Page 1

查询MC33030供应商

Order this document by MC33030/D

The MC33030 is a monolithic DC servo motor controller providing all

active functions necessary for a complete closed loop system. This device

consists of an on–chip op amp and window comparator with wide input

common–mode range, drive and brake logic with direction memory, Power

H–Switch driver capable of 1.0 A, independently programmable over–current

monitor and shutdown delay, and over–voltage monitor. This part is ideally

suited for almost any servo positioning application that requires sensing of

temperature, pressure, light, magnetic flux, or any other means that can be

converted to a voltage.

Although this device is primarily intended for servo applications, it can be

used as a switchmode motor controller.

• On–Chip Error Amp for Feedback Monitoring

• Window Detector with Deadband and Self Centering Reference Input

• Drive/Brake Logic with Direction Memory

• 1.0 A Power H–Switch

• Programmable Over–Current Detector

• Programmable Over–Current Shutdown Delay

• Over–Voltage Shutdown

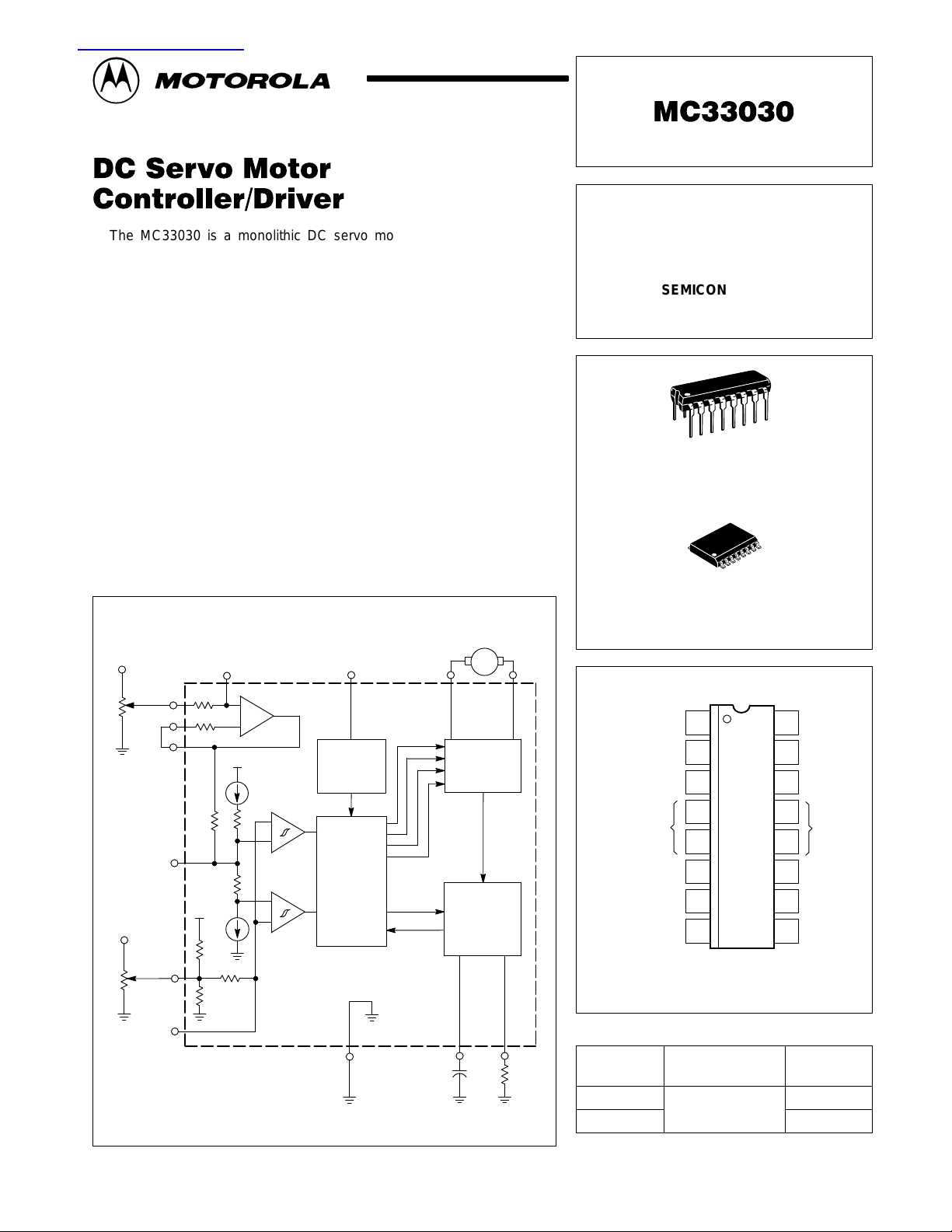

Representative Block Diagram

Motor

V

CC

Feedback

Position

V

CC

Reference

Position

9

8

7

6

3

+

1

2

Error Amp

+

–

+

+

–

Window

Detector

+

–

This device contains 119 active transistors.

V

CC

Over–

Voltage

Monitor

Drive/

Brake

Logic

Direction

Memory

4, 5, 12, 13

1011

Programmable

C

DLY

Power

H–Switch

Over–

Current

Detector

& Latch

14

1516

R

OC

DC SERVO MOTOR

CONTROLLER/DRIVER

SEMICONDUCTOR

TECHNICAL DATA

16

1

P SUFFIX

PLASTIC PACKAGE

CASE 648C

(DIP–16)

16

1

DW SUFFIX

PLASTIC PACKAGE

CASE 751G

(SOP–16L)

PIN CONNECTIONS

Reference

Reference

Input Filter

Error Amp Output

Filter/Feedback Input

Gnd

Error Amp

Error Amp

Inverting Input

Error Amp Non–

Inverting Input

Pins 4, 5, 12 and 13 are electrical ground and heat

sink pins for IC.

116

Input

2

3

4

5

6

Output

7

8

(Top View)

ORDERING INFORMATION

Operating

Device

MC33030DW

MC33030P

Temperature Range

TA = –40° to +85°C

Over–Current

Delay

Over–Current

15

Reference

Driver

14

Output A

13

Gnd

12

11

V

CC

Driver

10

Output B

Error Amp

9

Input Filter

Package

SOP–16L

DIP–16

MOTOROLA ANALOG IC DEVICE DATA

Motorola, Inc. 1996 Rev 2

1

Page 2

MC33030

pgg

IR

CC

Ch

Su , ua e Case 6 8C

Th

R

15

(Pins 4, 5, 12, 13)

Thermal Resistance, Junction to Case

R

θJC

18

Input Bias Current (V

Pi

R

L

100 k)

I

IB

7.0

nA

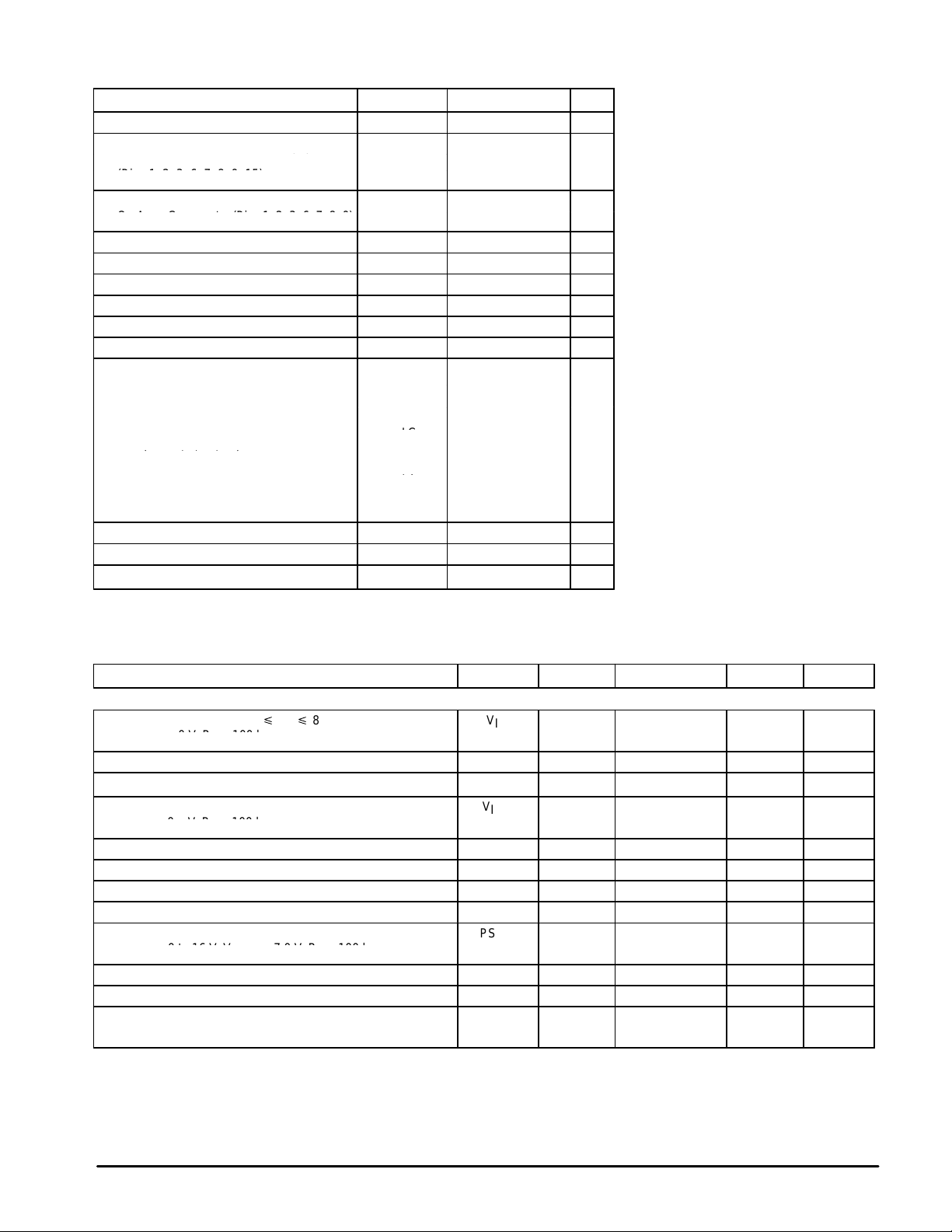

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Supply Voltage V

Input Voltage Range

Op Amp, Comparator, Current Limit

(Pins 1, 2, 3, 6, 7, 8, 9, 15)

Input Differential Voltage Range

Op Amp, Comparator (Pins 1, 2, 3, 6, 7, 8, 9)

Delay Pin Sink Current (Pin 16) I

Output Source Current (Op Amp) I

Drive Output Voltage Range (Note 1) V

Drive Output Source Current (Note 2) I

Drive Output Sink Current (Note 2) I

Brake Diode Forward Current (Note 2) I

Power Dissipation and Thermal

aracteristics

P Suffix, Dual In Line Case 648C

Thermal Resistance, Junction–to–Air

ermal Resistance, Junction–to–Case

(Pins 4, 5, 12, 13)

DW Suffix, Dual In Line Case 751G

Thermal Resistance, Junction–to–Air

Thermal Resistance, Junction–to–Case

(Pins 4, 5, 12, 13)

Operating Junction Temperature T

Operating Ambient Temperature Range T

Storage Temperature Range T

NOTES: 1.The upper voltage level is clamped by the forward drop, VF, of the brake diode.

2. These values are for continuous DC current. Maximum package power dissipation limits must

be observed.

CC

V

IR

V

IDR

DLY(sink)

source

DRV

DRV(source)

DRV(sink)

F

R

θJA

θJC

R

θJA

R

J

A

stg

–0.3 to (VCC + VF) V

36 V

–0.3 to V

–0.3 to V

20 mA

10 mA

1.0 A

1.0 A

1.0 A

80

94

18

+150 °C

–40 to +85 °C

–65 to +150 °C

CC

CC

V

V

°C/W

ELECTRICAL CHARACTERISTICS (V

Characteristic

ERROR AMP

Input Offset Voltage (– 40°C p TA p 85°C)

V

= 7.0 V, RL = 100 k

Pin 6

Input Offset Current (V

Input Common–Mode Voltage Range

∆VIO = 20 mV, RL = 100 k

Slew Rate, Open Loop (VID = 0.5 V, CL = 15 pF) SR – 0.40 – V/µs

Unity–Gain Crossover Frequency f

Unity–Gain Phase Margin φm – 63 – deg.

Common–Mode Rejection Ratio (V

Power Supply Rejection Ratio

VCC = 9.0 to 16 V, V

Output Source Current (V

Output Sink Current (V

Output Voltage Swing (RL = 17 k to Ground) V

NOTES: 3.The upper or lower hysteresis will be lost when operating the Input, Pin 3, close to the respective rail. Refer to Figure 4.

4.Low duty cycle pulse techniques are used during test to maintain junction temperature as close to ambient temperature as possible.

= 1.0 V, RL = 100 k) I

Pin 6

=

6 = 7.0 V,

n

Pin 6

= 7.0 V, RL = 100 k

Pin 6

= 12 V) IO

Pin 6

= 1.0 V) IO

Pin 6

= 14 V, TA = 25°C, unless otherwise noted.)

CC

Symbol Min Typ Max Unit

V

IO

IO

=

=

V

ICR

c

= 7.0 V, RL = 100 k) CMRR 50 82 – dB

PSRR – 89 – dB

+

–

OH

V

OL

– 1.5 10 mV

– 0.7 – nA

–

–

– 0 to (VCC – 1.2) – V

– 550 – kHz

– 1.8 – mA

– 250 – µA

12.5

–

13.1

0.02

–

–

–

–

V

V

2

MOTOROLA ANALOG IC DEVICE DATA

Page 3

MC33030

pg()

pg y

p(IN/DRV)

µ

()

y(

OC DRV

)

DLY(sink)

th(OC)

p(

A

)

()

pg g(

L

p)

()

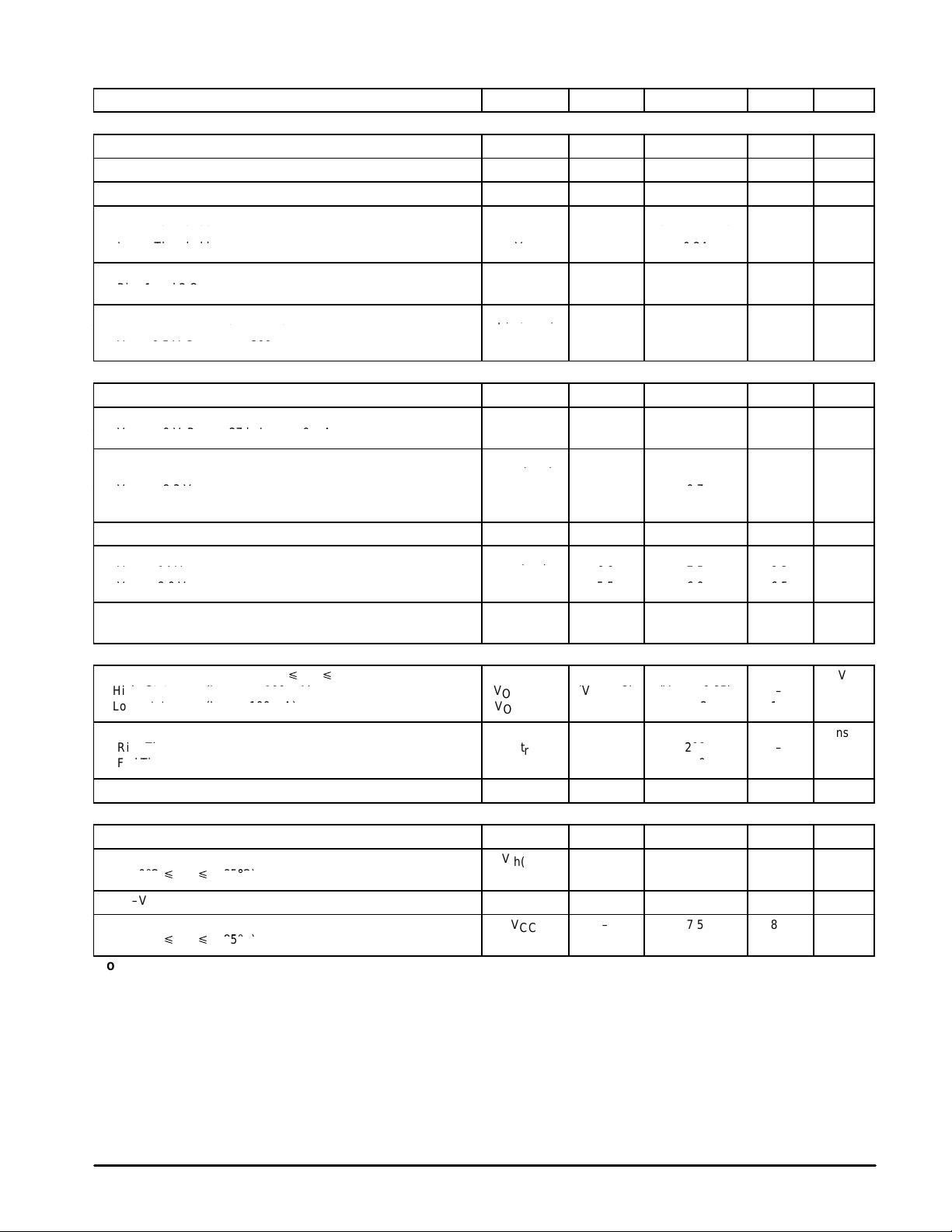

ELECTRICAL CHARACTERISTICS (continued) (V

Characteristic

WINDOW DETECTOR

Input Hysteresis Voltage (V1 – V4, V2 – V3, Figure 18) V

Input Dead Zone Range (V2 – V4, Figure 18) V

Input OffsetV oltage ([V2 – V

Input Functional Common–Mode Range (Note 3)

Upper Threshold

Lower Threshold V

Reference Input Self Centering Voltage

Pins 1 and 2 Open

Window Detector Propagation Delay

Comparator Input, Pin 3, to Drive Outputs

VID = 0.5 V, R

OVER–CURRENT MONITOR

Over–Current Reference Resistor Voltage (Pin 15) R

Delay Pin Source Current

V

= 0 V, ROC = 27 k, I

DLY

Delay Pin Sink Current (ROC = 27 k, I

V

= 5.0 V

DLY

V

= 8.3 V

DLY

V

= 14 V – 16.5 –

DLY

Delay Pin Voltage, Low State (I

Over–Current Shutdown Threshold

VCC = 14 V

VCC = 8.0 V 5.5 6.0 6.5

Over–Current Shutdown Propagation Delay

Delay Capacitor Input, Pin 16, to Drive Outputs, VID = 0.5 V

L(DRV)

= 390 Ω

] – [V

Pin 2

= 0 mA

DRV

= 0 mA) V

DLY

– V4] Figure 18) V

Pin 2

= 0 mA)

DRV

= 14 V, TA = 25°C, unless otherwise noted.)

CC

Symbol Min Typ Max Unit

H

IDZ

IO

V

IH

IL

V

RSC

t

p(IN/DRV)

OC

I

DLY(source)

I

DLY(sink)

OL(DLY)

V

th(OC)

t

p(DLY/DRV)

25 35 45 mV

166 210 254 mV

– 25 – mV

– (VCC – 1.05)

– 0.24 –

– (1/2 VCC) – V

– 2.0 – µs

3.9 4.3 4.7 V

– 5.5 6.9 µA

– 0.1

– 0.7

– 0.3 0.4 V

6.8

– 1.8 – µs

7.5

–

V

mA

–

–

V

8.2

POWER H–SWITCH

Drive–Output Saturation (– 40°C p TA p+ 85°C, Note 4)

High–State (I

Low–State (I

Drive–Output Voltage Switching T ime (CL = 15 pF)

Rise Time

Fall Time t

Brake Diode Forward Voltage Drop (IF = 200 mA, Note 4) V

TOTAL DEVICE

Standby Supply Current I

Over–Voltage Shutdown Threshold

(– 40°C p TA p + 85°C)

Over–Voltage Shutdown Hysteresis (Device “off” to “on”) V

Operating Voltage Lower Threshold

(– 40°C p TA p + 85°C)

NOTES: 3. The upper or lower hysteresis will be lost when operating the Input, Pin 3, close to the respective rail. Refer to Figure 4.

4.Low duty cycle pulse techniques are used during test to maintain junction temperature as close to ambient temperature as possible.

source

= 100 mA)

sink

= 100 mA)

V

OH(DRV)

V

OL(DRV)

t

r

f

F

CC

V

th(OV)

H(OV)

V

CC

(VCC – 2) (VCC – 0.85)

– 0.12 1.0

– 200

– 200 –

– 1.04 2.5 V

– 14 25 mA

16.5 18 20.5 V

0.3 0.6 1.0 V

– 7.5 8.0 V

–

V

ns

–

MOTOROLA ANALOG IC DEVICE DATA

3

Page 4

MC33030

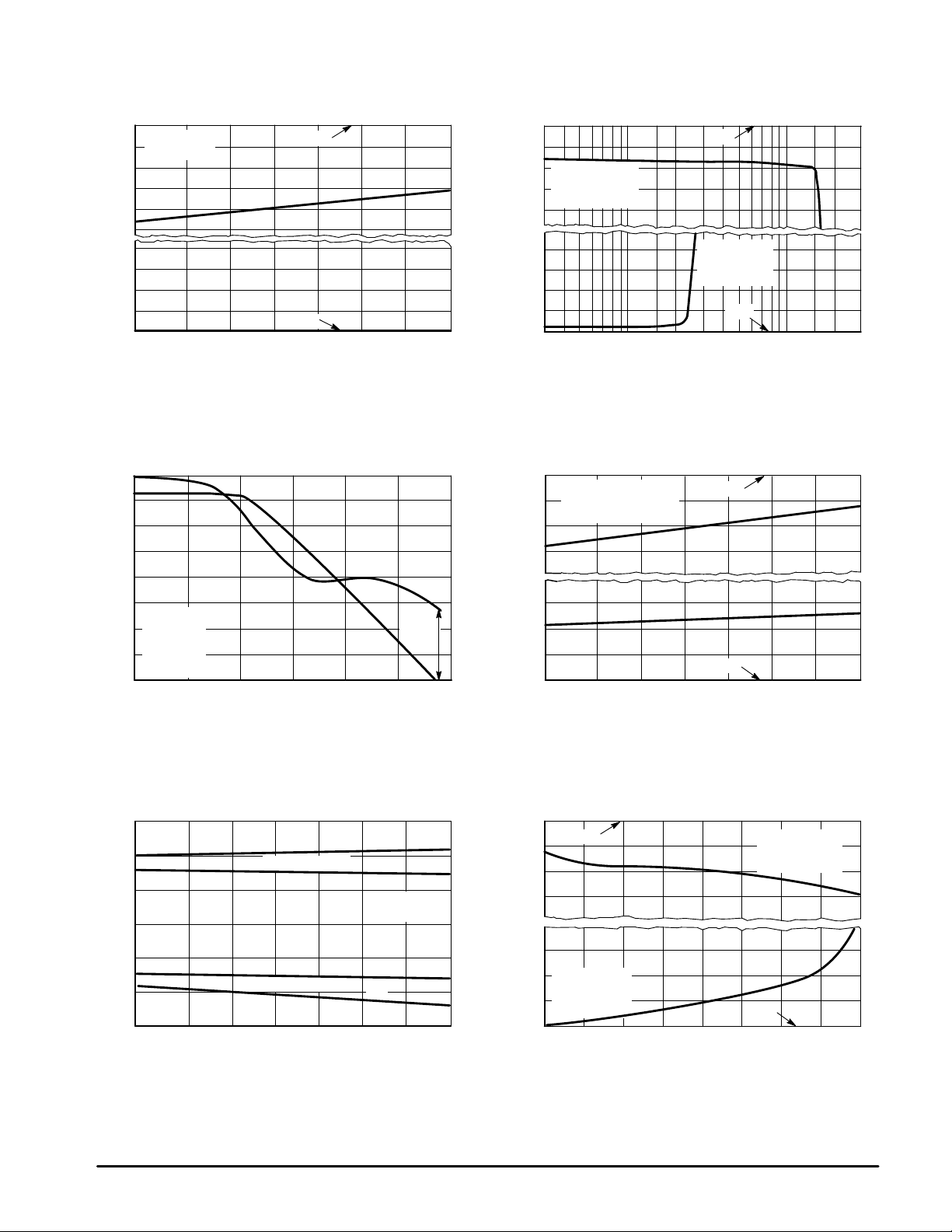

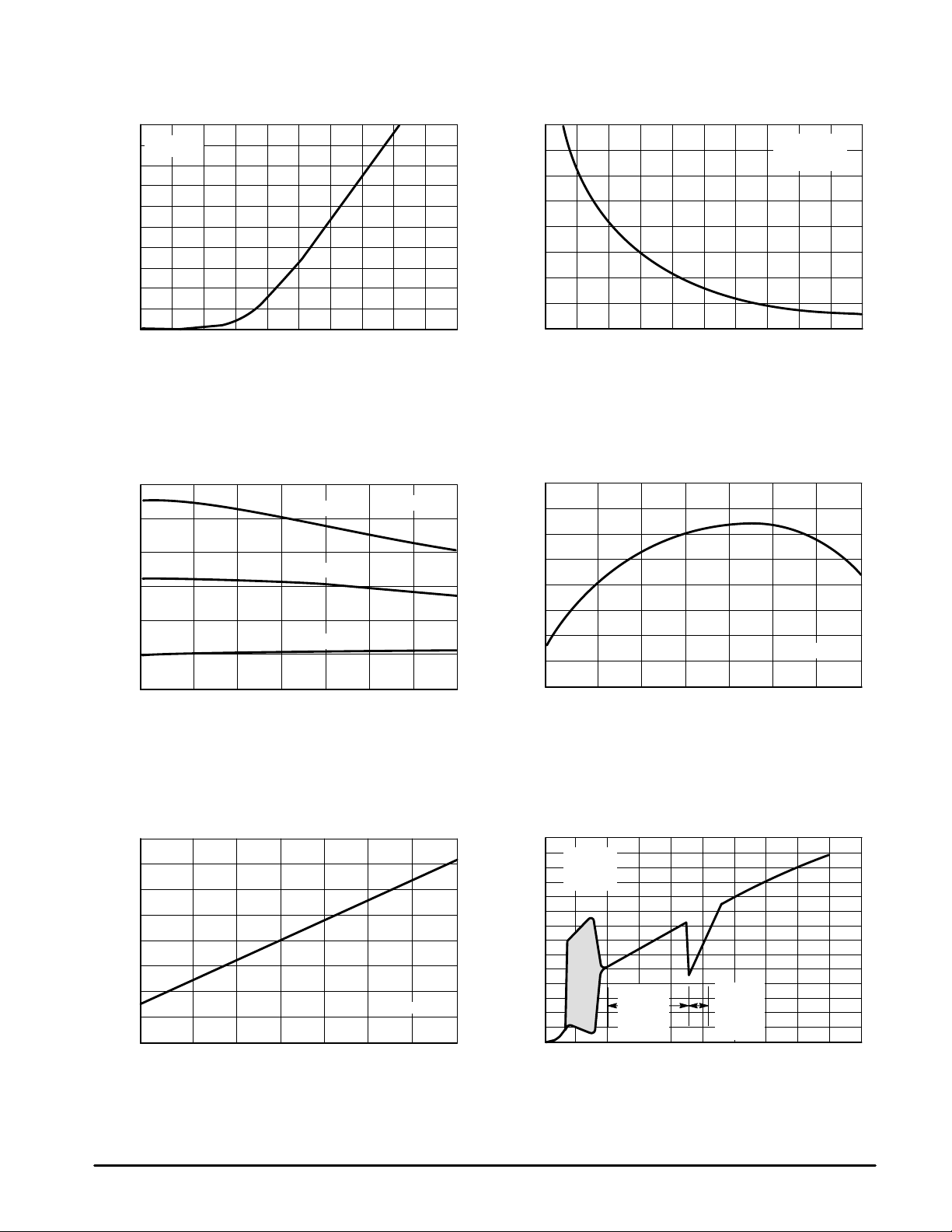

Figure 1. Error Amp Input Common–Mode

V oltage Range versus Temperature

0

∆

VIO = 20 mV

RL = 100 k

– 400

– 800

800

400

, INPUT COMMON–MODE RANGE (mV)

ICR

V

0

– 55

TA, AMBIENT TEMPERATURE (°C)

25 3.0 k100 1.0 k300

Figure 3. Open Loop V oltage Gain and

Phase versus Frequency

80

60

40

VCC = 14

V

= 7.0 V

20

out

RL = 100 k

, OPEN–LOOP VOLTAGE GAIN (dB)

CL = 40 pF

VOL

A

0

1.0 10 100 10 k 100 k 1.0 M1.0 k

TA = 25

°

C

Phase

f, FREQUENCY (Hz)

Gnd

V

CC

Gain

10050 750– 25

Phase

Margin

= 63

Figure 2. Error Amp Output Saturation

versus Load Current

125

0

– 1.0

Source Saturation

RL to Gnd

TA = 25

– 2.0

2.0

1.0

, OUTPUT SA TURATION VOLTAGE (V)

sat

V

0

30

°

C

IL, LOAD CURRENT (

V

CC

Sink Saturation

RL to VCC

°

C

TA = 25

Gnd

± µ

A)

Figure 4. Window Detector Reference–Input

Common–Mode V oltage Range

versus T emperature

0

45

90

135

°

, EXCESS PHASE (DEGREES)

φ

180

0

Max. Pin 2 V

Pin 3 can change

– 0.5

state of drive outputs.

– 1.0

– 1.5

0.3

0.2

, INPUT COMMON–MODE RANGE (V)

0.1

ICR

V

0

– 55

– 25

so that

ICR

0 255075100

TA, AMBIENT TEMPERATURE (

V

CC

Gnd

125

°

C)

Figure 5. Window Detector Feedback–Input

Thresholds versus T emperature

7.15

7.10

7.05

7.00

6.95

, FEEDBACK–INPUT VOLTAGE (V)

6.90

FB

V

6.85

– 55 – 25 125

TA, AMBIENT TEMPERATURE (

Upper Hysteresis

Lower Hysteresis

0 25 50 75 100

V

2

V

3

VCC = 14 V

Pin 2 = 7.00 V

V

1

V

4

°

C)

4

Figure 6. Output Driver Saturation

versus Load Current

0

V

CC

– 1.0

1.0

Sink Saturation

, OUTPUT SA TURATION VOLTAGE (V)

V

RL = VCC

°

C

TA = 25

sat

0

0 200 400 600 800

IL, LOAD CURRENT (±mA)

Source Saturation

RL to Gnd

TA = 25

Gnd

MOTOROLA ANALOG IC DEVICE DATA

°

C

Page 5

MC33030

, FORWARD CURRENT (mA)

F

I

500

400

300

200

100

600

400

Figure 7. Brake Diode Forward Current

versus Forward Voltage

TA = 25°C

0

VF, FORWARD VOLTAGE (V)

1.10.90.70.5

Figure 9. Output Source Current–Limit

versus T emperature

ROC = 15 k

ROC = 27 k

1.3

VCC = 14 V

1.5

, OUTPUT SOURCE CURRENT (mA)

source

I

1.04

1.00

0.96

Figure 8. Output Source Current–Limit versus

Over–Current Reference Resistance

800

VCC = 14 V

TA = 25

600

400

200

0

ROC, OVER–CURRENT REFERENCE RESISTANCE (k

Figure 10. Normalized Delay Pin Source

Current versus Temperature

°

C

806040020

100

Ω

)

200

, OUTPUT SOURCE CURRENT (mA)

source

I

0

– 55

TA, AMBIENT TEMPERATURE (°C)

Figure 11. Normalized Over–Current Delay

Threshold V oltage versus Temperature

1.04

1.02

1.00

(NORMALIZED)

0.98

, OVER–CURRENT DELAY THRESHOLD VOLTAGE

0.96

th(OC)

V

0– 25

TA, AMBIENT TEMPERATURE (

ROC = 68 k

25

VCC = 14 V

75 1005025– 55

°

C)

12575500– 25 100

125

(NORMALIZED)

, DELAY PIN SOURCE CURRENT

0.92

DLY(source)

0.88

I

– 55 12525 50 10075

– 25 0

TA, AMBIENT TEMPERATURE (

Figure 12. Supply Current versus

Supply V oltage

28

Pins 6 to 7

Pins 2 to 8

, SUPPLY CURRENT (mA)

CC

I

24

20

16

12

8.0

4.0

0

°

C

TA = 25

Minimum

Operating

Voltage

Range

8.0016

VCC, SUPPLY VOLTAGE (V)

Over–

Voltage

Shutdown

Range

24

VCC = 14 V

°

C)

32 40

MOTOROLA ANALOG IC DEVICE DATA

5

Page 6

MC33030

Figure 13. Normalized Over–Voltage Shutdown

Threshold versus T emperature

1.02

1.00

0.98

(NORMALIZED)

0.96

, OVER–VOLTAGE SHUTDOWN THRESHOLD

– 55 12525 50 100 75

th(OV)

V

– 25 0

TA, AMBIENT TEMPERATURE (°C)

Figure 14. Normalized Over–Voltage Shutdown

1.4

1.2

1.0

0.8

(NORMALIZED)

0.6

, OVER–VOLTAGE SHUTDOWN THRESHOLD

0.4

th(OV)

V

Figure 15. P Suffix (DIP–16) Thermal

Resistance and Maximum Power Dissipation

versus P.C.B. Copper Length

°

100

80

60

R

θ

JA

Printed circuit board heatsink example

2.0 oz

L

Copper

L

Graphs represent symmetrical layout

Hysteresis versus T emperature

– 25 0– 55 125

3.0 mm

25

TA, AMBIENT TEMPERATURE (

5.0

4.0

3.0

75 10050

°

C)

JA

θ

R , THERMAL RESISTANCE

°

JA

JUNCTION–TO–AIR ( C/W)

θ

R , THERMAL RESISTANCE

40

P

for TA = 70°C

20

JUNCTION–TO–AIR ( C/W)

0

0

D(max)

10 20 30 40 50

L, LENGTH OF COPPER (mm)

Figure 16. DW Suffix (SOP–16L) Thermal

Resistance and Maximum Power Dissipation

versus P.C.B. Copper Length

100

P

for TA = 50°C

90

80

70

60

50

40

30

02030504010

R

θ

L, LENGTH OF COPPER (mm)

D(max)

Graph represents symmetrical layout

2.0 oz.

L

Copper

JA

2.0

1.0

, MAXIMUM POWER DISSIPATION (W)

D

P

0

2.8

2.4

2.0

1.6

1.2

3.0 mmL

0.8

0.4

0

, MAXIMUM POWER DISSIPATION (W)

D

P

6

MOTOROLA ANALOG IC DEVICE DATA

Page 7

MC33030

OPERA TING DESCRIPTION

The MC33030 was designed to drive fractional horsepower

DC motors and sense actuator position by voltage feedback. A

typical servo application and representative internal block

diagram are shown in Figure 17. The system operates by

setting a voltage on the reference input of the Window

Dectector (Pin 1) which appears on (Pin 2). A DC motor then

drives a position sensor, usually a potentiometer driven by a

gear box, in a corrective fashion so that a voltage

proportional to position is present at Pin 3. The servo motor

will continue to run until the voltage at Pin 3 falls within the

dead zone, which is centered about the reference voltage.

The Window Detector is composed of two comparators, A

and B, each containing hysteresis. The reference input,

common to both comparators, is pre–biased at 1/2 VCC for

simple two position servo systems and can easily be

overriden by an external voltage divider. The feedback

voltage present at Pin 3 is connected to the center of two

resistors that are driven by an equal magnitude current

source and sink. This generates an offset voltage at the input

of each comparator which is centered about Pin 3 that can

float virtually from VCC to ground. The sum of the upper and

lower offset voltages is defined as the window detector input

dead zone range.

To increase system flexibility, an on–chip Error Amp is

provided. It can be used to buffer and/or gain–up the actuator

position voltage which has the effect of narrowing the dead

zone range. A PNP differential input stage is provided so that

the input common–mode voltage range will include ground.

The main design goal of the error amp output stage was to be

able to drive the window detector input. It typically can source

1.8 mA and sink 250 µA. Special design considerations must

be made if it is to be used for other applications.

The Power H–Switch provides a direct means for motor

drive and braking with a maximum source, sink, and brake

current of 1.0 A continuous. Maximum package power

dissipation limits must be observed. Refer to Figure 15 for

thermal information. For greater drive current requirements,

a method for buffering that maintains all the system features

is shown in Figure 30.

The Over–Current Monitor is designed to distinguish

between motor start–up or locked rotor conditions that can

occur when the actuator has reached its travel limit. A

fraction of the Power H–Switch source current is internally

fed into one of the two inverting inputs of the current

comparator, while the non–inverting input is driven by a

programmable current reference. This reference level is

controlled by the resistance value selected for ROC, and must

be greater than the required motor run–current with its

mechanical load over temperature; refer to Figure 8. During

an over–current condition, the comparator will turn off and

allow the current source to charge the delay capacitor, C

When C

over–current latch will go high, disabling the drive and brake

functions of the Power H–Switch. The programmable time

delay is determined by the capacitance value–selected for

C

DLY

t

DLY

This system allows the Power H–Switch to supply motor

start–up current for a predetermined amount of time. If the

charges to a level of 7.5 V, the set input of the

DLY

.

V

ref

+

I

DLY(source)

C

DLY

+

7.5 C

5.5 µA

DLY

+

1.36 C

DLY

DL Y

in µF

rotor is locked, the system will time–out and shut–down. This

feature eliminates the need for servo end–of–travel or limit

switches. Care must be taken so as not to select too large of

a capacitance value for C

an excessively long time–out period can cause the integrated

circuit to overheat and eventually fail. Again, the maximum

package power dissipation limits must be observed. The

over–current latch is reset upon power–up or by readjusting

V

as to cause V

Pin 2

zone. This can be achieved by requesting the motor to

reverse direction.

An Over–Voltage Monitor circuit provides protection for

the integrated circuit and motor by disabling the Power

H–Switch functions if VCC should exceed 18 V. Resumption

of normal operation will commence when VCC falls below

17.4 V.

A timing diagram that depicts the operation of the

Drive/Brake Logic section is shown in Figure 18. The

waveforms grouped in [1] show a reference voltage that was

preset, appearing on Pin 2, which corresponds to the desired

actuator position. The true actuator position is represented

by the voltage on Pin 3. The points V1 through V4 represent

the input voltage thresholds of comparators A and B that

cause a change in their respective output state. They are

defined as follows:

V1 = Comparator B turn–off threshold

V2 = Comparator A turn–on threshold

V3 = Comparator A turn–off threshold

V4 = Comparator B turn–on threshold

V1–V4 = Comparator B input hysteresis voltage

V2–V3 = Comparator A input hysteresis voltage

V2–V4 = Window detector input dead zone range

|(V2–V

voltage

It must be remembered that points V1 through V4 always

try to follow and center about the reference voltage setting if

it is within the input common–mode voltage range of Pin 3;

Figures 4 and 5. Initially consider that the feedback input

voltage level is somewhere on the dashed line between V

and V4 in [1]. This is within the dead zone range as defined

above and the motor will be off. Now if the reference voltage

is raised so that V

turn–on [3] enabling Q

and B to source motor current [8]. The actuator will move in

Direction B until V

B will turn–off, activating the brake enable [4] and Q

causing Drive Output A to go high and B to go into a high

impedance state. The inertia of the mechanical system will

drive the motor as a generator creating a positive voltage on

.

Pin 10 with respect to Pin 14. The servo system can be

stopped quickly, so as not to over–shoot through the dead

zone range, by braking. This is accomplished by shorting the

motor/generator terminals together. Brake current will flow

into the diode at Drive Output B, through the internal VCC rail,

and out the emitter of the sourcing transistor at Drive Output

A. The end of the solid line and beginning of the dashed for

V

Pin 3

actuator after braking.

) – (V

Pin2

[1] indicates the possible resting position of the

Pin 3

– V4)| = Window detector input

Pin2

Pin 3

Drive, causing Drive Output A to sink

becomes greater than V1. Comparator

Pin 3

. An over–current condition for

DLY

to enter or pass through the dead

is less than V4, comparator B will

2

Brake [6]

MOTOROLA ANALOG IC DEVICE DATA

7

Page 8

MC33030

Figure 17. Representative Block Diagram and T ypical Servo Application

V

CC

Gearbox and Linkage

Motor

V

CC

Inverting

Inverting

Input

Output

Error Amp

Output Filter/

Feedback

Input

V

CC

Reference

Input

Reference

Input Filter

Non–

Input

8

7

6

3

1

2

20 k

20 k

20 k

100 k

100 k

Window

Detector

Input

Filter

9

Error Amp

+

35

µ

A

3.0 k

3.0 k

35

µ

A

+

20 k

0.3 mA

B

A

4, 5,12,13

Gnd

18 V

Ref.

Over–Voltage

Monitor

Drive Brake Logic

Direction

Latch

Brake Enable

Q

Over–

Current

Latch

Q

Drive

Q

Q

R

Q

S

Q Drive

R

S

7.5 V

Ref.

Over–Current

Delay

Q Brake

Brake

Q

5.5

µ

A

50 k

16

C

DLY

11

Drive

Output B

+

R

10

Power

H–Switch

15

Over–Current

Reference

OC

Drive

Output A

14

+

Over–Current

Monitor

If V

should continue to rise and become greater than V2,

Pin 3

the actuator will have over shot the dead zone range and cause

the motor to run in Direction A until V

is equal to V3. The

Pin 3

Drive/Brake behavior for Direction A is identical to that of B.

Overshooting the dead zone range in both directions can cause

the servo system to continuously hunt or oscillate. Notice that the

last motor run–direction is stored in the direction latch. This

information is needed to determine whether Q or Q

enabled when V

enters the dead zone range. The dashed

Pin 3

Brake is to be

lines in [8,9] indicate the resulting waveforms of an over–current

condition that has exceeded the programmed time delay. Notice

that both Drive Outputs go into a high impedance state until V

is readjusted so that V

2

enters or crosses through the dead

Pin 3

Pin

zone [7, 4].

The inputs of the Error Amp and Window Detector can be

susceptible to the noise created by the brushes of the DC

motor and cause the servo to hunt. Therefore, each of these

inputs are provided with an internal series resistor and are

pinned out for an external bypass capacitor. It has been

found that placing a capacitor with

short leads

directly across

the brushes will significantly reduce noise problems. Good

quality RF bypass capacitors in the range of 0.001 to 0.1 µF

may be required. Many of the more economical motors will

generate significant levels of RF energy over a spectrum that

extends from DC to beyond 200 MHz. The capacitance value

and method of noise filtering must be determined on a

system by system basis.

Thus far, the operating description has been limited to

servo systems in which the motor mechanically drives a

potentiometer for position sensing. Figures 19, 20, 27, and 31

show examples that use light, magnetic flux, temperature,

and pressure as a means to drive the feedback element.

Figures 21, 22 and 23 are examples of two position, open

loop servo systems. In these systems, the motor runs the

actuator to each end of its travel limit where the Over–Current

Monitor detects a locked rotor condition and shuts down the

drive. Figures 32 and 33 show two possible methods of using

the MC33030 as a switching motor controller. In each

example a fixed reference voltage is applied to Pin 2. This

causes V

to be less than V4 and Drive Output A, Pin 14,

pin 3

to be in a low state saturating the TIP42 transistor. In Figure

32, the motor drives a tachometer that generates an ac

voltage proportional to RPM. This voltage is rectified, filtered,

divided down by the speed set potentiometer, and applied to

Pin. 8. The motor will accelerate until V

is equal to V1 at

Pin 3

which time Pin 14 will go to a high state and terminate the

motor drive. The motor will now coast until V

Pin 3

is less than

V4 where upon drive is then reapplied. The system operation

of Figure 31 is identical to that of 32 except the signal at Pin

3 is an amplified average of the motors drive and back EMF

voltages. Both systems exhibit excellent control of RPM with

variations of VCC; however, Figure 32 has somewhat better

torque characteristics at low RPM.

8

MOTOROLA ANALOG IC DEVICE DATA

Page 9

MC33030

Figure 18. Timing Diagram

Window

Detector

Comparator A

Non Inverting Input

Threshold

Reference Input Voltage

(Desired Actuator

Position)

Comparator B

Inverting Input

Threshold

Feedback Input

(True Actuator

Position)

Comparator

A Output

Comparator

B Output

Brake Enable

Direction Latch

Q Output

Direction Latch

Output

Q

V

2

V

3

[1]

V

1

V

4

[2]

[3]

[4]

[5]

Drive/Brake

Logic

Power

H–Switch

Over–Current

Monitor

Latch Reset Input

Drive

Output A

Drive

Output B

C

DLY

Q Brake

Brake

Q

Over–Current

Source

High Z

Sink

Source

High Z

Sink

Direction B

Feedback Input

less than V

1

Dead Zone

Feedback Input

between V1 & V

Feedback Input

greater than V

2

7.5 V

Direction A

Feedback Input

between V3 & V

2

Dead Zone

Direction B

Feedback Input

less than V

4

[6]

[7]

[8]

[9]

4

MOTOROLA ANALOG IC DEVICE DATA

9

Page 10

MC33030

Figure 19. Solar Tracking Servo System

R1, R2 – Cadium Sulphide Photocell

R1, R2 – 5M Dark, 3.0 k light resistance

CC

R3 – 30 k, repositions servo during

R3 – darkness for next sunrise.

20 k

8

7

20 k

6

V

CC

1

Adjust

10 k

≈15°

Offset

R

2

V

R

1

R

3

Servo Driven

Wheel

Centering

Figure 21. Infrared Latched T wo Position

Servo System

V

CC

470

MRD3056

Latch

Drive A

MRD3056

Latch

Drive B

470

39 k

68 k

VCC/2

20 k

8

7

20 k

1

9

9

Error Amp

+

–

Error Amp

Figure 20. Magnetic Sensing Servo System

Zero Flux

Centering

20 k

V

Linear

Hall

Effect

Sensor

B

CC

TL173C

Typical sensitivity with gain set at 3.9 k is 1.5 mV/gauss.

Servo motor controls magnetic field about sensor.

3.9 k

10 k

Gain

9

20 k

8

7

20 k

6

Error Amp

Figure 22. Digital T wo Position Servo System

V

Input

1

0

1 – Activates Drive A

0 – Activates Drive B

Over–current monitor (not shown) shuts down

servo when end stop is reached.

CC

MPS

A20

8

7

6

20 k

20 k

9

Error Amp

V

CC

Over–current monitor (not shown) shuts down

servo when end stop is reached.

Figure 23. 0.25 Hz Square–Wave

Servo Agitator

V

CC

100 k

100 k

22

100 k

130 k

+

R

C

8

7

6

9

20 k

20 k

0.72

[

f

Rq20 k

Error Amp

RC

Figure 24. Second Order Low–Pass Active Filter

9

20 k

R

C

Ǹ

Ǹ

1

R2C1C

2

C

1

C

2

2

R

C

2

1

p

V

in

f

+

o

+

Q

8

7

20 k

6

2

Error Amp

R = 1.0 M

C1 = 1000 pF

C2 = 100 pF

10

MOTOROLA ANALOG IC DEVICE DATA

Page 11

MC33030

Figure 25. Notch Filter Figure 26. Differential Input Amplifier

9

R

V

in

f

notch

R

2C

R/2

C

C

1

+

p

RC

2

For 60 Hz R = 53.6 k, C = 0.05

8

20 k

7

20 k

6

Error Amp

+

–

Figure 27. T emperature Sensing Servo System

V

Temperature

V

Pin 6

Cabin

Sensor

V

ǒ

CC

+

R

1

ǒ

R

2

In this application the servo motor drives the

heat/air conditioner modulator door in a duct system.

T

R

2

Temperature

R

4

)

1

R

3

Ǔ

)

1

CC

20 k

20 k

9

+

–

R

1

R

3

R

Set

8

7

4

6

V

CC

1

Ǔ

Error Amp

V

R +

V

V

A

B

∆

A

R

R

VA*

R1+

V

Pin 6

9

R

1

R

2

R

3

R

V

Pin 6

20 k

8

7

4

6

+

V

ǒ

A

20 k

R3)

)

R

1

+

–

R

4

R

2

Figure 28. Bridge Amplifier

V

Ref

R

R

V

B

R

R

3

VB+

V

Ref

R3,R2+

R

4

+

(VA–VB)

R

3

1

R

2

ǒ

4R

R4,R1uu

R

4

D

R

)2D

8

7

6

Ǔ

R

Error Amp

R

2

Ǔ

R

3

20 k

20 k

R

–

ǒ

9

R

4

V

B

R

3

Error Amp

+

–

Ǔ

Figure 29. Remote Latched Shutdown

R

Q

O.C.

SQ

7.5 V

16

C

DLY

A direction change signal is required at Pins 2 or 3 to

reset the over–current latch.

+

4.7 k

15

R

OC

MOTOROLA ANALOG IC DEVICE DATA

Figure 30. Power H–Switch Buffer

V

V

)

F(D1)

RE[

+

V

CC

8

2

7

1

4

3

LM311

V

V

in

Ref

From Drive

V

F(D2)–VBE(ON)

I

MOTOR–IDRV(max)

R

E

D

2D1

A

B

DRV(max)

470

≈ 0.5 A.

Outputs

This circuit maintains the brake and over–current

features of the MC33030. Set ROC to 15 k for

I

CC

Motor

R

E

D

D

1

2

11

Page 12

MC33030

Figure 31. Adjustable Pressure Differential Regulator

Zero Pressure

Offset Adjust

2.0 V for Zero

Pressure Differential

6.0 V for 100 kPa

(14.5 PSI)

Pressure Differential

2.0 k

1.0 k

VCC = 12 V

6.2 k

LM324 Quad

12 k

5.1 k

20 k

Gain

0.01

9

8

7

6

5.1 k

2.4 k

+

Op Amp

1.0 k

8.06 k

200

200

4.12 k

S –

1.0 k

1.76 k

S +

Pressure

Port

MPX11DP

Silicon

Pressure

Sensor

Vacuum

Port

VCC = 12 V

11

Gas Flow

10

Motor

14

+

Pressure

Differential

Reference Set

5.1 k

5.0 k

1.8 k

12 V

0.01

B

O.C.

S

DIR.

S

QR

Q

+

+

16

0.01

15

15 k

3

A

+

1

2

4, 5,12,13

QQR

12

MOTOROLA ANALOG IC DEVICE DATA

Page 13

MC33030

Figure 32. Switching Motor Controller With Buffered Output and Tach Feedback

VCC = 12 V

TACH

1N4001

MZ2361

Over

Current

Reset

1.0

12 V

Speed

Set

+

4.7 k

1N753

10 k

+

100

0.002

+

1.0 k

16

11

10

+

15

9

8

7

6

+

Q

3

+

1

2

4, 5,12,13

R

DIR.

SQ

Q

O.C.

SRQ

100

14

30 k

100

0.24

TIP42

+

10

1.0 k

Motor

+

MPS

A70

MOTOROLA ANALOG IC DEVICE DATA

13

Page 14

10 k

MC33030

Figure 33. Switching Motor Controller With Buffered Output and Back EMF Sensing

+

100

+

Speed

Set

10 k

1.0 10 k

2X–1N4001

+

20 k

8

7

6

3

1.0

9

+

Q

R

DIR.

SQ

+

1011

14

100

VCC = 12 V

0.24

100

TIP42

+

10

1.0 k

+

MPS

A70

Motor

Over

Current

Reset

+ 12 V

1N753

1

2

4, 5, 12, 13

Q

O.C.

+

SRQ

16

1.0 k

+

15

30 k

14

MOTOROLA ANALOG IC DEVICE DATA

Page 15

–T–

SEATING

PLANE

MC33030

OUTLINE DIMENSIONS

PLASTIC PACKAGE

CASE 648C–03

–A–

916

–B–

18

NOTE 5

C

N

0.25 (0.010)

–T–

SEATING

PLANE

S S

K

PLASTIC PACKAGE

CASE 751G–02

J

F

F

D

0.13 (0.005) T A

E

G

16 PL

M

–A–

916

–B–

18

G 14 PL

16 PL

D

0.25 (0.010) T A B

K

M

S

P 8 PL

C

P SUFFIX

(DIP–16)

L

J

0.13 (0.005) T B

DW SUFFIX

(SOP–16L)

M M

B

M

16 PL

R

X 45°

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD

FLASH.

5. INTERNAL LEAD CONNECTION, BETWEEN 4

AND 5, 12 AND 13.

INCHES

MIN MINMAX MAX

DIM

0.740

A

0.240

B

0.145

C

0.015

D

E

M

M

S

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE

DAMBAR PROTRUSION. ALLOWABLE

DAMBAR PROTRUSION SHALL BE 0.13

(0.005) TOTAL IN EXCESS OF D DIMENSION

AT MAXIMUM MATERIAL CONDITION.

DIM

A

B

C

D

F

G

J

K

M

P

R

0.050 BSC

0.040

F

0.100 BSC

G

0.008

J

0.115

K

0.300 BSC

L

0

M

°

N

0.015

MILLIMETERS INCHES

MIN MINMAX MAX

10.45

10.15

7.40

2.35

0.35

0.50

1.27 BSC 0.050 BSC

0.25

0.10

0

°

10.05

10.55

0.25

7.60

2.65

0.49

0.90

0.32

0.25

7

0.75

0.840

0.260

0.185

0.021

0.070

0.015

0.135

10

0.040

°

°

MILLIMETERS

18.80

6.10

3.69

0.38

1.27 BSC

1.02

2.54 BSC

0.20

2.92

7.62 BSC

0

°

0.39

0.400

0.411

0.292

0.299

0.093

0.104

0.014

0.019

0.020

0.035

0.010

0.012

0.004

0.009

0

°

0.395

0.415

0.010

0.029

7

21.34

6.60

4.69

0.53

1.78

0.38

3.43

1.01

°

10

°

MOTOROLA ANALOG IC DEVICE DATA

15

Page 16

MC33030

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 or 602–303–5454 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–81–3521–8315

MFAX: RMF AX0@email.sps.mot.com – TOUCHT ONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

16

◊

MOTOROLA ANALOG IC DEVICE DATA

MC33030/D

*MC33030/D*

Loading...

Loading...