTOR CAP 1

B70 3503600 ANGLE SELECT GUIDE A 1

B71 M5T4334200 ANGLE DIAL PLATE 1

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 23

Page 24

MB25Hd — HOusinG asseMBly (COntinued)

PAGE 24 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 25

MB25Hd — HOusinG asseMBly (COntinued)

NO. PART NO. PART NAME QTY. REMARKS

B72 H9XR0410M0 BOLT XR456 4

B73 M5T4328300 ANGLE SELECT KNOB 1

B74 MSRP054000 SPRING PIN SRP5540 1

B75 7540020 BOLT XF 5X15 2

B76 7810040 SPRING PIN SRP 4X16 2

B77 3503610 ANGLE SELECT GUIDE B 1

B78 M5HB082500 BOLT HB 8X25 1

B79 M5SCNH3002 FOOT SWITCH CONNECTOR F 1

B80 3302320 PANEL A 1

B81 M5HDLCP272 RUBBER CAP (ø27.2) 1

B82 M5T4269000 HANDLE 1

B83 C5HB0830M0 BOLT HB 8X30 2

B84 M5T42272N1 HANDLE BRACKET 1

B85 M5SRP10350 SPRING PIN SRP10X36 (STAINLESS) 1

B86 M5SRP05260 SPRING PIN SRP 5X25 1

B87 M5HB082000 BOLT HB 8X20 1

B88 7700020 NUT NM3 1

B89 M5T43284N1 ANGLE SELECT BAR 1

B90 M5T4330700 SPIRAL GEAR A 1

B91 M5WM160100 WASHER WM16 1

B92 M5T4328800 COIL SPRING 1

B93 7101040 BALL BEARING 6002Z 1

B94 M5T4459900 ROLLER SHAFT 1

B95 M5SB123500 BOLT SB 12X35 4

B96 M5XR0410M0 BOLT W/WASHER, LOCK XR4510 6

B97 M5T4332800 PANEL B 1

B98 M5XR0410M0 BOLT W/WASHER, LOCK XR4510 4

B99 C5HB0830M0 BOLT HB 8X30 2

B100 90003000 HANDLE SET 1

B101 M5T4332900 PANEL C 1

B102 C5HB0830M0 BOLT HB 8X30 2

B103 90003000 HANDLE SET 1

B104# 7538090 BOLT W/WASHER, LOCK XR 5X10 1

B105# 7538160 BOLT W/WASHER, LOCK XR 5X25 1

B106# 7538190 BOLT W/WASHER, LOCK XR 5X15 1

B107 M5KOKUSFM1 FOOT SWITCH ASSEMBLY 1

B108 M5SCH3002P FOOT SWITCH CONNECTOR 1

B109# M5OPR10900 RECTIFIER 1

B110# 6200410 MAGNET SWITCH 1

B111# M5MGSWBOX0 MAGNET SWITCH BOX 1

B112 M5SK20ASSY MAGNET SWITCH ASSEMBLY ............................ 1 ...........INCLUDES ITEMS W/#

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 25

Page 26

MB25Hd — tOOl BOx and tOOls asseMBly

PAGE 26 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 27

MB25Hd — tOOl BOx and tOOls asseMBly

NO. PART NO. PART NAME QTY. REMARKS

1 9010060 TOOL BOX SET..................................................... 1 ...........INCLUDES ITEMS W/#

2* 8103030 TOOL BOX 1

3 3150570 ROLLER NO. 25 (ø51) 1

4 9000850 ROLLER NO.19 (ø92) 1

5 9000840 ROLLER NO.16 (ø138) 1

6 9000890 COLLAR NO.25 (ø125) 1

7 3505720 COLLAR NO.22 (ø110) 1

8 3505730 COLLAR NO.19 (ø95) 1

9 3505740 COLLAR NO.16 (ø56) 1

10 3505750 COLLAR NO.13 (ø46) 1

11* 8201020 OPEN END WRENCH 17 X19 MM 1

12* 8201510 SCREWDRIVER 1

13* 8200020 ALLEN WRENCH M2 1

14* 8200120 ALLEN WRENCH M17 1

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 27

Page 28

MB25Hd — WirinG diaGraM

PAGE 28 — MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10)

Page 29

terMs and COnditiOns Of sale — parts

PAYMENT TERMS

Terms of payment for parts are net 30 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a

signed manifest has been obtained from the

carrier, and any claim for shortage or damage

must be settled between the consignee and

the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and

credit will be allowed, subject to the following

provisions:

A Returned Material Authorization 1.

must be approved by Multiquip prior to

shipment.

To obtain a Return Material Authorization, 2.

a list must be provided to Multiquip

Parts Sales that defines item numbers,

quantities, and descriptions of the items

to be returned.

The parts numbers and descriptions a.

must match the current parts price

list.

The list must be typed or computer b.

generated.

The list must state the reason (s) c.

for the return.

The list must reference the sales d.

ord er( s ) o r in vo ice (s ) un der

which the items were originally

purchased.

The list must include the name e.

and phone number of the person

requesting the RMA.

A copy of the Return Material Authorization 3.

must accompany the return shipment.

Freight is at the sender’s expense. All 4.

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

Parts must be in new and resalable 5.

co ndition , in the ori ginal Mult iquip

package (if any), and with Multiquip part

numbers clearly marked.

The following items are not returnable:6.

Obsolete parts. (If an item is in the a.

price book and shows as being

repla ced by anoth er item, it is

obsolete.)

Any parts with a limited shelf life b.

(such as gaskets, seals, “O” rings,

and other rubber parts) that were

purchased more than six months

prior to the return date.

Any line item with an extended c.

dealer ne t pri ce of les s than

$5.00.

Special order items.d.

Electrical components.e.

Paint, chemicals, and lubricants.f.

Decals and paper products.g.

Items purchased in kits.h.

The sender will be notified of any material 7.

received that is not acceptable.

Su ch materia l will be held for five 8.

working days from notification, pending

instructions. If a reply is not received

within five days, the material will be

returned to the sender at his expense.

Credit on returned parts will be issued 9.

at dealer net price at time of the original

purch as e, le ss a 15 % res to cking

charge.

In cases where an item is accepted, for 10.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

Credit issued will be applied to future 11.

purchases only.

PRICING AND REBATES

Prices are subject to change without prior

notice. Price changes are effective on a

specific date and all orders received on or

after that date will be billed at the revised price.

Rebates for price declines and added charges

for price increases will not be made for stock

on hand at the time of any price change.

Multiquip reser ves the right to quote and

sell direct to Government agencies, and to

Original Equipment Manufacturer accounts

who use our products as integral parts of their

own products.

SPECIAL EXPEDITING SERVICE

A $ 35.00 surcharge will be added to the

invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

parts to the carrier.

LIMITATIONS OF SELLER’S LIABILITY

Multiquip shall not be liable hereunder for

damages in excess of the purchase price of

the item with respect to which damages are

claimed, and in no event shall Multiquip be

liable for loss of profit or good will or for any

other special, consequential or incidental

damages.

LIMITATION OF WARRANTIES

No warranties, express or im plied , are

made in connection with the sale of parts or

trade accessories nor as to any engine not

manufactured by Multiquip. Such warranties

made in connection with the sale of new,

complete units are made exclusively by a

statement of warranty packaged with such

units, and Multiquip neither assumes nor

authorizes any person to ass ume for it

any other obligation or liability whatever in

connection with the sale of its products. Apart

from such written statement of warranty,

there are no warranties, express, implied or

statutory, which extend beyond the description

of the products on the face hereof.

Effective: February 22, 2006

MB25HD REBAR BENDER • OPERATION AND PARTS MANUAL — REV. #0 (04/05/10) — PAGE 29

Page 30

OperatiOn and parts Manual

Your Local Dealer is:

HERE’S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

© COPYRIGHT 2010, MULTIQUIP INC.

Multiquip Inc and the MQ logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All other trademarks are the property

of their respective owners and used with permission.

This manual

MUST accompany the equipment at all times. This manual is considered a permanent part of the equipment and should remain with the unit if resold.

The information and specifications included in this publication were in effect at the time of approval for printing. Illustrations, descriptions, references and technical data contained in

this manual are for guidance only and may not be considered as binding. Multiquip Inc. reserves the right to discontinue or change specifications, design or the information published

in this publication at any time without notice and without incurring any obligations.

United StateS

Multiquip Corporate Office MQ Parts Department

18910 Wilmington Ave.

Carson, CA 90746

Contact: mq@multiquip.com

Tel. (800) 421-1244

Fax (800) 537-3927

800-427-1244

310-537-3700

Fax: 800-672-7877

Fax: 310-637-3284

Mayco Parts Warranty Department

800-306-2926

310-537-3700

Fax: 800-672-7877

Fax: 310-637-3284

800-421-1244, Ext. 279

310-537-3700, Ext. 279

Fax: 310-537-1173

Service Department Technical Assistance

800-421-1244

310-537-3700

Fax: 310-537-4259 800-478-1244 Fax: 310-631-5032

mexico United Kingdom

MQ Cipsa Multiquip (UK) Limited Head Office

Carr. Fed. Mexico-Puebla KM 126.5

Momoxpan, Cholula, Puebla 72760 Mexico

Contact: pmastretta@cipsa.com.mx

Tel: (52) 222-225-9900

Fax: (52) 222-285-0420

Unit 2, Northpoint Industrial Estate,

Global Lane,

Dukinfield, Cheshire SK16 4UJ

Contact: sales@multiquip.co.uk

Tel: 0161 339 2223

Fax: 0161 339 3226

Canada

Multiquip

4110 Industriel Boul.

Laval, Quebec, Canada H7L 6V3

Contact: jmartin@multiquip.com

Tel: (450) 625-2244

Tel: (877) 963-4411

Fax: (450) 625-8664

Loading...

Loading...