查询MC141800AT供应商

MOTOROLA

SEMICONDUCTOR TECHNICAL DATA

Product Preview

LCD Segment / Common Driver

CMOS

MC141800A is a CMOS LCD Driver which consists of 193 high voltage

LCD driving signals to drive 128 Segment and 65 Common display. It has

6800-series parallel, IIC serial interface and Serial Peripheral interface (SPI)

capability for operating with general MCU. Besides the general LCD driver

features, it has on chip LCD Smart Bias Divider circuit such that minimize

external component required in applications.

MC141800AT: TAB (Tape Automated Bonding)

MCC141800AZ: Gold Bump Die

• Single Supply Operation, 2.4 V - 3.5 V

• Maximum 16.5V LCD Driving Output Voltage

• Low Current Stand-by Mode (<1uA)

• On Chip Internal DC/DC Converter / External Power Supply

• Smart Bias Divider

• 4X / 5X DC-DC Converter

• 8 bit 6800-series Parallel Interface, 1 MHz IIC Serial Interface and

Serial Peripheral Interface (SPI)

• On chip Oscillator

• Graphic Mode Operation

• On Chip 128 x 65 Display Data RAM

• Master Clear RAM

• Low Power Icon Mode (128 icons, <25uA)

• Display Masks for Implementation of Blinking Effect

• 1 to 65 Selectable Multiplex Ratio

• 1:7 / 1:9 Bias Ratio

• Re-mapping of Row and Column Drivers

• 16 level Internal Contrast Control

• External Contrast Control

• Built-in Temperature Compensation Circuit

• Selectable Display Waveform: Type B or Type C Waveform

• 2V Icon Mode Display On

MC141800A

MC141800AT

TAB

MCC141800AZ

Gold bump die

ORDERING INFORMATION

MC141800AT 70 mm TAB

MCC141800AZ Gold Bump Die

This document contains information on a product under development. Motorola reserves the right to change or discontinue this product without notice.

REV O

2/97

MC141800AMOTOROLA

3–277

Com0 to

Com64

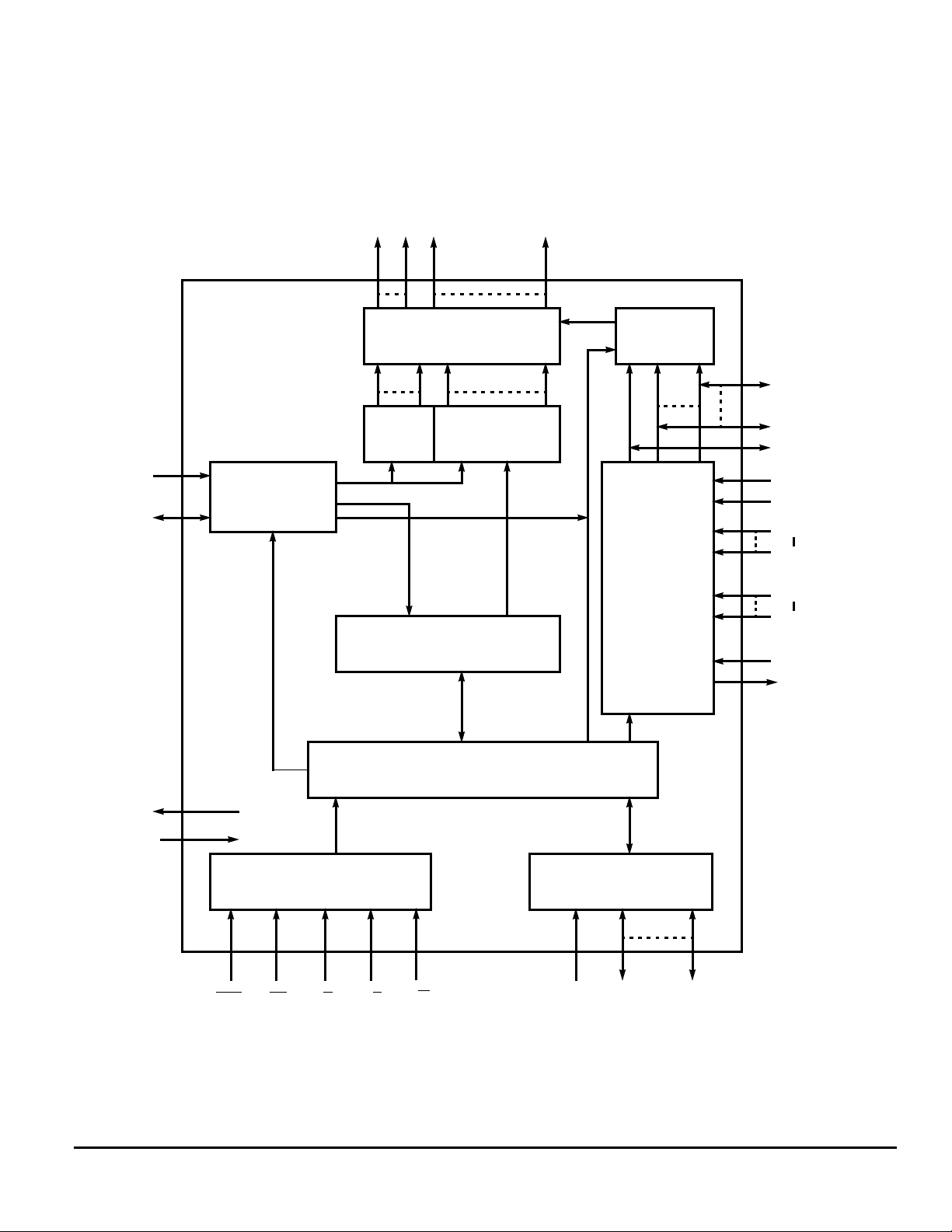

Block Diagram

Seg0~Seg127

OSC1

OSC2

Display

Timing

Generator

HV Buffer Cell Level Shifter

65 Bit

Latch

128 Bit Latch

GDDRAM

65 x 128Bits

Command Decoder

Level

Selector

LCD Driving

Voltage Generator

4x and 5x

DC/DC Converter,

Voltage Regulator,

Smart Bias Divider,

Contrast Control,

Temperature

Compensation

VLL6

VLL2

VCC

VR

VF

C1P

C3P

C1N

C3N

AVDD

AVSS

DVSS

DVDD

MC141800A

3–278

RES

D/

CCE S/P

Parallel / Serial InterfaceCommand Interface

R/

W

CLK

D0~D7

MOTOROLA

COM31

DUMMY

236

COM30

COM29

235

234

COM28

COM27

233

232

COM2

COM1

207

206

COM0

COM64B

205

204

SEG127

SEG126

SEG125

203

202

201

SEG124

SEG123

200

199

SEG66

SEG65

142

141

SEG64

SEG63

140

139

SEG62

SEG61

138

137

SEG2

SEG1

SEG0

COM32

7877767574

COM33

COM34

73

COM61

COM62

464544

COM63

COM64A

43

DUMMY

1234567891011121314151617181920212223242526272829303132333435363738394041

P

C

W

D6

DUMMY

S/

DVDD

RES

D5

SPI

D/

R/

D7/IIC/

D2/A2

D3/Din

D4/Dout

D1/A1

D0/SDA

CEVFVR

CLK

C1P

C1N

C2P

C2N

C3P

C3N

NC

NC

VLL2

VLL3

NCNCNC

NC

VLL4

VLL5

VLL6

OSC1

DVSS

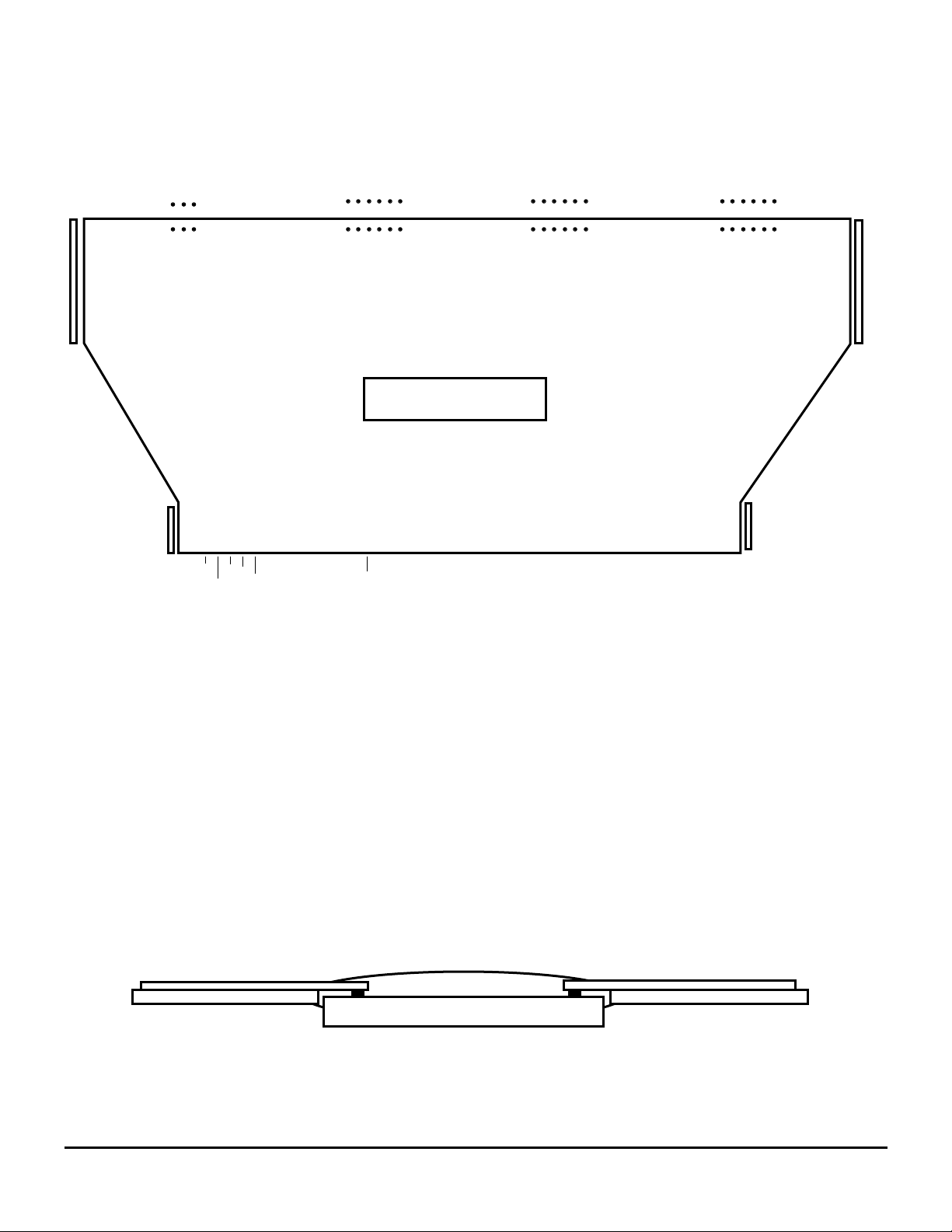

MC141800AT PIN ASSIGNMENT

(COPPER VIEW)

ENCAPSULANT

NC

NC

VCC

AVSS

42

OSC2

AVDD

COPPER

DUMMY

DIE

Mirror Design TAB

POLYIMIDE

MC141800AMOTOROLA

3–279

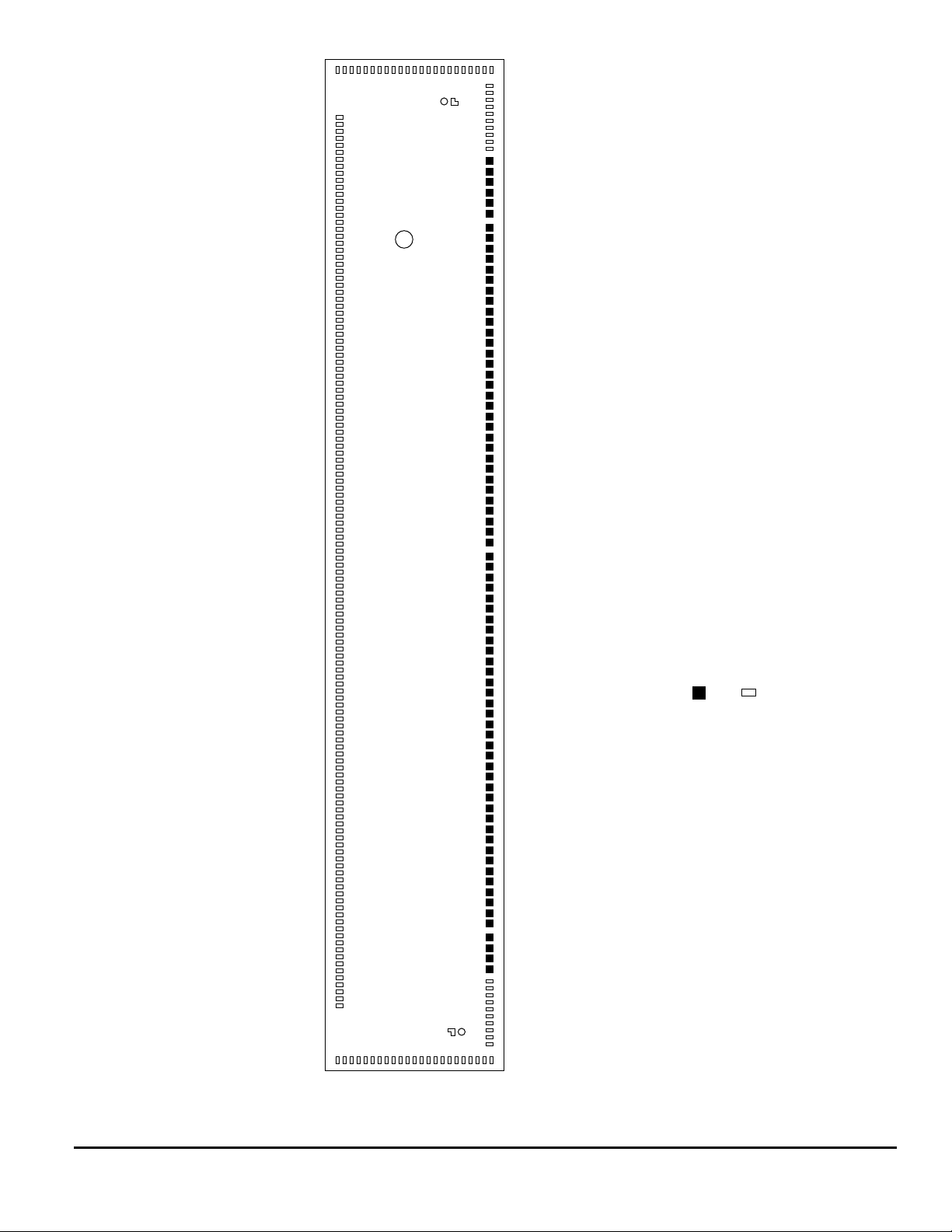

Die Pad Layout for MC141800A

SEG0

SEG1

SEG2

SEG126

SEG127

COM32

COM33...........COM53

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

MC141800A

M

COM54

COM55

COM56

.

.

COM63

COM64A

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

AVDD

OSC2

AVSS

VCC

VCC

DVSS

DVSS

OSC1

DVSS

VLL6

VLL6

VLL5

VLL5

VLL4

VLL4

VLL3

VLL3

VLL2

VLL2

C3N

C3P

C2N

C2P

C1N

C1P

VR

VF

AVSS

AVSS

AVDD

AVDD

DVSS

DVSS

DVDD

DVDD

CE

CLK

CLK

D0

D0

D1

D2

D3

D4

D5

D6

D7

R/W

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

D/C

RES

S/P

DVDD

COM31

.

.

.

.

.

COM22

Input Pad, 65 x 65 (um)

Gold Bump Size :

Output Pad, 42 x 100 (um)

MC141800A

3–280

...........

COM0

COM64B

COM20

COM21

MOTOROLA

MAXIMUM RATINGS* (Voltages Referenced to V

, TA=25˚C)

SS

Symbol Parameter Value Unit

AV

,DV

DD

V

CC

V

in

I Current Drain Per Pin Excluding VDD and V

T

A

T

stg

Supply Voltage -0.3 to +4.0 V

DD

VSS-0.3 to VSS+16.5 V

Input Voltage VSS-0.3 to VDD+0.3 V

SS

25 mA

Operating Temperature -30 to +85 ˚C

Storage Temperature Range -65 to +150 ˚C

This device contains circuitry to protect the inputs

against damage due to high static voltages or electric fields; however, it is advised that normal precautions to be taken to avoid application of any voltage

higher than maximum rated voltages to this high

impedance circuit. For proper operation it is recommended that V

and V

in

range VSS < or = (Vin or V

be constrained to the

out

) < or = VDD. Reliability

out

of operation is enhanced if unused input are connected to an appropriate logic voltage level (e.g.,

either VSS or VDD). Unused outputs must be left

open. This device may be light sensitive. Caution

should be taken to avoid exposure of this device to

* Maximum Ratings are those values beyond which damage to the device may occur. Functional

operation should be restricted to the limits in the Electrical Characteristics tables or Pin Descrip-

any light source during normal operation. This

device is not radiation protected.

tion section.

VSS = AVSS = DVSS (DVSS = VSS of Digital circuit, AVSS = VSS of Analogue Circuit)

VDD = AVDD = DVDD (DVDD = VDD of Digital circuit, AVDD = VDD of Analogue Circuit)

ELECTRICAL CHARACTERISTICS (Voltage Referenced to VSS, VDD=2.4 to 3.5V, TA=25˚C)

Symbol Parameter Test Condition Min Typ Max Unit

DV

AV

Logic Circuit Supply Voltage Range

DD

Voltage Generator Circuit Supply Voltage Range

DD

I

Access Mode Supply Current Drain

AC

(AVDD + DVDD Pins)

I

Display Mode Supply Current Drain

DP

(AVDD + DVDD Pins)

(Absolute value referenced to VSS) 2.4

2.4

VDD=3.0V, Internal DC/DC Converter On, 5X DC/DC

Converter Enabled, R/W accessing, T

=1MHz,

cyc

Osc. Freq.=50KHz, Display On.

VDD=3.0V, Internal DC/DC Converter On, 5X Converter Enabled, R/W Halt, Osc. Freq.=50KHz, Display On.

3.0

-

-

-

500

300

3.5

3.5

TBD

TBD

V

V

µA

µA

I

SB

I

ICON

V

CC

V

LCD

V

ICON

V

OH1

V

OL1

V

R1

V

R2

Standby Mode Supply Current Drain

VDD=3.0V, Display off, Oscillator Disabled, R/W halt.

-

TBD

1

µA

(AVDD + DVDD Pins)

Icon Mode Supply Current Drain

(AVDD + DVDD Pins)

LCD Driving Internal DC/DC Converter Output

(VCC Pin)

LCD Driving Voltage Input (VCC Pin)

VDD=3.0V, Internal Oscillator, Oscillator Enabled,

Display On, Icon On, R/W halt, Freq.=50KHz.

Display On, DC/DC Converter Enabled, Osc. Freq.=

50KHz, Internal Regulator Enabled, Divider Enabled.

Internal DC/DC Converter Disabled.

-

7

7

TBD

15

15

25

16.5

16.5VV

µA

Low Power Icon mode Voltage -2-V

Output High Voltage

I

out

=100µA

0.9*V

DD

-

V

DD

V

(D0-D7, OSC2)

Output Low Voltage

I

out

=100µA

0

-

0.1*V

DD

V

(D0-D7, OSC2)

LCD Driving Voltage Source (VR Pin)

Internal Regulator Enabled (VR voltage depends on

0

-

VCC-0.5

V

Int/Ext Contrast Control)

LCD Driving Voltage Source (VR Pin)

Internal Regulator Disable.

-

Floating

-

V

MC141800AMOTOROLA

3–281

ELECTRICAL CHARACTERISTICS (Voltage Referenced to VSS, VDD=2.4 to 3.5V, TA=25˚C)

Symbol Parameter Test Condition Min Typ Max Unit

V

Input high voltage

IH1

(RES, OSC2, CLK, CE, D0-D7,R/W, D/C, S/P,

OSC1)

V

Input Low voltage

IL1

(RES, OSC2, CLK, CE, D0-D7, R/W, D/C, S/P,

OSC1)

V

LCD Display Voltage Output

LL6

V

LL5

V

LL4

V

LL3

V

LL2

V

LL6

V

LL5

V

LL4

V

LL3

V

LL2

V

LL6

V

LL5

V

LL4

V

LL3

V

LL2

I

OH

(V

, V

LL6

LCD Display Voltage Output

(V

, V

LL6

LCD Display Voltage Input

(V

, V

LL6

Output High Current Source

(D0-D7, OSC2)

LL5

LL5

LL5

, V

, V

, V

LL4

LL4

LL4

, V

, V

, V

LL3

LL3

LL3

, V

, V

, V

LL2

LL2

LL2

Pins)

Pins)

Pins)

Smart Bias Divider Enabled, 1:9 bias ratio

Smart Bias Divider Enabled, 1:7 bias ratio

External Voltage Generator, Smart Bias Divider Disable

V

out=VDD

-0.4V

0.8*V

50

DD

0

-

-

-

-

-

-

-

-

-

-

7

0

0

0

0

-

-

V

8/9*V

7/9*V

2/9*V

1/9*V

V

6/7*V

5/7*V

2/7*V

1/7*V

-

-

-

-

-

-

V

DD

0.2*V

DD

R

R

-

-

R

-

R

-

R

-

R

-

-

R

-

R

-

R

-

R

V

CC

V

LL6

V

LL5

V

LL4

V

LL3

-

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

µA

I

Output Low Current Drain

OL

(D0-D7, OSC2)

I

Output Tri-state Current Drain Source

OZ

(D0-D7, OSC2)

IIL/IIHInput Current

(RES, OSC2, CLK, D0-D7, R/W, D/C, S/P,

OSC1)

C

Input Capacitance

IN

(OSC1, OSC2, all logic pins)

V

Internal Contrast Control

CN

(VR Output Voltage)

Temperature Coefficient Compensation

PTC0

PTC1

PTC2

PTC3

Flat Temperature Coefficient

Temperature Coefficient 1*

Temperature Coefficient 2*

Temperature Coefficient 3*

* The formula for the temperature coefficient is:

TC(%)=

VR at 50˚C - VR at 0˚C

50˚C - 0˚C

X

VR at 25˚C

V

out

=0.4V

-

-1

-

-

-50

1

µA

µA

-1 - 1 µA

- 5 7.5 pF

Internal Regulator Enabled, Internal Contrast control

- ± 12 - %

Enabled. (16 Voltage Levels Controlled by Software.

Each level is typically 1.5% of the Internal Regulator

Output Voltage.)

(TC1=0, TC2=0, Internal Regulator Disabled.)

(TC1=0, TC2=1, Internal Regulator Enabled.)

(TC1=1, TC2=0, Internal Regulator Enabled.)

(TC1=1, TC2=1, Internal Regulator Enabled.)

1

X100%

-

-

-

-

0.0

-0.18

-0.22

-0.35

-

%

-

%

-

%

-

%

MC141800A

3–282

MOTOROLA

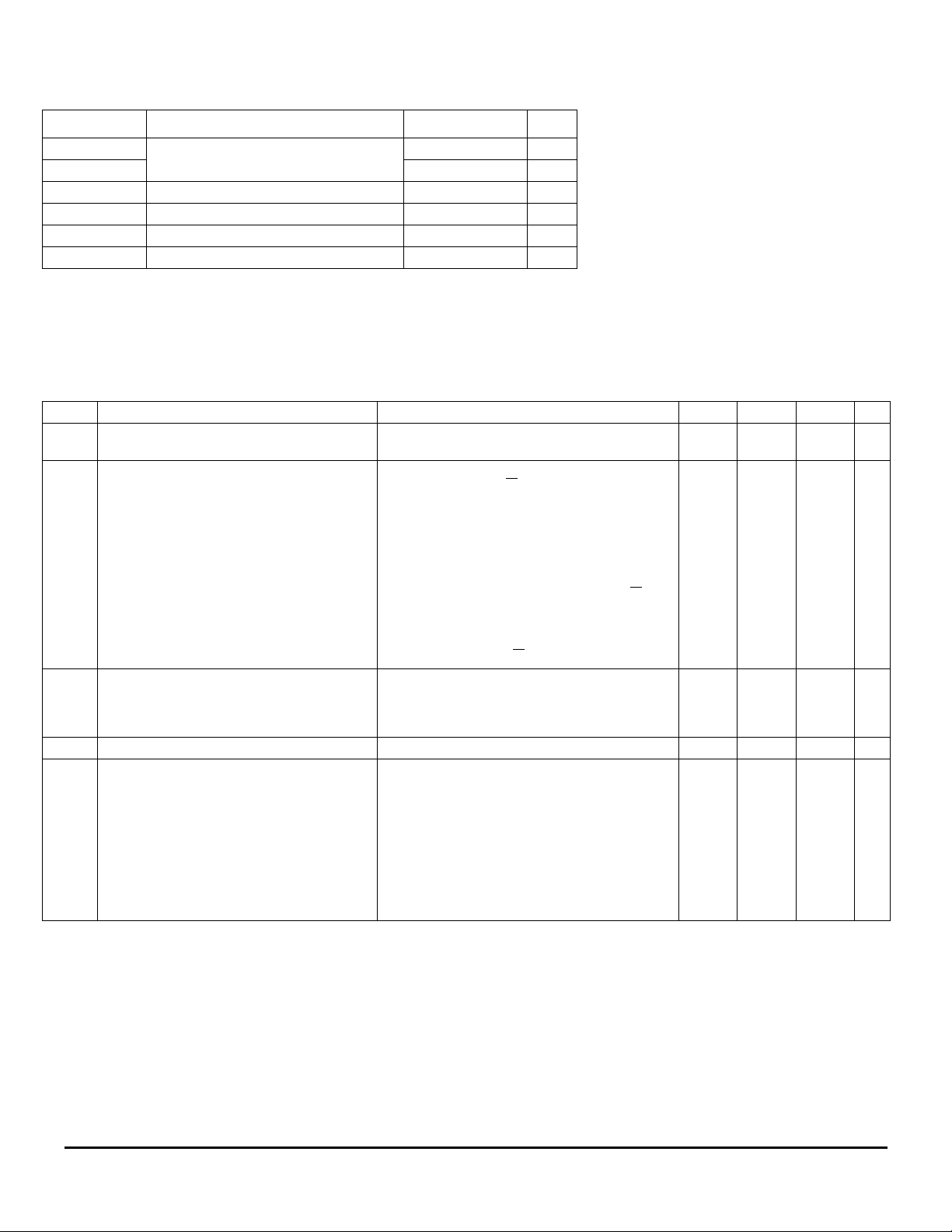

AC ELECTRICAL CHARACTERISTICS (TA=25˚C, Voltage referenced to VSS, AVDD=DVDD=3V)

Symbol Parameter Test Condition Min Typ Max Unit

F

F

Oscillation Frequency of Display timing generator 60Hz Frame Frequency

OSC

Either External Clock Input or Internal Oscillator

Enabled

Frame Frequency Graphic Display Mode, Normal Frequency Mode,

FRM

65 - 49 MUX

45 60 55 KHz

-

F

OSC

-

15 * MUX

Hz

OSC Internal Oscillation Frequency with different value

of feedback resistor

Graphic Display Mode, Half Frequency Mode,

65 - 49 MUX

Graphic Display Mode, Normal Frequency Mode,

48 - 33 MUX

Graphic Display Mode, Half Frequency Mode,

48 - 33 MUX

Graphic Display Mode, Normal Frequency Mode,

32 - 2 MUX

Graphic Display Mode, Half Frequency Mode,

32 -2 MUX

6-Phase Low Power Icon Mode, Normal Frequency

Mode

6-Phase Low Power Icon Mode, Half Frequency

Mode

4-Phase Low Power Icon Mode, Normal Frequency

Mode

4-Phase Low Power Icon Mode, Half Frequency

Mode

Internal Oscillator Enabled, VDD within operation

range

-

F

OSC

-

30 * MUX

-

F

OSC

-

23 * MUX

F

-

-

OSC

46 * MUX

F

OSC

-

-

30 * MUX

F

-

-

OSC

60 * MUX

F

OSC

-

-

960

-

F

OSC

-

1920

-

F

OSC

-

1024

-

F

OSC

-

2048

See Figure 1 for the relationship

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Oscillation

Frequency

(Hz)

280k

260k

90k

70k

50k

30k

10k

100k 500k 1.0M 1.5M 2.0M

Resistor Value between OSC1 and OSC2 (Ω)

Figure 1. Internal Oscillator Frequency Relationship with External Resistor Value

MC141800AMOTOROLA

3–283

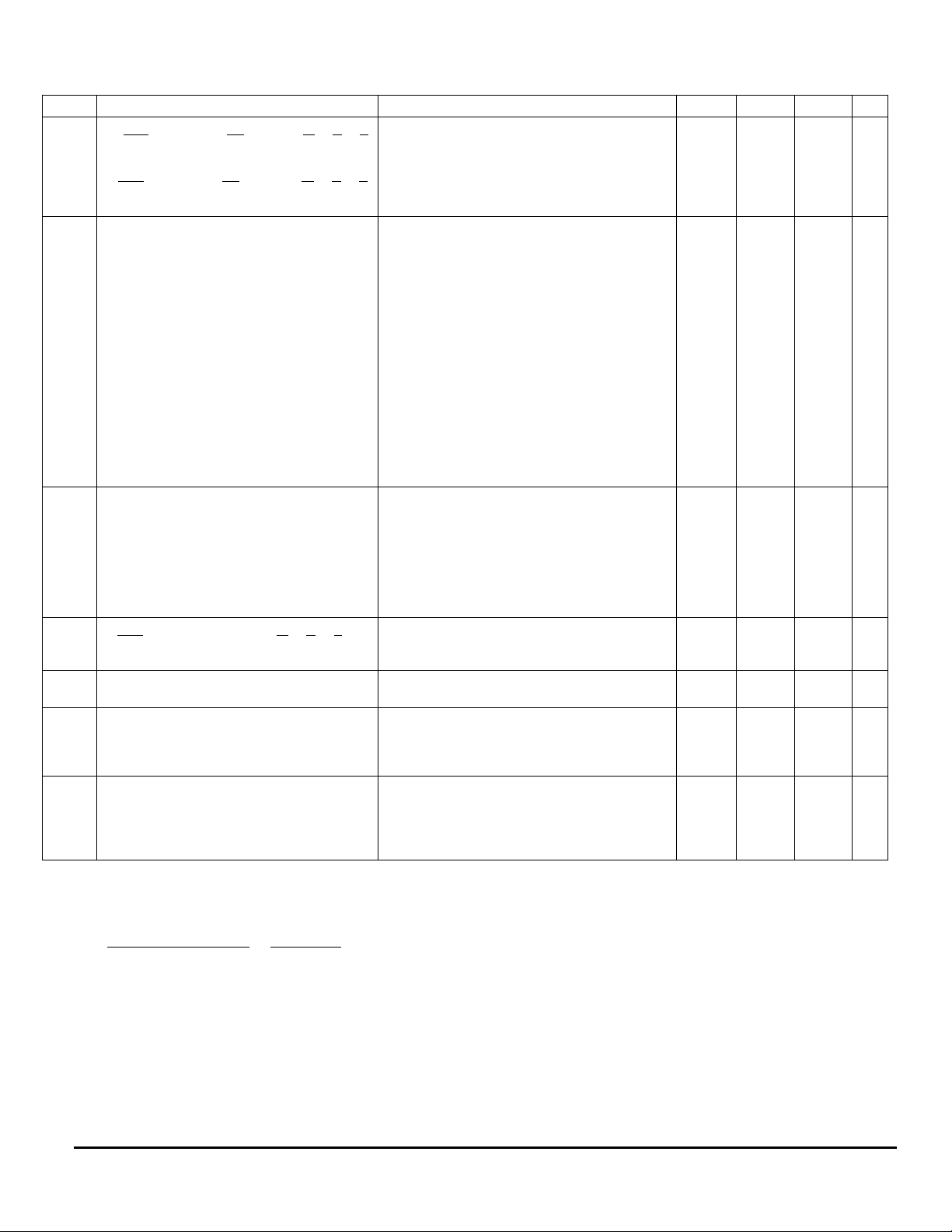

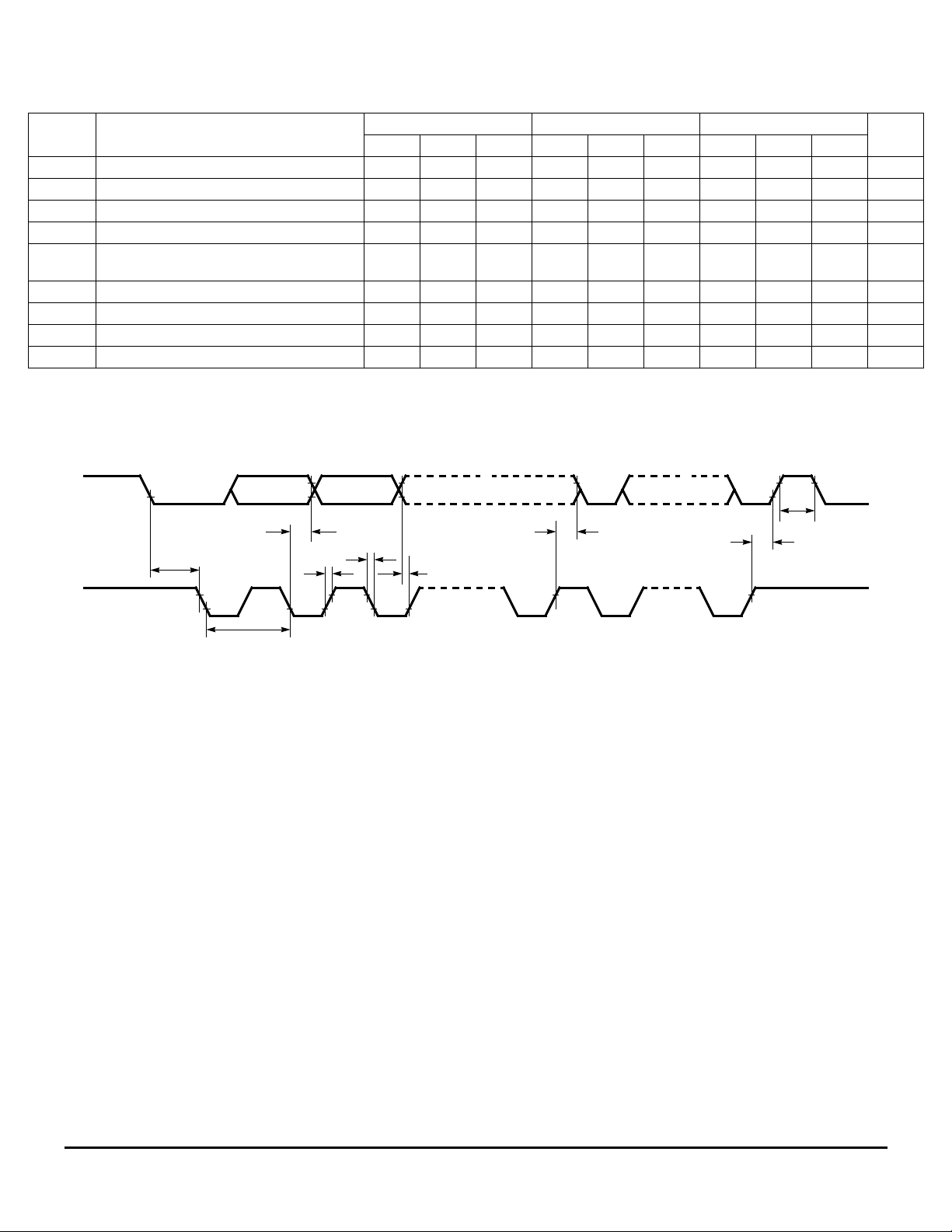

TABLE 3. Parallel Timing Characteristics (TA=-30 to 85˚C, DVDD=2.4 to 3.5V, VSS=0V)

Symbol Parameter Min Typ Max Unit

t

cycle

t

t

DSW

t

DHW

t

DSR

t

DHR

t

ACC

PW

PW

t

AS

AH

EL

EH

t

R

t

F

Clock Cycle Time 1000 - - ns

Address Setup Time 90 - - ns

Address Hold Time 60 - - ns

Write Data Setup Time 210 - - ns

Write Data Hold Time 75 - - ns

Read Data Setup Time 250 - - ns

Read Data Hold Time 75 - - ns

Access Time - - 250 ns

Enable Low Pulse Width 390 - - ns

Enable High Pulse Width 390 - - ns

Rise Time - - 45 ns

Fall Time - - 45 ns

R/W

D/

C

CE

CLK

D0-D7

(Write data to driver)

D0-D7

(Read data from driver)

t

AS

t

cycle

t

AH

PW

PW

t

R

EH

t

F

t

DHW

Valid Data

t

DSW

t

ACC

t

DSR

t

DHR

Valid Data

Figure 2. Parallel 6800-series Interface Timing Characteristics

EL

MC141800A

3–284

MOTOROLA

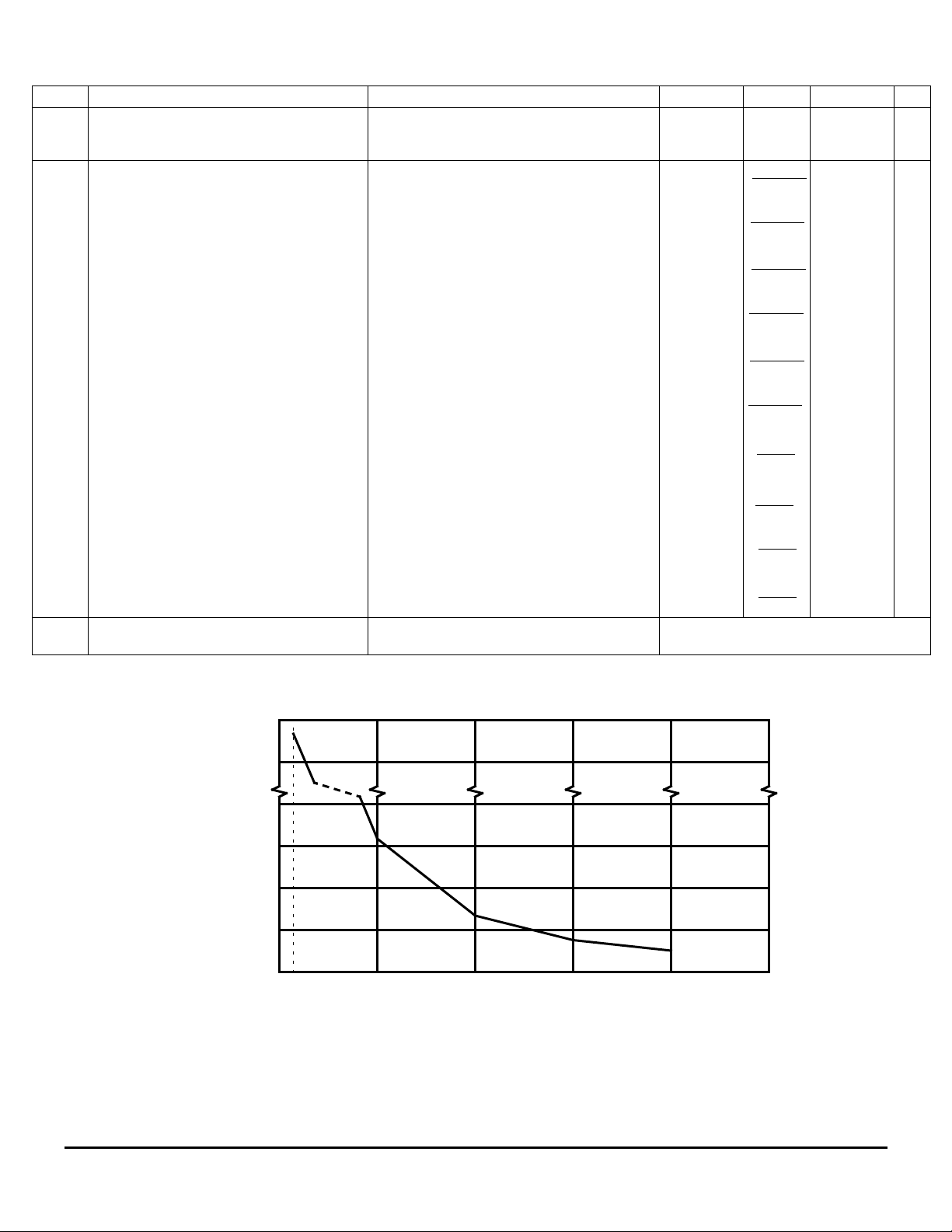

TABLE 4. IIC Serial Timing Characteristics (TA=-30 to 85˚C, DVDD=2.4 to 3.5V, VSS=0V)

100kHz 400kHz 1MHz

Symbol Parameter

t

cycle

t

HSTART

t

t

t

SSTART

Clock Cycle Time 10 - - 2.5 - - 1 - - µs

Start condition Hold Time 4.0 - - 0.6 - - 0.3 - - µs

Data Hold Time 500 - - 300 - - 150 - - ns

HD

Data Setup Time 250 - - 100 - - 50 - - ns

SD

Start condition Setup Time (Only relevant for a

repeated Start condition)

t

SSTOP

t

IDLE

Stop condition Setup Time 4.0 - - 0.6 - - 0.3 - - µs

t

Rise Time for data and clock pin - - 1000 - - 300 - - 150 ns

R

t

Fall Time for data and clock pin - - 300 - - 300 - - 150 ns

F

Idle Time before a new transmission can start 4.7 - - 1.3 - - 0.6 - - µs

Min Typ Max Min Typ Max Min Typ Max

4.7 - - 0.6 - - 0.3 - - µs

Unit

SDA

CLK

t

HSTART

t

cycle

()(

)

t

HD

t

F

t

t

R

SD

t

SSTART

()(

)

t

IDLE

t

SSTOP

Figure 3. IIC Serial Interface Timing Characteristics

MC141800AMOTOROLA

3–285

P

STOP

CONDITION

P

STOP

CONDITION

ACK

)

)

(

)

(

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

9

ACK

)

(

)

(

)

(

)

(

)

(

)

(

1 - 8

DATA

)

(

)

(

)

(

)

(

)

(

)

(

ACK

CR/W

D/

(A0)

9

1 - 8

ACK

ACK

DATA

ACK

CR/W

D/

(A0)

SDA

(From controller)

SDA

(From Driver)

A1

A2

Figure 4. IIC Serial Interface Input Protocol (Write Data to Driver)

ADDRESS

23456789

1

S

START

CONDITION

CLK

SDA

SDA

(From controller)

(From Driver)

A1

A2

ADDRESS

Figure 5. IIC Serial Interface Output Protocol (Read Data from Driver)

23456789

1

S

START

CONDITION

CLK

MC141800A

3–286

MOTOROLA

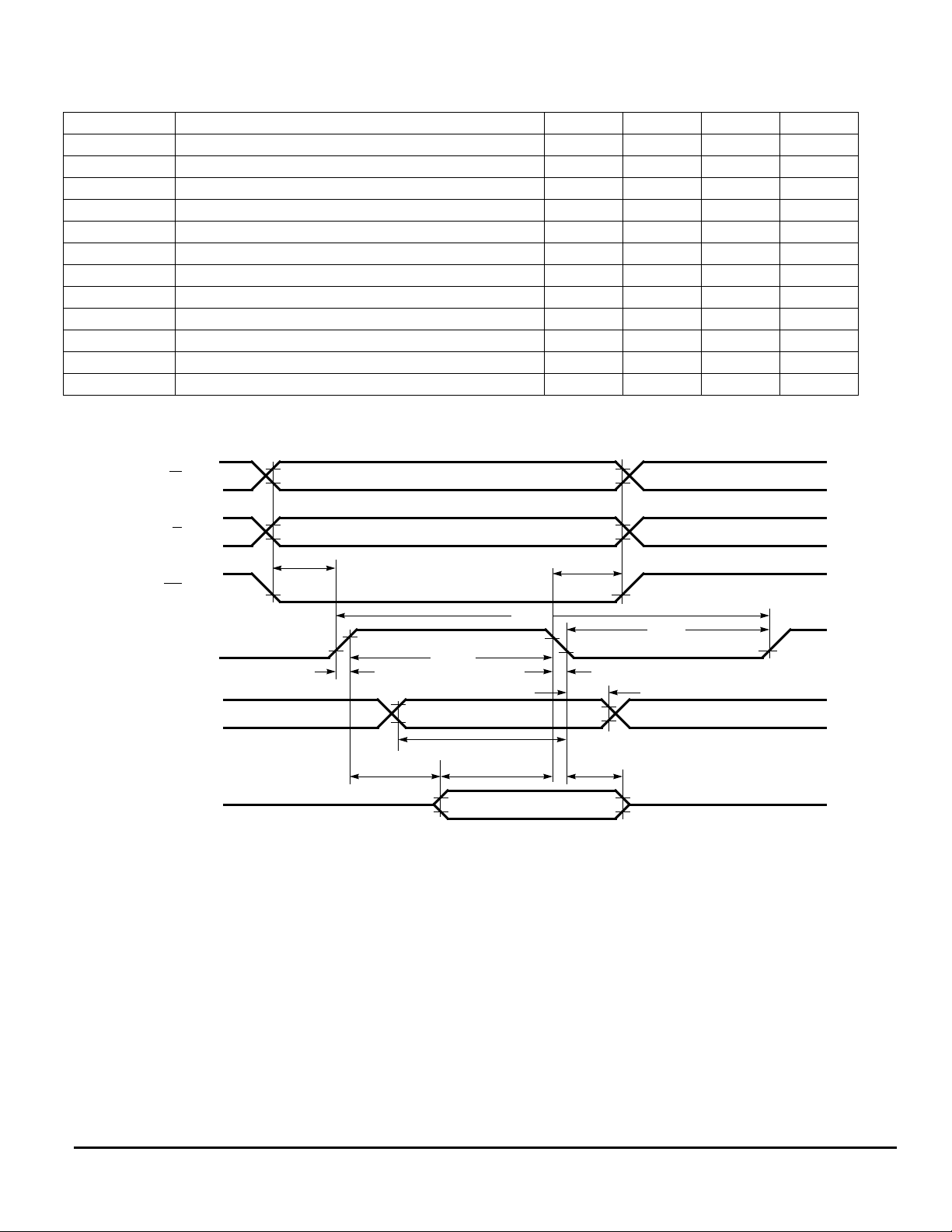

TABLE 5. SPI Timing Characteristics (TA=-30 to 85˚C, DVDD=2.4 to 3.5V, VSS=0V)

Symbol Parameter Min Typ Max Unit

t

cycle

t

LEAD

t

LAG

t

DSW

t

DHW

t

DVR

t

DHR

t

ACC

t

DIS

t

CLKL

t

CLKH

t

R

t

F

Clock Cycle Time 1000 - - ns

Enable Lead Time 500 - - ns

Enable Lag Time 500 - - ns

Write Data Setup Time 100 - - ns

Write Data Hold Time 100 - - ns

Read Data Valid Time - - 240 ns

Read Data Hold Time 10 - - ns

Access Time - - 120 ns

Disable Time - - 240 ns

Clock Low Time 380 - - ns

Clock High Time 380 - - ns

Rise Time - - 100 ns

Fall Time - - 100 ns

CE

CLK

Dout

Din

t

ACC

t

LEAD

t

CLKH

t

DSW

t

F

t

CLKL

t

cyc

t

DVR

MSB

t

DHW

MSB

Figure 6. SPI Timing Characteristics

)

()(

t

R

)

()(

)

()(

)

()(

t

)

()(

)

()(

DHR

t

LAG

LSB

LSB

t

DIS

MC141800AMOTOROLA

3–287

PIN DESCRIPTIONS

S/P (Serial / Parallel Interface)

This pin is an input pin. The pin is sampled out when reset to

determine what type of interface is desired. The S/P pin input HIGH

for serial interface while input LOW for parallel interface.

OSC2 (Oscillator Output / External Oscillator Input)

For internal oscillator mode, this is an output for the internal low

power RC oscillator circuit. For external oscillator mode, OSC2 will

be an input pin for external clock and no external resistor is needed.

D/C (Data / Command)

If parallel interface is selected, this input pin acknowledges the

LCD driver the input at D0-D7 is data or command. Input High for

data while input Low for command. If serial interface is selected, float

this pin.

CLK (Input Clock)

This pin is normal Low clock input. If parallel interface is selected,

data on D0-D7 are latched at the falling edge of CLK. If IIC serial

interface is selected, data on SDA is latched at the falling edge of

CLK. If SPI is selected, data on Din and Dout are latched at the falling edge of CLK.

RES (Reset)

A Low input pulse to this pin resets the internal status of the driver

(same as power on reset). The minimum pulse width is 10 µs.

CE (Chip Enable)

If parallel interface is selected, this input pin is used for chip

enable. If IIC serial interface is selected, leave this pin float and it will

be internally tied to VDD.

D0 - D7 (Data)

This bi-directional bus is used for data / command transferring. If

parallel interface is selected, D0 - D7 are connected directly to MCU

for data transfer. When serial interface is selected, D7 (IIC/SPI) is an

input pin to determine which type of serial interface is desired. The

IIC/SPI pin HIGH indicates IIC interface is used. The IIC/SPI pin

LOW indicates SPI is used.

When IIC serial interface is selected, D0 (SDA) is connected

directly to MCU for data transfer, D1 (A1) and D2 (A2) are used to

define the 2 bit programmable address. The address of this device is

0111xyab where x, y, a, b represent A2, A1, D/C and R/W respectively.

When SPI is selected, D3 (Din) is used to write data / command

from MCU to driver and D4 (Dout) is used to read data / command to

MCU from driver.

R/W (Read / Write)

If parallel interface is selected, this is an input pin. To read the display data RAM or the internal status (Busy / Idle), pull this pin High.

The R/W input Low indicates a write operation to the display data

RAM or to the internal setup registers. If serial interface is selected,

let this pin float.

OSC1 (Oscillator Input)

For internal oscillator mode, this is an input for the internal low

power RC oscillator circuit. In this mode, an external resistor of certain value should be connected between the OSC1 and OSC2 pins

for a range of internal operating frequencies (refer to Figure 1). For

external oscillator mode, OSC1 should be left open.

VLL6 - VLL2

Group of voltage level pins for driving the LCD panel. They can

either be connected to external driving circuit for external bias supply

or connected internally to built-in divider circuit if internal divider is

enable.

C1N and C1P, C2N and C2P, C3N and C3P

If Internal DC/DC Converter is enabled, a 0.1 µF capacitor is

required to connect these three pair of pins.

VR and V

trol) of VLL1 to VLL6. For adjusting the LCD driving voltage, it

requires a feedback resistor placed between VR and VF, a gain control resistor placed between VF and AVSS, a 10 µF capacitor placed

between VR and AVSS. (Refer to the Application Circuit)

COM0-COM63, COM64A and COM64B (Row Drivers)

0V during display off. COM64A and COM64B are icon lines with

same signal output so as to provide the flexibility to hav e the icon line

on top or bottom of panel, or both top and bottom of the panel.

COM64A/B also serves as the common driving signal in the icon

mode.

special commands to program it separately (e.g. Set Icon Mask,

Smart Icon Mode, Low Power Icon Mode)

SEG0-SEG127 (Column Drivers)

They output 0V during display off.

AVDD and AVSS

verter. AVSS is ground.

VCC

this pin to AVSS is required. It can also be an external bias input pin

if Internal DC/DC Converter is not used. Power is supplied to the

LCD Driving Level Selector and HV Buffer Cell with this pin. Normally, this pin is not intended to be a power supply to other component.

DVDD and DVSS

these two pins. DVDD is power and DVSS is ground.

F

This is a feedback path for the gain control (external contrast con-

These pins provide the row driving signal to LCD panel. Output is

COM64A/B is special design icon line (128 icons). There are some

These 128 pins provide LCD column driving signal to LCD panel.

AVDD is the positive supply to the LCD bias Internal DC/DC Con-

For using the Internal DC/DC Converter, a 0.1 µF capacitor from

Power is supplied to the digital control circuit of the driver using

MC141800A

3–288

MOTOROLA

OPERATION OF LIQUID CRYSTAL DISPLAY DRIVER

Description of Block Diagram Module

Command Decoder and Command Interface

This module determines whether the input data is interpreted as

data or command. Data is directed to this module based upon the

input of the D/C pin. If D/C high, data is written to Graphic Display

Data RAM (GDDRAM). D/C low indicates that the input at D0-D7 is

interpreted as a Command.

Reset is of same function as Power ON Reset (POR). Once RES

received the reset pulse, all internal circuitry will back to its initial status. Refer to Command Description section for more information.

MPU Parallel 6800-series Interface

The parallel interface consists of 8 bi-directional data pins (D0D7), R/W, D/C, CE and the CLK. The R/W input High indicates a

read operation from the Graphic Display Data RAM (GDDRAM). R/W

input Low indicates a write operation to Display Data RAM or Internal

Command Registers depending on the status of D/C input. The CLK

input serves as data latch signal (clock). Refer to AC operation conditions and characteristics section for Parallel Interface Timing

Description.

MPU Serial IIC Interface

The IIC interface consists of two communication bus: data pin

SDA and clock pin CLK. The CLK input serves as data latch signal

(clock). Before communication begins, a start condition must be

setup on the bus by the controller. To establish a start condition, the

controller must pull the data pin low while the clock pin is high.

After the start condition has been established for t

eight-bit address should be sent. The six most significant bits of the

address (0111xy) are used to uniquely define devices on the bus, the

7th bit is used as a data / command control: if it is 0, then the signal

on SDA is interpreted as a command; if it is 1, then data SDA is written to GDDRAM. The least significant bit is a data direction read /

write control; if it is 0, then the controller writes data / command to the

driver; if it is 1, then the controller reads data / command from LCD

driver.

Data is transferred with the most significant bit first. Each byte has

to be followed by an acknowledge bit. The transmitter releases the

SDA high during the acknowledge clock pulse. The receiver has to

pull down the SDA during the acknowledge clock pulse.

To end communication, a stop condition should be set up on the

bus. A low to high transition of data pin while the clock pin is high

defines a stop condition. However, if a master still wishes to communicate on the bus, another start condition and address can be generated without a stop condition. Refer to AC operation conditions and

characteristics section for IIC Serial Interface Timing Description.

HSTART

, an

MPU Serial Peripheral Interface

The SPI consists of 4 communication bus: data input pin Din, data

output pin Dout, clock pin CLK and chip enable pin

input serves as data latch signal (clock).

Data is transferred serially with most significant bit first, least significant bit last. During the communication, the controller must input

Low CE before data transactions and must stay low for the rest of the

transaction. By default, the LCD driver will receive command from

MCU. If messages on the data pin are data rather than command,

MCU should send Data Direction command (0100100X0) to control

the data direction and then one more command to define the number

of data bytes will be read / write. After these two continuous commands are send, the following messages will be data rather than

command. For read operation (X0= 1), MCU reads a group of data

from LCD driver through Dout pin. For write operation (X0= 0), MCU

writes a group of data to the LCD driver through Din pin. Refer to AC

operation conditions and characteristics section for Serial Peripheral

Interface Timing Description.

CE. The CLK

MC141800AMOTOROLA

3–289

Column address 00H

Column address 7FH

Row 0

Row 63

Page 9

LSB

Page 1

MSB

LSB

Page 2

MSB

LSB

Page 8

MSB

LSBRow 64

Seg0

Note: The configuration in parentheses represent the remapping of Rows and Columns in 65 MUX mode

Com0

(Com63)

Com63

(Com0)

Com64 (icon)

Seg127

MC141800A

3–290

Figure 7. Graphic Display Data RAM (GDDRAM) Address Map

MOTOROLA

Graphic Display Data RAM (GDDRAM)

The GDDRAM is a bit mapped static RAM holding the bit pattern

to be displayed. The size of the RAM is determined by number of row

times the number of column (128x65 = 8320 bits). Figure 7 is a

description of the GDDRAM address map. For mechanical flexibility,

re-mapping on both Segment and Common outputs are provided.

Display Timing Generator

This module is an on chip low power RC oscillator circuitry (Figure 8). The oscillator frequency can be selected in the range of

15kHz to 250kHz by external resistor. One can enable the circuitry by

software command. For external clock provided, feed the clock to

OSC2 and leave OSC1 open.

Internal Oscillator selected

enable1 enable

Oscillation Circuit

OSC1

Feedback for internal oscillator

For external CLK input

enable2

Figure 8. Oscillator Circuitry

LCD Driving Voltage Generator and Internal Regulator

This module generates the LCD voltage needed for display output.

It takes a single supply input and generate necessary bias voltages.

It consists of:

1. 4X and 5X DC-DC Converter

To generate the Vcc voltage. 4X DC-DC converter is used for LCD

panel which needs lower driving voltage for less power consumption. 5X DC-DC converter is used for LCD panel which needs

higher driving voltage.

2. Internal Regulator

Feedback gain control for initial LCD voltage. it can also be used

with external contrast control.

3. Smart Bias Divider

Divide the LCD display voltage (V

lator output. This is a low power consumption circuit which can

save the most display current compare with traditional resistor ladder method.

4. Contrast Control Block

Software control of 16 voltage levels of LCD voltage.

All blocks can be individually turned off if external voltage genera-

tor is employed

5. Bias Ratio Selection circuitry

Software control of 1/7 and 1/9 bias ratio to match the characteristic of LCD panel.

) from the Internal Regu-

LL2-VLL6

Oscillator enable

Buffer

MC141800A

OSC2

6. Self adjust temperature compensation circuitry

Provide 4 different compensation grade selections to satisfy the

various liquid crystal temperature grades. The grading can be

selected by software control.

65 Bit Latch / 128 Bit Latch

A register carries the display signal information. First 65 bits are

Common driving signals and other 128 bits are Segment driving signals. Data will be input to the HV-buffer Cell for bumping up to the

required level.

Level Selector

Level Selector is a control of the display synchronization. Display

voltage can be separated into two sets and used with different

cycles. Synchronization is important since it selects the required LCD

voltage level to the HV Buffer Cell for output signal voltage pump.

HV Buffer Cell (Level Shifter)

HV Buffer Cell works as a level shifter which translates the low

voltage output signal to the required driving voltage. The output is

shifted out with an internal FRM clock which comes from the Display

Timing Generator. The voltage levels are given by the level selector

which is synchronized with the internal M signal.

External component

LCD Panel Driving Waveform

The following is an example of how the Common and Segment

drivers may be connected to a LCD panel. The waveforms shown in

Figure 9a, 9b and 9c illustrate the desired multiplex scheme.

In order to reduce the crosstalk effect, invert the polarities of the

pixel-driving waveforms every 2 or 4 or 8 or 65 lines according to the

selected waveforms. In the power-up state, the default waveform will

be type “B”.

COM0

COM1

COM2

COM3

COM4

COM5

COM6

COM7

SEG1

SEG2

SEG3

SEG0

SEG4

Figure 9a. LCD Display Example “0”

MC141800AMOTOROLA

3–291

COM0

COM1

SEG0

123456789

. . .

65

123456789

TIME SLOT

. . .

65 123456789

. . .

65 123456789

. . .

65

VLL6

VLL5

VLL4

VLL3

VLL2

VLL1

VLL6

VLL5

VLL4

VLL3

VLL2

VLL1

VLL6

VLL5

VLL4

VLL3

VLL2

VLL1

SEG1

VLL6

VLL5

VLL4

VLL3

VLL2

VLL1

M

Figure 9b. LCD Driving Signal from MC141800A (Waveform B)

MC141800A

3–292

MOTOROLA

123456789

Polarities inverted every 2 lines

COM0

Polarities inverted every 2 lines

COM1

SEG0

SEG1

. . .

65

123456789

TIME SLOT

. . .

65 123456789

. . .

65 123456789

. . .

65

VLL6

VLL5

VLL4

VLL3

VLL2

VLL1

VLL6

VLL5

VLL4

VLL3

VLL2

VLL1

VLL6

VLL5

VLL4

VLL3

VLL2

VLL1

VLL6

VLL5

VLL4

VLL3

VLL2

VLL1

M

. . .. . .. . . . . .

Figure 9c. LCD Driving Signal from MC141800A (Waveform C with polarity inversion every 2 lines)

MC141800AMOTOROLA

3–293

Command Description

Set Display On / Off (Display Mode / Stand-by Mode)

The Display On command turns the LCD Common and Segment out-

puts on. This command starts the conversion of data in GDDRAM to

necessary waveforms on the Common and Segment driving outputs.

The on-chip bias generator is also turned on by this command. (Note:

“Oscillator On” command should be sent before “Display On” is

selected)

The Display Off command turn the display off and the states of the

LCD driver are as follow during display off:

1. All the Common and Segment outputs are fixed at V

2. The bias Internal DC/DC Converter is turned off.

3. The RAM and content of all registers are retained.

4. IC will accept new commands and data.

The Oscillator is not affected by this command.

Set GDDRAM Column Address

This command positions the address pointer on a column location.

The address can be set to location 00H-7FH (128 columns). The column address will be increased automatically after a read or write operation. Refer to “Address Increment Table” and command “Set GDDRAM

Page Address” for further information.

Set GDDRAM Page Address

This command positions the row address to 1 of 9 possible positions

in GDDRAM. Refer to figure 7.

Master Clear GDDRAM

This command is to clear the content of the Display Data RAM to

zero. Issue this command followed by a dummy write command. The

RAM for icon line will not be affected by this command.

Master Clear Icon

This command is a MASTER clear of the Icon Data RAM. After set-

ting the page pointer to icon page (page 9), the internal icon RAM data

will be set to Zero after the command is issued. Before using this command, set the page address to page 9 by the command “Set GDDRAM

Page Address”. A dummy write data is also needed after the “Master

Clear Icon” command to make the clear icon action effective.

Set Page Mask (Display Mask)

The following command will be written to the Page Mask Register.

Page Mask is an 8-bit register. Each bit represents one of the 8 pages:

page mask bit 0 represents Page 1, page mask bit 1 represents Page

2,...etc.

LL1

(VSS).

Set Display Frequency

In half display frequency mode, the display frame frequency will be

halved. Also, the operation frequency of analog circuitries will be halved

for power saving purpose.

Save / Restore Column Address

Save Column Address command saves a copy of the Column

Address of GDDRAM. Restore Column Address command restores the

copy obtained from the previous execution of saving column address.

This instruction is very useful for writing full graphics characters that are

larger than 8 pixels vertically.

Set Column Mapping

This instruction selects the mapping of Display Data RAM to Segment drivers for mechanical flexibility. There are 2 mappings to select:

1. Column 0 - Column 127 of GDDRAM mapped to Seg0-Seg127

respectively;

2. Column 0 - Column 127 of GDDRAM mapped to Seg127-Seg0

respectively.

COM64 will not be affected by this command. Detail information

please refer to section “Display Output Description”.

Set Row Mapping

This instruction selects the mapping of Display Data RAM to Common Drivers for mechanical flexibility. There are 2 selected mappings:

1. Row 0 - Row x of GDDRAM to Common 0 - Common x respectively;

2. Row 0 - Row x of GDDRAM to Common x - Common 0 respectively.

(x+2 is the multiplex ratio)

COM64 will not be affected by this command. See section “Display

Output Description” for related information.

Set MUX Ratio

This command is to select any a ratio from 2 to 65. Row 64 (icon line)

is not affected by this command and it would be turned on for normal

display. This command contain two commands bytes, the first byte

inform the driver that the second byte will be the no. of mux ratio.

e.g. second byte = 0H to turn on Row 0 and 64 (2 MUX)

second byte = 63H to turn on Row 0 to 64 (65 MUX)

The unused common pins output non-scanning signals.

Set Bias Ratio

This command sets the 1/7 bias or 1/9 bias for the divider output.

The selection should match the characteristic of LCD Panel.

Page Mask

When the Page Mask is enabled, the display of those pages, with

page mask bit set, will be cleared. Meanwhile, the data in the display

RAM is retained.

Icon Mask

When the Icon Mask is enabled, the display of the icons will be

cleared. Meanwhile, the data in the icon display RAM is retained.

Set Display Mode

This command switch the driver to full display mode or icon display

mode. In low power icon mode, only icons (driven by COM64) are displayed. Display on row 0 to row 63 will be disabled. The DC-DC converter and the Internal Regulator are off. All VCC, VLLs pins do not

have external bias voltage supply in the lo w pow er icon mode. In normal

display mode, COM0 to COM64 will be turned on.

MC141800A

3–294

Set Oscillator Disable / Enable

This command is used to either turn on / off Oscillator. For using

internal or external oscillator, this command should be executed. The

setting for this command is not affected by command “Set Display On/

Off”. See command “Ext/Int Oscillator” for more information.

Set Internal / External Oscillator

This command is used to select either internal or external oscillator.

When internal oscillator is selected, feedback resistor between OSC1

and OSC2 is needed. For external oscillation circuit, feed clock input

signal to OSC2 and leave OSC1 open.

Set Internal DC/DC Converter Enable

Use this command to select the Internal DC/DC Converter to generate the VCC from AVDD. Disable the Internal DC/DC Converter if external Vcc is provided.

MOTOROLA

Set 4X / 5X DC/DC Converter

This command selects the usage of 4X or 5X Converter when the

Internal DC/DC Converter is enabled.

Set Temperature Coefficient

A temperature gradient selector circuit controlled by two control bits

TC1 and TC2. This command can select 4 different LCD driving voltage

temperature coefficients to match various liquid crystal temperature

grades.

Increase / Decrease Contrast Level

If the internal contrast control is enabled, this command is used to

increase or decrease the contrast level within the 16 contrast levels.

The contrast level starts from lowest value after POR.

Set Contrast Level

This command is to select one of the 16 contrast levels when internal

contrast control circuitry is in use. After power-on reset, the contrast

level is lowest.

Set Internal Regulator On/Off

Choose bit option 0 to disable the on chip Internal Regulator. Choose

bit option 1 to enables Internal Regulator which consists of the internal

contrast control circuits.

Set Smart Bias Divider On/Off

If the Smart Bias Divider is disabled, external bias can be used for

V

LL6

to V

If the Smart Bias Divider is enabled, the internal circuit will

LL2.

generated the 1:7 or 1:9 bias driving voltage.

End of Command

This command is used as extra write end command follows the last

byte of data / command written. This command is not available if serial

mode is selected.

Set Internal Contrast Control Enable

This command is used to adjust the delta voltage of the bias voltages. With bit option = 1, the software selection for delta bias voltage

control is enabled. With bit option = 0, internal contrast control is disabled.

COMMAND TABLE

Bit Pattern Command Comment

0000X3X2X1X

0001X3X2X1X

0010000X

0010001X

0010010X

0010100X

0010101X

0010110X

0010111X

0

0

0

0

0

0

0

0

0

Set GDDRAM Page Address Set GDDRAM Page Address using X3X2X1X0 as address bits.

X3X2X1X0=0000 : page 1 (POR)

X3X2X1X0=0001 : page 2

X3X2X1X0=0010 : page 3

X3X2X1X0=0011 : page 4

X3X2X1X0=0100 : page 5

X3X2X1X0=0101 : page 6

X3X2X1X0=0110 : page 7

X3X2X1X0=0111 : page 8

X3X2X1X0=1000 : page 9

Set Contrast Level With R/W pin input low, set one of the 16 available values to the

internal contrast register, using X3X2X1X0 as data bits.

The contrast register is reset to 0000 during POR.

Set 4X / 5X DC-DC Converter X0=0: enable 4X Converter (POR)

X0=1: enable 5X Converter

Set Segment Mapping X0=0: Col0 to Seg0 (POR)

X0=1: Col0 to Seg127

Set Common Mapping X0=0: Row0 to Com0 (POR)

X0=1: Row0 to Com63

Set Display on/off X0=0: display off (POR)

X0=1: display on

Set Internal DC/DC Converter On/Off X0=0: Internal DC/DC Converter Off (POR)

X0=1: Internal DC/DC Converter On

Set Internal Regulator On/Off X0=0: Internal Regulator Off(POR)

X0=1: Internal Regulator On

Set Smart Bias Divider On/Off X0=0: Smart Bias Divider Off (POR)

X0=1: Smart Bias Divider On

When an external bias network is preferred, the Smart Bias

Divider should be disabled.

Set Smart Icon Mode

This command is to set 4-Phase or 6-Phase smart icon modes which

for lower VDD or higher Von of panel. Refer to Smart Icon Mode Output

Description for detail.

Set Display Waveform Type

This command will select the number of lines for the polarity inversion of the driving waveform. Four types of waveform types are available. Refer to Figure 9.

Set Data Direction

This command is used in SPI mode only. It will be two continuous

commands, the first byte control the data direction and inform the LCD

driver the second byte will be number of data bytes will be read / write.

After these two commands sending out, the following messages will be

data.

MC141800AMOTOROLA

3–295

COMMAND TABLE

Bit Pattern Command Comment

0011000X

0011001X

0011010X

0

0

0

00110110 Master Clear GDDRAM Master clear GDDRAM (64 x 128 bits), row 64 (icon line) will not

00110111 Master Clear Icons Master Clear of Icons

0011100X

0011101X

0

0

00111100 End of Command Write command to identify end of data frame

0011111X

0

01000000 Set Multiplex Ratio next command will define no. of MUX, 00X5X4X3X2X1X

01000001 Set Page Mask next command will be written to page mask register

0100010X

0100011X

0100100X

0100101X

0100110X

0

0

0

0

0

01010100 Reserved next command will define Smart Divider value, 000X4X3X2X1X

0101001X

011001X1X

0110100X

011011X1X

0111000X

0

0

0

0

0

Set Internal Contrast Control On/Off X0=0: Internal Contrast Control Off(POR)

X0=1: Internal Contrast Control On

Internal contrast circuits can be disabled if external contrast circuits is preferred.

Set Display Frequency X0=0 : normal display frequency (POR)

X0=1 : half display frequency

Save/Restore GDDRAM Column

Address

X0=0 : restore address

X0=1 : save address

be cleared

Set Bias Ratio X0=0 : bias = 1 : 9 (POR)

X0=1 : bias = 1 : 7

Reserved X0=0 : Normal Operation (POR)

X0=1 : Test Mode 1 Select

(Note : Make sure to set X0=0 during application)

Set Display Mode X0=0 : low power icon display mode

X0=1 : normal display mode (POR)

no. of mux=00111111 upon POR (65 MUX)

0

page mask register=0 upon POR

Page Mask X0=0 : disable page mask (POR)

X0=1 : enable page mask

Icon Mask X0=0 : disable icon mask (POR)

X0=1 : enable icon mask

Set Data Direction

(for SPI mode only)

X0=0 : Write Data (POR)

X0=1 : Read Data

next command will define the total number of data bytes will be

read / write

e.g. no. of data bytes = 01111111 for 128 bytes

Reserved X0=0 : Select Switch Resistor as HV divider (POR)

X0=1 : Select Buffer as HV dividier

Reserved X0=0 : Select 500ohm in switch resistor divider (POR)

X0=1 : Select 1kohm in switch resistor divider

Reserved X0=0 : Use diode approach for temperature compensation (POR)

X0=1 : Use band gap technique for temperature compensation

Set Display Waveform Type X1X0=00 : Waveform Type B (POR)

X1X0=01 : Waveform Type C with polarity inversion every 8 lines

X1X0=10 : Waveform Type C with polarity inversion every 4 lines

X1X0=11 : Waveform Type C with polarity inversion every 2 lines

Set Smart Icon Mode X0=1 : 4-Phase Smart Icon

X0=0 : 6-Phase Smart Icon (POR)

Set Temperature Coefficient X1X0=: 0.00% (POR)

X1X0=: -0.18%

X1X0=: -0.22%

X1X0=: -0.35%

Increase / Decrease Contrast Level X0=0: Decrease by one level

X0=1: Increase by one level

(Note: increment/decrement wraps round among the 16 contrast

levels. Start at the lowest level when POR.

0

MC141800A

3–296

MOTOROLA

COMMAND TABLE

Bit Pattern Command Comment

0111011X

0111101X

0111111X

1X6X5X4X3X2X1X

0

0

0

0

Reserved X0=0: Normal Operation (POR)

X0=1: Test Mode 2 Select

(Note: Make sure to set X0=0 during application)

Set Internal / External Oscillator X0=0: Internal oscillator (POR)

X0=1: External oscillator.

For internal oscillator place a resistor between OSC1 and OSC2.

For external oscillator mode, feed clock input to OSC2.

Set Oscillator On/Off X0=0: oscillator Off (POR)

X0=1: oscillator On.

This is the master control for oscillator circuitry. This command

should be issued after the “Set Internal / External Oscillator” command.

Set GDDRAM Column Address Set GDDRAM Column Address.

Use X6X5X4X3X2X1X0 as address bits.

Data Read / Write

To read data from the GDDRAM, input High to R/W pin and D/C pin in parallel mode or pull high at the 7th and 8th bit of the address in IIC

serial mode or send Data Direction command 01001001 in SPI mode. Data is valid at the falling edge of CLK. And the GDDRAM column

address pointer will be increased by one automatically.

To write data to the GDDRAM, input Low to R/W pin and High to D/C pin in parallel mode or pull low 7th bit and high 8th bit of the address in

IIC serial mode or send Data Direction command 01001000 in SPI mode. Data is latched at the falling edge of CLK. And the GDDRAM column

address pointer will be increased by one automatically. If parallel interface is selected, End of command should be followed after all data are

send out.

No auto address pointer increment will be performed for the Dummy Write Data after Master Clear GDDRAM. (Refer to the “Commands

Required for R/W Actions on RAM” Table)

Address Increment Table (Automatic)

D/CR/W Comment Address Increment Remarks

0 0 Write Command No

0 1 Read Command No (invalid mode) *1

1 0 Write Data Yes *2

1 1 Read Data Yes

Address Increment is done automatically data read write. The column address pointer of GDDRAM*3 is affected.

Remarks: *1. Only data is read from RAM.

*2. If write data is issued after Command Clear RAM, Address increase is not applied.

*3. Column Address will wrap round when overflow.

Commands Required for R/W Actions on RAM

R/W Actions on RAMs Commands Required

Read/Write Data from/to GDDRAM. Set GDDRAM Page Address

Set GDDRAM Column Address

Read/Write Data

End of command

Save/Restore GDDRAM Column Address. Save/Restore GDDRAM Column Address

End of command

Master Clear GDDRAM Set Clear Page GDDRAM (64 x 128 bits)

Dummy Write Data

Master Clear Icon RAM Set GDDRAM Page Address to Page 9

Master Clear Icon RAM (128 bits, row 64)

Dummy Write Data

(0000X3X2X1X0)*

(1X6X5X4X3X2X1X0)*

(X7X6X5X4X3X2X1X0)

(00111100)

(0011010X0)

(00111100)

(00110110)

(X7X6X5X4X3X2X1X0)

(00001000)

(00110111)

(X7X6X5X4X3X2X1X0)

* No need to resend the command again if it is set previously.

The read / write action to the Display Data RAM does not depend on the display mode. This means the user can change the RAM content

whether the target RAM content is being displayed.

MC141800AMOTOROLA

3–297

Display Output Description

This is an example of output pattern on the LCD panel. Figure 10b and 10c are data map of GDDRAM and the output pattern on the LCD

display with different command enabled.

COM0

Content of GDDRAM

COM63

COM64

SEG0 SEG127

PAGE 1 Upper Nibble

Lower Nibble

PAGE 2 Upper Nibble

Lower Nibble

PAGE 3 Upper Nibble

Lower Nibble

PAGE 4 Upper Nibble

Lower Nibble

.

.

.

PAGE 9 Upper Nibble

.

.

.

Lower Nibble

5A5A5A5A5A---------5A5A5A5A5A

5A5A5A5A5A---------5A5A5A5A5A

33CC33CC33---------CC33CC33CC

33CC33CC33---------CC33CC33CC

0000FFFF00---------FF0000FFFF

FFFF0000FF---------00FFFF0000

FFFFFFFF00---------FF00000000

FFFFFFFF00---------FF00000000

.

.

.

0000000000---------0000000000

0001110000---------0000111000

Icon Line

Figure 10a

Column remap disable

Row re-map disable

Column remap enable

Row re-map disable

Figure 10b

Column remap disable

Row re-map enable

MC141800A

3–298

Figure 10c. Examples of LCD display with different command enabled

MOTOROLA

Power Up Sequence (Commands Required)

Command Required POR Status Remarks

Set Display Frequency

Set Oscillator Enable

Set MUX Ratio

Set Bias Ratio

Set Internal DC/DC Converter

Set Internal Regulator On

Set Temperature Coefficient

Set Internal Contrast Control On

Set Contrast Level

Set Smart Bias Divider On

Set Segment Mapping

Set Common Mapping

Set Display On

Normal

Disable

65 MUX

1/9 bias

4X Converter

Off

TC=0%

Off

Contrast Level = 0

Off

Seg. 0 = Col. 0

Com. 0 = Row 0

Off

*1

*1

*1

*1

*1

*1

*1, *3

*1, *3

*1, *2, *3

*1

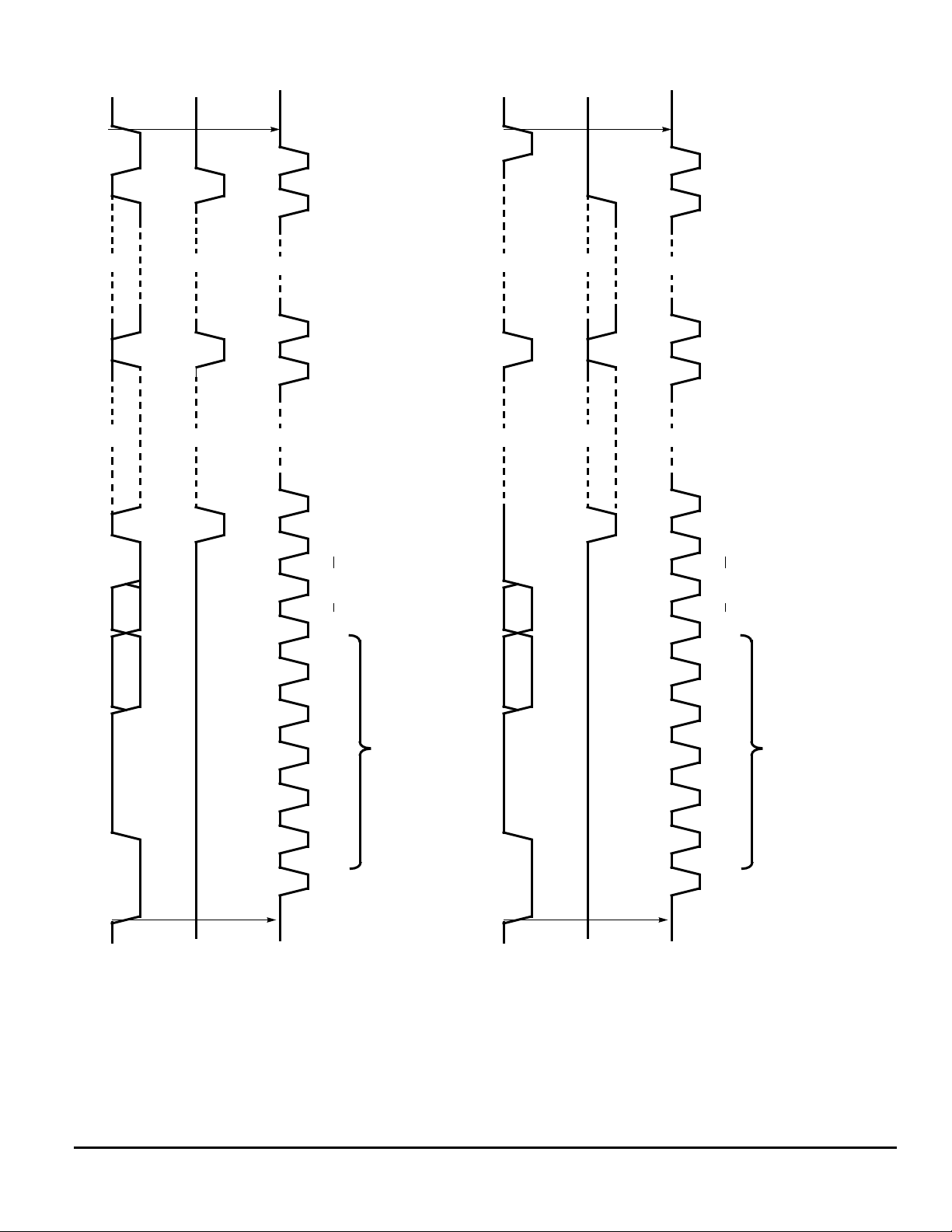

Smart Icon Mode Output Description

Remarks:

*1 -- Required only if desired status differ from POR.

*2 -- Effective only if Internal Contrast Control is enabled.

*3 -- Effective only if Internal Regulator is enabled.

There are two driving schemes of Smart Icon Mode for panel with different V

1) 4 - Phase Smart Icon: 1/4 ~ 3/4

V

> VDD * sqrt (1/4)

off

V

< VDD * sqrt (3/4)

on

2) 6 - Phase Smart Icon: 1/6 ~ 3/6

V

> VDD * sqrt (1/6)

off

V

< VDD * sqrt (3/6)

on

COM (non icon)

COM64(icon)

SEG(on)

SEG(off)

Figure 11a. LCD Driving Signal for 4 - Phase Smart Icon Mode

COM (non icon)

COM64(icon)

SEG(on)

SEG(off)

on/Voff

or VDD:

DVDD

DVSS

DVDD

DVSS

DVDD

DVSS

DVDD

DVSS

DVDD

DVSS

DVDD

DVSS

DVDD

DVSS

DVDD

DVSS

Figure 11b. LCD Driving Signal for 6 - Phase Smart Icon Mode

MC141800AMOTOROLA

3–299

Application Circuit:

All Internal Analog Circuitry disabled at IIC Serial mode operation

CMOS

MPU/MCU

SCL

SDA

EPROM

R

RAM

V

DD

V

R

DD

0.1µF

DVSS DVDD

CLK

D0/SDA

RES

D7/IIC/SPI

S/P

DV

DD

R3

AV

DD

V

CC

0.1µF

AVDD

AVSS

VLL2 VLL3

VLL4 VLL5 VLL6 VCC

D1/A1

D2/A2

IIC Address

COM0 to

MC141800A

COM64

T o LCD

Panel

SEG0 to

SEG127

OSC1OSC2

VRVF C3P C3N

C2P C2N

C1P C1N

MC141800A

3–300

Remark:

1. R3 can be omitted for external oscillator.

2. RES should be at a known state.

3. VLL2 - VLL6 can be left open for internal divider is enable.

4. R/W, CE, D/C and D3-D6 can be open for IIC serial mode.

5. D1/A1 and D2/A2 should be at predefined state for device identification.

t

6. R is pull up resistance, R <

2 * C

r

(R = 300 ohm for 1MHz, assume C

bus

= 200pF)

bus

MOTOROLA

All Internal Analog Circuitry enabled at IIC Serial mode operation

CMOS

MPU/MCU

SCL

SDA

EPROM

DD

AV

DD

0.1µF

DV

0.1µF

0.1µF

V

DVSS DVDD

DD

R

R

AVDD

AVSS

CLK

D0/SDA

RES

V

DD

D7/IIC/SPI

S/

P

R3

VCC

MC141800A

VLL2

VRVF C3P C3NOSC1OSC2

VLL3

0.1µF

VLL4

VLL5

C2P C2N

0.1µF

VLL6

D1/A1

D2/A2

COM0 to

COM64

SEG0 to

SEG127

C1P C1N

0.1µF

IIC Address

T o LCD

Panel

RAM

Remark:

1. R3 can be omitted for external oscillator.

2. VR and VF can be left open for Internal Regulator disable and Contrast Disable.

3. RES should be at a known state.

4. R/W, CE, D/C and D3-D6 can be open for IIC serial mode.

5. D1/A1 and D2/A2 should be at predefined state for device identification.

t

6. R is pull up resistance, R <

2 * C

r

(R = 300 ohm for 1MHz, assume C

bus

bus

= 200pF)

MC141800AMOTOROLA

3–301

All Internal Analog Circuitry disabled at SPI Serial mode operation

CMOS

MPU/MCU

SCK

MOSI

MISO

EPROM

RAM

RES

CE

CLK

D3/Din

D4/Dout

D7/IIC/SPI

V

DD

0.1µF

DVSS DVDD

S/P

DV

DD

R3

AV

DD

0.1µF

AVDD

AVSS

OSC1OSC2

VLL2 VLL3

MC141800A

VRVF C3P C3N

VLL4 VLL5 VLL6 VCC

C2P C2N

C1P C1N

V

COM0 to

COM64

SEG0 to

SEG127

CC

T o LCD

Panel

MC141800A

3–302

Remark:

1. R3 can be omitted for external oscillator.

2. RES should be at a known state.

3. VLL2 - VLL6 can be left open for internal divider is enable.

4. R/W, D/C, D0-2 and D5-6 can be open for SPI serial mode.

MOTOROLA

All Internal Analog Circuitry enabled at SPI Serial mode operation

CMOS

MPU/MCU

SCK

MOSI

MISO

EPROM

RAM

RES

CE

CLK

D3/Din

D4/Dout

D7/IIC/SPI

V

DD

0.1µF

DVSS DVDD

S/P

DV

DD

R3

AV

DD

0.1µF

0.1µF

AVDD

AVSS

VCC

VLL2

VLL3

VLL4

VLL5

VLL6

COM0 to

MC141800A

COM64

T o LCD

Panel

SEG0 to

SEG127

OSC1OSC2

VRVF C3P C3N

0.1µF

C2P C2N

0.1µF

C1P C1N

0.1µF

Remark:

1. R3 can be omitted for external oscillator.

2. VR and VF can be left open for Internal Regulator disable and Contrast Disable.

3

. RES should be at a known state.

4. R/W, D/C, D0-2 and D5-6 can be open for SPI serial mode.

MC141800AMOTOROLA

3–303

All Internal Analog Circuitry disabled at Parallel mode operation

CMOS

MPU/MCU

with

Parallel

Interface

EPROM

RAM

DVSS DVDD

RES

CE

D/C

R/W

CLK

D0 .. D7

S/P

0.1µF

DV

DD

R3

AV

DD

0.1µF

AVDD

AVSS

OSC1OSC2

VLL2 VLL3

MC141800A

VRVF C3P C3N

VLL4 VLL5 VLL6 VCC

C2P C2N

C1P C1N

V

COM0 to

COM64

SEG0 to

SEG127

CC

T o LCD

Panel

MC141800A

3–304

Remark:

1. R3 can be omitted for external oscillator.

2. RES should be at a known state.

3. VLL2 - VLL6 can be left open for internal divider is enable.

MOTOROLA

All Internal Analog Circuitry enabled at Parallel mode operation

CMOS

MPU/MCU

with

Parallel

Interface

EPROM

RAM

DVSS DVDD

RES

CE

D/C

R/W

CLK

D0 .. D7

S/P

0.1µF

DV

DD

R3

AV

DD

0.1µF

0.1µF

AVDD

OSC1OSC2

AVSS

VCC

VLL2

MC141800A

VRVF C3P C3N

0.1µF

VLL3

VLL4

C2P C2N

0.1µF

VLL5

C1P C1N

0.1µF

VLL6

COM0 to

COM64

SEG0 to

SEG127

T o LCD

Panel

Remark:

1. R3 can be omitted for external oscillator.

2. VR and VF can be left open for Internal Regulator disable and Contrast Disable.

3

. RES should be at a known state.

MC141800AMOTOROLA

3–305

PACKAGE DIMENSIONS

MC141800AT

TAB PACKAGE DIMENSION - 1

(DO NOT SCALE THIS DRAWING)

MC141800A

3–306

Reference: 98ASL00269A Issue “0” released on 11 Feb 97

MOTOROLA

PACKAGE DIMENSIONS

MC141800AT

TAB PACKAGE DIMENSION - 2

(DO NOT SCALE THIS DRAWING)

Reference: 98ASL00269A Issue “0” released on 11 Feb 97

MC141800AMOTOROLA

3–307

Die Pad Coordinate of MC141800A

Pad Name X(um) Y(um) Pad Name X(um) Y(um) Pad Name X(um) Y(um) Pad Name X(um) Y(um) Pad Name X(um) Y(um)

1 COM(22) -4826.0 -807.6 61 C3P 1198.4 -857.8 121 SEG(0) 4826.0 807.6 181 SEG(60) 266.0 807.6 241 SEG(120) -4294.0 807.6

2 COM(23) -4750.0 -807.6 62 C3N 1304.4 -857.8 122 SEG(1) 4750.0 807.6 182 SEG(61) 190.0 807.6 242 SEG(121) -4370.0 807.6

3 COM(24) -4674.4 -811.8 63 VLL2: 1410.4 -857.8 123 SEG(2) 4674.0 807.6 183 SEG(62) 114.0 807.6 243 SEG(122) -4446.0 807.6

4 COM(25) -4598.0 -807.6 64 VLL2: 1516.4 -857.8 124 SEG(3) 4598.0 807.6 184 SEG(63) 38.0 807.6 244 SEG(123) -4522.0 807.6

5 COM(26) -4522.0 -807.6 65 VLL3: 1622.4 -857.8 125 SEG(4) 4522.0 807.6 185 SEG(64) -38.0 807.6 245 SEG(124) -4598.0 807.6

6 COM(27) -4446.0 -807.6 66 VLL3: 1728.4 -857.8 126 SEG(5) 4446.0 807.6 186 SEG(65) -114.0 807.6 246 SEG(125) -4674.0 807.6

7 COM(28) -4370.0 -807.6 67 VLL4: 1834.4 -857.8 127 SEG(6) 4370.0 807.6 187 SEG(66) -190.0 807.6 247 SEG(126) -4750.0 807.6

8 COM(29) -4294.0 -807.6 68 VLL4: 1940.4 -857.8 128 SEG(7) 4294.0 807.6 188 SEG(67) -266.0 807.6 248 SEG(127) -4826.0 807.6

9 COM(30) -4218.0 -807.6 69 VLL5: 2046.4 -857.8 129 SEG(8) 4218.0 807.6 189 SEG(68) -342.0 807.6 249 COM64B -5328.4 835.4

10 COM(31) -4142.0 -807.6 70 VLL5: 2152.4 -857.8 130 SEG(9) 4142.0 807.6 190 SEG(69) -418.0 807.6 250 COM(0) -5328.4 759.4

11 DVDD: -4042.2 -857.8 71 VLL6: 2258.4 -857.8 131 SEG(10) 4066.0 807.6 191 SEG(70) -494.0 807.6 251 COM(1) -5328.4 683.4

12 S/P -3940.6 -857.8 72 VLL6: 2364.4 -857.8 132 SEG(11) 3990.0 807.6 192 SEG(71) -570.0 807.6 252 COM(2) -5328.4 607.4

13 RES -3839.0 -857.8 73 DVSS: 2470.4 -857.8 133 SEG(12) 3914.0 807.6 193 SEG(72) -646.0 807.6 253 COM(3) -5328.4 531.4

14 D/C -3737.4 -857.8 74 OSC1 2576.4 -857.8 134 SEG(13) 3838.0 807.6 194 SEG(73) -722.0 807.6 254 COM(4) -5328.4 455.4

15 DVSS: -3569.0 -857.8 75 DVSS: 2682.4 -857.8 135 SEG(14) 3762.0 807.6 195 SEG(74) -798.0 807.6 255 COM(5) -5328.4 379.4

16 DVSS: -3467.4 -857.8 76 DVSS: 2788.4 -857.8 136 SEG(15) 3686.0 807.6 196 SEG(75) -874.0 807.6 256 COM(6) -5328.4 303.4

17 DVSS: -3365.8 -857.8 77 VCC: 2894.4 -857.8 137 SEG(16) 3610.0 807.6 197 SEG(76) -950.0 807.6 257 COM(7) -5328.4 227.4

18 DVSS: -3264.2 -857.8 78 VCC: 3000.4 -857.8 138 SEG(17) 3534.0 807.6 198 SEG(77) -1026.0 807.6 258 COM(8) -5328.4 151.4

19 DVSS: -3162.6 -857.8 79 AVSS: 3106.4 -857.8 139 SEG(18) 3458.0 807.6 199 SEG(78) -1102.0 807.6 259 COM(9) -5328.4 75.4

20 DVSS: -3061.0 -857.8 80 OSC2 3212.4 -857.8 140 SEG(19) 3382.0 807.6 200 SEG(79) -1178.0 807.6 260 COM(10) -5328.4 -0.6

21 DVSS: -2959.4 -857.8 81 AVDD: 3318.4 -857.8 141 SEG(20) 3306.0 807.6 201 SEG(80) -1254.0 807.6 261 COM(11) -5328.4 -76.6

22 DVSS: -2857.8 -857.8 82 DVSS: 3493.0 -857.8 142 SEG(21) 3230.0 807.6 202 SEG(81) -1330.0 807.6 262 COM(12) -5328.4 -152.6

23 DVSS: -2756.2 -857.8 83 DVSS: 3594.6 -857.8 143 SEG(22) 3154.0 807.6 203 SEG(82) -1406.0 807.6 263 COM(13) -5328.4 -228.6

24 DVSS: -2654.6 -857.8 84 DVSS: 3696.2 -857.8 144 SEG(23) 3078.0 807.6 204 SEG(83) -1482.0 807.6 264 COM(14) -5328.4 -304.6

25 DVSS: -2553.0 -857.8 85 DVSS: 3797.8 -857.8 145 SEG(24) 3002.0 807.6 205 SEG(84) -1558.0 807.6 265 COM(15) -5328.4 -380.6

26 DVSS: -2451.4 -857.8 86 DVSS: 3899.4 -857.8 146 SEG(25) 2926.0 807.6 206 SEG(85) -1634.0 807.6 266 COM(16) -5328.4 -456.6

27 DVSS: -2349.8 -857.8 87 DVSS: 4001.0 -857.8 147 SEG(26) 2850.0 807.6 207 SEG(86) -1710.0 807.6 267 COM(17) -5328.4 -532.6

28 DVSS: -2248.2 -857.8 88 COM64A 4142.0 -807.6 148 SEG(27) 2774.0 807.6 208 SEG(87) -1786.0 807.6 268 COM(18) -5328.4 -608.6

29 DVSS: -2146.6 -857.8 89 COM(63) 4217.0 -806.2 149 SEG(28) 2698.0 807.6 209 SEG(88) -1862.0 807.6 269 COM(19) -5328.4 -684.6

30 DVSS: -2045.0 -857.8 90 COM(62) 4293.0 -806.2 150 SEG(29) 2622.0 807.6 210 SEG(89) -1938.0 807.6 270 COM(20) -5328.4 -760.6

31 DVSS: -1943.4 -857.8 91 COM(61) 4369.0 -806.2 151 SEG(30) 2546.0 807.6 211 SEG(90) -2014.0 807.6 271 COM(21) -5328.4 -836.6

32 DVSS: -1841.8 -857.8 92 COM(60) 4445.0 -806.2 152 SEG(31) 2470.0 807.6 212 SEG(91) -2090.0 807.6

33 DVSS: -1740.2 -857.8 93 COM(59) 4521.0 -806.2 153 SEG(32) 2394.0 807.6 213 SEG(92) -2166.0 807.6

34 R/W -1638.6 -857.8 94 COM(58) 4597.0 -806.2 154 SEG(33) 2318.0 807.6 214 SEG(93) -2242.0 807.6

35 D7 -1537.0 -857.8 95 COM(57) 4673.0 -806.2 155 SEG(34) 2242.0 807.6 215 SEG(94) -2318.0 807.6

36 D6 -1435.4 -857.8 96 COM(56) 4749.0 -806.2 156 SEG(35) 2166.0 807.6 216 SEG(95) -2394.0 807.6

37 D5 -1333.8 -857.8 97 COM(55) 4826.0 -807.6 157 SEG(36) 2090.0 807.6 217 SEG(96) -2470.0 807.6

38 D4 -1232.2 -857.8 98 COM(54) 5328.4 -836.6 158 SEG(37) 2014.0 807.6 218 SEG(97) -2546.0 807.6

39 D3 -1130.6 -857.8 99 COM(53) 5328.4 -760.6 159 SEG(38) 1938.0 807.6 219 SEG(98) -2622.0 807.6

40 D2 -1029.0 -857.8 100 COM(52) 5328.4 -684.6 160 SEG(39) 1862.0 807.6 220 SEG(99) -2698.0 807.6

41 D1 -927.4 -857.8 101 COM(51) 5328.4 -608.6 161 SEG(40) 1786.0 807.6 221 SEG(100) -2774.0 807.6

42 D0 -825.8 -857.8 102 COM(50) 5328.4 -532.6 162 SEG(41) 1710.0 807.6 222 SEG(101) -2850.0 807.6

43 D0 -724.2 -857.8 103 COM(49) 5328.4 -456.6 163 SEG(42) 1634.0 807.6 223 SEG(102) -2926.0 807.6

44 CLK -622.6 -857.8 104 COM(48) 5328.4 -380.6 164 SEG(43) 1558.0 807.6 224 SEG(103) -3002.0 807.6

45 CLK -521.0 -857.8 105 COM(47) 5328.4 -304.6 165 SEG(44) 1482.0 807.6 225 SEG(104) -3078.0 807.6

46 CE -419.6 -857.8 106 COM(46) 5328.4 -228.6 166 SEG(45) 1406.0 807.6 226 SEG(105) -3154.0 807.6

47 DVDD: -317.8 -857.8 107 COM(45) 5328.4 -152.6 167 SEG(46) 1330.0 807.6 227 SEG(106) -3230.0 807.6

48 DVDD: -216.2 -857.8 108 COM(44) 5328.4 -76.6 168 SEG(47) 1254.0 807.6 228 SEG(107) -3306.0 807.6

49 DVSS: -114.6 -857.8 109 COM(43) 5328.4 -0.6 169 SEG(48) 1178.0 807.6 229 SEG(108) -3382.0 807.6

50 DVSS: -13.0 -857.8 110 COM(42) 5328.4 75.4 170 SEG(49) 1102.0 807.6 230 SEG(109) -3458.0 807.6

51 AVDD: 138.4 -857.8 111 COM(41) 5328.4 151.4 171 SEG(50) 1026.0 807.6 231 SEG(110) -3534.0 807.6

52 AVDD: 244.4 -857.8 112 COM(40) 5328.4 227.4 172 SEG(51) 950.0 807.6 232 SEG(111) -3610.0 807.6

53 AVSS: 350.4 -857.8 113 COM(39) 5328.4 303.4 173 SEG(52) 874.0 807.6 233 SEG(112) -3686.0 807.6

54 AVSS: 456.4 -857.8 114 COM(38) 5328.4 379.4 174 SEG(53) 798.0 807.6 234 SEG(113) -3762.0 807.6

55 VF 562.4 -857.8 115 COM(37) 5328.4 455.4 175 SEG(54) 722.0 807.6 235 SEG(114) -3838.0 807.6

56 VR 668.4 -857.8 116 COM(36) 5328.4 531.4 176 SEG(55) 646.0 807.6 236 SEG(115) -3914.0 807.6

57 C1P 774.4 -857.8 117 COM(35) 5328.4 607.4 177 SEG(56) 570.0 807.6 237 SEG(116) -3990.0 807.6

58 C1N 880.4 -857.8 118 COM(34) 5328.4 683.4 178 SEG(57) 494.0 807.6 238 SEG(117) -4066.0 807.6

59 C2P 986.4 -857.8 119 COM(33) 5328.4 759.4 179 SEG(58) 418.0 807.6 239 SEG(118) -4142.0 807.6

60 C2N 1092.4 -857.8 120 COM(32) 5328.4 835.4 180 SEG(59) 342.0 807.6 240 SEG(119) -4218.0 807.6

Note : *Power and ground die pads should be bonded correspondingly in COG application

Die Pad 15 - 33, 43, 45, 47 -54, 64, 66, 68, 70, 72 - 73, 76, 78 and 82 - 87 are multiple pads of critical signal

(Basically, these are D0, CLK, DVDD, DVSS, AVDD, AVSS, VCC and VLL2-VLL6 which special design for COG)

Bump Size : Pad X(um) Y(um) Die Size (including scribe) : 11226.8 x 2286 (um)

1-10 42 100

11-87 65 65

88-97 42 100

98-120 100 42

121-248 42 100

249-271 100 42

MC141800A

3–308

MOTOROLA

Loading...

Loading...