Motrona 7085.5010, 7386.5010, 8086.5010, 9085.5010 User guide

Operating Manual

Signal converter 7085.5010 / 7386.5010 / 8086.5010 / 9085.5010

Frequency (7085.5010)

Analog (current / voltage)

Serial (RS232 / RS485)

SSI absolute value (7386.5010)

Start-Stop (8086.5010)

Pulse counter (9085.5010)

Product features:

Multifunctional unit with several operating modes for incremental encoders or SSI absolute encoders

For incremental encoders:

Operating modes as frequency converter or position transducer (pulse counter)

Universal incremental inputs (HTL/TTL/RS422) for NPN/PNP/NAMUR encoders and sensors

Functions such as linkages (eg. A+B), scaling, filters, start-up bridging, …

Input frequencies up to 1 MHz

For SSI absolute encoders:

Master or Slave operation with clock frequencies up to 1 MHz

For single turn and multi turn encoders with SSI formats from 10 … 32 Bit

Functions such as bit suppression, round-loop function, scaling, …

For absolute and magnetostrictive position encoder with Start-Stop-Interface:

Operating modes for master or slave, for position, angle and speed measurement

16 bit analog output, configurable for voltage or current operation

USB interface and RS232/RS485-interface for configuration and serial readout

Extremely short conversion times

Linearization with 24 control points

Auxiliary voltage output 5 and 24VDC for encoder supply

Numerous connection options via 6 control inputs and 6 control outputs

Compact rail housing to EN60715

Easy parameterization via user interface OS (Freeware)

motrona GmbH, Zeppelinstraße 16, DE - 78244 Gottmadingen, Tel. +49 (0) 7731 9332-0, Fax +49 (0) 7731 9332-30, info@motrona.com, www.motrona.com

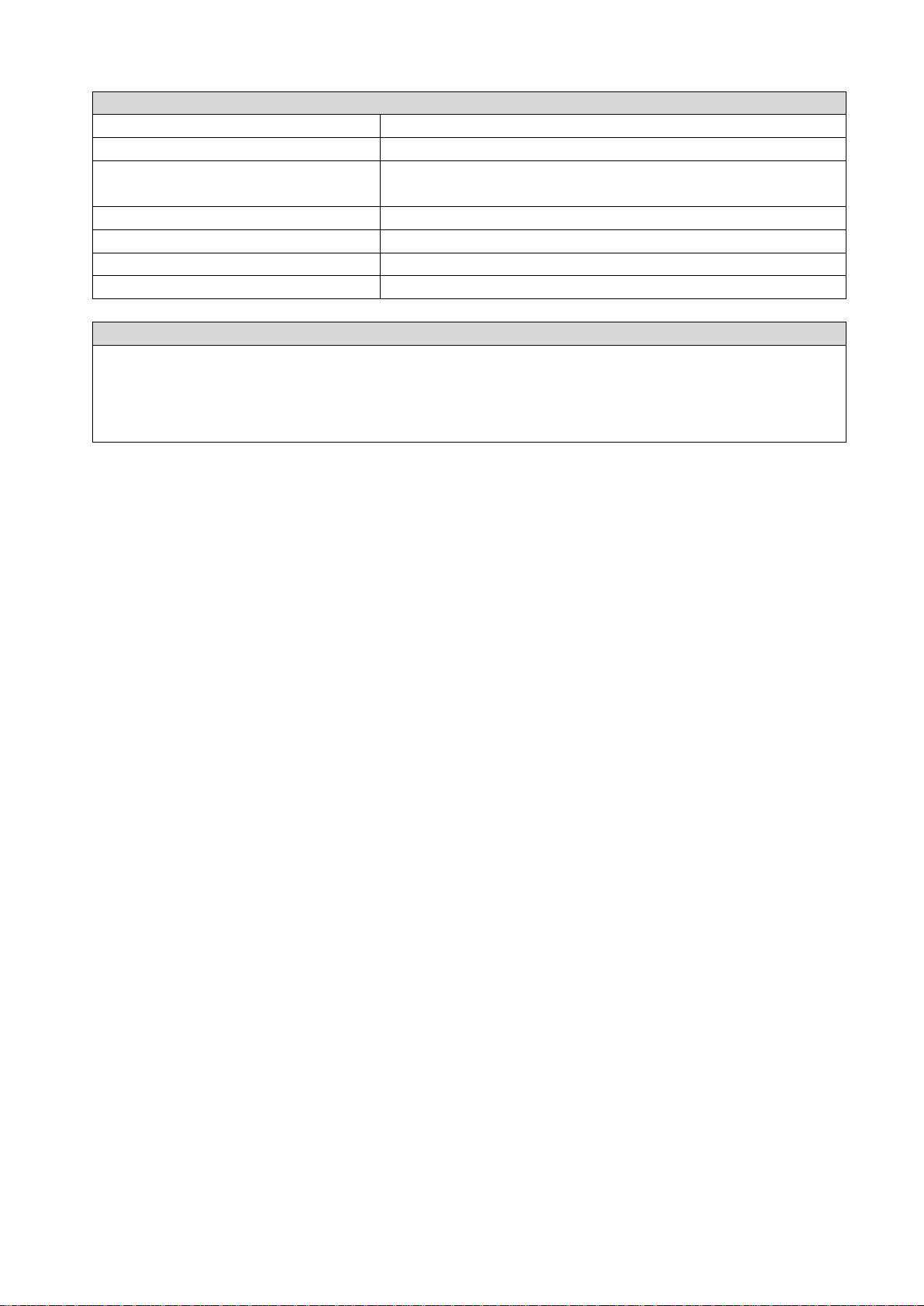

Version:

Description:

9085.5010_01a_oi/tgo/April 19

First Version

9085.5010_01b/mbo/August 19

New added: chapter “Compatibility Hint”

9085.5010_02a_oi/tgo/November 19

Extension of QR-code and of new filter functions at Mode

Frequency

9085.5010_02b_oi/mbo/December 19

Revised Version

9085.5010_03a_oi/mbo/tgo/Januar 20

Extension by start-stop-interface

9085.5010_03b_oi/mbo/April 2020

New connection diagram in chapter 4, failure rate added

9085.5010_04a_oi/mbo/August 2020

New USB interface at X7

Legal notices::

All contents included in this manual are protected by the terms of use and copyrights of motrona

GmbH. Any reproduction, modification, usage or publication in other electronic and printed media

as well as in the internet requires prior written authorization by motrona GmbH.

9085_5010_04a_oi_e.docx / Feb-21 page 2 / 72

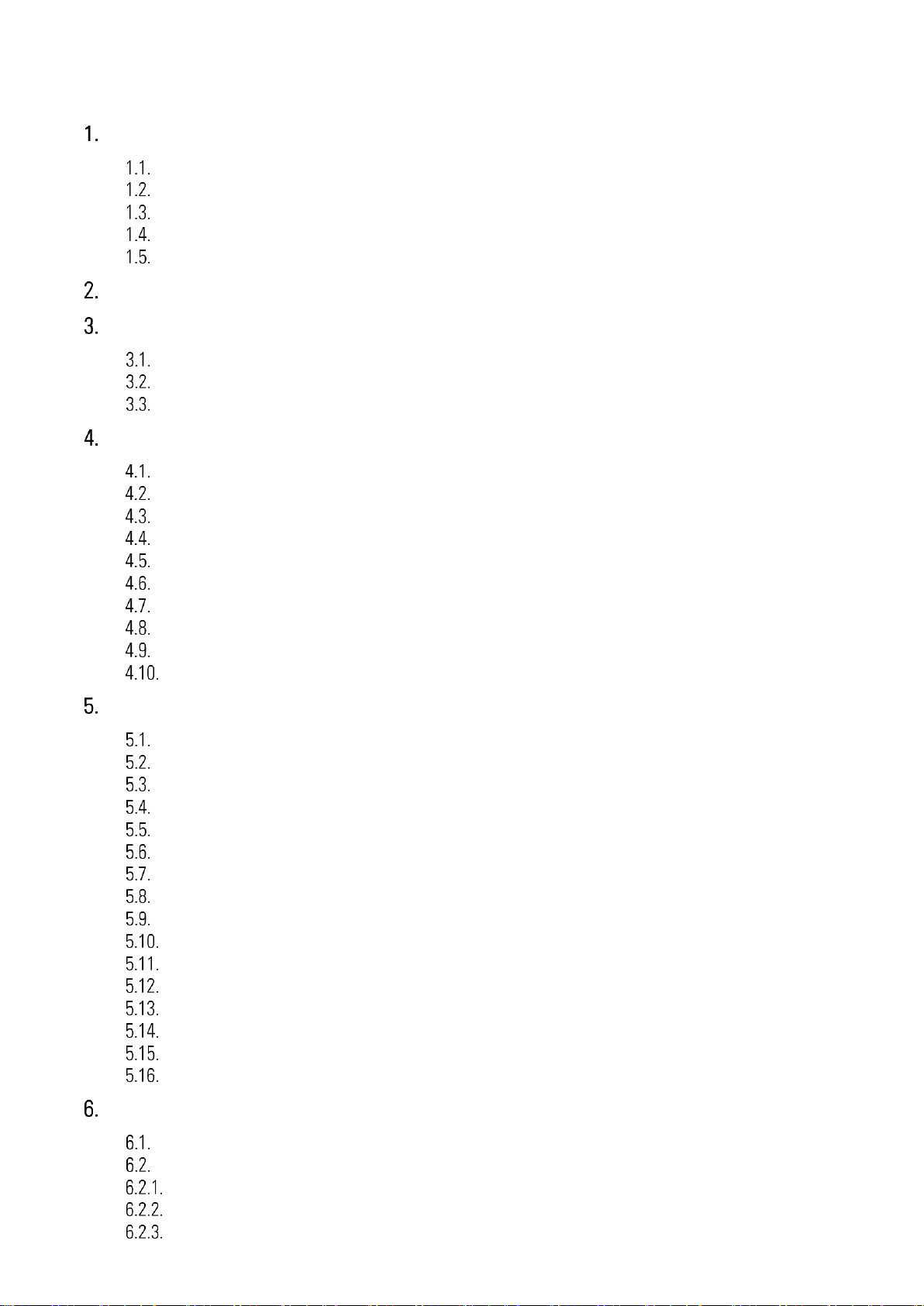

Table of Contents

Safety Instructions and Responsibility .......................................................................... 5

General Safety Instructions ............................................................................................................. 5

Use according to the intended purpose .......................................................................................... 5

Installation ....................................................................................................................................... 6

EMC Guidelines ............................................................................................................................... 7

Cleaning, Maintenance and Service Notes..................................................................................... 7

Compatibility Hint ........................................................................................................ 8

Introduction .................................................................................................................. 9

Operating Mode ............................................................................................................................... 9

Function diagram ............................................................................................................................. 9

Power – LED / Error messages ...................................................................................................... 10

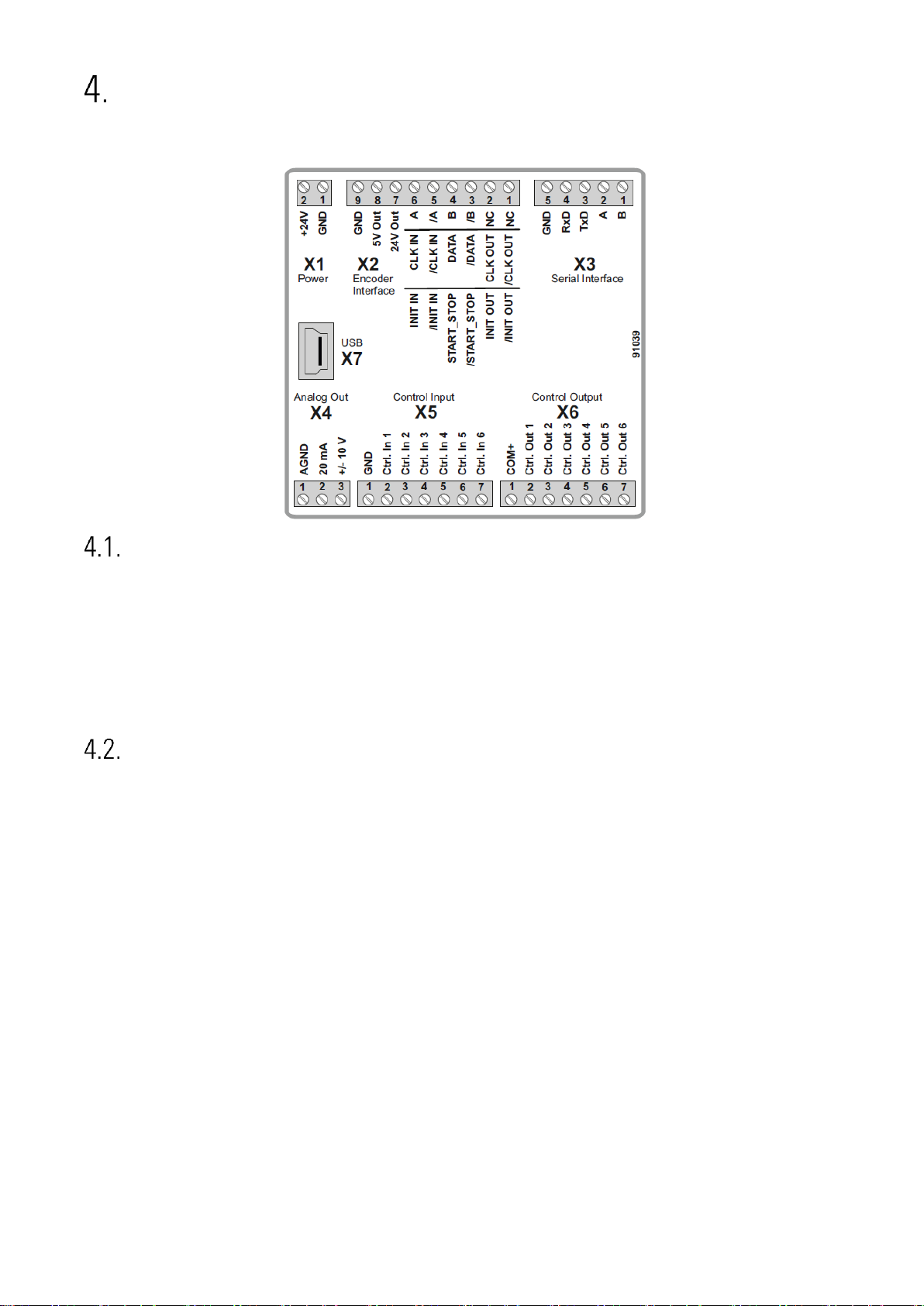

Electrical Connections ................................................................................................ 11

DC Power Supply (X1) .................................................................................................................... 11

Auxiliary voltage output (X2) ......................................................................................................... 11

Incremental encoder input (X2) ..................................................................................................... 12

SSI-Absolute encoder input (X2) ................................................................................................... 14

Start-stop encoder inputs (X2) ....................................................................................................... 16

Control Inputs (X5) ......................................................................................................................... 17

Analog output (X4) ......................................................................................................................... 18

Serial interface (X3) ....................................................................................................................... 19

USB interface (X7) .......................................................................................................................... 19

Control outputs (X6) ....................................................................................................................... 20

Parameter / Overview-Menu Structure ....................................................................... 21

General Menu ................................................................................................................................ 24

Mode Frequency ............................................................................................................................ 26

Mode Counter ................................................................................................................................ 31

Mode SSI........................................................................................................................................ 32

Mode Start/Stop ............................................................................................................................ 34

Preselection Values ....................................................................................................................... 36

Preselection 1 Menu ...................................................................................................................... 37

Preselection 2 Menu ...................................................................................................................... 40

Preselection 3 Menu ...................................................................................................................... 41

Preselection 4 Menu ...................................................................................................................... 42

Preselection 5 Menu ...................................................................................................................... 43

Preselection 6 Menu ...................................................................................................................... 44

Serial Menu ................................................................................................................................... 45

Analog Menu ................................................................................................................................. 48

Command Menu ............................................................................................................................. 49

Linearization Menu ........................................................................................................................ 51

Appendix .................................................................................................................... 52

Data readout via serial interface ................................................................................................... 52

Modbus RTU Interface ................................................................................................................... 53

Parameter setting .............................................................................................................................. 53

Read Holding Registers and Write Multiple Registers .................................................................... 54

Read Coils and Write Single Coil ...................................................................................................... 55

9085_5010_04a_oi_e.docx / Feb-21 page 3 / 72

Diagnose ............................................................................................................................................ 56

Parameter / serial codes................................................................................................................ 57

Linearization ................................................................................................................................... 63

Reading SSI-Value ......................................................................................................................... 65

Internal processing and calculation of SSI data ........................................................................... 66

Operating modes / OP modes of the Start/Stop interface ........................................................... 69

Dimensions .................................................................................................................................... 71

Technical Specifications: ............................................................................................................... 72

9085_5010_04a_oi_e.docx / Feb-21 page 4 / 72

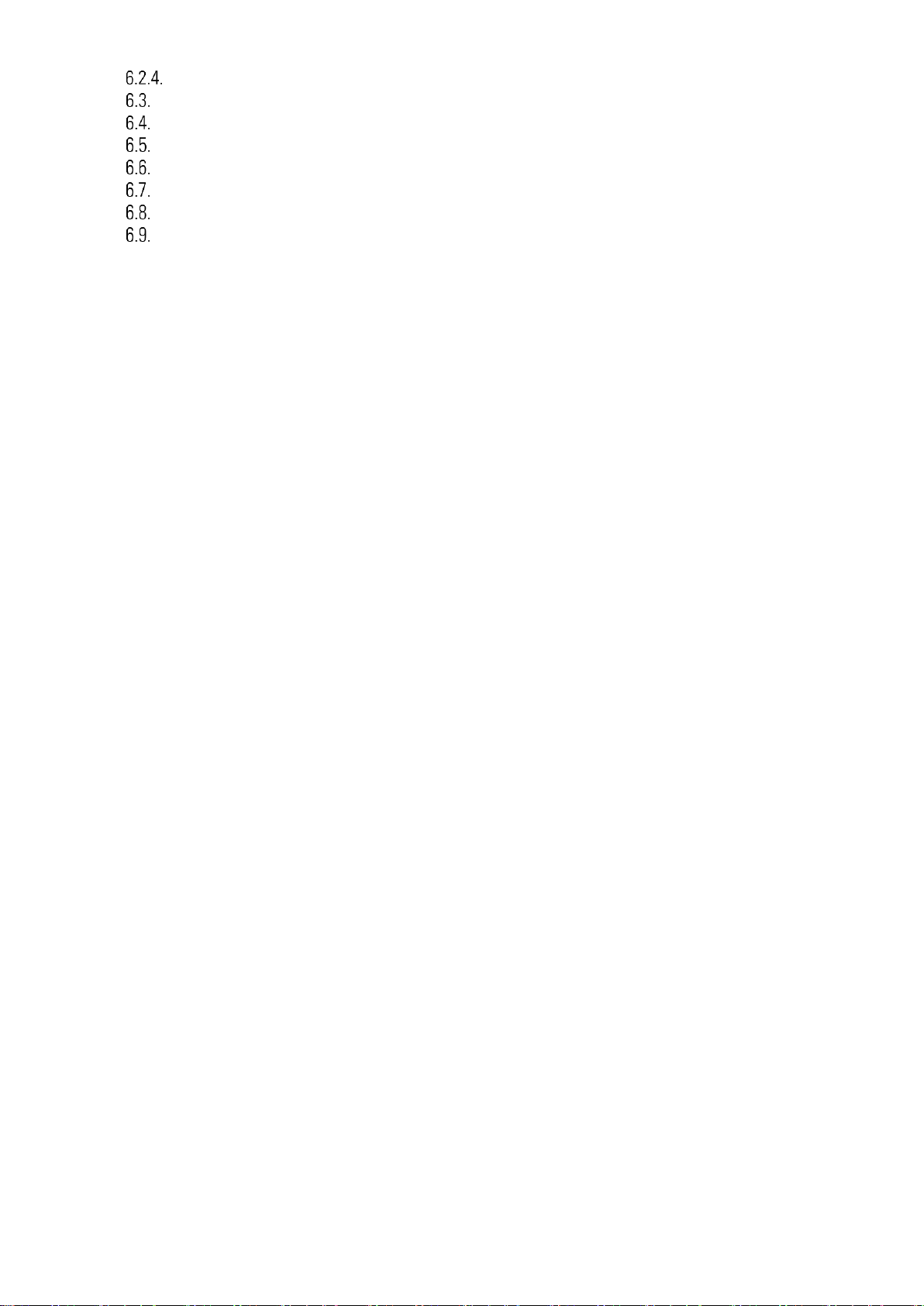

Safety Instructions and Responsibility

General Safety Instructions

This operation manual is a significant component of the unit and includes important rules and hints

about the installation, function and usage. Non-observance can result in damage and/or impairment

of the functions to the unit or the machine or even in injury to persons using the equipment!

Please read the following instructions carefully before operating the device and observe all safety

and warning instructions! Keep the manual for later use.

A pertinent qualification of the respective staff is a fundamental requirement in order to use these

manual. The unit must be installed, connected and put into operation by a qualified electrician.

Liability exclusion: The manufacturer is not liable for personal injury and/or damage to property and

for consequential damage, due to incorrect handling, installation and operation. Further claims, due

to errors in the operation manual as well as misinterpretations are excluded from liability.

In addition the manufacturer reserves the right to modify the hardware, software or operation

manual at any time and without prior notice. Therefore, there might be minor differences between

the unit and the descriptions in operation manual.

The raiser respectively positioner is exclusively responsible for the safety of the system and

equipment where the unit will be integrated.

During installation or maintenance all general and also all country- and application-specific safety

rules and standards must be observed.

If the device is used in processes, where a failure or faulty operation could damage the system or

injure persons, appropriate precautions to avoid such consequences must be taken.

Use according to the intended purpose

The unit is intended exclusively for use in industrial machines, constructions and systems. Nonconforming usage does not correspond to the provisions and lies within the sole responsibility of the

user. The manufacturer is not liable for damages which have arisen through unsuitable and improper

use.

Please note that device may only be installed in proper form and used in a technically perfect

condition (in accordance to the Technical Specifications). The device is not suitable for operation in

explosion-proof areas or areas which are excluded by the EN 61010-1 standard.

9085_5010_04a_oi_e.docx / Feb-21 page 5 / 72

Installation

The device is only allowed to be installed and operated within the permissible temperature range.

Please ensure an adequate ventilation and avoid all direct contact between the device and hot or

aggressive gases and liquids.

Before installation or maintenance, the unit must be disconnected from all voltage-sources. Further

it must be ensured that no danger can arise by touching the disconnected voltage-sources.

Devices which are supplied by AC-voltages must be connected exclusively by switches, respectively

circuit-breakers with the low voltage network. The switch or circuit-breaker must be placed as near

as possible to the device and further indicated as separator.

Incoming as well as outgoing wires and wires for extra low voltages (ELV) must be separated from

dangerous electrical cables (SELV circuits) by using a double resp. increased isolation.

All selected wires and isolations must be conform to the provided voltage- and temperature-ranges.

Further all country- and application-specific standards, which are relevant for structure, form and

quality of the wires, must be ensured. Indications about the permissible wire cross-sections for

wiring are described in the Technical Specifications.

Before first start-up it must be ensured that all connections and wires are firmly seated and secured

in the screw terminals. All (inclusively unused) terminals must be fastened by turning the relevant

screws clockwise up to the stop.

Overvoltages at the connections must be limited to values in accordance to the overvoltage

category II.

9085_5010_04a_oi_e.docx / Feb-21 page 6 / 72

EMC Guidelines

All motrona devices are designed to provide high protection against electromagnetic interference.

Nevertheless you must minimize the influence of electromagnetic noise to the device and all connected

cables.

Therefore the following measures are mandatory for a successful installation and operation:

Use shielded cables for all signal and control input and output lines.

Cables for digital controls (digital I/O, relay outputs) must not exceed a length of 30 m and are

allowed for in building operation only

Use shield connection clamps to connect the cable shields properly to earth

The wiring of the common ground lines must be star-shaped and common ground must be

connected to earth at only one single point

The device should be mounted in a metal enclosure with sufficient distance to sources of

electromagnetic noise.

Run signal and control cables apart from power lines and other cables emitting electromagnetic

noise.

Please also refer to motrona manual “General Rules for Cabling, Grounding, Cabinet Assembly”. You can

download that manual by the link

https://www.motrona.com/en/support/general-certificates.html

Cleaning, Maintenance and Service Notes

To clean the front of the unit please use only a slightly damp (not wet!), soft cloth. For the rear no

cleaning is necessary. For an unscheduled, individual cleaning of the rear the maintenance staff or

assembler is self-responsible.

During normal operation no maintenance is necessary. In case of unexpected problems, failures or

malfunctions the device must be shipped for back to the manufacturer for checking, adjustment and

reparation (if necessary). Unauthorized opening and repairing can have negative effects or failures to

the protection-measures of the unit.

9085_5010_04a_oi_e.docx / Feb-21 page 7 / 72

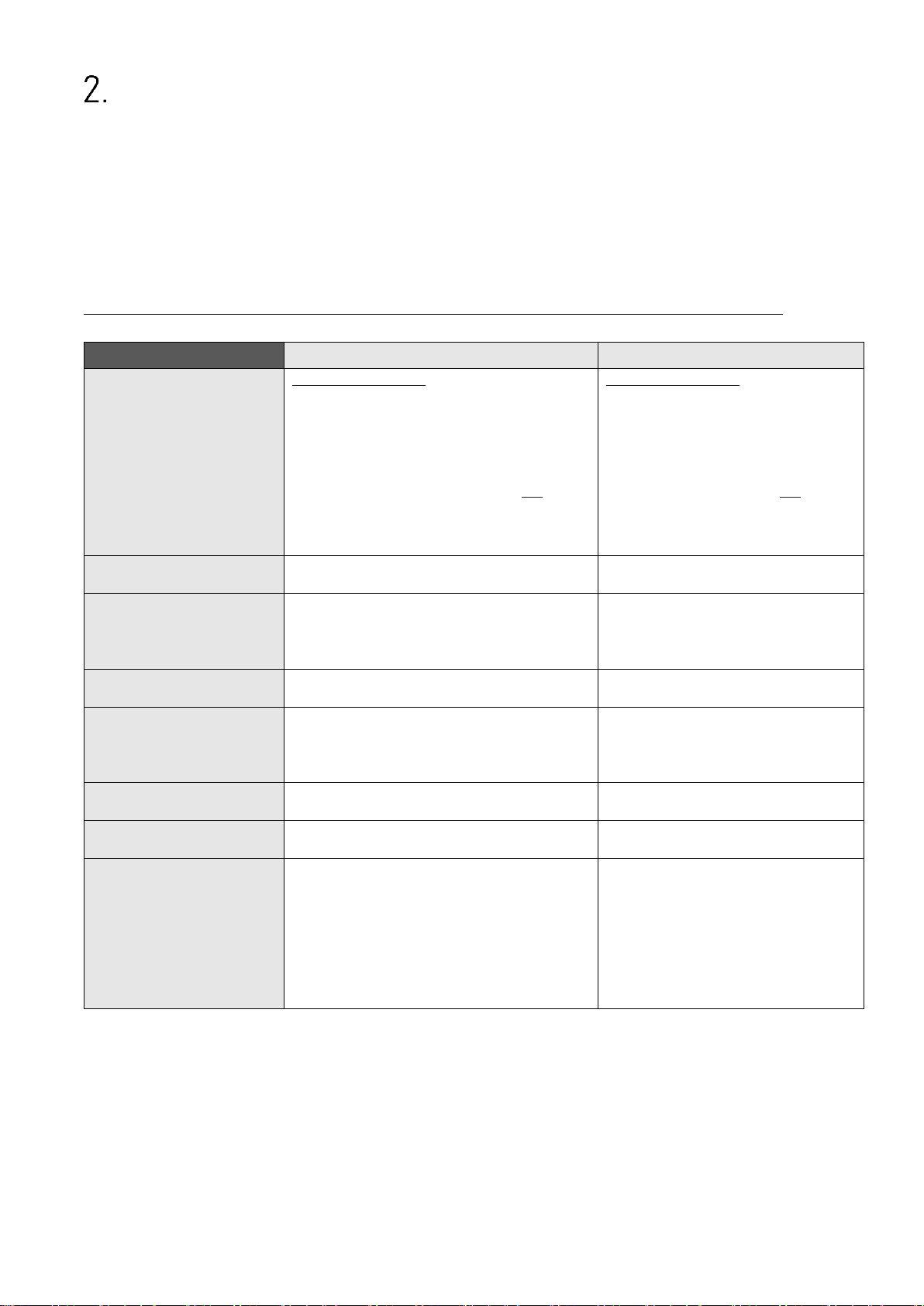

Compatibility Hint

9085.5010 / 7085.5010 / 7386.5010

9085.5052 / 7085.5052 / 7386.5051

Incremental Input:

(9085/7085)

Possible configurations:

RS422 (TTL), HTL Differential, HTL PNP, HTL

NPN or TTL PNP (asymmetrical)

The setting made in the corresponding

parameter then applies to both inputs (A and

B).

Possible configurations:

RS422 (TTL), HTL Differential, HTL

PNP, HTL NPN or TTL (asymmetrical)

The desired setting can be made

separately for each channel (A and B)

using the corresponding DIL

switches.

Control Inputs:

Number of inputs: 6

Format: HTL

Number of inputs 1

Format: HTL

Control Outputs:

Number of outputs: 6

Format / Level: 5…30 V, PNP

Output current: max. 200 mA

Reaction time: < 1ms

No switching outputs

Encoder Supply:

Output voltage: 5VDC u. 24VDC

Output current: max. 250 mA

Output voltage: 5VDC

Output current: max. 250 mA

Serial Interface:

RS232/RS485 via screw terminals

Baud rate: 9600, 19200 or 38400 Baud

RS232/RS485 via 9-position SUB-D

connector (female)

Baud rate: 600, 1200, 2400, 4800,

9600, 19200, or 38400 Baud

Housing:

Dimensions (w x h x d): 23 x 102 x 102 mm

Weight: approx. 100 g

Dimensions (w x h x d): 40 x 79 x 91 mm

Weight: approx. 190 g

Device parameterization:

Only by operator software OS.

By operator software OS and

partially via DIL switches

Operating modes for FU:

Only channel A

Ratio B/A

Percentage deviation from channel B to A

Sum A+B

Difference A-B

A/Bx90

Only channel A

Ratio A/B

Sum A+B

A/Bx90

Only channel B

Product AxB

Difference A-B

A= Impulse, B = Direction

This product is a successor model of the thousand fold proven converter type

9085.5052 / 7085.5052 / 7386.5051.

This converter is able to replace functionally the previous model; however some minor differences

have to be observed with regard to the parameter settings.

The main differences between this product and the respective predecessor model are listed below.

Differences of the 9085.5010 / 7085.5010 / 7386.5010 compared to the previous models are:

9085_5010_04a_oi_e.docx / Feb-21 page 8 / 72

Introduction

The device is designed as a signal converter with control inputs and outputs. Its extensive functions

make it universally applicable.

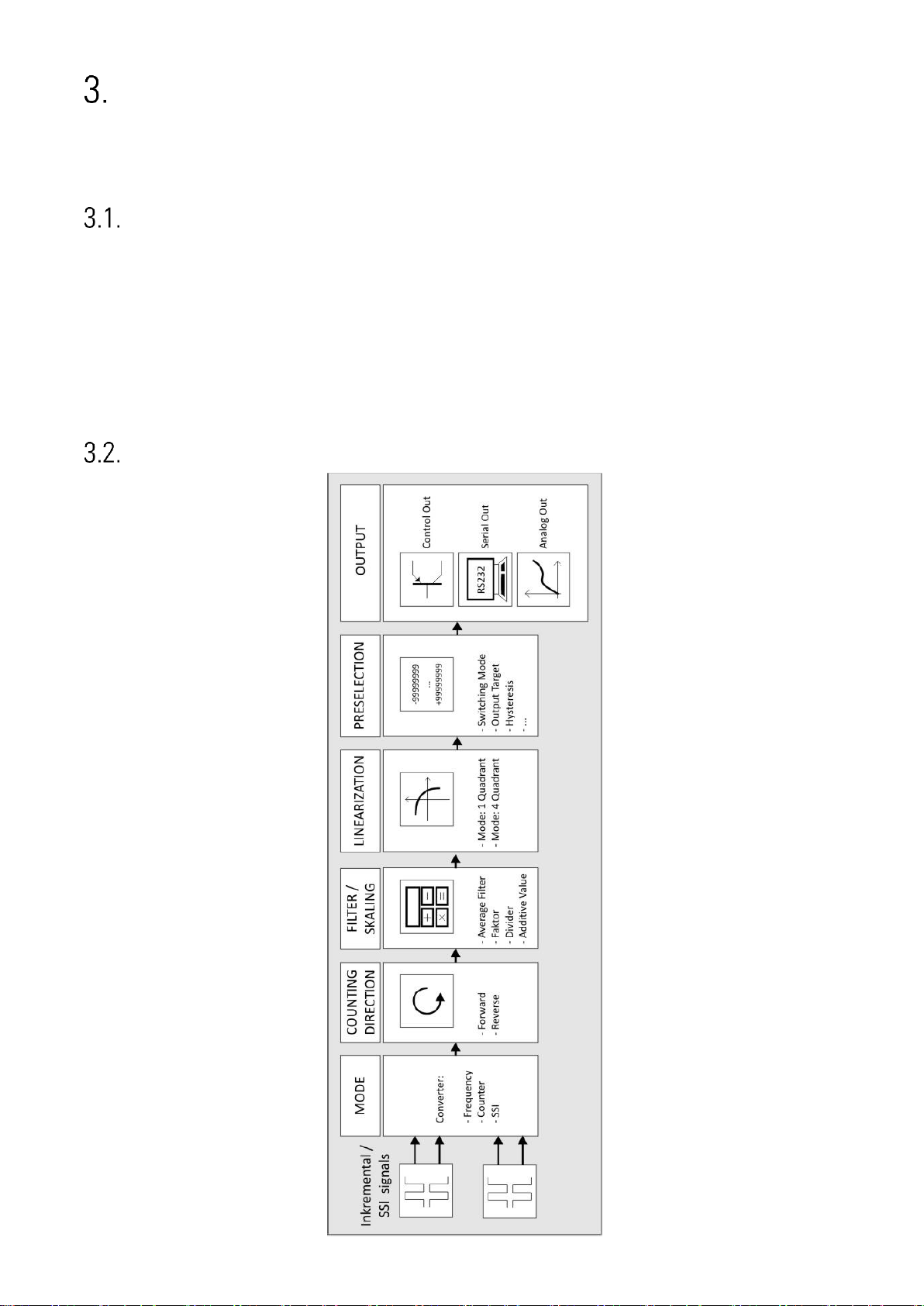

Operating Mode

Basically all functions have to be configured in the parameter menu. The device can be used in the

following operating modes:

Operation as frequency converter for incremental input signals (replaces 7085.5052)

Operation as position transducer / counter for incremental input signals (replaces 9085.5052)

Operation as absolute value converter for signals of a start-stop interface

Operation as absolute value converter for SSI signals (replaces 7386.5051)

Function diagram

9085_5010_04a_oi_e.docx / Feb-21 page 9 / 72

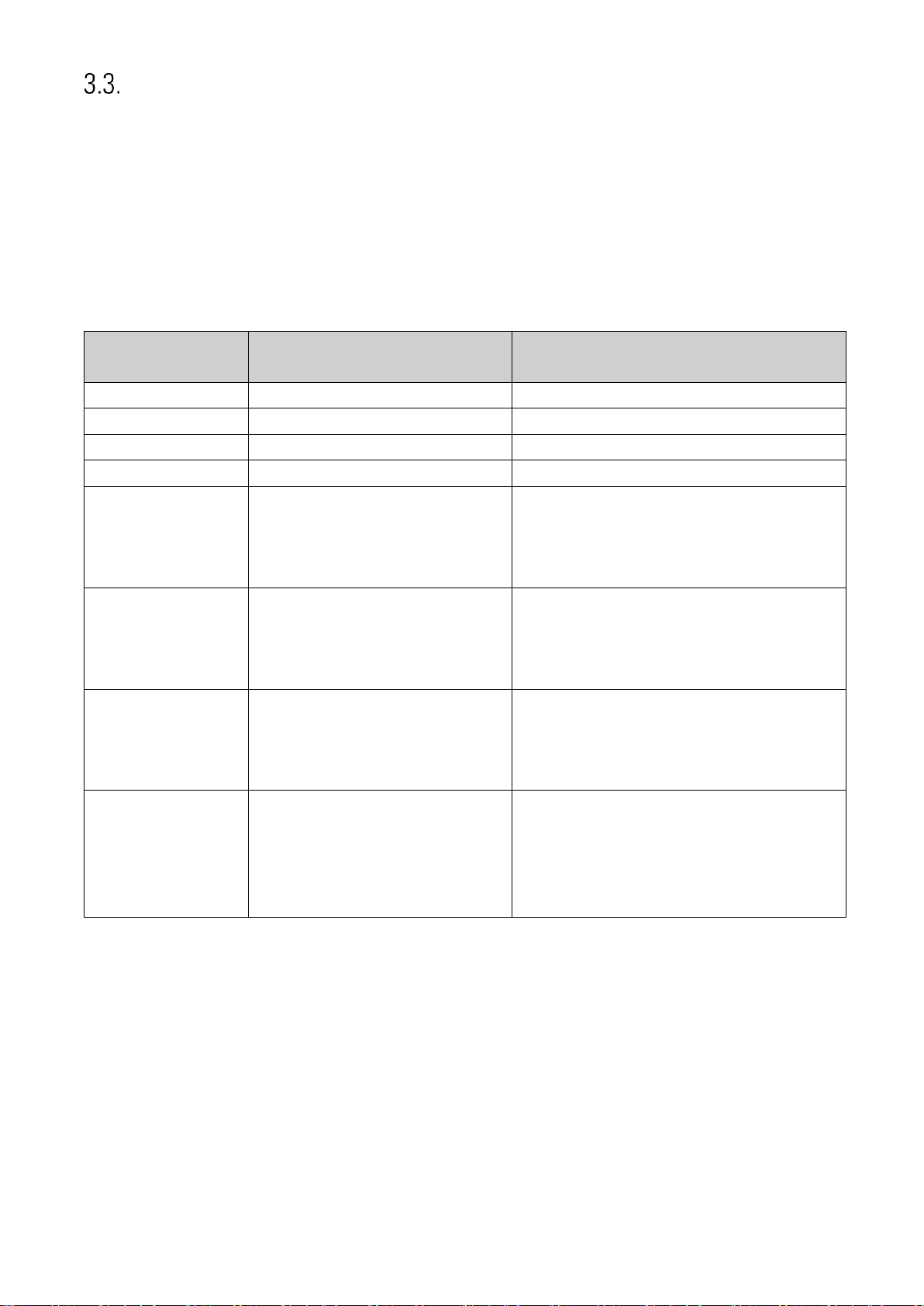

Power – LED / Error messages

Errorcode:

(Error_Status)

Error identification:

Error description:

0x00000001

Maximum Value

Measured value is greater than 99999999

0x00000002

Minimum Value

Measured value is less than -99999999

0x00000004

SSI Encoder Error

SSI error bit set (only for 7386.5010)

0x00000008

Encoder Fault

For internal test purposes only!

0x00000010

Frequency (Input A) out of range

Maximum or minimum permissible input

frequency at input A has been exceeded

or fallen below with the exponential filter

setting used.

0x00000020

Frequency (Input B) out of range

Maximum or minimum permissible input

frequency at input B has been exceeded

or fallen below with the exponential filter

setting used.

0x00000040

Start/Stop Encoder Error

No "start" and no "stop" pulse detected

between two "init" pulses. (only for

8086.5010)

Check sensor connections!

0x00000080

Position Encoder Outside the

Limit

No "start" and no "stop" pulse detected

between two "init" pulses. (only for

8086.5010)

Possible cause: No position sensor or

position sensor outside the limits.

The device has a green LED on its front foil. This lights up permanently as soon as the supply voltage

of the device has been applied. If an error occurs, the LED flashes at 1 Hz.

The analog output is also controlled with 0 V or 0/4 mA. If the error no longer exists, the LED

automatically lights up again permanently and the analogue output responds to the current result.

The exact error can be read out via the serial interface via the user interface (OS).

( Variable: Error_Status, Code: "; 3")

The individual error codes are explained below:

9085_5010_04a_oi_e.docx / Feb-21 page 10 / 72

Electrical Connections

The terminal screws should be tightened with a slotted screwdriver (blade width 2mm).

DC Power Supply (X1)

The unit accepts DC supply from 18 to 30 V at the terminals X1 1 and 2. The power consumption

depends on the level of the supply voltage with aprox. 50 mA and the additional current required at

the Auxiliary Voltage Output.

All GND terminals are internally interconnected.

Auxiliary voltage output (X2)

Two auxiliary voltages (24 VDC and 5 VDC) are available as encoder / sensor supply at terminal X2

pins 7, 8 and 9. The 24 VDC output voltage depends on the device supply (see technical data).

9085_5010_04a_oi_e.docx / Feb-21 page 11 / 72

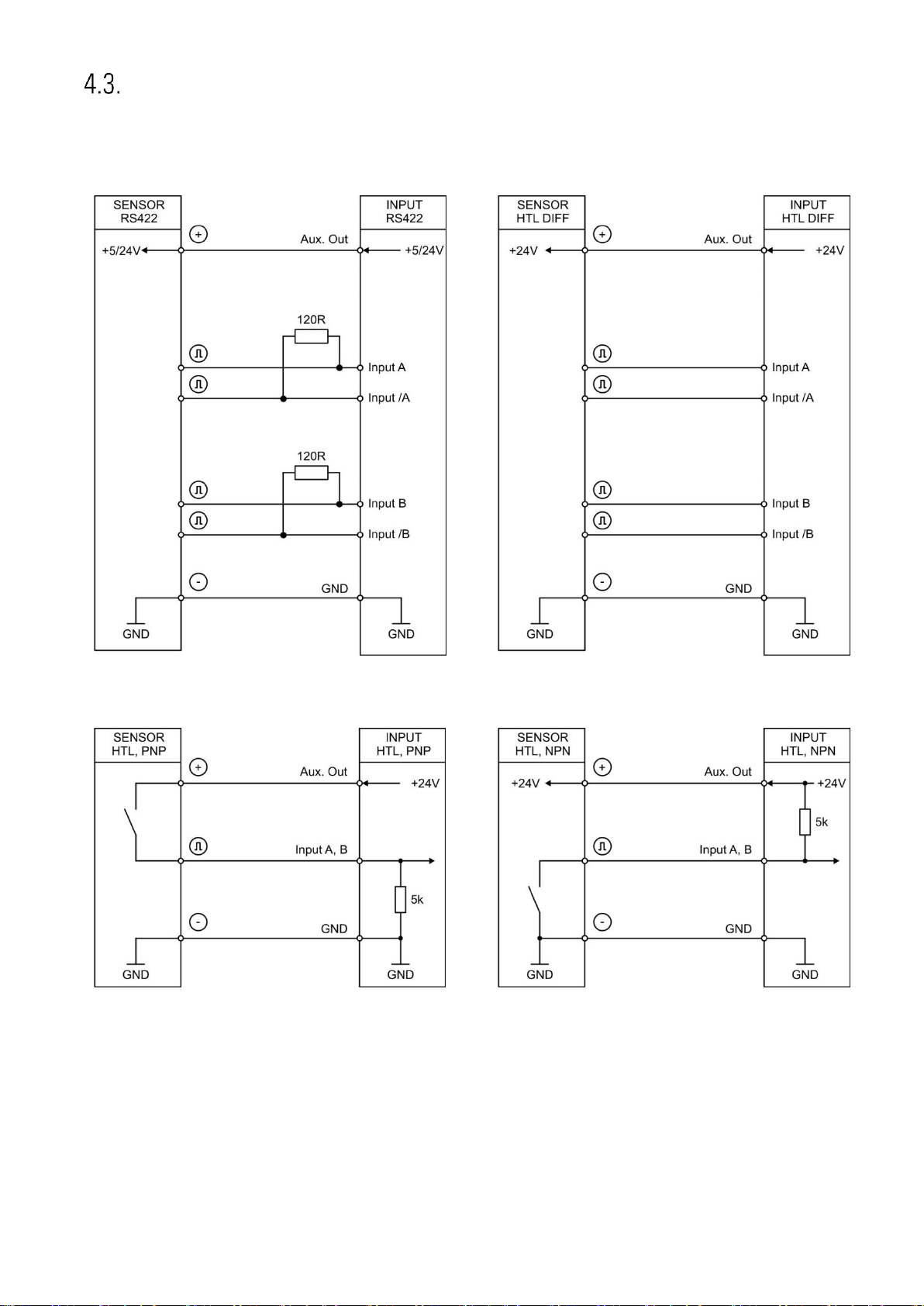

Incremental encoder input (X2)

RS422

HTL DIFFERENTIAL

HTL PNP

HTL NPN

Terminal X2 pins 3, 4, 5 and 6 provide a connection for various incremental signals.

9085_5010_04a_oi_e.docx / Feb-21 page 12 / 72

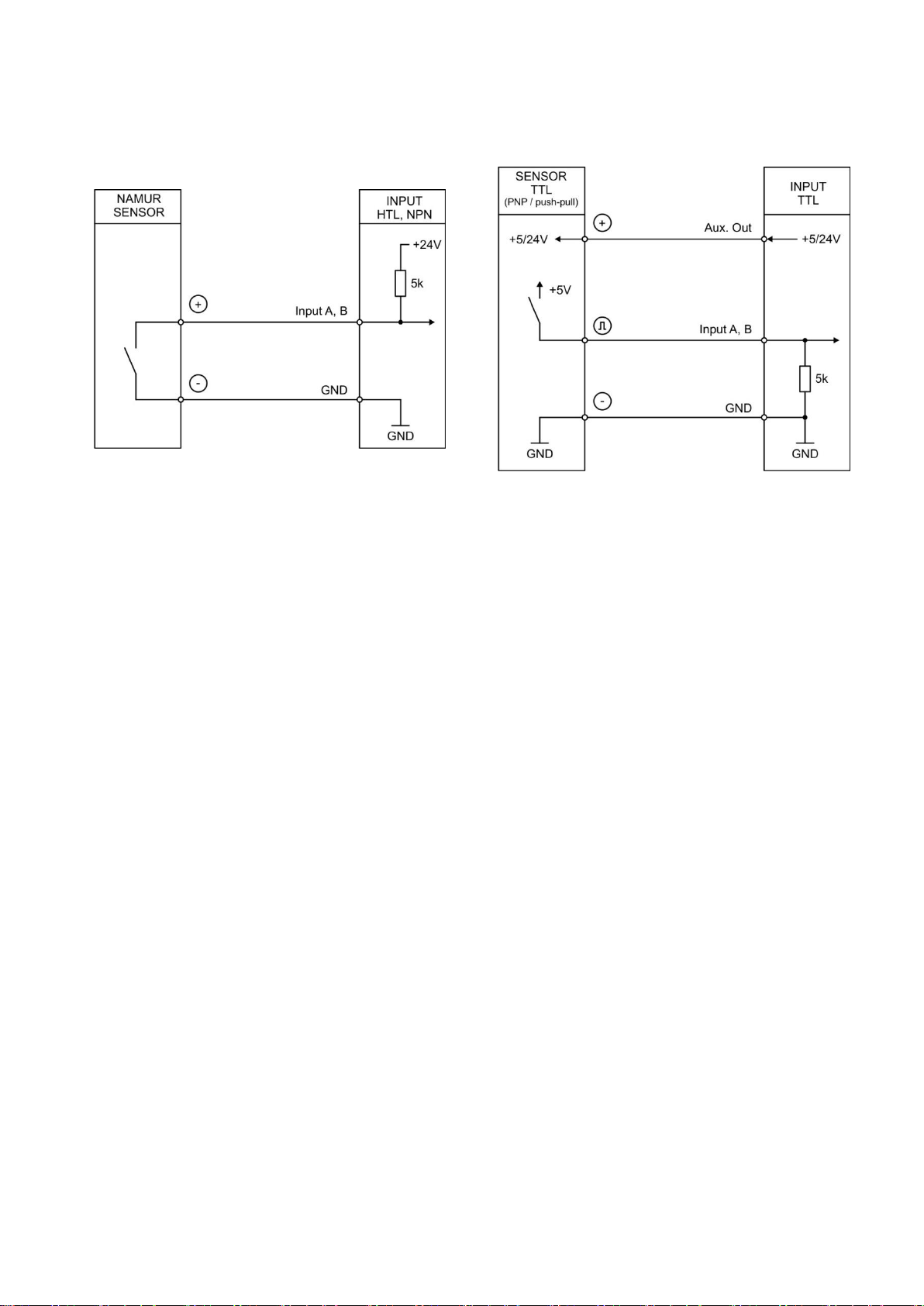

Continuation „Incremental encoder input (X2)“:

HTL NPN (NAMUR)

TTL (PNP)

Unconnected PNP inputs are always “LOW” and unconnected NPN inputs are always “HIGH”.

All inputs are designed to receive impulses from electrical impulse sources.

Notice for mechanical switching contacts:

When exceptionally mechanical contacts are used, please connect an external capacitor between

GND (-) and the corresponding input (+). A capacity of 10 µF will reduce the input frequency to

20 Hz and miscounting due to contact bouncing will be eliminated.

9085_5010_04a_oi_e.docx / Feb-21 page 13 / 72

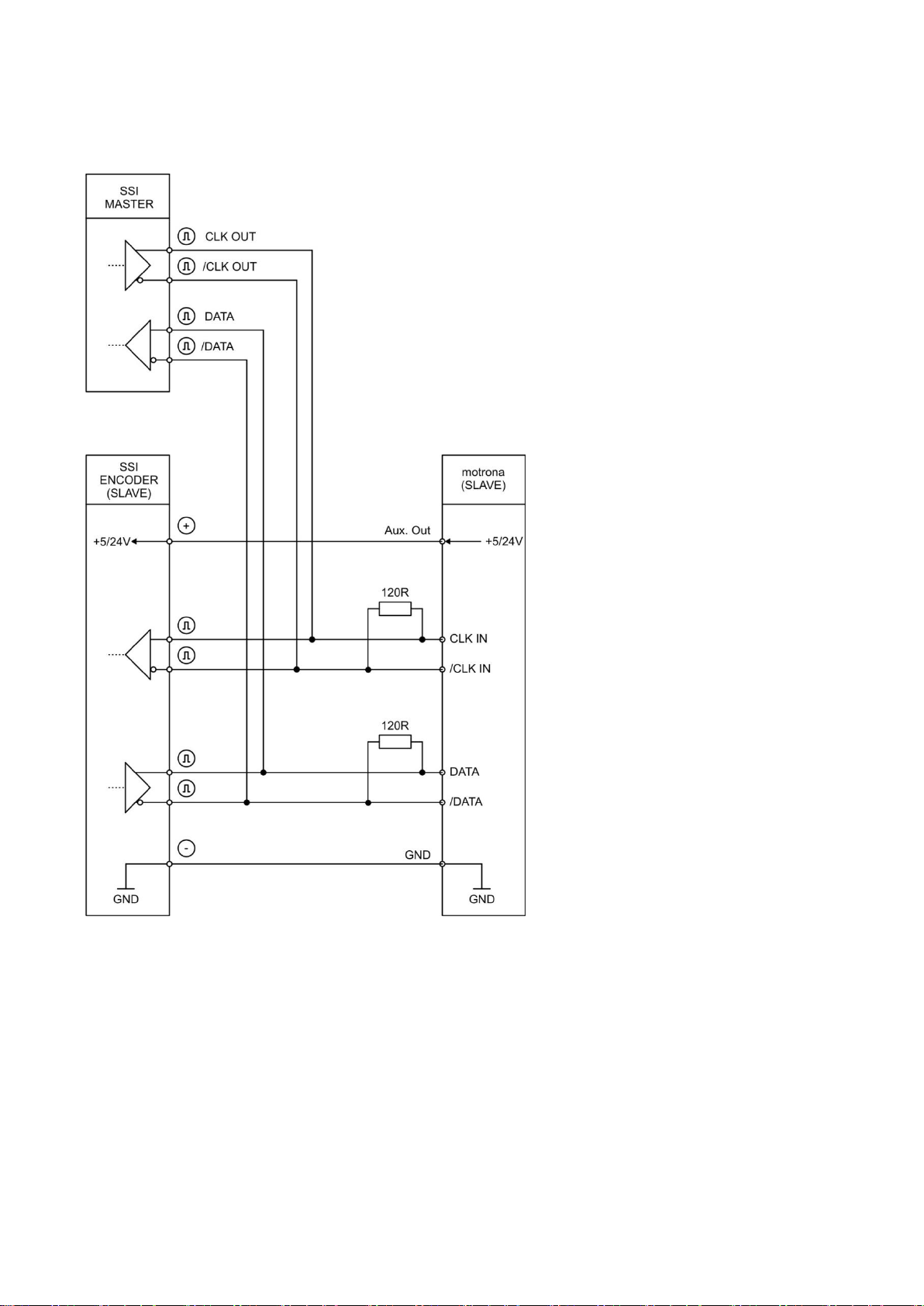

SSI-Absolute encoder input (X2)

At terminal X2 pin 1, 2, 3, 4 the SSI connection for the MODE MASTER is available.

At terminal X2 pin 3, 4, 5, 6 the SSI connection for the MODE SLAVE is available.

Connection for MODE Master:

9085_5010_04a_oi_e.docx / Feb-21 page 14 / 72

Continuation „SSI-Absolute encoder input (X2)“:

Connection for MODE Slave:

9085_5010_04a_oi_e.docx / Feb-21 page 15 / 72

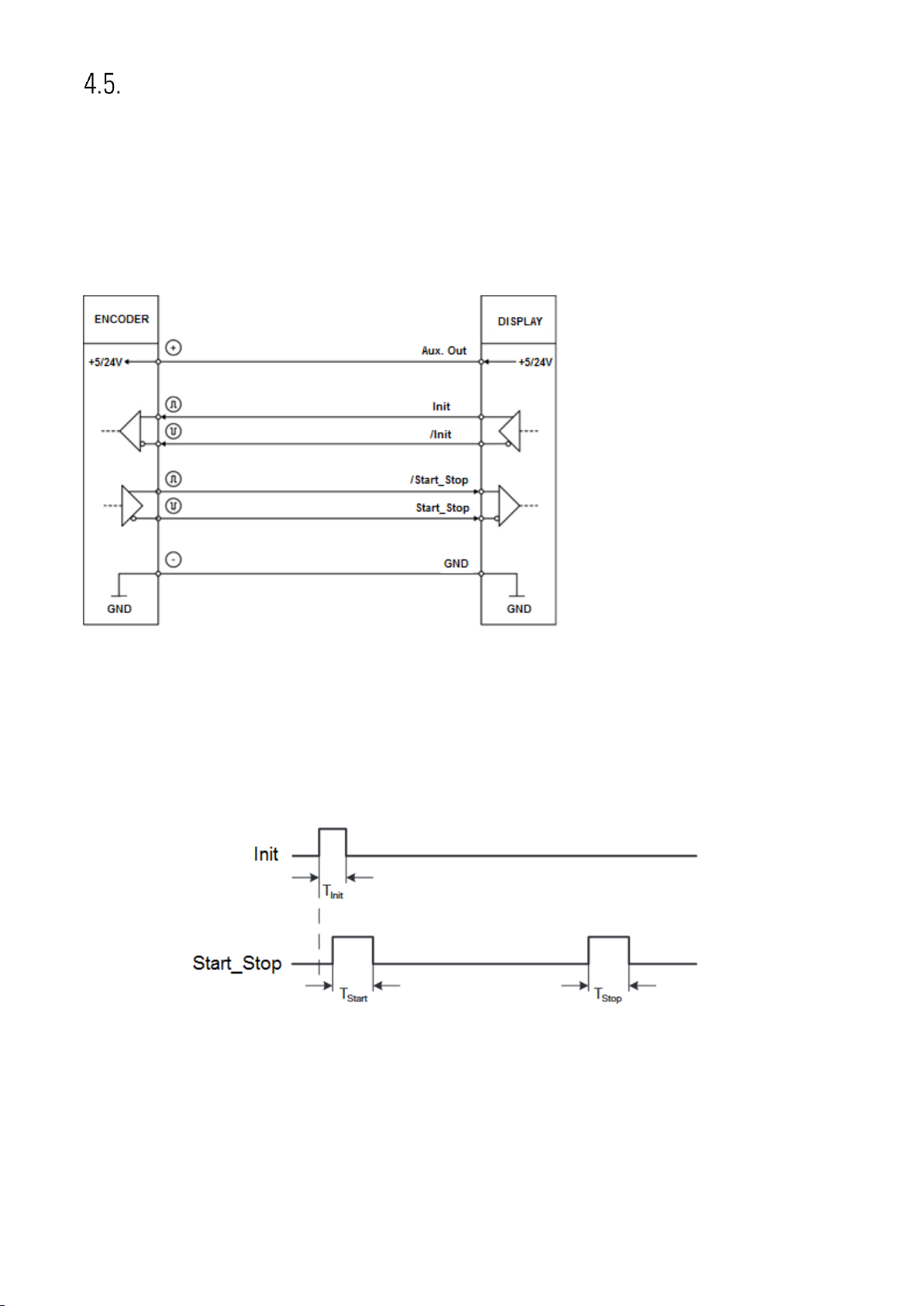

Start-stop encoder inputs (X2)

At terminal X2 - Pin 1+2 the RS422 connection for the init pulse in "MODE MASTER" is available.

(Device generates Init pulse itself!).

At terminal X2 - Pin 5+6 the RS422 connection for the init pulse in "MODE SLAVE" is available. (Init

pulse is generated by an external device!).

At terminal X2 - Pin 3 + 4 the RS422 connection for the Sart-Stop pulse is available.

Connection of the RS422 signals:

DPI measurement operation

In the "MODE MASTER", the init pulse is sent to the position sensor on the init line at regular

intervals (SAMPLING TIME (ms)), whose rising edge triggers a measurement.

The pulse width of the init pulse can be set by means of the "INIT PULSE TIME (µs)" parameter.

T

: 1…9 µs (adjustable)

Init

T

: ~3…5 µs

Start

T

: ~3…5 µs

Stop

9085_5010_04a_oi_e.docx / Feb-21 page 16 / 72

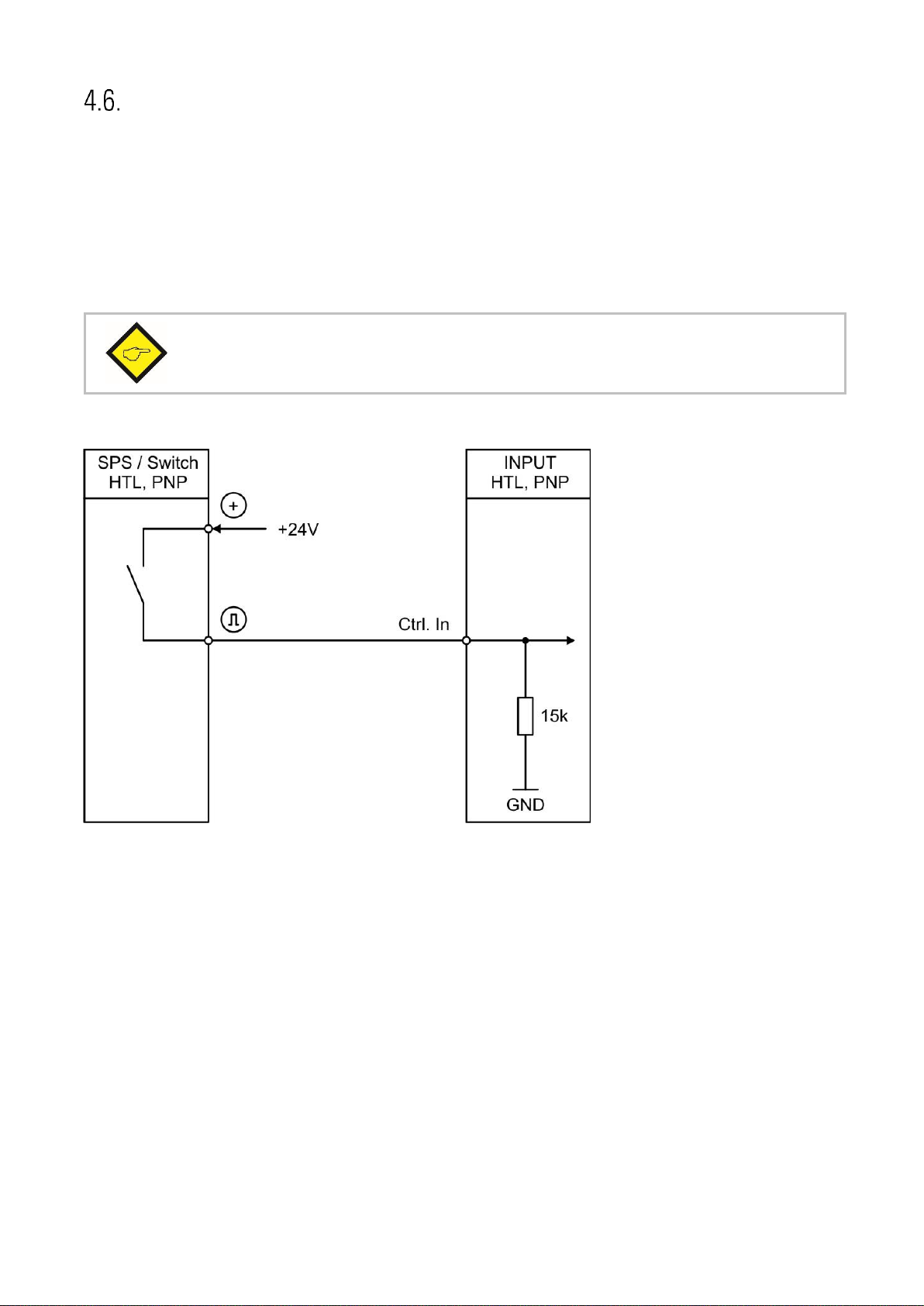

Note: With an HTL pulse (rising edge) on Ctrl. In 6, the device is reset to the factory

settings.

Control Inputs (X5)

At terminal X5 pins 2,3,4,5,6 and 7 there are six control inputs with HTL PNP characteristic available.

Control Input 1 (Ctrl. In 1) to Control Input 5 (Ctrl. In 5) are freely configurable in the COMMAND

MENU and are used for functions to be triggered externally. eg. for releasing the latching, resetting

the measurement result or for teaching the preset values or the analog output.

Control input 6 (Ctrl. In 6) is used exclusively for resetting the device parameters to the "default"

values. Thus, it is not freely configurable.

Wiring of the control inputs:

Unconnected control inputs are always “LOW”.

All inputs are designed to receive impulses from an electronic impulse source.

Notice for mechanical switching contacts:

When exceptionally mechanical contacts are used, please connect an external capacitor between

GND (-) and the corresponding input (+). A capacity of 10 µF will reduce the input frequency to

20 Hz and miscounting due to contact bouncing will be eliminated.

9085_5010_04a_oi_e.docx / Feb-21 page 17 / 72

Analog output (X4)

Important:

A parallel operation with voltage and current output at the analog output is not allowed.

A 16 bit analog output is available at terminal X4 pin 1, 2 and 3.

This output can be configured and scaled in the ANALOG MENU.

The following configuration is possible:

• Voltage output: -10 … +10 V

• Current output: 0 … 20 mA

• Current output: 4 … 20 mA

The analog output is proportional to the display value and is referenced to potential AGND.

AGND and GND are internally interconnected.

9085_5010_04a_oi_e.docx / Feb-21 page 18 / 72

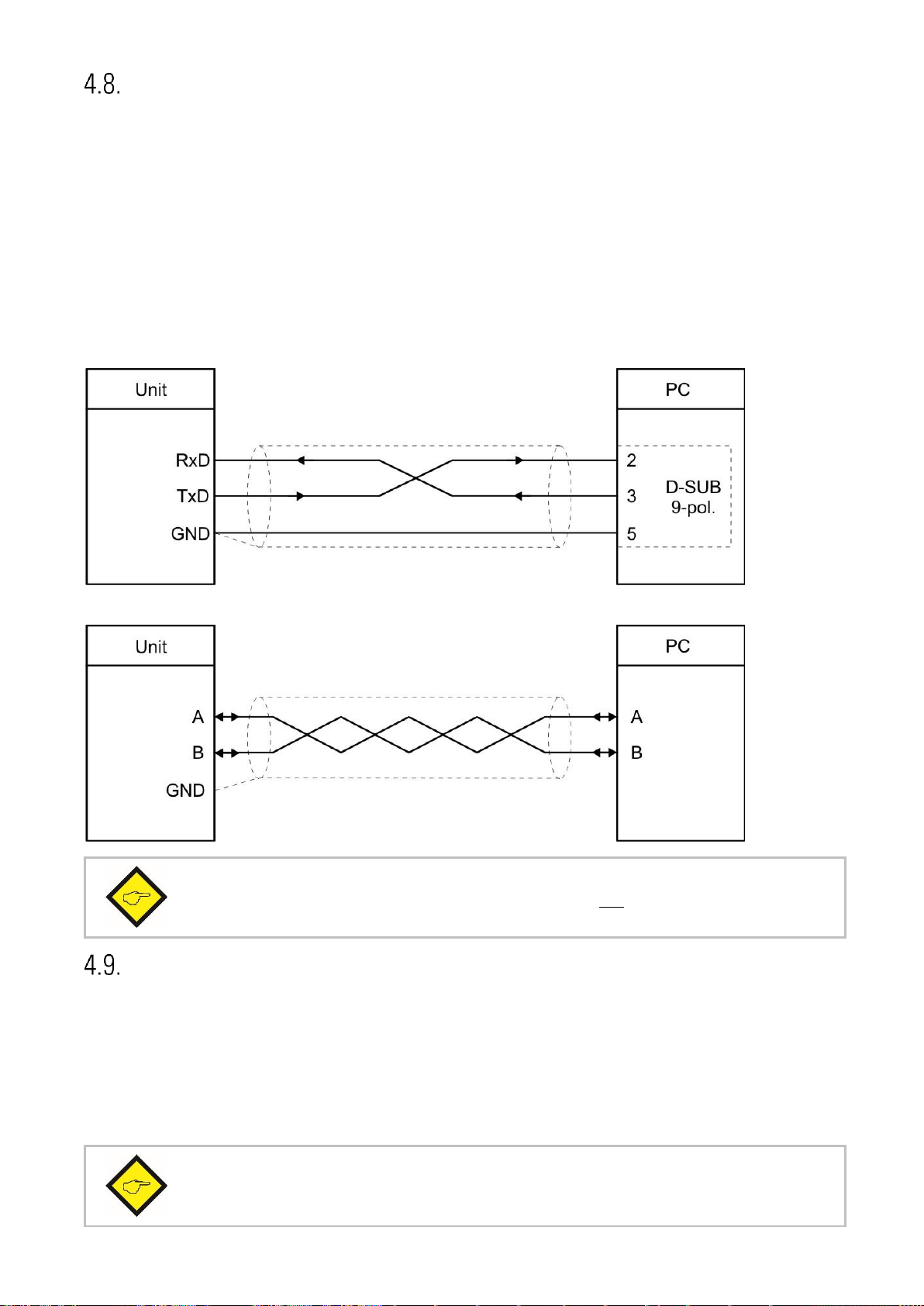

Serial interface (X3)

Important: Parallel operation of RS232 and RS485 is not allowed!

The serial USB communication is done with a baud rate of "

115200 Baud

" and a serial data

format of "

8none1

" and cannot be changed by the user!

A serial interface (RS232 or RS485) is available at terminal X3.

This interface can be configured in the SERIAL MENU.

The serial interface RS232 or RS485 can be used:

for easy setup and commissioning of the units

to modify settings and parameters during operation

to read out internal states and actual measuring values by PC or PLC

The following drawing shows the connection to a PC by using a standard Sub-D-9 connector:

Connection of the RS232 interface:

Connection of the RS485-interface:

USB interface (X7)

A serial USB interface (mini USB) is available at X7.

The USB interface can be used as follows:

For parameterization of the device during commissioning

To change parameters during operation

For reading out actual values via PC

9085_5010_04a_oi_e.docx / Feb-21 page 19 / 72

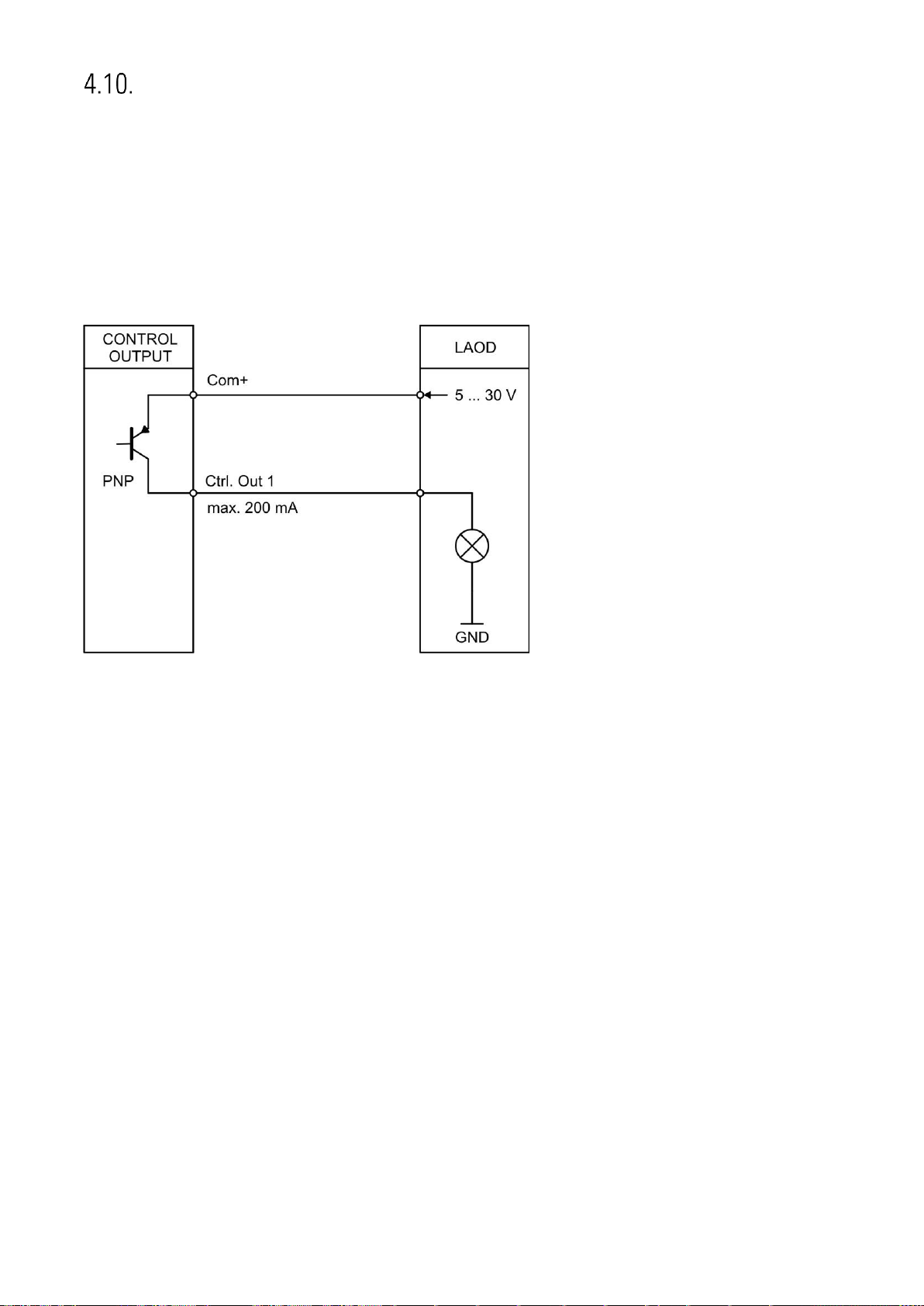

Control outputs (X6)

Six control outputs are available at terminal X6 pin 2, 3, 4, 5, 6 and 7.

Switching conditions can be set in the PRESELECTION MENU. The output Ctrl. Out1 – 6 are fast PNP

outputs with a switching capability of 5 – 30 Volt / 200 mA per channel.

The switching voltage of the outputs must be applied to input terminal X6 pin 1 (COM+).

In case of switching inductive loads it is advisable to use external filtering of the coils.

Wiring of the control-outputs:

9085_5010_04a_oi_e.docx / Feb-21 page 20 / 72

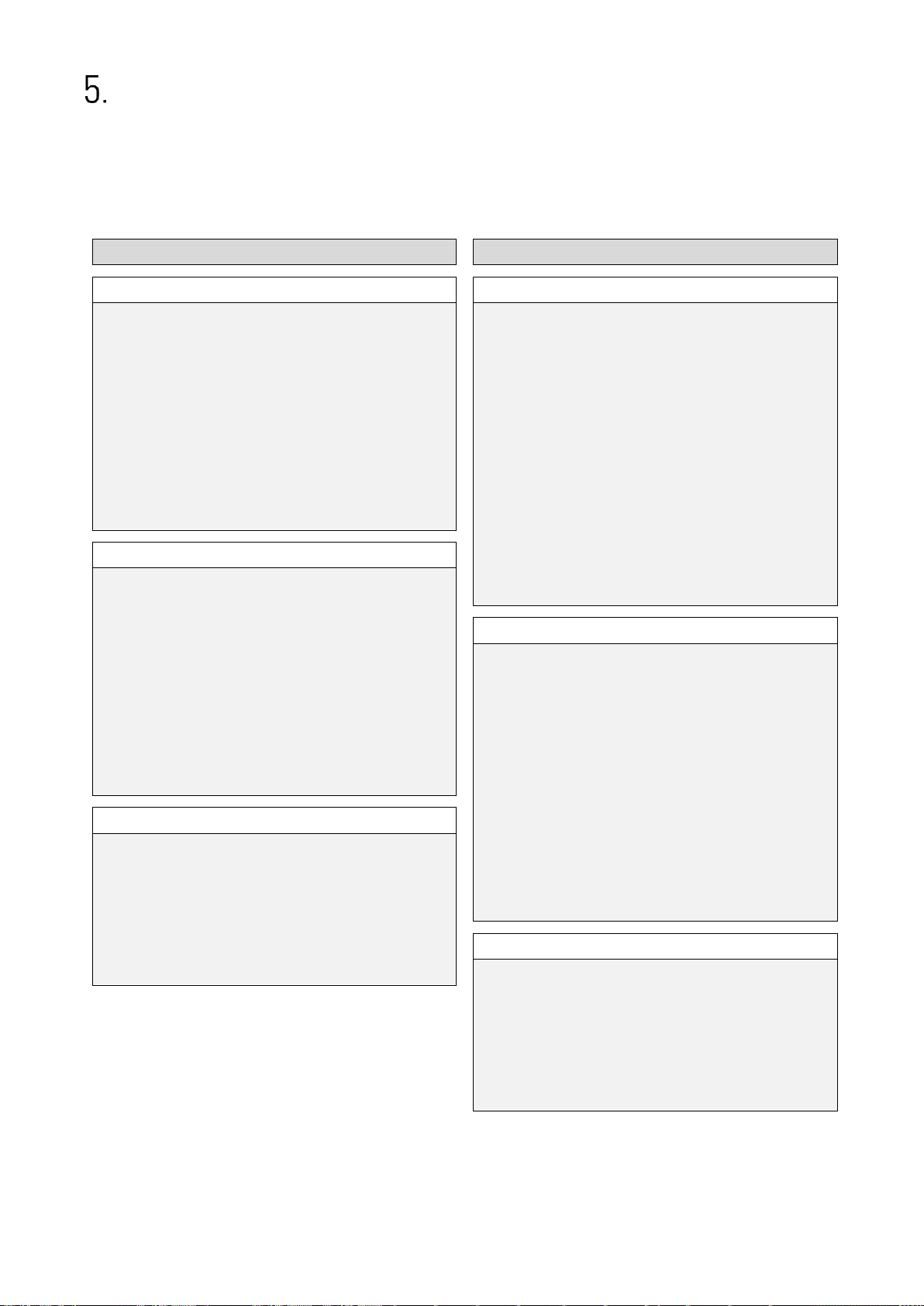

Parameter / Overview-Menu Structure

Menu / Parameter

GENERAL MENU

MODE

ENCODER PROPERTIES

ENCODER DIRECTION

FACTOR

DIVIDER

ADDITIVE VALUE

LINEARIZATION MODE

BACKUP MEMORY

FACTORY SETTINGS

MODE FREQUENCY

FREQUENCY MODE

FREQUENCY BASE

SAMPLING TIME 1 (S)

WAIT TIME 1(S)

STANDSTILL TIME 1 (S)

AVERAGE FILTER 1

SAMPLING TIME 2 (S)

WAIT TIME 2(S)

AVERAGE FILTER 2

MODE COUNTER

COUNT MODE

FACTOR A

SET VALUE A

FACTOR B

SET VALUE B

ROUND LOOP VALUE

Menu / Parameter

MODE SSI

SSI MODE

ENCODER RESOLUTION

DATA FORMAT

BAUD RATE

SSI ZERO

HIGH BIT

LOW BIT

SSI OFFSET

ROUND LOOP VALUE

SAMPLING TIME (S)

ERROR BIT

ERROR POLARITY

MODE START/STOP

INIT MODE

SAMPLING TIME (ms)

INIT PULSE TIME (µs)

VELOCITY (m/s)

OPERATIONAL MODE

OFFSET

CIRCUMFERENCE (mm)

ROUND LOOP VALUE

AVERAGE FILTER - POSITION

STANDSTILL TIME (s)

AVERAGE FILTER - SPEED

PRESELECTION VALUES

PRESELECTION 1

PRESELECTION 2

PRESELECTION 3

PRESELECTION 4

PRESELECTION 5

PRESELECTION 6

The parameterization of the device is realized via the serial interface with a PC and the operating

software OS. The link to the free download can be found on page 2.

This section provides an overview of the menus and their parameters. The menu names are printed

bold and the associated parameters are listed under the menu name.

9085_5010_04a_oi_e.docx / Feb-21 page 21 / 72

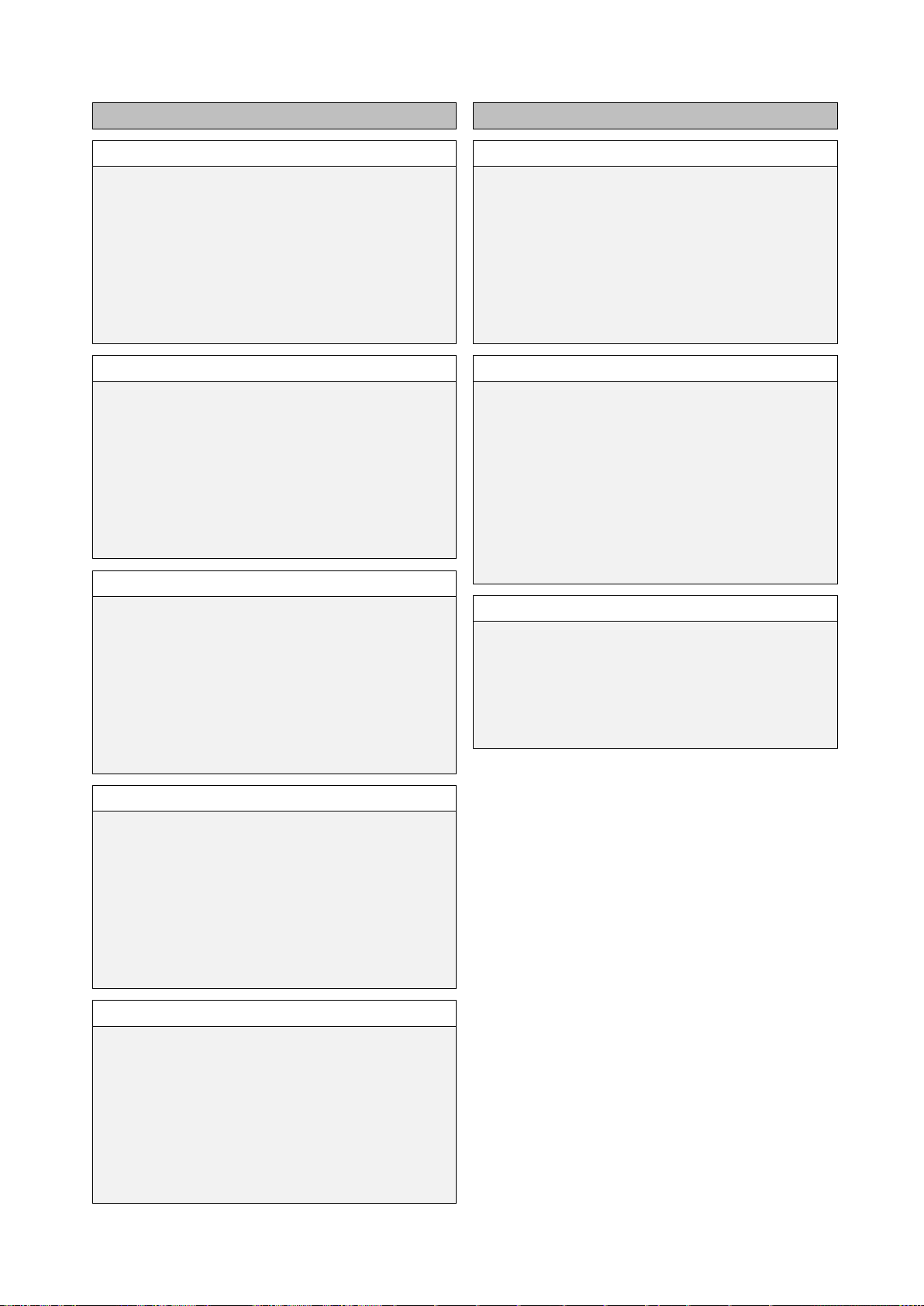

Continuation „Parameter / menu structure“:

Menu / Parameter

PRESELECTION 1 MENU

MODE 1

HYSTERESIS 1

PULSE TIME 1 (S)

OUTPUT TARGET 1

OUTPUT POLARITY 1

OUTPUT LOCK 1

START UP DELAY 1 (S)

PRESELECTION 2 MENU

MODE 2

HYSTERESIS 2

PULSE TIME 2 (S)

OUTPUT TARGET 2

OUTPUT POLARITY 2

OUTPUT LOCK 2

START UP DELAY 2 (S)

PRESELECTION 3 MENU

MODE 3

HYSTERESIS 3

PULSE TIME 3 (S)

OUTPUT TARGET 3

OUTPUT POLARITY 3

OUTPUT LOCK 3

START UP DELAY 3 (S)

PRESELECTION 4 MENU

MODE 4

HYSTERESIS 4

PULSE TIME 4 (S)

OUTPUT TARGET 4

OUTPUT POLARITY 4 (S)

OUTPUT LOCK 4

START UP DELAY 4 (S)

PRESELECTION 5 MENU

MODE 5

HYSTERESIS 5

PULSE TIME 5 (S)

OUTPUT TARGET 5

OUTPUT POLARITY 5

OUTPUT LOCK 5

START UP DELAY 5 (S)

Menu / Parameter

PRESELECTION 6 MENU

MODE 6

HYSTERESIS 6

PULSE TIME 6 (S)

OUTPUT TARGET 6

OUTPUT POLARITY 6

OUTPUT LOCK 6

START UP DELAY 6 (S)

SERIAL MENU

UNIT NUMBER

SERIAL BAUD RATE

SERIAL FORMAT

SERIAL INIT

SERIAL PROTOCOL

SERIAL TIMER (S)

SERIAL VALUE

MODBUS

ANALOG MENU

ANALOG FORMAT

ANALOG START

ANALOG END

ANALOG GAIN (%)

ANALOG OFFSET (%)

9085_5010_04a_oi_e.docx / Feb-21 page 22 / 72

Loading...

Loading...