Page 1

MSD Pro-Billet Chevrolet HEI Distributor

PN 8365

ONLINE PRODUCT REGISTRATION: Register your MSD product online and you’ll be entered

in our monthly 8.5mm Super Conductor Spark Plug Wire give-away! Registering your product

will help if there is ever a warranty issue with your product and helps the MSD R&D team create

new products that you ask for! Go to www.msdperformance.com/registration.

Important: Read these instructions before attempting the installation.

Parts Included:

1 - Pro-Billet Distributor, PN 8365

1 - Rotor, PN 84101

1 - Distributor Cap, PN 84111

1 - Coil Cover, PN 84022

1 - Digital HEAT Module, PN 83647

1 - Coil, PN 8225

1 - Advance Kit

1 - Gasket

WARNING: Before installing the MSD Distributor, disconnect the battery cables. When disconnect-

ing the battery cables, always remove the Negative (-) cable first and install it last.

TIMING FUNCTIONS

Before continuing with the installation, here are a few definitions you should be aware of:

Initial Timing: This is the base timing (also referred to as idle timing) of the engine before the

centrifugal advance begins.

1 - Tube of Gear Lubricant

1 - Vacuum Advance Lock-Out

2 - O-rings

1 - HEI Connector

2 - HEI Wiring Terminals

1 - HEI/Tach Connector

1 - Vacuum Advance Adjusting Kit

1 - Gray Tach Wire

Centrifugal Advance: The centrifugal (or mechanical) advance mechanism is made up of weights,

springs and an advance stop bushing. The amount and rate of advance that your distributor is capable

of is determined by the centrifugal timing. If you ever wish to lock out the centrifugal advance, refer

to the centrifugal advance section.

Note: MSD Distributors are supplied with the heavy (slow) advance springs and the 21° stop bushing

installed. This is to prevent detonation in certain applications. Review the information on pages

2-4 to determine the best advance curve for your application.

Total Timing: This is the total of the initial timing plus the centrifugal advance added together.

Example: 10° Initial + 25° centrifugal = 35° Total Timing. (When checking Total timing, disconnect

the vacuum canister and plug the vacuum source.)

Vacuum Advance: The vacuum advance will advance the timing up to 10° during partial throttle

driving (with 15 lbs of vacuum). The vacuum line should be routed to a ported vacuum outlet above

the throttle plates.

RPM LIMIT AND TACHOMETER INFORMATION

Tach Signal: The Pro-Billet HEI Distributor features a Gray Tach Output wire which provides a clean signal

for most tachometers and even some aftermarket fuel injection systems. The signal output

is a 12 volt square wave, 20° duty cycle. This wire is also responsible for programming the

built-in rev limiter.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 2

2 INSTALLATION INSTRUCTIONS

PROGRAMMING THE REV LIMIT

The rev limiter of the HEAT module requires a tachometer to set the rev limit. The limit is programmed by running

the engine at half the desired rpm, then momentarily grounding the Gray tach output wire from the MSD. A

Gray jumper wire is supplied to connect to the tach with another tee-splice coming off to use for programming.

A switch may also be installed to ease adjustments of the limiter. The default rpm limit is 10,000 rpm.

CHOOSING AN ADVANCE CURVE

The function of the advance curve is to match the ignition timing to the burning rate of the fuel and speed

(rpm) of the engine. Any factor that changes the burning rate of the fuel or the engine speed can cause a

need for an ignition timing change. Figure 1 shows some of the factors that will affect engine timing.

FACTOR Advance Timing Retard Timing

For For

Cylinder Pressure Low High

Vacuum High Low

Energy of Ignition Low High

Fuel Octane High Low

Mixture (Air/Fuel) Rich Lean

Temperature Cool Hot

Combustion Chamber Shape Open Compact

Spark Plug Location Offset Center

Combustion Turbulence Low High

Load Light Heavy

Figure 1 Ignition Timing Factors.

As you can see from the chart, most factors will change throughout the range of the engine operation.

The timing mechanism of the distributor must make timing changes based on these factors.

Example: An engine has 11:1 compression with a high energy ignition. With the specifications given,

you will have to retard the timing for the high compression and high energy ignition. By comparing

the engine’s specifications against the chart, a usable timing guideline can be found. Engines with

a combination of items from both columns will require a timing that is set in the mid range.

Obviously a full technical explanation of correct ignition timing would be very complicated. The best

way to arrive at a suitable ignition curve for your engine is to use the Ignition Timing Factors Chart

as a guide and compare it to the Advance Graphs in Figure 4 until a suitable curve is found. When

selecting your advance curve, use detonation (engine ping) as an indicator of too much advance,

and a decrease in power as an indicator of too little advance.

TIPS ON SELECTING AN ADVANCE CURVE

• Use as much initial advance as possible without encountering excessive starter load.

• Start the centrifugal advance just above the idle rpm.

• The starting point of the centrifugal advance curve is controlled by the installed length and

tension of the spring.

• How quickly the centrifugal advance (slope) comes in is controlled by the spring stiffness. The

stiffer the spring, the slower the advance curve.

• The amount of advance is controlled by the advance bushing. The bigger the bushing, the

smaller the amount of advance.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 3

INSTALLATION INSTRUCTIONS 3

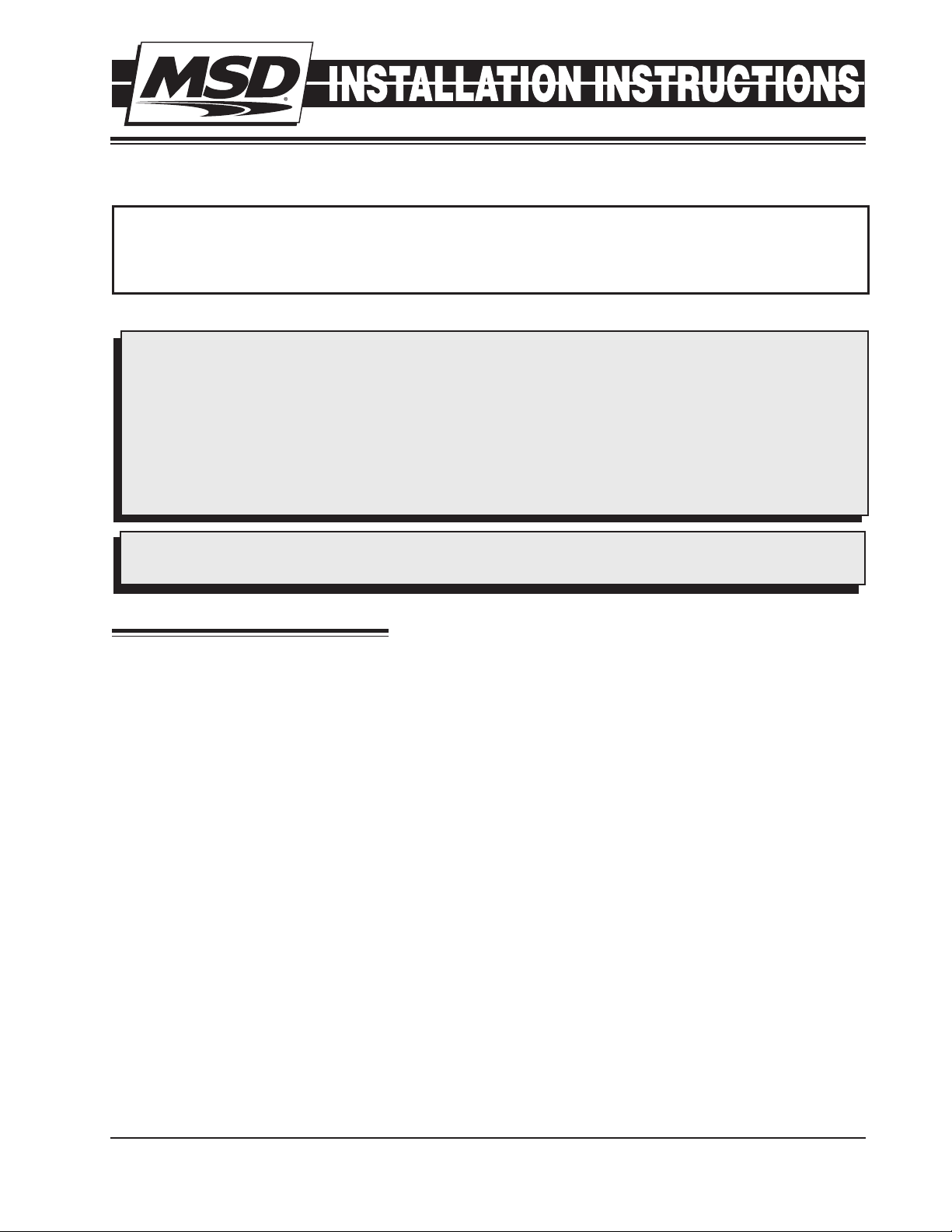

CENTRIFUGAL ADVANCE CURVE

SELECTING THE ADVANCE SPRINGS

The rate, or how quick the advance comes in

is determined by the type of springs which are

installed on the distributor. The MSD distributors

are equipped with two Heavy Silver springs

installed. These will give you the slowest advance

curve possible (Figure 2). The parts kit contains

two additional sets of springs which can be used

to match the advance curve to your particular

application. Refer to the Spring Combination

Chart (Figure 3) for combinations that can be

achieved.

To change the springs, remove the cap and rotor

and use needlenose pliers to remove the springs.

Be sure the new springs seat in the groove on

the pin.

Timing Curve From Factory

Figure 2 The Factory Equipped Curve.

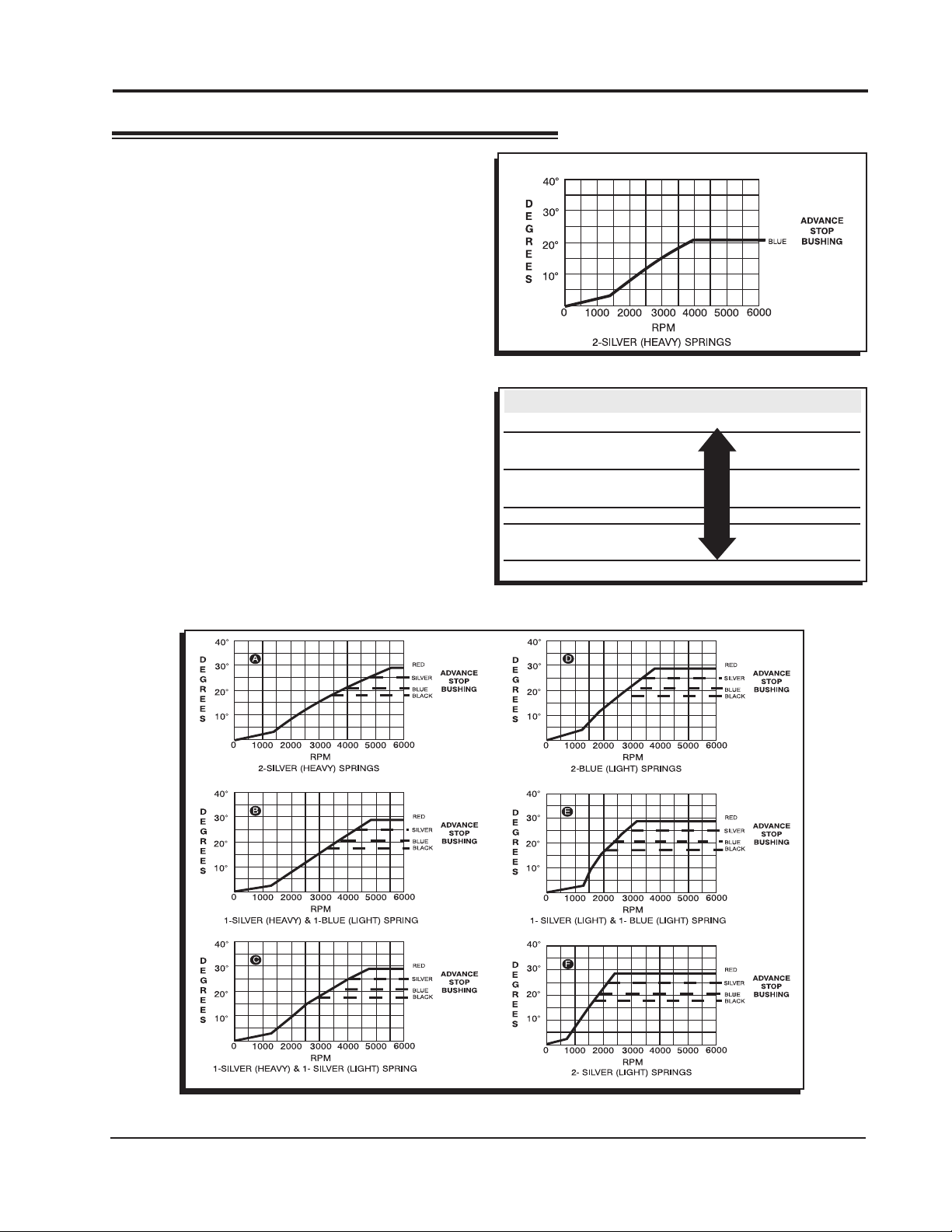

SPRING COMBINATION RATE OF ADVANCE FIGURE 4

2- Heavy Silver SLOWEST A

1- Heavy Silver B

1- Light Blue

1-Heavy Silver C

1-Light Silver

2- Light Blue D

1- Light Silver E

1- Light Blue

2- Light Silver FASTEST F

Figure 3 Spring Combination Chart.

Figure 4 Advance Curves.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 4

4 INSTALLATION INSTRUCTIONS

SELECTING THE ADVANCE STOP

BUSHING

Three different advance stop bushings are supplied

in the distributor kit. The distributor comes with a

Blue (21°) bushing already installed. If a different

amount of centrifugal advance is desired, follow the

next procedure to change the bushings. The chart

in Figure 5 gives the size and approximate degrees

for the corresponding bushings.

CHANGING THE ADVANCE STOP

BUSHINGS

1. Remove the distributor cap and rotor.

2. Remove the locknut and washer on the bottom

of the advance assembly (Figure 6).

3. Remove the bushing and install the new one.

Install the washer and locknut.

LOCKING OUT THE CENTRIFUGAL

ADVANCE

1. Remove the advance components including the

springs, weights and the advance stop bushing

from the advance assembly.

2. Remove the roll-pin from the drive gear and

remove the gear from the shaft.

3. Slide the shaft two inches out of the housing.

4. Rotate the shaft 180° and insert the advance stop

bushing pin into the small hole on the advance

plate (Figure 7).

5. Install the locknut and washer to the advance stop

bushing pin. This locks the advance in place.

6. Install the drive gear and roll-pin.

BUSHING SIZE APPROXIMATE

CRANKSHAFT

DEGREES

Red-Smallest 28

Silver 25

Blue 21

Black-Largest 18

Figure 5 Advance Stop Bushing Chart.

Figure 6 Changing the Advance Stop Bushing.

Note: If you want to lock out the vacuum advance

of the Distributor, see page 7.

Figure 6 Locking Out the Centrifugal Advance.

Figure 7 Locking Out the Advance.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 5

INSTALLATION INSTRUCTIONS 5

INSTALLING THE DISTRIBUTOR

1. Remove the existing distributor cap without

disconnecting any of the spark plug wires.

2. With the cap off, crank the engine until the

rotor is aimed at a fixed point on the engine or

firewall. Note this position by making a mark

(Figure 8).

3. Place the distributor cap back on and note

which plug wire the rotor is pointing to. MARK

THE SPARK PLUG WIRES and remove the

distributor cap.

4. Disconnect the wiring from the distributor.

5. Loosen the distributor hold down clamp and

slide the clamp out of the way.

6. Lift the distributor out of the engine. Note that

the rotor rotates as you lift the distributor out.

This is due to the helical cut gear and should

be taken into consideration when installing the

new distributor.

7. Install the gasket and apply a liberal amount of

the supplied lubricant to the distributor gear.

(The supplied O-rings can only be used if

the block has been modified as shown in

Figure 9.)

8. Install the distributor making sure that the

rotor comes to rest pointing at the same

fixed mark. If the distributor will not fully seat

with the rotor pointing to the marked position,

you may need to rotate the oil pump shaft

until the rotor lines up and the distributor fully

seats.

9. Position and tighten the hold down clamp onto

the distributor.

10. Install the distributor cap and spark plug wires

one at a time to ensure correct location.

11. Connect a switched 14-gauge wire from

a 12 volt source to the B+ terminal of the

Distributor Cap (Figure 10).

12. Page 7 shows how to set the rev limiter and

connect the tachometer.

Figure 8 Marking the Rotor Location.

Figure 9 Modified Block for use with O-Rings.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 6

6 INSTALLATION INSTRUCTIONS

REMOVE MODULE AND

INSTALL HARNESS

BLACK

GROUND

TO ENGINE

GROUND

BLACK

GRAY

Figure 10 General Wire Installation.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Figure 11 Wiring to an MSD Ignition Control.

Page 7

INSTALLATION INSTRUCTIONS 7

VACUUM ADVANCE LOCKOUT

If you do not want to use the vacuum advance canister,

MSD has supplied a lockout mechanism.

1. Remove the three Phillips screws that hold the

advance canister (Figure 12).

2. Remove the aluminum hex shaped spacer from

the housing.

3. Install the longer hex spacer supplied in the parts

bag in the threaded hole next to where the original

spacer was mounted. Use the same Phillips

screw.

4. Install the plastic cover to seal the distributor

HEX

SPACER

Figure 12 Removing the Vacuum Canister.

CANISTER

SCREWS

housing using the original advance hold down

screws (Figure 13).

LOCKOUT

Note: Do not forget to plug the original vacuum

COVER

advance hose.

VACUUM ADVANCE ADJUSTMENT

A kit is supplied that allows you to adjust the total

amount of vacuum advance.

TACHOMETER INFORMATION

The HEAT Digital HEI Module has a Gray wire that

provides a 12 volt square wave, 20° tachometer signal

that will trigger most tachometers. It is recommended

to connect this lead to your tach’s trigger input wire

VACUUM ADVANCE HOLE

(NOT USED)

Figure 13 Vacuum Lockout Installed.

and check its operation. If the tach requires a higher

voltage signal, connect its input wire to the Tach

terminal on the HEI Cap (Coil-/Tach).

No Rev Limit: To disable the rev limit function, cut and remove the

jumper shown in Figure 14.

PROGRAMMING THE REV LIMIT

A tachometer is required to set the rev limit. The limit is programmed

by running the engine at half the desired rpm, then momentarily

grounding the Gray tach output wire from the MSD. A Gray jumper

wire is supplied to connect to the tach with another tee-splice

coming off to use for programming. A switch may also be installed

to ease adjustments of the limiter (Figure 15). The default rpm limit

is 10,000 rpm. Note that the rpm limiter is extremely accurate and

due to the variety of tachometers available, there may be differences

in the displayed rpm.

1. Start the engine and bring the rpm to half the desired rev limit

(for a 6,000 rpm limit, raise the rpm to 3,000).

2. While holding the rpm steady, short the Gray tach wire to ground

for approximately one second. Note that the tach will go to zero

while grounded.

3. The tach will now display the programmed rev limit amount for

two seconds. If this value does not register on the tach, repeat

the procedure and try a different ground source.

LONGER

HEX SPACER

JUMPER

Figure 14 Disable the Rev Limit.

OPTIONAL

PROGRAMMING

SWITCH

TO

TACH

Figure 15 Setting the Rev Limiter.

JUMPER GRAY

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Page 8

Note: This rpm confirmation only displays when the HEI Gray wire is being used to trigger the

tachometer.

REV LIMITER VERIFICATION

The MSD HEAT HEI Module has an optional built-in Rev Limiter Verification feature. When the key

is in the On position (not cranking or running), an rpm signal is sent to the tachometer to verify the

unit's rev limit setting. With this function users can be sure of their rev limit settings before each drive

To enable this feature, follow the procedure below.

Note: It is important to note that this feature should not be used with EFI systems. When activated,

an rpm signal is sent to the tachometer. With an aftermarket EFI system, this could activate the

injectors causing a flooding situation.

ENABLE REV LIMIT VERIFICATION

1. With the ignition switch in the off position, ground the Gray tach output wire.

2. With the Gray wire connected to ground, turn the ignition on without starting the engine.

3. Hold the Gray tach output wire to ground for seven seconds. (AT LEAST five seconds.)

4. Release the wire from ground before ten seconds have passed.

5. To confirm the process has worked, cycle turn the key On. The tachometer should sweep to the

rpm limit set on the ignition.

To deactivate the verification feature, repeat the process.

Playback Tach: If you use a playback tach, be sure to check the high rpm value prior to turning the

key to the On position. When the key is in the On position, the rev limit will be displayed and may

override the tach memory.

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or visit

our website at www.msdperformance.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD at (915) 855-7123. MSD technicians are available from 7:00 a.m. to

5:00 p.m. Monday - Friday (mountain time).

Limited Warranty

M

SD warrants this product to be free from defects in material and workmanship under its intended normal use*,

when properly installed and purchased from an authorized MSD dealer, for a period of one year from the date of

the original purchase. This warranty is void for any products purchased through auction websites. If found to be

defective as mentioned above, it will be repaired or replaced at the option of MSD. Any item that is covered under

this warranty will be returned free of charge using Ground shipping methods.

This shall constitute the sole remedy of the purchaser and the sole liability of MSD. To the extent permitted by

law, the foregoing is exclusive and in lieu of all other warranties or representation whether expressed or implied,

including any implied warranty of merchantability or fitness. In no event shall MSD or its suppliers be liable for special

or consequential damages.

*Intended normal use means that this item is being used as was originally intended and for the original application

as sold by MSD. Any modifications to this item or if it is used on an application other than what MSD markets the

product, the warranty will be void. It is the sole responsibility of the customer to determine that this item will work for

the application they are intending. MSD will accept no liability for custom applications.

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

© 2012 Autotr onic Controls C orpora tion

FRM30256 Revised 04/12 Printed in U.S.A.

Loading...

Loading...