Page 1

Flying Magnet Crank Trigger Kit

General Wiring

ONLINE PRODUCT REGISTRATION: Register your MSD product online and you’ll be entered

in our monthly 8.5mm Super Conductor Spark Plug Wire give-away! Registering your product

will help if there is ever a warranty issue with your product and helps the MSD R&D team create

new products that you ask for! Go to www.msdperformance.com/registration.

These instructions cover the wiring and general installation tips of all the MSD Flying Magnet Crank

Trigger Kits. For installation of the brackets and trigger wheel refer to the enclosed Installation

Instructions for each specific kit.

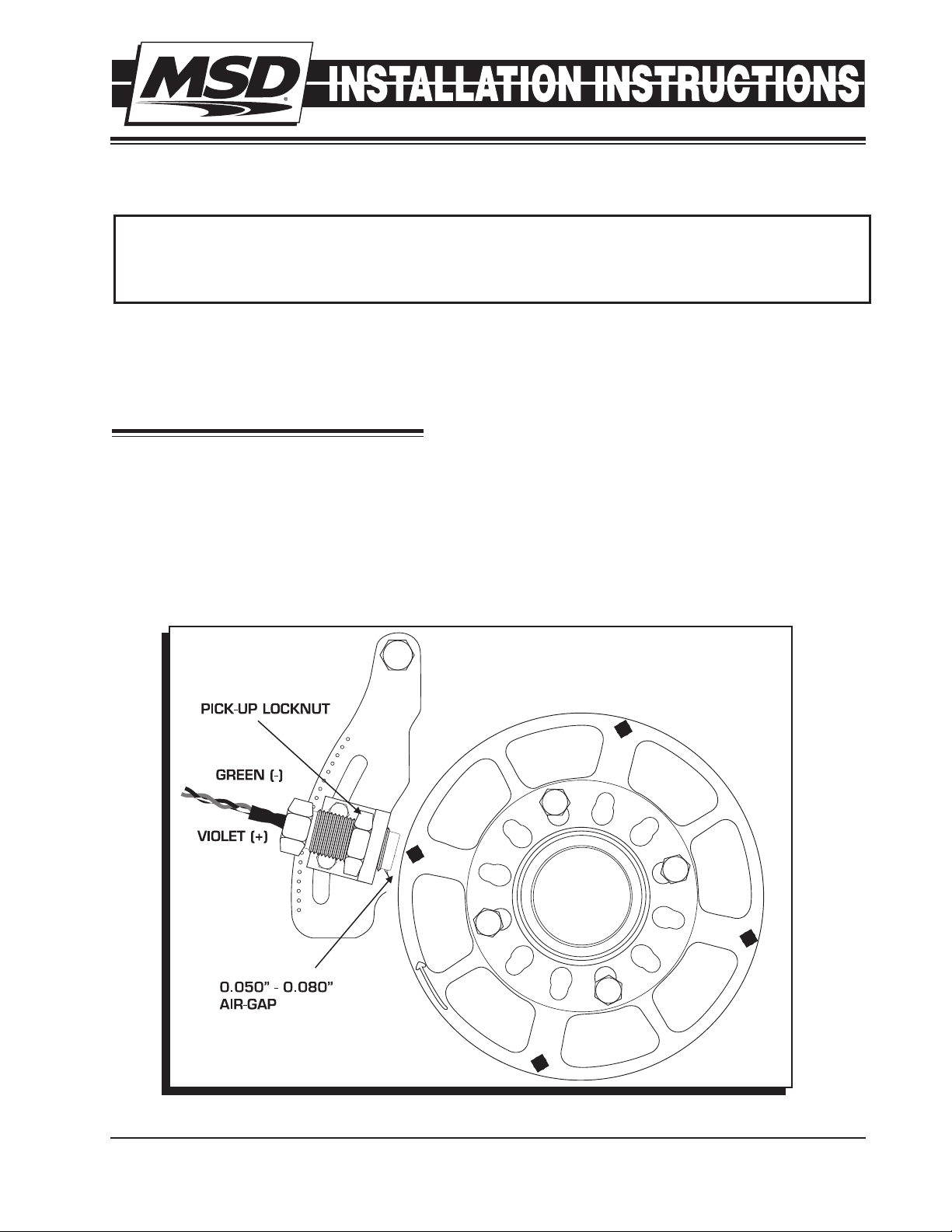

SETTING THE AIR-GAP

The air-gap between the trigger wheel and the non-magnetic pickup is important to the operation of

the crank trigger system, however its adjustment does not affect engine power or performance. The

proper air-gap will result in a good trigger signal at cranking rpm through high rpm with no interference

to the wheel. The optimum setting is generally between 0.050" – 0.080".

With the brackets and trigger wheel mounted (with the arrow on the wheel facing out) position the

pickup within 0.050" – 0.080" from the wheel then tighten the locknut (Figure 1). Do not over tighten

the locknut.

Figure 1 Setting the Air-Gap.

M S D • W W W . M S D P ER F O R M A N C E . C O M • ( 9 1 5) 8 5 7 - 5 2 0 0 • F A X ( 91 5 ) 8 57 - 3 3 4 4

Page 2

2

INSTALLATION INSTRUCTIONS

WIRING

The non-magnetic pickup acts much like a coil. The wires are wound around a small piece of iron so

that when the magnet passes the pickup a voltage signal is created. This signal is what triggers the

MSD Ignition Control. Before completing the wiring, review these tips to ensure the best performance

from your crank trigger system.

Like other pickups, the wiring is polarity sensitive. The Violet wire is Positive and the Green wire

is Negative. The resistance of the pickup should be 65 - 85 ohms. MSD offers replacement NonMagnetic Pickups as PN 8276 for Crank Triggers.

Twist the wires of the pickup together several times before connecting it to the MSD wiring harness.

Twisting these wires together helps reduce the chances of Electro Magnetic Interference (EMI).

Route the pickup harness along the chassis or engine block. This provides a ground plane that

protects against EMI.

Do not run the trigger wires along the coil primary wiring or spark plug wires. There are high

voltages running through these wires so they should not be close to the pickup wires.

Never use solid core spark plug wires with an MSD Ignition system or crank trigger. A helically or

spiral wound suppression wire such as MSD’s Heli-Core or 8.5mm Super Conductor Wire must

be used.

If you are running a digital ignition control or aftermarket EFI system, it is highly recommended

to use a shielded harness, PN 8862, to prevent the chance of EMI interfering with the trigger

signals.

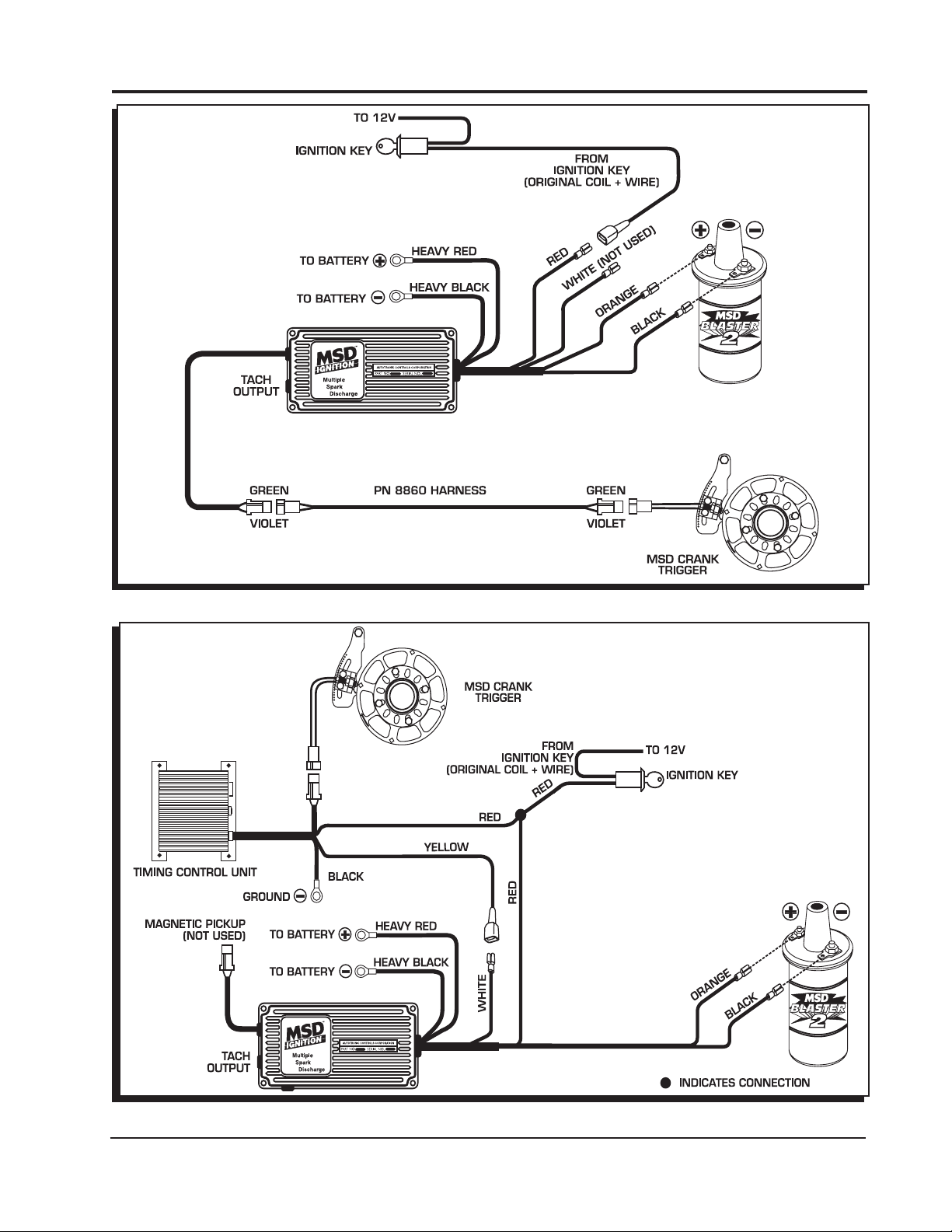

The following diagrams show how to wire the crank trigger to MSD Ignition systems.

SETTING UP THE DISTRIBUTOR

If your distributor is equipped with a centrifugal advance assembly, it must be locked out by welding

or bolting the advance mechanism. The distributor has nothing to do with the engine ignition timing

when using a crank trigger system. Its function is to distribute the high voltage spark to the spark

plugs. To achieve maximum performance from the ignition, the rotor should be properly phased to

the distributor cap as explained in the supplied Tech Bulletin on Rotor Phasing.

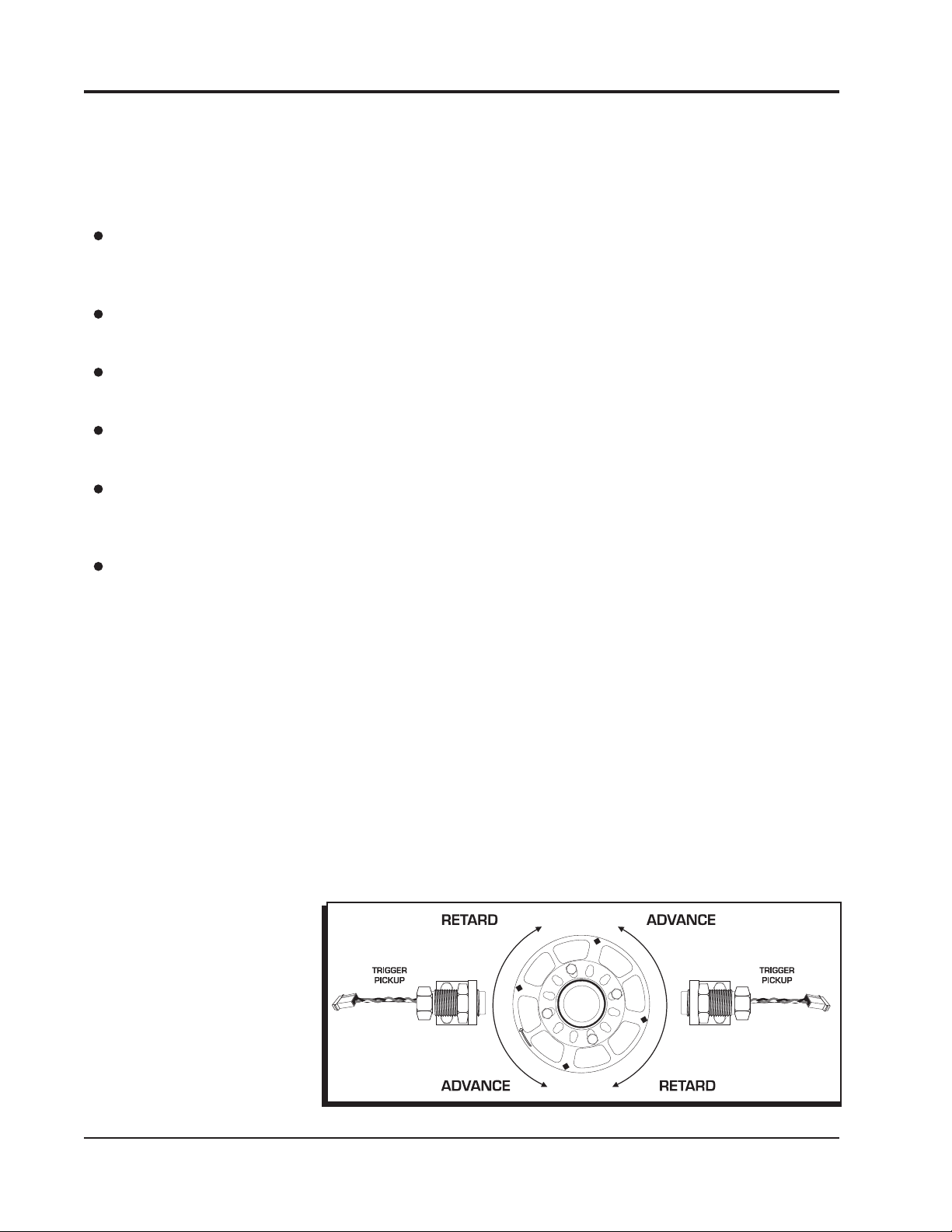

TIMING THE IGNITION SYSTEM

The timing can be adjusted by sliding the pickup holder assembly up or down in the bracket slot. To

retard the timing, move the pickup holder assembly in the direction that the crank trigger wheel rotates.

To advance the timing, move the pickup holder assembly in the opposite direction of the trigger wheel

rotation (Figure 2). Check the

air-gap whenever the timing is

changed.

Note: Do not attempt to adjust

the timing while the engine is

running.

Figure 2 Adjusting the Timing.

M S D • W W W . M S D P ER F O R M A N C E . C O M • ( 9 1 5) 8 5 7 - 5 2 0 0 • F A X ( 91 5 ) 8 57 - 3 3 4 4

Page 3

INSTALLATION INSTRUCTIONS

3

Figure 3 Wiring to an MSD 6AL Ignition Control.

Figure 4 Wiring to an MSD 6AL Ignition and Timing Control.

M S D • W W W . M S D P ER F O R M A N C E . C O M • ( 9 1 5) 8 5 7 - 5 2 0 0 • F A X ( 91 5 ) 8 57 - 3 3 4 4

Page 4

4

INSTALLATION INSTRUCTIONS

Figure 5 Wiring to an MSD Digital-6 Plus or Digital-7 Plus Ignition Control.

Figure 6 Wiring to an MSD 7AL-2 Ignition Control.

M S D • W W W . M S D P ER F O R M A N C E . C O M • ( 9 1 5) 8 5 7 - 5 2 0 0 • F A X ( 91 5 ) 8 57 - 3 3 4 4

Page 5

INSTALLATION INSTRUCTIONS

5

Figure 7 Wiring to an MSD 7AL-2 Ignition and Timing Control.

Figure 8 Wiring to an MSD Programmable Digital-7 Series Ignition Control.

M S D • W W W . M S D P ER F O R M A N C E . C O M • ( 9 1 5) 8 5 7 - 5 2 0 0 • F A X ( 91 5 ) 8 57 - 3 3 4 4

Page 6

6

INSTALLATION INSTRUCTIONS

Figure 9 Wiring to an MSD 8 Ignition Control.

Figure 10 Wiring to an MSD 10 PLUS Ignition.

M S D • W W W . M S D P ER F O R M A N C E . C O M • ( 9 1 5) 8 5 7 - 5 2 0 0 • F A X ( 91 5 ) 8 57 - 3 3 4 4

Page 7

INSTALLATION INSTRUCTIONS

7

Figure 11 Wiring to an MSD Pro Mag 12.

M S D • W W W . M S D P ER F O R M A N C E . C O M • ( 9 1 5) 8 5 7 - 5 2 0 0 • F A X ( 91 5 ) 8 57 - 3 3 4 4

Page 8

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or visit

our website at www.msdperformance.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD at (915) 855-7123. MSD technicians are available from 7:00 a.m. to

5:00 p.m. Monday - Friday (mountain time).

Limited Warranty

M

SD warrants this product to be free from defects in material and workmanship under its intended normal use*,

when properly installed and purchased from an authorized MSD dealer, for a period of one year from the date of

the original purchase. This warranty is void for any products purchased through auction websites. If found to be

defective as mentioned above, it will be repaired or replaced at the option of MSD. Any item that is covered under

this warranty will be returned free of charge using Ground shipping methods.

This shall constitute the sole remedy of the purchaser and the sole liability of MSD. To the extent permitted by

law, the foregoing is exclusive and in lieu of all other warranties or representation whether expressed or implied,

including any implied warranty of merchantability or fitness. In no event shall MSD or its suppliers be liable for special

or consequential damages.

*Intended normal use means that this item is being used as was originally intended and for the original application

as sold by MSD. Any modifications to this item or if it is used on an application other than what MSD markets the

product, the warranty will be void. It is the sole responsibility of the customer to determine that this item will work for

the application they are intending. MSD will accept no liability for custom applications.

M S D • W W W . M S D P ER F O R M A N C E . C O M • ( 9 1 5) 8 5 7 - 5 2 0 0 • F A X ( 91 5 ) 8 57 - 3 3 4 4

© 2012 Autotr onic Co ntrol s Corporation

FRM28731 Revised 12/11 Printed in U.S.A.

Loading...

Loading...