Page 1

Service Advisory

Edgers

MTD-003

Models Affected:

Serial Number Range:

Date:

Subject:

PURPOSE: MTD has become aware that the drive belt may experience premature wear and/or jumping off track under

some operating conditions. To address this issue a new Compression Spring, Drive Belt and Blade Adjustment Rod

have been incorporated into production as of May 1, 2003. Production units manufactured prior to May 1, 2003 may

have been reworked while in MTD warehouses. To tell if a unit has the new production hardware check the Compression Spring and Drive Belt. The new Compression Spring is gold in color and the new Drive Belt has orange paint over

the part number area.

NOTE: These materials are prepared for use by trained technicians who are experienced in the service and repair of

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced

individuals. Such individuals should seek the assistance of an authorized service technician or dealer.

NOTE: Save this Instruction Sheet. Refer to it when ordering replacement parts.

REF.

NO.

1 754-04032 1 “V” Belt, Polyester Tensile Cord (Color Code = Orange)

2 732-04169 1 Compression Spring (Gold color)

3 747-04110 1 Blade Adjustment Rod

2003 Model Year Vertical Crankshaft Engine Edgers

Models 25A-521; -550; -551; -553 and -556

November 18, 2002 (Date Code =...K182...) through

April 30th, 2003 (Date code =...D303...)

October 3, 2003

Drive Belt Wear

PART

NUMBER

QTY DESCRIPTION

Preparation for Disassembly: Refer to the Owner’s Manual for part terminology and controls location

1. Allow engine and muffler to cool before working on the unit.

2. Remove spark plug wire from spark plug and ground wire to engine block.

3. If there is fuel in the fuel tank, drain or remove the fuel cap and place a thin sheet of plastic over the opening and

replace and tighten the fuel cap.

4. Ensure that the oil plug is tight.

5. Rotate the edger blade so that both ends are within the Blade Guard. See Figure 1.

6. If so equipped - Set the Bevel Adjustment Lever to the left. Left and right are viewed from the operator’s position.

7. Set the Blade Depth Control Lever to the STARTING POSITION (H).

8. Proceed to the Disassembly Instructions on Page 2.

.

* Each unit is identified with a unique 11 digit serial number. The 2

month, day and year of production (date code). The rest of the digits should be ignored for

purposes of determining if your unit is affected. For example, in Ser. No. 3B063Z80001, the date

code is “B063”. B= February, 06= the 6

code. C= March, 21= the 21st day of the month and 3= 2003.

Warranty: Normal warranty terms apply. Indicate Service Advisory MTD-003 and 754-0465 and 732-0187 as the original failed part(s) on the claim. Repair time allowance is

SERVICE MANAGER PARTS MANAGER SALES MANAGER SERVICE TECH. SERVICE TECH.

th

day of the month and 3= 2003. In Ser. No. 3C213Z80999, “C213” is the date

Circulate and Initial

nd

through 5th digits identify the

Page 2

Disassembly Instructions:

r

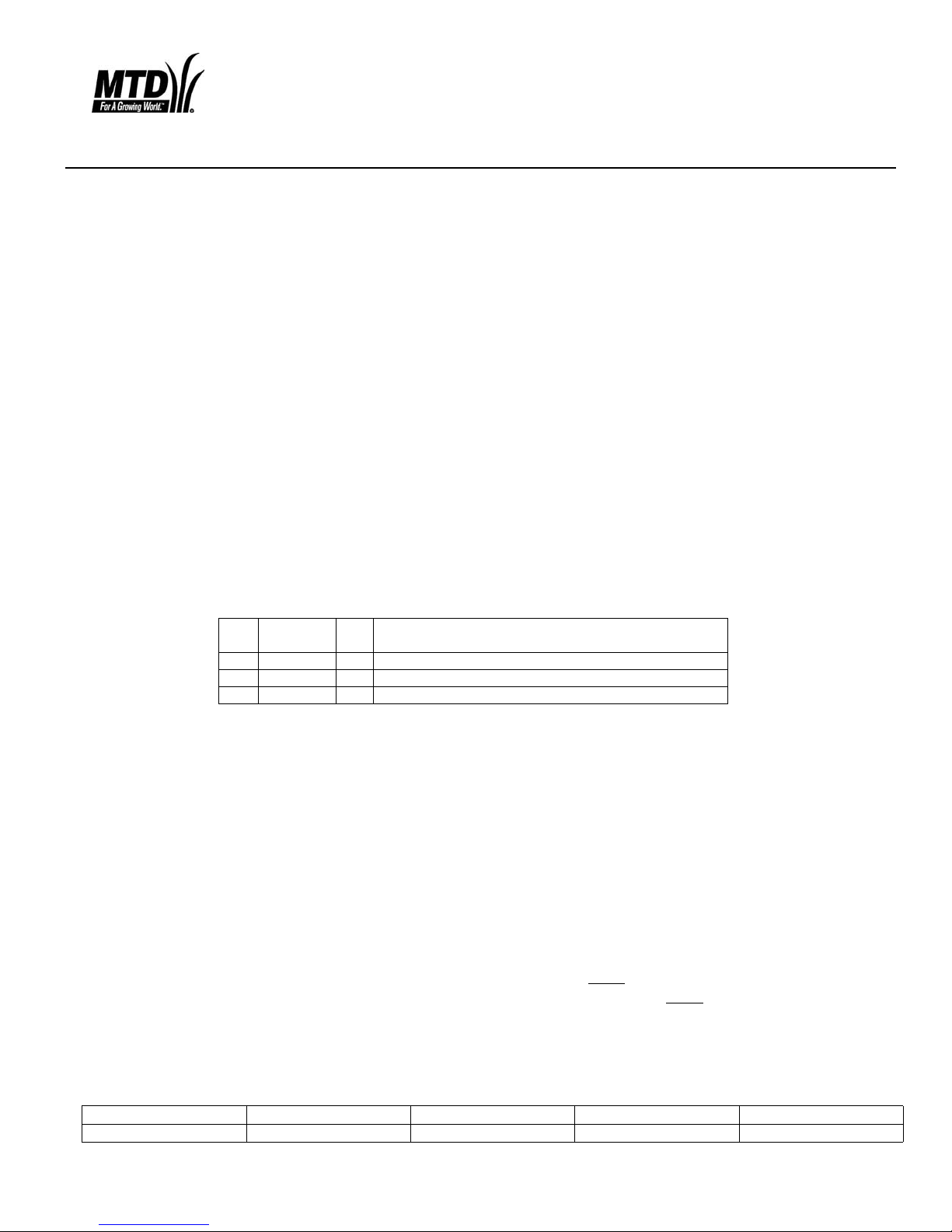

9. Remove and retain the Spindle Belt Guard and rubber

Debris Guard and their hardware. See Figure 1.

Spindle

Assembly

Blade within

Blade Guard

Spindle

Pulley

Debris

Spindle

Guard

Belt Guard

FIGURE 1

10. While an assistant holds down the Blade Control Bail

and slowly pulls the starter cord to rotate the spindle,

carefully work the belt off of the spindle pulley.

11. Rotate the blade so that both ends are within the

blade guard.

12. With a 9/16” box wrench and 9/16” socket and ratchet

remove and retain the two Pulleys and Pulley Mount

Spacer from the frame. Retain the washer and nut. See

Figure 2.

NOTE: There are several different pulley configurations

used during production.The photo represents only one of

these configurations.

Pulley Mount

Spacer

Taller shoulders

of the pulleys

must face towards

Pulley Mount Space

FIGURE 3

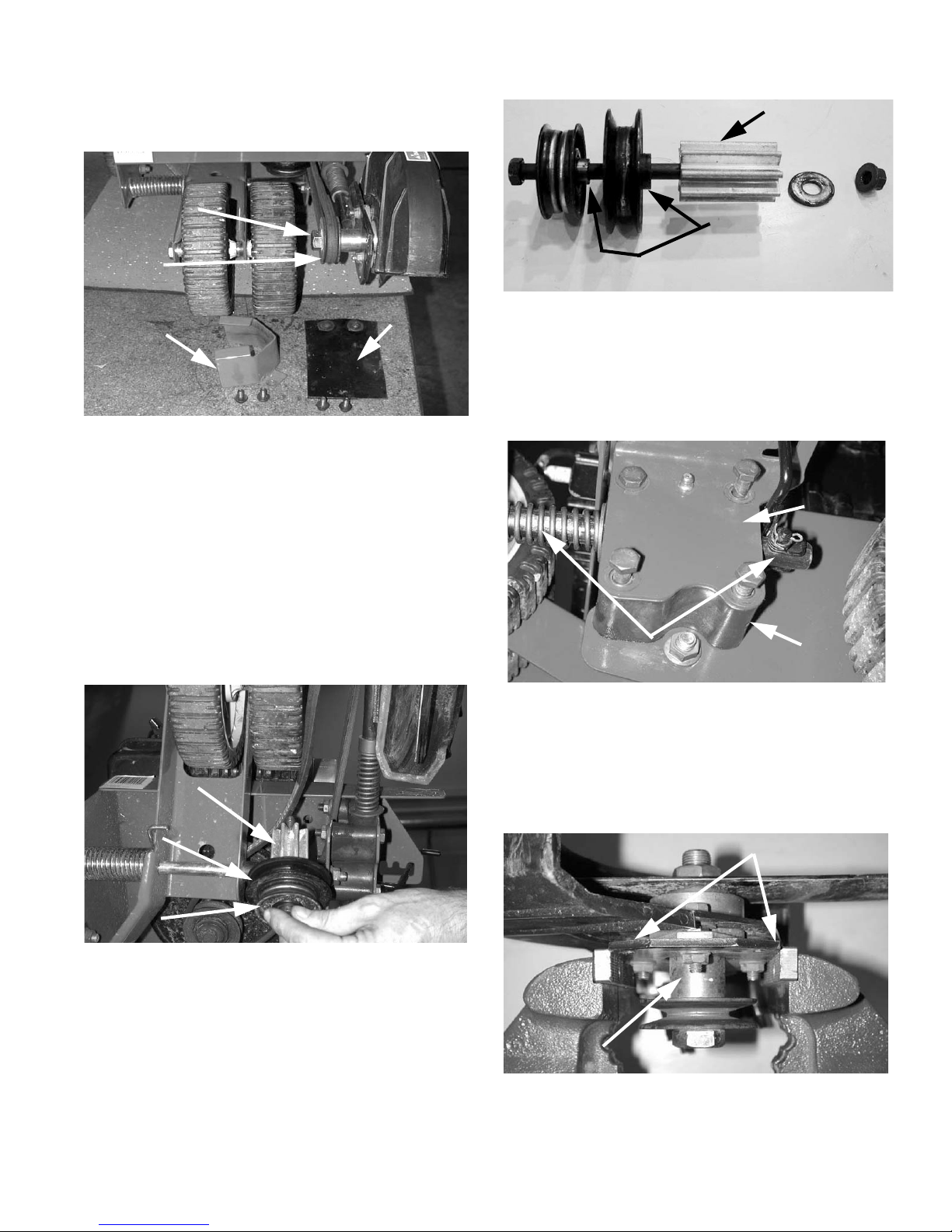

15. With a 1/2” box wrench and 1/2” socket and ratchet

remove and save the four (4) nuts and lock washers from

the bolts that hold the plastic Bearing Block/Spindle

Assembly to the frame. See Figure 4. Do not remove

bolts from Bearing Block and Spindle Assembly at

this time.

Index

Bracket

Blade Plate Assembly Rod

f the Spindle

Assembly

Bearing

Block

Pulley Mount

Spacer

“V” Idler

Spindle

Pulley

Belt

Debris

Guard

Guard

Flat Idler

Pulley

FIGURE 2

13. Remove and discard the original belt.

14. Refer to Figure 3. Remove the Pulley Mount Spacer

and both pulleys from the mounting bolt. Reassemble the

two pulleys and spacer as shown in Figure 3. Note the

position of the pulleys’ taller shoulders. Set the dual pulley stack assembly aside. It will be re-installed later.

FIGURE 4

16. Carefully remove the Bearing Block/Spindle Assembly

from the edger frame keeping the Bearing Block, Index

Bracket and the 4 bolts together.

17. Set the Bearing Block/Spindle Assembly in a vise as

shown in Figure 5. Note that the vise jaws are grabbing

the edge of the Blade Plate Assembly.

Blade Plate Assembly

Spindle

Assembly

FIGURE 5

18. Keeping the Bearing Block in position on the Blade

Plate Assembly Rod and releasing the tension on the

2

Page 3

Index Bracket from the Blade Adjustment Rod remove

the 4 bolts and Index Bracket. See Figure 6.

Blade Adjustment Rod

Blade Plate

Assembly Rod

Bearing

Block

FIGURE 6

19. Carefully remove the Bearing Block from the Blade

Plate Assembly Rod. CAUTION! The Bearing Block is

held in position by the Compression and Double Torsion

Springs.

20. Refer to Figure 7. Remove the cotter pin retaining the

Blade Adjustment Rod. Remove the Double Torsion

Spring from the Blade Plate Assembly Rod and Blade

Adjustment Rod. Discard the Blade Adjustment Rod.

NOTE: Observe how the Double Torsion Spring and

Blade Adjustment Rod interlock. You will need to

reassemble in the same manner later.

24. Re-install the flat washer onto the Blade Plate

Assembly Rod.

25. With the new Blade Adjustment Rod (Item 3) reassemble the Double Torsion Spring and new Blade

Adjustment Rod onto the Blade Plate Assembly Rod.

See Figure 8 for Double Torsion Spring orientation.

Blade Adjustment Rod

shown not fully through

Double Torsion Spring

for clarity

FIGURE 8

26. Re-install the cotter pin in the end of the Blade Control Rod.

27. Position the Bearing Block onto the Blade Plate

Assembly Rod as shown in Figure 9.

21. Remove the flat washer and gray colored Compression Spring from the Blade Plate Assembly Rod. Do not

remove the silver spacer from the rod. Discard the gray

colored Compression Spring.

Blade

Cotter Pin Removed

Adjustment

Rod

Washer

Double

Compression

Spring

Torsi on

Spring

FIGURE 7

22. This completes the disassembly of the edger.

Reassembly of Edger with New Parts:

23. Refer to Figure 7. Install the new Compression

Spring (gold colored) (Item 2) onto the Blade Plate

Assembly Rod.

FIGURE 9

28. Re-install the Index Bracket onto the Bearing Block

ensuring that the Blade Adjustment Rod is within the

Index Bracket cutout. Re-install the 4 bolts through the

Index Bracket and Bearing Block. See Figure 10.

3

Page 4

Smaller

Bottom

Pulley

FIGURE 10

29. Remove Bearing Block/Spindle Assembly from vise.

With a 1/2” box wrench and 1/2” socket and ratchet reinstall the Bearing Block/Spindle Assembly onto the

edger frame with the four (4) nuts and lock washers previously removed in Step 15. Tighten nuts securely.

30. Position the edger so that you can install the new “V”

Belt (Item 1) and reconfigured Pulley/Spacer Stack from

Step 14.

31. Install the new “V” Belt (Color Code- Orange) (Item 1)

by first installing the belt around the blade spindle pulley.

32. Keep the belt next to the Bearing Block as shown in

Figure 11.

Blade

Spindle

Pulley

FIGURE 12

36. The upper leg of the belt coming from the blade spindle pulley goes to the larger top idler pulley with the V of

the belt against the upper idler pulley. This also results in

a quarter turn twist in the belt between the spindle pulley

and the larger top idler pulley.

37. Keeping the belt correctly oriented against the top

and bottom idler pulleys dress the belt around the engine

pulley. To facilitate this final step of the belt installation

use a 9/16” open end wrench to rotate the engine pulley

as you work the belt around and on.

38. The belt leg coming off the larger top idler pulley goes

to the rear side of the engine pulley. See Figure 13.

NOTE: There should be no twist in either leg of the belt

between the engine pulley and idler pulleys.

Bearing Block

FIGURE 11

33. With a 9/16” box wrench and 9/16” socket and ratchet

re-install the the re-configured dual idler pulley stack from

Step 14. Ensure that both legs of the belt run along next

to the Bearing Block.

34. It is critical that the flat back of the belt goes against

the smaller bottom idler pulley and the V of the belt goes

against the larger top idler pulley.

35. The bottom leg of the belt coming from the bottom of

the blade spindle pulley goes to the smaller bottom pulley

with the back of the belt against the idler pulley. This will

result in a quarter turn twist in the belt between the spindle pulley and the smaller bottom idler pulley. See Figure

12.

Coming

off top

idler

pulley

Rear of Edger

FIGURE 13

39. Re-install the Debris Guard and Spindle Belt Guard

removed in Step 9. Securely tighten all hardware.

40. Remove the plastic sheet from under the fuel cap.

41. Pull the engine through with the starter cord the blade

should rotate in counterclockwise direction when looking

at the blade through the open (left) side of the blade

guard.

41. This completes the upgrade and reassembly of the

edger.

4

Loading...

Loading...