Page 1

LS60TD and LS600 (Deutz Engine)

Control Box Replacement

The following instructions are intended to assist the user in the installation of the replacement control box on the

LS60TD and LS600 Concrete Pump. Please read all instructions before installing the control box and relay kit.

REQUIRED TOOLS/COMPONENTS

Crimping Tool

Wire Cutter Tool

Wire Stripper Tool

Two 12-10 AWG Butt Splice

One 14-16 AWG Butt Splice

One 12-10 AWG Spade Lug

PARTS

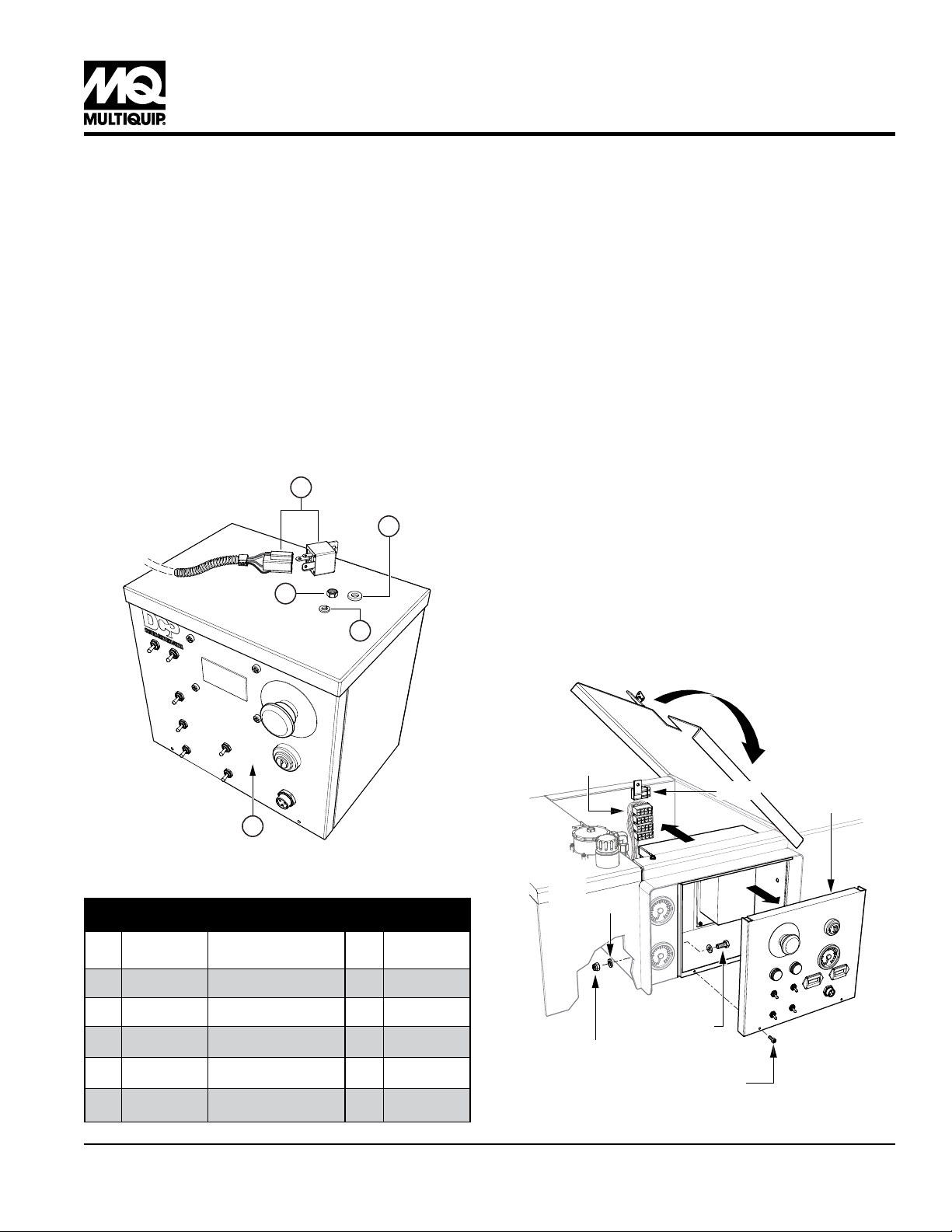

Verify that parts are accounted for. See Figure 1 and Table 1.

2

5

3

4

WORK SAFELY!

Only a qualified service technician with proper training

should perform this installation. Follow all shop safety rules

when performing this installation.

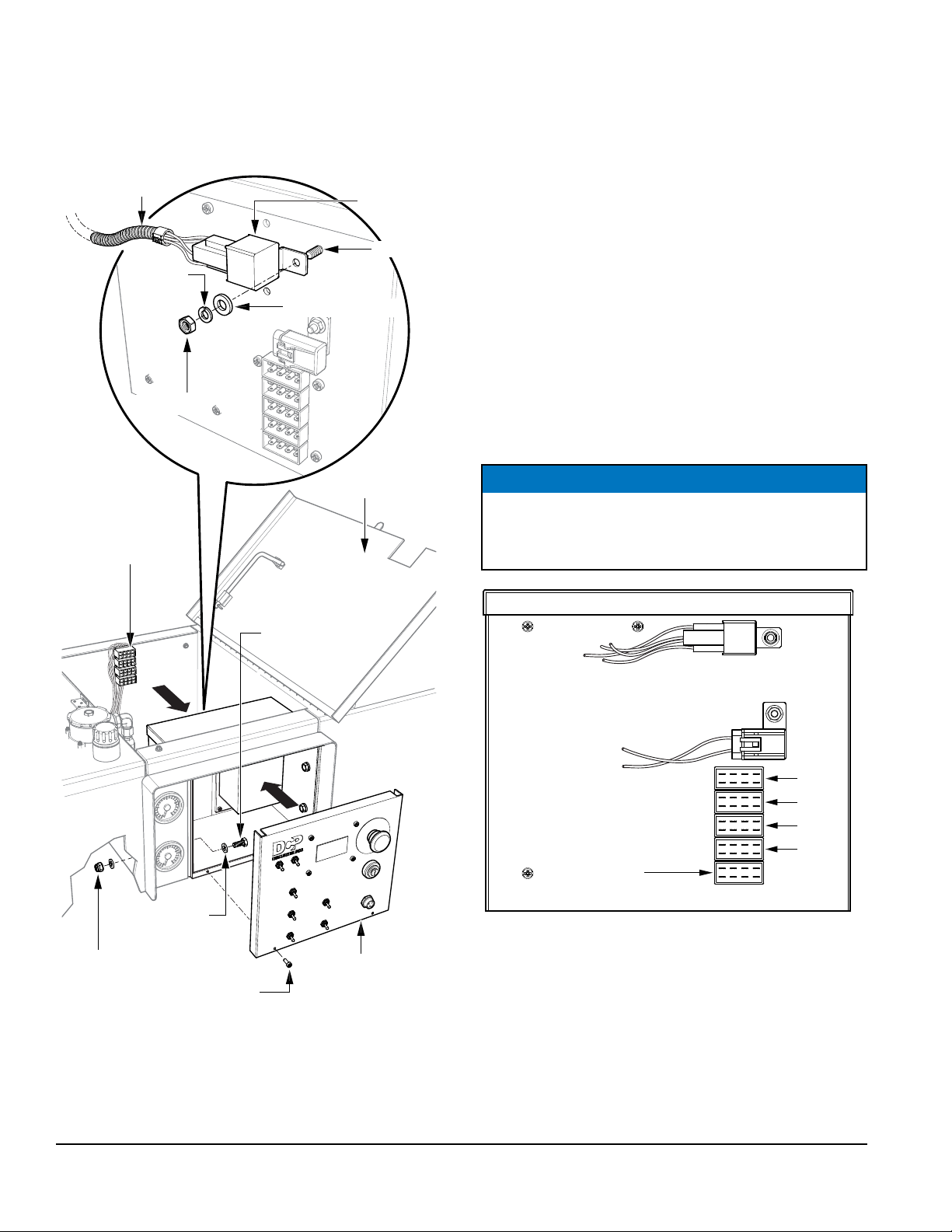

PREPARATION

1. Place the pump in an area free of dirt and debris.

2. Disconnect negative battery cable from the battery.

3. Disconnect the 4 plugs from the receptacles on the

rear of the control box currently installed on the pump

(see Figure 2). Mark and tag the plugs for reference

when new control box is installed. Remove the fuse

from the rear of the control box and keep the nut and

washers. They will be used to reinstall the fuse on the

new control box.

4. Remove the existing control box as shown in Figure 2.

Keep the hex bolts, flat washers and lock nuts. They

will be used in the installation of the new control box.

OPEN HATCH

1

Figure 1. Required Parts

Table 1. Required Parts

Item

No.

Part No. Description QTY. Remarks

1 EM517648A Digital Control Box 1

2 EM515799 Relay Kit 1

3 ___ 10/32" Hex Nut 1 Not Provided

4 ___ #10 Lock Washer 1 Not Provided

5 ___ #10 Flat Washer 1 Not Provided

LS60TD AND LS600 — CONTROL BOX REPLACEMENT — REV. #1 (03/23/12) — PAGE 1

PLUGS (4)

FUSE

FLAT

WASHER (8)

HEX BOLT (4)

LOCK NUT (4)

SCREW (2)

OLD

CONTROL

PANEL

Figure 2. Removing Existing Control Box

Page 2

INSTALLATION

CONNECTIONS

1. Install the replacement digital control box on the pump

using the existing hardware. See Figure 3.

CONTROL BOX REAR VIEW

HARNESS

RELAY

STUD

LOCK

WASHER

FLAT WASHER

HEX NUT

HATCH

PLUGS

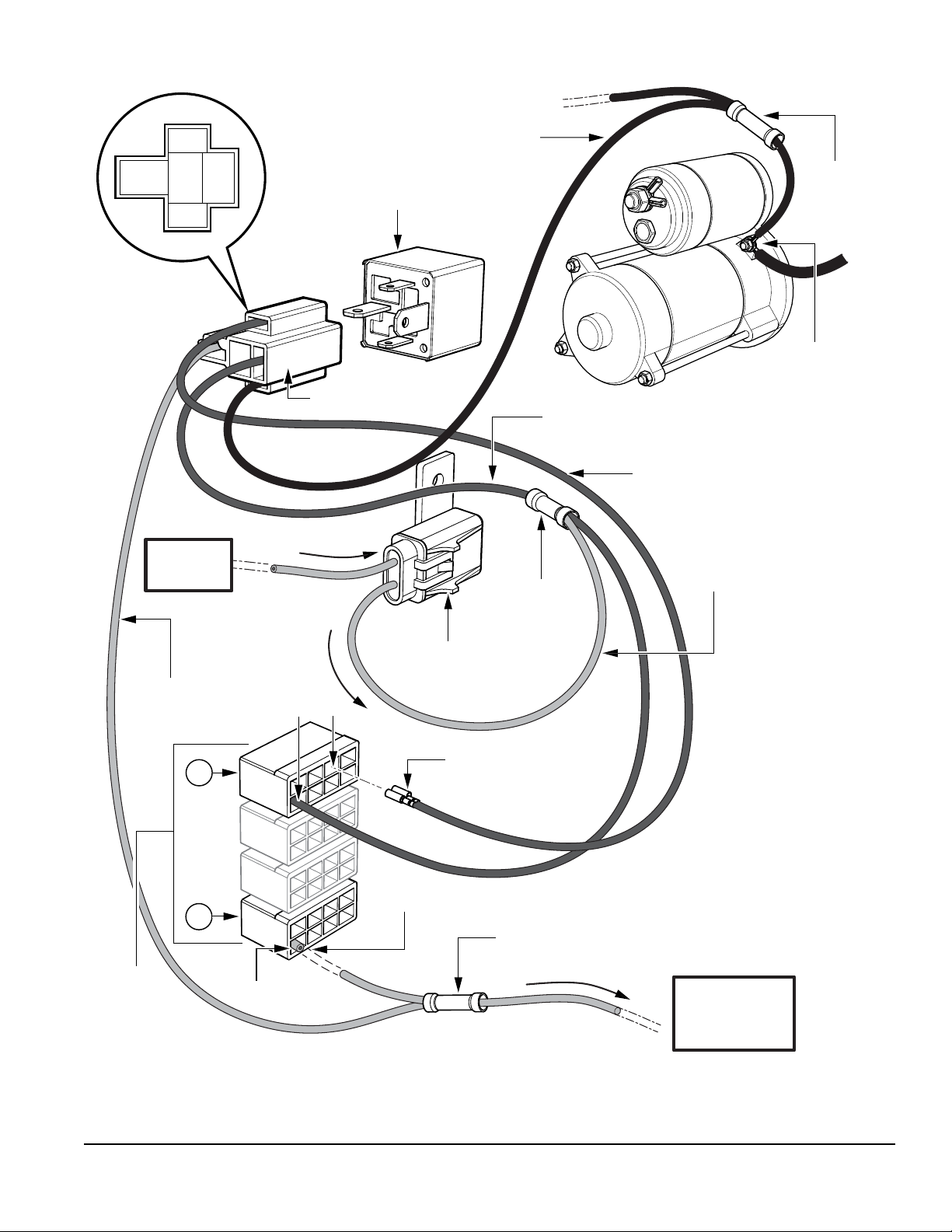

Refer to Figure 5 for connections from the relay to the plugs .

1. Connect #86 purple 12 AWG wire from Relay K1 to

terminal #6 on Plug P1 using a spade connector.

2. Connect #85 black wire from Relay K1 to starter ground

point using a butt splice.

3. Connect #87 purple 10 AWG wire from Relay K1 to

terminal #4 on Plug P1 using a butt splice.

4. Cut wire from terminal #4 on Plug P4 flush to the plug.

Terminal will not be used.

5. Connect #30 red wire from Relay K1 to the other end

of the cut wire using a butt splice.

6. Reconnect the 4 plugs to the corresponding receptacles

on the new control box. See Figure 4 for location of

receptacles. Receptacle J5 will not be used.

NOTICE

Use extreme care when connecting the control box rear

receptacle plugs to make sure that correct orientation

is followed.

HEX BOLT (4)

FLAT

WASHER (8)

LOCK NUT (4)

SCREW (2)

Figure 3. Replacement Digital Box Installation

NEW

CONTROL

PANEL

2. Attach the relay kit to the digital control box by securing

it to the stud shown in Figure 3, using the appropriate

hardware (user provided).

Relay

Fuse

J1

J2

J3

J4

J5

(Not Used)

Figure 4. Control Box Rear Receptacles

Receptacles

7. Install the fuse to the rear of the new control box.

8. After all connections are made, reconnect the battery.

Turn the control panel ignition switch to the ON position.

The control box panel should light. You will see and

hear the engine fuel solenoid energize.

9. Perform control box programming instructions.

LS60TD AND LS600 — CONTROL BOX REPLACEMENT — REV. #1 (03/23/12) — PAGE 2

Page 3

86

BLACK 16 AWG

30

85

REAR VIEW

+ 12V DC

Power

87

Relay Connector

IN

OUT

Butt Splice

Relay K1

STARTER

GROUND

POINT

PURPLE 10 AWG

PURPLE 12 AWG

ORANGE 10 AWG

Butt Splice

RED 10 AWG

Plugs

P1

P4

Existing Fuse

6

4

Spade Lug

Cut Flush

Butt Splice

4

TO

START/STOP

SOLENOID

Figure 5. Connections Between Control Box and Relay

LS60TD AND LS600 — CONTROL BOX REPLACEMENT — REV. #1 (03/23/12) — PAGE 3

Page 4

Plug P1

Plug P1

Outside Terminal # 6

(Ignition B+)

12 AWG Purple Wire

#86 #87

Outside Terminal # 4 Splice

B+ Power (Fuse)

10 AWG Purple Wire

#85 #30

16 AWG Black Wire

Starter Ground Point

Figure 6. Relay P/N EM515799 Relay Schematic Diagram

10 AWG Red Wire

Plug P4 Terminal # 4

(Cut Wire Flush)

Opposite End to Deutz

Start/Stop Solenoid

LS60TD AND LS600 — CONTROL BOX REPLACEMENT — REV. #1 (03/23/12) — PAGE 4

Page 5

CONTROL BOX PROGRAMMING

NOTICE

Control boxes come pre-programmed from the factory

and configured to Model LS300. It is necessary to

reprogram the model configuration to match your unit.

6. Once the language is selected, place the CONTROL

switch to the center off position.

7. Turn the IGNITION switch to OFF then ON again to

memorize final configuration.

Machine Model Configuration

See Figure 7 to identify control box switches.

Digital Screen

Reset Switch

SCROLL

RESET

SET

VOLUME

DECREASE INCREASE

FLOW

DIRECTION CONTROL

FORWARD REVERSE LOCAL

AUTOMATIC JOG

MULTIQUIP INC. CARSON, CALIFORNIA 90746 USA

310-537-3700 800-421-1244 WWW.MULTIQUIP.COM

Automatic/Jog

Switch

Flow Direction

Switch

CENTER

OFF

CYLINDER STROKE

JOG “A” JOG “B”

Control Switch

Ignition Switch

OFF

IGNITION

REMOTE

Cylinder Stroke

Switch

ON

START

1. Turn the IGNITION switch to the ON position. Do not

start engine.

2. Place the FLOW DIRECTION switch to reverse.

3. Place the AUTOMATIC/JOG switch to jog.

4. Place the CONTROL switch to remote.

5. Manually hold the CYLINDER STROKE switch to the

jog B position. While holding the switch to the jog B

position, toggle the RESET switch down 5 times. After

the fifth time, move the CYLINDER STROKE switch

to the jog A position. While holding the switch to the

jog A position, toggle the RESET switch down to the

desired model (LS60TD or LS600).

6. Once the model is selected, place the CONTROL

switch to the center off position.

7. Turn the IGNITION switch to OFF then ON again to

memorize final configuration.

Figure 7. Control Box Switches

Language Selection

1. Turn the IGNITION switch to the ON position. Do not

start engine.

2. Place the FLOW DIRECTION switch to reverse.

3. Place the AUTOMATIC/JOG switch to jog.

4. Place the CONTROL switch to remote.

5. Manually hold the CYLINDER STROKE switch to the

jog B position. While holding the switch to the jog B

position, toggle the RESET switch down 5 times. On

the fifth time, the digital screen will display the current

set language. Toggle RESET switch again to change

language, if desired.

LS60TD AND LS600 — CONTROL BOX REPLACEMENT — REV. #1 (03/23/12) — PAGE 5

Page 6

CONTROL PANEL COMPONENTS

5

12

13

0

0

0

1

0

5

7

0

0

5

0

ACCUMULATOR

PRESSURE

0

0

0

1

0

5

7

0

0

5

0

PUMPING

PRESSURE

4

1

2

5

0

1

5

0

0

11

2

0

0

0

1

2

5

0

1

5

0

0

2

0

0

0

Figure 8. Digital Control Panel Components

SCROLL

VOLUME

DECREASE

FLOW

7

DIRECTION

FORWARD

AUTOMATIC

1. Emergency Stop Button — Press emergency stop

button to stop pump in an emergency. Turn knob

counterclockwise to disengage the stop button.

2. Ignition Switch — Insert the ignition key here to start

the engine. Turn the key clockwise to the ON position,

then continue turning clockwise to the START position

and release. To stop the engine turn the key fully

counterclockwise to the STOP position.

3. Digital Readout Screen — Displays and monitors the

various functions of the machine.

4. Scroll Switch — Allows the operator to scroll the

various readout screens.

5. Reset Switch — Allows the operator to reset the

stroke counter.

6. Remote Cable Connector — Insert the remote control

input cable into this connector.

7. Direction Control Switch — This 2-position switch

controls the direction of flow for any mix in the pump.

The leftmost position sets the pumping direction to

forward and the rightmost position sets the pumping

direction to reverse.

8. Pumping Control Switch — This 3-position switch

controls the pumping of the pump. The rightmost

position (REMOTE) is for use with the remote control

unit, the leftmost position (LOCAL) is for normal

pumping operation, and the center most position

(CENTER OFF) prevents pumping.

3

RESET

SET

INCREASE

1

C

N

Y

E

G

S

R

T

O

E

P

M

E

ON

OFF

START

2

CONTROL

REMOTE

LOCAL

REVERSE

JOG

9

CYLINDER STROKE

JOG “A”

CENTER

OFF

10

JOG “B”

IGNITION

8

REMOTE

6

9. Cylinder Stroke Control Switch — This 2-position

switch controls the pumping function. The leftmost

position (AUTOMATIC) sets the pump to automatic

cycling. Set the switch to this position for normal pump

operation.

The rightmost position (JOG) changes the pump from

automatic to manual cycling. This allows the cylinders

to be manually cycled using the Manual Cylinder

Jogging Switch.

10. Manual Cylinder Jogging Switch — This 2-position

switch allows the operator to manually jog the cylinders

to assist in clearing material line packs and is used to

test pumping pressure.

The leftmost position jogs Cylinder “A” and the

rightmost position jogs Cylinder “B”.

11. Stroke Volume Control Switch — Increases or

decreases the number of strokes per minute of the

pump (not used on model LS60TD).

12. Accumulator Press ure Gau g e — This gauge

monitors the internal pressure of the Accumulator tank.

Normal internal pressure should read approximately

1750 PSI during pumping.

13. Main Pressure Gauge — This gauge monitors

the system pressure while pumping material. The

maximum pressure rating is 4400 PSI ± 50.

LS60TD AND LS600 — CONTROL BOX REPLACEMENT — REV. #1 (03/23/12) — PAGE 6

Page 7

DIGITAL READOUT SCREENS

Screen 5

Primary Screen

Screen 1

Indicates the various modes of the switch settings.

Monitors engine RPM - Idle speed 900, High speed

2550. Battery charge indicator - Normal charge 13+ volts.

Indicates electrical malfunction.

Secondary Screens

Screen 2 (not used on Model LS60TD)

Displays the position of the VOLUME CONTROL switch

by indicating whether the increase or decrease position

is on or off.

INDICATES VOLUME

SWITCH IS NOT IN

THE - POSITION

FLOW DEC OFF

FLOW INC ON

Screen 3

Displays the number of hours the engine and pump

have been used and the number of faults the pump has

registered. All three indicators can be reset to zero by the

RESET switch on the control panel.

INDICATES NO.

OF HOURS

ENGINE HAS

BEEN USED

MESSAGE OR

INSTRUCTION

E HRS: 00000.0

PMP HRS: 00000.0

FAULTS: 00000000

RESET TO CLEAR

Screen 4

Displays the number of strokes the main hydraulic cylinders

have gone through. This indicator can be reset to zero by

the RESET switch on the control panel.

INDICATES A

RUNNING

COUNT OF

NO. OF STROKES

STROKE CTR: 0000

PRESS RESET TO

ZERO STROKE CTR

2

INDICATES VOLUME

SWITCH IS IN THE

+ POSITION

INDICATES NO.

OF HOURS

PUMP HAS

3

BEEN USED

INDICATES NO.

OF FAULTS

DETECTED

4

MESSAGE OR

INFORMATION

Displays the ON/OFF electrical signal status of the various

12 volt solenoids (Swing A circuit, Main A circuit, Main B

circuit).

INDICATES

SWING A

CIRCUIT IS OFF

INDICATES

MAIN B

CIRCUIT IS OFF

SWING A OFF

MAIN A OFF

MAIN B OFF

5

INDICATES

MAIN A

CIRCUIT IS OFF

Screen 6

Displays the ON/OFF electrical signal status for the

Proximity Switch A, Proximity Switch B, Engine Fuel

Solenoid, and Unloader Solenoid.

INDICATES

PROXIMITY A

CIRCUIT IS OFF

INDICATES

UNLOADER

CIRCUIT IS OFF

PROX A OFF

PROX B ON

FUEL SOL OFF

UNLOADER OFF

6

INDICATES

FUEL SOLENOID

CIRCUIT IS OFF

INDICATES

PROXIMITY B

CIRCUIT IS ON

Screen 7

Displays the number of times the main hydraulic cylinders

stroke and the yards per hour output. This indicator can be

reset to zero by the RESET switch on the control panel.

INDICATES

THROTTLE

IS ON

INDICATES THE

NO. OF YARDS

PER HOUR

THROTTLE ON

STROKES: 20

STROKES/MIN 8.2

YDS/HR 10.7

INDICATES THE

NUMBER OF

STROKES

7

INDICATES THE

NO. OF STROKES

PER MINUTE

Screen 8

Displays the electrical status of the engine fuel solenoid. To

test the 12-Volt solenoid status, activate with the RESET

switch on the control panel.

TO TEST FUEL

SOL PRESS RESET

FUEL SOL OFF

INDICATES THE

FUEL SOLENOID

IS OFF

8

INSTRUCTION

OR MESSAGE

Screen 9

Displays the communication status of the (optional) radio

remote control. To activate a new remote control connection,

use the reset switch on the control panel.

INDICATES

THAT RADIO

9

REMOTE IS ON

IINSTRUCTION

OR MESSAGE

RADIO ADDRESS

COMMUNICATING

PRESS RESET TO

LEARN A NEW ONE

LS60TD AND LS600 — CONTROL BOX REPLACEMENT — REV. #1 (03/23/12) — PAGE 7

Page 8

HERE’S HOW TO GET HELP

© COPYRIGHT 2012, MULTIQUIP INC.

Multiquip Inc

the MQ logo are registered trademarks of Multiquip Inc. and may not be used, reproduced, or altered without written permission. All other trademarks are the property

The information and specifications included in this publication were in effect at the time of approval for printing. Illustrations, descriptions, references and technical data contained in

this document are for guidance only and may not be considered as binding. Multiquip Inc. reserves the right to discontinue or change specifications, design or the information published

LS60TD and LS600

Control Box Replacement

PLEASE HAVE THE MODEL AND SERIAL

NUMBER ON-HAND WHEN CALLING

United StateS

Multiquip Corporate Office MQ Parts Department

18910 Wilmington Ave.

Carson, CA 90746

Contact: mq@multiquip.com

Service Department Warranty Department

800-421-1244

310-537-3700

Technical Assistance

800-478-1244 Fax: 310-943-2238

Tel. (800) 421-1244

Fax (800) 537-3927

Fax: 310-537-4259 800-421-1244

800-427-1244

310-537-3700

310-537-3700

Fax: 800-672-7877

Fax: 310-637-3284

Fax: 310-943-2249

mexico United Kingdom

MQ Cipsa Multiquip (UK) Limited Head Office

Carr. Fed. Mexico-Puebla KM 126.5

Momoxpan, Cholula, Puebla 72760 Mexico

Contact: pmastretta@cipsa.com.mx

Tel: (52) 222-225-9900

Fax: (52) 222-285-0420

Unit 2, Northpoint Industrial Estate,

Globe Lane,

Dukinfield, Cheshire SK16 4UJ

Contact: sales@multiquip.co.uk

Canada

Multiquip

4110 Industriel Boul.

Laval, Quebec, Canada H7L 6V3

Contact: jmartin@multiquip.com

Tel: (450) 625-2244

Tel: (877) 963-4411

Fax: (450) 625-8664

Tel: 0161 339 2223

Fax: 0161 339 3226

of their respective owners and used with permission.

in this publication at any time without notice and without incurring any obligations.

and

Your Local Dealer is:

Loading...

Loading...