Page 1

Presented By

Dallas HoustonAustinFt Worth

NicolScales.com

800.225.8181

Contact Us

Nicol Scales & Measurement is an ISO Accredited Calibration

Company that has provided calibration, repair and sales of all types

of weighing and measurement products since 1931.

Page 2

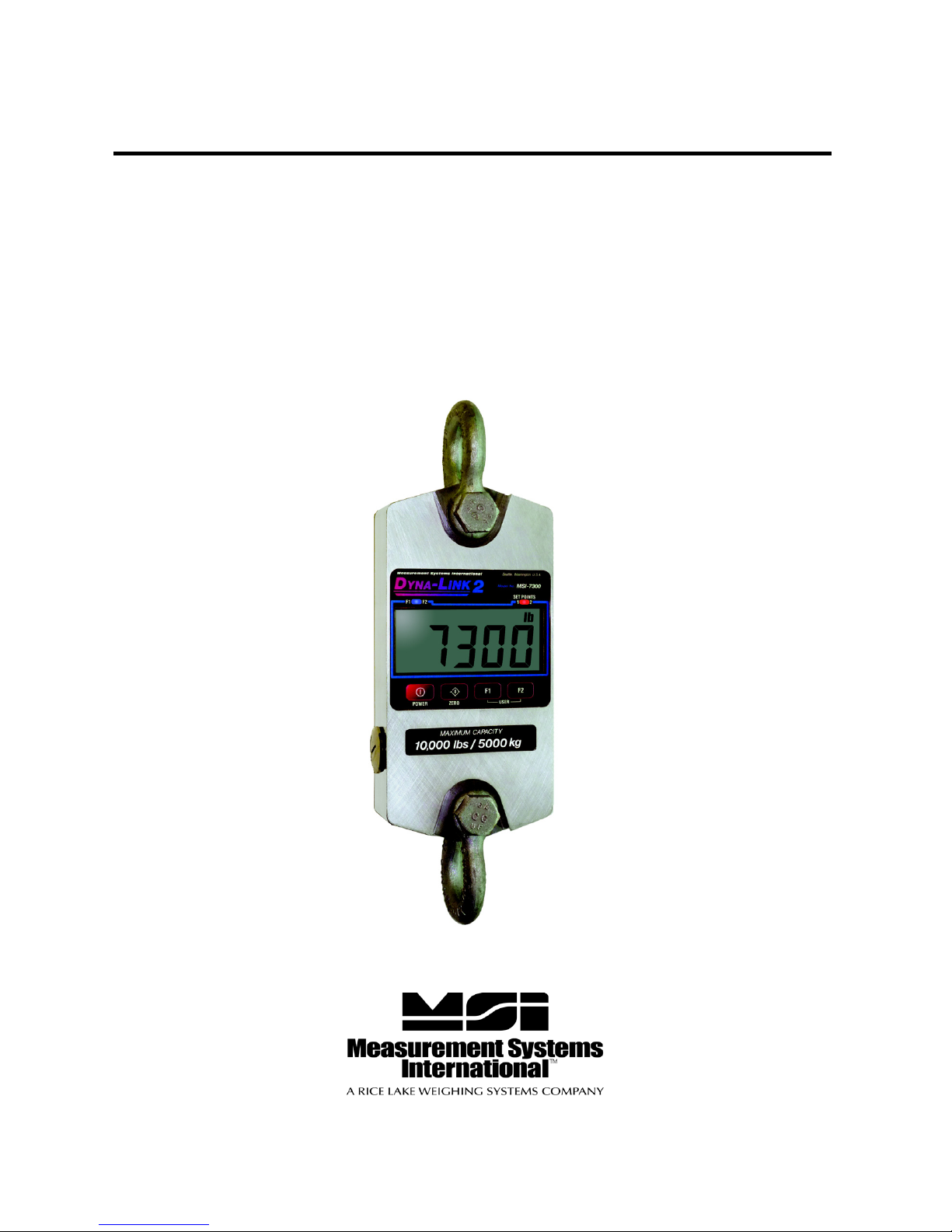

MSI-7300

Dyna-Link 2 Tension Dynamometer

Operator’s Manual

PN 152160 Rev C

Page 3

Page 4

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

Contents

1.0 Introduction ................................................................................1

1.1 Safety ..........................................................................................2

1.2 Key Descriptions ........................................................................ 3

1.3 General Information ...................................................................4

1.4 MSI-7300 Annunciators .............................................................6

1.5 Specifications .............................................................................7

1.5.1 Standard Capacities and Resolution ..........................................8

1.6 Features ......................................................................................9

1.7 Options .....................................................................................10

1.8 Unpacking ................................................................................10

1.9 Assembly ..................................................................................10

1.10 Battery Replacement ...............................................................11

2.0 Operation ..................................................................................12

2.1 Power .......................................................................................12

2.2 Zero ..........................................................................................12

3.0 User Key Functions (F1and F2) ................................................13

3.1 OFF ...........................................................................................13

3.2 TEST .........................................................................................13

3.3 TOTAL .......................................................................................13

3.3.1 MANUAL TOTAL .....................................................................13

3.3.2 AUTO TOTAL ..........................................................................14

3.4 Clear Total ................................................................................14

3.5 Net / Gross ...............................................................................14

3.6 TARE .........................................................................................14

3.6.1 To Tare and Display the Net Tension .......................................15

3.6.2 To Clear the Tare and Revert to Gross Tension .......................15

3.6.3 Tare- Rules for Use: ................................................................15

3.7 PEAK HOLD .............................................................................. 15

3.8 2-UNITS/ 5-UNITS ....................................................................16

3.9 HI-RES ......................................................................................17

3.10 PRINT .......................................................................................17

4.0 Dyna-Link Setup .......................................................................18

4.1 Menu Map ................................................................................18

4.2 Function Keys ..........................................................................19

4.3 Auto-Off ....................................................................................20

4.4 Setpoints ..................................................................................21

4.5 Total Mode ............................................................................... 23

4.6 Units ..........................................................................................24

4.7 Filter Setup ............................................................................... 25

5.0 Calibration ................................................................................26

5.1 Calibration Menu ...................................................................... 26

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Rice Lake Weighing Systems is an ISO 9001 registered company.

June 8, 2015

Page 5

ii MSI-7300 Operator’s Manual

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

5.2 Initial Calibration ......................................................................29

5.3 Guidelines for Capacity and Resolution .................................31

5.4 C-Cal Calibration ...................................................................... 32

5.5 Auto Zero Maintenance (AZM) ................................................ 34

5.6 Service Counters ...................................................................... 35

6.0 Communication Setup .............................................................36

6.1 RF Option ................................................................................. 36

6.2 Printer Setup ............................................................................ 37

6.2.1 Standard Print Strings .............................................................38

6.2.2 Printer Output Setup ...............................................................39

6.3 Comm Port Hardware .............................................................. 41

6.4 802.15.4 RF Network Setup ..................................................... 42

6.5 FCC Statement (For 802.15.4 Option) ..................................... 45

6.6 International RF CERTS (For 802.15.4 Option) .......................45

7.0 Appendix ..................................................................................46

7.1 Troubleshooting .......................................................................46

7.2 Error Codes ..............................................................................48

7.3 Mechanical Dimensions ........................................................... 49

7.4 Firmware Update Procedure ...................................................50

The MSI Limited Warranty ............................................................52

Page 6

Introduction 1

1.0 Introduction

The MSI-7300 Dyna-Link 2 is a combination of the sound and proven mechanical

design of the industry standard Dyna-Link with today’s most advanced electronics to

provide a superb feature set unmatched by any dynamometer in its class or price

range.

The Dyna-Link 2 is vers

atile, reliable, accurate, and easy to operate. The multipurpose tension dynamometer is ideal for situations in which headroom is at a

minimum. It is designed with safety factors exceeding the industry standard and is

fully sealed for outdoor use in any weather.

A remote display option is available to further enhance the saf

ety and usability. The

optional RF remote display allows tension monitoring from a distance and adds the

ability to print and store data.

If you have any questions or comments, please contact

MSI Scales

Phone (toll free): 1-800-874-4320

MSI SCALES

Authorized distributors and their employees can view or download this

manual from the MSI Scales distributor site at:

www.msiscales.com.

Page 7

2 MSI-7300 Operator’s Manual

1. 1 Sa fe ty

Safety Symbol Definitions:

Important

WARNING

Indicates a potentially hazardous situation that, if not avoided,

could result in serious injury or death, and includes hazards that

are exposed when guards are removed.

Indicates information about procedures that, if not observed,

could result in damage to equipment or corruption to and loss of

data.

General Safety

WARNING

Do not operate or work on this equipment unless you have read and

understand the instructions and warnings in this manual. Contact

any Measurement Systems International dealer for replacement

manuals. Proper care is your responsibility.

Failure to heed may result in serious injury of death.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT stand near the load being lifted as it

is a potential falling hazard. Keep a

safe distance.

DO NOT use for purposes other then weigh

t taking or dynamic load monitoring.

DO NOT use any load bearing component that is worn beyond 5% of the original

dimension.

DO NOT use the dynamometer if any of t

he components of the load train are

cracked, deformed, or show signs of fatigue.

DO NOT exceed the rated load limit of the dynamometer, rigging elements, or the

li

fting structure.

DO NOT allow multi-point contact with the shackles of the dynamometer unit.

DO NOT allow high torque on the dynamometer unless it

is specifically designed

for high torque.

DO NOT make alterations or modifications t

o the dynamometer or the shackles.

DO NOT use improperly rated or sized shackles. Use only MSI recommended

shackles.

DO NOT remove or obscure warning labels.

For guidelines on the safe rigging and l

oading of overhead scales and

dynamometers, read the "MSI Crane Scale Safety and Periodic Maintenance

Manual" (available at www.msiscales.com).

Keep hands, feet and loose clothing

away from moving parts.

There are no user serviceable parts within the Dyna-Link 2. Any repai

rs are to be

performed by qualified service personnel only.

Page 8

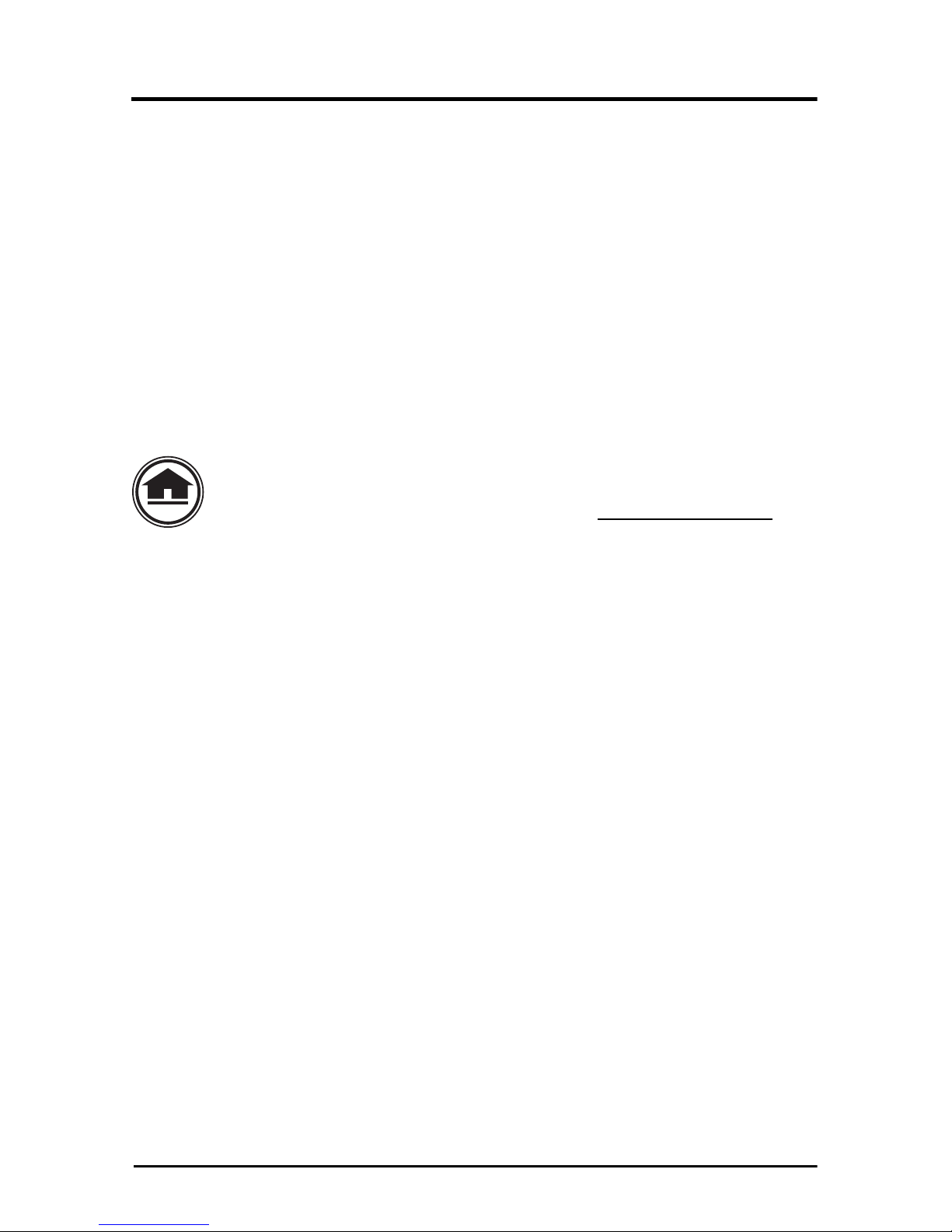

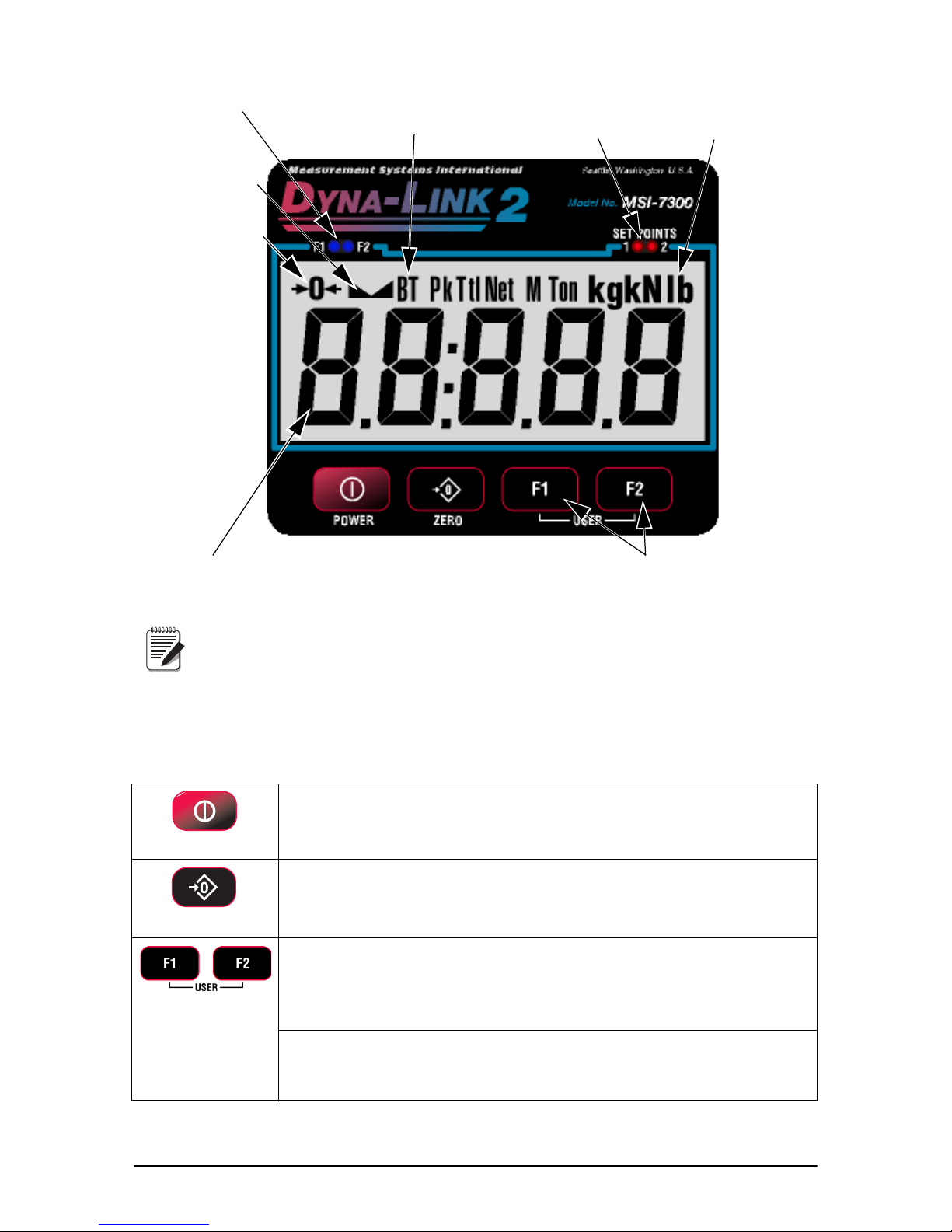

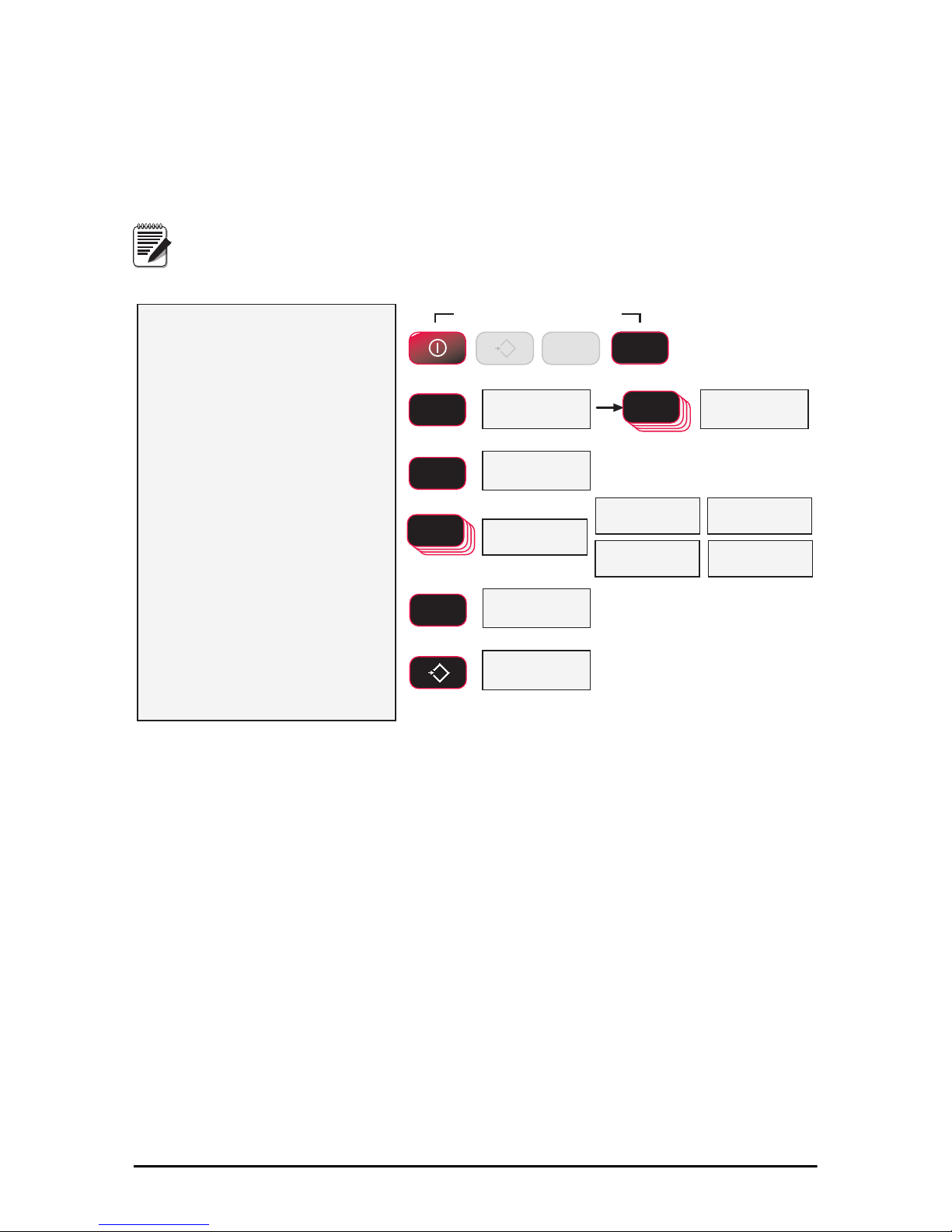

Function key LEDs

Battery low

Stable

Center of zero

5 Digit 1.22 in (31mm)

Sunlight visible

LCD Tension Display

Units with maximum capacity of

100000 lb and up come with a 6 digit

1 in (26 mm) display.

Note

Setpoint

alarm LEDs

Units & tension

mode annunciators

User programmable

function keys

Introduction 3

Figure 1-1. MSI-7300 Front Panel

1.2 Key Descriptions

POWER

Power Key - Turns the Dyna-Link 2 on and off.

Used as cancel or last menu in the menu mode.

ZERO

Zero Key - Used to zero out residual tension on the link.

Used as enter or save in the menu mode

Common uses are units change or peak hold for dynamic testing.

F1- Pr

ogrammable to user selectable functions, see Section 3.0.

Default – peak hold.

Functions as the ENTER/SELECT key in the menu mode.

F2 -

Programmable to user selectable functions, see Section 3.0.

Default – display & function test.

Functions as the scroll key in the menu mode.

Page 9

4 MSI-7300 Operator’s Manual

1.3 General Information

1. If the text is discussing a function key, the function key will be displayed as Fx-

YYYYY

with the programmed user key function in italics. F1 and F2 can both be

programmed to all available user functions.

2. If a function key does not work, it is probably because the Dyna-Link 2 is not

setup to support the key. For example, if the Function key is set for TOTAL, you

must also setup the TOTAL mode in the setup menu.

3. When in setup menus, the ZERO key drops back one menu level. At the root

menu level, the ZERO key stores the changes and returns to the tension mode.

4. When in setup menus, the POWER key returns you directly to the tension

display without storing the changes.

Page 10

5000 lbs / 2500 KG

MAXIMUM CAPACITY

7300

lb

Top shackle interface

Cotter pins

Battery

access

cover

Bottom shackle interface

RS-232 port

Introduction 5

Figure 1-2. Dyna-Link 2

Page 11

6 MSI-7300 Operator’s Manual

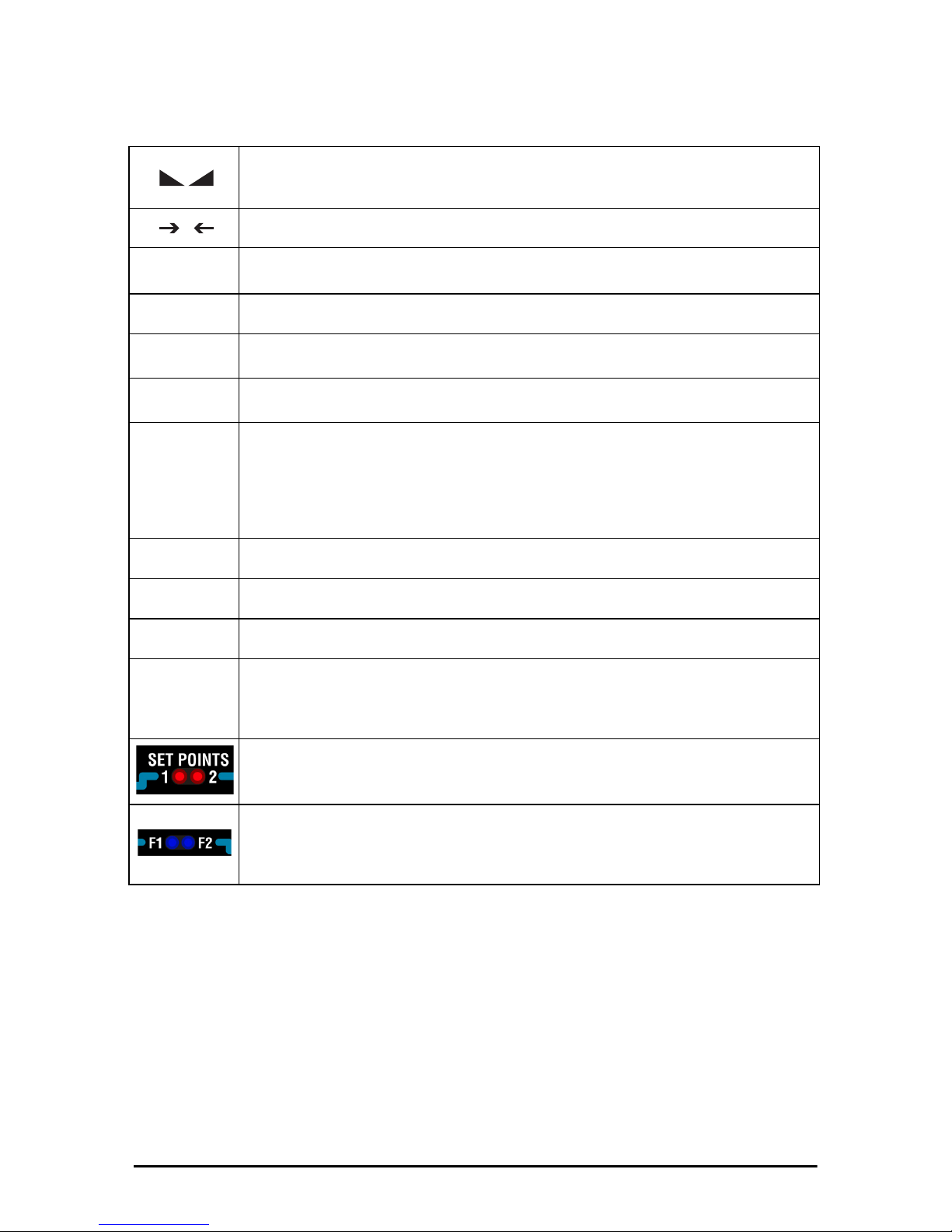

1.4 MSI-7300 Annunciators

The Dyna-Link 2 uses LCD annunciators to indicate tension mode and other

information.

Figure 1-3. MSI7300 Annunciators

Stable – indicates the tension force has settled within the motion window

(usually ±1d).

When standstill is off, the link will not zero, tare, or totalize.

Center-of-Zero – Indicates the ten

sion is within 1/4 d of zero.

BT

Low Battery – Appears when approximately 10% of battery life remains.

The BT symbol blinks when automatic shutdown is imminent.

Pk

PEAK- Indicates peak hold mode.

Ttl

TOTAL – Indicates the unit is displaying the total accumulated weight.

This is a temporary display lasting less than five seconds.

Net

NET – Indicates the unit is in the net tension mode.

A tare weight is subtracted from the gross tension.

M

Metric Ton – In conjunction with the ton annunciator, indicates the unit is

displaying metric tons.

When used with the total display, it is used for X1000 to allow

accumulation of weight beyond the five digit display capacity.

It is also used with the service counters when the number of lifts exceeds

five digits.

kg

kg – Indicates tension display is in kilograms.

kN

kN – Indicates the tension display is in kilonewtons.

lb

lb – Indicates tension display is in pounds.

Ton

Ton – Illuminated alone, indicates the unit is displaying in US short tons

(1 ton = 2000 lb).

When illuminated along with the ‘M’ the unit is displaying in metric tons

(1 metric ton = 1000 kg)

SETPOINTS – User programmable setpoints for early overload warnings.

Setpoints 1 and 2 are high brightness red LEDs

F1 F2 – These blue LEDs are used to indicate various operational features

of functions programmed into the F1 and F2 keys.

Example: In peak hold mode the associated LED will blink whenever a

new peak reading is captured.

0

Page 12

Introduction 7

1.5 Specifications

Table 1-1. MSI-7300 Specifications

Accuracy

Rated accuracy: ±0.1% of capacity. T

ypical accuracy ±(0.1%+1d) of

reading. ‘d’ equals one displayable increment.

Resolution

Standard displayed resolution: 2000-25

00 ‘d’ . Hi-Res mode increases

resolution to 5000-6250 ‘d’. Internal A/D resolution: 24 bits.

Overload

Power

Display

Operating

Te

m p

Operating

Tim

e

Load Cell &

Enclosure

Load Cell

F1 and F2

Calibration

Auto Zero

Maintenance

Auto-Off

Mode

Units

Filtering

Totalization

Peak

Setpoints

Service

Counte

r

WARNING

The MSI-7300 has a safe mechanical overload of 200% of capacity.

Overloads greater than 200% may result in physical damage to the

link. The ultimate overload is rated to 500%-700% of capacity (see

Table 1-2). At ultimate overload, structural failure and dropped

loads may occur. Dropped loads may cause serious personal injury

or death.

Safe link mechanical overload, 200% of capacity. Ultimate link overload,

>500% of capacity. Typical ultimate overload is 700% or greater. Note that

the Dyna-Link is designed to have a greater safety factor than the connecting

shackles which have a typical ultimate safety factor of 600%

Battery operated, see Table 1-2 for battery size

and quantity per unit.

Alkaline cells can be replaced with rechargeable NiMH cells.

Five digit, 1.22 in (31 mm) numeric digits.

Six digi

t, 1 in (26 mm) on 100000 lb units and higher

- 40°F to +122°F (-40°C to +50°C), Rate

d accuracy range -10°C to +40°C.

>150 hours typical (Alkaline C cells) / >300

hours typical (Alkaline D cells).

NEMA Type 4/IP65 anodized aluminum, 2024-T351 Aircraft Quality.

2000

Ω Bridge

Programmable multifunction buttons for use as TEST, TOTAL, UNIT, PEAK,

TARE, NET/GROSS, VIEW TOTAL, PRINT AND High Res mode.

Fully digital calibration from the front panel

or through a computer interface.

Standard, can be disabled internally.

Prolongs battery life by turning the power off after 15, 30, 45, or 60 minutes

(oper

ator determined) of no Dyna-Link activity.

kg, lb, Tons (US short ton), Metric Tons, k

ilonewtons (other Units available

with custom calibrations).

Selectable - OFF, Low (LO), Medium (HI-1), High (HI-2).

Standard - Press button or automatic; TOTAL weight up to 99999 X1000

un

its

Uses unfiltered faster reading of A/D, (>22

0 readings per second).

Two internal standard setpoints and two

ultrabright LEDs on indicator panel

Two independent 16 bit registers; registe

r 1 updated each time the force

exceeds 25% of capacity; register 2 updated each time the force exceeds

overload; when register 1 exceeds 16383 or register 2 exceeds 1023,

display reads “LCnt” for load cell counter; test function shows the two

readings in order.

Page 13

8 MSI-7300 Operator’s Manual

1.5.1 Standard Capacities and Resolution

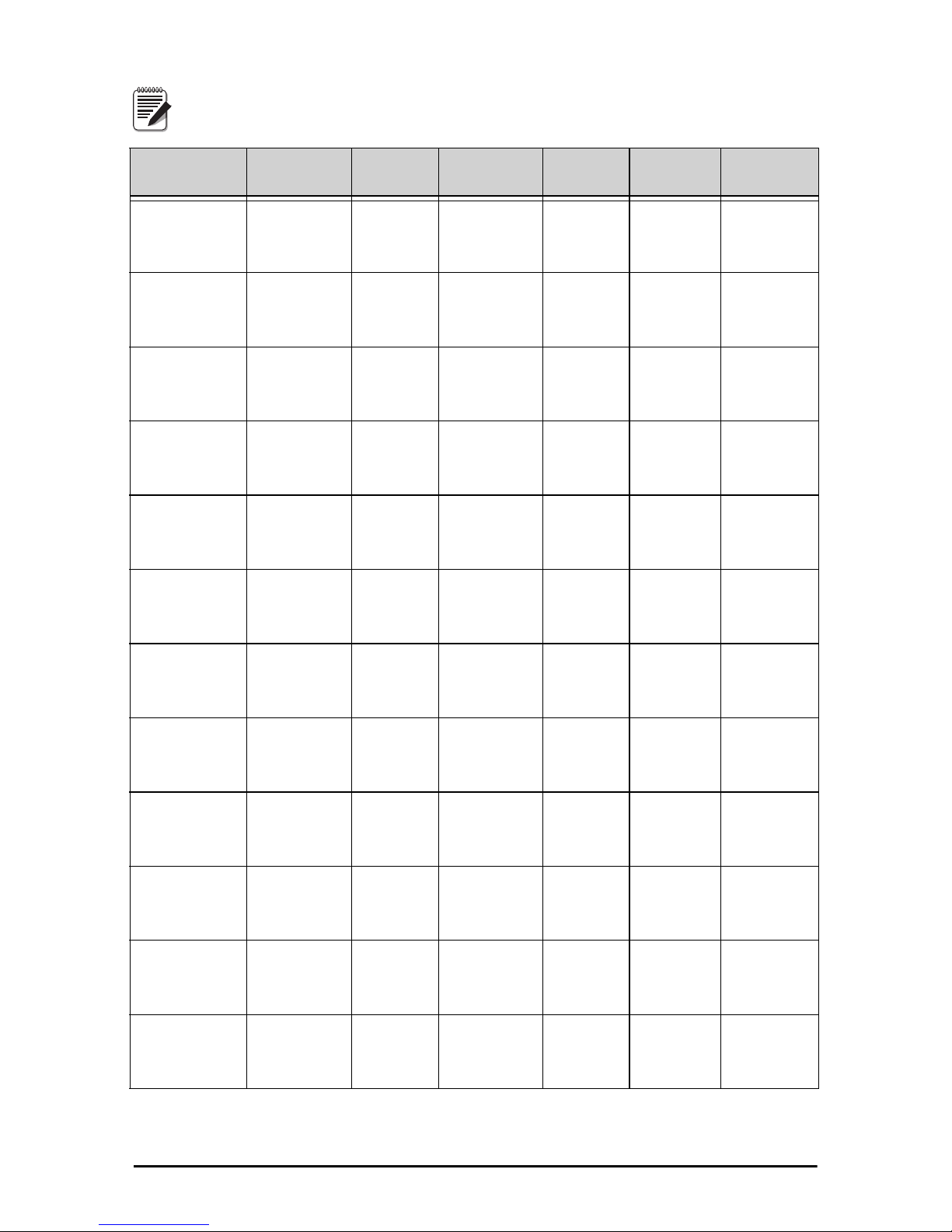

Table 1-2. Standard Capacities and Resolutions

Capacity

Std

‘d’

Std

Counts HiRes ‘d’

HiRes

Counts

Ultimate

Overload Config

1000 lb

500 kg

0.5 Ton

4.9 kN

0.5 lb

0.2 kg

0.0002 T

0.002 kN

2000

2500

2500

2450

0.2 lb

0.1 kg

0.0001 T

0.001 kN

5000

5000

5000

4900

>>700% Alum

2 C-Cells

2500 lb

1250 kg

1.25 ton

12.25 kN

1 lb

0.5 kg

0.0005 T

0.005 kN

2500

2500

2500

2450

0.5 lb

0.2 kg

0.0002 T

0.002 kN

5000

6250

5000

4900

700% Alum

2 C-Cells

5000 lb

2500 kg

2.5 Ton

24.5 kN

2 lb

1 kg

0.001 T

0.01 kN

2500

2500

2500

2450

1 lb

0.5 kg

0.0005 T

0.005 kN

5000

5000

5000

4900

700% Alum

2 C-Cells

10000 lb

5000 kg

5.0 Ton

4.9 kN

5 lb

2 kg

0.002 T

0.02 kN

2000

2500

2500

2450

2 lb

1 kg

0.001 T

0.01 kN

5000

5000

5000

4900

700% Alum

2 C-Cells

25000 lb

12500 kg

12.5 Ton

122.5 kN

10 lb

5 kg

0.005 T

0.05 kN

2500

2500

2500

2450

5 lb

2 kg

0.002 T

0.02 kN

5000

6250

6250

6125

700% Alum

2 D-Cells

50000 lb

25000 kg

25 Ton

245 kN

20 lb

10 kg

0.01 T

0.1 kN

2500

2500

2500

2450

10 lb

5 kg

.005 T

0.05 kN

5000

5000

5000

4900

600% Alum

2 D-Cells

100000 lb

50000 kg

50 Ton

490 kN

50 lb

20 kg

0.02 T

0.2 kN

2000

2500

2500

2450

20 lb

10 kg

0.01 T

0.1 kN

5000

5000

5000

4900

550% Alum

2 D-Cells

120000 lb

60000 kg

60 Ton

588 kN

50 lb

20 kg

0.02 T

0.2 kN

2400

3000

3000

2940

20 lb

10 kg

0.01 T

0.1 kN

6000

6000

6000

5880

500% Steel

2 D-Cells

180000 lb

90000 kg

90 Ton

882 kN

100 lb

50 kg

0.05 T

0.5 kN

1800

1800

1800

1764

50 lb

20 kg

0.02 T

0.2 kN

3600

3600

4500

4410

500% Steel

2 D-Cells

260000 lb

130000 kg

130 Ton

1275 kN

100 lb

50 kg

0.05 T

0.5 kN

2600

2600

2600

2550

50 lb

20 kg

0.02 T

0.2 kN

5200

6500

6500

6375

500% Steel

2 D-Cells

380000 lb

190000 kg

190 Ton

1863 kN

200 lb

100 kg

0.1 T

1 kN

1900

1900

1900

1863

100 lb

50 kg

0.05 T

0.5 kN

3800

3800

3800

3726

500% Steel

2 D-Cells

550000 lb

225000 kg

225 Ton

2206 kN

200 lb

100 kg

0. 1 T

1 kN

2750

2250

2500

2206

100 lb

50 kg

0.05 T

0.5 kN

5500

4500

5000

4412

440% Steel

3 D-Cells

Note

Short ton and metric ton resolutions are the same.

Page 14

Introduction 9

1.6 Features

• Designed to meet or exceed all U.S. and International safety and environmental

standards.

• Greater than 150 hours operation with two standard Alkaline ‘C’ cells. Greater

than 300 hours with two standard Alkaline ‘D’ Cells (25000 lb/12500 kg

capacities and above). Also works with off the shelf NiMH rechargeable cells.

• Automatic power off conserves battery life by sensing no activity after 15,30,45

or 60 minutes, determined by operator, and turns power off.

• Rugged construction throughout. IP65/NEMA Type 4 for outdoor use.

• Designed for use with USA made Crosby shackles (optional).

• Shackle holes reinforced with steel sleeves (25000 lb/12500 kg capacities and

above) to reduce wear.

• Shackle stops ensure ease of mounting. The stops prevent the shackles from

falling to the side of the unit and are held in position for easy rigging.

• MSI’s ScaleCore technology provides precision, high resolution (2500 division

standard and up to 10,000 possible) 24 bit A/D conversion coupled with an

advanced RISC microcontroller.

• Five large, 1.22 inch (31 mm) LCD digits for clear tension readings from a

distance. Six digits, i in (26 mm) on units 100,000 lb and over.

• Easy to maintain: Full digital calibration assures reliable, repeatable

measurements. Can be calibrated without test weights using MSI C-Cal

technology.

• Selectable kg/lb/tons (US Short)/metric tons/kilonewtons.

• Automatic or manual weight totalization for loading operations.

• Easily customized for special applications.

• Hi speed PEAK mode for stress and drop test analysis.

• Two setpoints can be set for any in-range tension/weight value for operator alerts

or process control. Optional audible alarm output.

• ScaleCore technology provides quick and easy firmware updates and calibration/

setup backup.

• Two Service counters ensure load train safety by warning the user to perform

safety checks when the lift count gets high or the Dyna-Link has been overloaded

repeatedly. Counter 1 (LFCnt) records the number of lifts above 25% of capacity.

Counter 2 (OLCnt) records the number of times the Dyna-Link overloads.

Page 15

10 MSI-7300 Operator’s Manual

1.7 Options

Options which you may have ordered with your Dyna-Link 2 may include the

following:

• Audible alarm (triggered by setpoint 1)

• Top and bottom shackles

• Portable carry case

• Serial I/O cable (RS-232)

• RF remote display (will also operate hard-wired)

. See RF remote display for

ScaleCore user guide.

• Hardwired cable for remote display.

• RF remote modem, RS-232, for direct connection to computers, scoreboards, or

serial printers. See

RF modem for ScaleCore user guide.

• RF remote modem, USB, for direct connection to computers. See RF modem for

ScaleCore user

guide.

• RF remote gateway for direct connection to an Ethernet LAN and for use with

MSI’

s SCCMP program. See RF modem for ScaleCore user guide.

• RF or hardwired scoreboard display.

1.8 Unpacking

When unpacking the Dyna-Link 2 from the shipping container, ensure that all

assembly parts are accounted for.

Check for any visible damage and immediately report any damage to your shipper.

Retain the original shipping container for future shipping or transporting.

1.9 Assembly

1. Identify and locate the following:

• Batteries, two ‘C’ cells or

‘D’ cells depending on capacity

• Top shackle and pin (option or customer supplied)

• Bottom shackle and pin (option or customer supplied)

• Two cotter pins

2. Slide top shackle over load cell and insert the pin.

3. Screw the shackle nut onto the pin.

WARNING

Note

Note

It is not necessary or desirable to tighten the nut too tight. Make sure

the nut is down far enough to expose the cotter pin hole.

4. Lock the shackle pin in place with the supplied cotter pin. Bend the cotter pin.

5. Repeat steps 1-3 for the bottom shackle.

6. Remove the battery access port

cover with a coin or a large screwdriver.

7. Insert the two batteries, positive end first, into the battery shaft.

8. Reinstall the battery access port cover. The Dyn

a-Link 2 is now ready for use.

The Dyna-Link2 will automatically start when the batteries are

installed.

The Dyna-Link 2 load train will be unsafe for use i

f the shackle pins

are not properly secured with cotter pins.

Page 16

Introduction 11

1.10 Battery Replacement

Disposable Batteries

The BT annunciator will display when the is battery is beginning to get low. When the

BT annunciator starts to blink, the batteries are close to being completely drained. For

maximum life, use the batteries until the system shuts off.

Rechargeable Batteries

When using Nickle-Metal-Hydrid

e (NiMH) Cells, it is recommended that the cells

are recharged immediately after the BT annunciator starts to blink. Do not allow the

batteries to discharge completely, it may compromise the recharge life of the battery.

NiMH Cells in C and D sizes have a lower

capacity then the Alkaline C and D sizes.

MSI recommends having two sets of NiMH batteries, so one set can be charging

while the other is in use.

Note

NiMH ‘D’ cells are often repackaged ‘C’ cells so you don’t get an

increase in battery life for Dyna-Links large enough for ‘D’ cells.

The use of NiCad batteries is not

recommended.

If the Dyna-Link 2 will not be used for an extended period, the batteries should be

removed. A small current is used when powered off which will discharge the batteries

in about six months.

Page 17

12 MSI-7300 Operator’s Manual

2.0 Operation

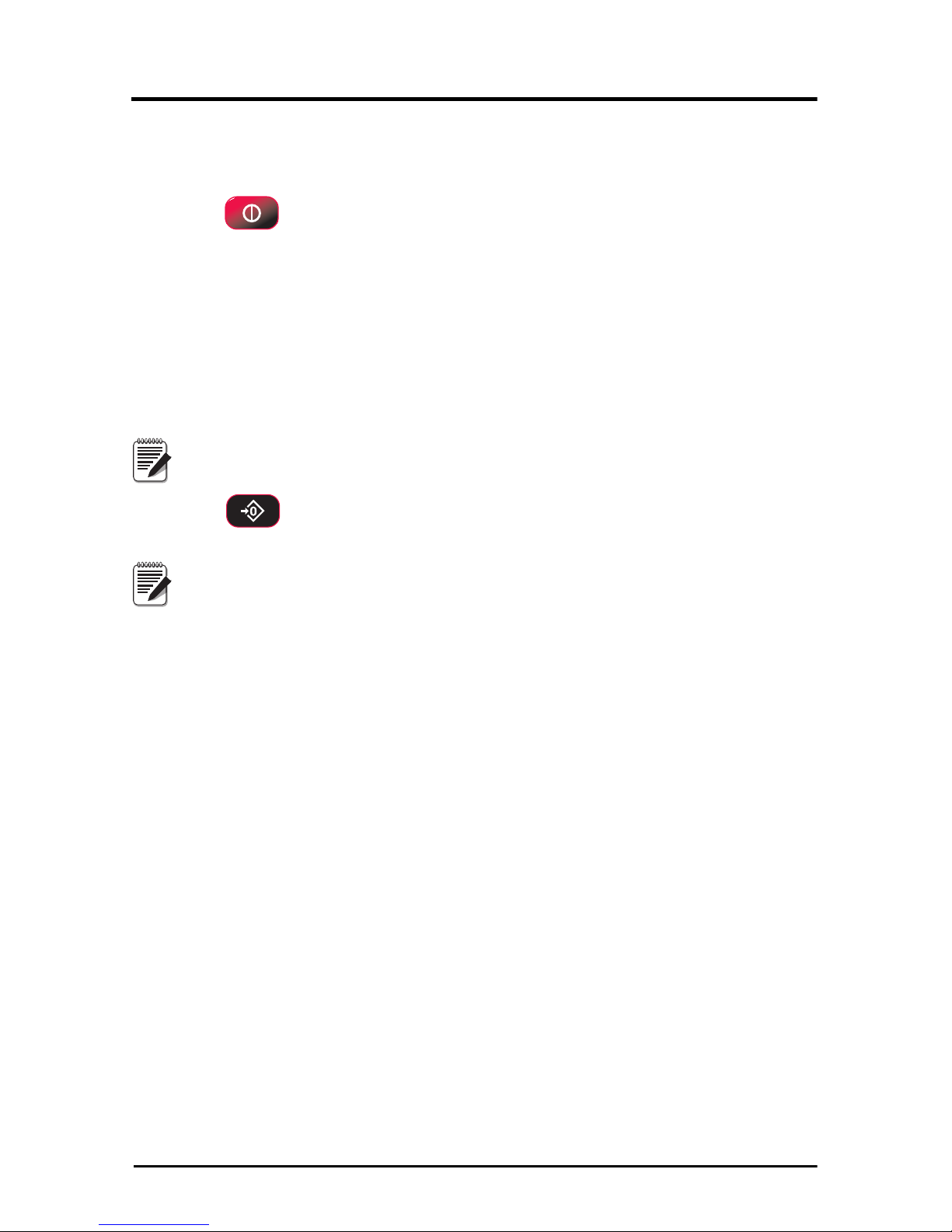

2.1 Power

To turn on the Power

1. Press

POWER

.

• The LCD will show all segments for a display test.

• The software version number will display.

The D

yna-Link 2 is ready for use.

2.2 Zero

Takes out small deviations in zero when the Dyna-Link 2 is unloaded. See Section 3.6

for zeroing (Taring) package or pallet weights.

Note

Note

The tension reading must be stable within the motion window for the

zero function to work.

1. Press

ZERO

. The display reads 0 (or 0.0 or 0.00, etc).

The backup memory stores the zero reading, and can restore it even if

power fails.

Zero - Rules for Use:

• Works in GROSS mode or NET mode. Zeroing while in NET mode will zero

the gross tension causing the display to show the negative tare value.

• The unit must be stable within the motion window, it will not zero until the

stable ann

unciator is on.

• The unit will “remember” that it has a zero

request for two seconds. If motion

clears in that time, it will zero.

• The unit will accept a zero setting over the full range of the Dyna-Link. Zero

setti

ngs above 4% of full Dyna-Link will subtract from the overall capacity.

For example, if you zero out 100 lb on a 1000 lb Dyna-Link, the overall

capacity will reduce to 900 lb plus the allowed over-range amount.

Page 18

User Key Functions (F1and F2) 13

3.0 User Key Functions (F1and F2)

There are optional functions that can be programmed for the function keys (F1 and

F2) on the front panel, as well as on the RF remote display. See Section 4.2 for setup

instructions.

Note

The functions PRINT (F3), and TARE are available full time on the RF

remote display.

3.1 OFF

No USER key function assigned. The F-Key is disabled.

3.2 TEST

The TEST function provides an LCD test that lights all LCD segments and the LED at

once and then counts from 00000 to 99999. Other internal tests are performed and if

any test fails, an error code will display. See Section 7.2 for a description of all error

codes.

3.3 TOTAL

Note

The Total Mode must be programmed from the setup menus before

the USER key will function. See Section 4.5.

For accumulation of multiple weighments. The accumulator always uses the

displayed weight, so GROSS and NET readings can be added into the same

TOTAL.

There are four modes of totalizing: manual and

three auto modes.

The manual mode requires the

TOTAL key be pressed with the tension on the unit. The

tension will then be added to the previously accumulated value. This assures that a

weight on the scale is only added to the total once. Both the manual and three auto

total modes require that the tension on the Dyna-Link return below 0.5% (relative to

full scale) of GROSS ZERO or NET ZERO before the next weighment can be added.

Applied weight must be ≥1% of full scale above GROSS ZERO or NET ZERO

before it can be totaled.

3.3.1 MANUAL TOTAL

The Fx-TOTAL key under the MANUAL TOTAL mode functions in this manner:

1. With the tension at more than 1% of capacity, push the

Fx-TOTAL key to add the

current tension to the TOTAL weight. The

Fx LED blinks to indicate the tension

value was accepted. The TOTAL LCD annunciator and the total weight is

displayed for about five seconds, then the number of samples is displayed for

about two seconds.

2. Remove the weight, when the tension is les

s than 1% of capacity, place next

load to be accumulated on the unit.

3. Repeat until all loads to be accumulate

d have been added to the total.

4. To view the total weight accumulated, push the

Fx-TOTAL key with the tension

at less than 1% of capacity (no weight on unit), the total weight will display for

five seconds (view total) without changing the total value. The TOTAL LCD

annunciator and the total weight is displayed for about five seconds and then the

number of samples is displayed for about two seconds.

Page 19

14 MSI-7300 Operator’s Manual

3.3.2 AUTO TOTAL

The Fx-TOTAL key under the AUTO TOTAL mode functions as auto total on/auto

total off:

The auto mode has three variations which are programmed in the setup menu:

• AutoLoad – Any settled tension above the ‘rise above’ threshold will be

automatically totaled. Then the Dyna-Link must fall below the ‘drop below’

threshold before another total is allowed.

• AutoNorm – This mode takes the last settled weight to auto total with. The total

occurs only once the scale goes below the threshold. This allows the load to be

adjusted without a total occurring. Once the load is removed, the scale uses the

last settled reading for total.

• AutoHigh – Similar to the AutoNorm mode except the scale uses the highest

settled reading. Useful for loads that can’t be removed all at once.

3.4 Clear Total

The Fx-VIEW TOTAL key activates the total weight display followed by the number of

samples. While the display is showing the total, total is cleared by pressing ZERO.

3.5 Net / Gross

Switches the display between net and gross modes. Net tension is defined as gross

tension minus a tare weight.

To switch between net mode and gross mode:

1. Press the Fx-NetGross key (setup to the net/gross function).

2. The Fx-NetGross key will only function if a tare value has been established.

3. Switching back to gross mode from net mode will not clear the tare value. This

allows the operator to use the gross mode temporarily without having to reestablish

the tare value. Only clearing the tare or setting a new tare will change the tare value

held before switching into gross mode.

3.6 TARE

In force measurement applications, tare is useful as a way to display differential force.

By taring out a known force, only positive and negative deviations from the tared

force are displayed. This can also increase accuracy as any initial error is removed

leaving only slope error. In scale applications, tare is typically used to zero out a

known weight such as rigging, a packing container, or pallet and display the load in

NET tension/weight. To use tare, one of the two function keys must be configured to

the

TARE function. A tare value is entered by pressing the Fx-TARE key. The TARE

function in the Dyna-Link 2 is defined as a tare-in/tare-out operation. The first press

of the

Fx-TARE key stores the current tension/weight as a tare value and then the

Dyna-Link subtracts the tare value from the gross tension and changes the display to

NET mode. The next press of the Fx-TARE key will clear the tare value and revert the

display to

GROSS mode. The optional RF remote display has a TA R E key

permanently available.

Page 20

User Key Functions (F1and F2) 15

3.6.1 To Tare and Display the Net Tension

1. Press (programmed as TA RE ).

2. The tension reading must be stable within the motion window for the tare

fu

nction to work.

3. The digits display 0 and the tension mode changes to

NET.

4. The backup memory in the Dyn

a-Link 2 stores the tare reading, and can restore

it even if power fails.

3.6.2 To Clear the Tare and Revert to Gross Tension

1. Press (programmed as TA RE ).

2. The

NET annunciator will turn off.

3. Absence of the

NET annunciator is the only indication that you are in GROSS

tension mode.

Note

To view the

GROSS

tension without clearing the tare value, program

the remaining function key to the function NET/GROSS.

3.6.3 Tare- Rules for Use:

1. Only positive gross tension readings can be tared.

2. The stable annunciator must be on. The tension/force reading must be stable.

3. Setting or changing the tare has no effect on the gross zero setting.

4. Taring will reduce the apparent over range

of the Dyna-Link. For example,

taring 100 pounds of rigging on a 1000 lb Dyna-Link, the Dyna-Link will

overload at a net tension of 900 lb (1000-100) plus any additional allowed

overload (usually ~4% or 9d).

5. The Dyna-Link stores the tare value in non-volatile memory is restored when

power is

cycled.

3.7 PEAK HOLD

Peak hold will only update the display when a higher peak tension reading is

established. The peak hold function uses a high speed mode of the A/D converter

allowing it to capture transient tensions at a far higher rate than typical

dynamometers.

Peak hold is cleared and re enabled with the Fx-Pea

k Hold key. When a new peak is

detected, the Fx LED will flash three times. The accuracy of the system in peak hold

mode is slightly reduced to .2% of capacity ± 5d. The filter setting is turned off while

in peak hold mode to ensure the fastest acquisition rate.

Example Peak Hold Application

The peak hold function is useful in materials and ‘Fall’ tests. Common tests for fiber

ro

pe include overall breaking strain (OB€), breaking force, and cycled breaking

strain. The Dyna-Link 2 combined with a force test stand, meets the speed and

accuracy requirements to properly conduct these tests.

Page 21

1) Program a function key to Peak

Hold (P-Hld)

In this example we’ll use F1 for Peak Hold.

2) Prepare the test stand and test

sample.

3) Press ZERO to zero out any

residual strain on the link.

4) Press F1 PkHold . Confirm that

the “Pk” annunciator is on.

A small jump in the reading may occur

depending on the stability of your test

stand.

5) Apply the test force. The F1 LED

will blink three times for every

new peak it detects.

6) When the test force is removed,

the Peak value can be recorded.

7) To run a new test, press

F1 PkHold to clear the peak

value. Confirm the “Pk”

annunciator is off. Then repeat

steps 3-6.

Peak Hold

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

Pk

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

Pk

Example Peak Captured Value

Peak Hold

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

Peak Cleared Value

F1

F1

0

ZERO

See Section 4.2 for

Function Key setup

16 MSI-7300 Operator’s Manual

Figure 3-1. Capture Peak Force

3.8 2-UNITS/ 5-UNITS

The Fx-2.Unit key will switch the force units between pounds force and kilograms

force. Selecting the Fx-5.Unit setting will scroll through all available units: lb, kg,

tons (U.S. short), metric tons, and kilonewtons.

Page 22

User Key Functions (F1and F2) 17

3.9 HI-RES

Set a function key (Fx) to Hi-Res, see Section 4.0.

Press the Fx key programmed to display the high resolution mode (see Table 1-2 on

page 8). The display will stay in high resolution mode until the selected Fx key is

pressed again, or power is cycled. While in the hi-res mode the appropriate Fx LED

will blink continuously at a slow rate.

Hi-res mode does not increase the accuracy, but allows for smaller weight increments

to be displayed.

Use Tare or the ZERO key to zero out any initial error. Hi-res mode will make the

Dyna-Link 2 more sensitive to motion and movement resulting in a less stable display.

When hi-res is on, the filter is automatically set to the Hi-1 setting (if Hi-2 is already

set, then the filter is not changed). This will have a small effect on settling time. When

hi-res is turned off, the filter setting resets to the previous filter setting.

3.10 PRINT

Set a function key (Fx) to Print, see Section 4.0.

Pressing the Fx key outputs a configured text string to the RS-232 port on the base of

the unit.

If an F-Key is programmed as print and the print setup is configured as continuous,

then the

Fx key is used for start print/stop print. See Section 6.2 for more details on

data output.

The print function is always available on the optional RF remote display, so it is not

necessary to program an F-Key to “print” if you intend to trigger print outputs from

the remote.

However, if you program F1 or F2 to “print” then pushing F1 or F2 on the Dyna-Link

will cause the comm port on the remote to output the selected data string.

If the RF remote display option is installed, the Dyna-Link cannot use its built in

comm port except for hard-wire connections to the RF remote display or firmware

updates.

Page 23

18 MSI-7300 Operator’s Manual

4.0 Dyna-Link Setup

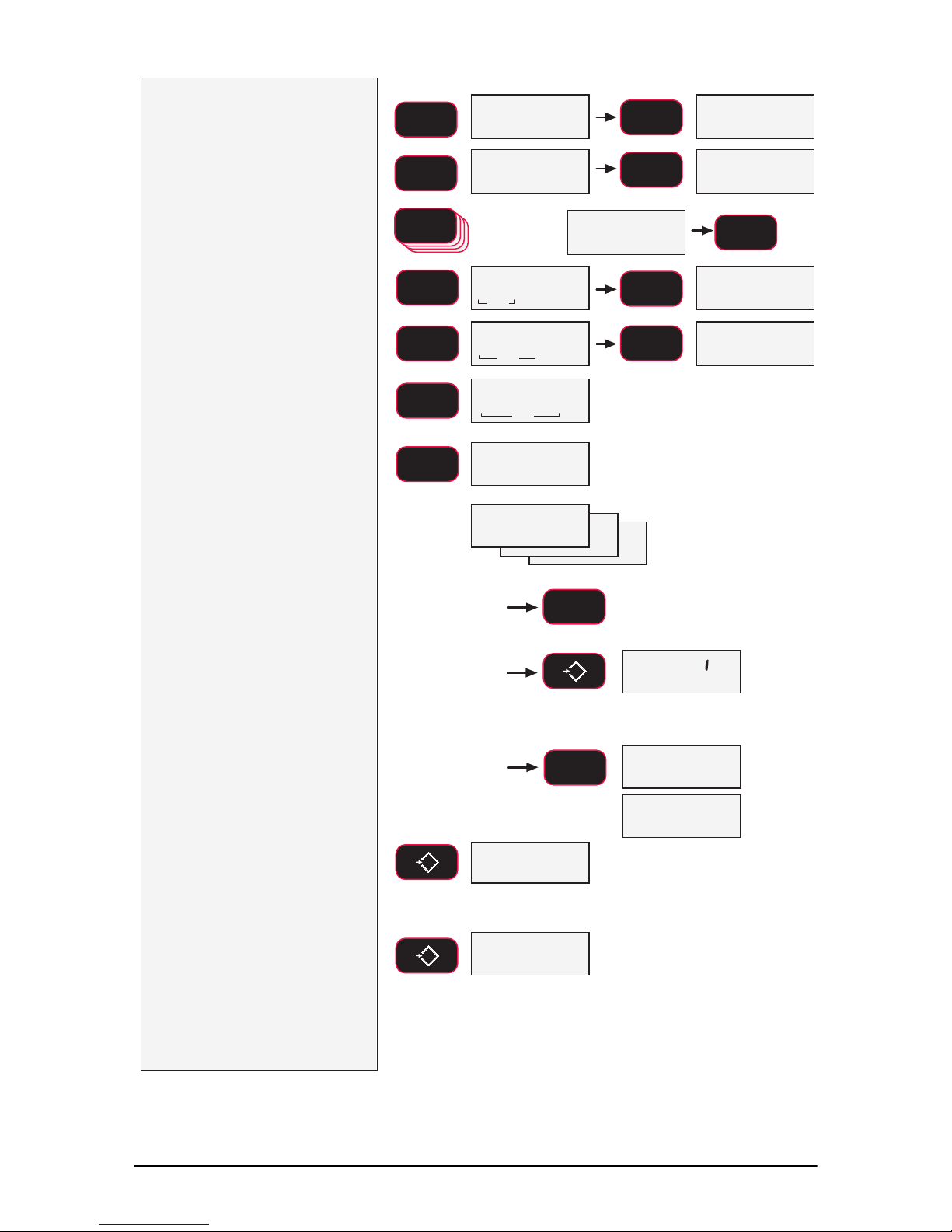

4.1

2II

WWO2Q

$/R$'

$/$6W

$+ L*K

)YQF

IYQF

DII

6W3W

6W3W

WRWDO

ILOWU

81L7

2II

II

/R

+L

+L

2))

*UHDW

/(66

Number Entry

Off

Test Display

Total

View Total

Net/Gross

Tare

Peak Hold

2 Units

5 Units

Hi Res

Print

F1 & F2 KEY

FUNCTIONS

TOTAL MODE

Total Off

(default)

Total On Manual

Autototal on Load

Autototal Last

Autototal on High Load

F2 Key F1

F2 Key F2

Auto Off Time

Set Point 1

Set Point 2

Total Mode

Weight Filter

Weight Units

SETUP MENU

Disabled (default)

15 minutes

30 minutes

45 minutes

60 minutes

AUTO OFF TIME

OFF (disabled)

Low

(default)

High Filter

Very High Filter

SOFTWARE FILTER

With the power on, press the F2

key and power key simultaneously

Set Point Off

(default)

Greater Than

Less Than

Totals on first stable load

Totals the last stable load before zero return

Totals the highest stable load

Totals by pressing an assigned F-key

Autototal Last and Autototal High total when the scale is unloaded.

*URVV

QH W*U

WRWDO

WFQW

SP WEIGHT MODE

Gross

(default)

Net or Gross

Total

Total Count (n)

(F1 default)

lb

kg

Ton

MTon

kN

Press Simultaneously

0

ZERO

POWER

F2F1

F2

Pounds

kilograms

Short Tons

Metric Tons

kiloNewtons

2))

WHVW

WRWDO

YWWO

1( W*U

WDUH

3+/G

8QLW

81LW

+L5HV

3ULQW

Menu Map

Figure 4-1 MSI-7300 Menu Map

Page 24

Dyna-Link Setup 19

4.2 Function Keys

The Dyna-Link 2 has two user definable function keys on the front panel that can be

programmed to several different functions. F1 is defaulted to peak hold, and F2 is

defaulted to test. This procedure also assigns the F1 & F2 keys on the optional RF

remote display.

)YQF

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

ENTER/SELECT

F1

ENTER/SELECT

F1

WRWD/

blinking

QHW U

blinking

3+OG

blinking

WHVW

blinking

2II

blinking

1) With the 7300 on, press the F2

key and the POWER key

simultaneously.

2)

The first item of the setup menu

is Func1.

To setup the F2 Key scroll to the next

menu item by pressing F2.

3) To set up the F1 key press F1.

The current F1 key function is

displayed.

4)

Select the F1 key function by

scrolling through the choices with

the F2 key. See the list of

available functions on the setup

menu map.

This procedure scrolls through all

available choices for illustration

purposes only.

In this example, we’ll set F1 to the TEST

function.

5)

When the desired F1 Key

function is displayed, press F1

.

The next item in the setup menu

appears.

6)

Either press ZERO to exit setup

and store all changes, or

continue to another setup menu

item using the F2 Key.

)YQF

Next Setup Menu Item

Store and return to

weight display

6WRUH

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

7HVW

blinking

blinking

XQLW

blinking

WDUH

blinking

YWWO

blinking

0

EXIT/SAVE

ZERO

Press Simultaneously

POWER

F2

SCROLL

F2

XQLW

blinking

SCROLL

F2

+LUHV

blinking

3ULQW

blinking

2II

blinking

0

ZERO

F1

Figure 4-2 Function Keys

Page 25

20 MSI-7300 Operator’s Manual

4.3 Auto-Off

When enabled, the Auto-Off prolongs the battery life of the unit by turning the power

off when it is not in use.

Any key press or detected tension in motion exceeding 10d, resets the time limit and

the un

it remains on.

When disabled, the unit will only turn off by pressing the POWER key (or if the

batt

ery is depleted).

1)

With the 7300 on, press the

F2

key and the POWER key

simultaneously.

2)

The first item of the Setup Menu

is Func1. Scroll to A-OFF with

theF2 key.

3)

To set up the A-Off timing, press

F1. The current auto-off time is

displayed.

4)

Select the auto off time by

scrolling through the choices with

the F2 key.

In this example, we’ll set 60 minutes as

the auto-off time.

5)

When the desired time is

displayed, press F1. The next

item in the setup menu appears.

6)

Either press ZERO to exit setup

and store all changes, or

continue to another setup menu

item using the F2 key.

)YQF $2))

Press Simultaneously

POWER

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

ENTER/SELECT

F1

0

EXIT/SAVE

ZERO

F2

SCROLL

ENTER/SELECT

F1

2II

blinking

blinking

blinking

6W3W

Next Setup Menu Item

Store and return to

weight display

6WRUH

blinking

blinking

0

ZERO

F1

Figure 4-3 Auto-Off Setup

Page 26

Dyna-Link Setup 21

4.4 Setpoints

The Dyna-Link 2 supports two setpoints. Common uses of set points are for warnings

or process control. The MSI-7300 Dyna-Link 2 comes standard with two high

brightness red LED outputs for a triggered set point. The MSI-7300 Dyna-Link 2 has

an audible output option that is triggered by setpoint 1. Contact MSI for other setpoint

output options.

1)

With the 7300 on, press the F2

and POWER keys

simultaneously.

2)

Scroll through the setup menu

choices by pressing the F2 key.

Stop when the LED displays

StPt1 or StPt2.

3)

When the desired setpoint is

displayed, press F1. The display

blinks OFF, or if previously

programmed, the last set mode.

4)

Select the setpoint mode by

scrolling through the choices with

the F2 key. GrEAt (greater than)

indicates the setpoint will trigger

when the tension exceeds the

value. LESS (less than) will

trigger the setpoint when the

tension is less than the value.

This example scrolled through all available

choices for illustration purposes only.

5)

When the desired setpoint

mode is displayed, press F1.

6)

Next select the type of tension

or weight value the set point is

assigned to. Use the F2 key to

scroll through the choices.

This example scrolled through all

available choices for illustration

purposes only.In this example, we’ll

enter Gross as the tension mode

because we are going to use the set

point as a safety warning.

7)

When the desired weight mode

is shown, push F1. Next the

current setpoint value is

displayed.

If there was a previous

value, it is displayed. If no value has

been entered, a zero will appear. To

keep the displayed value, press ZERO .

VWSW

UHDW

2II

blinking

/(66

UHDW

Current Value (if any)

Set Point responds to Gross

tension, regardless of the

display mode.

Set Point responds to the

tension on the display, Net

or Gross Weight.

Set Point responds to the

Totaled Weight.

Set Point responds to

the Total Count (number

of samples).

Press Simultaneously

POWER

F2

F2

SCROLL

ENTER/SELECT

F1

ENTER/SELECT

F1

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

F2

SCROLL

Set Point responds to Gross

tension, regardless of the

display mode.

URV6

blinking

QHW U

blinking

WRWDO

blinking

WFQW

blinking

URV6

blinking

0

ZERO

F1

Figure 4-4 Setpoint Setup

Page 27

8)

Press the F2 key. The first digit

blinks at zero. Use the F2 key to

scroll through the numbers.

When the desired number is

shown, push F1.

In this example,

we’ll enter 240 as a setpoint value.

To enter a decimal point, push

POWER while the digit is blinking.

Error Correction: If you input a

wrong value, press ZERO to step

back one digit and change the digit

with the F2 key.

blinking

ENTER/SELECT

F1

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

fixed

blinking blinking

blinking

blinking blinking

9)

When the desired number is

shown, push F1 a second time

to set the value. The next setup

menu item is displayed.

10)

Either press ZERO to exit setup

and store all changes, or

continue to another setup menu

item using the F2 key.

xed blinking

blinking blinking

6W3W

fixed next setup menu item

Store and return to

weight display

6WRUH

SCROLL

F2

SCROLL

F2

SCROLL

F2

ENTER/SELECT

F1

ENTER/SELECT

F1

ENTER/SELECT

F1

0

EXIT/SAVE

ZERO

22 MSI-7300 Operator’s Manual

Figure 4-4 Setpoint Setup (continued)

Page 28

Dyna-Link Setup 23

4.5 Total Mode

The MSI-7300 Dyna-Link 2 can keep track of all weighments using the total feature.

Either manual total, which totals by pushing a configured

USER key on the front

panel or the optional RF remote display, or auto-total which can be used to

automatically add up each weighment. See the total mode descriptions for details on

the various total modes. To use manual total, you must also program a user key. Auto

total modes do not need a user key, but if a user key is setup for total, then it will

function as a total on/total off.

1) With the 7300 on, press the F2

key and the POWER key

simultaneously.

2) The first item of the setup menu

is Func1. Scroll to totaL with

the F2 key.

3) To setup the total mode, press

F1. The current total mode

setting is displayed.

4) Select the total mode by scrolling

through the choices with the F2

key.

In this example, we’ll set the total mode

to the auto-high mode. The auto high

mode uses the highest stable reading

as the total value, and totals when the

load is removed.

5) When the desired total mode

setting is displayed, press F1.

The next item in the setup menu

appears.

6) Either press ZERO to exit setup

and store all changes, or

continue to another setup menu

item using the F2 key.

)YQF

)LOWU

Next Setup Menu Item

$/$67

Total last stable load

WRWD/

WWO2Q

Total with pushbutton

Store and return to

weight display

6WRUH

Press Simultaneously

POWER

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

ENTER/SELECT

F1

ENTER/SELECT

F1

0

EXIT/SAVE

ZERO

F2

SCROLL

$/RDG

Total on stable load

$+L +

Total highest stable Load

0

ZERO

F1

Figure 4-5 Total Mode Setup

Page 29

24 MSI-7300 Operator’s Manual

4.6 Units

Units can be changed in two ways:

• Program a user function key to two unit or five unit

• Change the units with the setup menu using the following procedure

To set the accessible units available by a fun

ction key, set the F key either as 2Unit

(lb/kg) or 5Unit (lb/kg/short tons/metric tons/kilonewton).

1)With the 7300 on, press the F2

key and the POWER key

simultaneously.

2)The first item of the setup menu

is Func1. Scroll to Unit with

the F2 key.

3)To set up the weight units, press

F1. The display will blink Unit.

4)Change the weight units by

pressing the F2 key until the

desired unit is displayed. The

selected unit is indicated by the

annunciators.

Not all units shown

are available on every capacity.

5)When the desired unit setting is

annunciated, press F1. The next

item in the setup menu appears.

6)Either press ZERO to exit setup

and store all changes, or

continue to another setup menu

item using the F2 key.

)YQF

)YQF

Next Setup Menu Item

8QLW

Blinking

8QLW

Store and return to

weight display

6WRUH

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

Press Simultaneously

POWER

F2

ENTER/SELECT

F1

ENTER/SELECT

F1

SCROLL

F2

F2

SCROLL

0

EXIT/SAVE

ZERO

F2

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

0

ZERO

F1

Note

If the Dyna-Link Calibration was originally in tons or metric tons, the

“2Unit” setting will switch from tons to metric tons instead of lb/kg.

Figure 4-6 Units Select Menu

Page 30

Dyna-Link Setup 25

4.7 Filter Setup

Changing the filter settings allows the Dyna-Link to adjust to situations where there is

a lot of movement in the lift or the crane structure. If the reading is not stable, it can

often be improved by increasing the filter setting. Settling time will be longer as the

filter setting is increased. However, the MSI-7300 Dyna-Link 2 employs algorithms

that speed up large tension changes while still controlling vibration even with higher

filter settings.

1) With the 7300 off, press and hold

the F2 key, then press the

POWER key.

...or while the 7300 is on, press F2 and

POWER simultaneously.

2) The first item of the setup menu

is Func1. Scroll to Filtr with

the F2 key.

3) To set up the filter, press F1. The

display will blink the current filter

setting.

4) Change the filter setting by

pressing the F2 key.

There are four available filter settings.

Not all choices are shown in this

example.

5) When the desired filter setting is

annunciated, press F1. The next

item in the setup menu appears.

6) Either press ZERO to exit setup

and store all changes, or

continue to another setup menu

item using the F2 key.

)YQF

+L

High Filter 1

2))

Blinking

)LOWU

2))

Blinking

/2

Low Filter, Blinking

8QLW

Next Setup Menu Item

Store and return to

weight display

6WRUH

Press Simultaneously

POWER

F2

0

EXIT/SAVE

ZERO

ENTER/SELECT

F1

ENTER/SELECT

F1

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

F2

SCROLL

0

ZERO

F1

Figure 4-7 Filter Setup Menu

Page 31

26 MSI-7300 Operator’s Manual

5.0 Calibration

The Dyna-Link 2 is calibrated using standard precision test weights. It is required that

the weight used is at least 10% of full capacity in order to achieve rated accuracy. For

example, use at least a 500kg test weight to calibrate a 5000kg capacity unit. The

Dyna-Link 2 supports load cell linearization with up to four span points that can be

calibrated in any order. Usually only one cal span point is necessary and is sufficient

to reach rated accuracy.

When adequate test weights are not available,

the Dyna-Link 2 can be calibrated using

a constant calibration which is referred to as C-Cal. To use C-Cal, a factory generated

C-Cal number must be known. MSI supplies original and replacement load cells for

the Dyna-Link 2 with the C-Cal value stamped on the serial number label.

There are three aspects of calibration:

• Standard calibration - used for maintenance and routine calibration.

• Initial calibration - used to setup both the capacity and resolution (d) of the DynaLink

. It differs from standard calibration only in the initial steps. Initial

calibration is performed after a calibration reset which completely erases the

calibration and setup memory.

• C-Cal - If C-Cal values are known, the Dyna-Link can be calibrated without

weig

hts.

5.1 Calibration Menu

The calibration menu contains three items: Cal, C-Cal, and auto zero maintenance.

The following procedures start with entering into the Cal menu, or for an initial

calibration, resetting the Dyna-Link 2 and then going to the Cal menu.

&$/

&&D/

6HWXS

Calibration Setup Menu

Calibrate with Weights

Calibrate with

Calibration number

Calibrate Menu

Figure 5-2 - Standard Calibration or

Figure 5-3 - Initial Calibration (After Reset)

Figure 5-4

Figure 5-5

Figure 5-1 Calibration Menu

Page 32

Calibration 27

Procedure for the Routine Calibration of the MSI-7300

XQ/G

/R$'

lb

Blinks

Capacity

1) With the power on, initiate

calibration by holding down

the F2 and ZERO keys until

the display reads CAL.

The CAL setup menu

appears.

2) Press F1 to start the

calibration procedure.

3) The display reads UnLd

(unload) indicating you

should remove all weight

from the link.

You can choose to

leave bottom fittings on the link as

long as they are always part of the

load train.

4) Press F1. The 7300 sets the

zero calibration point.

5) If the zero is in range, the

scale will display PASS.

Then LoAd1 is displayed.

6) Load the link with a precision

test weight.

For highest accuracy,

a test weight of 10% of capacity or

more is recommended.

7) Press F1. The 7300 flashes

the capacity and calibration

units. If you are loading the

scale with the capacity

weight, skip to step 10.

8) To enter a calibration

weight other than

capacity, press F2. The

displays far left digit will

flash zero indicating that

a number should be

entered.

&$/

blinking

3$66

No weight

on link

Flashes

Zero

Lift Test

Weight

example capacity

Error Correction: If you input a wrong

value, press ZERO to step back one digit

and reenter.

ENTER/SELECT

F1

ENTER/SELECT

F1

ENTER/SELECT

F1

SCROLL

F2

Press

Simultaneously

F2

0

ZERO

F1

Figure 5-2 Standard Calibration Procedure

Page 33

5 times

fixed

blinking blinking

blinking

blinking

blinking

blinking

fixed

fixed

fixed

3DVV

9) Press the F2 key to scroll

the number and the F1

key to enter each digit of

the calibration weight.

In this example, we’ll enter 2500

kg on a 5000 kg capacity scale.

Do not push the F1 key two times

in a row.

To add a decimal point, push the

POWER key while the number is

blinking.

10) When the entire value of the

test weight is displayed and

the weight and link are

stable, press F1 to finish off

the weight entry. If the

resultant cal value is within

limits, the display will read

PASS.

11) The display now reads

LoAd2. The Dyna-Link

allows multi-point

calibration. If more cal

points are desired (up to

three additional) press

F2

and repeat steps 8-10. If

finished with span points,

go to step 12.

12) Press ZERO to store the

calibration constants. The

LCD will read CAL’d to

indicate the calibration is

acceptable.

13) Skip to step 14, or press F1

to observe the CAL number.

The C-CAL number

appears. Make a note of the

value.

14) Press ZERO to exit

calibration. The next menu

item Setup appears.

15) Press ZERO to store the

calibration and return to

standard link operation, or

press F1 if you want to

adjust additional cal setup

parameters

(Standard, AZM, et c.)

You can cancel calibration by pressing

Power and the scale will reset to the

previous calibration constants.

To add span

points

Go to step 8

To complete

calibration

63DQ

63DQ

/RDG

6HW8S

Next Cal menu item

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

SCROLL

F2

F2

SCROLL

ENTER/SELECT

F1

ENTER/SELECT

F1

ENTER/SELECT

F1

ENTER/SELECT

F1

0

EXIT/SAVE

ZERO

0

EXIT/SAVE

ZERO

ENTER/SELECT

F1

Optional:

to display

Cal number

&&D/

ENTER/SELECT

F1

blinking

Example Cal#

VWRUH

0

EXIT/SAVE

ZERO

&$/ '

Cal saved to memory

F1

28 MSI-7300 Operator’s Manual

Figure 5-2 Standard Calibration Procedure (continued)

Page 34

Calibration 29

5.2 Initial Calibration

Use this procedure only if the capacity and count-by (d) needs to be modified. The

initial steps of this procedure will totally erase user setups as well as any previous

calibration.

1) Turn the 7300 on.

2) Press the ZERO switch and

the F1 switch simultaneously.

3) The display blinks rESEt.

4) To reset all calibration

constants and setup

parameters, press F1.

5) The 7300 requests a

confirmation by displaying

Sure?.

To cancel the Reset press

the POWER or the ZERO key.

6) To complete the reset, press

F1. The Calibrate menu

appears. You must now

recalibrate the system.

7) Press F1 to start the initial

calibration procedure. The

display shows Unit. You

select the force units you

wish to calibrate in.

8) Press F1 to select the

calibration unit.

9) Use the F2 key to scroll

through the available

calibration units.

10) When the desired unit is

shown, press F1.

11) Next, set the capacity in the

selected units. Capacity must

be set no higher than the load

cell rated capacity.

12) Press F1 to enter the capacity

setting screen. A capacity of

10000 is the initial value.

If 10000 is the desired capacity in

the selected Calibration Unit, press

F1 and skip to step 16.

13) To change the capacity, press

F2.

Resetting Capacity and Countby (d)

UHVHW

blinking

6YUH"

&$/

8QLW

8QLW

blinking

&$3

blinking

blinking

Error correction: if you input a wrong

value, press ZERO to step back one

digit and reenter.

To enter a decimal point, push

POWER while the digit is blinking.

For very large capacity Dyna-Links

Enter the capacity in weight X1000

and push the POWER key twice

(X1000 mode is indicated by the M

annunciator during data entry).

e.g. For a 100,000 lb 7300, enter

100, then press the POWER key

twice so the M indicator is on.

ENTER/SELECT

F1

ENTER/SELECT

F1

EXIT/CANCEL

POWER

To cancel

Reset

F1

ENTER/SELECT

F1

ENTER/SELECT

F1

SCROLL

F2

ENTER/SELECT

F1

ENTER/SELECT

F1

SCROLL

F2

kg

lb

M

kN

Ton

Press

&Hold

0

ZERO

F2F1

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

pounds Tons (US Short)

Metric Tons

(kg X 1000)

kiloNewtons

kilograms

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

kg

lb

M

kN

Ton

Figure 5-3 Initial Calibration

Page 35

The first digit blinks. Use the

F2 key to scroll through the

numbers. When the desired

number is shown, push F1

.

In this example, we’ll enter 2500 as

a capacity.

Continue inputing the desired

capacity using the F2 key for

scrolling the number and the

F1 key to store the number.

fixed

blinking blinking

blinking

SCROLL

F2

SCROLL

F2

SCROLL

F2

ENTER/SELECT

F1

5 times

blinking

blinking

blinking

fixed

fixed

fixed

15) Finalize the capacity value

by pressing the F1

key on an

unblinking display. In our

example, once the number

2500 is fixed on the display,

press F1

to store the capacity

value.

16) Next the scale division size

d is set. Press F1 to begin.

In this example we’ll set the d to

2.

17) Use the F2 key to scroll

through the recommended

scale divisions. The first d

offered is the standard division for

the given capacity. Setting a ‘d’ size

that results in total resolution higher

than 1:5000 is not recommended

for stability reasons.

18)When the desired scale d

is displayed, press F1.

The UnLd display

appears and the scale is

ready for calibration.

Follow the standard

calibration procedure

starting at step 3.

G

blinking

XQ/G

Capacity is set.

d is set.

Proceed to Standard

Calibration starting at Step 3.

F2

SCROLL

ENTER/SELECT

F1

ENTER/SELECT

F1

ENTER/SELECT

F1

ENTER/SELECT

F1

SCROLL

F2

SCROLL

F2

ENTER/SELECT

F1

Next Cal Screen

blinking

SCROLL

F2

ENTER/SELECT

F1

14)

30 MSI-7300 Operator’s Manual

Figure 5-3 Initial Calibration (continued)

Page 36

Calibration 31

5.3 Guidelines for Capacity and Resolution

Dyna-Links are subject to forces that static scales do not experience. Many bridge

cranes, hoist cranes, and mobile cranes lack rigidity and tend to bounce or swing

when loads are lifted. For this reason, MSI recommends that resolution is kept in the

1:2000 to 1:3000 range. Some improvement in stability can be achieved by increasing

the filtering. However, you should never program resolution that is far greater than

you need. If the MSI-7300 Dyna-Link 2 display is never stable, it is recommended that

the resolution is reduced as well as filtering increased. In any circumstance, the

resolution should never be set higher than 1:15000 due to temperature and noise

considerations common to all strain gage based load cells.

The tension must be stable for certain features to work: ZERO tensi

on must be stable

to be zeroed. TARE tension must be stable to be tared. TOTAL tension must be stable

to be added to the total registers. One way to improve the stability is to increase the

filtering, at the risk of increasing settling time. The other is to increase the ‘d’ (reduce

resolution). The third way is to increase the motion window. The MSI-7300 Dyna-

Link 2 defaults to ±1d as a motion window. It can be changed at MSI to a higher value

if desired. Often ±3d is chosen for bridge cranes as these tend to have a lot of bounce

to them. This of course carries an accuracy penalty adding ±3 d to the total accuracy

of the Dyna-Link if the zero or tare operation happens to capture the tension in a

valley or peak.

Setting capacity is dictated primarily by the

capability of the load cell. MSI supplies

the MSI-7300 Dyna-Link 2 in many capacities. Never set the capacity of the Dyna-

Link higher than the rating of the load cell. Due to the excellent linearity of the

MSI Link load cell, it is acceptable to set lower capacities to better match the crane

the MSI-7300 Dyna-Link 2 is used on. For example, if the hoist is rated for 9000lb,

you can use a 10000 lb capacity Dyna-Link and reset the capacity to 9000 lb so that

the Dyna-Link will indicate overload at 9000 lb instead of 100000 lb. Derating as

much as 50% of the capacity is usually acceptable, but the Dyna-Link may be less

stable if the ‘d’ is decreased (resolution increased).

Note

The capacity of all the MSI-7300 systems is rated approximately 20%

higher than the rated capacity in pounds. This is to allow the kg

capacity to be exactly 1/2 the number of the pounds capacity.

Page 37

32 MSI-7300 Operator’s Manual

5.4 C-Cal Calibration

When adequate test weights are not available, the MSI-7300 Dyna-Link 2 can be

calibrated using a cal number calibration which is referred to as C-Cal. To use C-Cal,

a factory generated C-Cal number must be known. MSI supplies replacement load

cells for the MSI-7300 Dyna-Link 2 with the C-Cal value stamped on the serial

number label. When a calibration is preformed with test weights, a new C-Cal is

generated.

Important

The C-Cal number must be known prior to starting this

procedure. For a MSI-7300 with its original load cell, MSI prints

this number on the Calibration Record, the serial number tag. CCalibration reduces slightly the absolute accuracy of the system

and is intended for non-critical use only. For highest accuracy,

calibrate the MSI-7300 with precision test weights.

XQ/G

1) With the power on, initiate

calibration by holding down

the F2 and ZERO keys until

the display reads CAL.

The CAL setup menu

appears.

2) Press F2 to scroll to the

C–Cal selection.

3) Press F1 to start the C-Cal

calibration procedure.

3) The display reads UnLd

(unload) indicating you

should remove all weight

from the link.

You can choose to

leave bottom fittings on the Link as

long as they are always part of the load

train.

4) Press F1. The 7300 sets the

zero calibration point.

5) If the zero is in range, the

scale will display PASS.

Then C-CAL is displayed.

6) Press F1. The last known

C–Cal value is displayed.

If the offered C-Cal value is correct,

push F1 and jump to step 10.

In this example we’ll enter 15200 as

an C-Cal value. You must use your

known C-Cal value, not 15200.

&$/

3$66

No weight

on link

Flashes

Zero

ENTER/SELECT

F1

ENTER/SELECT

F1

SCROLL

F2

&&$/

&&D/

lb

example C-Cal Value

ENTER/SELECT

F1

Press

Simultaneously

F2

0

ZERO

F1

Figure 5-4 C-Cal Calibration Procedure

Page 38

7) To input the C-Cal value,

press F2 to start the number

entry process.

8) Use F2 to change the

number, and F1 to enter

the number. Add the next

digit by pushing F2 and

scrolling as required.

Repeat this sequence

until the entire C-Cal

number is entered.

5 times

fixed

blinking blinking

blinking

blinking

SCROLL

F2

SCROLL

F2

SCROLL

F2

F2

SCROLL

ENTER/SELECT

F1

Error Correction: If you input a wrong value, press ZERO to step

back one digit and reenter.

To input a decimal point, push POWER while a digit is blinking.

F1

9) Once the entire C-Cal

value is entered, press

F1 to finalize the number.

The 7300 modifies its

span factor registers to

adjust the calibration to

the value of the C-Cal. If

the C-Cal input was in

the acceptable range, the

LCD will read PASS.

Multiple C-Cal span points are

possible, but are only

accessible using MSI’s

optional SCCMP program.

10) When the final C-Cal

number is finished, press

ZERO to exit and save

the new C-Cal

calibration. The LCD

reads STORE to

indicate a successful

calibration.

11) Press ZERO again to exit

the CAL menu and start

standard link tension

operation.

blinking

blinking

fixed

fixed

fixed

3DVV

SCROLL

F2

SCROLL

F2

ENTER/SELECT

F1

ENTER/SELECT

F1

ENTER/SELECT

F1

ENTER/SELECT

F1

blinking

SCROLL

F2

SCROLL

F2

blinking

0

EXIT/SAVE

ZERO

0

EXIT/SAVE

ZERO

6WRUH

SCROLL

F2

blinking

&$/ '

6HWYS

Calibration 33

Figure 5-4 C-Cal Calibration Procedure (continued)

Page 39

34 MSI-7300 Operator’s Manual

5.5 Auto Zero Maintenance (AZM)

The Dyna-Link 2 employs an auto zeroing maintenance mechanism to adjust the zero

reading to the center-of-zero (COZ). COZ is defined as the tension reading is within

¼’d’ of zero. AZM continuously adjusts zero to maintain COZ. It is recommended

that AZM is on to maintain the highest accuracy. However, there are circumstances

when it should be turned off. This can happen when minor variations of tension occur

while picking up Dyna-Link attachments and the variations fall within the AZM

capture window. The AZM capture window (usually 1 ‘d’) and capture time (usually

eight seconds) can be adjusted by MSI to meet custom requirements.

1) With the power on, initiate

calibration by holding down

the

F2 and ZERO

keys until

the display reads CAL.

The CAL setup menu

appears.

2) Press F2 to go the the

SetUP screen.

3) Press F1. The StAnd

menu appears.

4) Press F2 to scroll to the

Auto0 screen.

5) Press F1. The AutoZero

mode shows On or OFF.

In this example, we will turn off AZM

(not recommended for typical

operations)

6) Press F2 to change to AZM

between on and off.

7) When the desired mode is

displayed, press F1.

8) The next cal setup menu

item appears.

9) Press ZERO twice to exit

cal setup and store all

changes, or continue to

another cal setup menu

item using the F2 Key.

&$/

ENTER/SELECT

F1

F2

SCROLL

6HW8S

SCROLL

F2

ENTER/SELECT

F1

0

EXIT/SAVE

ZERO

6WDQG

2II

blinking

Press

Simultaneously

F2

0

ZERO

F1

ENTER/SELECT

F1

2Q