Page 1

®

T ech Bulletin

T ech Bulletin

Rotor Phasing

MSD’s Tech Bulletins are designed to give you a more in-depth

understanding of the ignition system and its components. If you have any other questions about the

subject or MSD products you can contact our Customer Support Department at (915) 855-7123 or

email your questions to msdtech@msdignition.com.

ROTOR PHASING

ROTOR PHASING

Rotor Phasing is defined as the alignment between the rotor tip and the distributor cap terminal when the spark occurs. This position can be very important to your engine’s performance. If the alignment is incorrect, the spark will jump

to the next closest terminal or another ground resulting in a misfire and loss of Power.

On engines with extreme cylinder pressures, such as nitrous and supercharged applications, correct rotor phasing

increases in importance. More voltage is required to ionize the plug gap and if the phasing is off, the spark is more apt

to find an easier path to ground rather than the correct cap terminal. This may result in severe engine damage.

Checking Rotor Phasing

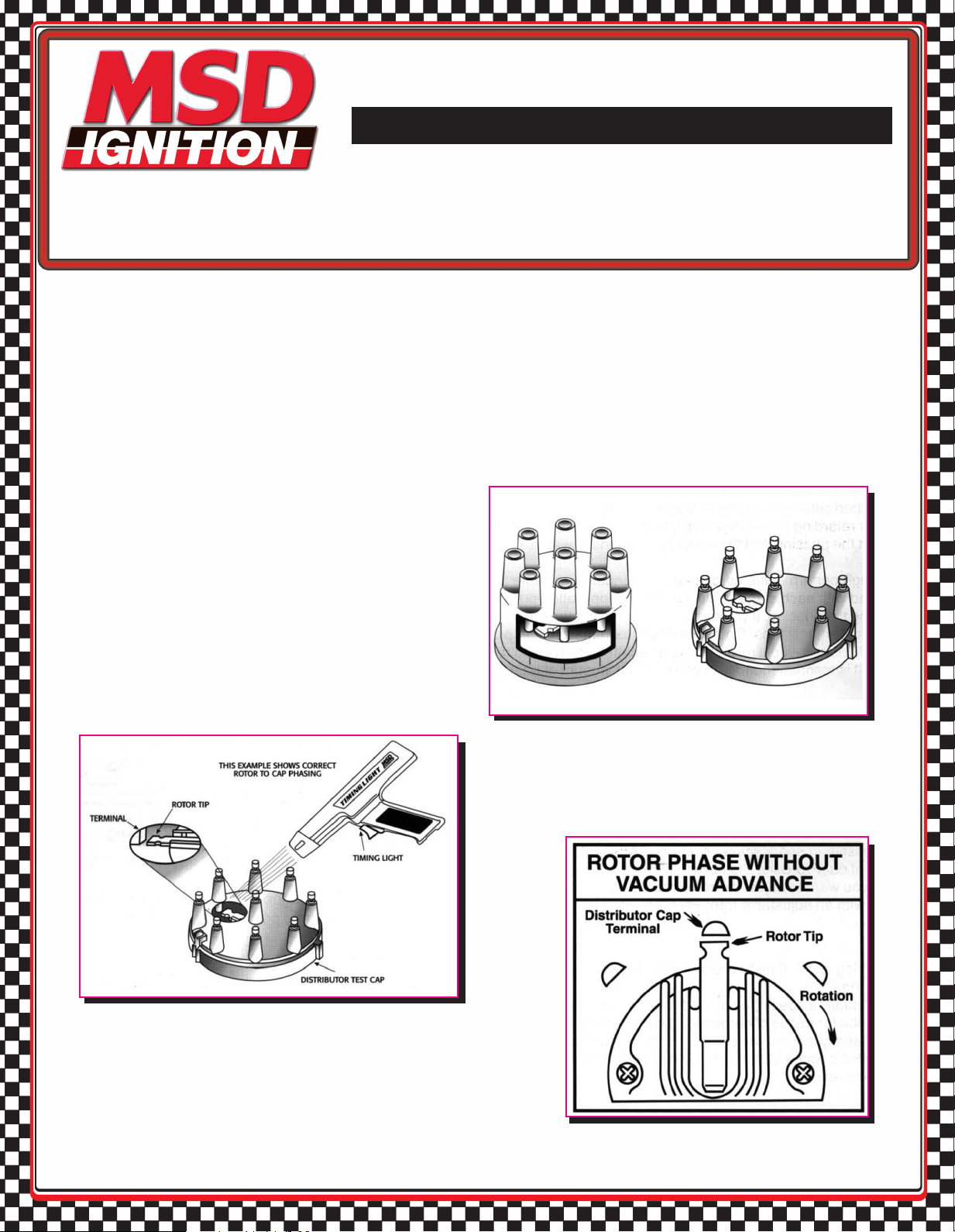

To check rotor phasing, you’ll have to modify a distributor cap so you can observe the rotor tip with a timing light

when the engine is running. Drill a large hole into a cap near

a terminal that will allow you an easy view of the terminal

(Figure 1).

To help see the rotor tip you may want to mark it with white

correction fluid. With your modified cap installed, connect the

timing light’s inductive lead to the corresponding plug wire.

Start the engine and run at a steady speed. Shine the timing

light in the modified cap and note the relation of the rotor tip

and the terminal when the spark jumps (Figure 2).

Note: MSD recommends using a non-dial back timing

Figure 2 - Drill a hole in a cap to view the location of the rotor

tip with one of the cap terminals.

No Vacuum Advance: The rotor tip should line up with the cap terminal or be on the leading edge of the terminal when the spark occurs

(Figure 3). This ensures that the spark is jumping to the correct cylinder

at the proper time.

Figure 1 - Examples of modified distributor caps.

light for best timing results.

Figure 3 - The rotor tip should align with the cap

terminal when the spark occurs.

Page 2

Vacuum Advance: Vacuum advance affects rotor phasing so it should be checked

with the vacuum disconnected and connected. On a distributor that turns clockwise,

the rotor tip should be at the right or just after the terminal when the spark occurs

with the vacuum disconnected and plugged. With the advance connected and the

engine at a steady speed off idle, the rotor tip should be just to the left or before

the terminal (Figure 4).

Note: On distributors that turn counterclockwise, these positions will be opposite.

Adjusting Rotor Phasing

Adjusting Rotor Phasing

Points and Magnetic Pickup Distributors

If the rotor phasing is off on your distributor, there are several options to adjust

the phasing. The points plate or pickup needs to be moved or the cap can be repositioned. In most cases these are major modifications which is why MSD checks

the phasing of every one of our Pro-Billet Distributors during the assembly process.

Figure 4 - Distributors with vacuum advance need to be checked with the vacuum

connected and disconnected.

Crank Trigger Applications

In crank trigger applications, the distributor does not control the ignition timing so adjusting rotor phasing is easy. Simply

rotate the distributor housing until the rotor tip is in the correct position.

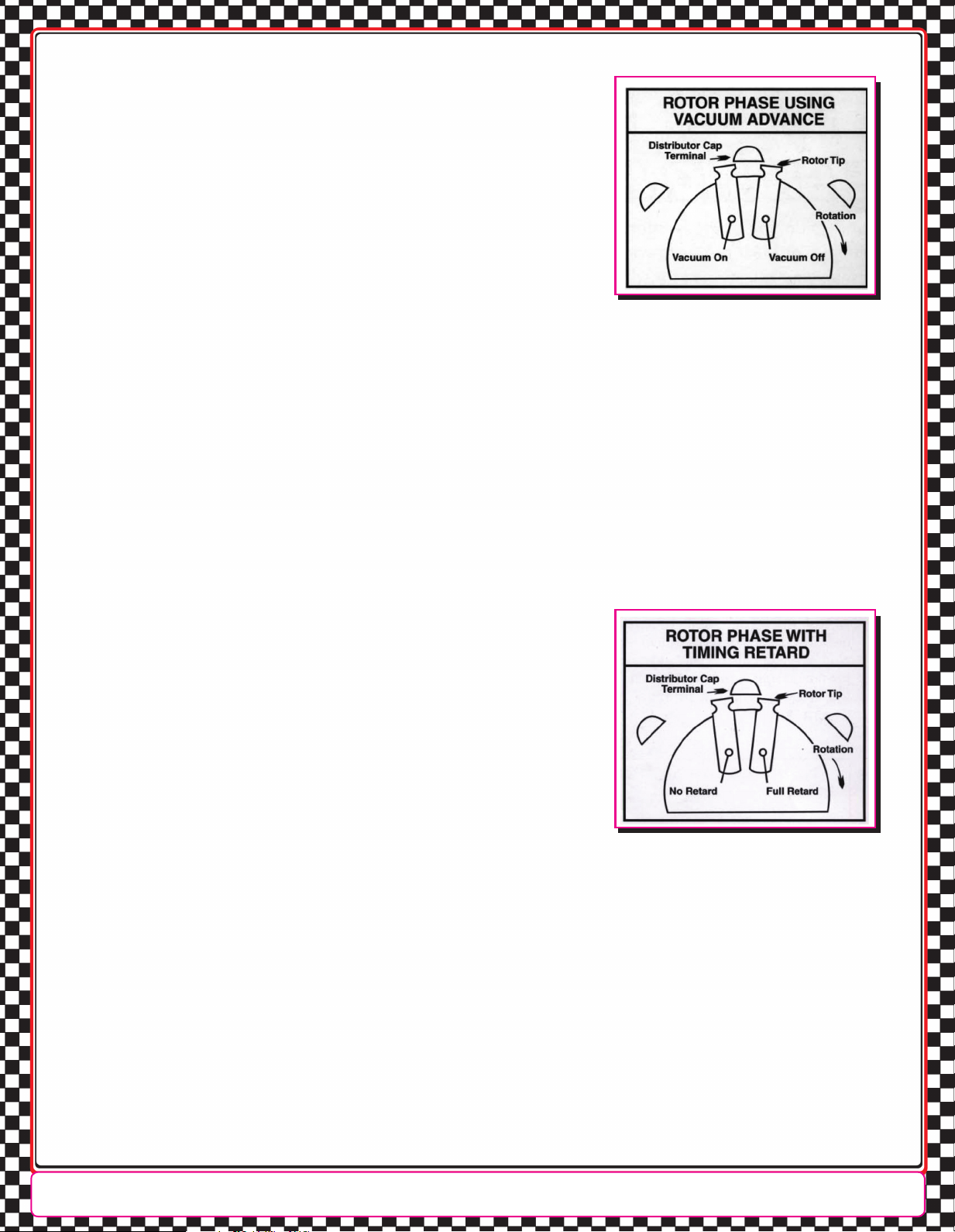

Phasing and Electronic Timing Controls

When setting the phasing, you also need to take into consideration any timing controls or retard controls. If you are advancing or retarding the timing electronically, you are affecting rotor phasing. In most cases, the timing change will not be enough

to affect the phasing, but there are applications to watch. One such application is with multiple stage nitrous systems and

retard steps.

High performance, nitrous engines undergo extreme increases in cylinder pressures which is why timing is generally removed with each stage of nitrous. If your

applications pulls out a total of 16° it is important to take this into consideration

when setting the phasing. If you remove 16° of timing, the rotor tip is going to be

past the cap terminal when it fires. On engines with extreme cylinder pressures

and high rpm, this could easily cause a misfire or spark scatter which could result

in sever engine damage. It is recommended to divide the total amount of retard

and set the phasing at that point.

For example, on an engine that pulls out 16° of timing, you should set the rotor phasing when the timing is 8° retarded (Figure 5). This way, with no retards

activated the phasing will be 8° advanced, or just in front of the distributor cap

terminal and when the full amount of retard is activated, the phasing will be just

after the terminal (Clockwise distributors). Whenever checking the rotor phasing

with an electronic timing control, it is important to check it with the retard activated

and not activated.

Figure 5 - When using a timing retard,

compensate the rotor phasing.

Cap-A-Dapts

If you have enough room to run a larger cap, you should take advantage of the real estate. A larger cap spaces the terminals farther apart so there is less chance of crossfire or spark scatter occurring. MSD offers a Cap-A-Dapt Kit, PN 8445, that

replaces the points/socket style cap on most of our Pro-Billet Distributors.

If you want to adjust the rotor phasing and use an MSD Pro-Billet Distributor with a magnetic pickup, we offer a Cap-A-Dapt

with an adjustable rotor PN 8420. This rotor is two pieces and is made so the rotor tip position can be altered.

Preventative Maintenance

Taking a little time between races to inspect your ignition system will help prevent minor problems. Periodically check the

following:

Visually inspect the cap and rotor for wear of the cap terminals and the rotor tip.

•

Look for traces of carbon tracks where spark scatter occurs.

•

Visually inspect the plug wires for burns or tears. Also, it is a good idea to periodically check the resistance of the wires.

•

MSD’s Spark Guard, PN 8804, is a dielectric grease that helps isolate the spark at the plug wire terminal and cap

•

connection.

M S D I G N I T I O N • ww w. ms di gn iti on .c o m • ( 91 5) 8 57 -5 20 0 • F AX (91 5) 8 57 -3 344

FRM28392 Revised 02/07 Printed in U.S.A.

© 2007 Autotronic Controls Corpo ration

Loading...

Loading...