Page 1

Tech Bulletin

Tech Bulletin

Trigger Pickups: Magnetic vs. Optical

MSD’s Tech Bulletins are designed to give you a more in-depth

understanding of the ignition system and its components. If you have any other questions about the

subject or MSD products you can contact our Customer Support Department at (915) 855-7123 or

email your questions to msdtech@msdignition.com.

TRIGGER PICKUPS: MAGNETIC VS. OPTICAL

TRIGGER PICKUPS: MAGNETIC VS. OPTICAL

There recently has been debate concerning trigger methods used in distributors. The two most common racing pic kups used

in distributors are a magnetic pickup and optical pickups.

Both pickups hav e been a v ailable for a number of years and in a v ariety of applications. The pickups perform the same job ,

triggering the ignition at the precise moment, just in a different manner. Both pickups accomplish their goals , how ever in the

long run for endurance and accuracy throughout the entire rpm range, the magnetic pickup is the best choice.

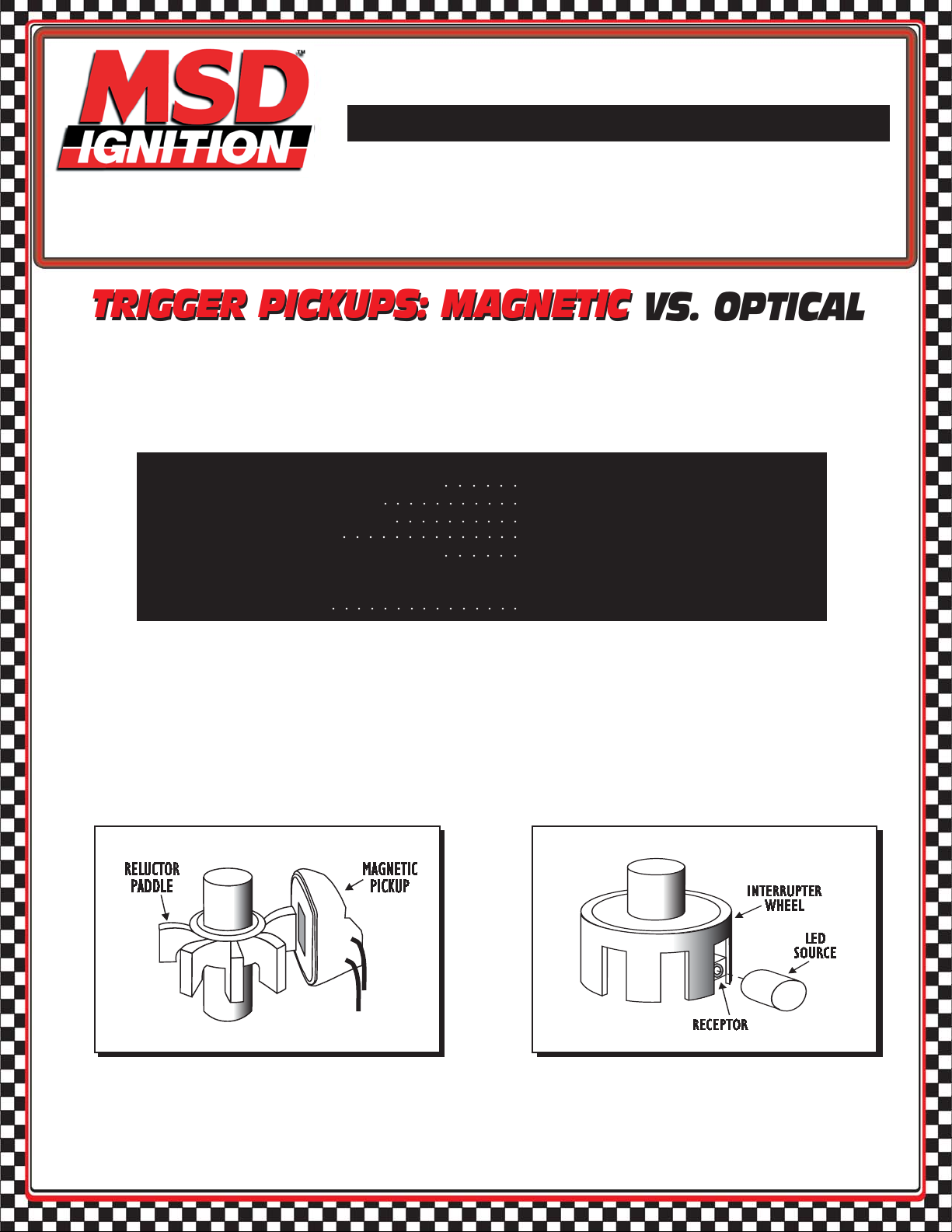

Magnetic Pickup

Withstands Higher Temperatures (+150°C)

No Mechanical Parts to Wear Out

Not Affected by Moisture or Debris

Simple, 2-Wire Connection

Creates a well defined Zero Volt reference

point for each firing that is not affected

by heat

Handles Static Electricity

OPERATION

The MSD magnetic pickup acts as a generator creating a strong, clear signal. It is made up of windings placed in a magnetic

field to produce an electric signal. With this simple design, there are only two wires to connect - so there are f ewer connections

to be concerned about.

When a pole, or the paddle of the reluctor passes in front of the pickup, a voltage is created. As rpm increases, the signal

strength increases as well giving it fast rise/fall times. At high rpm, this signal can reach well over 50 v olts . This trigger signal

will be addressed later in the text.

A magnetic pickup is very reliable at high temperatures and in extreme conditions. Moisture, oil or mild debris will not affect

the trigger signal making it the best choice in long races. Also , ozone and static electricity that builds inside the distribut or cap

will not affect the pickup’s output signal.

○○○○○○○○○○○○○○○

○○○○○○○○○○○

○○○○○○○○○○

○○○○○○○○○○○○○○

○○○○○○

○○○○○○

Affected by Higher Temperatures (+100°C)

LED will Wear Over Time

Affected by Moisture and Debris

Three Wires; 12 volts, Ground and Signal

Reference Point is fixed and can be affected

Susceptible to Static Electricity

Optical Pickup

by temperature changes

An optical trigger uses a Light Emitting Diode (LED) and a photo receptor. The LED’s light beam is interrupted by a wheel that

is connected to the distributor shaft. There are “windo ws” that let the LED beam shine through to the receptor which is responsible for producing the trigger signal. This signal is then usually processed into a 12 v olt signal and then sent to the ignition as

a trigger signal. This requires a three wire connection to each pickup; a 12 v olt source, ground and the trigger output wire.

Page 2

An optical trigger is very susceptible to debris or contaminants that may enter the distributor cap. A layer of dust, moisture or

grime on the lens of the LED or receiver will affect the signal strength resulting in the possibility of misfire or timing fluctuations.

If the rise/fall (On/Off) time of the signal voltage changes there will be a shift in the reference trigger point resulting in a timing

shift. Also , the LED’ s light output degrades ov er time, especially in a high rpm environment with higher temperatures. A low er

LED output may affect the saturation time of the photo receptor causing a weak output signal.

These reasons alone express the strengths of a mag pickup’ s reliability and endurance in racing conditions . There are also

facts to consider concerning the signals that they create.

Signal Strength and Flexibility

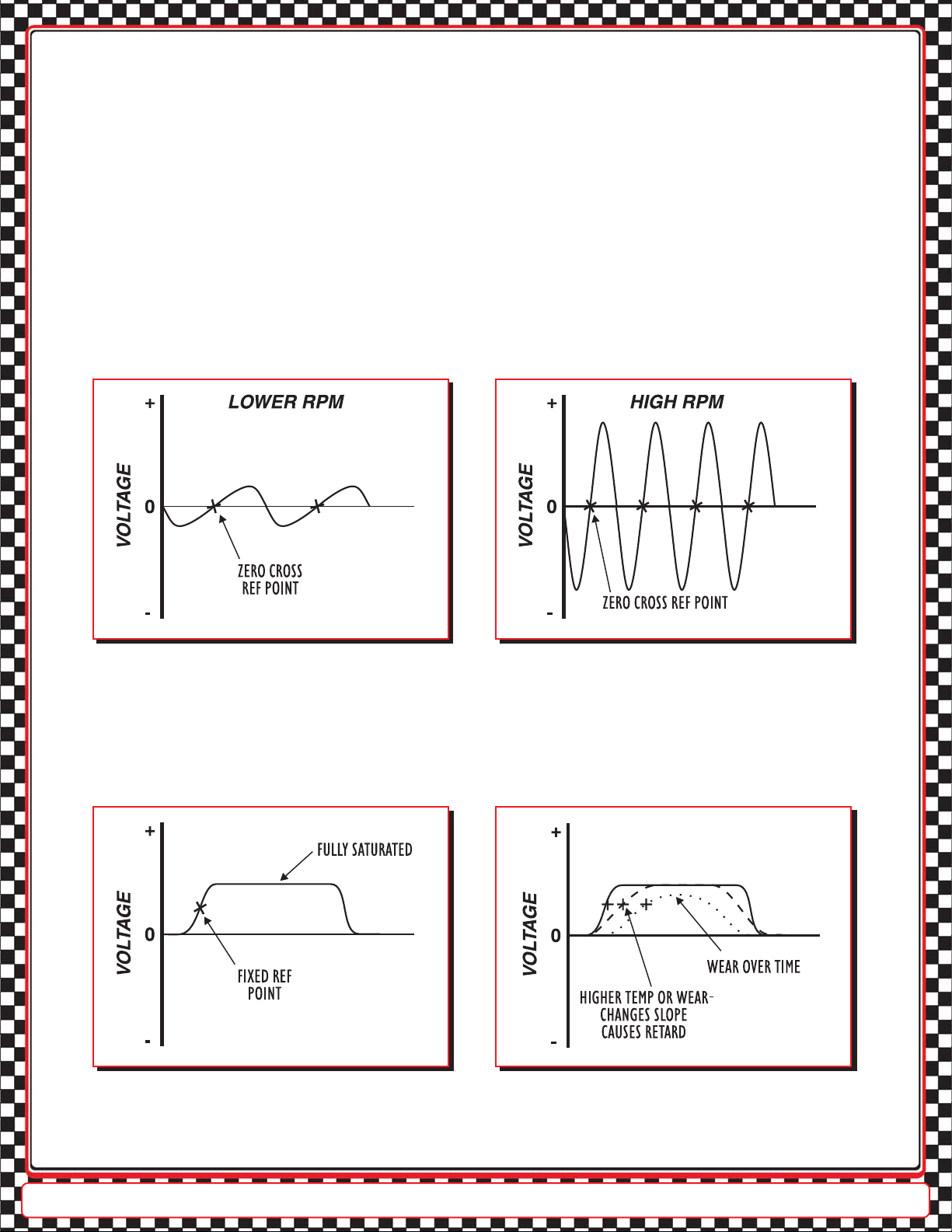

By design, a magnetic pickup creates a positive and negative trigger pattern. As the reluctor paddle nears the magnet, a

negative voltage is created. As it lines up with the magnetic pickup the signal begins swinging up and becomes a positive signal

until the reluctor paddle passes through the field. When the signal becomes a positive voltage , it creates an easily recognizable

point, the Zero Crossing. This point is e xtremely important because it is always the same trigger point.

As rpm increases, the signal that the mag pickup produces becomes stronger, how e ver this Crossing is always constant in

regards to distributor shaft position. With the predictability of this Zero Crossing , a mag pickup’ s inherent retard can be taken

into consideration and adjusted within the ignition. Also , due to the very fast rise and f all time of the trigger signal it is much less

susceptible to electronic noise which can affect triggering.

MAGNETIC PICKUP TRIGGER SIGNAL

Conversely, an optical trigger creates only a positive signal so a circuit must be added to set a fixed reference point for

triggering. Usually this reference point is about half the amplitude of the optical signal. If the saturation time of the receptor

changes due to a weak LED , debris or heat, this ref erence point is going to be affected which will cause a shift in the timing.

As the window of the interrupter begins to enter the beam of the LED a signal is created. During this process, the receiving

sensor begins to be uncovered and starts to turn “on”. Next, it reaches its maximum (saturation) point, then begins to be

covered followed by being completely turned off.

OPTICAL TRIGGER SIGNAL

MSD’s Magnetic Pickups have proven their endurance and precision on race tracks around the world. Don’t settle for an

unproven design - use the name and product you trust; MSD Ignition. If it wasn’t the best, MSD wouldn’t use them.

AUTO TRONIC CONTR OLS CORPORA TION •

FRM20987 Revised 08/99 PRINTED IN U.S.A.

1490 Henry Brennan Dr., El Paso , T e xas 79936

•

(915) 857-5200 Fax (915) 857-3344

•

Website: www.msdignition.com

Loading...

Loading...