Page 1

Symbol MiniScan MSXX04 Series

Integration Guide

Page 2

Page 3

Symbol MiniScan MSXX04 Series

Integration Guide

72E-67134-05

Revision A

January 2008

Page 4

ii Symbol MiniScan MSXX04 Series Integration Guide

© 2008 by Motorola, Inc. All rights reserved.

No part of this publication may be reproduced or used in any form, or by any electrical or mechanical means,

without permission in writing from Motorola. This includes electronic or mechanical means, such as

photocopying, recording, or information storage and retrieval systems. The material in this manual is subject to

change without notice.

The software is provided strictly on an “as i s” basis. All sof twar e, including firmware, furnished to the user is on

a licensed basis. Motorola grants to the user a non-transferab le and non-exclusive license to use each

software or firmware program delivered hereunder (licensed program). Except as noted below, such license

may not be assigned, sublicensed, or otherwise transferred by the user without prior written consent of

Motorola. No right to copy a licensed program in whole or in part is granted, except as permitted unde r

copyright law. The user shall not modify, merge, or incorporate any form or portion of a licensed program with

other program material, create a derivative work from a licensed program, or use a licensed program in a

network without written permission from Motorola. The user agrees to maintain Motorola’s copyright notice on

the licensed programs delivered hereunder, and to include the same on any authorized copies it makes, in

whole or in part. The user agrees not to deco mpile, disassemble, decode, or reverse engineer any licensed

program delivered to the user or any portion thereof.

Motorola reserves the right to make changes to any software or product to improve reliability, function, or

design.

Motorola does not assume any product liability arising out of, or in connection with, the application or use of

any product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under any Motorola, Inc.,

intellectual property rights. An implied license only exists for equipment, circuits, and subsystems contained in

Motorola products.

MOTOROLA and the Stylized M Logo and Symbol and the Symbol logo are registered in the US Patent &

Trademark Office. Bluetooth is a registered trademark of Bluetooth SIG. Microsoft, Windows and ActiveSync

are either registered trademarks or trademarks of Microsoft Corporation. All other product or service names

are the property of their respective owners.

Motorola, Inc.

One Motorola Plaza

Holtsville, New York 11742-1300

http://www.symbol.com

Patents

This product is covered by one or more of the patents listed on the website: http://www.symbol.com/patents.

Warranty

For the complete Motorola hardware product warranty statement, go to: http://www.symbol.com/warranty.

Page 5

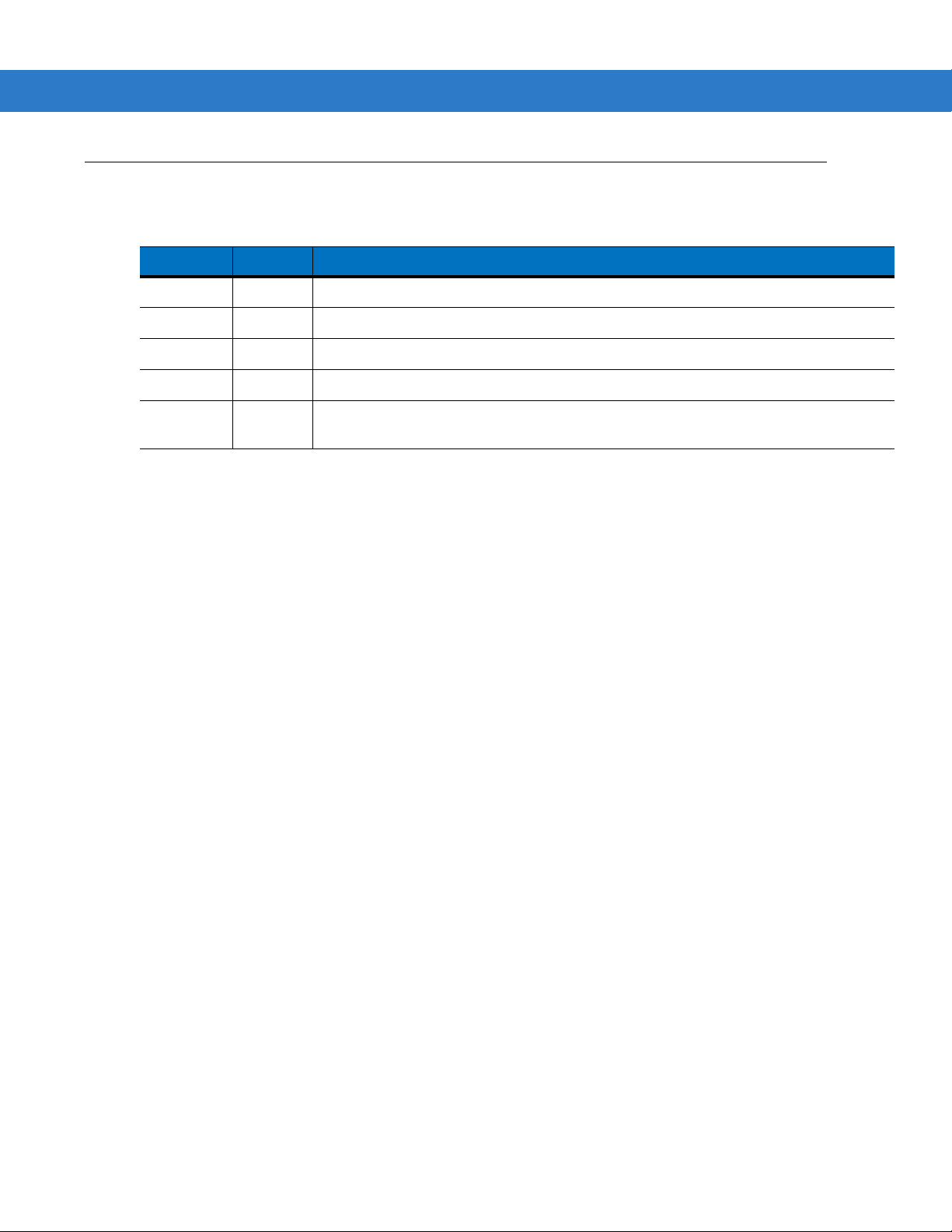

Revision History

Changes to the original manual are listed below:

Change Date Description

-01 Rev A 2/2004 Initial release.

-02 Rev A 6/2004 Added Embedded Application information.

-03 Rev A 8/2006 Software updates.

-04 Rev A 3/2007 Updated service information and specifications.

-05 Rev A 1/2008 Added new UPC/EAN supplemental options and Bookland ISBN format option,

iii

updated troubleshooting.

Page 6

iv Symbol MiniScan MSXX04 Series Integration Guide

Page 7

Table of Contents

About This Guide

Introduction.................................................................................................................... xiii

Chapter Descriptions..................................................................................................... xiii

Notational Conventions.................................................................................................. xiv

Related Documents....................................................................................................... xv

Service Information........................................................................................................ xv

Chapter 1: Getting Started

Introduction ................................................................................................................... 1-1

Symbol MS1204FZY, MS2204, MS2204VHD, and MS3204 Features ................... 1-2

Symbol MS954 Features ........................................................................................ 1-2

Typical Applications ...................................................................................................... 1-3

Symbol MS1204FZY, MS2204, MS2204VHD, and MS3204 Applications .............. 1-3

Symbol MS954 Applications ................................................................................... 1-3

Block Diagrams ............................................................................................................. 1-3

Symbol MS1204FZY, MS2204, MS2204VHD, and MS3204 Block Diagram .......... 1-4

Symbol MS954 Block Diagram ............................................................................... 1-4

Miniscan Block Diagram Descriptions ..................................................................... 1-5

Chapter 2: Installation

Introduction ................................................................................................................... 2-1

Unpacking ..................................................................................................................... 2-1

Mounting ....................................................................................................................... 2-2

Symbol MS1204FZY/MS2204/MS2204VHD Mounting Dimensions ....................... 2-2

Symbol MS3204 Mounting Dimensions .................................................................. 2-3

Symbol MS954 Mounting Dimensions .................................................................... 2-3

Mounting the Scanner on the Stand ....................................................................... 2-4

Mounting the Scanner on the Mounting Bracket ..................................................... 2-5

Connecting the MiniScan .............................................................................................. 2-7

Location and Positioning ............................................................................................... 2-8

Using the MiniScan as an Embedded Scanner ...................................................... 2-8

Conveyor Applications ............................................................................................ 2-11

Page 8

vi Symbol MiniScan MSXX04 Series Integration Guide

Embedded Applications Requiring a Window ......................................................... 2-12

Accessories .................................................................................................................. 2-16

Software Developer’s CD ........................................................................................ 2-17

Chapter 3: Scanning

Introduction ................................................................................................................... 3-1

MiniScan Scan Patterns ............................................................................................... 3-1

Symbol MS1204FZY / MS954 Scan Pattern ........................................................... 3-1

Symbol MS2204 and MS2204VHD Scan Patterns ................................................. 3-2

Symbol MS3204 Scan Patterns .............................................................................. 3-3

Scan Angle Selection .................................................................................................... 3-4

Selecting Scan Angle via SSI ................................................................................. 3-4

Selecting Scan Angle via Parameter Bar Code ...................................................... 3-4

Operation in Blink Mode .......................................................................................... 3-4

Scanning Tips ............................................................................................................... 3-5

Scan the Entire Symbol .......................................................................................... 3-5

Position at an Angle ................................................................................................ 3-5

Trigger Options ............................................................................................................. 3-5

Continuous .............................................................................................................. 3-5

Level Trigger ........................................................................................................... 3-6

Pulse Trigger ........................................................................................................... 3-6

Blink ....................................................................................................................... 3-6

Host Trigger ............................................................................................................ 3-6

Beeper and LED Definitions ......................................................................................... 3-7

Chapter 4: Symbol MS1204FZY Specifications

Introduction ................................................................................................................... 4-1

Symbol MS1204FZY Electrical Interface ...................................................................... 4-1

Symbol MS1204FZY Mechanical Drawings ................................................................. 4-3

Symbol MS1204FZY Technical Specifications ............................................................. 4-5

Symbol MS1204FZY Decode Zone .............................................................................. 4-7

Usable Scan Length ................................................................................................ 4-8

Chapter 5: Symbol MS2204 Specifications

Introduction ................................................................................................................... 5-1

Symbol MS2204 Electrical Interface ............................................................................. 5-1

Symbol MS2204 Mechanical Drawings ........................................................................ 5-3

Symbol MS2204 Technical Specifications .................................................................... 5-5

Symbol MS2204 Decode Zones ................................................................................... 5-8

Symbol MS2204 1D Decode Zone ......................................................................... 5-8

Symbol MS2204 1D Decode Distances .................................................................. 5-9

Symbol MS2204 2D Decode Zone ......................................................................... 5-10

Symbol MS2204 2D Decode Distances .................................................................. 5-11

Usable Scan Length ................................................................................................ 5-11

Page 9

Chapter 6: Symbol MS2204VHD Specifications

Introduction ................................................................................................................... 6-1

Symbol MS2204VHD Electrical Interface ..................................................................... 6-1

Symbol MS2204VHD Mechanical Drawings ................................................................. 6-3

Symbol MS2204VHD Technical Specifications ............................................................ 6-5

Symbol MS2204VHD Decode Zones ........................................................................... 6-8

Symbol MS2204VHD 1D Decode Zone .................................................................. 6-8

Symbol MS2204VHD 1D Decode Distances .......................................................... 6-9

Symbol MS2204VHD 2D Decode Zone .................................................................. 6-10

Symbol MS2204VHD 2D Decode Distances .......................................................... 6-11

Usable Scan Length ................................................................................................ 6-11

Chapter 7: Symbol MS3204 Specifications

Introduction ................................................................................................................... 7-1

Symbol MS3204 Electrical Interface ............................................................................. 7-2

Symbol MS3204 Mechanical Drawings ........................................................................ 7-3

Symbol MS3204 Technical Specifications .................................................................... 7-5

Symbol MS3204 Decode Zones ................................................................................... 7-8

Omnidirectional Decode Distances ......................................................................... 7-8

2D Slab/Raster Decode Distances (Symbol MS3204-I000 Only) ........................... 7-10

Usable Scan Length ................................................................................................ 7-11

Table of Contents vii

Chapter 8: Symbol MS954 Specifications

Introduction ................................................................................................................... 8-1

Symbol MS954 Electrical Interface ............................................................................... 8-2

Symbol MS954 Mechanical Drawings .......................................................................... 8-3

Symbol MS954 Technical Specifications ...................................................................... 8-5

Symbol MS954 Decode Zone ....................................................................................... 8-7

Usable Scan Length ................................................................................................ 8-8

Chapter 9: Maintenance and Troubleshooting

Introduction ................................................................................................................... 9-1

Maintenance ................................................................................................................. 9-1

Troubleshooting ............................................................................................................ 9-2

Chapter 10: Parameter Menus

Introduction ................................................................................................................... 10-1

Operational Parameters ................................................................................................ 10-2

Default Table ................................................................................................................ 10-2

Set Default Parameter .................................................................................................. 10-8

Set Defaults - Symbol MS1204, MS1204VHD, MS3204 ........................................ 10-8

Set Defaults - Symbol MS954 ................................................................................. 10-9

Scanning Options ......................................................................................................... 10-10

Beeper Volume ....................................................................................................... 10-10

Beeper Tone ........................................................................................................... 10-11

Beeper Frequency Adjustment ............................................................................... 10-11

Page 10

viii Symbol MiniScan MSXX04 Series Integration Guide

Laser On Time ........................................................................................................ 10-12

Scan Angle .............................................................................................................. 10-12

Power Mode ............................................................................................................ 10-13

Trigger Modes ......................................................................................................... 10-14

Scanning Mode ....................................................................................................... 10-15

Aiming Mode ........................................................................................................... 10-16

Programmable Raster Height And Raster Expansion Speed ................................. 10-17

Timeout Between Decodes ..................................................................................... 10-18

Beep After Good Decode ........................................................................................ 10-19

Transmit “No Read” Message ................................................................................. 10-20

Parameter Scanning ............................................................................................... 10-21

Linear Code Type Security Level ............................................................................ 10-22

Bi-directional Redundancy ...................................................................................... 10-24

UPC/EAN ...................................................................................................................... 10-25

Enable/Disable UPC-A ............................................................................................ 10-25

Enable/Disable UPC-E ............................................................................................ 10-25

Enable/Disable UPC-E1 .......................................................................................... 10-26

Enable/Disable EAN-8 ............................................................................................ 10-27

Enable/Disable EAN-13 .......................................................................................... 10-27

Enable/Disable Bookland EAN ............................................................................... 10-28

UPC/EAN Coupon Code ......................................................................................... 10-29

Decode UPC/EAN Supplementals .......................................................................... 10-30

User-Programmable Supplementals ....................................................................... 10-34

Decode UPC/EAN Supplemental Redundancy ...................................................... 10-34

Transmit UPC-A Check Digit .................................................................................. 10-35

Transmit UPC-E Check Digit .................................................................................. 10-35

Transmit UPC-E1 Check Digit ................................................................................ 10-36

UPC-A Preamble .................................................................................................... 10-37

UPC-E Preamble .................................................................................................... 10-38

UPC-E1 Preamble .................................................................................................. 10-39

Convert UPC-E to UPC-A ....................................................................................... 10-40

Convert UPC-E1 to UPC-A ..................................................................................... 10-41

EAN Zero Extend .................................................................................................... 10-41

Bookland ISBN Format ........................................................................................... 10-42

UPC/EAN Security Level ........................................................................................ 10-43

Linear UPC/EAN Decode ........................................................................................ 10-44

UPC Half Block Stitching ........................................................................................ 10-44

Code 128 ...................................................................................................................... 10-45

Enable/Disable Code 128 ....................................................................................... 10-45

Enable/Disable UCC/EAN-128 ............................................................................... 10-45

Enable/Disable ISBT 128 ........................................................................................ 10-46

Lengths for Code 128 ............................................................................................. 10-46

Code 128 Decode Performance ............................................................................. 10-47

Code 128 Decode Performance Level .................................................................... 10-48

Code 39 ........................................................................................................................ 10-49

Enable/Disable Code 39 ......................................................................................... 10-49

Enable/Disable Trioptic Code 39 ............................................................................ 10-49

Convert Code 39 to Code 32 .................................................................................. 10-50

Code 32 Prefix ........................................................................................................ 10-51

Set Lengths for Code 39 ......................................................................................... 10-52

Page 11

Table of Contents ix

Code 39 Check Digit Verification ............................................................................ 10-53

Transmit Code 39 Check Digit ................................................................................ 10-53

Enable/Disable Code 39 Full ASCII ........................................................................ 10-54

Code 39 Decode Performance ............................................................................... 10-55

Code 39 Decode Performance Level ...................................................................... 10-56

Code 93 ........................................................................................................................ 10-57

Enable/Disable Code 93 ......................................................................................... 10-57

Set Lengths for Code 93 ......................................................................................... 10-58

Code 11 ........................................................................................................................ 10-59

Enable/Disable Code 11 ......................................................................................... 10-59

Set Lengths for Code 11 ......................................................................................... 10-60

Code 11 Check Digit Verification ............................................................................ 10-61

Transmit Code 11 Check Digit ................................................................................ 10-62

Interleaved 2 of 5 .......................................................................................................... 10-63

Enable/Disable Interleaved 2 of 5 ........................................................................... 10-63

Set Lengths for Interleaved 2 of 5 ........................................................................... 10-64

I 2 of 5 Check Digit Verification ............................................................................... 10-65

Transmit I 2 of 5 Check Digit ................................................................................... 10-66

Convert I 2 of 5 to EAN-13 ...................................................................................... 10-66

Discrete 2 of 5 ............................................................................................................... 10-67

Enable/Disable Discrete 2 of 5 ................................................................................ 10-67

Set Lengths for Discrete 2 of 5 ............................................................................... 10-68

Chinese 2 of 5 ............................................................................................................... 10-69

Enable/Disable Chinese 2 of 5 ................................................................................ 10-69

Codabar ........................................................................................................................ 10-70

Enable/Disable Codabar ......................................................................................... 10-70

Set Lengths for Codabar ......................................................................................... 10-71

CLSI Editing ............................................................................................................ 10-72

NOTIS Editing ......................................................................................................... 10-72

MSI Plessey .................................................................................................................. 10-73

Enable/Disable MSI Plessey ................................................................................... 10-73

Set Lengths for MSI Plessey ................................................................................... 10-74

MSI Plessey Check Digits ....................................................................................... 10-75

Transmit MSI Plessey Check Digit .......................................................................... 10-75

MSI Plessey Check Digit Algorithm ........................................................................ 10-76

PDF417/MicroPDF417 ................................................................................................. 10-77

Enable/Disable PDF417 .......................................................................................... 10-77

Enable/Disable MicroPDF417 ................................................................................. 10-77

MicroPDF Performance .......................................................................................... 10-78

Code 128 Emulation ............................................................................................... 10-79

GS1 DataBar ................................................................................................................ 10-80

GS1 DataBar-14 ..................................................................................................... 10-80

GS1 DataBar Limited .............................................................................................. 10-80

GS1 DataBar Expanded ......................................................................................... 10-81

Convert GS1 DataBar to UPC/EAN ........................................................................ 10-82

Composite ..................................................................................................................... 10-83

Composite CC-C ..................................................................................................... 10-83

Composite CC-A/B .................................................................................................. 10-84

Composite TLC-39 .................................................................................................. 10-84

UPC Composite Mode ............................................................................................ 10-85

Page 12

x Symbol MiniScan MSXX04 Series Integration Guide

Data Options ................................................................................................................. 10-86

Transmit Code ID Character ................................................................................... 10-86

Prefix/Suffix Values ................................................................................................. 10-88

Scan Data Transmission Format ............................................................................ 10-89

Simple Serial Interface (SSI) Options ........................................................................... 10-91

Baud Rate ............................................................................................................... 10-91

Parity ....................................................................................................................... 10-93

Check Parity ............................................................................................................ 10-94

Software Handshaking ............................................................................................ 10-95

Host RTS Line State ............................................................................................... 10-96

Decode Data Packet Format ................................................................................... 10-97

Stop Bit Select ........................................................................................................ 10-97

Intercharacter Delay ................................................................................................ 10-98

Host Serial Response Time-out .............................................................................. 10-98

Host Character Time-out ......................................................................................... 10-98

Event Reporting ............................................................................................................ 10-99

Decode Event ......................................................................................................... 10-99

Boot Up Event ......................................................................................................... 10-100

Parameter Event ..................................................................................................... 10-100

Macro PDF Features ................................................................................................... 10-101

Transmit Symbols in Codeword Format .................................................................. 10-101

Transmit Unknown Codewords ............................................................................... 10-102

Escape Characters ................................................................................................. 10-103

Delete Character Set ECIs ...................................................................................... 10-104

ECI Decoder ........................................................................................................... 10-105

Transmit Macro PDF User-Selected Fields .................................................................. 10-106

Transmit File Name ................................................................................................. 10-106

Transmit Block Count .............................................................................................. 10-107

Transmit Time Stamp .............................................................................................. 10-107

Transmit Sender ..................................................................................................... 10-108

Transmit Addressee ................................................................................................ 10-108

Transmit Checksum ................................................................................................ 10-109

Transmit File Size ................................................................................................... 10-109

Transmit Macro PDF Control Header ..................................................................... 10-110

Last Blocker Marker ................................................................................................ 10-110

Numeric Bar Codes ...................................................................................................... 10-111

Cancel ..................................................................................................................... 10-113

Chapter 11: Simple Serial Interface (SSI)

Introduction ................................................................................................................... 11-1

Revision String .............................................................................................................. 11-1

SSI Commands Not Supported .................................................................................... 11-2

Chapter 12: Mounting Templates

Introduction ................................................................................................................... 12-1

Symbol MS1204FZY/MS2204/MS2204VHD Mounting Template ........................... 12-1

Symbol MS3204 Mounting Template ...................................................................... 12-2

Symbol MS954 Mounting Template ........................................................................ 12-2

Page 13

Appendix A: ASCII Character Sets

RS-232 ASCII Character Set ........................................................................................ A-1

USB ASCII Character Set ............................................................................................. A-6

Glossary

Index

Tell Us What You Think...

Table of Contents xi

Page 14

xii Symbol MiniScan MSXX04 Series Integration Guide

Page 15

About This Guide

Introduction

The Symbol MiniScan MSXX04 Series Integration Guide provides general instructions for mounting, setting up,

and programming the following Symbol MiniScan models:

•

MS954

•

MS1204FZY

•

MS2204

•

MS2204VHD

•

MS3204.

NOTE It is recommended that an opto-mechanical engineer perform an opto-mechanical analysis prior to

integration.

Chapter Descriptions

Topics covered in this guide are as follows:

•

Chapter 1, Getting Started, provides an overview of the MiniScan scanners and features, and provides a

block diagram of the scanner.

•

Chapter 2, Installation, describes how to mount and install the MiniScan scanner.

•

Chapter 3, Scanning, provides information on scan patterns, scanning, triggering options, and beeper and

LED definitions.

•

Chapter 4, Symbol MS1204FZY Specifications , p ro vid es the technic al an d sca n ning sp ecif ica tio ns fo r the

Symbol MS1204FZY scanner.

•

Chapter 5, Symbol MS2204 Specifications, provides the technical and scanning specifications for the Symbol

MS2204 scanner.

•

Chapter 6, Symbol MS2204VHD Specifications, provides the technical and scanning specifications for the

Symbol MS2204VHD scanner.

Page 16

xiv Symbol MiniScan MSXX04 Series Integration Guide

•

Chapter 7, Symbol MS3204 Specifications, provides the technical and scanning specifications for the Symbol

MS3204 scanner.

•

Chapter 8, Symbol MS954 Specifications, provides the technical and scanning specifications for the Symbol

MS954 scanner.

•

Chapter 9, Maintenance and Troubleshooting, provides information on maintaining and troubleshooting the

MiniScan scanners.

•

Chapter 10, Parameter Menus describes the programmable parameters, provides bar codes for

programming, and hexadecimal equivalents for host download programming.

•

Chapter 11, Simple Serial Interface (SSI) describes scanner-specific updates to the Simple Serial Interface

(SSI) Programmer’s Guide.

•

Chapter 12, Mounting Te mplates, provides mounting templates for the MiniScan scanners.

•

Appendix A, ASCII Character Sets, provides prefix and suffix values that can be assigned for ASCII character

data transmission.

Notational Conventions

The following conventions are used in this document:

•

Italics are used to highlight chapters and sections in this and related documents.

•

bullets (•) indicate:

• Action items

• Lists of alternatives

• Lists of required steps that are not necessarily sequential

•

Sequential lists (e.g., those that describe step-by-s te p pr oc ed ur e s) ap pe a r as nu m be re d lists.

NOTE This symbol indicates something of special interest or importance to the reader. Failure to read the note

will not result in physical harm to the reader, equipment or data.

CAUTION This symbol indicates that if this information is ignored, the possiblity of data or material damage may

occur.

WARNING! This symbol indicates that if this information is ignored the possibility that serious personal

injury may occur.

Page 17

Related Documents

The following documents provide more information for the Symbol MiniScan Seri es scanners.

•

MiniScan Family of Scanners Quick Reference Guide, p/n 72-58809-xx

•

Simple Serial Interface (SSI) Programmer’s Guide, p/n 72-40451-xx

•

Simple Serial Interface (SSI) Developer’s Guide, p/n 72-50705-xx

For the latest version of this guide and all guides, go to: http://www.symbol.com/manuals.

Service Information

If you have a problem with your equipment, contact Motorola Enterprise Mobility Support for your region. Contact

information is available at: http://www.symbol.com/contactsupport

When contacting Enterprise Mobility Support, please have the following information available:

•

Serial number of the unit

About This Guide xv

.

•

Model number or product name

•

Software type and version number.

Motorola responds to calls by E-mail, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Motorola Enterprise Mobility Support, you may need to return your equipment

for servicing and will be given specific directions. Motorola is not responsible for any damages incurred during

shipment if the approved shipping container is not used. Shipping the units improperly can possibly void the

warranty.

If you purchased your Enterprise Mobility business product from a Motorola business partner, contact that business

partner for support.

Page 18

xvi Symbol MiniScan MSXX04 Series Integration Guide

Page 19

Chapter 1 Getting Started

CAUTION Use of controls, adjustments or procedures other than those specified here can result in hazardous

laser light exposure.

Introduction

The MiniScan family of fixed-mount scanners are specifically designed for stand-alone applications, and OEM

applications such as kiosks.

Figure 1-1

Symbol MSXX04 Series scanners provide easy and flexible integration of bar code scanning into a host device,

and include the following models:

•

MiniScan Family of Scanners

The Symbol MS1204FZY offers fuzzy logic for premium scanning performance on all types of 1D bar codes

including poorly printed and low contrast symbols. The MS1204FZY features a compact design for superior

performance and durability in a form factor that easily integrates into OEM devices for embedded

applications such as medical instruments, diagnostic equipment, vending machines, and gaming. As a

fixed-mount scanner, the MS1204FZY is ideal for applications requiring unattended scanni ng such as

manufacturing, warehouse and shipping, conveyor belts, library and document tracking systems.

Page 20

1 - 2 Symbol MiniScan MSXX04 Series Integration Guide

•

The Symbol MS2204 and MS2204VHD offer a "smart" raster pattern optimized for 2D applications and

poorly printed 1D bar codes. The high scan rate ensures fast and reliable data on all 1D symbols, and 2D

codes such as PDF417, MicroPDF, GS1 DataBar and composite codes. These scann e rs ar e pe rf ec t for

automated data entry applications that require high-speed scanning, performance, and small size, such as

conveyor belts, manufacturing and warehouse, gas pumps, and security/ID verification.

•

The Symbol MS3204 features a high-speed omnidirectio nal scan p atter n that makes it easy and intuitive for

consumers to scan bar codes at the point of activity. The omnidirectional scan pattern reads bar codes

quickly and accurately, minimizing the need for precise positioning of linear 1D bar codes. The MS3204

provides an easy and cost-effective way to enhance existing OEM devices with high-performance 1D and 2D

scanning, making it the ideal solution for applications that require fast, accurate scanning such as kiosks,

ATMs, listening stations, lottery machines, and vending machines.

•

Symbol MS954 scanner is extremely compact, provides easy and flexible integration of bar code scanning

into a host device, and offers high-performance scanning on 1D bar codes. The MS954 is ideal for medical

instruments and kiosks.

Symbol MS1204FZY, MS2204, MS2204VHD, and MS3204 Features

•

Stand-alone or OEM applications

•

Quick and easy integration for OEM devices

•

Excellent scanning performance on all types of bar codes

(MS1204FZY supports 1D bar codes only)

•

Rugged IP54 sealed housing with integrated beeper

•

RS-232

•

Easy programming and configuration

•

Flexible mounting options

•

LEDs and an integrated beeper indicating scanner power status and successful decodes.

Symbol MS954 Features

•

Stand-alone or OEM applications

•

Quick and easy integration for OEM devices

•

Excellent scanning performance on 1D bar codes

•

RS-232

•

Easy programming and configuration

•

Flexible mounting options

•

LEDs indicating scanner power status and successful decodes.

Page 21

Typical Applications

Symbol MS1204FZY, MS2204, MS2204VHD, and MS3204 Applications

Fixed Mount Standalone Applications

•

Manufacturing / warehouse

•

Conveyer belts

•

Security / ID verification

•

POS.

OEM Applications

•

Kiosks / ATMs

•

Music listening stations

•

Security / ID verification

•

Lottery terminals / gaming.

Getting Started 1 - 3

Symbol MS954 Applications

Fixed Mount Standalone Applications

•

Clinical diagnostics

•

Medical instruments

•

Assembly lines.

OEM Applications

•

Kiosks / ATMs

•

Music listening stations

•

Medical instruments

•

Clinical diagnostics

•

Lottery terminals / gaming.

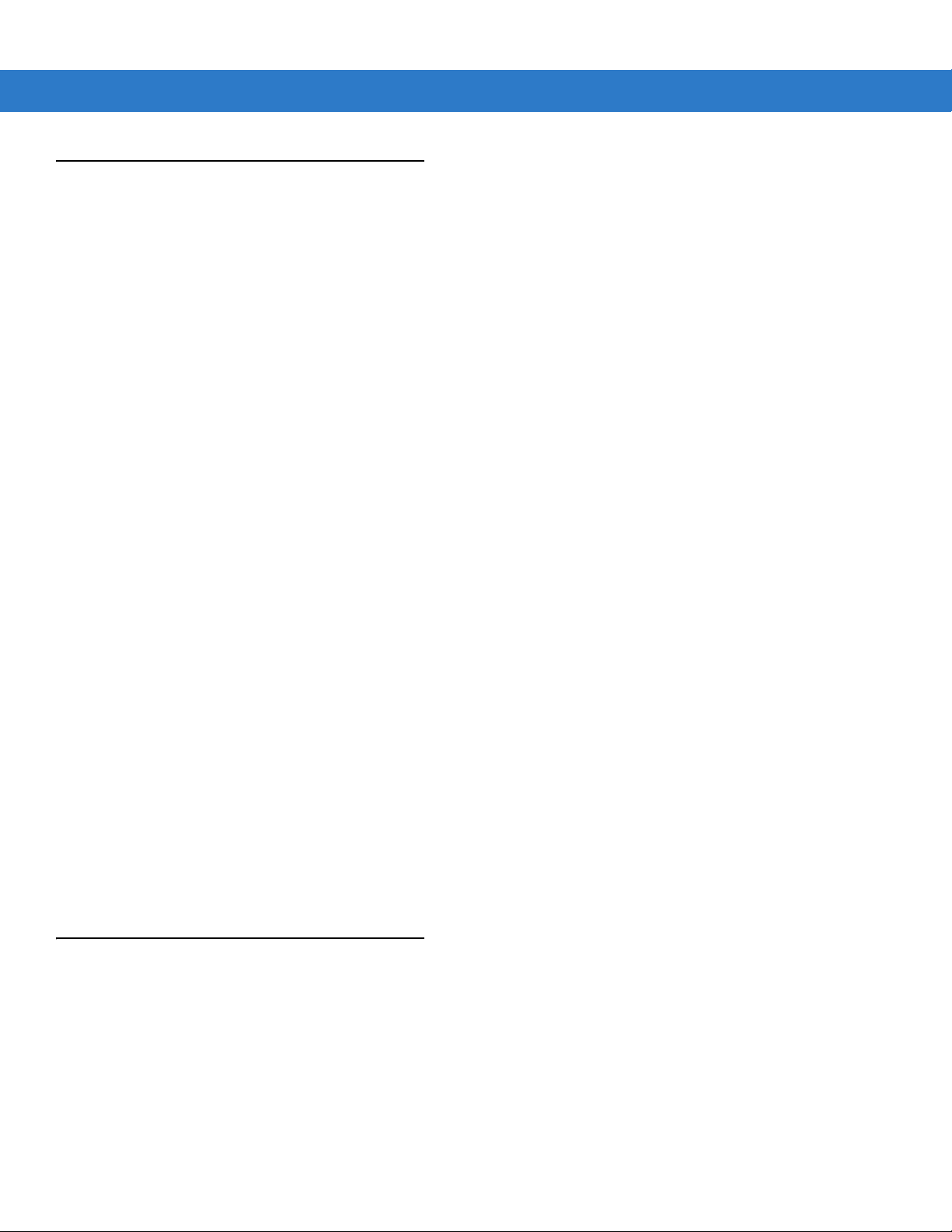

Block Diagrams

The MiniScan block diagrams illustrate the functional relationship of the MiniScan components. A detailed

description of each component in the block diagr ams is also pro vid ed .

Page 22

1 - 4 Symbol MiniScan MSXX04 Series Integration Guide

Symbol MS1204FZY, MS2204, MS2204VHD, and MS3204 Block Diagram

Interface Board

Beeper

External Beeper

DB9

Figure 1-2

flex flex

Symbol MS1204FZY, MS2204, MS2204VHD, and MS3204 Block Diagram

Interface Circuit

RS-232

Red/

Green

LED

External Trigger

Symbol MS954 Block Diagram

Interface Board

External Beeper

Interface

Decoded

Scan

Engine

DB9

Figure 1-3

Interface Circuit

RS-232

Red/

Green

LED

External Trigger

Symbol MS954 Block Diagram

Interface

flex

Decoded

Scan

Scan

Engine

Engine

Page 23

Getting Started 1 - 5

Miniscan Block Diagram Descriptions

Decoded Scan Engine - The scan engine emits a beam of laser light that reflects off the bar code to be decoded.

Black bars absorb light, white spaces reflect light. The scan engine collects the reflected light and processes the

signal through several analog filters. The filtered signal is digitized into a Digitized Barcode Pattern (DBP). Timing

information is analyzed by the decoder micro-controller to decode an d transmit the dat a contained in the bar code.

Data transmission is carried out using Motorola’s proprietary SSI Interface.

Interface Board - The interface board adapts the scan engine's interface into usable signals and data for the

intended host. It also contains a beeper (Symbol MS1204FZY/2204/2204VHD/3204 models only) and red/green

LED for audio/visual feedback, and provides for an external trigger and exter nal beeper.

The MiniScan interface board converts TTL level SSI signals to pro per RS-232 levels for connection to any RS-232

compliant host.

DB9 - The DB9 connector provides an outlet for the various interface signals used between a MiniScan scanner

and the host. It also maintains pin compatibility with the previous generation LS 1220 MiniScan host cables.

Page 24

1 - 6 Symbol MiniScan MSXX04 Series Integration Guide

Page 25

Chapter 2 Installation

Introduction

This chapter provides information on unpacking, mounting, and installing the MiniScan scanner.

Unpacking

Remove the MiniScan from its packing and inspect for damage. If the scan ner is damaged, call Motorola Enterprise

Mobility Support at the telephone number listed on page xv.

KEEP THE PACKING. It is the approved shipping container and should be used if the equipment needs to be

returned for servicing.

Page 26

2 - 2 Symbol MiniScan MSXX04 Series Integration Guide

Mounting

There are three mounting holes (threaded inser t s) on th e bottom of the Symb ol MS1204FZY/2204/2204VHD/3204

chassis; two mounting holes on the Symbol MS954.

The following figures provide mounting dimensions for the MiniScan scanner housings. For a mounting template,

see Chapter 12, Mounting Templates.

NOTE Use only non-magnetic M3x.5 screws with a maximum length of 3.6M to mount the MiniScan scanner

chassis.

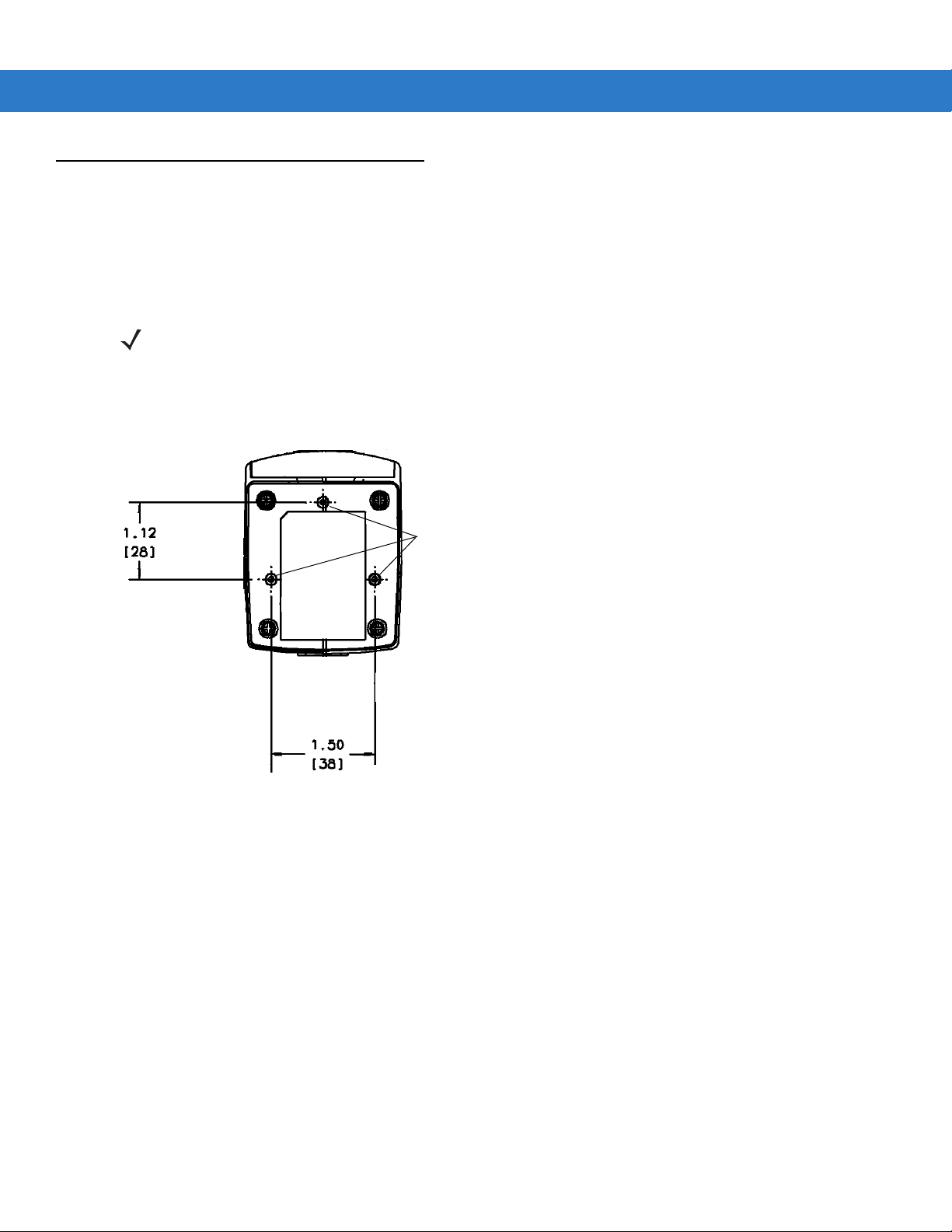

Symbol MS1204FZY/MS2204/MS2204VHD Mounting Dimensions

Threaded Inserts

Figure 2-1

Note:

Dimensions are in inches [mm].

Symbol MS1204FZY/MS2204/MS2204VHD Mounting Dimensions

Page 27

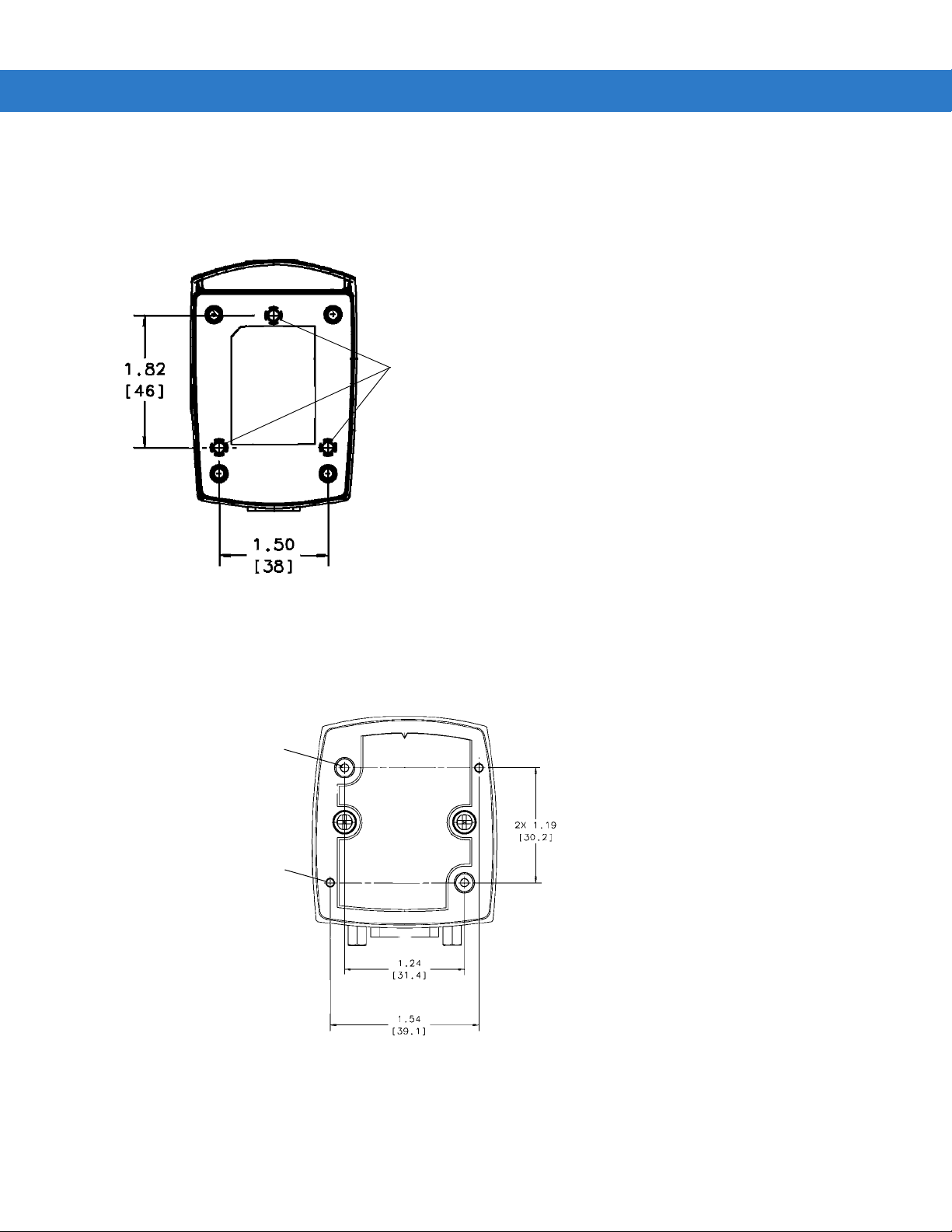

Symbol MS3204 Mounting Dimensions

Threaded Inserts

Note:

Dimensions are in inches [mm].

Installation 2 - 3

Figure 2-2

Symbol MS3204 Mounting Dimensions

Symbol MS954 Mounting Dimensions

2x M3 - 3.6 mm lg. max.

Threaded Inserts

2x - 0.080 [2.0]

Alignment Holes

Note:

Dimensions are in inches [mm].

Figure 2-3

Symbol MS954 Mounting Dimensions

Page 28

2 - 4 Symbol MiniScan MSXX04 Series Integration Guide

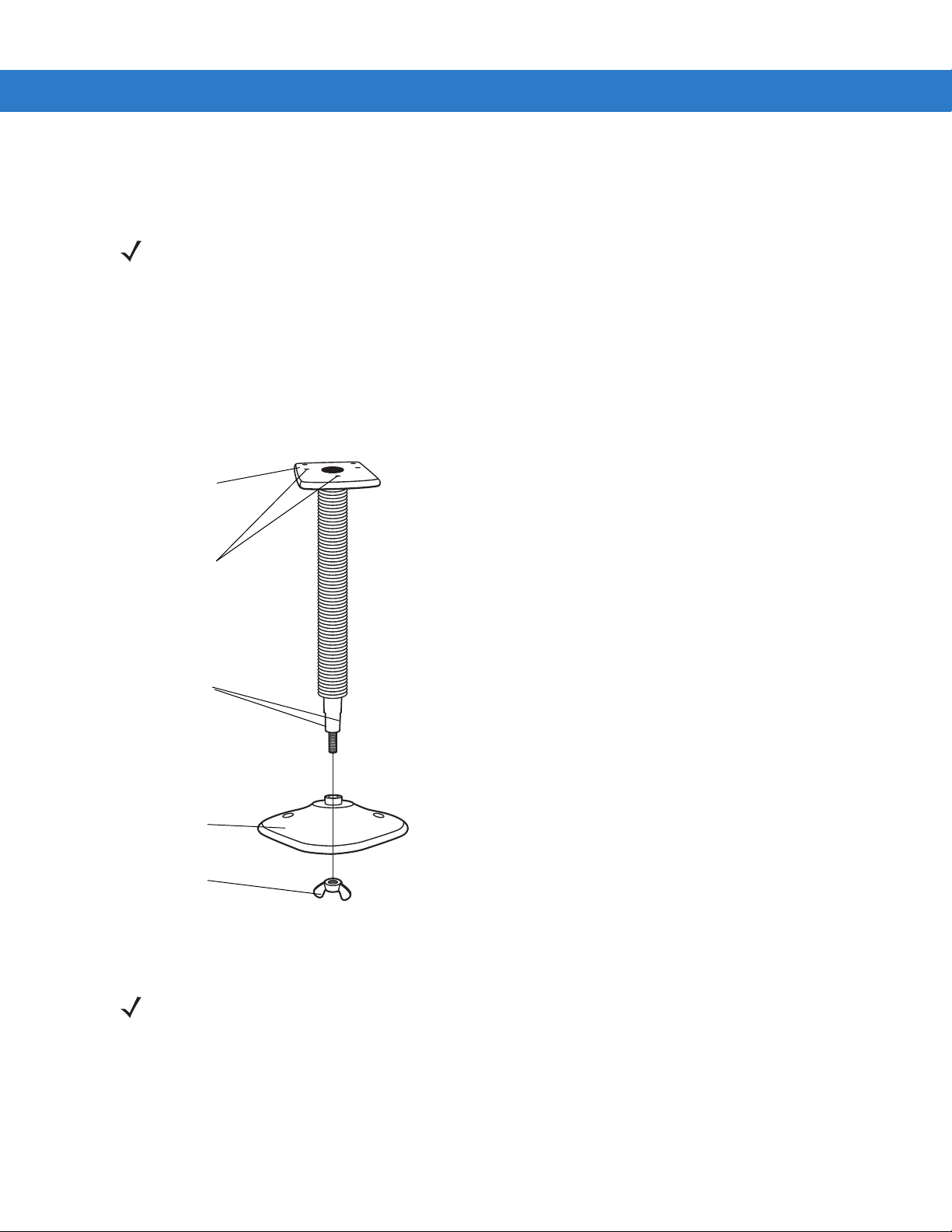

Mounting the Scanner on the Stand

NOTE The stand is optional for the Symbol MS1204FZY, MS2204, MS2204VHD, and MS3204 only.

To mount the scanner on the optional stand:

1. Place the bottom of the scanner on the stand’s sca nner mount, aligning the scanner’s center threaded insert

(beneath the scan window) with the center mounting hole on the front of the stand. The two rear threaded

inserts on the bottom of the scanner will align with the proper mounting holes on the stand.

2. Secure the scanner to the stand using the three screws provided with the stand.

Assembling the Stand

1. Unscrew the wingnut

Scanner mount

from the bottom of the

one-piece scanner

mount.

Mounting holes

Flat areas

Stand base

Wingnut

Figure 2-4

Assembling the Stand

2. Fit the bottom of the

neck piece into the

opening on the top of the

stand base.

3. Tighten the wingnut

underneath the base to

secure the cup and neck

piece (see the note

below).

4. Bend the neck to the

desired position for

scanning.

NOTE Before tightening the wingnut under the base, ensure that the flat areas on the flexible neck fit securely in

the grooves in the base.

Page 29

Installation 2 - 5

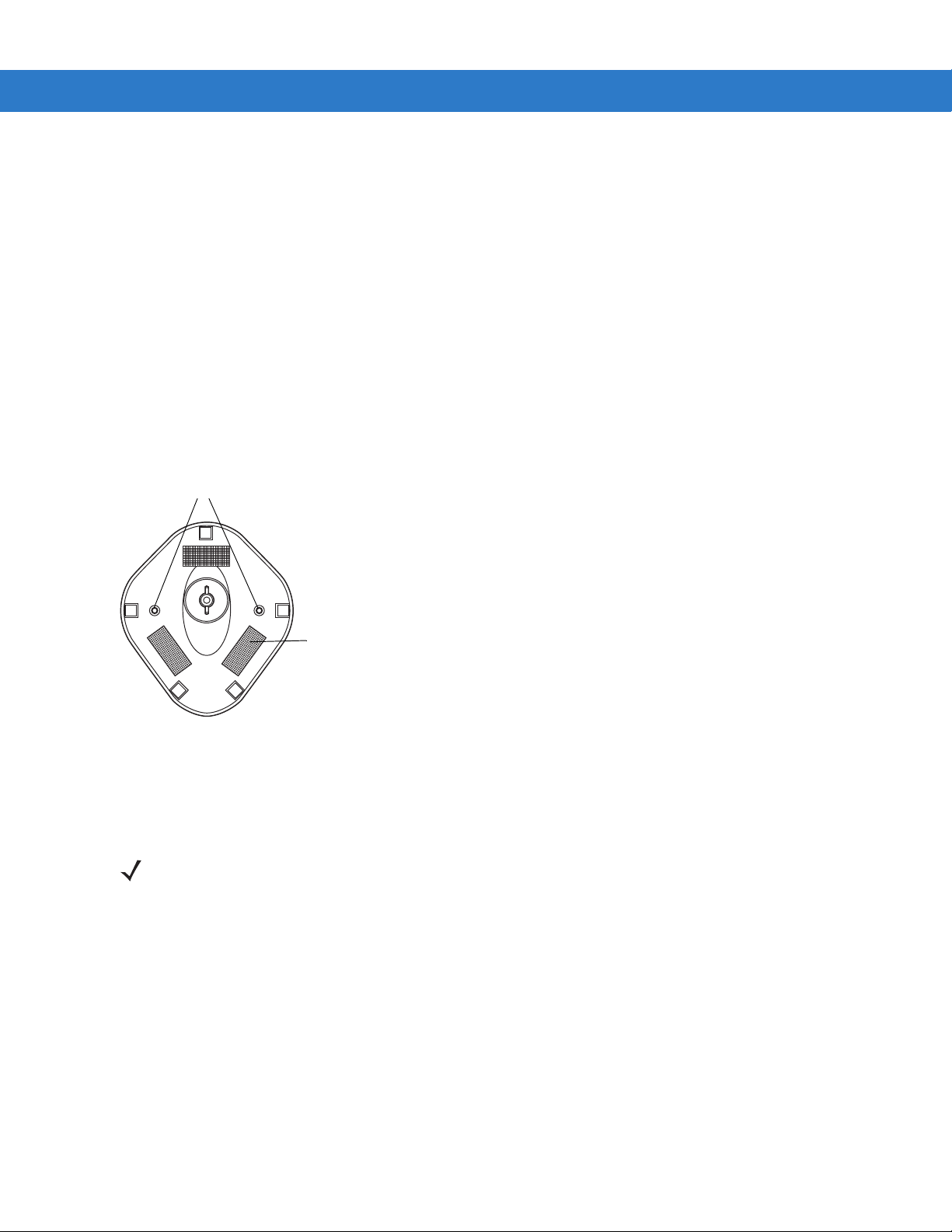

Mounting the Stand (optional)

You can attach the base of the scanner’s stand to a fl at surface using two screws or double-sided tape (not

provided).

Screw Mount

1. Position the assembled base on a flat surface.

2. Screw one #10 wood screw into each screw-mount hole until the base of the stand is secure.

Tape Mount

1. Peel the paper liner off one side of each piece of tape and place the sticky surface over each of the three

rectangular tape areas.

2. Peel the paper liner off the exposed sides of each piece of tape and press the stand on a flat surface until it is

secure.

Two screw-mount holes

Double-sided tape

areas (3 places)

(dimensions = 1” x 2”)

Figure 2-5

Mounting the Stand

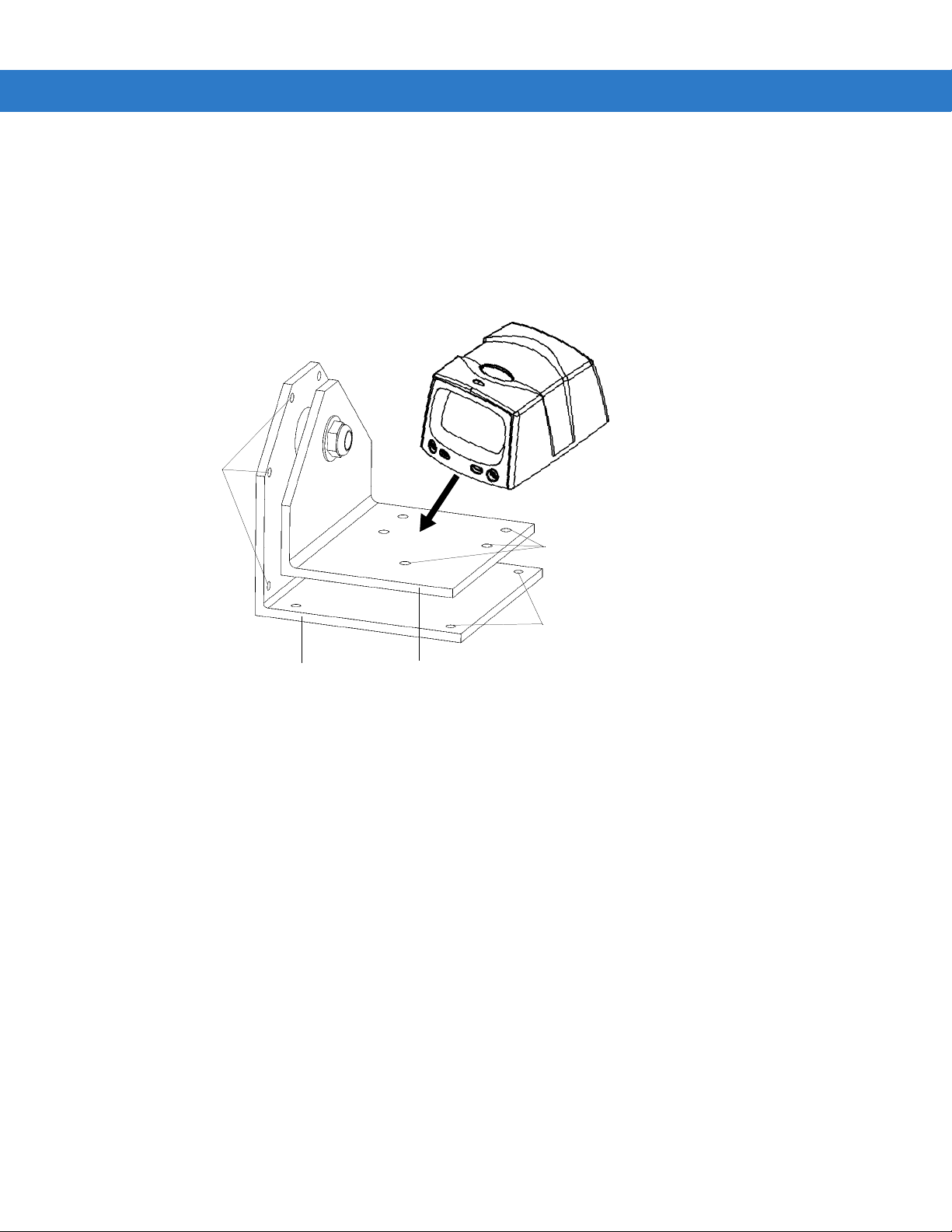

Mounting the Scanner on the Mounting Bracket

NOTE The mounting bracket is optional for the Symbol MS1204FZY, MS2204, MS2204VHD, and MS3204 only.

The optional mounting bracket kit consists of a scanner bracket, a moun ting br acket, and the h ardware re qui red to

mount the scanner. The bracket kit accommodates adjustable angles for optimal positioning of the scanner.

To mount the MiniScan scanner on the bracket, first secure the scanner to the scanner bracket, then attach the

mounting bracket to the wall (see Figure 2-6 on page 2-6):

1. Tilt the scanner bracket forward to access the center scanner mounting hole on the bracket.

2. Place the bottom of the scanner on the scanner br acket, aligning the scanner’s center threaded insert (b eneath

the scan window) with the center mounting hole on the scanner bracket.

3. Insert one of the screws provided through the mounting hole and into the scanner’s center threaded insert.

For the Symbol MS1204FZY, MS2204, and MS2204VHD, use a #0 Phillips screwdriver; for the Symbol

MS3204, use a #1 Phillips screwdriver.

Page 30

2 - 6 Symbol MiniScan MSXX04 Series Integration Guide

4. Tilt the scanner bracket in the opposite direction to access the rear scanner mounting holes (which ar e aligned

with the rear inserts on the bottom of the scanner), then insert the remaining two screws provided through the

two rear mounting holes and into the scanner’s threaded inserts.

5. Secure the mounting bracket to a flat surface by inserting 1/8” or smaller fasten ers through the surfac e and into

the bracket’s mounting holes. There are four mounting holes on the bottom of the mounting bracket for

horizontal mounting, and six holes on the side for vertical mounting.

Vertical

Mounting Holes

Scanner

Mounting Holes

Figure 2-6

Mounting Bracket

Scanner Bracket

Mounting the Scanner and Bracket

Horizontal

Mounting Holes

Page 31

Connecting the MiniScan

1

2

2

3

3

To connect the MiniScan to the host, connect the scanner cables in the order shown in Figure 2-7.

To Host

3

Installation 2 - 7

Beeper

(Optional)

5

Trigger or Photo

Sensor (Optional)

4

1

Trigger Jack (Optional)

See Figure 2-8

2

Figure 2-7

1

Figure 2-8

Typical Connection Diagram

Male jack shown for reference

Note: Due to many variations of

jack and socket styles, identify

terminals as shown before

soldering leads.

Trigger Jack Connector Pins

Insertion

Direction

1 - Ground (Sleeve)

1 - Ground (Sleeve)

2 - Battery (Middle Contact)

2 - Vcc (Middle Contact)

3 - Trigger (Tip)

3 - Trigger (Tip)

Page 32

2 - 8 Symbol MiniScan MSXX04 Series Integration Guide

Location and Positioning

CAUTION The location and positioning guidelines provided do not consider unique application characteristics. It

is recommended that an opto-mechanical engineer perform an opto-mechanical analysis prior to

integration.

NOTE Integrate the scanner in an environment no more extreme than the product’s specification, where the

scanner will not exceed its temperature range. For instance, do not mount the scanner onto or next to a

large heat source. When placing the scanner with another device, ensure there is proper convection or

venting for heat. Follow these suggestions to ensure product longevity, warranty, and overall satisfaction

with the scanner.

Using the MiniScan as an Embedded Scanner

The MiniScan can be mounted to read symbols that are automatically presented, or that are presented in a

pre-determined location. In these applications, MinScan positioning with respect to the symbol is critical. Failure to

properly position the MiniScan can result in unsatisfactory scanning performance. A thermal analysis is also

recommended.

Two methods of positioning the scanner are provided:

•

Use the Calculating the Usable Scan Length Method on page 2- 8 with consistently good quality symbols (see

page 2-9 for the Symbol MS954). This provides a mathematical solution to find the usable scan length.

•

The Testing the Usable Scan Length Method on page 2-10 uses real situation testing to adjust the usable

scan length to fit the application conditions.

Calculating the Usable Scan Length Method

Calculate usable scan length as follows (see Figure 2-9 on page 2-9):

L = 1.8 x (D+d+B) x Tan (A/2)

Table 2-1

MS1204FZY (Default) 1.17 42°

MS1204FZY (Narrow Mode) 1.17 30°

MS2204 1.53 34°

MS2204VHD 1.53 34°

Calculation Constants

Constants B A

MS3204 1.93 34°

Page 33

Installation 2 - 9

r

e

where:

D = Distance (in inches) from the front edge of the host housing to the bar code.

d = The host housing’s internal optical path from the edge of the housing to the front of the MiniScan scanner.

B = Internal optical path from the scan mirror to the front edge of the MiniScan scanner.

A = Scan angle in degrees.

NOTE Usable scan length is determined by this formula, or 90% of scan line at any working distance. This

formula is based on good quality symbols in the center of the working range and length of bar code.

Calculating the Usable Scan Length Method (Symbol MS954 Only)

Calculate usable scan length as follows (see Figure 2-9 on page 2-9):

L = 2.0 x (D+d+B) x Tan (A/2)

Table 2-2

Symbol MS954 Calculation Constants

Constants B A

MS954 0.87 47°

MS954 (Narrow Mode) 0.87 35°

where:

D = Distance (in inches) from the front edge of the host housing to the bar code.

d = The host housing’s internal optical path from the edge of the housing to the front of the MiniScan scanner.

B = Internal optical path from the scan mirror to the front edge of the MiniScan scanner.

A = Scan angle in degrees.

NOTE The Symbol MS954 does not require margin on either side of the bar code to decode. The 47° scan line

provides identical scanning performance to older minscan devices (e.g., Symbol MS923) with a scan line

of 53°.

Consider the width of the scan line at any given distance when designing a system.

Ba

Cod

Host System

MiniScan

Figure 2-9

A

B

d D

Usable Scan Length Diagram

1/2 L

L

1/2 L

Page 34

2 - 10 Symbol MiniScan MSXX04 Series Integration Guide

Testing the Usable Scan Length Method

Due to the variety of symbol sizes, densities, print quality, etc., there is no simple way to calculate the ideal symbol

distance. To op tim ize per fo rm a nc e, us e th e Testing The Usable Scan Length positioning method:

1. Measure the maximum and minimum distances at which the symbols can be read.

2. Check the near and far range on several symbols. If they are not reasonably consistent there ma y be a printing

quality problem that can degrade the performance of the system. Motorola can provide advice on how to

improve the installation.

NOTE Poor quality symbols (from bad printing, wear, or damage) may not decode well when placed in the center

of the depth of field (especially higher density codes). The scan beam has a minimum width in the central

area, and when the scanner tries to read all symbol imperfections in this area it may not decode. After a

preliminary spot is determined using good quality symbols, test several reduced quality symbols and

adjust the spot for the best overall symbol position.

3. Locate the scanner so the symbol is near the middle of the near/far range.

4. Center the symbol (left to right) in the scan line whenever possible.

5. Position the symbol so that the scan line is as near as possible to perpendicular to the bars and spaces in the

symbol.

6. Avoid specular reflection (glare ) off th e symbol by tilting the top or bottom of the symbol away from the scanner .

The exact angle is not critical, but it must be large enough so that if a mirror were inserted in the symbol

location, the reflected scan line would miss the front surface of the scanner. For the maximum allowable angles

refer to the Skew, Pitch and Roll ang les listed in each MiniScan Technical Specifications table.

7. If an additional window is to be placed between the scanner and the symbol, determine the optimum symbol

location using a representative window in the desired window po sitio n .

8. Give the scanner time to dwell on the symbol for several scans. When first enabled, the MiniScan may take two

or three scans before it reaches maximum pe rforman ce . Enable the MiniScan before the symbol is presented,

if possible.

Page 35

Installation 2 - 11

Conveyor Applications

Conveyor applications require setting the conveyor velocity to optimize the scanner’s ability to read symbols. Also

consider the orientation of the symbol with respect to the conveyor direction. Figure 2-10 on page 2-11 illustrates

the relationship of the conveyor velocity with respect to a symbol positioned perpendicular to the conveyor direction

and Figure 2-11 on page 2-12 illustrates the relationship of the conveyor velocity with respect to a symbol

positioned parallel to the conveyor direction.

Symbol is Perpendicular to Conveyor Movement

With the symbol bars perpendicular to the conveyor belt direction (Picket Fence presentation) the relationship is:

V = (R x (F-W)) / N

where: V = Velocity of the conveyor (inches/second)

R = Scan Rate (see technical specifications)

F = 80% of width of scan beam

W = Symbol Width (inches)

N = Number of scans over symbol (minimum of 10 scans)

F=Field Width

W=Symbol Width

Direction of Conveyor Perpendicular to Symbol

Scan Beam

Figure 2-10

Symbol Perpendicular To Conveyor Movement

Example

R = 640 scans per second

F = 80% of 6 in.

W = 4 in.

N = 10

V = (640 x ((0.8 x 6) - 4))) / 10 = 51.2 in./sec

Page 36

2 - 12 Symbol MiniScan MSXX04 Series Integration Guide

Symbol is Parallel to Conveyor Movement

With the symbol bars parallel to the conveyor belt direction (ladder presentation) the relationship is:

V = (R x H) / N

where: V = Velocity of the conveyor (inches/second)

R = Scan Rate of scanner (see technical specifications)

H = Symbol height

N = Number of scans over symbol (minimum of 10 scans)

H=Symbol Height

Scan Beam

Direction of Conveyor Parallel to Symbol

Figure 2-11

Symbol Parallel To Conveyor Movement

Example

Use the previous formula to calculate the number of scans fo r a specific bar code, scanner, and conveyor speed; a

minimum of 10 scans per symbol is recommended.

R = 640 scans/sec

H = 60 mil

N = 10 scans

V = (640 x .060) / 10 = 3.84 in./sec

Embedded Applications Requiring a Window

Use the following guidelines for applications that require a window in front of the MiniScan.

NOTE Motorola does not recommend placing an exit window in front of the MiniScan; however, the following

information is provided for applications that require such a window.

Window Material

Many window materials that look perfectly clear can contain stresses and distortions that can reduce scanner

performance. For this reason, only optical glass or cell-cast acrylic with an anti-reflection coating is highly

recommended. Following is a description of acrylic, and CR-39, another popular window material. T able 2-3 on

page 2-13 outlines the suggested window properties.

Page 37

Installation 2 - 13

CAUTION Consult an opto-mechanical engineer to recommend an appropriate window material and to

determine if coatings are appropriate for the specific application.

NOTE Do not use polycarbonate material.

Acrylic

When fabricated by cell-casting, acrylic has very good optical quality and low initial cost. However, protect the

surface from the environment as acrylic is susce pt ible to attack by chemicals, mechanical stresses, and UV light.

Acrylic has reasonably good impact resistance and can be ultrasonically welded.

CR-39

CR-39 is a thermal-setting plastic produced by the cell-casting process, and is commonly used in plastic eye

glasses lenses. CR-39 has excellent chemical and environmental resistance, including good surface hardness.

Typica lly it does not require hard- coating , but can be hard coated for severe environments. CR-39 has reasonably

good impact resistance and cannot be ultrasonically welded.

Chemically Tempered Float Glass

Glass is a hard material which provides excellent scratch and abrasion resistance. However, unannealed glass is

brittle. Increasing flexibility strength with minimal optical distortion requires chemical tempering. Glass cannot be

ultrasonically welded and is difficult to cut into odd shapes.

Table 2-3

Material Red cell-cast acrylic.

Spectral Transmission 85% minimum from 640 to 690 nanometers.

Thickness 0.059 ± 0.005

Wavefront Distortion (transmission) 0.2 wavelengths peak-to-valley maximum over any 0.08 in. diameter within

Clear Aperture To extend to within 0.04 in. of the edges all around.

Surface Quality 60-20 scratch/dig

Coating Both sides to be anti-reflection coated to provide 0.5% max reflectivity

Suggested Window Properties

Property Description

the clear aperture.

(each side) from 640 to 690 nanometers at nominal window tilt angle.

Coatings must comply with the hardness adherence requirements of

MIL-M-13508.

Page 38

2 - 14 Symbol MiniScan MSXX04 Series Integration Guide

Window Coatings

Table 2-4 on page 2-14 lists some exit window manufacturers and anti-reflection coaters.

Anti-Reflection Coatings

Apply an anti-reflection coating to the inside and/or out side of the window to significantly reduce the amount of light

reflected off the window, back into the scan engine. The coating can also improve the range of accept able window

positions and minimize performance degradation due to signal loss as the light pa sses through the window. Using

anti-reflection coatings on both the inside and outside of the window is high ly recommended.

Polysiloxane Coating

Polysiloxane type coatings are applied to plastic surfaces to improve the surface resistance to both scratch and

abrasion. They are usually applied by dipping, then air-drying in an oven with filtered hot air.

Table 2-4

Evaporated Coatings, Inc.

2365 Maryland Road

Willow Grove, PA 19090

(215) 659-3080

Fosta-Tek Optics, Inc.

320 Hamilton Street

Leominster, MA 01453

(978) 534-6511

Glasflex Corporation

4 Sterling Road

Sterling, NJ 07980

(908) 647-4100

Optical Polymers Int. (OPI)

110 West Main Street

Milford, CT 06460

(203)-882-9093

Window Manufacturers and Coaters

Company Discipline Specifics

Anti-reflection coater Acrylic window supplier

Anti-reflection coater

Cell-caster, hard coater,

laser cutter

Cell-caster Acrylic exit window

CR-39 cell-caster, coater,

laser cutter

CR39 exit window

manufacturer

manufacturer

CR39 exit window

manufacturer

Polycast

70 Carlisle Place

Stamford, CT 06902

800-243-9002

TSP

2009 Glen Parkway

Batavia, OH 45103

800-277-9778

acrylic cell-caster, hard

coater, laser cutter

acrylic cell-caster, coater,

laser cutter

Acrylic exit window

manufacturer

Acrylic exit window

manufacturer

Page 39

Installation 2 - 15

Embedded Window Angle and Position

If a window is placed between the MiniScan and the item to be scanned, observe the following guidelines:

•

Window Clear Opening - Make the clear opening of the window large enough so that the entire scan beam

passes through the window. Cutting off any part of the beam can result in internal reflections and degrade

decode range performance. Ensure that window placement relative to the MiniScan accounts for tolerances

on all parts involved in that assembly.

•

Window Angle - Angle the window at least 2o more than the tilt of the window on the scanner (see Table

2-5). Further tilting the window is acceptable and decreases the possibility of a secondary reflection from that

window degrading the scanner's performan ce.

•

Optical Working Range - Adding a window can reduce the working range of the scanner since there is a

signal loss when passing through window material. To minimize this reduction, use a special coating

described in Window Coatings on page 2-14. To understand the difference, test the scanner in the desired

orientation and see if the difference affects scanner performance.

Table 2-5

Secondary Window Angles

MiniScan Model

MS954

MS1204FZY, MS2204, MS2204VHD

MS3204

MiniScan Exit Window Angle

from Vertical

o

28

o

30

o

35

Minimum Secondary Window

Angle from Vertical

o

30

o

32

o

37

Page 40

2 - 16 Symbol MiniScan MSXX04 Series Integration Guide

Accessories

The following accessories are available for the MiniScan scanner, and can be found in Symbol’s Solution Builder

(ordering guide).

•

For power connection

• 110V power supply, US, p/n 50-14000-008

• 220V power supply, Europe, p/n 50-14000-009

• 100V power supply, Asia, p/n 50-14000-010

• 264V Universal power supply (also order cables below), p/n 50-14001-001

• DC line cord (power supply to scanner), p/n 50-16002-009

• AC line cord (wall outlet to power supply), p/n 23844-00-00

•

RS-232

• Female DB9 with straight connector to RS-232 host (female DB9), with trigger jack and no beeper, p/n

25-13227-XX

• Female DB9 with straight connector to RS-232 host (female DB9), with trigger jack and beeper, p/n

25-13228-XX

• Female DB9 with straight connector to RS-232 host (female DB9),

p/n 25-58918-XX

• Female DB9 with right angle connector to RS-232 host (female DB9),

p/n 25-58919-XX

• Female DB9 with straight connector to RS-232 host (female DB9), with trigger jack and no hardware

handshaking, p/n 25-63736-XX

•

Cable Adapters

• Female 25 pin D, TxD on pin 2, p/n 50-12100-378

• Female 25 pin D, TxD on pin 3, p/n 50-12100-377

• Male 25 pin D, TxD on pin 2, p/n 50-12100-380

• Male 25 pin D, TxD on pin 3, p/n 50-12100-379

•

Optional Accessories

• Push button trigger cable, p/n 25-04950-01R

• Photo sensor trigger cable, p/n 25-13176-01R (retroreflective, IR 850 nm, 7 foot range)

• Fixed-mount stand, p/n 20-60136-01R

• Mounting bracket, p/n KT-65578-01R

Page 41

Installation 2 - 17

Simple Serial Interface Software Developer's Kit (SSISDK)

The Software Developer's Kit, available from Motorola’s website, provides the software tools required to integrate

and communicate with the MiniScan scanners, including:

•

Sample Windows® program with source code

•

DLL with source code for building user applications

•

ActiveX component (including help file) for easy integration into VisualBasic programs

•

Simple Serial Interface documentation.

With over 70 programmable parameters, MiniScan scanners can be configured by scanning bar code menus, or

through the serial interface using Symbol’s Simple Serial Interface protocol.

For Windows

scanner's features and obtain maximum performance.

®

, DOS, and embedded system environments, this enables the user to take full advantage of the

Page 42

2 - 18 Symbol MiniScan MSXX04 Series Integration Guide

Page 43

Chapter 3 Scanning

Introduction

This chapter provides information on scan patterns, sca nning, triggering options, and beeper and LED definitions.

MiniScan Scan Patterns

Symbol MS1204FZY / MS954 Scan Pattern

Symbol MS1204FZY and MS954 scanners emit a single scan line to quickly decode 1D bar codes.

Figure 3-1

Single Scan Line Scan Pattern

Page 44

3 - 2 Symbol MiniScan MSXX04 Series Integration Guide

Symbol MS2204 and MS2204VHD Scan Patterns

The Symbol MS2204 and MS2204VHD generate different scan patterns (Smart Raster and High Density Single

Scan Line) based on the software command received at the interface. The raster pattern can be used to read 1D

bar codes and PDF417 symbols.

NOTE The Symbol MS2204 and MS2204VHD also support omnidirectional and semi-omn idirectional scan

patterns, but are not optimized for these patterns.

Smart Raster Scan Pattern

The Symbol MS2204 and MS2204VHD can create a single line which opens vertically to read PDF417 symbols

using the Smart Raster feature. This feature autodetects the type of bar code b eing scanned and adju sts it s pa ttern

accordingly, providing optimal performance on 1D, PDF417, GS1 DataBar, and Composite codes.

Stage 1: “Slab” Raster Pattern

Stage 2: Open Raster Pattern

Figure 3-2

Raster Scan Pattern

High Density Single Scan Line Scan Pattern

The High Density single scan line appears as a "mini" raster and scans multiple areas of

1D codes to swiftly and accurately capture data on poorly printed and damaged bar codes.

Figure 3-3

High Density Single Scan Line Scan Pattern

Page 45

Scanning 3 - 3

Symbol MS3204 Scan Patterns

The Symbol MS3204 generates four scan patterns based on the software command received at the interface.

These patterns are Smart Raster, Semi-omnidirectional, Omnidirectional, and High Density Single Scan Line. The

raster pattern can be used to read 1D bar codes and PDF417 symbols. The omnidirectio nal pattern reads 1D bar

codes in an omnidirectional manner.

Smart Raster Scan Pattern

The Symbol MS3204 can create a single line which opens vertically to read PDF417 symbols using the Smart

Raster feature. This feature autodetects the type of bar code being scanned and adjusts its pattern accordingly,

providing optimal performance on 1D, PDF417, GS1 DataBar, and Composite codes.

Stage 1: “Slab” Raster Pattern

Stage 2: Open Raster Pattern

Figure 3-4

Raster Scan Pattern

Semi-omnidirectional Scan Pattern

The semi-omnidirectional pattern is an alternative to the full omnidirectional pattern that scans highly truncated 1D

and GS1 DataBar bar codes. Present bar codes horizontally with no more than a 20

Figure 3-5

Semi-omnidirectional Scan Pattern

o

tilt.

Page 46

3 - 4 Symbol MiniScan MSXX04 Series Integration Guide

Omnidirectional Scan Pattern

The high-speed rotating omnidirectional scan pattern provides aggressive performance on 1D bar codes because

there are no “holes” in the pattern. This ensures fast throughput at the point of activity and the ability to read 1D

symbols in 360

o

of rotation, eliminating the need to orient the bar code in the field of view.

Figure 3-6

Omnidirectional Scan Pattern

High Density Single Scan Line Scan Pattern

The high density single scan line appears as a "mini" raster and scans multiple areas of

1D codes to swiftly and accurately capture data on poorly printed and damaged bar codes.

Figure 3-7

High Density Single Scan Line Scan Pattern

Scan Angle Selection

The Symbol MS1204FZY and MS954 scanners support two pre-set scan angles (see each scanner’s technical

specifications)

Selecting Scan Angle via SSI

To use SSI to select the scan angle, issue the SSI PARAM_SEND command with the NUM_SCAN_ANGLE (191)

parameter number. This is set to the default angle (182), or can be set to the alternate angle (181). Se e the Simple

Serial Interface (SSI) Programmer’s Guide (p/n 72-40451-xx) for more information.

Selecting Scan Angle via Parameter Bar Code

.

The scan angle can also be set by scanning a parameter bar code (see Scan Angle on page 10-12). Once the

parameter bar code is scanned, that scan angle setting is retained.

Operation in Blink Mode

The scan angle during Blink Mode is determined by the scan angle system parameter.

Page 47

Scanning Tips

When scanning, make sure the symbol to be scanned is within the scanning range. See Calculating the Usable

Scan Length Method on page 2-8. Align the bar code with the scan beam. The gr een decode LED light s to indicate

a successful decode.

Scan the Entire Symbol

•

The scan beam must cross every bar and space on the symbol.

•

The larger the symbol, the farther away the scanner should be positioned.

•

Position the scanner closer for symbols with bars that are close together.

Scanning 3 - 5

Position at an Angle

Do not position the scanner exactly perpendicular to the bar code. In this position, light can bounce back into the

scanner's exit window and prevent a successful decode.

Trigger Options

Continuous

The laser is enabled continuously and decode processing is continuously active. The scanner can be configured to

scan and transmit a bar code, and then not decode the same bar code or any bar code for a set pe riod of time. See

Timeout Between Decodes on page 10-18 to customize the application to the rate at which bar codes are

presented.

RIGHT

012345

WRONG

012345

Continuous

NOTE This option is not recommended during scanner programming via bar code menus.

Page 48

3 - 6 Symbol MiniScan MSXX04 Series Integration Guide

Level Trigger

The laser is enabled and decode processing begins when the trigger line is activated. Decode processing

continues until a good decode occurs, the trigger is released, or the Laser On Time expires. The laser is disabled

once decode processing is complete. The next decode attempt will not occur until the trigger line is released and

then reactivated.

Pulse Trigger

The laser is enabled and decode processing begins when the trigger line is activated. Decode processing

continues regardless of the trigger line until a good decode occurs, or until the Laser On Time expires. The la ser is

disabled once decode processing is complete. The next decode attempt will not occur until the trigger line is

released and then reactivated.

Level

Pulse

Blink

NOTE This option is supported by the Symbol MS1204FZY and MS954 only.

The laser blinks at a 25% duty cycle (reduced to 10% after 30 seconds of inactivity), until a bar code is presented.

When a bar code is presented, the laser remains on until either the bar code is decoded or removed, or the session

timeout expires. Once the bar code is decoded, the scanner will not decode it again until the bar code is removed.

Blink

Host Trigger