SERVICE STATION MANUAL

B043090

Stelvio 1200 NTX MY11

SERVICE STATION

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

MANUAL

Stelvio 1200 NTX MY11

THE VALUE OF SERVICE

Only the mechanics of the Official Moto Guzzi Service Network know this vehicle well, thanks to constant

technical professional development and Moto Guzzi specific training programmes, and have the tools

needed to carry out maintenance and repair operations correctly.

The reliability of the vehicle also depends on its mechanical conditions. Checking the vehicle before riding

it, carrying out routine maintenance and using only Moto Guzzi Original Spare parts is fundamental!

For information about the nearest Official Dealer and/or Service Centre, consult the Yellow Pages or

search directly on the inset map in our Official Website:

www.motoguzzi.it

Only by purchasing Moto Guzzi Original Spare Parts will you get a product designed and tested during

the bike designing phase. Moto Guzzi Original Spare Parts are subject to systematic quality control

procedures so that their reliability and performance over time is guaranteed.

The descriptions and illustrations given in this publication are not binding; While the basic features as

described and illustrated in this booklet remain unchanged, Moto Guzzi reserves the right, at any time

and without being required to update this publication beforehand, to make any changes to components,

parts or accessory supplies, which it deems necessary to improve the product or which are required for

manufacturing or commercial reasons.

Not all versions/models shown in this publication are available in all countries. The availability of individual

versions should be checked with the Official Moto Guzzi sales network.

© Copyright 2011- Moto Guzzi. All rights reserved. Reproduction of this publication in whole or in part is

prohibited. Moto Guzzi - After sales service.

The Moto Guzzi brand is owned by Piaggio & C. S.p.A.

SERVICE STATION MANUAL

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Stelvio 1200 NTX MY11

This manual provides the main information to carry out regular maintenance operations on your scooter.

This manual is intended to Moto Guzzi Dealers and their qualified mechanics; several concepts have

been deliberately omitted as they are considered unnecessary. As it is not possible to include complete

mechanical notions in this manual, users should have basic mechanical knowledge or minimum

knowledge about the procedures involved when repairing scooters. Without this knowledge, repairing or

checking the vehicle may be inefficient or even dangerous. As the vehicle repair and check procedures

are not described in detail, be extremely cautious so as not to damage components or injure individuals.

In order to optimise customer satisfaction when using our vehicles, Moto Guzzi s.p.a. commits itself to

continually improve its products and the relative documentation. The main technical modifications and

changes in repair procedures are communicated to all Moto Guzzi Sales Outlets and its International

Subsidiaries. These changes will be introduced in the subsequent editions of the manual. In case of

need or further queries on repair and check procedures, consult Moto Guzzi CUSTOMER

DEPARTMENT, which will be prepared to provide any information on the subject and any further

communications on updates and technical changes related to the vehicle.

2011

NOTE Provides key information to make the procedure easier to understand and carry out.

CAUTION Refers to specific procedures to carry out for preventing damages to the vehicle.

WARNING Refers to specific procedures to carry out to prevent injuries to the repairer.

Personal safety Failure to completely observe these instructions will result in serious risk of personal

injury.

Safeguarding the environment Sections marked with this symbol indicate the correct use of the vehicle

to prevent damaging the environment.

Vehicle intactness The incomplete or non-observance of these regulations leads to the risk of serious

damage to the vehicle and sometimes even the invalidity of the guarantee.

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

INDEX OF TOPICS

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

CHARACTERISTICS CHAR

SPECIAL TOOLS S-TOOLS

MAINTENANCE MAIN

ELECTRICAL SYSTEM ELE SYS

ENGINE FROM VEHICLE ENG VE

ENGINE ENG

POWER SUPPLY P SUPP

SUSPENSIONS SUSP

CHASSIS CHAS

BRAKING SYSTEM BRAK SYS

BODYWORK BODYW

PRE-DELIVERY PRE DE

INDEX OF TOPICS

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

CHARACTERISTICS CHAR

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Rules

Safety rules

Carbon monoxide

If you need to keep the engine running while working on the vehicle, please ensure that you do so in

an open or very well ventilated area. Never let the engine run in an enclosed area. If you do work in an

enclosed area, make sure to use a fume extraction system.

CAUTION

EXHAUST EMISSIONS CONTAIN CARBON MONOXIDE, A POISONOUS GAS WHICH CAN CAUSE

LOSS OF CONSCIOUSNESS AND EVEN DEATH.

Fuel

CAUTION

THE FUEL USED TO POWER INTERNAL COMBUSTION ENGINES IS HIGHLY FLAMMABLE AND

MAY BE EXPLOSIVE UNDER CERTAIN CONDITIONS. IT IS THEREFORE RECOMMENDED TO

CARRY OUT REFUELLING AND MAINTENANCE PROCEDURES IN A VENTILATED AREA WITH

THE ENGINE SWITCHED OFF. DO NOT SMOKE DURING REFUELLING OR NEAR FUEL VAPOUR.

AVOID ANY CONTACT WITH NAKED FLAME, SPARKS OR OTHER HEAT SOURCES WHICH MAY

CAUSE IGNITION OR EXPLOSION.

DO NOT ALLOW FUEL TO DISPERSE INTO THE ENVIRONMENT.

KEEP OUT OF THE REACH OF CHILDREN.

Hot components

The engine and the exhaust system components become very hot and remain hot for some time after

the engine has been switched off. Before handling these components, make sure that you are wearing

insulating gloves or wait until the engine and the exhaust system have cooled down.

Used engine oil and transmission oil

CAUTION

IT IS ADVISABLE TO WEAR LATEX GLOVES WHEN SERVICING THE VEHICLE.

THE ENGINE OR GEARBOX OIL MAY CAUSE SERIOUS INJURIES TO THE SKIN IF HANDLED

FOR PROLONGED PERIODS OF TIME AND ON A REGULAR BASIS.

WASH YOUR HANDS CAREFULLY AFTER HANDLING OIL.

HAND THE OIL OVER TO OR HAVE IT COLLECTED BY THE NEAREST USED OIL RECYCLING

COMPANY OR THE SUPPLIER.

DO NOT DISPOSE OF OIL IN THE ENVIRONMENT

KEEP OUT OF THE REACH OF CHILDREN.

Brake and clutch fluid

CHAR - 7

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

BRAKE AND CLUTCH FLUIDS CAN DAMAGE THE PLASTIC OR RUBBER PAINTED SURFACES.

WHEN SERVICING THE BRAKING OR THE CLUTCH SYSTEM PROTECT THESE COMPONENTS

WITH A CLEAN CLOTH. ALWAYS WEAR PROTECTIVE GOGGLES WHEN SERVICING THESE

SYSTEMS. BRAKE AND CLUTCH FLUIDS ARE EXTREMELY HARMFUL FOR YOUR EYES. IN

THE EVENT OF ACCIDENTAL CONTACT WITH THE EYES, RINSE THEM IMMEDIATELY WITH

PLENTY OF COLD, CLEAN WATER AND SEEK MEDICAL ADVICE.

KEEP OUT OF THE REACH OF CHILDREN.

Battery electrolyte and hydrogen gas

CAUTION

THE BATTERY ELECTROLYTE IS TOXIC, CORROSIVE AND, AS IT CONTAINS SULPHURIC

ACID, MAY CAUSE BURNING IF IT COMES INTO CONTACT WITH THE SKIN. WHEN HANDLING

BATTERY ELECTROLYTE, WEAR TIGHT-FITTING GLOVES AND PROTECTIVE APPAREL. IN

THE EVENT OF SKIN CONTACT WITH THE ELECTROLYTIC FLUID, RINSE WELL WITH PLENTY

OF CLEAN WATER. IT IS PARTICULARLY IMPORTANT TO PROTECT YOUR EYES BECAUSE

EVEN TINY AMOUNTS OF BATTERY ACID MAY CAUSE BLINDNESS. IN THE EVENT OF CON-

TACT WITH THE EYES, RINSE WITH PLENTY OF WATER FOR FIFTEEN MINUTES AND CON-

SULT AN EYE SPECIALIST IMMEDIATELY. IF THE FLUID IS ACCIDENTALLY SWALLOWED,

DRINK LARGE QUANTITIES OF WATER OR MILK, FOLLOWED BY MILK OF MAGNESIA OR

VEGETABLE OIL AND SEEK MEDICAL ADVICE IMMEDIATELY. THE BATTERY RELEASES EX-

PLOSIVE GASES; KEEP IT AWAY FROM FLAMES, SPARKS, CIGARETTES OR ANY OTHER

HEAT SOURCES. ENSURE ADEQUATE VENTILATION WHEN SERVICING OR RECHARGING

THE BATTERY.

KEEP OUT OF THE REACH OF CHILDREN.

BATTERY LIQUID IS CORROSIVE. DO NOT POUR IT OR SPILL IT, PARTICULARLY ON PLASTIC

COMPONENTS. ENSURE THAT THE ELECTROLYTIC ACID IS COMPATIBLE WITH THE BAT-

TERY BEING ACTIVATED.

Maintenance rules

GENERAL PRECAUTIONS AND INFORMATION

When repairing, dismantling and reassembling the vehicle, follow the recommendations given below

carefully.

BEFORE DISASSEMBLING COMPONENTS

•

Before dismantling components, remove dirt, mud, dust and foreign bodies from the vehicle.

Use the special tools designed for this bike, as required.

COMPONENTS REMOVAL

•

Do not loosen and/or tighten screws and nuts using pliers or any other tools than the specific

wrench.

•

Mark the positions on all connection joints (pipes, cables, etc.) before separating them, and

identify them with different distinctive symbols.

•

Each component needs to be clearly marked to enable identification during reassembly.

•

Clean and wash the dismantled components carefully using a low-flammability detergent.

CHAR - 8

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

•

Keep mated parts together since they have "adjusted" to each other due to normal wear.

•

Some components must be used together or replaced altogether.

•

Keep away from heat sources.

REASSEMBLING COMPONENTS

CAUTION

BEARINGS MUST ROTATE FREELY, WITHOUT JAMMING AND/OR NOISE, OTHERWISE, THEY

NEED TO BE REPLACED.

•

Only use ORIGINAL Moto Guzzi SPARE PARTS.

•

Comply with lubricant and consumables use guidelines.

•

Lubricate parts (whenever possible) before reassembling them.

•

When tightening nuts and screws, start from the ones with the largest section or from the

internal ones, moving diagonally. Tighten nuts and screws in successive steps before applying the tightening torque.

•

Always replace self-locking nuts, washers, sealing rings, circlips, O-rings (OR), split pins

and screws with new ones if their tread is damaged.

•

When assembling the bearings, make sure to lubricate them well.

•

Check that each component is assembled correctly.

•

After a repair or routine maintenance procedure, carry out pre-ride checks and test the vehicle on private grounds or in an area with low traffic density.

•

Clean all coupling surfaces, oil guard rims and gaskets before refitting them. Smear a light

layer of lithium-based grease on the oil guard rims. Reassemble oil guards and bearings

with the brand or lot number facing outward (visible side).

ELECTRIC CONNECTORS

Electric connectors must be disconnected as described below; failure to comply with this procedure

causes irreparable damage to both the connector and the wiring harness:

Press the relative safety clips, if applicable.

•

Grip the two connectors and disconnect them by pulling them in opposite directions.

•

If any signs of dirt, rust, moisture, etc. are noted, clean the inside of the connector carefully

with a jet of compressed air.

•

Ensure that the cables are correctly fastened to the internal connector terminals.

•

Then connect the two connectors, ensuring that they couple correctly (if fitted with clips, you

will hear them "click" into place).

CAUTION

DO NOT DISCONNECT CONNECTORS BY PULLING THE CABLES.

NOTE

THE TWO CONNECTORS CAN ONLY BE CONNECTED IN ONE DIRECTION: CONNECT THEM

THE RIGHT WAY ROUND.

TIGHTENING TORQUES

CAUTION

REMEMBER THAT THE TIGHTENING TORQUES FOR ALL FASTENING ELEMENTS ON WHEELS,

BRAKES, WHEEL AXLES AND ANY OTHER SUSPENSION COMPONENTS PLAY A KEY ROLE

CHAR - 9

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

IN ENSURING VEHICLE SAFETY AND MUST COMPLY WITH SPECIFIED VALUES. CHECK THE

TIGHTENING TORQUES OF FASTENING ELEMENTS ON A REGULAR BASIS AND ALWAYS USE

A TORQUE WRENCH TO REASSEMBLE THESE COMPONENTS. FAILURE TO COMPLY WITH

THESE RECOMMENDATIONS MAY CAUSE ONE OF THESE COMPONENTS TO LOOSEN OR

EVEN DETACH, CAUSING A WHEEL TO LOCK OR COMPROMISING VEHICLE HANDLING. THIS

MAY LEAD TO FALLS, WITH THE RISK OF SERIOUS INJURY OR DEATH.

Running-in

Engine run-in is essential to ensure engine long life and correct operation. Twisty roads and gradients

are ideal to run in engine, brakes and suspensions effectively. Vary your riding speed during the run-

in. This ensures that components operate under both "loaded" and "unloaded" conditions, allowing the

engine components to cool.

CAUTION

THE CLUTCH MAY EMIT A SLIGHT BURNING SMELL WHEN FIRST USED. THIS PHENOMENON

SHOULD BE CONSIDERED NORMAL AND WILL DISAPPEAR AS SOON AS THE CLUTCH DISCS

GET ADAPTED.

IT IS IMPORTANT TO STRAIN ENGINE COMPONENTS DURING RUN-IN, HOWEVER, MAKE SURE

NOT TO OVERDO THIS.

CAUTION

THE FULL PERFORMANCE OF THE VEHICLE IS ONLY AVAILABLE AFTER THE SERVICE AT

THE END OF THE RUNNING IN PERIOD.

Follow the guidelines detailed below:

•

Do not twist the throttle grip abruptly and completely when the engine is working at a low

revs, either during or after run-in.

•

During the first 100 Km (62 miles) use the brakes gently, avoiding sudden or prolonged

braking. That is to permit the adequate adjustment of the pad friction material to the brake

discs.

AFTER THE SPECIFIED MILEAGE, TAKE THE VEHICLE TO AN OFFICIAL Moto Guzzi DEALER

FOR THE CHECKS INDICATED IN THE "AFTER RUN-IN" TABLE IN THE SCHEDULED MAINTE-

NANCE SECTION TO AVOID INJURING YOURSELF, OTHERS AND /OR DAMAGING THE VEHI-

CLE.

Vehicle identification

SERIAL NUMBER LOCATION

These numbers are necessary for vehicle registration.

NOTE

ALTERING IDENTIFICATION NUMBERS MAY BE SERIOUSLY PUNISHABLE BY LAW. IN PAR-

TICULAR, MODIFYING THE CHASSIS NUMBER IMMEDIATELY VOIDS THE WARRANTY.

CHAR - 10

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

This number consists of numbers and letters, as in

the example shown below.

ZGULZG000YMXXXXXX

KEY:

ZGU: WMI (World manufacturer identifier) code;

LZ: model;

001: version variation;

0: free digit

Y year of manufacture

M: production plant (M= Mandello del Lario);

XXXXXX: serial number (6 digits);

CHASSIS NUMBER

The chassis number is stamped on the right hand

side of the headstock.

ENGINE NUMBER

The engine number is stamped on the left side,

close to the engine oil level check cap.

Dimensions and mass

WEIGHT AND DIMENSIONS

Specification

Maximum length (without accessories) 2,305 mm (90.75 in)

Maximum width to handlebar 956 mm (37.64 in)

Maximum width of the vehicle with accessories 1,080 mm (42.52 in)

Minimum / maximum height (adjustable windshield) 1436 / 1492 mm (56.53 / 58.74 in)

Saddle height 800 mm (31.5 in)

Minimum ground clearance 185 mm (7.3 in)

Wheelbase 1,535 mm (60.43 in)

Kerb weight 281 kg (619.50 lb)

Kerb weight of full house vehicle 296 kg (652.57 lb)

Desc./Quantity

Engine

ENGINE

Specification

Type traverse-mounted twin-cylinder four-stroke V 90°

Number of cylinders 2

Cylinder layout 90° V

Desc./Quantity

CHAR - 11

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Specification Desc./Quantity

Bore / stroke 95 x 81.2 mm (3.74 x 3.20 in)

Engine capacity 1151 cm³ (70 cu.in.)

Compression ratio 11 : 1

Ignition starter

Engine idle speed 1100 ± 100 rpm

Clutch hydraulically controlled single-plate dry clutch with incorpora-

Lubrication system Pressurised circuit with regulator valves and trochoidal pump

Air filter cartridge-type dry filter

Cooling air and oil cooled with independent trochoidal pump and oil

pressure control valve

Timing system diagram single overhead camshaft with bucket tappets and rocker-op-

Values valid with control clearance between rocker and valve intake: 0.15 mm (0.0059 in)

ted flexible coupling

erated valves

outlet: 0.20 mm (0.0079 in)

Transmission

TRANSMISSION

Specification Desc./Quantity

Primary drive Helical gears, ratio 26/35 = 1:1.346

Gearbox Mechanical, 6 speeds with foot lever on the left hand side of

Gear ratios, 1st gear 17/38 = 1:2.2353

Gear ratios, 2nd gear 20/34 = 1:1.7

Gear ratios, 3rd gear 23/31 = 1:1.3478

Gear ratios, 4th gear 26/29 = 1:1.1154

Gear ratios, 5th gear 31/30 = 1:0.9677

Gear ratios, 6th gear 29/25 = 1:0.8621

Final drive with U-joint

Ratio 12/44 = 1:3.6667

the engine

Capacities

Specification

Engine oil Oil change and oil filter replacement: 3,500 cm³ (214 cu.in)

Gearbox oil 500 cm³ (30.5 cu in)

Transmission oil 380 cm³ (23.2 cu in)

Fuel (reserve included) 32 l (7.04 UK gal)

Fuel reserve 7 l (1.54 UK gal)

Maximum weight limit 495 kg (1091.29 lb)

Electrical system

Specification

Spark plug NGK CR8EKB (long life)

Electrode gap 0.6 - 0.7 mm (0.024 - 0.028 in)

Alternator (permanent magnet type) 12 V - 550 W

Main fuses 20 (ABS version only) - 30 (2) - 40 A

Secondary fuses 3 - 10 - 15A

Front daylight running light 12V - 5W

Low/high beam light (halogen) 12 V - 55 W / 60 W H4

Turn indicators 12V - 10 W

CAPACITIES

Desc./Quantity

Fork oil 650 cm³ (39.66 cu.in) (for each stem)

Seats 2

ELECTRICAL SYSTEM

Desc./Quantity

Battery 12 V - 18 Ampere/hour

CHAR - 12

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Specification Desc./Quantity

Rear daylight running light/stop light LED

Supplementary headlamps (if fitted) 12 V/55W - H3

Dashboard lighting LED

License plate light 12V - 5 W

Turn indicator warning light LED

Neutral gear warning light LED

Alarm-shift warning light LED

Side stand down warning light LED

Low fuel warning light LED

High beam warning light LED

ABS warning light LED

Frame and suspensions

CHASSIS

Specification Desc./Quantity

Type high strength tubular steel frame with engine as stressed ele-

Trail 125 mm (4.92 in)

Headstock angle 27°

Front Upside down telescopic hydraulic fork, with 45mm (1.77 in) di-

am., stanchions and radial calliper mounting bracket with ad-

justable spring preload and hydraulic compression and re-

Front wheel travel 170 mm (6.69 in)

Rear single arm with progressive linkage, single shock absorber with

spring preload, hydraulic compression and rebound damping

Unloaded shock absorber spring length 180 mm (7.09 in)

Rear wheel travel 155 mm (6.10 in)

ment

bound damping.

adjustment.

Brakes

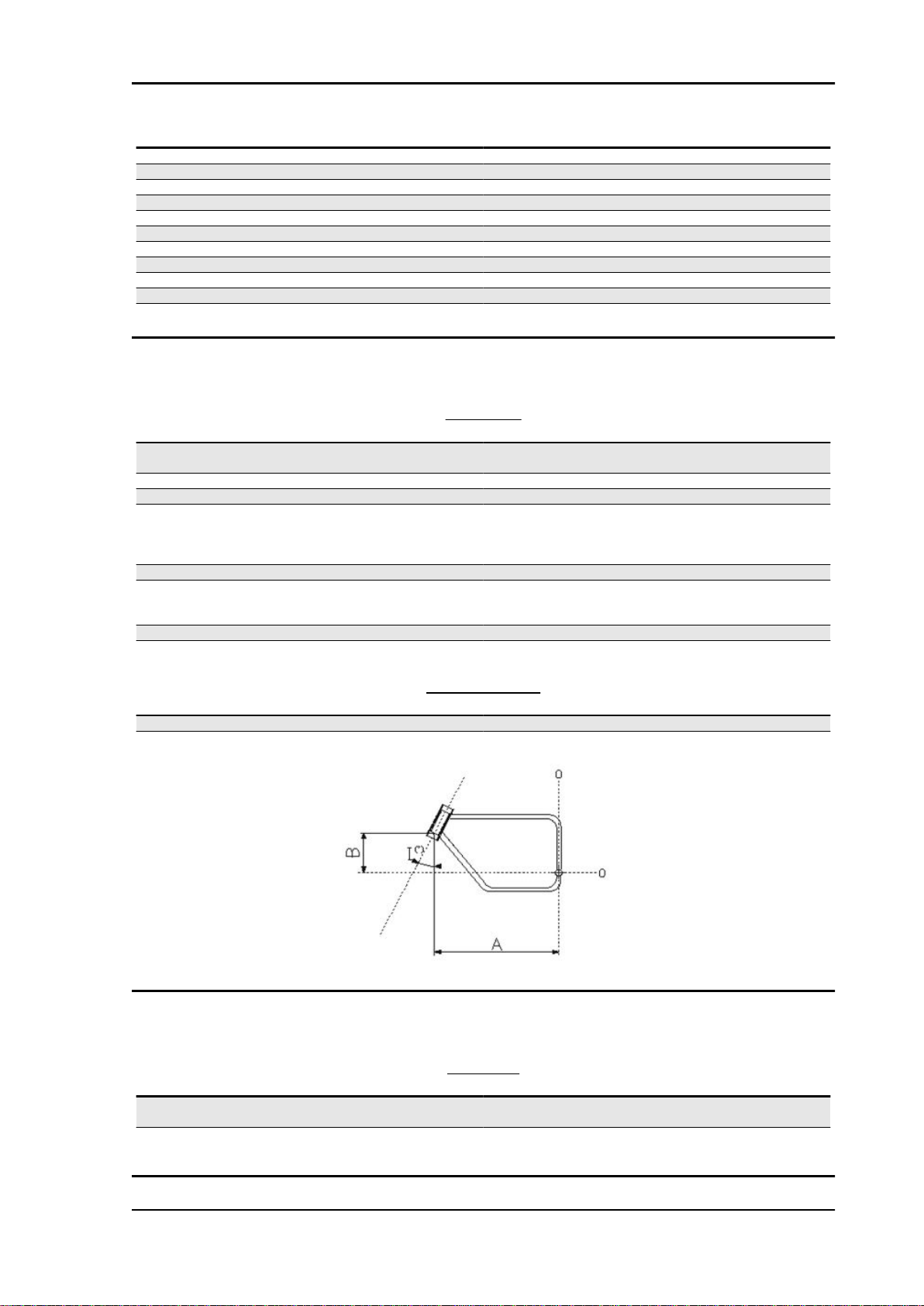

SIZES A AND B

Specification

Size A 745.0 mm (29.33 in)

Size B 403.16 mm (15.87 in)

Desc./Quantity

BRAKES

Specification

Front Ø 320-mm (12.6 in) stainless steel double floating disc, radial

Rear Ø 282-mm (11.1 in) stainless steel disc, floating calliper with 2

Desc./Quantity

callipers with 4 opposed pistons.

different pins

CHAR - 13

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

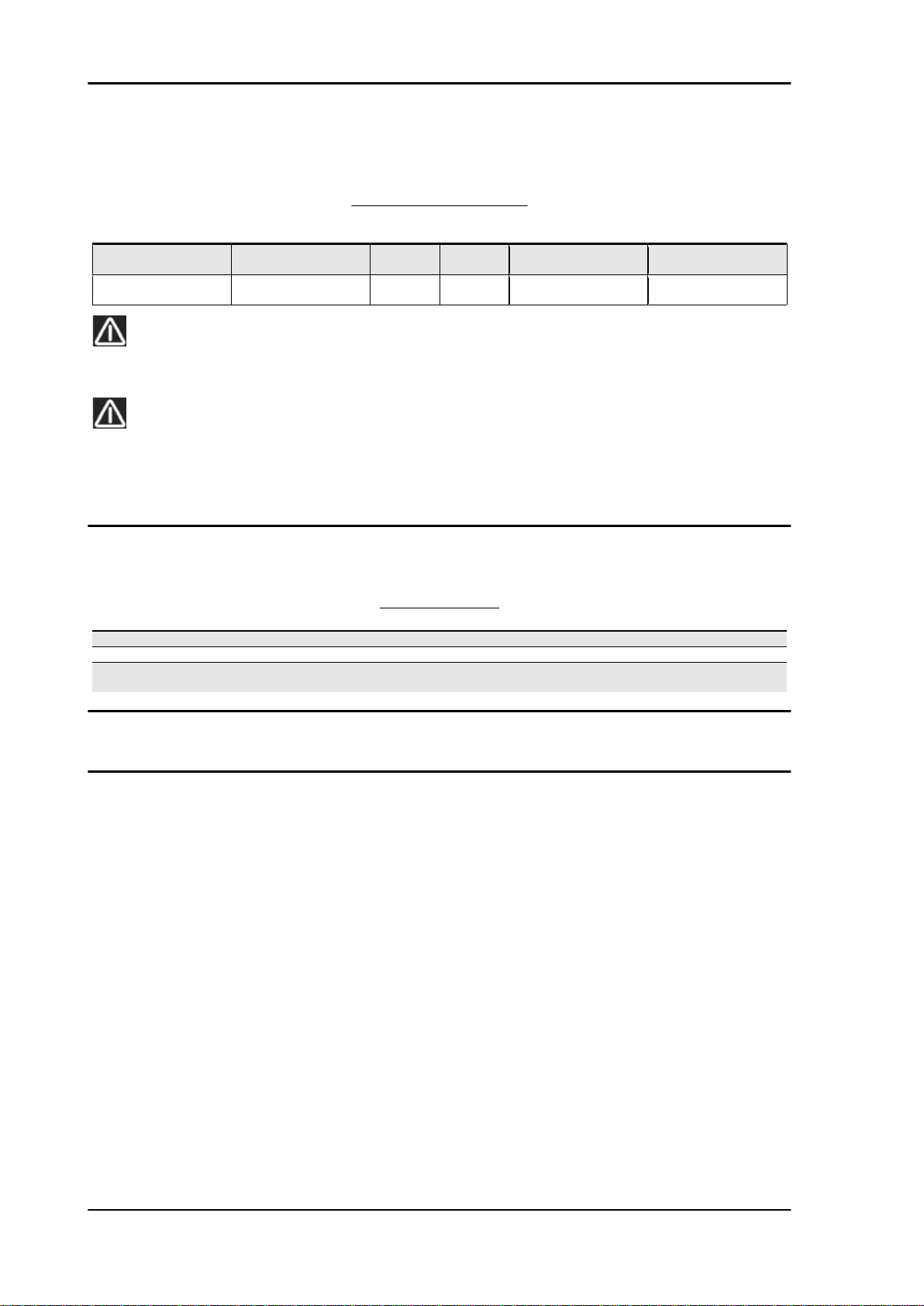

Wheels and tyres

WHEELS AND TYRES

Wheel Model Wheel rim Measure

Front (standard) H SPECIFIC Pirelli

Scorpion Trail

Rear (standard) H SPECIFIC Pirelli

Scorpion Trail

2.50 x 19" 110/80

4.25 x 17" 150/70

ment

R19 - 59V

R17 - 69V

THE USE OF M+S TYRES IS ALLOWED ONLY ON VEHICLES WITHOUT THE ABS SYSTEM.

WITH THIS TYRE TYPE, THE MAXIMUM SPEED ALLOWED IS 170 km/h (105.63 mi)

IT IS MANDATORY TO APPLY THE LABEL ONTO THE SPEEDOMETER (SUPPLIED WITH THE

TYRES) INDICATING THE MAXIMUM SPEED, WHEN FITTING M + S TYRES. WITH "OFF-ROAD /

ALLROUND" TYRES, PAY CLOSE ATTENTION WHEN DRIVING ON PAVED ROAD DUE TO ITS

LACK OF GRIP AND STABILITY.

Tyre pressure with

rider only

2.5 bar (250 kPa) (36.3

PSI)

2.9 bar (290 kPa) (42.1

PSI)

Tyre pressure, rider +

passenger

2.5 bar (250 kPa) (36.3

PSI)

2.9 bar (290 kPa) (42.1

PSI)

Supply

Specification

Fuel system Electronic injection (Weber . Marelli) with stepper motor

Diffuser diameter: 50 mm (1.97 in)

Fuel Premium unleaded petrol, minimum octane rating 95 (NORM)

Tightening Torques

FUEL SYSTEM

Desc./Quantity

and 85 (NOMM)

CHAR - 14

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

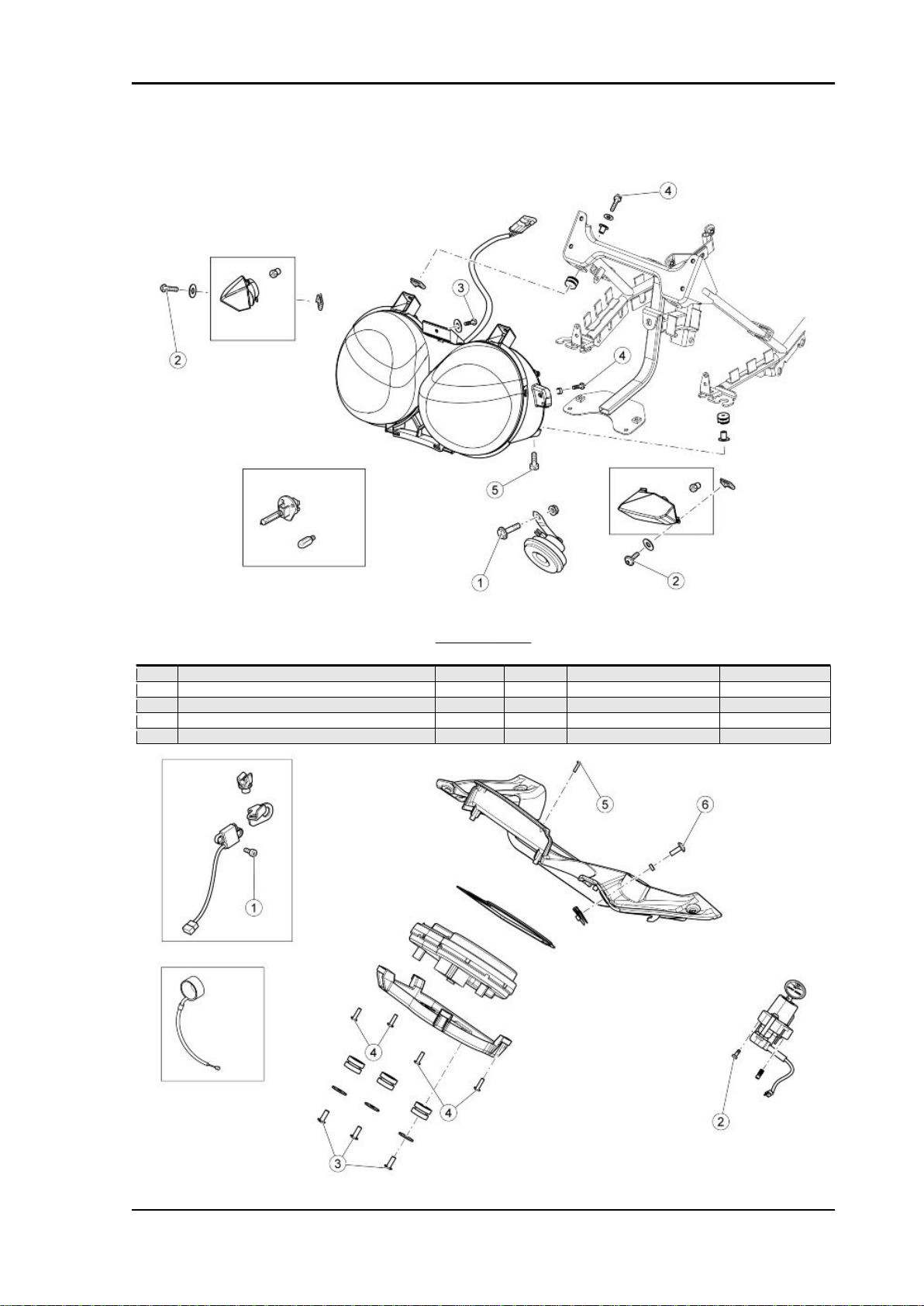

Front side

FRONT LIGHTS

pos.

1 Horn fixing screw M6x20 1 15 Nm (11.06 lbf ft) 2 Viti fissaggio freccie anteriori M4 2 3 Nm (2.21 lbf ft) 3 Vite fissaggio superiore fanale a carozzeria M4 1 3 Nm (2.21 lbf ft) 4 Viti fissaggio fanale a carozzeria M4x25 2 3 Nm (2.21 lbf ft) 5 Viti TCEI fissaggio fanale a telaietto M5x25 5 6 Nm (4.42 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 15

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

INSTRUMENT PANEL

pos. Description Type Quantity Torque Notes

1 Viti TCEI fissaggio sensore velocità anteriore M5x16 2 6 Nm (4.42 lbf ft) 2 Viti TCEI fissaggio blocchetto avviamento M8x30 1 25 Nm (18.44 lbf ft) 3 Viti autofil. fissaggio supporto cruscotto 5x14 3 Manual 4 Viti autofil. fissaggio supporto cruscotto a cor-

nice

5 Viti autofil. fissaggio cornice - 4 Manual 6 Viti TCE M5 2 6 Nm (4.42 lbf ft) -

3.9x14 4 Manual -

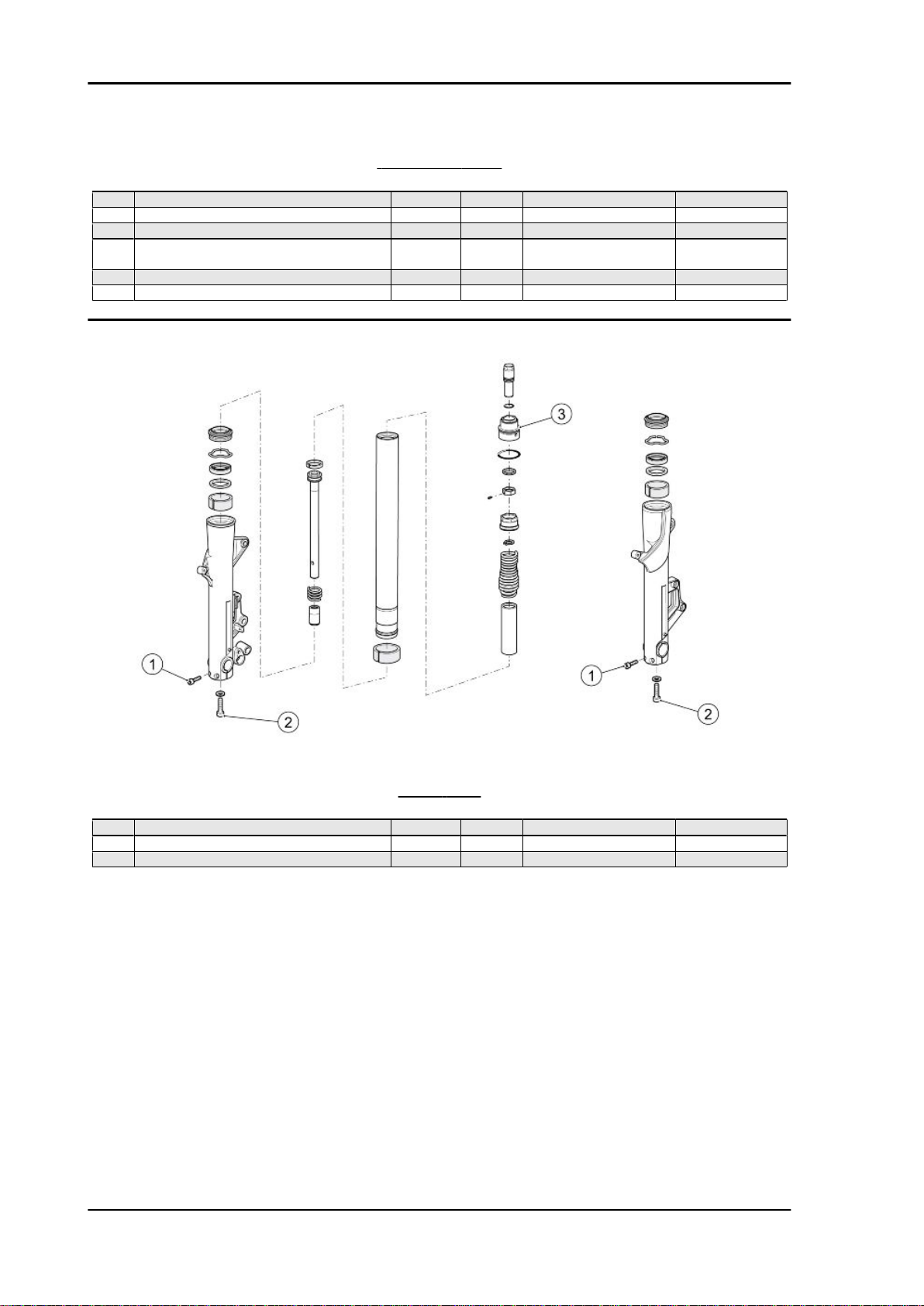

FRONT FORK

pos.

1 Viti piede forcella M8 1+1 25 Nm (18.44 lbf ft) 2 Viti chiusura mozzetti M6x30 2+2 10 Nm (7.38 lbf ft) 3 Fork cap - 1+1 - Nm (-.- lbf ft) -

CHAR - 16

Description Type Quantity Torque Notes

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

STEERING

pos.

1 Viti fissaggio piastra fermatubi - 2 6 Nm (4.42 lbf ft) 2 Viti fissaggio piastre M8x30 6 20 Nm (14.75 lbf ft) 3 Headstock ring nut - 1 40 Nm (29.50 lbf ft) 4 Headstock counter-lock ring - 1 manual + 90 degrees 5 Upper yoke fixing cap - 1 100 Nm (73.76 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 17

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

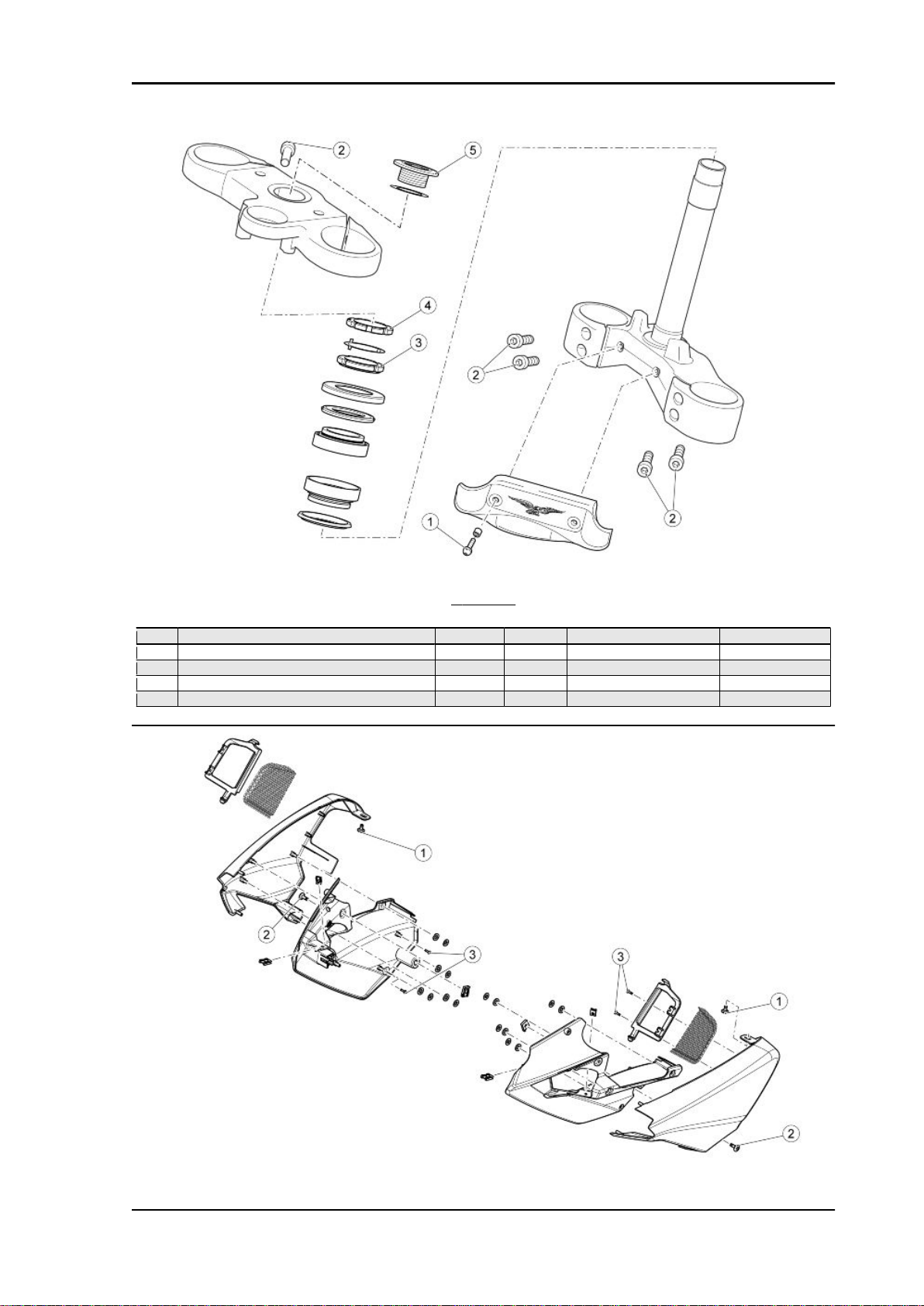

CARROZZERIA ANTERIORE - CONVOGLIATORI

pos. Description Type Quantity Torque Notes

1 Viti TBEI Flang. fissaggio convogliatori M5x9 2 6 Nm (4.42 lbf ft) 2 Viti TBEI Flang. fissaggio convogliatori M5 2 6 Nm (4.42 lbf ft) 3 Viti SWP Autofil. fissaggio telaietto griglie 2.9x12 4 Manual -

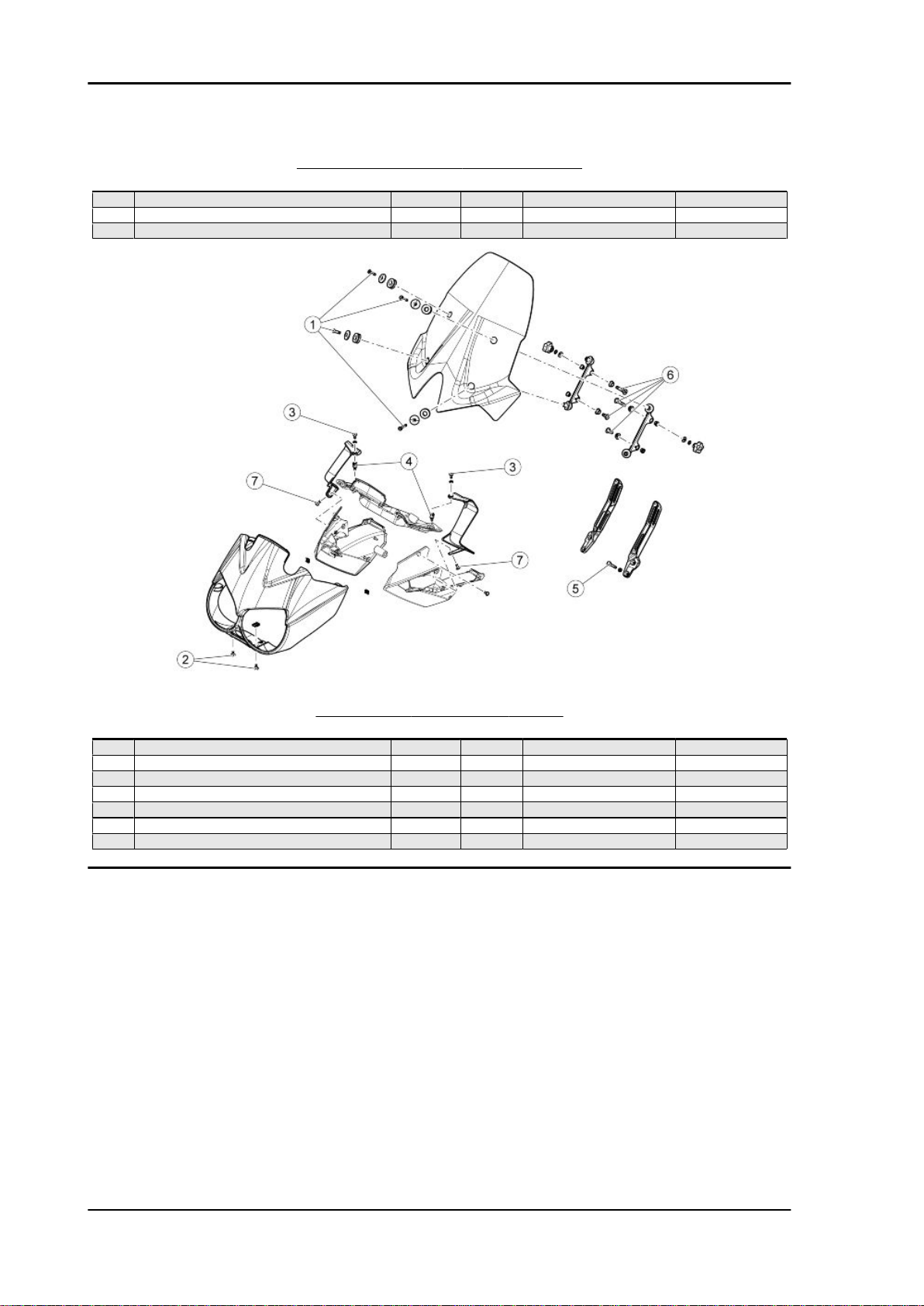

CARROZZERIA ANTERIORE - CUPOLINO

pos.

1 Viti fissaggio parabrezza M6 4 10 Nm (7.38 lbf ft) 2 Viti TBEI Flang. fissaggio cupolino M5x12 4 6 Nm (4.42 lbf ft) 3 Viti fissaggio deflettori superiori M5 4 6 Nm (4.42 lbf ft) 4 Colonnette fissaggio deflettori M5 2 6 Nm (4.42 lbf ft) 5 Viti TE Flang. fissaggio staffa parabrezza M6x16 4 10 Nm (7.38 lbf ft) 6 Perno filettato fissaggio supporto parabrezza M8 2 25 Nm (18.44 lbf ft) 7 Viti TBEI Flang. fissaggio deflettori inferiori M5 2 Manual -

Description Type Quantity Torque Notes

CHAR - 18

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

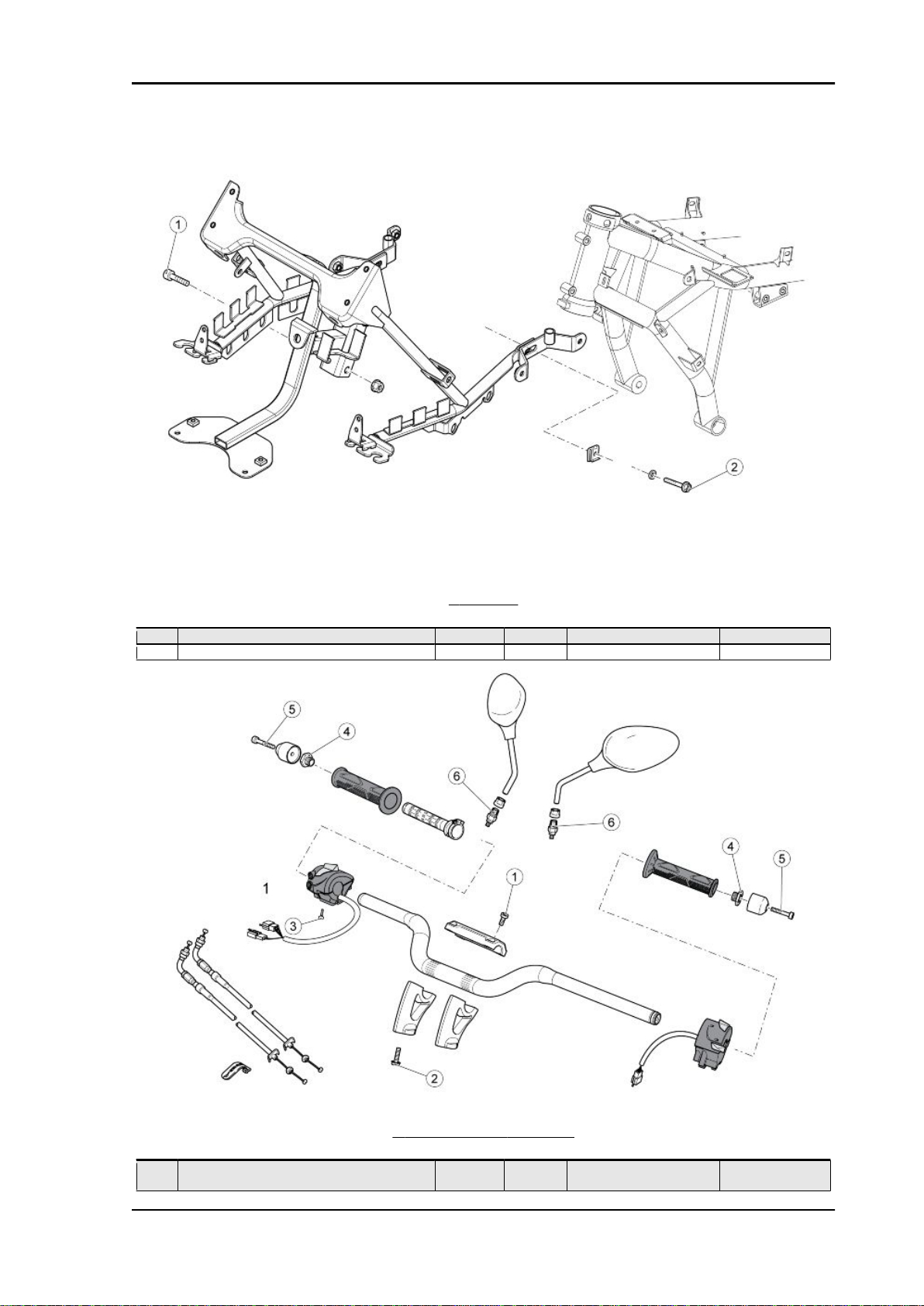

TELAIETTO

pos.

1 Viti TCEI fissaggio telaietto M8x40 2 25 Nm (18.44 lbf ft) 2 Viti TE Flang. M6x20 2 10 Nm (7.38 lbf ft) -

Description Type Quantity Torque Notes

HANDLEBAR AND CONTROLS

pos.

1 Viti TCC fissaggio cavallotti superiori manu-

Description Type Quantity Torque Notes

M8x30 4 25 Nm (18.44 lbf ft) -

brio

CHAR - 19

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

pos. Description Type Quantity Torque Notes

2 Viti TE Flangiate fissaggio cavallotti inf. man-

ubrio

3 Vite autof. - 1 1.5 Nm (1.11 lbf ft) 4 Raccordo fissaggio pesi antivibranti M18x15 2 - Nm (-.-- lbf ft) 5 Viti TCEI fissaggio pesi antivibranti - 2 10 Nm (7.38 lbf ft) Loct. 243

6 Raccordi fissaggio specchi retrovisori M10 2 30 Nm (22.13 lbf ft) -

- 2 50 Nm (36.88 lbf ft) -

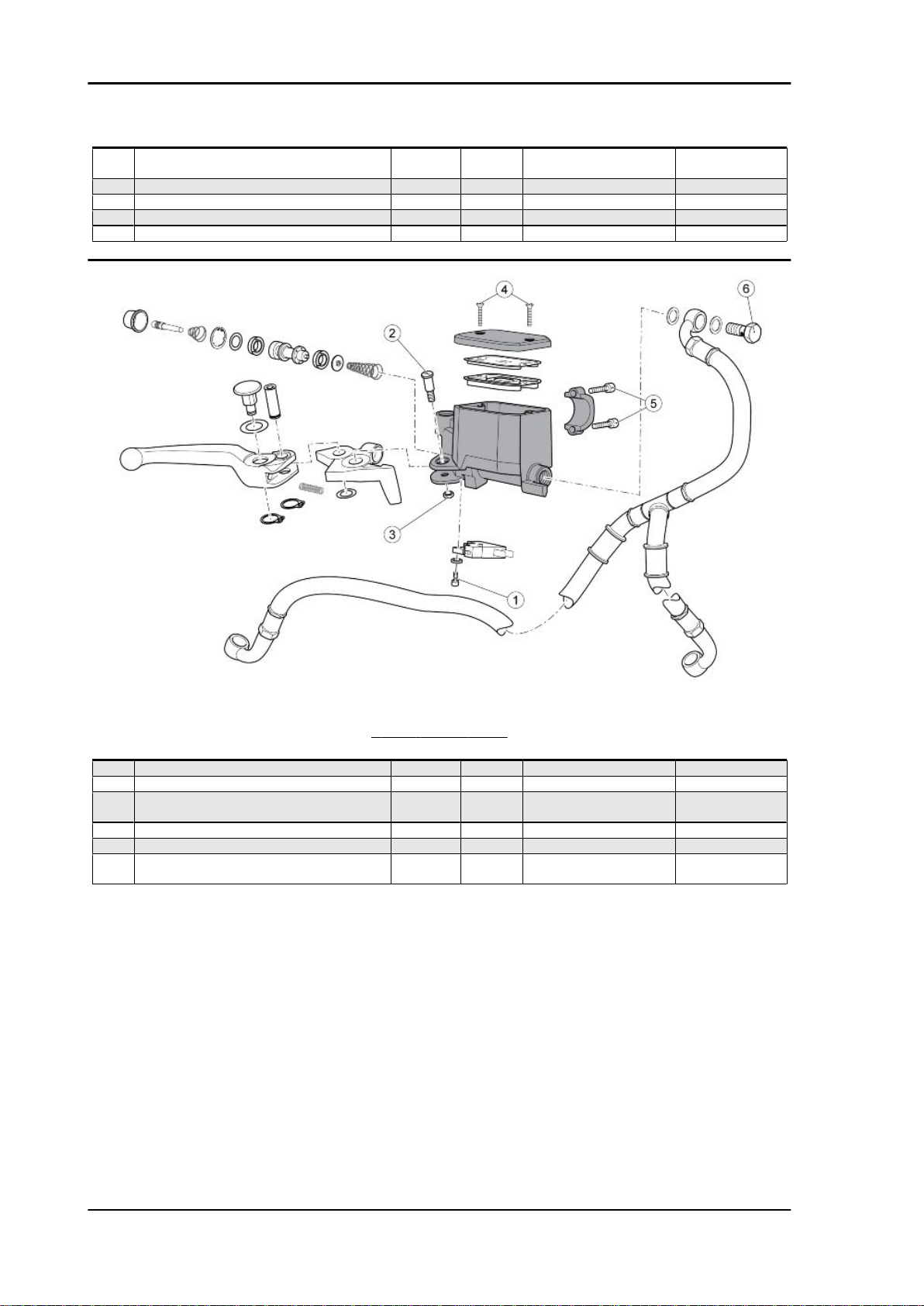

FRONT BRAKE LEVER

pos.

1 Viti TBEI fissaggio interruttore M4x12 1 3 Nm (2.21 lbf ft) 2 Lever pin M6 1 5-7 Nm (3.69-5.16 - lbf ft) 3 Viti fissaggio tappo serbatoio - 2 0.8-1.5 Nm (0.59-1.11 lbf

4 Dado perno leva M6 1 10 Nm (7.38 - lbf ft) 5 Viti fissaggio cavallotto M6 2 10 Nm (7.38 lbf ft) 6 Viti fissaggio tubo olio M10 1 23-26 Nm (16.96-19.18 lbf

Description Type Quantity Torque Notes

ft)

ft)

-

-

CHAR - 20

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

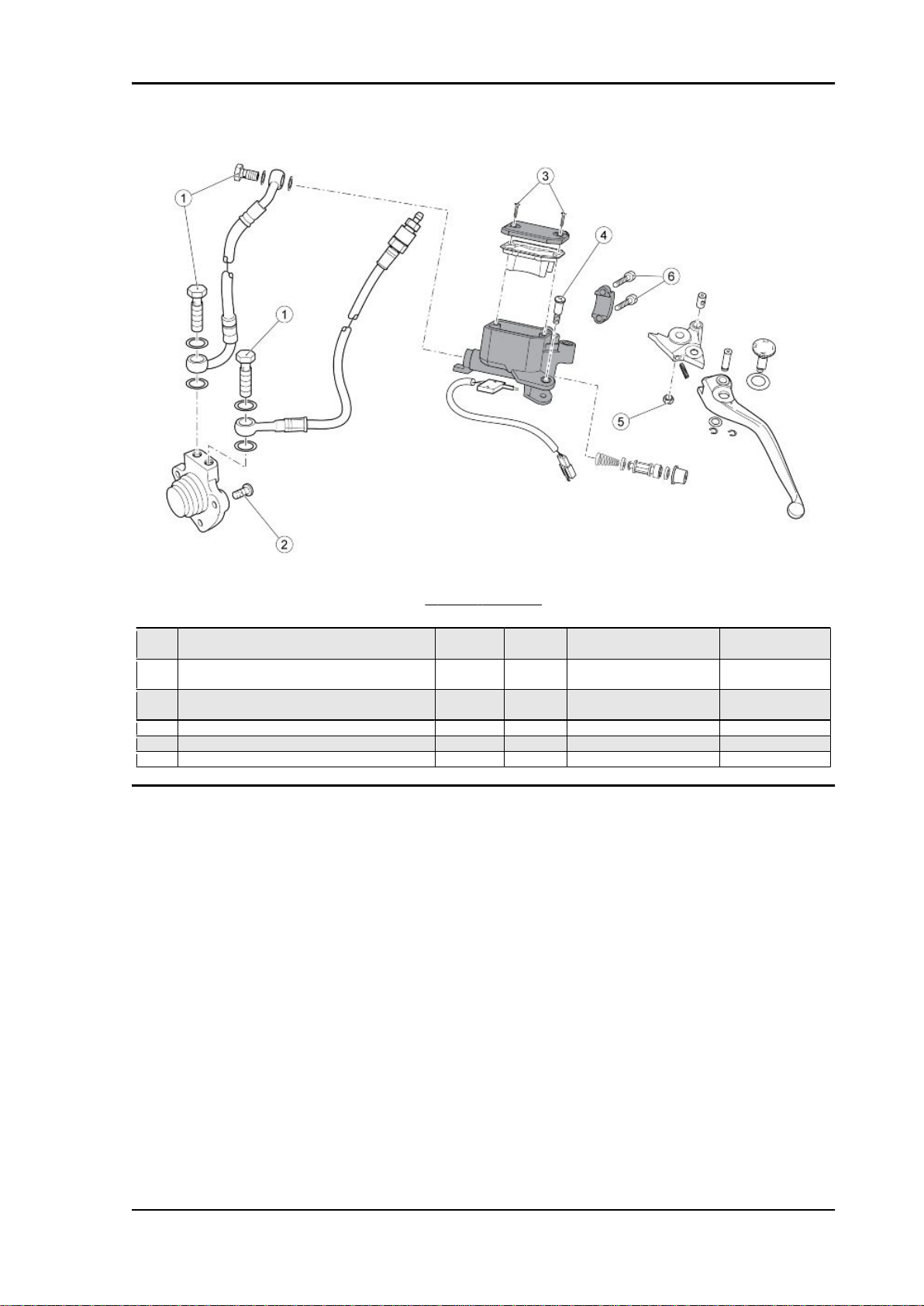

CLUTCH CONTROL

pos.

1 Viti fissaggio tubo olio M10 3 23-26 Nm (16.96-19.18 lbf

2 Viti TE Flang. fissaggio cilindro comando fri3 Viti fissaggio tappo serbatoio - 2 0.8-1.5 Nm (0.59-1.11 lbf

4 Lever pin - 1 5-7 Nm (3.69-5.16 lbf ft) -

5 Dado perno leva M6 1 10 Nm (7.38 lbf ft) 6 Viti fissaggio cavallotto - 2 10 Nm (7.38 lbf ft) -

Description Type Quantity Torque Notes

ft)

M6 3 10 Nm (7.38 lbf ft) -

zione

ft)

-

-

CHAR - 21

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

FRONT MUDGUARD

pos.

1 Viti TBEI Flang. fissaggio parafango anteriore M5x12 6 6 Nm (4.42 lbf ft) -

Description Type Quantity Torque Notes

FRONT WHEEL

pos.

1 Viti TE Flang. fissaggio dischi freno M8x20 12 25 Nm (18.44 lbf ft) 2 Nut fixing wheel pin - 1 80 Nm (59.00 lbf ft) 3 Vite flang. fissaggio sensore - 1 6 Nm (4.42 lbf ft) Loct. 243

CHAR - 22

Description Type Quantity Torque Notes

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

pos. Description Type Quantity Torque Notes

4 Vite TCB fissaggio passacavo M4x6 1 3 Nm (2.21 lbf ft) -

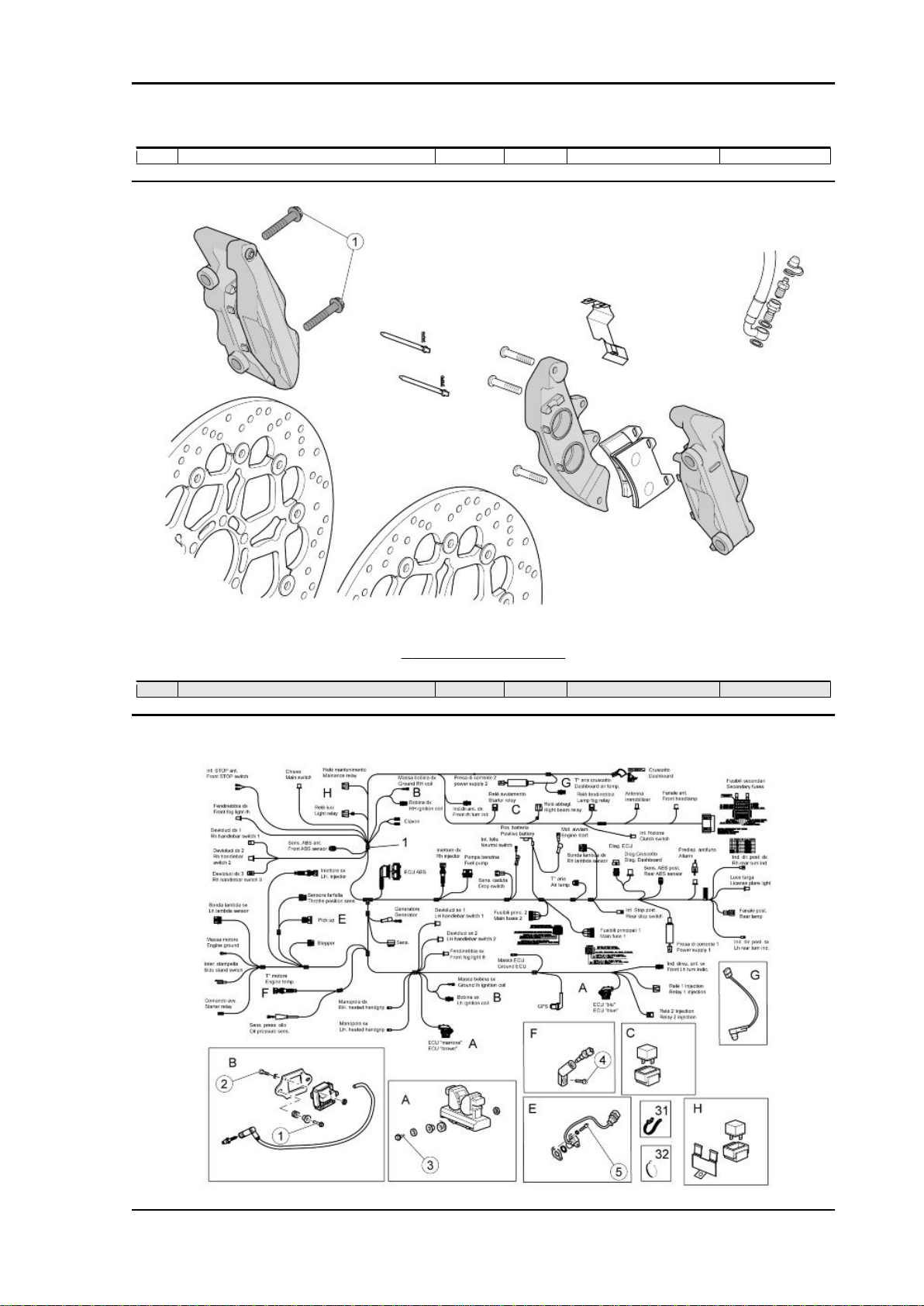

FRONT BRAKE CALLIPERS

pos.

1 Viti TE Flang. fissaggio pinze M10x55 4 50 Nm (36.88 lbf ft) -

Description Type Quantity Torque Notes

Central part

CHAR - 23

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

MAIN CABLE HARNESS

pos. Description Type Quantity Torque Notes

1 Viti TE Flang. fissaggio piastre bobine M6x20 2+2 10 Nm (7.38 lbf ft) 2 Viti TCEI fissaggio bobine - 2+2 2 Nm (1.47 lbf ft) 3 Viti TCEI fissaggio centralina - 2 10 Nm (7.38 lbf ft) 4 Viti TCEI fissaggio supporto sensore temp.

olio

5 Viti TCEI fissaggio sensore di fase - 2 3 Nm (2.21 lbf ft) -

M10x20 1 11 Nm (8.11 lbf ft) Loct. 243

CAVALLETTO CENTRALE E LATERALE

pos.

1 Viti TCEI fissaggio cavalletto centrale M10x30 2 50 Nm (36.88 lbf ft) Loct. 270

2 Viti TE Flang. fissaggio piastre M8 2 25 Nm (18.44 lbf ft) 3 Screw M8x35 1 25 Nm (18.44 lbf ft) 4 Viti TBEI fissaggio piastre M12x35 4 80 Nm (59.00 lbf ft) 5 Viti TCEI fissaggio interruttore cavalletto M5 2 6 Nm (4.42 lbf ft) Loct. 243

7 Dado fissaggio cavalletto laterale M10 1 30 Nm (22.13 lbf ft) Loct. 243

Description Type Quantity Torque Notes

CHAR - 24

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

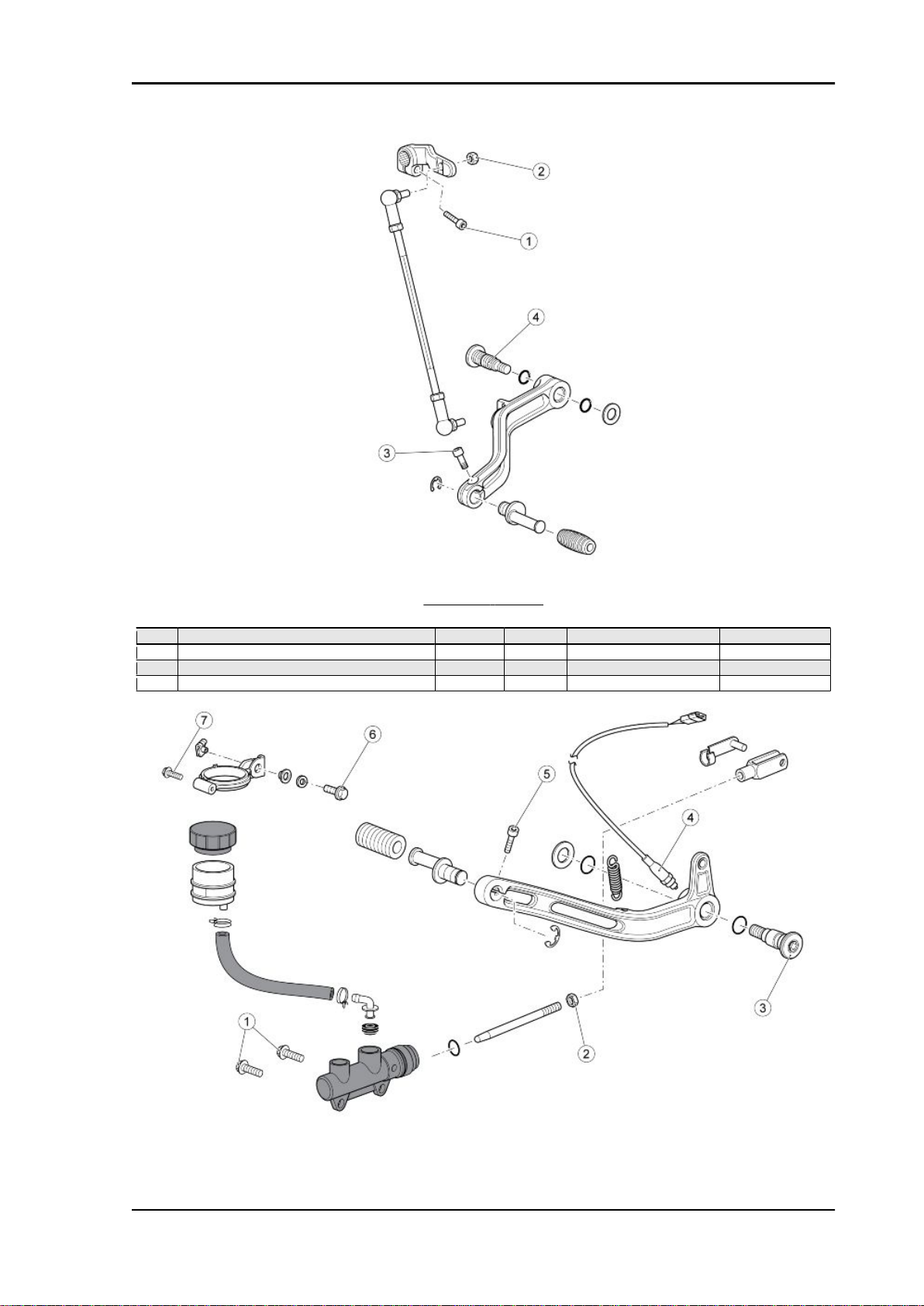

COMANDO CAMBIO

pos.

1 Viti TCEI fissaggio leva rinvio cambio M6x20 1 10 Nm (7.38 lbf ft) 2 Dadi fissaggio tirante - 2 10 Nm (7.38 lbf ft) 3 Vite TCEI fissaggio piolo leva freno M6x16 1 10 Nm (7.38 lbf ft) 4 Brake lever pin M8 1 15 Nm (11.06 lbf ft) Loct. 243

Description Type Quantity Torque Notes

CHAR - 25

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

REAR BRAKE LEVER

pos. Description Type Quantity Torque Notes

1 Viti te Flang. fissaggio pompa freno M6x20 2 10 Nm (7.38 lbf ft) Loct. 243

2 Dado bloccaggio asta pompa freno - 1 10 Nm (7.38 lbf ft) 3 Brake lever pin M8 1 15 Nm (11.06 lbf ft) Loct. 243

4 Stop switch M6 1 10 Nm (7.38 lbf ft) 5 Vite TCEI fissaggio piolo leva freno - 1 10 Nm (7.38 lbf ft) 6 Vite TE Flang. fissaggio supporto serbatoio M6x16 1 10 Nm (7.38 lbf ft) 7 Vite SWP autofil. per supporto serbatoio M5x20 1 Manual -

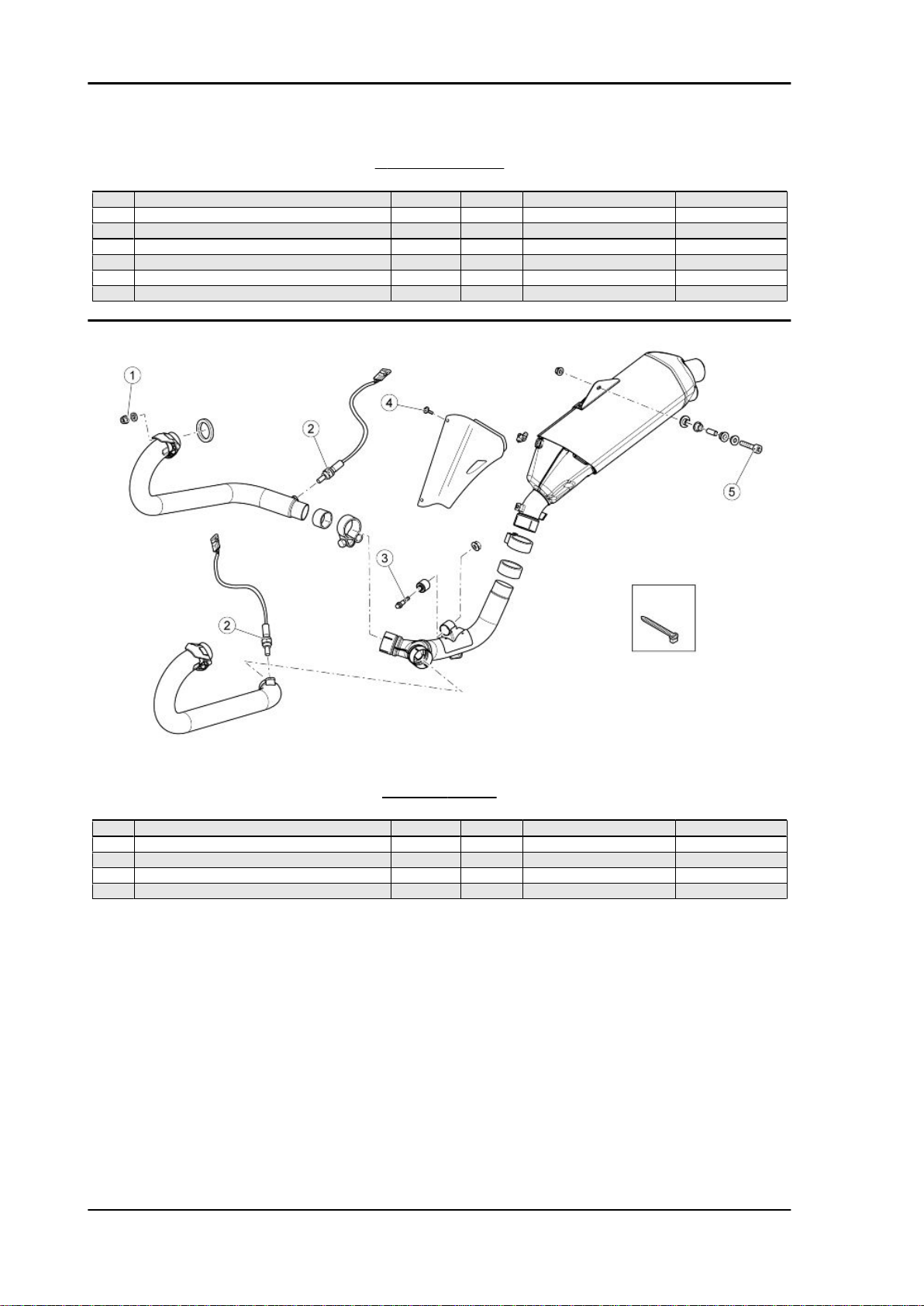

EXHAUST SYSTEM

pos.

1 Dadi Flang. fissaggio collettori M8 4 25 Nm (18.44 lbf ft) 2 Oxygen sensor fastener - 2 38 Nm (28.03 lbf ft) 3 Vite TE Flang. fissaggio parte centrale M10x55 1 25 Nm (18.44 lbf ft) 4 Viti fissaggio protezione - 2 10 Nm (7.38 lbf ft) 5 Vite TCEI fissaggio silenziatore a telaio M8x60 1 25 Nm (18.44 lbf ft) -

CHAR - 26

Description Type Quantity Torque Notes

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

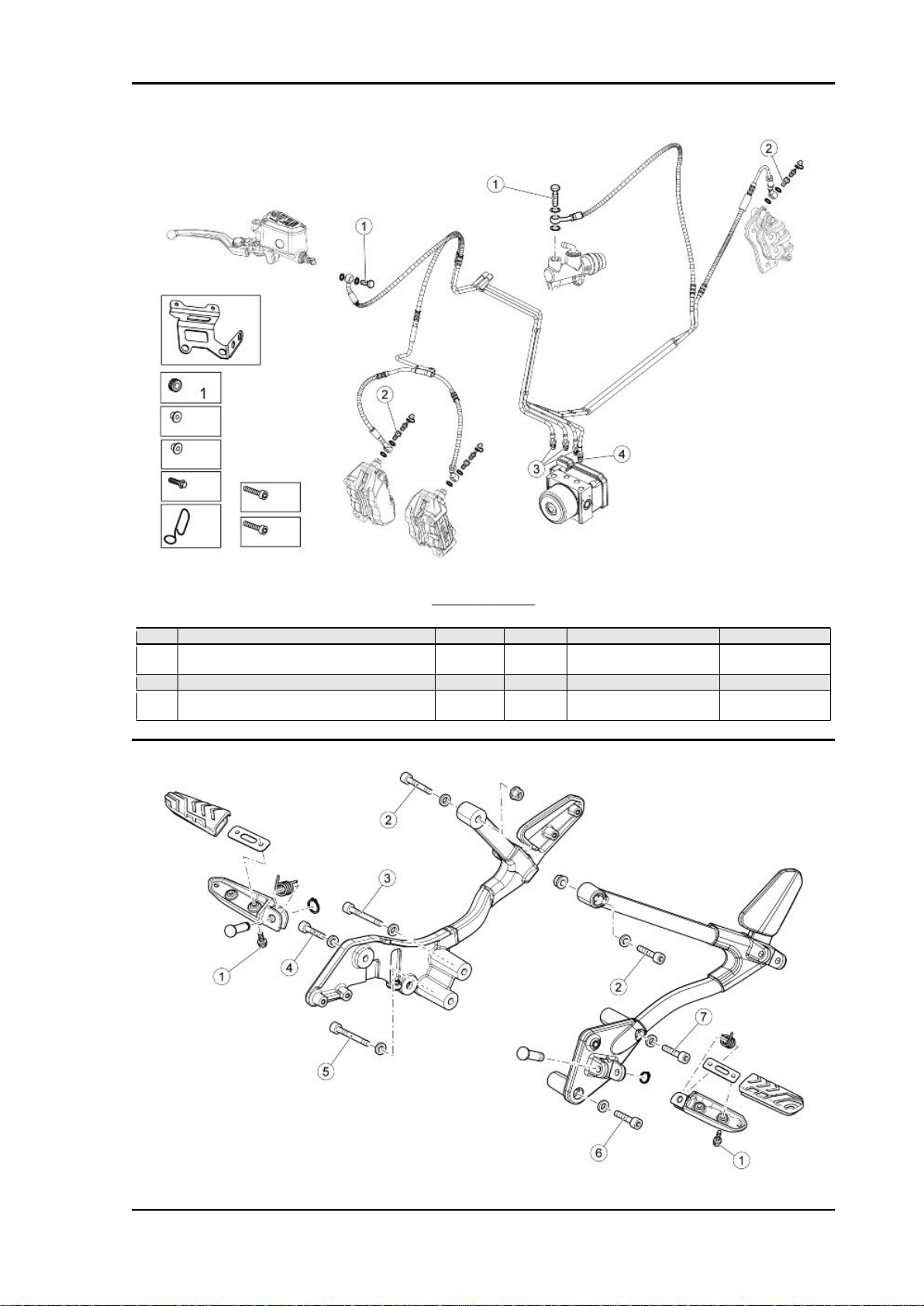

BRAKE SYSTEM

pos.

1 Brake pipe slot screw on the pump M10 2 25 Nm (18.44 lbf ft) 2 Joint with brake pipes retainer bleeding on the

3 Brake pipes joint on the ABS hydraulic unit - 3 25 Nm (18.44 lbf ft) 4 Brake pipes joint on the ABS hydraulic unit M12 1 30-34 Nm (22.13-25.08 lbf

Description Type Quantity Torque Notes

M10 3 25 Nm (18.44 lbf ft) -

calliper

ft)

-

CHAR - 27

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

SUPPORTO E PEDANE PILOTA

pos. Description Type Quantity Torque Notes

1 Viti Flang. fissaggio piastrine - 4 10 Nm (7.38 lbf ft) 2 Viti TCEI fissaggio supporto pedane M8x35 2 25 Nm (18.44 lbf ft) 3 Vite fissaggio supporto pedane - 1 25 Nm (18.44 lbf ft) 4 Vite TCEI fissaggio supporto pedane M8x25 1 25 Nm (18.44 lbf ft) 5 Vite fissaggio supporto pedane - 1 25 Nm (18.44 lbf ft) 6 Vite TCEI fissaggio supporto pedane M8x60 1 25 Nm (18.44 lbf ft) 7 Vite fissaggio supporto pedane - 1 25 Nm (18.44 lbf ft) -

PASSENGER FOOTRESTS

pos.

1 Viti TE Flang. fissaggio piastrine - 4 10 Nm (7.38 lbf ft) 2 Viti TE Flang. fissaggio protezione pedana

Description Type Quantity Torque Notes

M6x12 2 10 Nm (7.38 lbf ft) -

passeggero SX

CHAR - 28

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

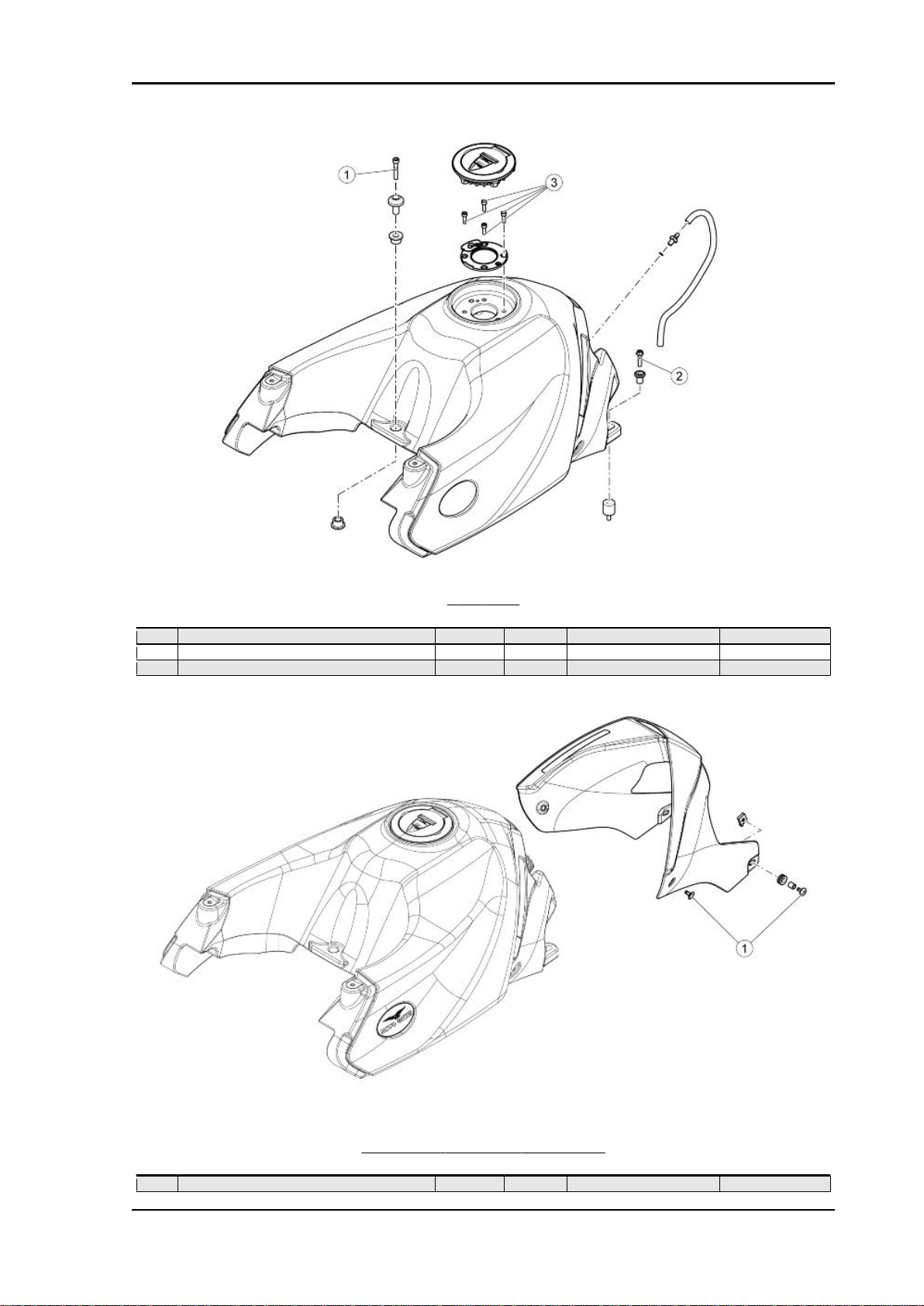

FUEL TANK

pos.

1 Vite TCEI fissaggio anteriore M6x35 1 10 Nm (7.38 lbf ft) 2 Vite TE Flang. fissaggio posteriore M6x25 2 10 Nm (7.38 lbf ft) 3 Viti TCEI fissaggio tappo benzina M5x15 4 4 Nm (2.95 lbf ft) -

Description Type Quantity Torque Notes

COPERTURA SERBATOIO CARBURANTE

pos.

1 Vite TBEI Flang. fissaggio copertura - 4 5 Nm (3.69 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 29

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

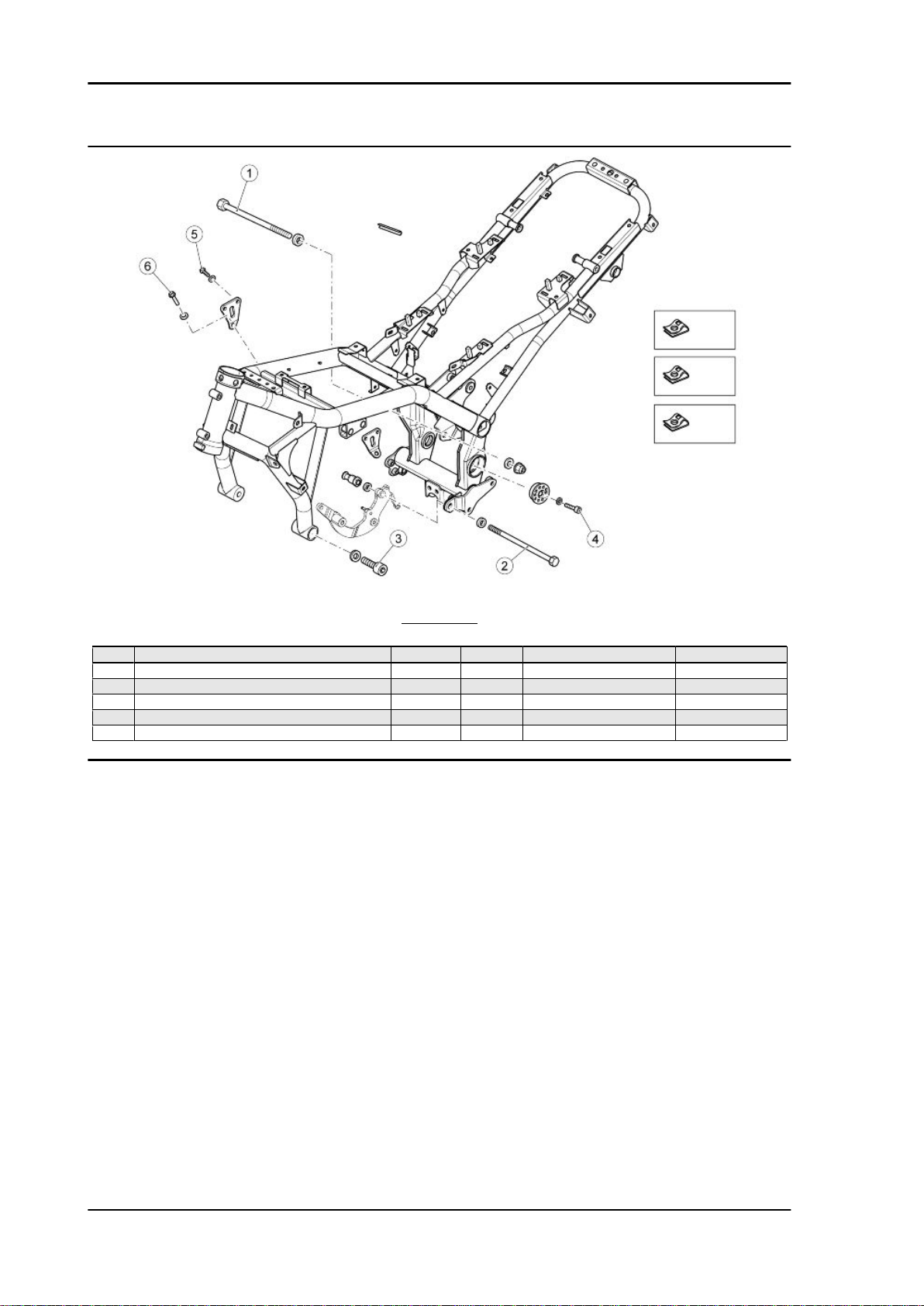

CHASSIS

pos.

1 Pin M12 1 50 Nm (36.88 lbf ft) 2 Pin M12x260 1 50 Nm (36.88 lbf ft) 3 Viti TCEI fissaggio anteriore motore a telaio M12x50 2 80 Nm (59.00 lbf ft) 4 Screws M8x14 2 25 Nm (18.44 lbf ft) 5 Viti TE Flang. M8x25 4 25 Nm (18.44 lbf ft) 6 Screws M10 2 50 Nm (36.88 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 30

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Back side

REAR BODYWORK

pos.

1 Viti SWP fissaggio piastra batteria M5x20 4 Manual 2 Viti TBEI Flang. fissaggio fianchetti e para-

3 Viti TE Flang. fissaggio supporti valigie M6 4 10 Nm (7.38 lbf ft) 4 Viti TBEI Flang. fissaggio paraspruzzi M5x12 2 6 Nm (4.43 lbf ft) -

Description Type Quantity Torque Notes

M5x9 10 6 Nm (4.42 lbf ft) -

spruzzi

CHAR - 31

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

LICENSE PLATE HOLDER

pos. Description Type Quantity Torque Notes

1 Viti TBEI Flang. fissaggio portatarga M5 2 6 Nm (4.43 lbf ft) 2 Viti TBEI speciali - 2 6 Nm (4.43 lbf ft) 3 Dado autobloc. flang. fissaggio catadiottro M5 1 6 Nm (4.43 lbf ft) -

TRANSMISSION CONNECTION - ENGINE

pos.

1 Reaction rod fixing screw M10x55 2 50 Nm (36.87 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 32

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

REAR SWINGARM

pos.

1 Swingarm clamp fixing screw on the bushing M6x25 2 10 Nm (7.37 lbf ft) 2 2 - Swingarm fixing screw on the transmission

3 Swingarm pin on the swingarm M12 1 60 Nm (44.25 lbf ft) 4 Preloading bushing to the swingarm pin M25 1 10 Nm (7.37 lbf ft) -

Description Type Quantity Torque Notes

M10x35 4 50 Nm (36.87 lbf ft) -

housing

CHAR - 33

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

LUCI POSTERIORI

pos. Description Type Quantity Torque Notes

1 Vite TBEI Flang. fissaggio fanale - 1 6 Nm (4.43 lbf ft) 2 Vite TCEI fissaggio fanale - 2 6 Nm (4.43 lbf ft) 3 Vite TCEI fissaggio fanale targa M5x25 1 6 Nm (4.43 lbf ft) -

MANIGLIONE E PORTAPACCHI

pos.

1 Vite TCEI fissaggio maniglione passeggero M6x25 4 10 Nm (7.38 lbf ft) 2 Vite TCEI fissaggio maniglione passeggero M8 2 25 Nm (18.44 lbf ft) 3 Vite fissaggio portatarga a maniglione M5 2 6 Nm (4.42 lbf ft) 4 Vite TBEI fissaggio supporti portapacchi M8x20 2 25 Nm (18.44 lbf ft) 5 Vite TBEI fissaggio supporti portapacchi M8x30 2 25 Nm (18.44 lbf ft) 6 Vite TSPEI fissaggio coperchio portapacchi M6x35 2 10 Nm (7.38 lbf ft) 7 Vite autofil. fissaggio coperchio portapacchi 5 4 Manual -

Description Type Quantity Torque Notes

CHAR - 34

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

REAR WHEEL

pos.

1 Vite TE Flang. fissaggio ruota fonica - 6 25 Nm (18.44 lbf ft) 2 Vite TE Flang. fissaggio sensore - 1 10 Nm (7.38 lbf ft) 3 Vite TE Flang. fissaggio sensore M12x65 1 110 Nm (81.13 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 35

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

REAR SUSPENSION

pos. Description Type Quantity Torque Notes

1 Vite TE Flang. fissaggio superiore ammortiz-

zatore

2 Vite TCEI fissaggio biella doppia/forcellone M10x82 1 50 Nm (36.88 lbf ft) 3 Vite TE fissaggio biella doppia/ammortizza-

tore

4 Vite TE flang. fissaggio biella singola/biella

doppia

5 Vite TE flang. fissaggio biella singola al telaio M10x85 1 50 Nm (36.88 lbf ft) -

M10x80 1 50 Nm (36.88 lbf ft) -

M10x47 1 40 Nm (29.50 lbf ft) M10x95 1 50 Nm (36.88 lbf ft) -

SADDLE

pos.

1 Vite TBEI fissaggio piastra attacco sella M6 2 10 Nm (7.38 lbf ft) 2 Dado serratura - 1 Manual -

CHAR - 36

Description Type Quantity Torque Notes

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Engine

LUBRICATION SYSTEM

pos.

1 Pump outlet oil pipe nipple M14x1.5 1 40 Nm (29.50 lbf ft) 2 Slot screw for oil pipe on the cylinder head M14x1.5 2 20 Nm (14.75 lbf ft) 3 Nipple on the radiator and the oil pipe M16x1.5 2 20 Nm (14.75 lbf ft) Apply vaseline oil

4 Oil delivery pipe to radiator slot screw M14x1.5 1 35 Nm (25.81 lbf ft) 5 Jets fixing screw - 3 Using a "T" spanner, close

6 Minimum oil pressure sensor M12 1 25 Nm (18.44 lbf ft) 7 Intake oil filter fixing screw - 2 4 Nm (2.95 lbf ft) -

Description Type Quantity Torque Notes

Loctite 243

by hand

CHAR - 37

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

ALTERNATOR

pos.

1 Generator control pulley locking nut M16 1 80 Nm (59.00 lbf ft) Loctite 243

2 Generator upper fixing screw M8 1 22 Nm (16.23 lbf ft) 3 Generator lower fixing screw M10x60 1 30 Nm (22.13 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 38

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

CRANKCASE AND OIL SUMP

pos. Description Type Quantity Torque Notes

1 Stud bolt M8x75 2 10 Nm (7.37 lbf ft) 2 Stud bolt M8x66 3 10 Nm (7.37 lbf ft) 3 Crankshaft rear support flange fixing screw M8x25 8 26 Nm (19.18 lbf ft) 4 Oil cap on the crankcase - 2 25 Nm (18.44 lbf ft) 5 Flange fixing screw under the crankcase M6x60 2 10 Nm (7.37 lbf ft) 6 Flange fixing screw under the crankcase - 2 10 Nm (7.37 lbf ft) 7 Oil sump fixing screw (filter contour) M6x35 4 10 Nm (7.37 lbf ft) 8 Oil sump fixing screw M6 14 10 Nm (7.37 lbf ft) 9 Cover on the flange under the crankcase - 2 20 Nm (14.75 lbf ft) 10 Magnetic oil drainage cap - 1 20 Nm (14.75 lbf ft) 11 Gear to engine fixing nut M8 5 20 Nm (14.75 lbf ft) 12 Gear to engine fixing screw - 1 20 Nm (14.75 lbf ft) Loctite 542

GEAR INTERNAL CONTROLS

pos.

1 Spring guide pin - 1 24 Nm (17.70 lbf ft) Loctite 243

Description Type Quantity Torque Notes

CHAR - 39

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

OIL SUMP COMPONENTS

pos.

1 Cover on the flange under the crankcase - 1 40 Nm (29.50 lbf ft) 2 Oil filter joint - 1 10 Nm (7.37 lbf ft) Loctite 243

3 Oil sump pipe - 1 20 Nm (14.75 lbf ft) Loctite 648

4 Oil filter - 1 15 Nm (11.06 lbf ft) Engine oil

5 Rose pipe fixing screw M6 - 10 Nm (7.37 lbf ft) 6 Maximum pressure valve cover M18 1 40 Nm (29.50 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 40

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

CYLINDER HEAD COVERS

pos. Description Type Quantity Torque Notes

1 Special cylinder head fixing screw - 8 8 Nm (5.90 lbf ft) Locked with cross

2 Spark plug cover fixing screw M5x10 2 8 Nm (5.90 lbf ft) -

sequence

GENERATOR COVER

pos.

1 Timing system cover cap fixing screw M6x20 2 10 Nm (7.37 lbf ft) Loctite 243

2 Timing system cover fixing screw M8x55 4 25 Nm (18.44 lbf ft) 3 Timing system cover fixing screw M6x30 9 12 Nm (8.85 lbf ft) 4 Generator cover fixing screw M6x16 5 12 Nm (8.85 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 41

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

AIR FILTER

pos.

1 Vite fissaggio cassa filtro aria a telaio - 2 10 Nm (7.38 lbf ft) 2 Air filter box cover fastening screw SWP 5x20 6 3 Nm (2.21 lbf ft) -

Description Type Quantity Torque Notes

THROTTLE BODY

pos.

1 Intake pipe fixing screw - 6 10 Nm (7.37 lbf ft) -

CHAR - 42

Description Type Quantity Torque Notes

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

pos. Description Type Quantity Torque Notes

2 Flange fixing screw on the throttle body M5x12 2 6 Nm (4.42 lbf ft) -

CLUTCH

pos.

1 Clutch to crankshaft fixing screw - 6 42 Nm (30.98 lbf ft) Tighten with cross

2 Clutch external flange fixing screw on flywheel M7x16 6 20 Nm (14.75 lbf ft) Loctite 243

3 Start-up crown fixing screw on flywheel - 6 10 Nm (7.37 lbf ft) Loctite 243

4 Clutch control cylinder fixing screw - 3 10 Nm (7.37 lbf ft) Loctite 243

Description Type Quantity Torque Notes

sequence

CHAR - 43

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

CONNECTING ROD ASSEMBLY - CYLINDERS

pos. Description Type Quantity Torque Notes

1 Thermal group fixing stud bolt M10x1.25 8 5 Nm (3.69 lbf ft) Loctite 243

2 Connecting rod screws - 4 40 Nm (29.50 lbf ft) Pre-tightening

2 Connecting rod screws - 4 80 Nm (59.00 lbf ft) Final tightening

3 Right hydraulic tensioner cover - 1 42 Nm (30.98 lbf ft) 4 Left hydraulic tensioner cover - 1 30 Nm (22.13 lbf ft) -

FUEL SUPPLY SYSTEM

pos.

1 Vite fissaggio protezioni corpo farfallato M6 2 10 Nm (7.38 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 44

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

BLOW-BY SYSTEM

pos.

1 Vite fissaggio distanziale vaso espansione

2 Reduction joint for oil return pipe - 1 20 Nm (14.75 lbf ft) -

3 Oil return pipe (on sump) - 1 20 Nm (14.75 lbf ft) Vaseline oil

Description Type Quantity Torque Notes

Blow - By a motore

SWP

M5x14

1 10 Nm (7.38 lbf ft) -

CHAR - 45

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

STARTER MOTOR

pos. Description Type Quantity Torque Notes

1 Starter motor fixing screw - 2 25 Nm (18.44 lbf ft) 2 Stud bolt - 1 10 Nm (7.37 lbf ft) 3 Starter motor cover fixing screw M6x10 2 8 Nm (5.90 lbf ft) -

OIL PUMP

pos.

1 Oil pump fixing screw M6x45 3 10 Nm (7.37 lbf ft) Loctite 243

2 Oil pump driven gear locking nut M6 1 8 Nm (5.90 lbf ft) Loctite 243

3 Oil pressure valve cap - 1 40 Nm (29.50 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 46

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

OIL RADIATOR

pos.

1 Viti fissaggio radiatore a telaio M6x30 3 10 Nm (7.38 lbf ft) -

Description Type Quantity Torque Notes

TESTA DESTRA

Pos.

1 Movable chain tensioner pad fixing screw - 1 20 Nm (14.75 lbf ft) Loctite 243

Descrizione Tipo Quantità Coppia Note

CHAR - 47

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Pos. Descrizione Tipo Quantità Coppia Note

2 Head tightening nut M10x1.25 4 15 Nm (11.06 lbf ft) Engine Oil Pre2 Head tightening nut M10x1.25 4 42 Nm (30.98 lbf ft) Final tightening

3 Head tightening screws (chain compartment) M6x120 2 10 Nm (7.37 lbf ft) 4 Plate locking screw and timing gear - 1 30 Nm (22.13 lbf ft) Loctite 243

5 Timing cover fixing screw on the cylinder head M5x10 2 8 Nm (5.90 lbf ft) 6 Camshaft support fixing screw - 6 18 Nm (13.28 lbf ft) 7 Vite fissaggio molla a tazza - 1 18 Nm (13.28 lbf ft) -

tightening

TESTA SINISTRA

Pos.

1 Movable chain tensioner pad fixing screw - 1 20 Nm (14.75 lbf ft) Loctite 243

2 Head tightening nut M10x1.25 4 15 Nm (11.06 lbf ft) Engine Oil Pre-

2 Head tightening nut M10x1.25 4 42 Nm (30.98 lbf ft) Final tightening

3 Head tightening screws (chain compartment) M6x120 2 10 Nm (7.37 lbf ft) 4 Plate locking screw and timing gear - 1 30 Nm (22.13 lbf ft) Loctite 243

5 Timing cover fixing screw on the cylinder head M5x10 2 8 Nm (5.90 lbf ft) 6 Camshaft support fixing screw - 6 18 Nm (13.28 lbf ft) 7 Vite fissaggio molla a tazza - 1 18 Nm (13.28 lbf ft) -

Descrizione Tipo Quantità Coppia Note

tightening

CHAR - 48

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

TIMING SYSTEM CONTROL

pos.

1 Control, timing system, shaft support flange

2 Bearing fixing screw M6x16 1 10 Nm (7.37 lbf ft) Loctite 243

3 Driving gears locking nut on the crankshaft M25 1 200 Nm (147.51 lbf ft) Loctite 601

4 Timing system driven gear locking nut M18 1 25 Nm (18.44 lbf ft) Pre-tightening

4 Timing system driven gear locking nut M18 1 150 Nm (110.63 lbf ft) Final tightening

Description Type Quantity Torque Notes

M6x14 2 8 Nm (5.90 lbf ft) -

fixing screw

CHAR - 49

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

GEARBOX

pos. Description Type Quantity Torque Notes

1 Clutch housing to gearbox fixing screw M6x55 14 13 Nm (9.59 lbf ft) 2 Neutral sensor - 1 10 Nm (7.37 lbf ft) 3 Breather stud bolt - 1 8 Nm (5.90 lbf ft) Loctite 243

4 Gear oil magnetic drainage cap - 1 24 Nm (17.70 lbf ft) 5 Oil filler cap M18x1.5 1 28 Nm (20.65 lbf ft) -

Overhaul data

Assembly clearances

Cylinder - piston assy.

Measurement of the cylinder diameter must be done at three heights, turning the dial gauge 90°.

Check that cylinders and pistons are of the same selection types (D, E, F).

Check clearance between cylinders and pistons on the selected diameter; if it exceeds the value specified, it is necessary to replace cylinders and pistons.

The pistons of an engine must be balanced; a weight difference of up to 1.5 g (0.0033 lb) is allowed.

PISTON - CYLINDER SELECTION TYPES

Specification

Piston diameter - selection D 94.935 - 94.945 mm (3.73759 - 3.73798 in)

Cylinder diameter - selection D 95.000 - 95.010 mm (3.74015 - 3.74054 in)

Piston diameter - selection E 94.945 - 94.955 mm (3.73798 - 3.73837 in)

Cylinder diameter - selection E 95.010 - 95.020 mm (3.74054 - 3.74093 in)

Piston diameter - selection F 94.955 - 94.965 mm (3.73837 - 3.73877 in)

Cylinder diameter - selection F 95.020 - 95.030 mm (3.74093 - 3.74133 in)

Desc./Quantity

CHAR - 50

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

PIN - PISTON COUPLING

Specification Desc./Quantity

Pin diameter 21.998 - 21.994 mm (0.86606 - 0.86590 in)

Pin hole diameter on piston 22.016 - 22.011 mm (0.86677 - 0.86657 in)

Clearance between pin and holes on piston 0.013 - 0.022 mm (0.00051 - 0.00087 in)

Piston rings

On each piston there are:

•

1 top piston ring;

•

1 middle piston ring;

•

1 oil scraper piston ring.

Turn the rings so that the coupling ends are 120 degrees from each other.

CLEARANCE BETWEEN PISTON RINGS AND SEATS ON PISTON

Specification Desc./Quantity

Top ring 0.030 - 0.065 mm (0.00118 - 0.00256 in)

Middle ring 0.020 - 0.055 mm (0.00079 - 0.00216 in)

Oil scraper ring 0.010 - 0.045 mm (0.00039 - 0.00177 in)

Gap between the end of the piston rings inserted in the cylinder:

•

Top and middle piston ring: 0.40 - 0.65 mm (0.00158 - 0.00255 in)

•

Oil scraper piston ring: 0.30 - 0.60 mm (0.00118 - 0.00236 in).

Crankcase - crankshaft - connecting rod

CRANKSHAFT SEAT (TIMING SYSTEM SIDE)

Specification

Diameter of crankshaft main journal, timing system side 37.975 - 37.959 mm (1.49507 - 1.49444 in)

Inside diameter of crankshaft bushing, timing system side 38.016 - 38.0 mm (1.49669 - 1.49606 in)

Clearance between bushing and main journal (timing system

side)

0.025 - 0.057 mm (0.00098 - 0.00224 in)

CRANKSHAFT SEAT ( CLUTCH SIDE)

Specification

Diameter of crankshaft main journal, clutch side 53.97 - 53.961 mm (2.12480 - 2.12444 in)

Inside diameter of crankshaft bushing on clutch-side flange 54.019 - 54.0 mm (2.12673 - 2.12598 in)

Clearance between bushing and main journal (clutch side) 0.030 - 0.058 mm (0.00118 - 0.00228 in)

Desc./Quantity

Desc./Quantity

CHAR - 51

Characteristics Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Slot packing system

•

Fit both pistons on the connecting rods.

•

Working from both sides, fit the gasket

between the crankcase and the cylinder on the crankcase.

•

Fit both cylinders.

•

Take the left cylinder piston to TDC and

lock crankshaft rotation.

Specific tooling

020675Y Service shaft gear lock

•

Thoroughly clean the upper surface of

both cylinders.

•

Place the tool on the left cylinder to determine the "squish" (X).

•

Fasten the tool with the nuts of the stud

bolts.

Specific tooling

020676Y Comparator support for piston position checking

•

Reset the micrometer on the cylinder rim.

•

Move the tool so that the micrometer feeler reaches the top point of the piston crown.

•

Take note of the measurement and, according to the values found, consult the chart at the

bottom of the page to decide the thickness of the gasket to be fitted between cylinder and

head.

•

Unlock crankshaft rotation.

•

Rotate the crankshaft by 90°until the right cylinder piston reaches the TDC.

•

Lock crankshaft rotation.

•

Place the tool on the right cylinder stud bolts to determine the "squish" (X).

Specific tooling

020676Y Comparator support for piston position checking

CHAR - 52

Stelvio 1200 NTX MY11 Characteristics

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

•

Repeat the same operations to determine the thickness of the left cylinder gasket between

cylinder and head also for the right cylinder.

CYLINDER GASKET THICKNESS - HEAD

Specification Desc./Quantity

Value (X) -0.56 / -0.37 mm (-0.022 / -0.0146 in) gasket thickness: 0.65 mm (0.0256 in)

Value (X) -0.37 / -0.19 mm (-0.0146 / -0.0075 in) gasket thickness: 0.85 mm (0.0335 in)

Value (X) -0.19 / 0 mm (-0.0075 / 0 in) gasket thickness: 1.05 mm (0.0413 in)

Recommended products chart

RECOMMENDED PRODUCTS

Product Description Specifications

ENI i-RIDE PG RACING 10W-60 Engine oil SAE 10W - 60. As an alternative to rec-

AGIP GEAR SAE 80 W 90 Transmission oil -

AGIP GEAR MG/S SAE 85 W 90 Gearbox oil -

AGIP ARNICA SA 32 Fork oil SAE 0W - ISO VG 32

AGIP GREASE SM2 Lithium grease with molybdenum for

bearings and other points needing lubri-

cation

Neutral grease or petroleum jelly. BATTERY POLES

AGIP BRAKE 4 / BRAKE 5.1 Brake fluid As an alternative for recommended flu-

AGIP BRAKE 4 / BRAKE 5.1 Clutch fluid As an alternative for recommended flu-

ommended fluids, use top branded oils

with performances that meet or exceed

the requirements of CCMC G-4 API. SG

specifications.

NLGI 2

ids, use top branded fluids that meet or

exceed the requirements of SAE J1703,

NHTSA 116 DOT 4, ISO 4925 synthetic

fluid specifications.

ids, use top branded fluids that meet or

exceed the requirements of SAE J1703,

NHTSA 116 DOT 4, ISO 4925 synthetic

fluid specifications.

CHAR - 53

INDEX OF TOPICS

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

SPECIAL TOOLS S-TOOLS

Stelvio 1200 NTX MY11 Special tools

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

MOTORE

Stores code Description

020677Y Generator belt tensioner, lever for belt

05.91.17.30 Front cover insertion cone

020716Y Connecting rod locking

tensioning

020470Y Pin snap ring fitting tool

05.92.72.30 Timing system cover sealing ring punch

01.92.91.00 Wrench for removing the cover on sump

and filter

S-TOOLS - 55

Special tools Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Stores code Description

05.90.25.30 Gearbox support

19.92.96.00 Graduated dial to control ignition timing

12.91.18.01 Tool to lock the flywheel and the starting

12.91.36.00 Tool to remove the flywheel-side flange

AP8140179 Support for valve fitting/removal

AP9100838 Tool for valve pressure plate

ring gear

14.92.71.00 Tool to fit the sealing ring on the flywheelside flange

S-TOOLS - 56

Stelvio 1200 NTX MY11 Special tools

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Stores code Description

12.91.20.00 Tool to fit the flywheel-side flange together with sealing ring on the crankshaft

19.92.71.00 Tool to fit the seal ring on the flywheel-

020673Y Graduated dial hub

020672Y Clutch spring centre and pusher

020674Y Piston ring clamp

side flange

020675Y Service shaft gear lock

020676Y Comparator support for piston position

checking

S-TOOLS - 57

Special tools Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Stores code Description

020678Y Tool for clutch rod checking

05.91.25.30 Gearbox opening

CHASSIS

Stores code Description

14.91.26.03 Hook spanner for fixing ring nut of the

clutch shaft internal body

AP8140190 Tool for steering tightening

BEVEL GEAR SET

Stores code

05.90.27.30 Gearbox support

Description

S-TOOLS - 58

Stelvio 1200 NTX MY11 Special tools

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Stores code Description

05.90.27.31 Gearbox oil seal buffer

05.90.27.32 Buffer handgrip

05.90.27.33 Ball joint sealing buffer

05.90.27.34 Wrench for pinion ring nut

05.90.27.35 Pinion oil seal buffer

FRONT FORK

Stores code

AP8140146 Weight

Description

S-TOOLS - 59

Special tools Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Stores code Description

AP8140149 Protection for fitting operations

9100903 Marzocchi fork oil seal; ø 45 mm (1.77 in)

S-TOOLS - 60

INDEX OF TOPICS

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

MAINTENANCE MAIN

Maintenance Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Maintenance chart

NOTE

CARRY OUT MAINTENANCE OPERATIONS AT HALF THE INTERVALS SPECIFIED IF THE VEHICLE IS USED IN PARTICULAR RAINY OR DUSTY CONDITIONS, OFF ROAD OR FOR TRACK

USE.

Routine maintenance table

I: INSPECT AND CLEAN, ADJUST, LUBRICATE OR REPLACE IF NECESSARY

C: CLEAN, R: REPLACE, A: ADJUST, L: LUBRICATE

(1) Check and clean and adjust or replace, if necessary, before every journey.

(2) Replace every 2 years or 20000 Km (12427 mi).

(3) Replace every 4 years.

(4) Check at each engine start.

(5) It is recommended to lubricate stands and footrests periodically with spray grease after use in particularly hard conditions (dirty with salts, dust, etc.) or after long inactivity periods.

(6) Lubricate if you are riding in the rain, on wet roads or after the vehicle has been washed.

ROUTINE MAINTENANCE TABLE

km x 1,000

Exhaust pipe flange bolts I I I I I

Spark plugs R R R R R R R R

Carburetion at idle (CO) I I I I I I I I

Throttle body C C C C

Stands (5) I I I I I I I I

Transmission cables and controls I I I I I I I I I

Alternator belt A A R A A

Steering bearings and steering clearance I I I I I I I I I

Wheel bearings I I I I I I I I

Brake discs I I I I I I I I I

Air filter I R I R I R I R

Engine oil filter R R R R R R R R R

Fork I I I I I

Vehicle general operation I I I I I I I I I

Braking systems I I I I I I I I I

Light circuit I I I I I I I I I

Safety switches I I I I I

Brake fluid (2) I I R I R I R I R

Clutch fluid (2) I I I I I I I I I

Gearbox oil R R R R R R R R R

Engine oil R R R R R R R R R

Fork oil / oil seals R R R R

Final drive oil R R R R R R R R R

Clutch lever pin (6) L L L L L L L L L

Tyres - pressure / wear (1) I I I I I I I I I

Engine idle speed A A A A A A A A A

Valve clearance adjustment A A A A A A A A A

Wheels I I I I I I I I I

Bolts and nuts tightening I I I I I I I I I

Battery terminals tightening I I I I I

Wheel nipple tightening (1) I I I I I I I I I

Cylinder synchronisation I I I I I I I I I

Footrests joint (5) I I I I I I I I

Suspension and setting I I I I I

Engine oil pressure warning light (4)

Empty oil drain pipe from the filter housing C C C C C C C C

Fuel lines (3) I I I I I I I I

1.5 10 20 30 40 50 60 70 80

MAIN - 62

Stelvio 1200 NTX MY11 Maintenance

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

km x 1,000 1.5 10 20 30 40 50 60 70 80

Brake lines (3) I I I I I I I I

Clutch wear I I I I I I I I

Brake pad wear (1) I I I I I I I I I

Transmission fluid

Check

• Keep the vehicle upright with both wheels on the

ground.

• Unscrew and remove the cap/dipstick (1).

• The level is correct if the oil is close to the hole

of the cap/dipstick (1).

• If the oil is lower than specified, top-up until it

reaches the cap/dipstick hole (1).

CAUTION

DO NOT ADD ADDITIVES OR ANY OTHER SUBSTANCE TO

THE FLUID. WHEN USING A FUNNEL OR ANY OTHER ELEMENT, MAKE SURE IT IS PERFECTLY CLEAN.

Replacement

CAUTION

THE UNIT MUST BE HOT WHEN THE OIL IS CHANGED AS UNDER SUCH CONDITIONS OIL IS

FLUID AND THEREFORE EASY TO DRAIN.

NOTE

RIDE SOME km (miles) TO WARM UP ENGINE OIL

•

Place a container with + 400 cm³ (25 cu in) capacity under the drainage plug (3).

•

Unscrew and remove the drainage plug (3).

•

Unscrew and remove the breather cap (2).

•

Drain the oil into the container; allow several minutes for oil to drain out completely.

•

Check and if necessary, replace the sealing washer of drainage plug (3).

•

Remove any metal scrap attached to the drainage plug (3) magnet.

•

Screw and tighten the drainage plug (3).

•

Pour new oil through the fill opening (1) until it reaches the cap/dipstick hole (1).

CAUTION

DO NOT ADD ADDITIVES OR ANY OTHER SUBSTANCE TO THE FLUID. WHEN USING A FUNNEL

OR ANY OTHER ELEMENT, MAKE SURE IT IS PERFECTLY CLEAN.

MAIN - 63

Maintenance Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

•

Screw and tighten the caps (1 - 2).

Engine oil

Check

CAUTION

ENGINE MUST BE WARM TO CHECK ENGINE OIL LEVEL

NOTE

DO NOT LET THE ENGINE IDLE WITH THE VEHICLE AT STANDSTILL TO WARM UP THE ENGINE

AND REACH THE OPERATING TEMPERATURE OF ENGINE OIL. OIL IS BEST CHECKED AFTER

RUNNING FOR ABOUT 15 KM (10 miles).

•

Shut off the engine.

•

Keep the vehicle upright with both wheels on the ground.

•

Pull the filler plug / oil level dipstick (1)

straight out.

•

Wipe the oil level dipstick (1) clean and

reinsert it.

•

Pull it out again and check the oil level.

•

The oil level is correct when it is close

to the "MAX" mark. Otherwise, top-up

with engine oil.

CAUTION

DO NOT ADD ADDITIVES OR ANY OTHER SUBSTANCE TO THE OIL. WHEN USING A FUNNEL

OR ANY OTHER ELEMENT, MAKE SURE IT IS PERFECTLY CLEAN.

Replacement

NOTE

HOT OIL IS LESS VISCOUS AND WILL DRAIN OUT MORE EASILY AND COMPLETELY.

It is necessary to remove the metal oil sump guard in order to change the engine oil and replace the oil

filter:

•

Operating from both sides, unscrew and remove both screws (1).

•

Remove the oil sump guard.

MAIN - 64

Stelvio 1200 NTX MY11 Maintenance

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

•

Place a container with +4,000 cm³ (244

cu in) capacity under the drainage plug

(3).

•

Unscrew and remove the drainage

plug (3).

•

Pull out the oil filler plug / engine oil

level dipstick (4).

•

Drain the oil into the container; allow

several minutes for oil to drain out completely.

•

Insert the oil filler plug / engine oil level

dipstick (4).

•

Check and if necessary, replace the

drainage plug (3) sealing washers.

•

Remove any metal deposits attached

to the drainage plug (3) magnet.

•

Screw and tighten the drainage plug

(3).

DO NOT DISPOSE OF OIL INTO THE ENVIRONMENT.

DISPOSE OF ENGINE OIL IN A SEALED CONTAINER AND

TAKE IT TO YOUR SUPPLIER OR TO THE NEAREST USED

OIL COLLECTION CENTRE.

MAIN - 65

Maintenance Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Engine oil filter

Replace the engine oil filter each time you

change the engine oil.

•

Drain the engine oil completely.

•

Unscrew and remove the engine oil filter from its seat.

NOTE

NEVER REUSE AN OLD FILTER.

•

Spread a thin layer of oil on the sealing ring of the new engine oil filter.

•

Fit and screw the new oil filter in its seat.

Gearbox Oil

Inspection

CHECKING AND TOPPING UP

CAUTION

ENGINE MUST BE WARM TO CHECK GEARBOX OIL LEVEL.

NOTE

DO NOT LET THE ENGINE IDLE WITH THE VEHICLE AT STANDSTILL TO WARM UP THE ENGINE

AND REACH THE OPERATING TEMPERATURE OF ENGINE OIL. OIL IS BEST CHECKED AFTER

RUNNING FOR ABOUT 15 KM (10 miles).

•

Shut off the engine.

•

Keep the vehicle upright with both

wheels on the ground.

•

Unscrew and remove the cap/dipstick

(1) placed on the gearbox right side.

•

• The level is correct if the oil is on the

rim of the hole of the cap/dipstick (1).

If necessary:

•

Top-up with oil until it reaches the dipstick opening (1).

CAUTION

DO NOT ADD ADDITIVES OR ANY OTHER SUBSTANCE TO

THE FLUID. WHEN USING A FUNNEL OR ANY OTHER ELEMENT, MAKE SURE IT IS PERFECTLY CLEAN.

Replacement

NOTE

HOT OIL IS MORE FLUID AND WILL DRAIN OUT MORE EASILY AND COMPLETELY.

MAIN - 66

Stelvio 1200 NTX MY11 Maintenance

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

• Place a container with suitable capacity under the

drainage plug (2).

• Unscrew and remove the drainage plug (2).

• Unscrew and remove the filler cap (1).

• Drain the oil into the container; allow several minutes for oil to drain out completely.

• Check and replace, if necessary, the sealing

washers of drainage plug (2).

• Remove any metal scrap attached to the drainage plug (2) magnet.

• Screw and tighten the drainage plug (2).

• Pour in new oil until it reaches the dipstick opening (1).

• Tighten the filler cap (1).

CAUTION

DO NOT ADD ADDITIVES OR ANY OTHER SUBSTANCE TO

THE FLUID. WHEN USING A FUNNEL OR ANY OTHER ELEMENT, MAKE SURE IT IS PERFECTLY CLEAN.

Air filter

AIR FILTER

pos.

1 Vite fissaggio cassa filtro aria a telaio - 2 10 Nm (7.38 lbf ft) 2 Air filter box cover fastening screw SWP 5x20 6 3 Nm (2.21 lbf ft) -

Description Type Quantity Torque Notes

MAIN - 67

Maintenance Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

•

Undo and remove the six screws.

•

Lift the filter housing cover.

•

Remove the air filter.

•

Cover the inlet duct with a clean cloth so that no foreign bodies get into the inlet ducts.

DO NOT START THE ENGINE WITHOUT THE AIR FILTER.

TO CLEAN THE FILTERING ELEMENT, USE A PRESSURE AIR JET FROM THE INSIDE TO THE

OUTSIDE.

Checking the valve clearance

If the timing system is very noisy, check the clearance between the valves and the rocking levers.

NOTE

ADJUST WITH COLD ENGINE, WITH PISTON AT TOP DEAD CENTRE (TDC) IN COMPRESSION

STROKE (VALVES CLOSED).

•

Scollegare la pipetta candela facendo

leva mediante un cacciavite attraverso

la feritoia.

CAUTION

PRESTARE ATTENZIONE A FARE LEVA SULLA GOMMA

DELLA PIPETTA CANDELA E NON SULLA CANDELA

STESSA ONDE EVITARE DI DANNEGGIARLA

MAIN - 68

Stelvio 1200 NTX MY11 Maintenance

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

•

Unscrew and remove the four head

cover fixing screws and collect the

sealing O-rings.

•

Remove the head cover together with

the gasket.

•

loosen the nut (1);

•

use a screwdriver on the set screw (2)

until the following clearances are obtained:

- inlet valve: 0.10 mm (0.0039 in)

- outlet valve: 0.15 mm (0.0059 in).

•

The measurement must be done using

a thickness gauge (3).

CAUTION

IF CLEARANCE IS LARGER THAN RECOMMENDED, THE TAPPET WILL BE NOISY. OTHERWISE, THE VALVES DO NOT CLOSE CORRECTLY, WHICH CAN LEAD TO PROBLEMS SUCH

AS:

•

PRESSURE DROP;

•

ENGINE OVERHEAT;

•

VALVE BURNOUT, ETC.

Braking system

Level check

Brake fluid check

•

Rest the vehicle on its stand.

•

For the front brake, turn the handlebar fully to the right.

•

For the rear brake, keep the vehicle upright so that the fluid in the reservoir is at the same

level with the plug.

•

Make sure that the fluid level in the reservoir is above the "MIN" reference mark:

MIN = minimum level

MAX = maximum level

If the fluid does not reach at least the "MIN" reference mark:

•

Check brake pads and disc for wear.

•

If the pads and/or the disc do not need replacing, top-up the fluid.

MAIN - 69

Maintenance Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Top-up

Front brake:

•

Unscrew the two screws (1) of the

brake fluid reservoir (2) using a Phillips

screwdriver.

•

Lift and remove the cover (3) and

screws (1) as well.

•

Remove the gasket (4).

Rear brake:

•

Unscrew and remove the cap (5).

•

Remove the gasket (6).

•

Top-up the reservoir with brake fluid to

the correct level, which is between the

two "MIN" and "MAX" reference marks.

RISK OF BRAKE FLUID SPILLS. DO NOT OPERATE THE

BRAKE LEVER WITH BRAKE FLUID RESERVOIR CAP

LOOSENED OR REMOVED.

CAUTION

AVOID PROLONGED AIR EXPOSURE OF THE BRAKE

FLUID. BRAKE FLUID IS HYGROSCOPIC AND ABSORBS

MOISTURE WHEN IN CONTACT WITH AIR. LEAVE THE

BRAKE FLUID RESERVOIR OPEN ONLY FOR THE TIME

NEEDED TO COMPLETE THE TOPPING UP PROCEDURE.

TO AVOID SPILLING FLUID WHILE TOPPING-UP, KEEP

THE TANK PARALLEL TO THE RESERVOIR EDGE (IN

HORIZONTAL POSITION).

DO NOT ADD ADDITIVES OR OTHER SUBSTANCES TO

THE FLUID.

WHEN USING A FUNNEL OR ANY OTHER ELEMENT,

MAKE SURE IT IS PERFECTLY CLEAN.

DO NOT EXCEED THE "MAX" LEVEL MARK WHEN TOPPING UP.

TOP-UP TO "MAX" LEVEL MARK ONLY WHEN BRAKE

PADS ARE NEW. WHEN TOPPING UP DO NOT EXCEED

THE "MAX" LEVEL MARK WHEN BRAKE PADS ARE

WORN AS YOU RISK SPILLING FLUID WHEN CHANGING

THE BRAKE PADS.

CHECK BRAKING EFFICIENCY. IN CASE OF EXCESSIVE

TRAVEL OF THE BRAKE LEVER OR POOR PERFORMANCE OF THE BRAKING SYSTEM, TAKE YOUR VEHICLE

MAIN - 70

Stelvio 1200 NTX MY11 Maintenance

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

TO AN Official Moto Guzzi Dealer, AS IT MAY BE NECESSARY TO PURGE THE AIR IN THE SYSTEM.

MAIN - 71

INDEX OF TOPICS

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

ELECTRICAL SYSTEM ELE SYS

Stelvio 1200 NTX MY11 Electrical system

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

MAIN CABLE HARNESS

pos.

1 Viti TE Flang. fissaggio piastre bobine M6x20 2+2 10 Nm (7.38 lbf ft) 2 Viti TCEI fissaggio bobine - 2+2 2 Nm (1.47 lbf ft) 3 Viti TCEI fissaggio centralina - 2 10 Nm (7.38 lbf ft) 4 Viti TCEI fissaggio supporto sensore temp.

5 Viti TCEI fissaggio sensore di fase - 2 3 Nm (2.21 lbf ft) -

Description Type Quantity Torque Notes

M10x20 1 11 Nm (8.11 lbf ft) Loct. 243

olio

ELE SYS - 73

Electrical system Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Components arrangement

Key:

1 Coil

2 Instrument panel

3 Fuel pump

4 Injector

5 Throttle valve potentiometer

ELE SYS - 74

Stelvio 1200 NTX MY11 Electrical system

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

6 Fall sensor

7 Rear light

8 Main fuses

9 Oxygen sensor

10 Battery

11 Starter motor

12 Intake air temperature sensor

13 Engine revolution sensor

14 Head temperature sensor

15 Engine control unit

16 Instrument panel air temperature sensor

17 Front headlamp

18 Alternator

19 Oil pressure sensor

20 Speed sensor

21 Auxiliary fuses

22 Relay

23 Additional headlamps

24 ABS Control unit

25 Rear speed sensor

26 ABS Fuses

Electrical system installation

INTRODUCTION

Scope and applicability

This document aims at defining the cable harness routing in order to achieve the vehicle reliability

targets.

Materials used and corresponding quantities

The electrical system consists of the following cable harnesses and parts:

•

1 Main cable harness

•

1 Ground lead

•

1 Headlamp cable harness

•

1 Fall sensor connector

•

1 Antitheft cable harness (optional equipment)

•

8 Small clamps

•

18 Medium clamps

•

1 Big clamp

ELE SYS - 75

Electrical system Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

•

4 Reused clamps

•

7 Cable grommets

•

5 Rubber clamps

•

7 Cable grommets

•

1 Adhesive cable grommet

•

1 Cable grommet with clip

Motorcycle division

The wiring timing is subdivided in three essential

sections, as indicated in the figure.

1. Front section

2. Central section

3. Rear part

Special checks for the correct connection and laying of cables

It is extremely important that any security-locks for the following connectors are properly connected and

correctly tightened to ensure proper engine, and therefore proper vehicle, operation.

•

Instrument panel connector

•

Pick Up connector and alternator

•

Side Stand Switch Connector

•

Coils connectors

•

Control unit connectors

•

Fuel pump connector

•

Key Connector

•

Right Light Switch Connectors

•

Left Light Switch Connectors

•

ABS connector and correct positioning of the cap

•

Front and rear speed sensor connector

•

Auxiliary Fuses (rubber housing correct positioning and closing)

•

Intake air temperature sensor

•

Fuel injector connectors

The connectors in the list are circled in the different pictures. The listed connectors are considered more critical than the others because their disconnection could cause the vehicle to

stop or malfunction. Obviously, the correct connection of the other connectors is also important

and essential for proper vehicle operation.

It is also important and essential that the instructions regarding the routing and fixing of the cable harness in the various areas are followed meticulously in order to guarantee functionality and reliability.

ELE SYS - 76

Stelvio 1200 NTX MY11 Electrical system

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Front side

TABLE A

1. Front headlamp

2. Small clamps

3. Cable grommet

4. Headlamp cable harness

TABLE B

1. Rubber clamps

TABLE C

1. Front brake switch

2. Faston

•

Check the faston are connected up to

the end.

TABLE D

1. Cable grommets

2. Pipe tightening clamp

3. Front ABS sensor

ELE SYS - 77

Electrical system Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

TABLE E

1. Main cable harness

2. Small clamp

3. Middle clamp

TABLE F

1. Middle clamp

2. Clamp already present on the cable harness

ELE SYS - 78

Stelvio 1200 NTX MY11 Electrical system

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

TABLE G

1. Medium clamp

TABLE H

•

No part of the cable harness must protrude to the inside of the support so as

not to obstruct the forks

TABLE I

1. Clamp that groups the cable harness of the right

light switch, the front stop switch, the front ABS

sensor and the key

TABLE L

1. Medium clamps

2. Small clamps

ELE SYS - 79

Electrical system Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

TABLE M

•

Check correct closure of the secondary

fuses housing cover

TABLE N

1. Middle clamp

2. Ground lead oriented as in the photo

3. Small clamp

4. Cable grommet

TABLE O

1. Medium clamps

TABLE P

1. Clamp that has the cable harness of the left light

switch and the key on the metal relay

2. Clamp that has the cable harness of the left light

switch on the pipe

3. Middle clamp

ELE SYS - 80

Stelvio 1200 NTX MY11 Electrical system

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

TABLE Q

1. Keep the cable harness outwards according to

the relay

2. Clamp

TABLE R

1. Middle clamp

TABLE S

1. Hook the clamp on the specific hole present in

the support.

2. Middle clamp

TABLE T

1. Front plug socket

2. Plug socket connector.

3. Correct alignment

4. Medium clamp to be placed after fitting the cap

so as to avoid it can remove

ELE SYS - 81

Electrical system Stelvio 1200 NTX MY11

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

TABLE U

1. Instrument panel

2. Instrument panel connector correctly connected

Central part

TABLE A

1. Main cable harness

2 Motor main cable harness

3. Grey taping as reference that must remain between the two covers

TABLE B

1. Engine oil pressure sensor

2. Small clamp

TABLE C

1. Generator

2. Sensor

3. Alternator positive

ELE SYS - 82

Stelvio 1200 NTX MY11 Electrical system

Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

TABLE D

1. Pick up cable harness

2. Medium clamp that fastens the right pick-Up cable to the chassis

TABLE E

1. Reused clamp

TABLE F

1. Cable guide

2. Plastic cable guides

TABLE G

1. Neutral switch

•

Correctly fit the hood on the gear

switch

ELE SYS - 83

Electrical system Stelvio 1200 NTX MY11