Page 1

Motorola GmbH, CSS Center, Mobile Devices

Title: Troubleshooting-Guide W220 Page: 1 / 11

Doc. No: TSG_W220

Version: 1.0

Date: 19.12.2006

DEBUG GUIDE W220 LEVEL 3

Repair Support Information

Writing by: Juan Ortiz

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 2

Motorola GmbH, CSS Center, Mobile Devices

Title: Troubleshooting-Guide W220 Page: 2 / 11

Doc. No: TSG_W220

Version: 1.0

Date: 19.12.2006

Modify Date By:

INDEX

Special sequence & Requirements Pag. 3

Tools Pag. 4

No power up Pag. 5

High consume Pag. 6 & 7

No TX Pag. 8 &9

No RX Pag. 10

Special Note Pag. 11

Repair Support Information

Writing by: Juan Ortiz

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 3

Doc. No: TSG_W220

Version: 1.0

Motorola GmbH, CSS Center, Mobile Devices

Date: 19.12.2006

Title: Troubleshooting-Guide W220 Page: 3 / 11

SPECIAL KEY SEQUENCE FOR SPECIAL FUNCTION

Requirements

- System Requirements

- Power supplies, Oscilloscope, Spectrum Analyzer, Test Set

- Pre-heater for lead free soldering/ solder machine for BGA´s

- Microscope

- Mobile Service Tools (MST)

- Field Service Bulletins

- Block diagrams/Schematics

- Basic information on troubleshooting Motorola Phones

- Make sure all contacts are clean

- Use newest approved Software

- RESET / MASTER CLEAR can fix some issues

- Do a visual inspection on customer abuse/liquid contamination

- Advice on working with lead free soldering

- Work very carefully because of underfill

- Use protection shields

- Use lead free flux

- Use pre heater (HAKKO 853)

Repair Support Information

Writing by: Juan Ortiz

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 4

Doc. No: TSG_W220

Version: 1.0

Motorola GmbH, CSS Center, Mobile Devices

Date: 19.12.2006

Title: Troubleshooting-Guide W220 Page: 4 / 11

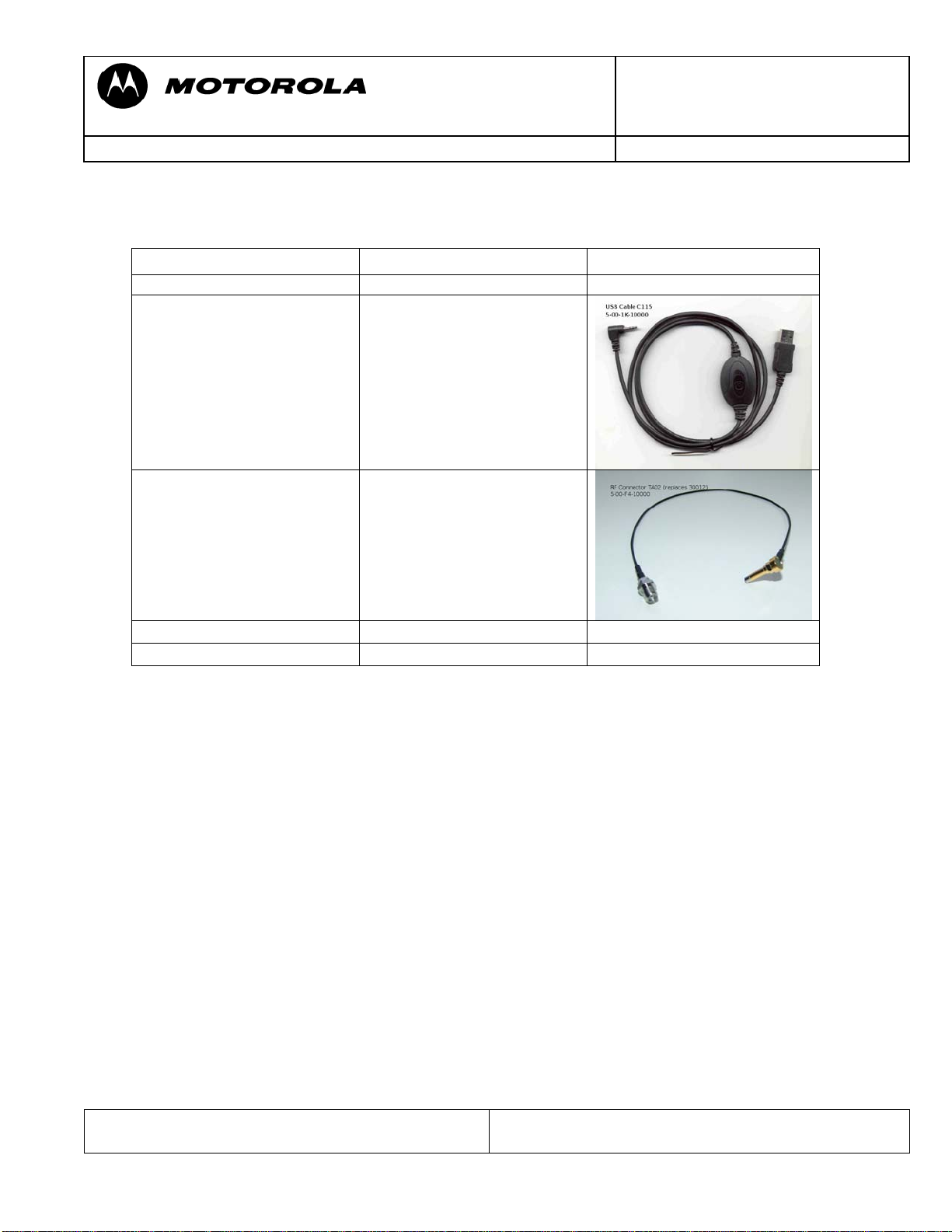

Tools Part-number Picture

USB cable C115, C116,

5-00-1K-10000

C117, C155, V170, V171

RF Probe TA02 (replaces

5-00-F4-10000

old revision 30012)

Main Battery W220/W300 5-00-X3-10000

Repair Support Information

Writing by: Juan Ortiz

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 5

p

Doc. No: TSG_W220

Version: 1.0

Motorola GmbH, CSS Center, Mobile Devices

Date: 19.12.2006

Title: Troubleshooting-Guide W220 Page: 5 / 11

Connect the PCB to power supply with a external

power supply 4.2 v.

NO

POWER UP

No

Is there current-consumption

when You try to power up the

PCB?

Replace U202

Yes

No

The voltage in TP207 changes

from 4 V to 0 V when the

ower button is pushed?

Clean or replace keypad mylar, if the

failure persist replace U202, if the

failure still persist replace PCB

Yes

Are there information signal

No

in test point between U201

Replace PCB

Yes

No

Is there 26 MHz signal from U606?

Replace

Yes

No

Is there 32,768 KHz signal from

Replace

Yes

Replace

PCB

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Writing by: Juan Ortiz

U606

X201

Page 6

Doc. No: TSG_W220

Version: 1.0

Motorola GmbH, CSS Center, Mobile Devices

Date: 19.12.2006

Title: Troubleshooting-Guide W220 Page: 6 / 11

SPECIAL PROCEDURE FOR HIGH CURRENT FAILURE - EXAMPLE

In probably most cases these problems are caused by an off current. One first look should

be to verify whether there is an off current. If there is an off current it should be checked

whether the device draws current via battery and/or via external connector.

In case of an off current via battery there should be a low resistance (less than ~200

Ohm)/ or a short from BATT+_RAW (M5400-4) to GND.

To localize the defective part causing the short/ low resistance a simple way is to freeze

the board with a coolant spray, supply a battery voltage from a power supply using micro

clamp-type test probes, and see which parts are getting warm. This is a very basic and

essential method to troubleshoot off current / high current consumption failures.

The power supply should be set to 3.6V with current limitation to 2A. We strictly

recommend checking the current the PCB draws on the display of the power supply.

Shields covering suspected parts should be removed before freezing the PCB.

The PCB should be handled with care. After removing the shields the PCB should be

given some time to cool down slowly before freezing it to far below zero to avoid physical

stress to the multilayer PCB with lead free soldered parts.

In some cases the part, which is getting warm has itself an internal short. After removing

this part the off current should be fixed. For verification check off current or measure

resistance BATT+_RAW (M5400-4) to GND. A new part can be placed.

If the short / low resistance remains after removing the part which was getting warm, it

should be checked which signals/ voltages this parts provide. In the most cases this part

will provide a supply voltage to other parts from which one possibly could have an

internal short and therefore is getting warm.

Repair Support Information

Writing by: Juan Ortiz

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 7

Doc. No: TSG_W220

Version: 1.0

Motorola GmbH, CSS Center, Mobile Devices

Date: 19.12.2006

Title: Troubleshooting-Guide W220 Page: 7 / 11

To find out the defective part an easy way is to use the Flensburg Layout Viewer to

follow the signal (check for Shorts Resistors after which the signals possibly could have a

changed name), and to remove the parts one after another, until the short is gone.

Most frequent parts with internal shorts causing these kinds of failures are the PA´s

Example:

- BAT00 – radio draws about 400 mA in standby, no off current

- Q3501/U3000 are getting warm

– Q3501 provides VRF_RX_2.775V for Blue Module U900 via Short Resistor

R902 (using Flensburg Layout Viewer )

- Blue Module U900 is also getting warm

Blue Module U900 itself has an internal short. Æ Defective U900

Repair Support Information

Writing by: Juan Ortiz

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 8

and C613 for GSM?

p

(See

g

ure 1)

(See

)

Doc. No: TSG_W220

Version: 1.0

Motorola GmbH, CSS Center, Mobile Devices

Date: 19.12.2006

Title: Troubleshooting-Guide W220 Page: 8 / 11

Let radio transmit on GSM900 or DCS using MST program

Measure if at the output of

No Yes

CON601 is signal and currentconsumtion of the in PCB is

Measure if at the input of

CON601 is a signal and

current-consumptionof the

Yes No

No

Is there a signal at C606 and

Check R601 and replace

it if is necessary if it is

OK replace U202

Yes

Is there a signal at C621 for DCS

No

Replace

U605

Yes

No

Is there a signal in C630?

Replace

U607

Yes

No

Is there a digital signal in PAON Test point?

fi

Replace

U202

Yes

No

Is there a digital signal in APC Test point?

figure 1

Replace

PCB

Yes

Checking and replacing if fail these components;

C605, C606, C611, C612, R602, R603, C613, C615,

L605, C621, C623, L604, C630, L611, C617, L608,

L612, C631 and R606 if the failure

ersist replace PCB

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Writing by: Juan Ortiz

NO TX

Replace

CON601

Page 9

Doc. No: TSG_W220

Version: 1.0

Motorola GmbH, CSS Center, Mobile Devices

Date: 19.12.2006

Title: Troubleshooting-Guide W220 Page: 9 / 11

Work table for duplexer

C619

VC2

Repair Support Information

Writing by: Juan Ortiz

C618

VC1

FIGURE 1

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

PAON

Test Point

APC

Test Point

Page 10

Doc. No: TSG_W220

Version: 1.0

Motorola GmbH, CSS Center, Mobile Devices

Date: 19.12.2006

Title: Troubleshooting-Guide W220 Page: 10 / 11

Inject a RF from Test Set and put in RX the PCB using MST program

NO RX

No

Is there the same input signal as C605 for GSM and

C606 for DCS?

Replace

U202

Yes

No

Is there the same input signal as L601 for GSM and

L602 for DCS?

Replace

U604

Yes

Is there the same input signal as L606 for GSM and

No

U602 for GSM

U603 for GSM

Yes

No

Is there the same input signal as C630?

Replace

U607

Yes

No

Is there the same input signal as R606?

Replace

CON601

Yes

No

VC1 and VC2 are a low value? (See Figure 1)

Replace

U608

Yes

Replace

PCB

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Writing by: Juan Ortiz

Replace

Page 11

Doc. No: TSG_W220

Version: 1.0

Motorola GmbH, CSS Center, Mobile Devices

Date: 19.12.2006

Title: Troubleshooting-Guide W220 Page: 11 / 11

SPECIAL NOTE

Follow up failures caused by repair action

Quite a lot of repairs which were sent to Level 4 service have a second fault, which is

caused by an unsuccessful repair trial.

We stricktly recommend visually checking the PCB for skewed or tombstoned parts,

soldering shorts or heating bubbles in PCB after every soldering action. Especially small

parts which are located close to shields can easily be misplaced during removal or setting

of the shields.

We experienced that some parts seems to be more heat sensitive than others.

Repair Support Information

Writing by: Juan Ortiz

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Loading...

Loading...