Page 1

MSD Dual Hall HVC Pro-Billet Distributor

Chevrolet - PN 83921, Ford 351W – PN 83922

SB Chrysler - PN 83923, Toyota - PN 83924,

Chevrolet R07 - PN 83925, Dodge - PN 83926

Parts Included:

1 - Distributor

1 - Wire Retainer

1 - Coil Wire Retainer

2 - Retainer Screws

1 - Gasket (Chevy Only)

2 - O-Rings (Chevy Only)

1 - O-Ring (Ford/Chrysler/Toyota Only)

Parts Required:

Distributor Gear

Harness Assembly, PN 8857

HVC Distributor Reluctor Removal

Tool, PN 83492

Note: The HVC Pro-Billet Distributor is NOT supplied with a gear. See page 2 for gears.

IMPORTANT

The MSD HVC Pro-Billet Distributors are the most advanced racing

distributors available. Take the time to read these instructions thoroughly

before installing the distributor. There are a variety of adjustments that

can be made to improve the performance of your engine and should be

understood prior to running the engine.

Use of a distributor spin machine (or equivalent), is recommended to

take full advantage of the HVC's adjustable features. With a degree

wheel and pointer, you will be able to easily and accurately set the

timing of the secondary pickup.

WIRING

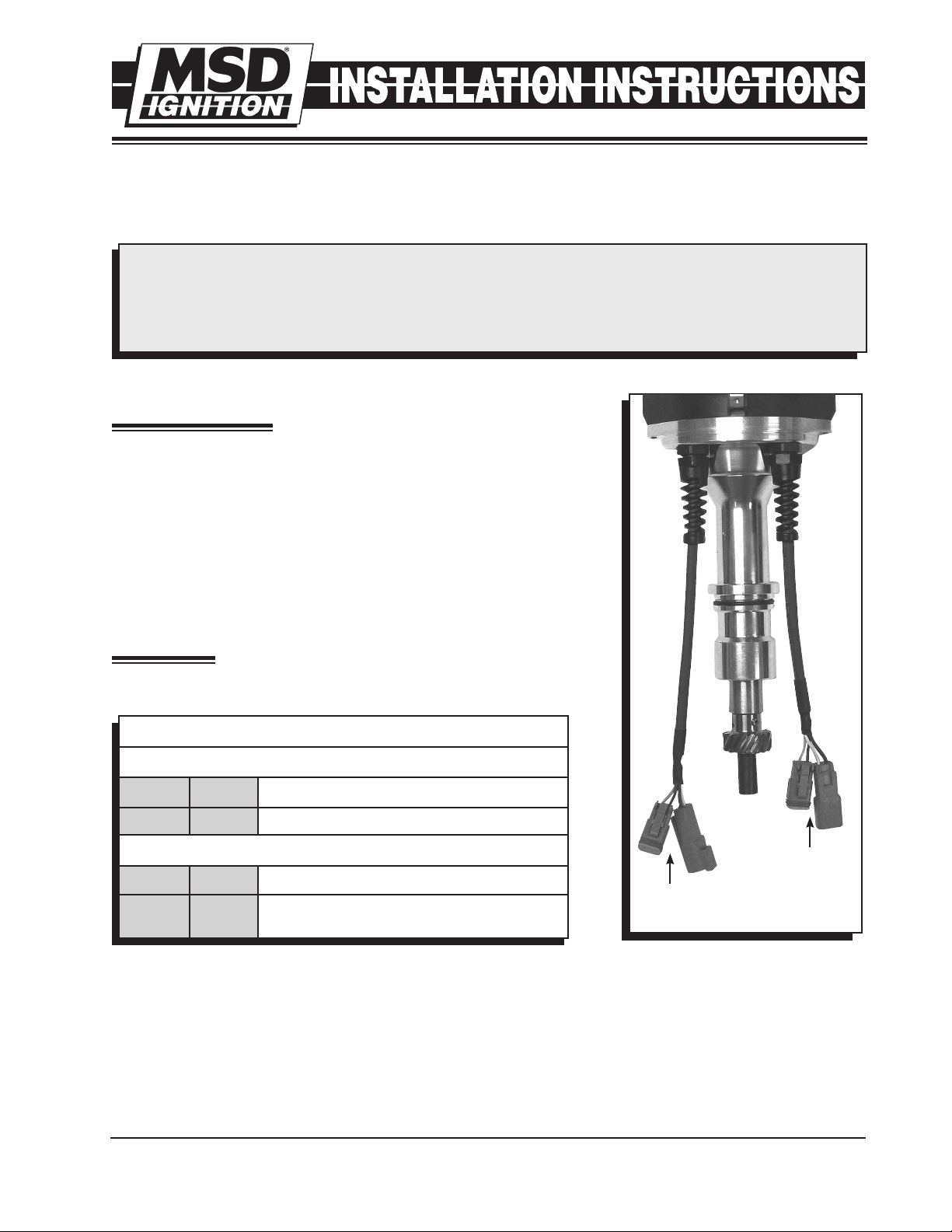

These Distributors have four 2-wire Deutsch connectors that connect

to the ignition control.

2-PIN CONNECTORS

MALE CONNECTOR

BLACK Pin 1 Connect to a common ground.

RED Pin 2 12-volt input. Connect to switched 12 volts.

FEMALE CONNECTOR

BROWN Pin 1 Shielded Ground. Connect to Ground.

WHITE Pin 2 Trigger Wire. Connect to the points input

(White) wire of the MSD Ignition Control.

PICKUP ALIGNMENT AND ADJUSTMENTS

PRIMARY

NON-ADJUSTABLE

PICKUP

Figure 1 Separate Pickup Connectors.

SECONDARY

ADJUSTABLE

PICKUP

The HVC Pro-Billet Distributor features a primary and secondary pickup.

These are stacked together with the primary positioned on the bottom. The primary is fixed while the

secondary pickup is adjustable +/- 8°. The pickups are aligned at the factory at 0° advance/retard. The

position of the secondary pickup will need to be set to your specifications.

When installing the distributor there is an alignment indicator (Figure 3). By aligning the reluctor paddle with

the indicator, the timing will be within approximately +/- 3° of the desired amount. To adjust the secondary

pickup, loosen the two allen head screws on the top pickup. Next, turn the eccentric using an 11/32" wrench

to move the pickup (Figure 3). Secure the screws when the desired timing is reached.

M S D I G N I T I O N • w ww . ms di g ni ti o n. co m • ( 91 5) 8 57 -5 20 0 • F AX ( 91 5) 85 7- 3 34 4

Page 2

2 INSTALLATION INSTRUCTIONS

RED

INDICATES CONNECTION

RED

TO

IGNITION

SWITCH

12VOLTS

AUTOMATIC COIL

SELECTOR

PN 8210

SPDT SWITCH

PN 8807

PRIMARY

GROUND

BROWN

TO TACH*

BROWN

TO TACH*

COIL

GROUND

ORANGE (+)

BLACK (-)

ORANGE (+)

BLACK (-)

HEAVY RED

TO BATTERY (+)

TO GROUND (-)

HEAVY BLACK

WHITE

TO REV CONTROL PN 8738

HEAVY RED

TO BATTERY (+)

TO GROUND (-)

HEAVY BLACK

WHITE

TO REV CONTROL PN 8738

COIL

BLACK

BLACK

* TO SWITCH TACH SIGNALS, MSD OFFERS A TACH SPLITTER, PN 8911.

SECONDARY

MAG PICKUP

(NOT USED)

MAG PICKUP

(NOT USED)

WHITE

BROWN

BROWN

RED

RED

WHITE

TO GROUND

PN 8857 HARNESS KIT

HVC PRO-BILLET

DISTRIBUTOR

Figure 2 Wiring a Complete Redundant System.

SERVICE

ADJUSTING

ECCENTRIC

MSD designed the HVC Pro-Billet Distributor to be completely

serviceable. Replacement parts are listed below.

SERVICE PARTS:

4 - Pin Deutsch Connector - PN 8181

Rotor - PN 8484

Extension Harness (set) - PN 8857

Reluctor Installation/Removal Tool - PN 83492

Finished Reluctor - PN 8349

Unfinished Reluctor - PN 83491

Pickup Assemblies

CW - Lower Chevrolet - PN 87571

CW - Upper Chevrolet - PN 87573

CCW - Lower Ford/Mopar/Toyota - PN 87572

CCW - Upper Ford/Mopar/Toyota - PN 87574

An unfinished reluctor, PN 83491 is available. This reluctor does not have

the individual cylinder paddles machined. Individual cylinder timing values

can be determined on the dyno using our electronic controls. These values

can then be machined into the reluctor.

SERVICE PROCEDURE

LOWER HOUSING

To replace the distributor bearings and seals, the lower housing must be disassembled. Both disassembly

and re-assembly require the lower housing to be heated for proper clearance. Review the following procedure

before starting the service. Figures 5 and 6 show exploded views of the five distributors available.

M S D I G N I T I O N • w ww . ms di g ni ti o n. co m • ( 91 5) 8 57 -5 20 0 • F AX ( 91 5) 85 7- 3 34 4

Bronze Gears

Chevrolet

Standard - PN 8471

+0.006" - PN 8472

+0.009" - PN 84722

+0.012" - PN 84723

+0.015" - PN 84724

Ford Windsor

Standard - PN 8585

Chrysler

Standard - PN 8525

+0.006" - PN 8526

Toyota

N/A: Contact TRD for

information

Figure 3 Adjusting the Secondary Pickup.

Figure 4 Unfinished

Reluctor, PN 83491.

SECONDARY

PICKUP

ALIGNMENT

INDICATOR

Page 3

HOUSING

MSD 20793

CHEVY

PN 83921

SHAFT

ASY 27223

BEARING

HDW 20788

SEAL

HDW 10080

BUSHING

HDW 10081

SLIP

COLLAR

ASSEMBLY

(PN 8539)

SEAL

HDW 11143

HOUSING

MSD 20885

FORD

PN 83922

BEARING

HDW 20788

SHAFT

ASY 27224

SPACER

MSD 21553

BEARING

HDW 11142

SEAL

HDW 10080

HOUSING

MSD 21262

CHRYSLER

PN 83923

BEARING

HDW 20788

SHAFT

ASY 27225

SPACER

MSD 21717

SHIM

MSD 11082

BEARING

HDW 13913

HOUSING

MSD 27433

SEAL

HDW 11143

TOYOTA

PN 83924

BEARING

HDW 20788

SHAFT

ASY 27226

SPACER

MSD 27646

BEARING

HDW 11142

8-32 X 1.25 SHCS

SCW 15508

#8 WASHER

WAS 21181

PICKUP UPPER

SEE SERVICE

PARTS PAGE 2.

PICKUP LOWER

SEE SERVICE

PARTS PAGE 2.

#10 WASHER

WAS 21186

HOUSING

MSD 27231

ARP-STUD

SCW 27285

STRAIN RELIEF

HDW 21491

10-32 x .625 SHCS

SCW 11067

NUT-ECCENTRIC

MSD 27230

SCREW - PLASTITE

SCW 20311

COIL WIRE

RETAINER

MSD 25843

SEE SERVICE PARTS PAGE 2.

PN 8408 CAP AND

RETAINER KIT

SCREW

10-32 X 1.50 PAN-PHIL

SCW 20168

BOLT-DOWN

MSD 23940

WASHER

WAS 23066

10-32 X .625 SHCS

SCW 11067

CAP-A-DAPT

MSD 22256

HOLD-DOWN

MSD 22582

ROTOR

PN 8484

1/4 - 28 NUT

NUT 27286

RELUCTOR

MSD 27229

SEE SERVICE PARTS PAGE 2.

PN 8408 CAP AND

RETAINER KIT

HOUSING

MSD 20793

CHEVY

PN 83921

SHAFT

ASY 27223

BEARING

HDW 20788

SEAL

HDW 10080

BUSHING

HDW 10081

SLIP

COLLAR

ASSEMBLY

(PN 8539)

SEAL

HDW 11143

HOUSING

MSD 20885

FORD

PN 83922

BEARING

HDW 20788

SHAFT

ASY 27224

SPACER

MSD 21553

BEARING

HDW 11142

SEAL

HDW 10080

HOUSING

MSD 21262

CHRYSLER

PN 83923

BEARING

HDW 20788

SHAFT

ASY 27225

SPACER

MSD 21717

SHIM

MSD 11082

BEARING

HDW 13913

HOUSING

MSD 27443

SEAL

HDW 11143

TOYOTA

PN 83924

CHEVROLET R07

PN 83925

DODGE

PN 83926

BEARING

HDW 20788

SHAFT

ASY 27226

SPACER

MSD 27646

BEARING

HDW 11142

HOUSING

MSD 28865

SEAL

HDW 10080

BEARING

HDW 20788

SHAFT

ASY 27226

SPACER

MSD 27646

BEARING

HDW 13913

SEAL

HDW 10080

HOUSING

MSD 28156

BEARING

HDW 20788

SHAFT

ASY 28155

BUSHING

HDW 10081

INSTALLATION INSTRUCTIONS 3

1. Remove dist rib utor

cap.

2. Remove the reluctor. Use

the installation/removal

tool PN 83492 to prevent

the shaft from turning

(Figure 7). Remove

the reluctor attaching

bolt using a 5/16", 12pt

deepwell socket.

3. Remove the two bolts

that retain the pickups.

4. Remove the four bolts

retaining the upper

housing and take it off.

5. Remove the distributor

gear and any spacers if

so equipped.

6. The upper bearing is

an interference fit and

needs to be heated to

be removed. Place the

lower housing and shaft

assembly in an oven at

300°F for approximately

30 minu tes. When

heated, the shaft and

bearing assembly

should slide out of the aluminum housing. A slight tap on the shaft may be necessary.

7. If distributor is equipped with a lower bearing remove it while the housing is hot. If equipped with a lower

bushing, it can be replaced if necessary.

Figure 5 Upper Housing Exploded Views.

8. Remove and replace the two seals in the housing. The new seals install with their flat sides facing each

other. Lubricate the seals with grease (Figure 8).

9. Place the lower housing in an oven at 250° for approximately 30 minutes.

M S D I G N I T I O N • w ww . ms di g ni ti o n. co m • ( 91 5) 8 57 -5 20 0 • F AX ( 91 5) 85 7- 3 34 4

Figure 6 Lower Housing Exploded Views.

Page 4

10. While the lower housing

is heating, install the

new bearing on the

shaft (Figure 9).

11. I n s t a l l t h e sha f t

3/4"

WRENCH

5/16"

SOCKET

FLAT SIDES OF

SEALS MUST

FACE EACH

OTHER.

ass embl y int o the

lower housing. It is

fully seated when the

bea ring pr otru des

approximately 0.005”

– 0.010” out of the

TOOL

PN 83492

Figure 7 Removing the Reluctor.

housing (Figure 10). If the clearance is more, the

housing may have cooled too much before the bearing was fully

Figure 8 Installing New Seals.

installed.

12. Install the gear.

a. Chevrolet – Check clearance between gear and housing. It should be

greater than 0.015”. If under 0.015” the bearing may not be seated

correctly (Figure 11).

b. Ford – Install gear spacer. Press on gear leaving 0.005” clearance

between it and the spacer.

c. Mopar R5 – Install gear spacer and shim. Check clearance between

gear and spacer. It should be between 0.005”-0.010”. If under 0.005”

the bearing may not be seated correctly.

Figure 9 Installing the New

Bearing.

d. Toyota – Install gear spacer with roll pin. Press on gear until it stops against the spacer.

13. Assemble the upper housing.

14. Install Pickup screws.

15. Install reluctor using special tool PN 83492. Apply moly lube to the nut and torque to 10 lb-ft. (Figure 7).

16. Adjust pickup phasing and tighten the pickup bolts.

BEARING SHOULD

PROTRUDE BY

0.005"-0.010"

GREATER THAN

0.015"

Figure 10 Checking Bearing to Housing Clearance.

Figure 11 Checking Gear to Housing Clearance.

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or

visit our website at www.msdignition.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD Ignition at (915) 855-7123. MSD technicians are available from 7:00

a.m. to 6:00 p.m. Monday - Friday (mountain time).

M S D I G N I T I O N • w ww . ms di g ni ti o n. co m • ( 91 5) 8 57 -5 20 0 • F AX ( 91 5) 85 7- 3 34 4

© 2007 Autotronic Con trols Corpo ration

FRM28906 Revised 08/07 Printed in U.S.A.

Loading...

Loading...