Page 1

®

ASTRO

TM

XTS

Portable Radio

Basic Service Manual

4000

Page 2

Page 3

Title Page

ASTRO® XTS™ 4000

Digital Portable Radios

Basic Service Manual

Motorola, Inc.

1301 E. Algonquin Rd.

Schaumburg, IL 60196-1078 U.S.A.

6871619L01-C

Page 4

Foreword

This manual covers all models of the ASTRO® XTS™ 4000 digital portable radio, unless otherwise specified. It includes all

the information necessary to maintain peak product performance and maximum working time, using levels 1 and 2

maintenance procedures. This level of service goes down to the board replacement level and is typical of some local

service centers, self-maintained customers, and distributors.

For details on radio operation or component-level troubleshooting, refer to the applicable manuals available separately. A

list of related publications is provided in the section, “ Related Publications” on page ix.

Product Safety and RF Exposure Compliance

Before using this product, read the operating instructions for safe usage contained in the Product Safety and RF Exposure booklet enclosed with your radio.

ATTENTION!

This radio is restricted to occupational use only to satisfy FCC RF energy exposure requirements.

Before using this product, read the RF energy awareness information and operating instructions in the

Product Safety and RF Exposure booklet enclosed with your radio (Motorola Publication part number

6881095C98) to ensure compliance with RF energy exposure limits.

For a list of Motorola-approved antennas, batteries, and other accessories, visit the following web site which lists approved accessories: http://www.motorola.com/governmentandenterprise

Manual Revisions

Changes which occur after this manual is printed are described in FMRs (Florida Manual Revisions). These FMRs provide

complete replacement pages for all added, changed, and deleted items, including pertinent parts list data, schematics, and

component layout diagrams. To obtain FMRs, contact the nearest Radio Products and Solutions Organization (refer to

“Appendix B Replacement Parts Ordering”).

Computer Software Copyrights

The Motorola products described in this manual may include copyrighted Motorola computer programs stored in

semiconductor memories or other media. Laws in the United States and other countries preserve for Motorola certain

exclusive rights for copyrighted computer programs, including, but not limited to, the exclusive right to copy or reproduce in

any form the copyrighted computer program. Accordingly, any copyrighted Motorola computer programs contained in the

Motorola products described in this manual may not be copied, reproduced, modified, reverse-engineered, or distributed in

any manner without the express written permission of Motorola. Furthermore, the purchase of Motorola products shall not

be deemed to grant either directly or by implication, estoppel, or otherwise, any license under the copyrights, patents or

patent applications of Motorola, except for the normal non-exclusive license to use that arises by operation of law in the

sale of a product.

Document Copyrights

No duplication or distribution of this document or any portion thereof shall take place without the express written permission

of Motorola. No part of this manual may be reproduced, distributed, or transmitted in any form or by any means, electronic

or mechanical, for any purpose without the express written permission of Motorola.

Disclaimer

The information in this document is carefully examined, and is believed to be entirely reliable. However, no responsibility is

assumed for inaccuracies. Furthermore, Motorola reserves the right to make changes to any products herein to improve

readability, function, or design. Motorola does not assume any liability arising out of the applications or use of any product

or circuit described herein; nor does it cover any license under its patent rights nor the rights of others.

Trademarks

MOTOROLA, the Stylized M logo, ASTRO, FLASHport, and CommPort are registered in the US Patent & Trademark

Office. All other products or service names are the property of their respective owners.

© 2007–2008 by Motorola, Inc.

Page 5

Document History iii

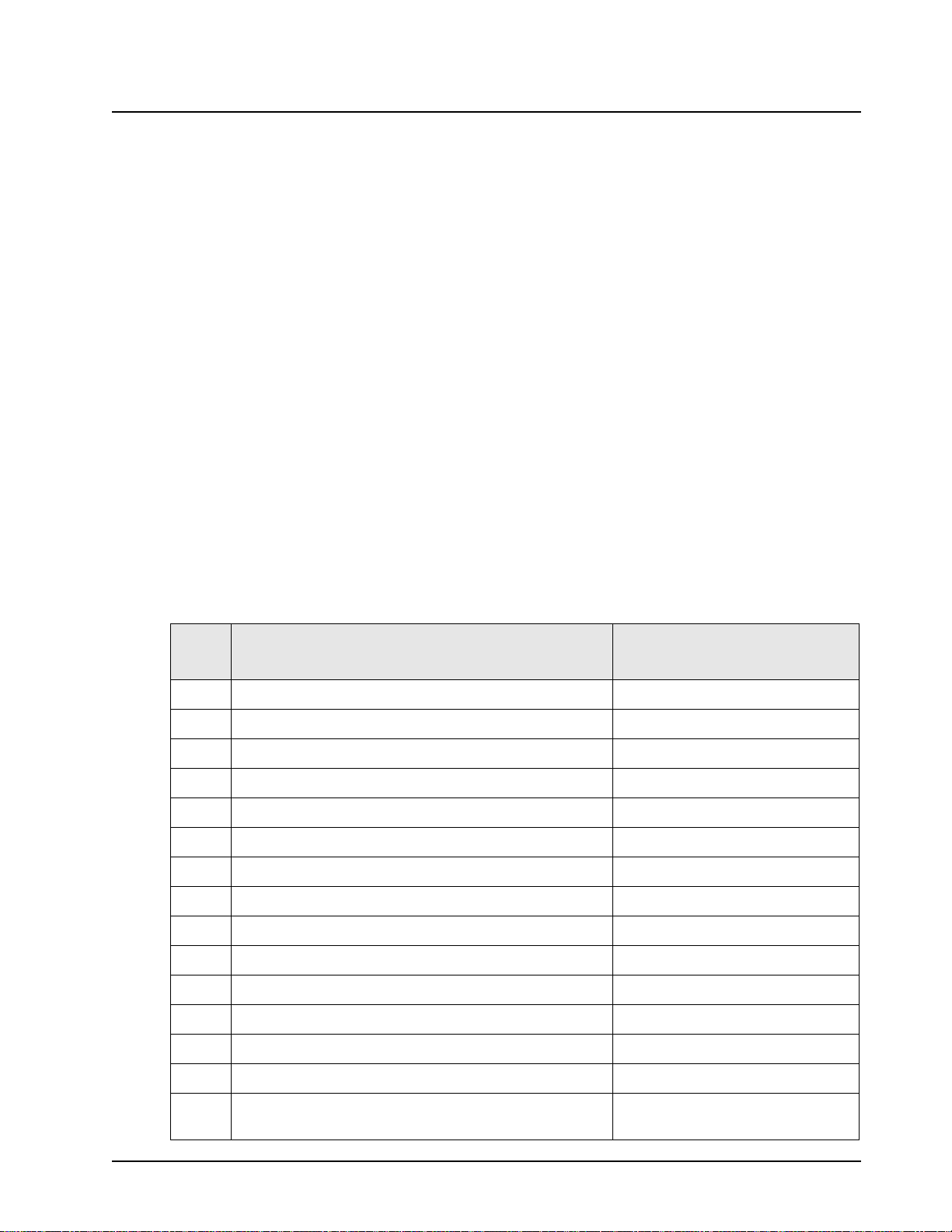

Document History

The following major changes have been implemented in this manual since the previous edition:

Edition Description Date

6871619L01-A Initial edition Mar. 2007

6871619L01-B Added UHF band Jan. 2008

6871619L01-C Added PMNN4083 1260 mAh Li-Ion Battery.

Modified Specifications and Accessories info.

Sep. 2008

6871619L01-C September 10, 2008

Page 6

iv Document History

Notes

September 10, 2008 6871619L01-C

Page 7

Table of Contents v

Table of Contents

Foreword.........................................................................................................ii

Product Safety and RF Exposure Compliance ............................................................................................ii

Manual Revisions ........................................................................................................................................ii

Computer Software Copyrights ................................................................................................................... ii

Document Copyrights .................................................................................................................................. ii

Disclaimer....................................................................................................................................................ii

Trademarks .................................................................................................................................................ii

Document History .........................................................................................iii

Table of Contents...........................................................................................v

List of Tables .................................................................................................ix

Commercial Warranty ..................................................................................xii

Limited Warranty ....................................................................................................................................... xii

MOTOROLA COMMUNICATION PRODUCTS ...............................................................................xii

I. What This Warranty Covers And For How Long .................................................................... xii

II. General Provisions ................................................................................................................ xii

III. State Law Rights ................................................................................................................. xiii

IV. How To Get Warranty Service ............................................................................................ xiii

V. What This Warranty Does Not Cover................................................................................... xiii

VI. Patent And Software Provisions ......................................................................................... xiv

VII. Governing Law................................................................................................................... xiv

Model Numbering, Charts, and Specifications..........................................xv

Portable Radio Model Numbering System ................................................................................................ xv

ASTRO XTS 4000 VHF Model Chart ....................................................................................................... xvi

ASTRO XTS 4000 UHF Model Chart ...................................................................................................... xvii

Specifications for VHF Radios................................................................................................................ xviii

Specifications for UHF Range 1 Radios ................................................................................................... xix

Chapter 1 Introduction ......................................................................... 1-1

1.1 Manual Contents............................................................................................................................ 1-1

1.2 Notations Used in This Manual...................................................................................................... 1-1

1.3 Radio Description .......................................................................................................................... 1-2

1.4 FLASHport

®

................................................................................................................................... 1-2

6871619L01-C September 10, 2008

Page 8

vi Table of Contents

Chapter 2 Basic Maintenance.............................................................. 2-1

2.1 General Maintenance..................................................................................................................... 2-1

2.2 Handling Precautions..................................................................................................................... 2-1

2.3 General Repair Procedures and Techniques.................................................................................2-2

Chapter 3 Basic Theory of Operation ................................................. 3-1

3.1 Major Assemblies........................................................................................................................... 3-1

3.2 Digital Mode of Operation .............................................................................................................. 3-2

3.3 Main Board.....................................................................................................................................3-3

Chapter 4 Recommended Test Equipment and Service Aids .......... 4-1

4.1 Recommended Test Equipment .................................................................................................... 4-1

4.2 Service Aids ................................................................................................................................... 4-2

4.3 Field Programming......................................................................................................................... 4-2

Chapter 5 Performance Checks .......................................................... 5-1

5.1 Test Equipment Setup ................................................................................................................... 5-1

5.2 Display Radio Test Mode............................................................................................................... 5-2

5.3 Receiver Performance Checks ...................................................................................................... 5-7

5.4 Transmitter Performance Checks ..................................................................................................5-8

Chapter 6 Radio Alignment Procedures............................................. 6-1

6.1 Test Setup......................................................................................................................................6-1

6.2 Tuner Main Menu........................................................................................................................... 6-2

6.3 Softpot............................................................................................................................................ 6-3

6.4 Radio Information........................................................................................................................... 6-4

6.5 Reference Oscillator Alignment .....................................................................................................6-4

6.6 Transmit Power Alignment............................................................................................................. 6-7

6.7 Transmit Deviation Balance Alignment .......................................................................................... 6-9

6.8 Transmit Deviation Limit Alignment ............................................................................................. 6-11

6.9 Front End Filter Alignment ........................................................................................................... 6-13

6.10 Bit Error Rate ............................................................................................................................... 6-15

6.11 Transmitter Test Pattern ..............................................................................................................6-16

Chapter 7 Encryption ........................................................................... 7-1

7.1 Load an Encryption Key................................................................................................................. 7-1

7.2 Multikey Feature ............................................................................................................................ 7-1

7.3 Select an Encryption Key...............................................................................................................7-1

7.4 Select an Encryption Index ............................................................................................................ 7-2

7.5 Erase an Encryption Key ............................................................................................................... 7-3

September 10, 2008 6871619L01-C

Page 9

Table of Contents vii

Chapter 8 Disassembly/Reassembly Procedures ............................. 8-1

8.1 XTS 4000 Exploded View (Partial) ................................................................................................ 8-1

8.2 Required Tools and Supplies......................................................................................................... 8-3

8.3 Fastener Torque Chart .................................................................................................................. 8-3

8.4 Antenna ......................................................................................................................................... 8-4

8.5 Battery ........................................................................................................................................... 8-5

8.6 Radio Disassembly ........................................................................................................................ 8-6

8.7 Radio Reassembly....................................................................................................................... 8-17

8.8 Servicing CID Bezel Only ............................................................................................................ 8-30

Chapter 9 Basic Troubleshooting ....................................................... 9-1

9.1 Power-Up Error Codes .................................................................................................................. 9-1

9.2 Operational Error Codes................................................................................................................ 9-2

9.3 Receiver Troubleshooting.............................................................................................................. 9-2

9.4 Transmitter Troubleshooting.......................................................................................................... 9-3

9.5 Encryption Troubleshooting ........................................................................................................... 9-4

Chapter 10 Exploded Views and Parts Lists ...................................... 10-1

10.1 Exploded View and Parts List – Main Assemblies ....................................................................... 10-2

10.2 Exploded View and Parts List – Flip-Front Housing Assemblies ................................................. 10-3

10.3 Exploded View and Parts List – Chassis Assembly..................................................................... 10-4

10.4 Parts List – Service Kit................................................................................................................. 10-5

Appendix A Accessories .........................................................................A-1

A.1 Antennas........................................................................................................................................ A-1

A.2 Batteries and Battery Accessories................................................................................................. A-1

A.3 Carry Accessories..........................................................................................................................A-1

A.4 Chargers........................................................................................................................................ A-1

A.5 Surveillance Accessories...............................................................................................................A-2

Appendix B Replacement Parts Ordering..............................................B-1

B.1 Basic Ordering Information ............................................................................................................B-1

B.2 Motorola Online .............................................................................................................................B-1

B.3 Mail Orders ....................................................................................................................................B-1

B.4 Telephone Orders..........................................................................................................................B-1

B.5 Fax Orders.....................................................................................................................................B-2

B.6 Parts Identification .........................................................................................................................B-2

B.7 Product Customer Service.............................................................................................................B-2

6871619L01-C September 10, 2008

Page 10

viii Table of Contents

Appendix C Motorola Service Centers...................................................C-1

C.1 Servicing Information .................................................................................................................... C-1

C.2 Motorola Service Center ............................................................................................................... C-1

C.3 Motorola Federal Technical Center............................................................................................... C-1

C.4 Motorola Canadian Technical Logistics Center ............................................................................ C-1

Glossary......................................................................................... Glossary-1

Index..................................................................................................... Index-1

September 10, 2008 6871619L01-C

Page 11

List of Tables ix

List of Tables

Table 1-1. ASTRO XTS 4000 Basic Features........................................................................................ 1-2

Table 2-1. Lead Free Solder Wire Part Number List.............................................................................. 2-2

Table 2-2. Lead Free Solder Paste Part Number List ............................................................................ 2-2

Table 3-1. Local Oscillator and First IF Frequencies .............................................................................3-3

Table 4-1. Recommended Test Equipment............................................................................................4-1

Table 4-2. Service Aids .......................................................................................................................... 4-2

Table 5-1. Initial Equipment Control Settings......................................................................................... 5-2

Table 5-2. Test-Mode Displays............................................................................................................... 5-3

Table 5-3. Test Frequencies (MHz)........................................................................................................ 5-4

Table 5-4. Test Environments ................................................................................................................ 5-5

Table 5-5. Receiver Tests for ASTRO Conventional Channels* ............................................................ 5-7

Table 5-6. Transmitter Tests for ASTRO Conventional Channels* ........................................................ 5-8

Table 6-1. Reference Oscillator Alignment ............................................................................................ 6-6

Table 6-2. Transmit Power Settings ....................................................................................................... 6-8

Table 7-1. Encryption Key Zeroization Options...................................................................................... 7-4

Table 8-1. Corresponding XTS 4000 Exploded View and Parts List...................................................... 8-2

Table 8-2. Required Tools and Supplies ................................................................................................ 8-3

Table 8-3. Fastener Torque Chart.......................................................................................................... 8-3

Table 9-1. Power-Up Error Code Displays............................................................................................. 9-1

Table 9-2. Operational Error Code Displays .......................................................................................... 9-2

Table 9-3. Receiver Troubleshooting Chart ........................................................................................... 9-2

Table 9-4. Transmitter Troubleshooting Chart ....................................................................................... 9-3

Table 9-5. Encryption Troubleshooting Chart ........................................................................................ 9-4

Table 10-1. XTS 4000 Exploded Views and Parts Lists......................................................................... 10-1

Table 10-2. Parts List – Main Assemblies.............................................................................................. 10-2

Table 10-3. Parts List – Flip-Front Housing Assemblies........................................................................ 10-3

Table 10-4. Parts List – Chassis Assembly............................................................................................ 10-4

Table 10-5. Service Kit Table ................................................................................................................. 10-5

Related Publications

XTS 4000 Digital Portable Radio User Guide ............................................................................ 6871618L01

XTS 4000 Digital Portable Radios Detailed Service Manual...................................................... 6871620L01

XTS 4000 Digital Portable Radio User Guide (CD).................................................................... PMLN5057_

Chassis Eliminator Leaflet......................................................................................................... 6871568M01

6871619L01-C September 10, 2008

Page 12

x List of Figures

List of Figures

Figure 3-1. XTS 4000 Overall Block Diagram ......................................................................................... 3-1

Figure 3-2. Receiver Block Diagram........................................................................................................ 3-2

Figure 3-3. Transceiver (VHF) Block Diagram (Power and Control Omitted).......................................... 3-3

Figure 5-1. Performance Checks Test Setup........................................................................................... 5-1

Figure 6-1. Radio Alignment Test Setup.................................................................................................. 6-1

Figure 6-2. Tuner Software Main Menu................................................................................................... 6-2

Figure 6-3. Typical Softpot Screen – VHF............................................................................................... 6-3

Figure 6-4. Typical Softpot Screen – UHF...............................................................................................6-3

Figure 6-5. Radio Information Screen ..................................................................................................... 6-4

Figure 6-6. Reference Oscillator Alignment Screen – VHF..................................................................... 6-5

Figure 6-7. Reference Oscillator Alignment Screen – UHF..................................................................... 6-6

Figure 6-8. Battery Eliminator with RF Connector and SMA ................................................................... 6-7

Figure 6-9. Transmit Power Alignment Screen (Typical) – VHF .............................................................. 6-8

Figure 6-10. Transmit Power Alignment Screen (Typical) – UHF.............................................................. 6-8

Figure 6-11. Transmit Deviation Balance Alignment Screen – VHF........................................................ 6-10

Figure 6-12. Transmit Deviation Balance Alignment Screen – UHF ....................................................... 6-10

Figure 6-13. Transmit Deviation Limit Alignment Screen – VHF ............................................................. 6-12

Figure 6-14. Transmit Deviation Limit Alignment Screen – UHF............................................................. 6-12

Figure 6-15. Battery Eliminator with RF Connector and SMA ................................................................. 6-13

Figure 6-16. Front End Filter Alignment Screen – VHF........................................................................... 6-14

Figure 6-17. Front End Filter Alignment Screen – UHF........................................................................... 6-14

Figure 6-18. Bit Error Rate Screen .......................................................................................................... 6-16

Figure 6-19. Transmitter Test Pattern Screen – VHF .............................................................................. 6-17

Figure 6-20. Transmitter Test Pattern Screen – UHF ..............................................................................6-17

Figure 8-1. XTS 4000 Partial Exploded View .......................................................................................... 8-2

Figure 8-2. Attaching the Antenna........................................................................................................... 8-4

Figure 8-3. Removing the Antenna .........................................................................................................8-4

Figure 8-4. Attaching the Battery............................................................................................................. 8-5

Figure 8-5. Removing the Battery ...........................................................................................................8-6

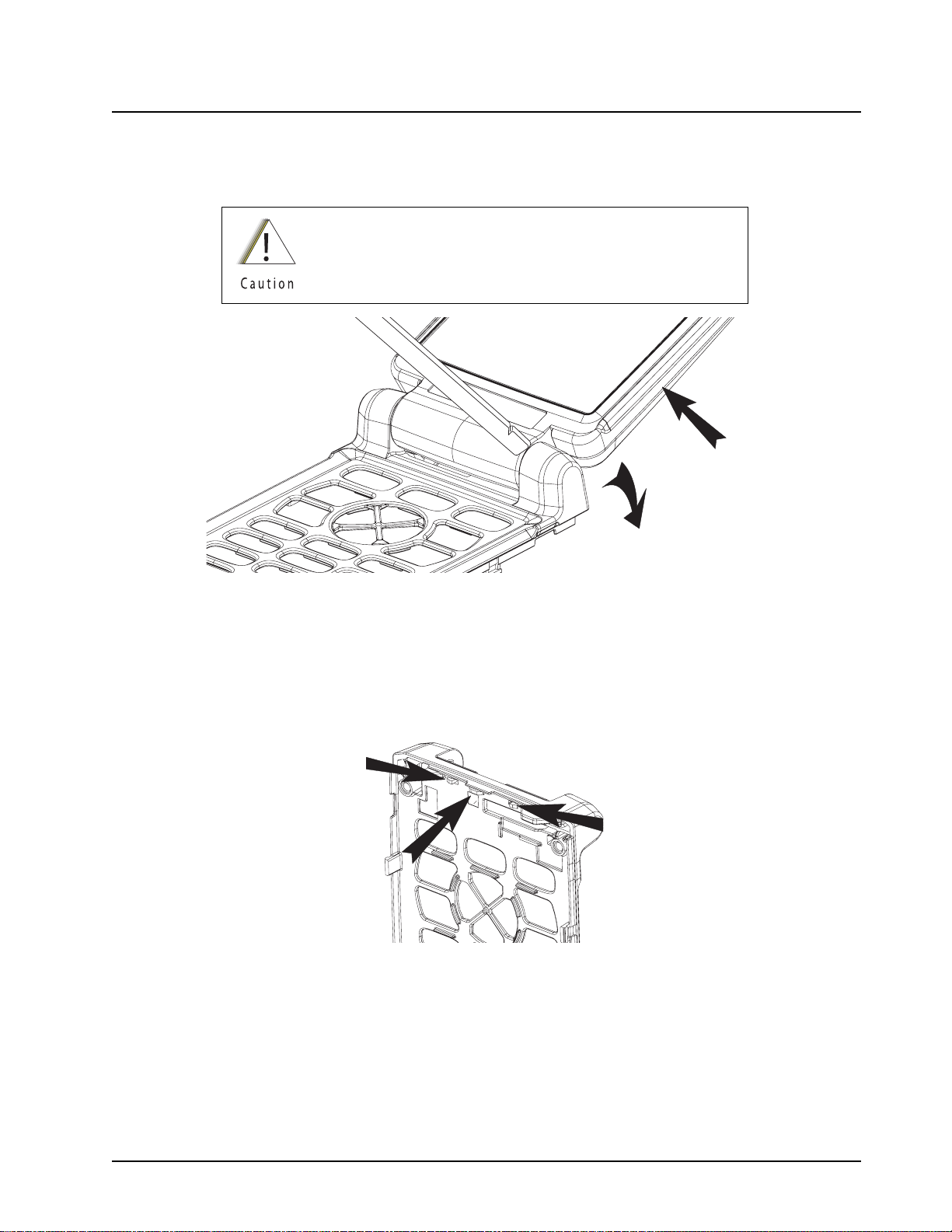

Figure 8-6. Separating Flip-Front Housing Assembly From Chassis Assembly......................................8-7

Figure 8-7. Unplugging Flexes ................................................................................................................ 8-8

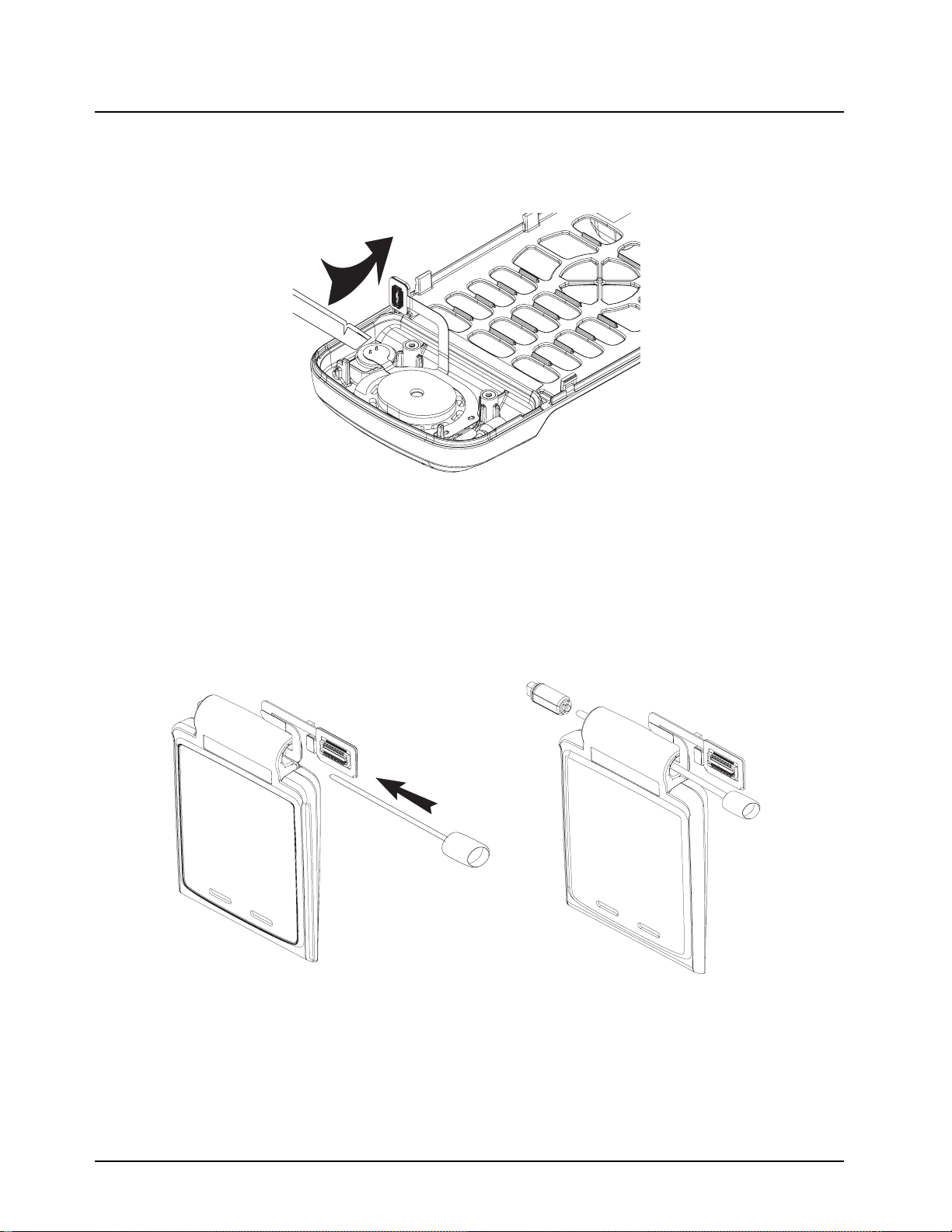

Figure 8-8. Disconnecting CE-UCM Connector Flex and Lifting Main Board.......................................... 8-8

Figure 8-9. Rotating Main Board 90° and Unplugging Top Control Inner Jumper Flex ...........................8-9

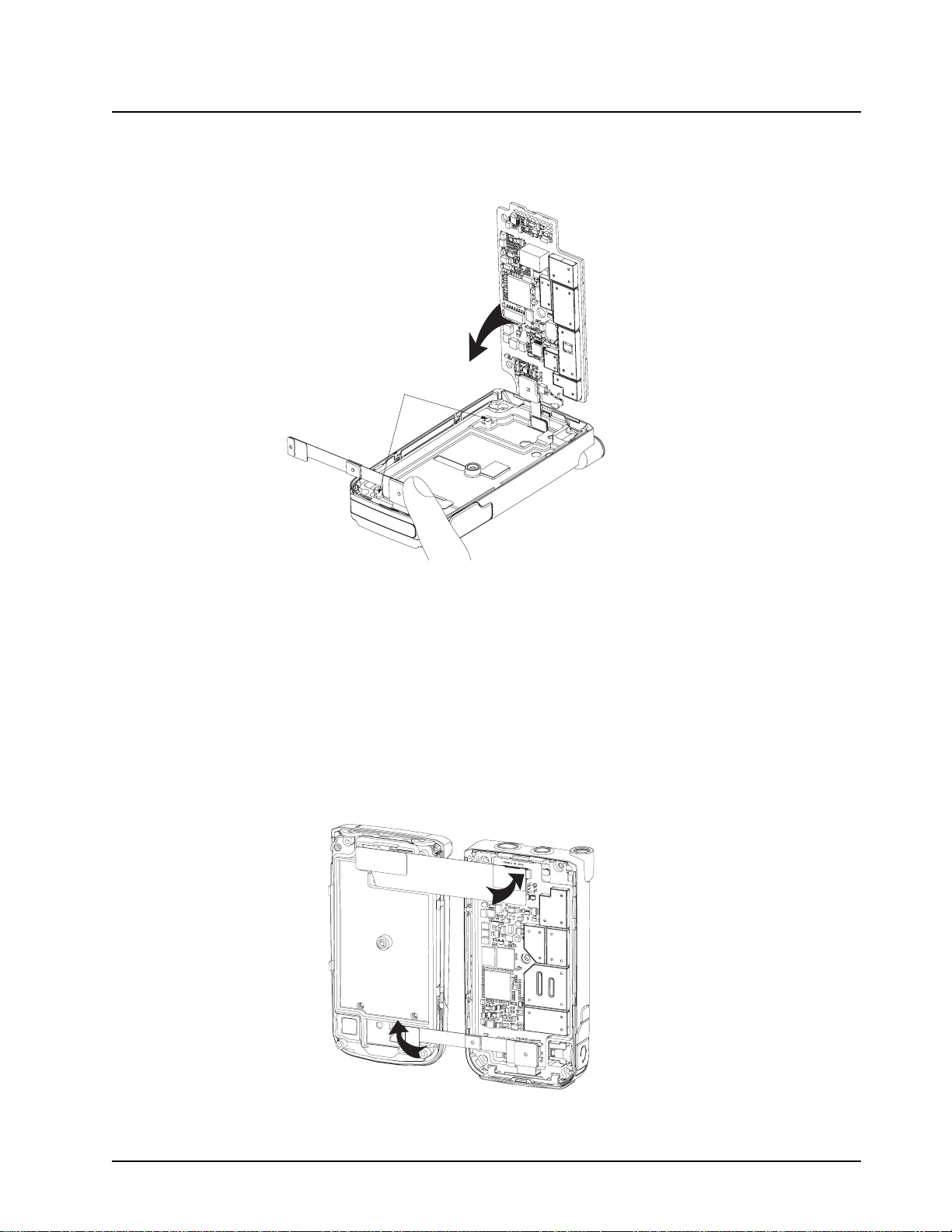

Figure 8-10. Removing Control Band ...................................................................................................... 8-10

Figure 8-11. Removing Audio Jack Dust Cover ......................................................................................8-10

Figure 8-12. Removing CE Dust Cover ................................................................................................... 8-11

Figure 8-13. Removing Audio Jack ......................................................................................................... 8-11

Figure 8-14. Removing CE Retainer and Spacer ....................................................................................8-12

Figure 8-15. Removing CE Board ........................................................................................................... 8-12

Figure 8-16. Disassemble Speaker Compartment Seal, Main Keyboard and UCM Board ..................... 8-13

Figure 8-17. Separating Keypad Backer Inner Jumper Flex ................................................................... 8-14

Figure 8-18. Removing Secure Pad ........................................................................................................8-14

Figure 8-19. Removing Front Housing from Flip Assembly..................................................................... 8-15

Figure 8-20. Removing Tabs from Flip Stopper Pad ............................................................................... 8-15

Figure 8-21. Removing Microphone Boot and Microphone from Front Housing ..................................... 8-16

Figure 8-22. Separating Hinge from Flip Inner Housing ..........................................................................8-16

Figure 8-23. Removing CID Bezel........................................................................................................... 8-17

Figure 8-24. Flip Flex .............................................................................................................................. 8-18

Figure 8-25. Inserting Flip Flex................................................................................................................ 8-19

Figure 8-26. Tongue in CID Bezel into Flip Sub-Assembly...................................................................... 8-19

September 10, 2008 6871619L01-C

Page 13

List of Figures xi

Figure 8-27. Adhere Flip Flex into Front Housing ................................................................................... 8-20

Figure 8-28. Reassemble UCM Board .................................................................................................... 8-21

Figure 8-29. Attach Secure Pad to Keypad Backer Sub-Assembly ........................................................ 8-21

Figure 8-30. Reassemble Flip Flex ......................................................................................................... 8-22

Figure 8-31. Assemble T6 screws to Front Housing ............................................................................... 8-22

Figure 8-32. Assemble T6 screws to Front Housing ............................................................................... 8-23

Figure 8-33. Inserting Spacer to CE Retainer ......................................................................................... 8-23

Figure 8-34. Reassemble CE Retainer and Spacer ................................................................................ 8-24

Figure 8-35. Reassemble Flip Flex ......................................................................................................... 8-24

Figure 8-36. Slide Audio Jack Insulator into Chassis .............................................................................. 8-25

Figure 8-37. Reassemble CE Connector Dust Cover ............................................................................. 8-25

Figure 8-38. Assemble Audio Jack Dust Cover....................................................................................... 8-26

Figure 8-39. Adhere Assembly Aid.......................................................................................................... 8-26

Figure 8-40. Reassemble Control Band.................................................................................................. 8-27

Figure 8-41. Assemble B Plus Seal to B Plus Connector........................................................................ 8-28

Figure 8-42. Assemble B Plus Seal to B Plus Connector........................................................................ 8-28

Figure 8-43. Holding CE-UCM Flex......................................................................................................... 8-29

Figure 8-44. Reassemble Flexes ............................................................................................................ 8-29

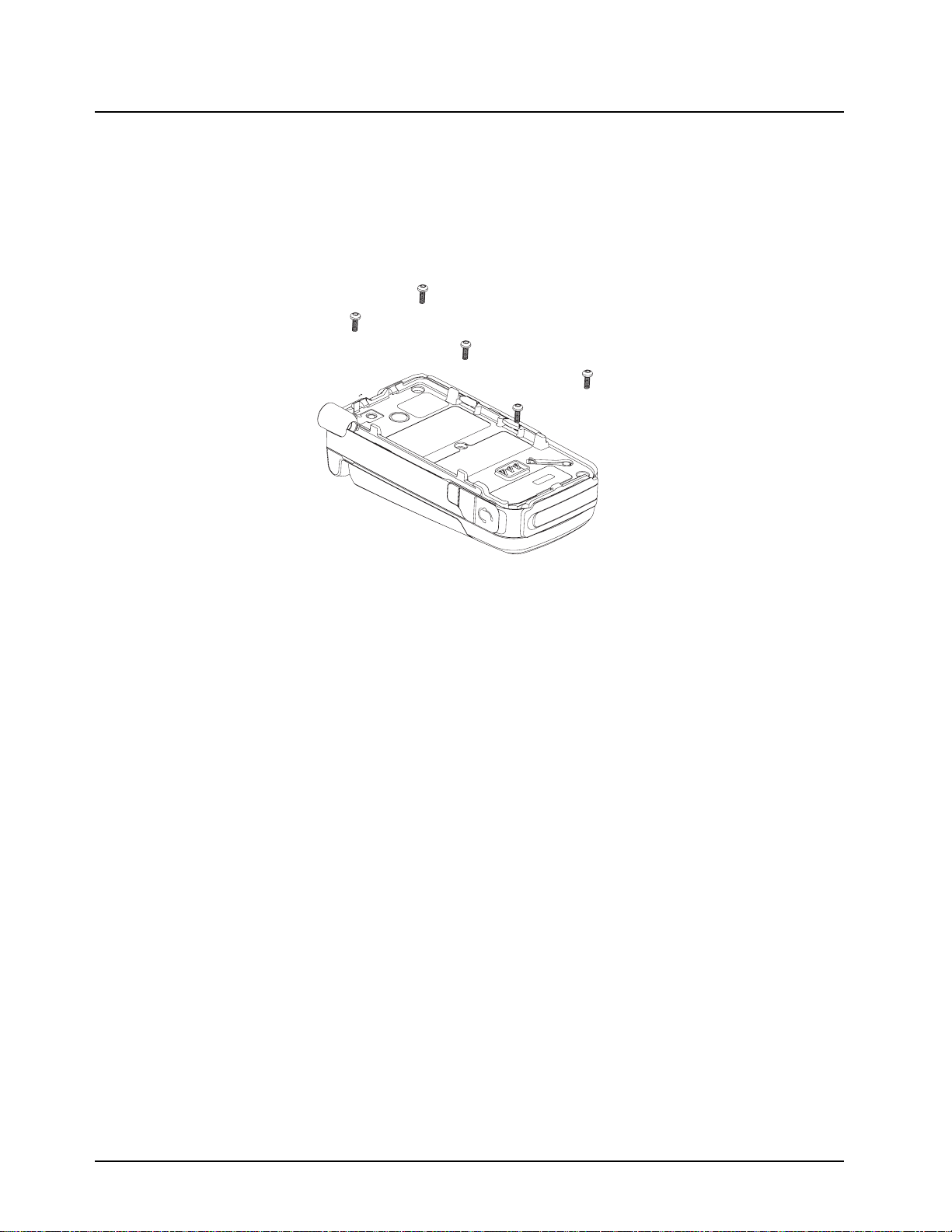

Figure 8-45. Screws Reassemble Sequence ..........................................................................................8-30

Figure 10-1. Exploded View – Main Assemblies .....................................................................................10-2

Figure 10-2. Exploded View – Flip - Front Housing Assemblies ............................................................. 10-3

Figure 10-3. Exploded View – Chassis Assembly................................................................................... 10-4

6871619L01-C September 10, 2008

Page 14

xii Commercial Warranty

Commercial Warranty

Limited Warranty

MOTOROLA COMMUNICATION PRODUCTS

I. What This Warranty Covers And For How Long

MOTOROLA INC. (“MOTOROLA”) warrants the MOTOROLA manufactured Communication

Products listed below (“Product”) against defects in material and workmanship under normal use and

service for a period of time from the date of purchase as scheduled below:

ASTRO XTS 4000 Digital Portable Units One (1) Year

Product Accessories One (1) Year

Motorola, at its option, will at no charge either repair the Product (with new or reconditioned parts),

replace it (with a new or reconditioned Product), or refund the purchase price of the Product during

the warranty period provided it is returned in accordance with the terms of this warranty. Replaced

parts or boards are warranted for the balance of the original applicable warranty period. All replaced

parts of Product shall become the property of MOTOROLA.

This express limited warranty is extended by MOTOROLA to the original end user purchaser only

and is not assignable or transferable to any other party. This is the complete warranty for the Product

manufactured by MOTOROLA. MOTOROLA assumes no obligations or liability for additions or

modifications to this warranty unless made in writing and signed by an officer of MOTOROLA.

Unless made in a separate agreement between MOTOROLA and the original end user purchaser,

MOTOROLA does not warrant the installation, maintenance or service of the Product.

MOTOROLA cannot be responsible in any way for any ancillary equipment not furnished by

MOTOROLA which is attached to or used in connection with the Product, or for operation of the

Product with any ancillary equipment, and all such equipment is expressly excluded from this

warranty. Because each system which may use the Product is unique, MOTOROLA disclaims

liability for range, coverage, or operation of the system as a whole under this warranty.

II. General Provisions

This warranty sets forth the full extent of MOTOROLA'S responsibilities regarding the Product.

Repair, replacement or refund of the purchase price, at MOTOROLA's option, is the exclusive

remedy. THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER EXPRESS WARRANTIES.

IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION, IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO THE

DURATION OF THIS LIMITED WARRANTY. IN NO EVENT SHALL MOTOROLA BE LIABLE FOR

DAMAGES IN EXCESS OF THE PURCHASE PRICE OF THE PRODUCT, FOR ANY LOSS OF

USE, LOSS OF TIME, INCONVENIENCE, COMMERCIAL LOSS, LOST PROFITS OR SAVINGS

OR OTHER INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE

USE OR INABILITY TO USE SUCH PRODUCT, TO THE FULL EXTENT SUCH MAY BE

DISCLAIMED BY LAW.

September 10, 2008 6871619L01-C

Page 15

Commercial Warranty xiii

III. State Law Rights

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LIMITATION ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION OR EXCLUSIONS MAY NOT APPLY.

This warranty gives specific legal rights, and there may be other rights which may vary from state to

state.

IV. How To Get Warranty Service

You must provide proof of purchase (bearing the date of purchase and Product item serial number)

in order to receive warranty service and, also, deliver or send the Product item, transportation and

insurance prepaid, to an authorized warranty service location. Warranty service will be provided by

Motorola through one of its authorized warranty service locations. If you first contact the company

which sold you the Product, it can facilitate your obtaining warranty service. You can also call

Motorola at 1-888-567-7347 US/Canada.

V. What This Warranty Does Not Cover

A. Defects or damage resulting from use of the Product in other than its normal and customary

manner.

B. Defects or damage from misuse, accident, water, or neglect.

C. Defects or damage from improper testing, operation, maintenance, installation, alteration,

modification, or adjustment.

D. Breakage or damage to antennas unless caused directly by defects in material workmanship.

E. A Product subjected to unauthorized Product modifications, disassemblies or repairs

(including, without limitation, the addition to the Product of non-Motorola supplied equipment)

which adversely affect performance of the Product or interfere with Motorola's normal

warranty inspection and testing of the Product to verify any warranty claim.

F. Product which has had the serial number removed or made illegible.

G. Rechargeable batteries if:

H. any of the seals on the battery enclosure of cells are broken or show evidence of tampering.

I. the damage or defect is caused by charging or using the battery in equipment or service other

than the Product for which it is specified.

J. Freight costs to the repair depot.

K. A Product which, due to illegal or unauthorized alteration of the software/firmware in the

Product, does not function in accordance with MOTOROLA's published specifications or the

FCC type acceptance labeling in effect for the Product at the time the Product was initially

distributed from MOTOROLA.

L. Scratches or other cosmetic damage to Product surfaces that does not affect the operation of

the Product.

M. Normal and customary wear and tear.

6871619L01-C September 10, 2008

Page 16

xiv Commercial Warranty

VI. Patent And Software Provisions

MOTOROLA will defend, at its own expense, any suit brought against the end user purchaser to the

extent that it is based on a claim that the Product or parts infringe a United States patent, and

MOTOROLA will pay those costs and damages finally awarded against the end user purchaser in

any such suit which are attributable to any such claim, but such defense and payments are

conditioned on the following:

A. that MOTOROLA will be notified promptly in writing by such purchaser of any notice of such

claim;

B. that MOTOROLA will have sole control of the defense of such suit and all negotiations for its

settlement or compromise; and

C. should the Product or parts become, or in MOTOROLA's opinion be likely to become, the

subject of a claim of infringement of a United States patent, that such purchaser will permit

MOTOROLA, at its option and expense, either to procure for such purchaser the right to

continue using the Product or parts or to replace or modify the same so that it becomes

noninfringing or to grant such purchaser a credit for the Product or parts as depreciated and

accept its return. The depreciation will be an equal amount per year over the lifetime of the

Product or parts as established by MOTOROLA.

MOTOROLA will have no liability with respect to any claim of patent infringement which is based

upon the combination of the Product or parts furnished hereunder with software, apparatus or

devices not furnished by MOTOROLA, nor will MOTOROLA have any liability for the use of ancillary

equipment or software not furnished by MOTOROLA which is attached to or used in connection with

the Product. The foregoing states the entire liability of MOTOROLA with respect to infringement of

patents by the Product or any parts thereof.

Laws in the United States and other countries preserve for MOTOROLA certain exclusive rights for

copyrighted MOTOROLA software such as the exclusive rights to reproduce in copies and distribute

copies of such Motorola software. MOTOROLA software may be used in only the Product in which

the software was originally embodied and such software in such Product may not be replaced,

copied, distributed, modified in any way, or used to produce any derivative thereof. No other use

including, without limitation, alteration, modification, reproduction, distribution, or reverse

engineering of such MOTOROLA software or exercise of rights in such MOTOROLA software is

permitted. No license is granted by implication, estoppel or otherwise under MOTOROLA patent

rights or copyrights.

VII. Governing Law

This Warranty is governed by the laws of the State of Illinois, USA.

September 10, 2008 6871619L01-C

Page 17

Model Numbering, Charts, and Specifications: Portable Radio Model Numbering System xv

Model Numbering, Charts, and Specifications

Portable Radio Model Numbering System

Typical Model Number:

Position:

Position 1 - Type of Unit

H = Hand-Held Portable

Positions 2 & 3 - Model Series

18 = XTS 4000

Position 4 - Frequency Band

A

=

Less than 29.7MHz

B

=

29.7 to 35.99MHz

C

=

36 to 41.99MHz

D

=

42 to 50MHz

F

=

66 to 80MHz

G

=

74 to 90MHz

H

=

Product Specific

J

=

136 to 162MHz

K

=

146 to 178MHz

L

=

174 to 210MHz

M

=

190 to 235MHz

Values given represent range only; they are

not absolute.

Position 5 - Power Level

A

=

0 to 0.7 Watts

B

=

0.7 to 0.9 Watts

C

=

1.0 to 3.9 Watts

D

=

4.0 to 5.0 Watts

E

=

5.1 to 6.0 Watts

F

=

6.1 to 10 Watts

Position 6 - Physical Packages

A

=

RF Modem Operation

B

=

Receiver Only

C

=

Standard Control; No Display

D

=

Standard Control; With Display

E

=

Limited Keypad; No Display

F

=

Limited Keypad; With Display

G

=

Full Keypad; No Display

H

=

Full Keypad; With Display

J

=

Limited Controls; No Display

K

=

Limited Controls; Basic Display

L

=

Limited Controls; Limited Display

M

=

Rotary Controls; Standard Display

N

=

Enhanced Controls; Enhanced Display

P

=

Low Profile; No Display

Q

=

Low Profile; Basic Display

R

=

Low Profile; Basic Display, Full Keypad

Position 7 - Channel Spacing

1 = 5kHz

2 = 6.25kHz

3 = 10kHz

4 = 12.5kHz

H18 K CN 9 P W 9 A N

1234 5 6 7 8 9101112

P

=

336 to 410MHz

Q

=

380 to 470MHz

R

=

438 to 482MHz

S

=

470 to 520MHz

T

=

Product Specific

U

=

764 to 870MHz

V

=

825 to 870MHz

W

=

896 to 941MHz

Y

=

1.0 to 1.6GHz

Z

=

1.5 to 2.0GHz

5 = 15kHz

6 = 20/25kHz

7 = 30kHz

9 = Variable/Programmable

Position 12 -

Unique Model Variations

C = Cenelec

N = Standard Package

Position 11 - Version

Version Letter (Alpha) - Major Change

Position 10 - Feature Level

1 = Basic

2 = Limited Package

3 = Limited Plus

4 = Intermediate

5 = Standard Package

Position 9 - Primary System Type

A

=

Conventional

B

=

Privacy Plus

C

=

Clear SMARTNET

D

=

Advanced Conventional Stat-Alert

E

=

Enhanced Privacy Plus

F

=

Nauganet 888 Series

G

=

Japan Specialized Mobile Radio (JSMR)

H

=

Multi-Channel Access (MCA)

J

=

CoveragePLUS

K

=

MPT1327* - Public

L

=

MPT1327* - Private

M

=

Radiocom

N

=

Tone Signalling

P

=

Binary Signalling

Q

=

Phonenet

W

=

Programmable

X

=

Secure Conventional

Y

=

Secure SMARTNET

6 = Standard Plus

7 = Expanded Package

8 = Expanded Plus

9 = Full Feature/

Programmable

* MPT = Ministry of Posts and Telecommunications

Position 8 - Primary Operation

A

=

Conventional/Simplex

B

=

Conventional/Duplex

C

=

Trunked Twin Type

D

=

Dual Mode Trunked

E

=

Dual Mode Trunked/Duplex

F

=

Trunked Type I

G

=

Trunked Type II

H

=

FDMA* Digital Dual Mode

J

=

TDMA** Digital Dual Mode

K

=

Single Sideband

L

=

Global Positioning Satellite Capable

M

=

Amplitude Companded Sideband (ACSB)

P

=

Programmable

* FDMA = Frequency Division Multiple Access

** TDMA = Time Division Multiple Access

6871619L01-C September 10, 2008

Page 18

xvi Model Numbering, Charts, and Specifications: ASTRO XTS 4000 VHF Model Chart

ASTRO XTS 4000 VHF Model Chart

MODEL NUMBER DESCRIPTION

H18KCN9PW9AN XTS4000 PORTABLE ASTRO DIGITAL 136–174MHZ 1–2W

ITEM NUMBER DESCRIPTION

X NUD2897_ XTS 4000 VHF Tanapa

X NUD7115_ XTS 4000 VHF Main

X NNTN7097_ XTS 4000 UCM Board

X NNTN7098_ Hardware, Tanapa XTS4000

X NNTN7101_ Assembly, Chassis XTS4000

X NNTN7100_ Assembly, Keypad Backer, XTS4000

X NNTN7099_ Assembly, Flip Front Housing, XTS4000

X PMLN5057_ XTS4000 CD UG & Safety

X 6871618L01 XTS4000 User Guide

Notes:

X = Item Included

*•The model number and (sometimes) the FLASHcode can be found on the FCC label on the back of the radio.

• The model number, Host code, DSP code, and (sometimes) the FLASHcode can be found by putting the radio into the Test

Mode.

• The model number, Host code, DSP code, and FLASHcode can be found by using the Programming Cable (NKN1027_ or

NKN1029_) and the CPS to read the radio.

September 10, 2008 6871619L01-C

Page 19

Model Numbering, Charts, and Specifications: ASTRO XTS 4000 UHF Model Chart xvii

ASTRO XTS 4000 UHF Model Chart

MODEL NUMBER DESCRIPTION

H18QCN9PW9AN XTS4000 PORTABLE ASTRO DIGITAL 380–470MHZ 0.25–2W

ITEM NUMBER DESCRIPTION

X NUE3623_ XTS 4000 UHF Tanapa

X NUE7350_ XTS 4000 UHF Main

X NNTN7097_ XTS 4000 UCM Board

X NNTN7098_ Hardware, Tanapa XTS4000

X NNTN7101_ Assembly, Chassis XTS4000

X NNTN7100_ Assembly, Keypad Backer, XTS4000

X NNTN7099_ Assembly, Flip Front Housing, XTS4000

X PMLN5057_ XTS4000 CD UG & Safety

X 6871618L01 XTS4000 User Guide

Notes:

X = Item Included

*•The model number and (sometimes) the FLASHcode can be found on the FCC label on the back of the radio.

• The model number, Host code, DSP code, and (sometimes) the FLASHcode can be found by putting the radio into the Test

Mode.

• The model number, Host code, DSP code, and FLASHcode can be found by using the Programming Cable (NKN1027_ or

NKN1029_) and the CPS to read the radio.

6871619L01-C September 10, 2008

Page 20

xviii Model Numbering, Charts, and Specifications: Specifications for VHF Radios

Specifications for VHF Radios

All specifications are per Telecommunications Industries Association TIA-603 unless otherwise

noted.

GENERAL

FCC Designation: AZ489FT3814

Frequency Ranges: 136–151 MHz,

(Subject to Antenna operating 145–166 MHz,

band - See Appendix A: Antennas

Temperature Range:

Operating: -30°C to +60°C

Storage: -40°C to +85°C

Power Supply: Lithium-Ion Battery (Li-Ion)

Battery Voltage:

Nominal: 7.5 Vdc

Range: 6 to 9 Vdc

Transmit Current Drain (Typical): 950 mA

Receive Current Drain (Rated Audio): 210 mA

Standby Current Drain: 89 mA

Recommended Battery:

630 mAh Li-Ion: NNTN6944_

or 1260 mAh Li-Ion: PMNN4083_

Dimensions (H x W x D):

Radio Only (w/o battery, w/o antenna):

(103.2 mm x 55.3 mm x 29.6 mm)

Radio With 630 mAh Li-Ion (NNTN6944_)

Only (w/o antenna):

(103.2 mm x 55.3 mm x 34.6 mm)

Radio With 1260 mAh Li-Ion (PMNN4083_)

Only (w/o antenna):

(103.2 mm x 55.3 mm x 40.2 mm)

Weight: (w/ Antenna):

Less Battery: 5.6 oz (160 g)

With 630 mAh Li-Ion (NNTN6944_):

With 1260 mAh Li-Ion (PMNN4083_):

)162–174 MHz

4.06" x 2.18" x 1.17"

4.06" x 2.18" x 1.36"

4.06" x 2.18" x 1.58"

7.8 oz (220 g)

9.9 oz (280 g)

RECEIVER

(TYPICAL PERFORMANCE)

Bandwidth: 38 MHz

Frequency Stability

(-30 to +60°C; 25°C ref.): ±0.0002%

Rated Audio: 500 mW

Analog Sensitivity*

12 dB SINAD: 0.22 µV

Selectivity*

12.5 kHz Channel: -67 dB

25 kHz Channel: -78 dB

Intermodulation*: -75 dB

Spurious Rejection*: -75 dB

FM Hum and Noise*:

12.5 kHz Channel: -45 dB

25 kHz Channel: -50 dB

Distortion*: 1.50%

Digital Sensitivity**

1% BER: 0.25 µV

5% BER: 0.22 µV

Selectivity**: -63 dB

Intermodulation**: -73 dB

Spurious Rejection**: -75 dB

Residual Audio Noise Ratio (silence)**: -65 dB

Residual Audio Noise Power (mute)**:

-65 dBm

Distortion**: 1.00%

TRANSMITTER

(TYPICAL PERFORMANCE)

RF Power:

136–174 MHz: 1–2 Watts

Frequency Stability (typical)

(-30 to +60°C; 25°C ref.): ±0.0002%

Emission (typical conducted): -75 dBc

FM Hum and Noise*

12.5 kHz Channel: -43 dB

25 kHz Channel: -48 dB

Distortion*: 1.0%

Modulation Limiting*

12.5 kHz Channel: ±2.5 kHz

25 kHz Channel: ±5.0 kHz

Adjacent Channel Power Ratio*

12.5 kHz Channel: -67 dB

25 kHz Channel: -78 dB

Modulation Fidelity**

Deviation: 1750 Hz

Carrier Frequency Offset: ±0.0002%

Error Vector Magnitude: 1.5%

Symbol Rate Accuracy**: 0%

Adjacent Channel Power Ratio**: -69 dB

Emissions Designators:

20K0F1E, 16K0F3E, 11K0F3E, 8K10F1D, and

8K10F1E

Notes:

Specifications subject to change without notice.

* Measured in ANALOG mode per TIA/EIA 603 under nominal conditions.

** Measured in DIGITAL mode per TIA/EIA IS 102.CAAA under nominal conditions.

September 10, 2008 6871619L01-C

Page 21

Model Numbering, Charts, and Specifications: Specifications for UHF Range 1 Radios xix

Specifications for UHF Range 1 Radios

All specifications are per Telecommunications Industries Association TIA-603 unless otherwise

noted.

GENERAL

FCC Designation: AZ489FT4881

Frequency Ranges: 380–470 MHz

(Subject to Antenna operating

band - See Appendix A: Antennas

Temperature Range:

Operating: -30°C to +60°C

Storage: -40°C to +85°C

Power Supply: Lithium-Ion Battery (Li-Ion)

Battery Voltage:

Nominal: 7.5 Vdc

Range: 6 to 9 Vdc

Transmit Current Drain (Typical): 950 mA

Receive Current Drain (Rated Audio): 210 mA

Standby Current Drain: 89 mA

Recommended Battery:

630 mAh Li-Ion: NNTN6944_

or 1260 mAh Li-Ion: PMNN4083_

Dimensions (H x W x D):

Radio Only (w/o battery, w/o antenna):

(103.2 mm x 55.3 mm x 29.6 mm)

Radio With 630 mAh Li-Ion (NNTN6944_)

Only (w/o antenna):

(103.2 mm x 55.3 mm x 34.6 mm)

Radio With 1260 mAh Li-Ion (PMNN4083_)

Only (w/o antenna):

(103.2 mm x 55.3 mm x 40.2 mm)

Weight: (w/ Antenna):

Less Battery: 5.6 oz (160 g)

With 630 mAh Li-Ion (NNTN6944_):

With 1260 mAh Li-Ion (PMNN4083_):

)

4.06" x 2.18" x 1.17"

4.06" x 2.18" x 1.36"

4.06" x 2.18" x 1.58"

7.8 oz (220 g)

9.9 oz (280 g)

RECEIVER

(TYPICAL PERFORMANCE)

Bandwidth: 90 MHz

Frequency Stability

(-30 to +60°C; 25°C ref.): ±0.0002%

Rated Audio: 500 mW

Analog Sensitivity*

12 dB SINAD: 0.25 µV

Selectivity*

12.5 kHz Channel: -63 dB

25 kHz Channel: -73 dB

Intermodulation*: -70 dB

Spurious Rejection*: -75 dB

FM Hum and Noise*:

12.5 kHz Channel: -40 dB

25 kHz Channel: -45 dB

Distortion*: 2%

Digital Sensitivity**

1% BER: 0.25 µV

5% BER: 0.25 µV

Selectivity**: -63 dB

Intermodulation**: -70 dB

Spurious Rejection**: -75 dB

Residual Audio Noise Ratio (silence)**: -65 dB

Residual Audio Noise Power (mute)**:

-53 dBm

Distortion**: 1.00%

TRANSMITTER

(TYPICAL PERFORMANCE)

RF Power:

380–470 MHz: 0.25–2 Watts

Frequency Stability (typical)

(-30 to +60°C; 25°C ref.): ±0.0002%

Emission (typical conducted): -75 dBc

FM Hum and Noise*

12.5 kHz Channel: -40 dB

25 kHz Channel:

Distortion*: 1.2%

Modulation Limiting*

12.5 kHz Channel: ±2.5 kHz

25 kHz Channel: ±5.0 kHz

Adjacent Channel Power Ratio*

12.5 kHz Channel: -67 dB

25 kHz Channel: -75 dB

Modulation Fidelity**

Deviation: 1630 Hz < UHF1 < 1800 Hz

Carrier Frequency Offset: ±0.0002%

Error Vector Magnitude: < 5%

Symbol Rate Accuracy**: 0%

Adjacent Channel Power Ratio**: -67 dB

Emissions Designators:

20K0F1E, 16K0F3E, 11K0F3E, 8K10F1D, and

8K10F1E

-43 dB

Notes:

Specifications subject to change without notice.

* Measured in ANALOG mode per TIA/EIA 603 under nominal conditions.

** Measured in DIGITAL mode per TIA/EIA IS 102.CAAA under nominal conditions.

6871619L01-C September 10, 2008

Page 22

xx Model Numbering, Charts, and Specifications

Notes

September 10, 2008 6871619L01-C

Page 23

Introduction: Manual Contents 1-1

Chapter 1 Introduction

This manual contains information needed for Levels One and Two radio servicing. Level One

servicing consists of radio programming, radio alignment, and installation and removal of the

antenna and battery. Level Two servicing covers disassembly and reassembly of the radio to replace

circuit boards.

1.1 Manual Contents

Included in this manual are radio specifications for the VHF (136–174 MHz) and

UHF (380–470 MHz) frequency bands, a general description of XTS 4000 model, recommended test

equipment, service aids, radio alignment procedures, general maintenance recommendations,

procedures for assembly and disassembly, and exploded views and parts lists.

1.2 Notations Used in This Manual

Throughout the text in this publication, you will notice the use of note, caution, warning, and danger

notations. These notations are used to emphasize that safety hazards exist, and due care must be

taken and observed.

NOTE: An operational procedure, practice, or condition that is essential to emphasize.

CAUTION indicates a potentially hazardous situation which, if

not avoided, might

WARNING indicates a potentially hazardous situation

which, if not avoided, could

result in equipment damage.

result in death or injury.

DANGER indicates an imminently hazardous

situation which, if not avoided, will

result in death or

injury.

6871619L01-C September 10, 2008

Page 24

1-2 Introduction: Radio Description

1.3 Radio Description

The ASTRO XTS 4000 radios are among the most sophisticated two-way radios available. The

radios are available in the VHF (136–174 MHz) and UHF (380–470 MHz) frequency bands.

The ASTRO XTS 4000 radio provides improved voice quality across more coverage area. The digital

process, called embedded signaling, intermixes system signaling information with digital voice,

resulting in improved system reliability and the capability of supporting a multitude of advanced

features.

Table 1-1 describes the basic features of ASTRO XTS 4000 radios.

Table 1-1. ASTRO XTS 4000 Basic Features

Feature XTS4000

Main Display 130 x130 dot matrix, liquid-crystal display (LCD)

CID Display 112 x 32 dot matrix, liquid-crystal display (LCD)

Keypad 3 x 3 Menu Keypad (with 4-way Navigation button)

3 x 4 Alphanumeric Keypad

Channel Capability 850

Dialing from Prestored List Yes

Programmable Softkeys Yes

1.4 FLASHport

The ASTRO XTS 4000 radio utilizes Motorola’s FLASHport technology. FLASHport makes it

possible to add software that drives the radio’s capabilities both at the time of purchase and later on.

Previously, changing a radio’s features and capabilities meant significant modifications or buying a

new radio. But now, similar to how a computer can be loaded with different software, the radio’s

features and capabilities can be upgraded with FLASHport software.

®

September 10, 2008 6871619L01-C

Page 25

Basic Maintenance: General Maintenance 2-1

Chapter 2 Basic Maintenance

This chapter describes preventive maintenance and handling precautions. Each of these topics

provides information vital to the successful operation and maintenance of your radio.

2.1 General Maintenance

In order to avoid operating outside the limits set by the FCC, we recommend that you align the

ASTRO XTS 4000 radio’s reference oscillator every time the radio is taken apart, or once per year,

whichever comes first. Periodic visual inspection and cleaning is also recommended.

2.1.1 Inspection

Check that the external surfaces of the radio are clean and that all external controls and switches are

functional. A detailed inspection of the interior electronic circuitry is not needed.

2.1.2 Cleaning

The following procedures describe the recommended cleaning agents and the methods to be used

when cleaning the external surfaces of the radio. External surfaces include the housing assembly

and battery case. These surfaces should be cleaned whenever a periodic visual inspection reveals

the presence of smudges, grease, and/or grime.

The only recommended agent for cleaning the external radio surfaces is a 0.5% solution of a mild

dishwashing detergent in water.

The effects of certain chemicals and their vapors can have harmful results

on certain plastics. Aerosol sprays, tuner cleaners, and other chemicals

should be avoided.

The detergent-water solution should be applied sparingly with a stiff, non-metallic, short-bristled

brush to work all loose dirt away from the radio. A soft, absorbent, lintless cloth or tissue should be

used to remove the solution and dry the radio. Make sure that no water remains entrapped near the

connectors, cracks, or crevices.

2.2 Handling Precautions

Complementary metal-oxide semiconductor (CMOS) devices, and other high-technology devices,

are used in this family of radios. While the attributes of these devices are many, their characteristics

make them susceptible to damage by electrostatic discharge (ESD) or high-voltage charges.

Damage can be latent, resulting in failures occurring weeks or months later. Therefore, special

precautions must be taken to prevent device damage during disassembly, troubleshooting, and

repair. Handling precautions are mandatory for this radio, and are especially important in lowhumidity conditions.

6871619L01-C September 10, 2008

Page 26

2-2 Basic Maintenance: General Repair Procedures and Techniques

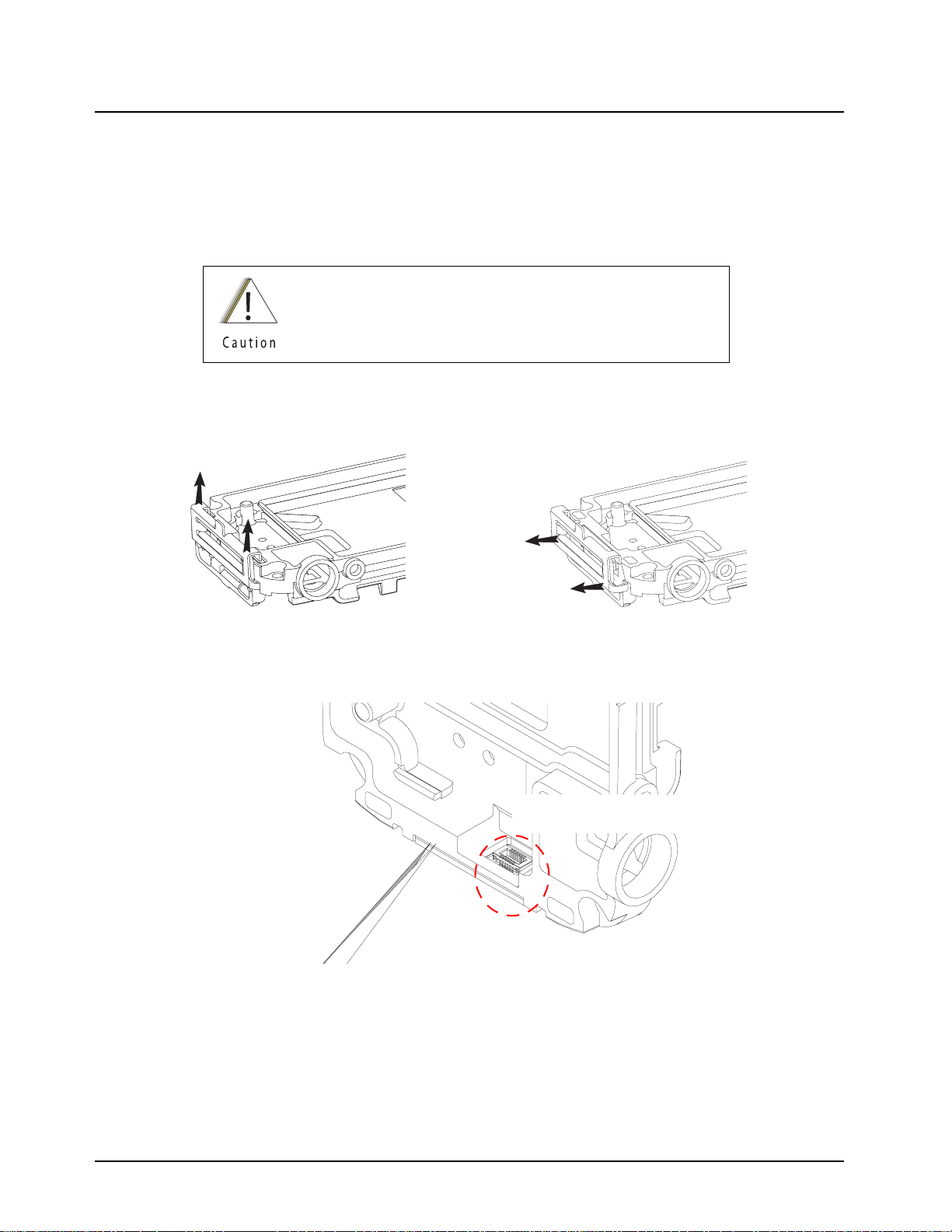

• The XTS 4000 radio casting has a vent port that allow for pressure

equalization in the radio. Never poke this vent with any object, such as

needles, tweezers, or screwdrivers. This could create a leak path into the

radio.

• The pressure equalization vent is located on the chassis, just below the

battery contact. Never obstruct or cover the slot with any object, except

the designated Audio Jack PC Label (48). Ensure that no oily substances

come in contact with this vent.

2.3 General Repair Procedures and Techniques

NOTE

Environmentally Preferred Products (EPP) (refer to the marking on the printed circuit

boards — examples shown below) were developed and assembled using

environmentally preferred components and solder assembly techniques to comply with

the European Union’s Restriction of Hazardous Substances (ROHS) Directive 2002/

95/EC and Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/

EC. To maintain product compliance and reliability, use only the Motorola specified parts

in this manual.

Any rework or repair on Environmentally Preferred Products must be done using the appropriate

lead-free solder wire and lead-free solder paste as stated in the following table:

Table 2-1. Lead Free Solder Wire Part Number List

Motorola

Part Number

1088929Y01 95.5Sn/3.8Ag/0.7Cu RMA Version 2.7-3.2% 217C 52171 0.015” 1lb spool

Alloy Flux Type

Flux Content

by Weight

Melting

Point

Supplier Part

number

Diameter Weight

Table 2-2. Lead Free Solder Paste Part Number List

Motorola Part

Number

1085674C03 NC-SMQ230 900-1000KCPs

Manufacturer Part

Number

Viscosity Type Composition & Percent Metal

Brookfield (5rpm)

Type 3

(-325/+500)

(95.5%Sn-3.8%Ag-0.7%Cu)

89.3%

Liquid

Temperature

217°C

2.3.1 Parts Replacement and Substitution

When damaged parts are replaced, identical parts should be used. If the identical replacement

component is not locally available, check the parts list for the proper Motorola part number and order

the component from the nearest Motorola Radio Products and Solutions Organization listed in

Appendix B of this manual.

September 10, 2008 6871619L01-C

Page 27

Basic Maintenance: General Repair Procedures and Techniques 2-3

2.3.2 Rigid Circuit Boards

The family of radios uses bonded, multi-layer, printed circuit boards. Since the inner layers are not

accessible, some special considerations are required when soldering and unsoldering components.

The through-plated holes may interconnect multiple layers of the printed circuit. Therefore, care

should be exercised to avoid pulling the plated circuit out of the hole.

When soldering near the connector pins:

• avoid accidentally getting solder in the connector.

• be careful not to form solder bridges between the connector pins

• closely examine your work for shorts due to solder bridges.

2.3.3 Chip Components

Use the RLN4062 Hot-Air Repair Station for chip component replacement. Adjust the temperature

control to 390 °C (735 °F), and adjust the airflow to a minimum setting. Airflow can vary due to

component density.

• To remove a chip component:

1. Use a hot-air hand piece and position the nozzle of the hand piece approximately 0.3 cm

(1/8”) above the component to be removed.

2. Begin applying the hot air. Once the solder reflows, remove the component using a pair

of tweezers.

3. Using a solder wick and a soldering iron or a power desoldering station, remove the

excess solder from the pads.

• To replace a chip component using a soldering iron:

1. Select the appropriate micro-tipped soldering iron and apply fresh solder to one of the

solder pads.

2. Using a pair of tweezers, position the new chip component in place while heating the

fresh solder.

3. Once solder wicks onto the new component, remove the heat from the solder.

4. Heat the remaining pad with the soldering iron and apply solder until it wicks to the

component. If necessary, touch up the first side. All solder joints should be smooth and

shiny.

• To replace a chip component using hot air:

1. Use the hot-air hand piece and reflow the solder on the solder pads to smooth it.

2. Apply a drop of solder paste flux to each pad.

3. Using a pair of tweezers, position the new component in place.

4. Position the hot-air hand piece approximately 0.3 cm (1/8” ) above the component and

begin applying heat.

5. Once the solder wicks to the component, remove the heat and inspect the repair. All

joints should be smooth and shiny.

6871619L01-C September 10, 2008

Page 28

2-4 Basic Maintenance: General Repair Procedures and Techniques

2.3.4 Shields

Removing and replacing shields is recommended to be done with the Air Blower,

BOSCH GHG 603 or equivalent.

• To remove the shield:

1. Place the circuit board in the circuit board holder.

2. Add solder paste flux around the base of the shield.

3. Position the heat-focus head onto the shield.

4. Turn on the heater and wait until the shield lifts off the circuit board.

5. Once the shield is off, turn off the heat, and grab the part with a pair of tweezers.

6. Remove the circuit board from the circuit board holder.

• To replace the shield:

1. Add solder to the shield if necessary, using a micro-tipped soldering iron.

2. Next, rub the soldering iron tip along the edge of the shield to smooth out any excess

solder. Use solder wick and a soldering iron to remove excess solder from the solder

pads on the circuit board.

3. Place the circuit board back in the circuit board holder.

4. Place the shield on the circuit board using a pair of tweezers.

5. Position the heat-focus head over the shield.

6. Turn on the heater and wait for the solder to reflow.

7. Once complete, turn off the heat, raise the heat-focus head and wait approximately one

minute for the part to cool.

8. Remove the circuit board and inspect the repair. No cleaning should be necessary.

September 10, 2008 6871619L01-C

Page 29

Basic Theory of Operation: Major Assemblies 3-1

Chapter 3 Basic Theory of Operation

This chapter discusses the basic operational theory of the ASTRO XTS 4000 radio, which is a

wideband, synthesized radio available in the VHF (136–174 MHz) and UHF (380–470 MHz)

frequency bands. All ASTRO XTS 4000 radios are capable of ASTRO mode (digital) operation

(12.5 kHz).

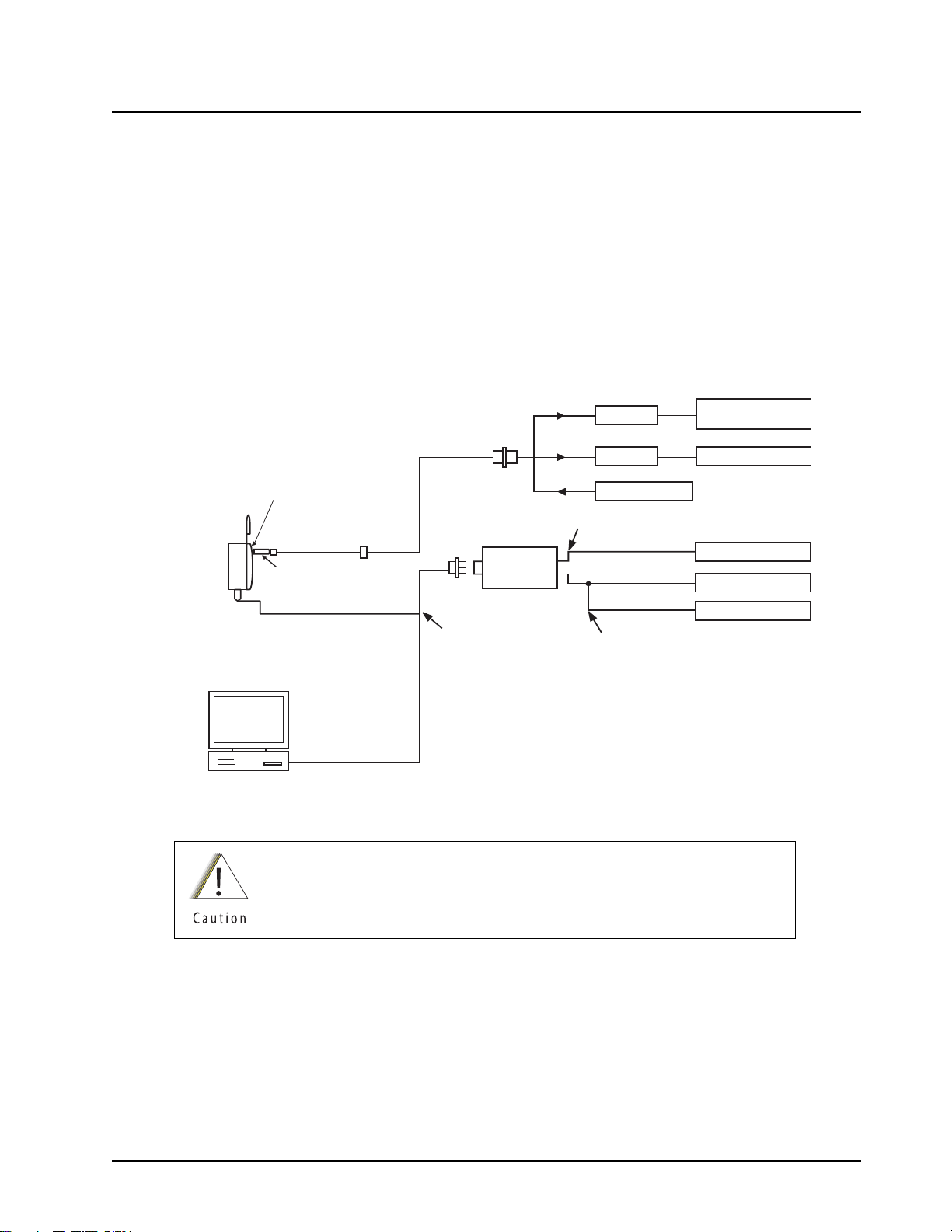

3.1 Major Assemblies

The ASTRO XTS 4000 radio includes the following major connections to the main board

(See Figure 3-1):

• Main Board — contains a dual-core processor which includes both the microcontroller unit

(MCU) and a digital signal processor (DSP) core, the processor’s memory devices, an audio

and power supply support integrated circuit (IC), a digital support IC, and the audio power

amplifier. It also contains all transmit, receive, and frequency generation circuitry, including the

digital receiver back-end IC and the reference oscillator.

• CE-UCM Flex — contains vibrator, speaker, microphone and encryption connector.

• Main Display — 130 x 130 dot matrix, liquid-crystal display (LCD).

• CID Display — 112 x 32 dot matrix, liquid-crystal display (LCD).

• Keypad — a 3 x 3 Menu keypad with 4-way navigation button, and a 3 x 4 alphanumeric

keypad.

Display, Keypad and

External

Accessory

Connector

Vibrator

Speaker and

Microphone

Earpiece

Controls

2

3

60

16

CE

Connector

8

Main Board

Encryption

Module

Audio jack

7

3

Figure 3-1. XTS 4000 Overall Block Diagram

30

3

Antenna

7.5V

Battery

6871619L01-C September 10, 2008

Page 30

3-2 Basic Theory of Operation: Digital Mode of Operation

3.2 Digital Mode of Operation

This section provides an overview of the digital mode receive and transmit theory of operation.

3.2.1 Receiving

When the radio is receiving (See Figure 3-2), the signal comes from the antenna connector to the

Main board, passing through the antenna switch and the receiver front end. The signal is then

filtered, amplified, and mixed with the first local-oscillator signal, generated by the voltage-controlled

oscillator (VCO).

RF Input

Harmonic

XTAL

Filter

Filter

Antenna

Switch

LO

Tuneable

Pre-Selector

Filter

ABACUS III - RX Back End

RX Front End

LNA

CKO

Tuneable

Post-Selector

Filter

ADC

1st LO

1st

Mixer

3

to VOCON Section

MAEPF-27278-A

RX_SSI_ DATA

Figure 3-2. Receiver Block Diagram

The resulting intermediate frequency (IF) signal is fed to the IF circuitry, where it is again filtered and

passed to the Abacus III digital back-end IC. In the digital back-end IC, the IF signal is mixed with the

second local oscillator to create the second IF at 2.25 MHz. In the back-end IC, a bandpass, sigmadelta, analog-to-digital converter then decodes the second IF signal, and outputs, on the radio’s

serial synchronous interface (SSI) bus, digital audio to the digital signal processor (DSP).

The dual-core processor’s digital-signal processor (DSP) digitally filters the PCM audio. The DSP

decodes the information in the signal and identifies the appropriate destination for it.

• For a voice signal, the DSP will route the digital voice data to the CODEC inside the audio and

power supply support IC, for conversion to an analog signal. The CODEC will then present the

signal to the receive audio pre-amplifier, then to the audio power amplifier, which drives the

speaker.

• For signaling information, the DSP will decode the message and pass it internally to the

microcontrol unit of the dual-core processor.

September 10, 2008 6871619L01-C

Page 31

Basic Theory of Operation: Main Board 3-3

3.2.2 Transmitting

When the radio is transmitting, microphone audio is passed through gain stages to the CODEC,

where the signal is digitized. The CODEC passes digital data to the DSP, where pre-emphasis and

low-pass (splatter) filtering are done. The DSP passes this signal to a digital/analog converter (DAC),

where it is reconverted into an analog signal and scaled for application to the voltage-controlled

oscillator as a modulation signal (See Figure 3-3).

PCIC

Post-Selector

Filter

Power

Module

Current

Sensing

RX LNA

Pre-Selector

Filter

MAEPF-27322-O

Antenna

Switch

Harmonic

TX

Reference

Oscillator

2ND

LO

Loop

Filter

EPIC

FracN

3

DAC

3

LPF

Sample

Clk

MOD

IN

ABACUS III

VCO

VCO

VCOBIC

Crystal

Filter

Buffer

Mixer

TX Driver

Amplifier

Figure 3-3. Transceiver (VHF) Block Diagram (Power and Control Omitted)

Transmitted signaling information is applied to the DSP from the microcontrol unit, where it is coded,

and passed to the DAC, which handles it the same as a voice signal. The DAC output connects to

the synthesizer modulation input. A modulated carrier is provided to the transmitter power amplifier,

which transmits the signal under dynamic power control.

Filter

To

Antenna

3.3 Main Board

3.3.1 Transceiver Operation

Refer to Figure 3-3, on page 3-3. The receiver front end consists of a pre-selector filter, low-noise

amplifier, a post-selector filter, and a mixer. Both the pre-selector filter and pro-selector filter are

varactor-tuned bandpass filters, controlled by the microcontroller. See Table 3-1 for local oscillator

(LO) and first IF information.

Table 3-1. Local Oscillator and First IF Frequencies

VHF UHF1

LO Frequency Range 180.85–218.85 MHz 306.65–396.65 MHz

First IF Frequency 44.85 MHz 73.35 MHz

6871619L01-C September 10, 2008

Page 32

3-4 Basic Theory of Operation: Main Board

The frequency generation function is performed by two ICs - two VCOs, and associated circuitry.

The reference oscillator IC provides a frequency standard to the synthesizer. The fractional-N

synthesizer turns on the two external VCOs and tunes it to RX LO or TX carrier frequency. The VCO

buffer amplifies the signal to the required power level. The synthesizer is controlled by the

microcontroller unit through a serial peripheral interface (SPI) bus. Most of the synthesizer circuitry is

enclosed in rigid metal cans on the transceiver section to reduce interference and microphonic

effects.

The receiver back end consists of a bandpass crystal filter, input and output impedance matching

networks, and the digital back-end IC. Final filtering is done digitally in the DSP.

The Abacus III digital back-end IC contains a low-noise amplifier, a mixer, a variable gain amplifier

with integral anti-alias filter, a bandpass, sigma delta, analog-to-digital converter, and a decimation

filter with a programmable decimation factor. The Abacus III also contains an automatic gain control

(AGC) circuit to provide 12 dB of continuous gain adjustments. For the second LO, the Abacus III

has an internal, integer-N frequency synthesizer, and an external, discrete loop filter and voltagecontrolled oscillator (VCO). The output of the Abacus III is digital data on the RX_SSI bus.

The transmitter power amplifier (PA) consists of a driver amplifier IC and a discrete final-stage.

Transmit power is controlled by a power control IC (PCIC) that monitors the currents and adjusts PA

control voltages. The transmitter RF signal then passes through a PIN diode antenna switch and a

low-pass harmonic filter, which connects to the antenna connector.

3.3.2 VOCON Operation

The vocoder and controller (VOCON) circuitry contains the radio's microcontroller unit (Patriot) with

its memory and support circuits, the DSP, its memory devices, and the DSP-support IC, voltage

regulators, audio, and power control circuits. Connected to the VOCON circuitry are the display

circuitry, RF circuitry, keypad circuitry, encryption module, microphone, speaker and vibrator.

The microcontrol unit controls receive/transmit frequencies, power levels, display, and other radio

functions, using either direct logic control or serial communications paths to the devices.The

microcontrol unit executes a stored program located in the FLASH ROM. Data is transferred to and

from memory by the microcontrol unit data bus. The memory location from which data is read, or to

which data is written, is selected by the address lines.

The DSP-support IC is supplied with a 16.8 MHz clock from the RF circuitry. Both the DSP and the

microprocessor have their clocks generated by the DSP-support IC. They can both be adjusted so

that the harmonics do not cause interference with the radio’s receive channel.

The regulator and power-control circuits include 3.3-volt analog, 3.3-volt digital, and 5-volt

regulators. The audio PA is sourced from 7.5V. The regulator’s power-down mode is controlled by