Page 1

BCR4 BCK

Brushcutter Kit

OPERATOR’S

MANUAL

IMPORTANT MANUAL DO NOT THROW AWAY

Page 2

2

Thank You

Thank you for purchasing this quality product. This

modern outdoor power tool is designed to provide

many hours of useful service. You will find it to be a

great labor-saving device.

This operator’s manual provides you with easy-tounderstand operating instructions. Read the entire

manual and follow all of the instructions to keep your

new outdoor power tool in top operating condition.

PRODUCT REFERENCES, ILLUSTRATIONS

AND SPECIFICATIONS

All information, illustrations and specifications in this

manual are based on the latest product information

available at the time of printing. We reserve the right to

make changes at any time without notice.

Copyright© 2002 MTD SOUTHWEST INC

All Rights Reserved.

SpeedSpool® is a registered trademark of

MTD SOUTHWEST INC

SERVICE INFORMATION

Service on this unit both within and after the warranty

period should be performed only by an authorized and

approved service dealer.

NOTE: PROOF OF PURCHASE WILL BE REQUIRED

FOR WARRANTY SERVICE.

Make sure you carefully read and understand

this manual before starting or operating this

equipment.

THIS PRODUCT IS COVERED BY ONE OR MORE US PATENTS,

OTHER PATENTS PENDING.

INTRODUCTION TABLE

of CONTENTS

Rules for Safe Operation . . . . . . . . . . . . . . . . . 3-5

Important Safety Information . . . . . . . . . . . . . . .3

Safety and International Symbols . . . . . . . . . . . .5

Assembly Instructions . . . . . . . . . . . . . . . . . . 6-11

Install the Brush Cutter Kit . . . . . . . . . . . . . . . . 6

Remove the D-Handle . . . . . . . . . . . . . . . . . . . . 6

Install the J-Handle . . . . . . . . . . . . . . . . . . . . . . .6

Install the Harness . . . . . . . . . . . . . . . . . . . . . . . 7

Remove the Cutting Attachment . . . . . . . . . . . . .8

Remove the Old Cutting Attachment Shield . . . .8

Install the New Cutting Shield Mount . . . . . . . .9

Install the Cutting Blade . . . . . . . . . . . . . . . . . . .9

Remove the Cutting Blade/Install Attachment .10

Remove and Install the Cutting Shield . . . . . . .11

Operating Instructions . . . . . . . . . . . . . . . . 11-12

Holding the Unit . . . . . . . . . . . . . . . . . . . . . . . . .11

Using the Cutting Blade . . . . . . . . . . . . . . . . . . .12

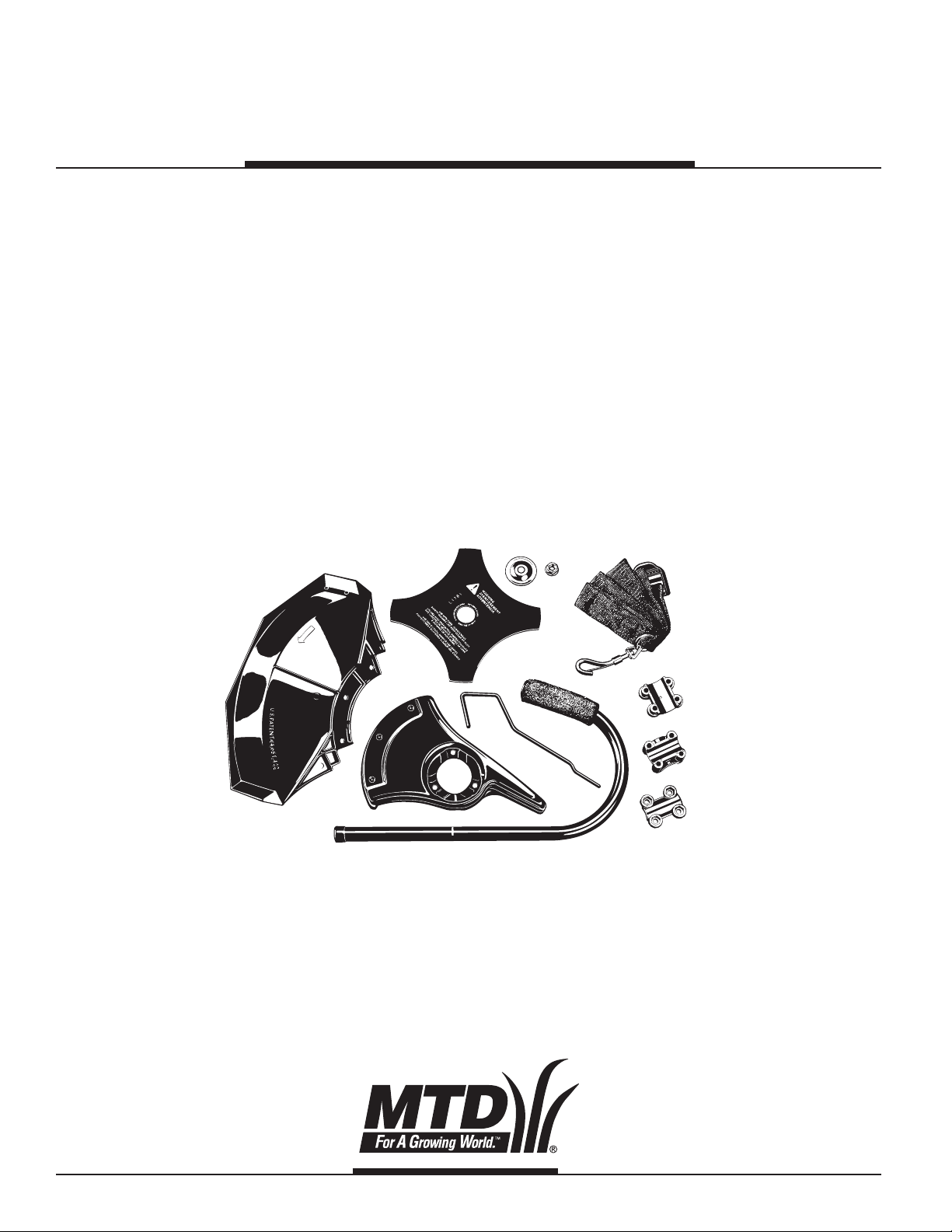

CONTENTS OF CARTON

This unit should consist of the following:

• J-Handle and Hardware

• 4-Tooth Cutting Blade with Hardware

• Cutting Attachment Shield Mount and Hardware

• Cutting Attachment Shield and Hardware

• Shoulder Harness

• Locking Rod

• Operator's Manual

Examine all parts to make certain that nothing is

missing and no breakage has occurred during

shipping. Any damaged or missing part must be

replaced before using this product.

TOOLS REQUIRED

The following tools are needed for assembly:

• 7/16” Wrench

• 5/8” Closed End or Socket Wrench

•Torx T-20 Screwdriver or Flat Blade Screwdriver

• Phillips Screwdriver

• Flat Blade Screwdriver

Page 3

RULES FOR SAFE OPERATION

3

SYMBOL MEANING

WARNING: Failure to obey a safety

warning can result in serious personal

injury to yourself or to others. Always

follow the safety precautions to reduce the

risk of fire and personal injury.

CAUTION: Failure to obey a safety

warning can result in serious personal

injury to yourself or to others. Always

follow the safety precautions to reduce the

risk of fire and personal injury

SYMBOL MEANING

SAFETY ALERT SYMBOL: Indicates danger,

warning or caution. Special attention is

required in order to avoid serious personal

injury. May be used in conjunction with

other symbols or pictographs.

NOTE: Advises you of information or instructions

vital to the operation or maintenance of

the equipment.

DANGER: Failure to obey a safety

warning will result in serious injury to

yourself or to others. Always follow the

safety precautions to reduce the risk of

fire, and personal injury.

• IMPORTANT SAFETY INFORMATION •

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols and their

explanations deserve your careful attention and understanding. The safety warnings do not, by themselves,

eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

READ ALL INSTRUCTIONS

BEFORE OPERATING

• Read the instructions carefully. Follow all

instructions when assembling and using this kit with

your unit.

• Clear the area before each use. Remove all objects

like rocks, broken glass, nails, wire or string which

can be thrown or become entangled in the cutting

attachment.

• Keep all bystanders, especially pets and children,

outside a 15 m. (50 ft.) radius, at a minimum.

Bystanders should also be encouraged to wear eye

protection. If you are approached, stop the engine

and cutting attachment immediately.

WHILE OPERATING

•Wear safety glasses or goggles that are marked as

meeting ANSI Z87.1-1989 standards, and

ear/hearing protection when operating this unit.

Wear a face or dust mask if the operation is dusty.

Long sleeve shirts are recommended.

•Wear heavy, long pants, boots, gloves and a long

sleeve shirt. Do not wear loose clothing, jewelry,

short pants, sandals or go barefoot. Secure hair

above shoulder level.

• The cutting attachment shield must always be in

place while operating the unit as a trimmer. Do not

operate unit without both trimming lines extended,

and the proper line installed. Do not extend the

trimming line beyond the length of the shield.

• Read and follow the operator’s manual that details

the unit where this kit will be used.

• Adjust the J-handle to provide the best grip.

• Be sure the cutting attachment is not in contact

with anything before starting the unit.

• Use only in daylight or good artificial light.

• Do not overreach. Always keep proper footing and

balance.

• Always hold the unit with both hands when

operating. Keep a firm grip on both the front and

rear handle or grips.

Page 4

RULES FOR SAFE OPERATION

4

• Keep hands, face, and feet at a distance from all

moving parts. Do not touch or try to stop the cutting

attachment when it is rotating.

• Do not operate the engine faster than the speed

needed to cut, trim or edge. Do not run the engine

at high speed when not cutting.

• Always stop the engine when cutting is delayed or

when walking from one cutting location to another.

• If you strike or become entangled with a foreign

object, stop the engine immediately and check for

damage. Do not operate before repairing damage. Do

not operate the unit with loose or damaged parts.

• Stop and switch the engine to off for maintenance,

repair, or for changing the cutting attachment or

other attachments.

• Use the right tool. Only use this tool for the purpose

intended.

• Keep unit clean of vegetation and other materials.

They may become lodged between the cutting

attachment and shield.

WHILE OPERATING WITH CUTTING BLADE

• Read and understand all safety warnings before

operating this unit.

• Always use the shoulder harness when using the

brush blade accessory.

• Keep the handle between the operator and cutting

attachment or blade at all times.

• NEVER cut with the cutting blade located over 30

inches (76 cm) or more above the ground level.

• Blade thrust may occur when the spinning blade

contacts an object that it does not immediately cut.

Blade thrust can be violent enough to cause the unit

and/or operator to be propelled in any direction, and

possibly lose control of the unit. Blade thrust can

occur without warning if the blade snags, stalls or

binds. This is more likely to occur in areas where it

is difficult to see the material being cut.

• For operation with the blade, do not cut anything

thicker than 12.7 mm (1/2 in.) or a violent kickback

could occur.

• Do not attempt to touch or stop the blade when it is

rotating.

•A coasting blade can cause injury while it continues

to spin after the engine is stopped or the throttle

trigger is released. Maintain proper control until the

blade has completely stopped rotating.

• Do not run the unit at high speed when not cutting.

• If you strike or become entangled with a foreign

object, stop the engine immediately and check for

damage. Have any damage repaired before

attempting further operations. Do not operate unit

with a bent, damaged or dull blade. Discard blades

that are bent, warped, or damaged.

• Do not sharpen the cutting blade. Sharpening the

blade can cause the blade tip to break off while in

use. This can result in severe personal injury.

Replace the blade.

• Do not use the cutting blade for edging or as an

edger, severe personal injury to yourself or others

can occur. Use the cutting blade only for the purpose

as described in this manual.

• Stop the engine IMMEDIATELY if you feel excessive

vibration. Vibration is a sign of trouble. Inspect

thoroughly for loose nuts, bolts or damage before

continuing. Repair or replace affected parts as

necessary.

AFTER USE

• Clean cutting blades with a household cleaner to

remove any gum buildup. Oil the blade with

machine oil to prevent rust.

• Lock up and store the cutting blade in an

appropriate area to protect the blade from

unauthorized use or damage.

SAVE THESE INSTRUCTIONS

Page 5

RULES FOR SAFE OPERATION

5

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this

product. Read the operator's manual for complete safety, assembly, operating, maintenance and repair

information.

MEANING

SAFETY ALERT SYMBOL

Indicates danger, warning or caution. May be used in conjunction with other symbols or

pictographs.

WARNING - READ OPERATOR'S MANUAL

Failure to follow operating instructions and safety precautions in operator's manual can result

in serious injury. Read operator's manual before operating

WEAR EYE AND HEARING PROTECTION

WARNING: The operation of any power tool can be the source of thrown objects and loud noise

which can cause severe eye injury and hearing loss. Always wear safety glasses or eye protection

and ear protection when operating this unit. Use a full face shield when needed.

NOTE: Long term exposure to the sound pressure levels specified may cause permanent loss

of hearing. Wear hearing protectors in accordance with AS 1270.

KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially children and pets, at least 15 meters

(50 feet) from the trimming area.

THROWN OBJECTS AND ROTATING CUTTER CAN CAUSE SEVERE INJURY

WARNING: Do not operate without the string guard in place. Keep away from rotating cutting

head.

SHARP BLADE

WARNING: Sharp blade on string guard. To prevent serious injury, do not touch blade.

BRUSHCUTTERS: REPLACE DULL BLADES

Do not sharpen the cutting blade. Sharpening the blade can cause the blade tip to break off

while in use. This can result in severe personal injury.

TRIMMER/BRUSHCUTTER SAFETY

WARNING: Thrown objects and rotating cutter can cause severe injury. Keep bystanders,

especially children and pets, at least 50 feet (15 m) away from the cutting area. The cutting

attachment shield must be used when using the trimmer cutting attachment.

SYMBOL

Page 6

FIGURE 2

FIGURE 3

ASSEMBLY INSTRUCTIONS

6

INSTALL THE BRUSHCUTTER KIT

The Brush Cutter Kit consists of:

• J-handle and hardware

• Harness

• New cutting attachment mount

• New cutting attachment shield

• Cutting blade

• Blade retainer and nut

• Locking Rod

The D-handle and old cutting attachment shield must

be removed and replaced. All other kit items must be

assembled before using the unit with the cutting blade.

WARNING: To avoid serious personal injury

or damage to the unit, ALL of the items in

the brush cutter kit MUST be installed when

operating the unit with the cutting blade.

(4) Screws

Shaft

Housing

D-Handle

Bottom Clamp

(4) Nuts

Shaft Grip

REMOVE THE D-HANDLE

Remove the D-handle before assembling the

J-handle.

1. Remove the four (4) screws and four (4) hex nuts

with a Phillips screwdriver.

2. Remove the D-handle and bottom handle clamp

on the boom shaft. See Figure 1.

FIGURE 1

INSTALL AND ADJUST THE J-HANDLE

Installation

1. Remove the screws, nuts and clamp pieces that

were installed on the J-handle for shipping.

2. Lay the unit on its side. On the bottom of the shaft

housing is a pre-drilled hole. With a flat blade or

Torx T-20 screwdriver, insert the anti-rotation

screw through the hole in the bottom clamp and

into the hole in the shaft housing. Tighten

securely. See Figure 2.

Shaft Housing

Anti-rotation screw

Bottom Clamp

Pre-drilled Hole

3. Place the J-handle between the top and middle

clamp pieces. See Figure 3.

(4) Screws

Top Clamp

J-Handle

Middle Clamp

Bottom Clamp

Nuts

4. While holding the three pieces together, install the

four (4) screws through the top clamp and into

middle clamp.

NOTE: The holes in the top and middle clamp will

line up only when assembled correctly.

5. Place the clamps and J-handle over the shaft

housing and onto the bottom clamp.

6. Hold each hex nut in the bottom clamp recess with

a finger. Start screws with a large Phillips

screwdriver. Do not tighten until you make the

handle adjustment.

Page 7

FIGURE 8

FIGURE 7

FIGURE 6

FIGURE 5

FIGURE 4

7

ASSEMBLY INSTRUCTIONS

Adjustment

7. Loosen the screws so that the J-handle easily

moves in the clamp assembly. Do not remove the

screws or nuts.

8. Slide the J-handle in or out until the arrow/white

line on the decal touches the clamp assembly. See

Figure 4.

9. While holding the unit in the operating position,

arrange the J-handle in the location that provides

you with the best grip. See Figure 5.

10. Tighten the clamp screws evenly, until the

J-handle is secure.

Decal

Support Fitting

INSTALL THE HARNESS

WARNING: To avoid personal injury, always

use the shoulder harness when using the

cutting blade.

1. Push the strap through the center of the buckle.

2. Pull the strap over the cross bar and down through

the slot in the buckle. See Figure 6.

3. Put the harness on over your head and onto your

shoulder. Snap it on to the support fitting. See

Figure 7.

4. Adjust length to fit the operator’s size. Pull tab to

lengthen, pull strap to shorten. See Figure 8.

Page 8

FIGURE 12

FIGURE 9

8

ASSEMBLY INSTRUCTIONS

FIGURE 11

REMOVE THE CUTTING ATTACHMENT

NOTE: To make removing or installing the cutting

blade or cutting attachment easier, place the

unit on the ground or on a work bench.

WARNING: The gear housing gets hot with

use and can result in injury to the operator.

When the unit is turned off it remains hot

for a short time. Do not touch the gear

housing until it has cooled.

1. Align the shaft bushing hole with the locking rod

slot and insert the locking rod into the shaft

bushing hole. See Figure 9.

Shaft Bushing Hole

Locking Rod

Slot

Output Shaft Bushing

Locking Rod

Output Shaft

2. Hold the locking rod in place by grasping it next to

the boom of the unit. See Figure 10.

3. While holding the locking rod, remove the cutting

attachment by turning it clockwise off of the

output shaft. Store the cutting attachment for

future use. See Figure 11.

Cutting Attachment

Locking Rod

Slot

Locking Rod

REMOVE THE OLD CUTTING

ATTACHMENT SHIELD

WARNING: You MUST remove the cutting

attachment shield (on the existing unit) and

install the cutting attachment mount

(provided with the blade kit) when operating

the unit as a brushcutter.

Remove the cutting attachment shield from the gear

housing by the removing the three (3) bolts and nuts

with a 7/16 wrench. Keep the hardware to use while

installing the new cutting attachment shield mount.

See Figure 12.

Bolts

Cutting Attachment

Shield

Gear Housing

Nuts

FIGURE 10

Page 9

FIGURE 14

9

ASSEMBLY INSTRUCTIONS

FIGURE 15

FIGURE 16

FIGURE 17

FIGURE 13

INSTALL THE NEW CUTTING

ATTACHMENT SHIELD MOUNT

Install the cutting attachment shield mount on the

gear housing by installing the three (3) bolts and nuts

removed from the old cutting attachment shield with

a 7/16 wrench. Nuts must be positioned on top for

correct assembly. See Figure 13.

INSTALL THE CUTTING BLADE

WARNING: To avoid serious personal injury,

always wear gloves while handling or

installing the blade.

1. Align the shaft bushing hole with the locking rod

slot and insert the locking rod into the bushing

hole. See Figure 14.

2. Hold the locking rod in place by grasping it next to

the boom of the unit. See Figure 15.

Nuts

Cutting Attachment

Shield Mount

Shaft Bushing Hole

Locking Rod Slot

Output Shaft

Bushing

Locking Rod

Output Shaft

3. Place the cutting blade on the output shaft

bushing. See Figure 16.

Shield

Mount

Locking Rod

Cutting

Blade

Blade Retainer

Nut

Output Shaft

Bushing

Pilot Hole

4. Make sure that the cutting blade is centered on the

pilot step and sitting flat against the output shaft

bushing. See Figure 17.

Pilot Step

Page 10

10

FIGURE 18

ASSEMBLY INSTRUCTIONS

WARNING: If the cutting blade is off-center,

the unit will vibrate, and the blade may fly

off, which can cause serious personal injury.

5. Put the blade retainer and nut on the output shaft.

Make sure that the blade is installed correctly.

6. Tighten nut counterclockwise against the blade

while holding the locking rod.

If using a torque wrench and a 5/8-inch socket, tighten to:

325 - 335 in•lb

27 - 28 ft.•lb

37 -38 N•m

Without a torque wrench, use a 5/8-inch closed-end or

socket wrench, turning the nut until the blade retainer

is snug against the shaft bushing. Make sure that the

blade is installed correctly, then rotate the nut an

additional 1/4 to 1/2 turn, counterclockwise. See

Figure 18.

FIGURE 19

Clockwise

1/4-1/2 turn

Counterclockwise

7.Remove the locking rod from the locking rod slot.

WARNING: To avoid serious personal injury

or damage to the unit, do not start or

operate this unit with the locking rod in the

locking rod slot.

WARNING: Do not sharpen the cutting blade.

Sharpening the blade can cause the blade tip to

break off while in use. This can result in severe

personal injury. Replace the blade.

REMOVE THE CUTTING BLADE AND

INSTALL THE CUTTING ATTACHMENT

WARNING: To avoid serious personal injury,

always wear gloves while handling or

installing the blade.

Remove the Cutting Blade

1. Align the shaft bushing hole with the locking rod

slot and insert the locking rod into the bushing

hole. See Figure 14.

2. Hold the locking rod in place by grasping it next to

the boom of the unit. See Figure 15.

3. While holding the locking rod, loosen the nut on

the blade by turning it clockwise with a 5/8-inch

closed-end or socket wrench. See Figure 19.

4. Remove the nut, blade retainer and blade. Store

the nut and blade together for future use in a

secure place. Store out of reach of children.

Install the Cutting Attachment

5. Align the shaft bushing hole with the locking rod

slot and insert the locking rod into the shaft

bushing hole. See Figure 14. Place the blade

retainer on the output shaft with the flat surface

against the output shaft bushing as shown in

Figure 20. Screw the cutting attachment

counterclockwise onto the output shaft. Tighten

securely.

Cutting Attachment

Locking Rod

Blade Retainer

Output Shaft

Bushing

FIGURE 20

NOTE: The blade retainer must be installed on the

output shaft in the position shown for the

cutting attachment to work correctly.

Page 11

11

FIGURE 21

6. Remove the locking rod.

7. Install the cutting attachment shield. See Remove

and Install Cutting Attachment Shield.

WARNING: To avoid serious personal injury,

the cutting attachment shield MUST be in

place at all times during operation as a grass

trimmer.

REMOVE AND INSTALL THE CUTTING

ATTACHMENT SHIELD

Remove the cutting attachment shield when using the

unit as a brush cutter.

WARNING: The cutting attachment shield

should NOT be installed when operating the

unit with a blade. Remove the cutting

attachment shield before removing or

installing the blade.

Remove the cutting attachment shield from the shield

mount by removing the three (3) screws with a flat

blade screwdriver. Store parts for future use. See

Figure 21.

Install the cutting attachment shield when using the

unit as a grass trimmer.

WARNING: To avoid serious personal injury,

the cutting attachment shield MUST be in

place at all times during operation as a grass

trimmer.

Install the cutting attachment shield on the shield

mount by inserting the three (3) screws into the shield

mount. Tighten securely with a flat blade screwdriver.

See Figure 21.

(3) Screws

Cutting

Attachment

Shield

Shield Mount

Gear Housing

ASSEMBLY INSTRUCTIONS

OPERATING INSTRUCTIONS

HOLDING THE UNIT

WARNING: Always wear eye, hearing, foot

and body protection to reduce the risk of

injury when operating this unit.

Before operating the unit, stand in the operating

position. See Figure 23. Check for the following:

• The operator is wearing eye protection and proper

clothing

• With a slightly-bent right arm, the operator’s hand

is holding the shaft grip

• The operator’s left arm is straight, and the hand is

holding the D-Handle

• The unit is at waist level

• The cutting head is parallel to the ground and easily

contacts the vegetation without the need to bend

over

FIGURE 23

Page 12

FIGURE 24

OPERATING INSTRUCTIONS

USING THE CUTTING BLADE

WARNING: Always wear eye, hearing, foot,

body protection and the harness to reduce

the risk of injury when operating this unit.

WARNING: Do not use the cutting blade for

edging or as an edger; severe personal injury

to yourself or others can occur.

Before operating the unit with the cutting blade, stand

in the operating position See Figure 23. Refer to the

previous section, Holding the Unit.

Cutting Blade Operating Tips:

To establish a rhythmic cutting procedure:

•Plant feet firmly, comfortably apart.

• Bring the engine to full throttle before entering the

material to be cut. The blade has maximum cutting

power at full throttle and is less likely to bind, stall,

or cause blade thrust, which can result in serious

personal injury to the operator or others.

• Cut while swinging the upper part of your body

from right to left. See Figure 24.

• Always release the throttle trigger and allow the

engine to return to idle speed when not cutting.

• When done always unsnap unit from harness before

taking off the harness.

WARNING: Blade thrust may occur when

the spinning blade contacts an object that it

does not immediately cut. Blade thrust can

be violent enough to cause the unit and/or

operator to be propelled in any direction, and

possibly lose control of the unit. Blade thrust

can occur without warning if the blade

snags, stalls or binds. This is more likely to

occur in areas where it is difficult to see the

material being cut.

• The cutting blade is designed with a second cutting

edge, which can be used by removing the blade,

turning it upside down, and reinstalling it.

WARNING: Do not sharpen the cutting

blade. Sharpening the blade can cause the

blade tip to break off while in use. This can

result in severe personal injury to yourself or

others. Replace the blade.

To reduce the chance of material wrapping around the

blade, follow these steps:

• Cut at full throttle.

• Swing the unit into material to be cut from your

right to your left. See Figure 24.

•Avoid the material just cut as you make the return

swing.

WARNING: Do not clear away cut material

with the engine running or blade turning. To

avoid serious personal injury, turn off engine.

Allow the blade to stop before removing

materials wrapped around the blade shaft.

WARNING: The blade continues to spin

after the engine is turned off. The coasting

blade can seriously cut you if you

accidentally touch it.

• Swing the unit in the same direction as the blade

spins, which increases the cutting action.

• Move forward to the next area to be cut after the

return swing and plant feet again.

OPERATOR’S MANUAL PART NO. 10570 REV .A

PRINTED IN THE USA 7/02

Loading...

Loading...