Page 1

INSTRUMENT MANUAL

®

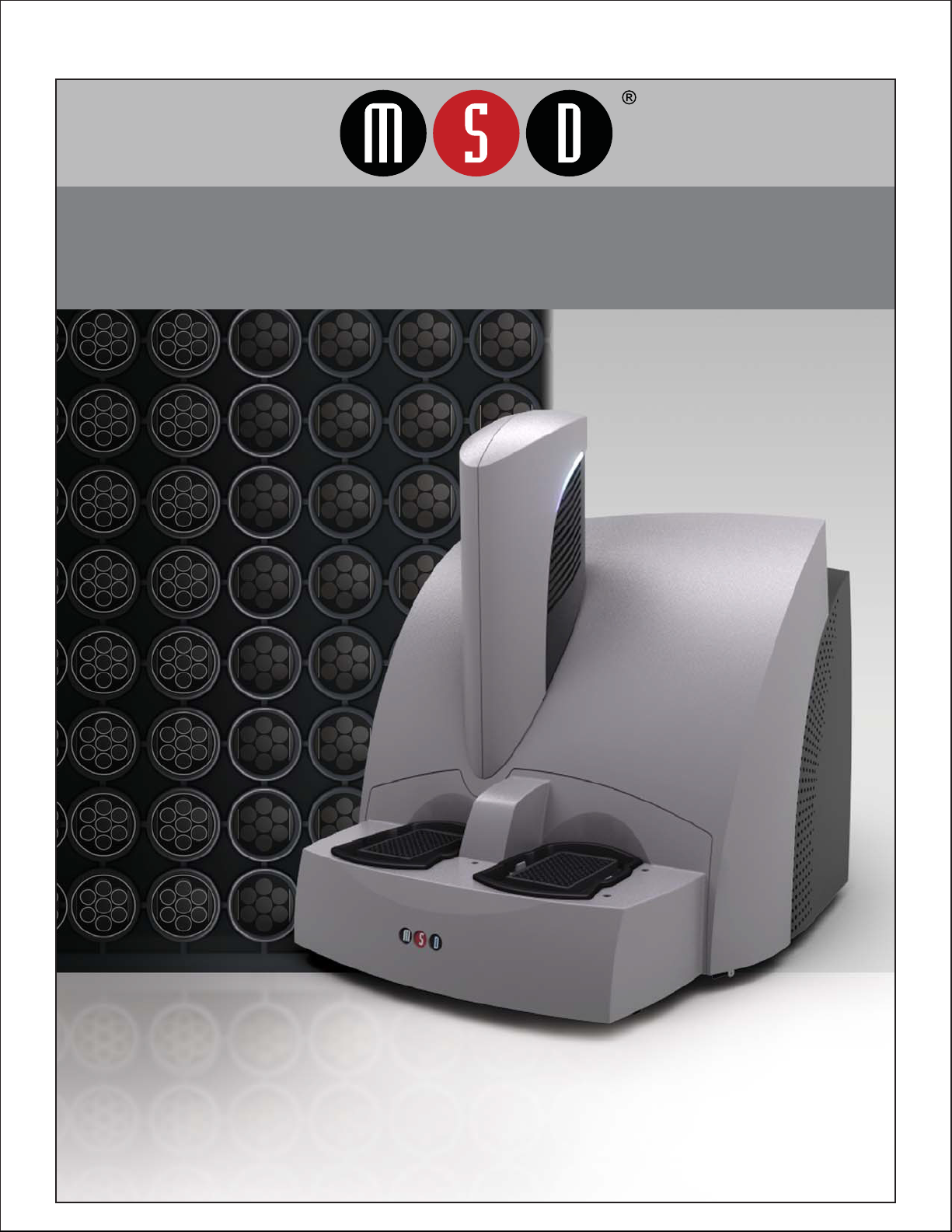

SECTOR Imager

Models 2400 & 6000

www.mesoscale.com

®

Page 2

FOR RESEARCH USE ONLY. NOT FOR USE IN DIAGNOSTIC PROCEDURES.

Disclaimer of Warranty and Liability

Changes in Publication

Unauthorized Use of Manual Material

Unauthorized Use of Trademarks or Service Marks

MESO SCALE DIAGNOSTICS, LLC. (“MSD”) MAKES NO REPRESENTATION OR WARRANTY OF ANY KIND, AND HEREBY

EXPRESSLY EXCLUDES AND DISCLAIMS ANY AND ALL REPRESENTATIONS AND WARRANTIES WITH REGARD TO THIS

INSTRUMENT MANUAL (THIS “MANUAL”), INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY,

SUITABILITY OR FITNESS FOR A PARTICULAR PURPOSE, DATA ACCURACY, SYSTEM INTEGRATION, QUIET TITLE OR

NONINFRINGEMENT. NO STATEMENT IN THIS MANUAL SHALL BE INTERPRETED TO GRANT OR EXTEND ANY WARRANTY ON

THE PRODUCTS DESCRIBED HEREIN. MSD SHALL NOT BE LIABLE FOR ERRORS OR OMISSIONS CONTAINED HEREIN OR FOR

ANY DAMAGES OF ANY KIND, INCLUDING, BUT NOT LIMITED TO DIRECT, INDIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL

OR PUNITIVE, WHETHER ARISING IN CONTRACT, TORT, STRICT LIABILITY OR OTHERWISE, THAT MAY BE INCURRED IN

CONNECTION WITH THE FURNISHING, PERFORMANCE OR USE OF THIS MANUAL.

The information contained in this Manual is subject to change without notice.

No part of this Manual may be duplicated, reproduced, stored in a retrieval system, translated, transcribed, or transmitted in any form

or by any means without the express prior written permission of MSD. This Manual shall be returned to MSD within two (2) business

days following any request by MSD.

MESO SCALE DISCOVERY, MESO SCALE DIAGNOSTICS, MSD, DISCOVERY WORKBENCH, MULTI-ARRAY, MULTI-SPOT,

QUICKPLEX, SECTOR, SECTOR PR, SECTOR HTS, SULFO-TAG, V-PLEX, STREPTAVIDIN GOLD, MESO, www.mesoscale.com,

SMALL SPOT (design), 96 WELL 1, 4, 7, & 10-SPOT (designs), 384 WELL 1 & 4-SPOT (designs), MSD (design), and SPOT THE

DIFFERENCE are trademarks and/or service marks of Meso Scale Diagnostics, LLC. Unauthorized use of any MSD trademark or

service mark may be a violation of federal and state trademark laws and is strictly prohibited by Meso Scale Diagnostics, LLC.

All other trademarks or service marks are the property of their respective owners.

© 2013. Meso Scale Diagnostics, LLC. All rights reserved.

Manual Part Number: 3-1200-0B0007-J

November 2013

Printed in USA

Page 3

Table of Contents

Introduction .............................................................................................................................................................. 7

1.1 Intended Audience .......................................................................................................................................... 7

1.2 How to Use This Manual ................................................................................................................................. 7

1.3 Formatting Information ................................................................................................................................... 8

Important Information .............................................................................................................................................. 10

2.1 General Operation ........................................................................................................................................ 10

2.2 Hazards ....................................................................................................................................................... 10

2.2.1 Electrical ....................................................................................................................................... 11

2.2.2 Chemical and Biological ................................................................................................................. 12

2.2.3 Visual ............................................................................................................................................ 12

2.2.4 Mechanical .................................................................................................................................... 13

2.2.5 ESD Sensitivity .............................................................................................................................. 13

2.2.6 Electromagnetic Interference and Susceptibility ............................................................................... 13

2.3 Software Compatibility ................................................................................................................................. 14

2.4 Decontamination Prior to Shipping or Servicing ............................................................................................ 14

System Description ................................................................................................................................................. 16

3.1 Intended Use ................................................................................................................................................ 16

3.2 Specifications Overview ................................................................................................................................ 16

3.3 Plate Compatibility ....................................................................................................................................... 16

3.4 System Components ..................................................................................................................................... 17

3.5 The SECTOR Imager ..................................................................................................................................... 17

3.5.1 CCD Camera and Telecentric Lens .................................................................................................. 18

3.5.2 Motion Control System .................................................................................................................. 19

3.5.3 Plate Barcode Readers .................................................................................................................... 19

3.5.4 MULTI-ARRAY Plate Input/Output Stacker ....................................................................................... 19

3.5.5 Stack Tubes ................................................................................................................................... 19

3.5.6 Single Plate Adaptor ...................................................................................................................... 20

3.5.7 Stacker Cover Plate ........................................................................................................................ 21

3.5.8 Status LEDs ................................................................................................................................... 21

3.5.9 Power Switch and Input/Output (I/O) Panel ...................................................................................... 22

3.5.10 Halt Button .................................................................................................................................... 23

3.6 Microsoft Windows-Compatible Workstations ................................................................................................ 24

3.7 MSD DISCOVERY WORKBENCH Software ..................................................................................................... 25

3.8 Operational Modes ....................................................................................................................................... 25

3.9 Image Readout ............................................................................................................................................. 25

3.10 SECTOR Imager Demonstration Test Plate ..................................................................................................... 26

3.11 Uninterruptible Power Supply ....................................................................................................................... 27

Installation ............................................................................................................................................................. 29

Quick Start ............................................................................................................................................................. 31

5.1 Start-up ....................................................................................................................................................... 31

5.2 Setup ........................................................................................................................................................... 33

5.3 Run ............................................................................................................................................................. 35

5.3.1 Operations ..................................................................................................................................... 35

5.4 Results ........................................................................................................................................................ 37

Using the SECTOR Imager ....................................................................................................................................... 39

1

2

3

4

5

6

Page 4

6.1 Single Plate Run .......................................................................................................................................... 39

6.2 Stack Run—Multiple Plates .......................................................................................................................... 39

6.2.1 Loading the Stack Tube .................................................................................................................. 39

6.2.2 Unloading the Stack Tube ............................................................................................................... 41

6.3 Robotics Integration ..................................................................................................................................... 41

Maintenance ........................................................................................................................................................... 43

7.1 Preventive Maintenance ................................................................................................................................ 43

7.2 Instrument Cleaning ..................................................................................................................................... 43

7.2.1 Adapter and Stack Tube Cleaning .................................................................................................... 43

7.3 Instrument Decontamination ......................................................................................................................... 44

Appendix ................................................................................................................................................................ 46

8.1 Troubleshooting Guide ................................................................................................................................. 46

8.2 Specifications .............................................................................................................................................. 50

8.2.1 SECTOR Imager ............................................................................................................................. 50

8.2.2 Scientific Performance ................................................................................................................... 50

8.2.3 Environmental Specifications .......................................................................................................... 50

8.2.4 Power Requirements ...................................................................................................................... 50

8.2.5 SECTOR Imager Physical Dimensions ............................................................................................. 51

8.2.6 Plate Standard Read Volume (per Well) ........................................................................................... 51

8.2.7 Custom Bar Code Compatibility* .................................................................................................... 51

8.2.8 Plate Specifications ........................................................................................................................ 51

8.3 Regulatory and Safety Certifications .............................................................................................................. 51

8.3.1 WEEE Compliance .......................................................................................................................... 52

8.4 Symbols and Labels ..................................................................................................................................... 53

Technical Support ................................................................................................................................................... 55

9.1 Bug Reports and Suggestions ....................................................................................................................... 55

9.2 Problems Running SECTOR Imagers ............................................................................................................. 55

9.3 How to Contact Us ....................................................................................................................................... 55

Figure 2:1 SECTOR Imager electrical hazards. SECTOR Imager 6000 shown. ..................................................................... 11

Figure 3:1 SECTOR Imager system. SECTOR Imager 6000 shown. .................................................................................... 17

Figure 3:2 SECTOR 6000 Imager components .................................................................................................................. 18

Figure 3:3 Input (right) stacker interface plate .................................................................................................................. 20

Figure 3:4 Fully loaded standard and high capacity stack tubes ........................................................................................ 20

Figure 3:5 SECTOR Imager plate in single plate adaptor ................................................................................................... 21

Figure 3:6 SECTOR Imager status LEDs ........................................................................................................................... 22

Figure 3:7 Power switch and I/O panel. SECTOR Imager 6000 (model 1200) shown. .......................................................... 23

Figure 3:8 SECTOR Imager halt button ............................................................................................................................ 24

Figure 3:9 Cable attachment locations for SECTOR Imager 2400/2400A ............................................................................ 24

Figure 3:10 The SECTOR 6000 reads 96-well plates in six sectors .................................................................................... 25

Figure 3:11 The SECTOR 2400/2400A reads 96-well plates in 24 sectors .......................................................................... 26

Figure 3:12 SECTOR Imager 6000 Demonstration Test Plate ............................................................................................. 26

Figure 3:13 Loading a SECTOR Imager demonstration plate ............................................................................................. 27

Figure 5:1 Instrument Status window............................................................................................................................... 31

Figure 5:2 MSD DISCOVERY WORKBENCH desktop icon ................................................................................................. 32

7

8

9

List of Figures

iv

Page 5

Figure 5:3 SECTOR Imager icon ...................................................................................................................................... 32

Figure 5:4: MSD DISCOVERY WORKBENCH splash screen ............................................................................................... 33

Figure 5:5 SECTOR Imager Window: Setup, Plate Summary, and Operations areas ............................................................ 34

Figure 5:6 Stacker cover over the output port with empty single plate adapter in the input port ........................................... 34

Figure 5:7 SECTOR Imager demonstration plate in the single plate adaptor ....................................................................... 35

Figure 5:8 SECTOR Imager window, Run Options dialog box ............................................................................................ 36

Figure 5:9 Demonstration plate results, Color Map layer .................................................................................................. 37

Figure 6:1 Loading MULTI-ARRAY plates into stack tube ................................................................................................. 40

Table 3:1 Stack tube plate capacities ............................................................................................................................... 19

Table 8:1: Troubleshooting guide .................................................................................................................................... 46

Table 8:2 Scientific performance ..................................................................................................................................... 50

Table 8:3 Symbols and labels ......................................................................................................................................... 53

List of Tables

v

Page 6

1

Introduction

6

Page 7

www.mesoscale.com

Introduction 1

MESO SCALE DISCOVERY® (MSD) develops, manufactures, and markets biological assays that provide cost-effective and valuable

information to scientists in drug discovery, therapeutic screening, and life science research. MSD's product portfolio is based on

MULTI-ARRAY

exceptional sensitivity, speed, dynamic range, and convenience.

MSD

develops, manufactures, and markets detection instrument systems as well as a line of assay kits for use with these instruments,

a proprietary line of reagents, and custom microplate printing and assay development services. MSD MULTI-ARRAY microplates are

available in 96-, 384-, and 1536-well formats with standard or high-binding surfaces. MSD plates may be purchased uncoated or

coated with proteins such as streptavidin or avidin, with anti-species antibodies such as goat anti-mouse or goat anti-rabbit, or with

antibodies against specific analytes. Custom coatings and surface treatments are available.

MSD MULTI-ARRAY plates are available as single spot (single assay) plates and as MULTI-SPOT

each well. MULTI-SPOT plates measure multiple analytes simultaneously in a single well, increasing throughput and enabling novel

assay panels.

®

technology, a proprietary combination of patterned arrays and electrochemiluminescence detection that results in

®

plates with patterned spot arrays in

For more details and information about applications, please visit the MSD website at

.

1.1 Intended Audience

This manual is for all users of the SECTOR Imagers. Users should understand general computer and Microsoft® Windows terminology,

and be familiar with standard laboratory practices. The intended users of the SECTOR Imagers are those conducting research in the life

sciences.

The SECTOR Imager 2400/2400A and SECTOR Imager 6000 share many features. Throughout this manual, the reader should assume

that a feature is common to all instruments unless otherwise noted. This manual describes how to operate SECTOR Imagers and

acquire data. The analysis of this data is treated in a separate manual: DISCOVERY WORKBENCH

®

User Guide.

1.2 How to Use This Manual

This publication is intended as reference and instruction for users of MSD SECTOR Imager 6000 (models 1200 and 1201) and

SECTOR Imager 2400/2400A (models 1250/1251). These instruments are designed to read MSD MULTI-ARRAY and MULTI-SPOT

plates.

This manual is divided into chapters containing main topics and subsections. Use the hyperlinked Table of Contents to find topics of

interest quickly. The List of Figures and List of Tables hyperlink to the images and tables that enhance understanding of written

information in this manual. The Appendix contains supplemental information on troubleshooting, instrument specifications, safety

symbols, regulatory information, and labels.

The term SECTOR Imager will be used to describe the SECTOR Imager 2400/2400A and the SECTOR Imager 6000 when the feature

being described is substantially the same. Differences between SECTOR Imagers will be described explicitly where appropriate.

Introduction 7

Page 8

Tips

Notes

Warnings and Caution Symbols

WARNING

Symbol

Explanation

CAUTION

CAUTION:

Symbol

Tips provide extra information or details that help users perform functions more efficiently.

Notes provide supplemental information on the proper use of the SECTOR Imager and its software.

General warnings advise operators of potential hazards and highlight the procedures or information necessary to avoid personal injury

during use of the SECTOR Imager.

A caution note highlights procedures or information necessary to avoid damage to equipment, corruption of software, loss of data, or

invalid test results.

instructions in this publication may result in damage to the product, injury to operating personnel or poor instrument

performance

Risk exists for a mechanical, chemical, or safety hazard

Risk exists for an electrical hazard

Carefully read and understand all information in this document. Failure to read, understand, and follow the

1.3 Formatting Information

This guide uses the following formatting conventions:

Internal hyperlinks are formatted bold/gray. Click to jump instantly to the referenced section or figure.

Clickstreams are indicated with arrows and always start with a top-level menu item: Select Tools Plate Data

History.

Information to be entered by the user is shown in italics: Enter 5.

Information that the user chooses based on what is displayed is bracketed: Double-click <experiment name>

When referring to a term as it appears in the software, we capitalize it exactly as it is capitalized on-screen: Select

Read from Bar Code from the Plate Type menu.

Introduction 8

Page 9

2

Important Information

9

Page 10

Important Information 2

WARNING:

CAUTION:

CAUTION:

CAUTION:

CAUTION:

CAUTION:

not

CAUTION:

NOTE:

8.2.3 Environmental Specifications

CAUTION:

not

CAUTION:

CAUTION:

2.1 General Operation

The SECTOR Imagers are designed to run 24 hours a day. Once initialized, the SECTOR Imager enters standby mode when plates are

not running. Standby maintains the CCD detector temperature. The SECTOR Imager requires no additional initialization when left in

standby mode.

in this manual, the protection provided by the equipment may be impaired.

Specifically, updating aspects of the operating system or installing any software that changes parameters of the computer

environment could interfere with proper operation of the instrument software.

software on the SECTOR Imager computer system could cause conflicts with the operation of the instrument software.

instrument operation. It is suggested that any virus checking software run on the instrument be configured to minimize the

scanning of newly generated files while the instrument is operating.

system power features that disable USB communication, such as Hibernate, will cause the system to stop responding and

requires a power off/on cycle of the instrument and PC to restore function.

The instrument can only be operated with all covers in place. If the unit is operated in any manner not specified

Installation of additional software on the computer system used to operate the SECTOR Imager is not supported.

Running screen-savers, automated maintenance software, network-security software, and other possible

The instrument generates files when running. Virus scanning on the instrument computer can interfere with

Use of other applications while plates are being read may interfere with system performance. Use of operating

error may also occur if a plate is being read when the time is automatically changed from standard to daylight savings time or

vice versa.

The SECTOR Imager should be operated in a dust-free environment with an ambient temperature between 20–26oC, and

humidity levels between 10–80% (non-condensing). Environments or locations with high levels of vibration should be avoided.

See Section

cooling vents and the CCD camera tower cooling vents on the SECTOR Imager are

the instrumentation or cause injuries. Avoid handling or storing infectious or radioactive materials near the SECTOR Imager.

Additional USB devices may

Changes to the computer clock can cause a system error if the changes are made during a plate read. A system

Keep the SECTOR Imager away from direct sources of heat or cold and direct sunlight. Ensure that the rear

Do not place any objects, materials, or liquid containers on top of the SECTOR Imager.

Falling objects or splashing liquids, including chemically reactive or infectious reagents, can cause damage to

be connected to the SECTOR Imager computer system.

for complete environmental specifications.

blocked.

2.2 Hazards

This section contains notices and warnings that should be read carefully. Before working with the SECTOR Imager, become familiar

with all safety precautions and regulations concerning the handling of materials and the instrument’s electrical and mechanical

components.

Important Information 10

Page 11

Operating this device in a manner not specified by MESO SCALE DISCOVERY may impair the electrical and thermal protection

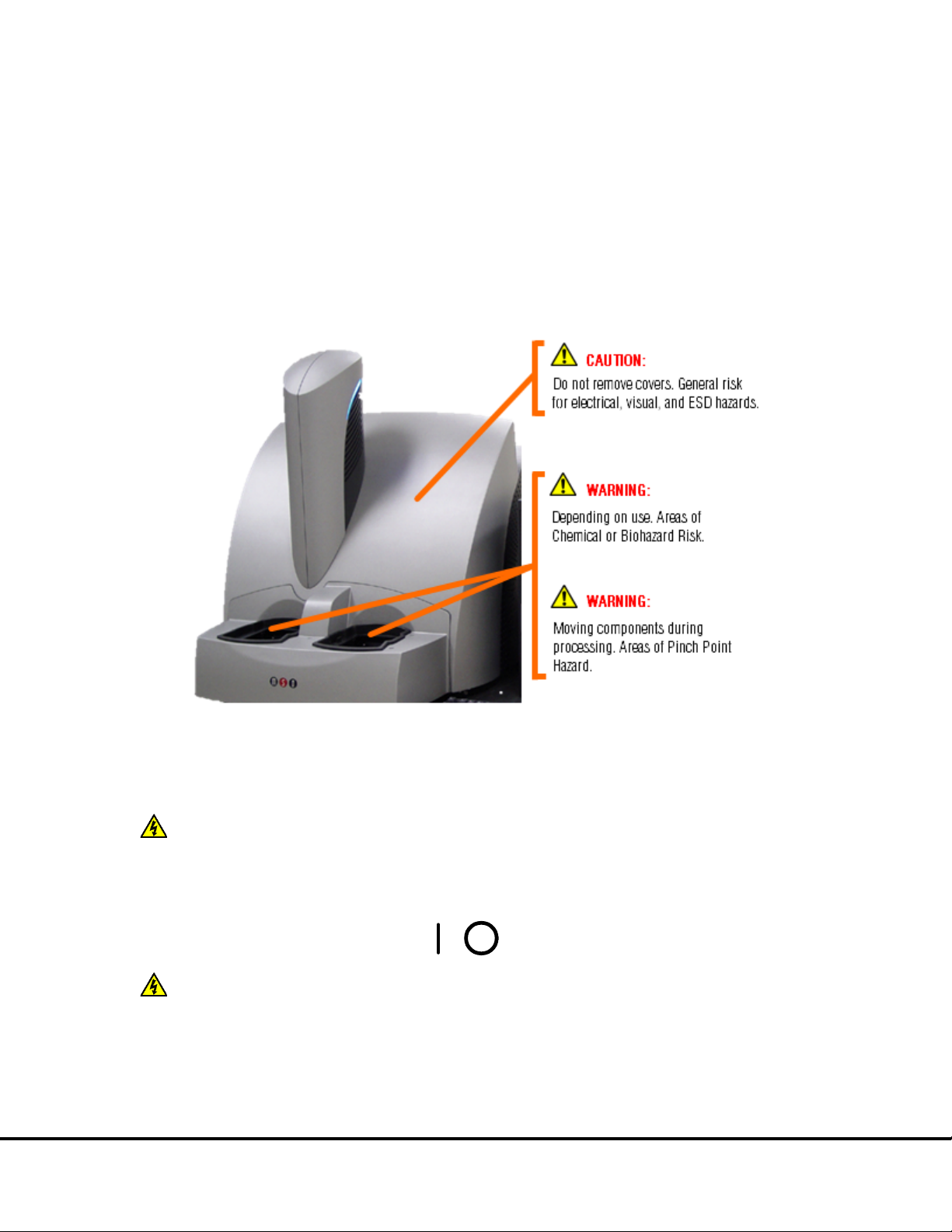

Figure 2:1 SECTOR Imager electrical hazards. SECTOR Imager 6000 shown.

WARNING:

Instrument Service

WARNING:

Instrument Service

provided by the equipment.

As with most laboratory instruments, the SECTOR Imager presents certain hazards for users. We have identified five key types of

hazards:

• Electrical

• Chemical and biological

• Visual

• Mechanical

• ESD sensitivity

2.2.1 Electrical

Do not attempt to open the instrument cover and work with any electronic elements. An electrical shock may occur. The SECTOR

Imager was designed and tested in compliance with appropriate electrical safety standards.

IMAGER. Please contact MSD

When the power switch is in the off position, all internal electrical circuits are disconnected from both the live and neutral lines of the

electrical power source.

should power down the instrument and disconnect the SECTOR Imager power cable from the wall socket prior to cleaning near

moving parts. For significant spills or liquid intrusion into the instrument enclosure (e.g. resulting from a fire protection water

sprinkler), contact MSD

The SECTOR Imager should not be operated in hazardous atmospheres, as defined by the National Fire Protection Association, the

National Electric Code, and International Standards.

The SECTOR Imager contains AC voltages. DO NOT ATTEMPT TO SERVICE OR REPAIR THE SECTOR

For best performance, remove any sample or reagent spillage from the instrument. For safety, the operator

for all service and repair, including electrical problems.

On Off

.

Important Information 11

Page 12

Although the SECTOR Imager is shielded and grounded, laboratory personnel should never remove any instrument covers that would

NOTE:

strongly

CAUTION:

CAUTION:

Scientific and Technical Support

WARNING:

WARNING:

WARNING:

expose electrical circuits. Only authorized MSD Service personnel should perform repairs to the interior of the SECTOR Imager.

We

Laboratory Standards Institute (CLSI) document entitled GP17-A2, Clinical Laboratory Safety; Approved Guideline, Section 19,

Instrument Testing.

tests should be documented. New or incoming equipment should also undergo electrical safety checks before use. Power cords

should be inspected annually for integrity.

prong adaptor disconnects utility ground, creating a shock hazard. Always connect the system power cord directly to a threeprong receptacle with a functional ground.

recommend that users of laboratory instruments (such as the SECTOR Imager) follow the Clinical and

Grounding and polarity checks should be conducted on all electrical outlets annually, and the results of these

Do not use a two-prong plug or extension cord to connect primary power to the SECTOR Imager. Use of a two-

2.2.2 Chemical and Biological

Users are responsible for taking all necessary precautions against hazards associated with the use of laboratory chemicals. Running

assays on the SECTOR Imager may involve the use of potent chemicals—such as bases and solvents, cleaning and disinfection

agents, and assay reagents. Such chemicals should be independently evaluated for chemical or biological hazards.

Laboratory regulations and good laboratory practices concerning the use of such chemicals should be followed at all times. Use

personal protective equipment recommended by your facility when handling any of these reagents.

Product labels, package inserts and product information sheets with specific usage recommendations are provided for all plates and

reagents used with the SECTOR Imager. Contact MSD

for MSD plates and reagents.

to obtain material safety data sheets (MSDS)

Samples, user reagents, or controls used in assays may be infectious or biohazardous. By working with these materials, users may be

exposed to biological hazards. Laboratory regulations concerning the handling of potentially infectious material should be followed at

all times.

Users should avoid breathing reagent fumes or aerosols. Gloves and goggles should be worn when disposing of used plates. If skin

comes in contact with reagents, rinse the exposed area with water immediately and follow appropriate safety protocols as determined

by your facility. Dispose of used plates according to federal, state, and local regulations.

hazardous reagents.

personal protective equipment and good laboratory practices are strongly suggested when working in these areas.

Wear gloves. Avoid skin contact and inhalation when handling plates that contain or have been exposed to

The stacker input and output locations are considered susceptible to contamination during normal use. Use of

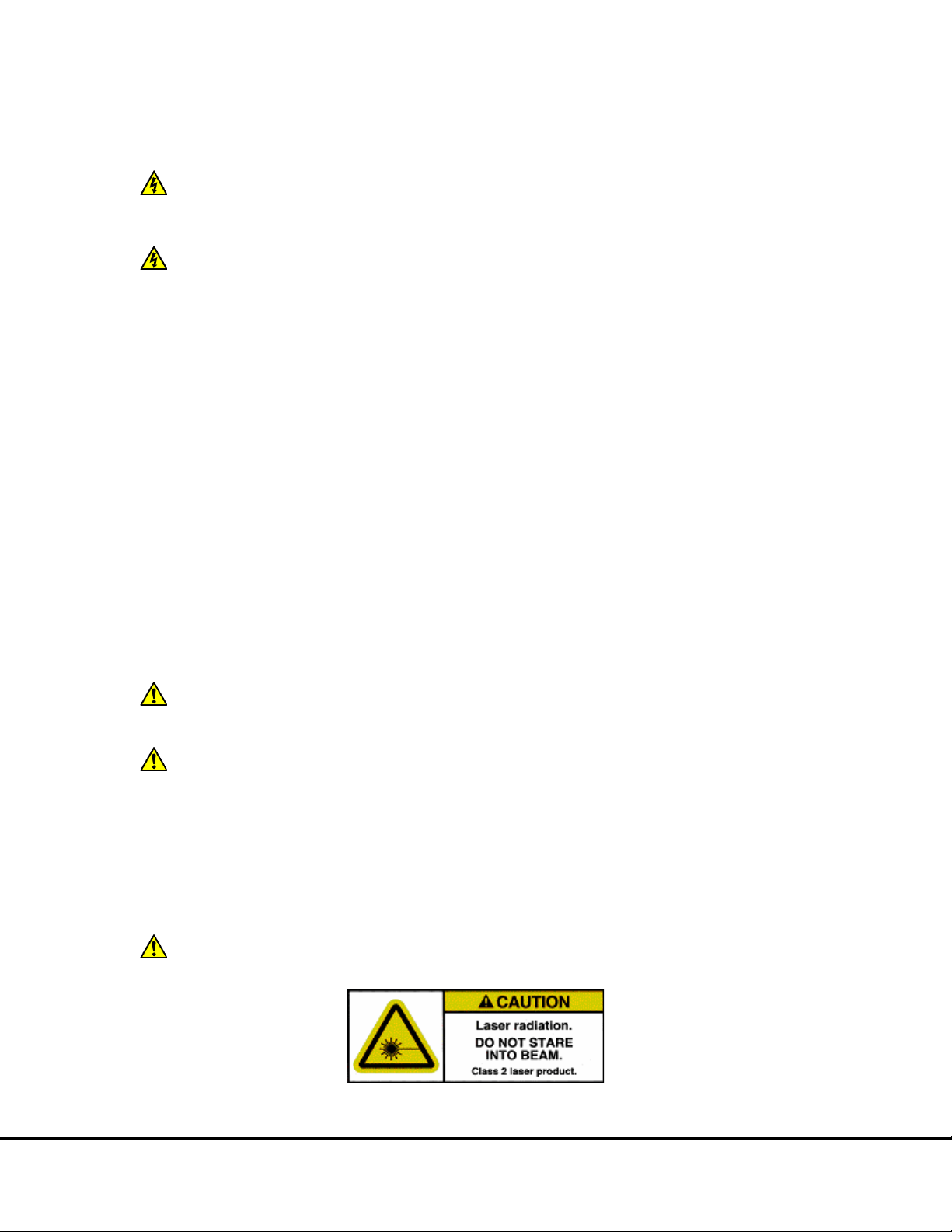

2.2.3 Visual

Older versions of the SECTOR Imager 6000 with last 3-digits of serial #’s below 198, and the SECTOR Imager 2400 with last 3-digits

of serial #’s below 109 have a scanning bar code reader with a class 2 Laser. Although the laser beam is not visible during normal

operation, personnel may be exposed if operating the SECTOR Imager with the light-tight door open or with the covers removed. Laser

output power is 1.0 mW maximum. Newer SECTOR Imagers use light emitting diodes (LEDs) to read bar codes.

personnel.

DO NOT STARE INTO THE BEAM. The laser is only directly viewable and accessible by qualified service

Important Information 12

Page 13

WARNING:

WARNING:

Instrument Service

WARNING:

CAUTION:

WARNING:

Figure 3:5

Figure 3:4

Figure 3:5

CAUTION:

hazardous radiation exposure.

Use of controls, or adjustment or performance of procedures other than those specified herein, may result in

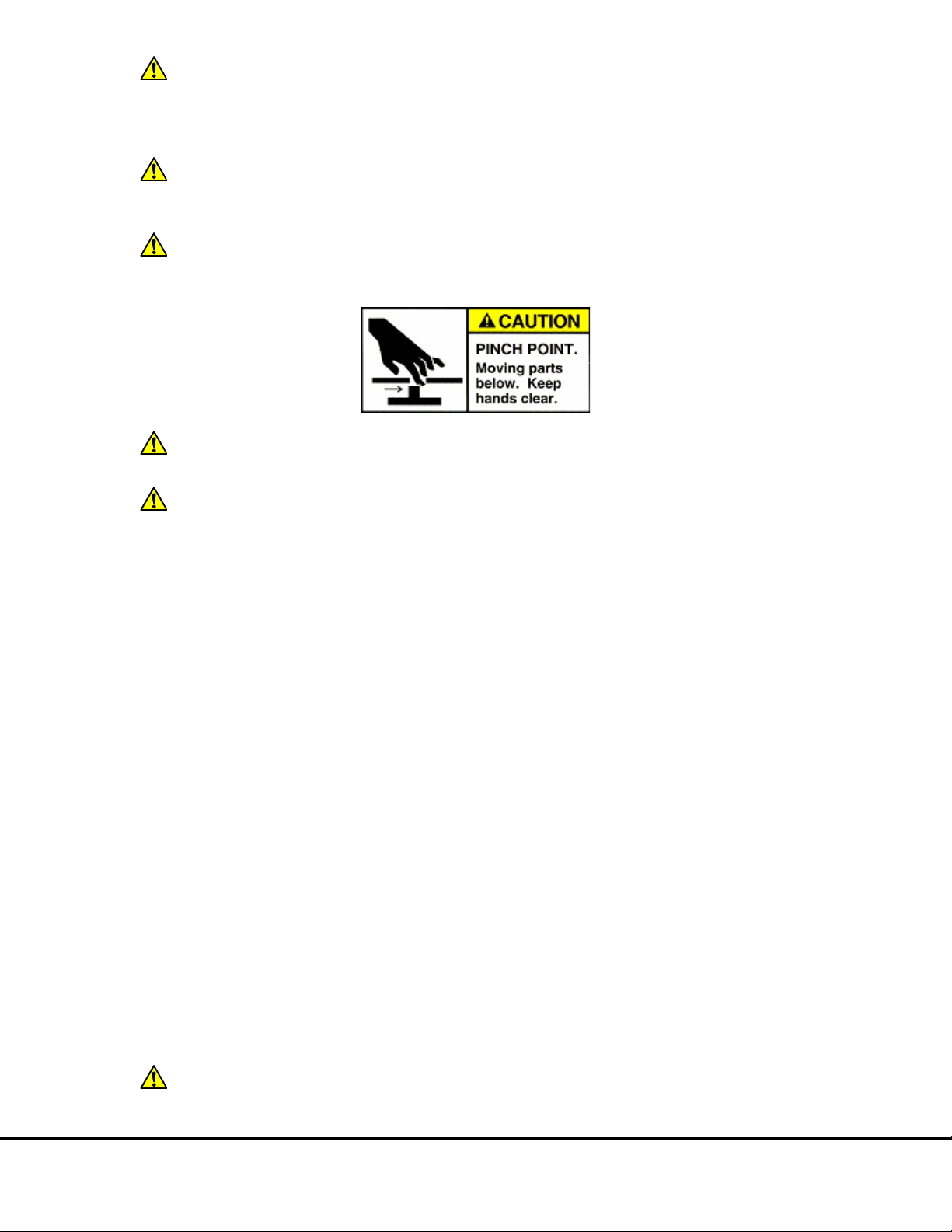

2.2.4 Mechanical

kg). Be careful to use proper technique when lifting it to minimize the risk of injury. Two or more people should lift from beneath

the instrument. Please contact MSD

instrument while it is in operation. Do not place fingers in stack tubes or the plate carrier when the instrument is in operation.

Labels are affixed to the stack tube platforms indicating a pinch hazard.

The SECTOR Imager 6000 weighs 150 lbs (68 kg) and the SECTOR Imager 2400/2400A weighs 140 lbs (64

The SECTOR Imager presents potential mechanical hazards. To avoid injury, do not touch any part of the

before attempting to move the instrument.

movement.

mechanical force. As with any mechanical instrument, you should take certain precautions when operating the SECTOR Imager:

• Do not wear loose garments or jewelry that could catch in moving mechanisms.

• Operate the instrument with the cover intact.

• Keep hands away from pathways of moving parts during operation.

• Do not attempt mechanical repair.

• Do not bump into or lean on the SECTOR Imager, or place any objects on top of it.

• Never operate the instrument unless both stacker ports contain a single plate adaptor (

When using robotic plate loaders (robots), ensure that there is nothing present that will obstruct robot

Moving parts of the SECTOR Imager can be damaged or become misaligned when exposed to strong

(

), or the stacker cover plate (

).

), a stack tube

2.2.5 ESD Sensitivity

The SECTOR Imager has been tested for electrostatic discharge (ESD) sensitivity and complies with the applicable international

standards. Standard installation precautions should be taken when stationing the instrument for regular use. Like many instruments of

its kind, the SECTOR Imager is sensitive to static discharge in excess of 4.0 kV. In typical laboratory environments, electrostatic

discharge should not be a problem.

2.2.6 Electromagnetic Interference and Susceptibility

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of FCC rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. The equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause interference, in which case users will be required to correct the interference at their

own expense.

Changes or modifications not expressly approved by MSD may void the warranty. The operator shall use any special accessories

provided with the equipment such as the power supply or shielded cables that are necessary for compliance with FCC standards.

controlled electromagnetic environment. Transmitters of RF energy such as mobile (cellular) telephones should not be used in

close proximity.

SECTOR Imager 6000 and SECTOR Imager 2400/2400A instruments have been tested for operation in a

Important Information 13

Page 14

CAUTION:

Scientific and Technical Support

Instrument Service

WARNING:

electrical circuit. This may be accomplished using an uninterruptible power supply (UPS), power strip of proper electrical rating,

or by verifying the power wall outlets. If one of these is not possible, a ground strap should be used to connect the instrument

chassis to the computer chassis. Please contact MSD

assistance.

To avoid interference from voltage transients, the computer and instrument should be powered by the same

if you have questions or need

2.3 Software Compatibility

The Microsoft Windows® Update service can affect the operation of the instrument software. When running, the update application can

turn off the database services upon which the instrument relies, causing errors and stopping instrument operation. Updates should not

be run during instrument use. Run manually or schedule Windows updates when you are sure that the instrument will not be in use.

Occasionally, Windows Update does not restart the database server after it runs. This will cause the instrument software to run

incorrectly. Restarting the computer will restart the database service and restore the instrument to full operation.

The SECTOR Imager system has not been tested for compatibility with all programs. Installation of additional applications, such as

anti-virus and security programs may interfere with function.

2.4 Decontamination Prior to Shipping or Servicing

The SECTOR Imager may have been used to analyze infectious materials or in an environment where infectious materials were

handled. For the protection of future users and service personnel, please follow site safety procedures and the directions of the site

safety officer to disinfect the SECTOR Imager before shipping or service. Please contact MSD

for details.

requirements for the SECTOR Imager before shipping or service.

Follow site safety procedures and the directions of the site safety officer to determine decontamination

Important Information 14

Page 15

3

System Description

15

Page 16

System Description 3

3.1 Intended Use

The SECTOR Imager 6000 and SECTOR Imager 2400/2400A are for research use only. The instruments are not for use in diagnostic

procedures.

3.2 Specifications Overview

The SECTOR Imager offers high sensitivity and six logs of dynamic range. The SECTOR Imager 6000 reads plates at a rate of

approximately 70 seconds per plate. The SECTOR Imager 2400/2400A reads plates at a rate of approximately 3 ½ minutes per plate.

Using MSD DISCOVERY WORKBENCH software, all models provide the capability to interact with a third party external robotic

controller.

3.3 Plate Compatibility

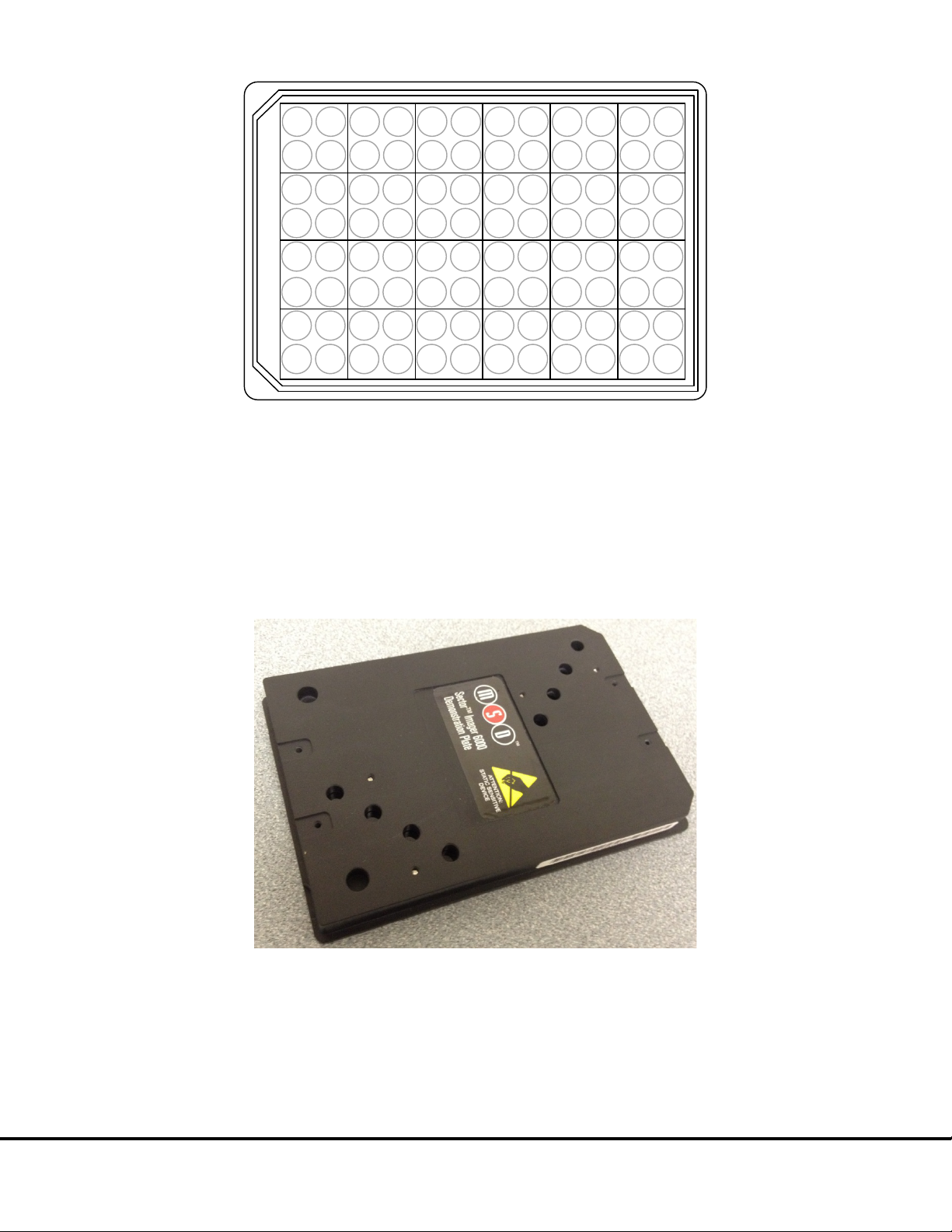

The SECTOR Imager 2400A is compatible with:

• 96-well MULTI-ARRAY plates

• 96-well, 4-, 7-, and 10-spot MULTI-SPOT plates

The SECTOR Imager 2400 is compatible with:

• 96- and 384-well MULTI-ARRAY plates

• 96-well, 4-, 7-, and 10-spot MULTI-SPOT plates

The SECTOR Imager 6000 is compatible with:

• 96- and 384-well MULTI-ARRAY plates

• 96-well, 4-, 7-, and 10-spot MULTI-SPOT plates

• 384-well, 4-spot MULTI-SPOT plates

• 1536-well MULTI-ARRAY plates

MULTI-ARRAY and MULTI-SPOT plates are designed to be read only once and may not be reused.

®

SECTOR Imagers cannot read plates designed for the SECTOR PR

instruments.

System Description 16

Page 17

3.4 System Components

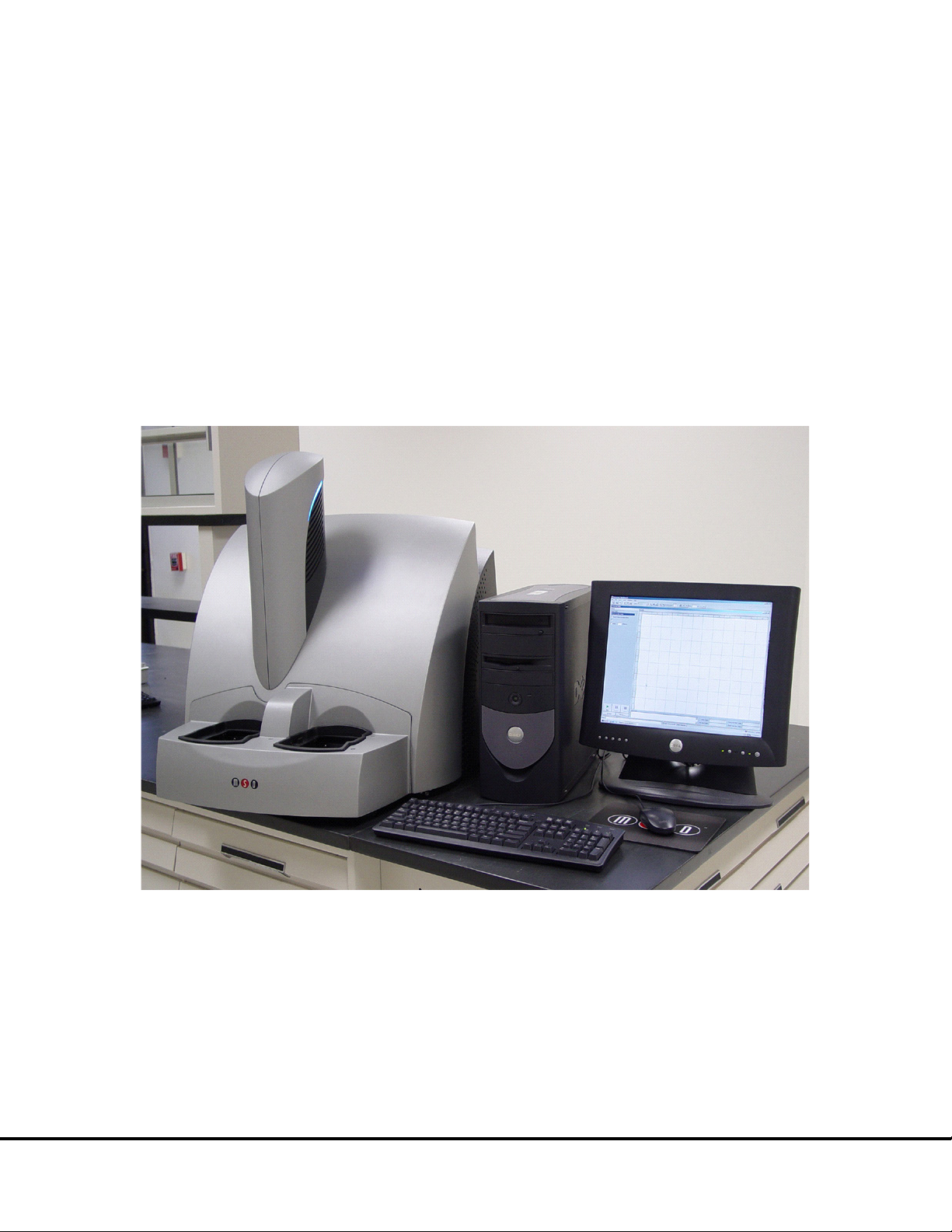

Figure 3:1

Figure 3:1 SECTOR Imager system. SECTOR Imager 6000 shown.

Figure 3:2

A standard SECTOR Imager system consists of the following (

• SECTOR Imager instrument

• Microsoft Windows-compatible workstation

• MSD DISCOVERY WORKBENCH software

• SECTOR Imager demonstration plate

• Cables (SECTOR Imager 6000 [model 1200] and SECTOR Imager 2400/2400A [models 1250/1251]): power, RS-232, USB,

and camera serial cable

• Cables (SECTOR Imager 6000 [model 1201]): power and USB

• Uninterruptible power supply (UPS)

• SECTOR Imager 2400 and 6000 Instrument Manual

• DISCOVERY WORKBENCH User Guide

):

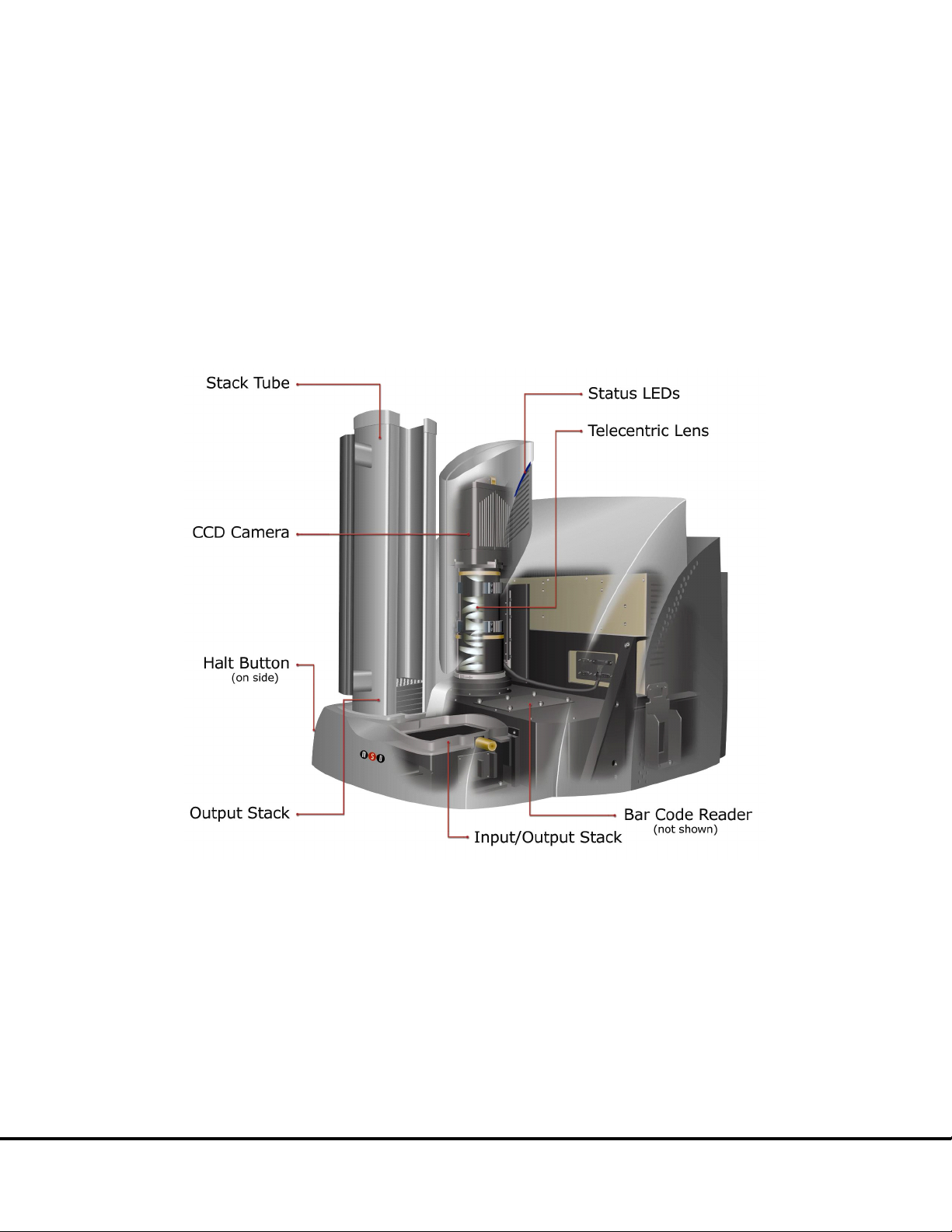

3.5 The SECTOR Imager

The main components of the SECTOR Imager include (

• CCD camera and telecentric lens

• Motion control system

• Plate barcode readers (short and long side)

• Integrated MULTI-ARRAY plate input/output stack

):

System Description 17

Page 18

• Stack tubes (2, standard capacity)

NOTE:

not

Figure 3:2 SECTOR 6000 Imager components

NOTE:

• Single plate adaptor (1, not shown)

• One stacker cover plate (1, not shown)

• Instrument status LEDs

• Power switch and I/O panel (not shown)

• Halt button

The stacker cover plate comes preinstalled on the SECTOR Imager 2400A. This model does

include) stack tubes or the output stacker mechanism.

Additional stack tubes, single plate adaptors, and stacker cover plates may be purchased from MSD.

use (and does not

The SECTOR Imager 2400/2400A employs a different CCD camera and a different custom lens optimized to read

MULTI-ARRAY plates in 24 sectors (not shown).

3.5.1 CCD Camera and Telecentric Lens

Each SECTOR Imager uses a sensitive, high-resolution CCD camera and lens system to detect light emitted from MULTI-ARRAY

plates. The SECTOR Imager 2400/2400A reads plates using 24 sectors or segments. The SECTOR Imager 6000 reads plates using 6

sectors or segments, yielding higher throughput.

Once the instrument is turned on and the software is started, it takes approximately 45 to 60 minutes for the CCD chip to reach and

stabilize at its normal operating temperature of –35 ±1°C (SECTOR Imager 6000) or -25 ±1°C (SECTOR Imager 2400/2400A). The

telecentric lens of both SECTOR Imagers provides high efficiency and uniform collection of light from MULTI-ARRAY plates.

System Description 18

Page 19

3.5.2 Motion Control System

6 Using the SECTOR Imager

Code 39

Code 128

Scientific and Technical Support

WARNING:

Note:

Table 3:1

Figure 3:3

Figure 3:4

Table 3:1

Table 3:1 Stack tube plate capacities

Stack Tube

Plate Type

Capacity

Standard

Standard (

Extended

Extended

The SECTOR Imager uses a precision mechanism for transporting MULTI-ARRAY plates from the input stacker, into the CCD

detector’s viewing area, and back to either the input or output stacker, depending on selections in the DISCOVERY WORKBENCH

Software. (See Section

) for more information on reading a plate.)

3.5.3 Plate Barcode Readers

The SECTOR Imager’s two barcode readers read the barcode(s) on the MULTI-ARRAY plates. The MULTI-ARRAY plates come with an

MSD barcode label that uniquely identifies the plate and allows the SECTOR Imager to detect the type of plate being run.

If desired, the user may apply a custom barcode label either on the same side of the plate as the MSD barcode or on one of the short

sides of the plate. The custom barcode label should be applied at the same height as the MSD barcode label. The custom barcode

must be of one of the following formats:

To enable custom bar codes, when the SECTOR Imager reader window is open, go to Tools Instrument Configuration. Select

Enable Long-side Custom Bar Code Reader and/or Enable Short-side Custom Bar Code Reader.

or

.

Please contact MSD

for additional information regarding the use of custom barcodes on MSD

MULTI-ARRAY plates.

3.5.4 MULTI-ARRAY Plate Input/Output Stacker

SECTOR Imagers 6000 and 2400 include an integrated mechanism to manipulate multiple MULTI-ARRAY plates arranged vertically

(referred to as the “stacker”). The stacker will automatically pull plates from the input (right) side and eject them into the output (left)

side. The stacker may be used with two single plate adaptors or two stack tubes or one of each. Stacker cover plates or single plate

adaptors containing an empty plate should be used over the stacker interface plates whenever the machine is not in use.

When running single plates, the input (right) stacker interface plate can act as both input and output ports. For safety, place a stacker

cover plate over the left stacker interface plate when not in use.

The stacker contains components that may move at any time. Users

of the SECTOR Imager should never place their fingers into the stacker for any reason

unless the instrument is powered off.

The SECTOR Imager 2400A is not equipped with an output stacker mechanism and

does not use stack tubes. All plates are returned to the input port after reading.

3.5.5 Stack Tubes

MSD offers standard-capacity (standard) and high capacity (extended) stack tubes (

SECTOR Imager 2400. When using stack tubes, ensure that the stack tube is fully seated on the stacker interface plate (

The standard tubes are provided with the SECTOR Imager 6000 and SECTOR Imager 2400, and both standard and extended tubes are

separately available for purchase (

).

) for both the SECTOR Imager 6000 and

).

Lists the capacity of MSD stack tubes for each plate type.

(Standard Capacity) 96-well MULTI-ARRAY 20 plates

Standard Capacity) 384-well MULTI-ARRAY 30 plates

(High Capacity)

(High Capacity)

384-well MULTI-ARRAY 75 plates

96-well MULTI-ARRAY 50 plates

System Description 19

Page 20

Figure 3:3 Input (right) stacker interface plate

Figure 3:4 Fully loaded standard and high capacity stack tubes

Figure 3:5

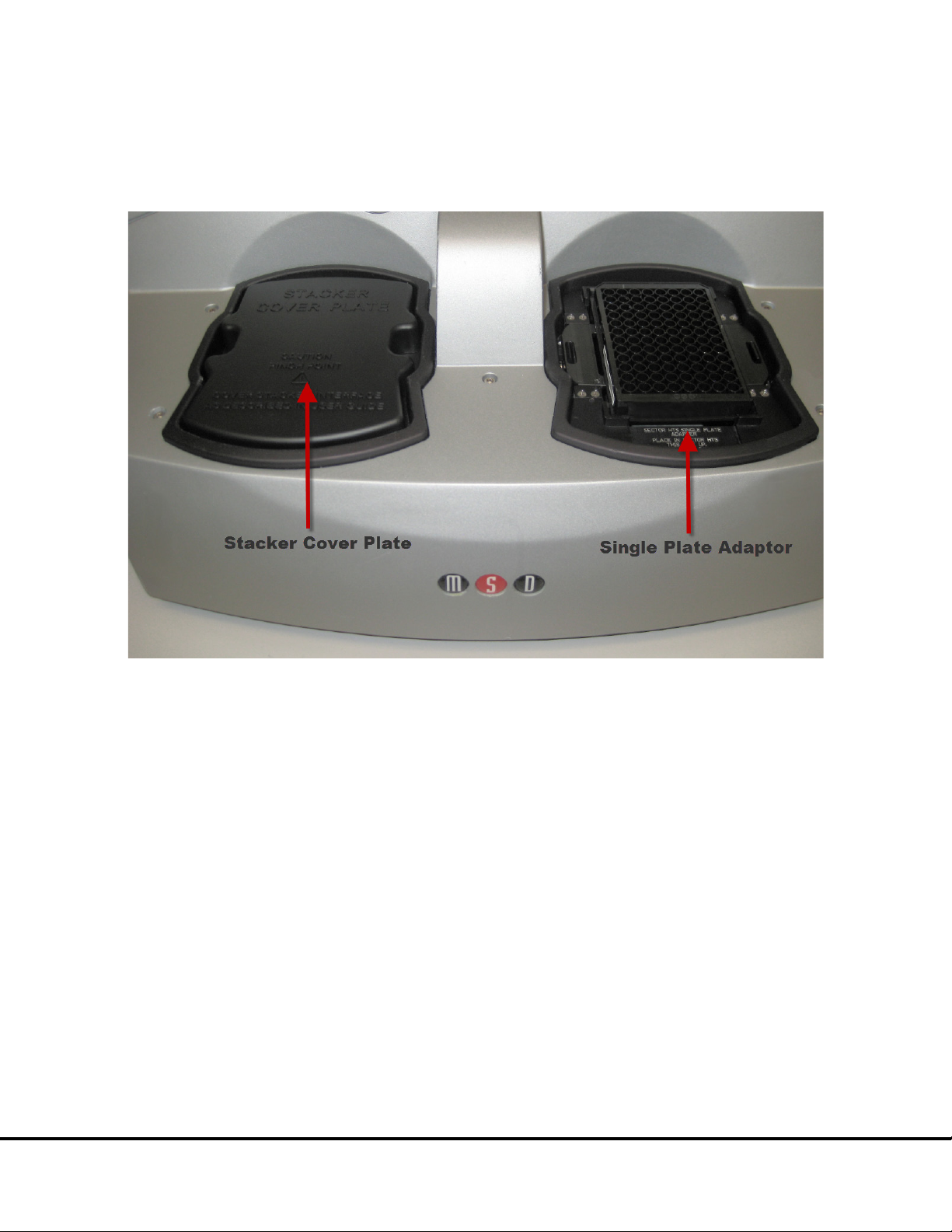

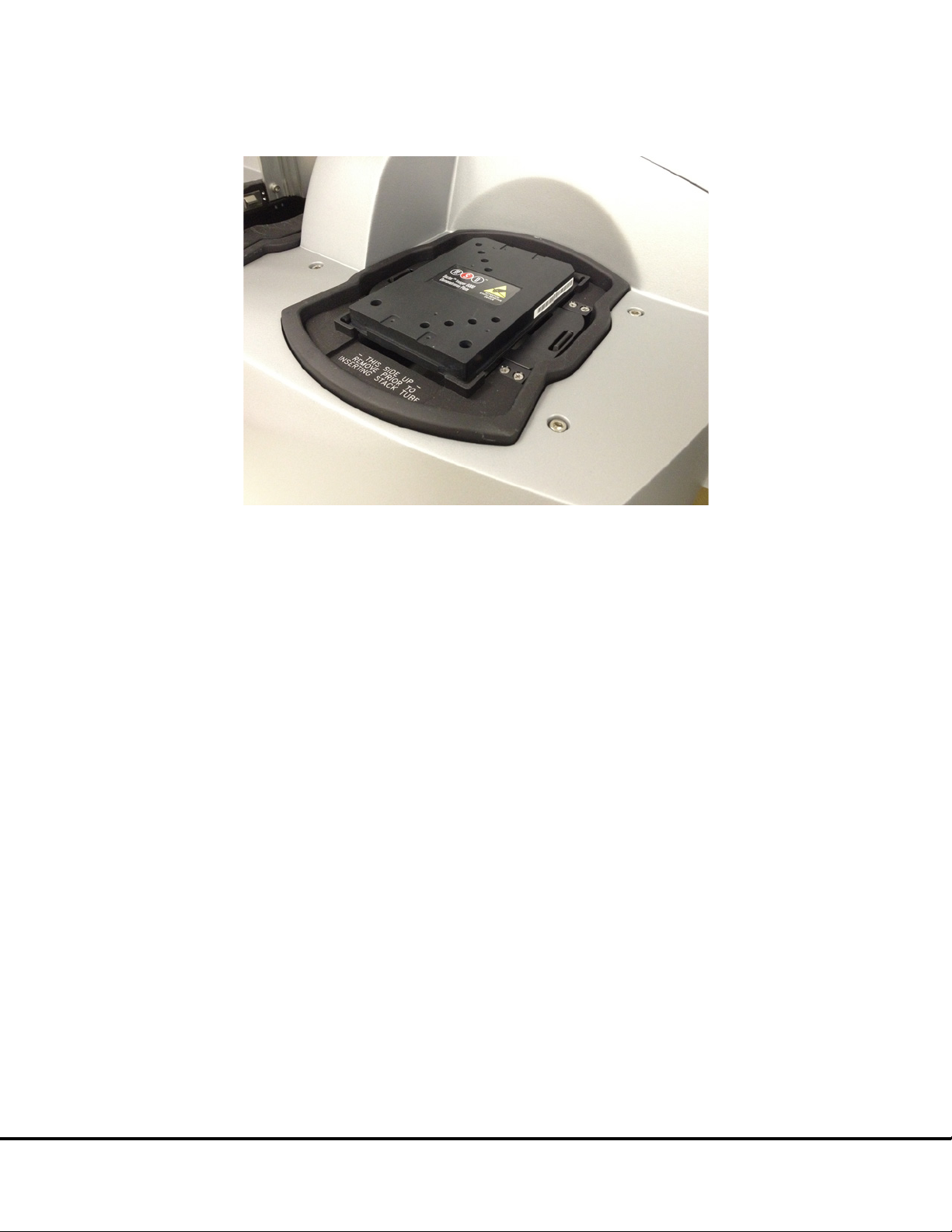

3.5.6 Single Plate Adaptor

The SECTOR Imager reads single plates placed manually into the single plate adaptor. When inserting the single plate adaptor into the

stacker, ensure that the single plate adaptor is fully seated on the stacker interface plate.

single plate properly loaded in the single plate adaptor. The single plate adaptor may also be used with laboratory robotics.

(right side of image) shows a

System Description 20

Page 21

3.5.7 Stacker Cover Plate

Figure 3:5

Figure 3:5 SECTOR Imager plate in single plate adaptor

Figure 3:6

Steady blue:

Blinking blue:

Steady red:

The stacker cover plate (

return single plates to the input side. Both stacker interface plates should be covered when the machine is not in use.

The SECTOR Imager 2400A comes preconfigured to return plates to the input side. A stacker cover plate is preinstalled on the output

port.

left side of image) is used to cover the output (left) stacker interface when the machine is set to

A stacker cover plate should always be in place when no stack tube or single plate adaptor is present.

3.5.8 Status LEDs

The status LEDs built into the camera tower indicate the current operational mode of the SECTOR Imager (

•

•

•

Instrument is in standby mode

Instrument is currently reading a plate

Instrument is in fault mode or is waiting for the addition of plates

).

System Description 21

Page 22

Figure 3:6 SECTOR Imager status LEDs

Figure 3:7

NOTE:

3.5.9 Power Switch and Input/Output (I/O) Panel

The I/O panel of the SECTOR Imager, located on the rear right side of the SECTOR Imager, includes the instrument’s power switch,

power entry module, and connectors for USB, RS-232, camera serial communications, and robotic halt activation cables (

The instrument can be powered-on and off via the power switch. Typically, the instrument should be left powered-on to maintain

camera temperature.

Only use the communications cables supplied with the SECTOR Imager. Use of cables other than those supplied may

degrade instrument performance.

A halt connector is present in order to add an external switch that will de-energize the motion control system. The SECTOR Imager

connector receptacle is Hirose Electric Co Ltd HRS, Part #SR30-10R-4S. The mating connector is Hirose Part #SR30-10PE-4P, SR3010PM-4P, or SR30-10PQ-4P.

).

System Description 22

Page 23

Figure 3:7 Power switch and I/O panel. SECTOR Imager 6000 (model 1200) shown.

Figure 3:8

NOTE:

must

Scientific and Technical Support

3.5.10 Halt Button

The halt button (

SECTOR Imager abruptly. This button immediately de-energizes the main motion control components in the instrument. However, the

remaining electronic components of the instrument remain powered and still pose a shock hazard.

pressed again before the motion system and software will function. For SECTOR Imager 6000 model 1200 and SECTOR Imager

2400/2400A, the halt switch is a momentary switch, so this not a concern.

The halt function can also be accessed through the rear I/O panel to enable external safety devices to halt the motion of the SECTOR

Imager. Please contact MSD

For SECTOR Imager 6000 model 1201, this switch is on/off. If it is pressed for any reason, all motion will halt. It

The halt switch should never be obstructed or restricted from access.

) is mounted on the front left side of the SECTOR Imager. It can be pressed to halt movement of the

for more information on this feature.

be

System Description 23

Page 24

Figure 3:8 SECTOR Imager halt button

3.7 MSD DISCOVERY WORKBENCH Software

Figure 3:9

Figure 3:9 Cable attachment locations for SECTOR Imager 2400/2400A

3.6 Microsoft Windows-Compatible Workstations

Computer workstations are configured by MSD for use with the SECTOR Imager and come preloaded with MSD DISCOVERY

WORKBENCH application software (

display, keyboard, and mouse. The instrument computer and its software are an integral part of the system and should only be

modified by a MSD service engineer.

). The workstation includes a personal computer,

I/O connections on the associated computer workstation are shown in

.

System Description 24

Page 25

3.7 MSD DISCOVERY WORKBENCH Software

The two-stack, stand-alone workstation mode

The one-position, single plate handling mode

The two-position, single plate handling mode

The single-plate loading and stack-unloading mode

6.3 Robotics Integration

Figure 3:10

Figure 3:11

Figure 3:10 The SECTOR 6000 reads 96-well plates in six sectors

1

2 3

4

5 6

DISCOVERY WORKBENCH is a Windows application that supports the operation of SECTOR Imagers, stores both current and

historical plate data, and analyzes and presents results. The application has several components: instrument modules, a secure

database (the Plate Data History), kit layouts, data integrity features, and data analysis functions. Please refer to the DISCOVERY

WORKBENCH User Guide for additional information.

3.8 Operational Modes

The SECTOR Imager can be configured as a stand-alone workstation or integrated into robotic systems using the single plate adaptor

provided. The single plate adaptor replaces the input stack tube and can serve as the load/unload location when using a robot for

loading plates or when loading a single plate manually.

SECTOR Imager 6000 and SECTOR Imager 2400 have four operational modes:

•

•

unloading single plates. The plate can be loaded either manually or by robotic plate handling equipment. In this mode, the

stacker cover plate should be placed over the interface for safety.

•

single plate adaptor on the output side for unloading.

•

stack tube on the output side for unloading.

SECTOR Imager 2400A operates exclusively in the one-position, single plate handling mode.

uses input and output stack tubes for loading and unloading.

uses the single plate adaptor in the input side for both loading and

uses a single plate adaptor on the input side for loading, and a second

uses the single plate adaptor on the input side for loading and a

See Section

for general information on robotic operational modes.

3.9 Image Readout

The SECTOR Imager uses a CCD camera to obtain images of the plate during detection. One advantage of imaging detection is that the

time required to read a plate is independent of the format of the plate (i.e., it is independent of the number of wells/plate or spots/well).

SECTOR Imagers read plates in sectors to improve sensitivity and optical detection efficiency. The SECTOR Imager 6000 reads plates

in 6 sectors at a rate of approximately 70 seconds per plate (

at a rate of approximately 3 ½ minutes per plate (

).

). The SECTOR Imager 2400/2400A reads plates in 24 sectors

System Description 25

Page 26

Figure 3:11 The SECTOR 2400/2400A reads 96-well plates in 24 sectors

1

2

3

4

5

6

7

8 9

10

11 12

13

14 15

16

17

18

19 20

21

22 23

24

Figure 3:12

Figure 3:12 SECTOR Imager 6000 Demonstration Test Plate

3.10 SECTOR Imager Demonstration Test Plate

Each SECTOR Imager is shipped with one demonstration plate. This demonstration plate verifies operation of the system and can be

used for operational qualification (OQ). It does not verify performance qualification (PQ) and is not to be used for calibration purposes.

It should be used to verify the function of the SECTOR Imager. The demonstration plate consists of an electronic circuit board housed

in a plastic carrier in the shape of a standard plate. The circuit board for the SECTOR Imager 6000 has six separate sectors, simulating

the structure of MSD MULTI-ARRAY plates (

SECTOR Imager 2400/2400A (not shown) uses a different electrode configuration designed to match the SECTOR Imager 2400/2400A.

) as read by the SECTOR Imager 6000. The demonstration plate for the

For the SECTOR Imager 6000, sectors 3 and 4 of the demonstration plate have LEDs that test the CCD camera in the SECTOR Imager.

The remaining four sectors of the plate contain known electronic components for testing the electrical functioning of the instrument

across its range of operation. The demonstration plate can be used without any chemical reagents, either to check instrument function

at the start of each day or as a tool for demonstrating the instrument and software to new users. The LEDs for the SECTOR Imager

2400/2400A demonstration plate are in sectors 5, 12, 14, and 19.

Store the demonstration plate in its custom case when not in use, and keep the demonstration plate clean and free of dust and debris.

System Description 26

Page 27

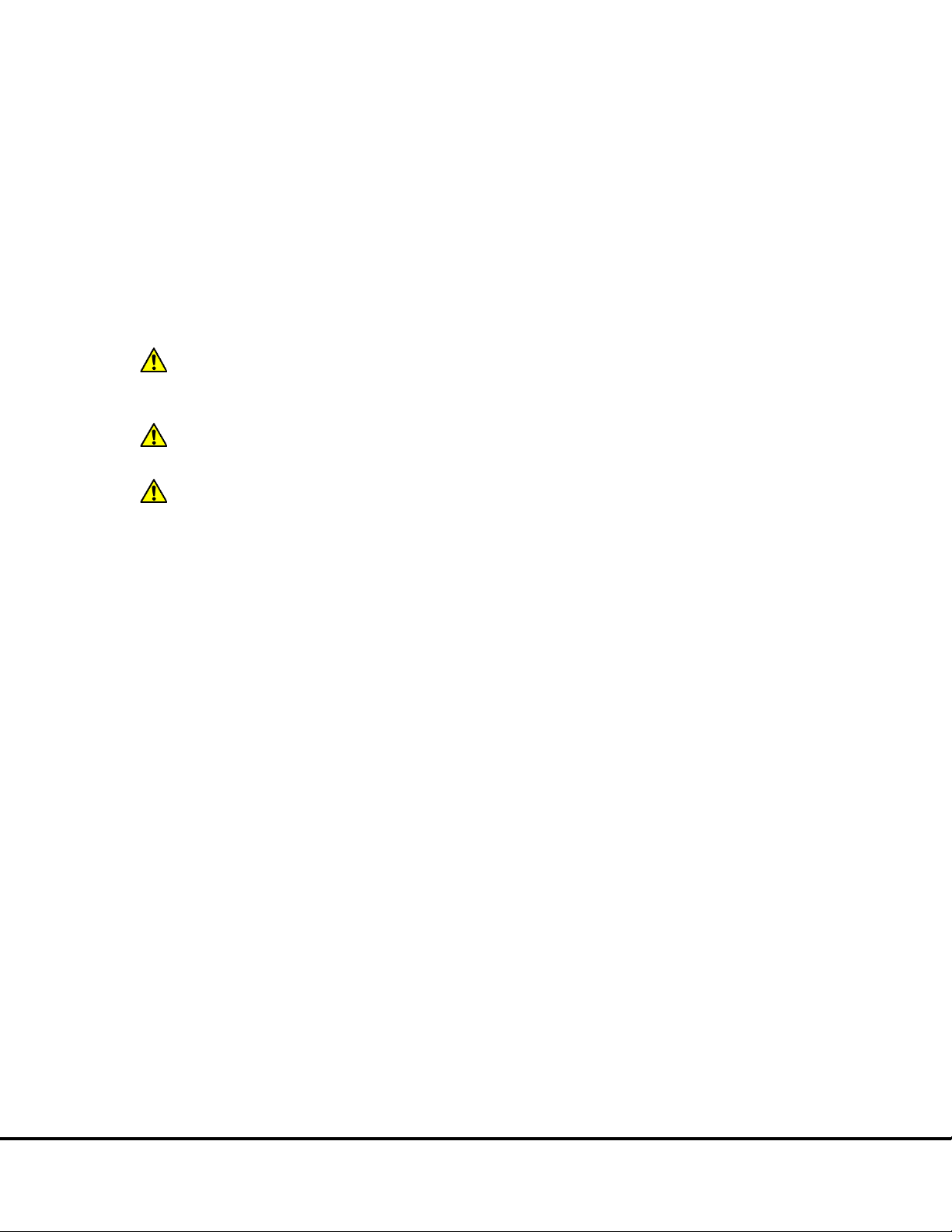

To use, place the demonstration plate in the single plate adaptor with the chamfered corners of the plate facing into the instrument

Figure 3:13

5 Quick Start

Figure 3:13 Loading a SECTOR Imager demonstration plate

NOTE:

strongly

(

for more details.

). This orientation ensures that the bar code reader can automatically read the bar code label. See Section

3.11 Uninterruptible Power Supply

The SECTOR Imager should be operated with an uninterruptible power supply (UPS) to ensure the integrity of data in the event of

power line transients.

The UPS required will depend on the standard operating voltage at your laboratory’s location. Please ensure that the proper UPS is

employed for the power conditions in your country and local area.

Although the SECTOR Imager has been tested and complies with applicable electrical standards, operation of the system

with a UPS is

encouraged for uninterrupted operation and protection from power line interference.

System Description 27

Page 28

4

Installation

28

Page 29

CAUTION:

CAUTION:

CAUTION:

Instrument Service

Installation 4

A qualified MSD service engineer must install and configure the SECTOR Imager before use. Installation includes setup, connection of

the instrument to its computer system, and verification that the instrument is functioning properly. Only the computer provided with the

instrument and configured by an MSD service engineer should be used to operate the SECTOR Imager.

Specifically, updating aspects of the operating system or installing any software that changes parameters of the computer

environment could interfere with proper operation of the instrument software.

other software on the SECTOR Imager computer could cause conflicts with the operation of the instrument software.

system power features that disable USB communication, such as Hibernate, will cause the system to stop responding; a power

off/on cycle of the instrument and PC is required to restore function.

Installation of additional software on the computer system used to operate the SECTOR Imager is not supported.

Running virus-checking software, screen-savers, maintenance software, network-security software, and possibly

Use of other applications while plates are being read may interfere with system performance. Use of operating

MSD

should be consulted prior to moving the instrument.

Installation 29

Page 30

5

Quick Start

30

Page 31

not

Figure 5:1

NOTE:

5.2 Setup

Figure 5:1 Instrument Status window

Quick Start 5

This chapter will guide you through running the SECTOR Imager demonstration plate and verifying that the instrument acquires data

and functions properly. Running the SECTOR Imager demonstration plate at the start of each day may be part of standard operation.

The SECTOR Imager has a cooled CCD camera that needs to be brought to operating temperature before plates are read. To initiate the

cooling process, the SECTOR Imager must be turned on, the MSD DISCOVERY WORKBENCH software must be started, and the

SECTOR Imager Tools must be running (see steps 1–4 below). Simply turning on the instrument will

If the instrument has been off, allow at least 45 to 60 minutes for the CCD camera to cool when restarting. Operating temperature,

either -25 ±1°C or -35 ±1°C for the SECTOR Imager 2400/2400A and SECTOR Imager 6000, respectively, must be reached before the

DISCOVERY WORKBENCH software will allow the processing of any plates.

initiate CCD camera cooling.

The Status window displays the temperature of the CCD camera while it is cooling (

operating temperature, the temperature indicator will disappear, indicating that the instrument is ready for use. (The status window is

accessible by selecting Tools from the menu bar in the DISCOVERY WORKBENCH software.)

If the SECTOR Imager has been idle, but has not been shut down (i.e., is in standby mode), then the CCD camera will

already be at the proper temperature, and users may skip to Section

.

). Once the CCD camera has reached its

5.1 Start-up

To start the system:

1. Turn on the SECTOR Imager and the computer connected to it. If a robot is connected, the startup sequence is SECTOR

Imager, then the robot, then the computer.

Quick Start 31

Page 32

2. Log on to the Windows operating system. To do this, enter Administrator as the user login name and MsdAdmin as the

Figure 5:2

Figure 5:2 MSD DISCOVERY WORKBENCH desktop icon

Figure 5:3

Figure 5:3 SECTOR Imager icon

Figure 5:4

password. (This is the default login shipped with the system; you may change this login/password or add additional

Windows user accounts.)

3. If DISCOVERY WORKBENCH does not start automatically, double-click the MSD DISCOVERY WORKBENCH icon on the

Windows desktop (

).

4. Click the

process.

The SECTOR Imager splash screen (

been powered-up, the cooling process will take approximately 45 to 60 minutes.

SECTOR Imager icon (

) on the toolbar to connect to the imager and initiate the CCD camera cooling

) will display while the instrument is initializing. If the instrument has just

Quick Start 32

Page 33

Figure 5:4: MSD DISCOVERY WORKBENCH splash screen

Figure

5:5

NOTE:

5.2 Setup

On the left side of the SECTOR Imager window, users can view and edit the Setup selections for the demonstration plate read (

).

1. Select Read from Bar Code from the Plate Type menu.

2. Select the Return Plates to Input Stack checkbox. If left unchecked, the demonstration plate will be placed in the output stack

on the left side of the SECTOR Imager after reading. Because the demonstration plate will be run as a single plate, it is most

convenient to return it to the input stack after processing.

It is very important to select Return Plates to Input Stack checkbox when the stacker cover plate is on the output

stack so that the SECTOR Imager will not attempt to place the plate into the covered interface at the end of the read. (The

SECTOR Imager 2400A has a cover plate permanently installed on the output stack and automatically returns plates to the

input side.)

3. Leave the Apply Kit Layout box unchecked. This option is covered in DISCOVERY WORKBENCH User Guide.

4. Select the Read __ Plate(s) checkbox and enter 1 in the text field.

Quick Start 33

Page 34

Figure 5:5 SECTOR Imager Window: Setup, Plate Summary, and Operations areas

Figure 5:6

Figure 5:6 Stacker cover over the output port with empty single plate adapter in the input port

Figure 5:7

5. Place the single plate adaptor on the input (right) stacker interface plate (

6. Load the SECTOR Imager demonstration plate into the single plate adaptor (

automatically identify the plate orientation and adjust the data acquisition and analysis accordingly.)

).

). (Sensors in the instrument will

Quick Start 34

Page 35

Figure 5:7 SECTOR Imager demonstration plate in the single plate adaptor

NOTE:

Scientific and Technical Support

Figure 5:8

5.2 Setup

Pause.

Stop.

Eject.

Retract.

If the SECTOR Imager is unable to read the barcode on the demonstration plate (or if no barcode label is present), the

plate will be skipped and ejected from the instrument. Please contact MSD

assistance.

for

5.3 Run

When the camera reaches proper operating temperature, the Instrument Log (click Show Log in the Status window) will indicate that

the temperature is locked. At that point, the instrument is ready.

Click Run in the SECTOR Imager window. The Run Options dialog window will open (

1. Verify Setup Selections. If changes are necessary, click Cancel, make changes in the area (

Imager window, and re-verify Setup Selections.

2. Run name is optional, but one can be entered in the second section.

3. Verify the Export information and make changes if necessary. (Refer to the DISCOVERY WORKBENCH User Guide for

additional details.) The export selections control the format and the location of the exported text data file that will be created

when the demonstration plate is read.

4. Click

OK. The plate read starts. View the status in the lower left region (Status bar) of the DISCOVERY WORKBENCH

software to monitor progress. When the plate read is complete, the demonstration plate is returned to the stacker and

enabled again.

5.3.1 Operations

The Pause, Stop, Eject, and Retract buttons operate the motion control system that moves plates through the instrument.

•

Pauses the plate read. Selecting Pause again resumes the read.

•

Stops the current run and ejects any plate inside the instrument.

•

Transfers a plate from inside the instrument (but not being read) to the stacker output port where it may be retrieved.

This function is disabled during a plate run.

).

) of the SECTOR

Run is

•

Moves a plate from the input port into the instrument. No further action is taken without input from the operator.

This function is disabled during a plate run.

Quick Start 35

Page 36

Figure 5:8 SECTOR Imager window, Run Options dialog box

Quick Start 36

Page 37

5.4 Results

Figure 5:9

Figure 5:9 Demonstration plate results, Color Map layer

Figure 3:10

Figure 5:9

Figure 3:11

The software provides several options for viewing results. Select View Layer Views from the menu or select a layer from the Layer

menu on the toolbar. Refer to the DISCOVERY WORKBENCH User Guide for details on data viewing options. If you observe the data as

it is acquired in Color Map view, bright wells should display numbers above 2000 and dark wells should display numbers below 200.

shows a Color Map view of the data from the demonstration plate.

When using the SECTOR Imager 6000 demonstration plate sectors 3 and 4 (

shown in

demonstration plate provided for the 2400/2400A (

wells.

. Sectors 1, 2, 5, and 6 should have uniform, low signal levels corresponding to instrument background. The

) functions similarly, with sectors 5, 12, 14 and 19 displaying bright

) should display four bright wells each, as

Quick Start 37

Page 38

6

Using the SECTOR Imager

38

Page 39

NOTE:

3.5 SECTOR Imager

Instrument

If the stacker cover plate is present on the output stack, remember to select the Return Plates to Input Stack

Figure 3:4

Figure 6:1

Using the SECTOR Imager 6

This chapter explains how to prepare and load single or multiple MULTI-ARRAY plates for typical use with SECTOR Imagers.

Additional information is provided to integrate the instrument with an external, third-party robotic system. Please refer to the

DISCOVERY WORKBENCH User Guide for detailed instructions on running MULTI-ARRAY plates on the SECTOR Imager system.

This section assumes that a qualified MSD service engineer has installed and configured the instrument, and that the user

has run a demonstration plate as described in the previous section.

6.1 Single Plate Run

To run a single MULTI-ARRAY plate, place the single plate adaptor in the right stacker interface (Section

The right stacker interface can act as both input and output locations. If not using the output (left) interface, place the stacker cover

plate over it. The SECTOR Imager will pull and eject plates from/to the input (right) interface. The SECTOR Imager 2400A has a stacker

cover plate preinstalled on the output side and is configured to automatically pull and eject plates from/to the input (right) interface.

).

If using the output side, install a second single plate adaptor or a stack tube on the output (left) stacker interface plate. The SECTOR

Imager (except the SECTOR Imager 2400A) will automatically pull plates from the right side and eject plates into the left side.

checkbox so that the SECTOR Imager will not attempt to place the plate into the covered stack at the end of the

read. (The SECTOR Imager 2400A is configured to automatically Return Plates to the input stacker port.)

Prepare the MULTI-ARRAY plate using the required reagents per the assay protocol. Place the plate into the single plate adapter.

Sensors within the instrument will automatically identify the plate orientation and compensate the data acquisition and analysis

accordingly. Per the detailed instructions in the DISCOVERY WORKBENCH User Guide, configure the options in DISCOVERY

WORKBENCH and run the plate.

6.2 Stack Run—Multiple Plates

Multiple plates may be loaded into SECTOR Imager 6000 and SECTOR Imager 2400 instruments using the standard or high-capacity

stack tubes (

stack tubes.)

6.2.1 Loading the Stack Tube

Prepare MULTI-ARRAY plates using the required reagents per the assay protocol.

To load prepared plates into the stack tube:

1. Stack plates on a stable surface.

). SECTOR Imagers read plates from the bottom of the stack tube. (The SECTOR Imager 2400A does not use

2. Place the stack of plates on top of an extra, standard 96-well MULTI-ARRAY plate. This extra plate serves as a spacer for

loading (

).

Using the SECTOR Imager 39

Page 40

3. Orient the stack tube so that the chamfers of the plates are toward the back of the instrument and the bar code labels are to

NOTE:

Figure 6:1

Figure 6:1 Loading MULTI-ARRAY plates into stack tube

If the stack of plates to be run is too tall for the above procedure, you can insert the additional plates through

CAUTION:

Table 3:1 Stack Tube

plate capacities

WARNING:

the left.

A label on the inside of the stack tube reminds users of the correct orientation for loading plates. The stack tube itself

will only fit on the interface plate in one orientation.

4. Slide the stack tube carefully over the top of the stack of plates such that the plates slide into the tube. Once the stack tube

base is flush with the stable surface, all but the extra plate will be loaded into the stack tube (

5. Remove the single plate adaptor if it is present on the stacker.

6. Place the full stack tube on the input (right) stacker interface plate.

7. Place an empty stack tube of the same size on the output (left) stacker interface plate.

).

the top of the stack tube (up to the stack tube capacity) during the run. Be careful to not to add more plates than

can be accommodated in the output stack tube.

loading the stack tubes.

When reading multiple plates in a run, ensure that the stack tube is not overloaded. See

.

Loading a tall stack of plates could lead to spilling potentially harmful chemical reagents. Use caution when

Using the SECTOR Imager 40

Page 41

6.2.2 Unloading the Stack Tube

CAUTION:

Scientific and Technical Support

After running a stack of plates, the consumed plates will be located in the output stack tube. These plates should be unloaded and

properly disposed of prior to running additional plate stacks to prevent the possibility of overfilling the output stack tube.

exceeds the capacity of the output stack.

Not removing the completed plates from the output stack may cause spills if the number of completed plates

The plates should be removed manually by sliding them up and out the top of the stack tube. The last few

plates can be accessed by pushing the last plate up from the bottom of the stack tube.

6.3 Robotics Integration

All SECTOR Imagers can be integrated with a robotics system for loading and unloading plates using the Remote Instrument Mode,

which allows the instrument to be used as a component through its remote interface. A Remote Instrument Manual that provides

descriptions of the commands recognized by the MSD software is available upon request. Contact

for more information on robotics integration.

Using the SECTOR Imager 41

Page 42

7

Maintenance

42

Page 43

WARNING:

Scientific

and Technical Support

Customer Service

CAUTION:

WARNING:

Instrument Service

Maintenance 7

This chapter contains basic maintenance instructions for the SECTOR Imager and some components. A qualified MSD service

engineer should perform all other maintenance procedures not described in this section.

The SECTOR Imager requires proper care, including occasional preventive maintenance. Only MSD service engineers should perform

standard preventive maintenance on the instrument. The schedule for these procedures depends on the usage of the instrument.

Please perform periodic system maintenance on the computer in order to maintain high performance. This includes running the

defragmentation program included with the operating system on a regular basis. A performance qualification kit containing plates,

reagents, and a protocol for verifying instrument performance, is available for purchase (MSD catalog #R31QQ-3). MSD

Opening the instrument to perform maintenance incurs risk of mechanical, electrical, and laser harm.

can provide more details on the performance qualification kit.

Inspect the SECTOR Imager before and after each use to ensure that there is no debris (liquid, dirt, plastic

items, etc.) on or near the stacker interface plate. Clean the SECTOR Imager after each use as described below.

7.1 Preventive Maintenance

Scheduled maintenance should include the cleaning and lubrication of all appropriate internal components. Only MSD service

engineers should perform this maintenance, usually once every 6 months.

Contact MSD

to ask about our service contracts.

7.2 Instrument Cleaning

Reasonable care should be taken to prevent unnecessary fluid spills onto and into the SECTOR Imager. Any spills onto the instrument

should be promptly cleaned using either water, 70% ethanol, 1% bleach in water, or a mild detergent. Choose a cleaning solvent that

is appropriate for the nature of the spill. Lint-free cleaning wipes are recommended for this cleaning.

Any of the outside surfaces of the SECTOR Imager can be cleaned. In addition, accessible regions of the stackers and elevators can be

cleaned. The stackers should only be cleaned when the power is disconnected.

put hands into these regions while the instrument is powered-up.

If chemical reagents are spilled inside the light tight enclosure of the SECTOR Imager, contact MSD

instructions.

7.2.1 Adapter and Stack Tube Cleaning

Spills on single plate adapters or stack tubes should be promptly cleaned to prevent a build-up of crystalline debris or dried salts that

could interfere with their operation. In particular, plates may not load correctly if the latch movement of these devices is compromised.

The instrument should be turned off and unplugged for all cleaning processes.

When the stack tubes are removed, the plate elevator and doors to the instrument pose a pinch hazard. Do not

for

Clean dirty latch mechanisms by soaking the latches in warm water (approximately 104°F/40°C) with a small amount of residue-free

detergent for 15 minutes. Rinse the latches thoroughly with running water, tip and/or shake gently to remove excess liquid, and allow

Maintenance 43

Page 44

to fully air dry. If there is any residue remaining, soak the latches in a 70% alcohol solution (isopropanol or ethanol in water) for 15

Scientific and Technical

Support.

Scientific and Technical Support

NOTE:

Scientific and

Technical Support

minutes; shake out the excess, and allow to air dry completely. If plate-loading problems persist, contact

7.3 Instrument Decontamination

Contact MSD

The SECTOR Imager must be decontaminated prior to shipping the instrument back to MSD. Contact MSD

prior to shipping for instructions and requirements.

for a detailed protocol for instrument decontamination.

Maintenance 44

Page 45

8

Appendix

45

Page 46

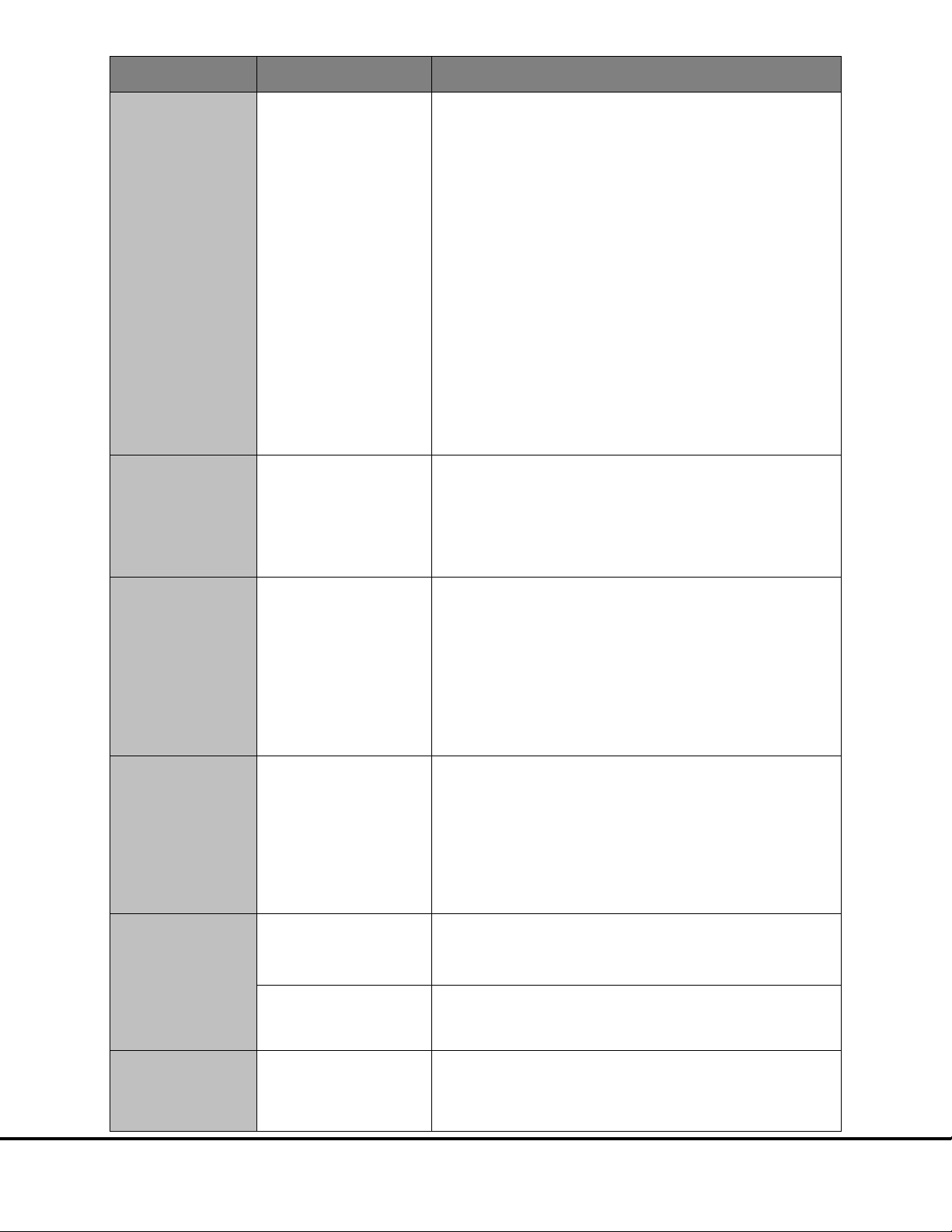

Table 8:1

Table 8:1: Troubleshooting guide

Symptom/Error message

on screen

Possible Cause

Corrective Action

Instrument or computer does

Loose or disconnected power

Ensure that the cables connecting the instrument and/or computer to the external power

No voltage at outlet

Test the outlet by connecting a different electrical device to the outlet.

One or more fuses activated

Fuse locations and specifications for the instrument are shown in Section 8.2.4: Power

Requirements

The plate passes through the

The instrument was unable to read

Verify a bar code is smoothly affixed to the side of the plate. Then, select the appropriate

Error 515 General error

Windows security settings,

Click OK to continue.

Incompatible anti-virus software has

Disable the antivirus program temporarily to see if that is the issue. There are several

Error 515 General error

The Windows theme has changed.

Click OK to continue.

Error 515 General error

The Plate Data History (database) is

Click OK to continue.

Scientific and Technical Support.

Appendix 8

8.1 Troubleshooting Guide

Refer to

Workbench.

below to troubleshoot hardware and operating errors. The software version may be found in Help About

not power on

instrument without being

read. The status window

jumps from 1% to 100%.

The instrument failed to read

the plate after clicking the

Run button.

The instrument failed to

initialize after clicking the

instrument icon.

cable(s)

the barcode on the plate. The bar

code may be damaged, smudged,

marked, or otherwise unreadable.

networking parameters, or the

instrument name has changed.

been installed on the instrument

computer.

source are plugged in properly.

.

plate type from the pull-down menu, and read the plate again.

Determine whether your IT department has made any changes to the instrument computer

recently.

methods:

1) Exclude the file: C:\Program Files\MSD Discovery