MOTO GUZZI V-7 700 Operating Manual

700

OPERATING HANDBOOK

CC

FOR

STRIPPING,

ASSEMBLING

CHECKING

OPERATIONS

AND

SEIMM

SOCIETA ESERC1ZIO INDUSTRIE MOTO MECCANICHE S.p_A. _

Clpilale

1OOe,11.

solloocr

iUo'

l.

&'5

Sode

IIO"Ie'

rl.

d.

Cri.tclo,I., J • To

71112

Milano

(4

linee urbane

Galle

Oirezlone e Stablllman\l;

Telelono:

Telegrammi: SEIMM MANOELLOLAAIO

l<l

lo"o

22054

.000.00II

_5

Mandello

)

d~1

lario

(Co)

...

=~

~.

~

...

_

__

MOTO GUZZI

V-7

OPERATING

FOR

STRIPPING

ASSEMBLING

700

HANDBOOK

,

CHECKING

OPERATIONS

cc.

AND

1

sl

EOITION

I

NTROOUCTION

The purpose

carrying

The data provided here are meant to give a general knowledge about the

maln

checking

groups.

The handbook is provided with

sary to

This hand book

manufacturi

such ch

perfo rming a good job.

of

this

handbovk

out overhauls and repairs in a rational way.

operations to

carry

out

stripping,

will also be a

ng

characteristics

aracteristics

by repairing personnel will be

is

to

supply the necessary

be

carried

illustrations, drawings and diagrams neces-

checking

guidance

of the parts in concern. The

out

when overhauling the

and assembling operations.

for

those who wish to

an

essential

instructions

different

know

knowledge

factor

'0\

the

of

for

NOTE · The terms

to

are

be

..

RIGHT HAND

considered as seen from the rider astri

.,

and

((

LEFT HAND " used In

de

the

the

text

saddle.

Pog.

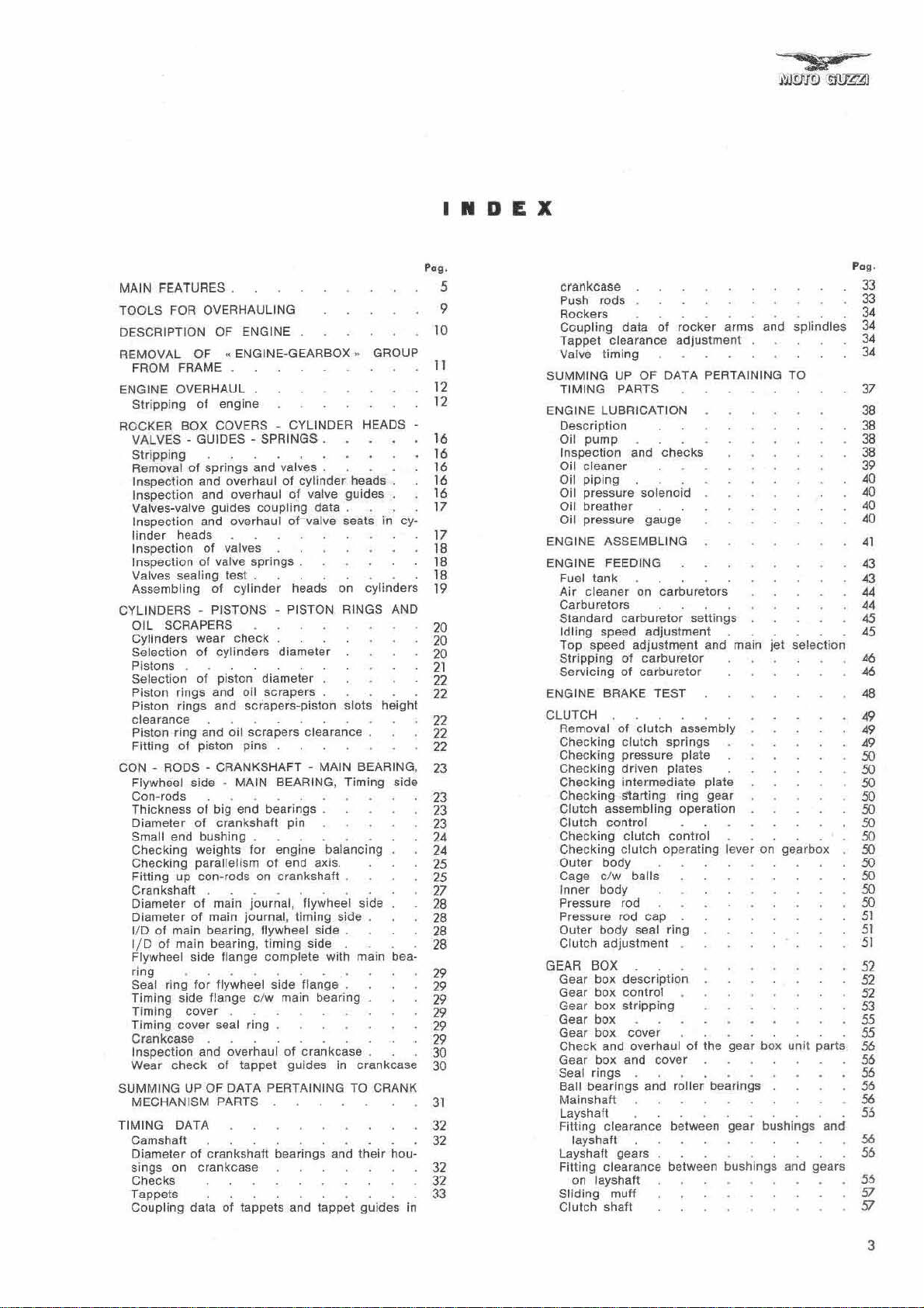

MAIN FEATURES. 5

TOOLS FOR OVERHAULING 9

DESCRIPTION OF ENGINE

REMOVAL OF

FROM

ENGINE OVERHAUL

Stripping

ROCKER BOX COVERS CYLINDER HEADS

...

FRAME .

of

engine

ENGINE-GEARBOX

..

GROUP

10

11

12

12

VALVES - GUIDES - SPRINGS. 16

Stripping 16

Removal of

Inspection

Inspection and overhaul of valve

Valves-valve guides

Inspection and overhaul of valve seats in cy-

linder

Inspection

Inspection

Valves sealing

Assembling

CYLINDERS - PISTONS - PISTON RINGS AND

Oil

Cylinders

Selection of

Pistons

Selection

Piston rings and

Piston rings and scrapers-piston slots height

clearance

Piston ring and oil scrapers clearance .

Fitting of piston

CON - RODS - CRANKSHAFT - MAIN BEARING, 23

Flywheel

Con-rods

Thickness

Diameter

Small end bushing .

Checking

Checking

Fitting

Crankshaft .

Diameter

Diameter

I/O of main bearing, flywheel side .

I/O

of

Flywheel side flange

ring , 29

Seal

Timing side flange

Timing

Timing

Crankcase .

Inspection and overhaul

Wear

SUMMING

MECHANISM PARTS

TIMING DATA 32

Camshaft 32

Diameter

sings

Checks 32

Tappets

Coupling

springs

and

heads 17

of

of

and

overhaul

valves 18

valve

lest.

of

cylinder

valves.

of

coupling

springs.

cylinder

data .

heads on

heads.

guides

cylinders

16

16

16

17

18

18

19

SCRAPERS 20

wear

check

cylinders

of

piston diameter

011

diameter

scrapers 22

20

20

21

22

22

22

pins

side

- MAIN BEARING,

01

big end bearings . 23

of crankshaft pin 23

Timing

22

side

23

24

weights

paraUelism of end axis. 25

up

con-rods on crankshaft . 25

for

engine balancing 24

27

of main journal, flywheel side

of

main journal, timing

side

.

28

28

28

main bearing. timing side

ring

for

flywheel side flange .

cover

cover

seal ring

check

of tappet guides

UP OF DATA PERTAINING TO CRANK

of crankshaft bearings and

on crankcase 32

data of tappets and tappet guides in

complete

c/w

main bearing

of

with main bea-

crankcase.

In

crankcase 30

their

28

']9

29

29

29

29

30

31

hou-

33

I

II

DE

X

crankcase

Push rods

Rockers 34

Coupling data of

Tappet clearance

Valve timing 34

SUMMING

TIMING PARTS

ENGINE LUBRICATION

Description

Oit

Inspection and

Oit

Oit

011

Oit

Oit pressure gauge

ENGINE ASSEMBLING

ENGINE FEEDING 43

Fuel tank 43

Air

Carburetors 44

Standard

Idling

Top speed adjustment and main

Stripping of

Servicing

ENGINE BRAKE TEST

CLUTCH

Removal

Checking

Checking

Checking

Checking

Checking

Clutch assembling operation 50

Clutch

Checking

Checking

Outer body 50

Cage

Inner

Pressure rod 50

Pressure rod cap

Outer body seal ring

Clutch adjustment .

GEAR

Gear

Gear

Gear

Gear

Gear

Check

Gear

Seal rings 55

Ball bearings and

Mainshaft 56

Layshaft

Fitting clearance between

Layshaft gears .

Fitting clearance between bushings and gears

Sliding muff 57

Clutch

UP

pump

cleaner

piping

pressure

breather

cleaner

carburetor

speed

of

of

clutch

pressure plate 50

driven plates 50

intermediate plate 50

s1arting ring gear 50

control

clutch

clutch

c/w

body 50

BOX

box

description

box control

box

stripping

box

box

cover

and overhaul of the gear box

box and

layshafl 56

on layshaft

shaft

rocker

adjustment

OF

DATA PERTAINING TO

checks

solenoid

on

carburetors

adjustment

carburetor

carburetor

clutch

springs

control

operating

balls 50

cover

roller

arms and

. 34

settings

jet

assembly

lever on gearbox 50

bearings

gear

bushings and

splindles

selection

unit

parts 56

Pa

5~

57

u·

33

33

34

37

38

38

38

38

39

40

40

40

40

41

44

45

45

046

46

48

49

49

49

50

50

51

51

51

52

52

52

53

55

55

5&

.55

5~

.50

3

Pog_

Clutch

shelt

Inner

Cush drive Shaft semi-collar 51

Cush drive plate 57

Cush drive spring

Sl

iding

Idle

geer

Gear selector drum

Preselector

Preselector

Gearshllt

Gear selector forks and fork

Assembling

REAR WHEEL DRIV

DescrlpUon _ _

Stripping

Check

sembly

Rear wheel drive box 60

Drive box Ilange 60

Distance shims _ _ 60

Internal toothed sleeve

Bevel

Cage retaIning ring 60

Rear wneel - drive box distance piece 60

Bear

ing housing 60

Adjusllng

Sh

ims

Bevel

Lockring

Lockring

Seal rings _

Drive shalt-bevel pinion sleeve

Dri

ve

Double Joint

M_

Rubber gaiters

8ali

bearings and

Assembling

Assembling rear wheel drive

fork

Contact

teeth

REAR SUSPENSION 65

Stripping

Check and overhaul 65

Flexib le bushings 65

Fitting up on frame

FRONT SUSPENSION AND STEERING 66

Str

ipping

Overhaul

Fork rods 67

Top

bushings _ 67

Bottom

Fork

bottom

Fork

Spnng

Top

plug

Top

plug seals 68

Steering

Steering adjusting

Steering tube _

Assembling fork and steering

STRIPPING OF REAR SWINGtNG FORK

Overhaul

Nuls

and

Support

Seals

8all

bear

Fi

tting

WHEELS AND BRAKES

Front wheet

Rear wheel

Wheels and brakes check

Wheels

Rims

Spokes

Brake

seal ring 51

body 57

57

sleeve 57

57

57

shalt

, with

sector

shall

01

gear box

E _

return spr ing

operating lever _ 57

gear

shalls

57

57

57

58

59

y;

01 rear wheet drive

and overhaul

of

rear wheel drive as-

59

&J

for

gear set 60

washers

gear

distance piece

safety washer

shalt

taper

01

rear wheel drive _ _

check

and adjustment 01 bevel gear

rear wheel coupling

roller

bearings

10

_ _ _ _ _ _

RlH arm of rear

61

61

61

61

61

61

61

61

61

~

61

61

61

62

63

from Irame 65

65

Of

tetescopic front fork and steering

01

tetescoplc front fork and steering 67

bushings

springs 68

covers

housings 68

rubber rings

taper

roller bearings 68

lockrings

60

67

67

68

68

68

on

Irame lug

68

70

of rear fork

locknuts

spindles

ings

up

rear

and taper

lark

roller

bee rings

70

70

70

70

71

71

72

72

72

73

73

7.

linings

7.

7'

Pall_

Brake springs

Brake cam_

Brake pins

Brake drums

Rear wheel central

Hub seals

Tapper

Tapper

AdJusling weshers

Brake cam lever

Front brake cable

Front brake adjustment

Rear

Assembling

Assembling of fronl

Fitting front

Assembling rear wheel hub

Fitting rear

TAPER ROLLER 8EARINGS AND BALL

BEARINGS

FRAME

Check and overhaul

Rear fender and

Center and side stand return springs

Crashbar

Rear brake

Alder and pillion fcotrests

Assemb!ing

ELECTRICAL EQUIPMENT

BATTERY

Features

Inspection and maintenance

Cleaning

Check

Electrolyte

Charge

Common battery faults

GENERATOR

Descr

Operati

Regulator unit

Testing data

Adlustmenl of generator belt tension

Generator faults

STARTER MOTOR

Description _

Operatlcn

Testing data

Slarler

IGNITION SYSTEM

General inlormation

Coil

Distributor

Automatic spark advance device

Contact breaker

Condensor

Distributor

Spark plugs

Ignition timing

Ignition faults

ELECTRIC HORN

Overhaul and repair In

Tesllng

Electric horn

LIGHTING 117

Head light 117

instruments panel 117

Tal! light and stop

Fuses 117

INSTRUMENTS AND CONTROLS 118

Wiring diagram legend 119

LUBRICATION AND GENERAL MAINTENANCE

CHAAT

roller

roller bearings

brake adjustment

01

wheel on fork and drive

conlrol

and smearing

level

ch

eck

iption

on

molar faults

cap

data

body

bearing housings

wheels

wheelan

wheel hub

lark

1001 boxes

lever,

spindle

and

01

terminal blocks

_ _ _

and

rotor

struction

laults

_ 115

light

box

rod

74

7.

7.

74

"

74

"

74

74

75

"

75

75

75

75

76

76

76

n

78

78

78

78

78

78

78

78

79

79

79

79

79

79

79

'"

81

83

83

B3

83

86

87

88

94

9'

95

W

99

103

103

103

10<

10<

105

105

105

105

106

100

113

113

II

117

121

..

•

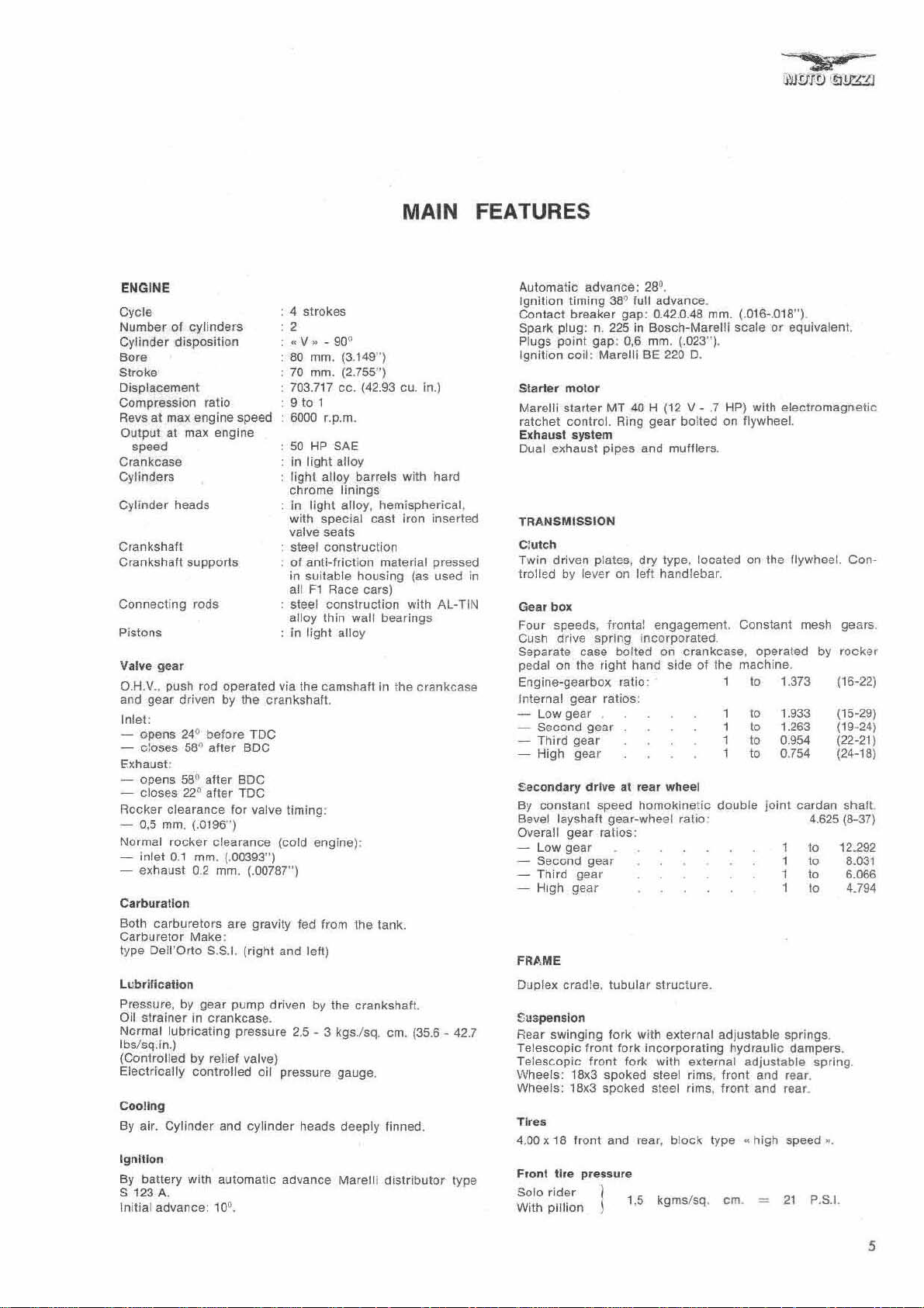

MAIN FEATURES

ENGINE

Cycle

Number

Cylinder disposition

80"

Stroke

Displacement

Compression ratio

Revs

Output at max engine

Crankcase

Cylinders

Cylinder

Crankshaft

Crankshaft

Connecting rods

Pistons

Va

O.H.V.,

and

Inlet :

- opens 24° before TOC

- c:oses

Exhaust:

- opens

- closes 22"

Rccker

- 0,5 mm. (.0196")

Normal

- inlet

- exhaust 0.2 mm. (.00787")

Carb

Both carb

Carburetor

type

La;brificatlon

Pressure,

Oil strainer in

Ncrmal

Ibs/sq.ln.)

(Controlled by

Electrfcally

Cooling

By ai

Ignition

By battery

5

Initial advance: 10°.

of

cylinders

:

at

max engine speed

speed

heads

supports

lve

gear

push rod operated via the camshaft

gear

driven by the crankshaft.

sa

n

aller

sa

o

alter

after

clearance

rocker

0.1

uratlon

Oell'Orto 5.

lubricating

r.

Cylinder

123

A.

uretors

by

for

clearance

mm. (.OO393

are gravity fed from the tank.

Make:

5.1.

gear

pump

crankcase

relief valve)

controlled

and

with automatic advance Marelll distri

: in

: steel

:

:

BOC

BOC

TOe

valve

(cold

")

(right and

driven by the crankshaft.

.

pressure

oil

pressure gauge.

cylinder

4 strokes

2

..

V~_90

80

70

703.717 cc. (42.93 cu. in.)

mm

mm

.

.

o

(3

.149

(2

.755")

")

9 to 1

6000 r.p.m.

50

HP

SAE

in 1i9ht alloy

light

alloy barrels with hard

chrome

with

valve

of

in suitable housing (as used in

all

steel

alloy

in

liming

2.5

linings

light

allo

y,

specia

seals

construction

anti-friction

F1

Race car

construction

thin

light alloy

:

engine):

lell)

- 3 kgs.lsq. cm. (35.6 _

heads deeply finned.

hemispherical,

l cast iron inserted

material pressed

s)

wall

with AL-TIN

bearings

In

the crankcase

butor

42.

type

Automatic advance:

Ignition

Contact

Spark

Plugs

Ignition

Starter

Marelli

ratchet control. Ring

Exhaust system

Dual exhaust pipes and mufflers.

TRANSMISSION

C:utch

Twin driven plates,

trolled

Gear box

Four speeds,

Cush

Separate case

pedal on the right hand side of the machine.

Engine-gearbox ratio:

Internal

-

-

- Third

- High

Seconda ry

By constant speed

Bevel layshalt gear-wheel ratio;

Overall

FR.f,ME

Duplex cradle, tUbular

7

~uspen

Rear

Telescopic

Telescopic

Wheels: 18x3 spoked steel rims, front and rear.

Wheels: 18x3 spoked steel rims.

Tires

4.

Front

Solo

With

liming

breaker

plug:

point

coil

molar

slarter

by lever on left

drive

gear

Low

gear

Second

gear

gear

gear

Low

gear

Second gear

Third gear

High gear

slon

swinging

00 x 18

front and rear,

tire

pressure

rider

pillion

n.

gap

: Marelli BE 220 D.

spring incorpora

gear

dri

front

front

2So

.

38° full advance .

gap:

0.42.0.48 mm. (.016-.018").

225 in Bosch-Marelll scale

: 0,6 mm. (.023") .

MT

40

H (12 V - .7 HP) with

gear

boiled

on

dry

type. located on the lIywheel. Con-

handlebar

fr

onta

l engagement. Constant mesh gears

bolted

on crankcase, operated by

ratios:

ve at rear wheel

homokinet

ratios:

.

ted .

1 to 1.373 (16-22)

ic

double

or

electromagneti

flywheel.

to 1.933

to 1.

to 0.954

to 0.

l

oint

1

1

1 to 6.066

1 to

struclure.

fork with external adjustable

fork

incorporating

fork with external

block

1,5 kgms/SQ.

hydraulic

front

type

om

adjustable

and rear.

..

high speed

.

eQuivalent.

263

754

cardan

4.625 (8-37)

to

to

springs

.

dampers.

spring

_.

21

P.

S.1.

rocker

(15-29)

(19-24)

(22-21 )

(24-18)

shal

12292

8.031

4]94

.

c

l

5

Rear

tire

Solo

rider

Wilh

pillon

Note

- The above reeommendation is

sing speed).

on

motorway

0.2

kgms/sq

!I

using Ihe maehlne

s !he above pressures should be Increased by

. cm. (2,8 P.S.I.).

1.8 kgmslsq. cm. = 25 P.S.I.

2.0

Bntkes

Twin

lead

ing

shoes

exp

hand

lever on the r

Large

rear brake operated by pedal on

mac

hine

.

Overall

dlmen

t lons and

-

Wheelba~e

-

Lenglh

- W

idth

-

Height

- M

-

(dry)

in

imum ground

Curb

weigh!

anding

ight

handlebar.

weight

clearance

kgms

/sq. cm. =

al

type

28

lor

normal

eonslanl

Ironl

1.445

2.230 mls. (abl. 87.5" )

0.

1.

O.

high

brake. operate

lell

hand

mls

795

miS.

0SO

miS. (abt. 41.2"')

ISO

mets. (abl. 5.

riding

. (ab

(abt.

P.S.!.

(crui·

speed

sioe

t.

56.9

31.2")

243 kgs 536 Lbs

or

d by

of

")

9")

Performance

Maximum permissi

each gear.

L

ew

Seco

ty 34%

Tl>

ird gear 120 kms/ h (74.5 m.p.h.)

ty

'<:3

High

Capacities

Fuel tank:

solo riding.

gear

nd gear 96

'/0

gear

20

reserve (about 1 USA gl) - Petrol

Sump 3

mission 0.750 liters

wheel drive 0.300

Front

1I1ers

lor

k dampers 0.160

ble

speed and

66

Kms/h

(41

kms/h

m.p.h.) Clmblng ability

(59.6 m.p.h.) Cli

170 kms/h (106 m.p.h.)

liters

(5.28 US gla.)

(3'1. Quarts) Shen

(1

~/.

liters

(5/8 Pints) Shell Splrax 90 E. P. -

98

/100

Pln!s) Shell Spirex 90

Multigrade

liters = 5,4

lux 33 -.

gradients

Climbing

inc

lud

ing

No

Climbing

(Regular

climbab

mbing

ability 14l/a

aboul 4 liters

20/40 _ Trans-

E.

P. - Rear

oz USA ~ Shell Tel-

le

in

60%

abili-

abil

oclane)

i-

6

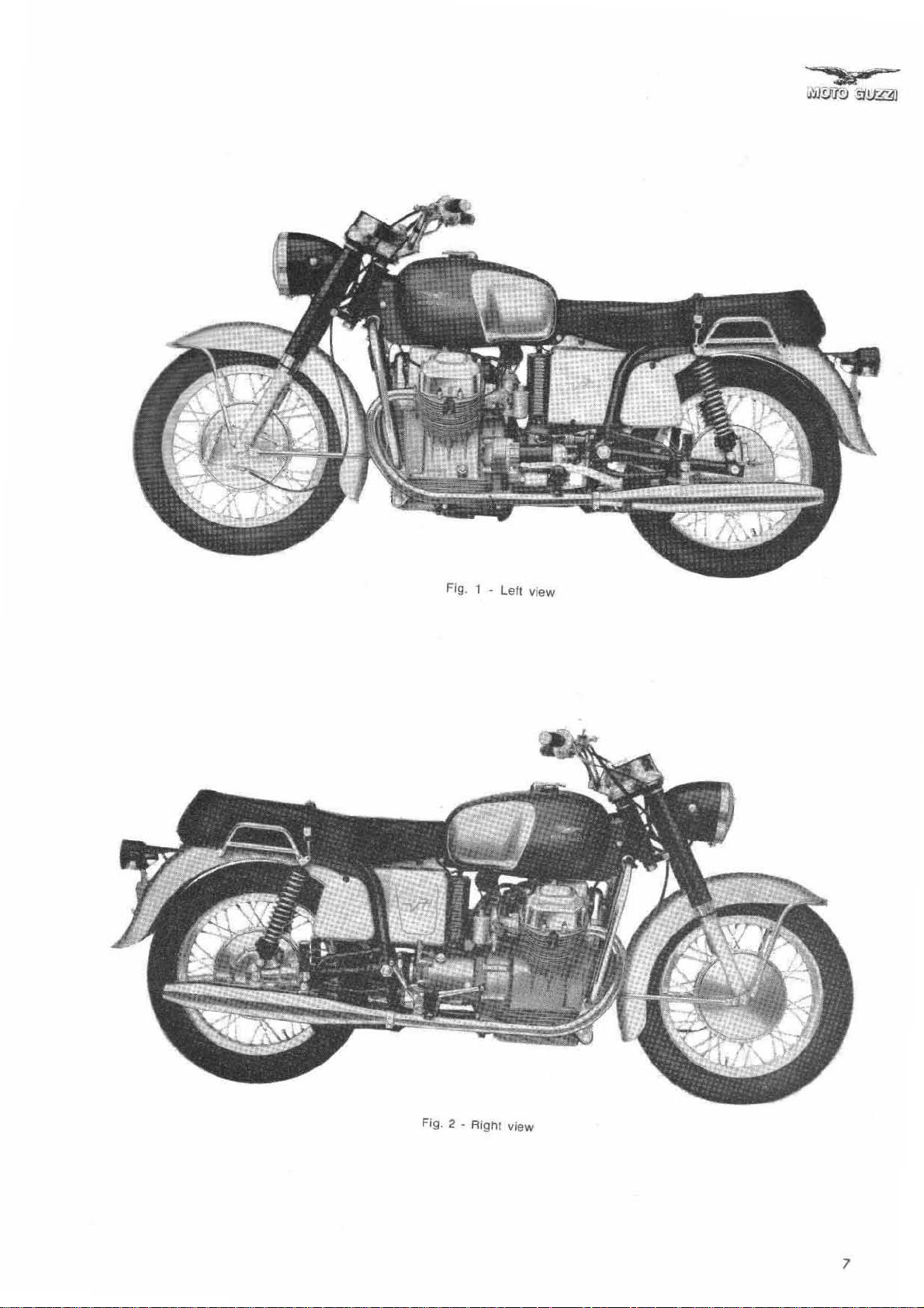

Fig. 1 -

lelt

view

Fig. 2

- RighI view

7

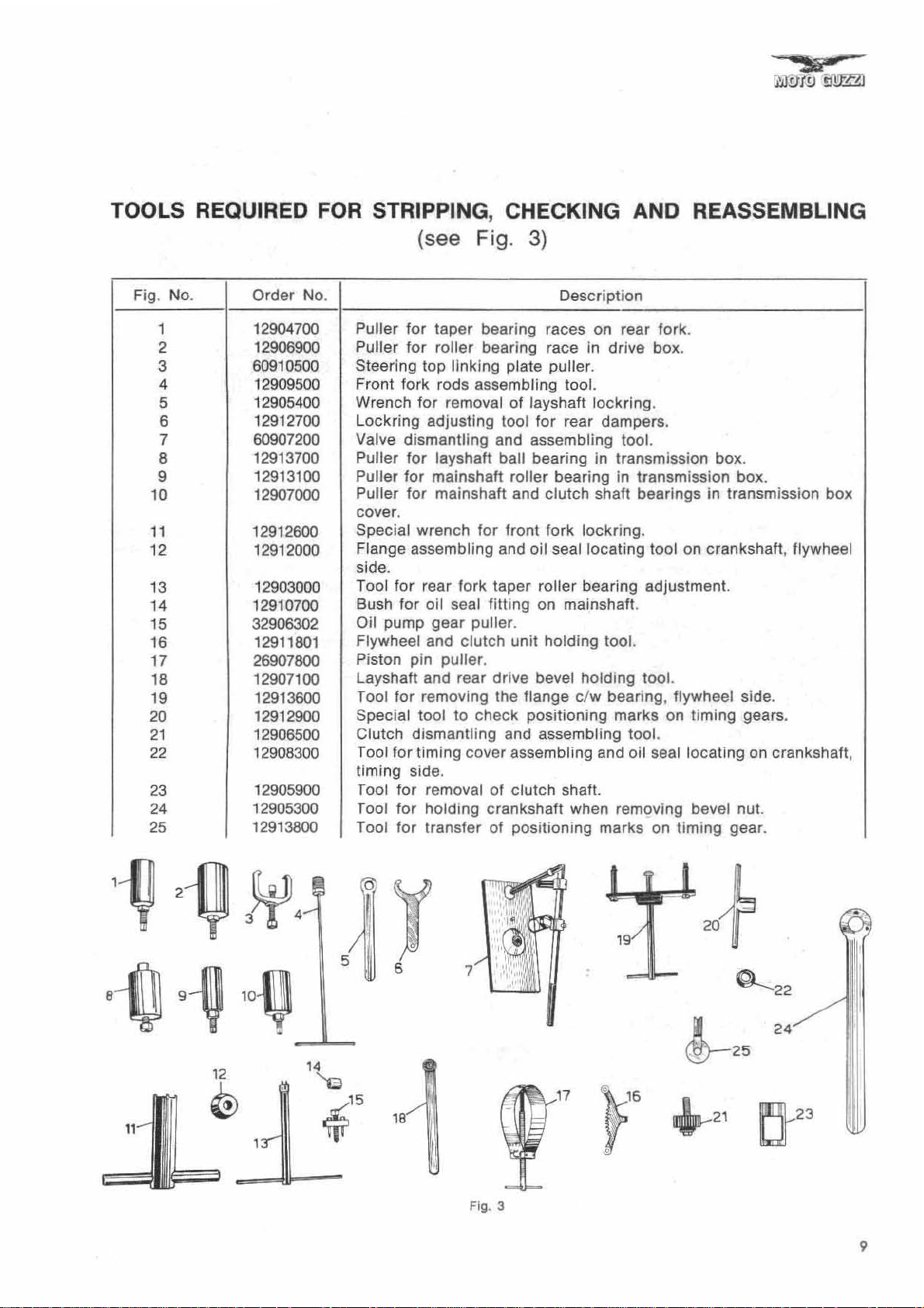

TOOLS REQUIRED

FOR

STRIPPING, CHECKING AND REASSEMBLING

Fig . No .

1 12904700

2 12906900

3 60910500

4 12909500

5

6

7

8

9 12913100

10 12907000

11

12

13 12903000

14

15

16

17 26907800

18 12907100

19 12913600

20 12912900

21

22 12908300

23

24 12905300

25 12913600

Order

12905400

12912700

60907200

12913700

12912600

12912000

12910700

32906302

12911801

12906500

12905900

No.

(see Fig.

Puller

Puller

Steering top linking plate puller.

Front fork rods assembling tool.

Wrench

L

Valve

Puller

Puller for mainshaft roller bearing in transmission box.

Puller for mainshaft and clutch shaft bearings in transmission

cover.

Special

Flange assembling and oil seal locating tool on crankshaft, flywheel

side.

Tool

Bush

Oil

Flywheel

Piston pin

layshaft

Tool

Special tool

Clutch

Tool

timing

Tool

Tool

Tool

for

for

ockring

dismantling

for

for

for

pump

for

for

side.

for

for

for

taper

bearing races on rear

roller

bearing race in

for

removal of Jayshaft

adjusting tool for rear dampers.

layshaft ball bearing in transmission

wrench

resr

oil seal

gear

and

and

removing the

dismantling

timing

removal of

holding

transfer

fork

clut

puller

rear

to

cover

for

puller

check

3)

Description

drive

lockring

and assembling tool.

front fork

taper

fitting

.

ch

unit

.

drive

flange

positioning

and

assembling and oil seal

clutch

crankshaft

of pOSitioning marks

lockring.

roller

bearing adjustment.

on

mainshaft.

holding

bevel

assembling

tool.

holding

c/w

bearing.

marks

shaft.

when removing bevel nut.

fork

box.

.

tool.

flywheel side.

on

tool.

on

.

box

timing

locating

timing

.

gears.

on crankshaft.

gear

.

box

1-IJ

8~

2~

9~

3~4

10~

12

@

.

~

19

5

14

~

~15

1

Y

6

18

7

Fig. 3

17

~'6

~+

~22

24

~

.21

25

rJ23

~

l'

I

9

DESCRIPTION OF ENGINE

..

(see Fig. 4 &

The"

V7»

model is

der 90' V engine.

rels

with

hard

finned

Cylinder

for

cooling

bottoms fit into

equipped

Cylinders

crame

.

lining

5)

with a

have

s and are deeply

suitab

light

le

housings

twin-cylin-

alloy

crankcase.

Crankcase

(four long,

cylinder

Cylinder

cast iron inserted valve seats.

Rocker

tion

crankshaft

main bearings, pressed in suitable housings.

Steel

ings

ends.

Piston in

piston

pin

(oil scraper),

O.H.V. valve gear,

tappets, push rods and rockers. Camshaft

driven

Pressure

in

ligllt

alloy ,

two

short)

heads.

heads are in

box

covers

construction

at big

ends

light

rings

and

by

crankshaft. Carburetors

lubrication

in

light

on

two

special

con-rods

and bronze bush es at small

alloy. with 4 rings: 3

one

oil

operated

from oil sump

provided

to

secure

light

alloy. Steel

scraper)

with

cylinders

alloy, with special

tin-aluminium

with thin

over

through camshaft,

are

six

construc-

wall

pin (t

and 1

gravity

through

bolts

alloy

bear-

belo

gear

gear

bar-

in

and

wo

w

fed.

.:.

,

'\'(r~'

";'~

:Y·!~

-

.

'.

..

'

,',

,

..

,

~

.. ' ..

,

'j:

••••••

~~

..

~

....

~

, \. '".

""':

'.

pump

driven by crankshaft. Oit recovery by

vity. Wire gauze

Lubrication

Breather

box

from which,

into

sump.

Pressure

tube

. Engine is

heads are

Ignition by battery ,

by

crankshaft

ctric

Ele

pressure control

tube

conveys

is discharged

air

suitably

through

starting,

Fig. "

type

oil

cleaner

led by relief valve .

oil

vapors Into

after

condensation.

outside

cooled. Cylinders

finned .

coil

and

distributor

built-in

electrically

gear

controlled.

in

crankcase

breather

oil

returns

through

and

cylinder

operated

.

gra-

.

vent

10

Fig. 5

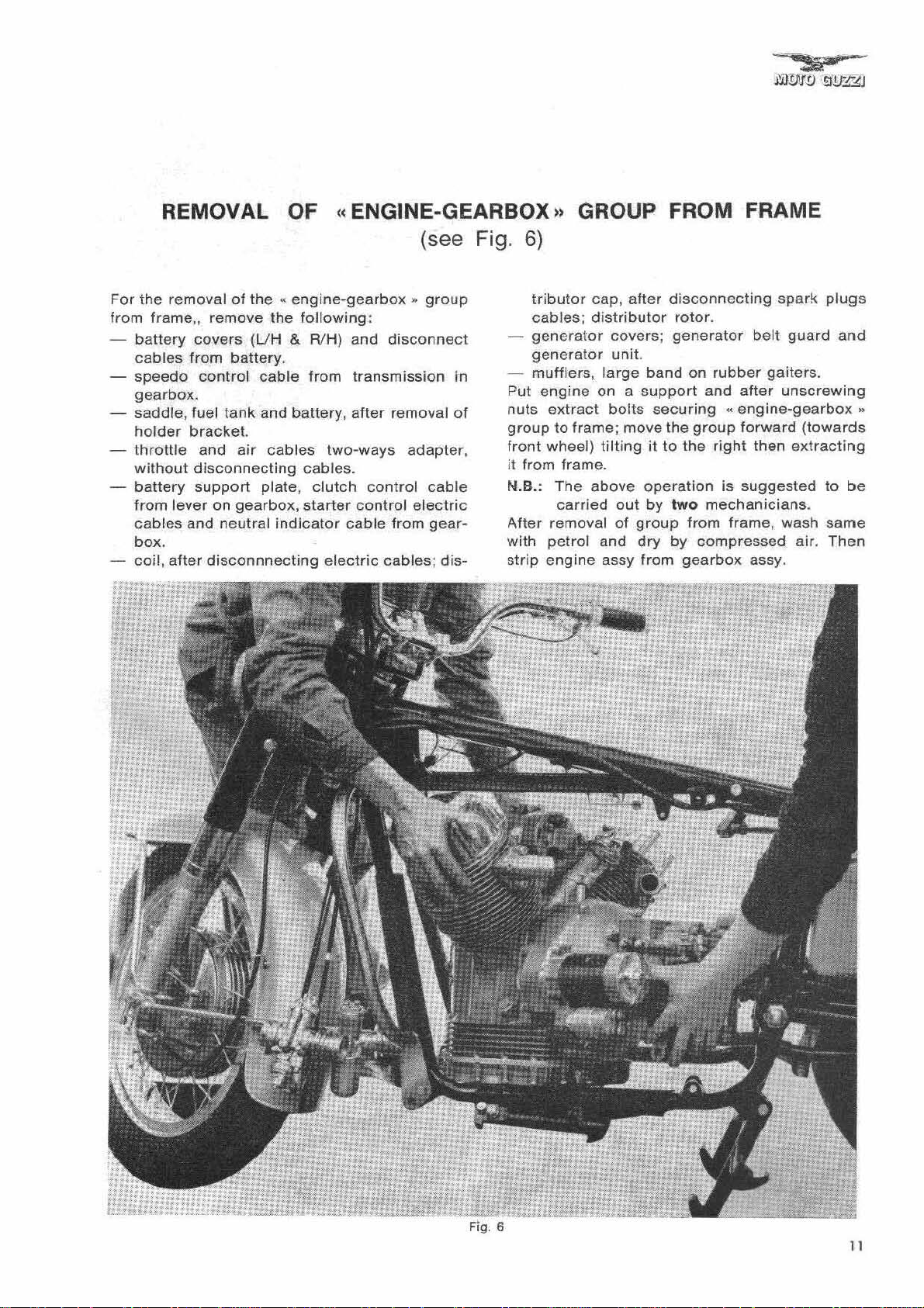

REMOVAL OF " ENGINE·GEARBOX» GROUP FROM FRAME

For

the

removal of the

from

frame"

battery

cab

les from

speedo

gearbox.

saddle, fuel

remove the

covers (UH & RlH)

battery

control

tank

holder bracket.

throttle

without

battery

from lever on gearbox,

cables and neutral

box.

coil, after

and

air

disconnecting

support

disconnnecting

(see Fig.

..

engine·gearbox,.

following:

and

.

cable

and battery , after removal

plate,

from

transmission

cables two-ways adapter,

cables.

clutch

starter

indicator

control

control

cable

electric

group

disconne

cable

electric

from gear-

cables;

dis-

ct

in

of

6)

tributor

cables;

generator

generator

mufflers,

Put

engine

nuts

group

front wheel)

it

from frame .

N.B.: The

After removal

with petrol and dry by compressed air.

strip

cap, after

distributor

covers;

unit.

large

band

on a

support

extract

to frame; move the

carried

engine

bolts

securing

tilting

above

it to

operation

out by two mechanicians.

of

group

assy from

disconnecting

rotor.

generator

on

rubber

and

«engine·gearbox»

group

the

right

is suggested

from frame, wash same

gearbox

spark

belt

gaiters.

after

unscrewing

forward

then

assy.

guard

(towards

extracting

plugs

and

to

be

Then

11

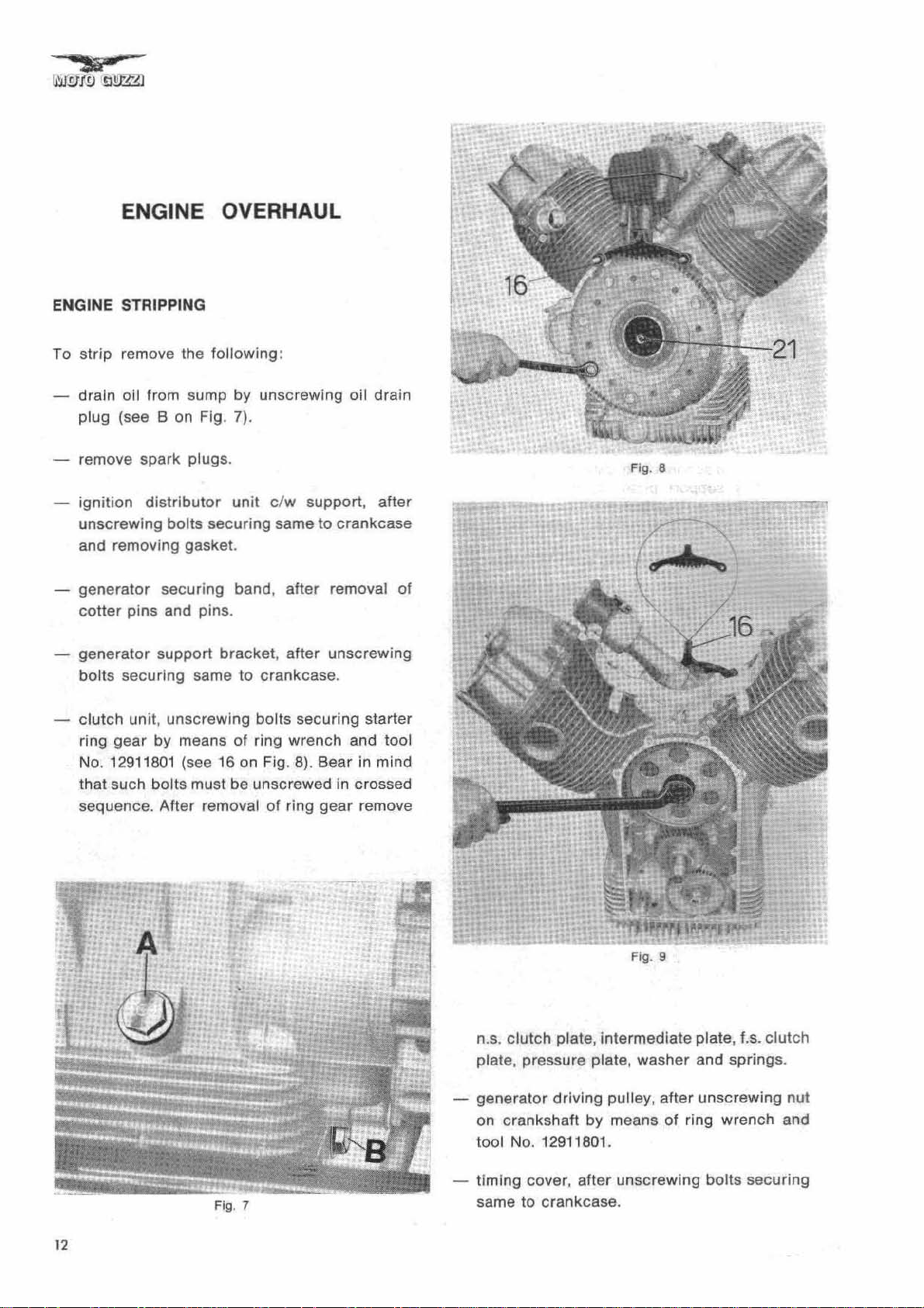

ENGINE OVERHAUL

ENGINE STRIPPING

To

strip remove the following:

drain oil from sump

plug (see B on Fig. 7).

remove spark plugs.

ignition

unscrewing bolts securing same to crankcase

and removing gasket.

generator

cotter pins and pins .

generator

bolts securing same to crankcase.

clutch

ring gear by means of ring wrench and tool

No. 12911801 (see 16 on Fig. 8).

that such bolts must be unscrewed in crossed

sequence. After removal of ring

distributor

secur ing band,

support

unit

, unscrewing bolts securing starter

by

unscrewing

unit c/w support,

after

removal

bracket, after

unscrewing

Bear

gear

oil

drain

after

in mind

remove

01

Fig. a

12

Jj

..

Fig

. 7

n.

S.

clutch plate, intermediate plate,

plate , pressure plate, washer and

generator

on crankshaft by means of ring wrench and

tool No. 12911801.

timing

same

driving

cover,

to

crankcase.

pulley,

after

after

unscrewing bolts securing

1.5.

springs

unscrewing

clutch

.

nut

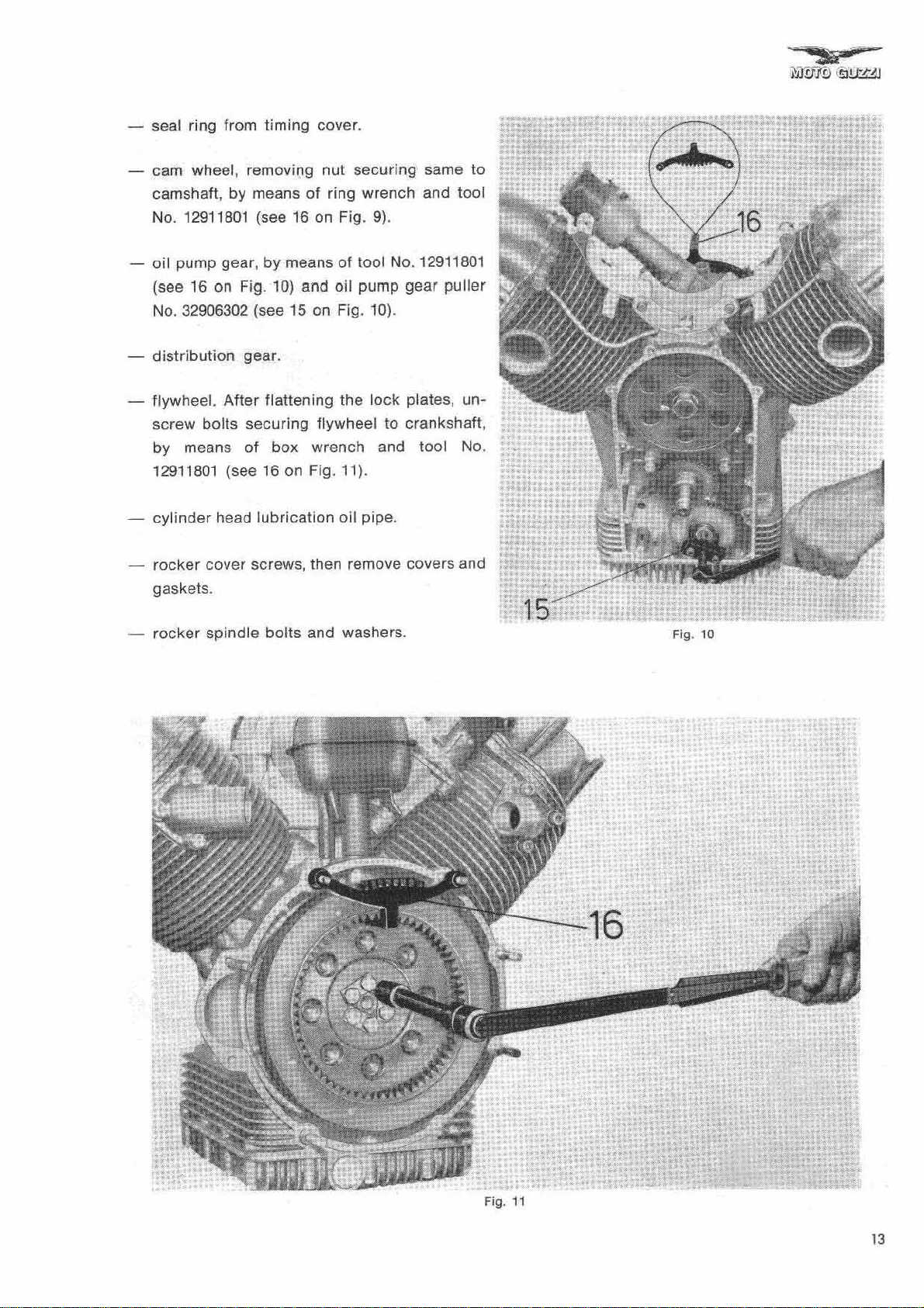

seal ring from

cam

wheel , removing nut securing same to

camshaft, by means

No. 12911801 (see 16 on Fig.

timing

cover.

of

ring wrench and tool

9)

.

oil pump

(see

No. 32906302 (see

distribution

flywheel.

screw

by means of

gear

, by means of

16

on Fig. 10) and

15

gear.

After

flattening the

bolts securing flywheel to crankshaft ,

box

12911801 (see 16 on Fig. 11).

cylinder

rocker

gaskets.

-

rocker

head

lubrication

cover screws, then remove covers and :;

spindle

bolts and washers.

1001

No. 12911801

oil

pump

on Fig. 10).

wrench and tool No.

oil

lock

pipe.

gear

puller

plates , un-

"

Fig.

10

--16

Fig.

11

..

13

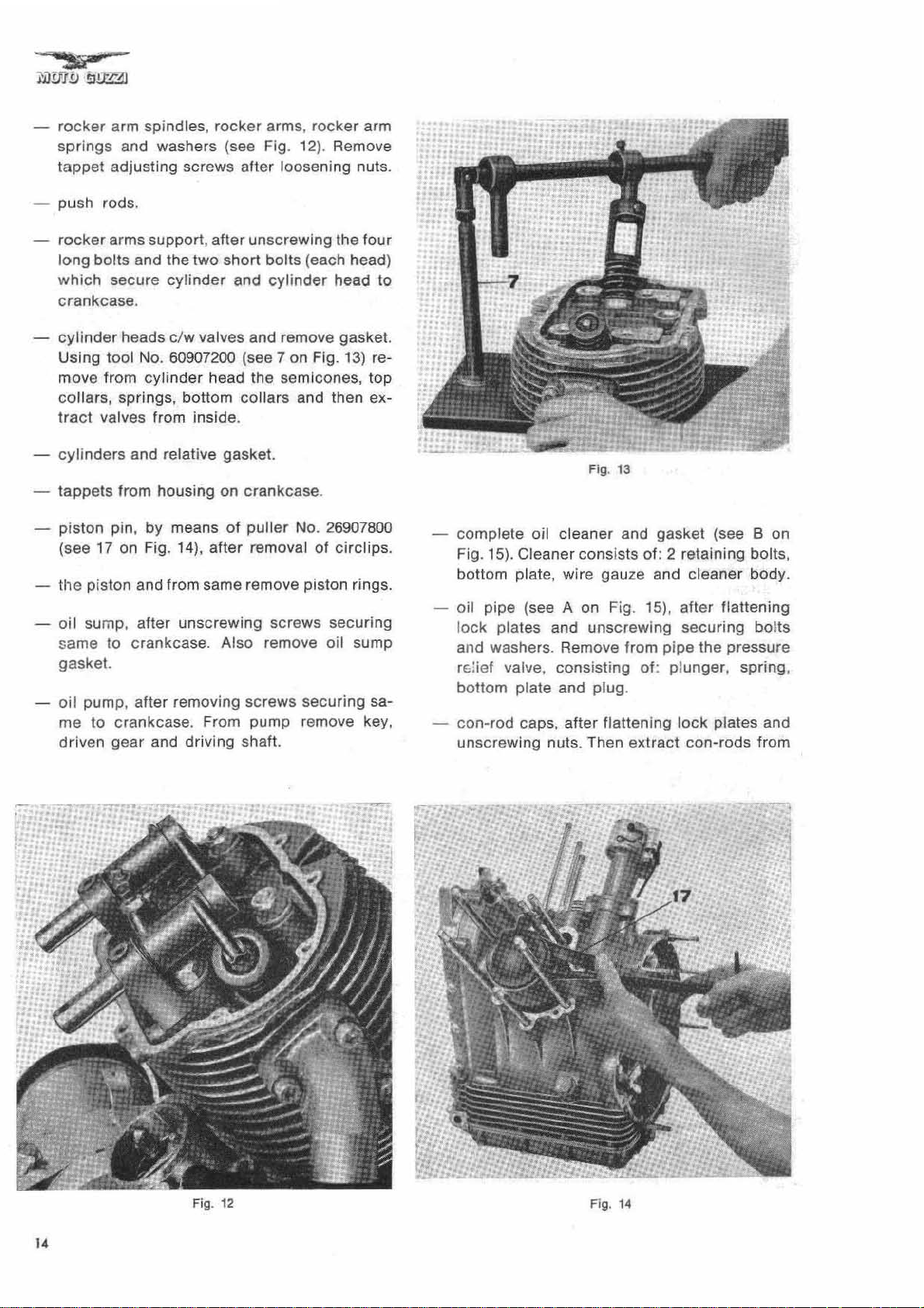

rocker

springs

arm spindles,

rocker

and washers (see Fig. 12). Remove

tappet adjusting screws

push rods.

arms,

after

loosening nuts.

rocker

arm

rocker

long

which

crankcase

cylinder

Using tool No. 60907200 (see 7 on Fig.

move from

arms support,

bolts and the two

secure

after

cylinder

unscrewing the

short

bolts (each head)

and

cylinder

.

heads c/w valves and remove gasket.

cylinder

head the semlcones,

head

13)

four

to

re-

top

collars, springs, bottom collars and then extract

valves from inside.

cylinders

tappets

piston pin, by means

(see

the

oil

same to

and relative gasket.

from housing on

17 on Fig. 14),

crankcase

of

puller

after

No. 26907800

removal of circlips.

.

piston and from same remove piston rings.

sump ,

after

unscrewing screws securing

crankcase

. Also remove

oil

sump

gasket.

oil

pump,

after

removing screws securing same to crankcase. From pump remove key,

driven

gear

and driving shaft.

Fig.

13

co mplete oil cleaner and

15)

Fig.

. Cleaner cons ists of: 2 retaining bolts,

gasket

(see B on

bottom plate, wire gauze and cleaner body .

oil pipe (see A on Fig. 15), after flattening

lo

ck

plates and

unscrewing

securing bolts

and washers . Remove from pipe the pressure

r

",!

ief valve , cons isting of: pl

ott

om

b

con-rod

plate and plug .

caps,

after

flattening

unger, spring

lock

plates and

unscrewing nuts. Then extract con- rods from

,

Fig.

12

Fig. 14

top

of crankcase. Remove

con-rods.

camshaft,

flange

after

to

crankcase.

half

bearings from

unscrewing bolts securing

flange c/w

after

flatten ing lock

bo

lts securing flange to crankcase.

crankshaft

bushing,

plates and

timing

unscrewing

flange c/w main bearing, flywheel side, after

flattening

securing flange

of

tool No. 12913600 (see 19 on Fig.

ve

flange c/w main bearing from crankcase .

lock

plates and unscrewing bolts

to

crankcase. Then, by means

16)

crankshaft.

oil

pressure solenoid .

oi l

filler

plug

(see A on Fig. 7).

After the above operations the crankcase is

pletely stripped,

except

for

the

long and

bolts.

N.B.:

During

ed

rod-piston

stripping

to

keep well apart

..

groups.

it

is

strong ly recommend-

the

two

..

cylinder-

side,

remo -

Fig. 15

com-

short

To remove timing cover

from frame,

- after removing

unscrew

sembly. Extra ct

it is necessary to proceed as

belt

the

three bolts securing pulley as-

pulley

without

cover and

removing engine

generator

outer

flange and

washers.

using the three bolts previously securing pulley, fit tool No. 12905300 on

24

on Fig. 17) and thus

unscrew crankshaft nut

pulley hub (see

holding

by

crankshaft

means

of

wrench.

unscrew

tool,

block

the

inner

or

support

three

body

bolts

and remove special

of

pulley and pulley

engine.

remove bottom frame/engine stud.

rem ove screws securing

timing

cover

crankcase.

follows

belt.

a ring

hub

.

Ie

:

16

Fig.

,

Fig.

17

15

ROCKER BOX COVERS - CYLINDER

HEADS - VALVES - GUIDES

- SPRINGS

Cylinder

se

nuts secure

STRIPPING

Removal and stripping of

quired

loss being imputable

and also

order

c

hamber.

When engine is on frame,

ping

Disconnect:

- sparks cables.

-

- exhaust pipes and muffler

-

-

-

Then remove cylinder head

No

linde

overhaulfng and assembling operations, and re·

quired

graphs:

heads, in light alloy, are finned to increa-

coo

ling surface. Long bolts, short bolts and

cylinder

when loss of compression

after

to remove carbon deposits in combustion

Is

carried

air

inlet tubes and

distributor

rocker

rocker

difficulties

r heads

tools, are lIsted in the

Qut

cap .

box

arms and

are involved

into

heads to crankcase.

cylinder

to

defective valve sealing,

a certain period

cylinder

as follows:

carburetors

s.

covers.

rocker

parts.

arms supports.

s.

in

strippi

In

any case all stripping,

heads are re-

is

noticed, such

of

operation, in

heads strip-

.

ng

down

following

cy·

para·

Fig.

18

REMOVAL OF SPRINGS AND VALVES

PositIon

7 on Fig.

the

co

linder

INSPECTION AND OVERHAUL

OF CYLINDER HEADS

Using a chamfered

move

INSPECTION AND OVERHAUL

OF

Valve

cylinder

ried

& 19). Valve

excessive lash between its hole and the valve

stem, whenever such lash

simply

After

reamed

same

Negative

housings

exhaust valves. is

mm.

cylinder

13)

valve top co llar so to remove semicones,

llar

, spring, bottom plate and, from inside

head,

carbon

VALVE GUIDES

guides

heads. Removal and refitting

out

by means

replacing valve.

pressing

wit

h a

to

size as shown

allowance

on

0.046 and 0.075 (.0018 - .(0295).

head on tool No. 60907200 (see

and with the arm of same press on

the

valve.

scraper

deposits

are pressed in

of

a round punch (see Fig. 18

guide

cylinder

must be replaced in case

guide

straight

in

to

and a wire brush re-

and Inspect valve seats.

their

housings in

are

is

not

eliminable

in housing , hole must be

reamer in

In

coupl ing

pressing

heads,

be

order

data

guides

for

both inlet and

comprised

to bring

in their

between

top

cy-

car-

of

by

chart.

•

f

r

fi

•

Fig.

19

t

Fig. 1

9/

1

16

Inlel

va lve

Exhaust valve

VALVES-VALVE GUIDES COUPLING DATA

Valve

guide

I.D.

8.000 + 8.022 mm.

{.3149 - .3158"}

Valve slem

di

ameter

7.987

7.980

rnm.

mm.

7.972

+

(.3138 - .3144") (.0005 - .0019")

7.965

-+

(.3136 - .3142") (.0008 - .0022

0.013

0.020

Clearances

-+

0.050

~

0.057 mm.

mm

")

.

INSPECTION AND OVERHAUL OF VALVE

SEATS IN CYLINDER HEADS

In

order

valve seats must be regrinded. Angles of

tion of the seats are as follows:

- exhaust valve: 45°

to

obtain a perfect

inlet valve:

60025

25'

match

'

with

valves,

inclina-

7.987

7.

972

Regrinding is

cutter,

After

it

emery paste .

guided

milling, in

is necessary to

rated that normal milling will not

replacement of same will then be required.

carried

by a stem inserted

Should

out

by

order

to

obtain a perfect

grind

the valve

valve seats be so

means of a

in

valve

in

its seat

be

milling

guide

match

deterio-

sufficient ,

7.980

7965

8.

000

.022

.

,

with

38

38

.6

38.4

Fig. 20

14.064

14.075

34

34.6

34.4

17

INSPECTION OF VALVES

Check

stem

data

valve stem

Grinder

table

tion as

- exhaust valve:

valves

and

guide

chart

(see Fig.

so

that valve

follows:

integrity

(for

and

Fig.

20)

In

self-centering

21)

will

4Se 25

and

clearance

. To

and

have an

existing

regrind

chuck

adjust

' +

1~'

lash between

refer

to

coupling

valves, insert

of

Universal

chuck

angle

of

swivel

inclina-

Whenever

to

check

ween 37 mm. and

by

adopting

between spring and cylinder head .

INSPECTION OF VALVE SPRINGS

Check

have

Spring, compressed at

show a load

regrinding

that valve

that valve

not

lost

valve seats, it is advisable

springs

38

mm . (1.456 - 1.496").

suitable

springs

their

elasticity.

of

Kg. 33 + 2 (72 Ibs - 12 ozsl

are

compressed

washers at

are

not cracked

37

mm. (1.456"), must

o

bottom

bet-

Adjust

collar

and

,

-

inlet

valve :

After

grinding

max. dia. to be

Sho

uld surface at stem end

mation.

regrind

SO

check

not

same on

Fig. 22).

U

25

'

thickness

Jess

o

+ 15'

of

valve head at

than 0.8 mm. (.0315") .

show

grinding

any defor-

wheel (see

(closed

Spring, compressed at

show a load

(open valve position).

Springs

apparatus (see Fig. 23). As to load and

tion data refer to Fig. 24.

VALVE SEALING TEST

After reassembling valves

up

if

any, will

bustion

valve position).

flexibility

inlet

and exhaust

be

chamber.

of

Kg.

can

ducts

detected

28

mm. (1.024"), must

o

60

+ 2 (132 Ibs - 4 ozs)

be

checked

on

cylinder

with gasoline. Losse

by

liquid

by

leaking

suitable

deforma-

head, fill

s.

in

com-

18

Fi

g.

23

J

.-J

~

:.J

.aooo

48.010

37

2t

Kq

33

Kg60.g

j (

r

(

r

(

•

Fig. 24

ASSEMBLING OF CYLINDER HEADS

ON

CYLINDERS

Assembling of

ried

out

- reposition a

and

cylinder

tion openings in gasket match with

holes

-

secure

crankcase.

-

fit

rocker

- position

-

screw down

crossed sequence , without tightening. Using

a

torque

ft.lb)

nuts

Fig.

25

cylinder

as

follows

in

cylinder

the head assembly

arms

washer

nuts

wrench

gradually

accordingly

(1-2-3-4-5-6).

heads on

:

new

gasket

head,

making

and

cylinder

support.

on

cylinder

on

long

rated at Kg/m. 3.800 (27.48

tighten

to

cylinders

between

sure that

head.

to

the

bolts

and

short

long

and

sequence

lubrication

six

.

cylinder

bolts

short

shown

is car-

lubrica-

bolts

, in

bolt

in

in

punch

by

-

fit

rocker

-

fit

head in

connect

-

- insert

head.

-

fit

-

fit

fit

-

-

connect

Repeat same assembling

cylinder

insert

bolt

a new gasket

rocker

inlet

air

inlet

air

inlet

distributor

head.

spindle

and washer.

box

cover

box

cover

crossed

cylinder

tube

tube

tube

cap.

sparks

between

.

sequence

head

reducing

seal.

complete

cable.

and secure it to

cylinder

and

screw

lubricating

operations

.

bush on

with

carburetor

it

to

for

support

head

cylinder

pipe

.

cylinder

second

and

.

N.B

.:

In

heads

ti

positioned, fit

Iy

c/w

After

order

to

avoid

during

ons

must be

adjusting

having lined them all up,

screw

deformation

assembling, above

strictly

on

followed

support

, spring and washer.

of

.

the

rocker

by

means of a

cylinder

instruc-

arms

Fi

g.

25

19

CYLINDERS - PISTONS - PISTON RINGS

CYLINDERS WEAR CHECK

Measurement

must

be

transversal and longitudinal directions.

Dial gauge must previously be set to zero on ring

gauge

Fig. 27).

Should sea rings ovalization

ing 0

ing (see

then be replaced.

SELECTION OF CYLINDERS DIAMETER

N.B.: Cylinders must always

(see Fig.

.1

0

Class "A"

80.000

(3.14963")

80.006

(3.1

4987")

piston of same class.

of

internal

taken at three

26)

and measurement

mm

. (.00394") be noticed in chrome lin-

top

portion

rnm

. 80.006 mm.

mm

.

60.01

diameter

different

or

of

cylinders) ,

Class

"8"

(3.14987") (3.15010

2

mm

(3.15010

. 80.018

")

of

cylinders

heights, both in

chart

any wear exceed-

cylinders

Class "

80.012 mm.

(3.15034 " )

be

matched with

C"

")

mm

(see

must

.

•

• h:'

..

.'#

.

'.,

• •

•

..

"

.

:

.

...

•

. .

,

..

"

.

..

.

.

..

...

.

Fig. 26

'"

20

eo.OOO+80

3tMisuraz.

.018

Fig.

27

PISTONS

When overhauling, decarbonize piston crowns

and

ring slots. Then

ance (see Fig. 28).

If clearance exceeds measurement stated by

chart, then replace cylinders and pistons.

For engine balancing, both pistons must be of

some

ference is 1.5 grammes

Selection

must be taken at 18.5 mm. (.7283")

bottom

to piston

have to be 0.055 :- 0.065 mm.

less than selection size.

weight.

As

to sizes refer to chart

measurements

edge, In

pin

axis

check

Maximum

orthogonal

(see Fig. 30) Qvalization shall

cylinder-piston

permissible

(23

grains) (see Fig.

on

Fig.

31.

shown

in

sense with

(.OO21

weight

chart

from

-;-.

clear-

dif

29)

below

piston

respect

.0025")

-

.

Fig.

29

Fig. 28

1.990

..JL

1.978

03+045

0.25'0.40

2.

490

2.478

22.00'

Q3"'0.45

rCJ:::::::J

0~.40

3.990

3.978

Fig.

31

18.5

/

~

Sele

Fig. 30

'"

,

ianatur

i~~70

7

.952

..

"

SELECTION OF PISTON DIAMETER

Class

"A"

79

.952 mm.

(3.14nq

79.958

mm

. 79.964 mm.

(3.14798

N.B.: Pistons must always be matched with cy-

")

linders of same class.

Class "B" Class "

79.958 mm. 79.964 mm.

(3

.14798'·) (3.14821")

79.970

(3.14821'·) (3.14845"\

C"

mm

'

.

-::t:::::::!:m:~:·.m:.!!.

,

............

!!

..

··t·,·

;;:.:.:t:;:::,;w::;:·

_

.:·_······

::.:.::

....

• 1"'" : ;

. .:::*'

..

. -

-

:

...•.........

...

r.··· · ..

·····1

.•

·:1:···

::;:::

.. : ..

:::

..

..

. .

...

..

:.

-:.

:

•

Fig.

..

32

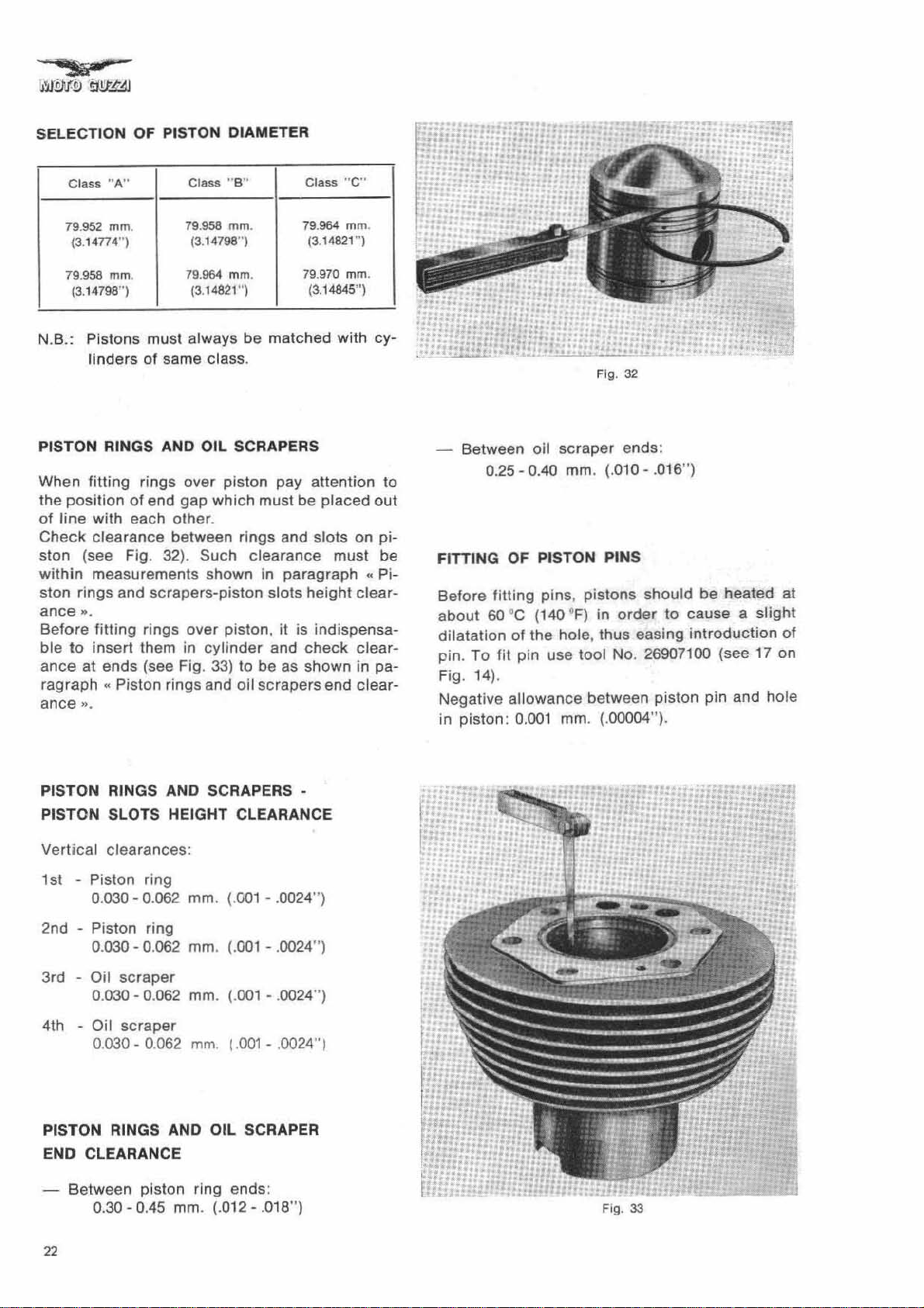

PISTON RINGS ANO OIL SCRAPERS

When fitting rings over piston pay attention

the position

of

line with each other.

Check clearance between rings and slots on piston (see Fig. 32). Such clearance must be

within

ston rings and scrapers-piston slots height clearance

".

Before fitting rings over piston,

ble

to

ance

at ends (see Fig.

ragraph

ance

".

PISTON RINGS AND SCRAPERS -

PISTON SLOTS HEIGHT CLEARANCE

Vertical clearances :

1 st -

of

end gap which must be placed

measurements shown in paragraph

it

is indispensa-

insert them in

..

Piston rings and oil scrapers end clear-

Piston ring

0.030 - 0.062

cylinder

33)

to be as shown in pa-

mm

. (.001 - .0024")

and check

to

out

..

Pi-

clear-

Between oil scraper ends:

0.25 - 0.40

FITTING

Before

about

dilatation

pin. To

Fig. 14

Negative allowance between piston pin and hole

in piston:

OF

fitling

60 °c (140 t

of

fil

pin use tool No. 26907100 (see

).

0.001

mm

. (.010 - .016

PISTON PI

pins

, pistons should be heated at

the

hole

mm. (.00004").

NS

F)

in

order

. thus easing

")

to

cause a slight

introduction

17

of

on

2nd - Piston ring

0.030 - 0.062

3rd Oil

4th Oil

PISTON RINGS AND OIL SCRAPER

END CLEARANCE

Between piston ring ends:

22

scraper

0.030 - 0.

scraper

0.030 - 0.062

0.30 - 0.45

mm

062

mm.

mm

mm

. (.012 - .018")

. (.001 - .0024")

(.001

- .0024

. I .

001

- .0024" I

")

,

H.l'l

Fig. 33

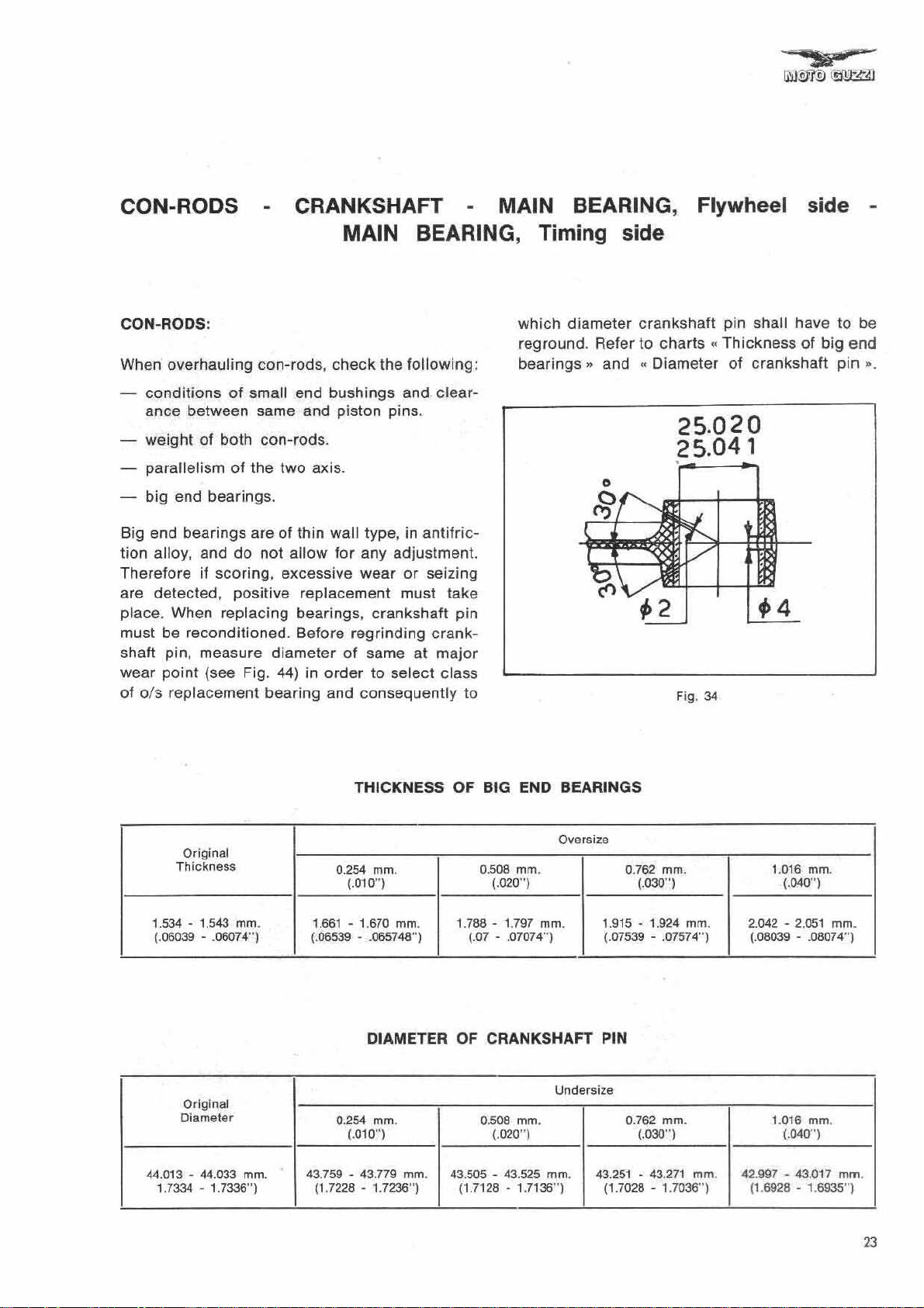

CON-RODS

CRANKSHAFT MAIN BEARING, Flywheel side

MAIN BEARING, Timing side

CON-RODS,

When overhauling con-rods. check the following:

-

conditions

ance

- weight

parallelism

big

end bearings.

Big end

of

small end

bushings

and_ c

between same and piston pins.

of

both con-rods.

of

the

two

axis.

bearings

are of

thin

wall

type, in

lear-

antifric-

tion alloy, and do not allow for any adjustment.

Therefore

are

place. When

must be

shaft pin, measure

wear

of

o/s

if

scoring,

detected,

replacing

reconditioned.

point

(see Fig. 44) in

replacement

positive

diameter

bearing

excessive

replacement

bearings,

Before

of same at

order

and

wear

or

seizing

must

crankshaft

regrinding

to

select

consequently

take

pin

crank-

major

class

to

which

diameter

reground.

bearings»

crankshaft

Refer

to

and

"Diameter of

charts

..

25.020

5.041

Fig.

34

pin shall have to be

Thickness

crankshaft

of

big

end

pin

D.

Original

Thickness

1.534 - 1.543 mm.

(.06039 - .06074"')

Original

Diameter

44.013 - 44.033 mm.

1.7334 - 1.7336

"')

THICKNESS OF BIG END BEARINGS

Oversize

0.254 mm.

(.010"') (.020") (.030")

1.661

- 1.670 mm. 1.788 - 1

(.

06539 - .065748"')

DIAMETER

0.254 mm. 0.508 mm. 0.762 mm.

(.010")

43

.759 - 43.779 mm. 43.505 - 43.525 mm .

(1.7226 - 1.7236

"')

0.508 mm . 0.762 mm .

.797

(.07

OF

CRANKSHAFT PIN

(.

(1.7126 - 1.7136

mm.

- .07074") (.07539 - .07574"')

Undersize

020

")

")

1.915 - 1.

43.251

(1.7028 - 1.7036" )

924

(.030")

-43.

271

mm.

mm.

1.

016

mm.

(.040"')

2.042 -

42

2.051

(.08039 - .08074"')

1.016 mm.

(.040"')

.997 - 43.017 mm .

(1.6926

- 1.6935")

mm.

23

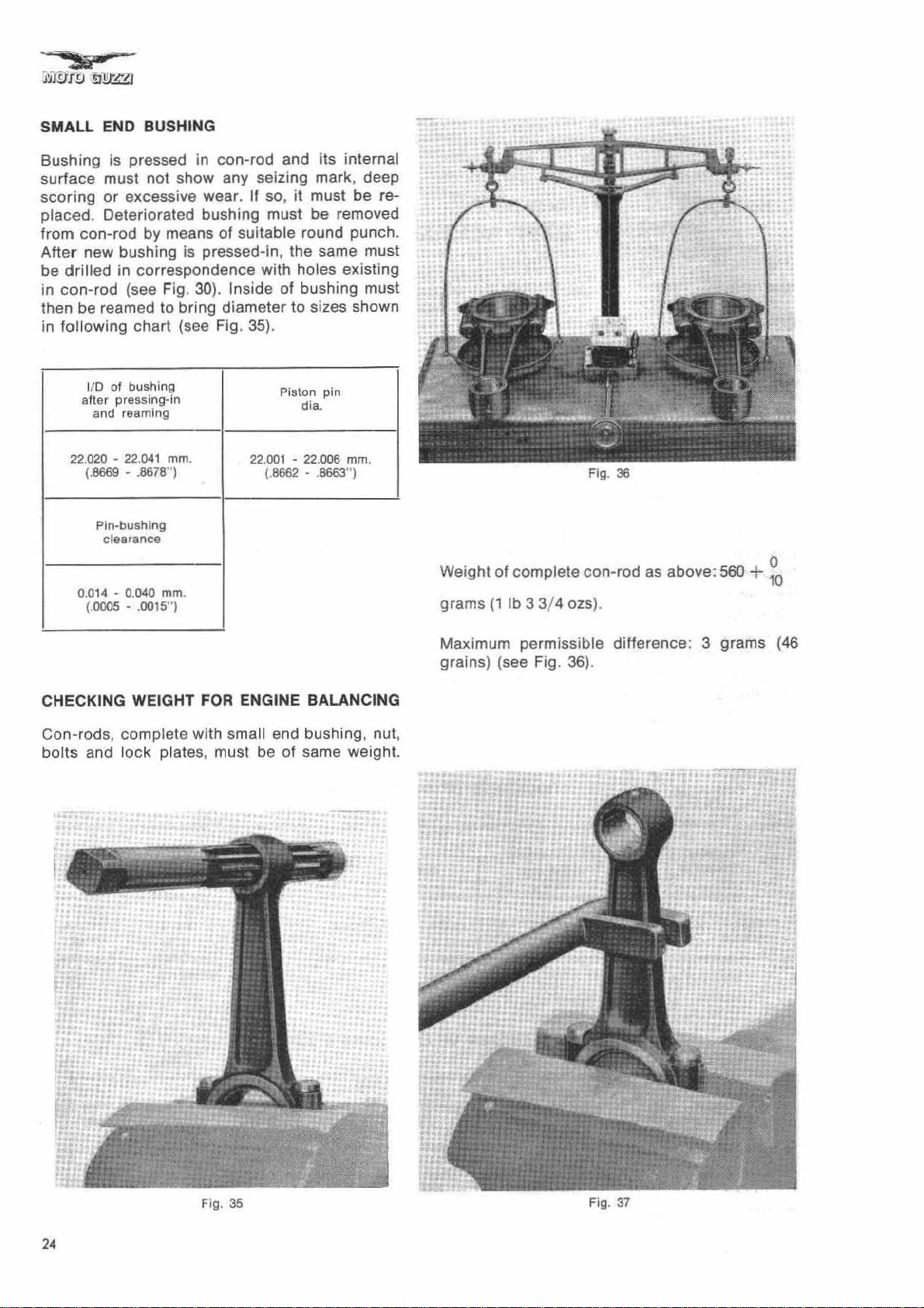

SMALL

END BUSHING

Bushing

surfa

is

pressed in con

ce

must not show any seizing mark,

-fod

and

scoring or excessive wear. II so, it

placed. Deteriorat

from con-rod

After

new

bushing

be

drilled

in

in con-rod (see

then be reamed

in

following

I/O

01

after pressing-In

22.020 -22.041

0.014 - 0.040

bushing

and reaming

(.8669 - .8678 ") (.8662 - .8663" )

Pin-bushing

clearance

(.0005 - .0015")

ed

bushing must be removed

by

means of suitable round punch.

Is pressed-In, the

correspondence

Fig. 30).

to

bring

chart

(see Fig. 35).

mm

.

mrn

.

with

Inside of bushing must

dia

meter to sizes shown

Piston pin

22.001 - 22.006

its internal

must

same

holes

existing

dis.

mm

deep

be

must

.

re-

Weigh t

grams

of

complete

(1

Ib 33/ 4 ozs).

Fig. 36

con-rod

as

above:

560 +

~O

CHECKING WEIGHT FOR ENGINE BALANCING

Con-rods,

bolts

and

complete

lock

plate

with

sma ll end bushing, nut,

s,

must be

of

same weight.

Maximum

perm

issible

grains) (see Fig. 36) .

difference

: 3

grams

(46

Fig. 35

Fig. 37

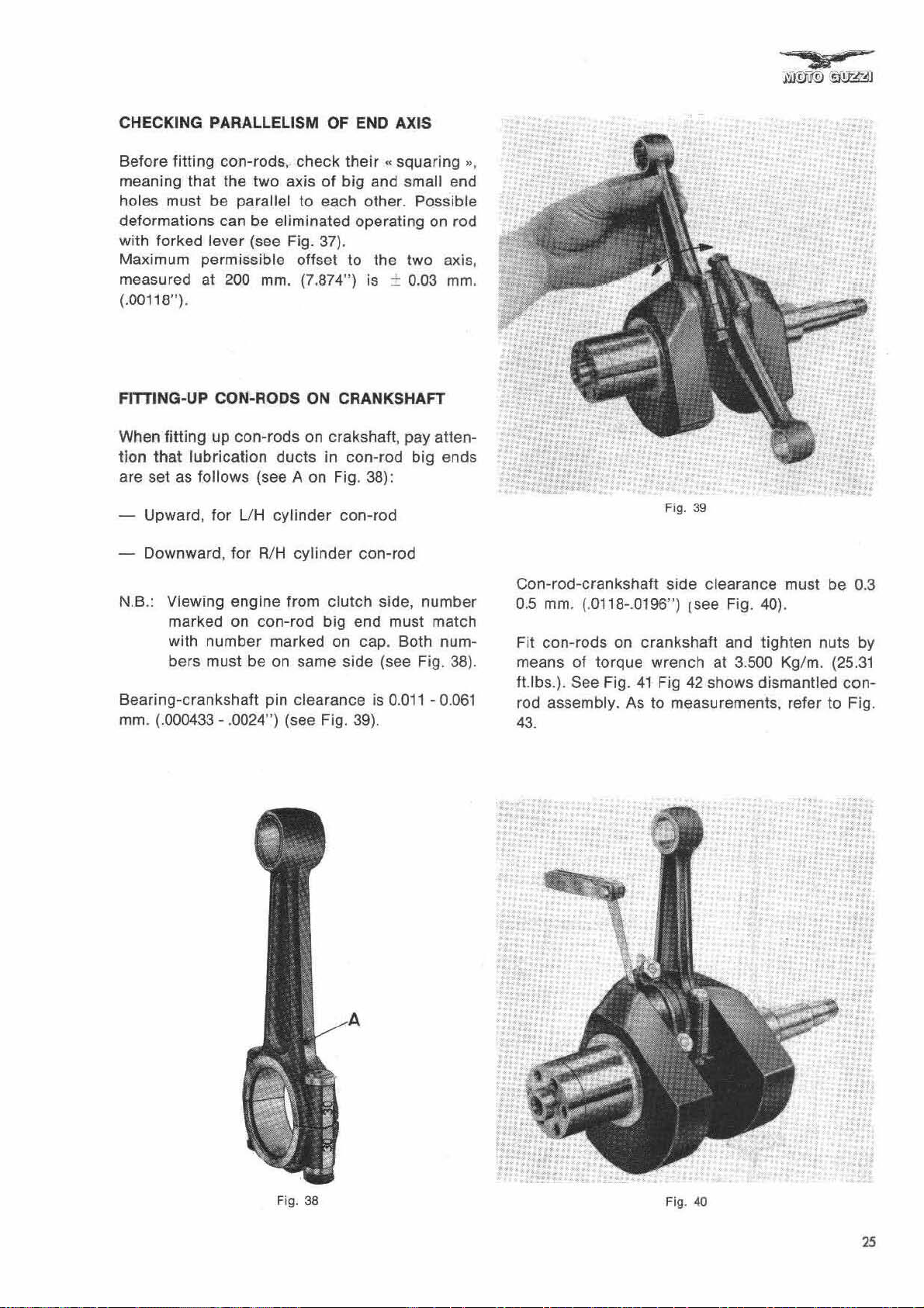

CHECKING PARALLELISM OF END AXIS

Before fitting

meaning

holes

deformations

wit

Maximum

measured

(.00118").

FITTING-UP CON-RODS ON CRANKSHAFT

When

tion

are set as

N.B.: Viewing

Bearingmm . (.000433 - .0024

must

h forked lever (see Fig. 37).

fitting

that

Upward, for

Downwa

marked on

with

bers must be on same side (see Fig. 38).

con-rods, check

that

the

two

be

parallel to

can be eliminated

permissible

at

200

mm.

up

con-rods

lubrication

follows

rd,

number

crankshaft

(see A

UH

for

RiH

engine

con-rod

pin

")

axis

of

big

each

offset

(7.874

on

crakshaft

ducts

cylinder

marked

in

on

Fig . 38) :

con-rod

cylinder

from c

(see Fig. 39).

lutch

big

on cap. Both

clearance

their",

to

") is ±

con-rod

squaring

and small end

other. Possible

operating

the

two

0.03

, pay atten-

big

con-rod

side,

number

end

must

is

0.011 -0.061

on rod

match

",

axis ,

mm

ends

num-

.

Con-rod-c

0.5

mm. (.0118-.0196") [see Fig.

Fit

con

means

fUbs.). See Fig.

rod assembly . As

43.

rankshaft side

-rods

on

crankshaft

of

torque

41

Fig. 39

clea

rance must be 0.3

40)

and

tighten

wrench at 3.500

Fig

42

shows

to

measurements. refer

dismantled

.

nuts by

Kg

/m. (25.31

to

con-

Fig.

Fig.

3B

.-

•

•

. ,

•

.

"

,to

,

•

.

,

•

.

: 1,

•

..

, ,

Fi

g. 40

25

--.~

....

....

-, . '

.

••

.

..

..

.....

....

..

,

.. , •••••

..

.

..

..

!:

..

-.

.

.

.

":::1

..

'.

~

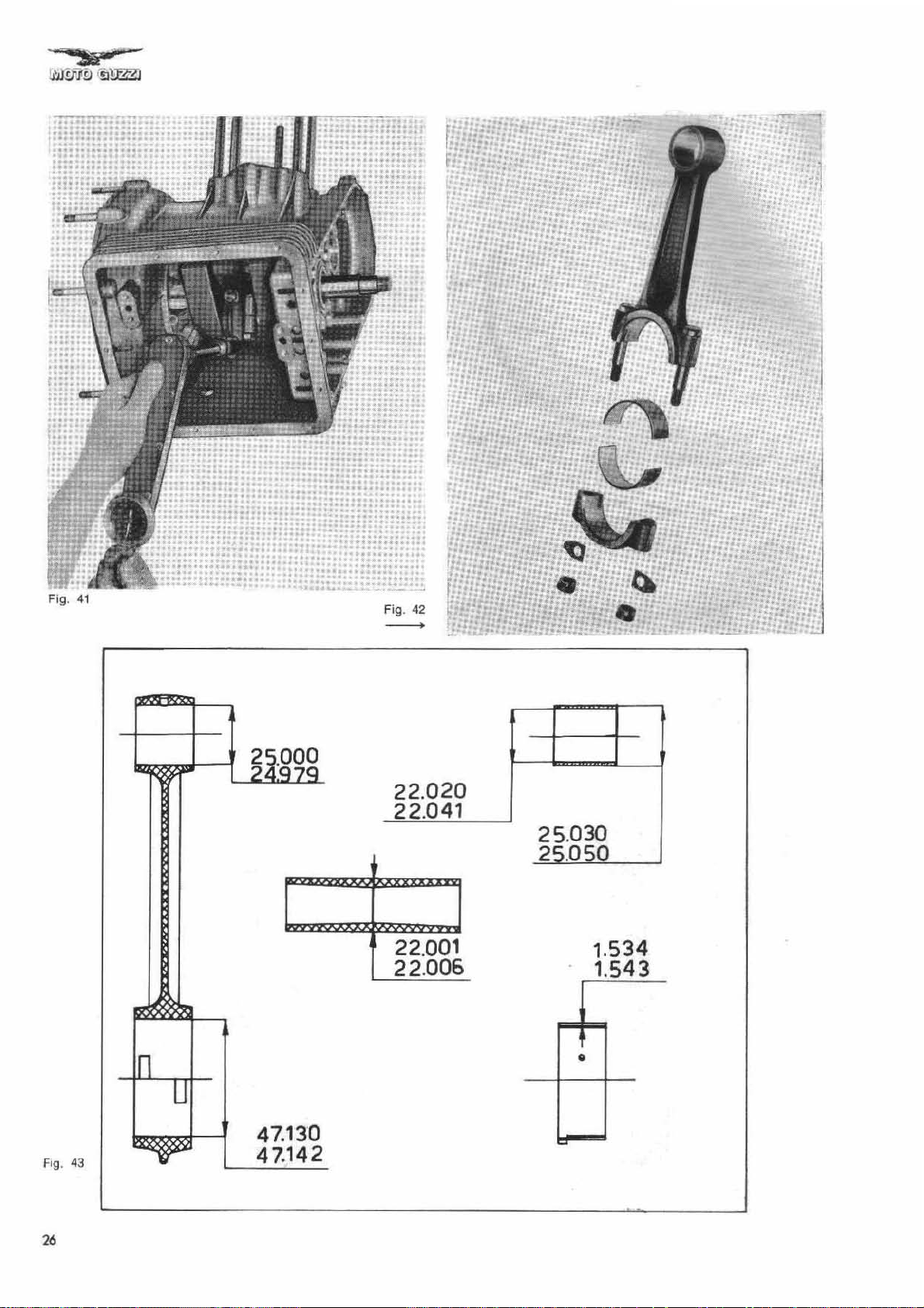

Fig. 41

22.020

22.041

22.001

22.006

25

.030

2~050

1.534

1543

26

47

47

•

.130

.142

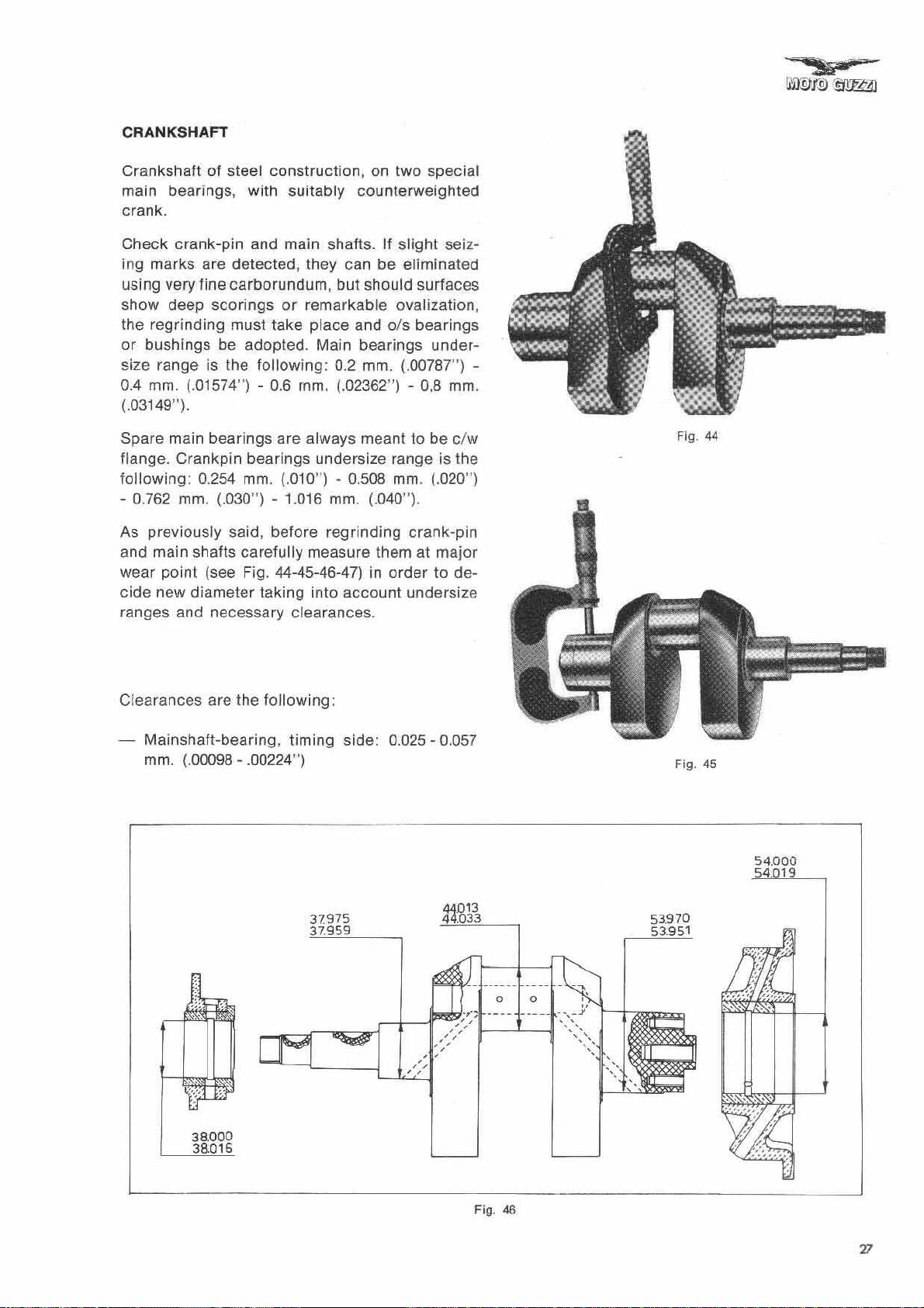

CRANKSHAFT

Crankshaft

main bearings, with

of steel

construction,

suitably

on

two

special

counterweighted

crank.

Check

ing marks are

crank-pin

detected,

and main shafts. If

they can

be

slight

seiz-

eliminated

using very fine carborundum, but should surfaces

show

the

or

size range is the

0.4

deep sea

regrinding

bushings

mm.

(.01574") - 0.6

rings

must take

be

adopted.

following:

or

remarkable

place

Main

mm.

ovalization,

and

ols

bearings

bearings

0.2 mm. (.00787") (.02362") - 0,8

under-

mm.

(.03149").

Spare

flange.

following:

- 0.762 mm. (.030") - 1.016 mm. (.040"),

As previously said, before

and main shafts

wear

cide

main bearings are always meant to

Crankpin

0.254 mm. (.010") - 0.508 mm. (.020")

bearings undersize range is the

regrinding

point

new

carefully

(see Fig. 44-45-46-47) in

diameter

taking

measure them at

order

into

account

be

c/w

crank-pin

major

to

de-

undersize

ranges and necessary clearances.

Fig. 44

Ciearances are the

Mainshaft-bearing,

mm. (.00098 - .00224")

following:

timing

side:

0.025 - 0.057

Fig.

45

Fig. 4S

17

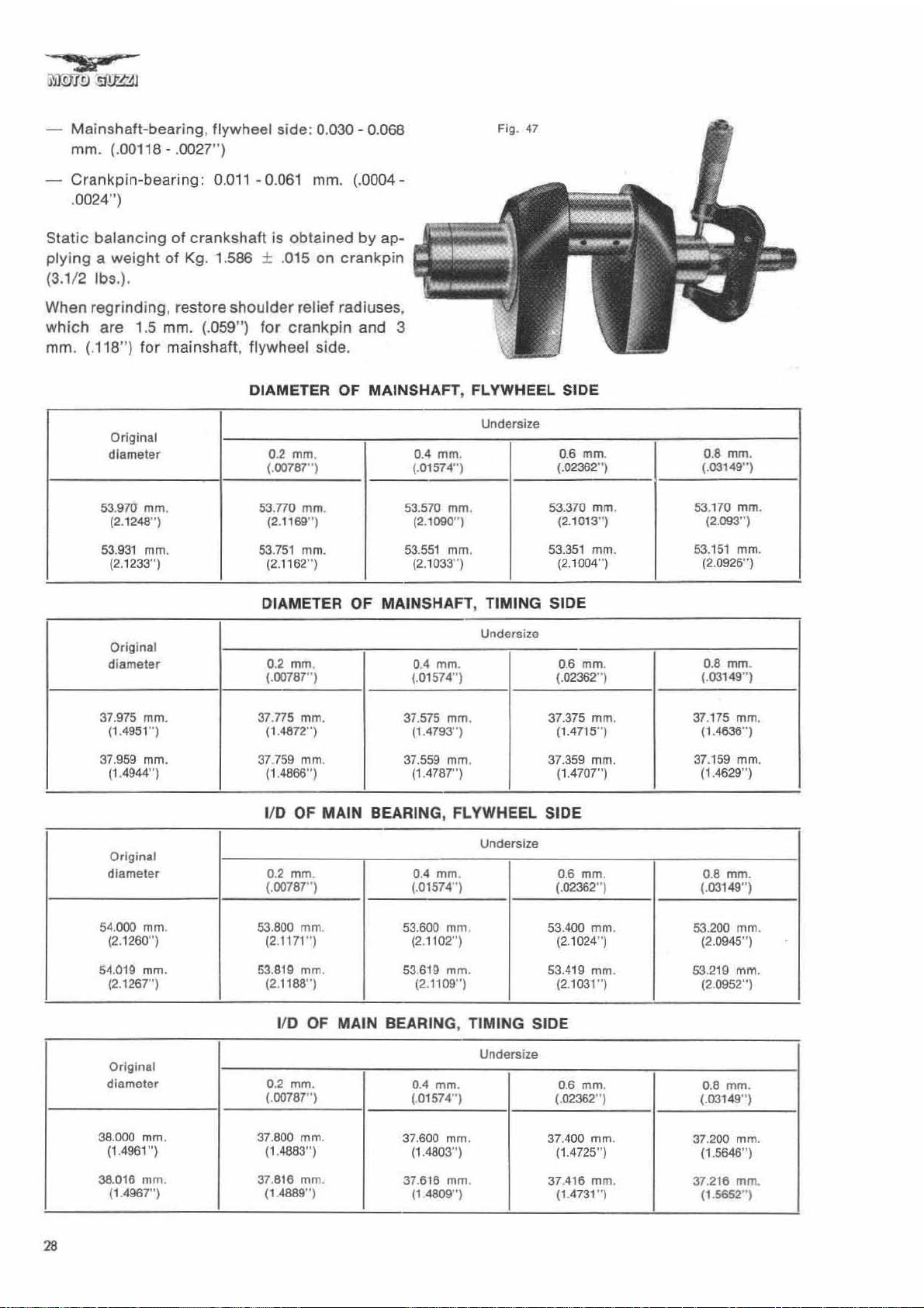

Mainshaft-bearing, flywheel side: 0.030 - 0.068

mm. (.00118 - .0027")

Crankpin-bearing:

.0024")

Static

balancing

plying a weight

(3.112

When

which

mm. (.118")

lb •.

).

regrinding

are

1.5 mm. (.059") for

for

Original

diameter

53.97a mm. 53.770 mm. 53.570 mm . 53.370 rnm.

(2

.1248") (2.1169

53.931

mm.

(2.1233") (2.1162")

0.011

- 0.061 mm. (.0004-

of

crankshaft

of Kg. 1.586 ±

, restore

is obtained by ap-

.0

15 on crankpin

shoulder

relief radiuses,

crankpin

mains haft, flywheel side.

DIAMETER OF MAINSHAFT, FLYWHEEL SIDE

0.2 mm.

(.00787

")

")

53.751

mm.

DIAMETER OF MAINS HAFT, TIMING SIDE

and 3

Undersize

0.4 mm . 0.6 mm.

(.

01574

")

(2.1090")

53.551

mm

(2.1033") (2.1004")

.

(.02362")

(2.1013")

53.351

mm

0.8 mm.

(.03149")

53.170 mm.

(2.093")

mm

.

53.151

(2

.0926")

.

Original

illmeter

d

37.975 Mm.

(1.4951··) (1.4872") (1.4793·

37.959 mm.

(1.4944") (1.4866

0.2 mm. 0.4 mm. 0.6 mm.

")

(.00787

37.775

mm.

37

.759 mm . 37.559 mm . 37.359 mm.

")

(.01574

37.575 mm. 37.375 mm.

(1.4787") (1.4707")

110 OF MAIN BEARING, FLYWHEEL SIDE

Or

igin

al

diameter

54.000 mm .

(2.1260")

54.019

mm.

(2.1267")

0.2 Mm. 0.4 Mm . 0.6 mm.

(.00787")

53

.800 mm 53.600 mm

(2.11 71")

53.819

mm.

(2.1188'

·)

(.01574")

(2.11

53

.619 mm .

(2.1109")

110 OF MAIN BEARING, TIMING SIDE

Original

diameter

0.2 mm.

(.

00787

")

0.4 mm .

(.01574

")

02")

")

Undersize

·)

Undersize

Undersi

(.02362")

(1.4715" )

(.02362

53.400

(2

53.419 mm.

(2.1031

ze

0.6 mm.

(.02362")

")

mm.

.1024")

")

mm.

0.8

(.03149" )

37.175 mm.

(1.4636")

37.159 mm.

(1.4629")

0.8 mm.

(.03149

")

53.200 mm.

(2.0945")

53.219 Mm.

(2

.0952")

0.8

mm.

(.03149")

28

mm. 37.800 mm.

38.000

(1.496''')

38.016 mm . 37.816

(1.4967

")

(1.4883")

(1.4889" )

mm.

37.600 mm.

(1

.4803") (1.4725")

37

.616 mm . 37.4

(1.4809") (1.4731")

37.400 mm .

16

mm.

37

.200 mm.

(1.5646

37

.216 mm.

(1

.5652

")

")

Loading...

Loading...