Page 1

MSD Power Grid System Controller

PN 7730/77303

ONLINE PRODUCT REGISTRATION: Register your MSD product online. Registering your product

will help if there is ever a warranty issue with your product and helps the MSD R&D team create

new products that you ask for! Go to www.msdperformance.com/registration.

Parts Included:

1 - System Controller, PN 7730 / PN 77303

1 - 4Gb SD Card

1 - Micro-USB Cable

1 - MSD View CD-Rom

1 - Fiber Optic Plug

Accessories (Purchased Separately):

Inductive Cam Sync Kit, PN 7555

Hub Connector, PN 7740 / PN 77403

Slew Rate and Time Based Rev Limiter, PN 7761

Boost Retard Module, PN 7762

Manual Launch Controller, PN 7751

WARNING: During installation, disconnect the battery cables. When disconnecting, always remove

the Negative cable first and install it last.

Note: Solid core spark plug wires cannot be used with an MSD Ignition Control.

Note: A crank trigger is recommended to supply the input signal to the Power Grid Ignition System to

ensure the most precise timing and rpm control.

1 - CAN Terminator Cap

1 - Power Cable-Loose

1 - Mag Cable

1 - 2-pin Legacy Cable

1 - Main Cable Loose

1 - Parts Bag

Racepak V-Net Tee

9” - 280-CA-VM-T009

18” - 280-CA-VM-T018

36” - 280-CA-VM-T036

OPERATION

DIGITAL OPERATION

The MSD Power Grid System Controller uses a high speed RISC microcontroller to control the ignition’s

output while constantly analyzing the various inputs such as launch, burnout, and step wires; trigger signals,

rpm, and CAN-Bus data. The high speed controller can make extremely quick updates to the ignition output,

timing, and rpm limits while maintaining +/- 0.1° timing and +/- 1 rpm resolution. The circuits and controller of

this system have been designed for superior protection against Electro Magnetic Interference (EMI).

The Power Grid System Controller, PN 7730 / PN 77303, is designed to be used with the Power Grid-7

Ignition Control, PN 7720. This is a high output CD ignition control. The Ignition System allows for the System

Controller to be mounted on top of the Power Grid-7 to save space and provide a neat, compact installation.

The System Controller can also be used with other MSD Ignitions such as the 7AL-2, MSD 8-Plus, and the

Pro-Mag series. In order to use the rev limiting features of the System Controller the paired ignition must

have a built-in Soft Touch Rev Control that uses plug-in RPM modules. Pages 10-12 show wiring diagrams

for a variety of different ignition options.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 2

2 INSTALLATION INSTRUCTIONS

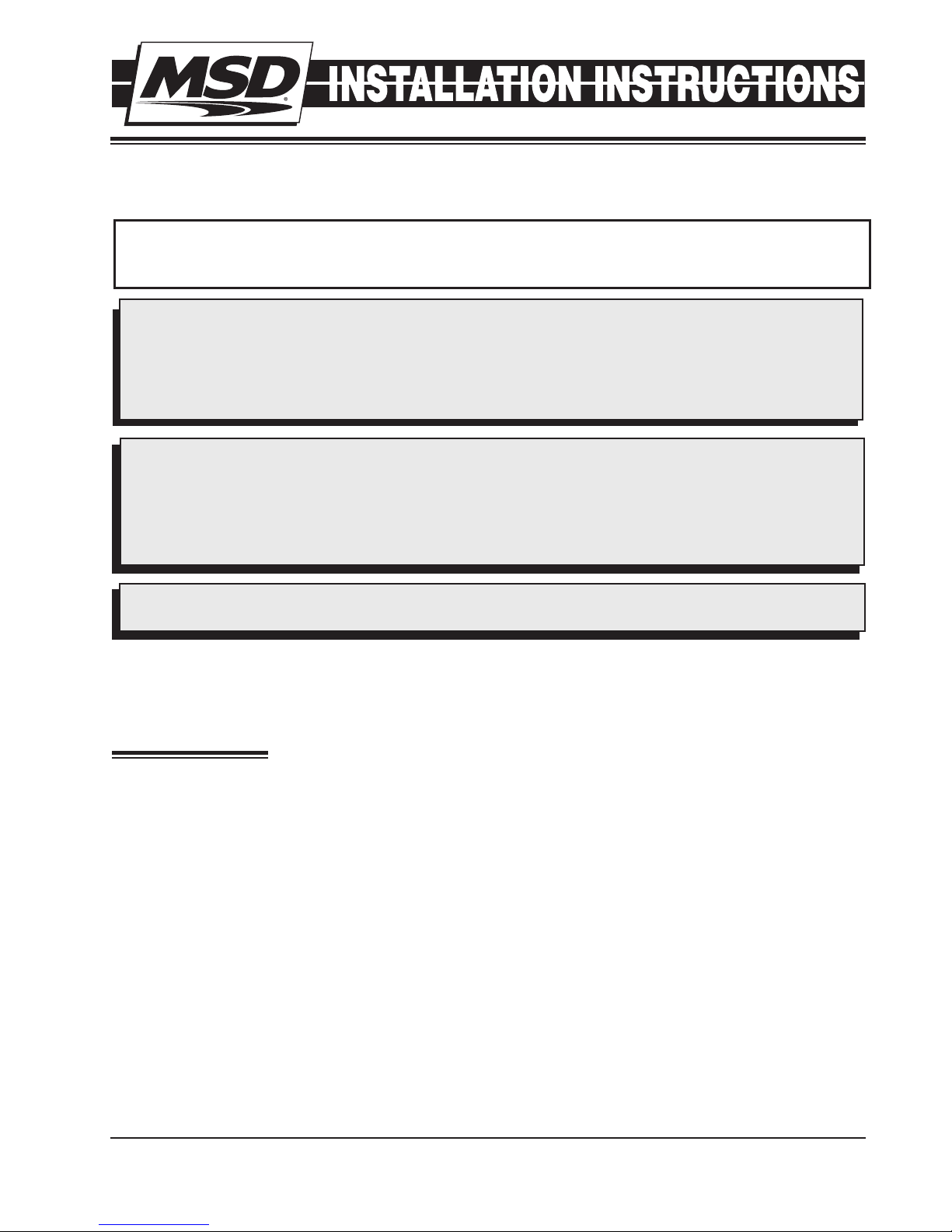

WIRING FEATURES

Leading

Group

4-Pin

Connector

(to PN 7720

or Power

Cable if not

used with

PN 7720)

LOOSE

WIRES

2-Pin

Connector

(Legacy)

3-Pin

Connector

Racepak

Assembly

6-Pin

Connector

(to Hub/

Modules)

Wire

Color PIN Function Description

BLACK 16 GROUND Ignition supply Ground wire. Connect to battery negative (-) terminal

or engine block.

ORANGE 17 BATT POWER Battery supply wire. Connects to battery positive (+) terminal or battery

junction. Note: Do not connect to the alternator.

YEL/WHT 33 TRIGGER OUT Trigger output for electronic ignition amplifiers.

RED 34 POWER OUT On/Off switch wiring. This wire supplies switched 12V power to the

7720.

RED 15 IGN 12V switched (Ignition)

GRAY 18 TACH Tach output. This wire will provide a 12 volt square wave tach signal.

WHITE 32 POINTS IN Trigger input from electronic ignition amplifiers, an ECU’s trigger or

points.

YELLOW 1 SHIFT LIGHT Shift Light output wire. It can handle up to 3 amps continuous to ground

when enabled.

LT BLUE 4 BURN OUT Burnout Rev Limit. When 12 volts are applied the Burnout Rev Limit is

active. This disables the Slew Rate rev limits and overrides other rev limits.

It is recommended to have this wire switched from an outside source, such

as the crew chief before the burnout and while staging the car.

DK BLUE 21 LAUNCH This wire activates the Launch Rev Limit and is the main reset wire for

several features of the Ignition. When 12 volts are applied to this wire it

will activate the Launch Rev Limit. It also resets the shift light, the gear

indicator to first gear, the Launch Retard curve and select Gear 1 curve.

When 12 volts is removed, the Launch Time begins as does the Gear 1

curve. When 12 volts are applied the Slew Rate Rev limit will be disabled

as well as the Time-Based Rev Limit curve.

PINK 22 STEP 1 Step 1 retard enabled with +12 volt input AND above Step 1 Rpm value

OR Gear 2 Select.

VIOLET 5 STEP 2 Step 2 retard enabled with +12 volt input AND above Step 2 Rpm value

OR Gear 3 Select.

TAN 23 STEP3 Step 3 retard enabled with +12 volt input AND above Step 3 Rpm value

OR Gear 4 Select.

LT GREEN 6 STEP4 Step 4 retard enabled with +12 volt input AND above Step 4 Rpm value

OR Gear 5 Select.

GREEN 10 STEP5 Step 5 retard enabled with +12 volt input AND above Step 5 Rpm value

OR spool rev limiter.

BRN/WHT 19 RPM SW RPM/Time switch output wire. It can switch up to 3 amps continuous

to ground when enabled.

YELLOW 7 RELAY LO Network Ignition Mode: Cam sync output to Racepak systems for

individual cylinder timing.

YELLOW 24 RELAY HI Legacy Ignition Mode: Rev limiter output to legacy ignition..

GREEN 8 MAG- This is a magnetic pickup, 2-pin connector. Plugs into an MSD

VIOLET 9 MAG+ Distributor or Crank Trigger pickup. Violet is positive, Green is negative.

BROWN 25 SHIELD Note: When this connector is used, the white POINTS IN wire is not

connected. Brown connects to ground.

WHITE 11 VNET HI Communicates data acquisition information with RacePak system.

BLACK VNET LO Only used to plug into VNet.

RED 13 MSD CAN HI Supplies 12V switched power to add on module units. Also communicates

BROWN 27 SHIELD

RED 29 POWER OUT

BLACK 30 MSD CAN LO

BLACK 31 MSD CAN GND

between modules and Power Grid System Controller. This connector

is only used with modules added onto the system. This is for the MSD

CAN-Bus accessories. It is only used when adding Power Grid Modules

to the system. The Hub Connector, PN 7769, is required.

or

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

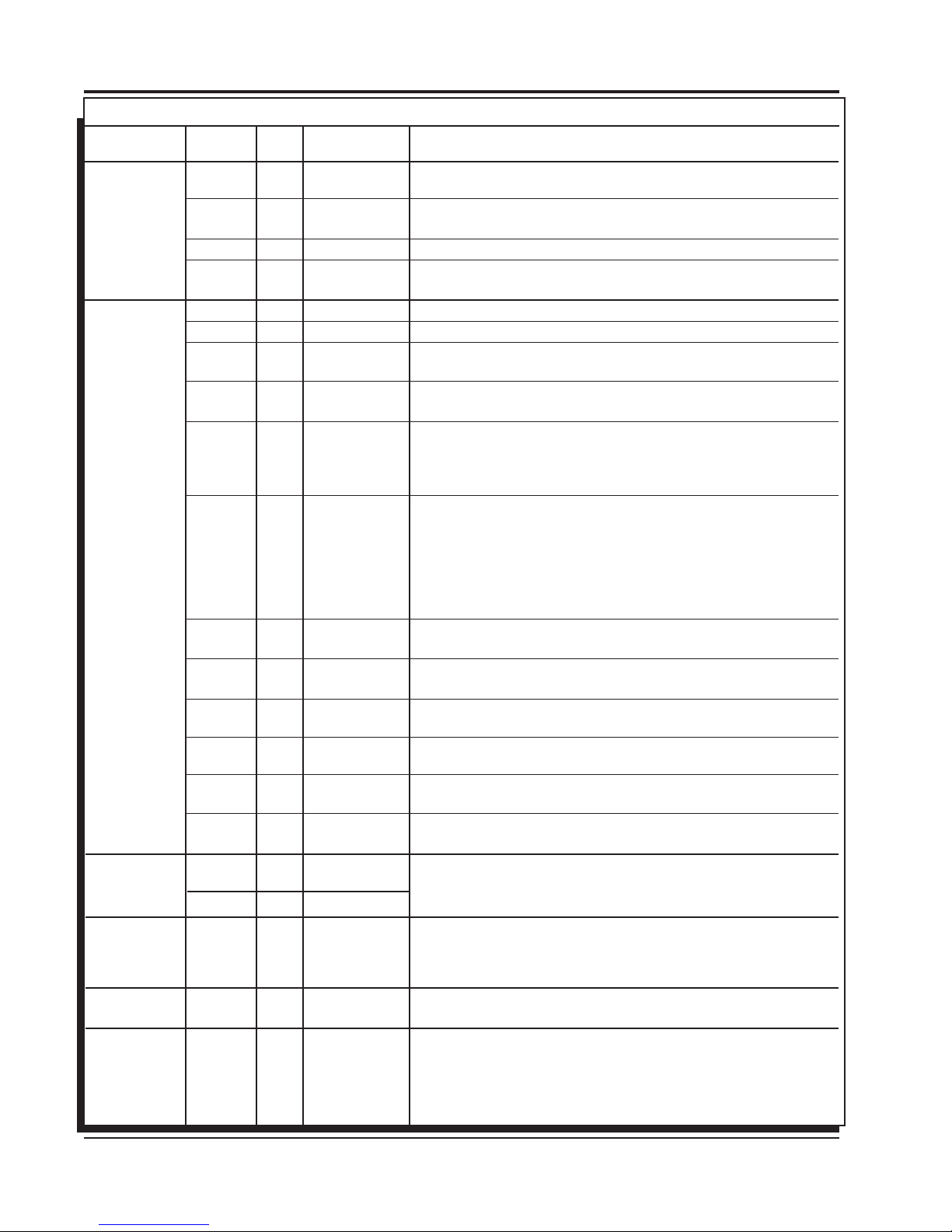

Page 3

INSTALLATION INSTRUCTIONS 3

BRN/WHITE - RPM/TIME SWITCH

YELLOW - SHIFT LIGHT

GRAY - TACH

V-NET

CABLE

RED - 12V SW OUT

BLACK - BATTERY (-)

ORANGE - BATTERY 12V

WHITE - POINTS OUT

MSD

CAN

MAG PICKUP

CONNECTOR

LEGACY IGNITION

LT. BLUE - BURN OUT

BLUE - LAUNCH

PINK - STEP 1

VIOLET - STEP 2

TAN - STEP 3

LT. GREEN - STEP 4

GREEN - STEP 5

SWITCHED IGNITION 12V

BRN/WHITE - RPM/TIME SWITCH

WHITE - POINTS IN

Figure 1 Wires of the Power Grid System Controller.

RED - 12V SW OUT

BLACK - BATTERY (-)

ORANGE - BATTERY 12V

WHITE - POINTS OUT

TO BATTERY POSITIVE

TO BATTERY NEGATIVE

HEAVY RED

+

HEAVY BLACK

-

-

+

BLACK

ORANGE

V-NET

CABLE

MSD

CAN

MAG PICKUP

CONNECTOR

NOTE: SEE PAGES 10-12 FOR SCHEMATICS

SHOWING INSTALLATION TO OTHER

MSD IGNITION CONTROLS.

YELLOW - SHIFT LIGHT

GRAY - TACH

LT. BLUE - BURN OUT

BLUE - LAUNCH

WHITE - POINTS IN

PINK - STEP 1

VIOLET - STEP 2

TAN - STEP 3

LT. GREEN - STEP 4

GREEN - STEP 5

SWITCHED IGNITION 12V

LEGACY IGNITION

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Figure 2 Wiring the Power Grid.

Page 4

4 INSTALLATION INSTRUCTIONS

MOUNTING

The Power Grid System Controller should be mounted in a

sturdy, dry location that does not expose the unit to extreme

heat. It is designed to be mounted on top of the PN 7720

Power Grid Ignition. Be sure to mount the Power Grid System

Controller so the USB connector and Micro-SD card are

accessible. The unit comes with thread-turning (aka. Selftapping) screws that will cut into the walls of the pre-drilled

holes on the top corners of the Power Grid-7. If the Power Grid

System Controller, PN 7730 / PN 77303, is not being mounted

on top of the Power Grid-7 the unit should be secured with

the supplied hardware.

Note: Insecure or otherwise improper mounting of the unit

Figure 3 Mounting

could result in damage or failure. Always make sure

the unit is dry, avoids unnecessary excess vibration,

and is not exposed to extreme heat.

MSD VIEW

The MSD View software controls all of the functionality of the Power Grid System Controller. The following

information gives a brief explanation of each function or feature in the system as well as the settings that

control it. While using the program, hover the mouse over a Function to display a brief explanation.

When the system controller is connected to a PC via USB MSD View will automatically recognize it and load

the settings stored in it.

Note: Ensure that MSD View is installed on the PC prior to connecting the Power Grid Ignition Controller.

INSTALLATION OF THE VIEW SOFTWARE

1. Insert the installation CD Rom into the CD drive, wait up to 30 seconds, the CD will auto run, IF THIS

DOES NOT OCCUR:

Locate and open the CD Drive.

Double click on the Setup file.

2. Select “Click here to Install Version X.XX”.

3. Once loaded, your monitor will have an MSD View X.XX logo. Accept the agreement. Drive the installation

to your program files folder, press the enter key. The installation will complete, select OK.

4. A window will be opened with two aliases, double-click on the MSD View alias to launch the software.

5. Connect the system controller via USB. If the software does not recognize the controller and auto-connect,

manually select the Power Grid in the popup window and click Connect.

Note: The View Software can be downloaded from www.msdignition.com.

SAVES AND TRANSFERS

Using the Power Grid System Controller changes are in real time if the computer is linked to the ignition.

You can create and save numerous files on your PC and transfer them for testing purposes or to use for

various locations and conditions.

The following instructions will go through a general description of the use of the Power Grid System Control

following the tab system that you will see in the software.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 5

INSTALLATION INSTRUCTIONS 5

PROGRAMMABLE FEATURES AND SETTINGS:

GENERAL

These are the most basic settings of the system. They will need to be set the first time the system is installed

in a vehicle.

Number of Cylinders: This tells the system the number of cylinders. Must be selected correctly for proper

timing and rev limiting.

Maximum Timing Reference: This is the advance that is set with a locked distributor or crank trigger. The

system controller will use this as its base for all timing marks and can never advance past the pre-set

point. It is critical that this advance is set properly.

Note: When using EFI the max timing reference and the main timing must be the same number.

Number of Gears: This tells the system the number of gears used in the transmission. This information can

be used a variety of ways depending on the functions and modules used in the system.

Ignition Type: Found under General Settings, this option allows a user to select between using the Power

Grid Ignition, PN 7720, or one of the MSD legacy ignitions.

DIAGNOSTIC LED INDICATOR

The LED is located on the far right side of the Power Grid Controller, next to the USB/SD Card cover. This

LED allows the user to quickly determine if; all systems are normal, data is being recorded or if there are

any active Alerts.

OFF – Unit is turned off

ORANGE for 1 Second – Power ON LED test

ORANGE for 10 Seconds – ARC Module (PN 7761) has been connected (*see notes below)

ORANGE - blinking – Data recording in process

GREEN - blinking – Input (crank pickup or Points wire) triggered; below 500 rpm, no active Alerts

RED - blinking – Input (crank pickup or Points wire) triggered; below 500 rpm, 1 or more active

Alerts

GREEN - solid – Running; above 500 rpm, no active Alerts

RED - solid – Running; above 500 rpm, 1 or more active Alertys

*NOTE: Many racing organizations (NHRA, IHRA, etc.) use an MSD Power Grid test tool that can check for

the following settings:

1. ARC Module - indicates if an ARC module (PN 7761) has been connected (Holds connection indicator

for the next 60 minutes of engine run time after the ARC codule has been disconnected)

2. Safety Limiter - the RPM that the engine will be limited to if it exceeds the Safety Run Time limit.

3. Safety Run Time - the run time, in seconds, after the Launch input (Blue wire) has been released. Activates

the Safety Limiter when timer reaches 0 seconds.

4. Part Numbers - lists the part numbers of any MSD compatible module connected to the Power Grid system.

5. Over Boost - Boost pressure ignition cut off value of the MSD Boost Controller (PN 7763). If connected.

CAMSHAFT SYNCHRONIZATION

This is used only in applications where the individual cylinder timing is going to be used. The fiber optic

connector communicates when the #1 cylinder fires. With this information, the controller knows which cylinder is being fired allowing for the individual cylinder timing capabilities. Only the MSD Fiber Optic Inductive Pickup Kit, PN 7555 will work for this system. Cam-sync’s cylinder #1 identification is also used in the

data acquisition recordings.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 6

6 INSTALLATION INSTRUCTIONS

GEAR SHIFT

In the Gear Shift selection the user can set items such as launch and shift delay so that the system will not

have a false shift detected immediately after launch or a shift should there be an rpm drop for any other reason.

Launch Delay: The amount of time in seconds after the launch that the system will ignore an rpm drop to

prevent false shift detection. This can be set from 0.00 to 10.00 in .01 second increments.

Shift Delay: The amount of time in seconds after sensing a shift that the system will ignore an rpm drop to

prevent false shift detection. This can be set from 0.00 to 10.00 in .01 second increments.

1->2 Shift: By setting the rpm drop the user tells the system how to sense when the car is being shifted

during a run. The setting is controlled by a drop down list with rpm from 200 – 1,500 or can be set

to be activated by a Step Retard wire instead. The number of shifts that is shown is controlled by the

number of gears the system is set to in the Settings – General tab.

SHIFT LIGHT

Using the Shift Light controls opens a variety of options designed to help make sure the light is exactly as

desired. The shift light setting can be set by single rpm increments. In this control tab, each value can be

entered to the exact rpm desired and the light’s intensity can be adjusted so that it is visible without blinding.

The number of gears that appear on this tab will be auto-populated by the program after the number of gears

is set in the general settings. This can also be used with a relay as a transmission shifter. The maximum

current for this circuit is 3 amps.

Light Intensity: This percentage setting controls brightness of the shift light for easy use in both day and

night racing. If being used for anything other than shift light control, the intensity must be 100%.

Power-On Test: Normally set to on but can be turned off if desired. The power-on test turns the shift light on

as soon as the controller receives power to show that the circuit is complete and working.

Launch Light: The Shift Light will turn on if the engine rpm is between the launch low limit and the launch

high limit. The light will blink if rpm is above the launch high limit.

Gear 1-5: A setting can be adjusted for each individual shift. To do this enter the engine RPM that should

turn the Shift Light ON for each gear.

OUTPUT SWITCH

When the switch is activated it will supply ground to a circuit in order to turn an item on by time and/or rpm.

The circuit can maintain up to 2 continuous amps. If more than 2 amps is needed a relay is recommended,

PN 8961.

To activate or deactivate this circuit the system must see a programmed time and/or rpm setting which is

programmed in the Settings – Output. Using both On and Off values will set a window to control the switch.

The output will only be activated while within the set window and will be deactivated as soon as one or both

sides of the windows are not met. All parameters must be met for the output switch to be activated. For

example, if values are entered for both RPM On and Activation Point (timed on) then both of those values

must be reached before the switch is activated. The rpm function becomes active and the time function begins

counting after the Dark Blue launch wire is released.

Note: If using the time activation function a duration MUST be set above 0.00 or the switch will not be

activated by time.

IGNITION TIMING

The user can set the timing from 0 - 60° BTDC. However, actual timing will never advance past the maximum

timing reference nor will the timing retard more than 30° from the max timing reference. MAX and MIN timing

lines will be displayed for convenient reference in the main engine timing tab. (Those lines can be turned off

by unchecking them in the upper left column.)

Note: When using EFI the max timing reference and the main timing must be the same number.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 7

INSTALLATION INSTRUCTIONS 7

Engine timing cannot exceed the maximum timing reference. In order to advance timing, the main timing

map must be set below the maximum timing reference. I.E. If the crank trigger is at 40° and the main timing

map is set to 35° there will be up to 5° of advance available.

ENGINE TIMING

Using MSD View software, an entire timing curve can be mapped. The map specifies the actual engine

timing. The Power Grid will retard the input trigger to obtain the correct engine timing. The maximum timing

reference must be set properly for correct engine timing. These maps include changes in 50 rpm increments

and timing changes down to 0.1 degrees. A maximum of 30 points can be set per map.

This map will show all engine timing maps that are drawn based on rpm values such as timing curves per

gear. The information for all of these maps is accumulative in the software. In order to edit a particular timing

curve the user must go into the proper tab per function.

Start Retard: As part of the general engine timing curve, users can specify a start retard. While each engine

responds differently, the typical recommendation for a start retard is to to pull out 10° from 0 - 600

rpm. A variety of other ideas can be applied to a start retard, including ramping timing in as engine

rpm climbs. Use of such techniques is at the discretion of the user.

GEAR CURVES

This program provides the ability to modify the timing curve for each gear. One curve can be created for each

gear, up to six, from 0 – 15,000 rpm in 0.1° increments for every 50 rpm. You can program up to 30 different

points on each Gear Curve. The number of gears shown and how a shift is detected are dependent on the

selected values in the Settings tab.

In the Ignition Timing – Gear Curves tab, an individual curve is plotted for each gear. Each change made for the

gear curves references off of the Main Timing curve are set in the Engine RPM tab, not off of the max timing

reference. Gear curves are NOT cumulative; i.e. Retarding 1° in 2nd gear does not affect 3rd gear settings.

Note: The gear curves are independent of each other. In order to make progressive changes, one gear’s

starting point must match the final timing of the previous gear’s curve. Leaving a gear curve unedited

will result in normal timing for that gear regardless of other gear curves ahead of or behind it.

INDIVIDUAL CYLINDER TIMING

Note: To control ICT an inductive pickup, PN 7555, is required.

To accomplish timing changes per cylinder the engine’s firing order must be entered first. Firing order is

programmed in the tab Ignition Timing – Individual Cylinder – Firing Order by numbering the order into the

Value column. Many common firing orders can also be imported from a database within the software; to do

so simply go to FileImport and open the “firing_order” folder where an engine description can be selected.

Similarly, if an engine uses a firing order not included in these options the settings can be exported to be

saved in the same file.

After the correct firing order is entered individual cylinder timing can be created by editing rules. Up to 10

rules can be entered to control various aspects of timing for a single cylinder at a time. Each rule has six

(6) values that can be controlled; Cylinder, Retard/Advance, Timing, From Gear, Delay, and Ramp Time. To

make a rule the first four control values must be entered, Delay and Ramp Time may be left at the default of

0 if desired. When timing is changed on an individual cylinder, in order to bring the cylinder back to original

timing an equivalent amount of timing must be used to offset (DO NOT use 0°). I.E. If cylinder two is retarded

by 3° in RULE 1, in order to put the timing back in the cylinder must be advanced in a later rule by 3°.

Cylinder: Double click this value to select the cylinder for which timing is to be altered.

Retard / Advance: Enter whether timing will be Retarded or Advanced. After using this option timing changes

will always be entered as a positive number.

Note: Engine timing cannot exceed the maximum timing reference. In order to advance timing, the main

timing map must be set below the maximum timing reference. I.E. If the crank trigger is at 40° the main

timing map is set to 35° there will be up to 5° of advance available.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 8

8 INSTALLATION INSTRUCTIONS

Timing Change: Enter the amount of timing that is to be retarded or advanced. This value will always be a

positive number, regardless of whether advance or retard is desired.

From Gear: This setting determines from which gear the timing change will become active. If gear one is

selected the timing change will be active at all times unless a delay is used.

Delay: This is the time, in seconds, that will pass prior to initiating the timing change after the proper gear

change. This setting defaults to 0.0 but can be taken up to 5.0 seconds. If a timing change is desired

during an entire run, but not other times the engine is running, this setting should be entered as 0.1 sec.

Ramp Time: The amount of time it takes for the Individual Cylinder Timing to be fully engaged. During this

time the controller will ramp the timing change from the starting point to full timing.

Note: Changes made in Individual Cylinder Timing are cumulative. If a cylinder’s timing is to be altered for a

duration of time two rules must be made, one to initiate the change and another to reverse the change

at the appropriate time.

LAUNCH RETARD (TIMING BY TIME)

This function allows a user to set an engine timing curve based on the run time from launch (release of the

dark blue wire). It can be programmed from 0° to 20° in 0.1° increments. Up to 30 trace points can be set per

0.01 sec. across the available 10 seconds. When the Launch wire is active, the retard value is the placement

of the first dot. When 12 volts are removed from the Dark Blue wire the engine timing will follow the prescribed

curve added to the base timing set at the engine RPM map.

STEP RETARDS

There are five step wires that control each of the corresponding step retards. These retards can be set so

that they are not active until a specified rpm is reached even if the wire receives voltage. Using this system

a step can activate as soon as the trigger wire receives 12 volts or after the engine reaches a specific rpm

with 12 volts at the trigger wire. Once the retard is activated, timing can be changed in a single step or be

ramped in over a period of time. The retard can also be turned off in a single step or ramp after a prescribed

time after power is removed.

Step Retard Activation Wires

Step 1 Step 2 Step 3 Step 4 Step 5

Pink Violet Tan Light Green Green

Note: These wires can also be used as Gear Select Indicators. See page 5.

Note: The Step-5 wire may be used as a Spool Rev Limiter. When using this wire for a retard and not a Spool

Rev Limiter, the rev limit setting must be set above the max rev setting.

Activation through Wiring: Each step is activated by applying 12 volts to the corresponding wire. When

multiple step retards are enabled at the same time the retard amounts are added together. The

maximum retard allowed by the system is a total of 30° (including other retard amounts from a launch,

boost, gear retard, etc).

Activation through RPM: Each step retard can also be activated through rpm. In order to achieve this,

12 volts must still be applied to the corresponding step retard, and an rpm must be entered in the

respective step retard control. When 12 volts is applied, the retard will not activate until the rpm value

is reached. Note that the retard will remain active until the rpm drops back below the set value. The

step retard is added to all other retards in the system, including other active steps until it is deactivated.

Each of the five step retards has its own tab under the Ignition Timing – Step Retard tab. Within the individual

tabs there are controls for the step retard.

Timing Retard: This is the amount of timing that will be retarded while this step is active. The timing can

be adjusted in 0.01° increments.

Engine RPM: When this setting is used the engine must be above the prescribed RPM before the step

retard will be activated.

On Ramp: The amount of time it takes for the step retard to retard the full amount. During this time the

controller will ramp the timing retard from the starting point to full step retard.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 9

INSTALLATION INSTRUCTIONS 9

Off Delay: This feature will set a time based delay to deactivate the step retards. The Off Delay is designed

to keep the timing retarded after the wire is deactivated. This setting defaults to 0.0 sec but can be

taken up to 5.0 sec by the user.

Off Ramp: The amount of time the system takes to turn the step retard off once power is removed from the

step wire and any delay is complete. During this time the controller will ramp the step retard out.

Note: If you prefer to activate the step retards through the activation wires alone without considering rpm the

setting for rpm should be left at the default of 0.

SHIFT RETARD

Using MSD View, a retard can be implemented momentarily to help maintain traction immediately after a

shift. To do this, simply enter the amount of timing retard desired and the length of time the retard should be

active for each shift. Whether using an rpm drop or a step retard activation wire for a trigger, as soon as the

system detects a shift it will retard the timing for the prescribed amount of time.

REV LIMITER

A variety of different rev limits can be programmed per individual vehicle needs. The actual rev limiter will

never exceed the maximum rev limiter.

Burnout Rev Limiter: This limit is activated when 12 volts are applied to the Light Blue wire. It is adjustable

from 1,000 to 15,000 rpm. Note that the Slew Rev Limiter is disabled by the Burnout Limit.

Launch Rev Limit: This limit is activated when 12 volts are applied to the Dark Blue wire. It is adjustable

from 1,000 to 15,000 rpm.

Latching: When this setting is enabled engine rpm must be below 7/8 of the launch limit setting while 12

volts is applied to the Dark Blue wire to engage the Launch Limiter. This allows clutch cars to wire

the Dark Blue wire directly to the clutch switch without the need to use a relay. If Latching is disabled,

the Launch Rev Limiter will be engaged anytime the Dark Blue wire receives 12 volts (such as during

each shift) regardless of engine rpm.

Maximum Rev Limiter: This is the overrev limit to help protect the engine from damage.

Spool/Step 5 Rev Limiter: This program gives turbo cars a fourth rev limit to help the engine spool the

turbo prior to the launch. It is active when 12 volts is applied to both the Light and Dark Blue wires

at the same time or when using the Step 5 retard wire. (The Step 5 wire can allow for activating the

Spool rev Limiter without activating the line-lock.) It is adjustable in 50 rpm increments from 1,000

to 15,000. Default is 12,000 rpm.

Safety Run Time Rev Limiter: Using two settings a safety limiter can be activated in case of incident. If for

any reason the engine is still revving after the set amount of time since the launch limiter is released,

this feature will lower the rev limit to a user specified rpm over 2 seconds. This will help anytime the

throttle is open much longer than it should be, such as a stuck throttle linkage or an accident.

Users have two options to activate the Safety Run Time countdown; the Launch limiter, or the Safety

RPM Start. In either case the Dark Blue wire must be activated so that time down can start upon

its release. Many users will activate the Safety countdown by bringing the engine up on the limiter.

Users who do not wish to use the launch rev limiter can activate the safety run time countdown by

taking the engine rpm equal or higher than the Safety RPM Start setting. This setting act only as a

countdown activator and has no rev limiting ability.

DATA ACQUISITION

The data recorder on the Power Grid System Controller comes with a 2GB micro SD card which will easily

hold more than an entire event’s worth of data. Within the settings for data acquisition on the system controller

there are four tabs that provide options for when and what data is recorded. If a new micro-SD card is needed

or wanted for any reason it is important to get a Class 6 or higher at the minimum, NOT all micro-SD cards

will work. If there is question as to whether an SD card will work test recording should be done prior to a run.

The Power Grid System Controller will also easily send the data it records to compatible Racepak data

acquisition systems. To connect the two systems simply plug the included VNet connector into an available

space on the on the Racepak system. To be compatible the user must have a Racepak Data VNet Logger

using DatLink Software v3.7.4 or higher. Default settings will send 13 channels of data to the RacePak system.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

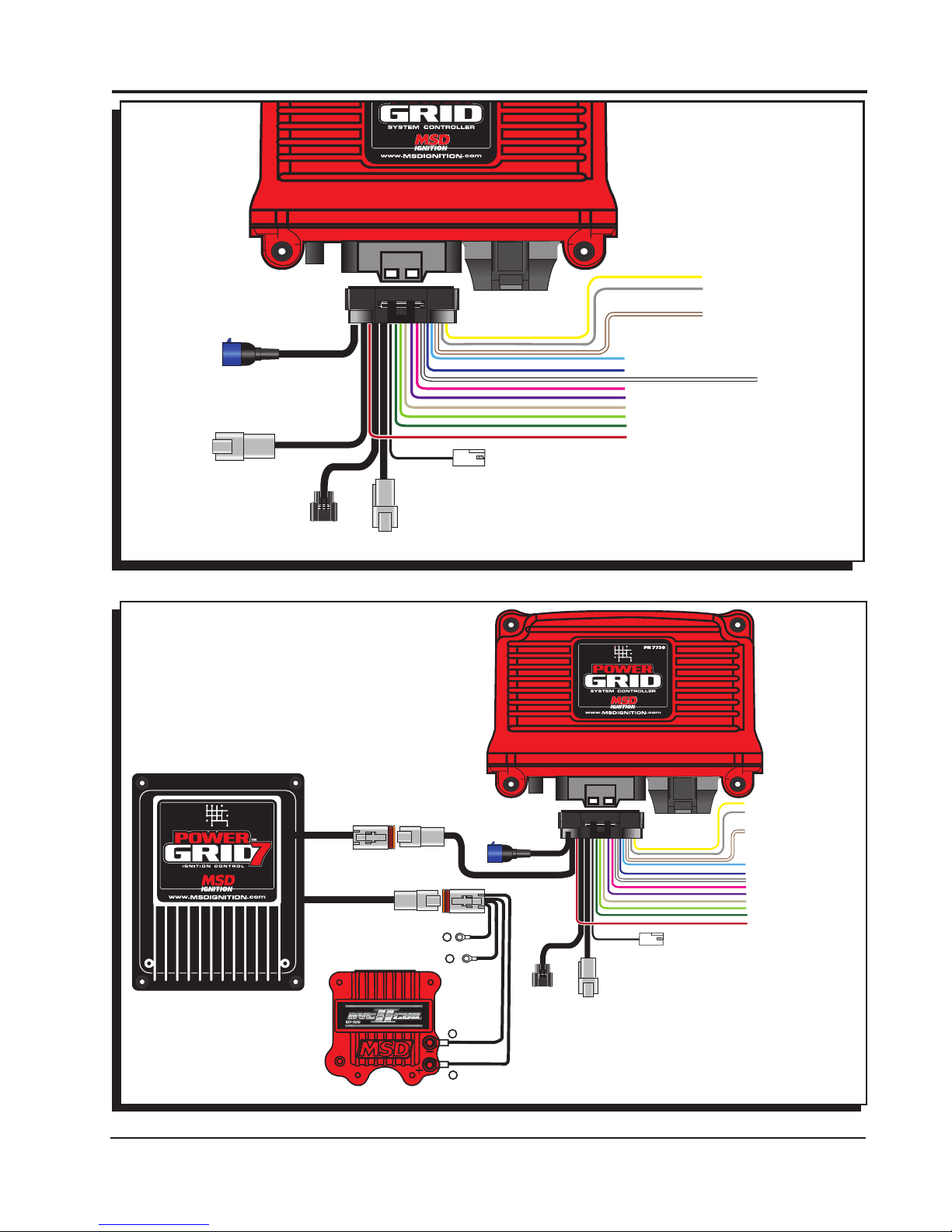

Page 10

10 INSTALLATION INSTRUCTIONS

Settings:

This tab has two possible adjustments. The first setting allows a user to turn the data recording off, if

desired. The second control tells the system what to do if the SD card is full. This setting allows the

system to either stop recording or begin to write over data with the lowest recording name. By default

the system is on and will overwrite once the memory is full.

Channels:

Each available data trace within the PN 7730 / PN 77303 is listed in this tab. Each trace can be

disabled individually in order to remove unneeded traces and generate smaller files. The Ignition In

channel and the Ignition Out channel are high resolution and they generate the most amount of data

at high engine rpm.

Start Recording:

The settings here tell the controller when to start recording data so that only useful information is

stored. The recorder can be started by RPM alone or by adding a function to the RPM. For example,

the default setting starts recording as soon as the Launch Rev wire is activated and the RPM is above

3,000.

Stop Recording:

In this tab the user controls when to stop recording. The recording can be stopped by reaching a lower

rpm limit or a trigger such as a step wire signal. When stopping recording only one of these setting

values must be triggered. There is also a setting to keep recording for some time after the trigger to

ensure that all useful data is captured. Finally, there is a user set maximum recording time limit to

ensure recording stops even if the system is not triggered for any reason.

-

BLACK

+

ORANGE

YELLOW - SHIFT LIGHT

GRAY - TACH

BRN/WHITE - RPM/TIME SWITCH

LT. BLUE - BURN OUT

BLUE - LAUNCH

PINK - STEP 1

VIOLET - STEP 2

TAN - STEP 3

LT. GREEN - STEP 4

GREEN - STEP 5

SWITCHED IGNITION 12V

WHITE - POINTS IN

-

+

ORANGE

BLACK

BATTERY

BATTERY

SUPPLIED JUMPER

WHITE

ORANGE

RED

V-NET

CABLE

LEGACY IGNITION

BLACK

MSD

CAN

GREEN

VIOLET

GREEN

VIOLET

Figure 4 Wiring the Power Grid Controller to MSD 8-Plus.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 11

INSTALLATION INSTRUCTIONS 11

V

CHASSIS

GROUND

IGNITION

MSD RPM

RECEPTICAL

VIOLET

BLACKRED

WHITE

TO GROUND

ON CYLINDER HEAD

LEGACY

IGNITION

RED

NOT USED

ORANGE

V-NET

CABLE

BLACK

BATTERY

POSITIVE

+

-

BATTERY

NEGATIVE

YELLOW - SHIFT LIGHT

GRAY - TACH

BRN/WHITE - RPM/TIME SWITCH

LT. BLUE - BURN OUT

BLUE - LAUNCH

WHITE - POINTS IN (NOT USED)

PINK - STEP 1

VIOLET - STEP 2

TAN - STEP 3

LT. GREEN - STEP 4

GREEN - STEP 5

RED - SWITCHWED IGNITION 12

NOT USED

MSD

CAN

GREEN

VIOLET

GREEN

VIOLET

Figure 5 Wiring the Power Grid Controller to Pro-Mag.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 12

12 INSTALLATION INSTRUCTIONS

PN 8253

-

BLACK

+

ORANGE

TACH

NOT

USED

IGNITION

Multiple

Spark

Discharge

V-NET

CABLE

AUTOTRONIC CONTROLS CORPORATION

PART NO.

SERIAL NO..

MSD RPM

RECEPTICAL

RED

BLACK

ORANGE BLACK

RED

WHITE

LEGACY IGNITION

INDICATES CONNECTION

BATTERY

POSITIVE

+

-

BATTERY

NEGATIVE

MSD

CAN

Figure 6 Wiring the Power Grid Controller to MSD 6AL.

GREEN

VIOLET

GREEN

VIOLET

YELLOW - SHIFT LIGHT

GRAY - TACH

BRN/WHITE - RPM/TIME SWITCH

LT. BLUE - BURN OUT

BLUE - LAUNCH

WHITE - POINTS IN (NOT USED)

PINK - STEP 1

VIOLET - STEP 2

TAN - STEP 3

LT. GREEN - STEP 4

GREEN - STEP 5

SWITCHED IGNITION 12V

ALERTS:

There are a variety of alerts that can arise in the Power Grid System Controller. If there are any errors or

other causes of alert, the LED on the front of the controller will show red. Any time the red light shows the

alerts should be checked so that errors can be corrected. By default, a pop-up box will appear as soon as

an alert is registered. The pop-up window has a check box to disable the pop-ups if desired.

The alerts window can also be opened manually two ways. On the bottom bar of the program window pane

there is an alert counter that will show the number of alerts present. A single click on the alert counter at

any time will open the alert window. The alert window can also be opened by going to the View menu on

the task bar.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 13

INSTALLATION INSTRUCTIONS 13

Alert Alert

ID Text Alert Activation Conditions Description

1 Low Battery Voltage EngineRPM > 500 AND Vbatt < This alert activates when there is low battery voltage

9.0 for 5 seconds with engine RPM. Make sure the 7730/77303 is properly

connected to battery voltage.

2 High Battery Voltage Vbatt > 18.0 This alert activates when there is high battery voltage.

Make sure the 7730/77303 is properly connected to battery voltage

3 Crank Sensor This alert activates due to weak crank sensor signal. Make sure

Voltage Low

5 No CAM Sync Engine RPM > 300 AND This alert activates when individual cylinder timing has been

6 12V Output Current > 3A for 10 ms This alert activates when there is too much load on

Sh utdown the 12V bus that is used to power accessory modules. Make sure

13 Low SDcard Storage This alert activiates when an SDCard is present and there is

14 SDcard Initialization This alert activates when the 7730/77303 cannot initialize the

Error

15 SDcard Write Error This alert activates when the 7730/77303 is unable to write to

16 SDcard Read Error This alert activates when the 7730/77303 is unable to read the

17 SDcard Missing SDcard not present AND data acquisition enabled AND Engine

18 Data Acquisition DAQ memory buffer overflow This alert activates if the interal data acquisition memory buffer

Memory Overflow

19 12V Output Overcurrent Current > 2A for 10 ms This alert occurs when there is too much load on the 12V bus

20 EEPROM CRC Error This alert occurs if the 7730/77303 is unable to recover

21 EEPROM Write Error This alert occurs if the 7730/77303 is unable to write

22 Data Acquisition This alert activates if the internal data acquisition memory

Memory Protection

Weak Crank Sensor

Individual Cylinder Timing Rule

Enabled AND no CAM Sync pulse

detected

SDcard present AND SDCard Free

Storage < 100 MB

SDcard present AND Error

Initializing SDCard

SDcard present AND Error

reading to SDcard

SDcard present AND Error

writing to SDcard

SDcard not present AND

data acquisition enabled AND

EngineRPM > 0

Unable to read MFF data at startup

after 3 attempts

Unable to write any data to

EEPROM after 3 attempts

DAQ memory buffer reaches

90% utilization

the crank sensor is properly located according to the installation

instructions.

configured and no optical CAM sync signal is detected. Make

sure the optical CAM sync cable is properly connected to the

7730/77303.

there are no short circuits and the 12V bus is not overloaded.

less than 100 MB of storage available on the card. Remove

some data from the SDCard to remove this alert.

SDCard. Make sure you are using the MSD factory supplied

SDCard.

the SDCard. Make sure you are using the MSD factory supplied

SDCard.

SDCard. Make sure you are using the MSD factory supplied

SDCard.

is running.

overflows. This will cause a recording to end prematurely. Try

deactivating some data acquisition channels. Make sure you

are using the MSD factory supplied SDCard.

that is used to power accessory modules. Make sure the 12V

bus is not overloaded.

configuration data from its internal EEPROM memory. The

7730/77303 will attempt to recover a back-up stored in its

internal Flash memory. Verify your configuration settings are

correct. If this error occurs frequently, contact MSD tech support

for an RMA.

data to its internal EEPROM memory. If this error occurs

frequently, contact MSD tech support.

buffer reaches a critical limit. This will cause some data

acquisition channels to be automatically disabled. Try

deactivating some data acquisition channels. Make sure

you are using the MSD factory supplied SDCard.

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 14

14 INSTALLATION INSTRUCTIONS

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 15

INSTALLATION INSTRUCTIONS 15

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

MSD • WWW.MSDPERFORMANCE.COM • (915) 855-7123 • FAX (915) 857-3344

Page 16

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of the warranty.

When returning MSD components for warranty service, Proof of Purchase must be supplied for verification. After

the warranty period has expired, repair service is based on a minimum and maximum fee.

All returns must have a Return Material Authorization (RMA) number issued to them before

being returned. To obtain an RMA number please contact MSD Customer Service at 1 (888) MSD-7859 or

visit our website at www.msdperformance.com/rma to automatically obtain a number and shipping information.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be sure to include

a detailed account of any problems experienced, and what components and accessories are installed on the vehicle.

The repaired unit will be returned as soon as possible using Ground shipping methods (ground shipping is covered

by warranty). For more information, call MSD at (915) 855-7123. MSD technicians are available from 7:00 a.m. to 5:00

p.m. Monday - Friday (mountain time).

Limited Warranty

MSD warrants this product to be free from defects in material and workmanship under its intended normal use*,

when properly installed and purchased from an authorized MSD dealer, for a period of one year from the date of the

original purchase. This warranty is void for any products purchased through auction websites. If found to be defective

as mentioned above, it will be repaired or replaced at the option of MSD. Any item that is covered under this warranty

will be returned free of charge using Ground shipping methods.

This shall constitute the sole remedy of the purchaser and the sole liability of MSD. To the extent permitted by law,

the foregoing is exclusive and in lieu of all other warranties or representation whether expressed or implied, including

any implied warranty of merchantability or fitness. In no event shall MSD or its suppliers be liable for special or

consequential damages.

*Intended normal use means that this item is being used as was originally intended and for the original application

as sold by MSD. Any modifications to this item or if it is used on an application other than what MSD markets the

product, the warranty will be void. It is the sole responsibility of the customer to determine that this item will work for

the application they are intending. MSD will accept no liability for custom applications.

MSD • WWW.MSDPERFORMANCE.COM • (915) 857-5200 • FAX (915) 857-3344

FRM 30299 Revised 04/16

© 2016 MSD LLC

Loading...

Loading...