MOTO GUZZI Stornello sportcc, Stornello sport 125 cc Owner's Manual

STORNEllO

SPORI

125

cc

RIDER'S

HANDBOOK

s " ( l

lllil

110111.

OIL

MOTO

GUZZI

SOCIETA

PER

AZIONI

STAB

ILlMENt O E AMMINISTRAZIONE :

Mandello

del Lario (Co

mo)

Via Emanuele V. Parodi,

57

Telefoni:

Mandello Lar

io

71

.112

(4

linee

con ricerca

autom at!ca

)

Le

eco

22.691

Collegamento

ponte-radio con Milano e Genova

Tel

egrammi:

Motoguzzi -

Mande

llo Lario

SEDE

LE

GA

LE :

Milan

o

Vi

a D

urini

N.

28

Telefoni :

705.784 -705.785

- Tele

grammi:

Motoguzzi

Milano

FILIALE

-

CENTRO

R I

CAMBI

Mi

lano

(640)

- Via

Giovanni

da '

p,r-C;it

ida, 14

Tel

efoni:

.<841.42 1

/341.296/381.997/384.033

Telegr

.:

Filialmotoguzzi - Milano

UFFICI :

Genova

- C.so

Aurelio

Saffi,

29

Telefoni :

55.242/55.243/55.244/55.245

T

elegrammi:

Peromer

• G

nova

Ro

ma

• Via

Barberlnl,

S6

. Telefono

484.758

T

elegremml:

Motoguzzi - Roma

Napoli - Piazza

Municipio,

84

- Telefono

310

.581

Tel

egrammi:

Motoguzzi - Napo li

Torino - Corso Unione Sovietica,

70

- T

elefono

500.

173

Tel

egrammi:

Motoguzzi - Torino

STORNEllO

SPORT

125

cc

TOOL

KIT

Allen

wr

ench

, oil

drain

cap:

Screwdriver

.

Spanner,

tapp

et

adjustmen

t

Double

ended

spanner

8-10

mm

.

Double

ended

box

spanner

14

-17

mm.

Spanner

, h

exagonal grooved

cylindriCal

head

icrews.

Plug spann

er,

19

-21-22

mm.,

box.

Tyre levers,

2.

Tyre

inflator

.

Instru

ction

booklet.

ENGINE

AND

FRAME

NUMBERS

E

c:h

machine

has

a sing le

seri

al

number

for

both

frame

and

engine

. This

number

is

stamped

on

the

right

down

tube

of

the

frame

and

on

the

front

crankcase

cove r. It is

the

onl y

numb

er

valid

for ell

$elling

end

legal

purposes

and

it

app

ears

also

in

the certlfleete

of. origin

and

the

circu

lation

boo

k.

This

number

should

always

be

referred

to

when

orde

ring

spa

re

parts

.

INDEX

Control

s

and

accessories

Page

9

General

characteristics

»

10

Maintenance

instructions

»

14

f=uel

taps

»

14

Ignition

key

» 14

Starting

the

engine

15

Racing the e

ngin

e

16

Starting

the

motor

cycle

16

Use

of

gear

box

»

16

Stopping

the

machine

»

17

Stopping

the

engin

e

17

Inspection

»

18

Storing

th

e

m

achIne

»

18

Carburat

ion

faults

end

cures

»

18

Ignition

fault

s

and cur

es

18

Loss

of

compressi

on

19

Overheating

19

III use

of

machine

»

20

Running

in

20

Important

notice

»

20

Table

for

periodical

maintenance

21

Lubrication

of

engin

e

gear-box

unit

23

Centrifugal

filter

»

26

Chain

lubrication

»

27

Telescopic

fr'ont

fork

»

28

Carburettor

»

31

Cleaning

of

silencer

Page

35

Valve

timing

»

35

Ignitio n

timing

»

38

Igniti

on

»

38

Spark

plug

»

40

Cylinder head

and

val

ves

»

40

Ta

ppet

adjustm

en

t

»

41

Clutch

adjus

tme

nt

»

41

Steering head

adjustment

»

41

Chain

adjustment

»

43

Adju

stment

of h

andl bar

contro

ls

»

44

Fr

ont

brllke

ad

j u

stment

"

44

Adju

stment

of

rear

brak

e

»

44

Removel

of

fron

t wheel

44

R

emove

l

of

rear

whee

l

»

46

Electrical equi

pmen

t »

47

Wiring

diagram

»

47

Headlalllp

»

47

Changing

bulbs

end

fuses

»

47

Battery

»

47

Horn

and

dipper

switch

»

52

Elec

tric

horn

"

52

Cables

»

52

Genera

l

maintenance

»

52

Re-to

uch

i ng

paint

work

»

53

Tran

sfe

rs

»

53

H

ome

co

ncessiona

ires

»

54

C

oncess

ionai res

abro

ad

»

61

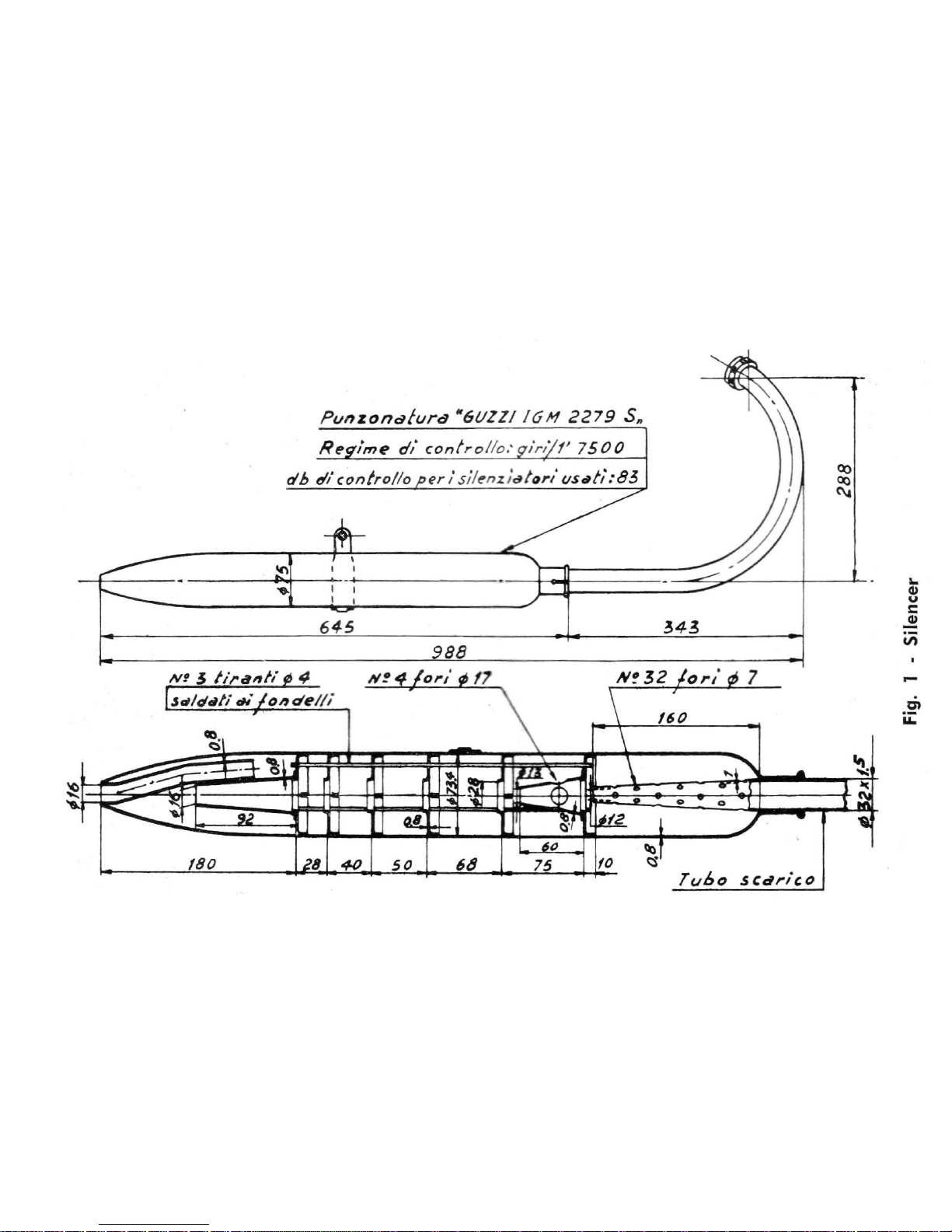

Punzonafura

"6l1ZZIIGM

2279

Sn

645

~

180

50

68

75

10

34~

TUbO

sCd,.i,()

~

CO

C\a

...

QI

u

C

~

iii

til

u:::

.

~

u..

-

..t:

tn

"

;:

01

u

>-

u

...

o

o

:E

M

tn

i.L

9

1 -

----

-JC-_

2-

----t----<

r-

""-'"

_______

'"

10

3

--~~1m

~~~

~~

4

5

---

--I--+

~

12

7---

--==~

Fig

. 4 . Controls and accessories

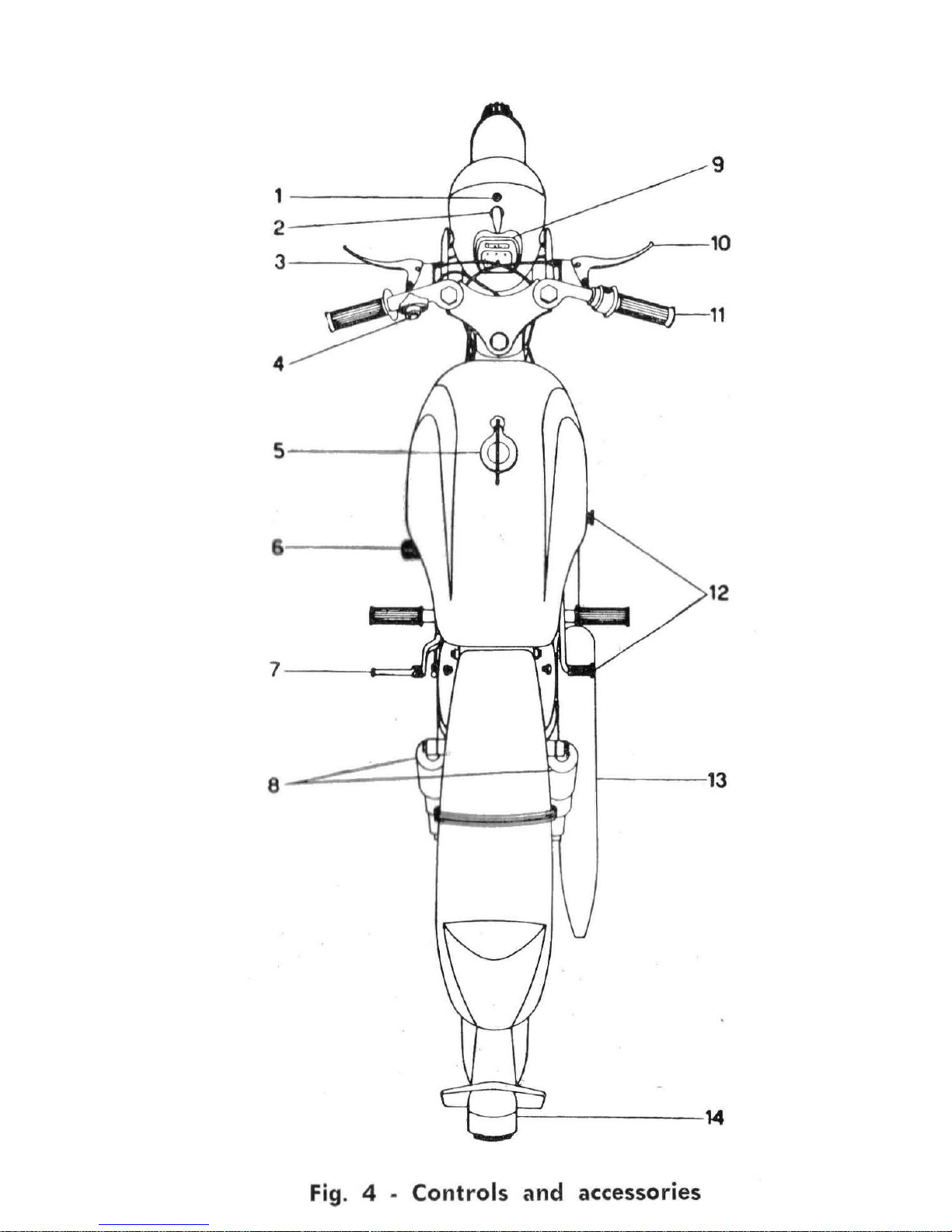

CONTROLS and ACCESSORIES

(see

fig.

4)

Green

lamp

for

city

light

s.

2

Ignition

key,

engine

starting, electrical

equipment,

and

lighting

system

.

3

Clutch

control lever

4 Dip

switch

and

electric

horn button

5 P

etrol

fi Iler

cap

6

Rear

brake peda

l

7

Ki

cks

tarter

8 R

ear

su

spe

nsion

and

hydrau

lic shock

absorbe

rs

9

Speedometer

10 - Fron·t

brake lev

er

11

Twist grip

throttle

control

12

Gear

lev

er

13

Silencer

14 -Rear

lamp for

plate

illuminati

on

an

d st

op

light

N.B. - I n

the

te xt

the

ter

ms

right

and

left are

used

in

the

sen

se

they

wo

uld

appear

to

one s

itting

in

the

saddle

.

9

Engine

GENERAL CHARACTERISTICS

ENGINE

Single cyl

inder four

stroke,

O.H.V.

Cylinder

In

lig

ht

alloy

with

special

cast

iron

inserted liner,

25" incli-

n

ation

.

Cylinder he d

In light

alloy

with

valve

gear

runn

ing in

Valve r

operation

Pu

sh

rod

and

rockers.

Stroke

Bore

Swept

vol

ume

R

tlng

Output

Compress

ion ratio

Ignition

o

il

bath

.

6

V -

:28

W

~

ywh

I alternator

with

remote

H.T. coil.

58

mm.

52 mm.

125

cc.

2 HP

8.5 HP

9.8

to 1

N.B. - Make sure the ba

ttery I. alway. on whilst

ri

ding Or the rectifier

might soon get damaged.

Plug

Marelli

CW260L

Fuel

High

octa

ne

petrol.

Petrol

tank

capacity

about

14

.5

liters

(3

and 1/4 gls. ). Tw

ist

grip

contr

olled

carburettor,

Dell'Orto

make

type

ME

18

BS with

air

filter a

nd

inlet silencer

type

B 20

B.

10

Lubrication

By

pressure

through

a

delivery

and

retu rn

gear

pump.

The

oil is

contained

in

a

crankcase

well

of

about

1.9

liter

s

(7/16th

gls.)

capacity. Screen

pa

ttern

oi l

filter

in

the

crankcase,

centrifugal

filter

on

the

crankshaft.

Cooling

By

air. Cylinder

and

cyl

inder

head

extens

ively

finned

.

Clutch

Multipl

ate

clut

ch

in

oil

bath,

controlled by

handlebar

le

ver

.

Gear

box

Constant

me

sh

gears. Four

speeds

foot

operated.

Bott

om

gear

Second

gear

Thi

rd

gear

T

op

gear

Transmission

3.04

1.81

1.29

Primary drive

by helical

gears.

Seco

ndary

drive

by

roller

chain.

Gear

ratios:

from

engine

to

gear

box

from

gear

box

to

chain

wheel

Overall

gear

rati

os (engine·rear

wheel)

:

Bottom

gear

Second

gear

Top

gear

Third

gear

2.8

2.94

(25·70)

( 16·

47)

25

14,9

10,6

8,2

11

Overa

ll

dimensions:

Wheelbase

Length

Width

Height

(dr

y ) .

F

RAM

E

Minimum

gro u

nd

clearance

(light

fr

om l

owe

st pa

rt

of

fra

me

)

Dry

we

igh

t

Susp

e

Ion

1.2

S0

1.9

00

O.SSO

0.900

0.160

about

m.

(SO

" )

m.

(76

" )

m.

(22')

m.

(36

" )

m.

(6

%

")

92 kgs

(202

Pr

on : , I s

copic fork

with hy d raulic

dam

pers

.

Ibs. )

Rear:

swin

ging

fork

with

coil

springs

in hy

draulic

shock

absorbe

rs.

Wheels

Spoked

wheel rims 17 x 2 'I • .

Ty"

Fro

nt

2 '/2 x 17 rlbbe

d, rea

r

2.75

x 17 R stu dded.

Brakes

E

xpand

ing t

ype. Two

brakes:

one

on

the

front

wheel operated

by

lever

on

the

right

handlebar,

the

other

on

the

rear

wheel

operated

by a pedal

on

the left

hand

side

of

the

machine

.

Electrical equipment

Gene rato r :

flywheel

alternator

.

Rectifier for

battery

charge

in

the

headlam

p.

12

Headlamp

with

key

for

engine

start

ing

and

operation

of

the

lighting

system.

This key is

also

used

as a

switch

for

city

and

country

lights.

5 inch

es

headlamp

. Dipp

er

sw

itch

and

electric

horn

button

on

handlebar

.

Rear

lamp

for

plate illumin

ation,

parking,

and

stop

light.

Electric

horn

.

6 V 7

ampere

battery

.

Speedometer

Inc

orporat

ed in the h

eadlamp.

Performances

Gradients

clim

babl

e:

31 %

so

lo

on

goo

d s

urf

aced

roads.

Fuel

consumpti

on : 2 .7 lit

ers

per 100

km

s. (

abo

ut 104

m.p.g.),

mea s u r

ed

acco

rding

to

CUNA standard

s.

Maximum

speed

s pe

rmissibl

e in t

he

vario

us

gears

:

bott

om

gear

km

s.

33

(20.5

miles)

second

ge

ar

})

55

(34.1

miles )

thire!

gear

})

77

(47

.8

miles)

to p

gear

.

})

110

(about

70

miles)

13

MAINTENANCE

INSTRUCTIONS

Before st

arting

make

su

re th

ere

is

sufficie

nt

petrol in

tbe

crankcase

well. Oi l level

is

checked

by

means

of

the dipstick

welded

on

to

the fill

er

cap.

Correct oil

level is in

between

the

minimum

and

maximum

marks

(fig. 5 ). Thi s c

heck

shou

ld

be

made

with

the

filler

cap

unsc r

ewed.

Under

no

circumstances

should

hills

be

descended

with

the

g

ear

in

neutral

or

the clutch

disengaged.

It

is

far

better

to

ut

ilize the

braking

effect of

the

engine with

the

throt

tle

control

at

min

imum

open.in

g.

Steep

hills s

hould

be

descended

in

th

e

l

ower gears,

as this will

save

ove

rheating

of

the

drum

s

and

wear

of

th linings.

On

w t

or

slippery

roads

proceed

with

the

ut

most

cere,

avoidin

9 viole

nt

ac

cele

ration

and/or

fierce

braklngs. In

such co

nditi

ons, it

Is

well to

consider decreasing

slightly

the

tyre

pressure.

Hills s

hould

be climbed

in

the

gear

which

allows

the

eng

ine

to

run

at

no

rmal

revolutions. Under

no

circumstances

whatever

sho

uld

hills

be

climbed

by

slipping

the

clutch. This

wo

uld

repidly

wear

the

plates

out.

Particular

care

shou

ld be

taken

not

to

exceed the

maximum

speeds

in

the

diff r

nt

gears

specified

in

« Pe

rform

ances:>.

Fuel taps

The left

tap

is

th e

reserve

tap

and should

be

kept

closed

for

use

in

an

emergency

only

: H

owever,

it is

1)

goed rule

to

oc

casionally check

its efficiency

and

to clec:n

it

out

if

obstructed

by

grit

or

other

foreign

matter

.

Ignition key

Before

the

eng

ine can

be started

or

the electrical equipment

used,

it is

necessa

ry

for

the

ignition

key to

be

pushed

right

14

down

in its «

contact»

position.

To

stop

the

engine,

the

key

should

always

be

withdrawn

from

contact.

Starting the engine

To

start

the

eng

ine

from

cold:

open

right

hand

fuel

tap,

check

if

gear lever

is in

neutra

l,

push

ignition

key

down

in

its

Fig.

5

15

co

ntact

positi

on,

turn

twist

gr

ip light

ly,

push

down

ca

rburettor

a

ir

slide

(Fig. 11

A), and

depress

the kickstarter sha

rply.

One

or

two

kick

are

genera

lly s

ufficient

to

start

the

eng

ine.

When starti

ng

fr

om

co

ld,

and

especially in w

int

er

tim

e,

it is

convenient

to

sl i

ghtly flood the

carburettor,

taking

care

not

to

overdo this

as

it

may

th

en

make

star

ting

rather

dif-

ficult.

This is

unnecessary

to

start

a

hot -eng

ine.

In

the

cold season,

it is well

to let

the

engine

idle a

shor

t

while

to

allow

the o il to

war

m

up

befo re

taking

off.

Be sure

to

res

tore

the

air sli

de to its o

rigin

al r

iding position

.

N.B. - This engin e can also

be

star

ted with

an

engaged

gear

by

depressing

the

kickst

arter

with

the

clutch

withdrawn

.

Racing the engine

Under

no circumste

nc s wh

ateve

r s hou ld

th

e

engine

be

al l

ow

d

to

run

at

high

revo

lutions b

efo

re ta

king

off.

Starting

the

motor

cycle

After the

eng ine is started , w

ithdraw

fully

the

clutch lever,

engage

bottom

gea

r,

and slow

ly re lease the c

lutch

accelerating

the

engine at

th

sam

ti

me

as the c

lut

ch s

tarts

to

« b ite ».

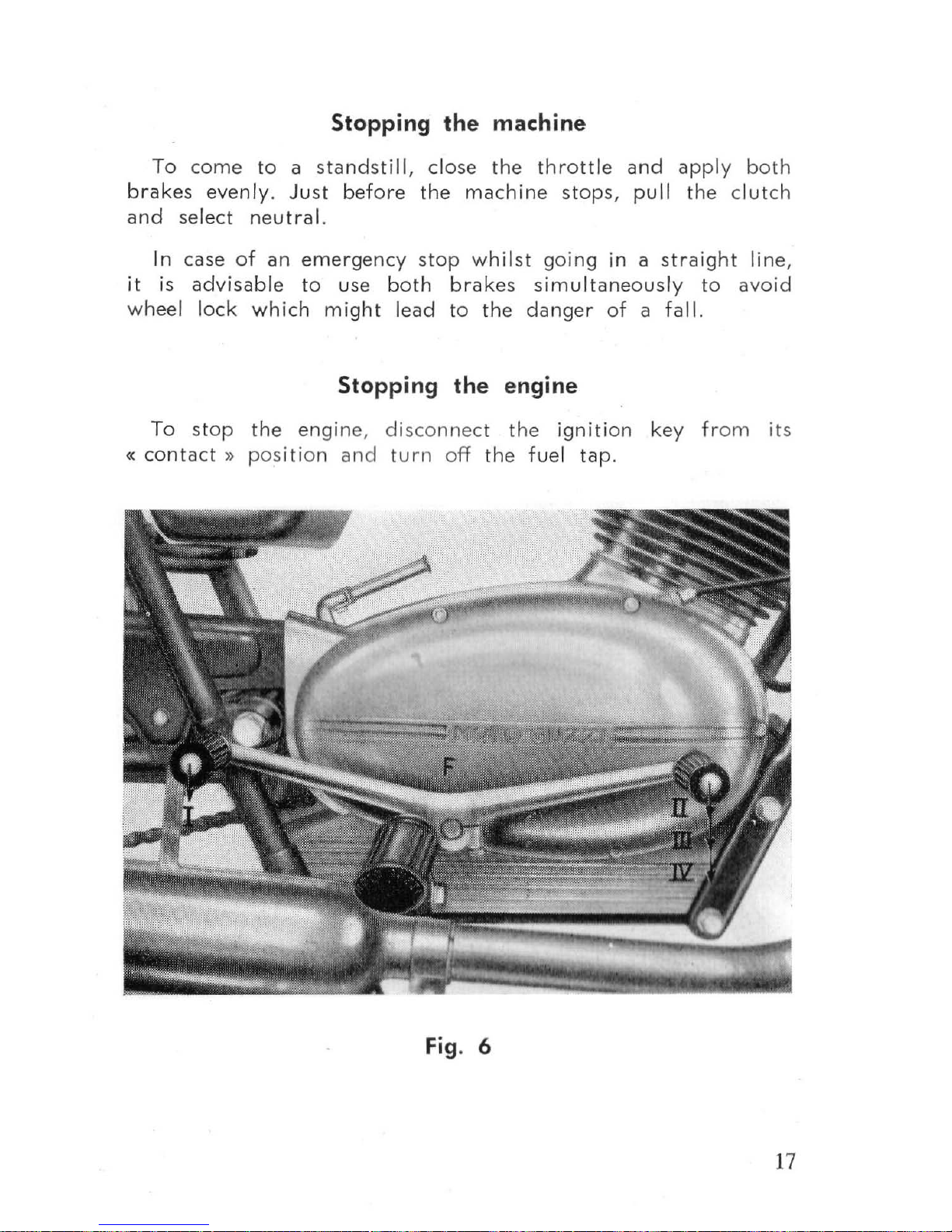

U

se

of

gear- box

(s fig.

6)

To

change

to a

high

er

gear,

the

thrott

le sho

uld

be shut

a

nd

th

e cl

utch simultane

ously w

ith

drawn,

moving

the

gear

leve r in

the

ne

xt p

osition.

The

clut

ch

shou

ld then

be

rele

ased

slow ly

and

the

throttle gradually

re-op

ened.

To

change

down,

the

pr

ocedure

is reve r

sed,

exce

pt that

the

throttle

sho

uld

not

be

co

mpl

etel y cl

ose

d.

Change

up

rather

than let

the

engine

race.

Change dow

n

rather

than

let is s log.

16

Stopping the machine

To

come

to

a

standsti

II,

close

the

throttle

and

apply

bo

th

brakes

evenly.

Just

before

the

machine

stops,

pull

the clutch

and

select

neutral.

In

case

of

an

emergency

stop

whilst

go

ing in a

straight

line,

it is

advisable

to

use

both

brakes

sim

ult

aneously

to

avoid

wheel

lock

which

might

lead

to

the

danger

of

a fall.

Stopping the engine

To

stop

the

en

gin

e, disconnect the

ignition

key

from

its

«

contact

})

pos

iti

on

and

turn

off

the

fuel

tap.

Fig.

6

17

Inspection

After

a

wet

ride or

one

over

particularly

bad

roads,

the

machine

should

always

be

checked

over

externally

and

dried.

Storing the machine

If

the

machine

is

being

put away

for

a fairly

long

period

:

-

Thoroughl

y

clean

the

mach

ine

«see

Periodical

Main-

tenance

».

-

Intr

oduce

a little o

il

into

the

cylind

er

through

the

plug

hole

and revo

lve the

eng

ine a

few

times

to

even

ly

distribute

the

oil

over

th e cylinder

wa

lls.

- Raise

the

machine

so

that

the

tyres

are

out

of

contact

with

th e

grou

nd,

especiall

y if

the floo

r is

slippery

or

greasy.

~

Cover

with V s lin

or

antirust

co

mpound

all

metal

parts

not

namelled.

Carburation faults and cures

If

the

engine will not

sta

rt

or stops

suddenly,

the

cause

may

be

one of the

following

:

-

Lack

of

fu

I.

Ch

ck

if

there

is fuel in

the

tank,

also

if

the

tap

is

open.

--

Ob$truc-tlon 0

blow

throu

gh 0 r

fu I

pipes

and/o

r

filters.

Clean

and

th

ob

true

Ion .

-

Carbu

rettor

I ts

obstruet

d. CI

an

with air

jet.

Ignition faults and cures

If

the

engine

will

not

start

and

the

carburation

is in

order,

s

uspect

the

fault

in

the

ignition.

Check

if

there

is

a

spark

at

the

plug

by

holding

its

body

against

the

cylinder

and

revolving th e

eng

ine

with

the

kicks

tarter

.

18

Loading...

Loading...