Page 1

MVME3100

Single-Board Computer

Installation and Use

V3100A/IH1

January 2006 Edition

Page 2

© Copyright 2006 Motorola Inc.

All rights reserved.

Printed in the United States of America.

Motorola and the stylized M logo are trademarks of Motorola, Inc., registered in the U.S.

Patent and Trademark Office.

All other product or service names mentioned in this document are the property of their

respective owners.

Page 3

Safety Summary

Warning

The following general safety precautions must be observed during all phases of operation, service, and repair of

this equipment. Failure to comply with these precautions or with specific warnings elsewhere in this manual

could result in personal injury or damage to the equipment.

The safety precautions listed below represent warnings of certain dangers of which Motorola is aware. You, as

the user of the product, should follow these warnings and all other safety precautions necessary for the safe

operation of the equipment in your operating environment.

Ground the Instrument.

To minimize shock hazard, the equipment chassis and enclosure must be connected to an electrical ground. If the

equipment is supplied with a three-conductor AC power cable, the power cable must be plugged into an approved

three-contact electrical outlet, with the grounding wire (green/yellow) reliably connected to an electrical ground

(safety ground) at the power outlet. The power jack and mating plug of the power cable meet International

Electrotechnical Commission (IEC) safety standards and local electrical regulatory codes.

Do Not Operate in an Explosive Atmosphere.

Do not operate the equipment in any explosive atmosphere such as in the presence of flammable gases or fumes.

Operation of any electrical equipment in such an environment could result in an explosion and cause injury or

damage.

Keep Away From Live Circuits Inside the Equipment.

Operating personnel must not remove equipment covers. Only Factory Authorized Service Personnel or other

qualified service personnel may remove equipment covers for internal subassembly or component replacement

or any internal adjustment. Service personnel should not replace components with power cable connected. Under

certain conditions, dangerous voltages may exist even with the power cable removed. To avoid injuries, such

personnel should always disconnect power and discharge circuits before touching components.

Use Caution When Exposing or Handling a CRT.

Breakage of a Cathode-Ray Tube (CRT) causes a high-velocity scattering of glass fragments (implosion). To

prevent CRT implosion, do not handle the CRT and avoid rough handling or jarring of the equipment. Handling

of a CRT should be done only by qualified service personnel using approved safety mask and gloves.

Do Not Substitute Parts or Modify Equipment.

Do not install substitute parts or perform any unauthorized modification of the equipment. Contact your local

Motorola representative for service and repair to ensure that all safety features are maintained.

Observe Warnings in Manual.

Warnings, such as the example below, precede potentially dangerous procedures throughout this manual.

Instructions contained in the warnings must be followed. You should also employ all other safety precautions

which you deem necessary for the operation of the equipment in your operating environment.

Warnin g

To prevent serious injury or death from dangerous voltages, use extreme

caution when handling, testing, and adjusting this equipment and its

components.

Page 4

Flammability

!

Caution

!

Caution

Attention

!

Vorsic h t

!

All Motorola PWBs (printed wiring boards) are manufactured with a flammability rating

of 94V-0 by UL-recognized manufacturers.

EMI Caution

Caution

This equipment generates, uses and can radiate electromagnetic energy. It

may cause or be susceptible to electromagnetic interference (EMI) if not

installed and used with adequate EMI protection.

Lithium Battery Caution

This product contains a lithium battery to power the clock and calendar circuitry.

Caution

Caution

Caution

Danger of explosion if battery is replaced incorrectly. Replace battery only

with the same or equivalent type recommended by the equipment

manufacturer. Dispose of used batteries according to the manufacturer’s

instructions.

Il y a danger d’explosion s’il y a remplacement incorrect de la batterie.

Remplacer uniquement avec une batterie du même type ou d’un type

équivalent recommandé par le constructeur. Mettre au rebut les batteries

usagées conformément aux instructions du fabricant.

Explosionsgefahr bei unsachgemäßem Austausch der Batterie. Ersatz nur

durch denselben oder einen vom Hersteller empfohlenen Typ. Entsorgung

gebrauchter Batterien nach Angaben des Herstellers.

Page 5

CE Notice (European Community)

!

Warning

Warnin g

Motorola products with the CE marking comply with the EMC Directive (89/336/EEC).

Compliance with this directive implies conformity to the following European Norms:

EN55022 “Limits and Methods of Measurement of Radio Interference Characteristics

of Information Technology Equipment”; this product tested to Equipment Class A

EN55024 “Information technology equipment—Immunity characteristics—Limits and

methods of measurement”

Board products are tested in a representative system to show compliance with the above

mentioned requirements. A proper installation in a CE-marked system will maintain the

required EMC performance.

In accordance with European Community directives, a “Declaration of Conformity” has

been made and is available on request. Please contact your sales representative.

This is a Class A product. In a domestic environment, this product may

cause radio interference, in which case the user may be required to take

adequate measures.

Page 6

Notice

While reasonable efforts have been made to assure the accuracy of this document,

Motorola, Inc. assumes no liability resulting from any omissions in this document, or from

the use of the information obtained therein. Motorola reserves the right to revise this

document and to make changes from time to time in the content hereof without obligation

of Motorola to notify any person of such revision or changes.

Electronic versions of this material may be read online, downloaded for personal use, or

referenced in another document as a URL to the Motorola Web site. The text itself may not

be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Motorola, Inc.

It is possible that this publication may contain reference to or information about Motorola

products (machines and programs), programming, or services that are not available in your

country. Such references or information must not be construed to mean that Motorola

intends to announce such Motorola products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S.

Government, the following notice shall apply unless otherwise agreed to in writing by

Motorola, Inc.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in

subparagraph (b)(3) of the Rights in Technical Data clause at DFARS 252.227-7013 (Nov.

1995) and of the Rights in Noncommercial Computer Software and Documentation clause

at DFARS 252.227-7014 (Jun. 1995).

Motorola, Inc.

Embedded Communications Computing

2900 South Diablo Way

Tempe, Arizona 85282

Page 7

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Overview of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Comments and Suggestions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

1 Hardware Preparation and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview of Startup Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

MVME3100 Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Configuration Switch (S4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Geographical Address Switch (S3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PMC I/O Voltage Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

RTM SEEPROM Address Switch (S1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the MVME3100 into a Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connection to Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Completing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Startup and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Switches and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 MOTLoad Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MOTLoad Implementation and Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MOTLoad Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MOTLoad Utility Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MOTLoad Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Using MOTLoad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Command Line Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Command Line Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MVME3100 Installation and Use (V3100A/IH1)

vii

Page 8

Contents

Command Line Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MOTLoad Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Default VME Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Firmware Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

CR/CSR Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Displaying VME Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Editing VME Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Deleting VME Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Restoring Default VME Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Remote Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Alternate Boot Images and Safe Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Firmware Startup Sequence Following Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Firmware Scan for Boot Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Valid Boot Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Checksum Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

MOTLoad Image Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

USER Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Alternate Boot Data Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

System Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Local Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Flash Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Control and Timers Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

I2C Serial Interface and Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Ethernet Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Asynchronous Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

PCI/PCI-X Interfaces and Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

MPC8540 PCI-X Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

TSi148 VME Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Serial ATA Host Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

PCI-X-to-PCI-X Bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

PCI Mezzanine Card Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

PMC Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

General-Purpose Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Real-time Clock Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Reset Control Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Debug Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

viii

MVME3100 Installation and Use (V3100A/IH1)

Page 9

Contents

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

PMC Expansion Connector (J4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Ethernet Connectors (GENET1/J41B, GENET2/J2B, ENET1/J2A) . . . . . . . . . . . . . . . . . . . . . . 50

PCI Mezzanine Card (PMC) Connectors (J11 – J14, J21 – J23) . . . . . . . . . . . . . . . . . . . . . . . . 51

Serial Port Connectors (COM1/J41A, COM2–COM5/J2A-D) . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

VMEbus P1 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

VMEbus P2 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

MVME721 PMC I/O Module (PIM) Connectors (J10, J14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Planar sATA Power Connector (J30) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

USB Connector (J27) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

sATA Connectors (J28 and J29) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Headers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Boundary Scan Header (J24) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Processor COP Header (J25) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Supply Current Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

B Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Motorola Computer Group Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Manufacturers’ Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

MVME3100 Installation and Use (V3100A/IH1)

ix

Page 10

List of Figures

Figure 1-1. MVME3100 Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 4-1. MVME3100 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 4-2. MVME721 RTM Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MVME3100 Installation and Use (V3100A/IH1)

xi

Page 11

List of Tables

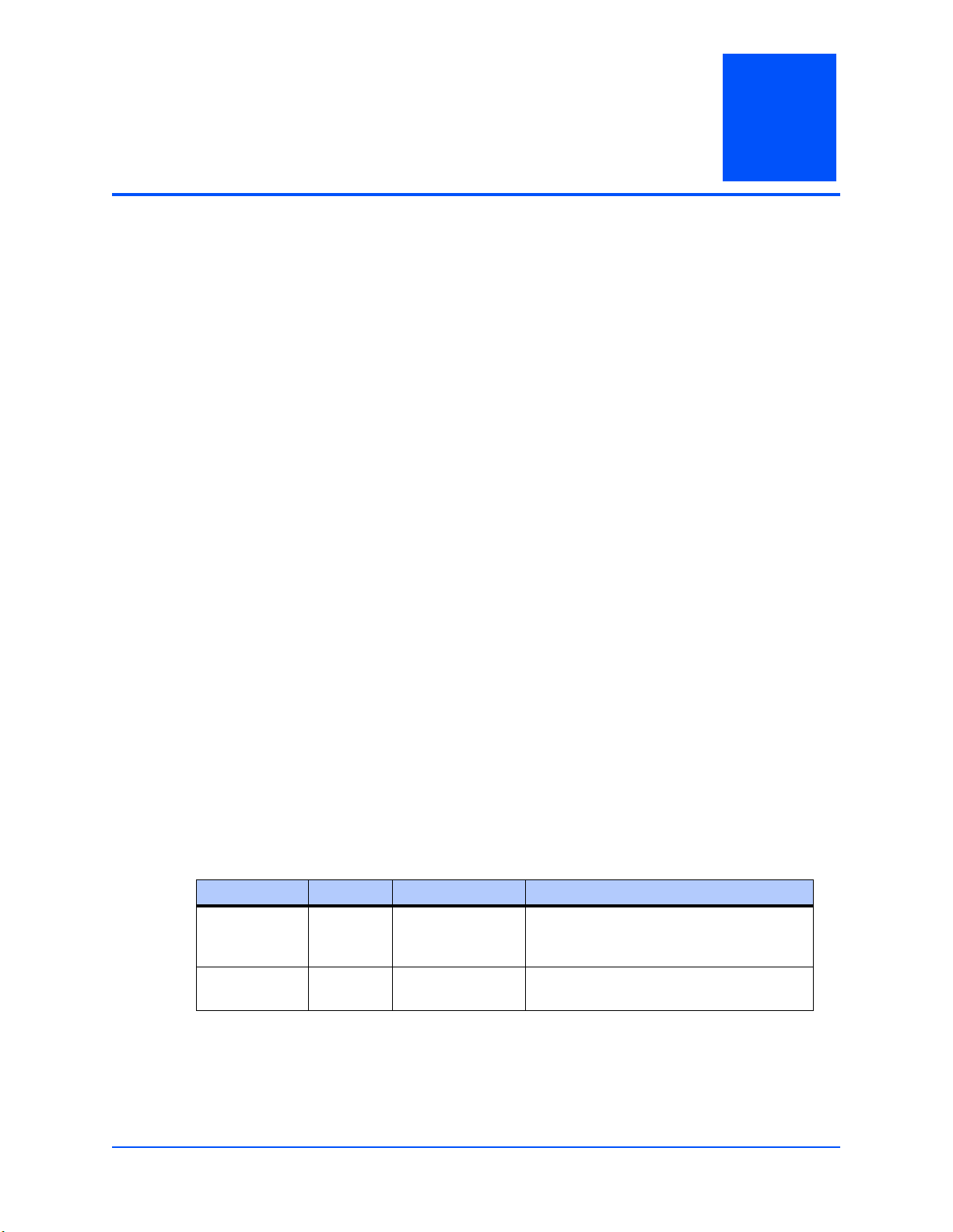

Table 1-1. Startup Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

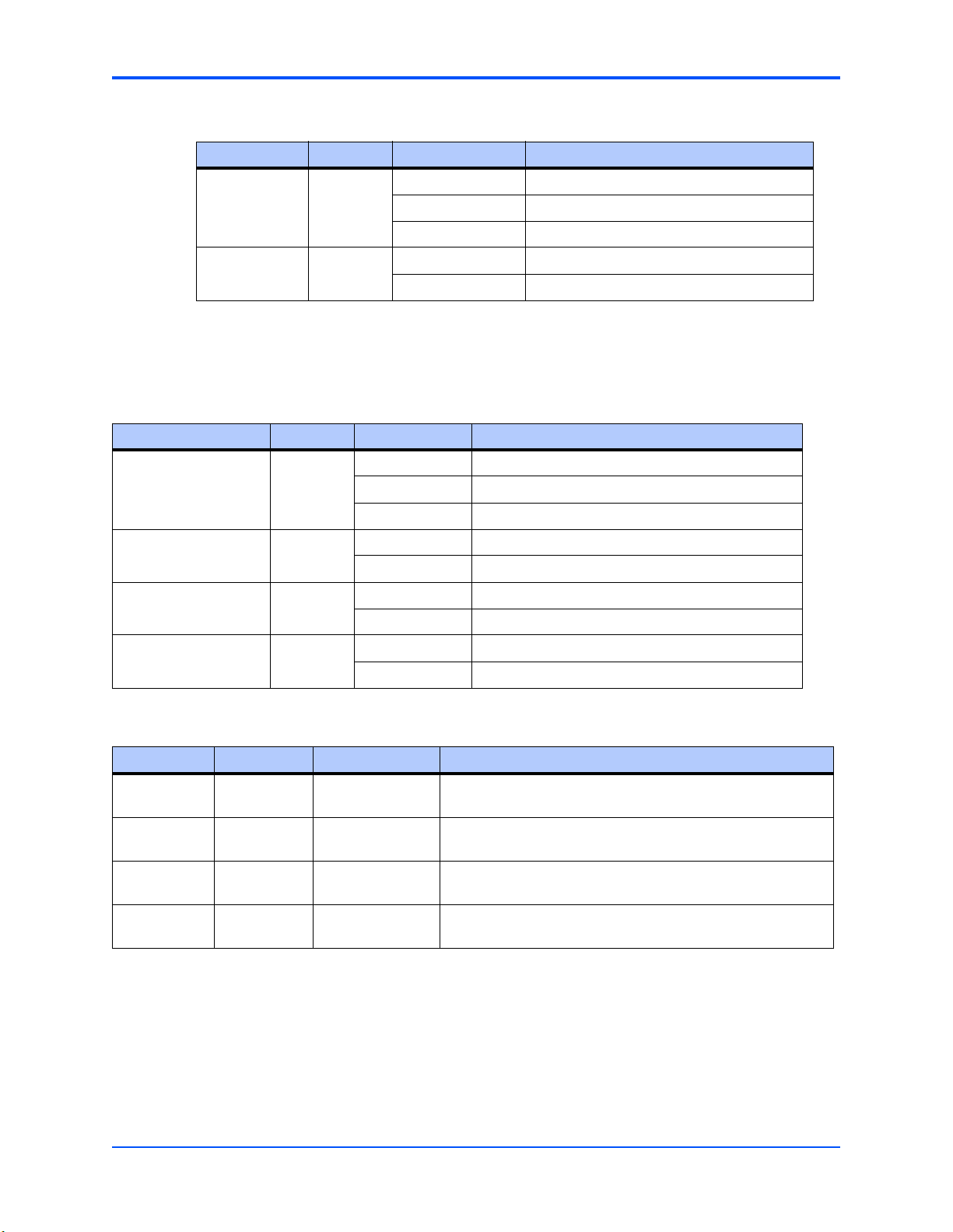

Table 1-2. Configuration Switch (S4) Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 1-3. Geographical Address Switch Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 1-4. Slot Geographical Address Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 1-5. RTM EEPROM Address Switch Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 1-6. EEPROM Address Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 1-7. MVME3100 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 1-8. MVME721 Rear Transition Module Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 2-1. Front-Panel LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 2-2. MVME721 LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 2-3. Additional Onboard Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 3-1. MOTLoad Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 3-2. MOTLoad Image Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 4-1. MVME3100 Features Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 4-2. MVME721 RTM Features Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 5-1. PMC Expansion Connector (J4) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 5-2. Ethernet Connectors Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 5-3. PMC Slot 1 Connector (J11) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 5-4. PMC Slot 1 Connector (J12) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 5-5. PMC Slot 1 Connector (J13) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 5-6. PMC Slot 1 Connector (J14) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 5-7. PMC Slot 2 Connector (J21) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 5-8. PMC Slot 2 Connector (J22) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 5-9. PMC Slot 2 Connector (J23) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 5-10. COM Port Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 5-11. VMEbus P1 Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 5-12. VME P2 Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 5-13. MVME721 Host I/O Connector (J10) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 5-14. Planar sATA Power Connector (J30) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 5-15. USB Connector (J27) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 5-16. sATA Connectors (J28 and J29) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 5-17. Boundary Scan Header (J24) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 5-18. Processor COP Header (J25) Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table A-1. Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table A-2. MVME3100 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table B-1. Motorola Computer Group Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table B-2. Manufacturers’ Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table B-3. Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

MVME3100 Installation and Use (V3100A/IH1)

xiii

Page 12

About This Manual

The MVME3100 Single-Board Computer Installation and Use manual provides the information

you will need to install and configure your MVME3100 single-board computer and MVME721

rear transition module (RTM). It provides specific preparation and installation information, and

data applicable to the board.

As of the printing date of this manual, the MVME3100 supports the models listed below.

Model Number Description

MVME3100-1152 677 MHz MPC8540 PowerQUICC III™ integrated processor,

256MB DDR SDRAM, 64MB flash, Gigabit Ethernet, SATA, IEEE

handles

MVME3100-1263 833 MHz MPC8540 PowerQUICC III integrated processor, 512MB

DDR SDRAM, 128MB flash, Gigabit Ethernet, SATA, USB, PCI

expansion connector, IEEE handles

MVME721-101 Rear Transition Module, direct connect, 75mm, PIM socket for

PMC-1 I/O, four serial, 10/100/1000 Enet, 10/100 Enet

Overview of Contents

This manual is divided into the following chapters and appendices:

Chapter 1, Hardware Preparation and Installation, provides MVME3100 board preparation and

installation instructions, as well as ESD precautionary notes.

Chapter 2, Startup and Operation, provides the power-up procedure and identifies the switches

and indicators on the MVMEM3100.

Chapter 3, MOTLoad Firmware, describes the basic features of the MOTLoad firmware

product.

Chapter 4, Functional Description, describes the MVME3100 and the MVME721 RTM on a

block diagram level.

Chapter 5, Pin Assignments, provides pin assignments for various headers and connectors on

the MMVE3100 single-board computer.

Appendix A, Specifications, provides power requirements and environmental specifications.

Appendix B, Related Documentation, provides a listing of related Motorola manuals, vendor

documentation, and industry specifications.

MVME3100 Installation and Use (V3100A/IH1)

xv

Page 13

About This Manual

Comments and Suggestions

Motorola welcomes and appreciates your comments on its documentation. We want to know

what you think about our manuals and how we can make them better. Mail comments to:

Motorola, Inc.

Embedded Communications Computing

Reader Comments DW278

2900 S. Diablo Way

Tempe, Arizona 85282

You can also submit comments to the following e-mail address:

reader-comments@mcg.mot.com

In all your correspondence, please list your name, position, and company. Be sure to include

the title and part number of the manual and tell how you used it. Then tell us your feelings about

its strengths and weaknesses and any recommendations for improvements.

Conventions Used in This Manual

The following typographical conventions are used in this document:

bold

is used for user input that you type just as it appears; it is also used for commands, options

and arguments to commands, and names of programs, directories and files.

italic

is used for names of variables to which you assign values, for function parameters, and for

structure names and fields. Italic is also used for comments in screen displays and

examples, and to introduce new terms.

courier

is used for system output (for example, screen displays, reports), examples, and system

prompts.

<Enter>, <Return> or <CR>

represents the carriage return or Enter key.

Ctrl

represents the Control key. Execute control characters by pressing the Ctrl key and the

letter simultaneously, for example, Ctrl-d.

xvi

MVME3100 Installation and Use (V3100A/IH1)

Page 14

1 Hardware Preparation and Installation

Introduction

This chapter contains the following information:

■ Board preparation and installation instructions

■ ESD precautionary notes

Description

The MVME3100 is a single-slot, single-board computer based on the MPC8540 PowerQUICC

III™ integrated processor. The MVME3100 provides serial ATA (sATA), USB 2.0, 2eSST

VMEbus interfaces, dual 64-bit/100 MHz PMC sites, up to 128MB of Flash, dual 10/100/1000

Ethernet, one 10/100 Ethernet, and five serial ports. This board supports front and rear I/O and

a single SODIMM module for DDR memory. Access to rear I/O is available with the MVME721

rear transition module (RTM).

1

Front-panel connectors on the MVME3100 board include: one RJ-45 connector for the Gigabit

Ethernet, one RJ-45 connector for the asynchronous serial port, one USB port with one type A

connector, one sATA port with one external sATA connector, and a combined reset and abort

switch.

Rear-panel connectors on the MVME721 board include: one RJ-45 connector for each of the

10/100 and 10/100/1000 BaseT Ethernets and four RJ-45 connectors for the asynchronous

serial ports. The RTM also provides two planar connectors for one PIM with rear I/O.

Getting Started

This section provides an overview of the steps necessary to install and power up the

MVME3100 and a brief section on unpacking and ESD precautions.

MVME3100 Installation and Use (V3100A/IH1)

1

Page 15

Chapter 1 Hardware Preparation and Installation

Overview of Startup Procedures

The following table lists the things you will need to do before you can use this board and tells

where to find the information you need to perform each step. Be sure to read this entire chapter,

including all Caution and Warning notes, before you begin.

Table 1-1. Startup Overview

What you need to do... Refer to...

Unpack the hardware. Unpacking Guidelines on page 2

Identify various components on the board. MVME3100 Layout on page 3

Install the MVME3100 board in a chassis. Installing the MVME3100 into a Chassis on page 8

Connect any other equipment you will be using Connection to Peripherals on page 9

Verify the hardware is installed. Completing the Installation on page 10

Unpacking Guidelines

Unpack the equipment from the shipping carton. Refer to the packing list and verify that all items

are present. Save the packing material for storing and reshipping of equipment.

Caution

!

Caution

ESD

Use ESD

Wrist Strap

Caution

!

Caution

Note If the shipping carton is damaged upon receipt, request that the carrier’s agent be present

during the unpacking and inspection of the equipment.

Avoid touching areas of integrated circuitry; static discharge can damage circuits.

Motorola strongly recommends that you use an antistatic wrist strap and a conductive

foam pad when installing or upgrading a system. Electronic components, such as disk

drives, computer boards, and memory modules can be extremely sensitive to

electrostatic discharge (ESD). After removing the component from its protective

wrapper or from the system, place the component flat on a grounded, static-free

surface (and, in the case of a board, component side up). Do not slide the component

over any surface.

If an ESD station is not available, you can avoid damage resulting from ESD by wearing

an antistatic wrist strap (available at electronics stores) that is attached to an active

electrical ground. Note that a system chassis may not be grounded if it is unplugged.

Inserting or removing modules with power applied may result in damage to module

components.

2

MVME3100 Installation and Use (V3100A/IH1)

Page 16

Chapter 1 Hardware Preparation and Installation

Warning

Warning

Dangerous voltages, capable of causing death, are present in this equipment. Use

extreme caution when handling, testing, and adjusting.

Hardware Configuration

This section discusses certain hardware and software tasks that may need to be performed

prior to installing the board in a chassis.

To produce the desired configuration and ensure proper operation of the MVME3100, you may

need to carry out certain hardware modifications before installing the module.

Most options on the MVME3100 are software configurable. Configuration changes are made by

setting bits in control registers after the board is installed in a system.

Jumpers/switches are used to control those options that are not software configurable. These

jumper settings are described further on in this section. If you are resetting the board jumpers

from their default settings, it is important to verify that all settings are reset properly.

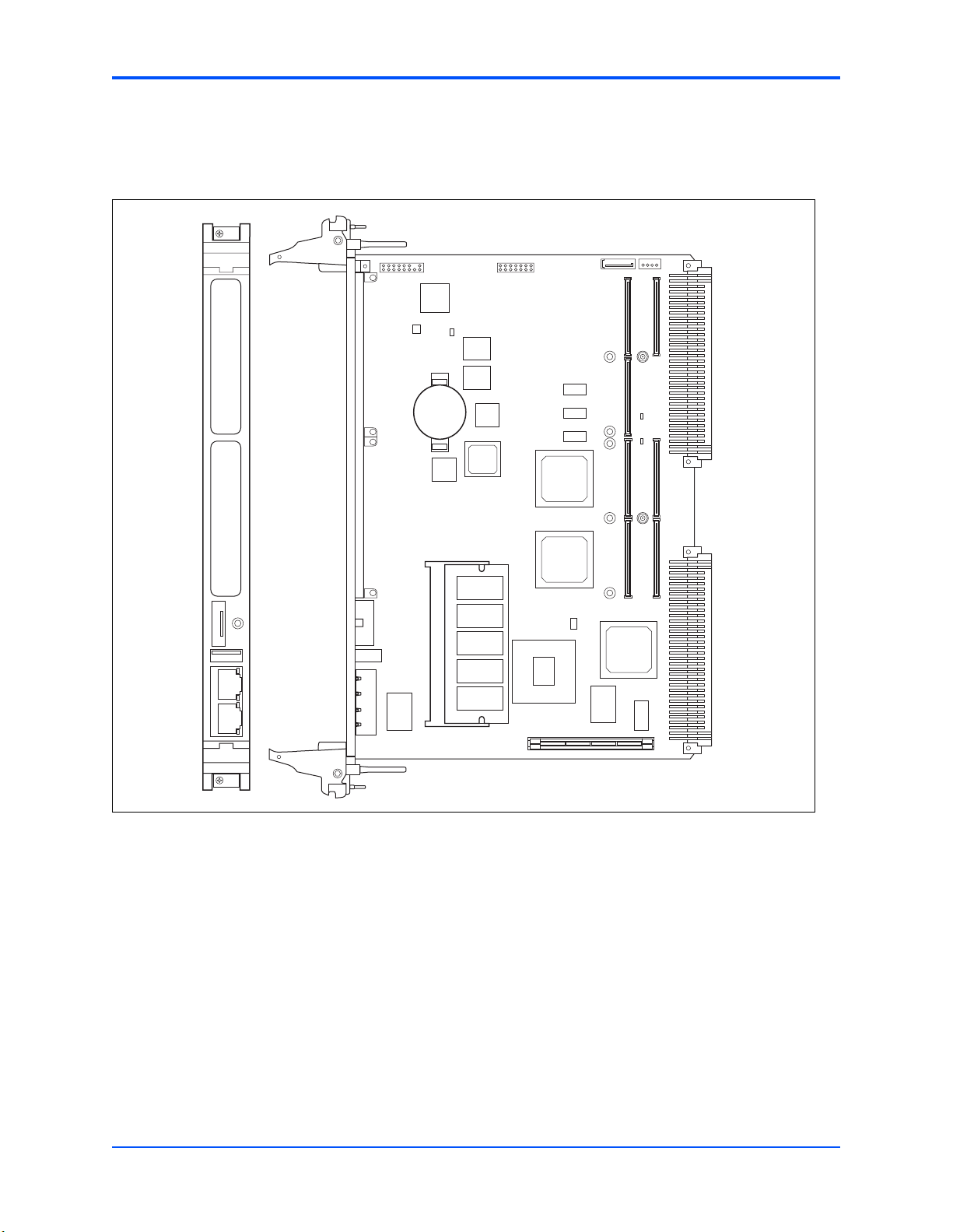

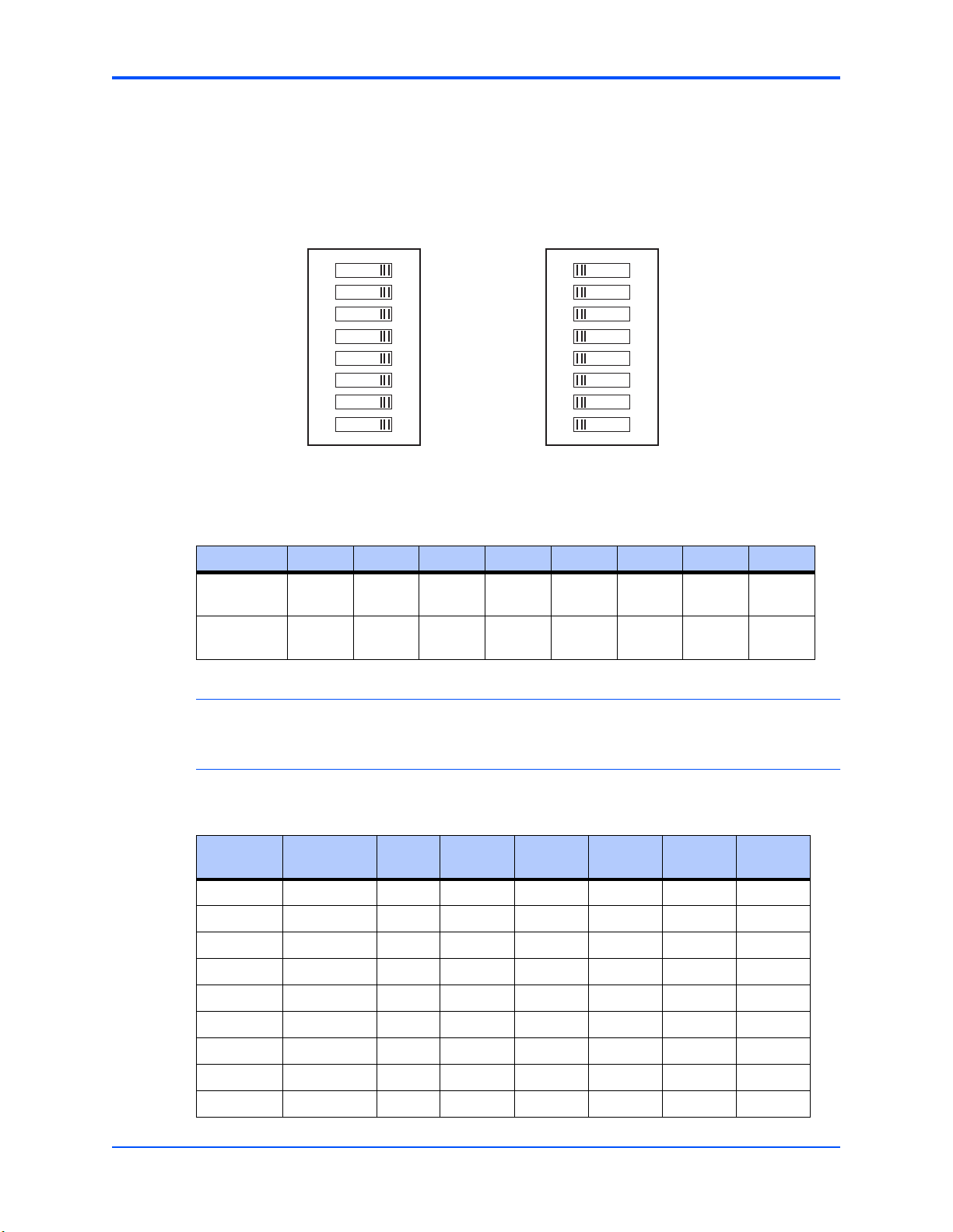

MVME3100 Layout

Figure 1-1 on page 4 illustrates the placement of the jumpers, headers, connectors, switches,

and various other components on the MVME3100.

There are two switch blocks which have user-selectable settings. Refer to Table 1-2, Table 1-3,

and Tab l e 1 -4 for switch settings. There is one switch on the MVME721. Refer to Table 1-5 and

Table 1-6 for switch settings.

MVME3100 Installation and Use (V3100A/IH1)

3

Page 17

Chapter 1 Hardware Preparation and Installation

The MVME3100 is factory tested and shipped with the configuration described in the following

sections.

Figure 1-1. MVME3100 Board Layout

PMC 1PMC 2

SATA 1

COM 1

G ENET 1

ABORT/RESET

USER 1 FAIL SPEED ACT

J25 J24

U1014

U1049

J2

U1024

U1050

U1051

U1020

U1019

U1052

U1008

U1025

U1026

U1027

U1012

U21

U1003

U1007

U1012

J21

J23

J11

J13

U1010

J30J28

J22

P1

U1046

U1047

J12

J14

P2

U1000

J4

4381 0106

4

MVME3100 Installation and Use (V3100A/IH1)

Page 18

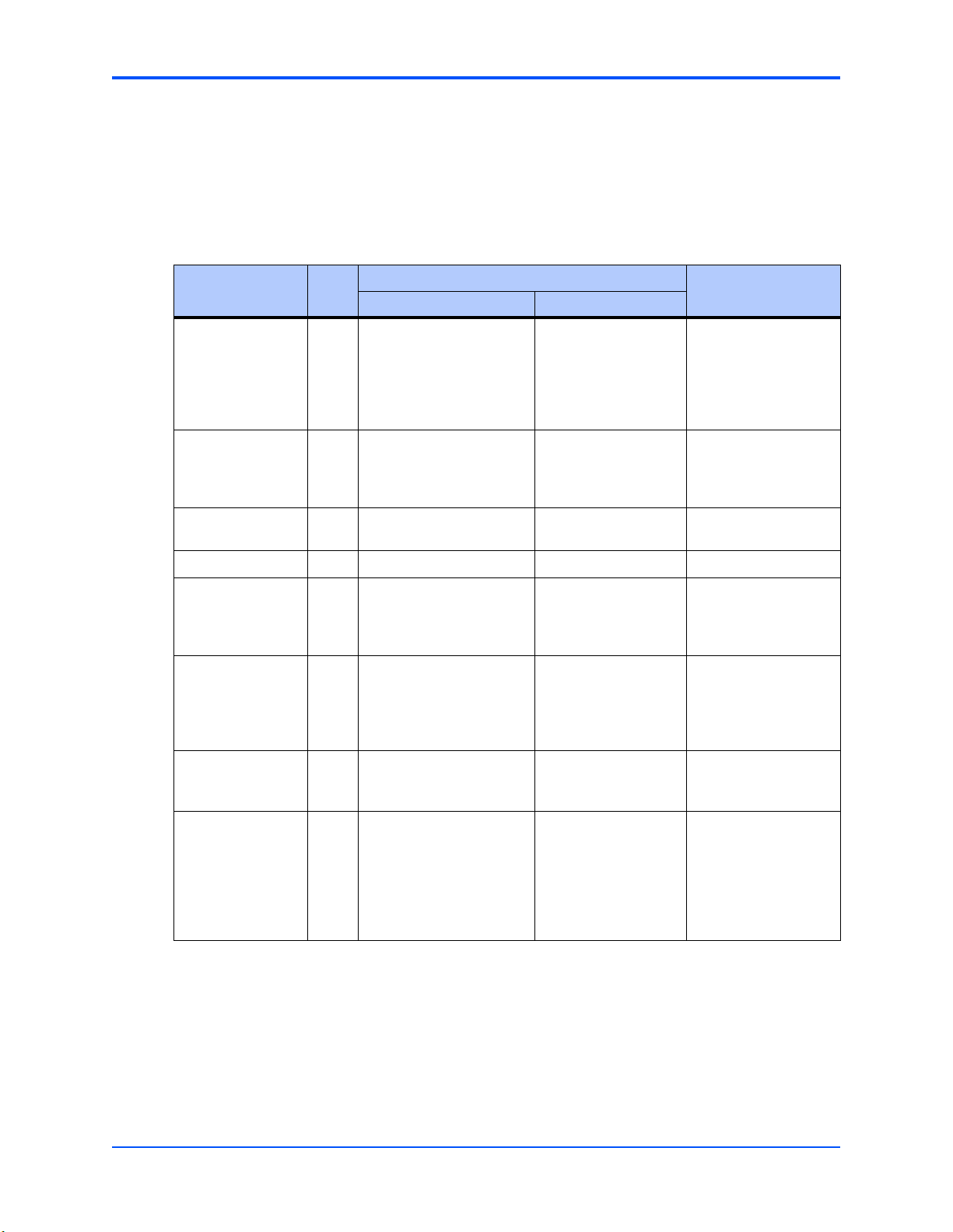

Configuration Switch (S4)

An 8-position SMT configuration switch controls the VME SCON setting, Flash bank writeprotect, and the safe start ENV settings. It also selects the Flash boot image. The default setting

on all switch positions is OFF.

Table 1-2. Configuration Switch (S4) Settings

Setting

Switch Pos.

Chapter 1 Hardware Preparation and Installation

NotesOFF (Factory Default) ON

SAFE_START 1 Normal ENV settings

should be used.

BOOT BLOCK

SELECT

FLASH BANK WP 3 Entire Flash is not write-

Reserved 4

VME SCON

AUTO /MANUAL

MODE

MANUAL VME

SCON SELECT

sATA Mode 7 Legacy Mode sATA Mode Sets GD31244 to

2 Flash memory map is

normal and boot block A is

selected.

protected.

5 Auto-SCON mode. Manual SCON mode. Manual SCON mode

6 Non-SCON mode. Always SCON mode. This switch is only

Safe ENV settings

should be used.

Boot block B is

selected and mapped

to the highest

address.

Flash is writeprotected.

This switch status is

readable from System

Status register 1, bit 5.

Software may check

this bit and act

accordingly.

works in conjunction

with the VME SCON

SELECT switch.

effective when the

VME SCON

AUTO/MANUAL

MODE switch is ON.

legacy or sATA mode

during reset

TRST SELECT 8 Normal MPC8540 TRST

mode where the board

HRESET will assert

TRST.

MVME3100 Installation and Use (V3100A/IH1)

Isolates the board

HRESET from TRST

and allows the board

to reset without

resetting the

MPC8540 JTAG/COP

interface.

This switch should

remain in the OFF

position unless a

MPC8540 emulator is

attached.

5

Page 19

Chapter 1 Hardware Preparation and Installation

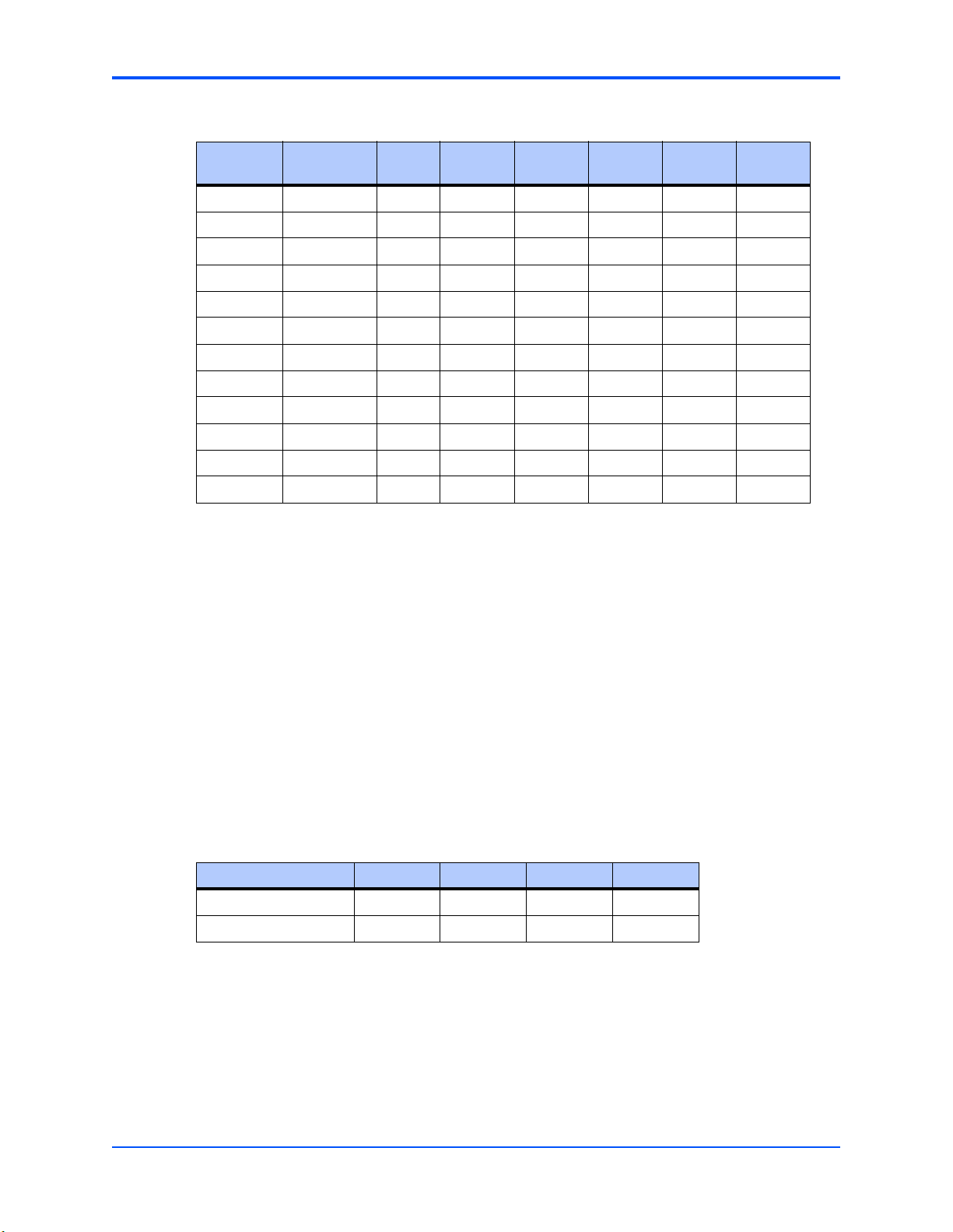

Geographical Address Switch (S3)

The TSi148 VMEbus Status register provides the VMEbus geographical address of the

MVME3100. This switch reflects the inverted states of the geographical address signals.

Applications not using the 5-row backplane can use the geographical address switch to assign

a geographical address.

1

4389 0106

1

2

3

4

5

6

7

8

16

Not used

PCI mode

GAP#=0

GA4#=0

GA3#=0

GA2#=0

GA1#=0

GA0#=0

1

1

2

3

4

5

6

7

8

ONON

Table 1-3. Geographical Address Switch Assignments

Position SW1 SW2

Function Not

Used

(Factory)

XPCI-X

OFF

1

PCI Bus

A mode

mode

SW3 SW4 SW5 SW6 SW7 SW8

GAP GA4 GA3 GA2 GA1 GA0

111111

16

Not used

PCI-X mode

GAP#=1

GA4#=1

GA3#=1

GA2#=1

GA1#=1

GA0#=1

Note1SW2 configures the operating mode of PCI Bus A during power up. In the default (OFF)

position, the bus is configured for PCI-X mode. In the ON position, the bus is configured for PCI

mode.

Table 1-4. Slot Geographical Address Settings

Slot

Address

1 1 11110 OFF OFF OFF OFF OFF ON

2 1 11101 OFF OFF OFF OFF ON OFF

3 0 11100 ON OFF OFF OFF ON ON

4 1 11011 OFF OFF OFF ON OFF OFF

5 0 11010 ON OFF OFF ON OFF ON

6 0 11001ONOFFOFFONONOFF

7 1 11000 OFF OFF OFF ON ON ON

8 1 10111 OFF OFF ON OFF OFF OFF

9 0 10110 ON OFF ON OFF OFF ON

6

MVME3100 Installation and Use (V3100A/IH1)

GAP

GA(4:0)

SW3 SW4 SW5 SW6 SW7 SW8

Page 20

Chapter 1 Hardware Preparation and Installation

Table 1-4. Slot Geographical Address Settings (continued)

Slot

Address

10 0 10101 ON OFF ON OFF ON OFF

11 1 10100 OFF OFF ON OFF ON ON

12 0 10011 ON OFF ON ON OFF OFF

13 1 10010 OFF OFF ON ON OFF ON

14 1 10001 OFF OFF ON ON ON OFF

15 0 10000 ON OFF ON ON ON ON

16 1 01111 OFF ON OFF OFF OFF OFF

17 0 01110 ON ON OFF OFF OFF ON

18 0 01101 ON ON OFF OFF ON OFF

19 1 01100 OFF ON OFF OFF ON ON

20 0 01011 ON ON OFF ON OFF OFF

21 1 01010 OFF ON OFF ON OFF ON

GAP

GA(4:0)

SW3 SW4 SW5 SW6 SW7 SW8

PMC I/O Voltage Configuration

The onboard PMC sites may be configured to support 3.3V or 5.0V I/O PMC modules. To

support 3.3V or 5.0V I/O PMC modules, both PMC I/O keying pins must be installed in the

holes. If both keying pins are not in the same location or if the keying pins are not installed, the

PMC sites will not function. Note that setting the PMC I/O voltage to 5.0V forces the PMC sites

to operate in PCI mode instead of PCI-X mode. The default factory configuration is for 3.3V

PMC I/O voltage.

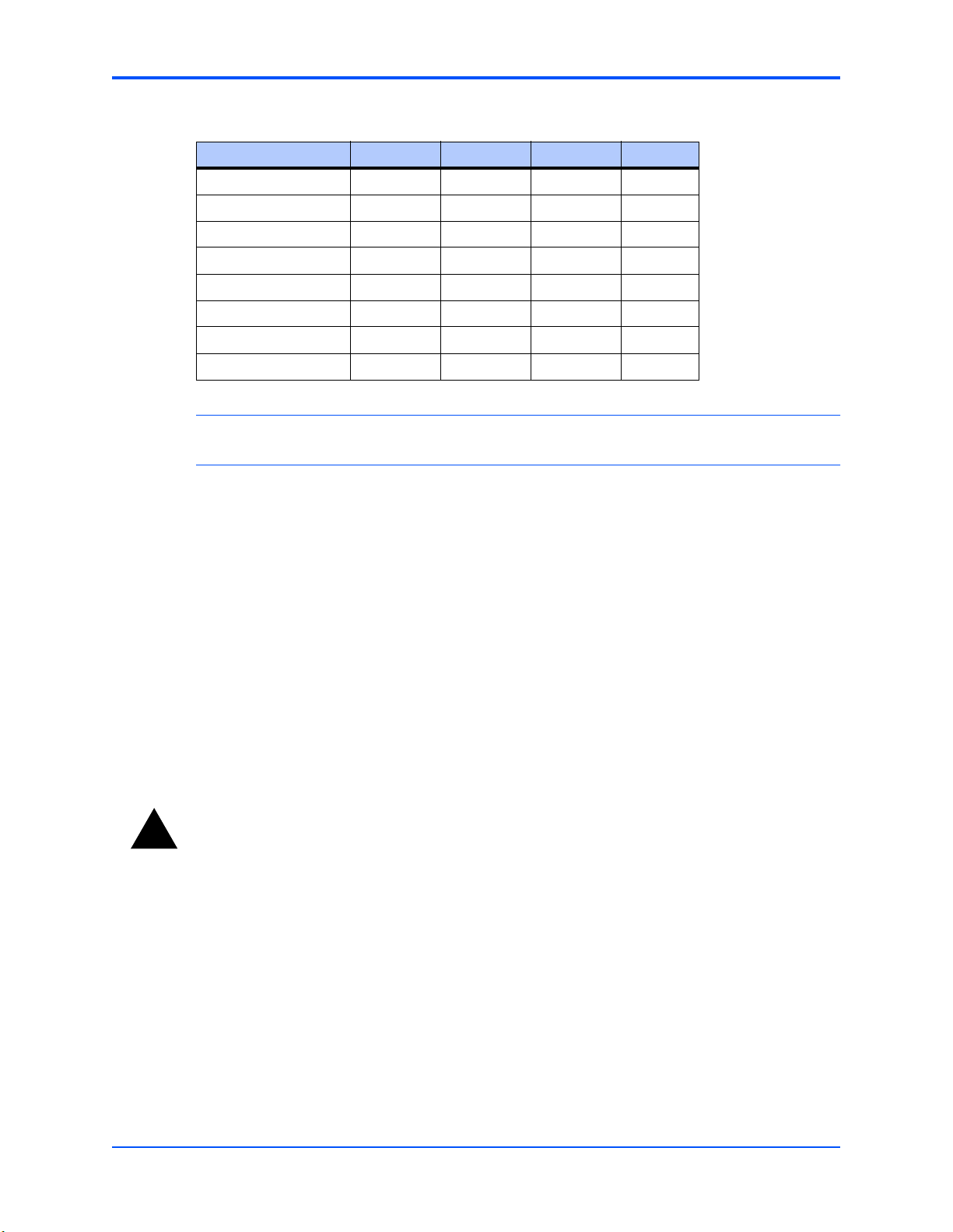

RTM SEEPROM Address Switch (S1)

A 4-position SMT configuration switch is located on the RTM to set the device address of the

RTM serial EEPROM device. The switch settings are defined in the following table.

Table 1-5. RTM EEPROM Address Switch Assignments

Position SW1 SW2 SW3 SW4

Function A0 A1 A2 Not Used

OFF 111

MVME3100 Installation and Use (V3100A/IH1)

7

Page 21

Chapter 1 Hardware Preparation and Installation

Table 1-6. EEPROM Address Settings

Device Address A(2:0) SW1 SW2 SW3

$A0 000 ON ON ON

$A2 001 OFF ON ON

$A4 010 ON OFF ON

$A6 011 OFF OFF ON

$A8 100 ON ON OFF

$AA (Factory) 101 OFF ON OFF

$AC 110 ON OFF OFF

$AE 111 OFF OFF OFF

Note The RTM EEPROM address switches must be set for address $AA in order for this device

to be accessible by MotLoad.

Hardware Installation

Installing the MVME3100 into a Chassis

Use the following steps to install the MVME3100 into your computer chassis.

1. Attach an ESD strap to your wrist. Attach the other end of the ESD strap to an electrical ground

(refer to Unpacking Guidelines). The ESD strap must be secured to your wrist and to ground

throughout the procedure.

2. Remove any filler panel that might fill that slot.

3. Install the top and bottom edge of the MVME3100 into the guides of the chassis.

Warning

!

Warning

Only use injector handles for board insertion to avoid damage/deformation to the front

panel and/or PCB. Deformation of the front panel can cause an electrical short or other

board malfunction.

4. Ensure that the levers of the two injector/ejectors are in the outward position.

5. Slide the MVME3100 into the chassis until resistance is felt.

6. Simultaneously move the injector/ejector levers in an inward direction.

7. Verify that the MVME3100 is properly seated and secure it to the chassis using the two screws

located adjacent to the injector/ejector levers.

8. Connect the appropriate cables to the MVME3100.

8

MVME3100 Installation and Use (V3100A/IH1)

Page 22

To remove the board from the chassis, press the red locking tabs (IEEE handles only) and

reverse the procedure.

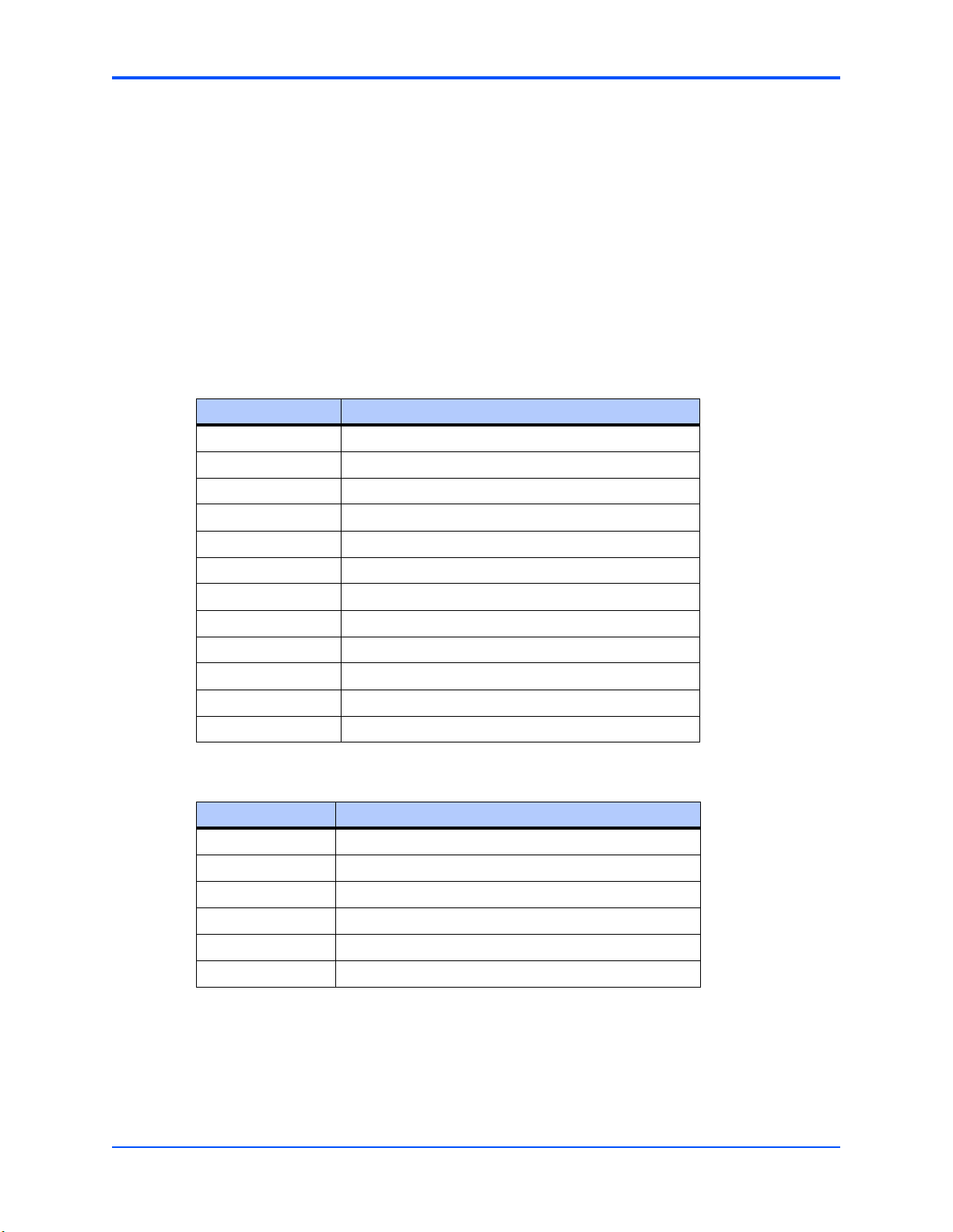

Connection to Peripherals

When the MVME3100 is installed in a chassis, you are ready to connect peripherals and apply

power to the board.

Figure 1-1 on page 4 shows the locations of the various connectors while Ta bl e 1 - 7 and Ta b le

1-8 list them for you. Refer to Chapter 5, Pin Assignments for the pin assignments of the

connectors listed below.

Table 1-7. MVME3100 Connectors

Connector Function

J4 PMC expansion connector

J11, J12, J13, J14 PCI mezzanine card (PMC) slot 1 connector

J21, J22, J23 PCI mezzanine card (PMC) slot 2 connector

Chapter 1 Hardware Preparation and Installation

J24 Boundary scan header

J25 COP header

J27 USB connector

J28 Front panel sATA connector

J29 Planar sATA connector

J30 Planar sATA power connector

J41B 10/100/1000Mb/s Ethernet connector

J41A COM port connector

P1, P2 VME backplane connectors

Table 1-8. MVME721 Rear Transition Module Connectors

Connector Function

J1A, J1B, J1C, J1D COM port connectors

J2A 10/100/1000Mb/s Ethernet connector

J2B 10/100Mb/s Ethernet connector

J10 PIM power/ground

J14 PIM I/O

P2 VME backplane connector

MVME3100 Installation and Use (V3100A/IH1)

9

Page 23

Chapter 1 Hardware Preparation and Installation

Completing the Installation

Verify that hardware is installed and the power/peripheral cables connected are appropriate for

your system configuration.

Replace the chassis or system cover, reconnect the system to the AC or DC power source, and

turn the equipment power on.

10

MVME3100 Installation and Use (V3100A/IH1)

Page 24

2 Startup and Operation

Introduction

This chapter gives you information about the:

■ Power-up procedure

■ Runtime switches and indicators

Applying Power

After you verify that all necessary hardware preparation is complete and all connections are

made correctly, you can apply power to the system.

When you are ready to apply power to the MVME3100:

■ Verify that the chassis power supply voltage setting matches the voltage present in the

country of use (if the power supply in your system is not auto-sensing)

2

■ On powering up, the MVME3100 brings up the MOTLoad prompt, MVME3100>

Switches and Indicators

The MVME3100 board provides a single push button switch that provides both abort and reset

(ABT/RST) functions. When the switch is pressed for less than five seconds, an abort interrupt

is generated to the processor. If the switch is held for more than five seconds, a board hard reset

is generated. The board hard reset will reset the MPC8540, local PCI/PCI-X buses, Ethernet

PHYs, serial ports, Flash devices, and PLD(s). If the MVME3100 is configured as the VME

system controller, the VME bus and local TSi148 reset input are also reset.

The MVME3100 has four front-panel indicators. The following table describes these indicators:

Table 2-1. Front-Panel LED Status Indicators

Function Label Color Description

Board Fail FAIL Yellow Board has a failure. After Power On or reset,

User Defined USER 1 Green This indicator is illuminated by software

this LED is ON until extinguished by

firmware or software.

assertion of its corresponding register bit.

MVME3100 Installation and Use (V3100A/IH1)

11

Page 25

Chapter 2 Startup and Operation

Table 2-1. Front-Panel LED Status Indicators (continued)

Function Label Color Description

GENET 1 Link /

Speed

GENET 1

Activity

SPEED Off No link

Yellow 10/100Base-T operation

Green 1000Base-T operation

ACT Blinking Green Activity proportional to bandwidth utilization.

Off No activity

The MVME721 rear transition module also has four status indicators. The following table

describes these indicators:

Table 2-2. MVME721 LED Status Indicators

Function Label Color Description

GENET 2 Link/Speed SPEED Off No link

Yellow 10/100Base-T operation

Green 1000Base-T operation

GENET 2 Activity ACT Blinking Green Activity proportional to bandwidth utilization.

Off No activity

ENET 1 Link/Speed SPEED Off No link

Yellow 10/100Base-T operation

ENET 1 Activity ACT Blinking Green Activity proportional to bandwidth utilization.

Off No activity

Table 2-3. Additional Onboard Status Indicators

Function Label Color Description

User Defined

LED 2

User Defined

LED 3

Power Supply

Fail

sATA 0

Activity

DS7

(silkscreen)

DS8

(silkscreen)

DS1

(silkscreen)

DS4

(silkscreen)

Green This indicator is illuminated by software assertion of its

corresponding register bit.

Green This indicator is illuminated by software assertion of its

corresponding register bit.

Red This indicator is illuminated to indicate a power supply fail

condition.

Green sATA 0 or 1 activity in legacy mode (default). sATA 0 activity in

DPA mode.

12

MVME3100 Installation and Use (V3100A/IH1)

Page 26

Chapter 2 Startup and Operation

Table 2-3. Additional Onboard Status Indicators (continued)

Function Label Color Description

sATA 1

Activity

MPC8540

Ready

GENET 1

Link Quality

GENET 2

Link Quality

DS5

(silkscreen)

DS3

(silkscreen)

DS2

(silkscreen)

DS3 [Same as DS2}

Green No function in legacy mode (default). sATA 1 activity in DPA

Green Indicates that the MPC8540 has completed the reset

Off

Slow Blink Green

Fast Blink Green

Green

mode.

operation and is not in a power-down state. The MPC8540

Ready is multiplexed with the MPC8540 TRIG_OUT so the

LED can be programmed to indicate one of three trigger

events based on the value in the MPC8540 TOSR register.

Extremely poor Signal to Noise ratio - cannot receive data

Poor SNR - receive errors detected

Fair SNR - close to data error threshold

Good SNR on link

MVME3100 Installation and Use (V3100A/IH1)

13

Page 27

3 MOTLoad Firmware

Introduction

This chapter describes the basic features of the MOTLoad firmware product, designed by

Motorola as the next generation initialization, debugger, and diagnostic tool for highperformance embedded board products using state-of-the-art system memory controllers and

bridge chips, such as the MPC8540 processor.

In addition to an overview of the product, this chapter includes a list of standard MOTLoad

commands, the default VME and firmware settings that are changeable by the user, remote

start, and the alternate boot procedure.

Overview

The MOTLoad firmware package serves as a board power-up and initialization package, as well

as a vehicle from which user applications can be booted. A secondary function of the MOTLoad

firmware is to serve in some respects as a test suite providing individual tests for certain

devices.

3

MOTLoad is controlled through an easy-to-use, UNIX-like, command line interface. The

MOTLoad software package is similar to many end-user applications designed for the

embedded market, such as the real time operating systems currently available.

Refer to the MOTLoad Firmware Package User’s Manual, listed in Appendix B, Related

Documentation, for more details.

MOTLoad Implementation and Memory Requirements

The implementation of MOTLoad and its memory requirements are product specific. The

MVME3100 single-board computer (SBC) is offered with a range of memory (for example,

DRAM or flash). Typically, the smallest amount of on-board DRAM that a Motorola SBC has is

32MB. Each supported Motorola product line has its own unique MOTLoad binary image(s).

Currently the largest MOTLoad compressed image is less than 1MB in size.

MOTLoad Commands

MOTLoad supports two types of commands (applications): utilities and tests. Both types of

commands are invoked from the MOTLoad command line in a similar fashion. Beyond that,

MOTLoad utilities and MOTLoad tests are distinctly different.

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

15

Page 28

Chapter 3 MOTLoad Firmware

MOTLoad Utility Applications

The definition of a MOTLoad utility application is very broad. Simply stated, it is considered a

MOTLoad command, if it is not a MOTLoad test. Typically, MOTLoad utility applications are

applications that aid the user in some way (that is, they do something useful). From the

perspective of MOTLoad, examples of utility applications are: configuration, data/status

displays, data manipulation, help routines, data/status monitors, etc.

Operationally, MOTLoad utility applications differ from MOTLoad test applications in several

ways:

■ Only one utility application operates at any given time (that is, multiple utility applications

cannot be executing concurrently)

■ Utility applications may interact with the user. Most test applications do not.

MOTLoad Tests

A MOTLoad test application determines whether or not the hardware meets a given standard.

Test applications are validation tests. Validation is conformance to a specification. Most

MOTLoad tests are designed to directly validate the functionality of a specific SBC subsystem

or component. These tests validate the operation of such SBC modules as: dynamic memory,

external cache, NVRAM, real time clock, etc.

All MOTLoad tests are designed to validate functionality with minimum user interaction. Once

launched, most MOTLoad tests operate automatically without any user interaction. There are a

few tests where the functionality being validated requires user interaction (that is, switch tests,

interactive plug-in hardware modules, etc.). Most MOTLoad test results (error-data/status-data)

are logged, not printed. All MOTLoad tests/commands have complete and separate

descriptions (refer to the MOTLoad Firmware Package User’s Manual for this information).

All devices that are available to MOTLoad for validation/verification testing are represented by

a unique device path string. Most MOTLoad tests require the operator to specify a test device

at the MOTLoad command line when invoking the test.

A listing of all device path strings can be displayed through the devShow command. If an SBC

device does not have a device path string, it is not supported by MOTLoad and can not be

directly tested. There are a few exceptions to the device path string requirement, like testing

RAM, which is not considered a true device and can be directly tested without a device path

string. Refer to the devShow command description page in the MOTLoad Firmware Package

User’s Manual.

Most MOTLoad tests can be organized to execute as a group of related tests (a testSuite)

through the use of the testSuite command. The expert operator can customize their testing by

defining and creating a custom testSuite(s). The list of built-in and user-defined MOTLoad

testSuites, and their test contents, can be obtained by entering testSuite -d at the MOTLoad

prompt. All testSuites that are included as part of a product specific MOTLoad firmware

package are product specific. For more information, refer to the testSuite command description

page in the MOTLoad Firmware Package User’s Manual.

16

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

Page 29

Test results and test status are obtained through the testStatus, errorDisplay, and taskActive

commands. Refer to the appropriate command description page in the MOTLoad Firmware

Package User’s Manual for more information.

Using MOTLoad

Interaction with MOTLoad is performed via a command line interface through a serial port on

the SBC, which is connected to a terminal or terminal emulator (for example, Window’s

Hypercomm). The default MOTLoad serial port settings are: 9600 baud, 8 bits, no parity.

Command Line Interface

The MOTLoad command line interface is similar to a UNIX command line shell interface.

Commands are initiated by entering a valid MOTLoad command (a text string) at the MOTLoad

command line prompt and pressing the carriage-return key to signify the end of input. MOTLoad

then performs the specified action. An example of a MOTLoad command line prompt is shown

below. The MOTLoad prompt changes according to what product it is used on (for example,

MVME6100, MVME3100).

Chapter 3 MOTLoad Firmware

Example:

MVME3100>

If an invalid MOTLoad command is entered at the MOTLoad command line prompt, MOTLoad

displays a message that the command was not found.

Example:

MVME3100> mytest

"mytest" not found

MVME3100>

If the user enters a partial MOTLoad command string that can be resolved to a unique valid

MOTLoad command and presses the carriage-return key, the command is executed as if the

entire command string had been entered. This feature is a user-input shortcut that minimizes

the required amount of command line input. MOTLoad is an ever changing firmware package,

so user-input shortcuts may change as command additions are made.

Example:

MVME3100> version

Copyright: Motorola Inc.1999-2005, All Rights Reserved

MOTLoad RTOS Version 2.0, PAL Version 1.0 RM01

Mon Aug 29 15:24:13 MST 2005

MVME3100>

Example:

MVME3100> ver

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

17

Page 30

Chapter 3 MOTLoad Firmware

Copyright: Motorola Inc.1999-2005, All Rights Reserved

MOTLoad RTOS Version 2.0, PAL Version 1.0 RM01

Mon Aug 29 15:24:13 MST 2005

MVME3100>

If the partial command string cannot be resolved to a single unique command, MOTLoad

informs the user that the command was ambiguous.

Example:

MVME3100> te

"te" ambiguous

MVME3100>

Command Line Help

Each MOTLoad firmware package has an extensive, product-specific help facility that can be

accessed through the help command. The user can enter help at the MOTLoad command line

to display a complete listing of all available tests and utilities.

Example

MVME3100> help

For help with a specific test or utility the user can enter the following at the MOTLoad prompt:

help <command_name>

The help command also supports a limited form of pattern matching. Refer to the help

command page.

Example

MVME3100> help testRam

Usage: testRam [-aPh] [-bPh] [-iPd] [-nPh] [-tPd] [-v]

Description: RAM Test [Directory]

Argument/Option Description

-a Ph: Address to Start (Default = Dynamic Allocation)

-b Ph: Block Size (Default = 16KB)

-i Pd: Iterations (Default = 1)

-n Ph: Number of Bytes (Default = 1MB)

-t Ph: Time Delay Between Blocks in OS Ticks (Default = 1)

-v O : Verbose Output

MVME3100>

Command Line Rules

18

There are a few things to remember when entering a MOTLoad command:

■ Multiple commands are permitted on a single command line, provided they are separated

by a single semicolon (;)

■ Spaces separate the various fields on the command line (command/arguments/options)

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

Page 31

■ The argument/option identifier character is always preceded by a hyphen (-) character

■ Options are identified by a single character

■ Option arguments immediately follow (no spaces) the option

■ All commands, command options, and device tree strings are case sensitive

Example:

MVME3100> flashProgram –d/dev/flash0 –n00100000

For more information on MOTLoad operation and function, refer to the MOTLoad Firmware

Package User’s Manual.

MOTLoad Command List

The following table provides a list of all current MOTLoad commands. Products supported by

MOTLoad may or may not employ the full command set. Typing help at the MOTLoad command

prompt will display all commands supported by MOTLoad for a given product.

Chapter 3 MOTLoad Firmware

Table 3-1. MOTLoad Commands

Command Description

as One-Line Instruction Assembler

bcb bch bcw Block Compare Byte/Halfword/Word

bdTempShow Display Current Board Temperature

bfb bfh bfw Block Fill Byte/Halfword/Word

blkCp Block Copy

blkFmt Block Format

blkRd Block Read

blkShow Block Show Device Configuration Data

blkVe Block Verify

blkWr Block Write

bmb bmh bmw Block Move Byte/Halfword/Word

br Assign/Delete/Display User-Program Break-Points

bsb bsh bsw Block Search Byte/Halfword/Word

bvb bvh bvw Block Verify Byte/Halfword/Word

cdDir ISO9660 File System Directory Listing

cdGet ISO9660 File System File Load

clear Clear the Specified Status/History Table(s)

cm Turns on Concurrent Mode

csb csh csw Calculates a Checksum Specified by Command-line Options

devShow Display (Show) Device/Node Table

diskBoot Disk Boot (Direct-Access Mass-Storage Device)

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

19

Page 32

Chapter 3 MOTLoad Firmware

Table 3-1. MOTLoad Commands (continued)

Command Description

downLoad Down Load S-Record from Host

ds One-Line Instruction Disassembler

echo Echo a Line of Text

elfLoader ELF Object File Loader

errorDisplay Display the Contents of the Test Error Status Table

eval Evaluate Expression

execProgram Execute Program

fatDir FAT File System Directory Listing

fatGet FAT File System File Load

fdShow Display (Show) File Discriptor

flashLock Flash Memory Sector Lock

flashProgram Flash Memory Program

flashShow Display Flash Memory Device Configuration Data

flashUnlock Flash Memory Sector Unlock

gd Go Execute User-Program Direct (Ignore Break-Points)

gevDelete Global Environment Variable Delete

gevDump Global Environment Variable(s) Dump (NVRAM Header + Data)

gevEdit Global Environment Variable Edit

gevInit Global Environment Variable Area Initialize (NVRAM Header)

gevList Global Environment Variable Labels (Names) Listing

gevShow Global Environment Variable Show

gn Go Execute User-Program to Next Instruction

go Go Execute User-Program

gt Go Execute User-Program to Temporary Break-Point

hbd Display History Buffer

hbx Execute History Buffer Entry

help Display Command/Test Help Strings

l2CacheShow Display state of L2 Cache and L2CR register contents

l3CacheShow Display state of L3 Cache and L3CR register contents

mdb mdh mdw Memory Display Bytes/Halfwords/Words

memShow Display Memory Allocation

20

mmb mmh mmw Memory Modify Bytes/Halfwords/Words

netBoot Network Boot (BOOT/TFTP)

netShow Display Network Interface Configuration Data

netShut Disable (Shutdown) Network Interface

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

Page 33

Chapter 3 MOTLoad Firmware

Table 3-1. MOTLoad Commands (continued)

Command Description

netStats Display Network Interface Statistics Data

noCm Turns off Concurrent Mode

pciDataRd Read PCI Device Configuration Header Register

pciDataWr Write PCI Device Configuration Header Register

pciDump Dump PCI Device Configuration Header Register

pciShow Display PCI Device Configuration Header Register

pciSpace Display PCI Device Address Space Allocation

ping Ping Network Host

portSet Port Set

portShow Display Port Device Configuration Data

rd User Program Register Display

reset Reset System

rs User Program Register Set

set Set Date and Time

sromRead SROM Read

sromWrite SROM Write

sta Symbol Table Attach

stl Symbol Table Lookup

stop Stop Date and Time (Power-Save Mode)

taskActive Display the Contents of the Active Task Table

tc Trace (Single-Step) User Program

td Trace (Single-Step) User Program to Address

testDisk Test Disk

testEnetPtP Ethernet Point-to-Point

testNvramRd NVRAM Read

testNvramRdWr NVRAM Read/Write (Destructive)

testRam RAM Test (Directory)

testRamAddr RAM Addressing

testRamAlt RAM Alternating

testRamBitToggle RAM Bit Toggle

testRamBounce RAM Bounce

testRamCodeCopy RAM Code Copy and Execute

testRamEccMonitor Monitor for ECC Errors

testRamMarch RAM March

testRamPatterns RAM Patterns

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

21

Page 34

Chapter 3 MOTLoad Firmware

Table 3-1. MOTLoad Commands (continued)

Command Description

testRamPerm RAM Permutations

testRamQuick RAM Quick

testRamRandom RAM Random Data Patterns

testRtcAlarm RTC Alarm

testRtcReset RTC Reset

testRtcRollOver RTC Rollover

testRtcTick RTC Tick

testSerialExtLoop Serial External Loopback

testSeriallntLoop Serial Internal Loopback

testStatus Display the Contents of the Test Status Table

testSuite Execute Test Suite

testSuiteMake Make (Create) Test Suite

testThermoOp Thermometer Temp Limit Operational Test

testThermoQ Thermometer Temp Limit Quick Test

testThermoRange Tests That Board Thermometer is Within Range

testWatchdogTimer Tests the Accuracy of the Watchdog Timer Device

tftpGet TFTP Get

tftpPut TFTP Put

time Display Date and Time

transparentMode Transparent Mode (Connect to Host)

tsShow Display Task Status

upLoad Up Load Binary Data from Target

version Display Version String(s)

vmeCfg Manages user specified VME configuration parameters

vpdDisplay VPD Display

vpdEdit VPD Edit

waitProbe Wait for I/O Probe to Complete

22

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

Page 35

Default VME Settings

As shipped from the factory, the MVME3100 has the following VME configuration programmed

via Global Environment Variables (GEVs) for the Tsi148 VME controller. The firmware allows

certain VME settings to be changed in order for the user to customize the environment. The

following is a description of the default VME settings that are changeable by the user. For more

information, refer to the MOTLoad User’s Manual and Tundra’s Tsi148 User Manual, listed in

Appendix B, Related Documentation.

■ MVME3100> vmeCfg –s –m

Displaying the selected Default VME Setting

- interpreted as follows:

VME PCI Master Enable [Y/N] = Y

MVME3100>

The PCI Master is enabled.

■ MVME3100> vmeCfg –s –r234

Displaying the selected Default VME Setting

- interpreted as follows:

VMEbus Master Control Register = 00000003

MVME3100>

The VMEbus Master Control Register is set to the default (RESET) condition.

Chapter 3 MOTLoad Firmware

■ MVME3100> vmeCfg –s –r238

Displaying the selected Default VME Setting

- interpreted as follows:

VMEbus Control Register = 00000008

MVME3100>

The VMEbus Control Register is set to a Global Timeout of 2048 μseconds.

■ MVME3100> vmeCfg –s –r414

Displaying the selected Default VME Setting

- interpreted as follows:

CRG Attribute Register = 00000000

CRG Base Address Upper Register = 00000000

CRG Base Address Lower Register = 00000000

MVME3100>

The CRG Attribute Register is set to the default (RESET) condition.

■ MVME3100> vmeCfg –s –i0

Displaying the selected Default VME Setting

- interpreted as follows:

Inbound Image 0 Attribute Register = 000227AF

Inbound Image 0 Starting Address Upper Register = 00000000

Inbound Image 0 Starting Address Lower Register = 00000000

Inbound Image 0 Ending Address Upper Register = 00000000

Inbound Image 0 Ending Address Lower Register = 1FFF0000

Inbound Image 0 Translation Offset Upper Register = 00000000

Inbound Image 0 Translation Offset Lower Register = 00000000

MVME3100>

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

23

Page 36

Chapter 3 MOTLoad Firmware

Inbound window 0 (ITAT0) is not enabled; Virtual FIFO at 256 bytes, 2eSST timing at

SST320, respond to 2eSST, 2eVME, MBLT, and BLT cycles, A32 address space, respond

to Supervisor, User, Program, and Data cycles. Image maps from 0x00000000 to

0x1FFF0000 on the VMbus, translates 1x1 to the PCI-X bus (thus 1x1 to local memory). To

enable this window, set bit 31 of ITAT0 to 1.

Note For Inbound Translations, the Upper Translation Offset Register needs to be set to

0xFFFFFFFF to ensure proper translations to the PCI-X Local Bus.

■ MVME3100> vmeCfg –s –o1

Displaying the selected Default VME Setting

- interpreted as follows:

Outbound Image 1 Attribute Register = 80001462

Outbound Image 1 Starting Address Upper Register = 00000000

Outbound Image 1 Starting Address Lower Register = 91000000

Outbound Image 1 Ending Address Upper Register = 00000000

Outbound Image 1 Ending Address Lower Register = AFFF0000

Outbound Image 1 Translation Offset Upper Register = 00000000

Outbound Image 1 Translation Offset Lower Register = 70000000

Outbound Image 1 2eSST Broadcast Select Register = 00000000

MVME3100>

Outbound window 1 (OTAT1) is enabled, 2eSST timing at SST320, transfer mode of 2eSST,

A32/D32 Supervisory access. The window accepts transfers on the PCI-X Local Bus from

0x91000000-0xAFFF0000 and translates them onto the VMEbus using an offset of

0x70000000, thus an access to 0x91000000 on the PCI-X Local Bus becomes an access

to 0x01000000 on the VMEbus.

■ MVME3100> vmeCfg –s –o2

Displaying the selected Default VME Setting

- interpreted as follows:

Outbound Image 2 Attribute Register = 80001061

Outbound Image 2 Starting Address Upper Register = 00000000

Outbound Image 2 Starting Address Lower Register = B0000000

Outbound Image 2 Ending Address Upper Register = 00000000

Outbound Image 2 Ending Address Lower Register = B0FF0000

Outbound Image 2 Translation Offset Upper Register = 00000000

Outbound Image 2 Translation Offset Lower Register = 40000000

Outbound Image 2 2eSST Broadcast Select Register = 00000000

MVME3100>

Outbound window 2 (OTAT2) is enabled, 2eSST timing at SST320, transfer mode of SCT,

A24/D32 Supervisory access. The window accepts transfers on the PCI-X Local Bus from

0xB0000000-0xB0FF0000 and translates them onto the VMEbus using an offset of

0x40000000, thus an access to 0xB0000000 on the PCI-X Local Bus becomes an access

to 0xF0000000 on the VMEbus.

■ MVME3100> vmeCfg –s –o3

Displaying the selected Default VME Setting

- interpreted as follows:

Outbound Image 3 Attribute Register = 80001061

Outbound Image 3 Starting Address Upper Register = 00000000

Outbound Image 3 Starting Address Lower Register = B3FF0000

24

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

Page 37

Chapter 3 MOTLoad Firmware

Outbound Image 3 Ending Address Upper Register = 00000000

Outbound Image 3 Ending Address Lower Register = B3FF0000

Outbound Image 3 Translation Offset Upper Register = 00000000

Outbound Image 3 Translation Offset Lower Register = 4C000000

Outbound Image 3 2eSST Broadcast Select Register = 00000000

MVME3100>

Outbound window 3 (OTAT3) is enabled, 2eSST timing at SST320, transfer mode of SCT,

A16/D32 Supervisory access. The window accepts transfers on the PCI-X Local Bus from

0xB3FF0000-0xB3FF0000 and translates them onto the VMEbus using an offset of

0x4C000000, thus an access to 0xB3FF0000 on the PCI-X Local Bus becomes an access

to 0xFFFF0000 on the VMEbus.

■ MVME3100> vmeCfg –s –o7

Displaying the selected Default VME Setting

- interpreted as follows:

Outbound Image 7 Attribute Register = 80001065

Outbound Image 7 Starting Address Upper Register = 00000000

Outbound Image 7 Starting Address Lower Register = B1000000

Outbound Image 7 Ending Address Upper Register = 00000000

Outbound Image 7 Ending Address Lower Register = B1FF0000

Outbound Image 7 Translation Offset Upper Register = 00000000

Outbound Image 7 Translation Offset Lower Register = 4F000000

Outbound Image 7 2eSST Broadcast Select Register = 00000000

MVME3100>

Outbound window 7 (OTAT7) is enabled, 2eSST timing at SST320, transfer mode of SCT,

CR/CSR Supervisory access. The window accepts transfers on the PCI-X Local Bus from

0xB1000000-0xB1FF0000 and translates them onto the VMEbus using an offset of

0x4F000000, thus an access to 0xB1000000 on the PCI-X Local Bus becomes an access

to 0x00000000 on the VMEbus.

Firmware Settings

The following sections provide additional information pertaining to the VME firmware settings

of the MVME3100. A few VME settings are controlled by hardware jumpers while the majority

of the VME settings are managed by the firmware command utility vmeCfg.

CR/CSR Settings

The CR/CSR base address is initialized to the appropriate setting based on the Geographical

address; that is, the VME slot number. See the VME64 Specification and the VME64

Extensions for details. As a result, a 512K byte CR/CSR area can be accessed from the

VMEbus using the CR/CSR AM code.

Displaying VME Settings

To display the changeable VME setting, type the following at the firmware prompt:

■ To display Master Enable state

vmeCfg –s –m

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

25

Page 38

Chapter 3 MOTLoad Firmware

■ To display selected Inbound Window state

vmeCfg –s –i(0 - 7)

■ To display selected Outbound Window state

vmeCfg –s –o(0 - 7)

■ To display PCI Miscellaneous Register state

vmeCfg –s –r184

■ To display Special PCI Target Image Register state

vmeCfg –s –r188

■ To display Master Control Register state

vmeCfg –s –r400

■ To display Miscellaneous Control Register state

vmeCfg –s –r404

■ To display User AM Codes Register state

vmeCfg –s –r40C

■ To display VMEbus Register Access Image Control Register state

vmeCfg –s –rF70

Editing VME Settings

To edit the changeable VME setting, type the following at the firmware prompt:

■ Edits Master Enable state

vmeCfg –e –m

■ Edits selected Inbound Window state

vmeCfg –e –i(0 - 7)

■ Edits selected Outbound Window state

vmeCfg –e –o(0 - 7)

■ Edits PCI Miscellaneous Register state

vmeCfg –e –r184

■ Edits Special PCI Target Image Register state

vmeCfg –e –r188

■ Edits Master Control Register state

vmeCfg –e –r400

■ Edits Miscellaneous Control Register state

vmeCfg –e –r404

26

■ Edits User AM Codes Register state

vmeCfg –e –r40C

MVME3100 Single-Board Computer Installation and Use (V3100A/IH1)

Page 39

■ Edits VMEbus Register Access Image Control Register state

vmeCfg –e –rF70

Deleting VME Settings

To delete the changeable VME setting (restore default value), type the following at the firmware

prompt:

■ Deletes Master Enable state

vmeCfg –d –m

■ Deletes selected Inbound Window state

vmeCfg –d –i(0 - 7)

■ Deletes selected Outbound Window state

vmeCfg –d –o(0 - 7)

■ Deletes PCI Miscellaneous Register state

vmeCfg –d –r184

■ Deletes Special PCI Target Image Register state

Chapter 3 MOTLoad Firmware

vmeCfg –d –r188

■ Deletes Master Control Register state

vmeCfg –d –r400

■ Deletes Miscellaneous Control Register state

vmeCfg –d –r404

■ Deletes User AM Codes Register state

vmeCfg –d –r40C

■ Deletes VMEbus Register Access Image Control Register state

vmeCfg –d –rF70

Restoring Default VME Settings

To restore all of the changeable VME setting back to their default settings, type the following at

the firmware prompt:

vmeCfg –z

Remote Start

As described in the MOTLoad Firmware Package User’s Manual, listed in Appendix B, Related

Documentation, remote start allows the user to obtain information about the target board,