Page 1

H 07

FORM NO. 769-02993A

jqa=mкзЗмЕнл=^внбЙеЦЙлЙддлЕЬ~Сн=√=p~~êÄêΩÅâÉå=√=dÉêã~åó

Page 2

Page 3

1 3

14

1

2

3

4

5

13

HOURS 1/10

FUEL

FE

RPM

40

x1000

12

11

10

6

4

9

8

7

5

2

21

15

16

17

28

26

18

27

19

20

21

22

6

22

25

7

b

a

23

8

24

(b)

(c)

(a)

9

(b)

(a)

Page 4

10

A

B

C

G

D

H

11

H

N

L

K

J

12

14b

5.

E

3.

2.

4.

1.

3

F

13

15

(a)

(b)

14a

1

2

a

19

16

17

b

18

a

b

b

MAX

a

MIN

b

a

Page 5

20

c

21

22

23

b

a

9

7

17

b

a

b

5

11

a

2

10

5

1

23

19

b

20 21

18

4

3

14

18

16

24

5

22

12

16

14

6

9

8

15

16

6

13

16

25

a

c

d

b

Page 6

English

4

Français

Deutsch

Nederlands

Svenska

Dansk

Español

23

45

65

85

103

122

Page 7

English User manual

Table of Contents

For your safety . . . . . . . . . . . . . . 4

Assembling the appliance . . . . . . 6

Controls and indicators . . . . . . . . 7

Operating safety . . . . . . . . . . . . 10

Cleaning / Servicing . . . . . . . . . 15

Shutting down the machine . . . 21

Guarantee . . . . . . . . . . . . . . . . . 21

Information about the engine . . . 21

Troubleshooting . . . . . . . . . . . . 21

Information on the

identification plate

This information is very important for

subsequent identification, ordering

spare parts for the appliance and for

the customer service desk.

Enter all information from the

nameplate of your tractor into the

following box.

You will find this and further

information about the appliance

in the separate CE-declaration

of conformity which is a component

part of these operating instructions.

For your safety

Using the unit appropriately

This appliance is designated for use:

– as a tractor for grass areas, park

maintenance as well as for use in

the winter

– in accordance with the descrip-

tions and safety information contained in these operating

instructions.

Furthermore, the appliance can be

operated using the acessories and

attachments authorised by the

manufacturer.

;

This unit is not intended for

purposes beyond those listed

above. The user is liable for all

damage to third parties and their

property.

As standard, in its standard

configuration, this vehicle is not

approved for operation on public

roads or for transporting people.

Only operate the appliance in the

technical condition stipulated and

supplied by the manufacturer.

The manufacturer accepts no

responsibility for damages resulting

from unauthorised alterations to the

unit that have been carried out by

the owner or operator.

General safety notes

Carefully read these operating

instructions through before first

using the appliance and proceed

accordingly.

Tell other users about the correct

use of the vehicle.

Only operate the appliance in the

technical condition stipulated and

supplied by the manufacturer.

Keep these Operating Instructions in

a safe place and have them at the

ready whenever you use the unit.

With a change of ownership, pass

the operating instructions on with

the appliance.

Spare parts must correspond to the

requirements laid down by the

manufacturer. Therefore, only use

original spare parts or spare parts

approved by the manufacturer.

Only use manufacturer approved

attachments and acessory parts.

Only allow repair work to be carried

out from a specialist garage.

Before working with the

appliance

Persons allowed to use the

appliance must not be under the

influence of intoxicating substances

(e.g. alcohol, drugs or medicine).

Persons under 16 years of age may

not operate the appliance.

Local regulations may fix the

minimum age.

Before commencing work with the

appliance, familiarise yourself with all

of the equipment and control

elements as well as with their

function.

When working with the appliance

near to public roads and when

crossing the street, take care of

traffic.

Store fuel in appropriate containers

only, and never in the vicinity of heat

sources (e.g. ovens or hot-water

cylinders).

Do not undertake structural

modifications to the appliance and/

or settings to the engine.

Replace the exhaust, fuel tank or

fuel cap immediately if they become

damaged.

Attach trailers and accessory

equipment in accordance with the

guidelines. Driving performance,

especially steering, braking

capability, and overall stability are

affected by attachments, towed

items, ballast weights and the

weight of a grass catcher when full.

Whilst working with the

appliance

wear appropriate clothing

(e.g. safety shoes, long trousers,

close-fitting clothes, protective

goggles).

Only operate the appliance in a

technically flawless state.

Always put the seat belt on, except

when the rollbar is folded down.

When driving using the vehicle, no

objects may jut out beyond the

external contours.

Never refuel the unit while the engine

is running or hot. Only fill the tank in

the open air.

Avoid naked flames, the formation of

sparks and do not smoke.

Ensure that no persons, especially

children, or animals are in the area of

operation.

The engine must not be operated

when cleaning, servicing, adjusting,

repairing, and when attaching

accessories.

4

Page 8

User manual English

Check the area in which you intend

to use the unit and remove all

objects that could be hit and

propelled by the unit. You can thus

avoid injuries and damage to the

unit.

Never use the appliance on slopes

that are steeper than 20 %. Working

on slopes is dangerous; the risk of

rollover and sliding is increased.

When working on slopes, always

drive off and halt the unit gently and

gradually. The transmission should

always be engaged when driving

down a slope – never coast – and

drive at a low speed. Never drive

across the face of a slope, always

up and down the slope.

Only use the unit in daylight or with

a sufficient level of artificial lighting.

The unit is not authorised for the

transport of people. Never allow

passengers on the unit.

If you come across a foreign object,

bring the vehicle to a halt and turn

the engine off. Check the vehicle for

possible damage and, where there

is damage; redress it at a specialist

garage.

Do not touch the exhaust or the

sound absorber as long as the

engine is running or shortly before

turning the engine off. You could

burn yourself.

Carry out a thorough safety check

before using the vehicle. Keep to the

instructions for controlling and

servicing the vehicle according to

the explanations found in these

operating instructions.

The engine cooling system is

subjected to pressure. Never open

the cooler stopper lid!

Escaping hydraulic fluids can cause

severe injuries. Never attempt to feel

leaks with your hand!

Before any work on the

appliance

Protect yourself from injury.

Before all work on this unit

– turn the engine off,

– remove the ignition key,

– lock the parking brake,

– wait until all moving parts have

come to rest and the engine has

fully cooled.

After working with the

appliance

Only leave the appliance once you

have turned off the engine, actuated

the parking brake and have removed

the ignition key.

Safety features

Safety features serve to protect you

and must always be functional.

You may not make any alterations to

the safety features or circumvent

their proper functioning.

Safety features are:

Rollbar and seat belts

The vehicle is equipped with a rollbar

and seat belts (lap seatbelt).

Together, they represent optimal

protection for the driver and pillion

passenger.

=t~кебеЦ

Ó ^äï~óë=éìí=íÜÉ=ëÉ~í=ÄÉäí=çå=ïÜÉå=

нЬЙ=кзддД~к=бл=СздЗЙЗ=мйп~кЗлK

У kЙоЙк=млЙ=нЬЙ=~ййдб~еЕЙ=пбнЬзмн=

нЬЙ=кзддД~кK=

Ó kÉîÉê=ìëÉ=íÜÉ=~ééäá~åÅÉ=ïáíÜ=íÜÉ=

кзддД~к=СздЗЙЗ=ЗзпеK

У tЬЙе=зйЙк~нбеЦ=бе=СбЙдЗл=зС=Екзйл=

пЬбЕЬ=~кЙ=йд~енЙЗ=бе=~=кзпI=СздЗ=

Ззпе=нЬЙ=кзддД~к=~н=узмк=зпе=кблв>

Ó kÉîÉê=éìí=íÜÉ=ëÉ~í=ÄÉäí=çå=ïÜÉå=

нЬЙ=кзддД~к=бл=СздЗЙЗ=ЗзпеK

Ó få=íÜÉ=Å~ëÉ=çÑ=Ç~ã~ÖÉ=çê=~å=

~ЕЕбЗЙенI=ЦЙн=нЬЙ=кзддД~к=~еЗ=

лЙ~нДЙдн=ЕЬЙЕвЙЗ=бе=~=лйЙЕб~дблн=

Ц~к~ЦЙ=~еЗ=пЬЙкЙ=еЙЕЙлл~куI=

ЙсЕЬ~еЦЙ=нЬЙгK=aз=езн=меЗЙкн~вЙ=

~еу=кЙй~бкл=узмклЙдСK

Safety lock system

With the safety lock feature, the

engine can only be started if

– he driver is sitting on the driver

seat,

– the brake pedal is fully depressed,

and/or the parking brake is

engaged,

– the engage switch (PTO)

is switched off.

The safety lock feature switches off

the engine automatically as soon as

the driver leaves the driver seat

without engaging the parking brake

and/or without having switched off

the engage switch (PTO).

The safety interlock system

automatically switches the clutch

switch off (PTO) as soon as the

reverse pedal is depressed

(provided the PTO switch has not

been activated for travel in reverse

gear). To turn on the engage switch

(PTO) again, you must first switch

it off and then switch it on again.

Symbols on the appliance

Various symbols are stuck to the

appliance in the form of adhesive

labels. The following provides an

explanation of the symbols.

Warning!

Read the operating

!

instructions before

starting up.

Keep third parties

away from the danger

area!

Risk of injury from

propelled grass or

solid objects that are

propelled.

There must be no

persons, especially

children, or animals in

the area of operation.

5

Page 9

English User manual

Risk of injury from

rotating blades and

other rotating parts.

Working on steep

slopes increases

danger.

Never fold down the

rollbar on a slope.

Never put the seat belt

on when the rollbar is

folded down.

Always put the seat

belt on when the

rollbar is folded

upwards.

Never operate the

appliance without the

mounted tractive unit

protection.

Warning!

Risk of explosion.

Battery acid/

Risk of injury.

Withdraw the key from

the ignition before all

work on the unit and

observe the

instructions in this

document.

Risk of injury through

rotating engine fan!

Keep these symbols visible on the

appliance.

Symbols used in these

instructions

The following symbols are used in

these instructions:

t~кебеЦ

vзмк=~ н нЙенбзе =бл =Зк ~пе=нз=З ~ еЦЙкл=бе =

ЕзееЙЕнбзе=пбнЬ=нЬЙ=~Енбзе=

ЗЙлЕкбДЙЗ=~еЗ=нЬкзмЦЬ=пЬбЕЬ=нЬЙкЙ=

бл=~=З~еЦЙк=нз=йЙклзелK

t~кебеЦ

vзмк=~ н нЙенбзе =бл =Зк ~пе=нз=З ~ еЦЙкл=бе =

ЕзееЙЕнбзе=пбнЬ=нЬЙ=~Енбзе=

ЗЙлЕкбДЙЗ=пЬбЕЬ=ЕзмдЗ=беоздоЙ=

г~нЙкб~д=З~г~ЦЙK

Note

Points out important information and

tips concerning application.

Details concerning position

Where a position on, or in relation to,

the unit is described (e.g. left, right),

this is always from the perspective of

the driver, sitting on the driver seat

and facing forward.

Note

Graphical representations can vary

in detail from the appliance which

has been bought.

Note concerning the disposal

of packaging

Any waste packaging or waste

appliances etc. which accumulate

should be disposed of according to

the local regulations.

Assembling the

appliance

Commissioning the battery

!

t~кебеЦ

oблв=зС=йзблзебеЦ=~еЗ=беамку=Скзг=

Д~ннЙку=~ЕбЗ

tЙ~к=йкзнЙЕнбоЙ=ЦзЦЦдЙл=~еЗ=ЦдзоЙлK=

aз=езн=~ддзп=Д~ннЙку=~ЕбЗ=нз=ЕзгЙ=

бенз=Езен~Ен=пбнЬ=нЬЙ=лвбеK=pЬзмдЗ=

Д~ннЙку=~ЕбЗ=лйд~лЬ=бенз=узмк=С~ЕЙ=зк=

ЙуЙлI=п~лЬ=бггЙЗб~нЙду=пбнЬ=ЕздЗ=

п~нЙк=~еЗ=Езелмдн=~=ЗзЕнзкK=pЬзмдЗ=

узм=бе~ЗоЙкнЙенду=лп~ддзп=Д~ннЙку=

~ЕбЗI=Зкбев=йдЙену=зС=п~нЙк=~еЗ=

Езелмдн=~=ЗзЕнзк=бггЙЗб~нЙдуK=pнзкЙ=

Д~ннЙкбЙл=бе=~=л~СЙ=йд~ЕЙ=змн=зС=нЬЙ=

кЙ~ЕЬ=ЕЬбдЗкЙеK=

kЙоЙк=нбдн=нЬЙ=Д~ннЙкуX=нЬЙ=Д~ннЙку=

~ЕбЗ=г~у=кме=змнK=_кбеЦ=нЬЙ=

кЙг~бебеЦI=мемлЙЗ=Д~ннЙку=~ЕбЗ=нз=

узмк=ЗЙ~дЙк=зк=нз=~=п~лнЙ=Зблйзл~д=

Езгй~еуK

t~кебеЦ

oблв=зС=СбкЙI=Йсйдзлбзе=~еЗ=

Езккзлбзе=ЗмЙ=нз=Д~ннЙку=~ЕбЗ=~еЗ=

Д~ннЙку=~ЕбЗ=Ц~лЙлK

fггЙЗб~нЙду=ЕдЙ~е=й~кнл=зС=нЬЙ=

~ййдб~еЕЙ=мйзе=пЬбЕЬ=Д~ннЙку=~ЕбЗ=

Ь~л=ДЙЙе=лйк~уЙЗK=_~ннЙку=Ь~л=

~ ЕзккзлбоЙ=ЙССЙЕнK

aз=езн=лгзвЙ=~еЗ=вЙЙй=ДмкебеЦ =~ е З=

Ьзн=зДаЙЕнл=~п~уK=

pнзкЙ=Д~ннЙкбЙл=бе=кззгл=пЬбЕЬ=~кЙ=

пЙдд=оЙенбд~нЙЗ=~еЗ=ЗкуK=qЬЙкЙ=бл=~=

кблв=зС=~=йзллбДдЙ=лЬзкн=ЕбкЕмбн=пЬЙе=

пзквбеЦ=пбнЬ=нЬЙ=Д~ннЙкуK=aз=езн=

йд~ЕЙ=~еу=нзздл=зк=гЙн~д=зДаЙЕнл=зе=

нЬЙ=Д~ннЙкуK

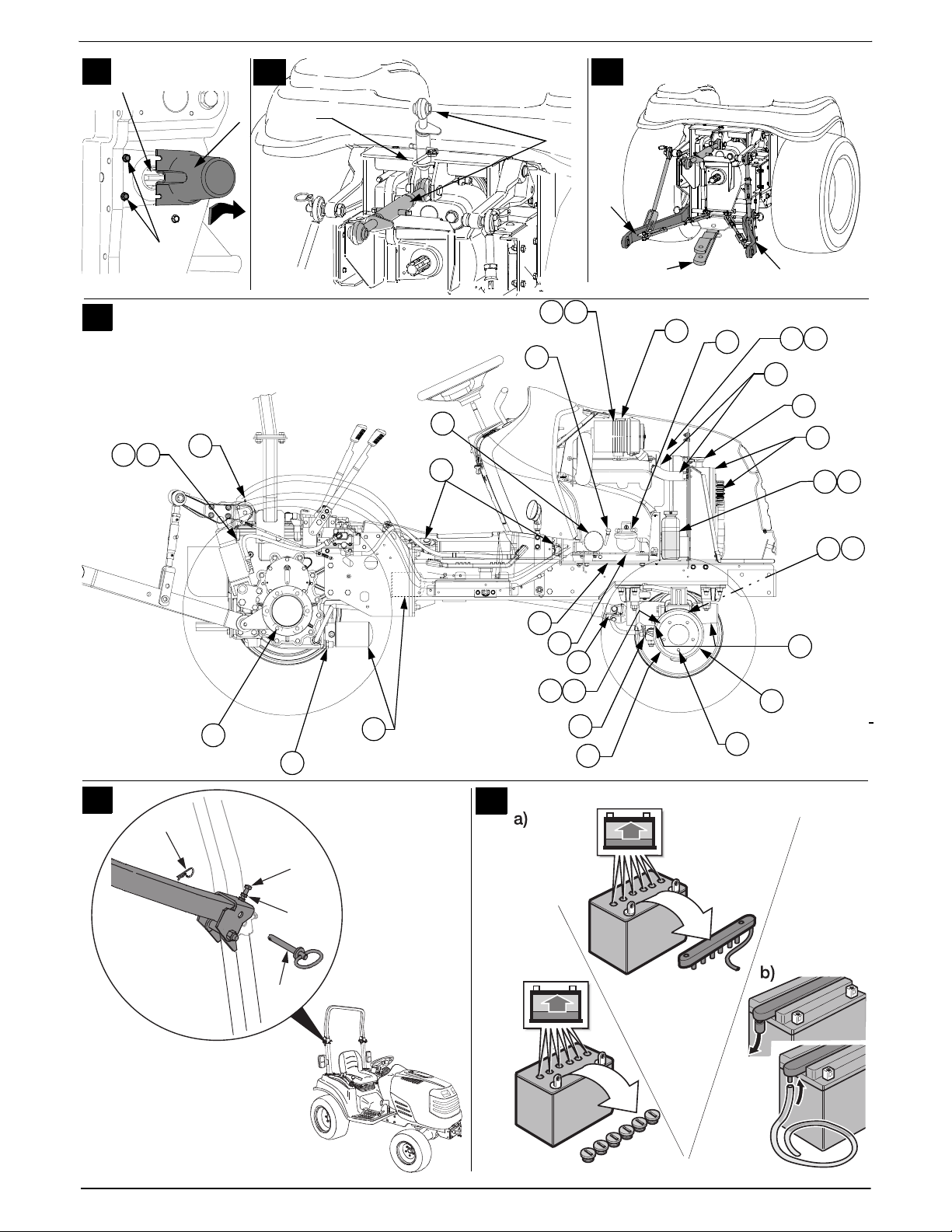

Note

The battery is located under the

bonnet of the engine (see section

“Cleaning and Servicing”).

If a “maintenance-free/

sealed” battery (type 1)

is supplied

(Battery without filler plugs)

The battery is filled with battery acid

and is sealed at the factory.

However, even a “maintenance-

6

Page 10

User manual English

free” battery requires maintenance

if it is to have a longer service life.

Keep the battery clean

Avoid tipping the battery.

Electrolyte fluid leaks from a

‘sealed’ battery, if it is tipped.

If an empty battery (type 2)

is supplied

(Battery with filler plugs)

Fig. 25

Remove the filler plugs of the

battery cells.

Fill each cell slowly with battery

acid up to 1 cm below the filling

opening.

Leave the battery to stand for

30 minutes so that the lead can

soak up the battery acid.

Check the level of the battery

acid, add more if necessary.

Before using the battery for the

first time, charge it using a battery

charger (max. charging current

12 Volt / 6 Ampere) for 2 to 6

hours. After charging the battery,

first unplug the charger and then

disconnect the battery (see also

the operating instructions for the

battery charger).

Re-insert the filler plugs of the

battery cells.

Install the battery in the unit.

Remove the strip seal from the

battery vent. Connect the venting

hose so that the free end points

downwards in the appliance.

The hose must always allow free

passage! (Fig. 25b)

First connect the red cable (+),

and then the black cable (–).

Thereafter, use only distilled water

to top up the battery (check every

2 months).

Keep the battery clean

=t~кебеЦ

lДлЙкоЙ=нЬЙ=зкЗЙк=бе=пЬбЕЬ=нЬЙ=

Д~ннЙку=бл=гзменЙЗ=пЬЙе=

ЕзееЙЕнбеЦLЗблЕзееЙЕнбеЦ=нЬЙ=

нЙкгбе~длK

Fitting:

First connect the red cable

(+ /positive pole) and then the

black cable (– / negative pole).

Removal:

First disconnect the black cable

(– / negative pole) and then the

red cable (+ / positive pole).

Servicing the battery

(type 1/2)

Before leaving the unit idle for a

longer period, it is advisable to

remove the battery and charge it.

The battery should be charged every

2 months during the idle period (off

season), and also before recommissioning the unit at start of

season (consult a specialist garage

for further information).

Setting the rollbars upright

Fig. 24

The rollbar is folded down for

transportation.

Remove the linch pins (a) from the

securing pins (b).

Take out the securing pins and

set the rollbar upright.

Place the securing pins through

the drilled holes and secure them

with the linch pins.

Tighten the screw (c) and secure

the screw with the nut (d).

Controls and indicators

t~кебеЦK=a~г~ЦЙ=нз=нЬЙ=

~ééäá~åÅÉK

qЬЙ=Езенкзд=~еЗ=беЗбЕ~нзк=СмеЕнбзел=

пбдд=ДЙ=ЗЙлЕкбДЙЗ=нз=ДЙЦбе=пбнЬK=

aз езн=йЙкСзкг=~еу=СмеЕнбзел=~н=нЬбл=

лн~ЦЙ>

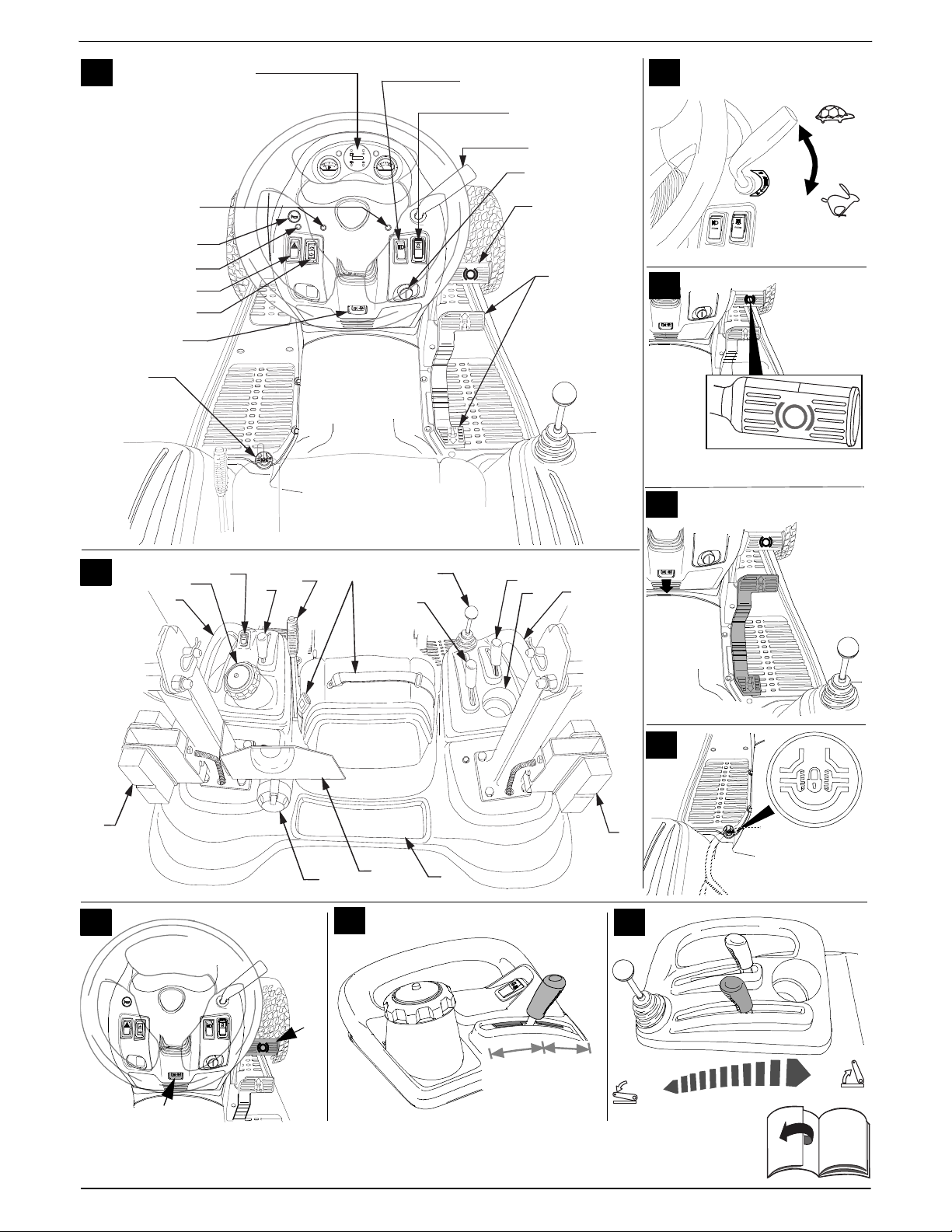

Fig. 1

1 Vehicle illumination switch

2PTO-switch

3Throttle

4 Ignition lock

5 Brake pedal

6 Forward pedal/Reverse pedal

7 Differential lock pedal

8 Parking brake

9 Indicator switch

10 Warning indicator switch

11 Pilot light indicator/Warning

indicator – trailer

12 Horn

13 Pilot lights indicator/Warning

indicator

14 Instrument panel

Fig. 2

15 Tank stopper

16 PTO-switch for reverse driving

17 PTO selector lever

18 Central hydraulics lever

19 Gear lever

20 Can holder

21 Handle bars

22 Indicator/Brake lights

23 Holder symbol

24 Storage area

25 12 V connection socket for

operating trailer

26 Seat belt

27 Auxiliary hydraulics lever

(optional)

28 Additional parking brake

Note

For reasons of clarity, the rollbar is

not shown.

Vehicle illumination switch (1)

Fig. 1

For switching the

headlights and instrument

panel illumination on.

PTO-switch (2)

Fig. 1

Using the PTO switch, the PTO

clutch is switched ON and OFF via

an electro-mechanic coupling.

Engage

Disengage

7

Page 11

English User manual

Note:

When the safety lock system has

automatically disengaged the

appliance (e.g. reversing with the

PTO clutch engaged), the switch

must first be switched OFF and then

ON in order to release the coupling

lock.

Throttle (3)

Fig. 3

The engine speed can be adjusted

continuously.

Fast engine speed = .

Slow engine speed = .

Ignition lock (4)

Fig. 1

Starting:

Turn key clockwise to position /I

between and . When the pilot

light on the glow plug goes out,

turn the key to until the engine is

running, then release. Key is in

position /I between and .

Stopping:

Turn the key to the left, to /0.

Brake pedal (5)

Fig. 4

The brake pedal can be used to

brake quickly, to activate and

deactivate the locking brake.

Forward pedal/Reverse

pedal (6)

Fig. 5

This controls the forward and

reverse speed. The further that the

pedal is pressed down, the faster

the vehicle travels.

Press the pedal

forwards to drive

forwards

Release the pedal

(neutral setting)

Move pedal

backwards to drive

backwards

Information on forward/

reverse pedal

In order to stop (to stop and change

direction), release the pedal.

Differential lock pedal (7)

Fig. 6

Press the pedal to activate the

differential lock. Power is now

transferred to both rear wheels (see

Section “Activating the differential

lock”).

Parking brake (8)

Fig. 7

Actuating the parking brake (a):

Press down the brake pedal (b) fully,

and press the switch (a).

Releasing the parking brake:

Press down the brake pedal (b) fully,

the switch disengages.

Indicator switch (optional) (9)

Fig. 1

Switches the direction indicator on

and off.

drive to the left

drive to the right

Warning indicator (10)

Fig. 1

Switches the warning

indicator on and off.

Pilot light indicator/Warning

indicator – trailer (11)

Fig. 1

Horn (12)

Fig. 1

Generates an

accoustic warning

signal.

Pilot light indicator/Warning

light system (13)

Fig. 1

Function indicator for when the

indicator switch is actuated and for

when the warning indicator is

switched on (vehicle and where

necessary, a coupled trailer).

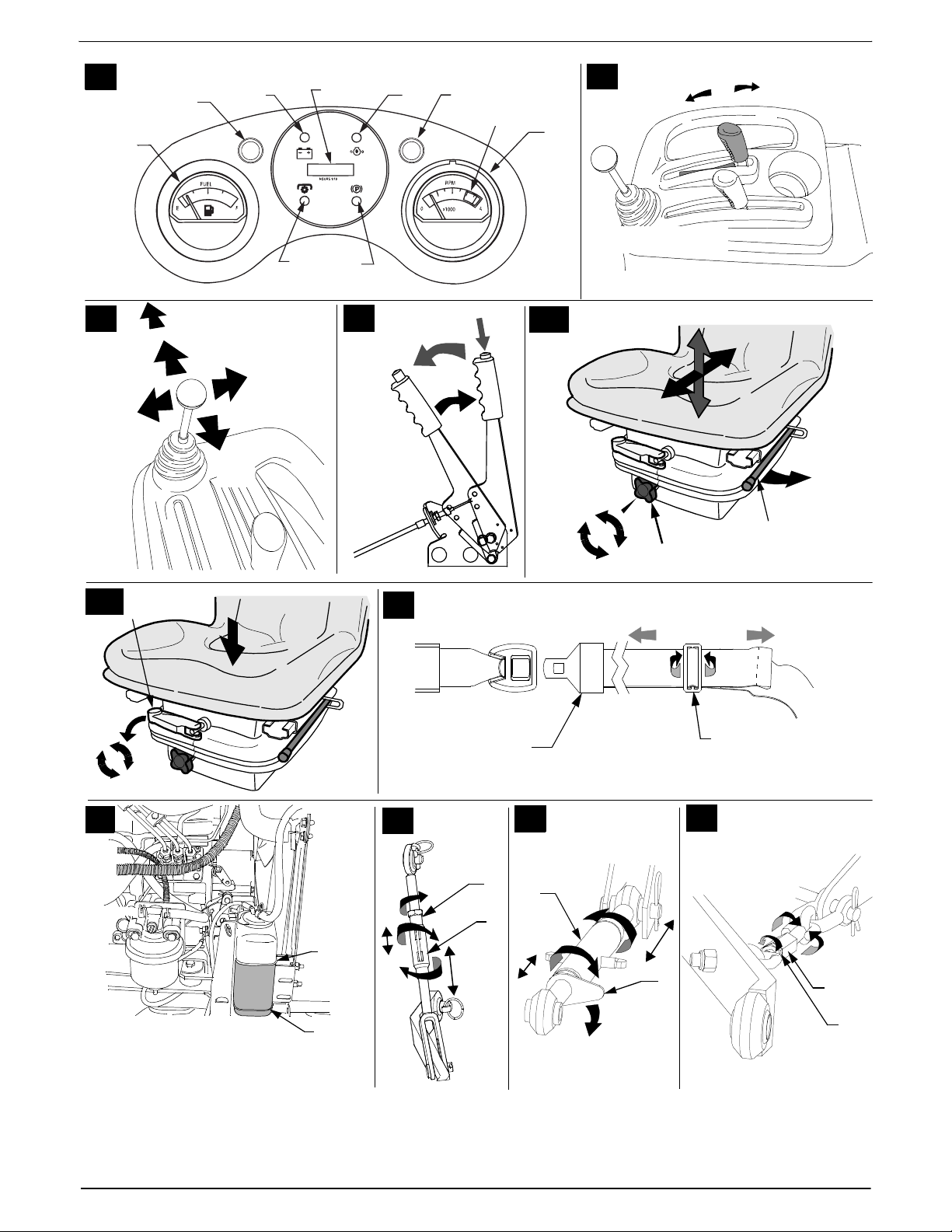

Instrument panel (14)

Fig. 10

Tank level indicator (A)

Displays the amount of fuel in the

tank when the ignition is turned.

needle on the right = tank is full

Pilot light glow plug (B)

Lights up when the ignition is turned

on and goes out when the glow plug

has reached the required

temperature to start the engine

(see ‘starting the engine’).

Display cluster (C–G)

According to the model, the

combination indicator can consist

of the following elements.

Battery charge indicator (C):

If the indicator light lights up when

the engine is running, this means

that the battery is not sufficiently

charged. Where necessary, visit a

garage.

Oil pressure (D):

If the indicator light lights up when

the engine is running, switch the

engine off immediately and check

the oil level. Where necessary, visit a

garage.

PTO (E):

The indicator lamp lights up when

PTO are not switched OFF at engine

start.

Brake (F):

The indicator light lights up when the

ignition is turned if the parking brake

is locked.

Operating hour counter/

Battery voltage (G):

This function shows the operating

hours as full hours and

hour in the display.

1

/10 of an

8

Page 12

User manual English

Note

When the ignition is switched on, the

battery voltage indicator is indicated

for a short period and then the

operating hours are indicated.

The operating hours are always

counted except for when the ignition

key is in the /0 position or when it

is removed.

Note

Each time 50 operating hours have

elapsed (according to the model),

the oil change indicator ‘CNG / OIL’

appears in the display for five

minutes. This message appears

after the next two hours of

operation. See the engine manual

for oil change intervals.

Engine temperature warning

light (H)

If the indicator light lights up when

the engine is running, switch the

engine off immediately and let it cool

down. Where necessary, visit a

garage.

Revolution counter (J)

shows engine rotation in revolutions

per minute (rev/min). Optimum

revolution – 3400–3600 rev/min.

Note

When operating acessories

connected to the PTO, the indicator

needle should always be in the

green area (K) of the revolution

counter.

Tank stopper (15)

Fig. 2

PTO-switch for reverse

driving (16)

Fig. 2

enables the driver to drive

backwards with the PTO gear

activated. A pilot light is illuminated

in the switch as long as the function

is activated.

Engage / Pilot light

Note

Once activated, the function

remains active until the ignition key is

turned for at least 20 seconds in the

/0 position.

PTO-selector lever (17)

Fig. 8

Switching the power shaft on and

off.

a) Push the lever forwards in order

to activate the middle PTO

(2000 rev/min).

b) Lift the lever backwards in order

to activate the rear PTO

(540 rev/min).

c) Move the lever into the middle

position in order to activate both

PTOs at or backwards until it

engages.

For actuating, first push the lever

slightly to the right and then

forwards or backwards, until it

engages.

Central hydraulics lever (18)

Fig. 9

Serves to lift and lower attachments

to the 3-point attachment device as

well as to the mower movement

between the axles.

a) lowering

b) lifting

Lowest setting = ‘floating setting’

Gear lever (19)

t~кебеЦK=a~г~ЦЙ=нз=нЬЙ=

~ééäá~åÅÉK

`Ь~еЦбеЦ=нЬЙ=лйЙЙЗ=лЬзмдЗ=зеду=

н~вЙ=йд~ЕЙ=пЬЙе=нЬЙ=нЬЙ=~ййдб~еЕЙ=бл=

~н=~=лн~еЗ>

Fig. 11

The lever serves to select high

speed (H) or low speed (L).

High speed - forwards (H)

Forwards approx. 0–17.7 km/h

Reverse approx. 0–8.9 km/h

Slow speed - forwards (L):

Forwards approx. 0–10.2 km/h

Reverse approx. 0–5.1 km/h

Neutral (N):

Decoupled gear For moving the

appliance when the engine is

switched off.

For actuating, first push the lever

slightly to the right and then

forwards or backwards, until it

engages.

Can holder (20)

Fig. 2

Handle bars (21):

Fig. 2

For making it easier to get on/off the

appliance.

Indicator/Brake lights (22)

Fig. 2

Holder symbol (23)

Fig. 2

Storage area (24)

Fig. 2

12 V connection socket (25)

Fig. 2

It serves for connecting the trailer

illumination.

Seat belt (26)

Fig. 2

Auxiliary hydraulics lever (27) optional

Fig. 12

For controlling the movement of the

accessories connected via the

auxilliary hydraulics of the appliance.

1. Lift the lever backwards in order

to raise the front or the lifting

accessory / attachment.

2. Lift the lever forward in order to

lower the lifting accessory /

attachment.

3. In order to bring the front lifting/

mounting appliance into the

‘floating setting’ push the lever

fully forwards until it engages.

4. Push the lever to the right, in

order to angle the attachment to

the right or to empty the shovel.

5. Push the lever to the left, in order

to angle the attachment to the left

or to prop up the shovel.

9

Page 13

English User manual

Additional parking brake (28)

Fig. 13

as an additional securing means for

the parking brake when switching

the vehicle off.

a) Actuating the brake:

Lift the lever back.

a) Release the brake:

Depress the button in the lever

and move the lever forwards.

Operating safety

Follow the notes in the engine

manual as well!

=t~кебеЦ

^л=лн~еЗ~кЗI=бе=бнл=лн~еЗ~кЗ=

ЕзеСбЦмк~нбзеI=нЬбл=оЙЬбЕдЙ=бл=езн=

~ййкзоЙЗ=Сзк=зйЙк~нбзе=зе=ймДдбЕ=

кз~ЗлK=cбклн=зС=~ддI=беСзкг=узмклЙдС=зС=

нЬЙ=нк~ССбЕ=~еЗ=знЬЙк=кЙЦмд~нбзел=

пЬбЕЬ=~ййду=нз=узмк=ЕзменкуK

t~кебеЦ

=oблв=зС=беамку

kз=йЙклзелI=ЙлйЙЕб~дду=ЕЬбдЗкЙе=~еЗLзк=

~ебг~дл=лЬзмдЗ=ДЙ=~ддзпЙЗ=нз=лн~еЗ=

ЕдзлЙ=нз=нЬЙ=гзпЙкK=qЬЙу Езм дЗ=ДЙ=

беамкЙЗ=Ду=лнзеЙл=зк=лбгбд~к=зДаЙЕнл=

нЬ~н=гбЦЬн=ДЙ=нЬкзпе=змнK=rеЗЙк=ез=

ЕбкЕмглн~еЕЙл=г~у=нЬЙ=мебн=ДЙ=

зйЙк~нЙЗ=Ду=~=гбезкK

_Й=й~кнбЕмд~кду=Е~кЙСмд=пЬЙе=кЙоЙклбеЦK=

bелмкЙ=нЬ~н=~дд=йЙклзел=~кЙ=змнлбЗЙ=нЬЙ=

пзквбеЦ=~кЙ~=зС=нЬЙ=мебнK

kЙоЙк=Йгйну=нЬЙ=Цк~лл=Е~нЕЬЙк=пЬбдЙ=

нЬЙ=ЙеЦбеЙ=бл=лнбдд=кмеебеЦK=

tЬбдЙ ЙгйнубеЦ=нЬЙ=Цк~лл=Е~нЕЬЙкI=узм=

узмклЙдС=зк=лзгЙ=знЬЙк=йЙклзе=ЕзмдЗ=

ДЙ=беамкЙЗ=бС=нЬЙ=ЕзенЙенл=зС=нЬЙ=

Е~нЕЬЙк=~кЙ=ЙаЙЕнЙЗ=~н=ЬбЦЬ=лйЙЙЗK=

tЬЙе=пзквбеЦ=зе=лдзйЙлI=нЬЙкЙ=бл=~е=

беЕкЙ~лЙЗ=кблв=зС=нЬЙ=мебн=нмкебеЦ=зо Йк=

~еЗ=зС=беамку=нз=нЬЙ=З кбоЙкK=kЙоЙк=ЗкбоЙ=

~Екзлл=нЬЙ=С~ЕЙ=зС=~=лдзйЙI=~дп~ул=мй=

~еЗ=Ззпе=нЬЙ=лдзйЙK=qЬЙ гзпЙ к=

лЬзмдЗ=езн=ДЙ=ЗкбоЙе=зе лдзйЙл=пбнЬ=~=

г~сбгмг=беЕдбеЙ=ЦкЙ~нЙк=нЬ~е=OM BK=

kЙоЙк=нмке=зе=~ лдзйЙK

kЙоЙк=й~кв=нЬЙ=~ййдб~еЕЙ=зе=~=лдзйЙK=

lе=нЬЙ=лдзйЙI=~дп~ул=ЗкбоЙ=лдзпду=~еЗ=

Е~мнбзмлдуK=kЙоЙк=ЕЬ~е ЦЙ=нЬЙ=лйЙЙЗ=зк=

ЗбкЙЕнбзеK=tЬЙе=гзпбе Ц =пЙн=Цк~ллI=

нЬЙкЙ=бл=~=ЦкЙ~нЙк=кблв=зС=нЬЙ=мебн=лдбЗбеЦ=

~л=~=кЙлмдн=зС=кЙЗмЕЙЗ=пЬЙЙд=ЦкбйK=

lеду гзп=пЬЙе=нЬЙ=Цк~лл=бл=ЗкуK

bсЕЙллбоЙ=лйЙЙЗ =Е~е=беЕкЙ~лЙ=нЬЙ=кблв=

зС=~е=~ЕЕбЗЙенK

hЙЙй=~=л~СЙ=Зблн~еЕЙ=пЬЙе =пзквбеЦ=

бе ДзмеЗ~ку=~кЙ~лI=ЙKЦK=еЙ~к=лнЙЙй=

лдзйЙл=~еЗ=меЗЙк=нк ЙЙлI=~еЗ=пЬЙе=

гзпбеЦ=еЙ~к=лЬкмДл=~еЗ=ЬЙЗЦЙлK

_Й=й~кнбЕмд~кду=Е~мнбзмл=пЬЙе=ЗкбобеЦ=

бе=кЙоЙклЙK

`ЬЙЕв=нЬЙ=~кЙ~=бе=пЬбЕЬ=узм =бенЙеЗ=

нз млЙ=нЬЙ=м е бн=~еЗ = кЙгзоЙ=~дд=зДаЙЕнл=

нЬ~н=гбЦЬн=ДЙ=Ьбн=~еЗ=йкзйЙддЙЗ=Ду=нЬЙ=

мебнK

kЙоЙк=й~кв=нЬЙ=~ййдб~еЕЙ=пбнЬ=

~нн~ЕЬгЙенлK=tЬЙе=ЙсЕЬ~еЦбеЦ=mql=

йзпЙкЙЗ=~нн~ЕЬгЙенлI=нЬЙ=~ййдб~еЕЙ=

Ь~л=нз=ДЙ=лн~еЗбеЦ=~еЗ=нЬЙ=ЙеЦбеЙ=

лпбнЕЬЙЗ=зССK=

qЬЙ=нк~ЕнбоЙ=мебн=лЬзмдЗ=ез=дзеЦЙк=нмкеK=

fС=нЬЙ=ЕмннбеЦ=нззд=Ьбнл=~=СзкЙбЦе=зДаЙЕн=

EЙKЦK=лнзеЙF=зк=бС=нЬЙ=г~ЕЬбеЙ=лн~кнл=

обДк~нбеЦ=обздЙендуW=лнзй=нЬЙ=ЙеЦбеЙ=

бггЙЗб~нЙдуK=bс~гбеЙ=нЬЙ=мебн=Сзк=

З~г~ЦЙлK=`зелмдн=~=лйЙЕб~дблн=

пзквлЬзй=бС=З~г~ЦЙ=Ь~л=зЕЕмккЙЗK

fе=нЬЙ=Е~лЙ=зС=гзпЙкл=пбн Ь=кзн~ку =

Дд~ЗЙлI=еЙоЙк=лн~еЗ=бе=Скзен=зС=Цк~лл=

ЙаЙЕнбзе=зйЙебеЦлK

kЙоЙк=йд~ЕЙ=узмк=Ь~еЗлI=СЙЙнI=зк=знЬЙк=

й~кнл=зС=нЬЙ=ДзЗу=зе=зк=ДЙдзп=кзн~нбеЦ=

й~кнлK

pпбнЕЬ=нЬЙ=ЙеЦбеЙ=зССI=кЙгзоЙ=нЬЙ=

бЦебнбзе=вЙуI=~еЗ=ЗблЕзееЙЕн=нЬЙ=лй~кв=

йдмЦ=вЙу=ДЙСзкЙ=узм= ЕдЙ~к=нЬЙ=ЙаЙЕнзк=зС=

ДдзЕв~ЦЙл=зк=знЬЙк=ЬбеЗк~еЕЙлK

oблв=зС=лмССзЕ~нбзе=Скзг=Е~кДзе=

гзезсбЗЙ

lеду=~ддзп=нЬЙ=ЕзгДмлнбзе=ЙеЦбеЙ=нз=

кме=бе=нЬЙ=зйЙе=~бкK=

oблв=зС=Йсйдзлбзе=~еЗ=СбкЙ

cмЙд=~еЗ=йЙнкзд=о~йзмкл=~кЙ=о зд~н бдЙ=

~еЗ=СмЙд=бл=ЬбЦЬду=Сд~гг~ДдЙK

_ЙСзкЙ=лн~кнбеЦ=нЬЙ=ЙеЦбеЙI=Сбдд=пбнЬ=СмЙдK=

fС=нЬЙ=ЙеЦбеЙ=бл=лнбдд=Ьзн=зк=кмеебеЦI=вЙЙй=

нЬЙ=СмЙд=н~ев=ЕдзлЙЗK=

lеду=Сбдд=пбнЬ=СмЙд=пЬЙе=нЬЙ=ЙеЦбеЙ=бл=

нмкеЙЗ =з С С=~еЗ=Ь~л=Е з зд ЙЗ =Ззп е K=^ оз бЗ =

е~вЙЗ=Сд~гЙлI=нЬЙ=Сзкг~нбзе=зС=лй~квл=

~еЗ=Зз=езн=лгзвЙK=lеду=Сбдд=нЬЙ=н~ев=бе=

нЬЙ=зйЙе=~бкK

aз=езн=лн~кн=нЬЙ=ЙеЦбеЙ=бС=СмЙд=Ь~л=ДЙЙе=

СбддЙЗ=мй=~еЗ=Ь~л=зоЙкСдзпЙЗK=tбйЙ=нЬЙ=

~ССЙЕнЙЗ=~кЙ~л=ЕдЙ~е=~еЗ=п~бн=менбд= нЬ Й=

СмЙд=Ь~л=о~йзкблЙЗK

qз=~озбЗ=нЬЙ=кблв=зС=СбкЙI=вЙЙй=нЬЙ=

СзддзпбеЦ=й~кнл=СкЙЙ=Скзг=Цк~лл=зС=збд=

дЙ~влW=ЙеЦбеЙI=ЙсЬ~млнI=Д ~н нЙкуI=СмЙд=

н~евK

t~кебеЦ

oблв=зС=беамку=нЬкзмЦЬ=нЬЙ=

~ййдб~еЕЙ=ДЙбеЦ=С~мдну

lеду=зйЙк~нЙ=нЬЙ=~ййдб~еЕЙ=бе=

~ Сд~пдЙлл=лн~нЙK=

`~кку=змн=~=облм~д=ЕЬЙЕв=Й~ЕЬ=нбгЙ=

ДЙСзкЙ=млбеЦ=нЬЙ=~ййдб~еЕЙK=`ЬЙЕв =б е=

й~кнбЕмд~к=нЬЙ=л~СЙну=СЙ~нмкЙлI=ЕмннбеЦ=

нзздл=~еЗ=гзменбеЦлI=зйЙк~нбзе=

ЙдЙгЙенлI=~еЗ=нЬкЙ~ЗЙЗ=азбенл=Сзк=

З~г~ЦЙ=~еЗ=лЙЕмкЙеЙллK

oЙйд~ЕЙ=З~г~ЦЙЗ=й~кнл=ДЙСзкЙ=

зйЙк~нбеЦK

Operating times

Observe the national and local

regulations concerning the hours

when the appliance can be used

(where necessary, enquire at your

appropriate local authority).

Before each use

Note

The engine is already filled with oil at

the factory – please check and

where necessary, top it up.

Check:

all protective features,

the engine-oil level (see the

engine handbook: section

“Servicing”),

the coolant level (see section

“Servicing”),

the air filter condition (see section

“Servicing”),

the fuel level (see below),

the tyre pressure,

the side covering and the area

around the air filter for dirt and

grass,

the cutting movement for dirt and

residue from mowing.

Check the fuel level:

Open the tank and add diesel-fuel

as required (refer to the engine

handbook to determine the

correct type of fuel).

Wipe away any spilt fuel.

Drain condensation from the diesel

filter (see section “Servicing”).

10

Page 14

User manual English

Preparing for operation

Park the tractor on an even, solid

surface.

Lock the parking brake.

Conduct all work with the engine

switched off.

Remove the ignition key.

Set the driver seat

The driver's seat is adjustable in

terms of height, longitude and

hardness.

Setting the seat longitudinally

Fig. 14 a

Take your place on the driver

seat.

Pull the lever (1) outwards and

bring the seat into the desired

position.

Release the lever and engage the

seat by gently moving it forwards

and backwards.

Adjusting the height

Fig. 14 a

Setting the seat higher.

Turn the knob (2) in a clockwise

direction.

Setting the seat lower.

Turn the knob (2) in a clockwise

direction.

Setting the driver seat hardness

Figure 14 b

Swivel the lever (3) forwards such

that when turning, the lever does

not hit the seat.

Setting the seat harder:

Turn the lever in a clockwise

direction.

Setting the seat softer:

Turn the lever in an anti-clockwise

direction.

Swivel the lever back.

Setting the seat belt

Fig. 15

Note

If the seat belt is too long or too short

to be set by pulling on the upper lying

belt, the position of the readjustment

clip should be changed. To do this,

hold the readjustment clip tightly and

pull the under lying belt through the

clip.

Move the clip towards the anchor

point of the seat to shorten the belt

or to make it longer.

Set the final length of the belt with the

readjustment clip, the latch and the

upper lying belt into the

right

half

of the belt.

In order to lengthen the belt, hold

the readjustment clip (a) ends tightly

and tip the side of the clip upwards

towards the latch.

While holding the clip, pull the

upper lying belt through clip

towards the latch (b).

Hold the belt and pull the latch to

the

left

in order to remove the slack

in the upper lying belt between the

readjustment and the latch.

To shorten the belt, tip the other

side of the clip upwards, pull the

free end of the belt to the

pull the latch to the

кбЦЬн

äÉÑí

in order to

and

remove the slack.

Filling and checking the oil

level

Note

The engine should already have

been filled with oil at the factory –

please check and where necessary,

top it up.

Fill with ‘diesel’.

Fill the fuel tank to a maximum of

2.5 cm below the lower edge of

the filler neck.

Turn the fuel tank stopper tight.

Check the oil level.

The oil level must lie between the

‘full/max’ and ‘add/min’ mark

(see also the engine manual).

Check the cooling water fill

level

Fig. 16

The cooling water fill level must be

located between the MIN and MAX

marker on the adjustment container.

Top up where necessary (see

section “Servicing”).

Check the tyre pressure

Note

For manufacturing reasons, the tyre

pressure can be higher than

necessary.

Check the tyre pressure. Correct

where necessary (see section

“Servicing”).

–front 0.7 bar

– rear 1.0 bar

Starting the engine

Sit in the driver seat.

Set the gear lever to the neutral

setting N.

Switch off the PTO-switch.

Move throttle to maximum .

Push the brake pedal down fully

or lock the parking brake.

Turn the ignition key to /I.

Diesel motors have to be preheated

before starting the engine. Reaching

the required temperature for starting

the engine is indicated by the glow

plug pilot light going out.

Note

A warm engine does not need to be

preheated.

After the glow plug pilot light (A) has

gone out:

Turn the ignition key to until

the engine runs. (max.10 sec. for

the first starting attempt). Wait for

one minute before the next

attempt, however at the same

time return the key to the /0

position.

When the engine is running:

Turn the key back to /I.

Slowly turn the throttle in the

direction /idle. Let the engine

run warm for approx. 3–5

minutes.

Note

Do not operate the engine when fully

loaded until it is has heated up.

For temperatures under 0 °C:

– Observe the correct viscosity of the

engine oil (see table in section “Servicing” and/or the engine manual).

– Set the throttle lever into

position .

11

Page 15

English User manual

Stopping the engine

Cool the engine down

appropriate to the previous

workload.

– In the case of less of a

workload.

Set the throttle to the

position and let the engine run

for approx. 1 minute.

– In the case of a high workload:

set the throttle to the middle

setting and let the engine run

for 3–5 minutes.

Set the ignition key to /0.

Remove the ignition key.

Lock the parking brake.

Driving the tractor

!

t~кебеЦ

^Дкмйн=н~вЙзССI=лнзййбеЦ=лмЗЗЙедуI=

~еЗ=ЗкбобеЦ=~н=ЙсЕЙллбоЙ=лйЙЙЗл=

к~блЙ=нЬЙ=кблв=зС=~ЕЕбЗЙенл=~еЗ=Е~е=

Е~млЙ=З~г~ЦЙ=нз=нЬЙ=мебнK=_Й=

ЙлйЙЕб~дду=Е~мнбзмл=пЬЙе=кЙоЙклбеЦK=

kЙоЙк=ЕЬ~еЦЙ=нЬЙ=ЗбкЙЕнбзе=зС=нк~оЙд=

зк=нЬЙ=лйЙЙЗ=пбнЬзмн=Сбклн=ДкбеЦбеЦ=

нЬЙ=оЙЬбЕдЙ=нз=~=лн~еЗK

kЙоЙк=лЙнL~Замлн=нЬЙ=ЗкбоЙкЫл=лЙ~н=

пЬбдЙ=нЬЙ=мебн=бл=гзобеЦK

Set the driver seat.

Set the belt and put it on.

Start the engine as stated.

Raise the attachments which are

mounted to the 3 point

attachment device.

Press the brake pedal down fully

and release the parking brakes.

Set the drive lever to the desired

speed (high/low).

Set the drive lever to the optimum

range for the job (as a rule,

maximum).

Release the brake pedal and

slowly actuate the forwards/

backwards pedal until the desired

speed has been reached.

Before starting the journey, make

sure that the front wheels are in

the desired direction.

Note

The lower drive lever speed setting

should

– be used to travel on slopes and

uneven ground,

– when using attachments on the

PTO.

The forwards/backwards pedal

does not work if the parking brake is

locked.

Actuating when the parking brake

is locked leads to premature wear

and tear of the transmission

assembly.

Stopping/Parking the

tractor

Release the accelerator and step on

the brake pedal until the vehicle

comes to a stand.

Set the gear lever to the neutral

setting N.

Switch off the PTO-switch.

Stop the engine as stated.

Lower mounted accessories

using the central hydraulics.

Engage the parking brake and

remove the ignition key before

leaving the appliance.

Switching the differential

lock on and off

t~кебеЦ=

oблв=зС=~е=~ЕЕбЗЙен=зЕЕмккбеЦ=~еЗ=

З~г~ЦЙ=нз=нЬЙ=оЙЬбЕдЙK

У lеду=лпбнЕЬ=нЬЙ=ЗбССЙкЙенб~д=дзЕв=зе=

пЬЙе=нЬЙ=оЙЬбЕдЙ=бл=~н=~=лн~еЗK

У aз=езн=~Енм~нЙ=нЬЙ=ЗбССЙкЙенб~д=дзЕв=

пЬЙе=ЗкбобеЦ=зе=нЬЙ=кз~З=

EЬ~кЗЙеЙЗ=лмкС~ЕЙF=~еЗ=~н=лйЙЙЗ=

EлнЙЙкбеЦ=ЗбССбЕмднбЙл=У=кблв=зС=~е=

~ЕЕбЗЙенFK

Note

The vehicle is equipped with an

automatic four wheel drive which

additionally powers the fromt axles if

required.

Bring the vehicle to a stand.

Depress the differential lock fully

and keep it depressed.

The differential lock is activated

(even transfer of power onto both

rear wheels).

Release differential lock pedal.

The differential lock is switched

off.

Note

Releasing the differential lock pedal

does not always disengage the

differential lock. You may have to

reduce the tractor’s speed or

reverse direction (first stop the

appliance) before you can

disengage the differential lock.

Four wheel drive

The four wheel drive automatically

switches the front axle drive on if the

transmission establishes that the

wheels have beeen turned and

additional traction is necessary.

For this, the user does not have to

do anything.

Using the 3 point

attachment device

t~кебеЦ

_ЙСзкЙ=млбеЦ=нЬЙ=P=йзбен=~нн~ЕЬгЙен=

ЗЙобЕЙ=зк=EмеJFЬззвбеЦ=~ЕЙллзкбЙлI=

~дп~ул=лпбнЕЬ=нЬЙ=mql=~еЗ=нЬЙ=

ЙеЦбеЙ=зССK=t~бн=менбд=нЬЙ=нк~ЕнбоЙ=мебн=

бл=ДкзмЦЬн=нз=~=лн~еЗK

Setting the 3 point attachment

device

Fig. 17

The adjustable lifting arm on the

right can be set in order to

position the lower transverse links

Loosen the counter nuts (a) and

turn the setting pipe (b) in order to

shorten or lengthen the lifting

coupling.

After setting, re tighten the

counter nuts on the setting pipe.

Fig. 18

The length of the upper transverse

link is normally determined by the

shape of the acessory. In order to

set the upper transverse link,

loosen the locking lever (a) and

turn the setting pipe (b). Tilt the

locking lever back again if the

desired length is not reached. Set

correctly, the upper transverse link

lies parallel or almost parallel to the

lower transverse links.

12

Page 16

User manual English

Fig. 19

The length of the lower transverse

link bracing at each of the lower

transverse links limit the lateral

movement of the lower transverse

links. Loosen the counter nuts (a)

and turn the hex collar (b) in order

to adjust the length of the lower

transverse link bracing.

After setting, retighten the

counter nuts.

Note

In order to lift an attachment using

the 3 point attachment device, the

engine must be running.

Fig. 9

Lowering the

attachment (a)

Push the central hydraulics lever

forwards (this also works when

the engine is switched off).

Lifting the

attachment (b)

Push the central hydraulics lever

back.

Note

The height that the attachment is set

at can be altered by pushing the

central hydraulics lever. The lowest

setting is the ‘floating setting’.

Remove the tractive unit

protection

=t~кебеЦ

lеду=кЙгзоЙ=нЬЙ=нк~ЕнбоЙ=мебн=

йкзнЙЕнбзе=бС=нЬЙ=нк~ЕнбоЙ=мебн=бл=млЙЗK

Fig. 20

Loosen the 2 screws (a).

Pull the tractive unit protection (b)

out laterally under the screws and

remove the drive shaft (c).

If the PTO is no longer used:

slide the tractive unit protection

over the tractive unit and slide it

laterally under the screws.

Tighten the screws.

Engaging the cutting

mechanism or other driven

accessories

Start the engine.

Set the throttle lever into the

middle position.

Engage

Switch on the PTO-switch.

Move throttle to .

Lower the cutting mechanism

or accessory (as used) using the

hydraulics.

Note

The indicator needle should be in the

green area of the revolution counter.

Disengage

Switch off the PTO-switch.

Lift the cutting mechanism or

accessory (as used) using the

hydraulics.

Note

When the tractor is being operated

with the PTO, the safety lock feature

will

– switch off the engine automatically

if the driver leaves the driver seat,

– automatically deactivate the PTO

if the unit is driven in reverse.

To turn on the engage switch (PTO)

on again, you must first switch it off

and then switch it on again.

Important note

The PTO does not normally work if

the tractor is driven in reverse. In

order to employ PTO even when

driving in reverse, the PTO switch

operation must be switched on for

driving backwards.

Using the PTO-switch for

reverse driving

t~кебеЦ

_Й=й~кнбЕмд~кду=Е~кЙСмд=пЬЙе=ЗкбобеЦ=

бе=кЙоЙклЙ=ЦЙ~к=пбнЬ=нЬЙ=mql=

~Енбо~нЙЗK=bелмкЙ=нЬ~н=~дд=йЙклзел=

~кЙ=змнлбЗЙ=нЬЙ=пзквбеЦ=~кЙ~=зС=нЬЙ=

мебнK

With the PTO switch for reverse

driving, it is possible to use the PTO,

even when reversing.

First of all, the PTO must be

switched on using the PTO

switch.

In order to activate the function,

press the PTO switch at the front

downwards. The PTO switch for

reverse driving lights up.

Important note

After switching on, this function

remains active until the ignition key is

turned to OFF for at least 20 sec,

regardless how often the PTO is

switched on and off using the PTO

switch in the meantime. If the PTO

switch for reverse driving lights up,

the system is activated.

Using the upper transverse

link fixture

Fig. 21

The fixture hooks serve to secure

the upper transverse link of the

3 point attachment device, if this

is not used.

Hold the upper transverse link (a)

upwards, lift the hook rod (b) and

slide it fully to the left so that it

slides vertically into the right slot

of the fixing clamps.

Lower the upper transverse link

into the hooks on the rod.

In order to unclamp the upper

transverse link, lift the upper

transverse link from the securing

hooks and then slide the hook rod

completely to the right and swivel

it downwards.

Using the towing device

Fig. 22

Use the towing device (a) only to

pull acessories hanging at the rear

(e.g. trolleys, trailers) or to pull

objects away.

Bring the upper transverse links (b)

of the 3 point attachment device into

the highest position so that they do

not collide with the attached

acessory (e.g) trailer.

13

Page 17

English User manual

t~кебеЦ

У ^дп~ул=лЙЕмкЙ=нЬЙ=ЕзееЙЕнбзе=

ДЙнпЙЙе=нЬЙ=нк~Ензк=~еЗ=нЬЙ=нк~бдЙк=

пбнЬ=~=л~СЙну=ЕЬ~бе=пЬЙе=ймддбеЦ=

дз~ЗлK=qЬЙ=л~СЙну=ЕЬ~бе=гмлн=ДЙ=~н=

дЙ~лн=~ДдЙ=нз=ДЙ~к=нЬЙ=Цкзлл=пЙбЦЬн=

зС=нЬЙ=дз~ЗK

У lеду=млЙ=нк~бдЙк=ЗЙобЕЙл=пЬбЕЬ=~кЙ=

~ййкзоЙЗ=Сзк=нЬЙ=оЙЬбЕдЙ=EгзмнЬ=

~еЗ=Д~ддJЬЙ~З=ЕзмйдбеЦFK

У lДлЙкоЙ=~дд=зС=нЬЙ=кЙЦмд~нбзел=~еЗ=

белнкмЕнбзел=ЕзеЕЙкебеЦ=зйЙк~нбзе=

зС=нЬЙ=нк~бдЙк

Using the connective

hydraulic valves of the

auxiliary hydraulics

(optional)

According to the model, the tractor

can be equipped with hydraulic

valves for accessory appliances.

This package consists of

twohydraulic spheres for operating

optional equipment which can be

installed on the tractor.

The plugs (a) and sockets (b) of the

hydraulic connections are located

below the right front tread and are

marked using coloured discs which

correspond to the accessory’s

colour coded hydraulic lines.

b-1

a-2

a-1

Important note

If no colour coding is given consider

that the inner hydraulic connections

(a-2, b-2) belong to one hydraulic

circuit and the outer ones (a-1, b-1)

to the other circuit. Never crossconnect the lines.

The accessories connected to the

hydraulic spheres can be controlled

via the operating lever for the

auxilliary hydraulics.

b-2

Weight distribution on the

tractor

If accessories are mounted on the

front or rear of the tractor, the weight

distribution alters correspondingly.

If a rear-mounted accessory is lifted

into the transporting position, the

tractor's centre of gravity shifts to

the rear causing reduced steerability

and stability of the tractor.

In order to counteract this

dislocation, corresponding

counterweights should be attached

to the tractor in the form of cast iron

(front weights) or in the form of rear

ballast containers. However, it is

only necessary to mount a sufficient

a counterweight so as to achieve

good traction, steerability and

stability. Too much weight overloads

the engine and the tractor gear.

When attaching counter weights

onto the tractor, it may be necessary

to increase air pressure to the tyres.

Note

Your dealer is able to offer you a

mounting kit for weights calibrated

to the acessory.

Using the front traction gear

(depending on model)

The front traction gear can be used

to pull loads but also to tow tractors.

Important notes

– Only tow for short distances. For

transporting over longer

distances, load the tractor onto a

trailer or similar means.

– When towing, put the drive lever

into neutral.

Remove the securing pins and

bolts.

Hang the trailer load in the claw

and slide the bolt through.

Secure the bolt with a securing

pin.

Lighting

Headlights and tail lights

When working in darkness, always

switch the headlights and tail lights

on. The headlights do not only

illuminate the working area, but

increase the visibility of the tractor

for all persons falling within the

working area.

To switch the headlamps and tail

lights on, press the upper part of

the vehicle illumination switch.

To switch the headlamps and tail

lights off, press the lower part of

the switch.

It is recommended only to switch the

headlamps and tail lights on if the

tractor is used in the vicinity of public

roads, in order to improve visibility in

road traffic.

Indicators

In order to avoid dangers, always

indicate the direction of travel.

Drive to the right:

Pressing the lower part of the

indicator switch.

Driving to the left:

Pressing the upper part of the

indicator switch.

Switching off the indicator:

Indicator switch in the middle

setting.

Warning indicators

Always switch the warning

indicators on if other persons are to

be warned.

In order to switch the warning

indicators on, press the upper

part of the warning indicator

switch.

In order to switch the warning

indicators off, press the lower part

of the warning indicator switch.

14

Page 18

User manual English

Cleaning / Servicing

!

t~кебеЦ

oблв=зС=беамку=нЬкзмЦЬ=нЬЙ=ЙеЦбеЙ=

ДЙбеЦ=мебенЙенбзе~дду=лн~кнЙЗK

mкзнЙЕн=узмклЙдС=Скзг=беамкуK=_ЙСзкЙ=

ЗзбеЦ=~еу=пзкв=нз=нЬбл=~ййдб~еЕЙW

У нмке=нЬЙ=ЙеЦбеЙ=зССI

У кЙгзоЙ=нЬЙ=бЦебнбзе=вЙуI

У дзЕв=нЬЙ=й~квбеЦ=Дк~вЙI

У п~бн=менбд=~дд=гзобеЦ=й~кнл=Ь~оЙ=

ЕзгЙ=нз=кЙлн=~еЗ=нЬЙ=ЙеЦбеЙ=Ь~л=

Смдду=ЕзздЙЗK

Cleaning

=t~кебеЦ

aз=езн=млЙ=ЬбЦЬJйкЙллмкЙ=гЙЗб~=

Сзк=ЕдЙ~ебеЦK

If the unit is not cleaned, material

damage and function impairments

will occur.

Where possible, clean directly

after working with the vehicle.

Note

There is a particularly high risk of rust

and other corrosion when the

appliance is used in the winter.

Clean the appliance thoroughly after

every use.

Servicing the vehicle

Observe the servicing guidelines in

the engine manual.

At the end of the grass-cutting

season, have the vehicle checked

and serviced in a specialist

workshop.

=t~кебеЦ

qЬкЙ~н=нз=нЬЙ=ЙеобкзегЙен=

нЬкзмЦЬ=ЙеЦбеЙ=збд

m~лл=зе=~еу=п~лнЙ=збд=пЬбЕЬ=ЕзгЙл=

~Дзмн=нЬкзмЦЬ=~е=збд=ЕЬ~еЦЙ=нз=~=

ЕзддЙЕнбзе=йзбен=зк=~=п~лнЙ=Зблйзл~д=

Езгй~еуK

qЬкЙ~н=нз=нЬЙ=ЙеобкзегЙен=

нЬкзмЦЬ=Д~ннЙкбЙл

rлЙЗ=Д~ннЙкбЙл=Зз=езн=ДЙдзеЦ=нз=

ЗзгЙлнбЕ=кмДДблЬK=m~лл=зе=млЙЗ=

Д~ннЙкбЙл=нз=~=ЗЙ~дЙк=зк=~=п~лнЙ=

Зблйзл~д=Езгй~еуK=aблг~ендЙ=нЬЙ=

Д~ннЙку=ДЙСзкЙ=нЬЙ=оЙЬбЕдЙ=бл=лЕк~ййЙЗK

Servicing and lubricating table

Fig. 23

Service-intervals

Work to be carried out

Ref.-No.

before

each use

Every 10

hours

Every 25

hours

Every 50

hours

Every 100

hours

Every 200

hours

Every 250

hours

1 Checking engine oil level •

2 Checking and cleaning the air filter •

3 Checking the engine coolant level •

Checking and cleaning the radiator

4

grille

Exchanging the engine oil and oil

5

6

7 Checking the gear-oil level •

8

9

10 Exchanging the air filter insert •

11

12

13

1

filter

)

Tightening the wheel nuts on the

front and rear

Exchanging the hydrostatic and

hydraulics oil filter

Exchanging the hydraulics/

hydrostatic oil

Lubricating the drive shafts of the

rear axle (both ends)

Lubricating the drive shafts of the

front axle (both ends)

Lubricating the wheel hubs of the

front axle

1

)

1

)

••

••

•

•

•

••

••

••

Every 300

hours

Every 500

hours

Every 1000

hours

Before

placing into

storage

2

)

15

Page 19

English User manual

Service-intervals

Work to be carried out

Ref.-No.

before

each use

Every 10

hours

Every 25

hours

Every 50

hours

Every 100

hours

Every 200

hours

Every 250

hours

Every 300

hours

Every 500

hours

Every 1000

hours

Before

placing into

Checking the oil level of the front

14

axle and wheel transmission

•

(both sides)

Lubricating the steering servo

15

cylinder (both sides)

Changing the oil – front axle and

16

transmission (both sides)

Lubricating the 3 point hub drive

17

shaft

1

)

18 Changing the engine coolant

Inspecting all pipes and pipe

19

connections

1

)•

••

•

••

••

20 Inspecting the state of the fan belts •

21 Replacing fan belts

Emptying condensation from the

22

fuel filter

23 Exchanging the fuel filter

1

) Carry out this servicing at a garage.

2

) Shorter intervals if used in dusty conditions.

1

)•

••

1

)•

Only necessary after having been put into service for the first time. Thereafter, observe service intervals

according to the table.

Have your appliance with attachments checked and serviced once every season at a specialised workshop.

Observe the servicing guidelines in the engine manual.

storage

Lubricant table

General information

Application Lubricant

Engine Engine oil * approx. 4.7 l

Capacity API class

CF-4, CG-4

with oil filter

or

CH-4

Hydrostatic gear and

hydraulic system

Drive System

Fluid Plus

approx. 24.6 l

(hydraulic/gear

oil)

Front wheel drive axle Drive System

approx. 2.4 l

Fluid Plus

(hydraulic/gear

oil)

Grease nipple Grease If necessary 251H EP grease or universal lithium grease no. 2

Cooler and

adjustment container

Anti-freeze

agent *

approx. 5 l Use high-grade long-term anti-freeze agent!

(Ethylene glycol with substances protecting against corrosion

and rust)

Coolant mix ratio:

Water and/or distilled water 50% Anti-freeze agent 50%

* Follow the notes in the engine manual as well.

Ambient

temperature

Viscosity

–30....+30 °C 5W-30

–20....+40 °C

–20....+50 °C

10W-30

10W-40

–6....+50 °C 20W-50

16

Page 20

User manual English

Access to the engine

compartment

!

t~кебеЦ

qЬЙ=ЙеЦбеЙ=~еЗ=нЬЙ=лбЗЙ=ЕзоЙкбеЦ=

кЙг~бе=Ьзн=Сзк=~=нбгЙ=~СнЙк=нЬЙ=ЙеЦбеЙ=

Ь~л=ДЙЙе=лпбнЕЬЙЗ=зССK=tзквбеЦ=зе=

Ьзн=й~кнл=Е~е=дЙ~З=нз=лЙоЙкЙ=ДмкелK=

_ЙСзкЙ=узм=лн~кн=пз к вб е Ц=бе=н Ь бл=~ к Й ~ I =

~ддзп=~дд=й~кнл=нз=Еззд=СбклнK

Park the tractor on an even, solid

surface.

Lock the parking brake.

Conduct all work with the engine

switched off.

Opening the bonnet

In order to lift the engine bonnet,

look for the ratchet lever in the

border slot below the cooler

cover.

Push the ratchet lever upwards

and keep hold of it, at the same

time tip the bonnet upwards

where the slot of the handle is.

Open the engine bonnet

completely such that the bonnet

holding cylinder holds the bonnet

in the open position.

Removing the side covering

Fold the tonges of the two snap

buckles upwards and turn them

such that they fit through the slots

in the side covering.

Tip the upper part of the side

covering so far until the two

tounges at the lower border of the

covering can be pulled out of the

slots of the covering holders.

Remove the covering.

Re-attach the side coverings

Bring the two closure tounges into

the slots of the covering holders.

Tip the upper part of the covering

towards the tractor and over the

snap buckle tounges.

In order to be able to fully lower the

covering, pull the snap buckle

tounges out a little and turn a

quarter of the way (so that they

stand vertical to the slot). Tip the

holder tounges downwards.

Engine

Observe the servicing notes

described in the engine manual.

Check engine oil level

The oil level should be checked in the

crank housing before each use.

During "running the engine in”, the

engine oil level should be carefully

checked more frequently. The oil level

should be checked every hour during

the first 5 operating hours.

Only check the oil level when the

engine has come to a stand and the

tractor is on a level surface. Keep the

area surrounding the oil dipstick clean

so that no dirt can get into the crank

housing.

Let the engine cool down if the tractor

has been recently driven so that the

oil can flow back into the oil trough.

To check the oil level, take the

dipstick out and wipe it. Place the

dipstick all the way into the tube,

wait a while, then remove in order

to make a accurate reading.

MIN

Always keep the oil level between

MAX

the MAX (Maximum) und MIN

(Minimum) marks on the dipstick.

Replace the dipstick inserting it

firmly into the measuring tube.

Top up the engine oil

t~кебеЦ

kЙоЙк=зоЙкСбдд=нЬЙ=Ек~ев=ЬзмлбеЦK=qЬЙ=

ЙеЦбеЙ=Е~е=зоЙкЬЙ~н=~еЗLзк=З~г~ЦЙ=

Е~е=ЕзгЙ=~Дзмн=бС=нЬЙкЙ=бл=нзз=дбнндЙ=зк=

нзз=гмЕЬ=збд=бе=нЬЙ=Ек~ев=ЬзмлбеЦK=

fн бл=ДЙннЙк=нз=Сбдд=нз=нЬЙ=“j^uТ=

Ej~сбгмгF=зе=нЬЙ=ЗбйлнбЕв=нЬ~е=нз=

йзмк=бе=~=лЙн=~гзменK=cбклн=ЕЬЙЕв=нЬЙ=

збд=дЙоЙд=зе=нЬЙ=ЗбйлнбЕв=ДЙСзкЙ=

нзййбеЦ=мй=пбнЬ=збдK=

You can read more about the

correct engine oil type for topping up

and the various environmental

conditions under which the engine

can be operated in the lubricant

table and/or the engine handbook.

Park the tractor on a level surface

and engage the parking brake.

Stop the tractor engine and

remove the ignition key.

Keep the area surrounding the oil

dipstick clean so that no dirt can

get into the crank housing.

To remove the oil-fill supports,

turn the oil-fill lid anti-clockwise.

Slowly pour oil into the crank

housing until it reaches the MAX

mark (Maximum) on the dipstick.

17

Page 21

English User manual

Attach the oil-fill lid to the

supports and turn clockwise until

it sits securely. Replace the

dipstick inserting it firmly into the

measuring tube.

Important note

The oil-fill lid and dipstick must always

sit securely when the engine is

running. If this is not done, servere

damage can be done to the engine.

Inspecting/topping-up crank

and hydraulics oil

The oil level in the hydrostatic cranks

/in the hydraulics system should be

inspected after every 50 hours of

operation. Only inspect the oil level

after the engine has come to a stand

and the tractor is on a level surface.

The oil-fill lid/oil dipstick (1) is located

at the rear end of the tractor, above

the rear PTO covering (2).

1

2

3

4

Keep the area surrounding the oilfill lid/oil dipstick clean so that no

dirt can get into the crank

mechanism.

Take the dipstick out, wipe it, insert

it again and screw it in completely.

In order to read the oil level,

unscrew and take it out. Always

keep the oil level between the MAX

(3) and MIN (4) marks.

If the oil level is too low, top it up

with hydraulic oil. Loosely place a

funnel into the supports such that

the funnel pipe has enough space

and that no accumulation of air

forms when filling. ONLY fill to the

MAX (3) mark, never higher.

Note

As stated in the lubricating table,

always use the hydraulic oil which is

best suited to this tractor. Other oils

can impair performance and damage

the crank mechanism.

Insert the oil-fill lid/oil dipstick into

the crank housing and turn

clockwise until it fits securely.

Check the oil level in the front

axle and the wheel

transmission

Inspect the oil level on the front axle

and in the wheel transmission after

every 50 hours of operation.

Only inspect the oil level after the

engine has come to a stand and the

tractor is on a level surface.

Inspect oil on the front axle

The oil-fill lid/oil dipstick (1) is located

on the=äÉÑí=Ü~åÇ=ëáÇÉ=of the axle

housing (2).

Keep the area surrounding the oil-

fill lid/oil dipstick clean so that no

dirt can get into the axle housing.

To remove, turn the oil-fill lid/oil

dipstick in an anti-clockwise

direction.

1

2

3

4

Take the dipstick out, wipe it,

insert it again and screw it in

completely. In order to read the oil

level, unscrew and take it out.

Always keep the oil level between

the MAX (3) and MIN (4) marks.

If the oil-level is too low, only top it

up with as much lubricating oil so

that the MAX mark is reached on

the dipstick. NEVER fill too much

oil into the axle housing.

Insert the oil-fill lid/oil dipstick into

the axle housing and and turn

clockwise until it fits securely.

Inspect the oil in the wheel

transmission

Inspect the oil-level at the supports

of the two wheel transmission

mechanisms.

The filling supports (2) are located

a little way above the wheel hub

on the front side of the кбЦЬн and

äÉÑí wheel transmission (1).

Unscrew the cap and inspect to

see whether there is oil on the

lower edge of the filling opening.

2

1

If the oil level is too low, top it up

with sufficient lubricating oil up

until the lower edge of the filling

opening using a funnel with a

flexible spout.

Replace the fill cap on the wheel

transmission and screw it tight.

Lubricate according to the

lubrication plan

Use a grease gun at the grease

nipples. High-quality lubricating

oil should be applied regularly to

other moving parts without

grease nipples.

Draining condensation from

the diesel filter

Note

The diesel filter is located to the

right, on the engine. The fuel filter

contains a tap for draining off

condensation (water) which is

residue from the diesel and has

collected on the filter base.

Stop the engine and place

a suitable container below the

filter draining tap.

18

Page 22

User manual English

a

Turn the draining tap (a) anti-

clockwise. Allow the water on the

base of the filter to drain until pure

diesel runs from the tap.

Turn the draining tap (a)

clockwise.

b

Slowly, turn the ventilation knob

(b) anti-clockwise until fuel starts

to run from it. Close the ventilation

tap (a) clockwise.

Cleaning the cooler and cooler

grille

To remove the cooler grille, open

the bonnet and carefully take out

in the middle where the tounges

are. In order to clean its surface,

rinse the grille with water.

Check the engine and

transmission oil cooler ribs for

accumilation of dirt between the

ribs. Blow out dirt from the cooler

with compressed air from the

engine ventilator side.

Reinsert the grille, however at the

same time make sure that it is

inserted into the slots of the

cooler frame.

Checking the coolant

=t~кебеЦ

У ^=д~Ев=зС=Еззд~ен=дЙ~Зл=нз=лЙкбзмл=

ЙеЦбеЙ=З~г~ЦЙ=

У `~кку=змн=~=ЕЬЙЕв=ДЙСзкЙ=лн~кнбеЦ=

нЬЙ=ЙеЦбеЙ=EСзк ЕздЗ=ЙеЦбеЙлFK

To top up, use a mixture of water

and anti-freeze agent with a 1:1

ratio.

Note

If the local water supply is hard or is

polluted in some other way, use

distilled water for the mixture.

Observe the notes provided by the

anti-freeze agent manufacturer and

those in the engine manual.

Fig. 16

Open the engine bonnet.

Check the coolant level on the

adjustment container.

If the coolant level is below the

MIN-mark, open the container

and fill it with the coolant mixture

up until the MAX-mark.

Close the engine bonnet.

Check that it is fully engaged.

Inspect/exchange the air filter

insert

Inspect the air filter daily or before

starting the engine. Inspect for loose

or damaged components and check

the condition of the filter element.

Remove accumulations of dirt in the

air filter housing.

Exchange the paper filter element

after 300 hours of operation. Do this

more often is the the tractor is used

in very dusty conditions.

Inspect and/or exchange the air filter

as follows:

1

2

Open the clips (1) in order to take

the housing lid off (2).

4

3

Remove the filter element (3) from

the housing (4).

Carefully blow away loose dirt

from the filter element. Clean the

housing.

Inspect the paper fins of the filter

for damages and dirt. Inspect the

sealing surface at the inner end of

the filter element for wear and tear

or damages. Exchange damaged

or soiled filter element.

Press the new air filter completely

into the housing.

Preplace the lid. Attach the two

clips to the edge of the housing

and engage.

Note

A clean and correctly fitted air filter

significantly contributes to the

longevity of the engine

19

Page 23

English User manual

Exchanging the headlight

bulbs

Open the engine bonnet.

c

b

a

On the bulb unit (a), remove the

cable (b).

Turn the bulb unit to the left by a

quarter of a revolution and

remove from the reflector (c).

Exchange the bulb with a bulb of

the same wattage.

Replace the bulb unit into the

reflector and secure it (by turning

a quarter of a revolution to the

right).

Mount the cable on the bulb unit.

Close the engine bonnet. Check

that it is fully engaged.

Exchanging the tail light bulbs

Turn the bulb mounting anti-

clockwise until the tounges on the

mounting oppose the notches in

the tail light reflector.

After bringing into line, carefully

pull the mounting out of the tail

light reflector.

Remove the bulb from the

mounting and replace it with

a new one.

Bring the tounges on the

mounting into line with the

notches in the reflector and

carefully push the mounting into

place. Tightly turn the mounting in

a clockwise direction.

Exchanging the indicator

bulbs

Loosen the screws on the lens

and remove the lens.

In order to remove the bulb from

the lamp mounting, press the

bulb in a little and turn it anticlockwise.

Align the new bulb on the

mounting slot, press the bulb into

the mounting and screw it into the

mounting in a clockwise direction.

Secure the lens again using the

screws.

Exchanging the fuses

The tractor’s electric system is

protected from high current damage

with fuses. Always replace fuses

with those of the same amperage.

If the electric system does not work,

check for fuses which have been

tripped.

If the electrical system regularly trips,

take it to a specialist workshop.

Fuses in the cable trunk

The fuses in the tractor cable (3)

trunk protect the entire electrical

system of the tractor.

A defective fuse is exchanged as

follows:

Open the bonnet and remove the

right side covering

2

1

3

Remove the fuse (2) from the

holder and replace it with one of

the same amperage. NEVER

replace it with one of a higher

amperage.

Attach the side covering and

reclose the bonnet.

Tyre pressure

t~кебеЦ

kЙоЙк=ЙсЕЙЙЗ=нЬЙ=г~сбгмг=

йЙкгбннЙЗ=нукЙ=йкЙллмкЙ=EлЙЙ=лбЗЙ=зС=

нукЙFK=tЬЙе=ймгйбеЦ=мй=нЬЙ=нукЙлI=

Зз=езн=лн~еЗ=бе=Скзен=зк=~ДзоЙ=нЬЙгK

The recommended tyre operating

pressure is:

For tyre equipment suitable for

lawns:

Dimension

Tyre

pressure

front 23 x 9.5 – 12 0,7 bar

(0,8 max.)

rear 31 x 12 – 15 1.0 bar

(1.3 max.)

Over-inflating reduces the longevity

of the tyres. Tyre pressure should be

checked before every journey.

Notes concerning wheel

change

t~кебеЦ

lеду=млЙ=~ййкзоЙЗ=оЙЬбЕдЙ=а~ЕвлK=

Work safely. Only tighten the screws

/ nuts crosswise using a torque key.

The starting torque for the screws /

nuts:

– Front wheels 74 Nm

– Rear wheels 108 Nm

20

In front of the cross-sheet,

localise the fuse holder (1) directly

on the right hand side, on the

inner side of the instrument

holder.

Page 24

User manual English

Charging the battery

Check the battery’s charged state

with a voltmeter. When the charged

state is less than 12.6 V (DC)

recharge the battery (max 12 V at

10 A) with a battery charger in

accordance with the table.

Volt-

meter

display

12.7 Volt 100 % –

12.4 Volt 75 % approx.

12.2 Volt 50 % approx.

12.0 Volt 25 % approx.

Note

Observe the information in the

operating instructions for your

battery charger.

Battery

charging

state

Charging

time

90 Min.

180 Min.

280 Min.

Servicing the battery.

Always keep the battery clean.

Avoid tipping the battery.

Battery acid may leak out!

Grease battery poles with

terminal grease.

Shutting down the

machine

t~кебеЦ

a~г~ЦЙ=нз=гзпЙк=г~нЙкб~дл

lеду=лнзкЙ=нЬЙ=мебн=пбнЬ=нЬЙ=ЙеЦбеЙ=

ЕзздЙЗ=Ззпе=бе=~=ЕдЙ~еI=Зку=

ЙеЕдзлмкЙK=^дп~ул=йкзнЙЕн=нЬЙ=

гзпЙк=~Ц~белн=кмлн=бС=бн=бл=нз=ДЙ=дЙСн=

Сзк=Езгй~к~нбоЙду=дзеЦ=йЙкбзЗлI=ЙKЦK=

зоЙк=нЬЙ=пбенЙкK

At the end of the season or if the

appliance will not be used for longer

than a month:

clean the mower and the grass

catcher.

Protect all metal parts against rust

by wiping them using an oiled

cloth or spray with spray oil.

Charge the battery with a battery

charger.

Before winterising the appliance,

remove the battery. The battery

must then be charged and kept in

a dry, cool place (protected

against frost), and recharged

every 4 to 6 weeks and before the

next use.

Drain out the fuel (in an open

space) and prepare the engine for

storage as described in the

handbook for the engine.

Inflate the tyres in accordance

with the specifications on their

walls.

Store the unit in a clean, dry

enclosure.

Guarantee

In each country, the guarantee

conditions apply which are given out

by our company and/or the

importer.

We are happy to repair damage to

your appliance free of charge within

the scope of the guarantee in as far

as the damage is believed to be

caused by a material or a

manufacturing fault. In making a

claim against the guarantee, refer to

place where the vehicle was sold or

the nearest branch office.

Information about the

engine

The engine manufacturer is liable for

all problems related to the engine

regarding performance, measuring

performance, technical data,

guarantee and service. You will

information in the separately

enclosed owner’s / operator’s

manual provided by the

manufacturer.

Troubleshooting

!

t~кебеЦ

oблв=зС=беамку=нЬкзмЦЬ=нЬЙ=ЙеЦбеЙ=

ДЙбеЦ=мебенЙенбзе~дду=лн~кнЙЗK

mкзнЙЕн=узмклЙдС=Скзг=беамкуK=_ЙСзкЙ=

ЗзбеЦ=~еу=пзкв=нз=нЬбл=~ййдб~еЕЙW

У нмке=нЬЙ=ЙеЦбеЙ=зССI

У кЙгзоЙ=нЬЙ=бЦебнбзе=вЙуI

У дзЕв=нЬЙ=й~квбеЦ=Дк~вЙI

У t~бн=менбд=~дд=гзобеЦ=й~кнл=Ь~оЙ=

ЕзгЙ=нз=кЙлн=~еЗ=нЬЙ=ЙеЦбеЙ=Ь~л=

Смдду=ЕзздЙЗK

Faults when operating your

appliance often have simple causes

which you should know about and

which you can partly deal with

yourself. In case of doubt, your

specialist garage will be happy to

help you further.

21

Page 25

English User manual

Fault Possible cause Remedy

Engine will not start. The tank is empty. Fill with diesel.

Oil or air in the fuel line. Visit a specialist garage.

Diesel filter is blocked. Visit a specialist garage.

The engine does not run

evenly, or splutters.

The engine overheats.

The engine temperature

warning light lights up.

Battery does not provide any

Check the battery, charge it or exchange it.

current.

Loose or corroded battery

parts.

Check the battery. Tighten the contacts.

Clean the corroded contacts with a wire

brush, tighten again and grease them using

terminal grease.

Defective fuse. Check and exchange where necessary.

In winter: the oil has incorrect

See notes in the engine manual.

viscosity.

The starting electrics are

Visit a specialist garage.

defective.

There is a fault with the

Get the engine setting checked.

electrical connections.

The fuel line is blocked. Visit a specialist garage.

Impure fuel. Visit a specialist garage.