Page 1

Other steps to avoid EMI problems include routing your coil’s primary wires away from other plug wires. The mag-

netic pickup harness coming from the distributor or crank trigger should be routed away from other wires and is a

good idea to have it mounted along a metal surface that will act as a ground plain. MSD also offers a six feet long

shielded mag pickup cable, PN 8862, that can be used if you are having problems with EMI interfering with other

electronics on your vehicle.

9. How can I test an MSD ignition to see if it is working?

Checking for spark output of your MSD is easy. Following is a simple procedure for testing your MSD for spark.

1. Turn the ignition switch “OFF”.

2. Remove the coil wire from the distributor cap and place it 1/2” from ground. DO NOT CRANK OVER THE ENGINE. When

you continue with this test, a high voltage spark will jump this 1/2” gap so make sure there is no fuel or flammable

mixtures near the plug wire end.

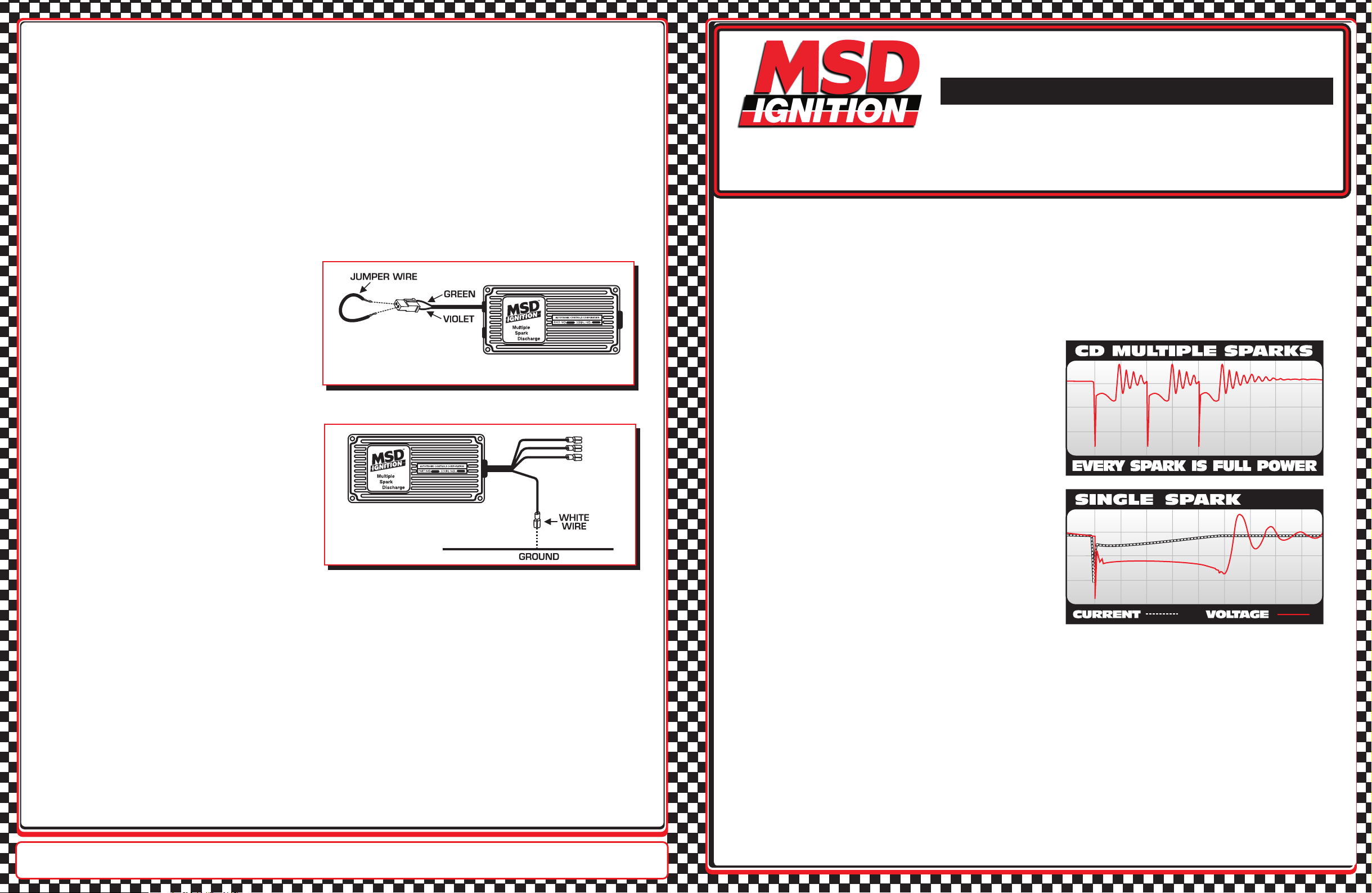

3. If triggering with the Magnetic Pickup (Green and Violet):

A. Disconnect the magnetic trigger wires from the MSD. Turn the Ignition Switch “On”. DO NOT CRANK OVER

THE ENGINE.

B. Use a paper clip or jumper wire to short the Green and Violet wires going to the MSD together several times. A

spark should jump the gap every time the wires are shorted.

4. If triggering with the White wire (points/amplifier):

A. Disconnect the White wire of the MSD from the

distributor trigger or ignition amplifier. Turn the

Ignition Switch “On”. DO NOT CRANK OVER

THE ENGINE.

B. Tap the White MSD wire to ground several

times. A spark should jump the gap as you do

this.

5. If there is no spark, substitute another ignition coil

and repeat the test. If there is now spark, the coil is

at fault. If there is still no spark it is possible that the

MSD Ignition needs to be serviced. If the warranty

period is over, MSD offers repairs at nominal fees.

For more information on repair services, contact our

Customer Support Department at (915) 855-7123

or msdtech@msdignition.com

10. Why should I purchase MSD

products over another manufacturer?

In the last few years a lot of other “performance”

ignition companies have cropped up and not surprisingly, their ignitions are all similar to an MSD. They’re

capacitive discharge, multiple sparking designs

with rev limiters and timing controls. MSD was the

first ignition company to use capacitive discharge,

multiple sparking technology. We were the first to

offer rev limiters, billet distributors and crank triggers. We know what it takes to deliver ignition performance and reliability. These are things you only learn with experience and we have over 25 years of exclusive performance ignition

experience.

MSD goes to great lengths to provide the best performing and most reliable ignition components available. Every

ignition that leaves our building has undergone a battery of tests including a four hour burn-in. The complete MSD

line features a one year warranty and we have an excellent core of engineers, technicians and support personel at

the races and available to answer your calls about ignition systems.

In short, MSD builds the best performing and most reliable ignition products available and we have the wins and

records to back this up. When you’re reading through the magazines or walking through the pits at a race, look inside

the winners’ cars to see what ignition they’re running; MSD Ignition.

Bonus Pointers:

• You don’t need a ballast resistor if you are using an MSD Ignition Control. If you are using a points system

with a Blaster Coil a ballast resistor is required.

• You can run an MSD Ignition Control to a 16 volt battery source.

• Do not run solid core spark plug wires with an MSD Ignition.

• Yes, an MSD will install to a late model LT-1 Chevrolet engine.

M S D I G N I T I O N • ww w. ms di gn iti on .c o m • ( 91 5) 8 57 -5 20 0 • F AX (91 5) 8 57 -3 344

© 2008 Aut otronic Con trols Corpo ration

Checking for spark with the magnetic pickup as a trigger.

Checking for spark with the white wire as a trigger.

FRM29233 Revised 03/08 Printed in U.S.A.

®

Tech Bulletin

Tech Bulletin

Top Ten Ignition Questions

MSD’s Tech Bulletins are designed to give you a more in-depth

understanding of the ignition system and its components. If you have any other questions about the

subject or MSD products you can contact our Customer Support Department at (915) 855-7123 or

email your questions to msdtech@msdignition.com.

TOP TEN IGNITION QUESTIONS

TOP TEN IGNITION QUESTIONS

MSD’s Customer Support Department receives numbers of calls and e-mails everyday from racers and enthusiasts

seeking recommendations or ways to tweak out another tenth of performance. To help you learn more about ignitions, they

all got together and came up with this list of the top ten questions they receive.

If your top question isn’t included in this list, call our Customer Support Team at (915) 855-7123 or e-mail us at msdtech@

msdignition.com. Our techs are ready and able to answer all of your questions!

1. What’s the differences between a Capacitive Discharge (CD) ignition like an MSD and my stock ignition system?

The biggest difference is that the majority of stock ignitions

are inductive ignitions. Inductive ignition systems are used

due to their simplicity and inexpensive production. For stock

applications these ignitions are adequate, but when it comes

to gaining performance, factory inductive ignitions fall short.

The primary weak link of a stock ignition is because the coil

serves double duty. The coil must act as a step-up transformer

to create a higher voltage spark, plus it needs to store this

power until the ignition is triggered. As engine rpm increases

there isn’t enough time to completely step-up the voltage

before the ignition is triggered resulting in a weaker spark.

This low voltage spark may not be enough to light the fuel

mixture in the cylinder which will result in a misfire and loss

of power.

A CD ignition, like an MSD 6 Series, is capable of producing

full power sparks throughout the entire rpm range. It draws

its energy directly from the battery where a custom wound

transformer steps it up to over 460 volts. This voltage is then

stored in a capacitor until the ignition is triggered. At this point,

all of the voltage is dumped into the coil where it is transformed

into even more voltage, anywhere from 30,000 - 45,000 volts

depending on the coil, which is sent to the distributor and

finally to the plugs.

The ability to produce high power sparks throughout the

entire rpm range of your engine is why you need a CD ignition. The payoff is complete combustion of the fuel mixture which results in more power, increased throttle response, a smooth idle, quick starts, improved economy and

reduced plug fouling.

All engines will benefit from a CD ignition but when you’re planning on engine modifications, the need for an MSD

Ignition increases. In particular, if you’re planning these types of engine modifications, you should be installing a CD

ignition:

• Improving air flow into the engine or richening the fuel mixture (rejetting or larger injectors)

• Adding a super/turbocharger or a nitrous oxide system

• Increasing the compression ratio and consistent high rpm operation

2. Why does an MSD produce multiple sparks and what are the benefits?

Conventional CD ignitions supply one spark of intense energy but for a short duration (time). An MSD uses mul-

tiple sparking technology to take advantage of the quick rise time and power of a CD Ignition by producing a series

of sparks. More sparks equal more heat in the combustion chamber resulting in complete combustion of the fuel

mixture which produces more power. At lower rpm, there are many benefits to multiple sparks including a smooth

Page 2

idle, improved throttle response plus the spark series prevents fouling plugs or fuel loading up in the cylinder when

air/fuel distribution is poor.

The multiple spark series of an MSD Ignition Control lasts for 20° of crankshaft rotation. At lower rpm, 1,000 rpm

for example, there is plenty of time to fire the plug a number of times to ensure ignition of the fuel mixture. As rpm

increases, the piston travels up on the compression stroke faster resulting in a shorter amount of time available to

fire the plug so the number of sparks that occur decreases. By about 3,000-3,300 rpm, there is only enough time to

fire the plug once. From about this rpm range on, an MSD ignition control delivers one intense, full power spark.

3. What is the best spark plug gap for my application?

The spark plug is the point in the ignition system where electrical energy is converted into heat, consequently, the

larger the gap the greater the amount of heat available to light the air/fuel mixture. However, too large of gap combined with increased cylinder pressures can put excessive pressures on the initial voltage needed to ionize (cross)

the gap. Finding the optimum plug gap for your application is best determined by experimentation because there are

so many engine variables to consider.

An MSD Ignition Control has enough output power to consistently fire wider spark plug gaps on a performance

engine. As a starting point, follow the engine builder or manufacturer’s recommendation for the plug gap. With that,

you can experiment with increasing the gap until the best performance is found.

As a rule of thumb, it is recommended to increase the plug gap by .005” - .010” followed by testing and tuning.

Keep in mind that larger spark plug gaps also place increasing demands on the secondary portion of the ignition

system including the distributor cap and rotor, coil wire, and spark plug wires. They should all be in top condition and

checked periodically during the race season. Remember that electricity takes the path of least resistance to a ground

so if the gap is too large the spark may short to another point with less resistance.

4. What size battery do I need if using an MSD ignition?

The battery is the fuel tank for the ignition system (magnetos excluded). When it’s empty there is no electrical power

available for the ignition system to convert into heat at the plug gap. In long duration racing events such as circle

track racing, an alternator is highly recommended. In drag racing, a charging system is not a complete necessity as

long as you have a good battery and charge it in between each round. Also keep in mind that electric fuel and water

pumps, fans and solenoids eat up a lot of current as well.

Race cars without charging systems must have a battery with a large enough capacity to power all the electrical

parts. For example, an MSD 6 or 7 series ignition consumes approximately one amp per thousand rpm, so at 5,000

rpm the MSD alone is using five amps. An MSD is designed to produce full power sparks with a supply voltage of

10 volts, but if the supply drops below that, ignition output will suffer.

An MSD can be used with 16 volt batteries, but no performance gain will occur because the output power of the

MSD is regulated. The advantage of a 16 volt battery is increased electrical capacity. For more information on battery

requirements with an MSD, ask your MSD Customer Support Tech for our Battery Tech Bulletin.

5. What do you have to replace my points distributor and what are

the advantages with electronic versus points?

MSD does not have a module to replace the breaker points system in your stock distributor, however an MSD Igni-

tion Control will work great with a points trigger ignition. In fact, if you replace the points when you install your MSD,

you’ll probably won’t have to replace or adjust them for years!

The MSD’s trigger wire connects directly to the breaker points wire so when the points open, the MSD is triggered.

Since the MSD’s capacitor is responsible for sending the spark energy to the coil, the points are only used as a trigger

reference signal. With this connection there is very little current crossing the points so the wear is nominal at best.

Also, the MSD controls the dwell so the adjustment of the points is not that critical either. This setup works great with

street cars and budget racers, but when you begin stepping up performance more and more, the need for a quality

distributor comes into play.

MSD’s Pro-Billet Distributors are engineered to deliver precise trigger signals, provide accurate distribution of the

sparks and are reliable. A magnetic pickup is used to trigger the ignition. Unlike points, this pickup is maintenancefree and is capable of accurate trigger signals throughout 10,000 rpm.

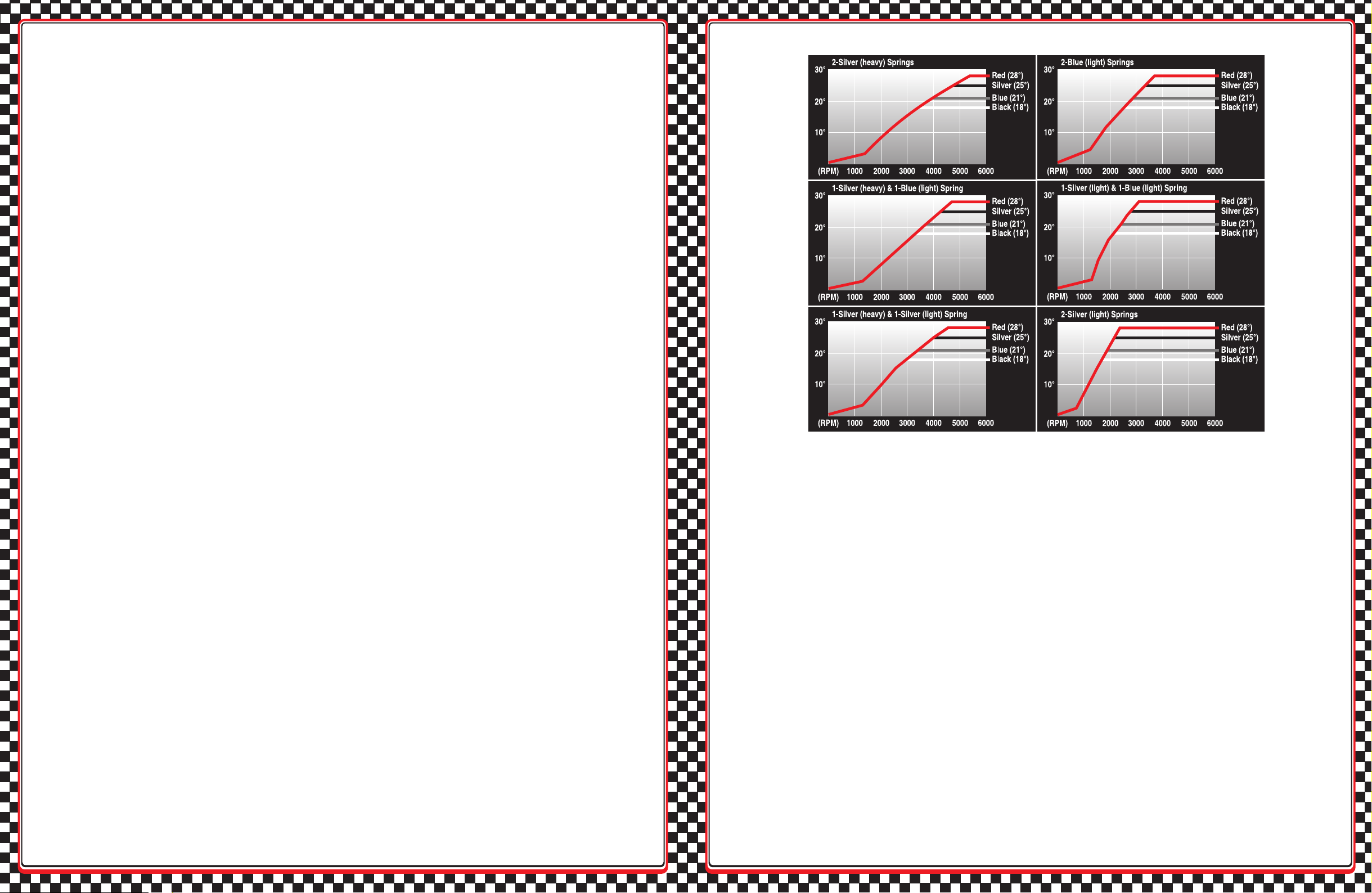

6. What is the best Timing Curve for my car?

There is no real way for our Techs to answer this question but they can point you in the right direction. It takes

testing and tuning time to find the best curve that fits your application. Many variables affect the ignition timing curve

such as compression, cam specs, intake system, fuel, exhaust, altitude, driving habits and so on. The chart on page

3 lists some factors that will help you determine what sort of timing curve you should work towards for your specific

application.

MSD’s mechanical advance mechanism is accurate and easy to adjust so you can try different combinations with

the supplied springs and stop bushings. We also offer a variety of electronic timing controls so engines with locked

out timing or crank triggers can take advantage of altering the timing as rpm changes.

Note: When you are testing different curves, listen for detonation (spark knock) which is a sign of over-advanced timing.

A variety of timing curves can be achieved with MSD’s mechanical advance.

7. Tach Adapters; What are they and why do I need one?

MSD’s Tach Adapters are solutions to two problems that may occur in a few applications after installing an MSD

Ignition. They will modify the tach signal of the MSD so tachs that have trouble picking up the MSD’s signal and on

select import vehicles with fuel injection systems, they will boost the signal so the ECU can trigger the EFI.

Some tachometers, original equipment and aftermarket, may have trouble reading the MSD’s tach signal causing

erratic readings or just not working. An MSD Tach Adapter modifies the tach signal so these tachometers can read

them correctly. MSD lists different tachs and applications that may require an Adapter in our catalog and the Ignition

Control Instructions.

Some import vehicles may experience a no run situation after installing an MSD. This is because some systems

use the same trigger source to operate the ignition and the fuel injection. When the MSD is installed this voltage

signal becomes too low to accurately trigger the fuel injection. The PN 8910 Tach Adapter will usually remedy this

problem. Ford Probes and Toyotas require a special Adapter that can be ordered directly from MSD.

If you experience any of these problems after installing your MSD, contact our Customer Support Department for

more information on your application.

8. How do I fix:

• A high rpm miss when the engine is under load?

• An rpm limiter that seems to activate at the wrong rpm?

• Erratic operation of electronic devices/ECUs?

• A tachometer needle that seems to “bounce”?

All of the above can be caused by Electro Magnetic Interference (EMI) generated by the ignition system. Specifi-

cally through the coil and spark plug wires. The ignition system is a miniature power station and the spark plug wires

are its transmission lines. The wires (in particular, “solid core” wires) can broadcast EMI that seeps into electronics

and causes erratic behavior.

To combat EMI you need to run a set of helically wound spark plug wires such as MSD’s Heli-Core or 8.5mm Su-

per Conductor Wires. Having the conductor wound around a special center core produces a “choke” that holds EMI

inside the wire. Solid core wires on the other hand, have no suppression capabilities and should not be used with

an MSD Ignition. MSD’s Super Conductor Wires have extremely low resistance (less than 50 ohms per foot), yet are

designed to suppress EMI like a high resistance wire.

Loading...

Loading...