Page 1

4135H - 4155H - 4155 H 4WD

INSTRUCTIONS FOR USE

8211-0069-80

INSTRUCTIONS FOR USE

MODE D’EMPLOI

GEBRUIKSAANWIJZING

EN.....7

FR... 20

NL .. 34

Page 2

1

2

S

4

3

5

2

Page 3

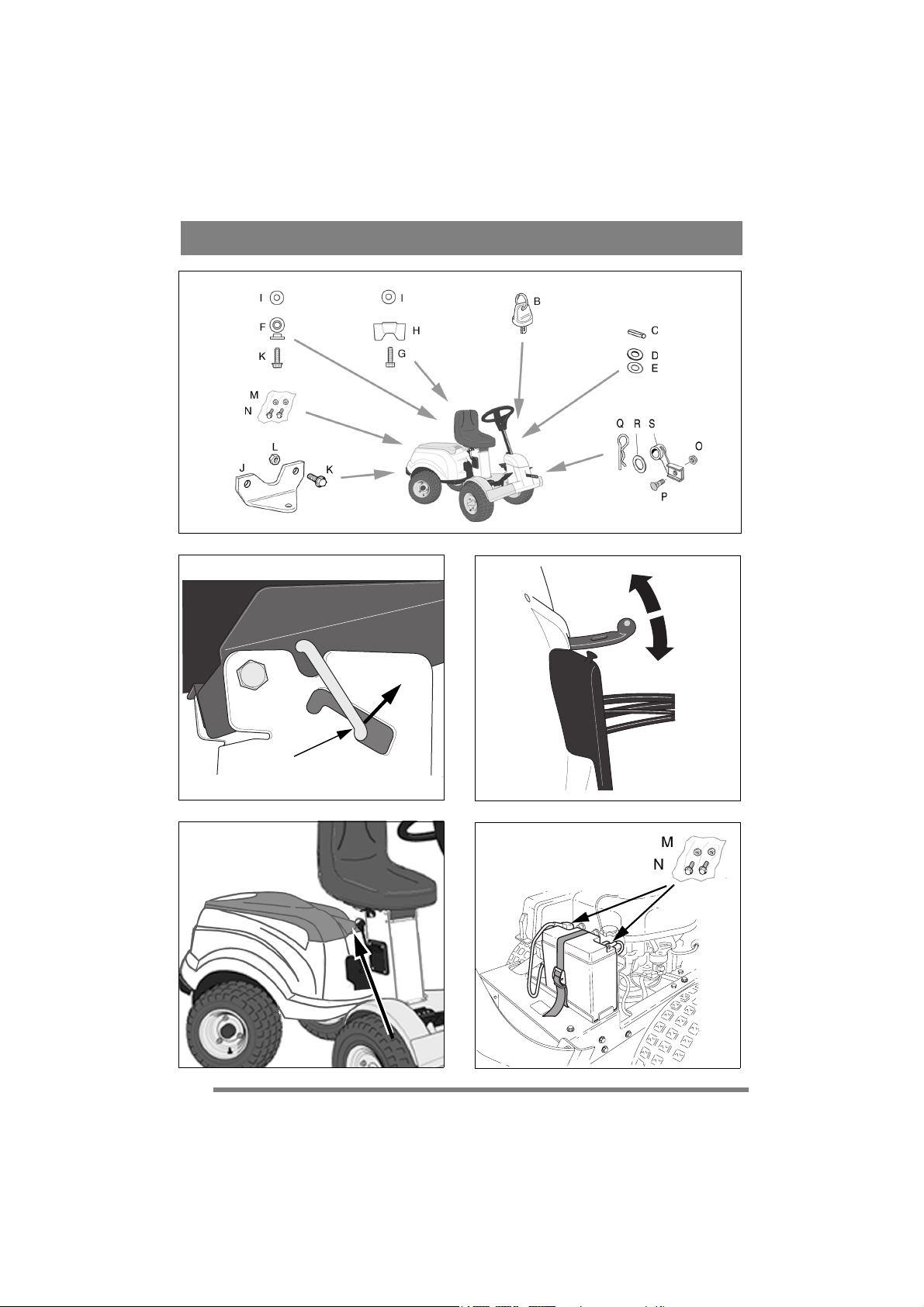

6

I

F

K

I

H

G

S

7

C

D, E

8

10

9

L

L

QR S

K

J

K

11

3

Page 4

12

13

DEF

14

B C

G

A

15

I

J

K

L

M

16

HST

N

17

4WD

OP

4

Page 5

18

Max

Q

19

05_119

20

R S T

22

21

0

1

U

V

23

Y

5

Page 6

24

25

26

28

27

29

6

Page 7

ENGLISH

EN

1 GENERAL

This symbol indicates WARNING. Serious personal injury and/or damage to

property may result if the instructions

are not followed carefully.

You must read these instructions for use

and the accompanying pamphlet

“SAFETY INSTRUCTIONS” carefully, before starting up the machine.

1.1 SYMBOLS

The following symbols appear on the machine.

They are there to remind you of the care and attention required during use and maintenance.

This is what the symbols mean:

Warning!

Read the instruction manual and the safety

manual before using the machine.

Warning!

Watch out for discarded objects. Keep onlookers away.

Warning!

Always wear hearing protectors.

Warning!

This machine is not designed to be driven

on public roads.

Warning!

The machine, equipped with original accessories, must not be driven in any direction on slopes with a gradient greater than

10º.

Warning!

Risk of crushing injuries. Keep hands and

feet well away from the articulated steering joint.

Warning!

Risk of burn injuries. Do not touch the silencer/catalytic converter.

1.2 Designations

Three versions of Park Compact are available and

are designated in the table below:

Machine

4135 H with hydrostatic transmission.

4155 H with hydrostatic transmission.

4155 H with hydrostatic transmission and four wheel drive.

Designation

HST

HST

4WD

1.3 References

1.3.1 Figures

The figures in these instructions for use are numbered 1, 2, 3, etc.

Components shown in the figures are marked A, B,

C, etc.

A reference to component C in figure 2 is written

“2:C”.

1.3.2 Headings

The headings in these instructions for use are numbered in accordance with the following example:

“1.3.1 General safety check” is a subheading to

“1.3 Safety checks” and is included under this

heading.

When referring to headings, only the number of the

heading is normally specified. E.g. “See 1.3.1”.

2 SAFETY INSTRUCTIONS

2.1 GENERAL

• Please read through these instructions carefully.

Learn all the controls and the correct use of the

machine.

• Before use, all drivers must apply for and

receive practical training in the operation of the

machine. Particular emphasis should be placed

on the fact that:

a. The use of ride-on lawnmowers requires care

and concentration.

b. On slopes, it is not possible to control a

sliding ride-on lawnmower by braking. The

main reasons for losing control are insufficient

traction, excessively high speed, insufficient

braking, the machine not being suited to the

task, lack of attention to the surface or incorrect

use as a towing vehicle.

• Never let children or anyone who is not familiar

with these instructions to use the machine.

Local regulations may impose restrictions as

regards the age of the driver.

• Never use the machine if others, particularly

children or animals, are in the vicinity.

• Remember that the driver is responsible for

accidents that happen to other people or their

property.

• Do not let children or other passengers to ride

with you on the machine. They might fall off

and be seriously injured, or they might prevent

the machine being driven safely.

• Do not use the machine if you are under the

influence of alcohol, drugs or medication.

Neither should you use it when you are tired or

feeling unwell.

7

Page 8

EN

ENGLISH

2.2 PREPARATIONS

• Wear strong shoes and long trousers when using

the machine. Do not operate it barefoot or

wearing sandals.

• Wear appropriate clothing when using the

machine. Do not wear loose, hanging clothes,

jewellery, scarves, ties, etc., which can get

caught in rotating parts. Tie up long hair.

• Carefully check the area that is to be cut/cleared

of snow. Remove all loose stones, sticks, steel

wire and other foreign objects which the

machine could throw out.

• Warning – Petrol is highly inflammable.

a. Always store petrol in containers that are

made especially for this purpose.

b. Only fill or top up with petrol outdoors, and

never smoke when filling or topping up.

c. Fill with petrol before starting the motor.

Never remove the filler cap or fill with petrol

while the engine is running or still warm.

d. If petrol is spilt, do not try to start the engine

but instead move the machine away from the

place where the spillage occurred and avoid any

possible causes of sparks until the petrol fumes

have evaporated.

e. Do not forget to screw the cap on the petrol

tank and the storage container after filling.

• Replace faulty silencers.

• Before use, always check that blades and

mounting devices are not worn or damaged.

Replace worn or damage parts as a set so that

the correct balance is maintained.

• The battery (on electrically started machines)

gives off explosive gases. Keep sparks, flames

and cigarettes away. Ensure there is sufficient

ventilation during charging.

• The battery contains toxic material. Do not

damage the battery casing. If the casing is

damaged, avoid contact with the content of the

battery.

• Do not throw out old, defective batteries with

the rubbish. Contact the local authorities for

correct waste Management.

• Do not short circuit the battery. Sparks occur

which can result in fire.

2.3 DRIVING

• Start the engine according to the instructions in

the user guide. Keep your feet away from the

blades.

• Do not run the engine in confined areas where

hazardous carbon monoxide gases can collect.

• Only use the machine in daylight or where there

is good lighting.

• Always use hearing protectors.

• Take care when approaching obstacles which

obscure your vision.

• Always keep children away from the machine’s

working area. Get another adult to keep the

children under supervision.

• Take care when reversing. Look behind you

both before and during reversing to check for

any obstacles. Look out for small children.

• Disengage the blade(s) and the connection

before starting the engine.

• Never have your hands or feet near or under

rotating parts. Watch out for the blades. Do not

stand right in front of the discharge opening.

• Avoid using the machine on wet lawns.

• Be careful when driving on slopes. No sudden

starting or stopping when moving up or down a

slope.

• Release the clutch pedal slowly. Always drive

with the gear engaged, and do not disengage

when driving down slopes.

• Never cut across a slope. Move from the top

down, and from the bottom to the top.

• Use low acceleration when engaging the drive,

especially in long grass. Reduce the speed on

slopes and when making sharp turns to prevent

the machine from tipping over or you losing

control of the machine.

• Watch out for holes in the ground and other

hidden dangers.

• Do not drive too near ditches or high edges.

The machine can turn over if a wheel drives

over the edge or the edge breaks.

• Take care when towing and when using heavy

equipment.

a. Only use an approved towing device.

b. Limit the load so that it can be controlled

safely.

c. Do not make any sudden turns. Take care

when reversing.

d. Use wheel weights or front weight when

recommended in the user instructions.

• Look out for traffic at crossings or when driving

near roads.

• Stop the blade(s) when crossing a surface other

than grass during mowing.

• When using any of the accessories, never direct

the discharge at somebody standing beside it,

and do not allow anyone to stand near the

machine when it is running.

• Never operate the machine with insufficient

protection or without the safety devices in

place.

8

Page 9

ENGLISH

EN

• Existing safety devices may not be

disconnected or disengaged. Check that the

safety devices work each time before using the

machine.

• Do not alter the engine’s regulator setting and do

not race the engine. The danger of personal injury

increases when the engine is run at high revs.

• Do not touch engine components which become

warm during use. Risk of burn injuries.

• Do not leave the driving seat without:

a. Disengaging the power take-off and lowering

the accessories.

b. Putting the gear in neutral and activating the

parking brake.

c. Stopping the engine and removing the key.

• Only use accessories that are approved by the

machine’s Manufacturer.

• The machine may not be used without

accessories/tools being installed in the

machine’s tool mounts. Driving without

accessories can have a negative effect on the

stability of the machine.

• Take care when using grass collectors and other

accessories. These can alter the machine’s

stability. Particularly on slopes.

• Disengage the drive to the accessories, shut off

the engine and disconnect the spark plug cable

or remove the starter key:

a. To remove sticks and rubbish or when the

discharge has become clogged.

b. To check, clean or service the machine.

c. To check whether damage has occurred and

to carry out any repairs before starting and

using the machine again after a collision with a

foreign object.

d. To check the machine if it begins to vibrate

excessively. (Check immediately).

• Disengage the drive to accessories during

transport or when the machine is not in use.

• Shut off the engine and disconnect the drive to

the accessories:

a. Before filling with petrol.

b. Before removing the grass collector.

c. Before adjusting the height setting, assuming

this cannot be done from the driver’s position.

• Reduce the acceleration when the engine is to

be stopped, and if the engine is equipped with a

fuel shut-off valve, this should be switched off

when the work is finished.

• Take care with multiple blade decks as one

rotating blade can cause other blades to rotate.

• The machine, equipped with original

accessories, must not be driven in any direction

on slopes with a gradient greater than 10º.

• The cutting deck’s original blade(s) may not be

replaced with non-original devices intended for

e.g. moss scarification. If such devices are used,

the guarantee will cease to be valid. There is

also a risk of serious injury or damage to people

or property.

• Take care when unloading and loading the

machine onto a trailer or lorry.

2.4 MAINTENANCE AND STORAGE

• Tighten all nuts and screws so that the machine

is in safe working condition.

• At regular intervals check that the cutting

deck’s blade screw(s) are properly tightened.

• Regularly check the operation of the brakes. It

is important to maintain and repair the brakes if

necessary.

• Never store the machine with petrol in the tank

in buildings where the fumes can come into

contact with open flames or sparks.

• Allow the engine to cool before placing the

machine in a store.

• To reduce the risk of fire, keep the engine,

silencer, battery and petrol tank free from grass,

leaves and surplus oil.

• Check frequently whether there is any wear or

damage to the grass collector.

• For the sake of safety, replace worn or damaged

parts.

• Always use genuine spare parts. Non-genuine

spare parts can entail a risk of injury, even if

they fit the machine.

• Replace damaged warning and instruction

stickers.

• If there is no mechanical lock for the transport

position, the cutting deck must be lowered

when parked, stored or when the machine is left

unsupervised.

• If the petrol tank is to be emptied, this must take

place outdoors.

• Store the machine so that children cannot get to it.

3 STORAGE

Empty the petrol tank. Start the engine and let it

run until it stops.

Replace the oil while the engine is still warm.

Unscrew the spark plug and pour a tablespoonful

of oil into the cylinder. Rotate the engine a few

turns to that the oil is distributed in the cylinder.

Install the spark plug.

9

Page 10

EN

ENGLISH

Clean the entire machine. It is particularly

important to clean under the cutting deck. Touch

up paint damage to prevent rust.

Store the machine indoors in a dry place.

Machines with an electric starter:

Remove the battery. Store it well charged in a cool

place (between 0°C and +15°C).

At the correct storage temperature, the battery

should be maintenance-charged every four

months.

The battery acid is extremely corrosive

and can cause injuries and damage to

skin and clothing. Always use rubber

gloves and glasses (goggles) to protect

your eyes. Avoid inhaling any acid

vapour.

Do not incline the battery too much so

that the battery acid can run out onto

hands or clothing. If this should

happen, rinse with plenty of water.

4 ASSEMBLY

To avoid injury and damage to people

and property, do not use the machine

until all the measures in this instruction

have been carried out..

4.1 Accessories bag

The machine is supplied with a plastic bag containing components which shall be used during the assembly. The bag contains (fig. 1):

Pos. No. Designation Dimension

B Spare key

C 1 Tension pin 6 x 36

D 1 Shim washer 16 x 38 x 0.5

E 1 Shim washer 16 x 38 x 1.0

F 2 Shoulder washer

G 2 Screw 8 x 20

H 2 Screw knob

I 4 Washer 8.4 x 24 x 1.5

J 1 Drawing plate

K 4 Screw 8 x 20

L2Nut

M 2 Screw for battery

N 2 Nut for battery

O 2 Screw M10 x 35

P2Nut M10

Supplied installed on the front axles:

Pos No. Designation

Q 2 Lock pin

R2 Washer

Secure to the implement lifter:

Pos No. Designation

S 2 Deck mount

4.2 Engine casing

To fill with fuel and to inspect and maintain the engine and battery, open the engine casing.

The engine must not be running when

the casing is opened.

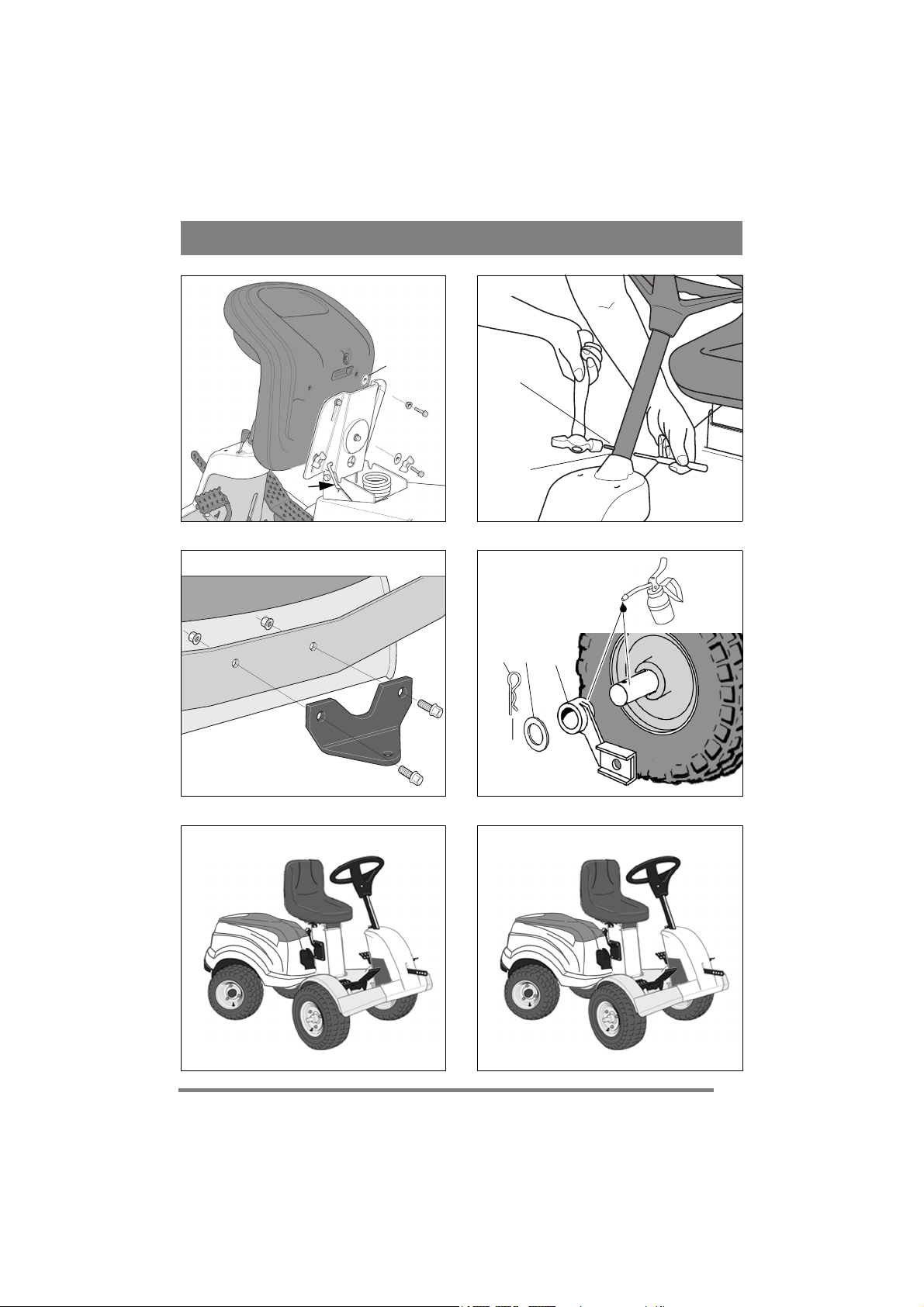

4.2.1Opening

1. Raise the seat lock (fig. 2) and fold the seat forwards.

2. Pull up the rubber strap at the front edge of the

casing (fig. 3).

3. Grasp the front edge of the engine casing and

fold up the casing (fig. 4).

4.2.2 Closing

1. Grasp the front edge of the engine casing and

fold down the casing (fig. 4).

2. Secure the front edge of the casing with the rubber strap (fig. 3).

The machine may not be operated unless the engine casing is closed and

locked. Risk of burns and crushing injuries.

4.3 Battery

See “8.8 Battery”.

4.4 Seat, fig. 6

Release the catch (S) and fold up the seat bracket.

Install the mounting in the rear (upper) holes as

follows:

1. Install the shoulder washers (F) on the screws

(K).

2. Insert the screws through the slots in the bracket. Place a washer (I) between the seat and the

bracket.

3. Tighten the screws in the seat. Tightening

torque: 9±1.7 Nm.

If the screws are tightened more than

9±1.7 Nm, the seat will be damaged.

4. Check that the seat moves easily in the slots in

the bracket.

Install the mounting in the front (lower) holes as

follows:

1. Install the screw knobs (H) on the screws (G).

2. Install a washer (I) on each screw.

3. Insert the screws through the slots in the bracket

and tighten by hand in the seat.

4. Fold the seat down and place it in the desired

position.

5. Tighten the screw knobs (H) by hand.

The screw knobs (H) and the seat will

be damaged if tools are used.

10

Page 11

ENGLISH

The seat can be folded. If the machine is parked

outside when it is raining, fold the seat forward to

protect the seat cushion from getting wet.

The seat is locked. To fold the seat up or down, release the catch (S).

4.5 Steering wheel

See fig. 7. In order to minimise the axial play in the

steering column, the shim washers (D) and/or (E)

must be installed on the steering column between

the steering column jacket and the bracket as follows.

1. Install the steering column jacket on the steering column and secure by knocking in the tension pin (C) approximately 1/3 of its length.

2. Pull the steering column jacket and the steering

column up.

3. From the outside, check whether no washers,

the 0.5 mm washer, the 1.0 mm washer or both

washers can be inserted into the gap. The washer/washers must not be forced in, as there must

be a little axial play.

4. Pull out the cotter pin and dismantle the steering

wheel jacket.

5. Install the washer/washers in accordance with

point 3 above.

6. Install the steering column jacket on the steering column and secure by knocking in the tension pin fully. Use a counterhold.

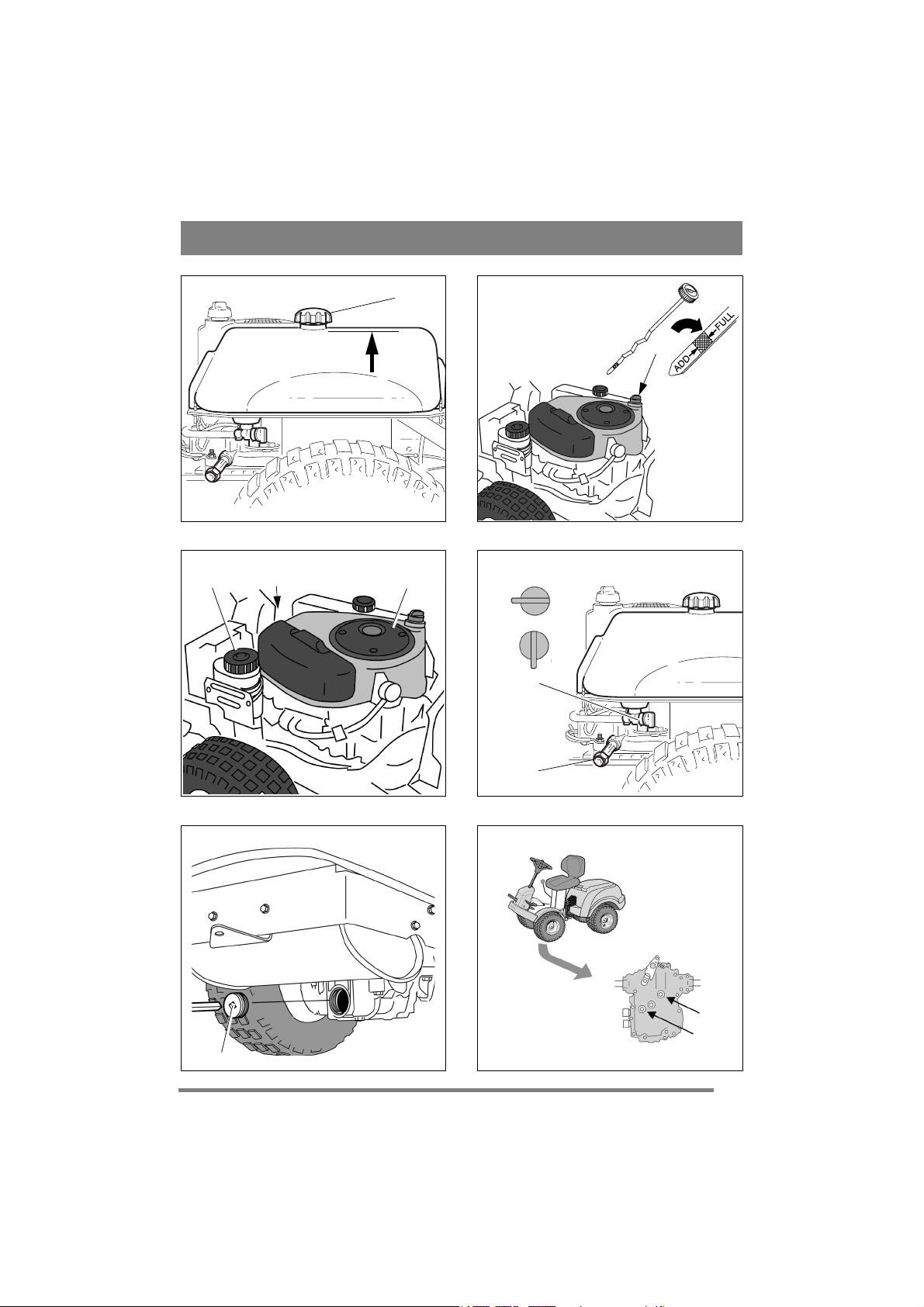

4.6 Towing hitch

See fig. 8. Screw the towing hitch (J) into the two

holes on the underside of the rear axle using screws

(L+K). Tighten the screws properly.

Tightening torque: 22 Nm.

4.7 Deck mounts

This only describes installation on the right-hand

axle. Same procedure must be carried out on the

left-hand axle.

1. Lubricate the axle ends and the deck mount’s

bearing surface with oil before installation.

2. Install the deck mounts to the machine according to fig. 9.

3. Install the locking pin (9:Q) in the hole in the

axle.

4.8 Tyre pressure

Check the air pressure in the tyres. Correct air

pressure:

Front: 0.6 bar (9 psi)

Rear: 0.4 bar (6 psi)

4.9 Accessories

For the installation of accessories, see separate installation guide supplied with each accessory.

Note: The cutting deck is regarded as an accessory

here.

EN

5 DESCRIPTION

5.1 Transmission

5.1.1 HST

The machine is rear wheel drive.

The rear axle is equipped with a hydrostatic trans-

mission with infinitely variable forward and reverse gear ratios.

The rear axle is also equipped with a differential to

facilitate turning.

Front mounted tools are driven by drive belts.

5.1.2 4WD

The machine has 4-wheel drive. The power from

the engine to the drive wheels is transferred hydraulically. The engine drives an oil pump, which

pumps oil through the rear and front axle drives.

The front axle and rear axle are connected in series, which means that the front wheels and rear

wheels are forced to rotate at the same speed.

To make turning easier, both axles are equipped

with differential.

Front-mounted implements are powered via drive

belts.

5.2 Steering

The machine is articulated. This means that the

chassis is divided into a front and a rear section,

which can be turned in relation to each other.

The articulated steering means that the machine

can turn around trees and other obstacles with an

extremely small turning radius.

5.3 Safety system

The machine is equipped with an electrical safety

system. The safety system interrupts certain activities that can entail a danger of incorrect manoeuvres. For example, the engine cannot be started if

the clutch-parking brake pedal is depressed.

The operation of the safety system must

always be checked every time before

use.

5.4 Controls

5.4.1 Implement lifter, mechanical (12:A)

To switch between working position and transport

position:

1. Depress the pedal fully.

2. Release the pedal slowly.

11

Page 12

EN

ENGLISH

5.4.2 Clutch-parking brake (12:B)

Never press the pedal while driving.

There is a risk of overheating in the

power transmission.

The pedal has the following

three positions:

• Released. The clutch is not activated. The parking brake is not activated.

• Depressed halfway. Forward drive disengaged.

The parking brake is not activated.

• Fully depressed. Forward drive disengaged.

The parking brake is fully activated but not

locked. This position is also used as emergency

brake.

5.4.3 Inhibitor, parking brake (12:C)

The inhibitor locks the “clutch-brake”

pedal in the depressed position. This function is used to lock the machine on slopes,

during transport, etc., when the engine is

not running.

Locking:

1. Depress the pedal (14:B) fully.

2. Move the inhibitor (14:C) to the right.

3. Release the pedal (14:B).

4. Release the inhibitor (14:C).

Unlocking:

Press and release the pedal (14:B).

5.4.4 Driving-service brake (12:F)

If the machine does not brake as expected when the pedal is released, the left

pedal (12:B) should be used as an emergency brake.

The pedal determines the gearing ratio between the

engine and the drive wheels (= the speed). When

the pedal is released, the service brake is activated.

1. Press the pedal forward –

the machine moves forward.

2. No load on the pedal – the machine is stationary.

3. Press the pedal backward –

the machine reverses.

4. Reduce the pressure on the

pedal – the machine brakes.

5.4.5 Throttle and choke control (12:D)

A control for setting the engine speed and to choke

the engine when starting from cold.

If the engine runs unevenly there is a

risk that the control is too far forward

so that the choke is activated. This damages the engine, increases fuel consumption and is harmful to the

environment.

1. Choke – for starting a cold engine. The

choke position is located at the front of the

groove.

Do not operate in this position when the

engine is warm.

2. Full throttle – when the machine is in

operation, full throttle should always be

used.

The full throttle position is approximately

2 cm behind the choke position.

3. Idling.

5.4.6 Ignition lock (12:E)

Do not leave the machine with the key

in position 2 or 3. There is a fire risk,

fuel can run into the engine through the

carburettor, and there is a risk of the

battery being discharged and damaged.

Ignition lock used for starting/stopping the engine.

Four positions:

1. Stop position – the engine is shortcircuited. The key can be removed.

2/3. Operating position.

4. Start position – the electric start motor

is activated when the key is turned to the

spring-loaded start position. Once the engine has started, let the key return to operating position 2/3.

5.4.7 Power take-off (13:G)

The power take-off must never be

engaged when the front-mounted

implement is in transport position. This

will destroy the belt transmission.

A lever for engaging and disengaging the power

take-off for operating front-mounted accessories.

Two positions:

1. Lever in forward position – power takeoff disengaged.

12

2. Lever in backward position - power

take-off engaged.

Page 13

ENGLISH

EN

5.4.8 Clutch release lever

A lever for disengaging the variable transmission.

HST is equipped with a lever, connected to the rear

axle. See (16:N).

4WD is equipped with two levers, connected to the

rear axle (17:O) and the front axle (17:P).

The disengagement lever must never be

between the outer and inner positions.

This overheats and damages the transmission.

The levers enable the machine to be moved by

hand without the help of the engine. Two positions:

1. Lever in the inner position –

transmission engaged for normal

operation.

2. Lever in the outer position –

transmission disengaged. The

machine can be moved by hand.

The machine may not be towed over long distances

or at high speeds. The transmission could be damaged.

The machine must not be operated with

the forward most lever in the outer position. Risk of damage and oil leakage in

the front axle.

5.4.9 Seat (14:I)

The seat can be folded and is adjustable

front-rear. The seat is locked in the folded

up position using the catch (14:K) and adjusted front-rear using the knobs (14:J).

The seat is equipped with a safety switch that is

connected to the machine’s safety system. This

means that certain dangerous activities are not possible when there is nobody in the seat.

5.4.10 Engine casing (15:L)

To access the fuel cock, battery and engine

the engine is equipped with engine casing

that can be opened. The engine casing is

locked by a rubber strap.

The engine casing is opened as follows:

1. Detach the rubber strap (15:M) at the front edge

of the engine casing.

2. Carefully lift the engine casing back.

Close in reverse order.

The machine may not be operated unless the engine casing is folded down

and locked. Risk of burns and crushing

injuries.

6 AREAS OF USE

The machine may only be used for the following

tasks using the genuine GGP accessories stated.

Operation Accessories, GGP original

Mowing With cutting deck 95 C (all).

Snow clearance With snow blade. Snow chains

Grass clipping and

leaf collection

Grass and leaf

transport

The maximum vertical load on the towing hitch

must not exceed 100 N.

The maximum over-run load on the towing hitch

from towed accessories must not exceed 500 N.

NOTE! Before using a trailer – contact your insurance company.

NOTE! This machine is not intended to be driven

on public roads.

With cutting deck 105 C (only

4155 H).

and frame weights recommended.

With towed collector 30" or 42".

With dump cart Pro or Combi.

7 STARTING AND OPERATION

The machine may not be operated unless the engine casing is closed and

locked. Risk of burns and crushing injuries.

7.1 Filling with petrol (18:Q)

Always use lead-free petrol. You must never use 2stroke petrol mixed with oil.

The tank holds 6 litres. The level can easily be read

through the transparent tank.

NOTE! Ordinary lead-free petrol is a perishable

and must not be stored for more than 30 days.

Environmental petrol can be used, i.e. alkylate

petrol. This type of petrol has a composition that is

less harmful for people and nature.

Petrol is highly inflammable. Always

store fuel in containers that are made

especially for this purpose.

Only fill or top up with petrol outdoors,

and never smoke when filling or topping up. Fill up with fuel before starting

the engine. Never remove the filler cap

or fill with petrol while the engine is

running or still warm.

13

Page 14

EN

ENGLISH

Never completely fill the petrol tank. Leave an

empty space (= at least the entire filler tube plus 1

- 2 cm at the top of the tank) to allow the petrol to

expand when it warms up without overflowing.

See fig. 18.

7.2 Checking the engine oil level

On delivery, the crankcase is filled with SAE 10W30 oil.

Check the oil level every time before using to

ensure it is correct. The machine should be

standing on level ground.

Wipe clean around the oil dipstick. Unscrew and pull it up. Wipe off the dipstick.

Slide it down completely and tighten it.

Then unscrew it and pull it up again. Read off the

oil level. Top up with oil to the “FULL” mark, if

the level comes below it. See fig. 19.

The oil level must never exceed the “FULL” mark.

This results in the engine overheating. If the oil

level exceeds the “FULL” mark, the oil must be

drained until the correct level is achieved.

7.3 Checking transmission oil level

Check the oil level every time before using to

ensure it is correct. The machine should be

standing on level ground.

Read off the oil level in the reservoir (20:R). It

should be between the MAX and MIN marks. If

necessary, top up with more oil.

Type of oil:

Oil type

4WD Synthetic oil 5W-50

HST SAE 10W-30 (20W-50)

7.4.1 General safety check

Object Result

Fuel lines and connections.

Electrical cables. All insulation intact.

Exhaust system. No leaks at connections.

Oil lines No leaks. No damage.

Drive the machine

forwards/backwards and release

the driving-service

brake pedal.

Test driving No abnormal vibrations.

7.4.2 Electrical safety check

The operation of the safety system

should always be checked every time

before use.

Status Action Result

The clutch-brake

pedal not

depressed.

Power take-off not

activated.

Engine running.

Power take-off

activated.

Engine running. Remove the fuse.

No leaks.

No mechanical damage.

All screws tightened.

The machine will stop.

No abnormal sound.

Attempt to start. The engine

The operator

leaves the seat.

See 20:S.

must not

start.

The power

take-off

must disengage.

The engine

must stop.

7.4 Safety checks

Check that the results of the safety checks below

are achieved when testing the machine in question.

The safety checks must always be carried out every time before use.

If any of the results below is not

achieved, the machine must not be

used! Take the machine to a service

workshop for repair.

14

7.5 Start

1. Open the fuel cock. See (21:U).

2. Check that the spark plug cable(s) is/are installed on the spark plug(s).

3. Check to make sure that the power take-off is

disengaged.

4. Do not keep your foot on the drive pedal.

5. Starting cold engine – put the throttle control in

the choke position.

Starting warm engine – put the throttle control

at full throttle (approx. 2 cm behind the choke

position).

6. Depress the clutch-brake pedal fully.

7. Turn the ignition key and start the engine.

8 Once the engine has started, move the throttle

control gradually to full throttle (approx. 2 cm

behind the choke position) if the choke has been

used.

Page 15

ENGLISH

EN

9. When starting from cold, do not make the machine work under load immediately, but let the

engine run for a few minutes first. This will allow the oil to warm up.

When the machine is in operation, full throttle

should always be used.

7.6 Operating tips

Always check that there is the correct volume of

oil in the engine. This is particularly important

when operating on slopes. See 7.2 Checking the

engine oil level.

Be careful when driving on slopes. No

sudden starting or stopping when driving up or down a slope. Never drive

across a slope. Move from the top down

or from the bottom to the top.

The machine may not be driven on

slopes greater than 10º in any direction.

Reduce the speed on slopes and when

making sharp turns in order to retain

control and reduce the risk of tipping

over.

Do not turn the steering wheel to full

lock when driving in top gear and at full

throttle. The machine can easily topple

over.

Keep hands and fingers well away from

articulated steering joint and seat

bracket. Risk of crushing injuries. Never drive with the engine casing open.

7.7 Stop

Disengage the power take-off. Apply the parking

brake.

Allow the engine to idle 1-2 mins. Stop the engine

by turning off the ignition key.

Shut off the petrol cock. This is particularly important if the machine is to be transported on a trailer

for example.

If the machine is left unattended, remove the spark plug cable(s) and remove the ignition key.

The engine may be very warm immediately after it is shut off. Do not touch the

silencer, cylinder or cooling fins. This

can cause burn injuries.

7.8 Cleaning

To reduce the risk of fire, keep the engine, silencer, battery and fuel tank free

from grass, leaves and oil.

To reduce the risk of fire, regularly

check the machine for oil and/or fuel

leakage.

Clean the machine after each use. The following

instructions apply for cleaning:

• When washing the machine with water under

high pressure, do not point the jet directly at

axle seals, electrical components or hydraulic

valves.

• Do not spray water directly at the engine.

• Clean the engine with a brush and/or compressed air.

• Clean the engine’s cooling air intake (20:T).

8 MAINTENANCE

8.1 Service programme

In order to keep the machine in good condition as

regards reliability and operational safety as well as

from an environmental perspective, GGP’s Service

programme should be followed.

Servicing carried out at an authorised workshop

guarantees professional work using genuine spare

parts.

8.2 Preparation

All service and all maintenance must be carried out

on a stationary machine with the engine switched

off.

Prevent the machine from rolling by always applying the parking brake.

Stop the engine.

Prevent unintentional starting of the

engine by disconnecting the spark plug

cable(s) from the spark plug(s) and removing the ignition key.

8.3 Tyre pressure

Adjust the air pressure in the tyres as follows:

Front: 0.6 bar (9 psi).

Rear: 0.4 bar (6 psi).

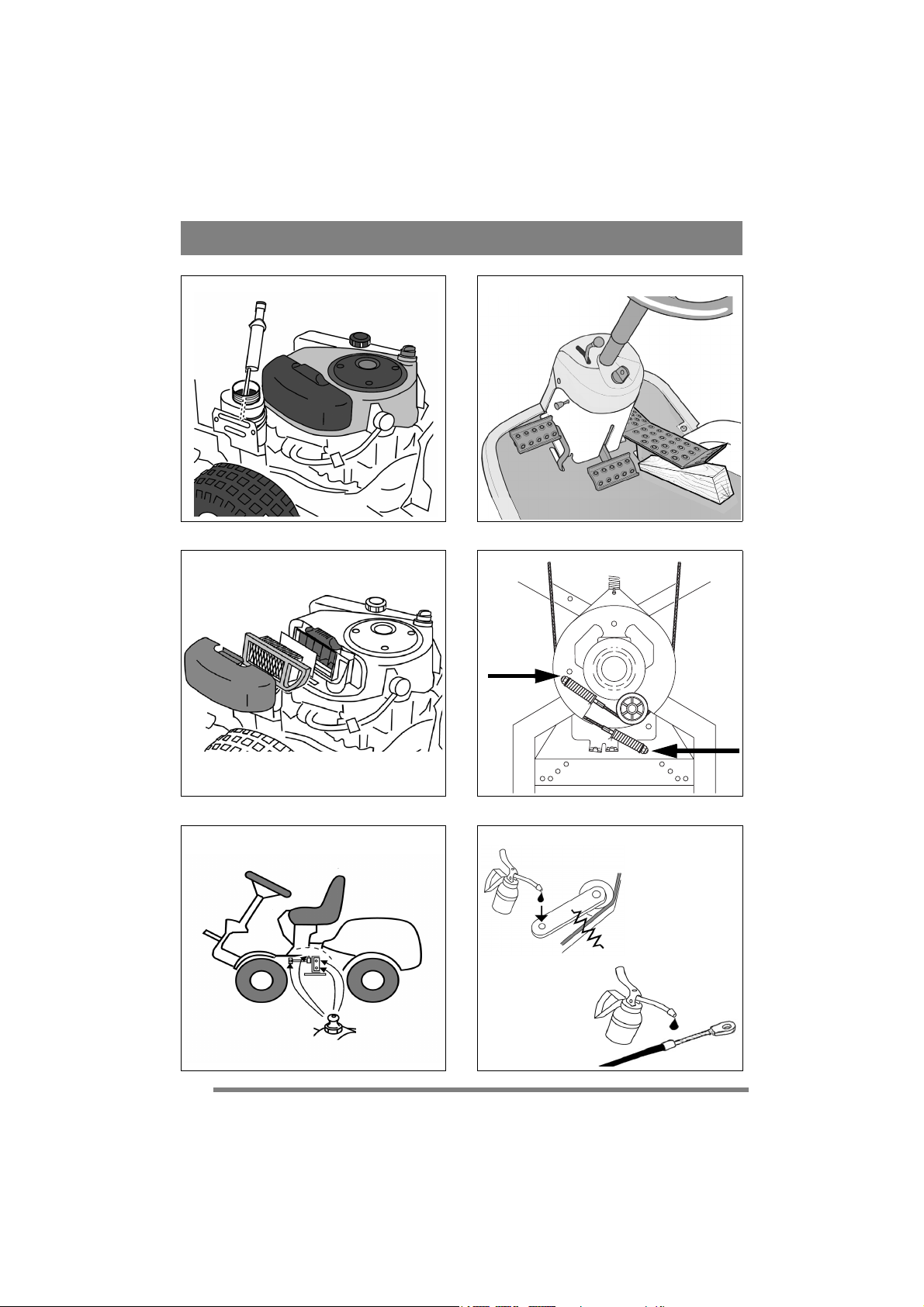

8.4 Changing engine oil

Change engine oil for the first time after 5 hours of

operation, and subsequently after every 50 hours

of operation or once a season.

Change the oil more often (after 25 hours of operation or at least once a season) if the engine has to

operate under demanding conditions or if the ambient temperature is high.

Use oil according to the table below.

Oil SAE 10W-30

Service class SJ or higher

Use oil without any additives.

15

Page 16

EN

ENGLISH

Do not fill with too much oil. This can cause the

engine to overheat.

Change oil when the engine is warm.

The engine oil may be very hot if it is

drained off directly after the engine is

shut off. Therefore allow the engine to

cool a few minutes before draining the

oil.

1. Attach the clamp on the oil drainage hose. Use

a polygrip or similar. See fig. (21:V).

2. Move the clamp up 3-4 cm on the oil drainage

hose and pull out the plug.

3. Collect the oil in a collection vessel.

NOTE! Do not spill any oil on the drive belts.

4. Hand in the oil for disposal in accordance with

local provisions.

5. Install the oil drainage plug and move the clamp

back so that it clamps above the plug.

6. Remove the dipstick and fill up with new oil.

Oil volume: 1.4 litres

7. After filling up the oil, start the engine and idle

for 30 seconds.

8. Check to see if there is any oil leakage.

9. Stop the engine. Wait for 30 seconds and then

check the oil level in accordance with 7.2

Checking the engine oil level.

8.5 Transmission, oil (4WD)

The oil in the hydraulic power transmission must

be checked/adjusted and changed at the intervals

given in the table below.

1st time Then at

Action

Hours of operation

Checking – adjusting level. - 50

Changing the oil. 50 200

Type of oil: Synthetic oil 5W-50

Oil quantity when changing: approximately 3.5 li-

tres.

8.5.1 Checking - adjusting

Se “7.2 Checking the engine oil level”.

8.5.2 Draining

1. Run the machine at variable speeds for 10-20

minutes to heat up the transmission oil.

2. Position the machine completely horizontally.

3. Pull out both disengagement levers according to

fig. 17.

4. Place one container under the rear axle and one

under the front axle.

5. Open the oil reservoir by removing the cover.

See (20:R).

intervals

of

Only a 3/8” square drive may be used

for the oil plug. Other tools will damage

the plug.

6. Remove the oil plug from the rear axle. Clean

the hole and use a 3/8” square drive. See figure

22.

7. Remove 2 drain plugs from the front axle. Use

a 12 mm socket. Allow the oil in the front axle

and pipes to run out. See fig. 23.

8. Check that the gaskets on the drain plugs of the

front axle are intact. See fig. 23. Reinstall the

plugs. Tightening torque: 15-17 Nm.

The oil plug will be damaged if it is

tightened more to than 5 Nm.

9. Check that the gasket on the oil plug of the rear

axle is intact. See fig. (22:Y). Reinstall in the

rear axle. Tighten the oil plug to 5 Nm.

10.Draw out the oil from the deeper section of the

reservoir using an oil extractor. See fig. 24.

11.Dispose of the oil according to local regulations.

8.5.3 Filling

The engine must never be run when the

rear clutch release lever is pushed in

and the front clutch release lever is

pulled out.

This will damage the front axle seals.

1.Fill the oil reservoir with the new oil.

If the engine is run indoors, exhaust extraction equipment must be connected

to the engine’s exhaust pipe.

2. Check that the rear axle’s clutch release lever is

pulled out.

3. Start the engine. When the engine is started, the

front axle’s clutch release lever slides inwards

automatically.

4. Pull out the front axle’s clutch release lever.

NOTE! The oil is drawn into the system very

quickly. The reservoir must always be

topped up. Air must never be drawn in.

5. Set the accelerator pedal to the forward position

by blocking it using a wooden wedge. See fig.

25. Fill the oil reservoir by hand using new oil.

6. Run in the forward position for one minute.

7. Move the wooden wedge and set the accelerator

pedal to the reverse position. Continue filling

with oil.

8. Run in reverse mode for one minute.

9. Change driving direction once every minute as

above and continue filling with oil until the

bubbling in the reservoir stops.

10.Switch off the engine, install the oil reservoir

cover and close the engine cover.

11.Test drive for several minutes and adjust the oil

level in the reservoir.

16

Page 17

ENGLISH

EN

8.6 Belt transmissions

After 5 hours of operation, check that all the belts

are intact and undamaged.

8.7 Steering

The steering must be checked/adjusted after 5

hours of operation and thereafter after 100 hours of

operation.

8.7.1 Checks

Briefly turn the steering wheel back and forth.

There must be no mechanical clearance in the

steering chains.

8.7.2 Adjustment

Adjust the steering chains if required as follows:

1. Put the machine in the straight-ahead position.

2. Adjust the steering chains with the two nuts, located under the central point. See fig. 27.

3. Adjust both nuts by the same amount until there

is no clearance.

4. Test drive the machine straight forwards and

check that the steering wheel is not off centre.

5. If the steering wheel is off centre, undo one nut

and tighten the other.

Do not over-tighten the steering chains. This will

cause the steering to become heavy and will increase wear on the steering chains.

8.8 Battery

If acid comes into contact with the eyes

or skin, this can cause serious injuries.

If any part of the body has come into

contact with acid, rinse immediately

with copious amounts of water and seek

medical assistance as soon as possible.

The battery is a valve-regulated battery with 12 V

nominal voltage. The battery fluid does not need to

and cannot be checked or topped up. The only

maintenance that is required is charging, for example after extended storage.

The battery must be fully charged before being used for the first time. The

battery must always be stored fully

charged. If the battery is stored while

discharged, serious damage will occur.

8.8.1 Charging with the engine

The battery can be charged using the engine’s generator as follows:

1. Install the battery in the machine as shown below.

2. Place the machine outdoors or install an extraction device for the exhaust fumes.

3. Start the engine according to the instructions in

the user guide.

4. Allow the engine to run continuously for 45

minutes.

5. Stop the engine. The battery will now be fully

charged.

8.8.2 Charging using battery charger

When charging using a battery charger, a battery

charger with constant voltage must be used.

Contact your dealer to purchase a battery charger

with constant voltage.

The battery can be damaged if a standard type

battery charger is used.

8.8.3 Removal/Installation

The battery is placed under the engine casing. During removal/installation, the following applies regarding connection of the cables:

• During removal. First disconnect the black cable from the battery’s negative terminal (-).

Then disconnect the red cable from the battery’s

positive terminal (-).

• During installation. First connect the red cable

to the battery’s positive terminal (+). Then connect the black cable to the battery’s negative terminal (-).

If the cables are disconnected/connected in the wrong order, there is a risk of

a short-circuit and damage to the battery.

If the cables are interchanged, the generator and the battery will be damaged.

Tighten the cables securely. Loose cables can cause a fire.

The engine must never be driven with

the battery disconnected. There is a risk

of serious damage to the generator and

the electrical system.

8.8.4 Cleaning

If the battery terminals are coated with oxide, they

should be cleaned. Clean the battery terminals with

a wire brush and lubricate them with terminal

grease.

8.9 Air filter, engine

The pre-filter (foam filter) must be cleaned/replaced after 25 hours of operation.

The air filter (paper filter) must be cleaned/replaced after 100 hours of operation.

NOTE! The filters should be cleaned/replaced

more often if the machine operates on dusty

ground.

Remove/install the air filters as follows.

1. Clean carefully around the air filter cover.

2. Dismantle the air filter cover (26:A) by removing the two clamps.

17

Page 18

EN

ENGLISH

3. Dismantle the filter assembly (26:B). The prefilter is placed over the air filter. Make sure that

no dirt gets into the carburettor. Clean the air filter housing.

4. Clean the paper filter by tapping it gently

against a flat surface. If the filter is very dirty,

replace it.

5. Clean the pre-filter. If the filter is very dirty, replace it.

6. Assemble in the reverse order.

Compressed air or petroleum-based solvents such

as kerosene may not be used for cleaning the paper

filter insert. This will damage the filter.

8.10 Spark plug

The spark plug(s) must be replaced every 200

hours of operation (=at every other basic service).

Before disconnecting the spark plug, clean around

its mounting.

Spark plug

Electrode distance

: Champion RC12YC or equivalent.

: 0.75 mm.

8.11 Air intake

See 19:T. The engine is air-cooled. A blocked

cooling system can damage the engine. Clean the

engine’s air intake after 50 hours of operation.

More meticulous cleaning of the cooling system is

carried out during each basic service.

8.12 Lubrication

All lubrication points in accordance with the table

below must be lubricated every 50 hours of operation as well as after every wash.

Object Action Figure

Centre point 4 grease nipples.

Steering

chains

Tensioning

arms

Control

cables

Use a grease gun filled with

universal grease. Pump until

the grease emerges.

Brush the chains clean with

a wire brush.

Lubricate with universal

chain spray.

Lubricate the bearing points

with an oil can when each

control is activated.

Ideally carried out by two

people.

Lubricate the cable ends

with an oil can when each

control is activated.

Must be carried out by two

people.

28

-

29

29

8.13 Fuse

In the event of electrical faults, check/replace the

fuse, 20 A. See 20:S.

9 PATENT - DESIGN REGISTRA-

TION

This machine or parts thereof is covered by the following patent and design registration:

SE9901091-0, SE9901730-3, SE9401745-6,

US595 7497, FR772384, DE69520215.4,

GB772384, SE0301072-5, SE04/000239 (PCT),

SE0401554-1, SE0501599-5.

10 SERVICE

Authorised service workshops carry out repairs

and guarantee service. They use original spare

parts.

Original spare parts are supplied by service

workshops and by Many dealers.

We recommend that the machine be handed in to

an authorised service workshop for service,

maintenance and checking of the safety devices

once a year.

11 PURCHASE TERMS

A full guarantee is issued against Manufacturing

and material defects. The user must carefully follow the instructions given in the enclosed documentation.

Guarantee period

For consumer use: two years from purchase date.

For batteries: six months from the purchase date.

Exceptions

The guarantee does not cover damage due to:

- neglect of the user to acquaint himself with accompanying documentation

- carelessness

- incorrect and non-permitted use or assembly

- the use of non-genuine spare parts

- the use of accessories not supplied or approved

by GGP

Neither does the guarantee cover:

- wearing components such as blades, belts,

wheels and cables

- normal wear

- engine and transmission. These are covered by

the appropriate Manufacturer’s guarantees with

separate terms and conditions.

The purchaser is covered by each country’s

national laws. The rights to which the purchaser is

entitled with the support of these laws are not

restricted by this guarantee.

18

Page 19

ENGLISH

EN

12 ENVIRONMENT

For environmental reasons, we recommend that

particular attention is given to the following

points:

• Always use Alkylate petrol (“Environmental

petrol“).

• Always use a funnel and/or a petrol can with

overfill protection to avoid spillage when filling

with petrol.

• Do not fill the petrol tank right to the top.

• Do not fill too much engine and/or transmission

oil (see user instructions for the correct

amount).

• Collect up all oil during oil changes. Do not

spill any. Hand in the oil to a recycling station.

• Do not discard replaced oil filters with normal

rubbish. Hand them in to a recycling station.

• Do not discard replaced lead batteries with

normal rubbish. Hand in to a battery collection

point for recycling.

• Replace the silencer if it is broken. Always use

original spare parts when carrying out repairs.

• If the machine was originally equipped with a

catalytic converter and this is broken, a new

catalytic converter must be installed after

removing the old one.

• Always get a specialist to adjust the carburettor

if necessary.

Clean the air filter according to the instructions

given (see user instructions).

13 PRODUCT IDENTITY

The identity of the product is determined by two

parts:

1. The machine’s item and serial numbers:

2. The engine’s model, type and serial numbers:

Found on the machine’s fan housing as illustrated:

Use these identification terms during all contact

with service workshops and when purchasing

spare parts.

As soon as possible after acquiring the machine,

the above number should be written in on the last

page of this publication.

GGP reserves the right to make alterations to the

product without prior notification.

19

Page 20

FR

FRANÇAIS

1 GÉNÉRALITÉS

Ce symbole est un AVERTISSEMENT.

Risque de blessure ou de dégât matériel

en cas de non-respect des instructions.

Avant de démarrer la machine, lire attentivement les instructions ainsi que

les consignes contenues dans le fascicule

« RÈGLES DE SÉCURITÉ » ci-joint.

1.1 Symboles

Les symboles suivants figurent sur la machine. Ils

attirent votre attention sur les dangers et les

mesures à respecter lors de l’utilisation et de la

maintenance.

Explication des symboles :

Attention!

Lire le mode d’emploi et le manuel de sécurité avant d’utiliser la machine.

Attention!

Attention aux projections. Travailler à une

distance suffisante de toute présence.

Attention !

Porter des protections auditives.

Attention !

Cet engin n’est pas conçu pour circuler sur

la voie publique.

Attention !

La machine, équipée d’accessoires d’origine, ne peut en aucun cas être utilisée sur

des pentes dont l’inclinaison est

supérieure à 10°.

Attention !

Risque de blessure par écrasement. Garder

les mains et les pieds à distance du joint de

direction articulé.

Attention !

Ne pas les toucher sous peine de se brûler.

Ne pas toucher le silencieux ou le convertisseur catalytique.

1.2 Désignation

Park Compact existe en 3 versions :

Machine

4135 H à transmission hydrostatique.

4155 H à transmission hydrostatique.

4155 H à transmission hydrostatique et quatre roues motrices.

Désignation

HST

HST

4WD

1.3 Références

1.3.1 Numérotation

Dans les instructions qui suivent, les figures sont

numérotées 1, 2, 3, etc.

Les composants illustrés sont indiqués par A, B, C,

etc.

Une référence renvoyant à l’élément C de la figure

2 sera indiqué « 2:C ».

1.3.2 Titres

Les titres sont numérotés selon l’exemple suivant :

« 1.3.1 Contrôle de sécurité générale » est un sous-

titre intégré au chapitre « 1.3 Contrôles de sécurité

».En principe, lorsqu’on renvoie à un titre, seul son

numéro est indiqué, par ex. « Voir 1.3.1 ».

2 RÈGLES DE SÉCURITÉ

2.1 GÉNÉRALITÉS

• Veuillez lire attentivement les instructions qui

suivent et apprendre les commandes et le

maniement correct de la machine avant de

l’utiliser.

• Les utilisateurs de la tondeuse doivent suivre

une formation pratique préalable. Soyez

particulièrement attentif au fait que :

a. L’utilisation de tondeuses autoportées

requiert de l’attention et de la concentration.

b. Si on perd le contrôle d’une tondeuse

autoportée sur un terrain en pente, il est

impossible de le récupérer en freinant.

Principales causes des pertes de contrôle :

traction insuffisante, vitesse excessive, freinage

insuffisant, machine inadaptée à la tâche à

exécuter, manque d’attention sur les

irrégularités du terrain et présence d’une

remorque.

• Ne jamais confier l’utilisation de la tondeuse à

des enfants ou à des personnes

inexpérimentées. L’âge minimum du

conducteur est déterminé par les

réglementations locales.

• Ne pas tondre à proximité de personnes, en

particulier des enfants, ou d’animaux.

• Le conducteur de l’engin assume seul la

responsabilité des accidents impliquant des

personnes ou des biens.

• Ne pas embarquer de passagers à bord de la

tondeuse. Ils pourraient se blesser en cas de

chute ou gêner les manœuvres du conducteur.

• Ne pas conduire la machine sous l’influence de

l’alcool, de drogues, de substances

médicamenteuses, ni en cas de fatigue ou de

malaise.

20

Page 21

FRANÇAIS

FR

2.2 PRÉCAUTIONS

• Pour utiliser la machine, le port de chaussures

renforcées et d’un pantalon est recommandé.

Ne pas tondre à pieds nus ou en sandales.

• Porter des vêtements appropriés. Ne pas porter

de vêtements amples ou flottants, de bijoux,

écharpes, cravates, etc. susceptibles de se

prendre dans les pièces en rotation. Attacher les

cheveux longs.

• Contrôler attentivement la zone à tondre ou à

déneiger. Retirer toutes les pierres, bouts de

bois, fils de fer et autres objets étrangers qui

pourraient être éjectés par la machine.

• Attention – l’essence est très inflammable.

a. Toujours conserver l’essence dans des

récipients spécialement conçus à cet effet.

b. Faire le plein d’essence uniquement à

l’extérieur, et ne pas fumer pendant l’opération.

c. Faire le plein d’essence avant de démarrer le

moteur. Ne jamais retirer le bouchon du

réservoir et ne pas ajouter d’essence lorsque le

moteur tourne ou tant qu’il est chaud.

d. Si de l’essence se répand, ne pas démarrer le

moteur. Déplacer la tondeuse en la poussant

pour l’éloigner de la flaque d’essence et veiller

à ce qu’aucune étincelle ne se produise tant que

l’essence ne s’est pas évaporée.

e. Ne pas oublier de revisser le bouchon du

réservoir et du jerrycan après avoir fait le plein.

• Remplacer les pots d’échappement défectueux.

• Avant l’emploi, vérifier l’état des lames et de

leur support. Si ces éléments sont usés ou

endommagés, les remplacer complètement pour

conserver l’équilibre du dispositif.

• La batterie (sur les machines à démarreur

électrique) dégage des gaz explosifs. La

conserver à l’écart des étincelles, flammes et

cigarettes. Veiller à une bonne aération pendant

que la batterie est en charge.

• La batterie contient des matériaux toxiques.

Veiller à ne pas l’endommager. Si l’extérieur de

la batterie est endommagé, éviter tout contact

avec son contenu.

• Ne pas jeter les batteries usées ou défectueuses

dans les poubelles. Renseignez-vous auprès de

votre administration pour savoir comment vous

en débarrasser en respectant l’environnement.

• Ne pas provoquer de court-circuit dans la

batterie. Cela provoquerait des étincelles

susceptibles de mettre le feu.

2.3 CONDUITE

• Suivre les instructions du manuel pour démarrer

le moteur. Tenir les pieds à l’écart des lames.

• Ne pas démarrer le moteur dans des espaces

confinés où il existe un risque d’intoxication au

monoxyde de carbone.

• Utiliser la machine uniquement à la lumière du

jour ou dans des zones bien éclairées.

• Porter des protections auditives.

• Redoubler de vigilance à proximité d’obstacles

qui masquent la vue.

• Tenir les enfants à l’écart, sous la surveillance

d’un adulte.

• Faire attention en changeant de direction.

Regarder derrière soi avant et pendant la

marche arrière pour vérifier l’absence

d’obstacles. Faire particulièrement attention aux

enfants en bas âge.

• Débrayer les lames et se mettre au point mort

avant de démarrer le moteur.

• Ne pas approcher les mains et les pieds des

pièces en rotation. Attention aux lames. Ne pas

se tenir devant l’orifice d’évacuation.

• Éviter de tondre les pelouses humides.

• Être particulièrement vigilant sur les terrains en

pente. Ne pas démarrer ou s’arrêter brutalement

sur un terrain en pente.

• Débrayer progressivement. Rester en vitesse

pendant toute la conduite et ne pas débrayer en

descente.

• Ne jamais tondre en suivant une trajectoire

transversale à la pente. Se déplacer de haut en

bas, et de bas en haut.

• Accélérer lentement pour engager une vitesse,

surtout si la pelouse est haute. Ralentir dans les

pentes et dans les virages pour éviter de

basculer ou de perdre le contrôle de la machine.

• Éviter les trous dans le sol et les autres dangers

potentiels.

• Rester à distance des fossés et des bordures

hautes. La machine risque de se renverser si la

roue passe sur la bordure ou si la bordure

s’effondre.

• Prudence en cas de remorquage et d’utilisation

de matériel lourd.

• a. N’utiliser que des dispositifs de

remorquage agréés.

• b. Limiter la charge pour en garder le

contrôle en toute sécurité.

• c. Ne pas effectuer de virage brusque. Faire

attention en changeant de direction.

• d. Placer des poids sur les roues ou à l’avant

de la tondeuse. Voir manuel.

• Faire preuve de prudence à l’approche d’un

carrefour ou d’une route.

• Arrêter les lames sur les surfaces autres que de

la pelouse.

• Lorsque des accessoires sont montés sur la

21

Page 22

FR

FRANÇAIS

tondeuse, ne jamais diriger l’évacuation vers

des personnes se trouvant dans les parages.

Écarter toute présence à proximité d’une

tondeuse en marche.

• Ne jamais utiliser la machine si les protections

et dispositifs de sécurité sont insuffisants.

• Il est interdit de déconnecter les dispositifs de

sécurité ou d’en empêcher le fonctionnement.

Vérifier l’état des dispositifs de sécurité avant

chaque utilisation de la machine.

• Ne pas modifier le réglage du moteur. Ne pas

pousser le moteur à plein régime. Le risque de

blessure augmente lorsque le moteur tourne à

plein régime.

• Certains éléments du moteur chauffent pendant

l’utilisation. Ne pas les toucher sous peine de se

brûler.

• Avant de quitter le siège du conducteur :

• a. Neutraliser la prise de force et abaisser les

accessoires.

• b. Engager le point mort et serrer le frein à

main.

• c. Arrêter le moteur et retirer la clé.

• Utiliser exclusivement des accessoires

approuvés par le fabricant.

• Ne pas utiliser la machine si les accessoires/

outils ne sont pas fixés sur le châssis prévu à cet

effet. L’utilisation de la tondeuse sans

accessoires peut réduire sa stabilité.

• Attention : les bacs de ramassage et autres

accessoires peuvent réduire la stabilité de la

machine, surtout sur les terrains en pente.

• Immobiliser les accessoires, couper le moteur et

débrancher la bougie ou enlever la clé du

démarreur pour :

• a. Retirer les branchages et autres éléments qui

bouchent l’évacuation.

• b. Inspecteur, nettoyer ou entretenir la machine.

• c. Vérifier les éventuels dégâts et procéder aux

réparations qui s’imposent avant de pouvoir

réutiliser la machine à la suite d’un impact avec

un corps étranger.

• d. Inspecter la machine si elle se met à vibrer

excessivement. (Vérifier immédiatement.)

• Immobiliser les accessoires pendant le transport

ou lorsque la machine est arrêtée.

• Couper le moteur et immobiliser les accessoires

avant de :

• a. faire le plein de carburant.

• b. retirer le bac de ramassage.

• c. régler la hauteur, pour autant que cette

opération ne puisse s’effectuer sans quitter le

siège du conducteur.

• Ralentir avant de couper le moteur. Si l’arrivée

d’essence est équipée d’un robinet d’arrêt,

fermer celui-ci à la fin du travail.

• Attention : sur les plateaux à lames multiples,

une lame peut en entraîner une autre dans sa

rotation.

• La machine, équipée d’accessoires d’origine,

ne peut en aucun cas être utilisée sur des pentes

dont l’inclinaison est supérieure à 10°.

• Les lames originales ne peuvent être

remplacées par des systèmes d’autres marques

conçus, par ex. pour la scarification de la

mousse. En cas d’utilisation de ces systèmes, la

garantie cesse d’être valable. En outre,

l’utilisation de matériel non conforme

représente un danger pour les personnes et les

biens.

• Le chargement et déchargement de la machine

sur un tracteur ou un camion doit s’effectuer

avec prudence.

2.4 MAINTENANCE ET REMISAGE

• Serrer tous les boulons et vis pour assurer la

sécurité de la machine.

• Contrôler régulièrement le serrage des vis des

lames.

• Contrôler régulièrement le fonctionnement des

freins. L’entretien et l’éventuelle réparation des

freins est un point vital.

• Ne pas stationner la machine à l’intérieur si son

réservoir contient du carburant dont les

émanations sont susceptibles d’entrer en

contact avec des flammes nues ou des

étincelles.

• Laisser refroidir le moteur avant de ranger la

machine dans un local.

• Pour réduire le risque d’incendie, dégager

l’herbe, les feuilles et l’excédent d’huile se

trouvant sur le moteur, le pot d’échappement, la

batterie et le réservoir.

• Vérifier régulièrement l’état du bac de ramassage.

• Pour garantir la sécurité, remplacer les pièces

usées ou endommagées.

• N’utiliser que des pièces d’origine.

L’utilisation d’autres types de pièces de

rechange, même si elles s’adaptent à la

machine, peut se révéler dangereuse.

• Remplacer les autocollants d’avertissement et

d’instructions devenus illisibles.

• Si la machine n’est pas pourvue d’un dispositif

de blocage pour le transport, le plateau de coupe

doit être abaissé lorsque la machine est

stationnée, rangée ou laissée sans surveillance.

• La vidange éventuelle du réservoir de carburant

doit s’effectuer à l’extérieur.

22

Page 23

FRANÇAIS

FR

• La machine doit être entreposée hors de portée

des enfants.

• La batterie contient de l’acide. En cas de

surcharge ou de dégâts, il peut y avoir une fuite

d’acide.

• Ne jamais surcharger la batterie pour éviter

qu’elle explose en projetant de l’acide dans tous

les sens.

• Les projections d’acide dans les yeux ou sur la

peau peuvent provoquer des blessures graves.

En cas de contact avec de l’acide, rincer

abondamment à l’eau claire et consulter le plus

rapidement possible un médecin.

• L’inhalation de vapeurs d’acide peuvent

provoquer des lésions des muqueuses et des

organes internes. Consulter un médecin en cas

d’inhalation.

• L’acide peut endommager sérieusement les

outils, vêtements et autres éléments. Rincer

immédiatement tout acide renversé.

• Ne pas provoquer de court-circuit aux bornes de

la batterie. Cela provoquerait des étincelles

susceptibles de mettre le feu. Éviter également

tout contact entre les bijoux en métal et les

bornes de la batterie.

• Si l’extérieur, le couvercle ou les bornes de la

batterie sont endommagés ou qu’il y a des

interférences au niveau des barrettes de

connexion, remplacer immédiatement la

batterie.

2.5 REMISAGE

Vidanger le réservoir d’essence. Démarrer le

moteur et le laisser tourner jusqu’à ce qu’il

s’arrête.

Faire la vidange d’huile lorsque le moteur est

encore chaud.

Dévisser la bougie et verser une cuiller d’huile

dans le cylindre. Donner quelques tours au moteur

pour que l’huile se répartisse dans le cylindre.

Remettre la bougie.

Nettoyer entièrement la machine. Une attention

particulière doit être apportée à la propreté du

plateau de coupe. Mettre une peinture antirouille

sur les éclats.

Entreposer la machine dans un local sec.

Machines à allumage électrique :

Retirer la batterie. La conserver bien chargée dans

un endroit frais (entre 0 °C et +15 °C).

Si la température de stockage est correcte,

entretenir la batterie en la rechargeant tous les

quatre mois.

La batterie contient des acides très

corrosifs, agressifs pour la peau et les

vêtements. Porter des gants en

caoutchouc et des lunettes de

protection. Ne pas inhaler les vapeurs

d’acides.

Ne pas trop incliner la batterie pour

éviter que de l’acide ne s’en échappe et

coule sur les mains ou les vêtements. En

cas de contact avec l’acide, rincer

abondamment à l’eau.

3 ASSEMBLAGE

Pour éviter les risques de blessures ou

de dégâts matériels, ne pas utiliser la

machine avant d’avoir exécuté toutes

les instructions.

3.1 Accessoires

La machine est livrée avec un sac en plastique qui

contient des éléments à installer avant la première

utilisation. Le sac contient (fig. 1) :

Pos. N° Désignation Dimensions

B Clé supplémentaire

C 1 Goupille de tension 6 x 36

D 1 Rondelle de réglage 16 x 38 x 0,5

E 1 Rondelle de réglage 16 x 38 x 1,0

F 2 Rondelle de butée

G 2 Vis 8 x 20

H2 Papillon

I 4 Rondelle 8,4 x 24 x 1,5

J 1 Plaque d’accouplement

K 4 Vis 8 x 20

L 2 Écrou.

M 2 Rondelle de butée

N 2 Écrou pour batterie

O 2 Vis M10 x 35

P 2 Écrou M10

Installé sur l’essieu avant à la livraison:

Pos n° Désignation

Q 2 Goupille

R 2 Rondelle

Attaché au dispositif de levage :

Pos n° Désignation

S 2 Montant du plateau

3.2 Carter de moteur

Pour faire le plein de carburant et procéder à l’inspection et à l’entretien du moteur et de la batterie,

ouvrir le carter de moteur.

Le moteur doit être coupé pour ouvrir

le carter.

23

Page 24

FR

FRANÇAIS

3.2.1 Ouverture

1. Rabattre le siège vers l’avant en levant le dispositif de verrouillage (fig. 2).

2. Tirer vers le haut la sangle en caoutchouc située

à l’avant du carter (fig. 3).

3. Saisir l’avant du carter moteur et le soulever

(fig. 4).

3.2.2 Fermeture

1. Saisir l’avant du carter moteur et le refermer

(fig. 4).

2. Attacher l’avant du carter au moyen de la sangle

(fig. 3).

Ne pas utiliser la machine si le capot du

moteur n’est pas fermé et verrouillé.

Risque de brûlure et de blessure par

écrasement.

3.3 Batterie

Voir ““Batterie” 7.8”.

3.4 Siège fig. 6

Relâcher la sécurité (S) et replier le support du

siège.

Visser le support par les orifices arrière

(supérieurs), comme suit :

1. Mettre les rondelles (F) sur les vis (K).

2. Guider les vis par les encoches du support.

Placer une rondelle (I) entre le siège et le support.

3. Serrer les vis dans le siège. Couple de serrage :

9±1,7 Nm.

Serrer davantage les vis endommagera

le siège.

4. Vérifier que le siège coulisse facilement dans

les encoches du support.

Visser le support par les orifices arrière (inférieurs), comme suit :

1. Placer les papillons (H) sur les vis (G).

2. Placer une rondelle (I) sur chaque vis.

3. Guider les vis par les encoches du support et les

engager à la main.

4. Rabattre le siège et le placer dans la position

souhaitée.

5. Serrer les papillons (H) à la main.

Ne pas utiliser d’outils sous peine d’endommager les papillons (H) et le siège.

Le siège est rabattable. Si la machine reste à l’extérieur sous la pluie, rabattre le siège pour éviter de

mouiller les coussins.

Le siège possède un dispositif de verrouillage.

Pour le replier, tirer la sécurité (S) vers le haut.

3.5 Volant

Voir fig. 7. Placer les rondelles de réglage (D) et/

ou (E) entre la partie inférieure de la colonne de direction et le support comme suit pour minimiser le

jeu latéral.

1. Assembler la jupe sur la colonne de direction et

fixer l’ensemble en enfonçant la goupille de

tension (C) à environ 1/3 de sa longueur.

2. Lever l’ensemble support/colonne.

3. De l’extérieur, vérifier si vous pouvez placer,

entre les pièces, les deux rondelles, celle de 1

mm, celle de 0,5 mm ou aucune. Ne pas forcer ;

un jeu axial limité est nécessaire.

4. Retirer la goupille et démonter la partie inférieure de la colonne.

5. Monter la ou les rondelles comme décrit au

point 3 ci-dessus.

6. Installer la jupe sur la colonne de direction et

fixer l’ensemble en enfonçant à fond la goupille

de tension. Utiliser une clé de retenue.

3.6 Barre d´attelage

Voir fig. 8. Visser la barre d’attelage (J) au moyen

des vis (L+K) dans les deux trous situés sous l’essieu arrière. Serrer fermement les vis.

Couple de serrage : 22 Nm.

3.7 Montants du plateau

La procédure qui suit décrit l’installation sur le

côté droit de l’essieu. Les mêmes opérations doivent être répétées du côté gauche.

1. Avant l’installation, lubrifier à l’huile les extrémités de l’essieu et la surface des paliers des

montants du plateau.

2. Installer les montants sur la machine conformément à la fig. 9.

3. Introduire la goupille (9:Q) dans le trou de l’essieu.

3.8 Pression des pneus

Vérifier la pression des pneus.

Pressions correctes :

À l’avant : 0,6 bar (9 psi).

À l’arrière : 0,4 bar (6 psi)

3.9 Accessoires

Pour le montage des accessoires, voir le manuel

d’installation fourni séparément avec chaque élément.

Remarque : le plateau de coupe est considéré ici

comme un accessoire.

24

Page 25

FRANÇAIS

FR

4 DESCRIPTION

4.1 Transmission

4.1.1 HST

La machine est équipée de roues arrière motrices.

L’essieu arrière est équipé d’une transmission hy-

drostatique à 5 rapports en marche avant et 1 en

marche arrière, variables en continu.

L’essieu arrière est également équipé d’un différentiel pour faciliter le braquage.

Les outils montés à l’avant sont actionnés par

courroies.

4.1.2 4WD

La machine possède 4 roues motrices. La puissance dégagée par le moteur est transmise aux roues par un système hydraulique. Le moteur actionne

une pompe qui fait circuler de l’huile dans le dispositif d’entraînement des trains avant et arrière.

Les trains avant et arrière sont connectés en série,

ce qui signifie que les roues avant et arrières tournent obligatoirement à la même vitesse.

Pour faciliter les manœuvres, les deux essieux sont

équipés d’un différentiel.

Les accessoires montés à l’avant sont mus par les

courroies d’entraînement.

4.2 Direction

La machine est articulée. Cela signifie que le châssis est divisé en deux sections, avant et arrière, qui

pivotent l’une par rapport à l’autre.

Grâce au châssis articulé, la machine possède un

rayon de braquage très faible qui lui permet de

contourner arbres et obstacles.

4.3 Dispositifs de sécurité

La machine est équipée d’une sécurité électrique

qui interrompt certaines activités susceptibles de

provoquer des manœuvres dangereuses. Par exemple, le moteur ne démarre pas lorsque la pédale

d’embrayage et de frein de stationnement est enfoncée.

Contrôler le fonctionnement du dispositif de sécurité avant chaque utilisation.

4.4 Commandes

4.4.1 Dispositif mécanique de levage des

accessoires, (12:A)

Pour passer de la position de travail à la position de

transport :

1. Enfoncer à fond la pédale.

2. Relâcher la pédale progressivement.

4.4.2 Embrayage - frein de stationnement

(12:B)

Ne jamais enfoncer cette pédale pendant les déplacements pour éviter toute

surchauffe des organes de transmission.

La pédale se règle sur trois positions :

• Relâchée. L'embrayage n'est pas activé. Le

frein de stationnement n'est pas activé.

• Enfoncée à moitié. La marche avant est désac-

tivée. Le frein de stationnement n'est pas activé.

• Totalement enfoncé. La marche avant est dés-

activée. Le frein de stationnement est tout à fait

activé mais n'est pas verrouillé. Cette position

est également utilisée comme frein d’arrêt d’urgence.

4.4.3 Inhibiteur, frein de stationnement

(12:C)

L'inhibiteur bloque la pédale « embrayage-frein » en position enfoncée. Cette

fonction permet de circuler sur des terrains en pente, de transporter la machine,

etc. lorsque le moteur est à l’arrêt.

Verrouillage :

1. Enfoncer à fond la pédale (12:B).

2. Déplacer l’inhibiteur (12:C) vers la droite.

3. Relâcher la pédale (12:B).

4. Relâcher l'inhibiteur (12:C).

Déverrouillage :

Enfoncer et relâcher la pédale (12:B).

4.4.4 Conduite - frein de service (12:F)

Si la machine ne freine pas comme prévu en relâchant la pédale, utiliser la

pédale de gauche (12:B) comme frein

d’arrêt d’urgence.

La pédale détermine le rapport de transmission entre le moteur et les roues motrices (= vitesse). Le

frein de service est activé lorsque la pédale est

relâchée.

1. Pédale enfoncée vers l'avant –

la machine avance.

2. Pas de pression sur la pédale –

la machine reste immobile.

3. Pédale enfoncée vers l'ar-

rière–

la machine recule.

4. Pression réduite sur la pédale

– la machine freine.

25

Page 26

FR

FRANÇAIS

4.4.5 Accélérateur et choke (12:D)

Réglage du régime moteur, permettant d’enrichir

le mélange pour le démarrage à froid.

En cas d’irrégularité du moteur, il y a

un risque que la commande ait été

poussée trop loin en avant et que le

choke soit activé. Outre les risques de

dégâts au moteur, cela augmente la consommation de carburant et la pollution.

1. Choke – pour les démarrages à froid. Le

choke est situé à l’avant de la rainure.

Ne pas utiliser dans cette position le moteur est chaud.

2. Plein régime – le mode plein régime

doit toujours être enclenché lorsque la machine fonctionne.

Pour le plein régime, enfoncer la manette

d’environ 2 cm par rapport à la position du

choke.

3. Ralenti.

4.4.6 Démarreur (12:E)

Ne pas quitter la machine lorsque la clé

est sur la position 2 ou 3 pour éviter tout

risque d’incendie, de passage de

carburant dans le moteur via le

carburateur, de déchargement de la

batterie et tout dégât en général.

Le contact permet de démarrer et d’arrêter le

moteur. Quatre positions :

1. Arrêt – le moteur est court-circuité. La

clé peut être retirée.

2/3. Position de conduite.

4. Démarrage – le démarreur électrique est

activé lorsque la clé est tournée à fond

dans la position de démarrage. Lorsque le