Page 1

T

40° t

85°C

查询MC33035/D供应商

The MC33035 is a high performance second generation monolithic

brushless DC motor controller containing all of the active functions required

to implement a full featured open loop, three or four phase motor control

system. This device consists of a rotor position decoder for proper

commutation sequencing, temperature compensated reference capable of

supplying sensor power, frequency programmable sawtooth oscillator, three

open collector top drivers, and three high current totem pole bottom drivers

ideally suited for driving power MOSFETs.

Also included are protective features consisting of undervoltage lockout,

cycle–by–cycle current limiting with a selectable time delayed latched

shutdown mode, internal thermal shutdown, and a unique fault output that

can be interfaced into microprocessor controlled systems.

Typical motor control functions include open loop speed, forward or

reverse direction, run enable, and dynamic braking. The MC33035 is

designed to operate with electrical sensor phasings of 60°/300° or

120°/240°, and can also efficiently control brush DC motors.

• 10 to 30 V Operation

• Undervoltage Lockout

• 6.25 V Reference Capable of Supplying Sensor Power

• Fully Accessible Error Amplifier for Closed Loop Servo Applications

• High Current Drivers Can Control External 3–Phase MOSFET Bridge

• Cycle–By–Cycle Current Limiting

• Pinned–Out Current Sense Reference

• Internal Thermal Shutdown

• Selectable 60°/300° or 120°/240° Sensor Phasings

• Can Efficiently Control Brush DC Motors with External MOSFET

H–Bridge

ORDERING INFORMATION

Operating

Device

MC33035DW

MC33035P

Temperature Range

°

A

= –

o +

°

Package

SO–24L

Plastic DIP

Order this document by MC33035/D

BRUSHLESS DC

MOTOR CONTROLLER

SEMICONDUCTOR

TECHNICAL DATA

P SUFFIX

PLASTIC PACKAGE

CASE 724

DW SUFFIX

PLASTIC PACKAGE

CASE 751E

(SO–24L)

PIN CONNECTIONS

Top Drive

Output

Sensor

Inputs

Output Enable

Reference Output

Current Sense

Noninverting Input

Noninverting Input

Inverting Input

B

T

A

T

S

A

S

B

S

C

Oscillator

Error Amp

Error Amp

24

1

24

1

2

3

4

5

6

7

8

9

10

11

1

C

24

T

23

Brake

22

°

/120°SelectFwd/Rev

60

A

21

B

20

B

B

19

C

B

18

V

C

17

V

CC

Gnd

16

Current Sense

15

Inverting Input

14

Output

Fault

Error Amp Out/

1312

PWM Input

Bottom

Drive

Outputs

(Top View)

MOTOROLA ANALOG IC DEVICE DATA

Motorola, Inc. 1998 Rev 3

1

Page 2

Fwd/Rev

60°/120

Enable

V

R

T

C

T

°

in

Speed

Set

Faster

22

17

18

11

12

13

10

4

5

6

3

7

8

Reference

Regulator

Error Amp

Oscillator

Undervoltage

Lockout

PWM

MC33035

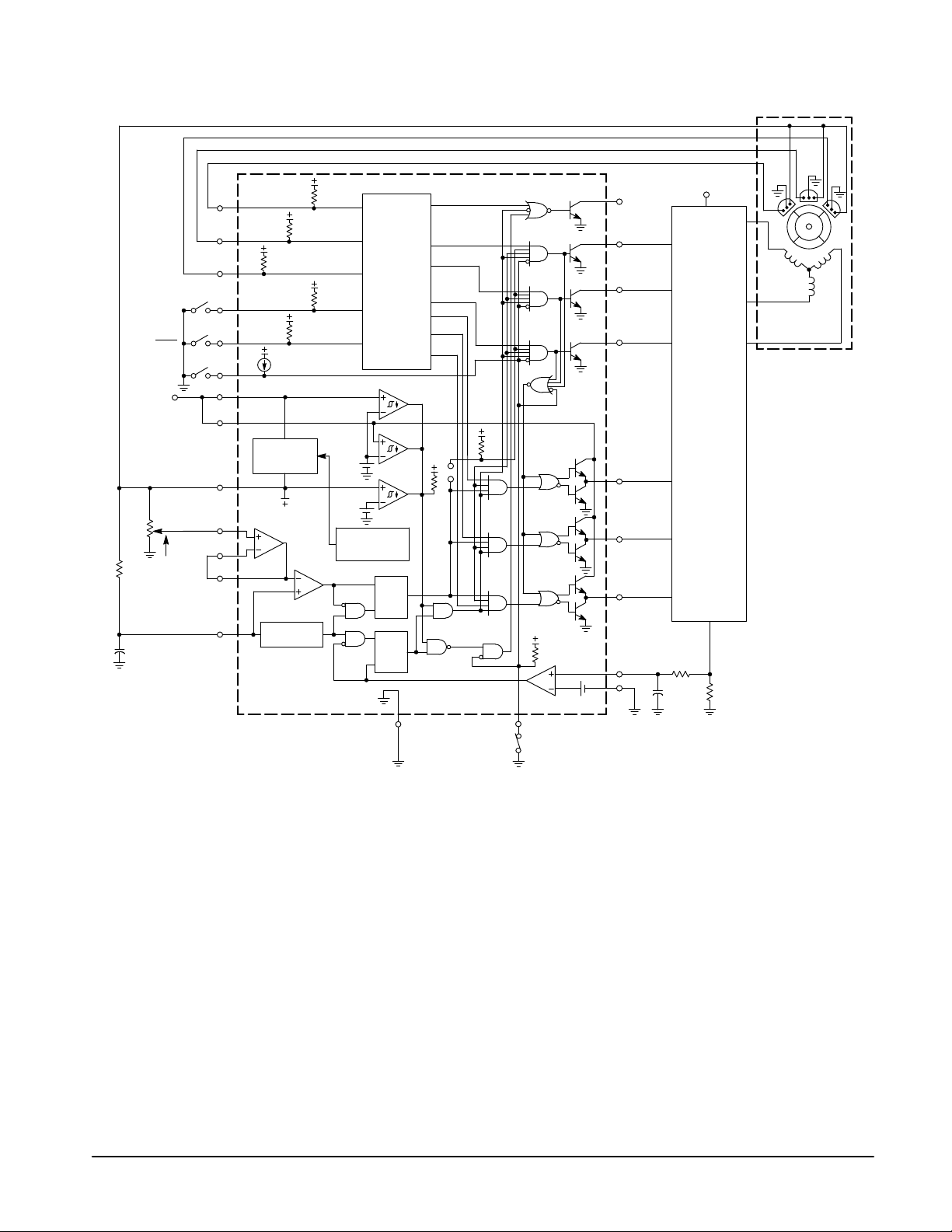

Representative Schematic Diagram

Rotor

Position

Decoder

Thermal

Shutdown

R

Q

S

S

Q

R

14

24

21

20

19

2

1

9

Fault

V

M

Output

Buffers

N

SS

N

Motor

2316

Brake

This device contains 285 active transistors.

15

Current Sense

Reference

2

MOTOROLA ANALOG IC DEVICE DATA

Page 3

MC33035

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Supply Voltage V

Digital Inputs (Pins 3, 4, 5, 6, 22, 23) – V

Oscillator Input Current (Source or Sink) I

Error Amp Input Voltage Range

(Pins 11, 12, Note 1)

Error Amp Output Current

(Source or Sink, Note 2)

Current Sense Input Voltage Range (Pins 9, 15) V

Fault Output Voltage V

Fault Output Sink Current I

Top Drive Voltage (Pins 1, 2, 24) V

Top Drive Sink Current (Pins 1, 2, 24) I

Bottom Drive Supply Voltage (Pin 18) V

Bottom Drive Output Current I

(Source or Sink, Pins 19, 20, 21)

Power Dissipation and Thermal Characteristics

P Suffix, Dual In Line, Case 724

Maximum Power Dissipation @ TA = 85°C P

Thermal Resistance, Junction–to–Air R

DW Suffix, Surface Mount, Case 751E

Maximum Power Dissipation @ TA = 85°C P

Thermal Resistance, Junction–to–Air R

Operating Junction Temperature T

Operating Ambient Temperature Range T

Storage Temperature Range T

CC

OSC

V

IR

I

Out

Sense

CE(Fault

Sink(Fault)

CE(top)

Sink(top)

C

DRV

D

θJA

D

θJA

J

A

stg

–0.3 to V

–0.3 to 5.0 V

)

–40 to +85 °C

–65 to +150 °C

40 V

ref

30 mA

ref

10 mA

20 V

20 mA

40 V

50 mA

30 V

100 mA

867 mW

75 °C/W

650 mW

100 °C/W

150 °C

V

V

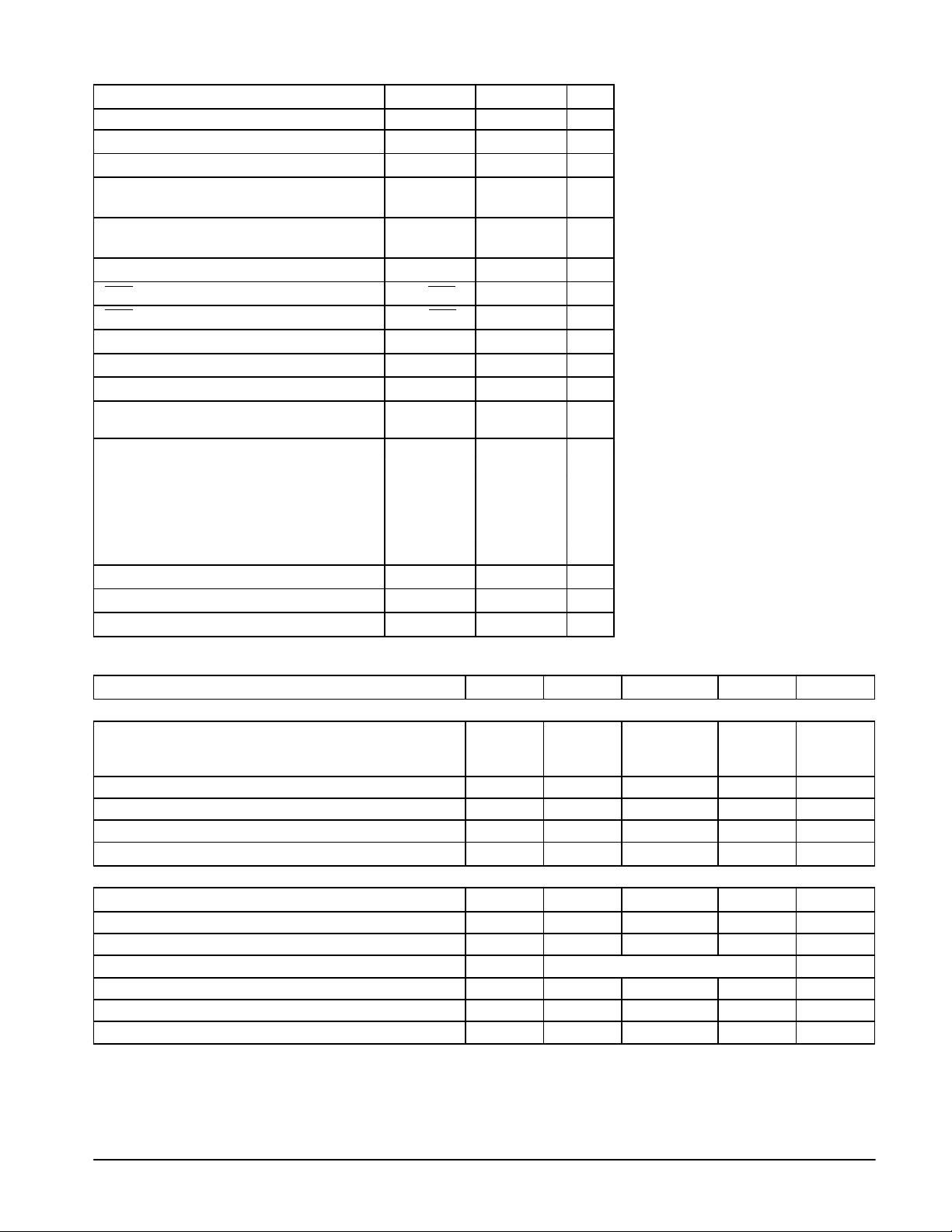

ELECTRICAL CHARACTERISTICS (V

Characteristic

REFERENCE SECTION

Reference Output Voltage (I

TA = 25°C

TA = –40° to +85°C

Line Regulation (VCC = 10 to 30 V, I

Load Regulation (I

Output Short Circuit Current (Note 3) I

Reference Under Voltage Lockout Threshold V

ERROR AMPLIFIER

Input Offset Voltage (TA = –40° to +85°C) V

Input Offset Current (TA = –40° to +85°C) I

Input Bias Current (TA = –40° to +85°C) I

Input Common Mode Voltage Range V

Open Loop Voltage Gain (VO = 3.0 V, RL = 15 k) A

Input Common Mode Rejection Ratio CMRR 55 86 – dB

Power Supply Rejection Ratio (VCC = VC = 10 to 30 V) PSRR 65 105 – dB

NOTES: 1. The input common mode voltage or input signal voltage should not be allowed to go negative by more than 0.3 V.

2.The compliance voltage must not exceed the range of –0.3 to V

3.Maximum package power dissipation limits must be observed.

= 1.0 to 20 mA) Reg

ref

= 1.0 mA)

ref

ref

= VC = 20 V, RT = 4.7 k, CT = 10 nF, TA = 25°C, unless otherwise noted.)

CC

Symbol Min Typ Max Unit

V

= 1.0 mA) Reg

.

ref

ref

line

load

SC

th

IO

IO

IB

ICR

VOL

5.9

5.82

– 1.5 30 mV

– 16 30 mV

40 75 – mA

4.0 4.5 5.0 V

– 0.4 10 mV

– 8.0 500 nA

– –46 –1000 nA

70 80 – dB

6.24

–

(0 V to V

6.5

6.57

) V

ref

V

MOTOROLA ANALOG IC DEVICE DATA

3

Page 4

MC33035

Output Enable

µA

gp (IH)

IH

Bottom Drive Output Voltage

V

g(

CC C source

)

OH

(

CC

)

(

CC

)

Power Supply Current

mA

Pin 17 (VCC VC 20 V)

I

CC

121416

(

CC

0,C30 )

0

(

CC C

)

C

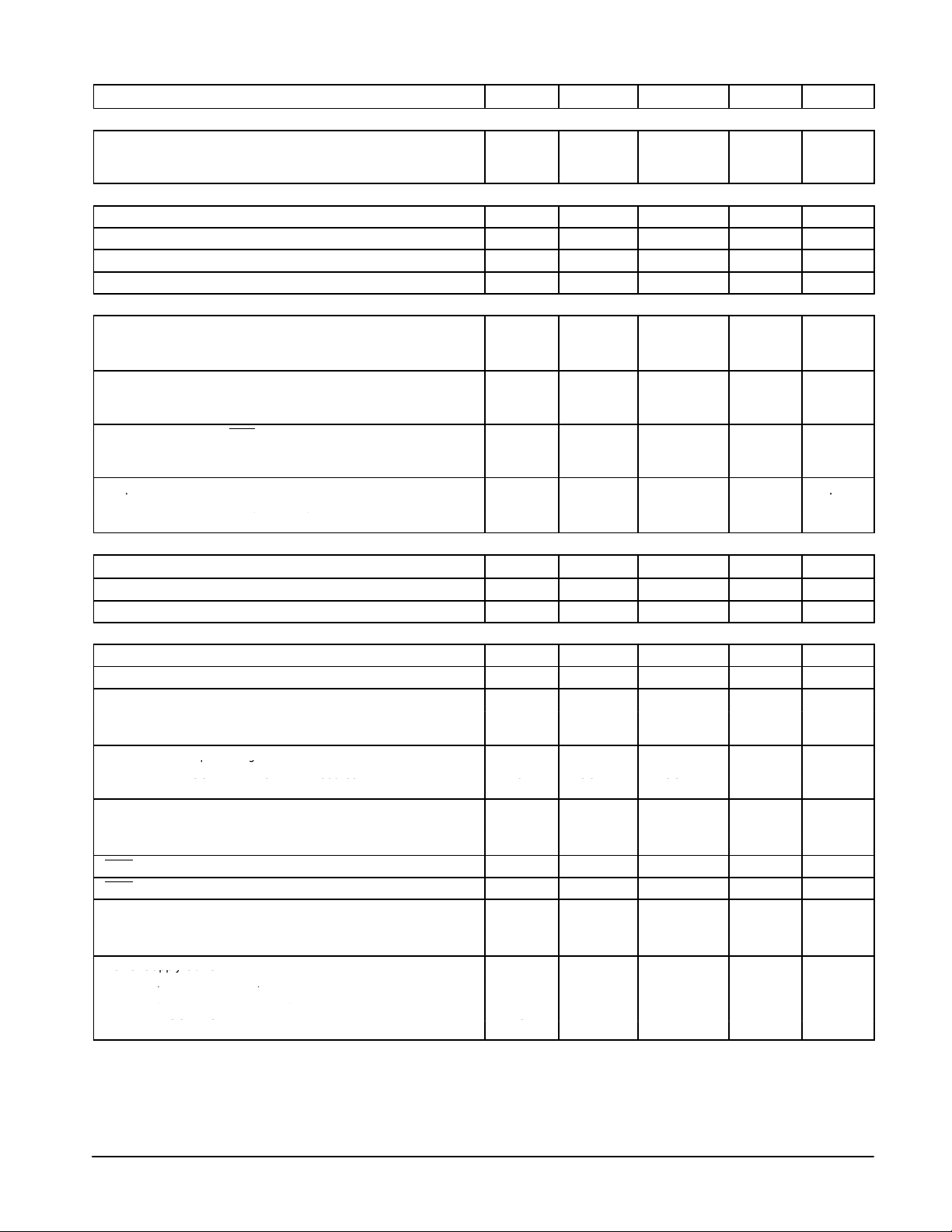

ELECTRICAL CHARACTERISTICS (continued) (V

Characteristic

ERROR AMPLIFIER

Output Voltage Swing

High State (RL = 15 k to Gnd)

Low State (RL = 15 k to V

OSCILLATOR SECTION

Oscillator Frequency f

Frequency Change with Voltage (VCC = 10 to 30 V) ∆f

Sawtooth Peak Voltage V

Sawtooth Valley Voltage V

LOGIC INPUTS

Input Threshold Voltage (Pins 3, 4, 5, 6, 7, 22, 23)

High State

Low State

Sensor Inputs (Pins 4, 5, 6)

High State Input Current (VIH = 5.0 V)

Low State Input Current (VIL = 0 V)

Forward/Reverse, 60°/120° Select (Pins 3, 22, 23)

High State Input Current (VIH = 5.0 V)

Low State Input Current (VIL = 0 V)

Output Enable µA

High State Input Current (VIH = 5.0 V)

Low State Input Current (VIL = 0 V)

CURRENT–LIMIT COMPARATOR

Threshold Voltage V

Input Common Mode Voltage Range V

Input Bias Current I

OUTPUTS AND POWER SECTIONS

Top Drive Output Sink Saturation (I

Top Drive Output Off–State Leakage (VCE = 30 V) I

Top Drive Output Switching Time (CL = 47 pF, RL = 1.0 k) ns

Rise Time t

Fall Time t

Bottom Drive Output Voltage V

High State (VCC = 20 V, VC = 30 V, I

Low State (VCC = 20 V, VC = 30 V, I

Bottom Drive Output Switching Time (CL = 1000 pF) ns

Rise Time t

Fall Time t

Fault Output Sink Saturation (I

Fault Output Off–State Leakage (VCE = 20 V) I

Under Voltage Lockout V

Drive Output Enabled (VCC or VC Increasing) V

Hysteresis V

Power Supply Current mA

Pin 17 (VCC = VC = 20 V) I

Pin 17 (VCC = 20 V, VC = 30 V)

Pin 18 (VCC = VC = 20 V) I

Pin 18 (VCC = 20 V, VC = 30 V)

)

ref

= 25 mA) V

sink

= 50 mA)

source

= 50 mA)

sink

= 16 mA) V

sink

= VC = 20 V, RT = 4.7 k, CT = 10 nF, TA = 25°C, unless otherwise noted.)

CC

Symbol Min Typ Max Unit

V

OH

V

OL

OSC

/∆V – 0.01 5.0 %

OSC

OSC(P)

OSC(V)

V

IH

V

IL

I

IH

I

IL

I

IH

I

IL

I

IH

I

IL

th

ICR

IB

CE(sat)

DRV(leak)

r

f

V

OH

V

OL

r

f

CE(sat)

FLT(leak)

th(on)

H

CC

C

4.6

–

22 25 28 kHz

– 4.1 4.5 V

1.2 1.5 – V

3.0

–

–150

–600

–75

–300

–60

–60 –29 –10

85 101 115 mV

– 3.0 – V

– –0.9 –5.0 µA

– 0.5 1.5 V

– 0.06 100 µA

– 107 300

– 26 300

(VCC –2.0) (VCC –1.1)

–

– 38 200

– 30 200

– 225 500 mV

– 1.0 100 µA

8.2 8.9 10

0.1 0.2 0.3

– 12 16

–

– 3.5

– 5.0 10

5.3

0.5

2.2

1.7

–70

–337

–36

–175

–29

1.5 2.0

–

1.0

–

0.8

–20

–150

–10

–75

–10

–

20

6.0

V

V

µA

µA

4

MOTOROLA ANALOG IC DEVICE DATA

Page 5

MC33035

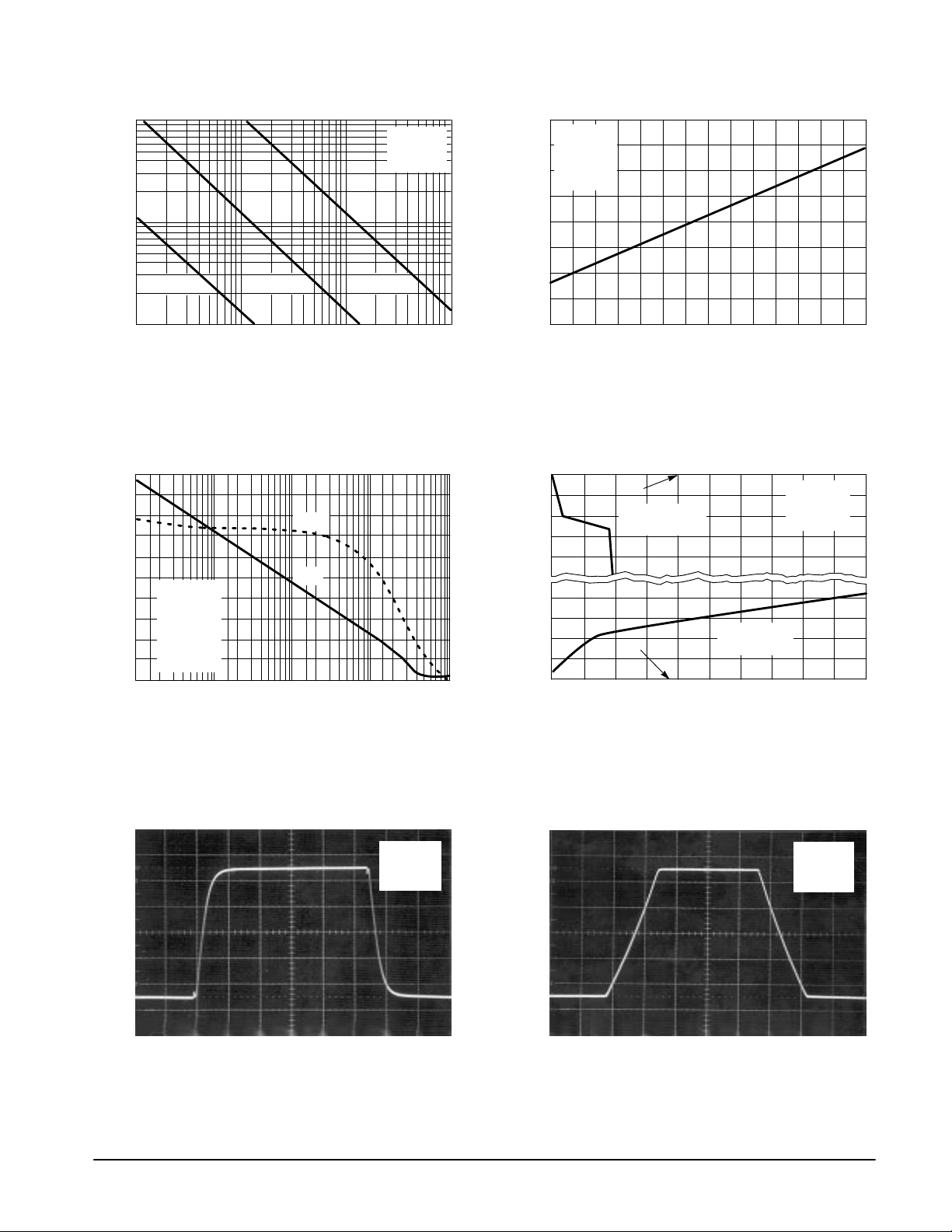

Figure 1. Oscillator Frequency versus

100

10

OSCILLA TOR FREQUENCY (kHz)

CT = 100 nF

,

OSC

f

0

1.0

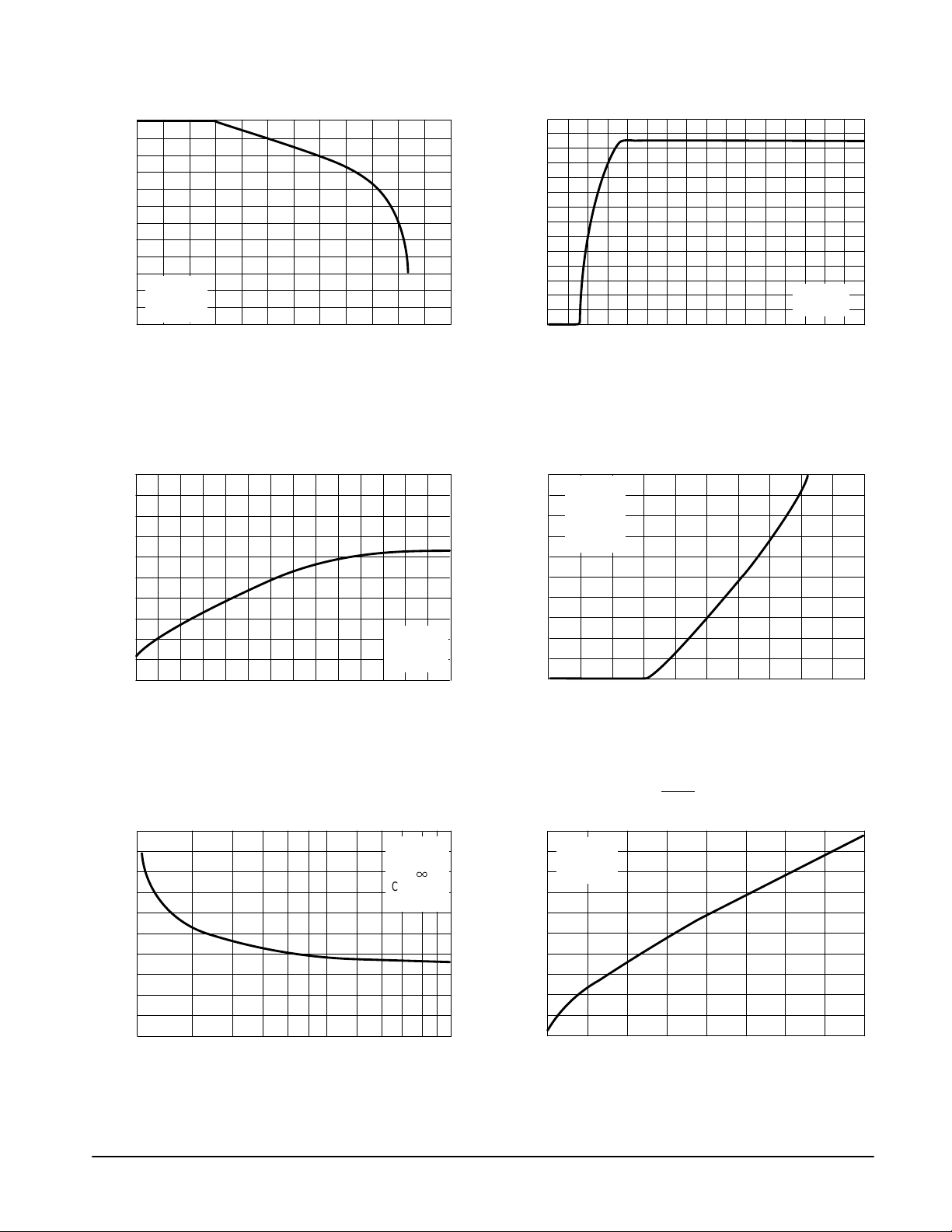

Figure 3. Error Amp Open Loop Gain and

56

48

40

32

24

16

VCC = 20 V

8.0

VC = 20 V

VO = 3.0 V

0

–8.0

, OPEN LOOP VOL TAGE GAIN (dB)

–16

VOL

A

–24

RL = 15 k

CL = 100 pF

TA = 25

1.0 k

Timing Resistor

CT = 10 nF

RT, TIMING RESISTOR (k

Phase versus Frequency

Phase

Gain

°

C

f, FREQUENCY (Hz)

CT = 1.0 nF

Ω

)

VCC = 20 V

VC = 20 V

°

C

TA = 25

100010010

10 M1.0 M100 k10 k

Figure 2. Oscillator Frequency Change

4.0

VCC = 20 V

VC = 20 V

RT = 4.7 k

2.0

CT = 10 nF

0

–2.0

OSCILLA T OR FREQUENCY CHANGE (%)

,

OSC

–4.0

f

∆

–55

Figure 4. Error Amp Output Saturation

40

60

80

100

120

140

160

180

EXCESS PHASE (DEGREES)

,

200

φ

220

240

– 0.8

–1.6

, OUTPUT SA TURATION VOLTAGE (V)

sat

V

0

1.6

0.8

0

versus T emperature

TA, AMBIENT TEMPERATURE (°C)

V oltage versus Load Current

V

ref

Source Saturation

(Load to Ground)

Sink Saturation

Gnd

1.0 2.0

IO, OUTPUT LOAD CURRENT (mA)

(Load to V

ref

1007550250–25

VCC = 20 V

VC = 20 V

TA = 25

)

125

°

C

5.04.03.00

Figure 5. Error Amp Small–Signal

Transient Response

3.05

3.0

, OUTPUT VOL TAGE (V)

O

V

2.95

µ

s/DIV

1.0

MOTOROLA ANALOG IC DEVICE DATA

AV = +1.0

No Load

°

TA = 25

Figure 6. Error Amp Large–Signal

Transient Response

AV = +1.0

No Load

TA = 25

°

C

, OUTPUT VOL TAGE (V)

V

4.5

3.0

O

1.5

5.0 µs/DIV

C

5

Page 6

MC33035

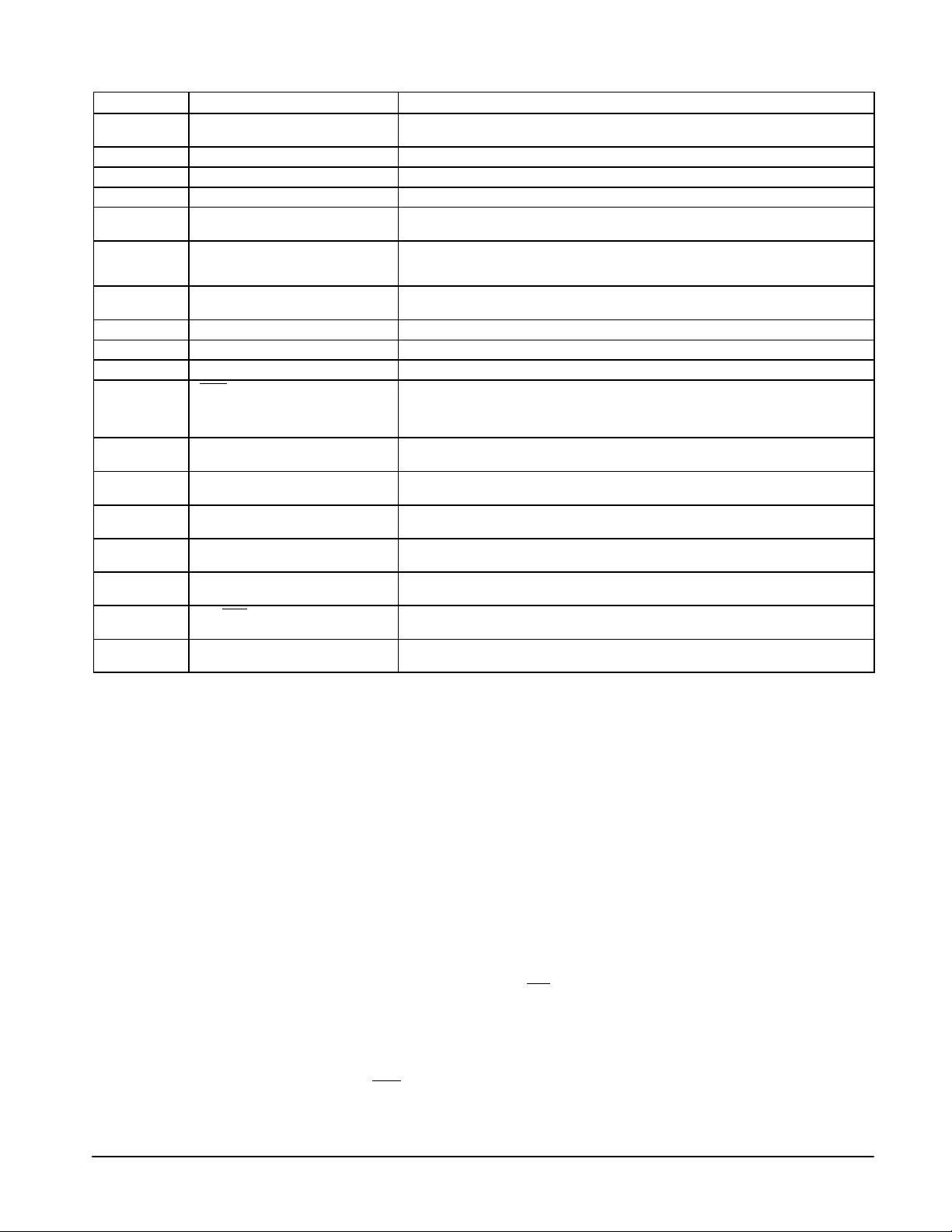

Figure 7. Reference Output V oltage Change

versus Output Source Current

0

–4.0

–8.0

– 12

– 16

VCC = 20 V

–20

VC = 20 V

°

C

TA = 25

, REFERENCE OUTPUT VOLTAGE CHANGE (mV)

–24

ref

0

V

∆

I

, REFERENCE OUTPUT SOURCE CURRENT (mA)

ref

Figure 9. Reference Output Voltage

versus T emperature

40

20

0

–20

–40

, NORMALIZED REFERENCE VOLTAGE CHANGE (mV)

ref

V

∆

–25

–55 0

TA, AMBIENT TEMPERATURE (

°

C)

VCC = 20 V

VC = 20 V

No Load

Figure 8. Reference Output Voltage

versus Supply V oltage

7.0

6.0

5.0

4.0

3.0

2.0

1.0

, REFERENCE OUTPUT VOLTAGE (V)

ref

V

0

605040302010

0

VCC, SUPPLY VOLT AGE (V)

No Load

TA = 25

°

C

40302010

Figure 10. Output Duty Cycle versus

PWM Input Voltage

100

VCC = 20 V

VC = 20 V

RT = 4.7 k

80

CT = 10 nF

°

C

TA = 25

60

40

20

OUTPUT DUTY CYCLE (%)

125100755025

0

0

PWM INPUT VOLTAGE (V)

5.04.03.02.01.0

Figure 11. Bottom Drive Response T ime versus

Current Sense Input Voltage

250

200

150

100

50

, BOTTOM DRIVE RESPONSE TIME (ns)

HL

t

0

1.0 2.0 3.0 4.0 5.0 7.0 8.0 10

CURRENT SENSE INPUT VOLTAGE (NORMALIZED TO Vth)

VCC = 20 V

VC = 20 V

RL =

CL = 1.0 nF

TA = 25

6.0 9.0

6

Figure 12. Fault

Output Saturation

versus Sink Current

0.25

VCC = 20 V

VC = 20 V

1

°

C

0.2

TA = 25

0.15

0.1

0.05

, OUTPUT SA TURATION VOLTAGE (V)V

sat

0

016128.04.0

°

C

I

, SINK CURRENT (mA)

Sink

MOTOROLA ANALOG IC DEVICE DATA

Page 7

1.2

0.8

Figure 13. Top Drive Output Saturation

V oltage versus Sink Current

VCC = 20 V

VC = 20 V

°

C

TA = 25

MC33035

Figure 14. Top Drive Output Waveform

100

, OUTPUT SA TURATION VOLTAGE (V)

sat

V

OUTPUT VOLTAGE (%)

0

VCC = 20 V

VC = 20 V

RL = 1.0 k

CL = 15 pF

°

C

TA = 25

100 ns/DIV

0.4

0

0

10 30 40

I

Sink

20

, SINK CURRENT (mA)

Figure 15. Bottom Drive Output Waveform Figure 16. Bottom Drive Output Waveform

VCC = 20 V

100

VC = 20 V

CL = 1.0 nF

°

C

TA = 25

0

100

OUTPUT VOLTAGE (%) OUTPUT VOLTAGE (%)

0

VCC = 20 V

VC = 20 V

CL = 15 pF

°

C

TA = 25

, OUTPUT SA TURATION VOLTAGE (V)

V

50 ns/DIV

Figure 17. Bottom Drive Output Saturation

V oltage versus Load Current

–1.0

–2.0

sat

0

VCC = 20 V

VC = 20 V

TA = 25

2.0

1.0

0

0

V

C

°

C

Gnd

40

IO, OUTPUT LOAD CURRENT (mA)

Source Saturation

(Load to Ground)

Sink Saturation

(Load to VC)

50 ns/DIV

Figure 18. Power and Bottom Drive Supply

Current versus Supply Voltage

16

14

12

10

8.0

6.0

4.0

, POWER SUPPLY CURRENT (mA)

2.0

CC

, I

C

I

806020

0

0 5.0 10 15 20 25 30

I

CC

RT = 4.7 k

CT = 10 nF

Pins 3–6, 9, 15, 23 = Gnd

Pins 7, 22 = Open

°

TA = 25

I

C

VCC, SUPPLY VOLT AGE (V)

C

MOTOROLA ANALOG IC DEVICE DATA

7

Page 8

MC33035

PIN FUNCTION DESCRIPTION

Pin Symbol Description

1, 2, 24 BT, AT, C

3 Fwd/Rev The Forward/Reverse Input is used to change the direction of motor rotation.

4, 5, 6 SA, SB, S

7 Output Enable A logic high at this input causes the motor to run, while a low causes it to coast.

8 Reference Output This output provides charging current for the oscillator timing capacitor CT and a

9 Current Sense Noninverting Input A 100 mV signal, with respect to Pin 15, at this input terminates output switch

10 Oscillator The Oscillator frequency is programmed by the values selected for the timing

11 Error Amp Noninverting Input This input is normally connected to the speed set potentiometer .

12 Error Amp Inverting Input This input is normally connected to the Error Amp Output in open loop applications.

13 Error Amp Out/PWM Input This pin is available for compensation in closed loop applications.

14 Fault Output This open collector output is active low during one or more of the following

15 Current Sense Inverting Input Reference pin for internal 100 mV threshold. This pin is normally connected to the

16 Gnd This pin supplies a ground for the control circuit and should be referenced back to

17 V

18 V

19, 20, 21 CB, BB, A

22 60°/120° Select The electrical state of this pin configures the control circuit operation for either 60°

23 Brake A logic low state at this input allows the motor to run, while a high state does not

T

C

CC

C

B

These three open collector Top Drive outputs are designed to drive the external

upper power switch transistors.

These three Sensor Inputs control the commutation sequence.

reference for the error amplifier. It may also serve to furnish sensor power.

conduction during a given oscillator cycle. This pin normally connects to the top

side of the current sense resistor.

components, RT and CT.

conditions: Invalid Sensor Input code, Enable Input at logic 0, Current Sense Input

greater than 100 mV (Pin 9 with respect to Pin 15), Undervoltage Lockout

activation, and Thermal Shutdown.

bottom side of the current sense resistor.

the power source ground.

This pin is the positive supply of the control IC. The controller is functional over a

minimum VCC range of 10 to 30 V.

The high state (VOH) of the Bottom Drive Outputs is set by the voltage applied to

this pin. The controller is operational over a minimum VC range of 10 to 30 V.

These three totem pole Bottom Drive Outputs are designed for direct drive of the

external bottom power switch transistors.

(high state) or 120° (low state) sensor electrical phasing inputs.

allow motor operation and if operating causes rapid deceleration.

INTRODUCTION

The MC33035 is one of a series of high performance

monolithic DC brushless motor controllers produced by

Motorola. It contains all of the functions required to

implement a full–featured, open loop, three or four phase

motor control system. In addition, the controller can be made

to operate DC brush motors. Constructed with Bipolar Analog

technology, it offers a high degree of performance and

ruggedness in hostile industrial environments. The MC33035

contains a rotor position decoder for proper commutation

sequencing, a temperature compensated reference capable

of supplying a sensor power, a frequency programmable

sawtooth oscillator, a fully accessible error amplifier, a pulse

width modulator comparator, three open collector top drive

outputs, and three high current totem pole bottom driver

outputs ideally suited for driving power MOSFETs.

Included in the MC33035 are protective features

consisting of undervoltage lockout, cycle–by–cycle current

limiting with a selectable time delayed latched shutdown

mode, internal thermal shutdown, and a unique fault output

that can easily be interfaced to a microprocessor controller.

Typical motor control functions include open loop speed

control, forward or reverse rotation, run enable, and dynamic

braking. In addition, the MC33035 has a 60°/120

which configures the rotor position decoder for either 60° or

120° sensor electrical phasing inputs.

° select pin

FUNCTIONAL DESCRIPTION

A representative internal block diagram is shown in

Figure 19 with various applications shown in Figures 36, 38,

39, 43, 45, and 46. A discussion of the features and function

of each of the internal blocks given below is referenced to

Figures 19 and 36.

Rotor Position Decoder

An internal rotor position decoder monitors the three

sensor inputs (Pins 4, 5, 6) to provide the proper sequencing

of the top and bottom drive outputs. The sensor inputs are

designed to interface directly with open collector type Hall

Effect switches or opto slotted couplers. Internal pull–up

resistors are included to minimize the required number of

external components. The inputs are TTL compatible, with

their thresholds typically at 2.2 V. The MC33035 series is

designed to control three phase motors and operate with four

of the most common conventions of sensor phasing. A

60°/120

the MC33035 to configure itself to control motors having

either 60°, 120°, 240° or 300° electrical sensor phasing. With

three sensor inputs there are eight possible input code

combinations, six of which are valid rotor positions. The

remaining two codes are invalid and are usually caused by an

open or shorted sensor line. With six valid input codes, the

° Select (Pin 22) is conveniently provided and affords

8

MOTOROLA ANALOG IC DEVICE DATA

Page 9

MC33035

decoder can resolve the motor rotor position to within a

window of 60 electrical degrees.

The Forward/Reverse input (Pin 3) is used to change the

direction of motor rotation by reversing the voltage across the

stator winding. When the input changes state, from high to

low with a given sensor input code (for example 100), the

enabled top and bottom drive outputs with the same alpha

designation are exchanged (AT to AB, BT to BB, CT to CB). In

effect, the commutation sequence is reversed and the motor

changes directional rotation.

Motor on/off control is accomplished by the Output Enable

(Pin 7). When left disconnected, an internal 25 µA current

source enables sequencing of the top and bottom drive

outputs. When grounded, the top drive outputs turn off and

the bottom drives are forced low, causing the motor to coast

and the Fault

output to activate.

Dynamic motor braking allows an additional margin of

safety to be designed into the final product. Braking is

accomplished by placing the Brake Input (Pin 23) in a high

state. This causes the top drive outputs to turn off and the

bottom drives to turn on, shorting the motor–generated back

EMF. The brake input has unconditional priority over all other

inputs. The internal 40 kΩ pull–up resistor simplifies

interfacing with the system safety–switch by insuring brake

activation if opened or disconnected. The commutation logic

truth table is shown in Figure 20. A four input NOR gate is

used to monitor the brake input and the inputs to the three

top drive output transistors. Its purpose is to disable braking

until the top drive outputs attain a high state. This helps to

prevent simultaneous conduction of the the top and bottom

power switches. In half wave motor drive applications, the

top drive outputs are not required and are normally left

disconnected. Under these conditions braking will still be

accomplished since the NOR gate senses the base voltage

to the top drive output transistors.

Error Amplifier

A high performance, fully compensated error amplifier with

access to both inputs and output (Pins 11, 12, 13) is provided

to facilitate the implementation of closed loop motor speed

control. The amplifier features a typical DC voltage gain of

80 dB, 0.6 MHz gain bandwidth, and a wide input common

mode voltage range that extends from ground to V

. In most

ref

open loop speed control applications, the amplifier is

configured as a unity gain voltage follower with the

noninverting input connected to the speed set voltage source.

Additional configurations are shown in Figures 31 through 35.

Oscillator

The frequency of the internal ramp oscillator is

programmed by the values selected for timing components

RT and CT. Capacitor CT is charged from the Reference

Output (Pin 8) through resistor RT and discharged by an

internal discharge transistor. The ramp peak and valley

voltages are typically 4.1 V and 1.5 V respectively . To provide

a good compromise between audible noise and output

switching efficiency, an oscillator frequency in the range of

20 to 30 kHz is recommended. Refer to Figure 1 for

component selection.

Sensor

Inputs

Forward/Reverse

60°/120°Select

Output Enable

V

in

Reference Output

Noninv. Input

Faster

R

T

Error Amp Out

PWM Input

C

T

Sink Only

Positive True

=

Logic With

Hysteresis

Figure 19. Representative Block Diagram

V

14

2

A

1

B

24

C

21

20

19

9

15

20 k

20 k

40 k

25

µ

A

Undervoltage

Lockout

PWM

20 k

40 k

9.1 V

4.5 V

Rotor

Position

Decoder

Thermal

Shutdown

Latch

R

S

Latch

S

R

16

Q

Q

40 k

100 mV

23Gnd

Brake Input

4

S

A

5

S

B

6

S

C

3

22

7

17

V

CC

18

V

C

Reference

Regulator

8

11

Error Amp

12

13

10

Oscillator

M

Fault

Output

T

T

T

A

B

B

B

C

B

Current Sense Input

Current Sense

Reference Input

Top

Drive

Outputs

Bottom

Drive

Outputs

MOTOROLA ANALOG IC DEVICE DATA

9

Page 10

MC33035

Figure 20. Three Phase, Six Step Commutation Truth Table (Note 1)

Inputs (Note 2) Outputs (Note 3)

Sensor Electrical Phasing (Note 4) Top Drives Bottom Drives

60°

S

S

A

1

1

1

0

0

0

1

1

1

0

0

0

1

0

1

0

V V V V V V X 1 1 X 1 1 1 1 1 1 1 (Note 8)

V V V V V V X 0 1 X 1 1 1 1 1 1 0 (Note 9)

V V V V V V X 0 0 X 1 1 1 0 0 0 0 (Note 10)

V V V V V V X 1 0 1 1 1 1 0 0 0 0 (Note 1 1)

NOTES: 1. V = Any one of six valid sensor or drive combinations X = Don’t care.

SCS

B

0

0

1

0

1

1

1

1

0

1

0

0

0

0

1

0

1

1

1

1

0

1

0

0

011

0

011

0

2. The digital inputs (Pins 3, 4, 5, 6, 7, 22, 23) are all TTL compatible. The current sense input (Pin 9) has a 100 mV threshold with respect to Pin 15.

A logic 0 for this input is defined as < 85 mV, and a logic 1 is > 115 mV.

3. The fault and top drive outputs are open collector design and active in the low (0) state.

4. With 60°/120

is for 120° sensor electrical phasing inputs.

5. Valid 60° or 120° sensor combinations for corresponding valid top and bottom drive outputs.

6. Invalid sensor inputs with brake = 0; All top and bottom drives off, Fault

7. Invalid sensor inputs with brake = 1; All top drives off, all bottom drives on, Fault

8. Valid 60° or 120°sensor inputs with brake = 1; All top drives off, all bottom drives on, Fault

9. Valid sensor inputs with brake = 1 and enable = 0; All top drives of f, all bottom drives on, Fault

10. Valid sensor inputs with brake = 0 and enable = 0; All top and bottom drives off, Fault

11. All bottom drives off, Fault

Pulse Width Modulator

The use of pulse width modulation provides an energy

efficient method of controlling the motor speed by varying the

average voltage applied to each stator winding during the

commutation sequence. As CT discharges, the oscillator sets

both latches, allowing conduction of the top and bottom drive

outputs. The PWM comparator resets the upper latch,

terminating the bottom drive output conduction when the

positive–going ramp of CT becomes greater than the error

amplifier output. The pulse width modulator timing diagram is

shown in Figure 21. Pulse width modulation for speed control

appears only at the bottom drive outputs.

Current Limit

Continuous operation of a motor that is severely

over–loaded results in overheating and eventual failure.

This destructive condition can best be prevented with the

use of cycle–by–cycle current limiting. That is, each

on–cycle is treated as a separate event. Cycle–by–cycle

current limiting is accomplished by monitoring the stator

current build–up each time an output switch conducts, and

upon sensing an over current condition, immediately turning

off the switch and holding it off for the remaining duration of

oscillator ramp–up period. The stator current is converted to

a voltage by inserting a ground–referenced sense resistor R

(Figure 36) in series with the three bottom switch transistors

(Q4, Q5, Q6). The voltage developed across the sense

resistor is monitored by the Current Sense Input (Pins 9 and

15), and compared to the internal 100 mV reference. The

current sense comparator inputs have an input common

mode range of approximately 3.0 V. If the 100 mV current

sense threshold is exceeded, the comparator resets the

120°

S

S

low.

C

0

0

0

1

1

1

0

0

0

1

1

1

0

0

F/R Enable

1

1

1

1

1

1

0

0

0

0

0

0

X

X

X

X

B

A

1

0

1

1

0

1

0

1

0

0

1

0

1

0

1

1

0

1

0

1

0

0

1

0

10101

10101

° select (Pin 22) in the high (1) state, configuration is for 60°sensor electrical phasing inputs. With Pin 22 in low (0) state, configuration

Brake

1

1

1

1

1

1

1

1

1

1

1

1

X

X

X

X

Current

Sense

0

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

0

0

0

0

0

0

0

0

0

0

0

0

X

X

X

X

low.

BTCTABBBCBFault

A

T

0

1

1

0

1

1

1

1

0

1

1

0

0

1

1

111

111

low.

low.

0

0

1

1

1

1

1

1

1

0

0

1

1

high.

low.

1

1

0

0

1

0

0

1

1

1

1

1

1

1

1

0

0

0

1

0

1

0

0

1

0

1

1

0

0

1

0

1

0

0

0

0

1

0

0

000

0

1

111

1

1

1

1

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

1

1

1

1

0

1

0

0

0

Brake = 0

0

1

0

Brake = 1

lower sense latch and terminates output switch conduction.

The value for the current sense resistor is:

RS+

0.1

I

stator(max)

The Fault output activates during an over current condition.

The dual–latch PWM configuration ensures that only one

single output conduction pulse occurs during any given

oscillator cycle, whether terminated by the output of the error

amp or the current limit comparator.

Figure 21. Pulse Width Modulator Timing Diagram

Capacitor C

Error Amp Out/

Sense Input

S

Bottom Drive

Fault Output

T

PWM Input

Current

Latch “Set”

Inputs

Top Drive

Outputs

Outputs

(Note 5)

F/R = 1

(Note 5)

F/R = 0

(Note 6)

(Note 7)

10

MOTOROLA ANALOG IC DEVICE DATA

Page 11

MC33035

Reference

The on–chip 6.25 V regulator (Pin 8) provides charging

current for the oscillator timing capacitor, a reference for the

error amplifier, and can supply 20 mA of current suitable for

directly powering sensors in low voltage applications. In

higher voltage applications, it may become necessary to

transfer the power dissipated by the regulator off the IC. This

is easily accomplished with the addition of an external pass

transistor as shown in Figure 22. A 6.25 V reference level

was chosen to allow implementation of the simpler NPN

circuit, where V

– VBE exceeds the minimum voltage

ref

required by Hall Effect sensors over temperature. With

proper transistor selection and adequate heatsinking, up to

one amp of load current can be obtained.

Figure 22. Reference Output Buffers

UVLO

UVLO

39

17

18

8

To

Control

Circuitry

6.25 V

17

18

0.1

8

REF

REF

V

in

MPS

U01A

Sensor

Power

≈

5.6 V

V

in

MPS

U51A

To Control Circuitry

and Sensor Power

6.25 V

The NPN circuit is recommended for powering Hall or opto sensors, where the

output voltage temperature coefficient is not critical. The PNP circuit is slightly

more complex, but is also more accurate over temperature. Neither circuit has

current limiting.

Undervoltage Lockout

A triple Undervoltage Lockout has been incorporated to

prevent damage to the IC and the external power switch

transistors. Under low power supply conditions, it guarantees

that the IC and sensors are fully functional, and that there is

sufficient bottom drive output voltage. The positive power

supplies to the IC (VCC) and the bottom drives (VC) are each

monitored by separate comparators that have their

thresholds at 9.1 V. This level ensures sufficient gate drive

necessary to attain low R

when driving standard power

DS(on)

MOSFET devices. When directly powering the Hall sensors

from the reference, improper sensor operation can result if

the reference output voltage falls below 4.5 V. A third

comparator is used to detect this condition. If one or more of

the comparators detects an undervoltage condition, the Fault

Output is activated, the top drives are turned off and the

bottom drive outputs are held in a low state. Each of the

comparators contain hysteresis to prevent oscillations when

crossing their respective thresholds.

Fault

Output

The open collector Fault

Output (Pin 14) was designed to

provide diagnostic information in the event of a system

malfunction. It has a sink current capability of 16 mA and

can directly drive a light emitting diode for visual indication.

Additionally, it is easily interfaced with TTL/CMOS logic for

use in a microprocessor controlled system. The Fault

Output is active low when one or more of the following

conditions occur:

1) Invalid Sensor Input code

2) Output Enable at logic [0]

3) Current Sense Input greater than 100 mV

4) Undervoltage Lockout, activation of one or more of

the comparators

5) Thermal Shutdown, maximum junction temperature

being exceeded

This unique output can also be used to distinguish

between motor start–up or sustained operation in an

overloaded condition. With the addition of an RC network

between the Fault

Output and the enable input, it is possible

to create a time–delayed latched shutdown for overcurrent.

The added circuitry shown in Figure 23 makes easy starting

of motor systems which have high inertial loads by providing

additional starting torque, while still preserving overcurrent

protection. This task is accomplished by setting the current

limit to a higher than nominal value for a predetermined time.

During an excessively long overcurrent condition, capacitor

C

will charge, causing the enable input to cross its

DLY

threshold to a low state. A latch is then formed by the positive

feedback loop from the Fault

Output to the Output Enable.

Once set, by the Current Sense Input, it can only be reset by

shorting C

or cycling the power supplies.

DLY

Drive Outputs

The three top drive outputs (Pins 1, 2, 24) are open

collector NPN transistors capable of sinking 50 mA with a

minimum breakdown of 30 V. Interfacing into higher voltage

applications is easily accomplished with the circuits shown in

Figures 24 and 25.

The three totem pole bottom drive outputs (Pins 19, 20,

21) are particularly suited for direct drive of N–Channel

MOSFETs or NPN bipolar transistors (Figures 26, 27, 28

and 29). Each output is capable of sourcing and sinking up

to 100 mA. Power for the bottom drives is supplied from V

(Pin 18). This separate supply input allows the designer

added flexibility in tailoring the drive voltage, independent of

VCC. A zener clamp should be connected to this input when

driving power MOSFETs in systems where VCC is greater

than 20 V so as to prevent rupture of the MOSFET gates.

The control circuitry ground (Pin 16) and current sense

inverting input (Pin 15) must return on separate paths to the

central input source ground.

Thermal Shutdown

Internal thermal shutdown circuitry is provided to protect

the IC in the event the maximum junction temperature is

exceeded. When activated, typically at 170°C, the IC acts

as though the Output Enable was grounded.

C

MOTOROLA ANALOG IC DEVICE DATA

11

Page 12

MC33035

R

DLY

V

M

Reset

C

DLY

Figure 23. Timed Delayed Latched

Over Current Shutdown

4

5

22

17

18

6

3

REF

8

25

7

POS

DEC

UVLO

µ

A

14

2

1

24

21

20

Figure 24. High V oltage Interface with

NPN Power Transistors

14

2

Rotor

Position

Decoder

1

24

21

20

19

V

M

V

CC

Q

2

Q

Q

1

3

Load

Q

4

V

–(IILenable R

t

DLY

[

[

R

R

DLYCDLY

DLYCDLY

In

In

ref

ǒ

Vthenable – (IILenable R

6.25 – (20 x 10–6R

ǒ

1.4–(20x10–6R

Figure 25. High Voltage Interface with

N–Channel Power MOSFETs

Rotor

Position

Decoder

14

VCC = 12

2

1

24

21

DLY

DLY

1.0 k

1

2

1.0 M

4.7 k

MOC8204

Optocoupler

DLY

)

V

)

DLY

)

Ǔ

V

Boost

5

6

4

1N4744

Ǔ

)

VM =

Load

170 V

Transistor Q1 is a common base stage used to level shift from VCC to the

high motor voltage, VM. The collector diode is required if VCC is present

while VM is low.

Figure 26. Current Waveform Spike Suppression

21

20

19

23

40 k

100 mV

9

15

Brake Input

R

C

R

S

12

20

19

The addition of the RC filter will eliminate current–limit instability caused by the

Q

4

leading edge spike on the current waveform. Resistor RS should be a low

inductance type.

MOTOROLA ANALOG IC DEVICE DATA

Page 13

MC33035

Figure 27. MOSFET Drive Precautions Figure 28. Bipolar Transistor Drive

21

R

g

C

21

D

20

R

g

20

C

D

19

R

g

C

19

D

23

40 k

100 mV

9

15

Brake Input

40 k

100 mV

23

Series gate resistor Rg will dampen any high frequency oscillations caused

by the MOSFET input capacitance and any series wiring induction in the

gate–source circuit. Diode D is required if the negative current into the Bottom Drive Outputs exceeds 50 mA.

9

15

Brake Input

D = 1N5819

The totem–pole output can furnish negative base current for enhanced transistor turn–off, with the addition of capacitor C.

Figure 29. Current Sensing Power MOSFETs Figure 30. High Voltage Boost Supply

I

B

+

0

–

t

Base Charge

Removal

D

SENSEFET

21

S

G

K

M

20

19

9

R

15

S

100 mV

16 Gnd

Control Circuitry Ground (Pin 16) and Current Sense Inverting Input (Pin 15)

must return on separate paths to the Central Input Source Ground.

Virtually lossless current sensing can be achieved with the implementation of

SENSEFET power switches.

Power Ground:

To Input Source Return

RS@

Ipk@

R

V

[

9

Pin

r

DM(on)

DS(on)

)

R

S

If: SENSEFET = MPT10N10M

Ω

Pin 9

, 1/4 W

≈

0.75 I

pk

RS = 200

Then : V

VCC = 12 V

8

6

5

2

1

MC1555

0.001

This circuit generates V

R

S

18 k

VM + 12

VM + 8.0

4

Q

7

3

* = MUR115

Boost

BoostVoltage (V)

VM + 4.0

1.0/200 V

1N5352A

for Figure 25.

0

Boost Current (mA)

20

40

*

22

*

VM = 170 V

V

Boost

60

MOTOROLA ANALOG IC DEVICE DATA

13

Page 14

MC33035

Figure 31. Differential Input Speed Controller

REF

8

7

R

1

V

A

V

B

V

13

Pin

11

R

2

R

3

12

13

R

4

R3)

+

V

ǒ

A

)

R

1

25 µA

EA

PWM

R

R

4

Ǔ

R

2

R

2

4

*

V

ǒ

Ǔ

R

3

B

R

3

Figure 33. Digital Speed Controller Figure 34. Closed Loop Speed Control

5.0 V

BCD

Inputs

12

13

14

15

16

V

P3

P2

P1

P0

Gnd

8

11

Q

CC

9

10

Q

8

9

Q

7

7

Q

6

6

Q

5

5

Q

4

SN74LS145

4

Q

3

3

Q

2

2

Q

1

1

Q

0

166 k

145 k

126 k

108 k

92.3 k

77.6 k

63.6 k

51.3 k

40.4 k

100 k

8

7

11

12

13

REF

EA

25

µ

A

PWM

Figure 32. Controlled Acceleration/Deceleration

REF

8

Enable

R

1

Increase

Speed

Resistor R1 with capacitor C sets the acceleration time constant while R

controls the deceleration. The values of R1 and R2 should be at least ten

times greater than the speed set potentiometer to minimize time constant

variations with different speed settings.

To Sensor

Input (Pin 4)

0.01

10 k

0.1

R

10 k

100 k

1.0 M

2

C

0.22

7

11

12

13

8

7

11

12

13

1.0 M

25 µA

EA

PWM

REF

25 µA

EA

PWM

2

The SN74LS145 is an open collector BCD to One of T en decoder . When connected as shown, input codes 0000 through 1001 steps the PWM in

increments of approximately 10% from 0 to 90% on–time. Input codes 1010

through 1111 will produce 100% on–time or full motor speed.

Figure 35. Closed Loop T emperature Control

R3)

R

V

+

V

ǒ

3

Pi

V

B

R3§§

This circuit can control the speed of a cooling fan proportional to the difference

between the sensor and set temperatures. The control loop is closed as the

forced air cools the NTC thermistor. For controlled heating applications,

exchange the positions of R1 and R2.

ref

n

V

ref

+

R

5

)

ǒ

R

6

R5ø

4

Ǔ

)

R

R

2

1

1

Ǔ

R

5

R

6

R

6

14

The rotor position sensors can be used as a tachometer. By dif ferentiating

the positive–going edges and then integrating them over time, a voltage

proportional to speed can be generated. The error amp compares this

voltage to that of the speed set to control the PWM.

R

R

2

4

*

V

ǒ

Ǔ

R

3

R

1

R

3

B

R

3

8

7

T

11

R

2

12

R

13

4

REF

25 µA

EA

PWM

MOTOROLA ANALOG IC DEVICE DATA

Page 15

MC33035

SYSTEM APPLICATIONS

Three Phase Motor Commutation

The three phase application shown in Figure 36 is a

full–featured open loop motor controller with full wave, six

step drive. The upper power switch transistors are

Darlingtons while the lower devices are power MOSFETs.

Each of these devices contains an internal parasitic catch

diode that is used to return the stator inductive energy back to

the power supply. The outputs are capable of driving a delta

or wye connected stator, and a grounded neutral wye if split

supplies are used. At any given rotor position, only one top

and one bottom power switch (of different totem poles) is

enabled. This configuration switches both ends of the stator

winding from supply to ground which causes the current flow

to be bidirectional or full wave. A leading edge spike is usually

present on the current waveform and can cause a

current–limit instability. The spike can be eliminated by

adding an RC filter in series with the Current Sense Input.

Using a low inductance type resistor for RS will also aid in

spike reduction. Care must be taken in the selection of the

Figure 36. Three Phase, Six Step, Full Wave Motor Controller

4

bottom power switch transistors so that the current during

braking does not exceed the device rating. During braking,

the peak current generated is limited only by the series

resistance of the conducting bottom switch and winding.

I

peak

+

R

switch

VM)

)

EMF

R

winding

If the motor is running at maximum speed with no load, the

generated back EMF can be as high as the supply voltage,

and at the onset of braking, the peak current may approach

twice the motor stall current. Figure 37 shows the

commutation waveforms over two electrical cycles. The first

cycle (0° to 360°) depicts motor operation at full speed while

the second cycle (360° to 720°) shows a reduced speed with

about 50% pulse width modulation. The current waveforms

reflect a constant torque load and are shown synchronous to

the commutation frequency for clarity .

V

M

14

Fault

Ind.

Fwd/Rev

60°/120

Enable

V

R

T

C

T

°

M

Speed

Set

Faster

5

6

3

22

7

17

18

8

11

12

13

10

25

Reference

Regulator

Error Amp

Oscillator

µ

A

Undervoltage

Lockout

PWM

Rotor

Position

Decoder

Thermal

Shutdown

R

S

S

R

2

1

24

21

20

Q

Q

I

Limit

19

9

15

Q

3

Q

6

C

Q

1

Q

2

Q

4

Q

5

R

R

S

N

S

A

B

C

S

N

Motor

MOTOROLA ANALOG IC DEVICE DATA

Gnd 16

23

Brake

15

Page 16

MC33035

Figure 37. Three Phase, Six Step, Full Wave Commutation W aveforms

Rotor Electrical Position (Degrees)

Sensor Inputs

60°/120

Select Pin

Open

Sensor Inputs

60°/120

Select Pin

Grounded

Top Drive

Outputs

480420360300240180120600

S

A

S

B

°

S

C

Code

S

°

Code

100

A

S

B

S

C

100 110 001011 001011110100010 010 101101

A

T

B

T

100

000001011111110

011111110

720660600540

000001

Bottom Drive

Outputs

Conducting

Power Switch

Transistors

Motor Drive

Current

C

T

A

B

B

B

C

B

6

Q2 + Q

Q1 + Q

+

O

A

–

+

O

B

–

+

O

C

–

Q2 + Q4Q3 + Q4Q3 + Q5Q1 + Q5Q1 + Q

6

Fwd/Rev = 1

Q2 + Q6Q2 + Q4Q3 + Q4Q3 + Q

6

Reduced Speed ( ≈ 50% PWM)Full Speed (No PWM)

5

Q1 + Q

5

16

MOTOROLA ANALOG IC DEVICE DATA

Page 17

MC33035

Figure 38 shows a three phase, three step, half wave motor

controller. This configuration is ideally suited for automotive

and other low voltage applications since there is only one

power switch voltage drop in series with a given stator

winding. Current flow is unidirectional or half wave because

only one end of each winding is switched. Continuous braking

with the typical half wave arrangement presents a motor

overheating problem since stator current is limited only by the

winding resistance. This is due to the lack of upper power

switch transistors, as in the full wave circuit, used to

disconnect the windings from the supply voltage VM. A unique

Figure 38. Three Phase, Three Step, Half Wave Motor Controller

4

5

Rotor

Position

Decoder

Fwd/Rev

6

3

solution is to provide braking until the motor stops and then

turn off the bottom drives. This can be accomplished by using

the Fault

over current timer. Components R

Output in conjunction with the Output Enable as an

DL Y

and C

are selected

DL Y

to give the motor sufficient time to stop before latching the

Output Enable and the top drive AND gates low. When

enabling the motor, the brake switch is closed and the PNP

transistor (along with resistors R1 and R

the latch by discharging C

. The stator flyback voltage is

DLY

) are used to reset

DL Y

clamped by a single zener and three diodes.

Motor

C

DLY

14

2

1

R

DLY

R

2

R

1

N

SS

V

M

N

R

T

C

60°/120

V

T

°

M

Speed

Set

Faster

22

7

17

18

8

11

12

13

10

25

µ

Reference

Regulator

Error Amp

Oscillator

A

Undervoltage

Lockout

PWM

Thermal

Shutdown

R

S

S

R

24

21

20

Q

Q

I

Limit

19

9

15

MOTOROLA ANALOG IC DEVICE DATA

Gnd

16

23

Brake

17

Page 18

MC33035

Three Phase Closed Loop Controller

The MC33035, by itself, is only capable of open loop

motor speed control. For closed loop motor speed control,

the MC33035 requires an input voltage proportional to the

motor speed. Traditionally, this has been accomplished by

means of a tachometer to generate the motor speed

feedback voltage. Figure 39 shows an application whereby

an MC33039, powered from the 6.25 V reference (Pin 8) of

the MC33035, is used to generate the required feedback

voltage without the need of a costly tachometer. The same

Hall sensor signals used by the MC33035 for rotor position

decoding are utilized by the MC33039. Every positive or

negative going transition of the Hall sensor signals on any of

the sensor lines causes the MC33039 to produce an output

pulse of defined amplitude and time duration, as determined

by the external resistor R1 and capacitor C1. The output train

Figure 39. Closed Loop Brushless DC Motor Control

Using The MC33035 and MC33039

of pulses at Pin 5 of the MC33039 are integrated by the error

amplifier of the MC33035 configured as an integrator to

produce a DC voltage level which is proportional to the

motor speed. This speed proportional voltage establishes

the PWM reference level at Pin 13 of the MC33035 motor

controller and closes the feedback loop. The MC33035

outputs drive a TMOS power MOSFET 3–phase bridge.

High currents can be expected during conditions of start–up,

breaking, and change of direction of the motor.

The system shown in Figure 39 is designed for a motor

having 120/240 degrees Hall sensor electrical phasing. The

system can easily be modified to accommodate 60/300

degree Hall sensor electrical phasing by removing the

jumper (J2) at Pin 22 of the MC33035.

Enable

Speed

10 k

Faster

100 k

F/R

4.7 k

5.1 k

0.01

1

2

3

4

1

2

3

4

5

6

7

8

9

10

11

12

MC33039

MC33035

1.0 M

0.1

Close Loop

8

7

6

5

1.0 k

1.0 k

24

23

22

21

20

19

18

17

16

15

14

13

J

2

J

1

1.0 M

R

750 pF

C

TP

1

1

1

1.0 k

Brake

1N5819

1N5355B

18 V

VM (18 to 30 V)

1.1 k 1.1 k

470

470

470

330

0.1

1N4148

2.2 k

Latch On

Fault

1.1 k

2.2 k

Fault

0.1

Reset

47 µF

0.1

1000

100

33

TP

2

0.05/1.0 W

S

Motor

N

S

N

18

MOTOROLA ANALOG IC DEVICE DATA

Page 19

MC33035

Sensor Phasing Comparison

There are four conventions used to establish the relative

phasing of the sensor signals in three phase motors. With six

step drive, an input signal change must occur every 60

electrical degrees; however, the relative signal phasing is

dependent upon the mechanical sensor placement. A

comparison of the conventions in electrical degrees is shown

in Figure 40. From the sensor phasing table in Figure 41,

note that the order of input codes for 60° phasing is the

reverse of 300°. This means the MC33035, when configured

for 60° sensor electrical phasing, will operate a motor with

either 60° or 300° sensor electrical phasing, but resulting in

opposite directions of rotation. The same is true for the part

when it is configured for 120° sensor electrical phasing; the

motor will operate equally, but will result in opposite

directions of rotation for 120° for 240° conventions.

Figure 40. Sensor Phasing Comparison

Rotor Electrical Position (Degrees)

720660600540480420360300240180120600

S

A

60°

S

B

S

C

S

A

120°

S

B

S

C

S

A

S

240°

Sensor Electrical Phasing

300°

SASBSCSASBSCSASBSCSASBS

1 0 0 1 0 1 1 1 0 1 1 1

1 1 0 1 0 0 1 0 0 1 1 0

1 1 1 1 1 0 1 0 1 1 0 0

0 1 1 0 1 0 0 0 1 0 0 0

0 0 1 0 1 1 0 1 1 0 0 1

0 0 0 0 0 1 0 1 0 0 1 1

B

S

C

S

A

S

B

S

C

Figure 41. Sensor Phasing T able

Sensor Electrical Phasing (Degrees)

60° 120° 240° 300°

C

In this data sheet, the rotor position is always given in

electrical degrees since the mechanical position is a function

of the number of rotating magnetic poles. The relationship

between the electrical and mechanical position is:

Electrical Degrees+Mechanical Degrees

ǒ

Ǔ

2

#Rotor Poles

An increase in the number of magnetic poles causes more

electrical revolutions for a given mechanical revolution.

General purpose three phase motors typically contain a four

pole rotor which yields two electrical revolutions for one

mechanical.

Two and Four Phase Motor Commutation

The MC33035 is also capable of providing a four step

output that can be used to drive two or four phase motors.

The truth table in Figure 42 shows that by connecting sensor

inputs SB and SC together, it is possible to truncate the

number of drive output states from six to four. The output

power switches are connected to BT, CT, BB, and CB.

Figure 43 shows a four phase, four step, full wave motor

control application. Power switch transistors Q1 through Q

are Darlington type, each with an internal parasitic catch

diode. With four step drive, only two rotor position sensors

spaced at 90 electrical degrees are required. The

commutation waveforms are shown in Figure 44.

Figure 45 shows a four phase, four step, half wave motor

controller. It has the same features as the circuit in Figure 38,

except for the deletion of speed control and braking.

Figure 42. T wo and Four Phase, Four Step,

Commutation Truth Table

MC33035 (60°/120° Select Pin Open)

Inputs Outputs

Sensor Electrical

Spacing* = 90°

S

A

1

1

0

0

1

1

0

0

*With MC33035 sensor input SB connected to SC.

S

B

0

1

1

0

0

1

1

0

F/R B

Top Drives Bottom Drives

C

T

1

1

1

1

0

0

0

0

1

0

1

1

1

1

1

0

T

1

1

0

1

0

1

1

1

B

C

B

0

0

0

1

0

1

0

0

B

1

0

0

0

0

0

1

0

8

MOTOROLA ANALOG IC DEVICE DATA

19

Page 20

MC33035

1

Q

S

N

N

S

A

B

C

Motor

D

5

Q

M

V

Ind.

Fault

14

2

Q

3

Q

4

Q

6

Q

S

7

Q

8

Q

R

R

C

Limit

I

9

15

2

1

24

21

20

19

23

Figure 43. Four Phase, Four Step, Full Wave Motor Controller

4

20

Rotor

Position

Decoder

Thermal

Shutdown

Q

S

R

Q

R

S

Gnd 16

Lockout

Undervoltage

Error Amp

11

12

PWM

13

Oscillator

10

T

R

T

C

µ

25 A

22

7

Enable

17

18

M

V

3

5

6

Fwd/Rev

Regulator

Reference

8

MOTOROLA ANALOG IC DEVICE DATA

Page 21

Sensor Inputs

60°/120

Select Pin

Open

Top Drive

Outputs

Bottom Drive

Outputs

Conducting

Power Switch

Transistors

MC33035

Figure 44. Four Phase, Four Step, Full Wave Motor Controller

Rotor Electrical Position (Degrees)

180 270 360 450 540 630 720090

S

A

°

S

B

Code

B

T

C

B

B

C

T

B

Q3 + Q

Q4 + Q

5

Q1 + Q

6

Q2 + Q

7

Q3 + Q

8

Q4 + Q

5

Q1 + Q

6

0001111000011010

Q2 + Q

7

8

Motor Drive

Current

+

A

O

–

+

B

O

–

+

C

O

–

+

D

O

–

Full Speed (No PWM)

Fwd/Rev = 1

MOTOROLA ANALOG IC DEVICE DATA

21

Page 22

M

V

Fault

Ind.

MC33035

N

S

S

N

Motor

S

R

R

C

14

Figure 45. Four Phase, Four Step, Half Wave Motor Controller

4

24

Rotor

Position

1

Decoder

2

21

20

Thermal

Shutdown

19

Q

S

R

9

15

Limit

I

23

Brake

Q

R

S

Gnd 16

Lockout

Undervoltage

Error Amp

11

12

PWM

13

Oscillator

10

µ

25 A

22

7

17

18

3

5

6

Regulator

Reference

8

22

Fwd/Rev

V

Enable

M

T

R

T

C

MOTOROLA ANALOG IC DEVICE DATA

Page 23

MC33035

Brush Motor Control

Though the MC33035 was designed to control brushless

DC motors, it may also be used to control DC brush type

motors. Figure 46 shows an application of the MC33035

driving a MOSFET H–bridge affording minimal parts count to

operate a brush–type motor. Key to the operation is the input

sensor code [100] which produces a top–left (Q1) and a

bottom–right (Q3) drive when the controller’s forward/reverse

pin is at logic [1]; top–right (Q4), bottom–left (Q2) drive is

realized when the Forward/Reverse pin is at logic [0]. This

code supports the requirements necessary for H–bridge

drive accomplishing both direction and speed control.

The controller functions in a normal manner with a pulse

width modulated frequency of approximately 25 kHz. Motor

speed is controlled by adjusting the voltage presented to the

noninverting input of the error amplifier establishing the

PWM’s slice or reference level. Cycle–by–cycle current

limiting of the motor current is accomplished by sensing the

voltage (100 mV) across the RS resistor to ground of the

H–bridge motor current. The over current sense circuit makes

it possible to reverse the direction of the motor, using the

Figure 46. H–Bridge Brush–Type Controller

4

5

Rotor

Position

Decoder

Fwd/Rev

6

3

normal forward/reverse switch, on the fly and not have to

completely stop before reversing.

LAYOUT CONSIDERA TIONS

Do not attempt to construct any of the brushless

motor control circuits on wire–wrap or plug–in prototype

boards. High frequency printed circuit layout techniques are

imperative to prevent pulse jitter. This is usually caused by

excessive noise pick–up imposed on the current sense or

error amp inputs. The printed circuit layout should contain a

ground plane with low current signal and high drive and

output buffer grounds returning on separate paths back to the

power supply input filter capacitor VM. Ceramic bypass

capacitors (0.1 µF) connected

close to the integrated circuit at VCC, VC, V

amp noninverting input may be required depending upon

circuit layout. This provides a low impedance path for filtering

any high frequency noise. All high current loops should be

kept as short as possible using heavy copper runs to

minimize radiated EMI.

Fault

14

2

1

Ind.

20 k

1.0 k

and the error

ref

1.0 k

Q1*

+12 V

10 k

10 k

0.005

Enable

+12 V

Faster

22

7

17

18

8

11

12

13

10

µ

A

25

Reference

Regulator

Error Amp

Oscillator

Undervoltage

Lockout

PWM

Thermal

Shutdown

R

S

S

R

Gnd

24

DC Brush

Motor

21

22

20

9

15

19

1.0 k

0.001

Q

Q

16

I

23

Brake

Limit

M

Q2*

22

Q4*

Q3*

R

S

MOTOROLA ANALOG IC DEVICE DATA

23

Page 24

MC33035

OUTLINE DIMENSIONS

OUTLINE DIMENSIONS

-A-

1324

112

-B-

-T-

SEATING

PLANE

E

G

F

D

N

24 PL

0.25 (0.010) T A

-A-

24 13

-B-

112

D 24 PL

0.010 (0.25) A B

M

S S

T

C

-T-

SEATING

PLANE

G 22 PL

PLASTIC PACKAGE

C

K

M M

PLASTIC PACKAGE

P 12 PL

0.010 (0.25)

J

K

P SUFFIX

CASE 724–03

ISSUE D

L

J 24 PL

0.25 (0.010) T B

DW SUFFIX

CASE 751E–04

(SO–24L)

ISSUE E

M M

B

F

M

NOTE 1

M

M M

R X 45°

NOTES:

1. CHAMFERED CONTOUR OPTIONAL.

2. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

3. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

4. CONTROLLING DIMENSION: INCH.

INCHES MILLIMETERS

MIN MINMAX MAX

DIM

A

1.230

B

0.250

C

0.145

D

0.015

E

0.050 BSC

F

0.040

0.100 BSC

G

J

0.007

K

0.110

0.300 BSC

L

M

0

°

N

0.020

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.13 (0.005) TOTAL IN

EXCESS OF D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

MILLIMETERS INCHES

MIN MINMAX MAX

DIM

15.25

A

7.40

B

2.35

C

0.35

D

0.41

F

1.27 BSC 0.050 BSC

G

J

0.23

K

0.13

M

0

°

P

10.05

R

0.25

1.265

0.270

0.175

0.020

0.060

0.012

0.140

15

0.040

15.54

7.60

2.65

0.49

0.90

0.32

0.29

8

10.55

0.75

31.25

32.13

6.35

6.85

3.69

4.44

0.38

0.51

1.27 BSC

1.02

1.52

2.54 BSC

0.18

0.30

2.80

3.55

7.62 BSC

0

0.51

0.601

0.292

0.093

0.014

0.016

0.009

0.005

0

°

0.395

0.010

15

°

°

1.01

0.612

0.299

0.104

0.019

0.035

0.013

0.011

8

°

0.415

0.029

°

°

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

Mfax is a trademark of Motorola, Inc.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Motorola Japan Ltd.; SPD, Strategic Planning Office, 141,

P.O. Box 5405, Denver, Colorado 80217. 1–303–675–2140 or 1–800–441–2447 4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan. 81–3–5487–8488

Customer Focus Center: 1–800–521–6274

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 1–602–244–6609 ASIA/P ACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

Moto rola Fax Ba ck System – US & Canada ONLY 1–800–774–1848 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

– http://sps.motorola.com/mfax/

HOME PAGE: http://motorola.com/sps/

24

◊

MOTOROLA ANALOG IC DEVICE DATA

MC33035/D

Loading...

Loading...