Page 1

Operator's Manual

P R 8 F E S S | 8 N A L

Garden Tractor

Model No. 107.289850 PGT9500 30/54" CRAFTSMAN 2WD

For answers to your questions about this

product, call:

1-800-659-5917

Sears Craftsman Help Line

5 am - 5 pm, Mon- Sat

Nota: Una traducci6n en espa_ol de este Manual del

Operador puede encontrarse en la pagina 33.

Sears Brand Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

1750727

Revision A

Page 2

Thankyouforpurchasingthisquality-builtCRAFTSMANPROFESSIONALmower.We'repleasedthatyou've

placedyourconfidenceintheCRAFTSMANPROFESSIONALbrand.Whenoperatedandmaintainedaccordingto

theinstructionsinthismanual,yourCRAFTSMANPROFESSIONALproductwillprovidemanyyearsofdependable

service.

This manual contains safety information to make you aware of the hazards and risks associated with mowers and

how to avoid them. This product and its approved attachments/accessories are designed and intended only for lawn

work or snow removal and are not intended for any other purpose. It is important that you read and understand these

instructions thoroughly before attempting to start or operate this equipment. Save these original instructions for

future reference.

Where to Find Us

You never haveto lookfar to find supportand service for your CRAFTSMAN mower. There are authorized service dealers

worldwide who providequality service.You can contact Customer Service by phone at (800) 659-5917, or locatea dealer on the

lntemetat www.sears.com/craftsman.

Mower

Model Number

Serial Number

Engine

Model Type Trim

Date Code

Date Purchased

Copyright © 2010 All rights reserved.

2

Page 3

Identification Numbers 3

Warranty Statement 4

Emissions Statement 5

Operator Safety 6

Safety Instructions 8

Safety Decals 13

Features and Controls 14

Operation 18

Maintenance 22

Storage 28

Troubleshooting 29

Specifications 31

Spanish Operator's Manual 33

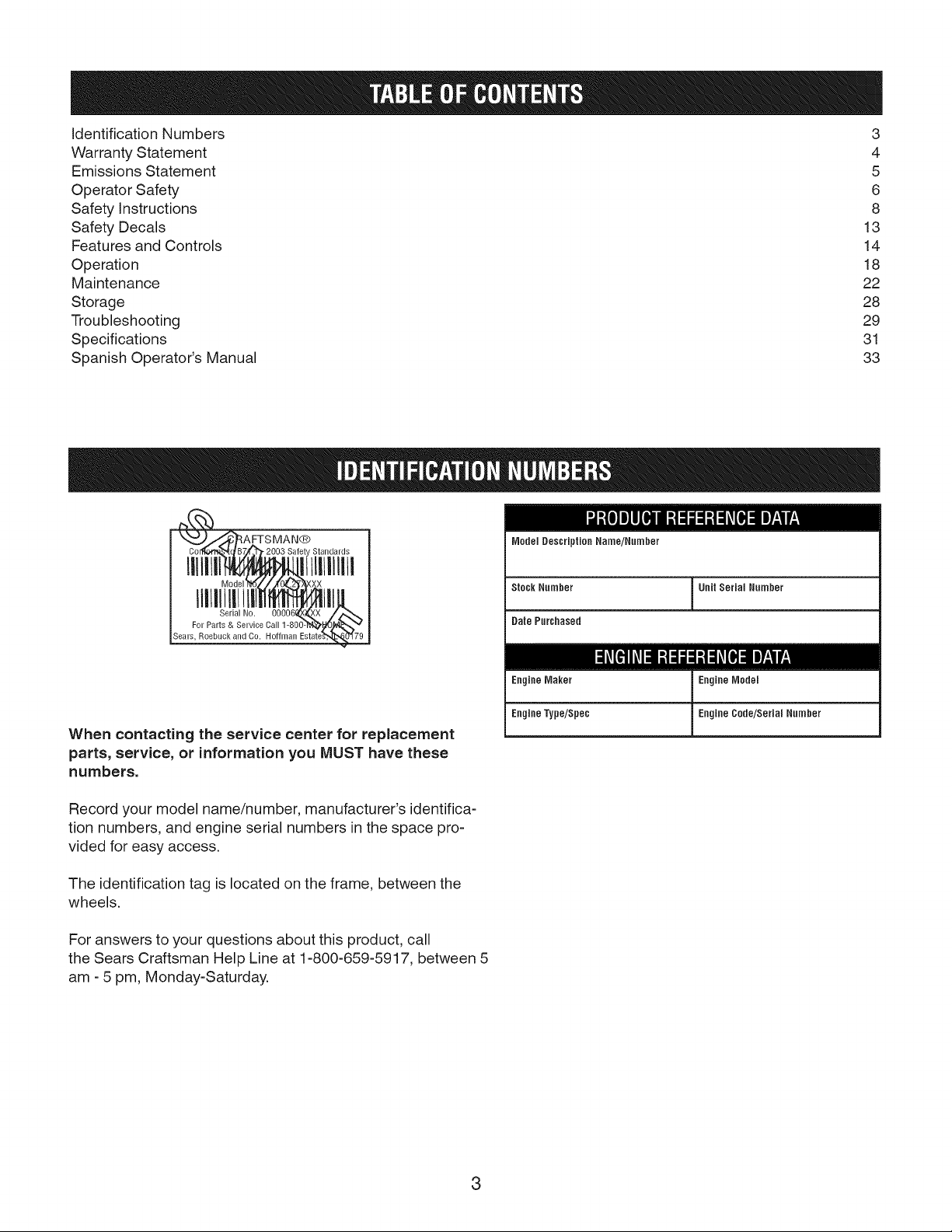

IVledelDescription Name/Number

lIHli[i[Il! xill

Sears, R0ebuck ind Cir.. ofl_l_-an E-starI_79

When contacting the service center for replacement

parts, service, or information you MUST have these

numbers.

Record your model name/number, manufacturer's identifica-

tion numbers, and engine serial numbers in the space pro-

vided for easy access.

The identification tag is located on the frame, between the

wheels.

For answers to your questions about this product, call

the Sears Craftsman Help Line at 1-800-659-5917, between 5

am - 5 pm, Monday-Saturday.

Stock Number Unit Serial Number

Date Purchased

I=1#1__ I-'I:IiI:I_leT-*Ifd

EngineMaker EngineModel

Engine Type/Spec Engine Cede/Serial Number

3

Page 4

CRAFTSMAN PROFESSIONAL FULL WARRANTY

When operated and maintained according to all supplied instructions, if any non-expendable part of this riding equip-

ment fails due to a defect in material or workmanship within two years from the date or purchase, call 1-800-659-5917 to

arrange for free in-home repair.

The frame and front axle will be repaired free of charge for five years from the date of purchase if defective in material or

workmanship.

All of the above warranty coverage applies for only 90 days from the date of purchase if this riding equipment is ever

used for commercial or rental purposes.

in all cases, if repair proves impossible, the riding equipment will be replaced free of charge with the same or an equiva-

lent model.

The battery will be replaced free of charge for 90 days from the date of purchase if defective in material or workmanship

(or testing proves that it will not hold a charge).

This warranty covers ONLY defects in material and workmanship. Sears will NOT pay for:

• Expendable items that become worn during normal use, including but not limited to blades, spark plugs, air clean-

ers, belts, and oil filters.

Standard maintenance servicing, oil changes, or tune-ups.

Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or maintenance.

Repairs necessary because of operator abuse, including but not limited to damage caused by towing objects be-

yond the capability of the riding equipment, impacting objects that bend the frame or crankshaft, or over-speeding

the engine.

Repairs necessary because of operator negligence, including but not limited to, electrical and mechanical damage

caused by improper storage, failure to use the proper grade and amount of engine oil, failure to keep the deck clear

of flammable debris, or failure to maintain the riding equipment according to the instructions contained in the opera-

tor's manual.

Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized (stale). In gen-

eral, fuel should be used within 30 days of its purchase date.

Normal deterioration and wear of the exterior finishes, or product label replacement.

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears Brand Management Corporation, Hoffman Estates, IL 60179

4

Page 5

EmissionsControl SystemWarrantyStatement

California,UnitedStatesandCanadaEmissionsControlDefectsWarranty

Statement

The CaliforniaAir ResourceBoard (CARB),U.S.EPAadn B&Sarephased toexplainthe

EmissionsControlSystem Warrantyonyour small off-roadengine (SORE).in Califor-

nia,newsmall off-road enginesmodel year2006 and bter must bedesigned,built and

equippedto meetthe State'sstrigent anti-smog standards.Elsewhereinthe UnitedStates,

newnon-road,spark-ignition enginescertified for modelyear1997 andbter must meet

simibr standardssetforth by the U.S.EPA.B&Smust warrant the emissionscontrol sys-

tem onyour enginefor the periodsof time listed below,providedtherehas beennoabuse,

negbct or impropermaintenanceofyour small off-roadengine.

Youremissions control systemincludesparts suchas the carburetor,air cleaner,ignition

system, fuel line,muffler and catalyticconverter.Alsoincludedmay beconnectorsand

otheremissions relatedassemblies.

Wherea warrantablecondition exists,B&Swill repairyour small off-roadengineat no

cost to you including diagnosis, partsand labor.

Briggs& Stratton EmissionsControl DefectsWarranty Coverage

Smalloff-roadenginesarewarrantedrelativetoemissionscontrolpartsdefectsfor a

Owner'sWarrantyResponsibility

As thesmall off-road engineowner,you are responsiblefor the performanceofthe required

maintenancelistedin your OperatingandMaintenanceInstructions. B&S recommends

thatyou retainallyour receiptscovering maintenanceon your small off-road engine,but

B&Scannotdeny warrantysolelyfor thelack of receiptsor for your failureto ensurethe

performanceofall scheduledmaintenance.

As thesmall off-road engineowner,you should howeverbe awarethatB&S maydenyyou

warrantycoverageif your small off-roadengineor a parthasfaileddue to abuse,neglect,

impropermaintenanceor unapprovedmodifications.

You areresponsiblefor presentingyour small off-road engineto an AuthorizedB&S Service

Dealerassoon asa problemexists.The undisputedwarrantyrepairsshould becompleted

in a reasonableamount of time, notto exceed30 days.

if you haveanyquestionsregardingyour warranty rights and responsibilities,you should

contacta B&SServiceRepresentativeat (414) 259-5262.

Theemissions warrantyis a defectswarranty. Defectsarejudged on normal engineperfor-

mance.Thewarrantyis not relatedtoan in-useemissionstest.

periodoftwoyears,subjecttoprovisionssetforthbelow.If anycoveredparton your

engineisdefective,thepartwillberepairedor replacedbyB&S.

The following are specific provisions relative to your Emissions Control Defects Warranty Coverage.It is inaddition to the B&S engine warranty for non-regulated engines found

in the Operating and Maintenance Instructions.

1. Warranted Parts 3.

Coverageunder this warranty extendsonly to the parts listed below (the emissions

control systems parts) to the extent these parts were present on the engine

purchased.

a. FuelMetering System

, Coldstart enrichment system (soft choke)

Carburetor and internal parts

, Fuelpump 4.

Fuelline, fuel line fittings, clamps

Fueltank, cap and tether

Carboncanister

b. Air Induction System

Aircleaner

Intake manifold

Purgeand vent line

c. Ignition System 5.

. Sparkplug(s)

Magneto ignition system

d. Catalyst System

Catalyticconverter

Exhaust manifold

Air injection system or pulsevalve

e. Miscellaneous Items Usedin Above Systems

Vacuum,temperature, position, time sensitive valves andswitches

Connectors and assemblies

2. Length of Coverage

B&S warrants to the initial owner and eachsubsequent purchaser that the Warranted 6.

Parts shall befree from defects in materials and workmanship which caused the

failure of the Warranted parts for a period of two years from the date the engine is

delivered to a retail purchaser.

No Charge

Repair or replacement of any Warranted Part will be performed at no charge to the

owner, including diagnostic labor which leadsto thedetermination that a War-

ranted Part is defecttive, if the diagnostic work is performed at an Authorized B&S

Service Dealeras listed in the "Yellow Pages" under "Engines, Gasoline,"" Gasoline

Engines," "Lawn Mowers," or similar category.

Claims and CoverageExclusions

Warranty claims shall befiled in accordance with the provisions ofthe B&S Engine

Warranty Policy. Warranty coverageshall be excludedfor failures of Warranted Parts

which are not original B&S parts or because of abuse, neglect or improper main-

tenanceas set forth in the B&S EngineWarranty Policy. B&S is not liable to cover

failures of Warranted Parts caused by the use of add-on, non-original, or modified

parts.

Maintenance

Any Warranted Part which is not scheduled for replacementas required maintenance

or which isscheduled only for regular inspection to the effect of "repair or replace as

necessary" shall be warranted as to defects for the warranty period. Any Warranted

Part which is scheduled for replacement as required maintenance shall be warranted

as to defects only for the period of time up to the first scheduled replacement for

that part. Any replacementpart that is equivalent in performance anddurability may

be used in the performance ofany maintenance or repairs. The owner is responsible

for the performance of all requiredmaintenance, as defined in the B&SOperating

and Maintenance Instructions.

Consequential Coverage

Coveragehereunder shall extend to the failure of any engine components causedby

the failure of anyWarranted Partstill under warranty.

Enginesthat are certified to meet the California Air Resources Board (CARB)Emis-

sions Standard must display information regarding the Emissions Durability period

and the Air Index. Briggs & Stratton makes this information available to the con-

sumer on our emissions labels. The engine emissions labelwill indicate certification

information.

The Emissions gnrability Period describes the number of hours of actual running

time for which the engine is certified to beemissions compliant, assuming proper

maintenance in accordance wiht the Operating and Maintenance Instructions. The

following categories are used:

Moderate:

Engineis certified to be emissions compliant for 125hours of actual running time.

intermediate:

Engineiscertifiedto beemissionscompliantfor 250hoursofactualrunningtime.

Extended:

Engineis certified to be emissions compliant for 500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used20 to 25 hours per year. There-

fore, the Emissions Durability Period of an enginewith an intermediate rating would

equate to 10 to 12years.

Briggs & Stratton engines are certified to meet the United States Environmental Protec-

tion Agency (ESEPA)Phase2 emissions standards. For Phase 2 certified engines, the

Emissions Compliance Period referred to on the Emissions Compliance label indicates the

number of operating hoursfor which the engine has been shown to meet Federalemis-

sions requirements.

For engines less than 225 cc displacement.

Category C= 125 hours, Category B=250 hours, Category A= 500 hours

For engines of 225 cc or more displacement.

Category C=250 hours, Category B= 500 hours, Category A= 1000 hours

5

Page 6

Operating Safety

Congratulations on purchasing a superior-quality piece of lawn and gar-

den equipment. Our products are designed and manufactured to meet

or exceed all industry standards for safety.

Power equipment is only as safe as the operator. If it is misused, or not

properly maintained, it can be dangerous! Remember, you are respon-

sible for your safety and that of those around you.

Use common sense, and think through what you are doing. If you are

not sure that the task you are about to perform can be safely done with

the equipment you have chosen, ask a professional: contact your local

authorized dealer.

Read the Manual

The operator's manual contains important safety information you need

to be aware of BEFORE you operate your unit as well as DURING op-

eration.

Safe operating techniques, an explanation of the product's features and

controls, and maintenance information is included to help you get the

most out of your equipment investment.

Be sure to completely read the Safety Rules and Information found on

the following pages. Also completely read the Operation section.

Children

Tragic accidents can occur with children. Do not allow them anywhere

near the area of operation. Children are often attracted to the unit and

mowing activity. Never assume that children will remain where you last

saw them. If there is a risk that children may enter the area where you

are mowing, have another responsible adult watch them.

DO NOT GIVE CHILDREN RIDES ON THIS UNIT! This encourages

them to come near the unit in the future while it is running, and they

could be seriously hurt. They may then approach the unit for a ride

when you are not expecting it, and you may run over them.

Reverse

Do not mow in reverse unless absolutely necessary. Always look down

and behind before and while traveling in reverse even with the mower

blades disengaged.

6

Page 7

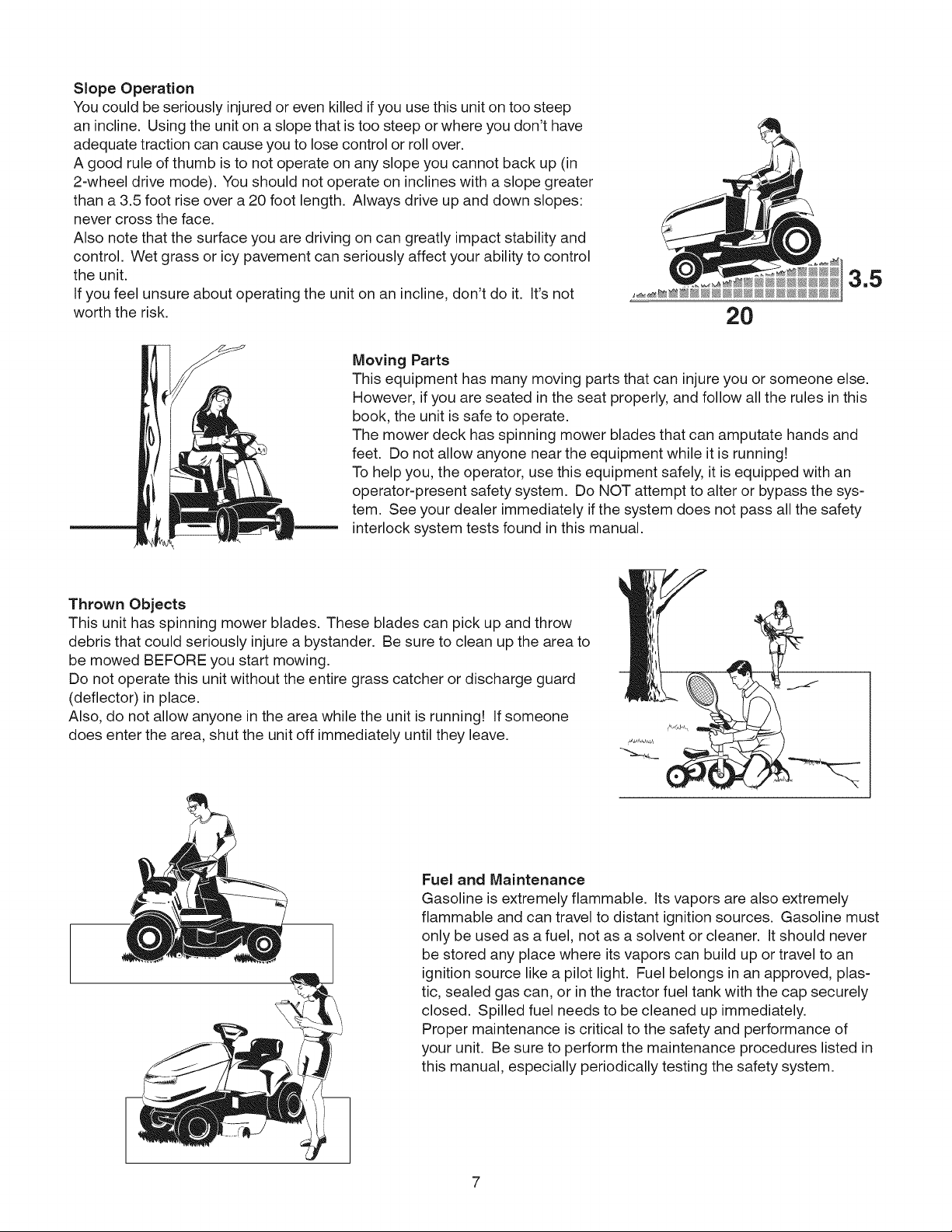

Slope Operation

You could be seriously injured or even killed if you use this unit on too steep

an incline. Using the unit on aslope that is too steep or where you don't have

adequate traction can cause you to lose control or roll over.

A good rule of thumb is to not operate on any slope you cannot back up (in

2-wheel drive mode). You should not operate on inclines with a slope greater

than a 3.5 foot rise over a 20 foot length. Always drive up and down slopes:

never cross the face.

Also note that the surface you are driving on can greatly impact stability and

control. Wet grass or icy pavement can seriously affect your ability to control

the unit.

If you feel unsure about operating the unit on an incline, don't do it. It's not

worth the risk.

Moving Parts

This equipment has many moving parts that can injure you or someone else.

However, if you are seated in the seat properly, and follow all the rules in this

book, the unit is safe to operate.

The mower deck has spinning mower blades that can amputate hands and

feet. Do not allow anyone near the equipment while it is running!

To help you, the operator, use this equipment safely, it is equipped with an

operator-present safety system. Do NOT attempt to alter or bypass the sys-

tem. See your dealer immediately ifthe system does not pass all the safety

interlock system tests found in this manual.

Thrown Objects

This unit has spinning mower blades. These blades can pick up and throw

debris that could seriously injure a bystander. Be sure to clean up the area to

be mowed BEFORE you start mowing.

Do not operate this unit without the entire grass catcher or discharge guard

(deflector) in place.

Also, do not allow anyone in the area while the unit is running! if someone

does enter the area, shut the unit off immediately until they leave.

Fuel and Maintenance

Gasoline is extremely flammable. Its vapors are also extremely

flammable and can travel to distant ignition sources. Gasoline must

only be used as a fuel, not as a solvent or cleaner. It should never

be stored any place where its vapors can build up or travel to an

ignition source like a pilot light. Fuel belongs in an approved, plas-

tic, sealed gas can, or in the tractor fuel tank with the cap securely

closed. Spilled fuel needs to be cleaned up immediately.

Proper maintenance is critical to the safety and performance of

your unit. Be sure to perform the maintenance procedures listed in

this manual, especially periodically testing the safety system.

Page 8

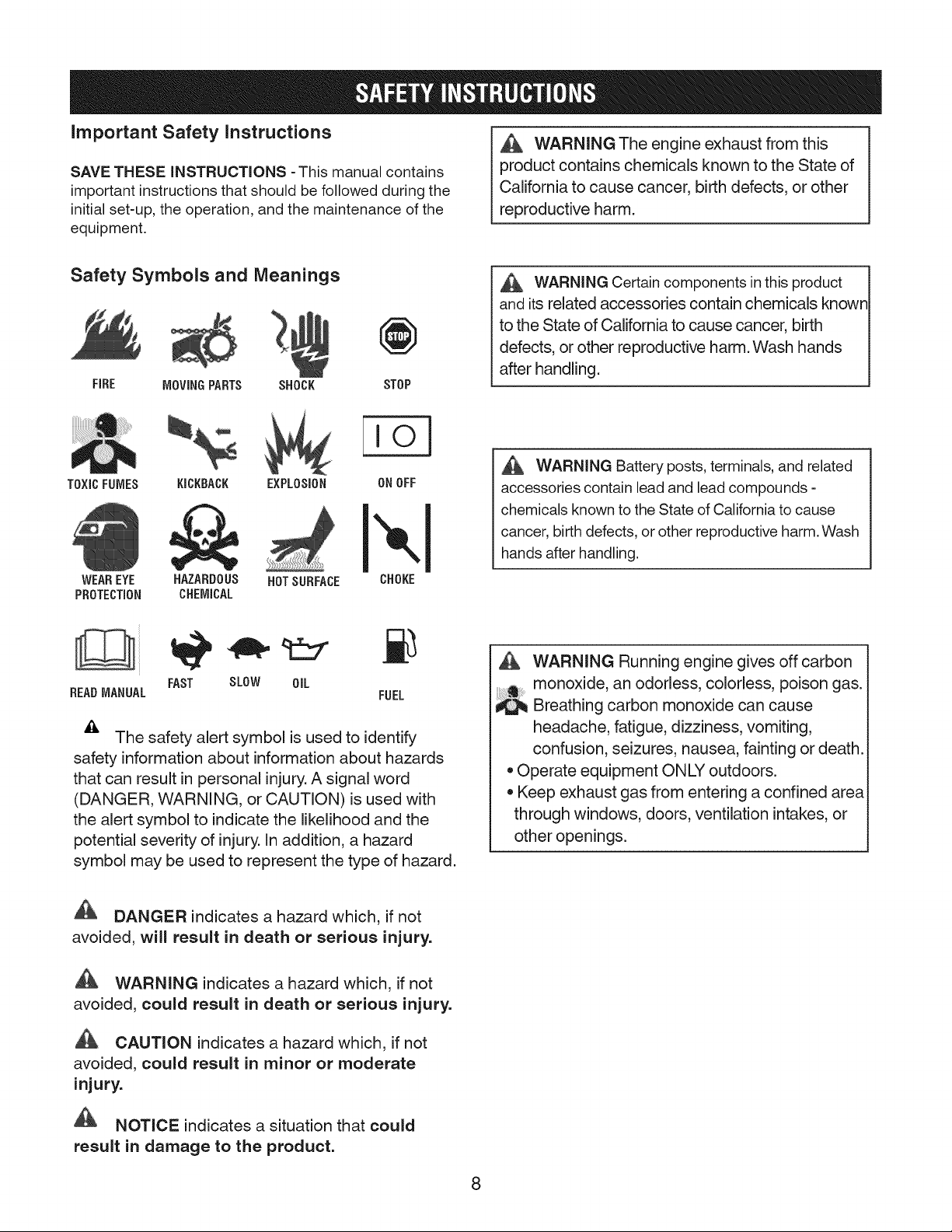

important Safety instructions

SAVE THESE iNSTRUCTiONS - This manual contains

important instructions that should be followed during the

initial set-up, the operation, and the maintenance of the

equipment.

WARNING The engine exhaust from this

product contains chemicals known to the State of

California to cause cancer, birth defects, or other

reproductive harm.

Safety Symbols and Meanings

@

FiRE MOVINGPARTS SHOCK

TOXICFUMES KICKBACK EXPLOSION

WEAREYE HAZARDOUS HOTSURFACE

PROTECTION CHEMICAL

BEADMANUAL

The safety alert symbol is used to identify

safety information about information about hazards

that can result in personal injury.A signal word

(DANGER, WARNING, or CAUTION) is used with

the alert symbol to indicate the likelihood and the

potential severity of injury. In addition, a hazard

symbol may be used to represent the type of hazard.

FAST SLOW OIL

STOP

io]

ONOFF

CHOKE

FUEL

WARNING Certain components in this product

and its related accessories contain chemicals knowr

to the State of California to cause cancer, birth

defects, or other reproductive harm. Wash hands

after handling.

WARNING Battery posts, terminals, and related

accessories contain lead and lead compounds -

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm. Wash

hands after handling.

WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause

headache, fatigue, dizziness, vomiting,

confusion, seizures, nausea, fainting or death.

* Operate equipment ONLY outdoors.

* Keep exhaust gas from entering a confined area

through windows, doors, ventilation intakes, or

other openings.

DANGER indicates a hazard which, if not

avoided, will result in death or serious injury.

WARNING indicates a hazard which, if not

avoided, could result in death or serious injury.

CAUTION indicates a hazard which, if not

avoided, could result in minor or moderate

injury.

NOTICE indicates a situation that could

result in damage to the product.

8

Page 9

Readthese safety rules and followthem closely.Failuretoobeythese rulescould resultin lossof control of unit,severe

personalinjury or deathto you, or bystanders,ordamage to propertyor equipment.This mowingdeck is capable of

amputating hands and feet and throwing objects. The triangle _ intext signifiesimportantcautionsor warnings

which must befollowed.

GENERAL OPERATION

1. Read, understand, and follow all instructions in the

manual and on the unit before starting.

2. Do not put hands or feet near rotating parts or under

the machine. Keep clear of the discharge opening at

all times.

3. Only allow responsible adults, who are familiar with

the instructions, to operate the unit (local regulations

can restrict operator age).

4. Clear the area of objects such as rocks, toys, wire,

etc., which could be picked up and thrown by the

blade(s).

5. Be sure the area is clear of other people before

mowing. Stop the unit if anyone enters the area.

6. Never carry passengers.

7. Do not mow in reverse unless absolutely necessary.

Always look down and behind before and while

travelling in reverse.

8. Never direct discharge material toward anyone. Avoid

discharging material against a wall or obstruction.

Material may ricochet back toward the operator. Stop

the blade(s) when crossing gravel surfaces.

9. Do not operate the machine without the entire grass

catcher, discharge guard (deflector), or other safety

devices in place.

10. Slow down before turning.

11. Never leave a running unit unattended. Always

disengage the PTO, set parking brake, stop engine,

and remove starter insert before dismounting.

12. Disengage blades (PTO) when not mowing. Shut off

engine and wait for all parts to come to a complete

stop before cleaning the machine, removing the grass

catcher, or unclogging the discharge guard.

13. Operate the machine only in daylight or good artificial

light.

14. Do not operate the unit while under the influence of

alcohol or drugs.

15 Watch for traffic when operating near or crossing

roadways.

16. Use extra care when loading or unloading the unit into

a trailer or truck.

17. Always wear eye protection when operating this unit.

18. Data indicates that operators, age 60 years and

above, are involved in a large percentage of power

equipment-related injuries. These operators should

evaluate their ability to operate the equipment safely

enough to protect themselves and others from injury.

19. Follow the manufacturer's recommendations for wheel

weights or counterweights.

20. Keep in mind the operator is responsible for accidents

occurring to other people or property.

21. All drivers should seek and obtain professional and

practical instruction.

22. Always wear substantial footwear and trousers. Never

operate when barefoot or wearing sandals.

23. Before using, always visually check that the blades

and blade hardware are present, intact, and secure.

Replace worn or damaged parts.

24. Disengage attachments before: refueling, removing

an attachment, making adjustments (unless the

adjustment can be made from the operator's position).

25. When the machine is parked, stored, or left

unattended, lower the cutting means unless a positive

mechanical lock is used.

26. Before leaving the operator's position for any reason,

engage the parking brake (if equipped), disengage the

PTO, stop the engine, and remove the starter insert.

27. To reduce fire hazard, keep the unit free of grass,

leaves, & excess oil. Do not stop or park over dry

leaves, grass, or combustible materials.

TRANSPORTING AND STORAGE

1. When transporting the unit on an open trailer, make

sure it is facing forward, in the direction of travel, ifthe

unit is facing backwards, wind lift could damage the

unit.

2. Always observe safe refueling and fuel handling

practices when refueling the unit after transportation or

storage.

3. Never store the unit (with fuel) in an enclosed poorly

ventilated structure. Fuel vapors can travel to an

ignition source (such as afurnace, water heater, etc.)

and cause an explosion. Fuel vapor is also toxic to

humans and animals.

4. Always follow the engine manual instructions for

storage preparations before storing the unit for both

short and long term periods.

5. Always follow the engine manual instructions for

proper start-up procedures when returning the unit to

service.

6. Never store the unit or fuel container inside where

there is an open flame or pilot light, such as in a water

heater. Allow unit to cool before storing.

9

Page 10

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tip-

over accidents, which can result in severe injury or death.

Operation on all slopes requires extra caution. If you cannot

back up the slope or ifyou feel uneasy on it, do not operate

on it.

Control of a walk-behind or ride-on machine sliding on a

slope will not be regained by the application of the brake.

The main reasons for loss of control are: insufficient tire grip

on the ground, speed too fast, inadequate braking, the type

of machine is unsuitable for its task, lack of awareness of the

ground conditions, incorrect hitching and load distribution.

1. Mow up and down slopes, not across.

2. Watch for holes, ruts, or bumps. Uneven terrain could

overturn the unit. Tall grass can hide obstacles.

3. Choose a slow speed so that you will not have to stop

or change speeds while on the slope.

4. Do not mow on wet grass. Tires may loose traction.

5. Always keep unit ingear especially when traveling

down slopes. Do not shift to neutral and coast

downhill.

6. Avoid starting, stopping, or turning on a slope, if tires

lose traction, disengage the blade(s) and proceed

slowly straight down the slope.

7. Keep all movement on slopes slow and gradual. Do

not make sudden changes in speed or direction, which

could cause the machine to rollover.

8. Use extra care while operating machines with grass

catchers or other attachments; they can affect the

stability of the unit. Do not use on steep slopes.

9. Do not try to stabilize the machine by putting your foot

on the ground (ride-on units).

10. Do not mow near drop-offs, ditches, or embankments.

The mower could suddenly turn over if a wheel is over

the edge of a cliff or ditch, or if an edge caves in.

11. Do not use grass catchers on steep slopes.

12. Do not mow slopes if you cannot back up them.

13. See your authorized dealer/retailer for

recommendations of wheel weights or counterweights

to improve stability.

14. Remove obstacles such as rocks, tree limbs, etc.

15. Use slow speed. Tires may lose traction on slopes

even through the brakes are functioning properly.

16. Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

TOWED EQUIPMENT (RIDE-ON UNITS)

1. Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

2. Follow the manufacturer's recommendations for

weight limit for towed equipment and towing on slopes.

3. Never allow children or others in or on towed

equipment.

4. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

6. Do not shift to neutral and coast down hill.

WARNING

Never operate on slopes greater than 17.6 percent

(10°) which is a rise of 3-1/2 feet (106 cm) vertically

in 20 feet (607 cm) horizontally.

When operating on slopes use additional wheel

weights or counterweights. See your dealer/retailer

to determine which weights are available and

appropriate for your unit.

Select slow ground speed before driving onto

slope. In addition to front weights, use extra

caution when operating on slopes with rear-

mounted grass catchers.

Mow UP and DOWN the slope, never across the

face, use caution when changing directions and

DO NOT START OR STOP ON SLOPE.

CHILDREN

Tragic accidents can occur if the operator is not alert to

the presence of children. Children are often attracted

to the unit and the mowing activity. Never assume that

children will remain where you last saw them.

1. Keep children out of the mowing area and under the

watchful care of another responsible adult.

2. Be alert and turn unit off if children enter the area.

3. Before and during reverse operation, look behind

and down for small children.

4. Never carry children, even with the blade(s) off.

They may fall off and be seriously injured or interfere

with safe unit operation. Children who have been

given rides in the past may suddenly appear in the

mowing area for another ride and be run over or

backed over by the machine.

5. Never allow children to operate the unit.

6. Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

EMISSIONS

1. Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

2. Look for the relevant Emissions Durability Period

and Air Index information on the engine emissions

label.

iGNITION SYSTEM

1. This spark ignition system complies with Canadian

ICES-002.

10

Page 11

SERVICE AND MAINTENANCE

Safe Handling of Gasoline

1. Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

2. Use only approved gasoline containers.

3. Never remove the gas cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. Never fuel the machine indoors.

5. Never store the machine or fuel container where there

is an open flame, spark, or pilot light such as near a

water heater or other appliance.

6. Never fill containers inside a vehicle or on a truck bed

with a plastic bed liner. Always place containers on the

ground away from your vehicle before filling.

7. Remove gas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible,

then refuel such equipment on a trailer with a portable

container, rather than from a gasoline dispenser

nozzle.

8. Keep nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use a nozzle lock-open device.

9. If fuel is spilled on clothing, change clothing

immediately.

10. Never over-fill the fuel tank. Replace gas cap and

tighten securely.

11. Use extra care in handling gasoline and other fuels.

They are flammable and vapors are explosive.

12. If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

13. Replace all fuel tank caps and fuel container caps

securely.

Service & Maintenance

1. Never run the unit in an enclosed area where carbon

monoxide fumes may collect.

2. Keep nuts and bolts, especially blade attachment

bolts, tight and keep equipment in good condition.

3. Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs ifthey

are not functioning properly.

4. Keep unit free of grass, leaves, or other debris build-

up. Clean up oil or fuel spillage, and remove any fuel-

soaked debris. Allow machine to cool before storage.

5. If you strike an object, stop and inspect the machine.

Repair, if necessary, before restarting.

6. Never make adjustments or repairs with the engine

running.

7. Check grass catcher components and the discharge

guard frequently and replace with manufacturer's

recommended parts, when necessary.

8. Mower blades are sharp. Wrap the blade or wear

gloves, and use extra caution when servicing them.

9. Check brake operation frequently. Adjust and service

as required.

10. Maintain or replace safety and instructions labels, as

necessary.

11. Do not remove the fuel filter when the engine is hot

as spilled gasoline may ignite. Do not spread fuel line

clamps further than necessary. Ensure clamps grip

hoses firmly over the filter after installation.

12. Do not use gasoline containing METHANOL, gasohol

containing more than 10% ETHANOL, gasoline

additives, or white gas because engine/fuel system

damage could result.

13. If the fuel tank must be drained, it should be drained

outdoors.

14. Replace faulty silencers/mufflers.

15. Use only factory authorized replacement parts when

making repairs.

16.Always comply with factory specifications on all

settings and adjustments.

17.Only authorized service locations should be utilized for

major service and repair requirements.

18. Never attempt to make major repairs on this unit

unless you have been properly trained. Improper

service procedures can result in hazardous operation,

equipment damage and voiding of manufacturer's

warranty.

19.On multiple blade mowers, take care as rotating one

blade can cause other blades to rotate.

20. Do not change engine governor settings or over-speed

the engine. Operating the engine at excessive speed

can increase the hazard of personal injury.

21. Disengage drive attachments, stop the engine,

remove the starter insert, and disconnect the spark

plug wire(s) before: clearing attachment blockages

and chutes, performing service work, striking an

object, or if the unit vibrates abnormally. After striking

an object, inspect the machine for damage and make

repairs before restarting and operating the equipment.

22. Never place hands near the moving parts, such as a

hydro pump cooling fan, when the tractor is running.

(Hydro pump cooling fans are typically located on top

of the transaxle).

23. Units with hydraulic pumps, hoses, or motors:

WARNING: Hydraulic fluid escaping under pressure

may have sufficient force to penetrate skin and cause

serious injury. If foreign fluid is injected into the skin

it must be surgically removed within afew hours by a

doctor familiar with this form of injury or gangrene may

result. Keep body and hands away from pin holes or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, and not hands, to search

for leaks. Make sure all hydraulic fluid connections

are tight and all hydraulic hoses and lines are in good

condition before applying pressure to the system. If

leaks occur, have the unit serviced immediately by

your authorized dealer.

24. WARNING: Stored energy device. Improper release of

springs can result in serious personal injury. Springs

should be removed by an authorized technician.

25. Models equipped with an engine radiator: WARNING:

Stored energy device. To prevent serious bodily injury

from hot coolant or steam blow-out, never attempt to

remove the radiator cap while the engine is running.

Stop the engine and wait until it is cool. Even then, use

extreme care when removing the cap.

11

Page 12

Po

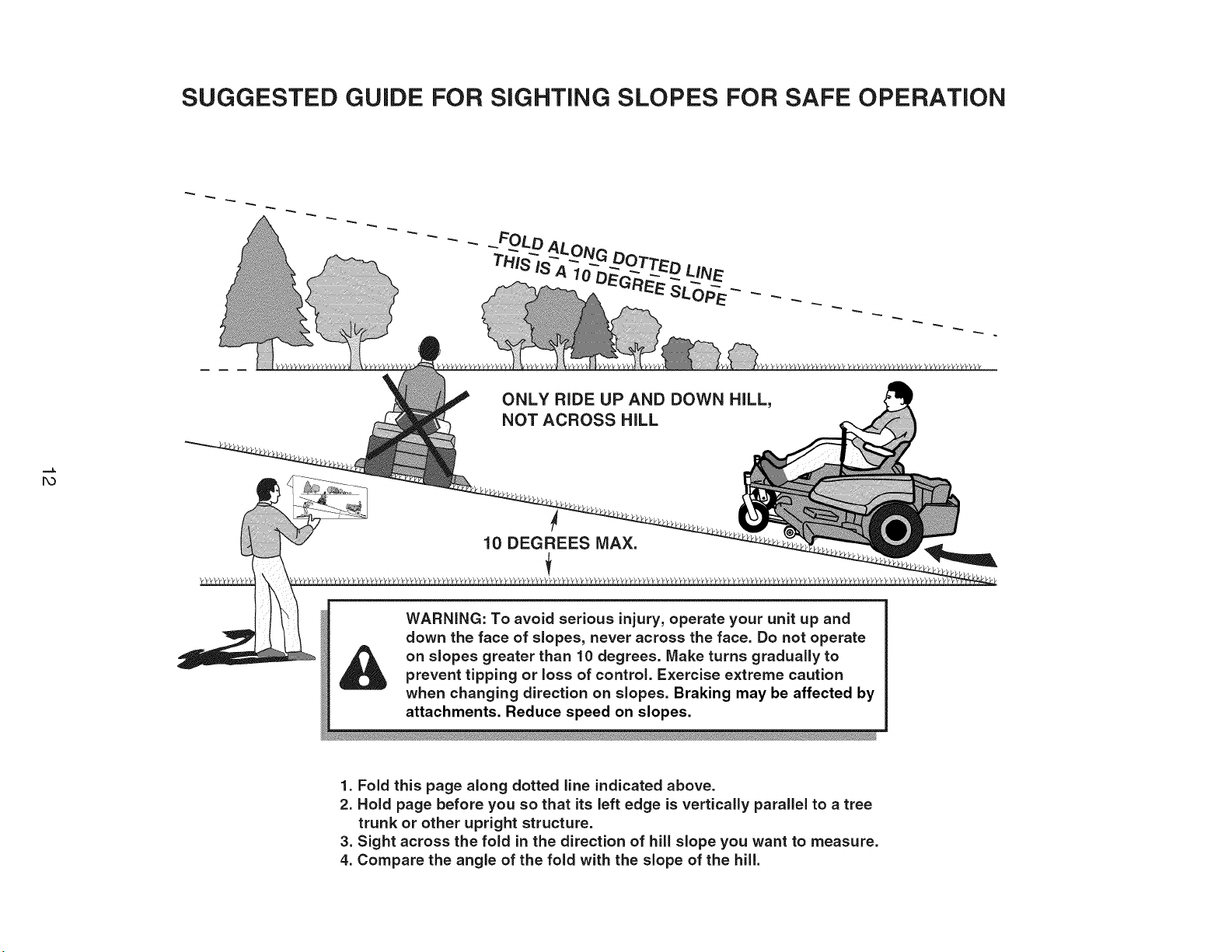

SUGGESTED GUIDE FOR SIGHTING SLOPES FOR SAFE OPERATION

ALONG

SLo

ONLY RiDE UP AND DOWN HILL,

NOT ACROSS HiLL

10 DEGREES MAX.

WARNING: To avoid serious injury, operate your unit up and

down the face of slopes, never across the face. Do not operate

on slopes greater than 10 degrees. Make turns gradually to

prevent tipping or loss of control. Exercise extreme caution

when changing direction on slopes. Braking may be affected by

attachments. Reduce speed on slopes.

1. Fold this page along dotted line indicated above,

2. Hold page before you so that its left edge is vertically parallel to a tree

trunk or other upright structure,

3. Sight across the fold in the direction of hill slope you want to measure,

4, Compare the angle of the fold with the slope of the hill.

Page 13

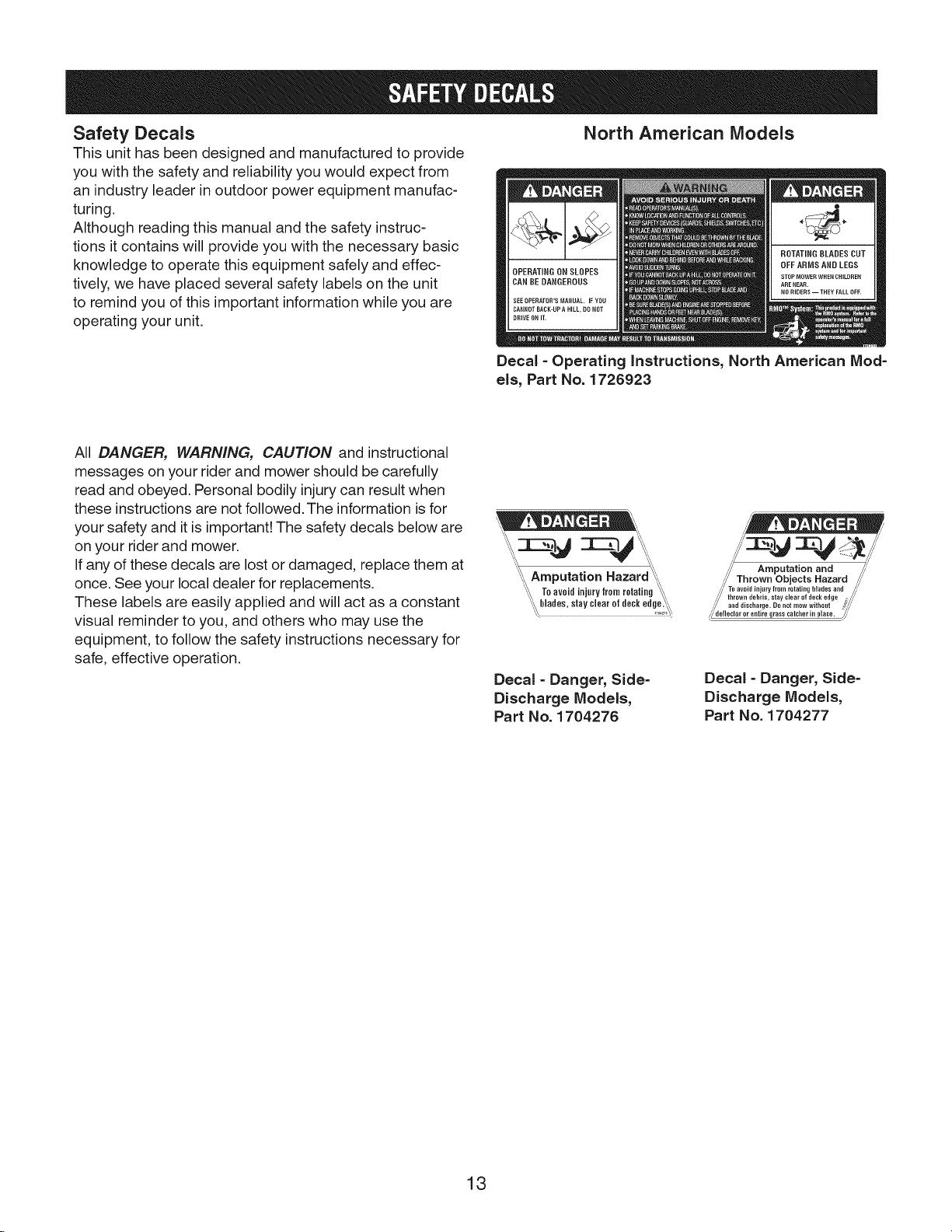

Safety Decals

This unit has been designed and manufactured to provide

you with the safety and reliability you would expect from

an industry leader in outdoor power equipment manufac-

turing.

Although reading this manual and the safety instruc-

tions it contains will provide you with the necessary basic

knowledge to operate this equipment safely and effec-

tively, we have placed several safety labels on the unit

to remind you of this important information while you are

operating your unit.

All DANGER, WARNING, CAUTION and instructional

messages on your rider and mower should be carefully

read and obeyed. Personal bodily injury can result when

these instructions are not followed. The information is for

your safety and it is important! The safety decals below are

on your rider and mower.

If any of these decals are lost or damaged, replace them at

once. See your local dealer for replacements.

These labels are easily applied and will act as a constant

visual reminder to you, and others who may use the

equipment, to follow the safety instructions necessary for

safe, effective operation.

North American lVlodels

Decal - Operating Instructions, North American Mod-

els, Part No. 1726923

"_ Amputation Hazard _,,

"\ Toavoidinjurylromrotating_

',,__lade_,0raycl0arofdock_d_e._

Decal - Danger, Side-

Discharge Models,

Part No. 1704276

/, . //

Decal- Danger, Side-

Discharge Models,

Part No. 1704277

13

Page 14

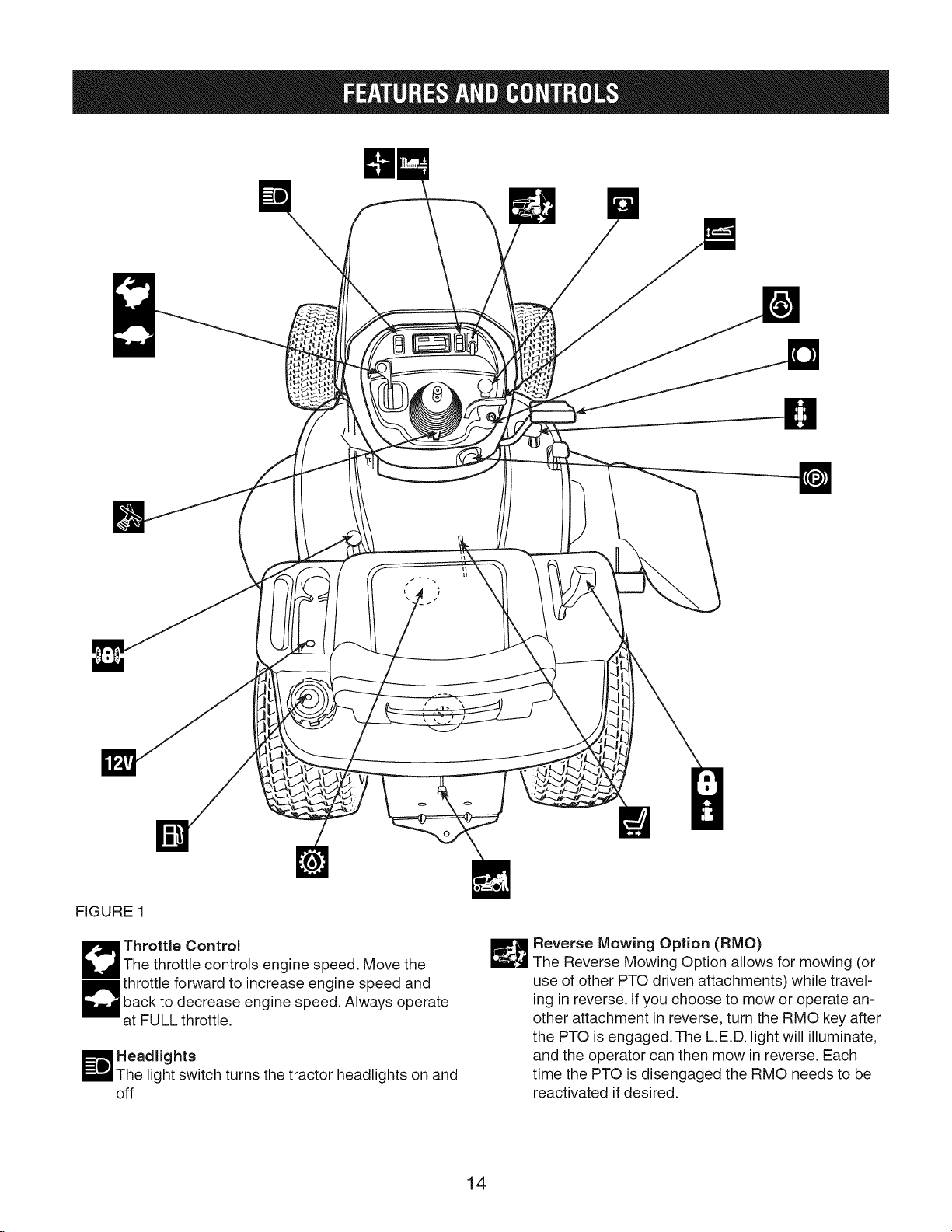

FIGURE 1

1_ Throttle Control

The throttle controls engine speed. Move the

throttle forward to increase engine speed andback to decrease engine speed. Always operate

at FULL throttle.

Headlights

light switch turns the tractor headlights on and

off

_ everse Mowing Option (RMO)

The Reverse Mowing Option allows for mowing (or

use of other PTO driven attachments) while travel-

ing in reverse. If you choose to mow or operate an-

other attachment in reverse, turn the RMO key after

the PTO is engaged.The L.E.D. light will illuminate,

and the operator can then mow in reverse. Each

time the PTO is disengaged the RMO needs to be

reactivated if desired.

14

Page 15

PTO Switch

m

The PTO (Power Take-Off) switch engages and dis-

engages attachments that use the PTO. To engage

the PTO, pull UP on the switch. Push DOWN to

disengage. Note that the operator must be seated

firmly in the tractor seat for the PTO to function.

'1 Ignition Switch

The ignition switch starts and stops the engine, it

has three positions:

OFF Stops the engine and shuts off the electri-

cal system.

RUN Allows the engine to run and powers the

electrical system.

START Cranks the engine for starting.

NOTE: Never leave the ignition switch in the RUN

position with the engine stopped-this drains the

battery.

Cruise Control

FI

The cruise control is used to lock the ground

speed control in forward. Move the lever forward

El

until the desired ground speed is reached. To

disengage the cruise control move the lever

back. In the event you need to stop quickly,

depressing the brake pedal will also return the

cruise control to neutral.

Seat Adjustment Lever

The seat can be adjusted forward and back.

Move the lever, position the seat as desired, and

release the lever to lock the seat into position.

Transmission Release Lever

The transmission release lever deactivates the

transmission so that the tractor can be pushed by

hand. See Pushing the Tractor by Hand.

Transmission Oil Expansion Chamber

Brake Pedal

pressing the brake pedal applies the tractor brake.

Ground Speed Pedals

The tractor's forward ground speed is controlled

by the forward ground speed control pedal. The

tractor's reverse ground speed is controlled by the

reverse ground speed control pedal.

Depressing either pedal will increase ground

speed. Note that the further down the pedal is de-

pressed, the faster the tractor will travel.

Parking Brake

The parking brake knob is used to lock the parking

brake when the tractor is stopped. Fully depressing

the brake pedal and pulling up on the knob engag-

es the parking brake

_ Mower Height of Cut Adjustment

The cutting height adjustment switch controls the

mower cutting height. The cutting height is infinitely

adjustable between 1.0" and 4.0" (2.5 and 10.2 cm).

Transmission oil is added through the transmis-

sion oil expansion chamber. It also serves as

extra holding capacity for oil as the transmission

heats up and the oil expands. See the Engine

Manual for oil level check and fill procedures.

Fuel Tank

I-oremove the cap, turn counterclockwise. On

models with a dashboard display, the fuel gauge is

part of the dashboard. Models without a dashboard

display have a fuel gauge located under the seat.

12-Volt Power Outlet

The power outlet is 12V-DC. Accessory must be

rated at 14 amps or less.

Differential Lock Pedal

Depressing this pedal locks the transmission dif-

ferential, locking both rear wheels into "drive".

Use this feature if the tractor is stuck because one

wheel is slipping. Engage the differential lock at

slow ground speeds only.

15

Steering Tilt Adjust

Use the tilt knob located on the bellows to release

the pivot mechanism and pivot the wheel to the

desired position. Release the tilt knob to lock in

position.

Page 16

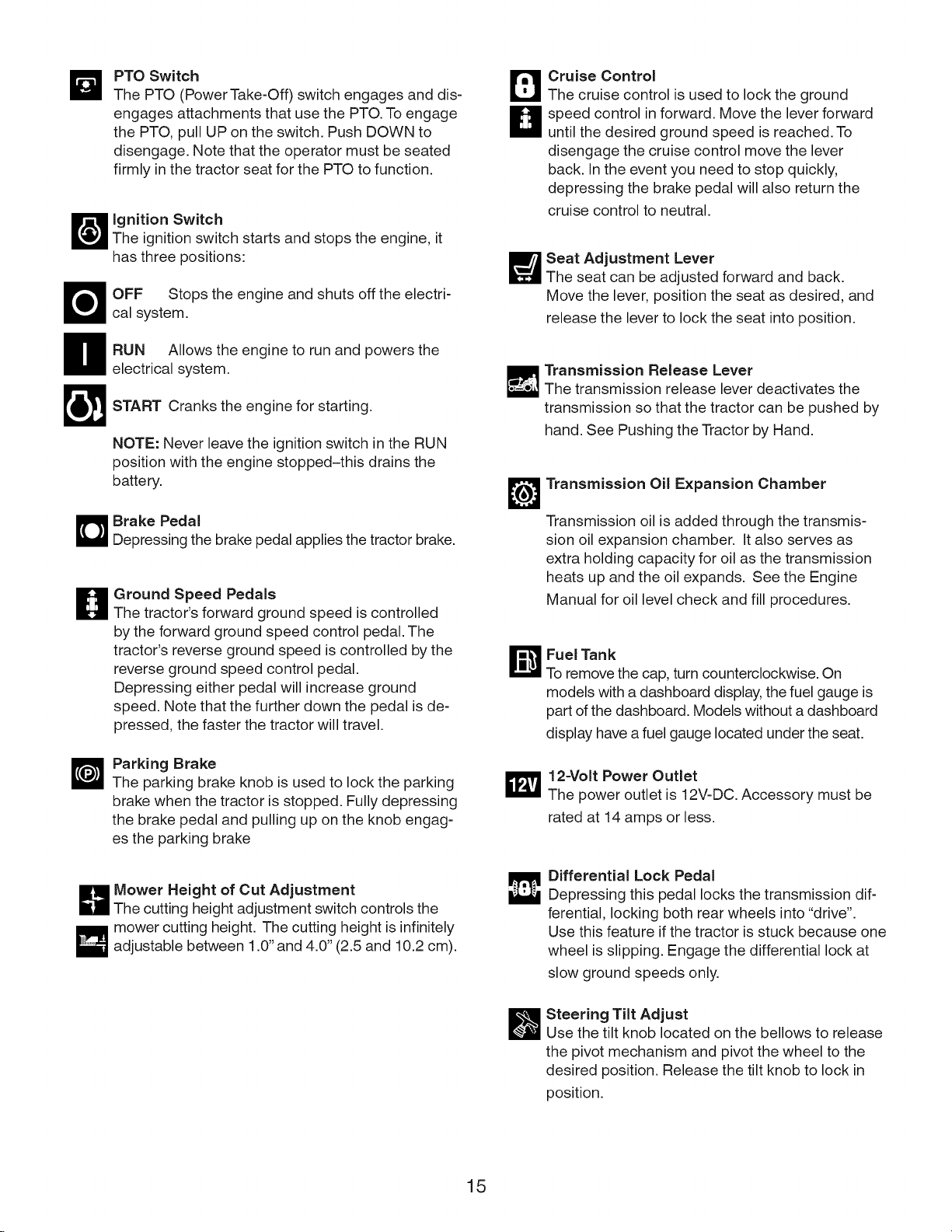

Dashboard Display & Functions

Display Items

Refer to Figure 2.

9

A. Fuel Level

Indicates the amount of fuel in the fuel tank (A). Left is

empty; right is full.

B. Hour Meter / Clock / Service Indicator

Displays the clock, hour meter, and maintenance re-

minder.

C. Select Button

Used to set the clock and reset the maintenance remind-

er.

D. Set Button

Used to set the clock and reset the maintenance remind-

er.

E. PTO Light

Indicates the PTO switch is in the ON position.

F.Cruise Control Light

Indicates that the cruise control is engaged.

G. Low Oil Pressure Light

Indicates that the engine oil pressure is low. The light

will turn on when the tractor is first started and then go

out. IF THIS LIGHT TURNS ON WHILE THE TRAC-

TOR IS IN USE, TURN THE ENGINE OFF IMMEDIATE-

LY. Contact your authorized dealer for service.

H. Low Voltage Light

Indicates that the electrical system voltage is low. The

light will turn on when the tractor is first started and then

go out. IF THIS LIGHT TURNS ON WHILE THE TRAC-

TOR IS IN USE, TURN THE ENGINE OFF IMMEDIATE-

LY. Contact your authorized dealer for service.

I[

o €

e

formation J

;i;e I

I

FIGURE 2

Functions

Dashboard Display Models (See Figure 2)

Display Total Running Hours - When the key switch

is first turned to the RUN position, all warning indicators

will light and the total running hours will be displayed. Be

sure all lights are functioning.

Display PTO Hours - Turn the key OFF, engage the PTO,

and turn the key to RUN (engine off).

Set the Clock - Start the engine, leave the engine run-

ning. Depress the select button (C) for three (3) seconds

and release. Depress set button and HOLD to advance

time. Depress select button to select minutes. Depress

and HOLD set button (D) to advance time. Leave alone

for 5 seconds and clock will activate. Shut off engine.

Demonstration Mode - With the engine off, hold down

the set button (D) and turn the key switch to RUN.

Maintenance Reminder - A maintenance reminder

will display in the information window (B) after the first 5

hours of operation, and then after every 50 hours. The re-

minder will automatically reset after 5 hours. The remind-

er can be manually reset by turning the key switch from

OFF to RUN (with engine off) and then depressing the set

(D) and select (C) buttons simultaneously for 5 seconds.

®

©

16

Page 17

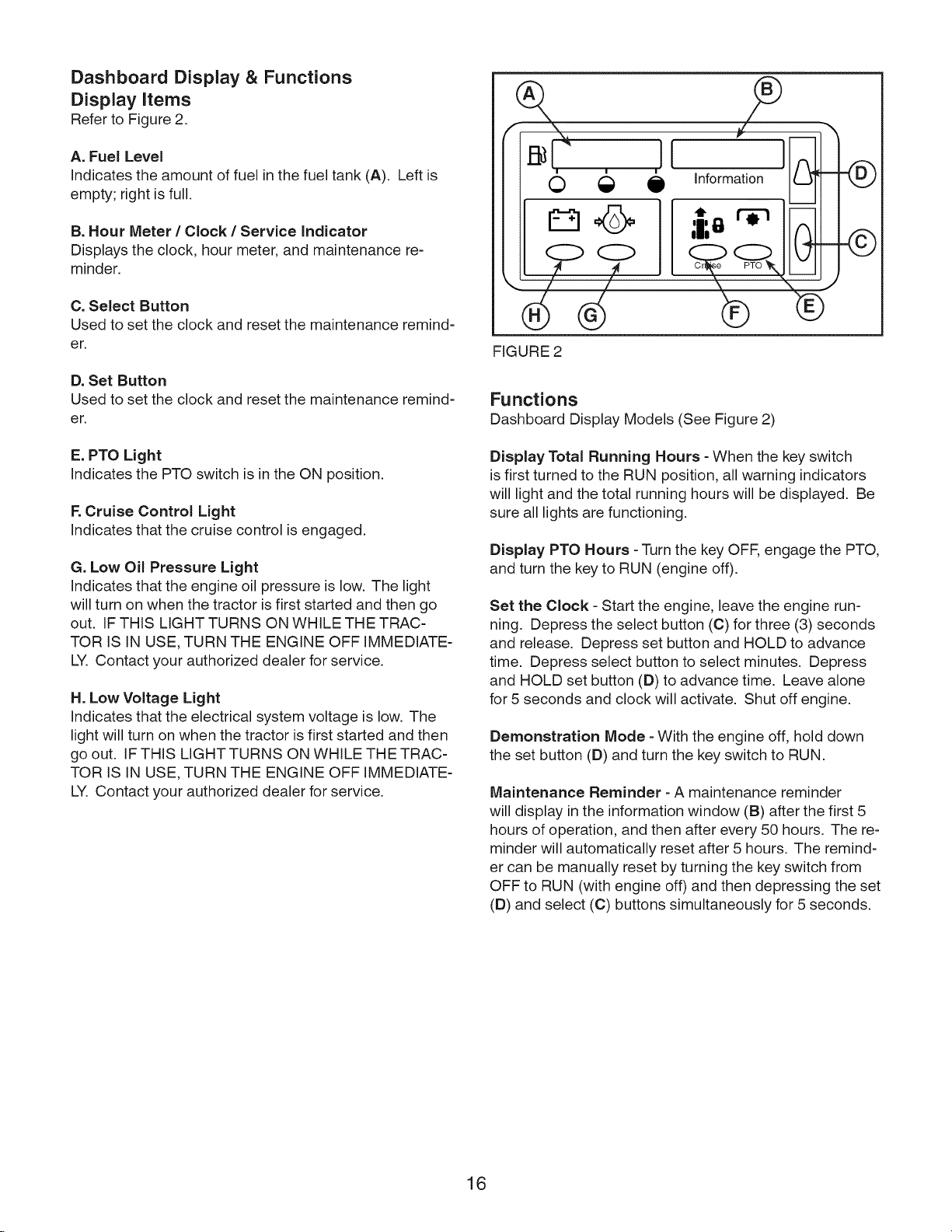

Parking Brake Function

Applying the Parking Brake - To lock the parking brake,

release the ground speed pedals (A), fully depress the

brake pedal (B), pull UP on the parking brake knob (C),

and then release brake pedal.

Releasing the Parking Brake - See Figure 2. To release

the parking brake, fully depress the brake pedal (B) and

push the parking brake knob (C) DOWN.

IMPORTANT NOTE. The tractor's hydraulic attachment lift

will not work when the parking brake is engaged.

FIGURE 3

Automatic Controlled Traction

What is Automatic Controlled Traction?

Automatic Controlled Traction (ACT) is an exclusive

feature of our transmissions that provides improved

traction. ACT applies a preset amount of torque to both

rear wheels even if one starts slipping (a transmission

without ACT will lose traction completely if one rear

wheel starts slipping). This preset torque is just enough

to provide additional traction, and still allow the wheels to

turn at different speeds in a tight turn without damaging

the lawn.

12 Volt Power Outlet

The 12-volt accessory plug is located in the left side pod.

It can be used to power small electronic devices. The ac-

cessory must be rated at 9 amps or less.

NOTICE: Operating a 12-volt accessory, especially with

the engine at idle, may cause battery discharge. When

not using the accessory plug it must be covered with the

rubber plug to prevent moisture from causing a short circuit.

Entrance of water into plug can cause a short circuit.

What to Expect from Your ACT Tractor

For the most part, while using your tractor you will not no-

tice ACT working, and you will simply become accustomed

to increased traction an ACT transmission provides.

Under certain circumstances the ACT system limit can

be exceeded, and one of the rear wheels may slip (for

instance if trying to turn up a hill while accelerating). This

is normal. If you start to lose traction, do not speed up.

Instead, slow to a stop, straighten the steering wheel, and

slowly accelerate. Stopping the tractor allows the trans-

mission to regain more traction.

17

Page 18

General Operating Safety

Be sure to read all information in the Operator Safety

section before attempting to operate this unit. Become

familiar with all of the controls and how to stop the unit.

WARNING

If the unit does not pass a safety test, do not oper-

ate it. See an authorized dealer.

Safety Interlock System Tests

This unit is equipped with a Safety Interlock System.

Do not attempt to bypass or tamper with the switches/

devices.

Test 1 -- Engine should NOT crank if:

• PTO switch is ON, OR

• Brake pedal is NOT fully depressed (parking brake

OFF), OR

• The cruise control lever is NOT in NEUTRAL.

Test 2 -- Engine SHOULD crank and start if:

• Operator is sitting in seat, AND.

• PTO switch is OFF, AND

• Brake pedal is fully depressed (parking brake ON),

AND

• The cruise control is in NEUTRAL.

Test 3 -- Engine should SHUT OFF if:

• Operator rises off seat with PTO engaged, OR

• Operator rises off seat with brake pedal NOT fully

depressed (parking brake OFF).

Test 4 -- Check Mower Blade Stopping Time

Mower blades and mower drive belt should come to a

complete stop within five seconds after electric PTO

switch is turned OFF. If mower drive belt does not stop

within five seconds, see an authorized dealer.

Test 5 -- Reverse Mow Option (RMO) Check

• Engine should shut off if reverse travel is attempted

if the PTO has been switched on and RMO has not

been activated.

• RMO light should illuminate when RMO has been

activated.

WARNING

Mowing in reverse can be hazardous to bystand-

ers. Tragic accidents can occur if the operator is not alert

to the presence of children. Never activate the RMO if

children are present. Children are often attracted to the

unit and the mowing activity.

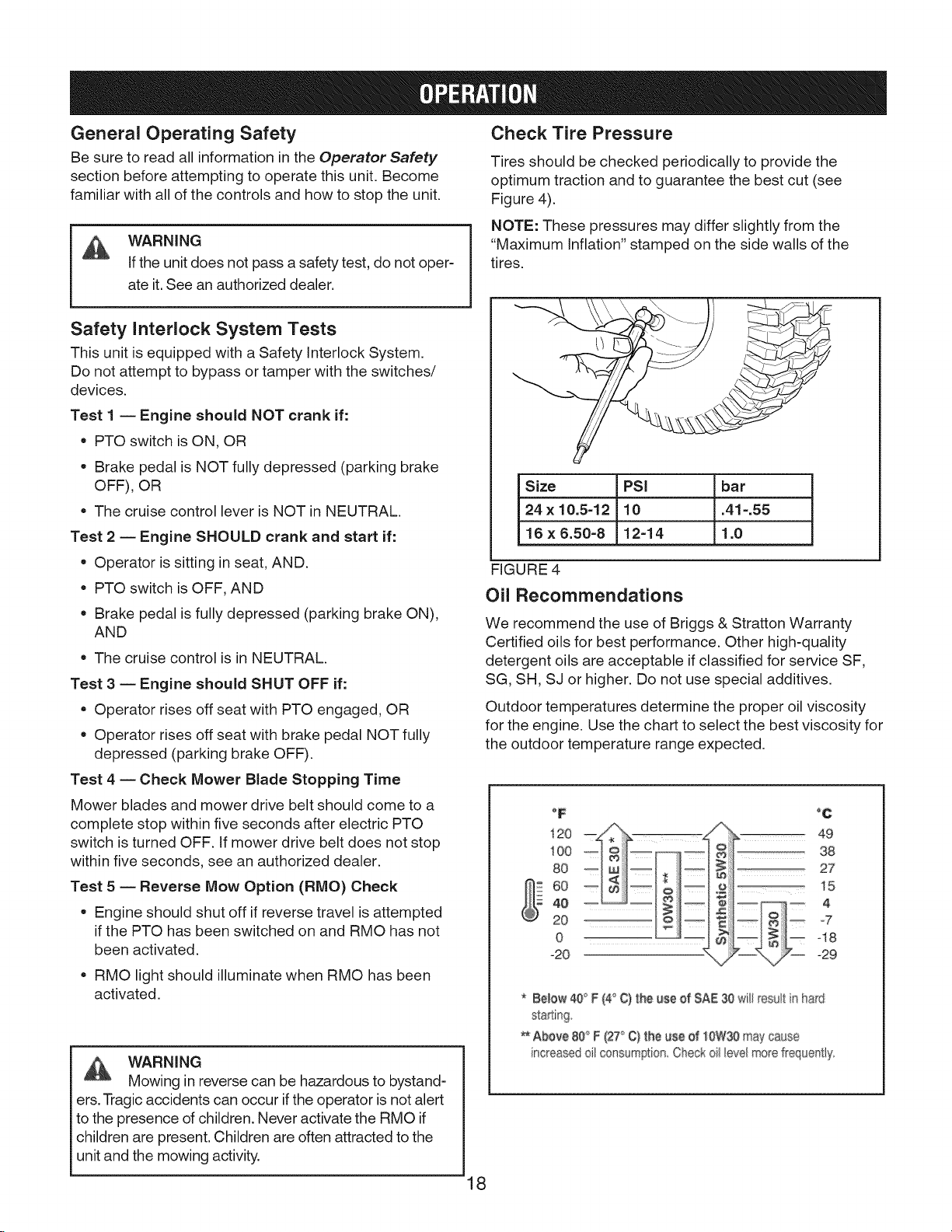

Check Tire Pressure

Tires should be checked periodically to provide the

optimum traction and to guarantee the best cut (see

Figure 4).

NOTE: These pressures may differ slightly from the

"Maximum Inflation" stamped on the side walls of the

tires.

Size PSi bar

24 x 10.5-12 10 .41-.55

16x6.50-8 12-14 1.0

FIGURE 4

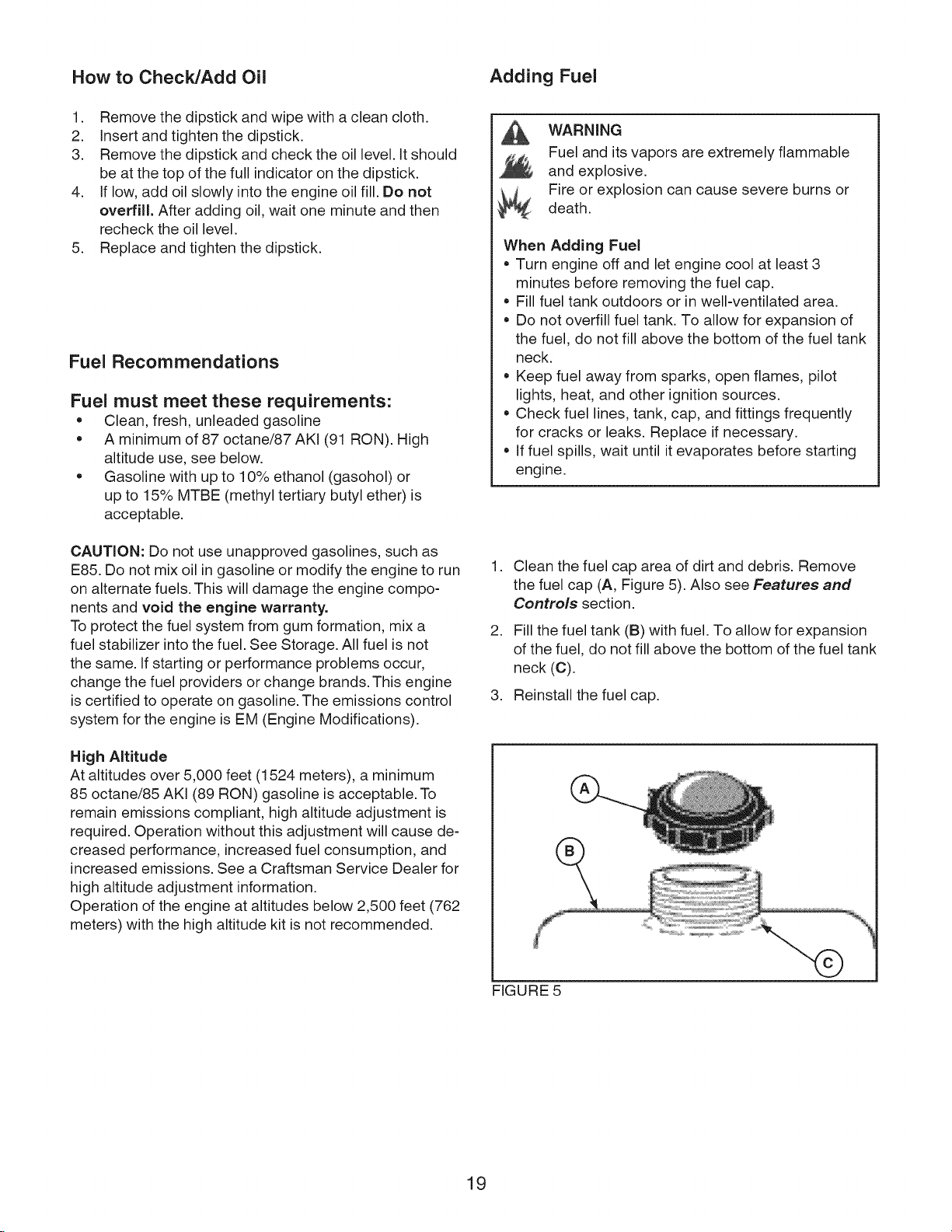

Oil Recommendations

We recommend the use of Briggs & Stratton Warranty

Certified oils for best performance. Other high-quality

detergent oils are acceptable if classified for service SF,

SG, SH, SJ or higher. Do not use special additives.

Outdoor temperatures determine the proper oil viscosity

for the engine. Use the chart to select the best viscosity for

the outdoor temperature range expected.

°F

i20

_, 38

?2

4O

2O

0

-20

* Below @° F(4'_C) the #se of SAE30 willresuatn hard

staking

Above 80'_F (2T' C) the #se of 10W30maycause

increasedoil consumption Checkoi_[,eve_morefrequentty_

_ii} -7

_ q 8

°C

27

_29

18

Page 19

How to Check/Add Oil Adding Fuel

1. Remove the dipstick and wipe with a clean cloth.

2. Insert and tighten the dipstick.

3. Remove the dipstick and check the oil level. It should

be at the top of the full indicator on the dipstick.

4. If low, add oil slowly into the engine oil fill. Do not

overfill. After adding oil, wait one minute and then

recheck the oil level.

5. Replace and tighten the dipstick.

Fuel Recommendations

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline

• A minimum of 87 octane/87 AKI (91 RON). High

altitude use, see below.

• Gasoline with up to 10% ethanol (gasohol) or

up to 15% MTBE (methyl tertiary butyl ether) is

acceptable.

CAUTION: Do not use unapproved gasolines, such as

E85. Do not mix oil in gasoline or modify the engine to run

on alternate fuels. This will damage the engine compo-

nents and void the engine warranty.

To protect the fuel system from gum formation, mix a

fuel stabilizer into the fuel. See Storage. All fuel is not

the same. If starting or performance problems occur,

change the fuel providers or change brands. This engine

is certified to operate on gasoline. The emissions control

system for the engine is EM (Engine Modifications).

WARNING

Fuel and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

When Adding Fuel

• Turn engine off and let engine cool at least 3

minutes before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of

the fuel, do not fill above the bottom of the fuel tank

neck.

• Keep fuel away from sparks, open flames, pilot

lights, heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently

for cracks or leaks. Replace if necessary.

• If fuel spills, wait until it evaporates before starting

engine.

.

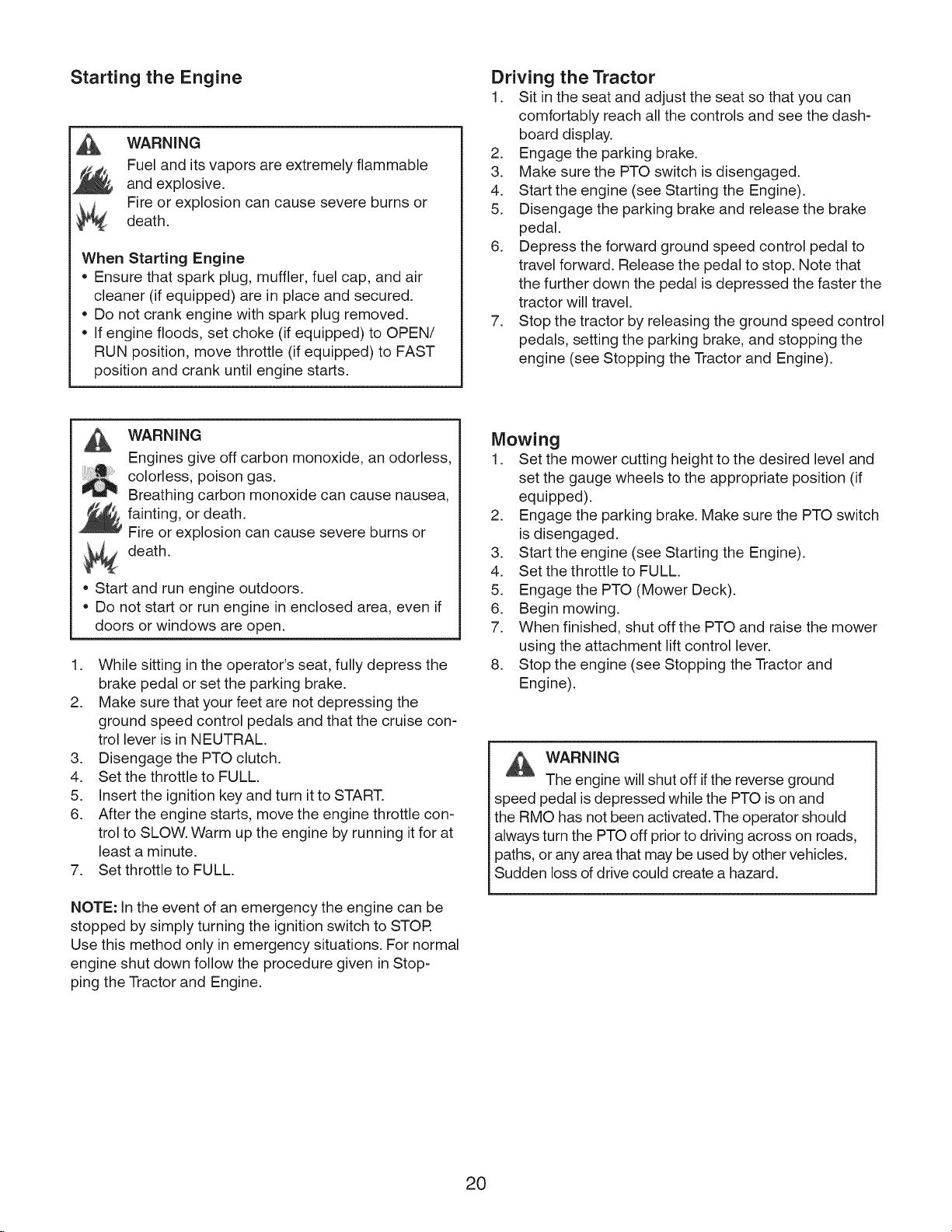

Clean the fuel cap area of dirt and debris. Remove

the fuel cap (A, Figure 5). Also see Features and

Controls section.

.

Fill the fuel tank (B) with fuel. To allow for expansion

of the fuel, do not fill above the bottom of the fuel tank

neck (C).

3. Reinstall the fuel cap.

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/85 AKI (89 RON) gasoline is acceptable. To

remain emissions compliant, high altitude adjustment is

required. Operation without this adjustment will cause de-

creased performance, increased fuel consumption, and

increased emissions. See a Craftsman Service Dealer for

high altitude adjustment information.

Operation of the engine at altitudes below 2,500 feet (762

meters) with the high altitude kit is not recommended.

FIGURE 5

19

Page 20

Starting the Engine

WARNING

Fuel and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap, and air

cleaner (if equipped) are in place and secured.

• Do not crank engine with spark plug removed.

• If engine floods, set choke (if equipped) to OPEN/

RUN position, move throttle (if equipped) to FAST

position and crank until engine starts.

Driving the Tractor

1. Sit in the seat and adjust the seat so that you can

comfortably reach all the controls and see the dash-

board display.

2. Engage the parking brake.

3. Make sure the PTO switch is disengaged.

4. Start the engine (see Starting the Engine).

5. Disengage the parking brake and release the brake

pedal.

6. Depress the forward ground speed control pedal to

travel forward. Release the pedal to stop. Note that

the further down the pedal is depressed the faster the

tractor will travel.

7. Stop the tractor by releasing the ground speed control

pedals, setting the parking brake, and stopping the

engine (see Stopping the Tractor and Engine).

WARNING

Engines give off carbon monoxide, an odorless,

colorless, poison gas.

Breathing carbon monoxide can cause nausea,

fainting, or death.

Fire or explosion can cause severe burns or

_ death.

• Start and run engine outdoors.

Do not start or run engine in enclosed area, even if

doors or windows are open.

1. While sitting in the operator's seat, fully depress the

brake pedal or set the parking brake.

2. Make sure that your feet are not depressing the

ground speed control pedals and that the cruise con-

trol lever is in NEUTRAL.

3. Disengage the PTOclutch.

4. Set the throttle to FULL.

5. Insert the ignition key and turn it to START.

6. After the engine starts, move the engine throttle con-

trol to SLOW. Warm up the engine by running it for at

least a minute.

7. Set throttle to FULL.

Mowing

1. Set the mower cutting height to the desired level and

set the gauge wheels to the appropriate position (if

equipped).

2. Engage the parking brake. Make sure the PTO switch

is disengaged.

3. Start the engine (see Starting the Engine).

4. Set the throttle to FULL.

5. Engage the PTO (Mower Deck).

6. Begin mowing.

7. When finished, shut off the PTO and raise the mower

using the attachment lift control lever.

8. Stop the engine (see Stopping the Tractor and

Engine).

_ ARNING

The engine will shut off ifthe reverse ground

speed pedal is depressed while the PTO ison and

the RMO has not been activated. The operator should

always turn the PTO off prior to driving across on roads,

paths, or any area that may be used by other vehicles.

Sudden loss of drive could create a hazard.

NOTE: In the event of an emergency the engine can be

stopped by simply turning the ignition switch to STOR

Use this method only in emergency situations. For normal

engine shut down follow the procedure given in Stop-

ping the Tractor and Engine.

20

Page 21

Reverse Mowing Option (RMO TM) Stopping the Tractor and Engine

WARNING

Mowing in reverse can be hazardous to

bystanders. Tragic accidents can occur if the operator is

not alert to the presence of children. Never activate the

RMO if children are present. Children are often attracted

to the unit and the mowing activity.

The Reverse Mowing Option (RMO) allows the operator

to mow in reverse (see Features and Controls). To

activate, turn the RMO key after the PTO is engaged.

The L.E.D. light will illuminate, and the operator can then

mow in reverse. Each time the PTO is engaged the RMO

needs to be reactivated if desired. The key should be

removed to restrict access to the RMO.

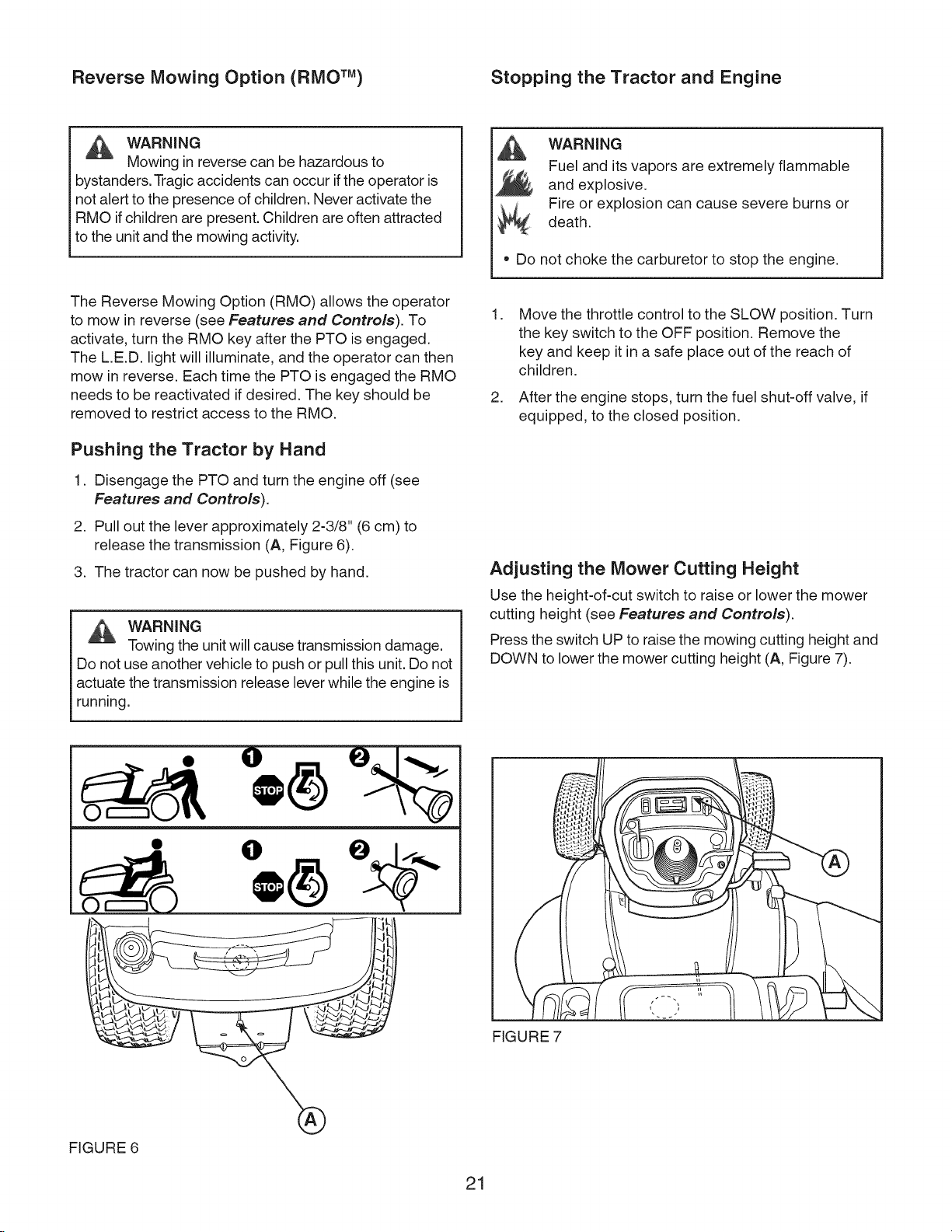

Pushing the Tractor by Hand

1. Disengage the PTO and turn the engine off (see

Features and Controls).

2. Pull out the lever approximately 2-3/8" (6 cm) to

release the transmission (A, Figure 6).

3. The tractor can now be pushed by hand.

WARNING

Towing the unit will cause transmission damage.

Do not use another vehicle to push or pull this unit. Do not

actuate the transmission release lever while the engine is

running.

WARNING

Fuel and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

• Do not choke the carburetor to stop the engine.

.

Move the throttle control to the SLOW position. Turn

the key switch to the OFF position. Remove the

key and keep it in a safe place out of the reach of

children.

.

After the engine stops, turn the fuel shut-off valve, if

equipped, to the closed position.

Adjusting the Mower Cutting Height

Use the height=of=cut switch to raise or lower the mower

cutting height (see Features and Controls).

Press the switch UP to raise the mowing cutting height and

DOWN to lower the mower cutting height (A, Figure 7).

FIGURE 6

e =, I

FIGURE 7

21

Page 22

Maintenance Chart

Every 8 Hours or Daily

Check safety interlock system

Clean debris off tractor and mower deck

Clean debris from engine compartment

Every 25 Hours or Annually*

Check tire pressure

Check mower blade stopping time

Check tractor and mower for loose hardware

Every 50 Hours or Annually *

Clean battery and cables

Check tractor brakes

see Dealer Annually tO ..........

Lubricate tractor and mower

Check mower blades **

* Whichever comes first

** Check blades more often in regions with sandy soils

or high dust conditions.

WARNING

Unintentional sparking can result in fire or elec-

tric shock.

Unintentional start-up can result in entangle-

ment, traumatic amputation, or laceration.

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away

from the spark plug.

• Disconnect battery at negative terminal (only en-

gines with electric start).

• Use only correct tools.

• Do not tamper with governor spring, links, or other

parts to increase engine speed.

• Replacement parts must be of the same design and

installed in the same position as the original parts.

Other parts may not perform as well, may damage

the unit, and may result in injury.

• Do not strike the flywheel with a hammer or hard

object because the flywheel may shatter during

operation.

i ii !ii! ii iliiiiii ii! !!i!!i!!i!!i!......................................................................................................................................................................................................................................................................................

First 5 Hours

Change engine oil

Every 8 Hours or Daily ...........

Check engine oil level

Every 25 Hours or Annually *

Clean engine air filter and pre-cleaner **

Every 50 Hours or Annually *

Change engine oil

Replace oil filter

Annually

Replace air filter

Replace pre-cleaner

See Dealer Annually to

inspect muffler and spark arrester

Replace spark plug

Replace fuel filter

Clean engine air cooling system

• Whichever comes first

•*Clean more often in dusty conditions or when

airborne debris is present.

Check Tire Pressure

Tires should be checked periodically to provide the optimum

traction and to guarantee the best cut (see Figure 4).

NOTE: These pressures may differ slightly from the

"Maximum inflation" stamped on the side walls of the tires.

Check Mower Blade Stopping Time

WARNING

if the mower blade does not come to a complete

stop within 5 seconds, the blade must be adjusted. Do

not operate the machine until the proper adjustment has

been performed by an authorized dealer.

Check the mower blade for proper function (see Safety

interlock System Tests). The blade should stop rotating

in 5 seconds or less after moving the blade control to the

OFF position.

22

Page 23

Battery Maintenance

WARNING

A

When removing or installing battery cables,

disconnect the negative cable FIRST and recon-

nect it LAST. If not done in this order, the positive

terminal can be shorted to the frame by a tool.

WARNING

Battery posts, terminals, and related accessories

contain lead and lead compounds - chemicals known to

the State of California to cause cancer, birth defects, or

other reproductive harm. Wash hands after handling.

Cleaning the Battery and Cables

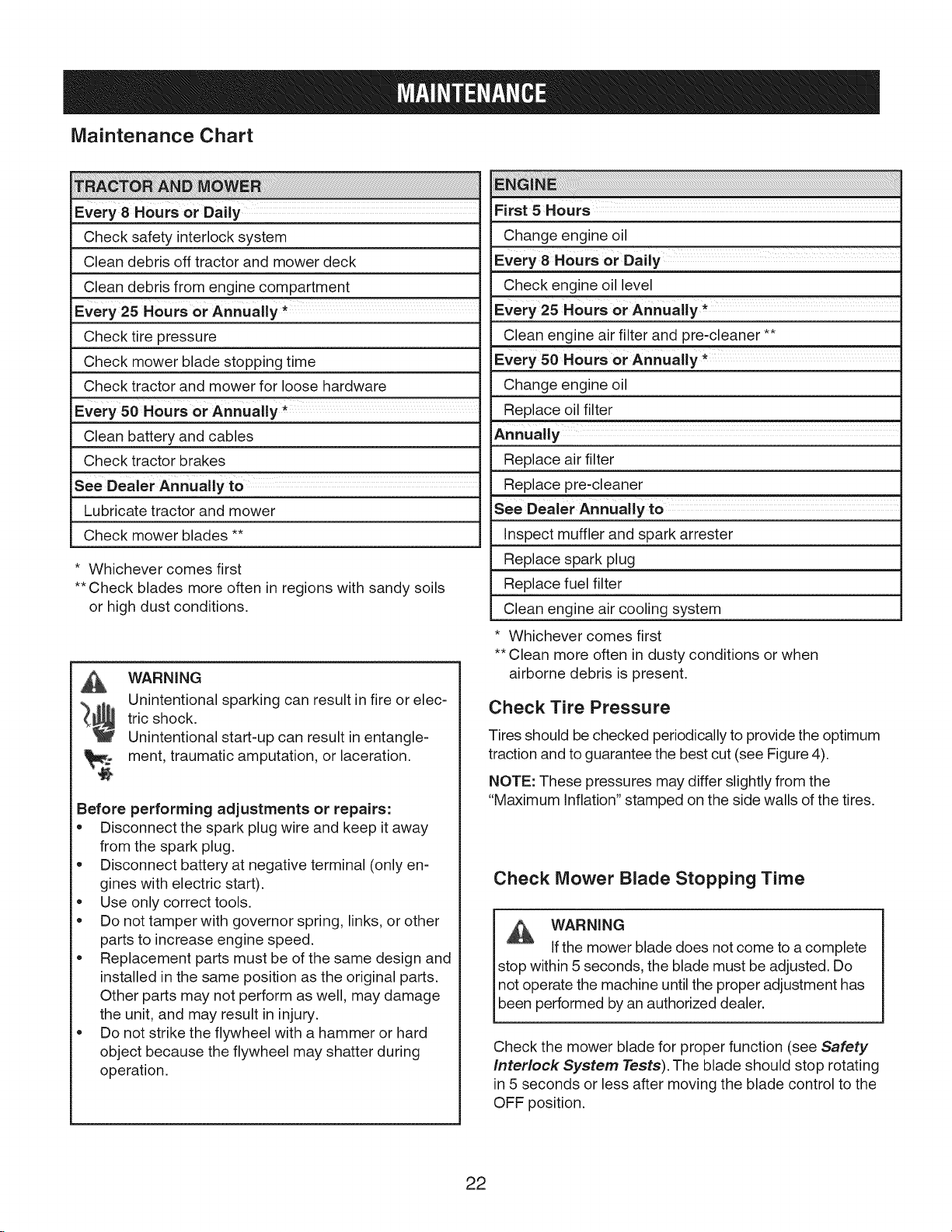

1. Disconnect the cable from the battery, negative cable

first (A, Figure 8).

2. Remove the battery hold-down strap (B) and battery.

3. Clean the battery compartment with a solution of

baking soda and water.

4. Clean the battery terminals and cable ends with a

wire brush and battery terminal cleaner until shiny.

5. Reinstall the battey in the battey compartment, and

secure with the battery hold-down strap.

6. Reattach the battery cables, positive cables first (C).

7. Coat the cable ends and battery terminals with petro-

leum jelly or non-conducting grease.

FIGURE 8

Charging the Battery

WARNING

Keep open flames and sparks away from the

battery;the gasses coming from itare highly

explosive. Ventilatethe battery well during charging.

A dead battery or one too weak to start the engine may

be the result of a defect in the charging system or other

electrical component. If there is any doubt about the

cause of the problem, see your dealer. If you need to

replace the battery, see the Cleaning the Battery and

Cables section.

To charge the battery, follow the instructions provided by

the battery charger manufacturer as well as all warnings

included in the Operator Safety section of this manual.

Charge the battery until fully charged. Do not charge at a

rate higher than 10 amps.

23

Page 24

Change The Oil

Used oil is a hazardous waste product and must be dis-

posed of properly. Do not discard with household waste.

Check with your local authorities, service center, or dealer

for safe disposal/recycling facilities.

Standard Oil Drain Plug

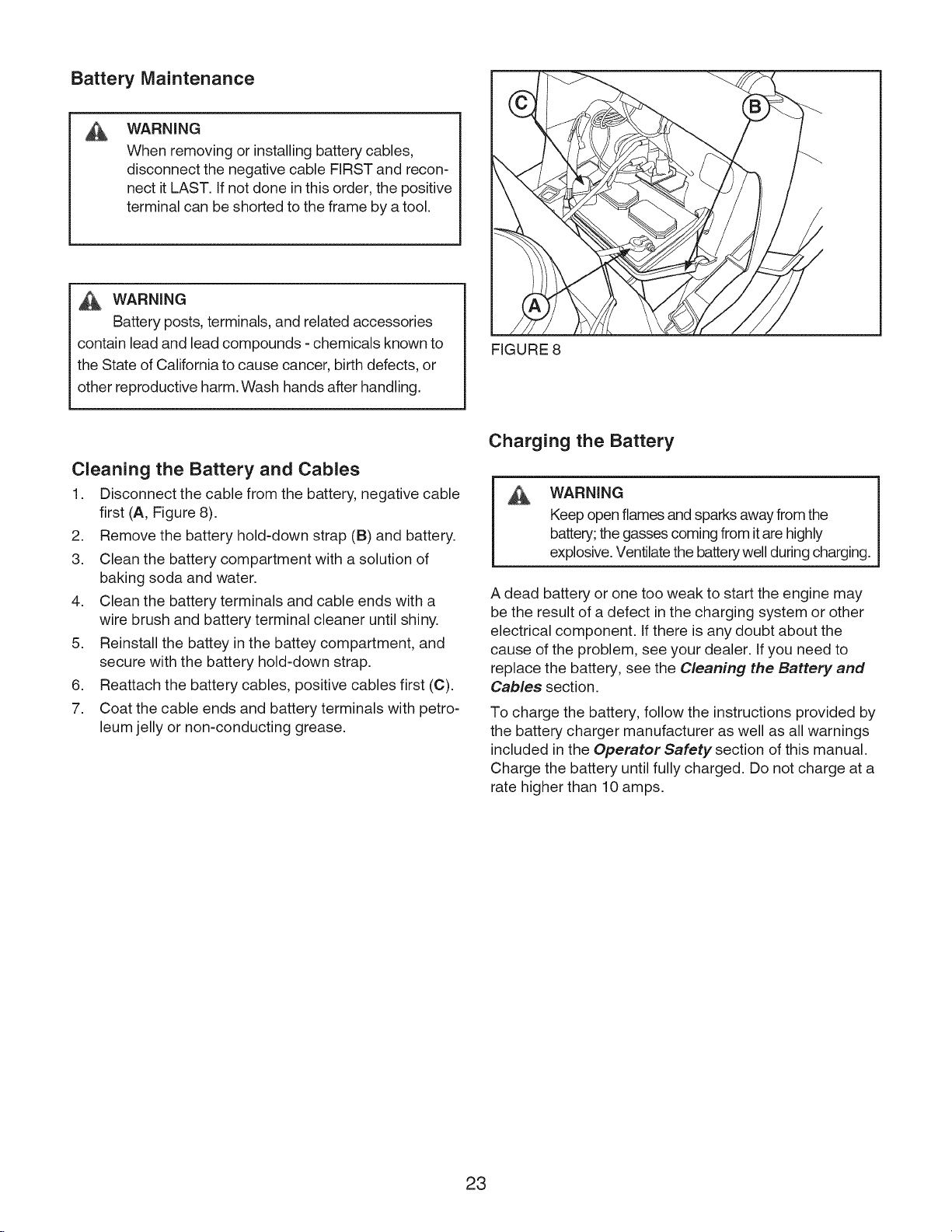

1. Remove the oil drain plug (B). Drain the oil into an

approved container.

2. After the oil has drained, install and tighten the oil

drain plug.

Remove Oil

1. With engine off but still warm, disconnect the spark

plug wire (A) and keep it away from the spark plug

(Figure 9).

2. Remove the dipstick (D).

Optional Quick Oil Drain

1. Disconnect the oil drain hose (G, Figure 9) from the

side of the engine.

2. Turn and remove the oil drain cap (H). Carefully lower

the quick oil drain (I) into an approved container (J).

3. After the oil has drained, install the oil drain cap. At-

tach the oil drain hose to the side of the engine.

Change The Oil Filter (if equipped)

For replacement intervals, see the Maintenance chart.

1. Drain the oil from the engine. See Remove Oil sec-

tion.

2. Remove the oil filter and dispose of properly.

3. Before you install the new oil filter, lightly lubricate the

oil filter gasket with fresh, clean oil.

4. Install the oil filter by hand until the gasket contacts

the oil filter adapter, then tighten the oil filter 1/2 to 3/4

turns.

5. Add oil. See Add Oil section.

6. Start and run the engine. As the engine warms up,

check for oil leaks.

7. Stop the engine and check the oil level. It should be

at the FULL mark on the dipstick.

FIGURE 9

©

" ............... JJ

Add Oil

1. Place engine level.

2. Clean the oil fill area of any debris.

3. See the Specifications section for oil capacity.

4. Remove the dipstick (D) and wipe with a clean cloth

(Figure 9).

5. Pour the oil slowly into the engine oil fill (E). Do not

overfill. After adding oil, wait one minute and then

check the oil level.

6. Install and tighten the dipstick.

7. Remove the dipstick and check the oil level. It should

be at the FULL mark (F) on the dipstick.

8. Install and tighten the dipstick.

24

Page 25

Service The Air Filter Servicing the Muffler

WARNING

Fuel and its vapors are extremely flammable

and explosive.

Fire or explosion can cause severe burns or

death.

• Never start or run the engine with the air cleaner

assembly or air filter removed.

NOTICE: Do not use pressurized air or solvents to clean

the filter. Pressurized air can damage the filter and solvents

will dissolve the filter. The air filter system uses either a flat

or oval cartridge. Some models are also equipped with a

pre-cleaner that can be washed and reused.

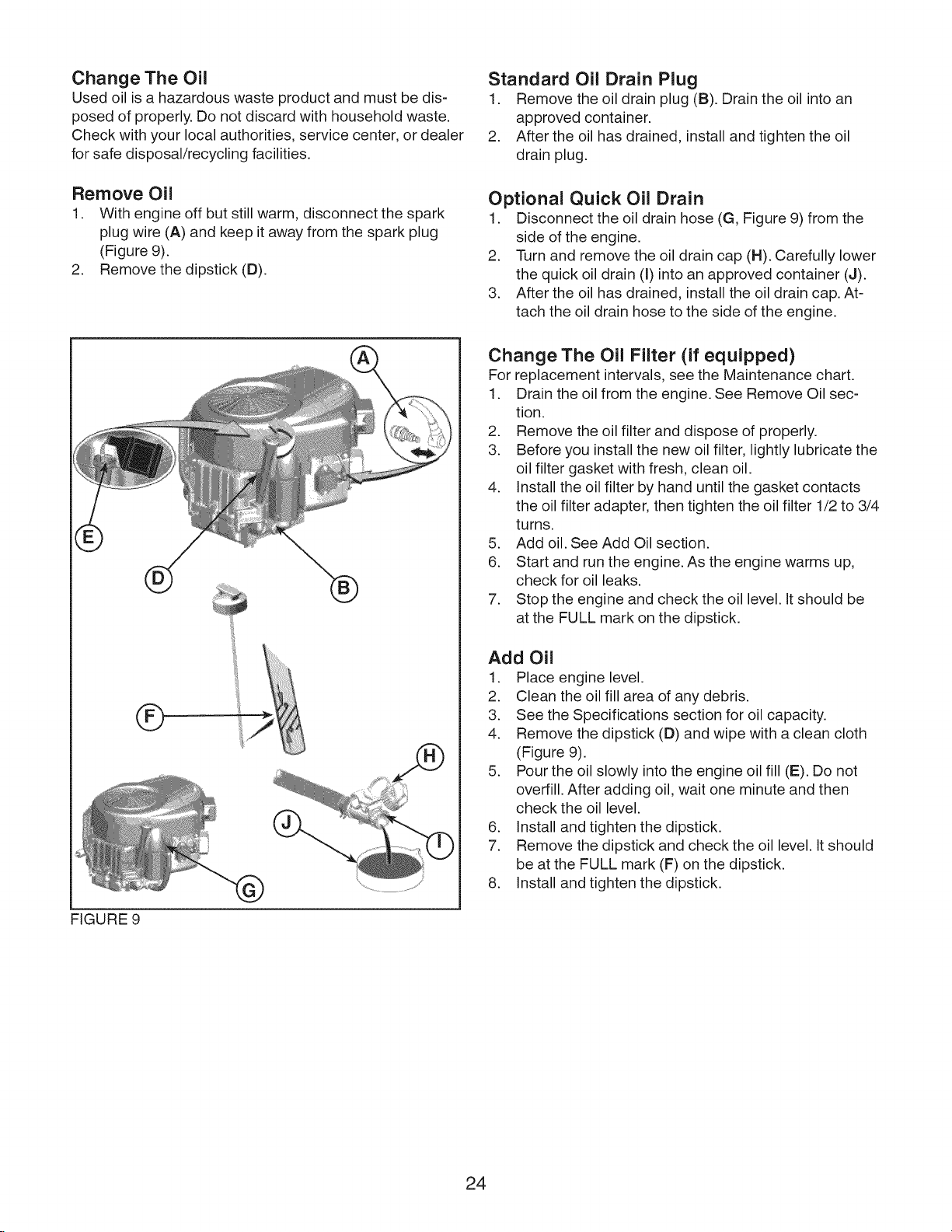

Oval Air Filter

1. Remove the cover (A, Figure 10).

2. To remove the filter (B), lift the end of the filter.

3. Remove the pre-cleaner (C) from the filter.

4. To loosen debris, gently tap the filter on a hard

surface. If the filter is excessively dirty, replace with a

new filter.

5. Wash the pre-cleaner in liquid detergent and water.

Then allow itto thoroughly air dry.Do not oil the pre-

cleaner.

6. Assemble the dry pre-cleaner and the filter into the

engine base (D).

7. Install the cover.

WARNING

Running engine produces heat. Engine parts,

especially muffler, become extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass,

brush, etc. can catch fire.

Allow muffler, engine cylinder and fins to cool before

touching.

Remove visible debris from engine compartment.

WARNING

Replacement parts must be the same position as

the original parts or fire could result.

To service the muffler, see an authorized dealer.

Servicing the Spark Plugs

WARNING

Unintentional sparking can result infire or electric

shock.

Unintentional start-up can result in entanglement,

traumatic amputation, or laceration.

®

FIGURE 10

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug removed.

CAUTION: Spark plugs have different heat ranges. It is

important that the correct spark plug is used, otherwise,

engine damage can occur.

Clean Spark Plug

Clean with wire brush and sturdy knife. Do Not use

abrasives.

25

Page 26

Check Spark Plug Gap

Use a spark plug feeler gauge to check the gap between

the two electrodes. When the gap is correct, the gauge

will drag slightly as you pull it through the gap.

If necessary, use the spark plug gauge to adjust the gap

by gently bending the curved electrode without touching

the center electrode or the porcelain.

Install Spark Plug

Finger tighten, then tighten with wrench.

• 180 in-lbs (20 Nm), OR

• 1/2 turn when reinstalling the original spark plug.

1/4 turn when installing a new spark plug.

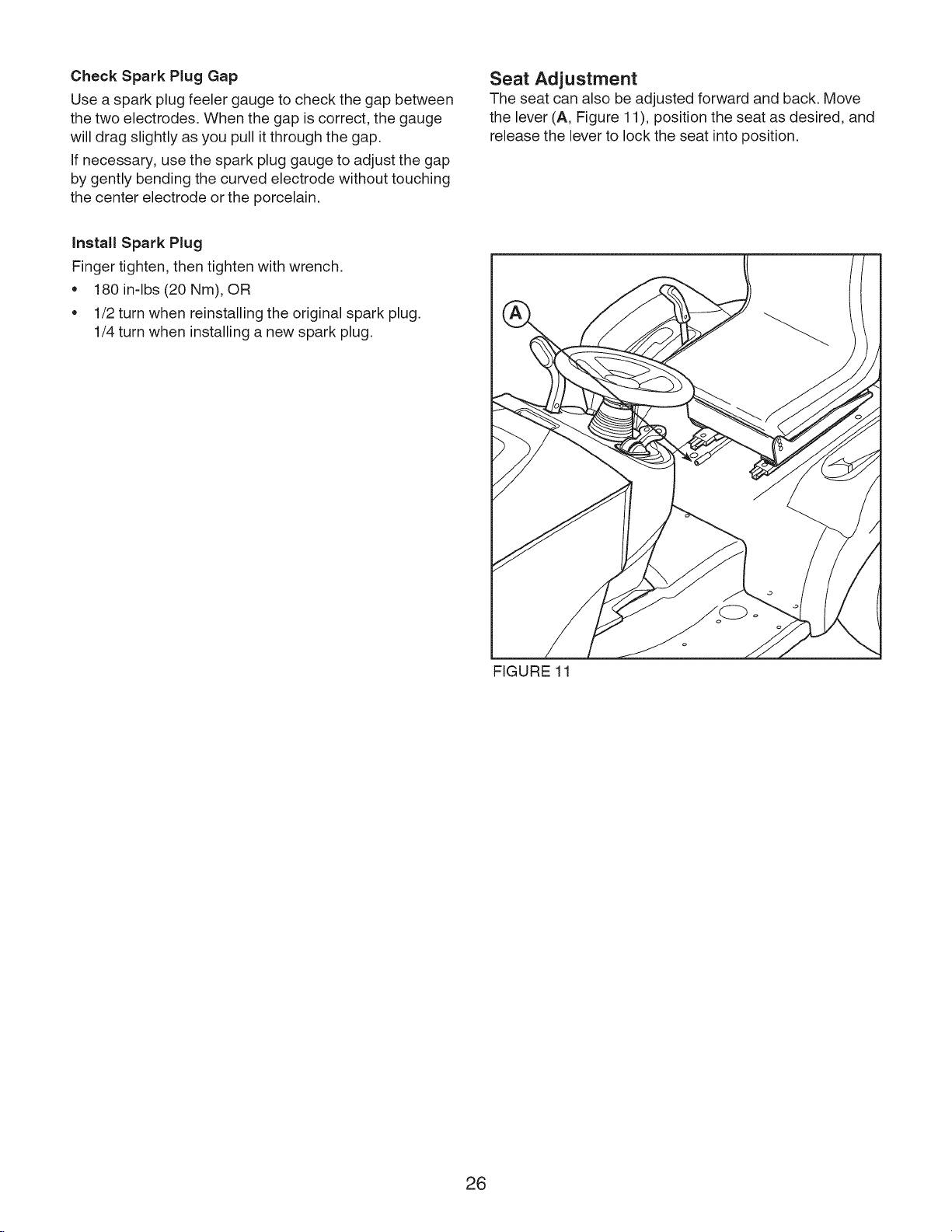

Seat Adjustment

The seat can also be adjusted forward and back. Move

the lever (A, Figure 11), position the seat as desired, and

release the lever to lock the seat into position.

FIGURE 11

26

Page 27

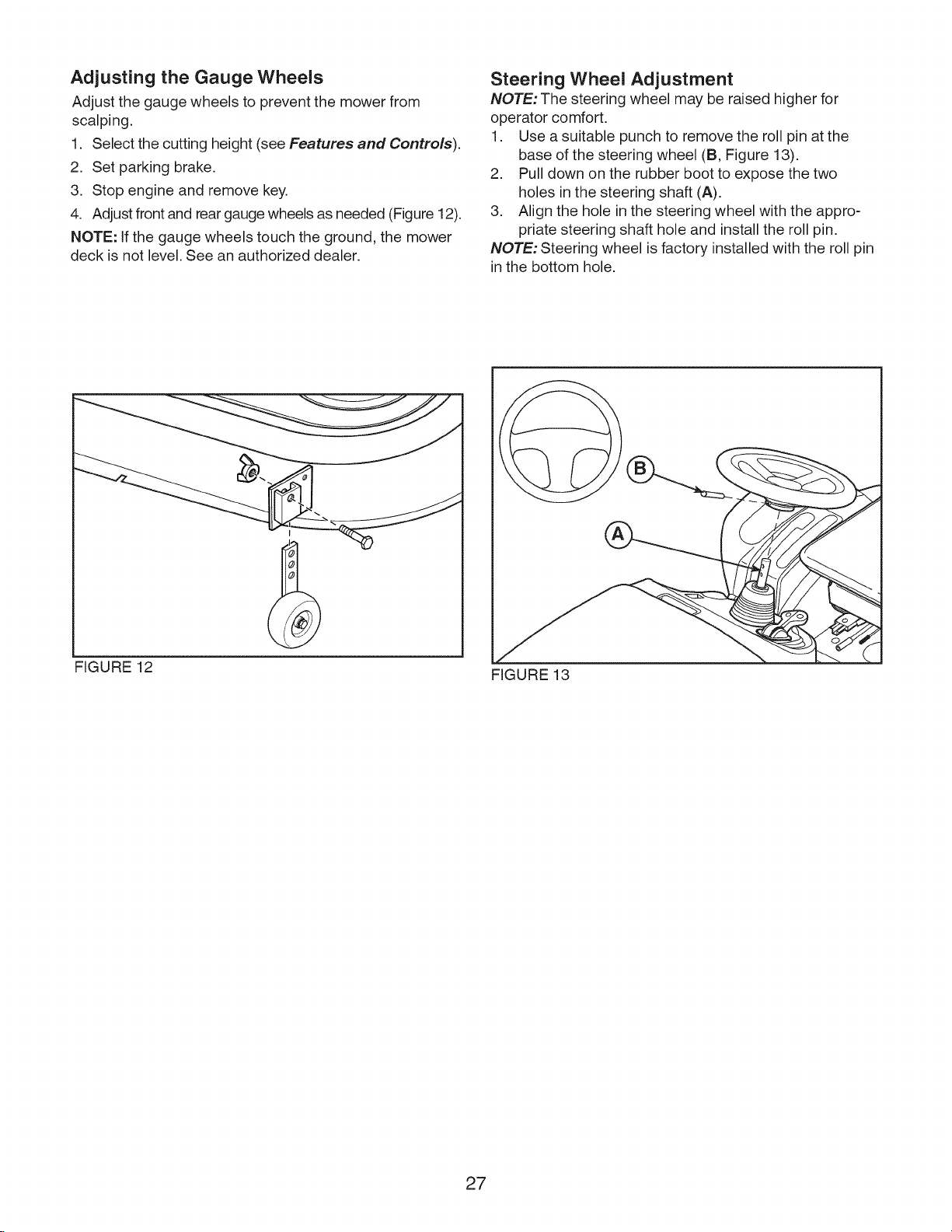

Adjusting the Gauge Wheels

Adjust the gauge wheels to prevent the mower from

scalping.

1. Select the cutting height (see Features and Controls).

2. Set parking brake.

3. Stop engine and remove key.

4. Adjust front and rear gauge wheels as needed (Figure 12).

NOTE: If the gauge wheels touch the ground, the mower

deck is not level. See an authorized dealer.

Steering Wheel Adjustment

NOTE: The steering wheel may be raised higher for

operator comfort.

1. Use a suitable punch to remove the roll pin at the

base of the steering wheel (B, Figure 13).

2. Pull down on the rubber boot to expose the two

holes in the steering shaft (A).

3. Align the hole in the steering wheel with the appro-

priate steering shaft hole and install the roll pin.

NOTE: Steering wheel is factory installed with the roll pin

in the bottom hole.

FIGURE 12

FIGURE 13

27

Page 28

WARNING

Never store the unit (with fuel) in an enclosed,

poorly ventilated structure. Fuel vapors can travel

to an ignition source (such as a furnace, water

heater, etc.) and cause an explosion. Fuel vapor is

also toxic to humans and animals.

When Storing Fuel Or Equipment With Fuel in Tank

oStore away from furnaces, stoves, water heaters or other

appliances that have pilot lights or other ignition sources

because they can ignite fuel vapors.

Equipment

Disengage the PTO, set the parking brake, and remove

the key.

Battery life will be increased if it is removed. Put in a cool,

dry place and fully charged about once a month, if the

battery is left in the unit, disconnect the negative cable.

Fuel System

Fuel can become stale when stored over 30 days. Stale

fuel causes acid and gum deposits to form in the fuel

system or on essential carburetor parts. To keep fuel

fresh, use Briggs & Stratton FRESH START@ fuel stabi-

lizer, available as a liquid additive or a drip concentrate

cartridge.

There is no need to drain gasoline from the engine if a

fuel stabilizer is added according to instructions. Run the

engine for 2 minutes to circulate the stabilizer throughout

the fuel system. The engine and fuel can then be stored

up to 24 months.

if gasoline in the engine has not been treated with a fuel

stabilizer, it must be drained into an approved container.

Run the engine until it stops from lack of fuel. The use of a

fuel stabilizer in the storage container is recommended to

maintain freshness.

28

Page 29

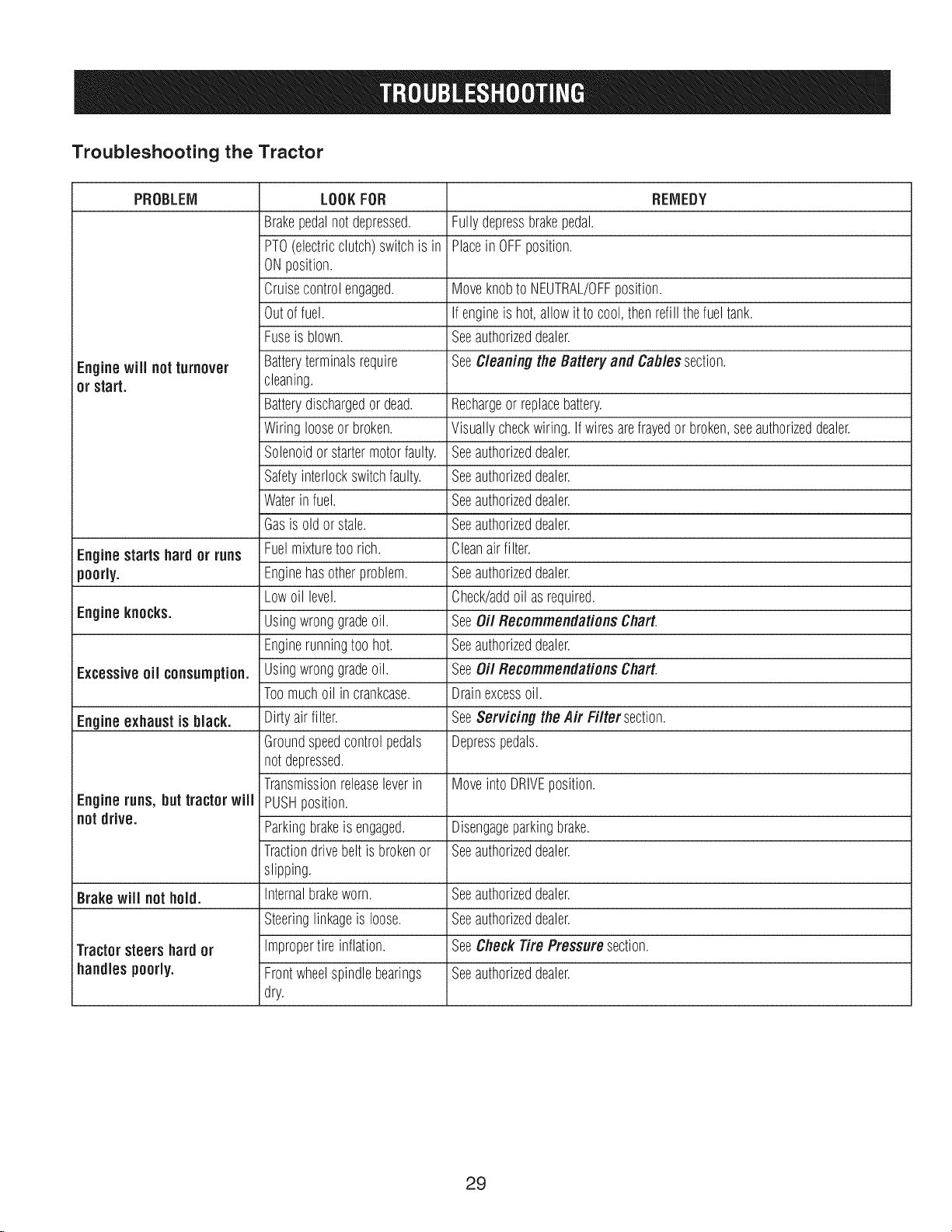

Troubleshooting the Tractor

PROBLEM LOOKFOR REMEDY

Brakepedalnotdepressed. Fullydepressbrakepedal.

PTO(electricclutch)switchisin PlaceinOFFposition.

ONposition.

Cruisecontrolengaged. Moveknobto NEUTRAL/OFFposition.

Outoffuel. If engineis hot,allowit tocool,thenrefill thefueltank.

Fuseis blown. Seeauthorizeddealer.

Enginewill not turnover Batteryterminalsrequire SeeCleaningthe Battery and Cablessection.

or start, cleaning.

Batterydischargedor dead. Rechargeor replacebattery.

Wiringlooseor broken. Visuallycheckwiring.Ifwiresarefrayedor broken,seeauthorizeddealer.

Solenoidor startermotorfaulty. Seeauthorizeddealer.

Safetyinterlockswitchfaulty. Seeauthorizeddealer.

Waterin fuel. Seeauthorizeddealer.

Gasisold orstale. Seeauthorizeddealer.

Enginestartshardor runs

poorly. Enginehasotherproblem. Seeauthorizeddealer.

Engineknocks.

Fuelmixturetoorich. Cleanairfilter.

Lowoil level. Check/addoil asrequired.

Usingwronggradeoil. SeeOil RecommendationsChart.

Enginerunningtoo hot. Seeauthorizeddealer.

Excessiveoil consumption. Usingwronggradeoil. See0il RecommendationsChart.

Toomuchoil in crankcase. Drainexcessoil.

Engineexhaustis black. Dirtyairfilter. SeeServicingtheAir Filter section.

Groundspeedcontrolpedals Depresspedals.

notdepressed.

Transmissionreleaseleverin MoveintoDRIVEposition.

Engine runs, but tractor will PUSHposition.

not drive. Parkingbrakeis engaged. Disengageparkingbrake.

Tractiondrivebeltisbrokenor Seeauthorizeddealer.

slipping.

Brake will not hold. Internalbrakeworn. Seeauthorizeddealer.

Steeringlinkageis loose. Seeauthorizeddealer.

Tractorsteershard or Impropertireinflation. SeeCheck Tire Pressuresection.

handlespoorly. Frontwheelspindlebearings Seeauthorizeddealer.

dry.

29

Page 30

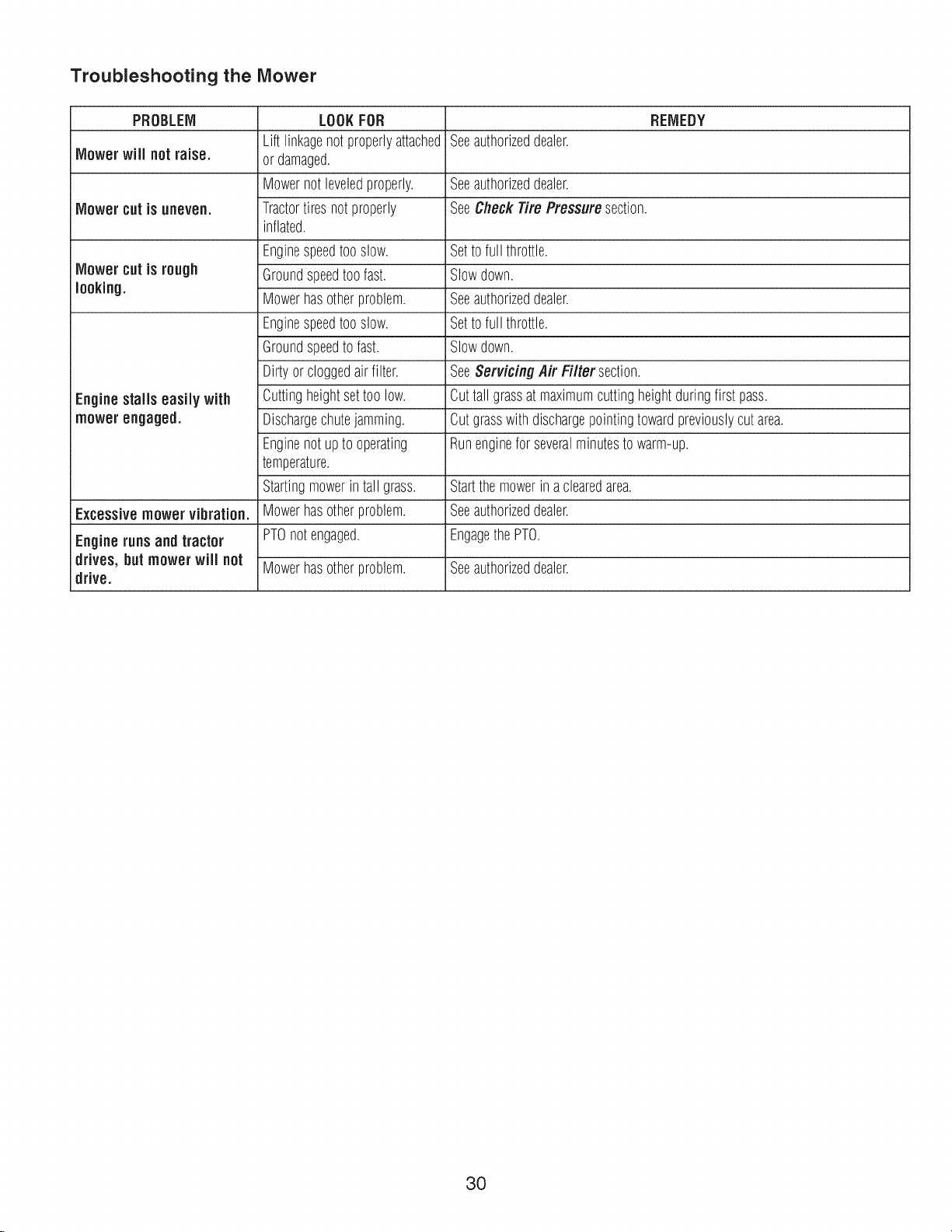

Troubleshooting the Mower

PROBLEM LOOKFOR REMEDY

Lift linkagenotproperlyattachedSeeauthorizeddealer.

Mower will not raise, ordamaged.

Mowernotleveledproperly. Seeauthorizeddealer.

Mower cut is uneven. Tractortiresnotproperly SeeCheck Tire Pressuresection.

inflated.

Enginespeedtooslow. Setto fullthrottle.

Mower cut is rough Groundspeedtoofast. Slowdown.

looking.

Enginestalls easily with Cuttingheightsettoolow. Cuttallgrassatmaximumcuttingheightduringfirstpass.

mower engaged. Dischargechutejamming. Cutgrasswithdischargepointingtowardpreviouslycutarea.

Excessivemowervibration. Mowerhasotherproblem. Seeauthorizeddealer.

Mowerhasotherproblem. Seeauthorizeddealer.

Enginespeedtooslow. Setto fullthrottle.

Groundspeedtofast. Slowdown.

Dirtyor cloggedairfiIter. SeeServicingAir Filter section.

Enginenotuptooperating Runengineforseveralminutestowarm-up.

temperature.

Startingmowerintallgrass. Startthemowerina clearedarea.

Engineruns and tractor PTOnotengaged. EngagethePTO.

drives, but mower will not Mowerhasotherproblem. Seeauthorizeddealer.

drive.

30

Page 31

Model # 107.289850

Overall Length 75"

Overall Width 54"

Deck Size (inches) 54"

Height of Cut (infinite) 1"to 4"

Transmission Type K71 - 2WD

Tire Pressure

Front 16x8.5-8 12-14 psi

Rear 24xl 0.5-12 10 psi

Turning Radius 18"

Engine Power (hp) 30

Engine Displacement (cc) 810 cc

Fuel Tank Capacity 4 gal.

Spark Plug Gap .030"

Weight 808 Ibs.

Engine Power Rating information: The gross power rating for individual gas engine models is labeled

in accordance with SAE (Society of Automotive Engineers) code J1940 (Small Engine Power & Torque

Rating Procedure), and rating performance has been obtained and corrected in accordance with SAE

J1995 (Revision 2002-05). Torque values are derived at 3060 RPM; horsepower values are derived at 3600

RPM. Actual gross engine power will be lower and is affected by, among other things, ambient operating

conditions and engine-to-engine variability. Given both the wide array of products on which engines are

placed and the variety of environmental issues applicable to operating the equipment, the gas engine

will not develop the rated gross power when used in a given piece of power equipment (actual "on-site"

or net power). This difference is due to a variety of factors including, but not limited to, accessories (air

cleaner, exhaust, charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating

conditions (temperature, humidity, altitude), and engine-to-engine variability. Due to manufacturing and

capacity limitations, Briggs & Stratton may substitute an engine of higher rated power for this Series engine.

31

Page 32