Motorola MURB1620CT Datasheet

SEMICONDUCTOR TECHNICAL DATA

Order this document

by MURB1620CT/D

D2PAK Power Surface Mount Package

Designed for use in switching power supplies, inverters and as free wheeling

diodes, these state–of–the–art devices have the following features:

• Package Designed for Power Surface Mount Applications

• Ultrafast 35 Nanosecond Recovery Times

• 175°C Operating Junction Temperature

• Epoxy Meets UL94, VO @ 1/8″

• High Temperature Glass Passivated Junction

• Low Leakage Specified @ 150°C Case Temperature

• Short Heat Sink Tab Manufactured — Not Sheared!

• Similar in Size to Industrial Standard TO–220 Package

Mechanical Characteristics

• Case: Epoxy, Molded

• Weight: 1.7 grams (approximately)

• Finish: All External Surfaces Corrosion Resistant and Terminal

Leads are Readily Solderable

• Lead and Mounting Surface Temperature for Soldering

Purposes: 260°C Max. for 10 Seconds

• Shipped 50 units per plastic tube

• Available in 24 mm Tape and Reel, 800 units per reel by

adding a “T4” suffix to the part number

• Marking: U1620T

1

3

Motorola Preferred Device

ULTRAFAST RECTIFIER

16 AMPERES

200 VOL TS

4

1

3

CASE 418B–02

D2PAK

4

MAXIMUM RATING, PER LEG

Rating Symbol Value Unit

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

Average Rectified Forward Current

Total Device, (Rated VR), TC = 150°C Total Device

Peak Repetitive Forward Current

(Rated VR, Square Wave, 20 kHz), TC = 150°C

Non–repetitive Peak Surge Current

(Surge applied at rated load conditions halfwave, single phase, 60 Hz)

Operating Junction and Storage Temperature TJ, T

V

RRM

V

RWM

V

I

F(AV)

I

FM

I

FSM

200 Volts

R

stg

8

16

16 Amps

100 Amps

– 65 to +175 °C

Amps

THERMAL CHARACTERISTICS, PER LEG

Maximum Thermal Resistance, Junction to Case R

Maximum Thermal Resistance, Junction to Ambient (1) R

Temperature for Soldering

Purposes: 1/8″ from Case for 5 Seconds

(1) See Chapter 7 for mounting conditions

Designer’s Data for “Worst Case” Conditions — The Designer’s Data Sheet permits the design of most circuits entirely from the information presented. SOA Limit

curves — representing boundaries on device characteristics — are given to facilitate “worst case” design.

Designer’s and SWITCHMODE are trademarks of Motorola, Inc.

Thermal Clad is a trademark of the Bergquist Company

Preferred devices are Motorola recommended choices for future use and best overall value.

θJC

θJA

T

L

3 °C/W

50 °C/W

260 °C

Rev 1

Rectifier Device Data

Motorola, Inc. 1996

1

MURB1620CT

ELECTRICAL CHARACTERISTICS, PER LEG

Characteristic Symbol Max Unit

Maximum Instantaneous Forward Voltage (2)

(iF = 8 Amp, TC = 150°C)

(iF = 8 Amp, TC = 25°C)

Maximum Instantaneous Reverse Current (2)

(Rated dc Voltage, TC = 150°C)

(Rated dc Voltage, TC = 25°C)

Maximum Reverse Recovery Time

(IF = 1 Amp, di/dt = 50 Amp/µs)

(IF = 0.5 Amp, iR = 1 Amp, I

(2) Pulse Test: Pulse Width = 300 µs, Duty Cycle ≤2.0%

= 0.25 Amp)

REC

v

F

i

R

t

rr

0.895

0.975

250

5

35

25

Volts

µA

ns

100

50

20

10

5.0

2.0

1.0

0.7

0.3

0.1

, INSTANTANEOUS FORWARD CURRENT (AMPS)

0.2 0.4 0.6 0.8 1 1.2

F

i

vF, INSTANTANEOUS VOLTAGE (V)

100°C 25°CTJ = 175°C

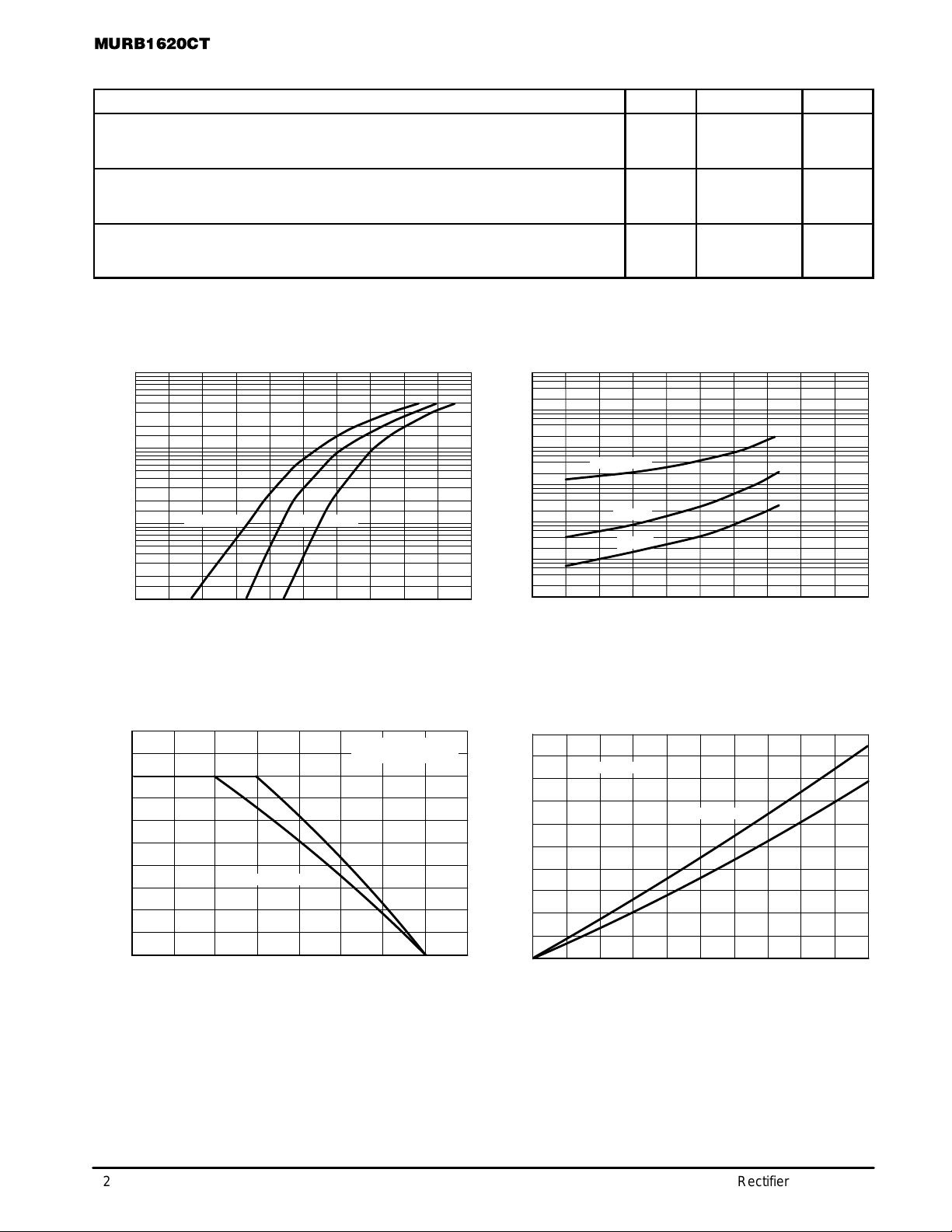

Figure 1. T ypical Forward Voltage, Per Leg

10

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

, AVERAGE POWER DISSIPA TION (WATTS)

1.0

F(AV)

I

DC

SQUARE WAVE

0

TC, CASE TEMPERATURE (°C)

RATED VR APPLIED

R

°

= 3

θ

JC

170160150140

Figure 3. Current Derating Case, Per Leg Figure 4. Power Dissipation, Per Leg

C/W

180

1.0 K

µ

, REVERSE CURRENT ( A)

R

I

, AVERAGE POWER DISSIPA TION (WATTS)

F(AV)

P

10 K

400

100

20

0.2

0.04

0.01

10

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

TJ = 175°C

4

1

20 60 100 140 180

100°C

25°C

VR, REVERSE VOLTAGE (V)

Figure 2. T ypical Reverse Current, Per Leg*

TJ = 175°C

SQUARE WAVE

0

I

, AVERAGE FORW ARD CURRENT (AMPS)

F(AV )

DC

20016012080400

10

9876543210

2

Rectifier Device Data

Loading...

Loading...