Page 1

Operating Manual

IP251

Universal SSI / RS232 signal converter for operation with absolute SSI sensors and encoders

Product Features:

Converts SSI data as well as serial data to parallel binary, Gray oder BCD data format

Linearization facilities by freely programmable in-/output curves

Additional facilities like bit-blanking, round-loop-operation etc.

Parallel output 25 bits (push-pull, short circuit proof)

RS232 interface for serial readout of the sensor data

SSI: Master or Slave operation

18 to 30 VDC power supply

motrona GmbH, Zeppelinstraße 16, DE - 78244 Gottmadingen, Tel. +49 (0) 7731 9332-0, Fax +49 (0) 7731 9332-30, info@motrona.com, www.motrona.com

Page 2

Version:

Description:

IP25101a/ HK/AF/ Apr-03

Original Version

IP25101b/ AF/HK/ Aug.03

Correction DIL-switch position 7 ON/OFF. “Parallel Mode” 3,4,5 and “Parallel

Value” for direct serial access to the parallel output

IP25101c/ PP/Nov. 12

Added chapter 7.5

IP25102a/ kk/nw/Sept. 13

Added Printermode

Ip251_02b_oi/Dez-15/ag

„RS485“ removed from parameter table. Legal Notices added. New design

and chapter for “Safety Instructions“. “Technical specifications” actualized.

Smaller corrections and modulations

Legal notices:

All contents included in this manual are protected by the terms of use and copyrights of motrona GmbH. Any

reproduction, modification, usage or publication in other electronic and printed media as well as in the internet

requires prior written authorization by motrona GmbH.

Ip251_02b_oi_e.doc / Apr-16 Page 2 / 28

Page 3

Table of Contents

1. Safety Instructions and Responsibility ........................................................ 4

1.1. General Safety Instructions ................................................................................... 4

1.2. Use according to the intended purpose ................................................................ 4

1.3. Installation ............................................................................................................. 5

1.4. Cleaning, Maintenance and Service Notes ........................................................... 5

2. Introduction ................................................................................................ 6

2.1. Applicable encoders and sensors: ........................................................................ 6

2.2. Remark about the encoder resolution: .................................................................. 6

3. Terminal Assignment .................................................................................. 6

4. Connections ................................................................................................ 7

4.1. SSI encoder, Master operation ............................................................................. 7

4.2. SSI encoder, Slave operation ................................................................................ 7

4.3. Hold input .............................................................................................................. 7

4.4. Parallel outputs ..................................................................................................... 8

4.5. “Data stable” output ............................................................................................. 8

4.6. Serial interface ...................................................................................................... 9

5. DIL Switch Settings .................................................................................. 10

6. Extended Functions with PC Setup ............................................................ 11

6.1. Self-Test .............................................................................................................. 12

6.2. Output value ........................................................................................................ 12

6.3. Hold key ............................................................................................................... 12

7. Parameters ............................................................................................... 13

7.1. Scaling of serial readout data ............................................................................. 13

7.2. Scaling of parallel output data ............................................................................ 13

7.3. Ring counter, parameter “Round Loop”: ............................................................. 15

7.4. More parameters: ................................................................................................ 17

7.5. Parameters for RS232 settings ........................................................................... 22

8. Test Functions ........................................................................................... 25

9. Technical Specifications ........................................................................... 26

10. Dimensions ............................................................................................... 27

11. Parameter List, Default Settings ............................................................... 28

Ip251_02b_oi_e.doc / Apr-16 Page 3 / 28

Page 4

1. Safety Instructions and Responsibility

1.1. General Safety Instructions

This operation manual is a significant component of the unit and includes important rules and

hints about the installation, function and usage. Non-observance can result in damage and/or

impairment of the functions to the unit or the machine or even in injury to persons using the

equipment!

Please read the following instructions carefully before operating the device and observe all

safety and warning instructions! Keep the manual for later use.

A pertinent qualification of the respective staff is a fundamental requirement in order to use

these manual. The unit must be installed, connected and put into operation by a qualified

electrician.

Liability exclusion: The manufacturer is not liable for personal injury and/or damage to property

and for consequential damage, due to incorrect handling, installation and operation. Further

claims, due to errors in the operation manual as well as misinterpretations are excluded from

liability.

In addition the manufacturer reserve the right to modify the hardware, software or operation

manual at any time and without prior notice. Therefore, there might be minor differences

between the unit and the descriptions in operation manual.

The raiser respectively positioner is exclusively responsible for the safety of the system and

equipment where the unit will be integrated.

During installation or maintenance all general and also all country- and application-specific

safety rules and standards must be observed.

If the device is used in processes, where a failure or faulty operation could damage the system

or injure persons, appropriate precautions to avoid such consequences must be taken.

1.2. Use according to the intended purpose

The unit is intended exclusively for use in industrial machines, constructions and systems. Nonconforming usage does not correspond to the provisions and lies within the sole responsibility

of the user. The manufacturer is not liable for damages which has arisen through unsuitable

and improper use.

Please note that device may only be installed in proper form and used in a technically perfect

condition - in accordance to the Technical Specifications (see chapter 9). The device is not

suitable for operation in explosion-proof areas or areas which are excluded by the EN 61010-1

standard.

Ip251_02b_oi_e.doc / Apr-16 Page 4 / 28

Page 5

1.3. Installation

The device is only allowed to be installed and operated within the permissible temperature

range. Please ensure an adequate ventilation and avoid all direct contact between the device

and hot or aggressive gases and liquids.

Before installation or maintenance, the unit must be disconnected from all voltage-sources.

Further it must be ensured that no danger can arise by touching the disconnected voltagesources.

Devices which are supplied by AC-voltages, must be connected exclusively by switches,

respectively circuit-breakers with the low voltage network. The switch or circuit-breaker must

be placed as near as possible to the device and further indicated as separator.

Incoming as well as outgoing wires and wires for extra low voltages (ELV) must be separated

from dangerous electrical cables (SELV circuits) by using a double resp. increased isolation.

All selected wires and isolations must be conform to the provided voltage- and temperatureranges. Further all country- and application-specific standards, which are relevant for structure,

form and quality of the wires, must be ensured. Indications about the permissible wire crosssections for wiring are described in the Technical Specifications (see chapter 9).

Before first start-up it must be ensured that all connections and wires are firmly seated and

secured in the screw terminals. All (inclusively unused) terminals must be fastened by turning

the relevant screws clockwise up to the stop.

Overvoltages at the connections must be limited to values in accordance to the overvoltage

category II.

For placement, wiring, environmental conditions as well as shielding and earthing/grounding of

the supply lines the general standards of industrial automation industry and the specific

shielding instructions of the manufacturer are valid. Please find all respective hints and rules on

www.motrona.com/download.html --> “[General EMC Rules for Wiring, Screening and

Earthing]”.

1.4. Cleaning, Maintenance and Service Notes

To clean the front of the unit please use only a slightly damp (not wet!), soft cloth. For the rear

no cleaning is necessary. For an unscheduled, individual cleaning of the rear the maintenance

staff or assembler is self-responsible.

During normal operation no maintenance is necessary. In case of unexpected problems, failures

or malfunctions the device must be shipped for back to the manufacturer for checking,

adjustment and reparation (if necessary). Unauthorized opening and repairing can have

negative effects or failures to the protection-measures of the unit.

Ip251_02b_oi_e.doc / Apr-16 Page 5 / 28

Page 6

2. Introduction

1

2

3

4

5

6

7

8

9

1

0

1

1

1

2

COM + (+5....+27V max)

SSI- Clock (-)

SSI- Clock (+)

GND ( - )

+18...30 VDC (typ. 200 mA)

NC

SSI Data (-)

SSI Data (+)

Hold

GND ( - )

P

O

W

E

R

NC

NC

IP251 represents a small and low-cost, but highly performing converter for industrial

applications, where the information of a sensor or encoder with SSI interface needs to be

converted to a parallel signal or a serial RS232 data format. Also it is possible to convert serial

RS232 data to a parallel format.

The unit has been designed as a compact module with 12 screw terminals, a 9-position and a

25-position SUB-D connector (female). The housing is suitable for simple and quick snap-on

mounting on a top hat rail (according to the EN 60715 standard).

2.1. Applicable encoders and sensors:

Single-turn or multi-turn absolute encoders and all similar sensors using a standard SSI

interface (6 to 25 bits of resolution with binary or Gray code). The unit can operate in either

Master mode (clock signal generated by the IP251 unit), or in

Slave mode (clock signal generated by a remote device)

2.2. Remark about the encoder resolution:

The unit provides settings for the standard resolutions of 13 bits, 21 bits and 25 bits. In general,

for sensors with other resolutions you can use the next higher setting (i.e. set the unit to 21 bits

with a sensor of 16 bits).

Depending on brand and specification of the encoder, in some cases it may be necessary to

blank out the surplus bits by using the bit blanking function described later. In general however,

the unit should work perfectly also without special bit blanking.

3. Terminal Assignment

The subsequent diagram shows the assignment of the screw terminals. GND terminals 4 and 6

are connected internally. Depending on input voltage and load of the auxiliary voltage output,

the total power consumption of the unit is about 200 mA.

Ip251_02b_oi_e.doc / Apr-16 Page 6 / 28

We recommend to connect the Minus wire of the power supply to earth potential.

Page 7

4. Connections

2

3

8

9

4 (GND)

Clock-

Clock+

GND

Data-

Data+

SSI encoder

IP251 converter

Master mode

2

3

8

9

4 (GND)

IP251 converter

Slave mode

+ -

C

l

o

c

k

+

C

l

o

c

k

-

D

a

t

a

+

D

a

t

a

-

Encoder

Master

ClockClock+

DataData+

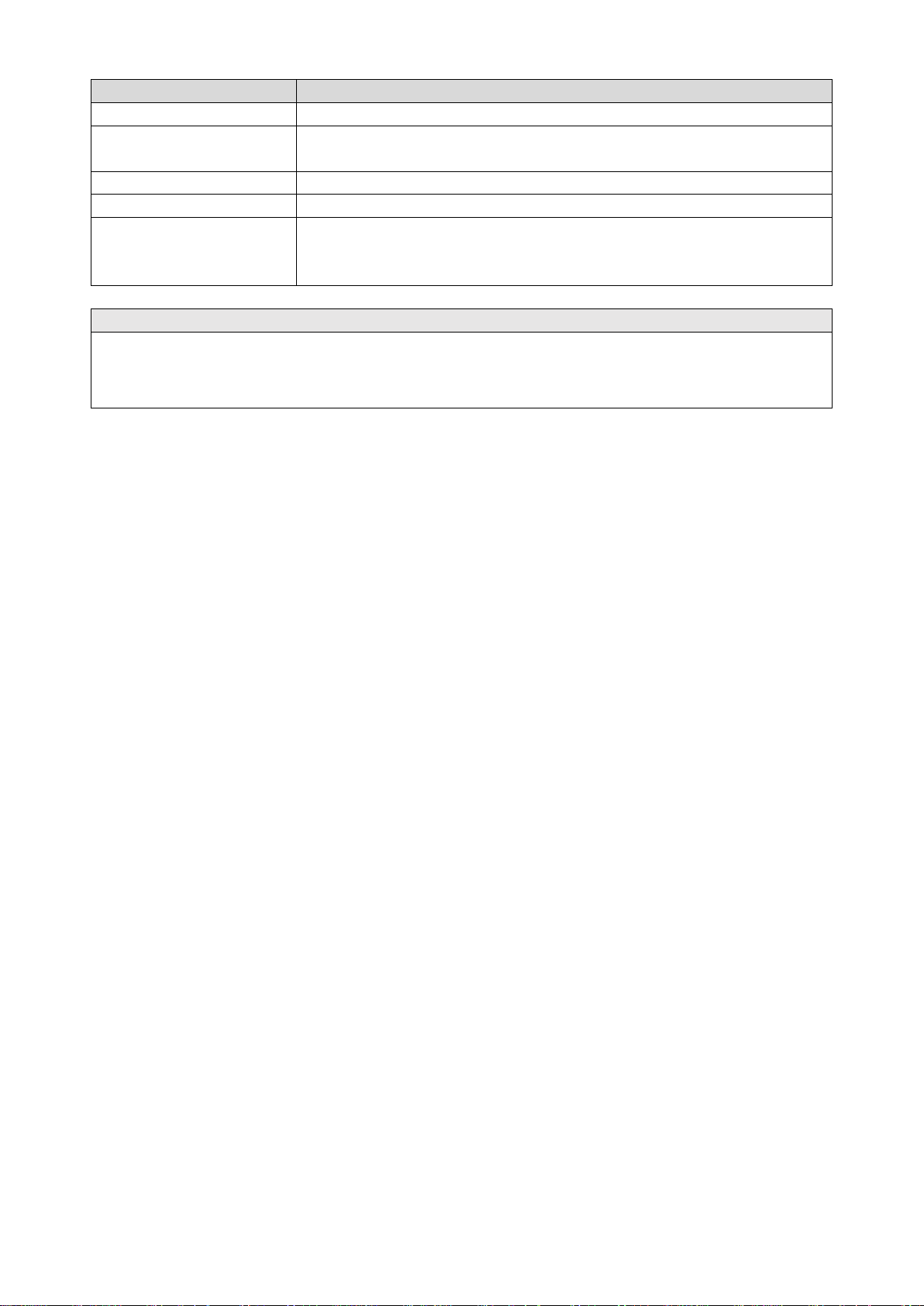

4.1. SSI encoder, Master operation

We recommend to connect the screen to GND and earth potential on both sites.

4.2. SSI encoder, Slave operation

With this mode, the IP251 converter operates in parallel to another unit, acting as a „listener“

to the existing data communication. Quite according to need, the common potential of the

master can be connected to terminal 4 (GND), or remain open for fully differential operation.

4.3. Hold input

A HIGH signal to this input freezes the parallel output data.

The Hold function becomes active 500 µs after the rising edge of the signal and remains active

for the duration of the signal. With PC setup, the polarity of the signal can be inverted (Falling

edge, active low, see register “Hold polarity”).

The Hold input provides PNP/HTL characteristics (LOW = open or 0 … 3 V, HIGH =10 … 30 V)

Ip251_02b_oi_e.doc / Apr-16 Page 7 / 28

Page 8

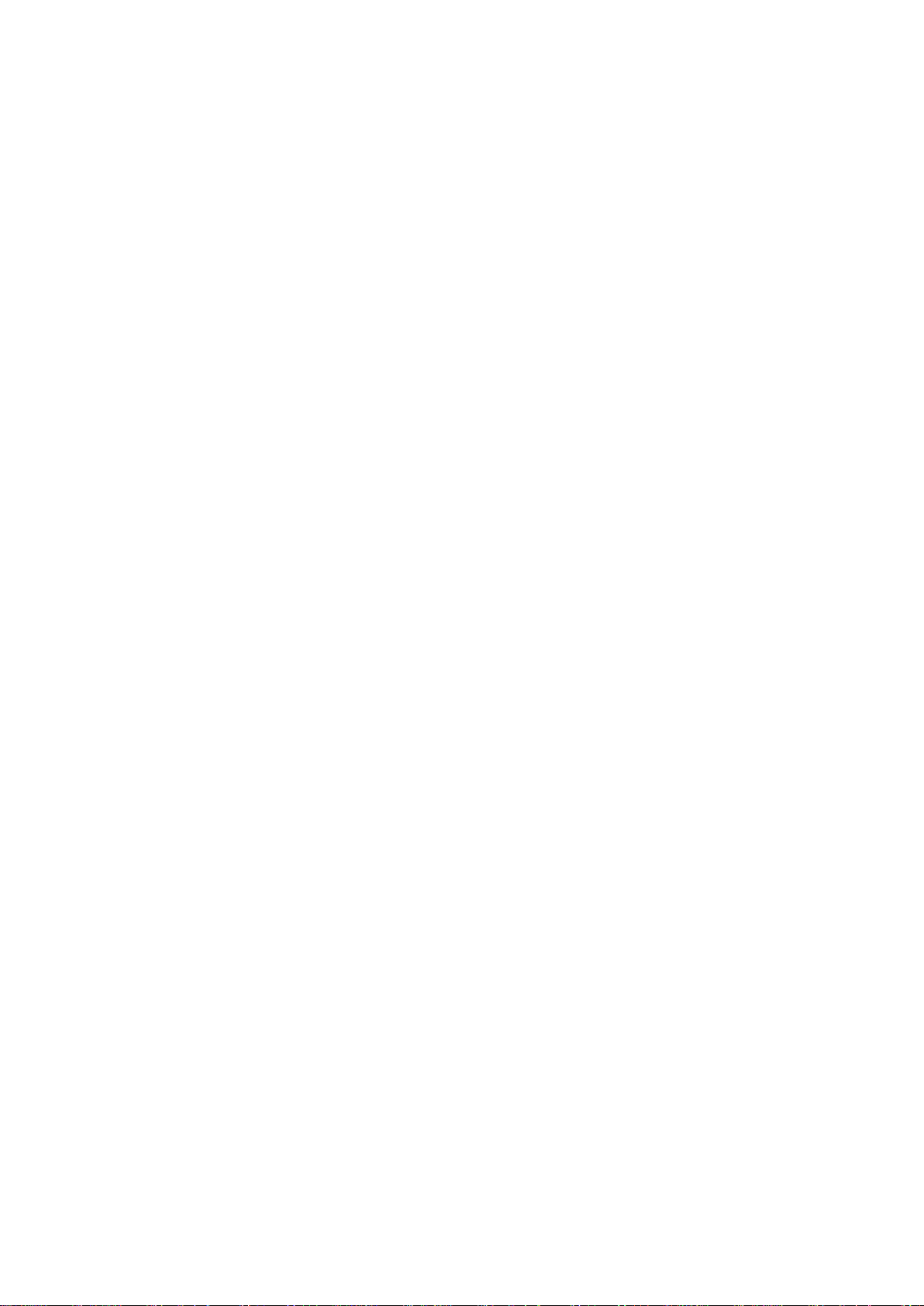

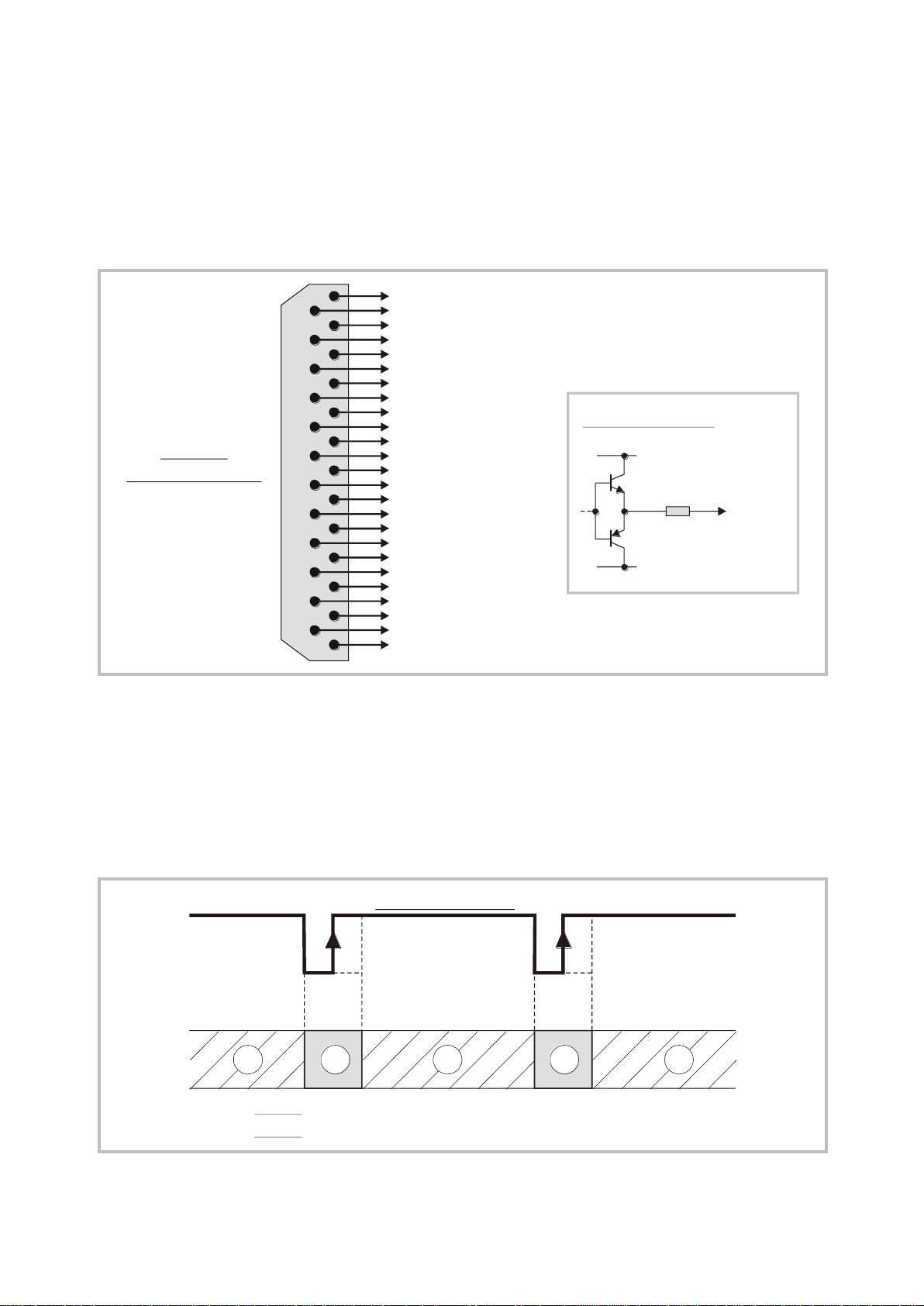

4.4. Parallel outputs

Bit13

Bit 25

Bit 12

Bit 24

Bit 11

Bit 23

Bit 10

Bit 22

Bit 9

Bit 21

Bit 8

Bit 20

Bit 7

Bit 19

Bit 6

Bit 18

Bit 5

Bit 17

Bit 4

Bit 16

Bit 3

Bit 15

Bit 2

Bit 14

Bit 1

R = 600 Ohms

GND

COM +

OUT

Typical output circuit:

SUB-D-25

(female on unit site)

13

25

12

24

11

23

10

22

9

21

8

20

7

19

6

18

5

17

4

16

3

15

2

14

1

12121

Data stable signal

Zone 1: Parallel output data subject to change

Parallel output data are stable

Zone 2:

The unit provides 25 push-pull outputs which are short-circuit proof. The separate common

output voltage for the outputs must be applied to screw terminal 1 (COM+). The maximum

voltage to COM+ should not exceed +27 V, otherwise no continuous short-circuit proof of

the outputs can be guaranteed.

The voltage drop between COM+ and an output in HIGH state is approx. 1 V (unloaded).

4.5. “Data stable” output

The output for bit 25 can be configured as a “Data-stable” signal by means of the DIL-switch.

In this case a LOW state indicates that parallel output data are stable and will not change. The

rising edge of the signal still guarantees stable data and can be used for remote Latch of the

parallel data.

The LOW duration of the signal is at least 1/3 of the SSI Wait Time setting.

Ip251_02b_oi_e.doc / Apr-16 Page 8 / 28

Page 9

4.6. Serial interface

5

4

3

2

1

9

8

7

6

GND int.

TxD

RxD

RS232

SUB-D-9-connector

( on unit site)female

GND

1

2

3

4

5

9

8

7

6

1

2

3

4

5

9

8

7

6

TxD

RxD

PC connection cable(female) (male)

IP251PC

For PC setup and for serial readout of the encoder position, a serial RS232 interface is available.

The serial interface allows to operate and setup the unit as well as readout the encoder position

by a PC or Notebook.

Ip251_02b_oi_e.doc / Apr-16 Page 9 / 28

Page 10

5. DIL Switch Settings

Changes of switch settings will become active only

after the next power-up cycle!

SSI Resolution:

3 OFF, 4 OFF : not valid

3 ON, 4 OFF : 25 bit encoder

3 OFF, 4 ON : 21 bit encoder

3 ON, 4 ON : 13 bit encoder

Set Default:

OFF: Unit loads default settings with every power-up cycle

ON : No loading of default settings upon power-up.

Update Mode

ON: Update of parallel output in a fixed preset time pattern

OFF: Update of parallel output after every SSI telegram

Pin 25 Function:

OFF: Pin 25 indicates that output data is stable (LOW)

ON : Pin 25 is a normal data output (bit 25 or error bit)

SSI Code

OFF: Gray Code

ON: Binary Code

SSI Mode:

OFF : Slave Operation

ON : Master Operation

Pin 25 Function:

OFF : Pin 25 = Error bit output

ON : Pin 25 = normal data output (bit 25)

1 2 3 4 5 6 7 8

The DIL switch located on the top site of the unit provides encoder settings and customerspecific settings of the desired operation modes.

The switch settings shown in the example are suitable for Master operation of a 25 bit SSI

encoder with Gray coded output. The parallel output operates with equidistant update times

and pin 25 is used to indicate valid and stable output data.

Ip251_02b_oi_e.doc / Apr-16 Page 10 / 28

Page 11

6. Extended Functions with PC Setup

Ex factory, all motrona units use the following serial standard settings:

Unit No. 11, Baud rate 9600, 1 start/ 7 data/ parity even/ 1 stop bit

If the serial settings of the unit should be unknown, you can run the

„SCAN“ function from the „TOOLS“ menu to find out.

For normal use with standard applications, the unit is ready to work after correct wiring and

setting of the DIL switches. In this case, the subsequent sections are not relevant.

With use of a PC however, you have full access to useful complementary functions and tests as

shown subsequently. For this you will need the PC operator software OS3.x which is available

for free download from

Connect your PC to the converter, using a serial RS232 cable like shown in section 4.6. of this

manual. Then run the OS3.x software and you will see the following screen:

www.motrona.com

In case your text and color fields remain empty and the headline says „OFFLINE“, you must

verify your serial settings. To do this, select „Comms“ from the menu bar.

Ip251_02b_oi_e.doc / Apr-16 Page 11 / 28

Page 12

6.1. Self-Test

On your PC screen, in the ”Outputs” field, you find several indicator boxes.

When the ”Self-test passed” box lights red, this indicates that the unit has correctly initialized

and is ready to work. The fields ”Status SSI-CLK” and ”Status SSI-Data” indicate that the clock

and data lines work correctly (red color = o.k.) *)

You may observe that these boxes blink, because of the update cycle of your PC. However, you

should see “red” predominantly with correct operation of the lines.

6.2. Output value

When the encoder position is changing, this window must show increasing or decreasing

encoder values. Where the color bar or the percentage display are jumping or hunting, please

check once more for correct setting of the DIL switch.

6.3. Hold key

This soft key operates in parallel to the hardware input terminal 10 and allows freezing the

parallel output from the PC screen. Indicator boxes in the RS column indicate that the Hold

function is active, either by software or by hardware command.

*) Testing the clock lines is primarily useful with Slave operation. Though the test works also in Master

mode, the result says only that the internal generation of the clock works fine. However, in Master mode,

this test cannot indicate faulty clock drivers or bad wiring of the clock lines

Ip251_02b_oi_e.doc / Apr-16 Page 12 / 28

Page 13

7. Parameters

Serial Readout = SSI encoder data x [

xOperand

/Operand

] + +/-Operand

Linearisation Mode = 0

Round Loop = 0

Parallel Mode = 0 (binary output)

= 1 (Gray coded output)

= 2 (BCD output)

Parallel Inv. = 0 (Log 1 = „HIGH“, normal output polarity)

= 1 (Log 1 = „LOW“, inverted output polarity)

7.1. Scaling of serial readout data

You can read out the actual SSI position of the encoder at any time from the serial link. For

setting of communication parameters (baud rate etc.) you need a PC.

IP251 uses the DRIVECOM communication standard according to ISO 1745. Details about this

protocol can be found in the file Serpro1a.doc,

(available for Download from www.motrona.com)

The serial access code for the actual encoder position is „ :8 ”

(ASCII characters for colon and 8)

Serial data be re-scaled by using the parameters xOperand, /Operand and +/-Operand :

There operands affect only serial readout of encoder data but not the parallel data output.

With the settings

xOperand = 1.0000,

/Operand = 1.0000

the serial readout value equals to the SSI encoder value.

+/-Operand = 0.0000

7.2. Scaling of parallel output data

7.2.1. If you like to convert the SSI encoder data to the parallel output straight 1:1

The settings of the Linearization registers are not important in this case.

Ip251_02b_oi_e.doc / Apr-16 Page 13 / 28

Page 14

7.2.2. If you like to convert the SSI encoder data to the parallel output with a

Linearisation Mode = 1

Round Loop = 0

Parallel Mode = 0 (binary output)

= 1 (Gray output)

= 2 (BCD output)

Parallel Inv. = 0 (Log 1 = „HIGH“, normal output polarity)

= 1 (Log 1 = „LOW“, inverted output polarity)

Linear In (100%) = 65 536

Linear Out (100%) = 10 000

P1 (x) = 000.0 %

P1 (y) = 000.0 %

P2 (x) = 100.0 %

P2 (y) = 100.0 %

Linearisation Mode = 1

Round Loop = 0

Parallel Mode = 0 (binary output)

= 1 (Gray output)

= 2 (BCD output)

Parallel Inv. = 0 (Log 1 = „HIGH“, normal output polarity)

= 1 (Log 1 = „LOW“, inverted output polarity)

Use registers P1(x) to P16(x) to specify the coordinates on the x-axis. These are the

original SSI data generated by the sensor. These settings are in % of full scale

Now enter the attached values to registers P1(y) to P16(y). These are the values

that the parallel output will generate instead of the x- values *)

*) Example:. P2(y) will substitute P2(x) etc.

different scaling:

Example: encoder 16 Bit = 65536 steps to be converted to a range of 0 - 10 000

on the parallel output

7.2.3. If you like to transform the SSI encoder data to a curve on the

parallel output site (Linearization)

Example: encoder 16 Bit = 65536 steps to be transformed to a programmable curve.

Ip251_02b_oi_e.doc / Apr-16 Page 14 / 28

Page 15

x-registers must follow continuously increasing settings, i.e. P1(x) must

receive the lowest setting and P16(x) must receive the highest setting

All entries use a percent format of xx.xxx% full scale. Setting 0.000%

means zero output and setting 100.000% means full scale encoder output

With Linearization Mode set to 1, it is a must to set P1(x) to 0% and P16(x)

to 100%. Linearization is defined in the positive range only and the negative

range will be a mirror image of the positive range with reference to zero.

With Linearisation Mode set to 2, it is a must to set P1(x) to –100% and

P16(x) to +100%. This enables the user to set curves which are not

symmetric to the zero position

P

1

(

x

)

=

0

P

1

(

y

)

=

0

P

4

(

x

)

=

2

0

%

P

4

(

y

)

=

5

0

%

P

6

(

x

)

=

3

0

%

P

6

(

y

)

=

6

0

%

P

1

6

(

x

)

=

1

0

0

%

P

1

6

(

y

)

=

0

%

100% Y

X

parallel data

SSI data

Example for Linearisation

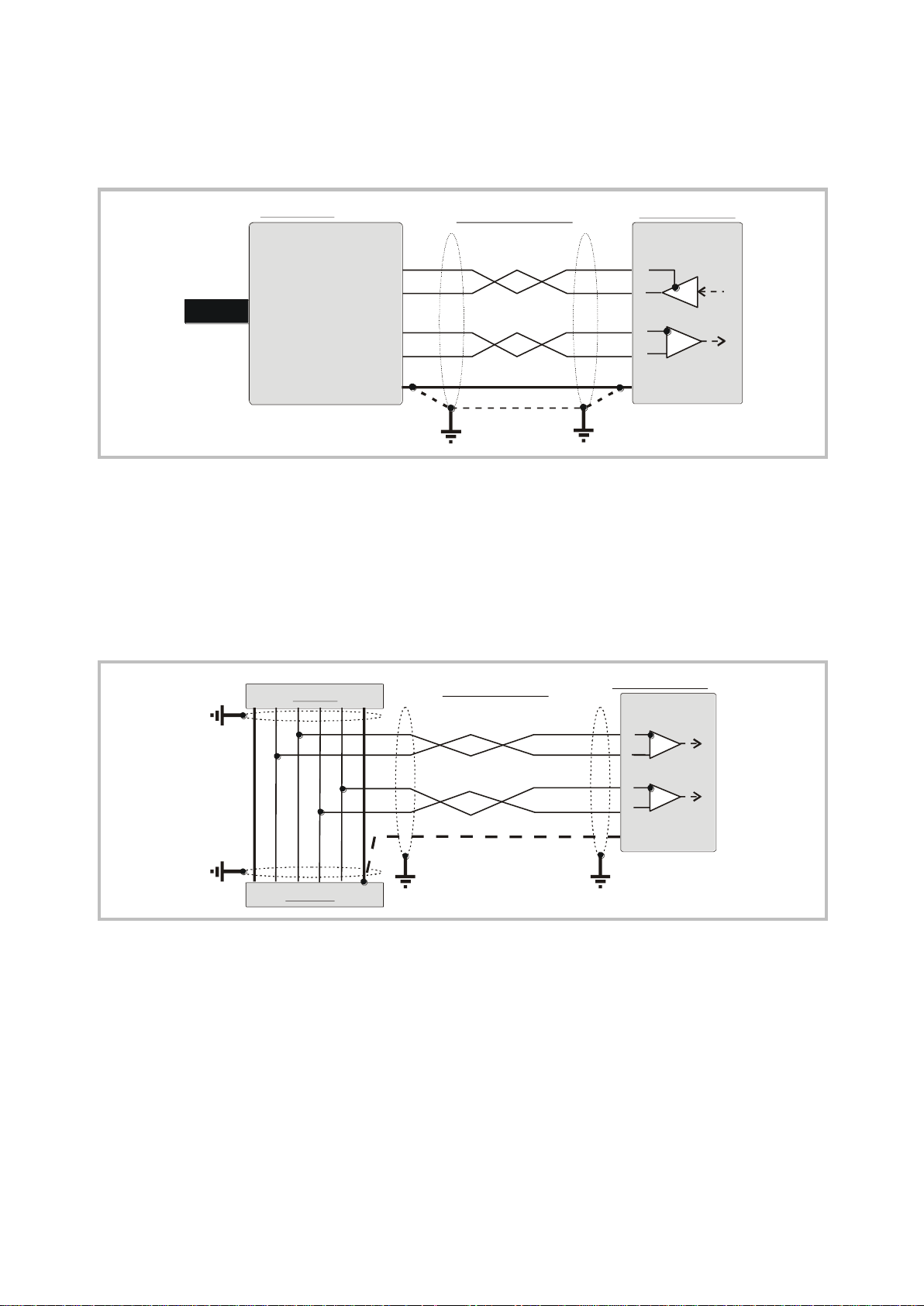

7.3. Ring counter, parameter “Round Loop”:

In general, this setting should be 00000. Any other setting will substitute the real encoder

position by a repeating cycle count.

Example: when the Round Loop register is set to 2048, the internal position register will only

count in a range between 0 and 2047. When we underpass zero with reverse direction, again

2047 will appear. When we exceed 2047 with forward direction, we will restart at 0 again.

Ip251_02b_oi_e.doc / Apr-16 Page 15 / 28

Page 16

The zero position of the round-loop counter can be set by register “SSI-Offset” which allows

8192

2048

Round-Loop= 2048SSI-Offset= 1024

0 360

180

degrees

1024

Original SSI encoder signal

parallel output signal

Encoder 13Bit

Direction = 0

SSI-Offset = 1024

Round-Loop = 2048

8192

2048

Round-Loop= 2048SSI-Offset= 1024

0 360

180

degrees

1024

Original SSI encoder signal

Round-Loop signal

Encoder 13Bit

Direction = 1

SSI-Offset = 1024

Round-Loop = 2048

settings between 0 and the Round-Loop value. Register “Direction” allows to set the counting

direction of the round loop counter (0 = up, 1 = down).

The following drawings explain the coherence between original SSI encoder data, Round-Loop

setting, SSI-Offset and Direction register.

Ip251_02b_oi_e.doc / Apr-16 Page 16 / 28

Page 17

The Round-Loop function is also suitable to suppress the encoder overflow, if you do not like to

8192

0

360°180°

Original encoder signal

Round-Loop signal (parallel 0utput)

Encoder 13Bit

Direction = 0

SSI-Offset = 2048

Round-Loop = 8192

2048

With each change of the Round-Loop parameter, the offset value must

be re-entered.

With use of the Round-Loop function it is also possible to change the

counting direction of the encoder, by appropriate setting the direction bit.

Parameter

Description

Parallel Mode:

Sets the code of the parallel output and the input source of the converter.

Parallel Mode :

Parallel output

Data source

0

Binary format

SSI encoder

1

Gray format

2

BCD format

3

Binary format

Serial RS 232

interface

4

Gray format

5

BCD format

Linearisation

Mode:

Sets the mode of linearization.

0: Linearisation off, all linearization registers are irrelevant.

1: Linearisation in a range of 0 – 100%

2: Linearisation over full range –100% to +100%

See example under section 7.2.3 „Linearisation”

change the mechanical situation. As shown in the subsequent picture, you need to set the

Round-Loop register to the full encoder resolution and then shift the zero transition by setting

the SSI Offset correspondingly.

7.4. More parameters:

Ip251_02b_oi_e.doc / Apr-16 Page 17 / 28

Page 18

Parameter

Description

SSI Low Bit:

SSI High Bit:

Defines the lowest bit (LSB) for evaluation when the bit blanking function

is used. Must be set to “01” for full evaluation of the encoder range.

Defines the highest bit (MSB) for evaluation when the bit blanking function

is used. Must be set to the total number of encoder bits for full evaluation

of the encoder range.

The following example uses a 13 bit encoder where High Bit is set to 12 and

Low Bit is set to 03, resulting in evaluation of bits 03 to 12 and blanking of positions

01, 02 and 13

13 12 11 10 09 08 07 06 05 04 03 02 01

(Hi_bit = 12, Lo_bit = 03)

evaluated bits

(LSB)(MSB)

Most significant bit Least significant bit

Bit blanking results in a different evaluation of the encoder information,

and you should be fully aware of what happens with the resolution and

the number of registered turns when you use this function. The

subsequent example uses a 13 bit single-turn encoder to explain

different result with blanking on one bit:

Without blanking, a 13 bit encoder would provide a 0 ... 8191

information with a 0 ... 360º turn of the encoder shaft.

This assumes setting of “High Bit = 13” and “Low Bit = 01”.

It is easy to understand that there are two different ways how to use

only 12 of the 13 bits available:

When we set High Bit to 12 while Low Bit remains 01, we have

blanked the high order bit. The result corresponds to an encoder

providing information 0 ... 4095 while we turn from 0 ... 180º, and

again the same 0 ... 4095 information while we turn from 180º to 360º.

The resolution remains unchanged with respect to the number of steps

per revolution.

We can also leave High Bit to 13 and set Low Bit to 02 instead.

This means blanking the low order bit. As a result, within one turn

of 0 ... 360º, we receive the encoder information 0 ... 4095 one time

only, but the total number of steps per revolution has been halved.

Ip251_02b_oi_e.doc / Apr-16 Page 18 / 28

Page 19

Parameter

Description

SSI Baud Rate:

Sets the communication speed of the SSI interface with SSI encoders.

Setting range: 100 Hz to 1MHz.

You are free to set any desired frequency between 0.1 kHz and 1000.0 kHz. For

technical reasons however, in the upper frequency range with Master operation, the

unit will only generate one of the following frequencies accurately:

1 000.0 kHz

888.0 kHz

800.0 kHz

727.0 kHz

666.0 kHz

615.0 kHz

571.0 kHz

533.0 kHz

500.0 kHz

470.0 kHz

444.0 kHz

421.0 kHz

400.0 kHz

380.0 kHz

363.0 kHz

347.0 kHz

333.0 kHz

320.0 kHz

307.0 kHz

296.0 kHz

285.0 kHz

275.0 kHz

266.0 kHz

258.0 kHz

250.0 kHz

With Master operation, therefore other settings will result in generation of the next

upper or lower value according to above list. With all settings < 250.0 kHz the error

between set rate and generated rate becomes negligible.

It is mandatory to set the Baud rate also with Slave operation.

In this case, however, the setting serves only to determine the pause time

for correct synchronizations (pause is detected after 4 clock cycles). The unit

automatically synchronizes with every remote clock signal within the

specified Baud rate range.

SSI Wait Time:

This register sets the waiting time between two SSI telegrams in a range

from 0.001 to 10.000 s. In normal operation, due to processor cycle times,

the real time may vary by 512 µs. with respect to the preset time.

The fastest sequence possible is 1.3 ms at a setting of 0.000.

With Slave operation mode, the distance of the SSI protocols depends on the remote

Master and the SSI Wait Time specifies the distance of evaluation data strings.

Setting to 100 ms results in evaluation of one telegram only every 100 ms, even

though the Master may have transmitted many telegrams more.

Especially with applications of closed-loop control loops, it may be of advantage to

have equidistant updating of the output (DIL switch 7 = OFF). This is possible with

Master mode only and the Wait Time setting (must be >0) directly corresponds to the

time pattern of updates.

Ip251_02b_oi_e.doc / Apr-16 Page 19 / 28

Page 20

The subsequent drawing explains the timing with use of equidistant update mode with a SSI

Wait Time setting of 3 ms.

With equidistant operation mode, the SSI wait time setting is limited to maximum 90 ms.

The shortest possible time for equidistant updating is 2 ms, due to

internal processing times (SSI Wait Time set to 0.001). While your PC

is communicating with the unit, it is even 5 ms.

The time marks TM1 and TM2 shown in above diagram can be

displayed with the Monitor function of the PC operator software. It is

easy to understand that the sum of both times must be equal to the

Wait Time setting, otherwise you must increase the Baud rate or

choose a longer update cycle. (The serial access codes are :3 for TM1

and :5 for TM2)

In critical cases you can reduce the internal processing times of the

unit, by omitting the conversion of serial RS232 encoder data. For

this, just set parameter “/Operand” to 00000

Parameter

Description

SSI Offset:

Defines the electrical zero position of the encoder with respect to the

mechanical zero position. When the Round-Loop function is not active

(Round-Loop = 0), the SSI Offset is subtracted from the SSI position reading,

which can also cause negative results. When the Round-Loop is active, SSI

Offset displaces the mechanical zero position, but always with only positive

results.

SSI Hold Polarity

Sets the polarity of the Hold signal on terminal 10

(active high or active low)

0 : Hold = High,

1 : Hold = Low,

Ip251_02b_oi_e.doc / Apr-16 Page 20 / 28

Page 21

SSI Error Bit:

Defines the position of the error bit (if available with the encoder in use).

00: no error bit available

13: bit 13 represents the error bit

25: bit 25 represents the error bit etc.

Errors indicated by the encoder can be read out via serial code ;9 (semicolon

nine, error indication = 2000hex). In case of an error, the “Error Bit active”

box on the PC screen appears red.

It is also possible to use pin 25 of the parallel output for error indication

(see DIL switch settings).

SSI Error Bit

Polarity:

Defines the polarity of the Error Bit

0: Bit is LOW in case of error

1: Bit is HIGH in case of error

P01 (x), P01 (y)

etc:

Linearisation registers

(see section 7.2.3)

Direction:

This parameter changes the internal direction of counting (0 or 1), provided

the unit operates in Round Loop mode.

Parallel Inv:

When you change this register from 0 to 1, the data on the parallel output

will be inverted.

Parallel Value:

The numerical value of this parameter appears directly at the parallel

output, provided the register „Parallel Mode“ has been set to a value

greater than 2 before. The serial access code of Parallel Value is “48” and

the setting can be changed at any time via serial link

This function may be useful for testing of function and wiring of the parallel output.

Ip251_02b_oi_e.doc / Apr-16 Page 21 / 28

Page 22

7.5. Parameters for RS232 settings

Parameter

Description

Unit Number :

Any address numbers between 11 and 99 * can be chosen

(Factory setting = 11).

* Please note: The address must not contain a “0“ because

these numbers are reserved for collective addressing.

Serial Baud

Rate:

Setting

Baud-Rate

0*

9600

1

4800

2

2400

3

1200

4

600

5

19 200

6

38 400

* = Factory setting

Serial Format:

Setting

Data bits

Parity

Stop bits

0 7 even

1

1 7 even

2

2 7 odd

1

3 7 odd

2

4 7 none

1

5 7 none

2

6 8 even

1

7 8 odd

1

8 8 none

1

9 8 none

2

* = Factory setting

Serial Protocol:

Determines the sequence of characters sent, when you use the serial

output for cyclic data transmission under timer control

(xxxxxxx is the measuring value transmitted). The length of the transmitted

value is dependent on its current value.

Both print formats are shown in the following table:

Unit No.

Serial Protocol = 0*:

1 1

+/- X X X X X X

LF

CR

Serial Protocol = 1 :

+/- X X X X X X

LF

CR

* = Factory setting

Ip251_02b_oi_e.doc / Apr-16 Page 22 / 28

Page 23

Parameter

Description

Serial Timer:

This register determines the cycle time in seconds for cyclic transmission

when the Printer Mode is switched on.

Range 0.001 to 99.999 seconds.

With setting “0” all cyclic transmission is switched off and the unit will

only send data upon request (PC mode *).

Serial Value:

Sets the code of the register of which the content should be sent with

cyclic transmission.

Setting range 00** – 09 (corresponds to register codes :0 to :9)

and 10 - 19 (corresponds to register codes ;0 to ;9).

For clarification of register codes see the following figure.

The most important register codes are:

Register

ASCII

SSI Value (HW)

;0

SSI Value

:9

Display Value

:8

Parallel Value

;2

Legende

Legende

** = Factory Setting

IP251 Overview

- SSI Format

(13,21,25 bit)

- Bin/Gray Code

- Bit Blanking

- SSI Error Bit

- Calculate Display Value

- Round_Loop

- …

- Calculate Parallel Value

Hardware

Evaluation of the

Hardware Value

SSI-Value

(:9)

Parallel-Value

(;2)

Evaluation of the

SSI Value

Hardware

Display-Value

(:8)

SSI Value (HW)

(;0)

Legend

Comments

Hardware

Parameter

Functionality

*) see next page…

Ip251_02b_oi_e.doc / Apr-16 Page 23 / 28

Page 24

*) The serial port of the unit can operate in either “PC mode“ or “Printer mode“.

With PC mode, the unit receives a request string and responds with a

corresponding data string. For details of the protocol see separate description

“SERPRO“.

With Printer mode, the unit sends data without any request and under Timer

control as described subsequently. As soon as the unit receives a character, it

automatically switches over to PC Mode and operates according to protocol.

When for a period of 20 sec. no character has been received, the unit switches

automatically back to “Printer Mode“ and starts cyclic data transmission again.

Ip251_02b_oi_e.doc / Apr-16 Page 24 / 28

Page 25

8. Test Functions

When you select TEST from the TOOLS menu, you are able to verify the following data, by

clicking to the corresponding field:

Actual encoder position, DIL switch settings, Internal supply voltages, Parallel output state

Additionally, the following registers can be recorded by using the monitor function:

Ip251_02b_oi_e.doc / Apr-16 Page 25 / 28

Page 26

9. Technical Specifications

Power supply:

Input voltage:

Protection circuit:

Ripple:

Consumption:

Connections:

18 … 30 VDC

reverse polarity protection

≤ 10 % at 24 VDC

approx. 200 mA

screw terminals, 1.5 mm² / AWG 16

Encoders / sensors:

Usable types:

Interface:

Encoder supply:

absolute encoders (single-turn, multi-turn or comparable)

SSI (6 … 25 Bit binary- or Gray code)

external input necessary

(voltage depends on the used encoder type)

SSI input:

Input format:

Frequency range:

Standard resolutions:

SSI interval time:

Operational modes:

Connections:

TTL differential, RS422-standard

100 Hz … 1 MHz

13, 21 or 25 Bit (selectable)

min. 4 x clock

master or slave (selectable)

screw terminals, 1.5 mm² / AWG 16

Control input:

Input logic

Signal levels:

Function:

Signal delay time:

Internal resistance:

Connections:

PNP, active high / low (reversible via PC)

LOW: 0 … 3 V, HIGH: 10 … 30 V

hold

approx. 500 µs

Ri ≈ 5 kOhm

screw terminals, 1.5 mm² / AWG 16

Parallel output:

Output format:

Resolution:

Signal levels:

Output current:

Internal resistance:

Protection circuit:

Connections:

Binary, Gray or BCD

25 bit

0 … 35 V * (external input at COM+ required)

max. 20 mA (at 24 V)

Ri ≈ 600 Ohm

*) short circuit proof up to max. 27 V

COM+: screw terminals, 1.5 mm² / AWG 16

outputs: 25-pin SUB-D connector (female)

Serial interface:

Format:

Baud rate (selectable):

Operation modes:

Connections:

RS232 or RS485 (selectable)

600, 1200, 2400, 4800, 9600 (default), 19200, 38400 Baud

PC or printer mode

9-pin SUB-D connector (female)

Housing:

Material:

Mounting:

Dimensions (w x h x d):

Protection class:

Weight:

plastic

35 mm top hat rail (according to EN 60715)

40 x 79 x 91 mm / 1.5748 x 3.1102 x 3.5827 inch

IP20

approx. 190 g

Ambient temperature:

Operation:

Storage:

0 °C … +45 °C / +32 … +113 °F (not condensing)

-25 °C … +70 °C / -13 … +158 °F (not condensing)

Failure rate:

MTBF in years:

65.6 a (long-term usage at 60 °C / 140 °F )

Conformity &

standards:

EMC 2004/108/EC:

Guideline 2011/65/EU:

EN 61000-6-2, EN 61000-6-3, EN 61000-6-4

RoHS-conform

Ip251_02b_oi_e.doc / Apr-16 Page 26 / 28

Page 27

10. Dimensions

74 mm (2.913’’)

91mm (3.583’’)

40 mm

(1.575’’)

79 mm

(3.110’’)

Front view

Side view

Top view

Ip251_02b_oi_e.doc / Apr-16 Page 27 / 28

Page 28

Parameter

Min. value

Max. value

Default

Pos.

Char.

Ser. Code

X Operand

-10.0000

+10.0000

1.0000

+/- 6 4 00

/ Operand

0

10.0000

1.0000

6 4 01

+/- Operand

-99999999

99999999

0

+/- 8 0 02

Linear In

-99999999

+99999999

0

+/- 8 0 03

Linear Out

-99999999

+99999999

10000

+/- 8 0 04

Round Loop

0

99999999

0 8 0

05

Parallel Mode

0 2 0 1 0

06

Linearisation Mode

0 2 0 1 0

07

SSI Low Bit

0

25

1 2 0

08

SSI High Bit

1

25

25

2 0 09

SSI Baudrate

100

1000000

100000

7 0 10

SSI Wait Time

0

10.000

0 5 3

11

SSI Offset

0

99999999

0 8 0

12

SSI Hold Polarity

0 1 0 1 0

13

SSI Error Bit

0

25

0 2 0

14

SSI Error Bit Polarity

0 1 0 1 0

15

P1(x)

-100.000

+100.000

100000

+/- 6 3 A0

P1(y)…..

-100.000

+100.000

100000

+/- 6 3 A1

P16(x)

-100.000

+100.000

100000

+/- 6 3 D0

P16(y)

-100.000

+100.000

100000

+/- 6 3 D1

Direction 0 1 0 1 0 46

Parallel Inv

0 1 1 1 0

47

Parallel Value

-999 999

33554431

+/-8

5 0 48

Unit Number

0

99

11

2 0 90

Serial Baud Rate

0 6 0 1 0

91

Serial Format

0 9 0 1 0

92

Serial Protocol

0 1 0 1 0

30

Serial Timer

0

99.999

0 5 3

31

Serial Value

0

19

0 2 0

32

11. Parameter List, Default Settings

Ip251_02b_oi_e.doc / Apr-16 Page 28 / 28

Loading...

Loading...