Operating Manual

7384.5010

Level Converter, Direction Signal Decoder and programmable pulse divider

Product features:

Level Converter (RS-422, HTL Single Ended, HTL Differential,

TTL and and vice-versa

Implementation between the two types of representations for the direction

of rotation (A/B 90 °, A/B Direction and vice versa)

Adjustable division ratio of directional A / B pulses

Adjustable division ratio for the Z pulse

Reset of the Z divider by external input (defined setting)

Zero setting of the A / B / Z divider by external input (defined Start / Stop)

Z divider can also be used as an independent second divider

Limit frequency up to 1 MHz, depending on the input format

Push-pull outputs direct SPS control

9 to 30 VDC power supply

motrona GmbH, Zeppelinstraße 16, DE - 78244 Gottmadingen, Tel. +49 (0) 7731 9332-0, Fax +49 (0) 7731 9332-30, info@motrona.com, www.motrona.com

Version:

Description:

7384.5010_01a/CF/ Oct 2018

Version 1

7384.5010_01b/CF/ Feb 2019

First revision

7384.5010_02a/AF/MBO/Dez 2019

7384.5010 extension

7384.5010_02b/MBO/Feb. 2021

Chapter 1.4 / EMC Guidelines added, standards updated

Legal notices:

All contents included in this manual are protected by the terms of use and copyrights of motrona GmbH. Any reproduction,

modification, usage or publication in other electronic and printed media as well as in the internet requires prior written

authorization by motrona GmbH.

7384_5010_02b_oi_e.docx / Feb-21 Page 2 / 24

Table of Contents

Safety Instructions and Responsibility ......................................................................... 4

General Safety Instructions ............................................................................................................. 4

Use according to the intended purpose .......................................................................................... 4

Installation ....................................................................................................................................... 5

EMC Guidelines ................................................................................................................................ 6

Cleaning, Maintenance and Service Notes ..................................................................................... 6

Compatibility Hint ........................................................................................................ 7

Introduction .................................................................................................................. 8

Block diagram .............................................................................................................. 8

Electrical Connections .................................................................................................. 9

DC Power Supply .............................................................................................................................. 9

Auxiliary Voltage Output .................................................................................................................. 9

Incremental Inputs A, /A, B, /B, Z, /Z ............................................................................................10

Control Inputs .................................................................................................................................11

Pulse output ...................................................................................................................................11

Error Ausgang .................................................................................................................................12

LED..................................................................................................................................................12

Input and output configuration ................................................................................... 13

Level converter A/B Pulse (A/B Divider: All OFF) ..........................................................................14

Input/Output Mode Converter (A/B Divider: All OFF) ....................................................................14

Adjustable divider A/B ............................................................................................... 15

Setting the A/B Divider (at A/B Dir to A/B 90°) ............................................................................15

Setting the A/B divider (for all other modes) ................................................................................16

Setting to zero the A/B divider with ZERO_A Signal ....................................................................18

Informationen over the signal change A/B Dir ..............................................................................18

Adjustable divider Z ................................................................................................... 19

Pegel conversion Z Puls (Z Divider: all OFF) ..................................................................................19

Setting the Z Divider ......................................................................................................................19

Location and width of the Z pulse .................................................................................................20

Independent Z Divider ....................................................................................................................21

Automatic generation of a Z pulse ................................................................................................22

Reset the Z divider with ZERO_Z Signal .......................................................................................22

Dimensions ................................................................................................................ 23

Technical Specifications ............................................................................................ 24

7384_5010_02b_oi_e.docx / Feb-21 Page 3 / 24

Safety Instructions and Responsibility

General Safety Instructions

This operation manual is a significant component of the unit and includes important rules and

hints about the installation, function and usage. Non-observance can result in damage and/or

impairment of the functions to the unit or the machine or even in injury to persons using the

equipment!

Please read the following instructions carefully before operating the device and observe all

safety and warning instructions! Keep the manual for later use.

A pertinent qualification of the respective staff is a fundamental requirement in order to use

these manual. The unit must be installed, connected and put into operation by a qualified

electrician.

Liability exclusion: The manufacturer is not liable for personal injury and/or damage to property

and for consequential damage, due to incorrect handling, installation and operation. Further

claims, due to errors in the operation manual as well as misinterpretations are excluded from

liability.

In addition the manufacturer reserve the right to modify the hardware, software or operation

manual at any time and without prior notice. Therefore, there might be minor differences

between the unit and the descriptions in operation manual.

The raiser respectively positioner is exclusively responsible for the safety of the system and

equipment where the unit will be integrated.

During installation or maintenance all general and also all country- and application-specific

safety rules and standards must be observed.

If the device is used in processes, where a failure or faulty operation could damage the system

or injure persons, appropriate precautions to avoid such consequences must be taken.

Use according to the intended purpose

The unit is intended exclusively for use in industrial machines, constructions and systems. Nonconforming usage does not correspond to the provisions and lies within the sole responsibility

of the user. The manufacturer is not liable for damages which has arisen through unsuitable

and improper use.

Please note that device may only be installed in proper form and used in a technically perfect

condition - in accordance to the “Technical Specifications” (see chapter 10). The device is not

suitable for operation in explosion-proof areas or areas which are excluded by the EN 61010-1

standard.

7384_5010_02b_oi_e.docx / Feb-21 Page 4 / 24

Installation

The device is only allowed to be installed and operated within the permissible temperature

range. Please ensure an adequate ventilation and avoid all direct contact between the device

and hot or aggressive gases and liquids.

Before installation or maintenance, the unit must be disconnected from all voltage-sources.

Further it must be ensured that no danger can arise by touching the disconnected voltagesources.

Devices which are supplied by AC-voltages, must be connected exclusively by switches,

respectively circuit-breakers with the low voltage network. The switch or circuit-breaker must

be placed as near as possible to the device and further indicated as separator.

Incoming as well as outgoing wires and wires for extra low voltages (ELV) must be separated

from dangerous electrical cables (SELV circuits) by using a double resp. increased isolation.

All selected wires and isolations must be conform to the provided voltage- and temperatureranges. Further all country- and application-specific standards, which are relevant for structure,

form and quality of the wires, must be ensured. Indications about the permissible wire crosssections for wiring are described in the Technical Specifications (see chapter 10).

Before first start-up it must be ensured that all connections and wires are firmly seated and

secured in the screw terminals. All (inclusively unused) terminals must be fastened by turning

the relevant screws clockwise up to the stop.

Overvoltages at the connections must be limited to values in accordance to the overvoltage

category II.

7384_5010_02b_oi_e.docx / Feb-21 Page 5 / 24

EMC Guidelines

All motrona devices are designed to provide high protection against electromagnetic interference.

Nevertheless you must minimize the influence of electromagnetic noise to the device and all

connected cables.

Therefore the following measures are mandatory for a successful installation and operation:

Use shielded cables for all signal and control input and output lines.

Cables for digital controls (digital I/O, relay outputs) must not exceed a length of 30 m and are

allowed for in building operation only

Use shield connection clamps to connect the cable shields properly to earth

The wiring of the common ground lines must be star-shaped and common ground must be

connected to earth at only one single point

The device should be mounted in a metal enclosure with sufficient distance to sources of

electromagnetic noise.

Run signal and control cables apart from power lines and other cables emitting

electromagnetic noise.

Please also refer to motrona manual “General Rules for Cabling, Grounding, Cabinet Assembly”.

You can download that manual by the link

https://www.motrona.com/en/support/general-certificates.html

Cleaning, Maintenance and Service Notes

To clean the front of the unit please use only a slightly damp (not wet!), soft cloth. For the rear

no cleaning is necessary. For an unscheduled, individual cleaning of the rear the maintenance

staff or assembler is self-responsible.

During normal operation no maintenance is necessary. In case of unexpected problems, failures

or malfunctions the device must be shipped for back to the manufacturer for checking,

adjustment and reparation (if necessary). Unauthorized opening and repairing can have

negative effects or failures to the protection-measures of the unit.

7384_5010_02b_oi_e.docx / Feb-21 Page 6 / 24

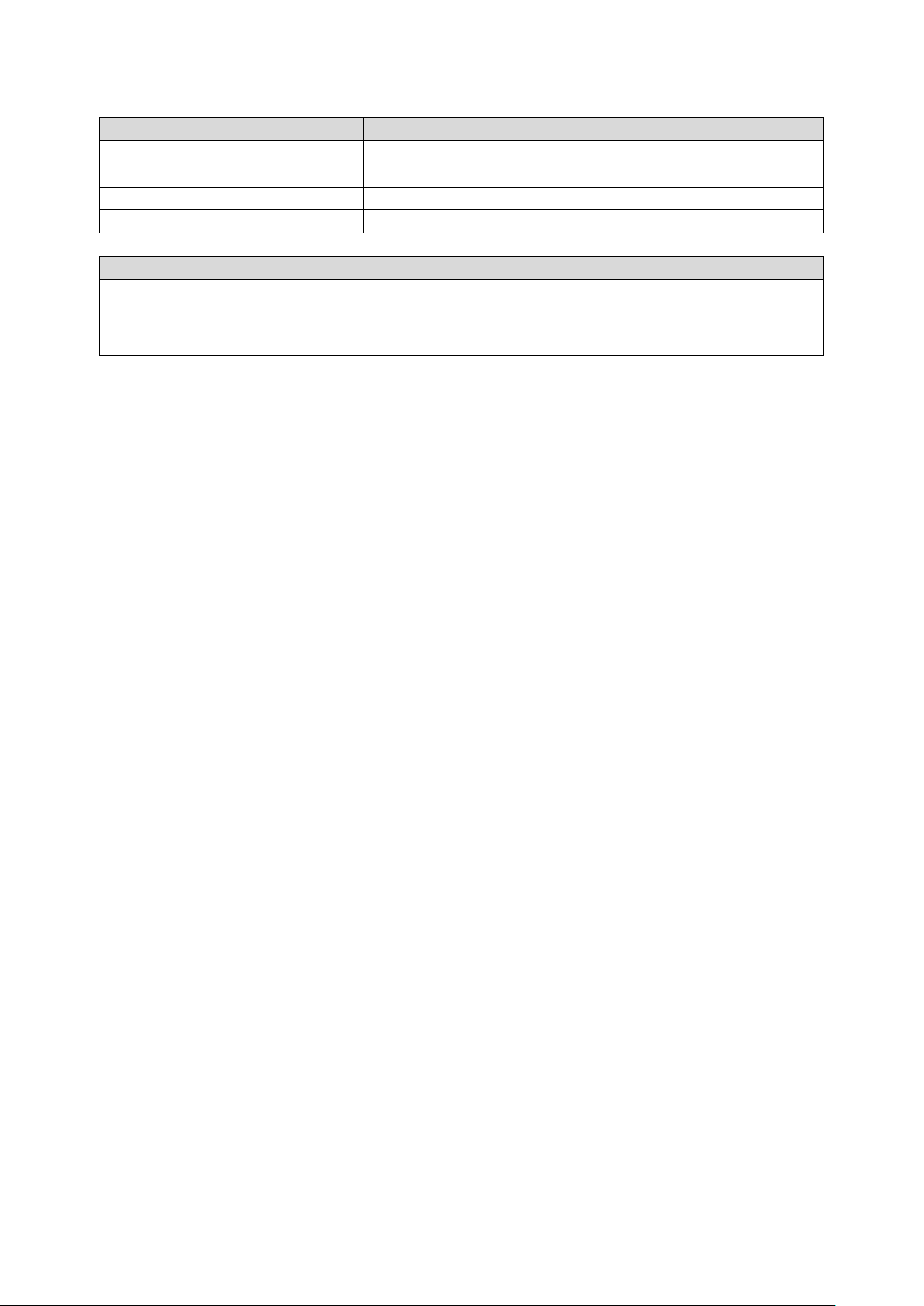

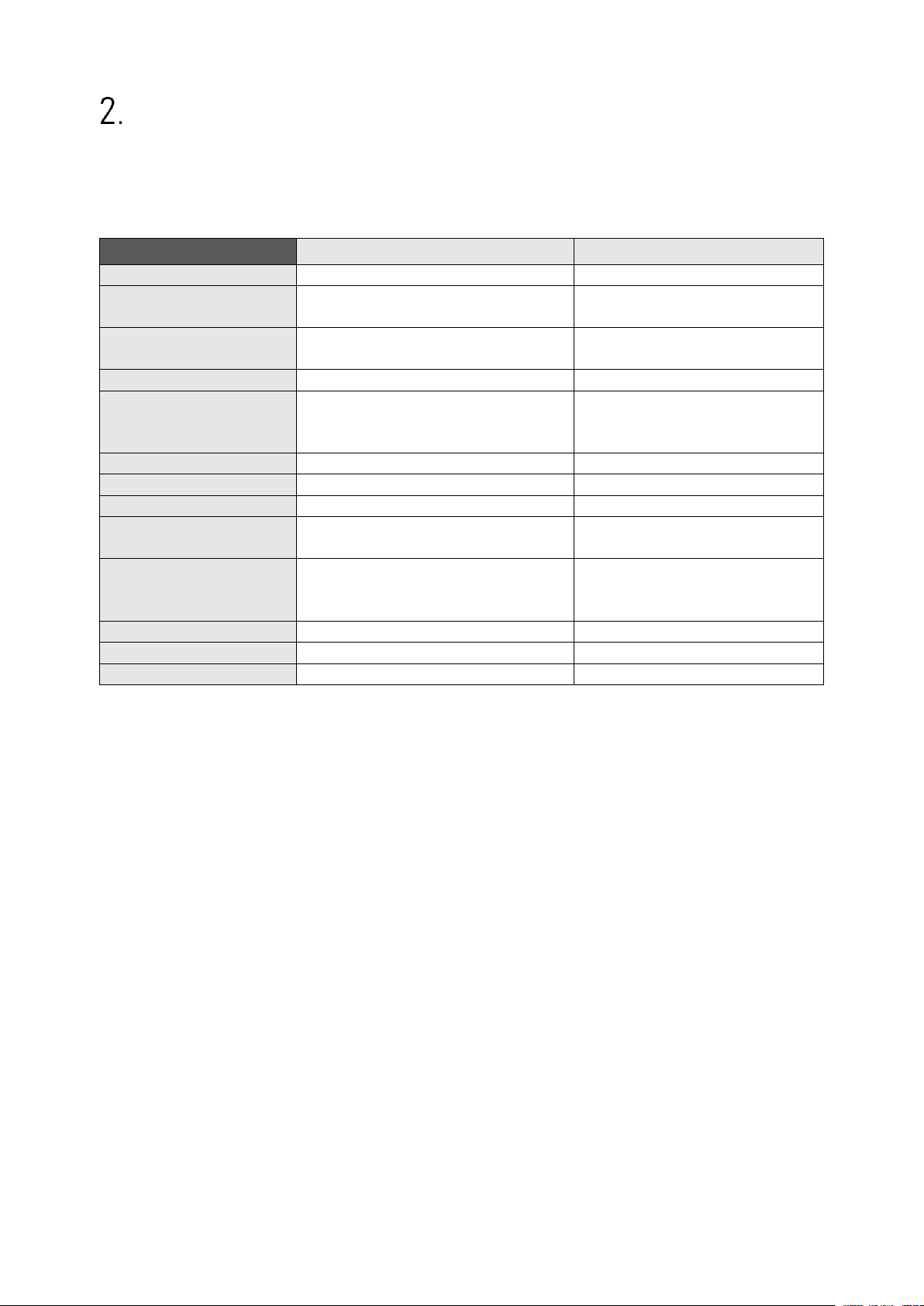

Compatibility Hint

7384.5051

7384.5010

Housing

5051

5010

Input

RS422/DSUB

HTL/clamps

clamps

Input characteristics

RS422/HTL Single

RS422/HTL Diff/HTL

Single/TTL

Frequency

Max. 300kHz

1MHz/1MHz/350kHz/350kHz

Output

RS422/DSUB

HTL/clamps

Parallel outputs

clamps

Only 1 output

Encoder supply

5.5V/130mA

5.5V/250mA

Temperature

0..45°

0..60°

MTBF

55,4a

109,3a

Supply

18..30V

9..30V (supply determines the

nominal output level)

Input type

A/B90°

A/BDir

APuls/BPuls

A/B90°

A/BDir

-

A/B-divider

1:4096

1:4096

Z-divider

1:256

1:256

Zero pulse length

Adjustable

Adjustable

The main differences between the 7384.5010 and the respective predecessor model 7384.5051

are listed below:

7384_5010_02b_oi_e.docx / Feb-21 Page 7 / 24

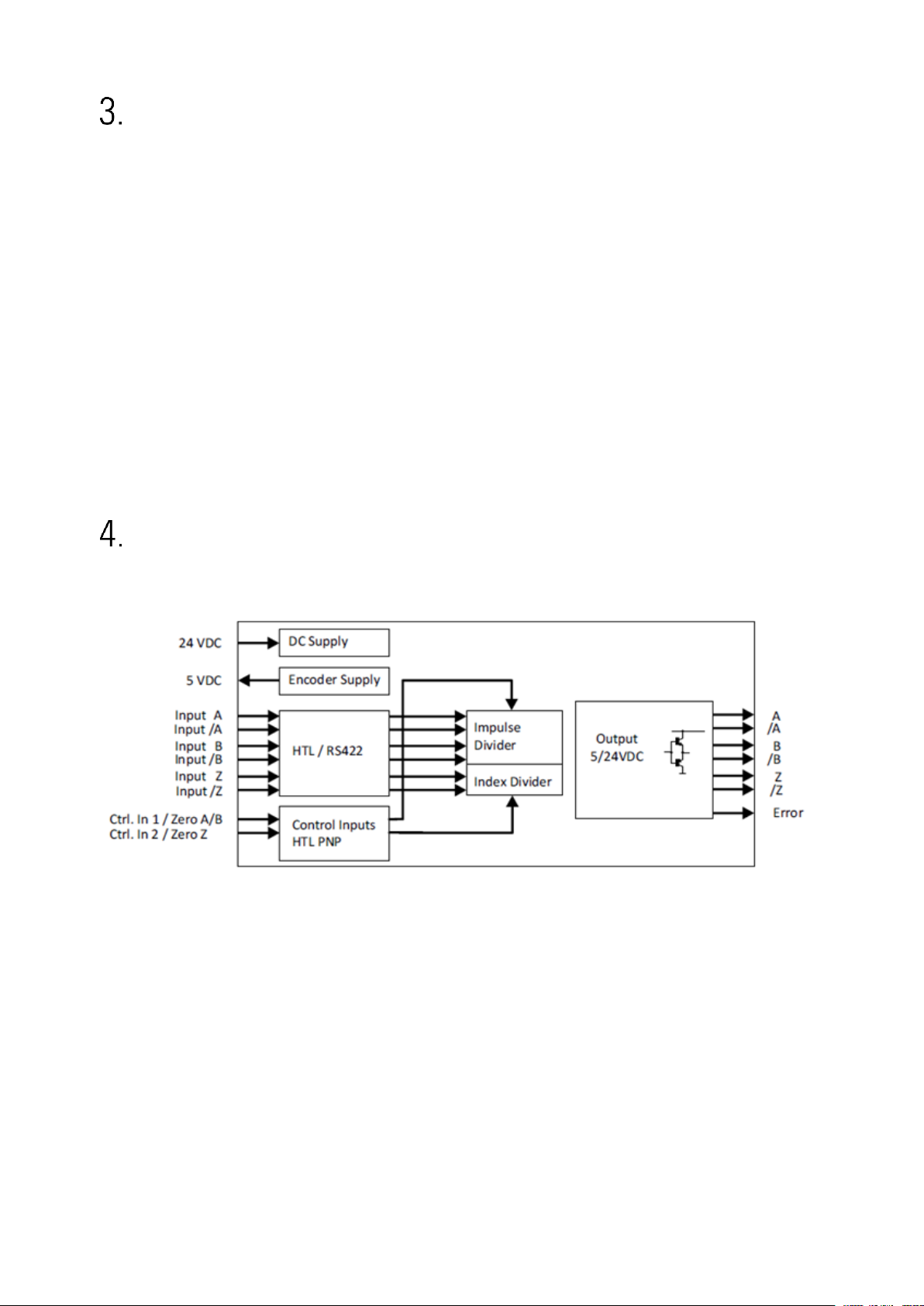

Introduction

The 7384.5010 is a universal interface using with incremental measuring systems.

The device allows the solution of the following problems:

• Level conversion (RS-422, HTL single ended, HTL differential, TTL and vice versa)

• Division of two-track A / B pulses with adjustable ratio 1: 1 to 1: 4096

• Division of the Z pulse with adjustable ratio 1: 1 to 1: 256

• External HTL signals for various functions

• Implementation between the two types of representations for the direction of rotation

(A/B 90 °, A/B Dir and vice versa, Division possible)

• Start / stop functionality via external ZERO_A signal

All settings are made on the DILL switches on the housing. The device consists of a compact

housing with screw terminals and can be mounted on a DIN rail.Block diagram

Block diagram

7384_5010_02b_oi_e.docx / Feb-21 Page 8 / 24

Electrical Connections

The terminal screws should be tightened with a slotted screwdriver (blade width 2mm).

DC Power Supply

The device is supplied with a DC voltage between 9 ... 30 VDC via terminals 1 and 2 of X1. The

current consumption depends on the level of the supply voltage and the settings and is approx.

35 mA without load from the sensor supply and additional on the extracted encoder current at

the auxiliary voltage output.

All GND terminals are internally interconnected.

Auxiliary Voltage Output

At terminal 8 and 9 of X4 the auxiliary voltage as encoder / sensor supply is +5.5 VDC and can

be charged with max. 250 mA.

7384_5010_02b_oi_e.docx / Feb-21 Page 9 / 24

Incremental Inputs A, /A, B, /B, Z, /Z

RS422

HTL DIFFERENTIAL

HTL PNP

At terminal 2 ... 7 of X4, 3 pulse inputs are available for HTL / TTL / RS422 signals. The unused

inputs must be open (HTL single ended vs. HTL differential) or terminated (unused Z track in RS422 or HTL differential format).

Wiring of the incremental inputs:

7384_5010_02b_oi_e.docx / Feb-21 Page 10 / 24

Control Inputs

Please note that all input and output signals refer to the same common

potential (GND) which at the same time is also the minus potential of the

power supply.

At any time, the total transmission characteristics of encoder, external

components and capacity of the cable must ensure proper signals at the

input terminals of the unit, with respect to the levels, the shape and the

phase displacement A/B.

Two control inputs with HTL PNP characteristics are available at terminals 2 and 3 of X2 and

are used for resetting the internal dividers

Unconnected control inputs are always “LOW”.

All inputs are designed to receive impulses from an electronic impulse source.

Notice for mechanical switching contacts:

When exceptionally mechanical contacts are used, please connect an external capacitor

between GND (-) and the corresponding input (+). A capacity of 10 µF will reduce the input

frequency to

20 Hz and miscounting due to contact bouncing will be eliminated.

Pulse output

Depending on the DIL switch setting, the pulses are available in HTL or RS-422 format at the

outputs of screw terminal X3 and are independent of the used format. The height of the pulse

level at the push-pull outputs in the HTL setting corresponds approximately to the input voltage

at the supply input X1.

7384_5010_02b_oi_e.docx / Feb-21 Page 11 / 24

Error Ausgang

An HTL error signal (input error, only with RS-422 or HTL differential) is available at the X3

screw terminal 1. (Error = low).

The error is triggered by a line fault (short circuit or line break) by the input lines A, / A, B, / B or

Z, / Z. (Test mode OFF, DIL2 / 2 = OFF.

The DIL switch DIL3 (right, 3-pin) can be used to select the corresponding channel. If the DIL3 /

1 contact is set to OFF, no errors are evaluated on the A, / A line, DIL3 / 2 refers to the line B, /

B and DIL3 / 3 to the line Z, / Z.

An error can only be detected in RS-422 or HTL differential format, all other formats will not

trigger an error.

LED

The green LED indicates operational readiness (power supply switched on).

The yellow LED signals an input error. (only with RS-422 or HTL differential)

7384_5010_02b_oi_e.docx / Feb-21 Page 12 / 24

Input and output configuration

Changes in the settings on the DIL switches will only be taken over by the

device after the supply voltage has been switched on again!

Configuration

DIL1 (Front 8-pole)

Function

1 2 3 4 5 6 7

8

ON

Level for HTL Single Ended: UL < 10V / UH > 14V

OFF

Level for HTL Single Ended: U < 5V / U > 9V

ON

ON Input format: TTL

ON

OFF

Input format: HTL Single Ended

OFF

ON Input format: RS-422

OFF

OFF

Input format: HTL Differential

ON

ON Z-pulse length: 1 Z-Puls, independent of A / B

OFF

ON Z-pulse length: ynchronized with AOUT / BOUT

ON

OFF

Z-pulse length: synchronized with AIN / BIN

OFF

OFF

Z-pulse length: 1 Z-Puls, a depending on A/B

ON

Input Mode : A/B Dir (Pulse / Direction)

OFF

Input Mode : A/B 90°

ON Output Mode : A/B Dir (Pulse / Direction)

OFF

Output Mode : A/B 90°

ON

Highest divider for A / B divider on (2048)

OFF

Highest divider for A / B divider off (2048) Configuration

DIL2 (Front 3-pole)

Function

1 2 3

ON

Z-pulse: Generation of a Z-pulse from AIN & BIN, AOUT & BOUT

OFF

Z-pulse: Z input is used

OFF

Test mode deactivated: OFF

ON

Output format : HTL Differential, HTL Single Ended (

UX1(2)

– 2V)

OFF

Output format: RS-422, TTL (5V)

7384_5010_02b_oi_e.docx / Feb-21 Page 13 / 24

Level converter A/B Pulse (A/B Divider: All OFF)

Divider [A/B]

DIL5

(Left 8-pole)

DIL6

(Left 3-pole)

DIL1

(Front)

Comment

1 2 3 4 5 6 7 8 1 2 3 8

Binary value

1 2 4

8

16

32

64

128 256 512

1024

2048

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

AIN = AOUT, BIN = BOUT

If the A/B pulse have to be switched unchanged from the input to the output (no division, no

change in length and position), then the DIL switch position listed below must be chosen. A

level conversion is only possible if the input mode (A/B 90 ° or A/B dir) corresponds to the

output mode. (DIL1/6 = DIL1/7).

Input/Output Mode Converter (A/B Divider: All OFF)

If input mode differs from output mode and in addition, the DIL switches DIL5 and DIL6 of the

divider A/B are all set to OFF, the following signal characteristics are set up at the output.

Case 1: Input A/B 90°, Output A/B Dir

DIL1/6 = OFF, DIL1/7 = ON with A/B Divider setting: DIL5, 6 = all OFF

If the direction of the A/B 90 ° signal changes at the input, a change takes place at the BOUT

output signal. (A/B dir). There is no division.

Case 2: Input A/B Dir, Output A/B 90°

DIL1/6 = ON, DIL1/7 = OFF with A/B Divider setting: DIL5, 6 = all OFF

If a change takes place at the BIN input signal (A/B dir), the direction of the A/B 90 ° signal

changes at the output. Here is a division 1:2, from the input in relation to the output.

7384_5010_02b_oi_e.docx / Feb-21 Page 14 / 24

Adjustable divider A/B

Divider [A/B]

DIL5

(Left 8-pole)

DIL6

(Left 3-pole)

DIL1

(Front)

Comment

1 2 3 4 5 6 7 8 1 2 3 8

Binary value

division =>

1 : (Binary value +1) x2

1 2 4

8

16

32

64

128 256 512

1024

2048

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 1 => 1 : 4

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 2 => 1 : 6

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 3 => 1 : 8

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 4 => 1 : 10

ON

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 5 => 1 : 12

OFF

...etc.

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

1 : 1026

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

1 : 2050

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

1 : 4096

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

1 : 8192

Setting the A/B Divider (at A/B Dir to A/B 90°)

The division ratio for the A/B pulses is set at the DIL switches DIL5 and DIL6. The switch

positions use a binary code like shown in the subsequent list. (DIL1/6 = ON, DIL1/7 = OFF).

Example: Input A/B dir, output A/B 90 ° with A/B division 1:6 (setting DIL6, 5: OFF ON OFF)

Division 1:2: See Input/Output Mode Conversion (A/B Divider: All OFF)

7384_5010_02b_oi_e.docx / Feb-21 Page 15 / 24

Setting the A/B divider (for all other modes)

Divider [A/B]

DIL5

(Left 8-pole)

DIL6

(Left 3-pole)

DIL1

(Front)

Comment

1 2 3 4 5 6 7 8 1 2 3

8

Binary value

division =>

1 : Binary value +1

1 2 4

8

16

32

64

128 256 512

1024

2048

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 1 => 1 : 2

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 2 => 1 : 3

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 3 => 1 : 4

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 4 => 1 : 5

ON

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 5 => 1 : 6

OFF

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 6 => 1 : 7

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

value 7 => 1 : 8

OFF

...etc.

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

1 : 513

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

1 : 1025

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

1 : 2048

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

1 : 4096

The division ratio for the A/B pulses is set at the DIL switches DIL5 and DIL6. The switch

positions use a binary code like shown in the subsequent list. (DIL1/6 = OFF, DIL1/7 = X).

Example: Input A/B 90°, output A/B 90 ° with A/B division 1:6 (setting DIL6, 5: OFF ON OFF

7384_5010_02b_oi_e.docx / Feb-21 Page 16 / 24

Example: Input A/B 90°, output A/B 90 ° with A/B division 1:3 (setting DIL6, 5: OFF ON OFF

Example: Input A/B 90°, output A/B 90 ° with A/B division 1:3 (setting DIL6, 5: OFF ON OFF

7384_5010_02b_oi_e.docx / Feb-21 Page 17 / 24

Setting to zero the A/B divider with ZERO_A Signal

The divider will only be reset in the zero phase of the output signals AOUT and BOUT and will

remain as long as the signal is attached. This prevents the miscounting of subsequent circuits.

This function can only be applied to A/B 90°, it is independent of the divider ratio.

If there is a high signal at ZERO_A the A/B divider is reset and has the starting state AOUT =

BOUT = Low. The divider is in a defined state. Depending on the direction of the input signals,

the next split A/B pulse appears immediately after the reset, or after the set division ratio. The

length of the ZERO_A pulse has to be greater than the period of frequency, than it can be

switched off. This feature can be used for define start and stop.

The Z track can be set to zero with the ZERO_A input. The DIL switch DIL1/8 has been set to

ON, A/B 90 ° output signals have been selected and the Z Pulse length has been synchronized

to the output.

Informationen over the signal change A/B Dir

Signal changes from B (direction) should appear shortly before or latest at the same time as the

A flank so that the change can be detected correctly.

7384_5010_02b_oi_e.docx / Feb-21 Page 18 / 24

Adjustable divider Z

Divider [Z]

DIL4 (right 8-pole)

Comment

Binary value

1 2 3 4 5 6 7

8

1 2 4

8

16

32

64

128

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ZIN = ZOUT (ZERO_Z = Low)

Divider [Z]

DIL4 (right 8-pole)

Comment

Binary value

Divider => 1: Binary value +1

1 2 3 4 5 6 7

8

1 2 4

8

16

32

64

128

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

1 : 2

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

1 : 3

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

1 : 4

OFF

OFF

ON

ON

ON

ON

ON

ON

1 : 253

ON

OFF

ON

ON

ON

ON

ON

ON

1 : 254

OFF

ON

ON

ON

ON

ON

ON

ON

1 : 255

ON

ON

ON

ON

ON

ON

ON

ON

1 : 256

Pegel conversion Z Puls (Z Divider: all OFF)

If the Z pulse have to be switched unchanged from the input to the output (no division, no

change in length and position), then the DIL switch position listed below must be chosen.

The output at the level conversion can be set to zero (ZOUT = Low) with the control input X2(3)

ZERO_Z = High.

The function is active as long as there is a high level at the control input. The Z pulse can be

trimmed by switching.

Setting the Z Divider

The programming of the Z divider is subject to the same rules as the programming of the A/B

divider.

7384_5010_02b_oi_e.docx / Feb-21 Page 19 / 24

Location and width of the Z pulse

DIL1 Front

8-pole

Wide Z pulse (a full encoder turn)

4

5

ON

ON

The pulse width at the output corresponds to the full distance between two Z

pulses at the input.

DIL1 Front

8-pole

Narrow Z pulse (1/4 output-periode)

(Only applicable to input signals A/B 90°, DIL1/6 = OFF)

4 5

ON

OFF

The pulse width at the output corresponds to ¼ period of pulse width at the input.

If the DIL switch DIL4 of the Z divider is completely set to OFF, the Z Pulse is forwarded from

the input directly to the output (see level conversion Z Puls).

All pictures in this section assume that the A/B divider is set to 8. The Z Pulse is divided

according to its divider (additionally DIL2/1 on OFF, ZIN is used, Z dividers not complete on

OFF).

Depending on the length or location of the Z Pulses input and through the synchronization to

the input or output signals, the Z pulse at the output can fluctuate around an input or output

period (not with DIL1/5 = DIL1/4 = ON).

7384_5010_02b_oi_e.docx / Feb-21 Page 20 / 24

DIL1 Front

8-pole

Narrow Z pulse (1/4 output-periode)

(Only applicable to output signals A/B 90°, DIL1/7 = OFF)

4 5

ON

OFF

The pulse width at the output corresponds to ¼ period of pulse width at the

output.

DIL1 Front

8-pole

Wide Z pulse (a full encoder turn)

4 5

ON

ON

The pulse width at the output corresponds to the full distance between two

Z pulses at the input.

In this operation mode, only division ratios may be used, which together with the A/B divisor

deliver clear and completely results. A division with rest causes that the Z pulse at the output

can fluctuate around an input or output period.

Example:

If at an encoder with 1000 pulses the A/B devider were set to 3 and at the same time the Z

Pulse divider were set to 2, then the Z Pulse at the output would have to appear after 666,666

pulses, which is not physically possible.

Independent Z Divider

The Z divider works independently of the A/B track, the directional evaluation of the A/B signal

does not affect the counting sequence (additionally DIL2/1 on OFF, ZIN is used, Z divider not

completely set to OFF).

7384_5010_02b_oi_e.docx / Feb-21 Page 21 / 24

Automatic generation of a Z pulse

DIL1 Front

8-pole

Narrow Z puls e (1/4 output- or input-period)

4

5

OFF

ON

The Z pulse is generated from the input signal A/B. Each input period

generates one count for the Z divider.

The Z pulse width at the output corresponds to 1/4 period of the pulse width of

the input signal A/B (Only applicable to input signals A/B 90°, DIL1/6 = OFF).

ON

OFF

The Z pulse is generated from the output signal A/B. Each output period

generates one count for the Z divider.

The Z pulse width at the output corresponds to 1/4 period of the pulse width of

the output signal A/B (Only applicable to output signals A/B 90°, DIL1/7 = OFF).

If the DIL switch DIL2/1 is set to ON, a Z pulse can be automatically generated.

The Z input is ineffective and does not need to be connected (Z divider not completely set on

OFF).

Reset the Z divider with ZERO_Z Signal

The Z divider can be reset by applying a high signal to the control input ZERO_Z.

The reset will act immediately and as long as the signal is applied.

Depending on the direction of the A/B track, the next Z pulse appears immediately after the

reset or according to the set division ratio (not at the independent Z divider).

The reset of the Z divider can also be performed in case of automatic generation of the Z pulse.

By setting the Z-divider = all OFF, the setting of the ZERO_Z input causes an immediate zero

setting of the output ZOUT (see level conversion Z pulse).

Note the special case in which the ZERO_A signal can also set the Z output to zero (see Setting

to zero of the A/B divider with ZERO_A signal)

7384_5010_02b_oi_e.docx / Feb-21 Page 22 / 24

Dimensions

7384_5010_02b_oi_e.docx / Feb-21 Page 23 / 24

Technical Specifications

Technical Specifications

Connections

Connection type:

Screw terminals, 1,5 mm² / AWG 16

Power supply:

Input voltage:

Protection circuit:

Ripple:

Consumption:

9 … 30 VDC

reverse polarity protection

≤ 10 %

approx. 40 mA (at 9 V, unloaded)

approx. 30 mA (at 30 V, unloaded)

Sensor supply:

Output voltage:

Output current:

+ 5,5 VDC +/- 5 %

max. 250 mA

Incremental inputs:

Number:

Traces:

Configuration:

RS422:

HTL Differential:

HTL Signal Ended:

TTL:

3

A, B, Z (HTL Single Ended, TTL)

A, /A, B, /B, Z, /Z (RS422, HTL Differential )

RS422, HTL Differential, HTL Single Ended, TTL

max. 1 MHz (RS422 Differential signal > 1 V)

max. 1 MHz (HTL Differential signal > 2 V)

max. 350kHz, level 1: Low 0 … 10V, High 14 … 30 V

level 2: Low 0 … 5V, High 9 … 30 V

max. 350kHz, Low 0 … 0.7V, High 2.2 … 5 V

Control inputs:

Number:

Format:

Frequency:

Response time:

Load:

2

HTL, PNP (Low 0 … 5 V, High 9 … 30 V)

max. 20kHz

50 µs

max. 3mA

Incremental outputs:

Number:

Traces:

Format / level:

Output current:

Response time:

3

A, /A, B, /B, Z, /Z

HTL: 8 … 29 V (depending on the supply voltage)

RS422: 5 V

max. 20 mA / Push-Pull

approx. 600ns

Housing:

Material:

Mounting:

Dimensions (w x h x d):

Protection class:

Weight:

plastic

35 mm top hat rail (according to EN 60715)

22,5 x 102 x 102 mm / 0,886 x 4,016 x 4,016”

IP20

approx. 100 g

Ambient temperature:

Operation:

Storage:

0 °C … +60 °C / +32 … +140 °F (not condensing)

-25 °C … +70 °C / -13 … +158 °F (not condensing)

Failure rate:

MTBF in years:

109,3 (long-term usage at 60 °C / 140 °F )

Conformity & standards:

EMC 2014/30/EU:

RoHS (Ⅱ) 2011/65/EU

RoHS (Ⅲ) 2015/863:

EN 61326-1: 2013 for industrial location

EN 55011: 2017 / CISPR11: 2017 Class A

EN IEC 63000: 2018

7384_5010_02b_oi_e.docx / Feb-21 Page 24 / 24

Loading...

Loading...