Page 1

PARTS AND OPERATION MANUAL

OPERATION AND PARTS MANUAL

®

MODEL DCA220SSJ/SSJU

60HZ WHISPERWATT™ GENERATOR

(JOHN DEERE 6068HF485 DIESEL ENGINE)

PARTS LIST NO. C1870300404 (DCA220SSJ)

PARTS LIST NO. M4870300104B (DCA220SSJU)

Revision #1 (02/28/14)

THIS MANUAL MUST ACCOMPANY

THE EQUIPMENT AT ALL TIMES.

Page 2

DCA-220SSJ/SSJU — PROPOSITION 65 WARNING

Diesel engine exhaust and some of

PAGE 2 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 3

DCA-220SSJ/SSJU — NOTE PAGE

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 3

Page 4

DCA-220SSJ/SSJU — TABLE OF CONTENTS

MQ POWER DCA-220SSJ/SSJUMQ POWER DCA-220SSJ/SSJU

MQ POWER DCA-220SSJ/SSJU

MQ POWER DCA-220SSJ/SSJUMQ POWER DCA-220SSJ/SSJU

TMTM

TM

WHISPERWHISPER

WHISPER

WHISPERWHISPER

California Proposition 65 Warning ..................................... 2

Table Of Contents ............................................................. 4

Parts Ordering Procedures ...............................................5

Specifications ................................................................... 6

Dimensions (Top, Side, Front) ........................................... 7

Safety Message Alert Symbols .................................... 8-9

Rules for Safe Operation ........................................... 10-13

Generator Decals....................................................... 14-15

Installation ................................................................. 16-17

General Information ........................................................ 18

Major Components ......................................................... 19

Diagnostic Display ..................................................... 20-36

Generator Control Panel ................................................. 37

Engine Operating Panel ............................................. 38-39

Output Terminal Panel Familiarization ........................ 40-42

Load Application ............................................................. 43

Generator Outputs .......................................................... 44

Gauge Reading ............................................................... 45

Output Terminal Panel Connections ........................... 46-47

Setup ......................................................................... 48-51

Generator Start-up Procedure (Manual) ..................... 52-54

Generator Start-up Procedure (Auto Mode) .................... 55

Generator Shut-Down Procedure .................................... 56

Maintenance (Engine) ................................................ 57-58

Maintenance Jacket Water Heater/Battery Charger ........ 59

Maintenance (Trailer) ................................................. 60-63

Trailer Wiring Diagram ..................................................... 64

Generator Wiring Diagram ............................................... 65

Engine Wiring Diagram ................................................... 66

Generator Troubleshooting .............................................. 67

Engine Controller Troubleshooting ................................... 68

Explanation of Code in Remarks Column ....................... 70

Suggested Spare Parts .................................................. 71

WW

W

WW

AA

A

AA

TTTT

TT

TTTT

TMTM

GENERATORGENERATOR

GENERATOR

GENERATORGENERATOR

COMPONENT DRACOMPONENT DRA

COMPONENT DRA

COMPONENT DRACOMPONENT DRA

Generator Assembly .................................................. 72-75

Control Panel Assembly ............................................ 76-77

Control Box Assembly ............................................... 78-81

Engine and Radiator Assembly ................................. 82-87

Output Terminal Assembly ......................................... 88-91

Battery Assembly ...................................................... 92-93

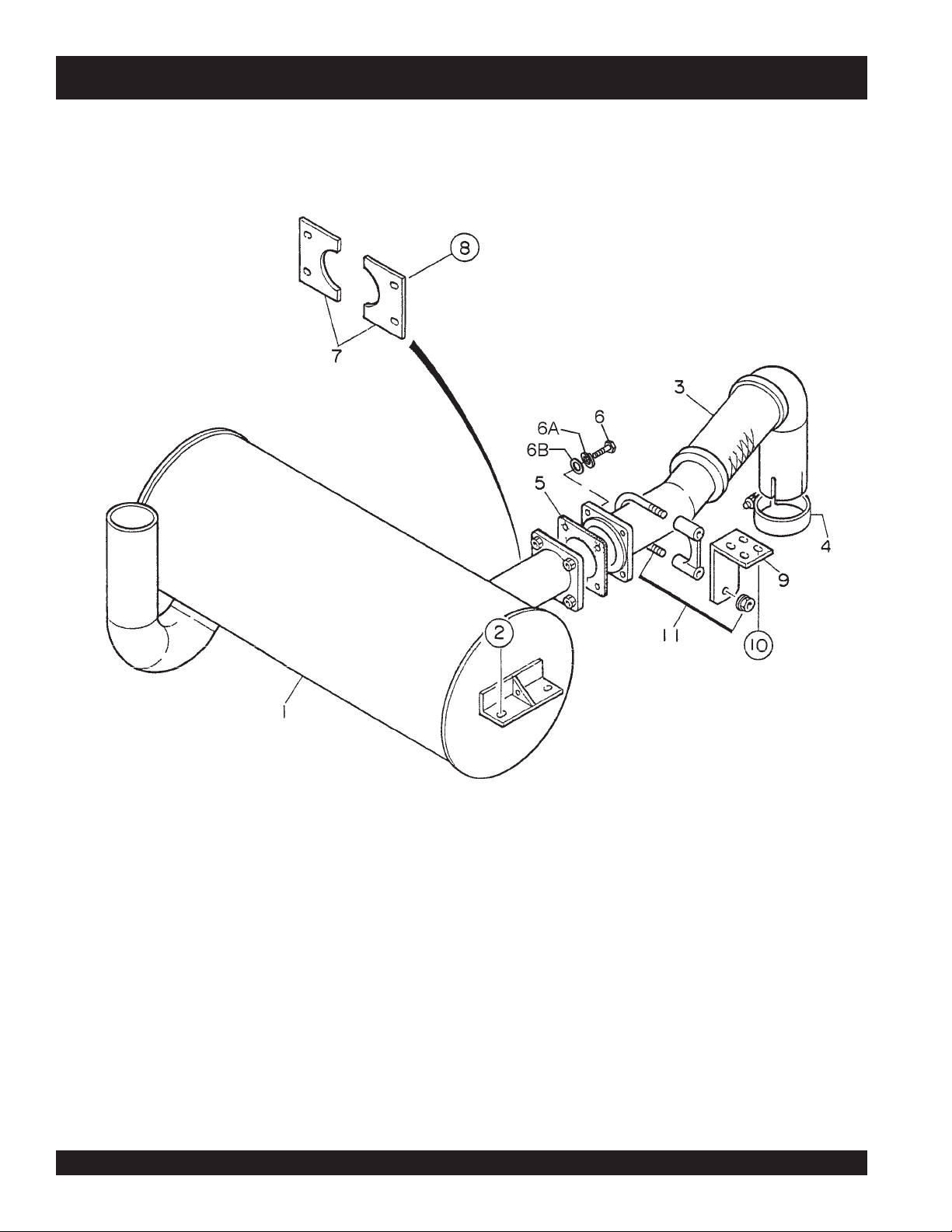

Muffler Assembly ...................................................... 94-95

Fuel Tank Assembly .................................................. 96-97

Enclosure Assembly ............................................... 98-105

Rubber Seals Assembly ........................................ 106-107

Nameplate and Decals .......................................... 108-111

Terms and Condition of Sale — Parts .......................... 112

NOTICE

Specification and part number are subject to

change without notice.

WINGSWINGS

WINGS

WINGSWINGS

PAGE 4 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 5

DCA-220SSJ/SSJU — PARTS ORDERING PROCEDURES

r

Ordering parts has never been easier!

Choose from three easy options:

January 1

Effective:

st

, 2006

Best Deal!

Order via Internet (Dealers Only):

Order parts on-line using Multiquip’s SmartEquip website!

■ View Parts Diagrams

■ Order Parts

■ Print Specification Information

Goto www.multiquip.com and click on

Order Par ts

Order via Fax (Dealers Only):

All customers are welcome to order parts via Fax.

Domestic (US) Customers dial:

1-800-6-PARTS-7 (800-672-7877)

Non-Dealer Customers:

Contact your local Multiquip Dealer for

parts or call 800-427-1244 for help in

locating a dealer near you.

to log in and save!

Order via Phone:

If you have an MQ Account, to obtain a Username

and Password, E-mail us at: parts@multiquip.

com.

To obtain an MQ Account, contact you

District Sales Manager for more information.

Use the internet and qualify for a 5% Discount

on Standard orders for all orders which include

complete part numbers.*

Fax your order in and qualify for a 2% Discount

on Standard orders for all orders which include

complete part numbers.*

Domestic (US) Dealers Call:

1-800-427-1244

International Customers should contact

their local Multiquip Representatives for

Parts Ordering information.

Note: Discounts Are Subject To Change

Note: Discounts Are Subject To Change

❒ Dealer Account Number

❒ Dealer Name and Address

❒ Shipping Address (if different than billing address)

❒ Return Fax Number

❒ Applicable Model Number

❒ Quantity, Part Number and Description of Each Part

www.multiquip.com

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 5

When ordering parts, please supply:

❒ Specify Preferred Method of Shipment:

✓ UPS/Fed Ex ✓ DHL

■ Priority One ✓ Tr uck

■ Ground

■ Next Day

■ Second/Third Day

NOTICE

All orders are treated as Standard Orders and will

ship the same day if received prior to 3PM PST.

WE ACCEPT ALL MAJOR CREDIT CARDS!

1

Page 6

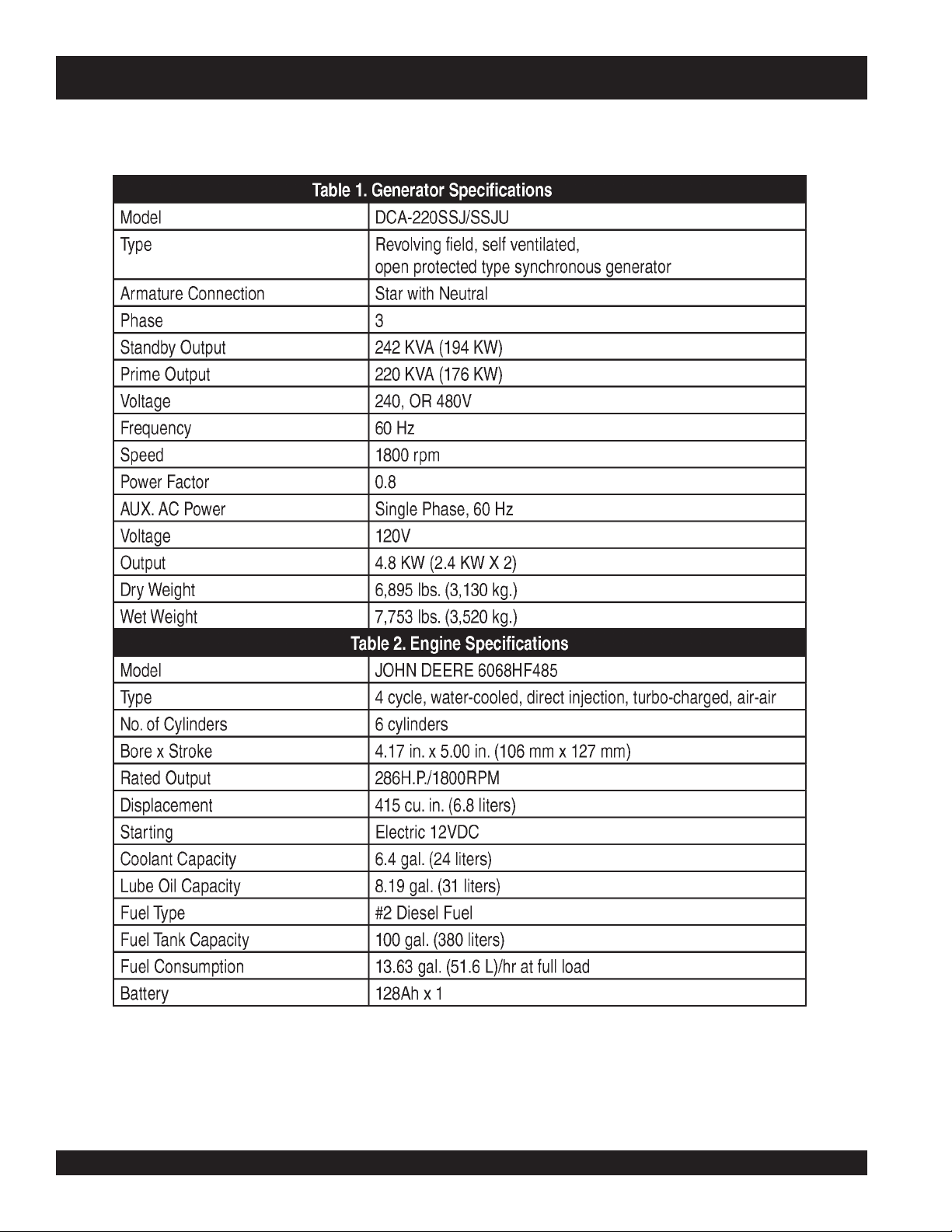

DCA-220SSJ/SSJU — SPECIFICATIONS

PAGE 6 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 7

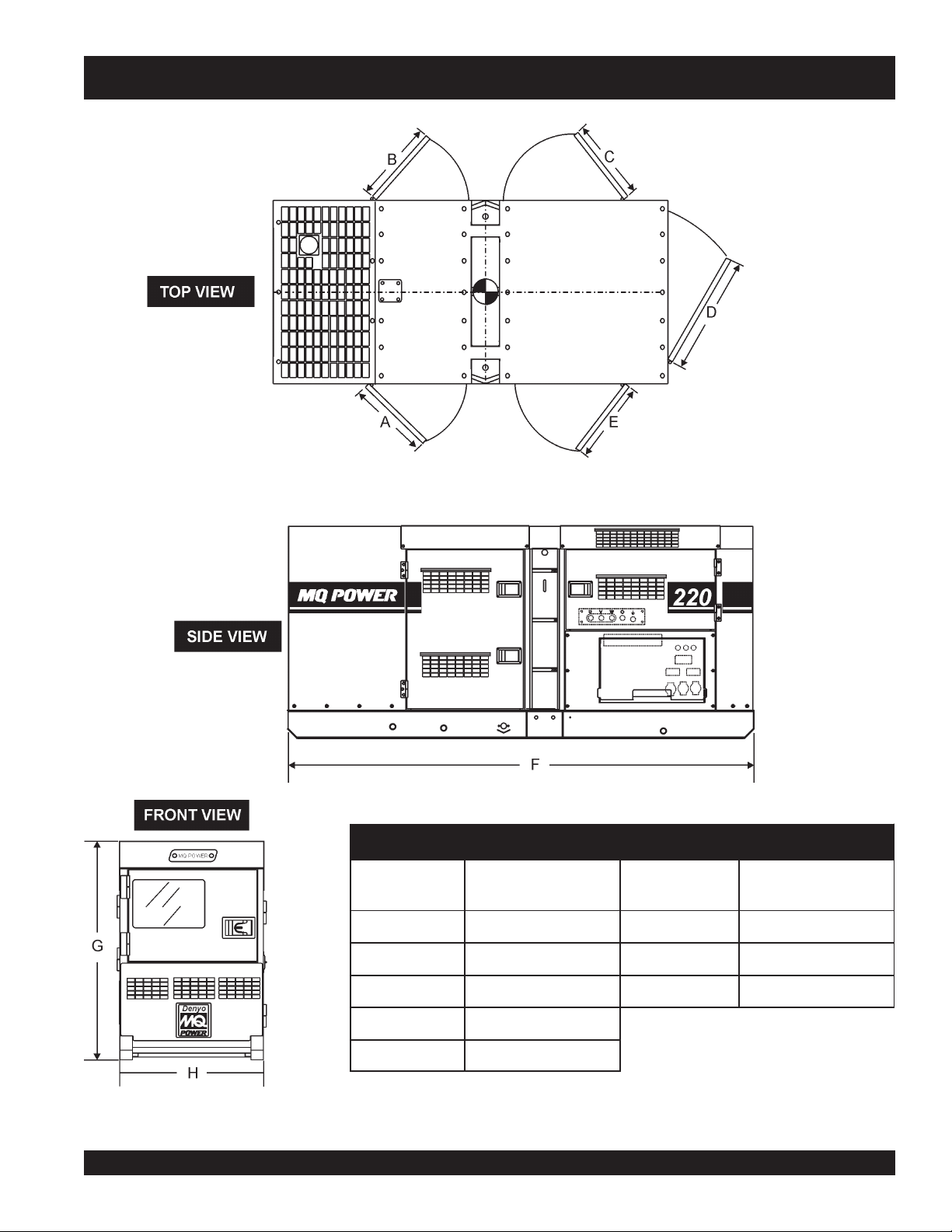

DCA-220SSJ/SSJU — DIMENSIONS (TOP, SIDE AND FRONT)

SNOISNEMID.3ELBAT

ecnerefeR

retteL

A).mm049(.ni00.73F ).mm005,3(.ni08.731

B).mm0

C).mm050,1(.ni33.14H ).mm042,1(.ni18.84

D).mm050,1(.ni33.14

E).mm050,1(.ni33.14

49(.ni00.73G ).mm007,1(.ni29.66

Figure 1. Dimensions

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 7

).mm(.tfnoisnemiDretteLecnerefeR).mm(.tfnoisnemiD

1

Page 8

DCA-220SSJ/SSJU — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed at all times when

operating this equipment. Failure to read and understand the

Safety Messages and Operating Instructions could result in

injury to yourself and others.

This Owner's Manual has been

NOTE

developed to provide complete

instructions for the safe and

efficient operation of the

MQ Power

Model DCA-220SSJ/

HAZARD SYMBOLS

Potential hazards associated with the operation of this

equipment will be referenced with "

appear throughout this manual, and will be referenced in

conjunction with Safety "

WARNING - LETHAL EXHAUST GASES

SSJU Whisperwatt™ Generator.

Before using this generator, ensure that the operating

individual has read and understands all instructions in

this manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure

to the operator, and are preceded by one of three words:

DANGER, WARNING, or CAUTION.

DANGER

You WILL be KILLED or SERIOUSLY injured if you

do not follow directions.

equipment in a confined area or enclosed structure that

does not provide ample free flow air.

WARNING - EXPLOSIVE FUEL

DO NOT overfill tank, since spilled fuel could ignite if it

comes into contact with hot engine parts or sparks from

the ignition system. Store fuel in approved containers, in

well-ventilated areas and away from sparks and flames.

NEVER use fuel as a cleaning agent.

Hazard Symbols

Message Alert Symbols

Gasoline engine exhaust gases contain

poisonous carbon monoxide. This gas is

colorless and odorless, and can cause

DEATH

if inhaled. NEVER operate this

Gasoline

its vapors can cause an explosion if

ignited. DO NOT start the engine near

spilled fuel or combustible fluids.

DO NOT fill the fuel tank while the engine

is running or hot.

is extremely flammable, and

" which

".

WARNING

You COULD be KILLED or SERIOUSLY injured if

you do not follow directions.

CAUTION

You CAN be injured if you do not follow directions

PAGE 8 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

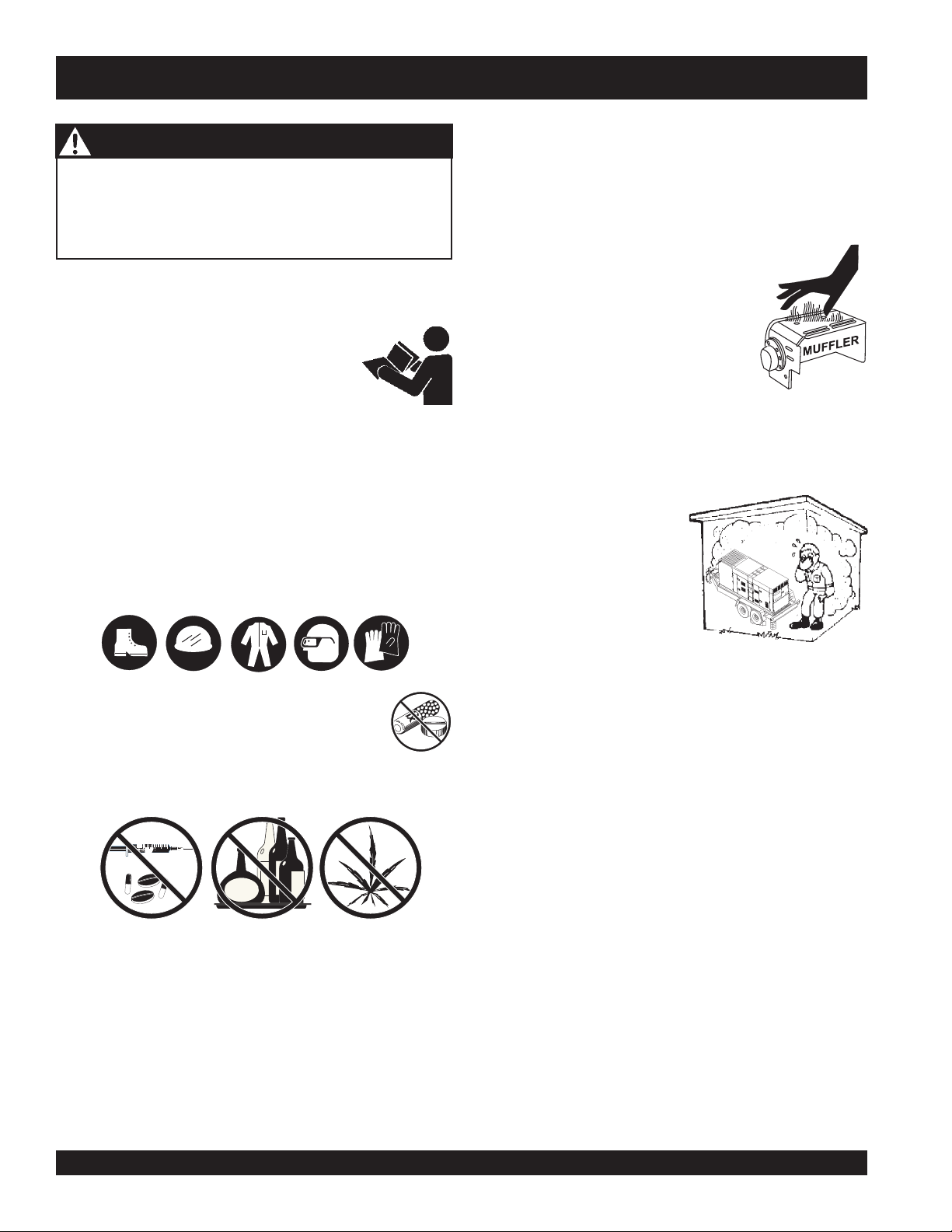

WARNING - BURN HAZARDS

Engine components can generate extreme

heat. To prevent burns, DO NOT touch these

areas while the engine is running or

immediately after operations. NEVER

operate the engine with heat shields or heat

guards removed.

DANGER - ELECTROCUTION HAZARDS

During operation of this generator, there

exists the possibility of

electrical shock or burn,

severe bodily harm

electrocution,

which can cause

or even

DEATH!

Page 9

DCA-220SSJ/SSJU — SAFETY MESSAGE ALERT SYMBOLS

WARNING - ROTATING PARTS

NEVER operate equipment with covers,

or guards removed. Keep

hair

and clothing away from all moving

parts to prevent injury.

CAUTION - ACCIDENTAL STARTING

ALWAYS place the MPEC control switch

in the OFF/RESET position when the

generator is not in use.

CAUTION - OVER-SPEED CONDITIONS

NEVER tamper with the factory settings

of the engine governor or settings.

Personal injury and damage to the engine

or equipment can result if operating in

speed ranges above maximum allowable.

fingers, hands

CAUTION - RESPIRATORY HAZARDS

,

CAUTION - SIGHT AND HEARING HAZARDS

CAUTION - EQUIPMENT DAMAGE MESSAGES

Other important messages are provided throughout this

manual to help prevent damage to your generator, other

property, or the surrounding environment.

ALWAYS wear approved

protection.

ALWAYS wear approved

hearing

protection.

respiratory

eye

and

NOTICE

This generator, other property, or the surrounding

environment could be damaged if you do not follow

instructions.

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 9

Page 10

DCA-220SSJ/SSJU — RULES FOR SAFE OPERATION

■

DANGER - READ THIS MANUAL!

Failure to follow instructions in this manual may lead to

serious injury

operated by trained and qualified personnel only! This

equipment is for industrial use only.

The following safety guidelines should always be used when

operating the

or even

DEATH

! This equipment is to be

DCA-220SSJ/SSJU Whisperwatt™ AC

Generator.

General Safety:

■

DO NOT operate or service this

equipment before reading this entire

manual.

The operator MUST BE familiar with proper safety

precautions and operations techniques before using

generator.

■

This equipment should not be operated by persons under

18 years of age.

■

NEVER operate this equipment without proper protective

clothing, shatterproof glasses, steel-toed boots and other

ALWAYS check the machine for loosened threads or bolts

before starting.

■

NEVER operate the generator in an explosive atmosphere

or near combustible materials. An explosion or fire could

result causing severe

■

NEVER touch the hot exhaust manifold, muffler

or cylinder. Allow these parts to cool before

servicing engine or generator.

■

High Temperatures – Allow the engine

to cool before performing service and

maintenance functions. Contact with

hot!

components can cause serious

burns.

■

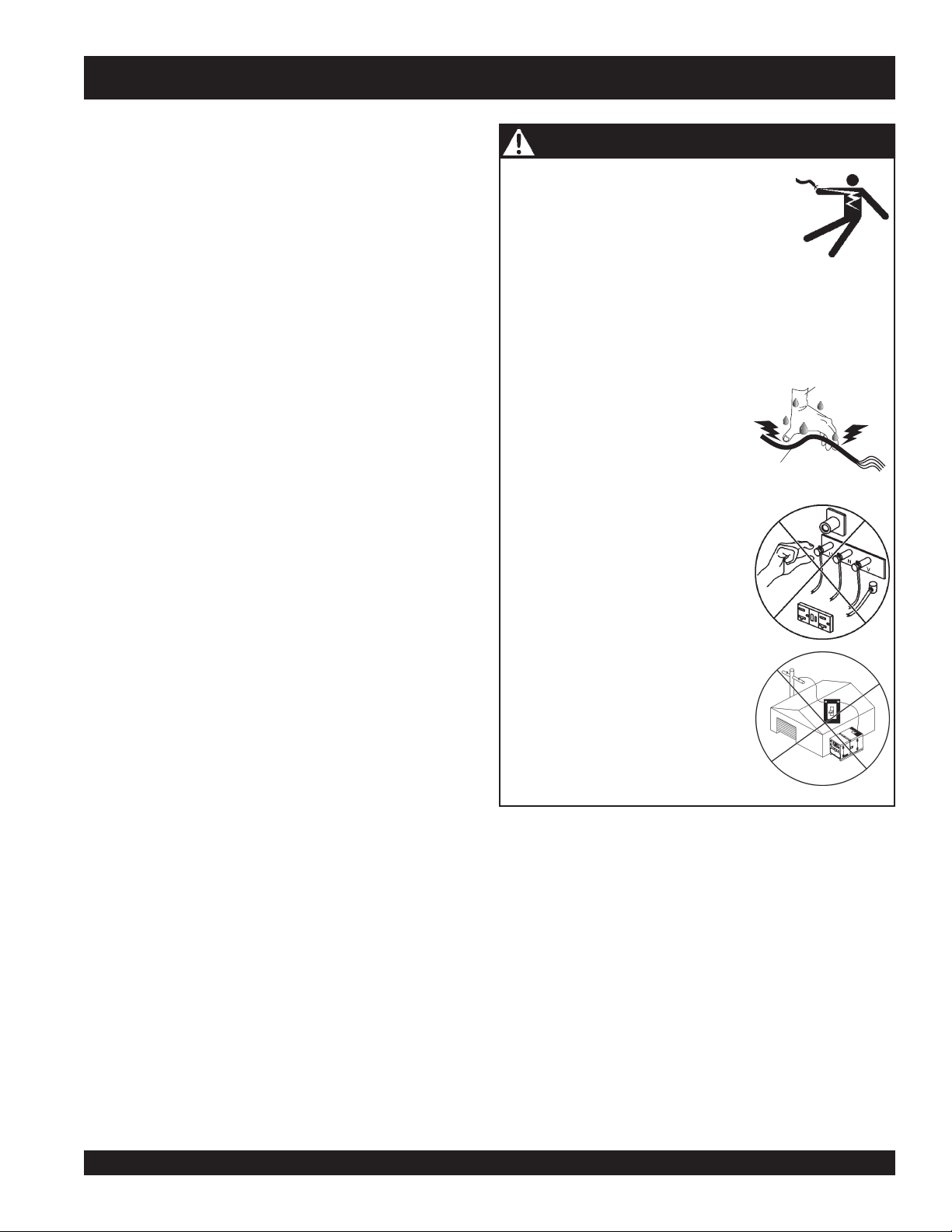

The engine of this generator requires an adequate free

flow of cooling air.

enclosed or narrow area where free flow of the air is

restricted. If the air flow is

restricted it will cause serious

damage to the generator or

engine and may cause injury

to people. The generator

engine gives off DEADLY

carbon monoxide gas.

bodily harm or even death.

NEVER

operate the generator in any

■

protective devices required by the job.

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate this equipment under the influence or

drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by MQ Power for this equipment. Damage

to the equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any

accident due to equipment modifications. Unauthorized

equipment modification will void all warranties.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

■

■

■

DO NOT place hands or fingers inside generator engine

compartment when engine is running.

NEVER run engine without air filter. Severe engine damage

may occur.

DO NOT leave the generator running in the

unattended.

Refer to the

engine technical questions or information.

ALWAYS store equipment properly when it is not being

used. Equipment should be stored in a clean, dry location

out of the reach of children.

John Deere Engine Owner's Manual

manual mode

for

PAGE 10 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 11

DCA-220SSJ/SSJU — RULES FOR SAFE OPERATION

Generator Grounding

DANGER - ELECTROCUTION HAZARDS

To guard against electrical shock and possible damage to

the equipment, it is important to provide a good EARTH

ground.

During operation of this generator, there

exists the possibility of

electrical shock or burn,

Article 250 (Grounding) of the

National Electrical Code

severe bodily harm

(NEC) provides guide lines for proper grounding and specifies

that the cable ground shall be connected to the grounding

system of the building as close to the point of cable entry

as practical.

The following safety recommendations should also be

followed:

To avoid these hazards:

NEVER use damaged or worn cables when connecting

equipment to the generator. Make sure power connecting

cables are securely connected to the generator’s output

terminals, insufficient tightening of the terminal connections

may cause damage to the generator

■

ALWAYS make sure generator is properly grounded.

■

NEVER use gas piping as an electrical ground.

■

ALWAYS make sure that electrical circuits are properly

grounded

local codes before operating generator. Severe

DEATH!

per the

National Electrical Code

(NEC) and

injury

by electrocution can result from operating an

ungrounded generator.

■

ALWAYS be sure to use the ground terminal (green wire)

when connecting a load to the U,V, and W output

terminal lugs.

and electrical shock.

NEVER grab or touch a live power

cord with wet hands.

NEVER touch output terminals

or

during operation. This is extremely

dangerous. ALWAYS stop the

machine and place the circuit

breaker in the OFF position when

contact with the output terminals is

required.

electrocution,

which can cause

or even

DEATH!

POWER

CORD

(POWER ON)

WET

HANDS

Electrical Safety

■

ALWAYS have a qualified electrician perform the

generator wiring installation.

■

ALWAYS make sure generator installation is accordance

with the

National Electrical Code

(NEC) and local codes

before operating generator.

■

NEVER use a defective or frayed power cable. Check

the cable for cuts in the insulation.

■

NEVER use a extension cord that is frayed or damaged

where the insulation has been cut.

■

ALWAYS make certain that proper extension cord has

been selected for the job. See Table 6.

■

NEVER power cables or cords

■

NEVER

stand in water

while AC power from the generator

lay in wate

r.

is being transfer to a load.

Backfeed to a utility system can

cause

electrocution

and or property

damage. DO NOT connect to any

building's electrical system except

through an approved device or after

building main switch is opened.

ALWAYS have a licensed electrician

perform the installation

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 11

Page 12

DCA-220SSJ/SSJU — RULES FOR SAFE OPERATION

Maintenance Safety

■

The electrical voltage required to operate the generator

can cause severe injury or even death through physical

contact with live circuits.

before performing maintenance on the generator.

■

NEVER lubricate components or attempt service on a

running machine.

■

ALWAYS disconnect the

before performing service on the generator.

■

Follow all Battery Safety Guidelines listed in this manual

when handleing or servicing the generator.

■

ALWAYS allow the machine a proper amount of time to

cool before servicing.

■

Keep the machinery in proper running condition.

■

Fix damage to the machine immediately and always

replace broken parts.

■

ALWAYS service air cleaner frequently to prevent engine

malfunction.

WARNING - BURN HAZARDS

To prevent burns, DO NOT touch or open any of the below

mentioned components while the engine is

running or immediately after operations.

Always allow sufficient time for the engine

and generator to cool before performing

maintenance.

■

Radiator Cap - Removing the radiator cap while the

engine is hot will result in high pressurized, boiling water

to gush out of the radiator, causing severe scalding to

any persons in the general area of the generator.

■

Coolant Drain Plug - Removing the coolant drain plug

while the engine is hot will result in hot coolant gushing

out of the coolant drain plug, therefore causing severe

scalding to any persons in the general area of the

generator.

Turn all circuit breakers OFF

NEGATIVE battery terminal

Battery Safety

Use the following guidelines when handling the battery:

■

■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

■■

■

■■

The battery contains acids that can

cause injury to the eyes and skin. To

avoid eye irritation,

glasses.

Use well insulated gloves when picking up the battery.

DANGER - EXPLOSION HAZARDS

The risk of an explosion exists when performing service

on the battery. To avoid

■■

■

DO NOT drop the battery. There

■■

is the possibility of risk that the

battery may explode.

■■

■

DO NOT expose the battery to

■■

open flames, sparks, cigarettes

etc. The battery contains combustible gases and liquids.

If these gases and liquids come in contact with a flame

or spark, an explosion could occur.

ALWAYS keep the battery charged. If the battery is not

charged a buildup of combustible gas will occur.

ALWAYS keep battery charging and cables in good working

condition. Repair or replace all worn cables.

ALWAYS recharge the battery in an vented air

environment, to avoid risk of a dangerous concentration

of combustible gases.

In case the battery liquid (dilute sulfuric acid) comes in

contact with

immediately with plenty of water.

In case the battery liquid (dilute sulfuric acid) comes in

contact with your

plenty of water and contact the nearest doctor or hospital

to seek medical attention.

always

clothing or skin

EYES

wear safety

severe injury

, rinse eyes immediately with

or

DEATH:

, rinse skin or clothing

■

Engine Oil Drain Plug - Removing the engine oil drain

plug while the engine is hot will result in hot oil gushing

out of the oil drain plug, therefore causing severe

scalding to any persons in the general area of the

generator.

PAGE 12 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 13

DCA-220SSJ/SSJU — RULES FOR SAFE OPERATION

■

Towing & Transporting Safety

To reduce the possibility of an accident while transporting

the generator on public roads, always make sure the trailer

that supports the generator and the towing vehicle are in

good operating condition and both units are mechanically

sound.

The following list of safety precautions should be followed

when towing your generator:

CAUTION - FOLLOW TOWING REGULATIONS

Check with your local county or state safety towing

regulations, in addition to meeting

Transportation

towing your generator.

■

ALWAYS shutdown engine before transporting.

■

Tighten both fuel tank caps securely.

■

If generator is mounted on a trailer, make sure trailer

complies with all local and state safety transportation

laws. Follow the listed

guidelines for basic towing techniques.

■

Make sure the hitch and coupling of the towing vehicle

are rated equal to, or greater than the trailer "gross vehicle

weight rating.”

■

ALWAYS inspect the hitch and coupling for wear. NEVER

tow a trailer with defective hitches, couplings, chains etc.

(DOT)

Safety Towing Regulations

Towing & Transporting Safety

Department of

, before

The maximum speed for highway towing is 55 MPH

unless posted otherwise. Recommended off-road towing

is not to exceed 15 MPH or less depending on type of

terrain.

■

Place

while parked.

■

Use the trailer’s swivel jack to adjust the trailer height to

a level position while parked.

■

Avoid sudden stops and starts. This can cause skidding,

or jack-knifing. Smooth, gradual starts and stops will

improve towing.

■

Avoid sharp turns.

■

Trailer should be adjusted to a level position at all times

when towing.

■

Raise and lock trailer wheel stand in up position when

transporting.

■

The maximum speed for highway towing is 55 MPH

unless posted otherwise. Recommended off-road towing

is not to exceed 15 MPH or less depending on type of

terrain.

■

Place

prevent tipping, while parked.

■

Avoid sharp turns to prevent rolling.

■

DO NOT transport generator with fuel in tank.

Emergencies

chock blocks

support blocks

underneath wheel to prevent rolling,

underneath the trailer’s bumper to

■

Check the tire air pressure on both towing vehicle and

trailer.

Also check the tire tread wear on both vehicles.

■

ALWAYS make sure the trailer is equipped with a "Safety

Chain".

■

ALWAYS attach trailer’s safety chains to towing vehicle

properly.

■

ALWAYS make sure the vehicle and trailer directional,

backup, brake, and trailer lights are connected and

working properly.

■

DOT Requirements include the following:

Trailer tires should be inflated to 50 psi cold.

Connect and test electric brake operation.

Secure portable power cables in cable tray with tie

wraps.

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 13

■

■

■

■

ALWAYS know the location of the

nearest

ALWAYS know the location of the

nearest and

ALWAYS know the location of the

nearest phone or

the job site,

ALWAYS have easy access to the phone

numbers of the nearest

and

be invaluable in the case of an emergency.

fire extinguisher

first aid kit

keep a phone on

in case of emergencies.

Fire Department

.

.

Ambulance, Doctor

. This information will

1

Page 14

DCA-220SSJ/SSJU — GENERATOR DECALS

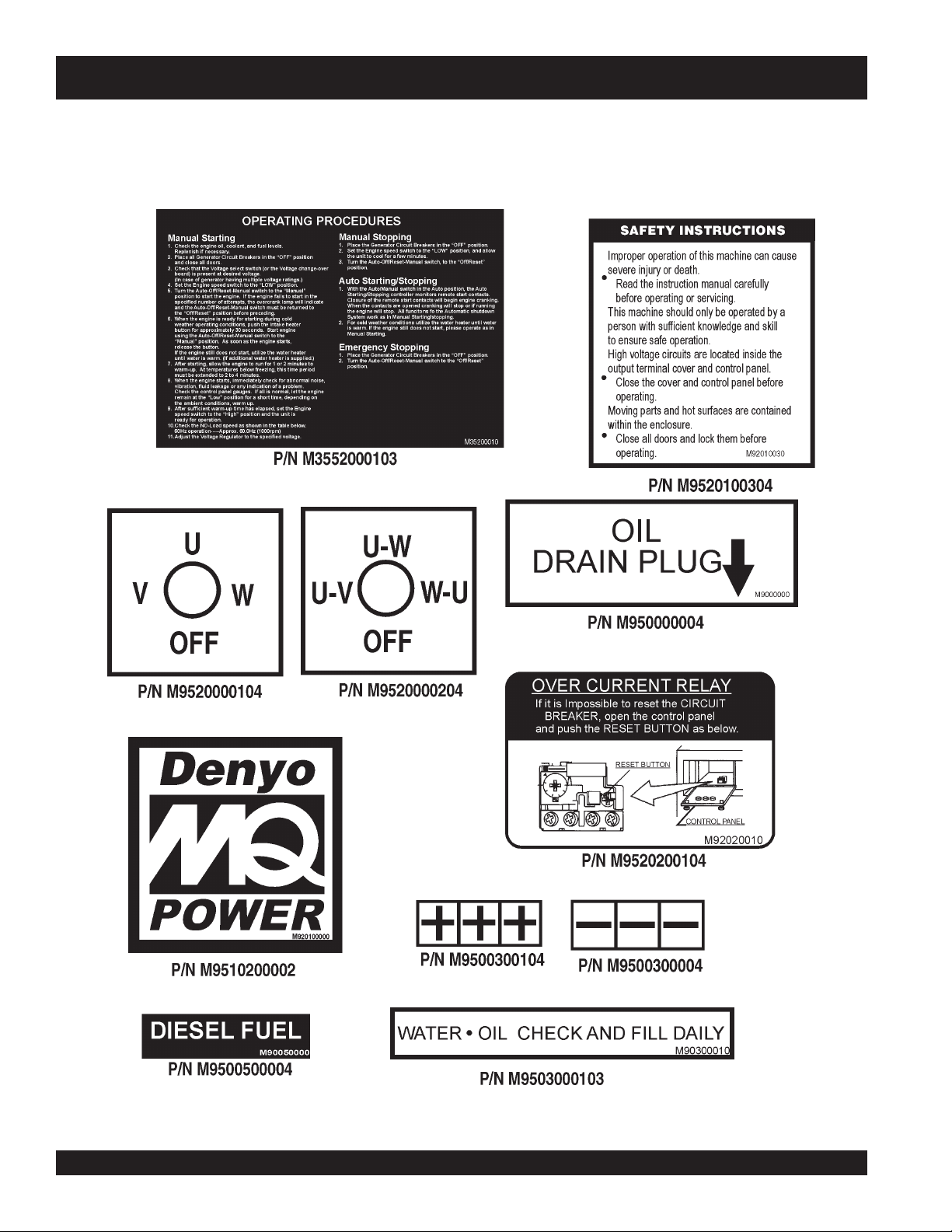

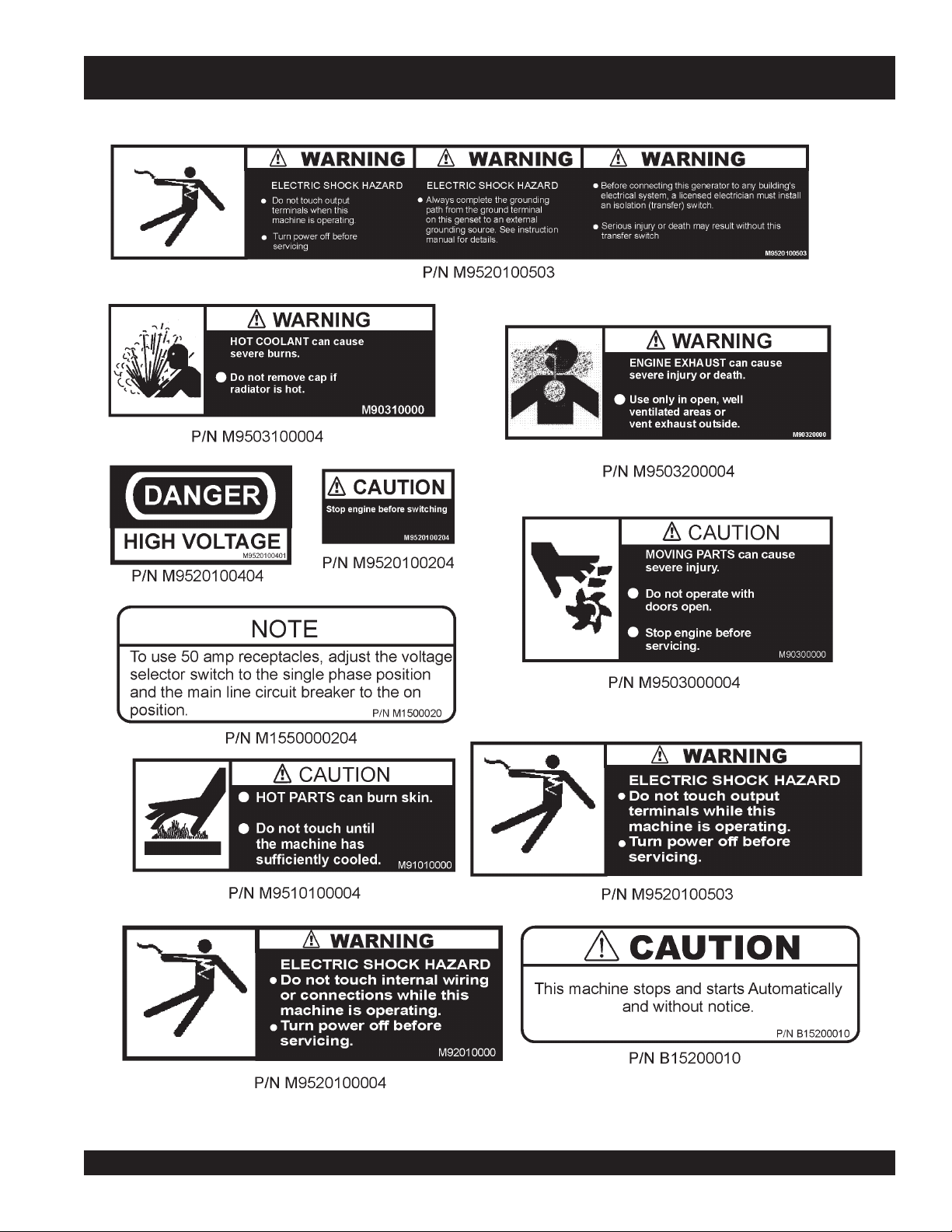

The DCA-220SSJ/SSJU generator is equipped with a number of safety decals (Figures 2 & 3). These decals are provided

for operator safety and maintenance information. The illustration below and on the preceding page show the decals as

they appear on the machine. Should any of these decals become unreadable, replacements can be obtained from your

dealer.

Figure 2. Generator Decals

PAGE 14 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 15

DCA-220SSJ/SSJU — GENERATOR DECALS

Figure 3. Generator Decals (Cont inued)

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 15

1

Page 16

DCA-220SSJ/SSJU — INSTALLATION

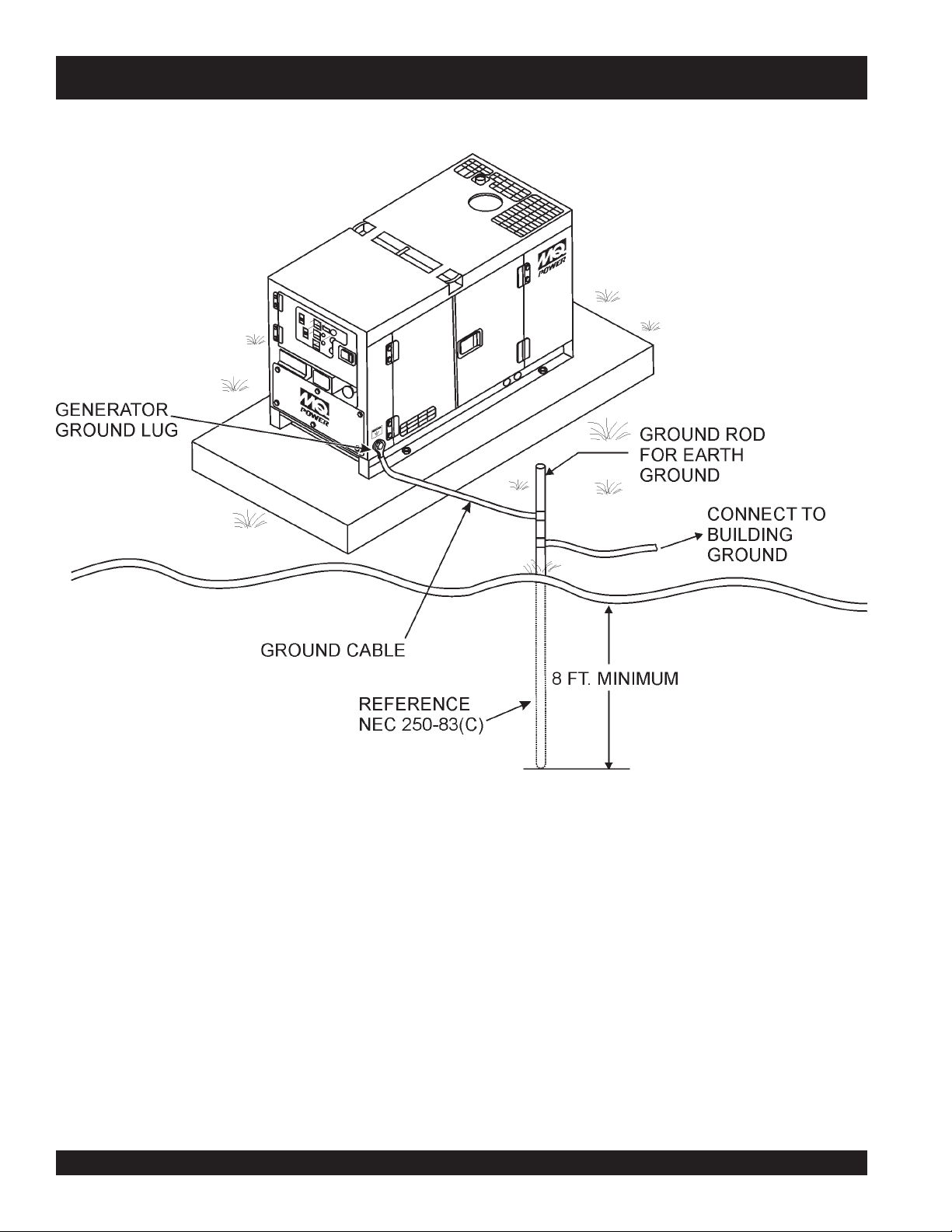

Figure 4. Typical Generator Grounding Application

PAGE 16 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 17

DCA-220SSJ/SSJU — INSTALLATION

Outdoor Installation

Install the generator in a area that is free of debris,

bystanders, and overhead obstructions. Make sure the

generator is on secure level ground so that it cannot slide or

shift around. Also install the generator in a manner so that

the exhaust will not be discharged in the direction of nearby

homes.

The installation site must be relatively free from moisture

and dust. All electrical equipment should be protected from

excessive moisture. Failure to do will result in deterioration

of the insulation and will result in short circuits and grounding.

Foreign materials such as dust, sand, lint and abrasive

materials have a tendency to cause excessive wear to

engine and alternator parts.

CAUTION - EXHAUST HAZARD

Pay close attention to ventilation when operating the

generator inside tunnels and caves. The engine exhaust

contains noxious elements. Engine exhaust must be routed

to a ventilated area.

Indoor Installation

Generator Grounding

To guard against electrical shock and possible damage to

the equipment, it is important to provide a good EARTH

ground.

Article 250 (Grounding) of the National Electrical Code (NEC)

provides guide lines for proper grounding and specifies that

the cable ground shall be connected to the grounding system

of the building as close to the point of cable entry as

practical.

NEC articles 250-64(b) and 250-66 set the following

grounding requirements:

1. Use one of the following wire types to connect the

generator to earth ground.

a. Copper - 8 AWG (5.3 mm

b. Aluminum - 6 AWG (8.4 mm2)

2. When grounding the generator (Figure 4) connect the

ground cable between the lock washer and the nut on

the generator and tighten the nut fully. Connect the other

end of the ground cable to earth ground.

3. NEC article 250-52(c) specifies that the earth ground

rod should be buried a minimum of 8 ft. into the ground.

2

)

Exhaust gases from diesel engines are extremely poisonous.

Whenever an engine is installed indoors the exhaust fumes

must be vented to the outside. The engine should be installed

at least two feet from any outside wall. Using an exhaust

pipe which is too long or too small can cause excessive

back pressure which will cause the engine to heat excessively

and possibly burn the valves.

Mounting

The generator must be mounted on a solid foundation (such

as concrete) and set firmly on the foundation to isolate

vibration of the generator when it is running. The generator

must set at least 6 inches above the floor or grade level (in

accordance to NFPA 110, Chapter 5-4.1). DO NOT remove

the metal skids on the bottom of the generator. They are to

resist damage to the bottom of the generator and to maintain

alignment.

NOTICE

When connecting the generator to any buildings

electrical system ALWAYS consult with a licensed

electrician.

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 17

Page 18

DCA-220SSJ/SSJU — GENERAL INFORMATION

DCA-220SSJ/SSJU Whisperwatt™ Series Familiarization

Open Delta Excitation System

The DCA-220SSJ/SSJU generator is equipped with the state

Generator

The MQ Power Model DCA-220SSJ/SSJU is a 176 kW

generator

(Figure 5) that is designed as a high quality

portable (requires a trailer for transport) power source for

telecom sites, lighting facilities, power tools, submersible

pumps and other industrial and construction machinery.

Engine Operating Panel

The “Engine Operating Panel” is provided with the following:

■■

Tachometer

■

■■

■■

■

Water Temperature Gauge

■■

■■

■

Oil Pressure Gauge

■■

■■

Charging Ammeter Gauge

■

■■

■■

■

Fuel Level Gauge

■■

■■

■

Engine Speed Switch

■■

■■

■

Panel Light/Panel Light Switch

■■

■■

■

Auto ON/OFF Engine Controller (MPEC)

■■

■■

■

Preheat Lamp

■■

■■

■

Warning Lamp

■■

■■

■

Emergency Stop Lamp

■■

■■

■

Emergency Stop Button

■■

of the art "

system consist of an electrically independent winding wound

among stationary windings of the AC output section.

There are four connections of the open delta A, B, C and D.

During steady state loads, the power from the voltage regulator

is supplied from the parallel connections of A to B, A to D,

and C to D. These three phases of the voltage input to the

voltage regulator are then rectified and are the excitation

current for the exciter section.

When a heavy load, such as a motor starting or a short

circuit occurs, the automatic voltage regulator (AVR)

switches the configuration of the open delta to the series

connection of B to C. This has the effect of adding the voltages

of each phase to provide higher excitation to the exciter

section and thus better voltage response during the

application of heavy loads.

The connections of the AVR to the AC output windings are

for sensing only. No power is required from these windings.

The open-delta design provides virtually unlimited excitation

current, offering maximum motor starting capabilities. The

Generator Control Panel

The “Generator Control Panel” is provided with the following:

■■

■

Frequency Meter (Hz)

■■

■■

■

AC Ammeter (Amps)

■■

■■

■

AC Voltmeter (Volts)

■■

■■

■

Ammeter Change-Over Switch

■■

■■

■

Voltmeter Change-Over Switch

■■

■■

■

Voltage Regulator

■■

■■

■

3-Pole, 600 amp Main Circuit Breaker

■■

■■

■

“Control Box” (located behind the Gen. Control Panel)

■■

■■

■

Automatic Voltage Regulator

■■

■■

■

Diagnostic Display

■■

■■

■

Current Transformer

■■

■■

■

Over-Current Relay

■■

■■

■

Voltage Rectifer

■■

■■

■

Starter Relay

■■

■■

■

Engine Controller (Computer Controlled)

■■

■■

■

Voltage Change-over Board

■■

Output Terminal Panel

The “Output Terminal Panel” is provided with the following:

■■

■

Three 120/240V output receptacles (CS-6369), 50A

■■

■■

■

Three auxilliary circuit breakers, 50A

■■

■■

■

Two 120V output receptacles (GFCI), 20A

■■

■■

■

Two GFCI circuit breakers, 20A

■■

■■

■

Five output terminal lugs (3Ø power)

■■

■■

■

Battery Charger (Optional)

■■

■■

■

Water Heater (Optional)

■■

excitation does not have a "

according the demands of the required load.

Engine

The DCA-220SSJ/SSJU is powered by a 6 cylinder, water

cooled, direct injection, turbocharged

6068HF485 Turbo Diesel Engine

to meet every performance requirement for the generator.

Reference Table 1 for engine specifications.

In keeping with MQ Power's policy of constantly improving

its products, the specifications quoted herein are subject to

change without prior notice.

Electric Governor System

The electric governor system controls the RPMs of the engine. When the engine demand increases or decreases, the

governor system regulates the frequency variation to ±.25%.

Extension Cables

When electric power is to be provided to various tools or

loads at some distance from the generator, extension cords

are normally used. Cables should be sized to allow for

distance in length and amperage so that the voltage drop

between the generator and point of use (load) is held to a

minimum. Use the cable selection chart (Table 6) as a guide

for selecting proper extension cable size.

Open-Delta

" excitation system. The open delta

fixed ceiling

" and responds

John Deere

. This engine is designed

PAGE 18 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 19

DCA-220SSJ/SSJU — MAJOR COMPONENTS

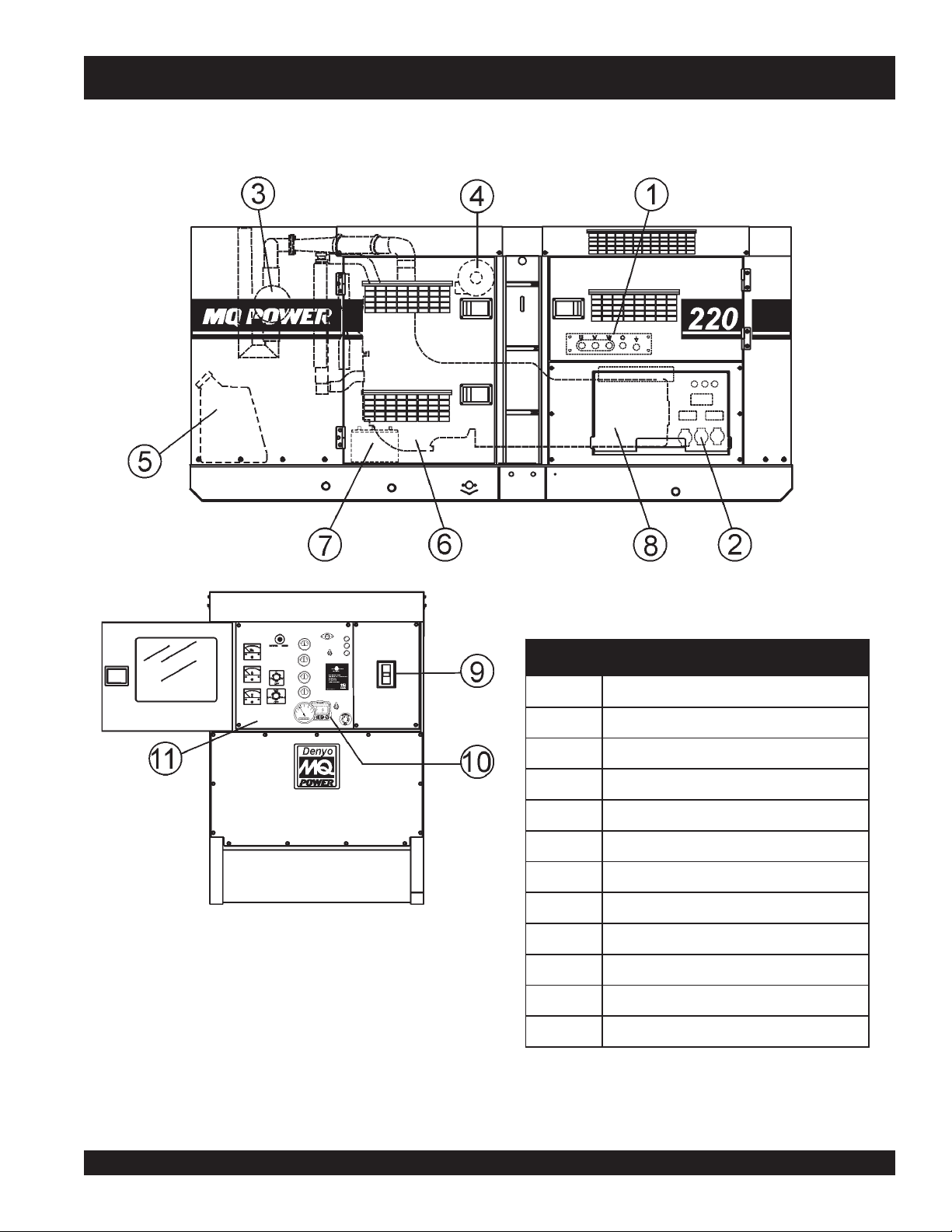

Figure 5. Major Components

4elbaT. stnenopmoCrojaMrotareneG

.ONMETINOITPIRCSED

1ylbmessAlenaPlanimreTtuptuO

2ylbmessAselcatpeceRtuptuO

3ylbmessAretliFriA

4ylbmessArelffuM

5ylbmessAknaTleuF

6ylbmessAenignE

7ylbmessAyrettaB

8ylbmessArotareneG

9ylbmessArekaerBtiucriC

01ylbmessAyalpsiDc

11ylbmessAlenaPlortnoCenignE/rotareneG

itsongaiD

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 19

Page 20

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

3. Right Arrow Button – Press this button to scroll through

the screen either moving the parameter selection toward

the right or downward.

4. Enter Key Button – Press this button to select the

parameter that is highlighted on the screen.

5. Emergency Stop LED – When lit (RED) indicates a

major fault has occured. This condition will shudown

the generator.

6. Warning LED – When lit (AMBER), indicates a engine

parameter has exceeded its limits (minor fault). The

generator will still run in this condition.

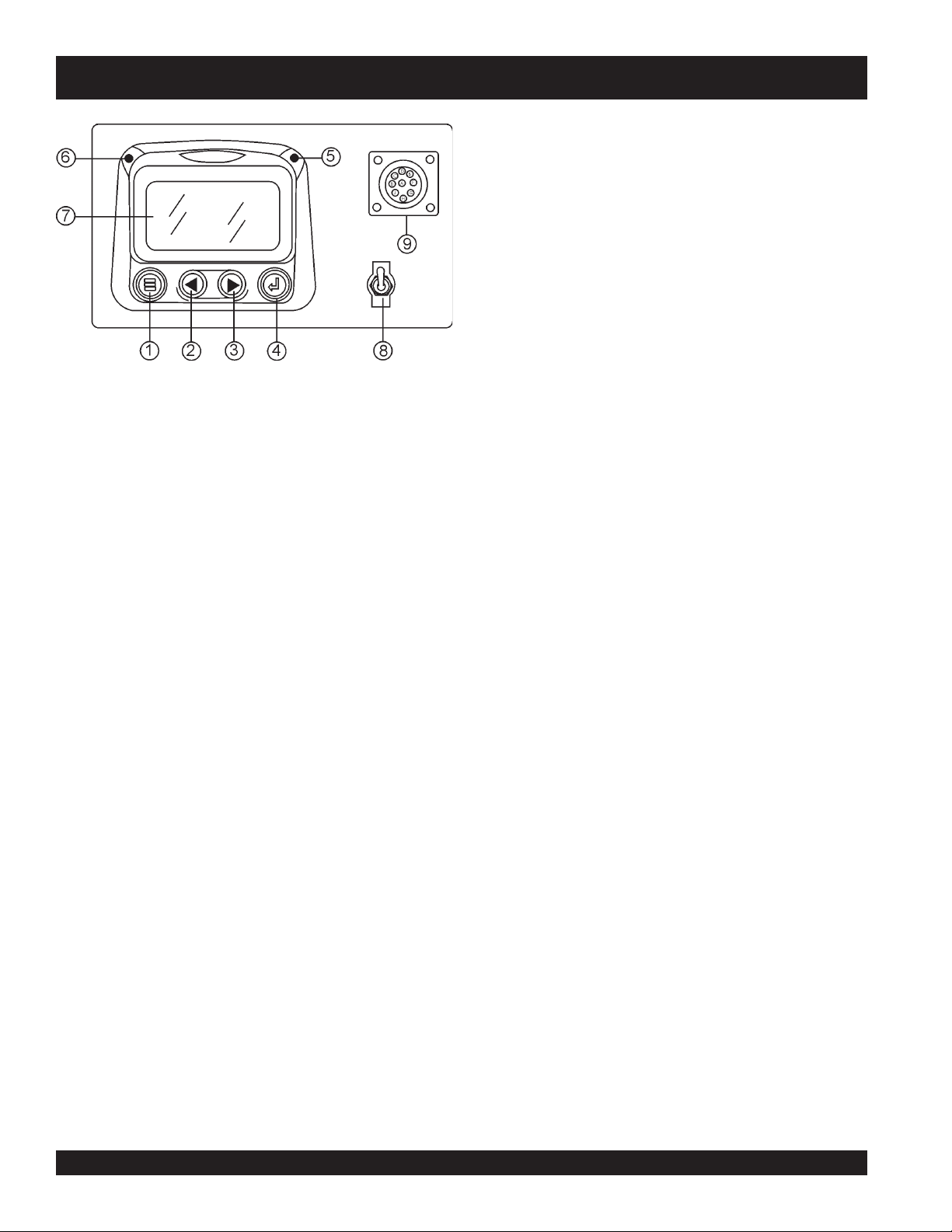

Figure 6. Diagnostic Display Panel

The diagnostic display panel located inside the control box

on the generator (Figure 6) is designed to meet the needs

for instrumentation and control of electronically controlled

engine communication using the SAEJ1939 Controller Area

Network (CAN). This diagnostic display is a multifunction

tool that enables equipment operators to view many different

engine parameters and service codes.

The keypad on the diagnostic display panel is a capacitive

touch sensing system. There are no mechanical switches to

wear or stick. This keypad (display unit) will operate in

extreme hot or cold weather conditions.

Other components in the system are microprocessor-based

components for displaying critical engine data broadcast by

an electronic engine or transmission’s Engine Control Unit

(ECU): engine RPM, oil pressure, coolant temperature,

system voltage, etc., and a combination audible alarm and

relay unit for warning and shutdown annunciation.

The Engine Control Unit (ECU) used with this generator

diagnosis engine faults that arise with the the engine control

system and the engine itself. Engine faults can be determined

by viewing the Diagnostic Trouble Codes (Active Fault Codes)

which are displayed on the Diagnostic Display Panel. See

the John Deere Engine Operator’s Manual for a complete

listing of active fault codes and countermeasures.

The following definitions describe the controls and functions

of the

Diagnostic Display Panel

(Figure 6).

7. Display Screen – Graphical backlight LCD screen. Back

lighting is controlled via menu or external dimmer

potentiometer. The display can show either a single

parameter or a quadrant display showing four parameters

simultaneously.

8. Diagnostic Switch – When placed in the ON position,

will activate the diagnostic display panel.

9. CAN Diagnostic Connector – Controller Area Network

connector. This connector outputs diagnostic error

codes. Connect a scanner or similar device into this

connector to read error codes.

Display Parameters

The following are some of the engine and transmission

parameters displayed on the diagnostic disply panel.

■■

■

Engine RPM’s

■■

■■

■

Engine Hours

■■

■■

■

System Voltage

■■

■■

■

% Engine Load at current RPM

■■

■■

■

Coolant Temperature

■■

■■

■

Oil Pressure

■■

■■

■

Fuel Economy

■■

■■

■

Current Fuel Consumption

■■

■■

■

Throttle Position

■■

■■

■

Engine Manifold Air Temperature

■■

■■

■

Active Service Codes

■■

■■

■

Set Units for Display (English or Metric)

■■

■■

■

English Configuration Parameters.

■■

1. Menu Button – Press this button to enter or exit menu

screens.

2. Left Arrow Button– Press this button to scroll through

the screen either moving the parameter selection toward

the left or upward.

PAGE 20 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 21

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

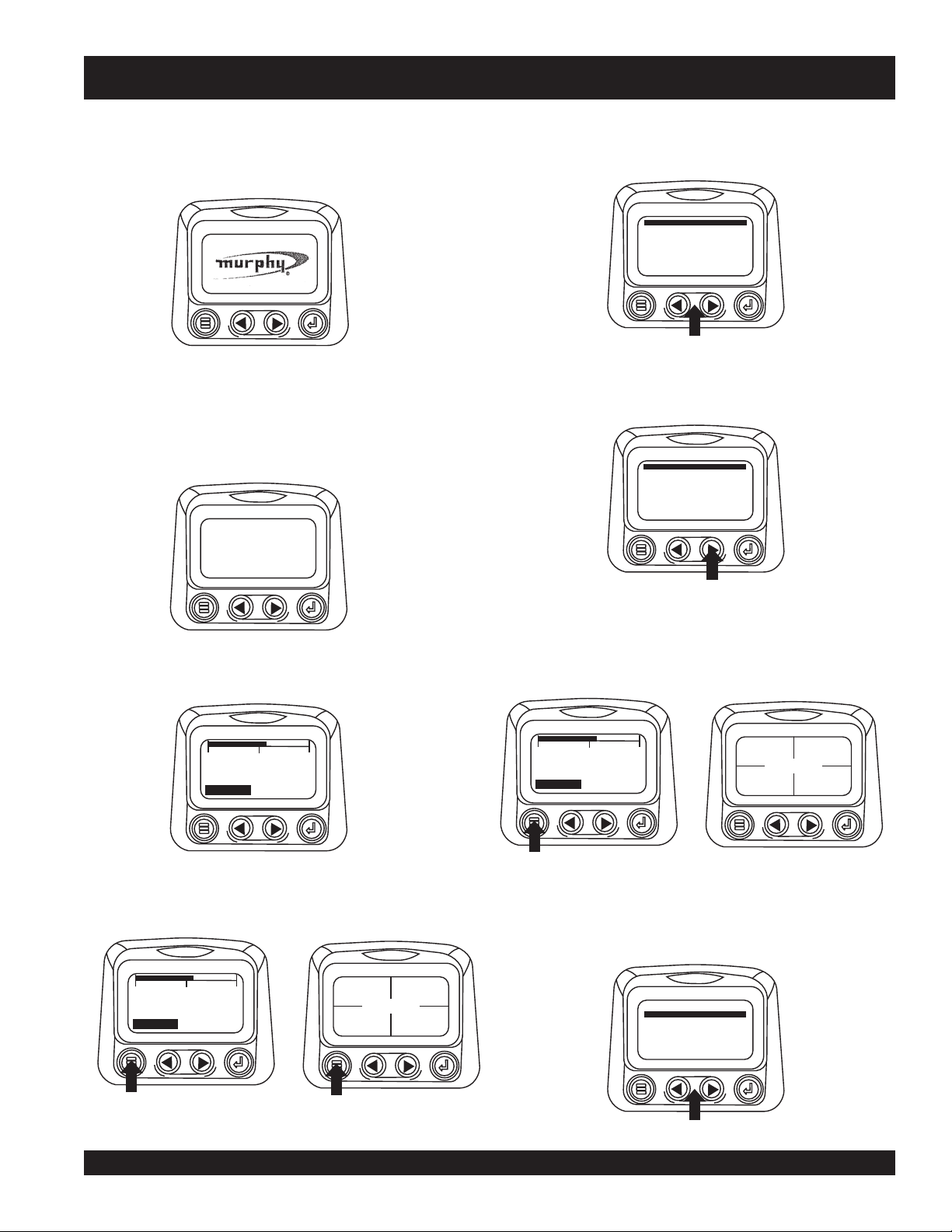

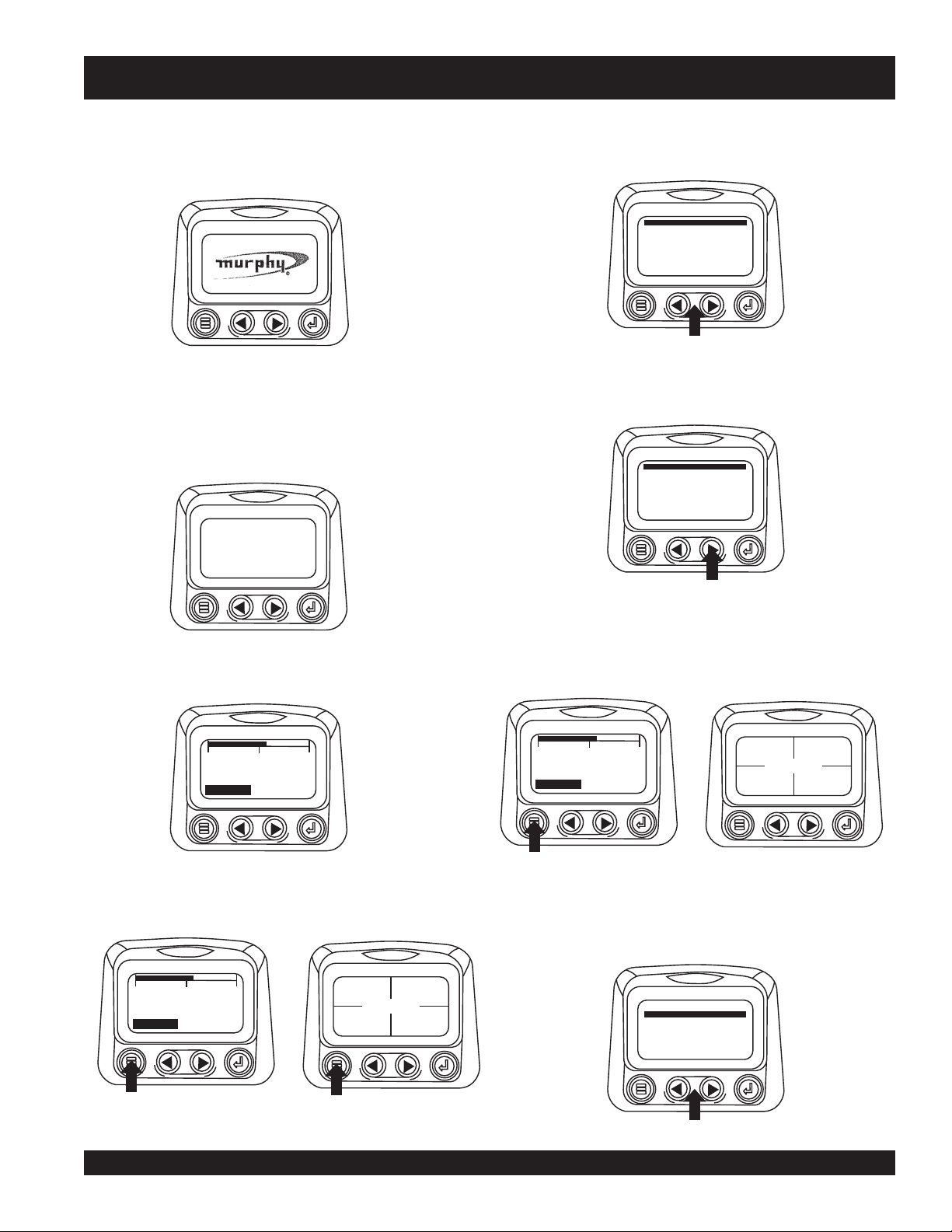

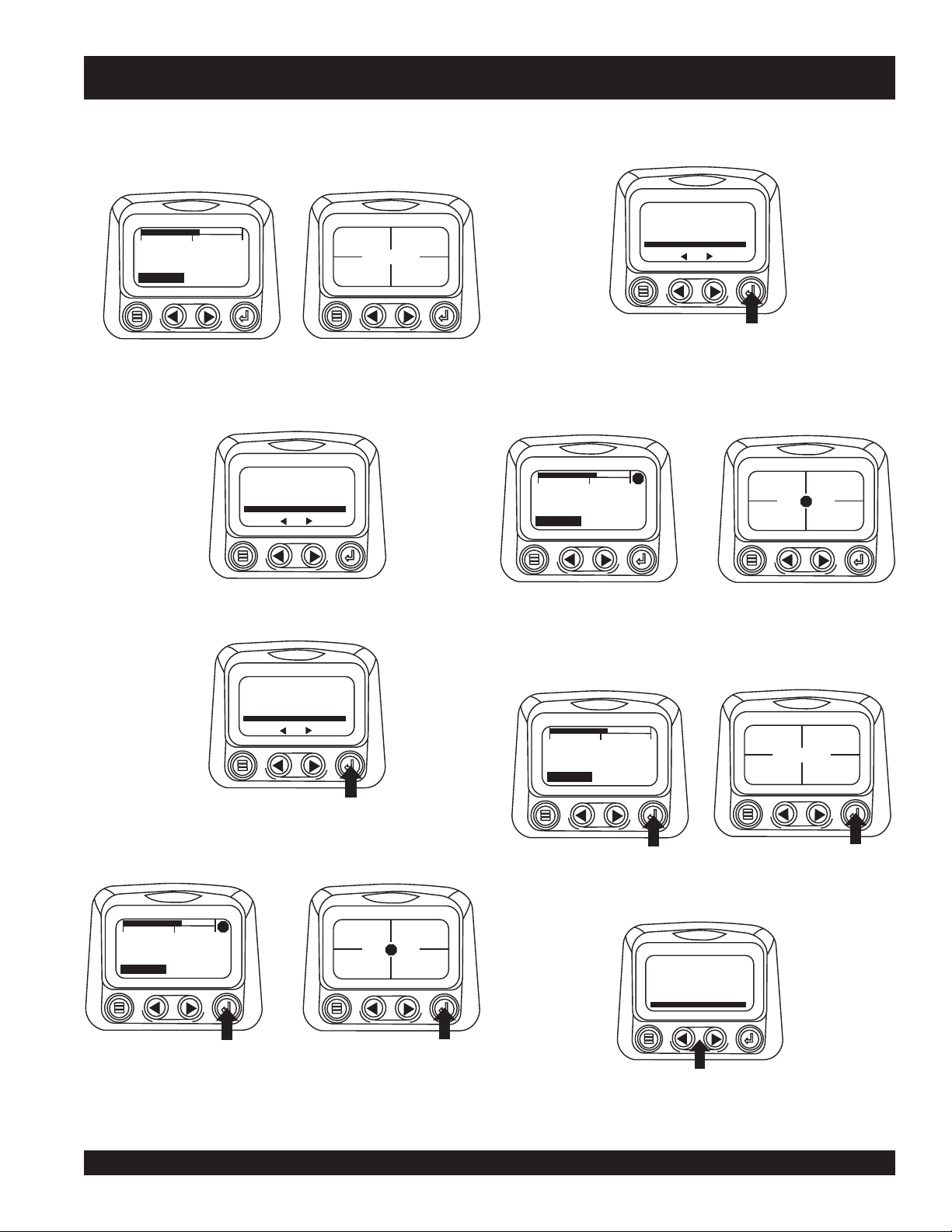

First Time Start Up

1. When power is first applied to the diagnostic display,

the “Logo” is displayed.

2. The “Wait to Start” message will be displayed for

engines with a pre-startup sequence. Once the “Wait to

Start” message is no longer displayed the operator may

start the engine. Note: Displays only when SAE J1939

message is supported by engine manufacturer.

WAIT TO

START

PREHEAT

2. The first seven items of the “Main Menu” will be

displayed. Touching the “Arrow Buttons” will scroll through

the menu selection.

GO TO 1-UP DISPLAY

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

G

3. Touching the right arrow button will scroll down to reveal

the last items of “Main Menu” screen highlighting the

next item down.

ADJUST BACKLIGHT

ADJUST CONTRAST

UTILITIES

3. Once the engine has started the single engine parameter

is displayed.

0

3000

1500

1800 RPM

TEMP

ENG RPM

COOL

Main Menu Navigation

1. Starting at the single or four engine parameter display,

touch “Menu”.

1000 RPM

0

3000

1500

98%

LOAD RPM

ENG RPM

1800 RPM

ENG RPM

COOL

TEMP

14.2

BATTVOLT

57 PSI

OIL PRES

4. Touch the Arrows” to scroll to the desired menu item or

touch “Menu” to exit the Main menu and return to the

engine parameter display.

1000 RPM

0

3000

1500

98%

LOAD RPM

ENG RPM

1800 RPM

ENG RPM

COOL

TEMP

14.2

BATTVOLT

57 PSI

OIL PRES

Selecting a Language

1. Starting at the main menu display use the “Arrows to

scroll to the “Language” menu and once highlighted touch

the “Enter” button.

GO TO 1-UP DISPLAY

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

G

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 21

Page 22

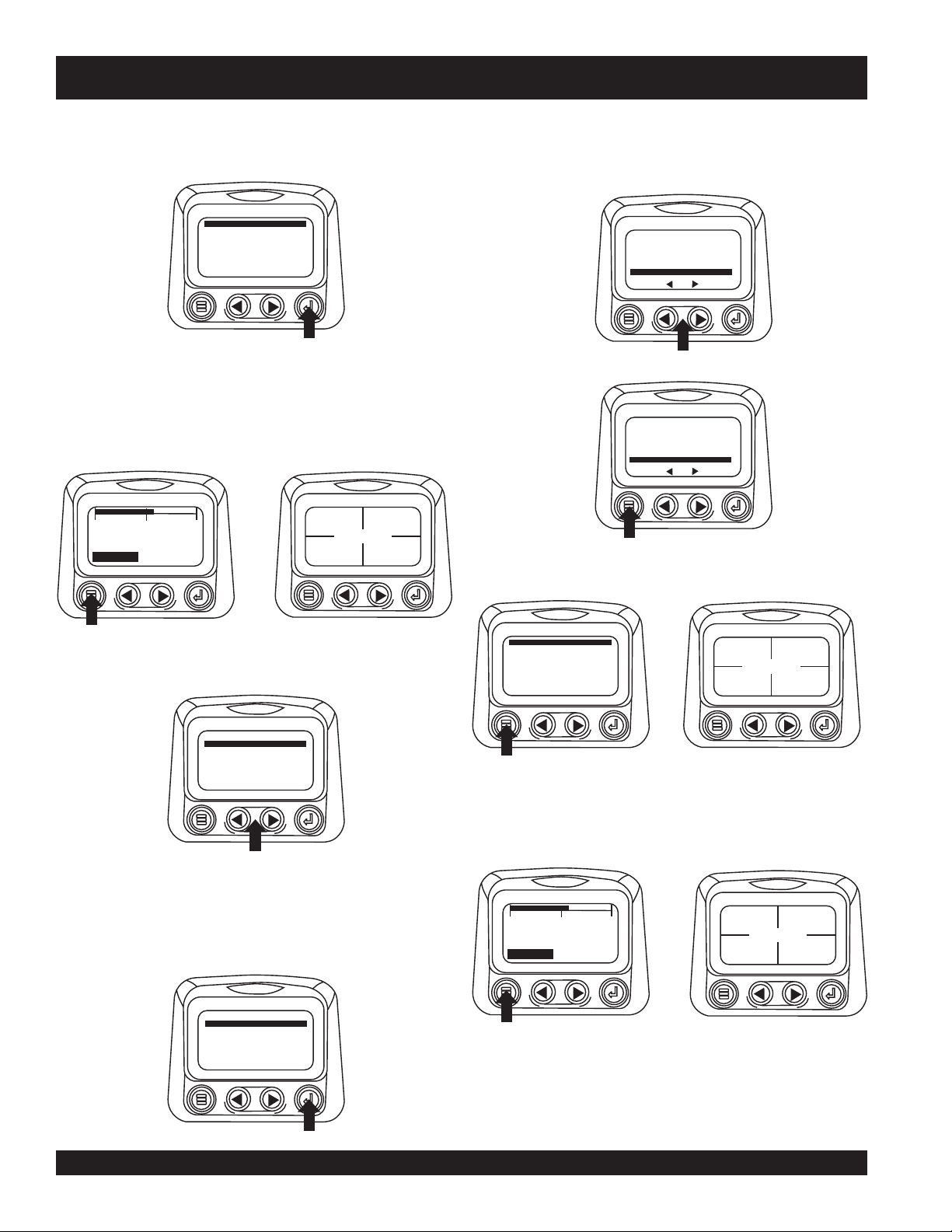

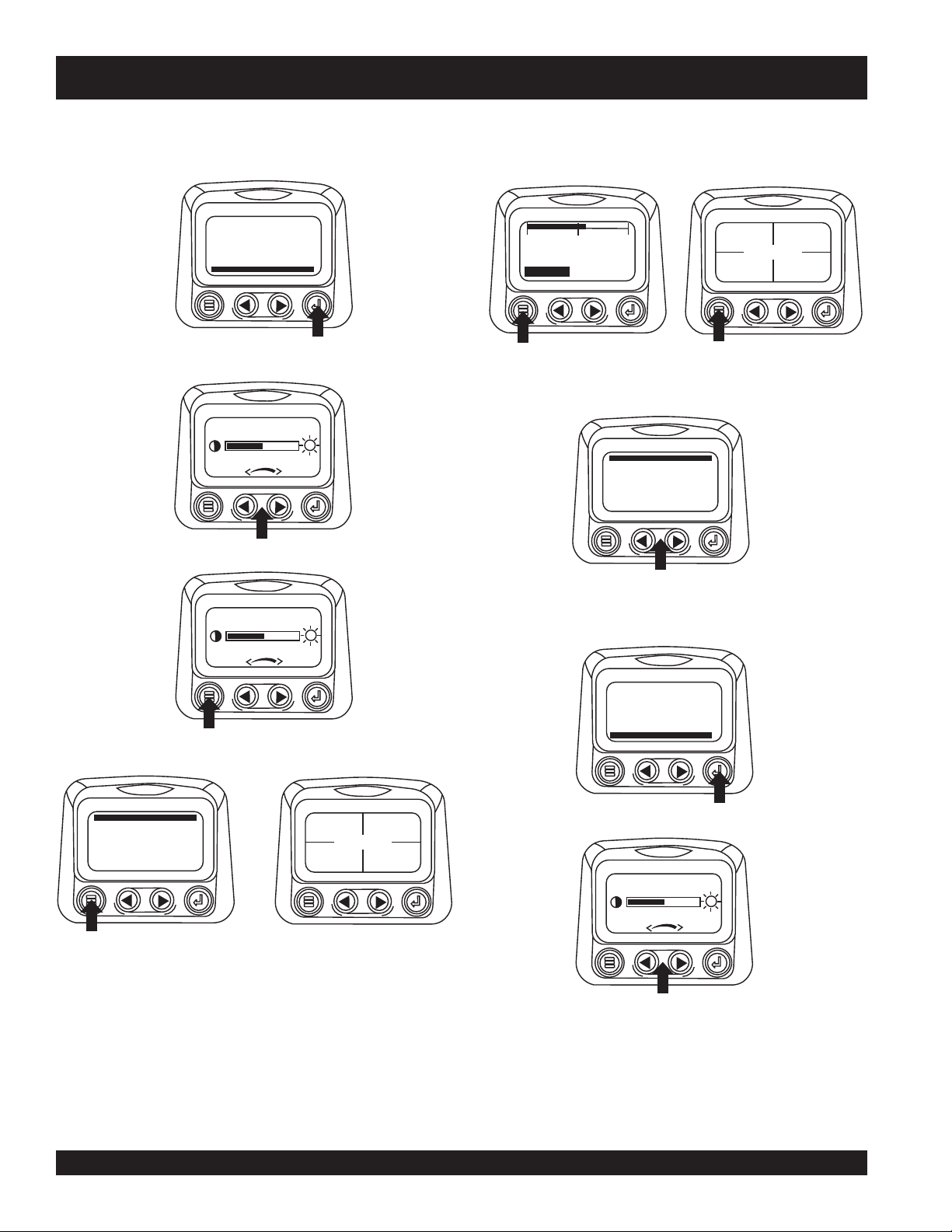

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

2. The language choices will be displayed. Use the “Arrow”

buttons to scroll through the selections and touch “Enter”

to make a selection.

4. If the word “MORE” appears above the “Arrow Buttons”

there are more stored fault codes that may be viewed.

Use the “Arrow Buttons” to scroll to the next Stored

Diagnostic Code.

ENGLISH

ESPANOL

FRANCAIS

DEUTSCH

3. Now that you have selected the language, touch the

“Menu” button to return to the main menu display.

5. Touch the “Menu Button to return to the main menu.

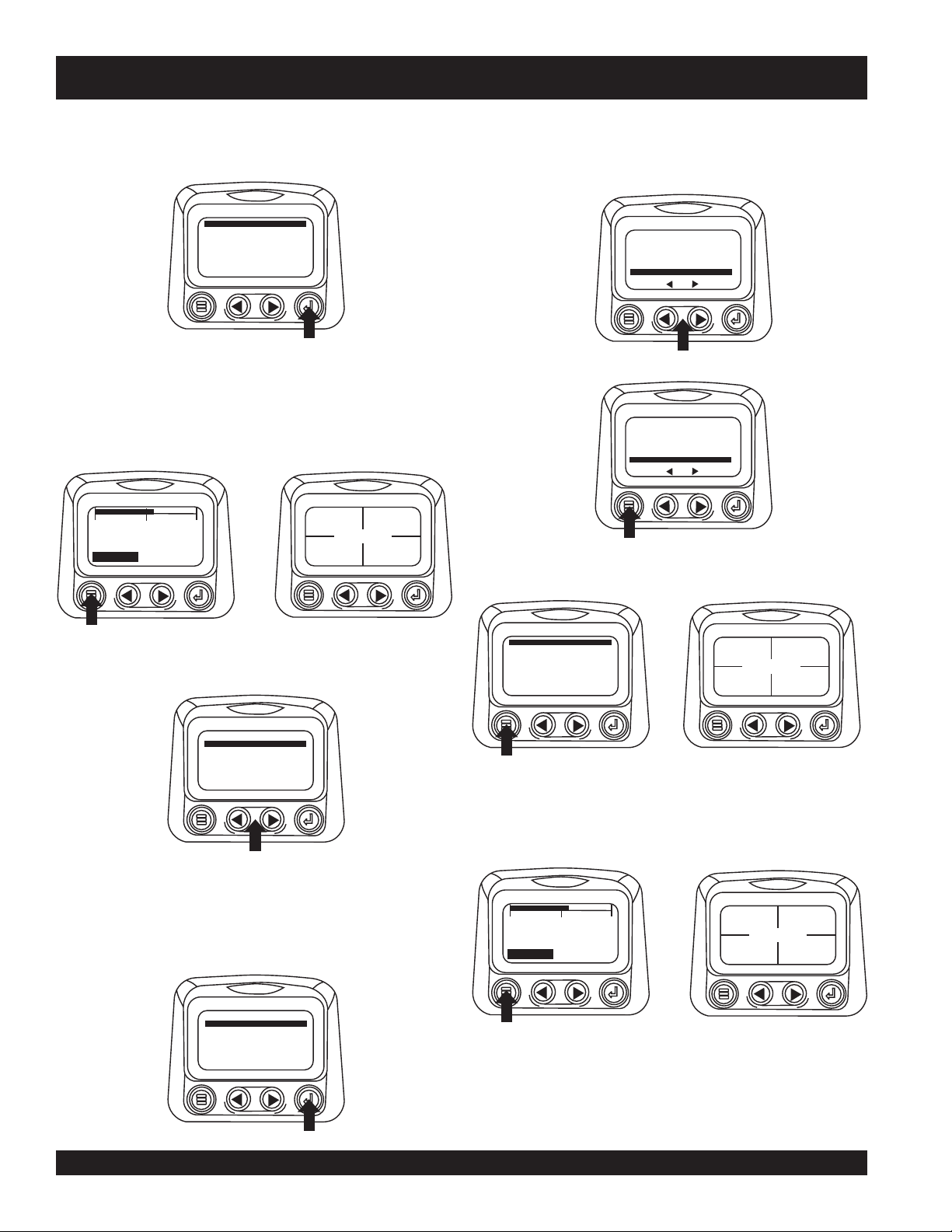

Stored Fault Codes

1. Starting at the single or the four engine parameter

display touch the “Menu button”.

0

1500

1800 RPM

ENG RPM

COOL

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

6. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

1ofx

SPN110 FMI10

HIGH COOLANT TEMP

MORE

1ofx

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

HIDE

2. The main menu will pop up on the display. Use the “Arrow

Buttons” to scroll through the menu until the Stored Fault

Codes is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

3. Once the “Stored Fault Codes” menu item has been

highlighted touch the “Enter Button” to view the “Stored

Fault Codes” (when applicable, consult engine or

transmission manufacturer for SAE J1939 supported

parameters).

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

Engine Configuration Data

1. Starting at the single or four engine parameter display

touch the “Menu Button”.

0

3000

1500

98%

LOAD RPM

1000 RPM

ENG RPM

1800 RPM

ENG RPM

COOL

TEMP

14.2

BATTVOLT

57 PSI

OIL PRES

PAGE 22 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 23

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

First Time Start Up

1. When power is first applied to the diagnostic display,

the “Logo” is displayed.

2. The “Wait to Start” message will be displayed for

engines with a pre-startup sequence. Once the “Wait to

Start” message is no longer displayed the operator may

start the engine. Note: Displays only when SAE J1939

message is supported by engine manufacturer.

WAIT TO

START

PREHEAT

2. The first seven items of the “Main Menu” will be

displayed. Touching the “Arrow Buttons” will scroll through

the menu selection.

GO TO 1-UP DISPLAY

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

G

3. Touching the right arrow button will scroll down to reveal

the last items of “Main Menu” screen highlighting the

next item down.

ADJUST BACKLIGHT

ADJUST CONTRAST

UTILITIES

3. Once the engine has started the single engine parameter

is displayed.

0

3000

1500

1800 RPM

TEMP

ENG RPM

COOL

Main Menu Navigation

1. Starting at the single or four engine parameter display,

touch “Menu”.

1000 RPM

0

3000

1500

98%

LOAD RPM

ENG RPM

1800 RPM

ENG RPM

COOL

TEMP

14.2

BATTVOLT

57 PSI

OIL PRES

4. Touch the Arrows” to scroll to the desired menu item or

touch “Menu” to exit the Main menu and return to the

engine parameter display.

1000 RPM

0

3000

1500

98%

LOAD RPM

ENG RPM

1800 RPM

ENG RPM

COOL

TEMP

14.2

BATTVOLT

57 PSI

OIL PRES

Selecting a Language

1. Starting at the main menu display use the “Arrows to

scroll to the “Language” menu and once highlighted touch

the “Enter” button.

GO TO 1-UP DISPLAY

LANGUAGES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

G

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 23

Page 24

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

2. The language choices will be displayed. Use the “Arrow”

buttons to scroll through the selections and touch “Enter”

to make a selection.

4. If the word “MORE” appears above the “Arrow Buttons”

there are more stored fault codes that may be viewed.

Use the “Arrow Buttons” to scroll to the next Stored

Diagnostic Code.

ENGLISH

ESPANOL

FRANCAIS

DEUTSCH

3. Now that you have selected the language, touch the

“Menu” button to return to the main menu display.

5. Touch the “Menu Button to return to the main menu.

Stored Fault Codes

1. Starting at the single or the four engine parameter

display touch the “Menu button”.

0

1500

1800 RPM

ENG RPM

COOL

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

6. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

1ofx

SPN110 FMI10

HIGH COOLANT TEMP

MORE

1ofx

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

HIDE

2. The main menu will pop up on the display. Use the “Arrow

Buttons” to scroll through the menu until the Stored Fault

Codes is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

3. Once the “Stored Fault Codes” menu item has been

highlighted touch the “Enter Button” to view the “Stored

Fault Codes” (when applicable, consult engine or

transmission manufacturer for SAE J1939 supported

parameters).

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

Engine Configuration Data

1. Starting at the single or four engine parameter display

touch the “Menu Button”.

0

3000

1500

98%

LOAD RPM

1000 RPM

ENG RPM

1800 RPM

ENG RPM

COOL

TEMP

14.2

BATTVOLT

57 PSI

OIL PRES

PAGE 24 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 25

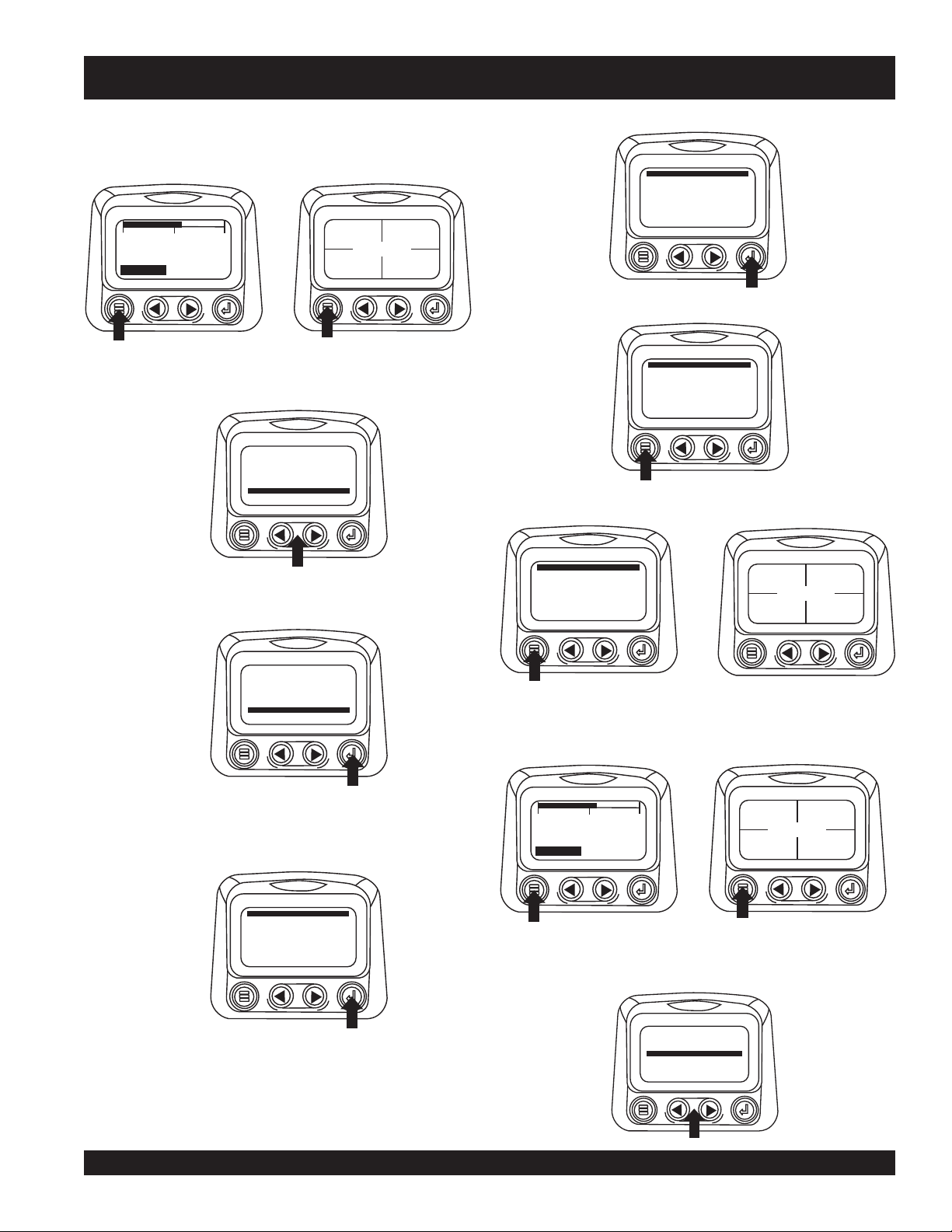

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

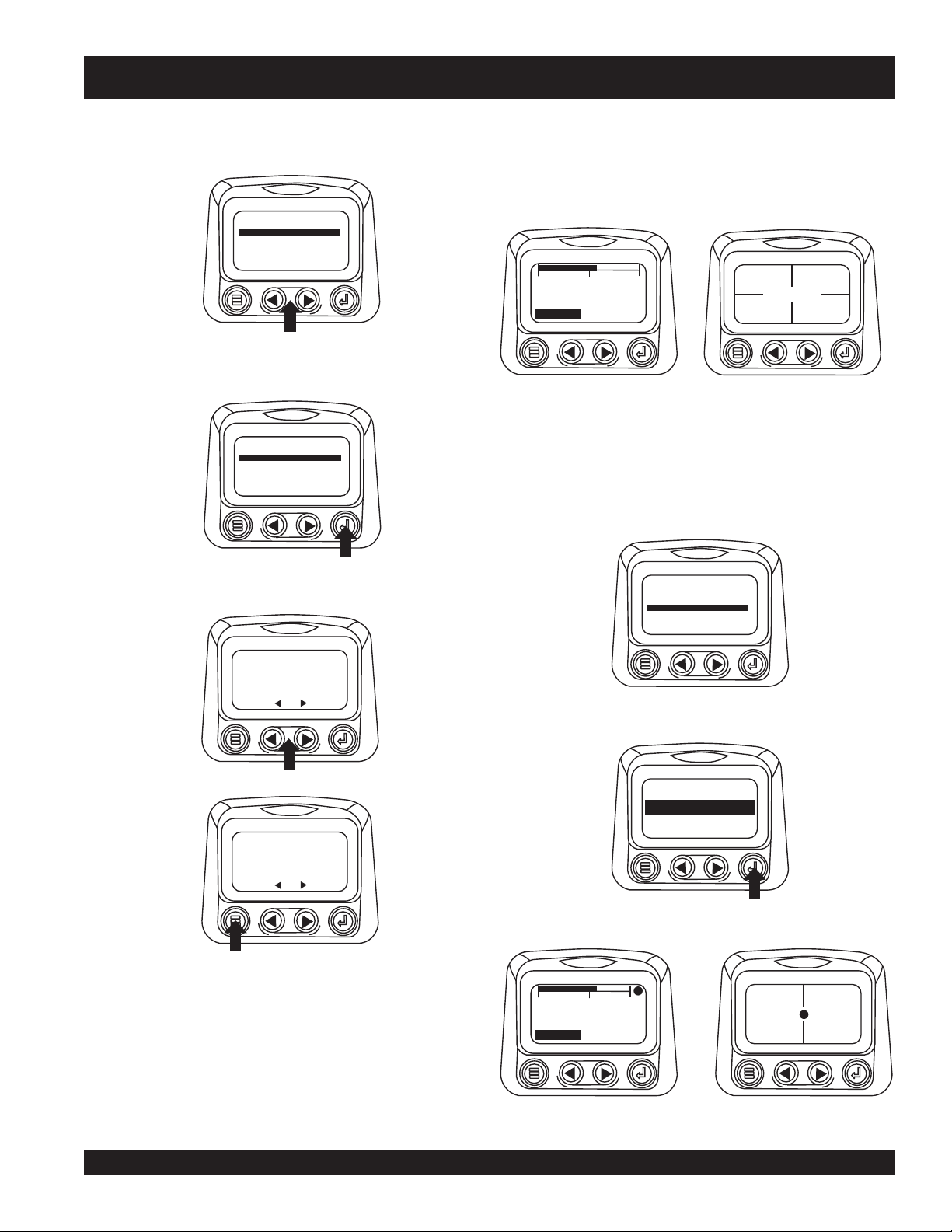

2. The main menu will pop up on the display. Use the “Arrow

FAULTS AND WARNINGS

Buttons” to scroll through the menu until the “Engine

Configuration” menu item has been highlighted.

Auxiliary Gage Fault

1. During normal operation the single or four parameter

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

screen will be displayed.

0

1800 RPM

ENG RPM

3. Once the “Engine Configuration” menu item has been

highlighted touch the “Enter Button” to view the engine

configuration data.

2. The PVA Series of auxiliary gages can be attached to

the PowerView. These auxiliary gages communicate with

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

the Modbus master PowerView via a daisy-chained RS485 port. If at any time during system initialization or

normal operation an auxiliary gage should fail, the single

or four parameter screen will be replaced with the “MLink

Gage Fault” message.

1500

COOL

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

4. Use the “Arrow Buttons” to scroll through the engine

configuration data.

ENGINE SPEED PT 1

1800 RPM

MORE

3. To acknowledge and “Hide” the fault and return to the

single or four parameter display, touch the “Enter Button”.

5. Touch the “Menu Button” to return to the main menu.

ENGINE SPEED PT 1

1800 RPM

MORE

4. The display will return to the single or four parameter

screen.

6. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

0

1800 RPM

ENG RPM

1500

COOL

1ofx

ENGINE OIL PRESSURE

GAGE NOT RESPONDING

1ofx

ENGINE OIL PRESSURE

GAGE NOT RESPONDING

!

3000

TEMP!

HIDE

HIDE

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

!

57 PSI

OIL PRES

!

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 25

Page 26

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

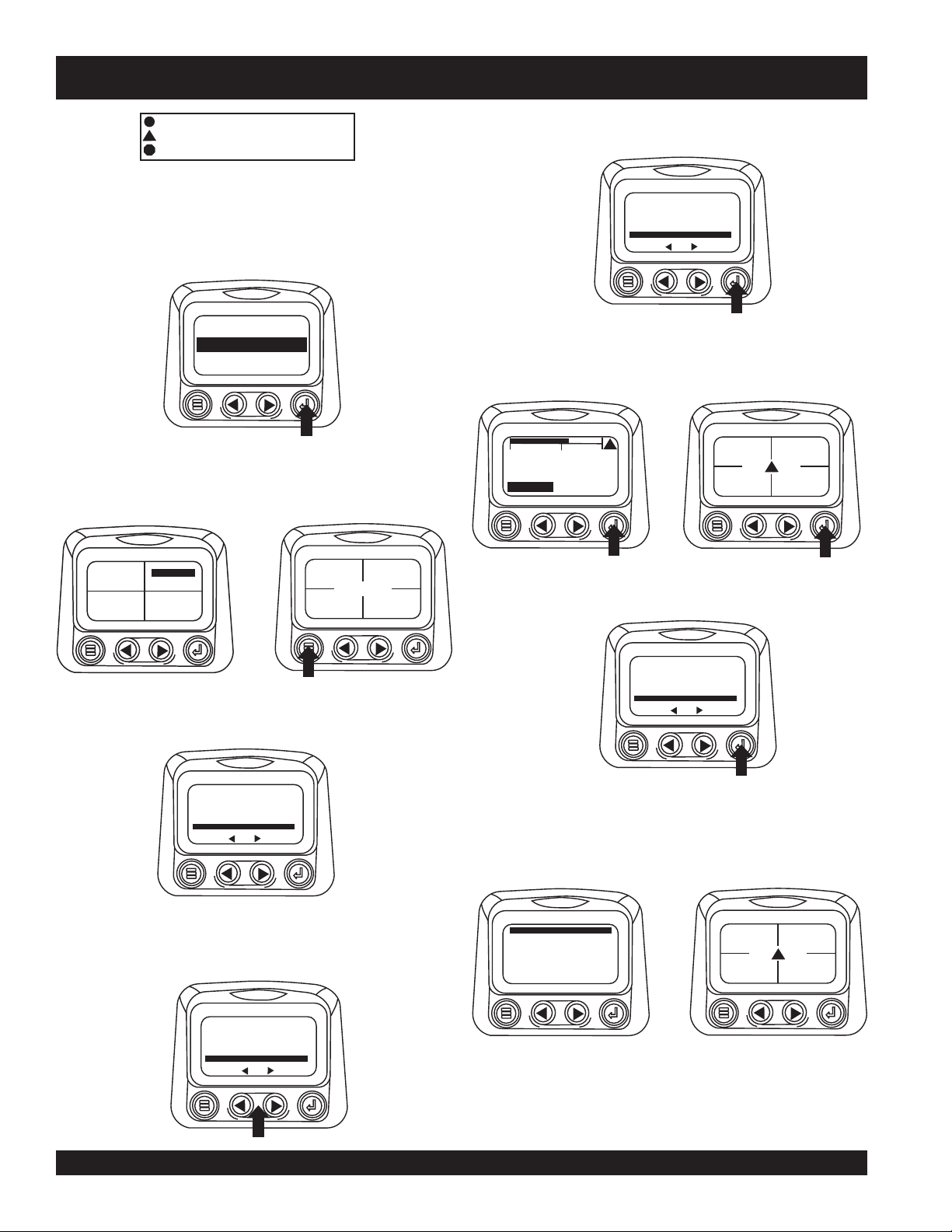

!

Indicates Auxiliary Gage Fault

!

Indicates Fault Warning

!

Indicates Derate or Shutdown Condition Fault

4. To acknowledge and “Hide” the fault and return to the

single or four parameter display touch the “Enter Button”.

5. Touching the “Enter Button” will redisplay the hidden

fault. Touching the “Enter Button” once again will hide

the fault and return the screen to the single or four

parameter display. NOTE: The fault can only be cleared

by correcting the cause of the fault condition.

1ofx

ENGINE OIL PRESSURE

GAGE NOT RESPONDING

HIDE

5. The display will return to the single or four parameter

display but the display will contain the “Active Fault”

warning icon. Touching the “Enter Button” will redisplay

the hidden fault.

Active Fault Codes

1. During normal operation the single or four parameter

0

1800 RPM

ENG RPM

screen will be displayed.

125°F

COOL TEMP

143°F

OIL TEMP

1000 RPM

ENG RPM

57 PSI

OIL PRES

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

6. Touching the “Enter Button” once again will hide the

fault and return the screen to the single or four parameter

display.

1500

COOL

3000

TEMP!

1ofx

SPN110 FMI10

HIGH COOLANT TEMP

!

MORE

HIDE

LOAD RPM

BATTVOLT

98%

14.2

1000 RPM

ENG RPM

!

57 PSI

OIL PRES

!

2. When the PowerView receives a fault code from an

engine control unit the single or four parameter screen

will be replaced with the “Active Fault Codes” message.

1ofx

WARNING

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

7. The Single or Four parameter screen will display the

fault icon until the fault condition is corrected. NOTE:

Ignoring active fault codes could result in severe engine

damage.

3. If the word “MORE” appears above the “Arrow Buttons”,

there are more active fault codes that may be viewed.

Use the “Arrow Buttons” to scroll to the next “Active

Fault Code”.

1ofx

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

1ofx

WARNING

SPN110 FMI10

HIGH COOLANT TEMP

MORE

G

HIDE

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

!

57 PSI

OIL PRES

PAGE 26 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 27

GO TO 1-UP DISPLAY

STORED CODES

GENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

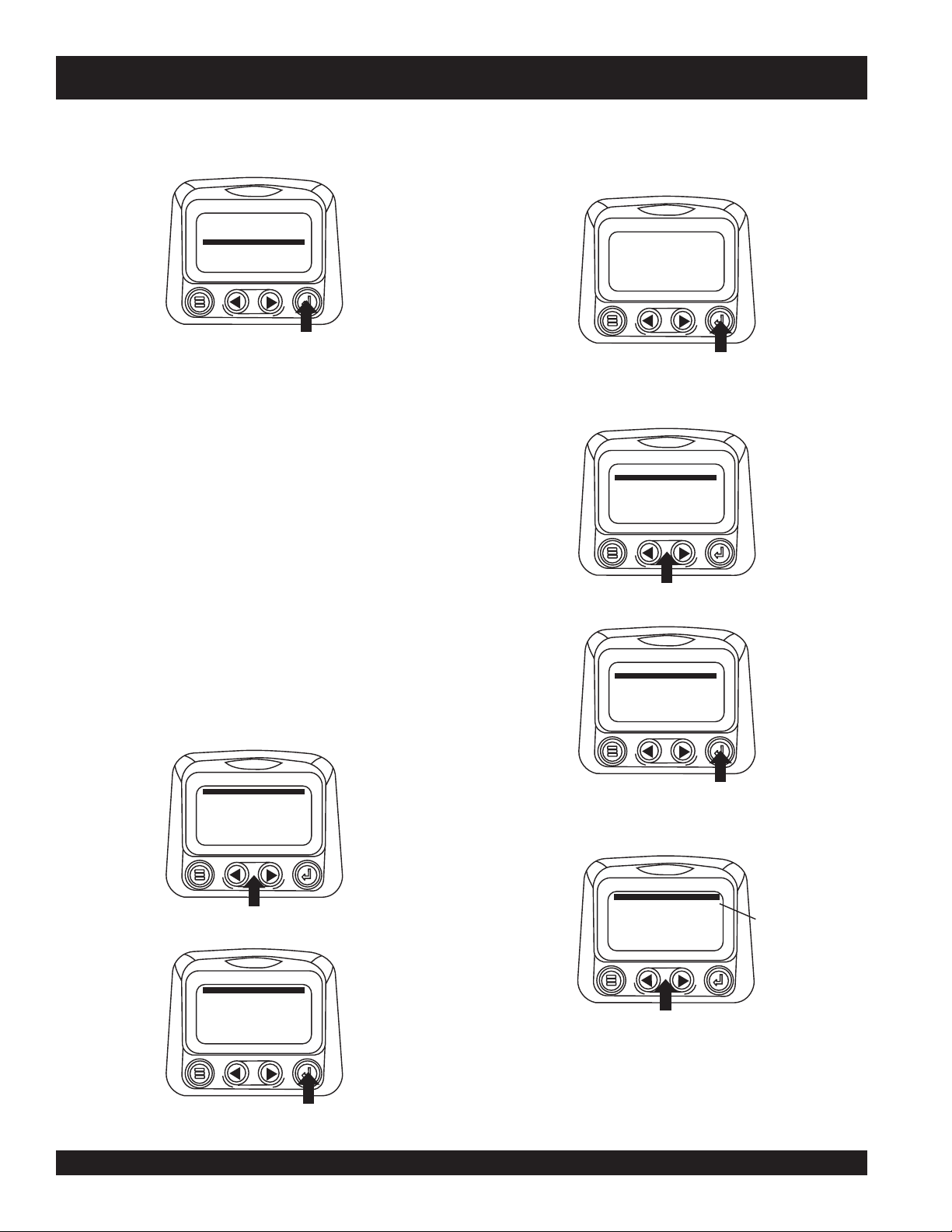

Shut Down Codes

1. During normal operation the single or four parameter

screen will be displayed.

0

1500

1800 RPM

ENG RPM

COOL

TEMP

98%

3000

LOAD RPM

14.2

BATTVOLT

ENG RPM

57 PSI

OIL PRES

1000 RPM

2. When the diagnostic display receives a severe fault

code from an engine control unit the single or four

parameter screen will be replaced with the “Shutdown”

message.

1ofx

SHUTDOWN

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

5. Touching the “Enter Button” once again will hide the

fault and return the screen to the single or four parameter

display.

6. The Single or Four parameter screen will display the

fault icon until the fault condition is corrected. NOTE:

Ignoring active fault codes could result in severe engine

damage.

0

1800 RPM

ENG RPM

1500

COOL

3000

TEMP!

!

1ofx

SHUTDOWN

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

!

57 PSI

OIL PRES

!

3. To acknowledge and “Hide” the fault and return to the

single or four parameter display touch the “Enter Button”.

Backlight Adjustment

1. Starting at the single or four engine parameter display

1ofx

SHUTDOWN

SPN110 FMI10

HIGH COOLANT TEMP

MORE

HIDE

touch the “Menu Button”.

ENG RPM

4. The display will return to the single or four parameter

display, but the display will contain the “Shut Down”

icon. Touching the “Enter Button” will redisplay the hidden

fault.

2. The main menu will pop up on the display. Use the “Arrow

Buttons” to scroll through the menu until the “Adjust

Backlight” is highlighted.

0

1500

1800 RPM

ENG RPM

COOL

3000

TEMP!

!

LOAD RPM

14.2

BATTVOLT

98%

1000 RPM

ENG RPM

!

57 PSI

OIL PRES

0

1500

1800 RPM

COOL

TEMP

98%

3000

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 27

Page 28

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

3. Once the “Adjust Backlight” menu item has been

highlighted touch the “Enter Button” to activate the

“Adjust Backlight” function.

GO TO 1-UP DISPLAY

STORED CODES

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

GENGINE CONF

4. Use the “Arrow Buttons” to select the desired backlight

intensity.

Contrast Adjustment

1. Starting at the single or four engine parameter display,

touch the “Menu Button”.

2. The main menu will pop up on the display. Use the “Arrow

Buttons” to scroll through the menu until “Adjust Contrast”

is highlighted.

ADJUST BACKLIGHT

5. Touch the “Menu Button” to return to the main menu.

0

1500

1800 RPM

ENG RPM

COOL

3000

TEMP

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

ADJUST BACKLIGHT

6. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

3. Once the “Adjust Contrast” menu item has been

highlighted touch the “Enter Button” to activate the

“Adjust Contrast” function.

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

ADJUST CONTRAST

G

4. Use the “Arrow Buttons” to select the desired contrast

intensity.

ADJUST CONTRAST

5. Touching the “Menu Button” will take you back through

the menus.

PAGE 28 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 29

GO TO 1-UP DISPLAY

STORED CODES

G

ADJUST BACKLIGHT

ENGINE CONF

SETUP-4-UP DISPLAY

SELECT UNITS

SETUP 1-UP DISPLAY

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

Select Units

5. Touch the “Enter Button” to select the highlighted units.

1. Starting at the single or four engine parameter display

touch the “Menu Button”.

0

1500

1800 RPM

ENG RPM

COOL

TEMP

98%

3000

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

6. Touch the “Menu Button” to return to the “Main Menu”.

2. The main menu will pop up on the display. Use the arrow

buttons to scroll through the menu until the “Select

Units” is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

7. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

GO TO 1-UP DISPLAY

STORED CODES

3. Once the “Select Units” menu item has been highlighted

touch the “Enter Button” to access the “Select Units”

function.

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

ENGLISH

METRIC KPA

METRIC BAR

ENGLISH

METRIC KPA

METRIC BAR

G

*

1000 RPM

98%

LOAD RPM

14.2

BATTVOLT

ENG RPM

57 PSI

OIL PRES

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

Setup 1- Up Display

1. Starting at the single engine parameter display, touch

the “Menu Button”.

4. Use the arrows to highlight the desired units. “English”

for imperial units i.e. PSI,”F or Metric kPa, Metric Bar

for IS units i.e. kPa, Bar, “C.

ENGLISH

ESPANOL

FRANCAIS

DEUTSCH

0

1800 RPM

ENG RPM

2. The main menu will pop up on the display. Use the

“Arrow Buttons” to scroll through the menu until the

“Setup 1-up Display” is highlighted.

1500

COOL

TEMP

98%

3000

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 29

Page 30

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

3. Once the “Setup 1-up Display” menu icon has been

highlighted touch the “Enter Button” to access the “Setup

1-up display” function.

7. A message indicating the “Single Engine” parameter

display parameters are reset to the factory defaults will

be displayed, then the display will return to the “Custom

Setup” menu.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

G

4. Three options are available for modification of the 1-Up

display.

8. Custom Setup- To perform a custom setup of the 1-Up

Display, use the arrow buttons to scroll to and highlight

a). Use defaults- This option contains a set of engine

“Custom Setup” on the display.

parameters: Engine Hours, Engine RPM. System

Voltage, Battery Voltage, % Engine Load at Current

RPM, Coolant Temperature, Oil Pressure.

b). Custom Setup- This option allows for the

modification of what parameter, the number of

parameters, and the order in which the parameters

are being displayed.

RESTORED TO

DEFAULTS

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

c). Automatic scan - Selecting the scan function will

cause the 1-Up Display to scroll through the

selected set of parameters one at a time,

momentarily pausing at each.

5. Use Defaults- To select “Use Defaults” use the arrow

buttons to scroll to and highlight “Use Defaults” in the

menu display.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

6. Touch the “Enter Button” to activate the “Use Defaults”

function.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

9. Touching the “Enter Button” will display a list of engine

parameters.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

10. Use the “Arrow Buttons” to scroll to and highlight a

selected parameter (parameter with a # symbol to right

of it).

ENGINE SPEED

PERCENT LOAD ATCURRENT RPM

ENGINE OIL PRESSURE

ENGINE COOLANT TEMPERATURE

1

3

2

This number indicates

the order of display for the

parameters and that the

parameter is selected

for display.

PAGE 30 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 31

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

11. Touch the “Enter Button” to deselect the selected

parameter removing it from the list of parameters being

16. Touching the “Enter Button” toggles the “Automatic

Scan” function on.

displayed on the 1-up display.

ENGINE SPEED

PERCENT LOAD ATCURRENT RPM

ENGINE OIL PRESSURE

ENGINE COOLANT TEMPERATURE

1

3

2

17. Touching the “Enter Button” again toggles the “Automatic

12. Use the “Arrow Button” to scroll and highlight the desired

Scan” function off.

parameter that has not been selected for display.

ENGINE SPEED

PERCENT LOAD ATCURRENT RPM

ENGINE OIL PRESSURE

ENGINE COOLANT TEMPERATURE

2

1

Note that the numbers

now indicate the new order

of display for the parameters.

18. Once the “Use Defaults”, “Custom Setup” and “Automatic

13. Touch the “Enter Button” to select the highlighted

parameter for inclusion in the Single Engine Parameter

Scan” functions have been set touch the “Menu Button”

to return to the main menu.

Display.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN ON

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

ENGINE SPEED

PERCENT LOAD ATCURRENT RPM

ENGINE OIL PRESSURE

ENGINE COOLANT TEMPERATURE

2

1

3

19. Touch the “Menu Button” to exit the Main menu and

14. Continue to scroll and select additional parameters for

return to the engine parameter display.

the custom 1-up Display. Touch the “Menu Button” at

any time to return to the “Custom Setup” menu.

15. Automatic Scan- Selecting the scan function will cause

the 1-Up Display to scroll through the selected set of

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

parameters one at a time. Use the “Arrow Buttons” to

scroll to the “Automatic Scan” function.

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN OFF

USE DEFAULTS

CUSTOM SETUP

AUTOMATIC SCAN ON

G

0

1800 RPM

ENG RPM

1500

COOL

3000

TEMP

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 31

Page 32

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

Setup 4-Up Display

1. From the single or four engine parameter display touch

the “Menu Button”.

0

1500

1800 RPM

ENG RPM

COOL

TEMP

3000

98%

LOAD RPM

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

5. The “Use Defaults” screen will be displayed during the

resetting period then will automatically return to the

“Setup 4- Up Display” menu.

6. Select the “4-Up Custom Setup” from the “4-Up Setup”

2. The main menu will pop up on the display. Use the “Arrow

menu.

Buttons” to scroll through the menu until the “Setup 4Up Display” is highlighted.

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

7. The quadrant with the backlit parameter value is the current

selected parameter. Use the “Arrow Buttons” to highlight

3. Once the “Setup 4-Up Display” menu item has been

highlighted touch the “Enter Button” to activate the

the parameter value in the quadrant you wish to place a

new parameter.

“Setup 4- Up Display” menu.

RESTORED TO

DEFAULTS

USE DEFAULTS

CUSTOM SETUP

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

4. Touch the “Enter Button” to activate the “Use Defaults”

function. This action will reset the unit to the factory

default.

USE DEFAULTS

CUSTOM SETUP

USE DEFAULTS

CUSTOM SETUP

8. Touch the “Enter Button” and a list of parameters will appear.

125°F

COOL TEMP

14.2

BATTVOLT

1000 RPM

ENG RPM

57 PSI

OIL PRES

PAGE 32 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 33

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

9. The parameter that is highlighted is the selected

14. Touch the “Menu Button” to return to the main menu.

parameter for the screen. Use the “Arrow Buttons” to

highlight the new parameter to be placed in the quadrant

selected in the previous screen.

ENGINE SPEED

ENGINE HOURS

ENGINE COOLANT TEMPERATURE

BATTERYPOTENTIAL

ENGINE OIL TEMPERATURE

ENGINE OIL PRESSURE

3

The number to the right

1

of the parameter indicates

the quadrant in which it

2

is displayed.

1= Upper Left Quadrant

4

2 = Lower Left Quadrant

3 = Upper Right Quadrant

4 = Lower Right Quadrant

15. Touch the “Menu Button” to exit the Main menu and

return to the engine parameter display.

10. Touch the “Enter Button” to change the selected

parameter in the quadrant to the new parameter.

ENGINE SPEED

ENGINE HOURS

ENGINE COOLANT TEMPERATURE

BATTERYPOTENTIAL

ENGINE OIL TEMPERATURE

ENGINE OIL PRESSURE

3

1

2

4

GO TO 1-UP DISPLAY

STORED CODES

ENGINE CONFG

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

Utilities

1. Starting at the single or four engine parameter display,

11. Use the “Menu Button” to return to the “4-Up Custom

touch the “Menu Button”.

Setup” screen.

125°F

COOL TEMP

143°F

OIL TEMP

1000 RPM

ENG RPM

57 PSI

OIL PRES

125°F

COOL TEMP

143°F

OIL TEMP

1000 RPM

ENG RPM

57 PSI

OIL PRES

(information and troubleshooting)

0

ENGINE SPEED

ENGINE HOURS

ENGINE COOLANT TEMPERATURE

BATTERYPOTENTIAL

ENGINE OIL TEMPERATURE

ENGINE OIL PRESSURE

3

1

2

4

Note the number to

the right of the selected

parameter indicating that the

parameter is now assigned

to that display location

1800 RPM

ENG RPM

2. The main menu will be displayed. Use the “Arrow Buttons”

12. The parameter in the selected quadrant has changed

to the parameter selected in the previous screen.

125°F

COOL TEMP

143°F

OIL TEMP

1000 RPM

ENG RPM

57 PSI

OIL PRES

to scroll through the menu until the “Utilities” is

highlighted.

3. Once the “Utilities” menu item has been highlighted, touch

the “Enter Button” to activate the “Utilities” functions.

13. Repeat the parameter selection process until all spaces

are filled.

1500

COOL

3000

TEMP

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

UTILITIES

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

UTILITIES

G

G

125°F

COOL TEMP

143°F

OIL TEMP

1000 RPM

ENG RPM

57 PSI

OIL PRES

1

DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14) — PAGE 33

Page 34

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

4. Touch “Select” to enter the “Gage Data” display. When

“Gage Data” is selected the PowerView will

communicate with the analog gages at a fixed rate of

38.4k Band, 8 data bits, no parity check, 1 stop bits,

8. When the gage data has cleared, the display

automatically returns to the “Utilities” menu. Scroll to

“Software Version”. Touch “Select” to view the software

version currently in the diagnostic display.

half duplex.

GAGE DATA

REMOVE ALL GAGES

SOFTWARE VERSION

MODBUS SETUP

FAULTCONVERSION

ADJUST BACKLIGHT

DEMO MODE ON

9. Touch “Menu” to return to “Utilities”. Highlight Fault

5. Use the “Arrow Buttons” to scroll through the items or

touch “Menu” to return to the “Utilities” menu.

1ofx

ENGINE OIL PRESSURE

ADDRESS:20

SOFTWARE REVISION #:

ERRORS: NONE

Conversion” using the “Arrows”. Touch “Select” to enter

the Fault conversion menu.

SOFTWARE

VERSION

MURPHY: X.XX

GAGE DATA

REMOVE ALL GAGES

SOFTWARE VERSION

FAULT CONVERSION

6. Touch “Menu Button” to return to the “Utilities” menu.

1ofx

ENGINE OIL PRESSURE

ADDRESS:20

SOFTWARE REVISION #:

ERRORS: NONE

7. Use the “Arrows” to highlight Remove All Gages”. Touch

“Select” to clear gage data from memory. It takes a

moment to clear all gages.

CLEARING GAGES

PLEASE WAIT

10. Use the “Arrows” to scroll to and highlight the desired

version then touch “Select”. An asterisk denotes which

version is currently selected.

NOTE: There are four (4) different methods for converting

fault codes. The diagnostic display always looks for J1939

Version 4 and can be set to read the code as one of three (3)

other J1939 versions if Version 4 is not being used. Most

engine ECU’s use Version 4, therefore in most cases

adjustment of this menu option will not be required.

Upon receiving an unrecognizable fault, change to a different

J1939 Version. If the fault SPN does not change when the

version is changed, the ECU generating the fault is using

Fault Conversion method 4. If the SPN number does not

change but is still unrecognizable, try changing to another

J1939 Version not yet used and continue to check the SPN

number.

J1939 VERSION 1

J1939 VERSION 2

J1939 VERSION 3

PAGE 34 — DCA-220SSJ/SSJU — OPERATION AND PARTS MANUAL — REV. #1 (02/28/14)

Page 35

DCA-220SSJ/SSJU — DIAGNOSTIC DISPLAY

11. Touch the “Menu” button to return to “Utilities” menu.

Touch the “Menu button again to return to the “Main”

menu.

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

UTILITIES

G

4. Use the “Arrows” to scroll down to and highlight either

the “Slave Active or Master Active” modes. Touch the

“Enter” button to toggle between master and slave.

MODBUS SETUP

1. Starting at the single or four engine parameter display,

touch the “Menu Button”.

1000 RPM

0

3000

1500

98%

LOAD RPM

ENG RPM

5. Use the “Arrows” to scroll to the “Serial Port” menu to

highlight it, then touch “Enter”.

1800 RPM

14.2

ENG RPM

COOL

TEMP

BATTVOLT

2. The main menu will be displayed. Use the “Arrow

Buttons” to scroll through the menu until the “Utilities”

57 PSI

OIL PRES

6. Use the “Arrow” button to scroll to each selection to

configure the MODBUS values for your application.

is highlighted, then touch “Enter”.

USE FACTORY DEFAULT

SERIAL PORT SETUP

SOFTWARE VERSION

SLAVE ADDRESS SETUP

MASTER ACTIVE

USE FACTORY DEFAULT

SERIAL PORT SETUP

SOFTWARE VERSION

SLAVE ADDRESS SETUP

MASTER ACTIVE

STORED CODES

ENGINE CONF

SETUP 1-UP DISPLAY

SETUP-4-UP DISPLAY

SELECT UNITS

ADJUST BACKLIGHT

UTILITIES

3. Once in the “Utilities” menu use the “Arrows” to scroll

through the menu until the “Modbus Setup” menu is

G

7. When finished, touch “Menu” to return to the previous

screen.