MC33560

Power Management and

Interface IC for Smartcard

Readers and Couplers

The MC33560 is an interface IC for smartcard reader/writer

applications. It enables the management of any type of smart or memory

card through a simple and flexible microcontroller interface. Moreover,

several couplers can be coupled in parallel, thanks to the chip select input

pin (pin #5). The MC33560 is particularly suited to low power and

portable applications because of its power saving features and the

minimum of external parts required. Battery life is extended by the wide

operating range and the low quiescent current in stand by mode. A highly

sophisticated protection system guarantees timely and controlled

shutdown upon error conditions.

• 100% Compatible with ISO 7816–3 Standard

• Wide Battery Supply Voltage Range: 1.8V < V

• Programmable V

Supply for 3V or 5V Card Operation

CC

• Power Management for Very Low Quiescent Current in Stand By

Mode (30µA max)

• Microprocessor Wake–up Signal Generated Upon Card Insertion

• Self Contained DC/DC Converter to Generate V

of Passive Components

• Controlled Power Up/Down Sequence for High Signal Integrity on

the Card I/O and Signal Lines

• Programmable Card Clock Generator

• Chip Select Capability for Parallel Coupler Operation

• High ESD Protection on Card Pins (4kV, Human Body Model)

• Fault Monitoring V

BATlow

, V

CClow

and I

CClim

• All Card Outputs Current Limited and Short Circuit Protected

• T ested Operating Temperature Range: –25°C to +85°C

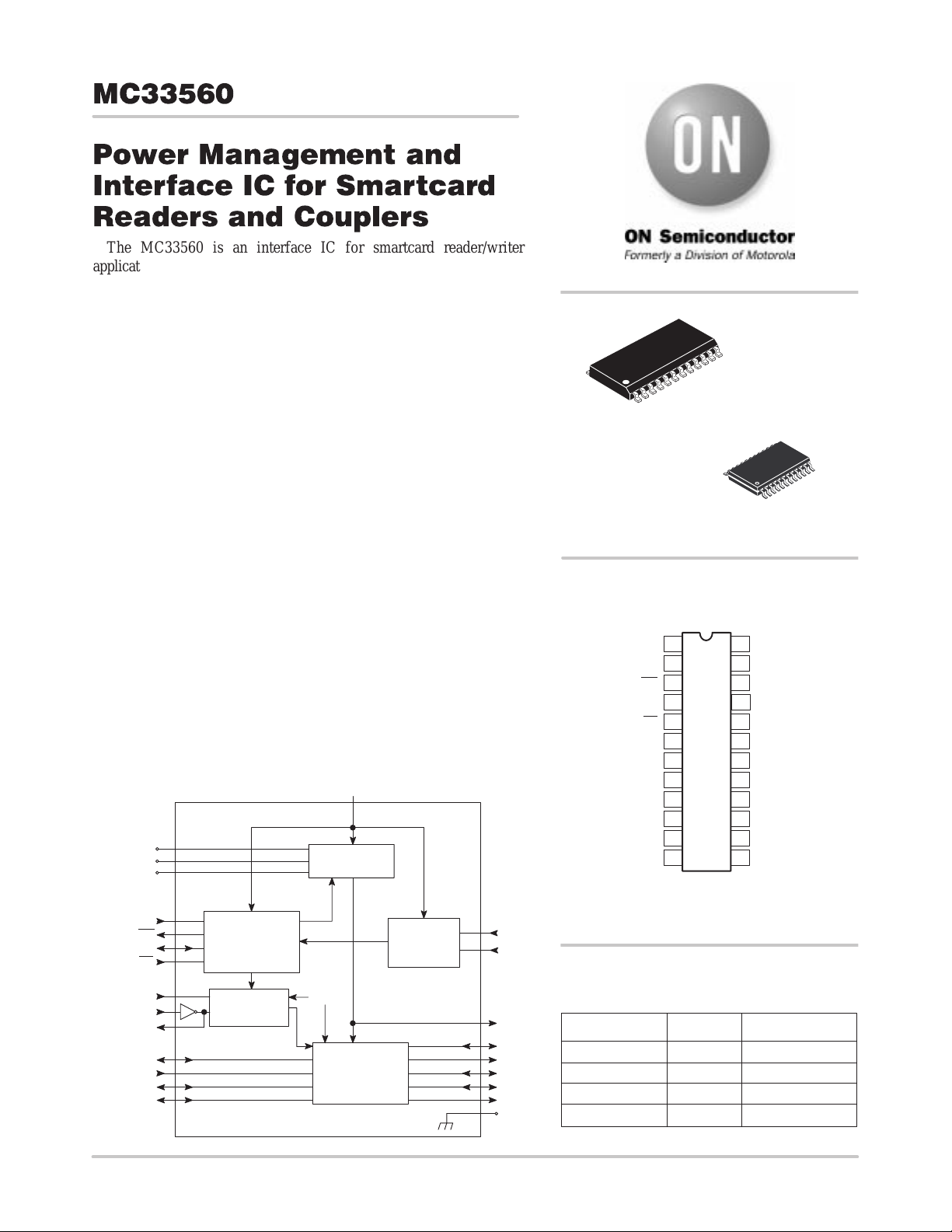

Figure 1. Simplified Functional Block Diagram

VBAT

ILIM

PGND

PWRON

INT

RDYMOD

CS

L1

POWER

MANAGER

AND

PROGRAMMING

DC/DC

CONVERTER

< 6.6V

BAT

using a Minimum

CC

CARD

DETECTOR

DELAY

CRDDET

CRDCON

24

DTB SUFFIX

http://onsemi.com

1

TSSOP–24

CASE 948H

24

PIN CONNECTIONS

124

PGND

PWRON

RDYMOD

INVOUT

ASYCLKIN

SYNCLK

CRDGND

2

INT

3

4

CS

5

RESET

6

7

IO CRDCON

8

9

10

11

CRDIO CRDRST

12

(Top View)

23

22

21

20

19

18

17

16

15

14

13

SO–24L

DW SUFFIX

CASE 751E

1

ILIM

VBAT

L1

C4

C8

CRDC8

CRDDET

CRDC4

CRDCLK

CRDVCC

SYNCLK

ASYCLKIN

INVOUT

IO

RESET

C4

C8

Semiconductor Components Industries, LLC, 1999

October, 1999 – Rev. 0

CLOCK

GENERATOR

VBAT

LEVEL

TRANSLATOR

ORDERING INFORMATION

CRDVCC

CRDIO

CRDRST

CRDC4

CRDC8

CRDCLK

CRDGND

1 Publication Order Number:

Device Package Shipping

MC33560DW

MC33560DWR2

MC33560DTB

MC33560DTBR2

SO–24WB 30 Units/Rail

SO–24WB 1000 Tape & Reel

TSSOP–24 62 Units/Rail

TSSOP–24 2500 Tape & Reel

MC33560/D

MC33560

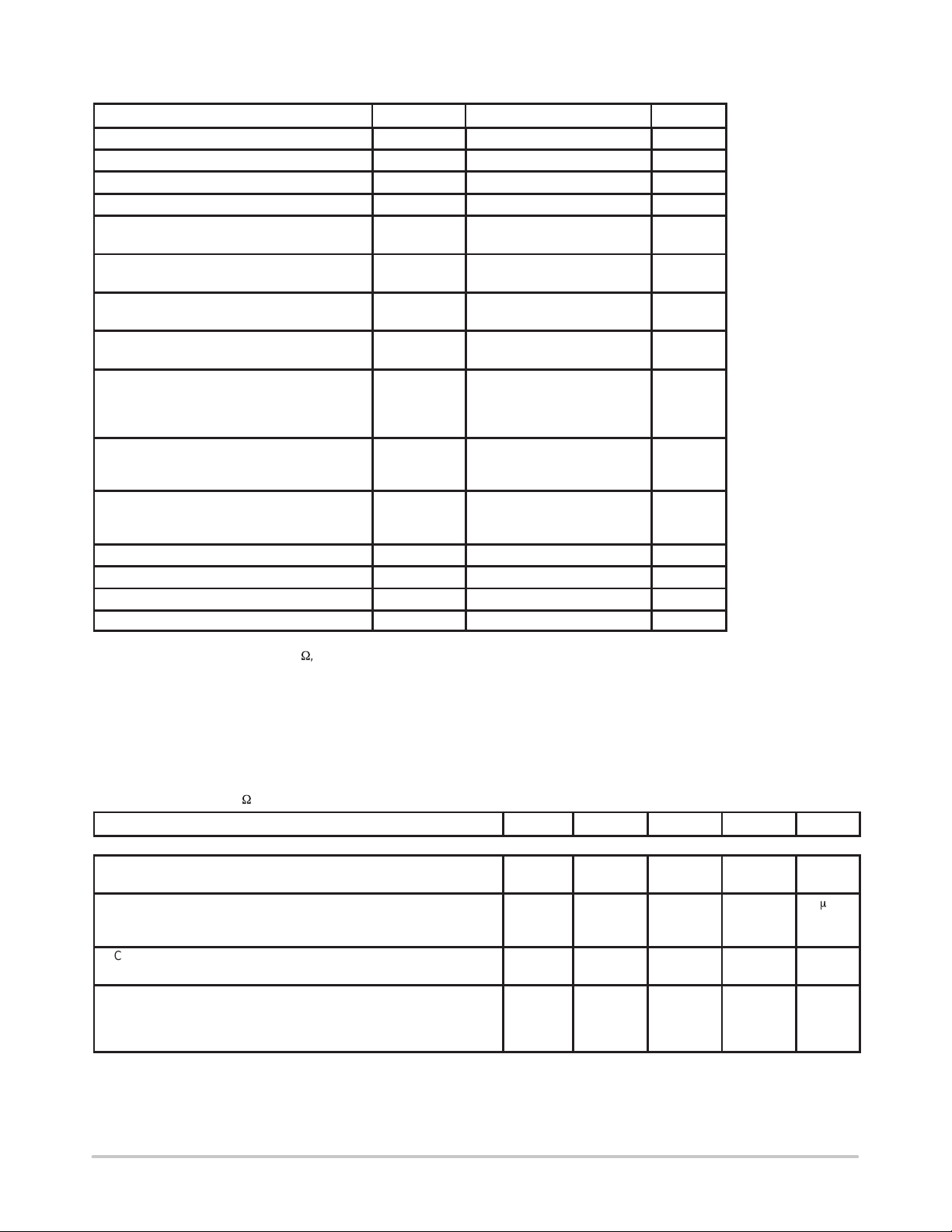

MAXIMUM RATINGS (Note 1)

Rating

Battery Supply Voltage V

Battery Supply Current I

Power Supply Voltage V

Power Supply Current I

Digital Input Pins

(2, 4, 5, 6, 7, 9, 10, 17, 18, 20, 21)

Digital Output Pins (3, 4, 8) V

Card Interface Pins (11, 13, 14, 15, 16, 19) V

Coil Driver Pin (22), ILIM (pin 24)

Power Ground (pin 1)

ESD Capability: (Note 2)

Standard Pins (2, 3, 4, 5, 6, 7, 8, 9, 10, 17, 18,

20, 21, 22, 23, 24)

Card Interface Pins (11, 13, 14, 15, 16, 19)

SO–24WB Package:

Power Dissipation @ TA = 85 °C

Thermal Resistance Junction to Air

TSSOP–24 Package:

Power Dissipation @ TA = 85 °C

Thermal Resistance Junction to Air

Operating Ambient Temperature Range T

Operating Junction Temperature Range T

Max. Junction Temperature (Note 3) T

Storage Temperature Range T

Note 1: Maximum electrical ratings are those values beyond which damage to the device may. TA = 25°C

Note 2: Human body model, R = 1500W, C = 100pF

Note 3: Maximum thermal rating beyond which damage to the device may occur

This device contains protection circuitry to guard against damage due to high static voltages or electric fields. However precautions must be

taken to avoid applications of any voltage higher than maximum rated voltages to this high impedance circuit. For proper operation, input

and output voltages should be constrained to the ranges indicated in the recommended operating conditions.

Symbol Value Unit

BAT

BAT

CC

V

I

OUT

I

OUT

Card

I

Card

V

ESD

P

R

θJAs

P

R

θJAt

Jmax

CC

IN

IN

I

L

Ds

Dt

A

stg

– 0.5 to VBAT + 0.5 but < 7

– 0.5 to VBAT + 0.5 but < 7

– 0.5 to VCC + 0.5

J

7 V

± 200 mA

6 V

± 150 mA

± 5

±10

± 25

± 200

± 100

2

4

285

140

220

180

– 40 to + 85 °C

– 40 to + 125 °C

150 °C

– 65 to + 150 °C

V

mA

V

mA

V

mA

mA

kV

kV

mW

°C/W

mW

°C/W

ELECTRICAL CHARACTERISTICS These specifications are written in the same style as common for standard

integrated circuits. The convention considers current flowing into the pin (sink current) as positive and current flowing out of the pin

(source current) as negative. (Conditions: V

85°C, L1 =47µH, R

BATTERY POWER SUPPLY SECTION

Supply Voltage Range

normal operating range extended operating range (Note 4)

MC33560 Stand By Quiescent Current

PWRON = GND, CRDCON = GND, ASYCLKIN = GND, V

all other logic inputs and outputs open

DC Operating Current

–ICC = 10mA ; VCC =5V ,V

V

undervoltage detection:

BAT

Upper Threshold

Lower Threshold

Hysteresis

Note 4: See figures 2 and 3.

=0W, CRDVCC capacitor=10µF, unless otherwise noted.)

LIM

Characteristic

= 6V

BAT

= 4V, VCC = 5V nom, PWRON = V

BAT

= 6V,

BAT

, operating mode, –ICC = 10mA, –25°C ≤ TA ≤

BAT

Symbol Min Typ Max Unit

V

BAT

I

oBAT

I

BATop

2.2

1.8

6.0

6.6

30

12.5 mA

1.6

1.4

0.2

http://onsemi.com

2

V

m

s

V

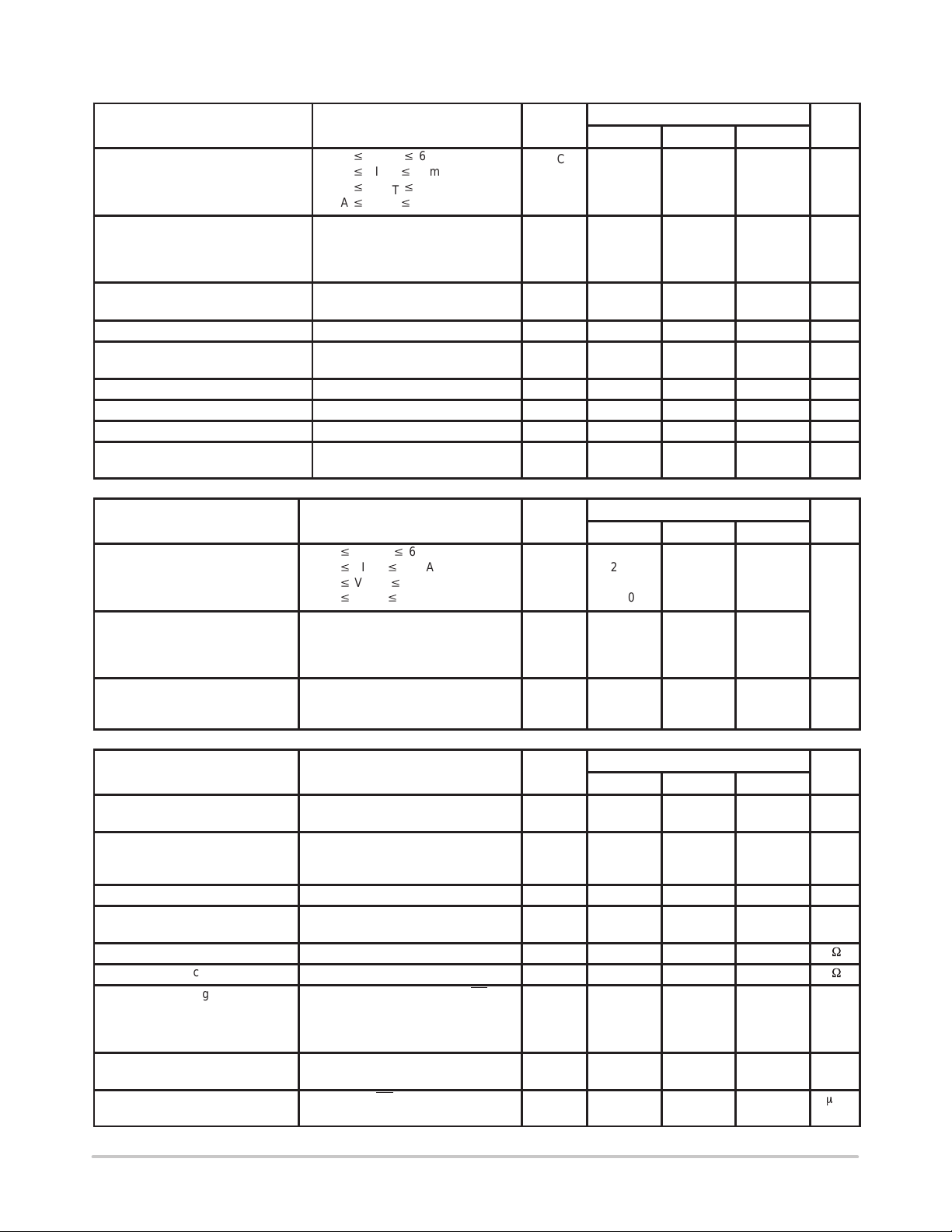

MC33560

VCC = 5V NOMINAL POWER SUPPLY SECTION

Characteristic

Output Voltage 2.2V v V

Card VCC Undervoltage Detection:

Upper Threshold

Lower Threshold

Switching Hysteresis

Peak Output Current VCC = 4V, internally limited

Current limit time–out VCC = 4V t

Start–up Current VCC = 2V; 0°C to +85°C

Low Side Switch Saturation Voltage IL = 50mA, pin 22 V

Rectifier on Saturation Voltage IL = 50mA, pin 22 to pin 13 V

Converter Switching Frequency TA = 25 °C f

Shut Down Current

(Card access deactivated)

VCC = 3V NOMINAL POWER SUPPLY SECTION (V

Characteristic

Output Voltage 2.2V v V

Card VCC Undervoltage Detection:

Upper Threshold

Lower Threshold

Switching Hysteresis

Start–up Current

Shut Down Current

(Card access deactivated)

APPLICATION INTERFACE DC SECTION (V

Characteristic

Input High Threshold Voltage

(increasing)

Input Low Threshold Voltage

(decreasing)

Switching Hysteresis pins 2, 4, 5, 6, 10, 17 V

Threshold Voltage pin 9

Pull–down resistance VIN = V

Pull–up resistance VIN = 0.5V, pin 3, 4, 5 R

Output High Voltage IOH = –2.5µA, pin 3, pin 4 for CS = H

Output Low Voltage IOL = 1.0 mA, pins 7, 20, 21

Input Leakage Current VIN = 2.5V, CS = H, pins 9, 17, 18,

1mA v –ICC v 10mA

2.5V v V

1mA v –ICC v 50mA

(RDYMOD output)

(see table 4)

VCC = 2V

PWRON = GND, VCC = 2V

pins 2, 4, 5, 6, 10, 17 V

pins 2, 5, 6, 10

pin 17

pin 4

pin18

IOH = –50µA, pins 7, 20,21

IOH = –0.2mA, pin 8

pin 4 ( in output mode)

IOL = 0.2mA, pins 3, 4, 8

20, 21

Test Conditions Symbol

v 6V

1mA v –ICC v 25mA

3.0V v V

1mA v –ICC v 60mA

(RDYMOD output)

(see table 4)

(RDYMOD = L)

PWRON = GND, VCC = 2V I

BAT

v 6V

BAT

–40°C to 0°C

= 2.5V, –ICC = 5mA)

BAT

Test Conditions Symbol

v 6V

BAT

v 6V

BAT

= 5V)

BAT

Test Conditions Symbol

–1V, pin 2, 6, 7, 10 R

BAT

Guaranteed Limits

Min Typ Max

V

CC

V

T5H

V

T5L

V

HYS5

–I

CClim

d

–I

CCst

sat22

Fsat22

sw

SD

V

CC

V

T3H

V

T3L

V

HYS3

–I

CCst

I

SD

IH

V

IL

HYST

V

TH

down

up

V

OH

V

OL

+/–Ileak 2.0

4.75

4.60

4.2

120

80 mA

80

50

80 mA

Min Typ Max

2.75

2.60

2.4

80

50

50

Min Typ Max

0.55*V

BAT

0.3*V

BAT

0.2*V

BAT

0.3*V

BAT

0.06*V

BAT

0.5*V

BAT

0.4*V

BAT

120 240 500

120 240 500

V

–1 V

BAT

5.0

5.0

VCC–0.14 V

4.5

180

160 ms

100 160 mV

400 520 mV

120 kHz

Guaranteed Limits

3.0

3.0

VCC–0.1

2.7

110

Guaranteed Limits

0.65*V

0.45*V

0.40*V

0.5*V

0.3*V

0.6*V

0.6*V

5.25

5.40

3.25

3.40

0.4 V

BAT

BAT

BAT

BAT

BAT

BAT

BAT

Unit

V

mV

mA

Unit

V

V

V

mV

mA

Unit

V

V

V

V

k

W

k

W

m

A

http://onsemi.com

3

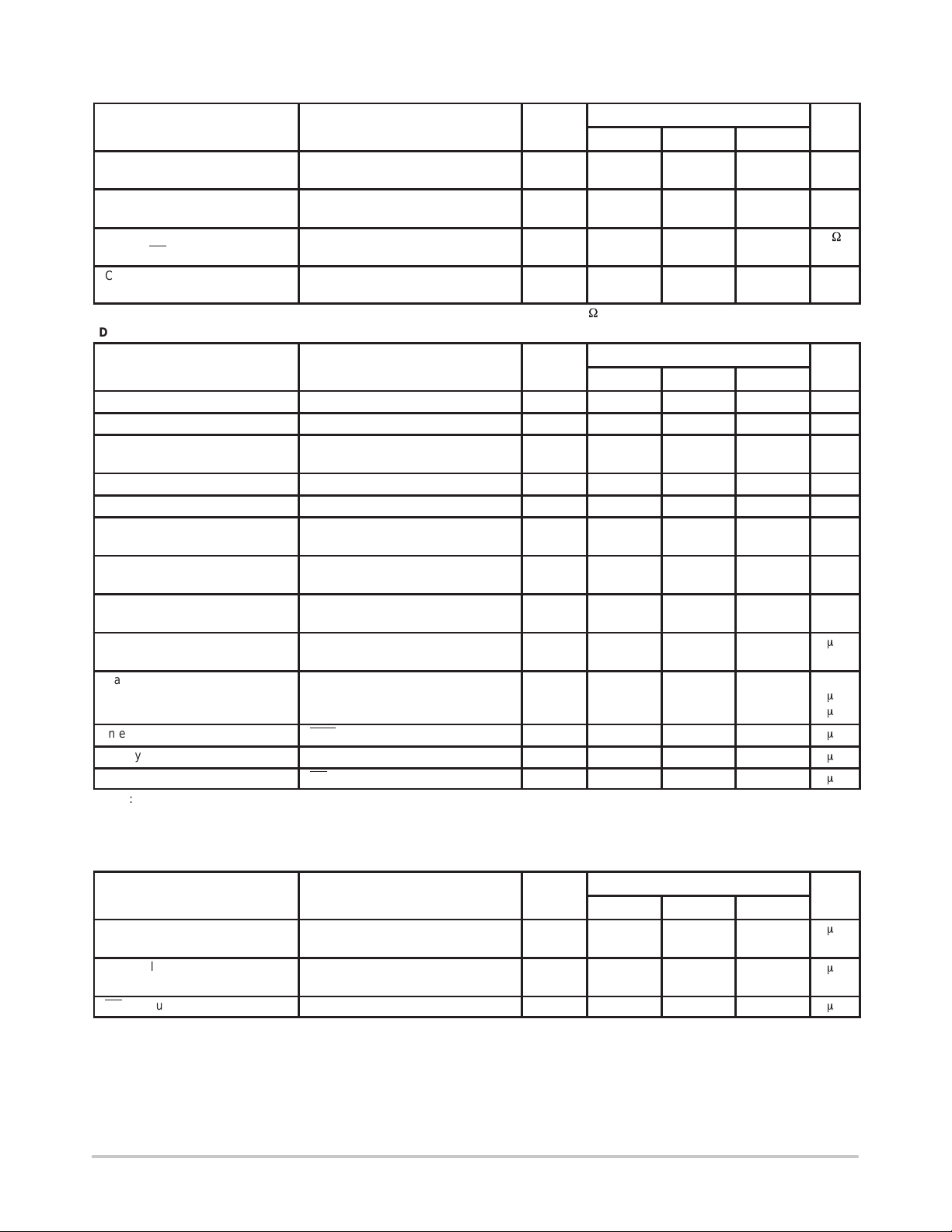

MC33560

CARD INTERFACE DC SECTION (V

Characteristic

Output High Voltage IOH = –20µA, pin 11, 16, 19

Output Low Voltage IOL = 1mA, pins 11, 16, 19

I/O Pull–up resistance, operating

mode, CS

Card pins security voltage

(Card access deactivated)

Note 5: the transistors T1 on lines IO, C4 and C8 (see figure 24) have a max Rdson of 250W.

DIGITAL DYNAMIC SECTION (V

Input Clock Frequency pin 9, duty cycle = 50% f

Card Clock Frequency pin 15 f

Card Clock Duty Cycle (Note 7) pin 15, 50% to 50% VCC ,

Card Clock Rise and Fall Time pin15, 10% ↔ 90% V

I/O Data Transfer Frequency pin [7, 11], [21, 16], [20, 19] (Note 8) f

I/O Duty Cycle pin [7, 11], [21, 16], [20, 19] (Note 8)

I/O Rise and Fall Time pin [7, 11], [21, 16], [20, 19] (Note 8)

I/O Transfer Time pin [7, 11], [21, 16], [20, 19] (Note 8)

Card Signal Sequence Interval pin 11, 14, 15, 16, 19,

Card Detection Filter Time:

Card insertion

Card extraction

Internal Reset Delay RES, VCC power up/down t

Ready Delay Time pin 4 t

PWRON low Pulse Width CS = L, pin 2 t

Note 6: Pin loading=30pF, except INVOUT=15pF

Note 7: As the clock buffer is optimized for low power consumption and hence not symmetrical, clock signal duty cycle is guaranteed for

divide by 2 and divide by 4 ratio.

Note 8: In either direction

DIGITAL DYNAMIC SECTION (V

Data Setup Time

RDYMOD, PWRON, RESET, IO

Data Hold Time

RDYMOD, PWRON, RESET, IO

CS low Pulse Width pin 5 t

=L, PWRON =H

Characteristic Test Conditions Symbol Min Typ Max Unit

Characteristic Test Conditions Symbol Min Typ Max Unit

= 5V)

BAT

Test Conditions Symbol

Min Typ Max

V

IOL = 0.2mA, pins 14, 15

IOL = 0.2mA, pins 14, 15

VOL = 0.5V , pin 11, 16, 19 18

PWRON = GND, lin=10mA, pin 11,

14, 15, 16, 19

= 5V, normal operating mode, Note 6)

BAT

fio = 16MHz

CC

50% to 50% V

10% ↔ 90% V

50% to 50% VCC , L H, H L

VCC power up/down

= 5V, programming mode, Note 6)

BAT

pin 2, 4, 6, 7 t

pin 2, 4, 6, 7 t

CC

CC

OH

V

OL

V

security

asyclk

crdclk

r

clk

t

rclk

r

t

rio

t

t

dseq

t

fltin

t

fltout

dres

drdy

won

smod

hmod

wcs

VCC –0.9 V

45 55 %

, t

fclk

io

io

, t

fio

tr

45 55 %

50

50

2.0

1.0

1.0

2.0

Guaranteed Limits

Guaranteed Limits

1.0 MHz

0.2 1.0

20

Guaranteed Limits

Unit

0.4 V

2.0 V

20 MHz

20 MHz

10 ns

150 ns

100 ns

150

150

2.0

k

W

m

s

m

s

m

s

m

s

m

s

m

s

m

s

m

s

m

s

http://onsemi.com

4

MC33560

IBATop

(

A)

I

(

A)

IBATop

M

(

A)

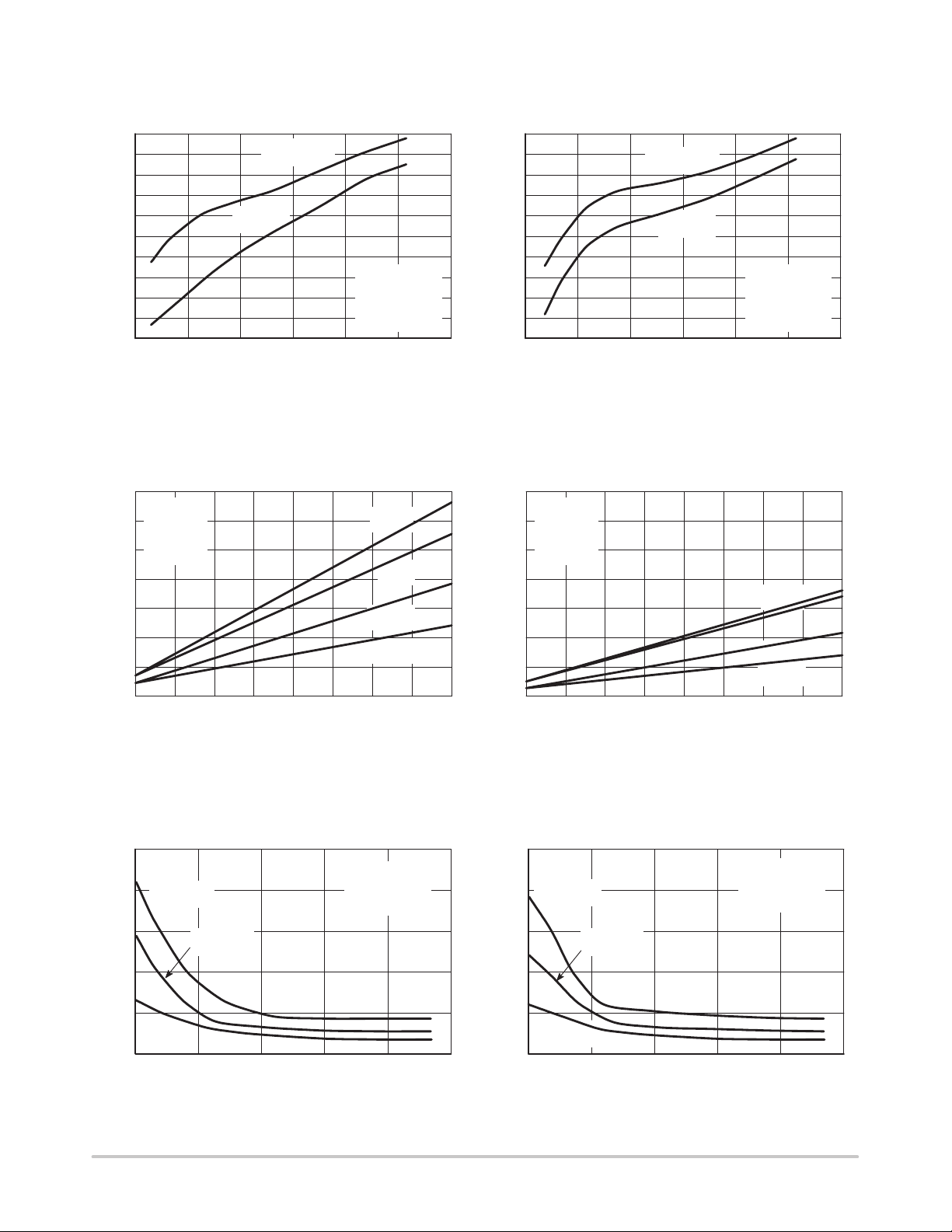

Figure 2. Maximum Battery and Card Supply

Current vs. V

200

180

160

140

120

m

100

80

60

40

20

0

1.5

2.5 3.5 7.5

ICC MAX

(V

CC

=5V)

BAT

IBATop MAX

4.5 5.5 6.5

VBAT (V)

Mode Sync

SYNCLK=4MHz

L1=47µH

Rlim=0

Figure 4. Battery Current vs. Input Clock Frequency

(ICC=0, V

14

VBAT=4V

12

L1=47µH

Rlim=0

10

ICC=0

m

8

6

4

2

0

2.0 4.0 6.0 8.0 10

0

Frequency (MHz)

BAT

=4V)

Async

Sync

Async/2

Async/4

12 14 16

Figure 3. Maximum Battery and Card Supply

200

180

160

140

120

100

I (mA)

Current vs. V

IBATop MAX

80

60

40

20

0

1.5

2.5 3.5 7.5

(VCC=3V)

BAT

ICC MAX

4.5 5.5 6.5

VBAT (V)

Mode Sync

SYNCLK=4MHz

L1=47µH

Rlim=0

Figure 5. Battery Current vs. Input Clock Frequency

(I

14

12

10

8

6

IBATop (mA)

4

2

0

=0, V

CC

VBAT=2.5V

L1=47µH

Rlim=0

ICC=0

2.0 4.0 6.0 8.0 10

0

Frequency (MHz)

BAT

=2.5V)

Async

Sync

Async/2

Async/4

12 14 16

Figure 6. Maximum Battery Current vs. R

(VCC=5V, V

250

200

L1=100µH

m

150

ax

100

50

L1=22µH

0

0

L1=47µH

12

Rlim (ohms)

=4V)

BAT

Mode Sync

SYNCLK=4MHz

VBAT=4V

34

LIM

5

Figure 7. Maximum Battery Current vs. R

250

200

150

100

IBATop Max (mA)

50

L1=22µH

0

0

(VCC=3V, V

L1=100µH

L1=47µH

12

Rlim (ohms)

BAT

=2.5V)

LIM

Mode Sync

SYNCLK=4MHz

VBAT=2.5V

34

5

http://onsemi.com

5

MC33560

Figure 8. Maximum Card Supply Current

vs. R

120 120

L1=100µH

100

80

60

ICC Max (mA)

40

20

L1=22µH

0

0

12

(VCC =5V, V

LIM

L1=47µH

Rlim (ohms)

=4V)

BAT

Mode Sync

SYNCLK=4MHz

VBAT=4V

34

5

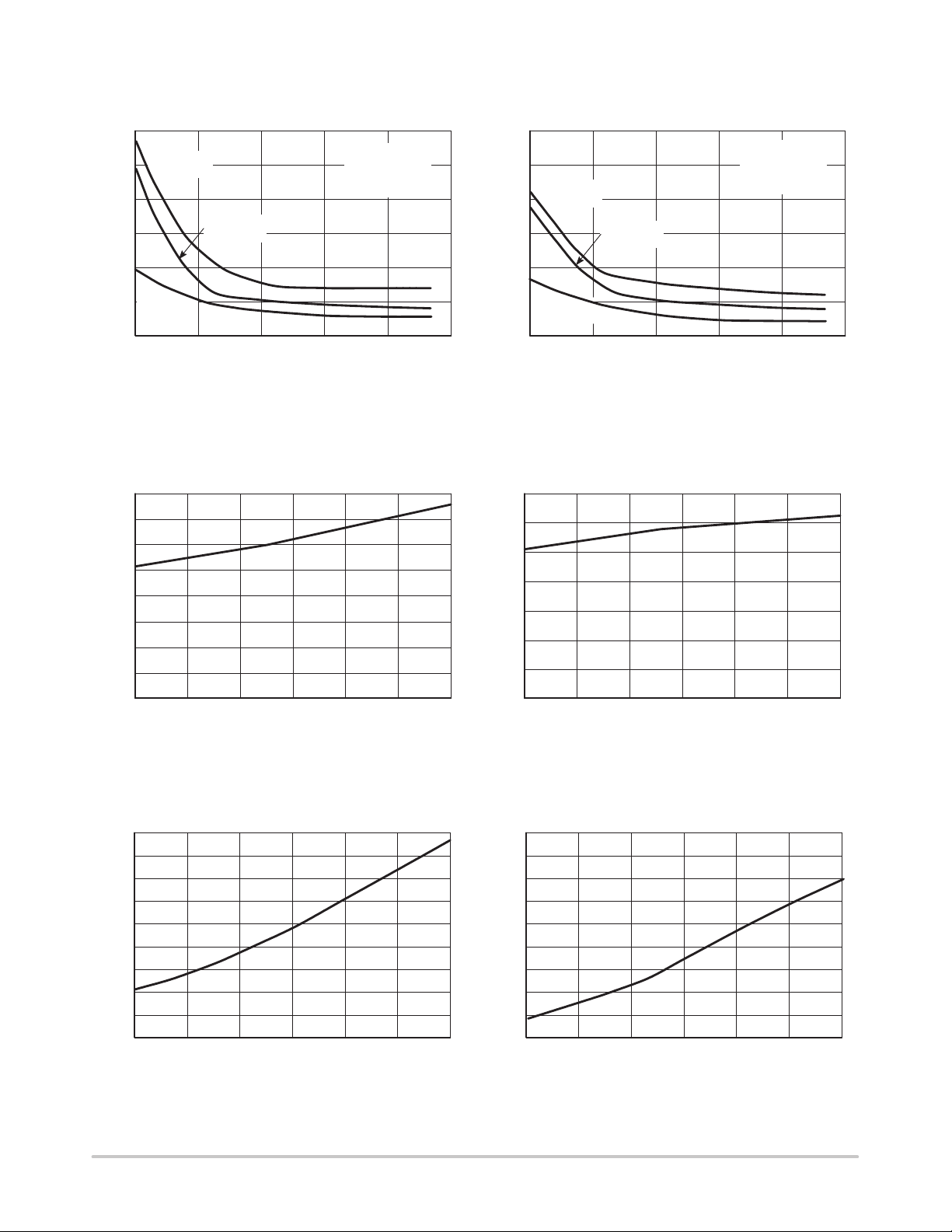

Figure 10. Low Side Switch Saturation Voltage

(I

=50mA) vs. Temperature

L

0.08

0.07

0.06

0.05

0.04

0.03

0.02

Low Side Switch Saturation Voltage (V)

0.01

0.00

–25

–5 15 9535 55 75

TA, Ambient Temperature (°C)

100

80

60

ICC Max (mA)

40

20

L1=22µH

0

0

0.35

0.30

0.25

0.20

0.15

0.10

Rectifier On Saturation Voltage (V)

0.05

0.00

–25

Figure 9. Maximum Card Supply Current

vs. R

L1=100µH

12

(VCC =3V, V

LIM

L1=47µH

Rlim (ohms)

=2.5V)

BAT

Mode Sync

SYNCLK=4MHz

VBAT=2.5V

34

Figure 11. Rectifier On Saturation Voltage

(I

=50mA) vs. Temperature

L

–5 15 9535 55 75

TA, Ambient Temperature (°C)

5

Figure 12. Card Detection (insertion) filter time

vs. T emperature

115

110

105

µ

100

95

90

85

tfltin, Filter Time ( s)

80

75

70

–5 15 9535 55 75–25 –5 15 9535 55 75–25

TA, Ambient Temperature (°C) TA, Ambient Temperature (°C)

115

110

105

µ

100

95

90

85

tfltout, Filter Time ( s)

80

75

70

http://onsemi.com

6

Figure 13. Card Detection (extraction) filter time

vs. T emperature

MC33560

Figure 14. Pull Down Resistance vs. T emperature

350

330

W

310

290

270

250

230

210

Pull Down Resistance (k )

190

170

150

–25

–5 15 7535 55

TA, Ambient Temperature (°C)

Figure 15. Transition from 5V to 3V Card Supply Figure 16. Transition from 3V to 5V Card Supply

95

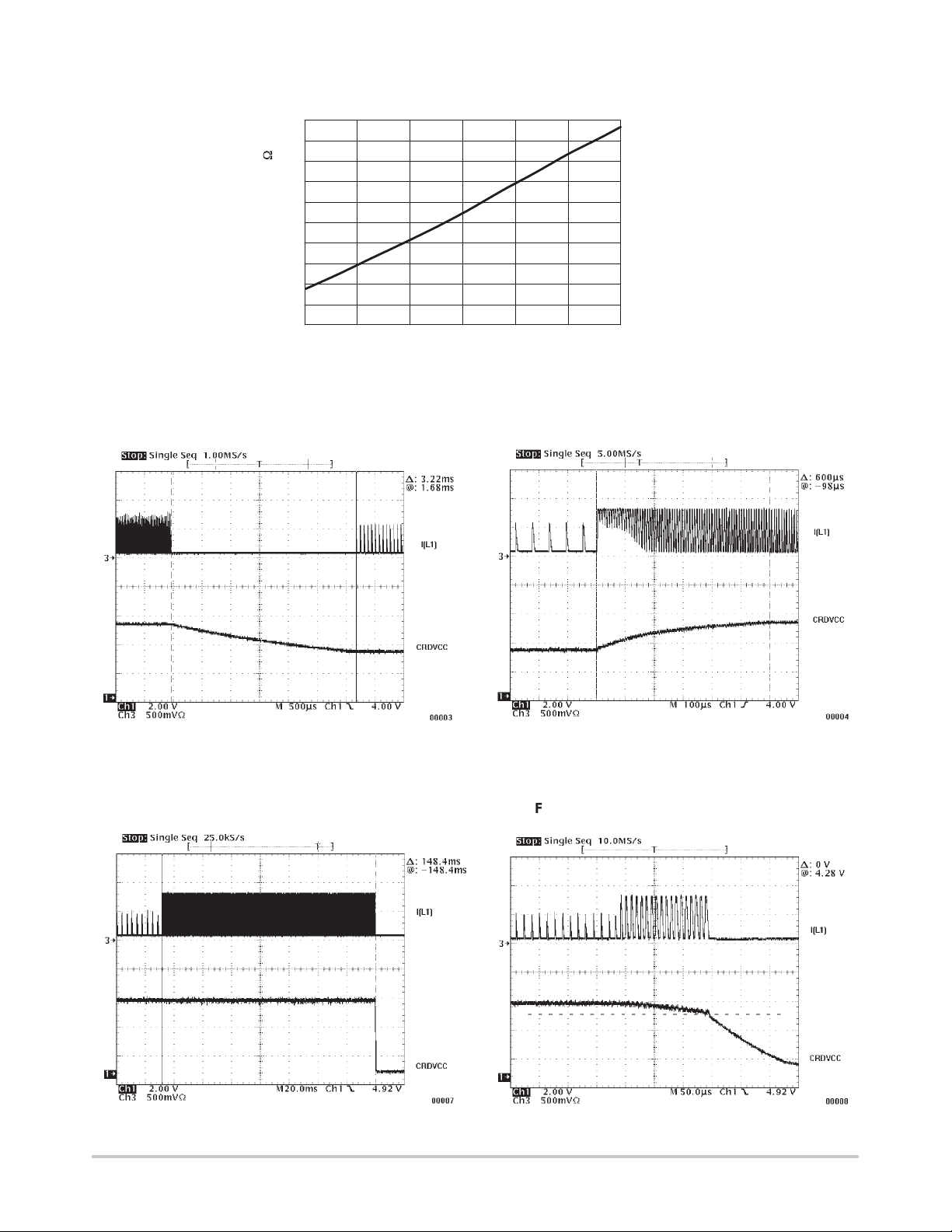

Figure 17. Overcurrent Shutoff (t

=160ms)

d

http://onsemi.com

7

Figure 18. Undervoltage Shutoff (V

T5L

=4.6 V)

CS

PWRON

INT

RDYMOD

VBAT

240 k

240 k

VBAT

240 k

VBAT

240 k

VBATOK

MC33560

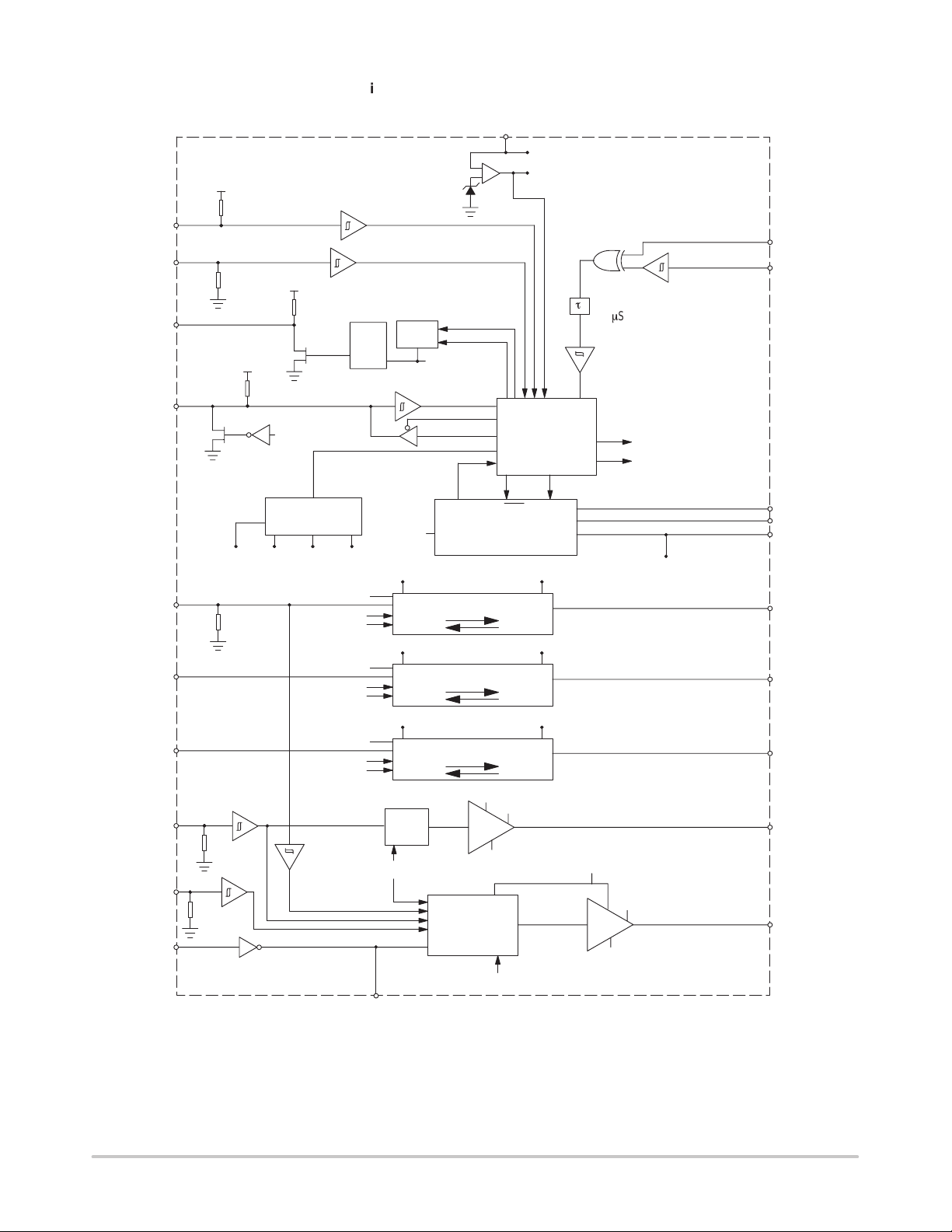

Figure 19. Functional Block Diagram

VBAT

VBAT

VBATOK

CS

PWRON

CS

CARD

CRDVCC

POWER

MANAGEMENT

LOGIC AND

PROGRAMMING

FAUL T

S

Q

LOGIC

R

CRDCON

CRDDET

DELAY

t

50 mS

PROGRAM

CARDENABLE

RESET

SYNCLK

ASYCLKIN

C4

C8

CARD PINS

SEQUENCER

SEQ2 SEQ3 SEQ4

SEQ1

VBAT

IO

240 k

SEQ1

CARDENABLE

VBATOK

VBAT

SEQ3

CARDENABLE

VBATOK

VBAT

SEQ3

CARDENABLE

VBATOK

DATA

LATCH

240 k

CARDENABLE

240 k

FAULT ON/OFF 3V/5V

VBAT

DC/DC CONVERTER

BIDIRECTIONAL

I/O

BIDIRECTIONAL

I/O

BIDIRECTIONAL

I/O

CLOCK

GENERATOR

AND

PROGRAMMING

VBAT

LEVEL

SHIFT

SEQ4

CRDVCC

CRDVCC

CRDVCC

CRDVCC

VBAT

LEVEL

SHIFT

CRDVCC

CRDVCC

ILIM

L1

CRDVCC

CRDIO

CRDC4

CRDC8

CRDRST

CRDCLK

SEQ2

INVOUT

PROGRAM

http://onsemi.com

8

MC33560

Table 1: PIN FUNCTION DESCRIPTION

Pin Symbol Type Name/Function

CONTROLLER INTERFACE

2 PWRON INPUT

pull down

3 INT OUTPUT

pull up

4 RDYMOD I/O & pull up This bidirectional pin has tri–state output and schmitt trigger input.

5 CS INPUT pull up This is the MC33560 chip select signal. Pins 2, 6, 7, 10, 20, 21 are disabled when CS=H. When

6 RESET INPUT

pull down

7 IO I/O This pin connects to the Serial I/O port of a microcontroller. A bi–directional level translator

8 INVOUT CLK

OUTPUT

9 ASYCLKIN CLK INPUT

high impedance

10 SYNCLK CLK INPUT

pull down

20 C8 I/O General purpose input/output. It has the same behavior as I/O, except for programming. It can

21 C4 I/O General purpose input/output. It has the same behaviour as I/O, except for programming. It

CARD INTERFACE

11 CRDIO I/O This pin connects to the serial I/O pin of the card connector. A bidirectional level translator

14 CRDRST OUTPUT This pin connects to the RESET pin of the card connector. A level translator adapts the

15 CRDCLK OUTPUT This pin connects to the CLK pin of the card connector. The CRDCLK signal is the output of

16 CRDC4 I/O General purpose input/output. It has the same behavior as CRDIO. It can be connected to the

17 CRDDET INPUT high

impedance

This pin is used to start operation of the internal DC/DC converter.

In programming mode, this pin is used to set the ”Output Voltage” switch. (see table 2).

This open collector pin indicates a change in the card presence circuit status. When a card is

inserted or extracted, the pin goes to logic level ”0”. The signal is reset to logic level ”1” upon

the rising edge of CS

application, two or more INT

poll all the MC33560s to identify which slot was detected.

* When RDYMOD is forced to 0, the MC33560 can be set to programming mode by a

negative transition on CS

* When RDYMOD is connected to a high impedance, the MC33560 is in normal operating

mode, and RDYMOD is in output mode (see tables 2 and 4):

– With CS

– With CS

RDYMOD=L, the MC33560 enters programming mode upon the falling edge of CS

20)

The signal present at this input pin is translated to pin 14 (the card reset signal) when CS=L.

The signal on this pin is latched when CS

table 2).

adapts the serial I/O signal between the smartcard and the microcontroller. The level

translator is enabled when CS

used in programming mode. (see table 2)

The ASYCLKIN (pin 9) signal is buffered and inverted to generate the output signal INVOUT.

This output is used for multislot applications, where the ASYCLKIN inputs and INVOUT

outputs are daisy–chained (see the multislot application example in figure 33).

This pin can be connected to the microcontroller master clock or any clock signal for

asynchronous cards. The signal is fed to the internal clock selector circuit, and is translated to

CRDCLK at the same frequency, or divided by 2 or 4, depending on programming (see table

3).

This function is used for communication with synchronous cards, and the pin is generally

connected to the controller serial interface clock signal. The signal is fed to the internal clock

selector circuit, and is translated to CRDCLK upon appropriate programming of the MC33560

(see table 3). When selected at programming, the signal on this pin is latched when CS

be connected to abidirectional port of the microcontroller. The level translator is en abled

when CS=L, and the signal is latched whenCS=H. (compare with pin 19)

can be connected to a bidirectional port of the microcontroller. The level translator is enabled

when CS

adapts the serial I/O signal between the card and the microcontroller (compare with pin 7)

RESET signal driven by the microcontroller (compare with pin 6).

the clock selector circuit.The clock selection is programmed using pins 2, 6 and 7 with

RDYMOD forced to ”0”.

C4 pin of the card connector.

This pin connects to the card detection switch of the card connector. Card detection phase is

determined with pin 18. This pin needs an external pull–up or pull–down resistor to operate

properly.

=L and PWRON=H, RDYMOD indicates the status of the DC/DC converter.

=L and PWRON=L, RDYMOD indicates the status of the card detector.

=L, and the signal is latched when CS=H. (compare with pin 16)

or upon the rising edge of PWRON. In the case of a multislot

outputs are connected together and the microcontroller has to

.

(see figure

=H. This pin is also used in programming mode (see

=L. The signal on thispin is latched when CS=H. This pin is also

=H.

http://onsemi.com

9

MC33560

Pin Name/FunctionTypeSymbol

CARD INTERFACE

18 CRDCON INPUT high

impedance

19 CRDC8 I/O General purpose input/output. It has the same behavior as CRDIO. It can be connected to the

CURRENT LIMIT AND THERMAL PROTECTION

1 PGND POWER This pin is the return path for the current flowing into pin 22 (L1). It must be connected to

12 CRDGND POWER This pin is the signal ground. It must be connected to the ground pin of the card connector. It

13 CRDVCC POWER This pin connects to the V

22 L1 POWER This pin connects to an external inductance for the DC/DC converter. Please refer to the

23 VBAT POWER This pin is connected to the supply voltage. Logic level ”1” of pins 2 to 10, 17, 18, 20 and 21 is

24 ILIM POWER This pin can be connected to the PGND pin, or to a resistor connected to PGND, or left open,

This pin connects to PGND or VBAT, or possibly to an output port of the microcontroller. With

this pin set to a logic “0”, the presence of a card is signalled with a logic ”1” on pin 17. With

this pin set to a logic ”1”, the presence of a card is signalled with a logic ”0” on pin 17.

C8 pin of the card connector

CRDGND using appropriate grounding techniques.

is the reference level for all analog and digital signals.

pin of the card connector. It is the reference level for a logic ”1”

of pins 11, 14, 15, 16 and 19.

description of the DC/DC converter functional block.

referenced to V

minimum value.

depending on the peak coil current needed to supply the card.

BAT

CC

. Operation of the MC33560 is inhibited when V

is lower than the

BAT

PROGRAMMING AND STATUS FUNCTIONS

The MC33560 features a programming interface and a status interface. Figure 20 shows how to enter and exit programming

mode; table 2 shows which pins are used to access the various functions.

Figure 20. MC33560 Programming Sequence

RDYMOD (in)

CS

PWRON

RESET

IO

ENTER

PROGRAMMING

MODE

Table 2: PIN USE FOR PROGRAMMING AND STATUS FUNCTIONS

Programs

CRDVCC

TO 3V/5V

RDYMOD

(in/out)

CS (in) rising edge 0 rising edge rising edge 0 0

PWRON 0/1 0/1 Programs CRDVCC Programs CRDVCC 0 or Hi–z 1

RESET (in) Programs CLK

IO (in) Programs CLK

Force to 0 READ Force to 0 Force to 0 READ READ

input/divide ratio

input/divide ratio

Select VCC

ON/OFF

NOT USED 0/1 0/1 NOT USED NOT USED

NOT USED 0/1 0/1 NOT USED NOT USED

PROGRAM DATA VALUE

PROGRAM DATA VALUE

PROGRAM DATA VALUE

Select

Clock Input

LATCH

PROGRAM

VALUE

Program ASYCLKIN

Divide Ratio

PROGRAMMING

EXIT

MODE

Poll Card

Status

Poll CRDVCC

Status

http://onsemi.com

10

MC33560

CARD VCC AND CARD CLOCK PROGRAMMING

The CRDV

frequency and to select 3V or 5V CRDV

options. The default power reset condition is state 4 (synchronous clock and CRDV

output variable in programming mode at the positive transition of CS (see figure 20).

Table 3 : CARD VCC AND CARD CLOCK TRUTH TABLE

STATE# PWRON RESET IO CRDVCC CRDCLK

Note : Card clock integrity is maintained during all frequency commutations (no spikes).

State 4 is the default state at power on.

DC/DC CONVERTER AND CARD DETECTOR STA TUS

The MC33560 status can be polled when

significance of the status message is described in table 4.

and ASYCLK programming options allow the system clock frequency to be matched to the card clock

CC

0 L L L 3V SYNCLK

1 L L H 3V ASYCLKIN/4

2 L H H 3V ASYCLKIN/2

3 L H L 3V ASYCLKIN

4 H L L 5V SYNCLK

5 H L H 5V ASYCLKIN/4

6 H H H 5V ASYCLKIN/2

7 H H L 5V ASYCLKIN

supply. Table 3 shows the values of PWRON, RESET and IO for the possible

CC

CS=L. Please consult table 2 for a description of input and output signals.The

=5V). All states are latched for each

CC

Table 4 : RDYMOD STATUS MESSAGES

PWRON

(input)

LOW LOW No card

LOW HIGH Card present

HIGH LOW DC/DC converter overload

HIGH HIGH DC/DC converter OK

RDYMOD

(output)

Message

http://onsemi.com

11

MC33560

DET AILED OPERATING DESCRIPTION

INTRODUCTION

The MC33560 smartcard interface IC has been designed

to provide all necessary functions for safe data transfers

between a microcontroller and a smartcard or memory card.

A card detector scans for the presence of a card and

generates a debounced wake–up signal to the

microcontroller.

Communication and control signal levels are translated

between the digital interface and the card interface by the

voltage level translator, and the card clock is matched to the

system clock frequency by the programmable card clock

Figure 21. MC33560 Operating Modes

CS: FALLING EDGE

STAND BY MODE

CS = H

PWRON = L

RDYMOD: 0 AND

CS: FALLING EDGE

RDYMOD: RISING EDGE

PROGRAMMING MODE

CS = L

RDYMOD = L

OPERATING MODES

CS: RISING EDGE

CS: 1 AND

ACTIVE MODE

CS = L

PWRON = L

CS: 0 AND

PWRON: RISING EDGE

ISO START SEQUENCE

The MC33560 has five operating modes:

⋅ stand by

⋅ programming

⋅ active

⋅ transaction

⋅ idle

The transitions between these different states are shown in

figure 21 above.

STAND BY MODE

Stand by mode allows the MC33560 to detect card

insertion and monitor the power supply while keeping the

power consumption at a minimum. It is obtained with CS

=H

and PWRON=L.

When the MC33560 detects a card, INT is asserted low to

wake up the Microcontroller.

PROGRAMMING MODE

The programming mode allows the user to configure the

card V

and the card clock signal for his specific

cc

application. The card supply , CRDVcc, can be programmed

to 3V or 5V, and the card clock signal can be defined to be

either synchronous, or asynchronous divided by 1, 2 or 4.

Programming mode is obtained with RDYMOD=L

followed by a negative transition on CS

. The programming

options are shown in table 3. Programmed values are latched

on a positive transition of CS

ACTIVE MODE

with RDYMOD=L.

In active mode, the MC33560 is selected, the RDYMOD

pin becomes an output, and the MC33560 status can be

polled. Power is not applied to the card.

generator. The power management unit enables the DC/DC

converter for card power supply, supervises the power

up/down sequence of the card’s I/O and signal lines, and

keeps the power consumption very low in stand by mode.

All card interface pins have adequate ESD protection, and

fault monitoring (V

BATlow

, V

CClow

, I

CClim

) guarantees

hazard–free card reader operation.

Several MC33560s can be operated in parallel, using the

same control and data bus, through the use of the chip select

signal

CS.

ERROR

ISO STOP SEQUENCE

PWRON: FALLING EDGE

OR ERROR CONDITION

TRANSACTION MODE

CS = L

PWRON = H

CONDITION

IDLE MODE

CS = H

PWRON = H

RDYMOD: 0 AND

CS: FALLING EDGE

RDYMOD: RISING EDGE

PROGRAMMING MODE

CS = L

RDYMOD = L

CS: 1 AND

The microcontroller polls the MC33560 by asserting

CS=L and reading the RDYMOD pin.

If a card is present, the microcontroller starts the DC/DC

converter by asserting PWRON=H. This starts the

automatic power on sequence: when CRDV

undervoltage level (V

T5H

or V

T3H

reaches the

cc

, depending on

programming), the card sequencer validates CRDIO,

CRDRST, CRDCLK, CRDC4, CRDC8 pins according to

the ISO7816–3 sequence (see figure 26). The MC33560 is

now in transaction mode, and the system is ready for data

exchange via the three I/O lines and the RESET

TRANSACTION MODE

line.

In transaction mode, the MC33560 maintains power and

the selected clock signal applied to the card, and the levels

of the IO, RESET, C4

and C8 signals between the

microcontroller and the card are translated depending on the

supply voltages V

BAT

and V

CC

.

The DC/DC converter status can be monitored on the

RDYMOD pin.

IDLE MODE

Idle mode is used when maintaining a card powered up

without communicating with it. When an asynchronous

clock is used, the selected clock signal is applied to the card

POWER DOWN OPERATION

Power–down can be initiated by the controlling

microprocessor, by stopping the DC/DC converter with

PWRON=L while CS=L, or by the MC33560 itself when

an error condition has been detected (CRDV

undervoltage,

cc

overcurrent longer than 160ms typ., overtemperature, “hot”

http://onsemi.com

12

MC33560

card extraction). The communication session is terminated

in a given sequence defined in ISO7816–3.

The MC33560 then goes into active mode, in which its

status can be polled.

Stand by mode is reached by deselecting the MC33560

(CS=H).

FUNCTIONAL BLOCKS

CARD DETECTOR

This block monitors the card contact CRDDET (during

insertion and extraction), filters the incoming waveform and

generates an interrupt signal INT

after each change. In order

to identify which coupler activated the INT line

(multicoupler application) the microcontroller scans both

circuits via CS and reads the RDYMOD pin.

The programming input CRDCON tells the level detector

which type of mechanical contact is implemented (normally

open or normally closed). Special care is taken to hold the

current consumption very low on this part of the circuit

which is continuously powered by the VBAT supply.

The CRDDET

pin has high impedance input, and an

external resistor must be connected to pull–up or pull– down,

depending on CRDCON. This resistor is chosen according to

the maximum leakage current of the card connector and the

PCB.

The card detector has an internal 50µs debouncing delay .

The micro controller has to insert an additional delay (in the

ms range) to allow the card contacts to stabilize in the card

connector before setting PWRON

=H.

When the card detector circuit detects a card extraction, it

activates the power–down sequence and stops the converter,

regardless of the PWRON

signal. The 50µs delay of the

debouncer is enough to ensure that all card signals have

reached a safe value before communication with the card

takes place.

CARD STATUS

The controlling microprocessor is informed of the

MC33560 status by interrupt and by polling. When a card is

extracted or inserted, the INT line is asserted low. The

interrupt is cleared upon the rising edge of CS

or upon the

rising edge of PWRON (INT line set to high state).

The microprocessor can poll the status at any time by

reading the RDYMOD pin with proper PWRON setting

(see tables 2 and 4 ).

Since INT

resistor (240k

and RDYMOD have a high value pull–up

W

typ.), their rise time can be as long as 10µs

if parasitic capacitance is high and no other pull–up circuitry

is connected.

POWER MANAGER

The task of the power manager is to activate only those

circuit functions which are needed for a determined operating

mode in order to minimize power consumption (see figure

19).

In stand by mode (PWRON=L) the power manager keeps

only the ”card present” detector alive. All card interface pins

are forced to ground potential.

In the event of a power–up request from the

microcontroller

(PWRON L to H transition, CS=L) the

power manager starts the DC/DC converter. As soon as the

CRDVCC supply reaches the operating voltage range, the

circuit activates the card signals in the following sequence:

CRDVCC, CRDIO, CRDCLK, CRDC4/C8, CRDRST

At the end of the transaction

(PWRON reset to L, CS=L)

or forced card extraction, the CRDVCC supply powers

down and the card signal deactivation sequence takes place:

CRDRST, CRDC4/C8, CRDCLK, CRDIO, CRDVCC

When CS

=L, the bi–directional signal lines (IO, C4 and

C8) are put into high impedance state to avoid signal

collision with the microcontroller in transmission mode.

BATTERY UNDERVOLTAGE DETECTOR

The task of this block is to monitor the supply voltage, and

to allow operation of the DC/DC converter only with valid

voltage (typically 1.5 V). The comparator has been designed

to have stability better than 20mV in the temperature range.

DC/DC CONVERTER

Upon request from the power manager, the DC/DC

converter generates the CRDVCC supply for the smartcard.

The output voltage is programmable for 3V or 5V (see table

3) to guarantee full cross compatibility of the reader for 5V

and 3V smartcards. The wide voltage supply range, 1.8V <

V

< 6.6V, accommodates a broad range of coupler

BAT

applications with different battery configurations (single

cell or multiple cells, serial or parallel connections).

The CRDVCC is current–limited and

short–circuit–proof.To avoid excessive battery loading

during a card short–circuit, a current integration function

forces the power–down sequence (see figure 28). To retry

the session, the microprocessor works through the power on

sequence as defined in the power manager section.

DC/DC Converter operating principles

The DC/DC converter architecture used in the MC33560

allows step–up and step–down voltage conversion to be

done. The unique regulation architecture permits an

automatic transition from step–up to step–down, and from

zero to full load, without affecting the output characteristics.

DC/DC Converter Description: The converter

architecture is very similar to the boost architecture, with an

active rectifier in place of the diode. The switching transistor

is connected to ground through a resistor network in order to

adjust the maximum peak current (see figure 22). A transistor

connected to the converter output

(CRDVCC) forces this pin

to a low voltage when the converter is not operating. This

prevents erratic voltage supply to the smartcard when not in

use.

http://onsemi.com

13

MC33560

The MC33560 has a built in oscillator; the DC/DC

converter requires only one inductor and the output filtering

capacitor to operate.

Step–Up Operation: When the card supply voltage is

lower than the battery voltage, the converter operates like a

boost converter; the active rectifier behavior is similar to

that of a diode.

Step–Down Operation: When the card supply voltage is

higher than the battery voltage, the rectifier control circuit

puts the power rectifying transistor in conduction when the

L1 voltage reaches V

BA T+VFSA T22

. The voltage across the

rectifying transistor is higher than in step–up operation. The

efficiency is lower, and similar to a linear regulator.

Figure 22. DC/DC Converter Functional Block

VBAT

L1

PWN

FEED

CLOCK OFF STOP

BACK

ILIMCOMP

DIGITAL

FILTER

ON /OFF

ON /OFF

OVER TEMP

DETECTION

–

+

LOGIC

AND

COUNTER

Low Side

Switch

120 mV

2

W

PGND ILIM

VBATOK

CONVERTER

FAULT

Fault Detection: The DC/DC converter has several

features that help to avoid electrical overstress of the

MC33560 and of the smartcard, and help to ensure that data

transmission with the smartcard occurs only when its supply

voltage is within predetermined limits. These functions are:

⋅ overtemperature detection,

⋅ current limitation, and

⋅ card supply undervoltage detection.

The level at which current will be limited is defined by the

maximum card supply current programmed with the

external components L1 and RLIM.

The undervoltage detection levels for 3V and 5V card

supply are preset internally to the MC33560.

Rectifier Switch CRDVCC

Active pull–down

switch

RECTIFIER

CONTROL

Internal

0.5

W

resistors

RLIM (external)

–

UNDER VOLTAGE

+

+

ERROR

AMP.

–

CRDGND

DETECTOR

VREF

ON /OFF

3V/5V

CRDGND

ON /OFF

The overcurrent and undervoltage protection features are

complementary, and will shut the circuit off either if the

overcurrent is high enough to bring the CRDVCC output

below the preset threshold, either after 160ms (typ.)

In addition, the DC/DC converter will be allowed to start

only if the battery supply voltage is high enough to allow

normal operation (1.8V).

The undervoltage comparator has a hysteresis and a delay

of typically 20ms to ensure stable operation. The current

detector is a comparator associated with two resistors: one

2W attached to PGND

and usually connected to analog

ground, and a 0.5W attached to ILIM, usually connected to

ground through an external resistor to adjust the maximum

peak current. The voltage developed across this resistor

network is then compared to a 120mV (typical) reference

voltage, and the comparator output performs a

cycle–by–cycle peak current limitation by switching off the

low side transistor when the voltage exceeds 120 mV.

The internal

ILIMCOMP signal is monitored to stop the

converter if current limitation is continuously detected

http://onsemi.com

during 160ms (typical). This allows normal operation with

high filtering capacitance and low peak current, even at

converter start–up. As a result, a short circuit to ground on

the card connector or a continuous overcurrent is reported by

RDYMOD 160ms (typical) after power up.

Unexpected card extraction: The MC33560 detects card

extraction and runs a power down sequence if card power is

still on when extraction occurs. An active pull–down switch

clamps CRDVCC to GND within 150µs (max) after

extraction is detected. The external capacitors will then be

discharged. With typical capacitor values of 10µF and 47nF

as indicated in the application schematic, the time needed to

discharge CRDVCC to a voltage below 0.4V can be

estimated to less than 750µs. The total time aftercard

extraction detection until CRDVCC reaches 0.4V is then

estimated to 900µs (max). All smartcard connector contacts

will be deactivated before CRDVCC deactivation. This

ensures that no electrical damage will be caused to the

smartcard under abnormal extraction conditions.

14

MC33560

3V/5V programming: It is possible to set the card supply

voltage to 3V or 5V at any time, before DC/DC converter

start, or during converter operation. When switching from

3V to 5V, a 160ms (typical) delay blanks the undervoltage

fault detection to allow filter capacitor charging.

PWM: The free–running integrated oscillator has two

working modes:

⋅ variable on–state and fixed frequency (typically

120KHz) for average to heavy loads.

⋅ variable on–state and variable frequency for light loads.

The frequency can be as low as a few kHz if no load is

connected to CRDVCC.

The charging current of the timing capacitor is related to

the V

supply voltage, to allow better line regulation, and

BA T

to increase stability.

Filtering Capacitor: A high value allows efficient

filtering of card current spikes. Low values allow low

start–up charging current. Care must be taken not to

combine low capacitor value with high current limiting, as

this can generate high ripple. Usual values range from 4.7µF

to 47µF, depending on current limiting.

Selecting the external components L1 and RLIM: The

choice of inductor L1 and resistor R4 is made by using figure

8 (5V card) and/or figure 9 (3V card) on page 8:

First, determine the maximum current that the application

requires to supply to the card (ICCmax, on the y–axis)

Then, select one curve that crosses the selected ICCmax

level. The curve is associated with an inductance value

(22µH, 47µH, or 100µH).

Finally , use the intersection of the curve and the ICCmax

level to find the Rlim value on the x–axis.

Good starting values are : L1

=47µH; R

lim

=0.5

W

Note also that, for a high inductance value (100µH), the

filtering capacitor is generally charged before inductance

current reaches current limitation, while for alow inductance

value, the current limitation is activated after a few converter

cycles.

Battery requirements: Having determined the L

R

values, the maximum current drawn from the battery

lim

1

and

supply is shown by the curves in figures 6 and 7.

When the application is powered by a single 3V battery,

special care has to be taken to extend its lifetime. When

lithium batteries approach the end–of–life, their internal

resistance increases, while voltage decreases. This

phenomenon can prevent the start–up of the DC/DC

converter if the current limiting is set too high, because of the

filtering capacitor charging current.

CLOCK GENERA T OR

The primary purpose of the clock generator module is to

match the smartcard operating frequency to the system

frequency. The source frequency can be provided to

ASYCLKIN by the microcontroller itself or from an

external oscillator circuit.

In programming mode

(RDYMOD=L and CS asserted

low) the three input variables PWRON, IO and RESET are

used to configure the two output variables CRDVCC and

CRDCLK as described in table 3. This circuit setup is

latched during the positive transition of CS

.

Furthermore, in asynchronous mode the system clock

frequency ASYCLKIN can be divided by a factor of 1, 2 or

4. The circuit controls the frequency commutation to

guarantee that the card clock signal remains free from spikes

and glitches. In addition, this circuit ensures that CRDCLK

signal pulses will not be shorter than the shortest and/or

longer than the longest of the clock signals present before

and after programming changes .

The INVOUT

output is provided to drive other circuits

without additional load to the microprocessor quartz

oscillator. It can also be used to build a local RC oscillator.

This driver has been optimized for low consumption; it has

no hysteresis, and input levels are not symmetrical. If the

ASYCLKIN pin is connected to a sine wave, the duty cycle

will not always be 50% at INVOUT.

Clock generator operating principles

Synchronous Clock: This clock is used mainly for

memory cards. It can also be used for asynchronous

(microprocessor) cards, allowing the use of two different

clock sources. The status of

SYNCLK is latched at CRDCLK

when CS goes high, so that data (the IO pin) and clock are

always consistent at the card connector, whatever the CS

status is. When using the synchronous clock, the clock

output becomes active only when the MC33560 is selected

with CS.

Asynchronous Clock: This clock is used mainly for

microprocessor cards. When applied, the clock output

remains active even when the MC33560 is not selected with

CS

, in order to keep the microprocessor running and avoid

an unwanted reset. The ASYCLKIN signal is buffered at the

INVOUT pin, so that several MC33560 systems can use the

same clock with one load only .

Depending on programming, the frequency is fed directly ,

or divided by 2 or by 4 to the CRDCLK

pin. If the duty cycle

of the applied clock signal is not exactly symmetrical, it is

recommended that the clock signal be divided by two or four

to guarantee 50% duty cycle.

Clock Signal Synchronization and Consistency (see

figure 29). The clock divider includes synchronization logic

that controls the switch from synchronous clock to

asynchronous (and vice–versa), from any division ratio to

any other ratio, during CS

changes and at power up. The

synchronization logic guarantees that each clock cycle on

the CRDCLK pin is finished before changing clock

selection (and has always the adequate duration), regardless

of the moment the programming is changed.

At power–up, when ASYCLKIN

is selected, the clock

signal at the CRDCLK pin has an entire length, according

to the selected divide ratio, whatever the ASYCLKIN signal

is versus the internal sequencer timing.

http://onsemi.com

15

MC33560

CARDENABLE

Figure 23. Clock Generator Functional Block

SYNCLK

CARDENABLE

ASYCLKIN

INVOUT

RESET

IO

LATCH

2

B

2

B

BIDIRECTIONAL LEVEL TRANSLATOR

This module (used on IO/CRDIO, C4/CRDC4,

C8/CRDC8, see figure 24) adapts the signal voltage levels

of the I/O and control lines between the micro controller

(supplied by V

) and the smartcard (supplied by

BAT

CRDVCC)

When CS

is low , with CRDVCC on, and start sequencing

completed, this module is transparent for the data, and acts

as if the card was directly connected to the reader

microcontroller. The core of the level shifter circuit defined

for the bidirectional CRDIO, CRDC4

and CRDC8 lines

consists of a NMOS switch which can be driven to the logic

low state from either side (microcontroller or card). If both

sides work in transmission mode with opposite phase, then

signal collision on the line is not avoidable. In this case, the

peak current is limited to a safe value for the integrated

circuit and the smartcard.

During high–to–low transitions, the NMOS transistor

impedance (T1=250W max.) is low enough to charge

parasitic capacitance, and have a high enough dv/dt. On low

to high transition, the NMOS transistor is not active above

a certain voltage, and an acceleration circuit is activated to

ensure a high dv/dt.

When the chip is disabled

(CS=H) with the voltage supply

CRDVCC still active, the IO, C4 and C8 lines keep their last

logic state.

When the converter is off, a transistor forces the CRDIO,

CRDC4 and CRDC8 lines to a low state, thus preventing

any unwanted voltage level to be applied to the data lines

when the card is not in use.

Figure 24. Bidirectional Translator Functional Block

IO

(C4)

(C8)

VBAT

CONTROL

LOGIC

SEQ1 (SEQ3)

T1

CRDVCC

T2

CRDGND

18 K

CRDIO

(CRDC4)

(CRDC8)

CRDVCC

SELECTOR

SYNCHRO

LATCH

SEQ3

CRDCLK

LOGIC

SYNCHRONISATION

SELECTOR

LATCH

PROGRAM

SECURITY FEATURES

The MC33560 has a number of unique security functions

to guarantee that no electrical damage will be caused to the

smartcard:

⋅ Battery supply minimum voltage threshold

⋅ Card supply undervoltage and overcurrent detection

with automatic shutdown

⋅ Card pin overvoltage clamp to CRDVCC

⋅ Card presence detector for ”clean” and fast shut–down

⋅ Consistent card signal sequencing at start–up and

power–down, according to ISO7816, even on error

conditions

⋅ Consistent clock signal, even when division ratio or

synchronization clock signal are changed ”on the fly” during

a card session (see figure 29)

⋅ Active pull–down on all card pins, including

CRDVCC, when not in normal operating mode.

A current limiting function and an overtemperature

detector are limiting power dissipation.

ESD PROTECTION

Due to the nature of smartcards, the card interface pins

must absorb high ESD (Electro Static Discharge) energy

during card insertion. In addition, the control circuits

attached to these pins must safely withstand short circuits

and voltage transients during forced card extraction.

Therefore, the MC33560 features enhanced ESD

protection, current limitation and short circuit protection on

all smartcard interface pins, including C4

and C8.

P ARALLEL OPERATION

For applications where two or more MC33560 are used,

the digital control and data bus lines are common to all

MC33560. Only the chip select signal, CS

, requires a

separate line for each interface.

While deselected, all communication pins except

CRDCLK will keep their logical state on the card side, and

will go to high impedance mode on the microprocessor side.

Figure 33 shows a typical application of a dual card reader.

This arrangement was chosen only to illustrate the parallel

operation of two card interfaces in the same module. The

discrete capacitor components are necessary to provide low

http://onsemi.com

16

MC33560

impedance on the supply lines VBA T and CRDVCC and to

suppress the high frequency noise due to the DC/DC

converter. The load resistors are external in order to adapt

the sense current of the ”cardpresent” switches.

MINIMUM POWER CONSUMPTION

CONSIDERATIONS

All analog blocks except the V

comparator and the

BAT

card presence detector are disabled in stand by mode

(CS

=H: DC/DC converter stopped).

Figure 25. Example of single sided PCB layout for MC33560

C8

C4

L1

VBAT

ILIM

PGND

C10

PWRON

R4 C6 C7

INT

RDYMOD

CS

In order to maintain stand by current at a minimum value,

all pins with pull–up resistance

(CS, INT, RDYMOD) have

to be kept in the high state or left open, and pins with

pull–down resistance

(RESET, SYNCLK, PWRON) have

to be kept in the low state or left open. ASYCLKIN should

not be connected to an active clock signal during stand by to

avoid dynamic currents. This is valid also for SYNCLK,

except that it can be left open.

CRDC8

CRDDET

CRDC4

CRDCLK

CRDRST

CRDVCC

CRDGND

SYNCLK

ASYCLKIN

INVOUT

IO

RESET

CRDIO

http://onsemi.com

17

CRDVCC

CS

MC33560

Figure 26. Card Signal Sequence During VCC Power Up/Down

POWER UP POWER DOWNNORMAL OPERATION

V

TxH

RDYMOD (out)

PWRON

CLK

C4. C8

RESET

CRDIO

CRDCLK

CRDC4, CRDC8

CRDRST

t

won

IO

t

tr

SEQ1 to SEQ4

SEQ4 to SEQ1

CRDDET

INT

CS

RDYMOD (out)

t

fltin

CS

to INT

15 mS typ.

INTERRUPT

SERVICING

Figure 27. Interrupt Servicing and Polling

t

fltout

t

drdy

POLLING

INTERRUPT

SERVICING

http://onsemi.com

18

POLLING

MC33560

Figure 28. Card Signal Sequence During VCC Overload and Unexpected Card Extraction

MCU deactivates PWRON

after card extraction

poll with PWRON = L –>

RDYMOD = H: card still present

CS

= L, PWRON = H

CRDVCC undervoltage

CRDVCC

card inserted

–> RDYMOD = L

t

fltin

overload time

smaller than t

(glitch not to scale)

dres

V

V

TxH

TxL

t

fltout

CRDDET

INT

CS

RDYMOD

PWRON

t

drdy

poll with PWRON = L –> RDYMOD = H:

card present

t

dres

MCU polls

RDYMOD = H

t

dres

greater than t

converter stop and

CRDVCC pull down

35 ns typ

overload time

dres

card extraction

poll with PWRON = H –> RDYMOD = L:

DC/DC converter overload

–>

http://onsemi.com

19

MC33560

Figure 29. ”On–the–fly” Card Clock Selection Examples

CS

RDYMOD

IO

RESET

ASYCLK

SYNCLK

CRDCLK

http://onsemi.com

20

CS

RDYMOD

IO

RESET

ASYCLK

SYNCLK

CRDCLK

http://onsemi.com

21

C5

10 uF

C1

Connector

DB9

10 uF

Q1: XTAL 4MHz

D1: General Purpose diode

R1: 47 kOhm

C1, C2, C4,C5: 10 uF

R2: 1 MOhm

C3: 220 nF

L1: MURATA LQH3C 47 uH

R3: 1 MOhm

C6: 200 nF

C7: 10 uF

C8, C9: 22 pF

M1: 7805 regulator

R4: Value depending on max. card current

Z1: General Purpose 40 V zener diode

U4: Card connector

U3

+

+

C2+

GND

C2–

VSS

RX1

TX1

RX2

TX2

RX3

TX3

MC145407

C1+

VCC

C1–

VDD

DO1

DI 1

DO2

DI 2

DO3

DI 3

M1

0.1 uF

R2

1M

C10

7805

Card Slot

U4

8..40 VDC

Z1

Card Detect

C8

C4

CLK

RST

VCC

GND

I/O

Figure 30. Card Reader/Writer Application

MC33560

47k

D1

R1

C4

10 uF

+

C reset

m

C2

10 uF

C3

220 nF

RESET

VDD

IRQ

0SC1

VPP

OSC2

NC

TCAP

PA7

PD7

PA6

NC

PA5

TCMP

PA4

SS

PA3

SCLK

PA2

MOSI

PA1

MISO

PA0

RDI

PB0

TDO

PB1

PC0

PB2

PC1

PB3

PC2

NC

PC3

PB4

PC4

PB5

PC5

PB6

PC6

PB7

PC7

VSS

NC

MC68HC705C9

U1

C8

22 pF

Q1

4 MHz

C9

R3

22 pF

1M

U2

MC33560

1 – PGND

2 – PWRON

3 –

INT

4 – RDYMOD

5 –

CS

6 – RESET

7 – IO

8 – INVOUT

9 – ASYCLKIN

10 – SYNCLK

11 – CRDIO

12 – CRDGND

R4*

ILIM – 24

VBAT – 23

L1 – 22

C4 – 21

C8 – 20

CRDC8 – 19

CRDCON – 18

CRDDET – 17

CRDC4 – 16

CRDCLK – 15

CRDRST – 14

CRDVCC – 13

L1

47 uH

C7

10 uFC6200 nF

MC33560

Figure 31. Multi Slot Card Reader/Writer Application

C8

C8

Card Detect

VBAT

C4

CLK

RST

VCC

GND

I/O

VBAT

Card Detect

C4

CLK

RST

VCC

GND

I/O

ILIM – 24

1 – PGND

MC33560

L1 – 22

C4 – 21

VBAT – 23

INT

2 – PWRON

3 –

4 – RDYMOD

C8 – 20

CRDC8 – 19

CRDCON – 18

CS

5 –

6 – RESET

7 – IO

CRDC4 – 16

CRDCLK – 15

CRDDET – 17

8 – INVOUT

9 – ASYCLKIN

10 – SYNCLK

VDD

0SC1

TCAP

OSC2

RESET

IRQ

VPPNCPA7

CRDRST – 14

CRDVCC – 13

11 – CRDIO

12 – CRDGND

NC

PD7

TCMP

PA6

PA5

SS

PA4

SCLK

PA3

MOSI

PA2

MISO

PA1

RDI

PA0

TDO

PB0

PC0

PB1

MC33560

PC1

PC2

PB2

PB3NCPB4

ILIM – 24

1 – PGND

PC3

PC4

L1 – 22

VBAT – 23

INT

2 – PWRON

3 –

PC5

PC6

PC7

PB5

PB6

PB7

C4 – 21

C8 – 20

CRDC8 – 19

CRDCON – 18

CS

4 – RDYMOD

5 –

6 – RESET

7 – IO

NC

MC68HC705

VSS

CRDC4 – 16

CRDCLK – 15

CRDDET – 17

8 – INVOUT

9 – ASYCLKIN

10 – SYNCLK

CRDRST – 14

CRDVCC – 13

11 – CRDIO

12 – CRDGND

C reset

m

VBAT

http://onsemi.com

22

U0.15 (0.006) T

U0.15 (0.006) T

–T–

S

L

S

0.10 (0.004)

SEATING

PLANE

2X L/2

PIN 1

IDENT.

D

MC33560

P ACKAGE DIMENSIONS

(TSSOP–24)

DTB SUFFIX

PLASTIC PACKAGE

CASE 948H–01

ISSUE O

24X REFK

0.10 (0.004) V

24

1

M

A

–V–

C

G

S

U

T

S

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

13

B

–U–

12

H

–W–

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD

FLASH, PROTRUSIONS OR GATE BURRS. MOLD

FLASH OR GATE BURRS SHALL NOT EXCEED 0.15

(0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE INTERLEAD

FLASH OR PROTRUSION. INTERLEAD FLASH OR

PROTRUSION SHALL NOT EXCEED

0.25 (0.010) PER SIDE.

5. DIMENSION K DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.08 (0.003) TOTAL IN

EXCESS OF THE K DIMENSION AT MAXIMUM

MATERIAL CONDITION.

6. TERMINAL NUMBERS ARE SHOWN FOR

REFERENCE ONLY.

7. DIMENSION A AND B ARE TO BE DETERMINED

AT DATUM PLANE –W–.

DIM MIN MAX MIN MAX

A 7.70 7.90 0.303 0.311

B 4.30 4.50 0.169 0.177

C ––– 1.20 ––– 0.047

D 0.05 0.15 0.002 0.006

F 0.50 0.75 0.020 0.030

G 0.65 BSC 0.026 BSC

H 0.27 0.37 0.011 0.015

J 0.09 0.20 0.004 0.008

J1 0.09 0.16 0.004 0.006

K 0.19 0.30 0.007 0.012

K1 0.19 0.25 0.007 0.010

L 6.40 BSC 0.252 BSC

M 0 8 0 8

____

INCHESMILLIMETERS

DETAIL E

K

N

K1

J1

SECTION N–N

J

N

F

DETAIL E

0.25 (0.010)

M

http://onsemi.com

23

–T–

SEATING

PLANE

MC33560

P ACKAGE DIMENSIONS

(SO–24L)

DW SUFFIX

PLASTIC PACKAGE

CASE 751E–04

ISSUE E

–A–

1324

–B– P12X

M

0.010 (0.25) B

1

D24X

0.010 (0.25) B

M

T

12

J

S

A

S

M

F

R

C

M

22X

G

K

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 (0.005) TOTAL IN

EXCESS OF D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

DIM MIN MAX MIN MAX

A 15.25 15.54 0.601 0.612

B 7.40 7.60 0.292 0.299

C 2.35 2.65 0.093 0.104

X 45

D 0.35 0.49 0.014 0.019

_

F 0.41 0.90 0.016 0.035

G 1.27 BSC 0.050 BSC

J 0.23 0.32 0.009 0.013

K 0.13 0.29 0.005 0.011

M 0 8 0 8

P 10.05 10.55 0.395 0.415

R 0.25 0.75 0.010 0.029

INCHESMILLIMETERS

____

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

USA/EUROPE Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line*: 303–675–2167

800–344–3810 Toll Free USA/Canada

*To receive a Fax of our publications

N. America Technical Support: 800–282–9855 Toll Free USA/Canada

http://onsemi.com

ASIA/PACIFIC: LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5487–8345

Email: r14153@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local Sales Representative.

MC33560/D

24

Loading...

Loading...