Moto Guzzi MG S01 Corsa 1949-2008 Manual de reparatie

Minibook

1

Minibook

www.guzzitek.org - Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

SUMMARY

0 FOREWORD............................................................................................................................................. 3

2 GENERAL FEATURES............................................................................................................................. 4

5 MAINTENANCE AND SETTINGS ............................................................................................................ 5

5.7.1 CHANGING THE AIR FILTER ............................................................................................................... 5

7 TIGHTENING TORQUE SETTINGS ........................................................................................................ 6

11 ENGINE UNIT ........................................................................................................................................... 7

11.2 REFITTING THE ENGINE............................................................................................................................... 7

11.3 CAM TIMING ................................................................................................................................................... 7

11.4 INSPECTIONS ................................................................................................................................................ 8

12 INJECTION – IGNITION SYSTEM ......................................................................................................... 14

12.1 INTAKE AIR CIRCUIT ................................................................................................................................... 14

12.3 FUEL CIRCUIT .............................................................................................................................................. 14

12.4 AIR CIRCUIT ................................................................................................................................................. 14

12.5 ELECTRIC CIRCUIT ..................................................................................................................................... 15

12.6 CALIBRATION STANDARDS FOR CHECKING AND SETTING CARBURETION ....................................... 15

12.11 FUNCTION OF THE "CHECK LAMP" FOR FAULT DIAGNOSIS.................................................................. 16

12.12 CONTROL UNIT RESET PROCEDURE ....................................................................................................... 16

12.13 SPARK PLUGS ............................................................................................................................................. 16

12.14 FUEL VAPOUR RECYCLING SYSTEM........................................................................................................ 16

13 CLUTCH.................................................................................................................................................. 17

14 GEARBOX .............................................................................................................................................. 17

15 REAR TRANSMISSION SHAFT AND BOX............................................................................................ 17

21 BATTERY................................................................................................................................................ 18

21.1 BATTERY ...................................................................................................................................................... 18

PROCEDURE FOR ROAD RUNNING-IN ....................................................................................................... 19

SCHEDULED MAINTENANCE ....................................................................................................................... 20

2

www.guzzitek.org - Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

Minibook

0 FOREWORD

NOTE The content of this Manual is not binding and GUZZI reserves the right to make alterations, if and when required,

of components, accessories, tooling, etc. which are deemed suitable for the purpose of improvement or for any technical

- commercial requirement, or in order to comply with law provisions in the different countries, without however

undertaking to promptly update this Manual.

- The purpose of this manual is to give the necessary instructions to rationally carry out the overhaul and repair

operations.

- The mentioned data are specified to give overall knowledge of the main inspections to be carried out while

overhauling the various assemblies.

- For this reason, the manual contains pictures, drawings and diagrams, necessary for the operations of removal,

inspection and installation.

- The manual is also a guide for the people who want to know the parts of the vehicle under exam: knowing these

parts is an essential feature for doing a good repair job.

NOTE The following information should be intended as variant to the Workshop manual - engine - for version V10

Centauro.

First edition: February 2005

Produced and printed by:

DECA s.r.l.

via Vincenzo Giardini, 11 - 48022 Lugo (RA) - Italy

Tel. +39 - 0545 246610

Fax +39 - 0545 32844

E-mail: deca@decaweb.it

www.decaweb.it

On behalf of:

Moto Guzzi s.p.a.

via E.V. Parodi, 57- 23826 Mandello del Lario (Lecco) - Italy

Tel. +39 - 709111-0341

Fax +39 - 709220-0341

www.motoguzzi.it

www.servicemotoguzzi.com

3

Minibook

www.guzzitek.org - Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

2 GENERAL FEATURES

ENGINE

Bore 100 [mm]

Stroke 78 [mm]

Total displacement 1225 [cu. cm]

Compression ratio 11.6 : 1

Maximum torque 112 [Nm] (11.4 [Kgm]) at 6400 [rpm]

Maximum power 90.2 [Kw] (122.7 [HP]) at 8000 [rpm]

TIMING SYSTEM

Overhead camshaft and 4 valves per cylinder.

Primary control with duplex chain, automatic tensioner and toothed belt.

For the primary chain installation and setting data, see version V11.

Timing system data (referred to tappet lift of 1 [mm]) are the following:

Intake

opens at 36° before TDC

closes at 69° 30' after BDC.

Exhaust

opens at 64° before BDC

closes at 38° after TDC.

Operating clearance with cold engine

intake valve 0.10 [mm]

exhaust valve 0.15 [mm]

LUBRICATION

There is no thermostatic valve.

GENERATOR

See model V11

TRANSMISSION

Primary transmission With gears, ratio 1:1.55 (Z=20/31)

Ignition Spark plug: Champion RA59GC

Gearbox The following information should be intended as variant to the Workshop

Final transmission

Total ratios (engine wheel)

1st gear 1:10.821 (Z=15/36)

2nd 1:8.017 (Z=18/32)

3rd 1:6.150 (Z=22/30)

4th 1:5.009 (Z=27/30)

5th 1:4.355 (Z=29/28)

6th 1:3.841 (Z=27/23)

PERFORMANCE

Maximum speed 255 [km/h]

TOP-UPS

Engine sump

Oil type: AGIP Racing 4T 5W40

Quantity: 3.5 [l] check level

Gearbox

Oil type: AGIP Rotra MPS 85W90

Quantity: 0.85 [l] check level

Bevel gears

Oil type: AGIP Rotra Truck Gear 85W140

Quantity: 0.37 [l] check level

manual - gearbox - for version V11

With six speeds, with constant mesh gears and front clutch dogs.

Integrated cush drive damper.

Control through a pedal on vehicle left side.

The following information should be intended as variant to the Workshop

manual - rear transmission shaft and box - for version V11.

4

www.guzzitek.org - Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

5 MAINTENANCE AND SETTINGS

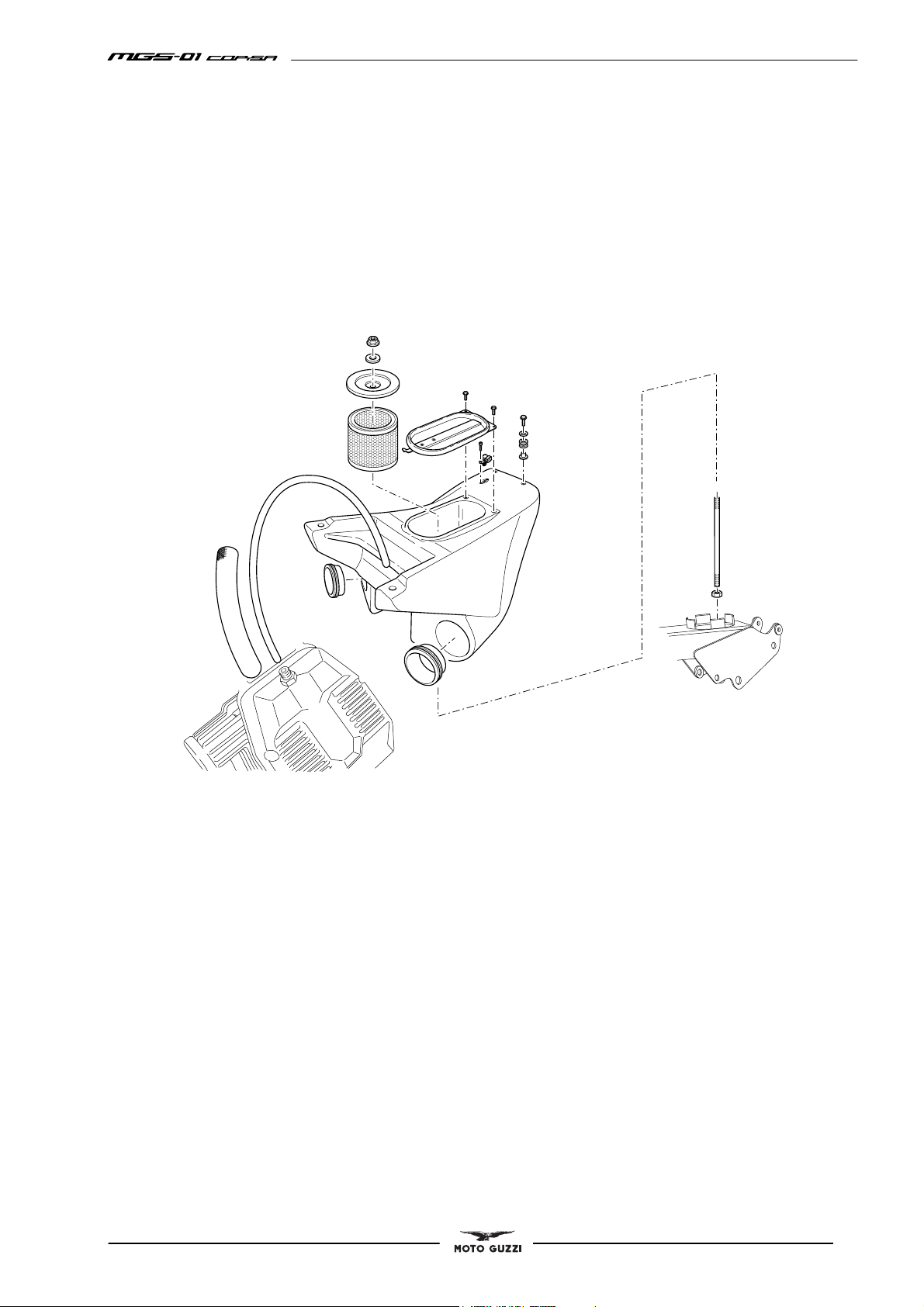

5.7.1 CHANGING THE AIR FILTER

Diagrams 05-12 and 05-13 are no longer valid.

See update

Minibook

5

Minibook

www.guzzitek.org - Revente Interdite - Revendita Vietata - Resaling Forbiden - Wiederverkauf Verboten

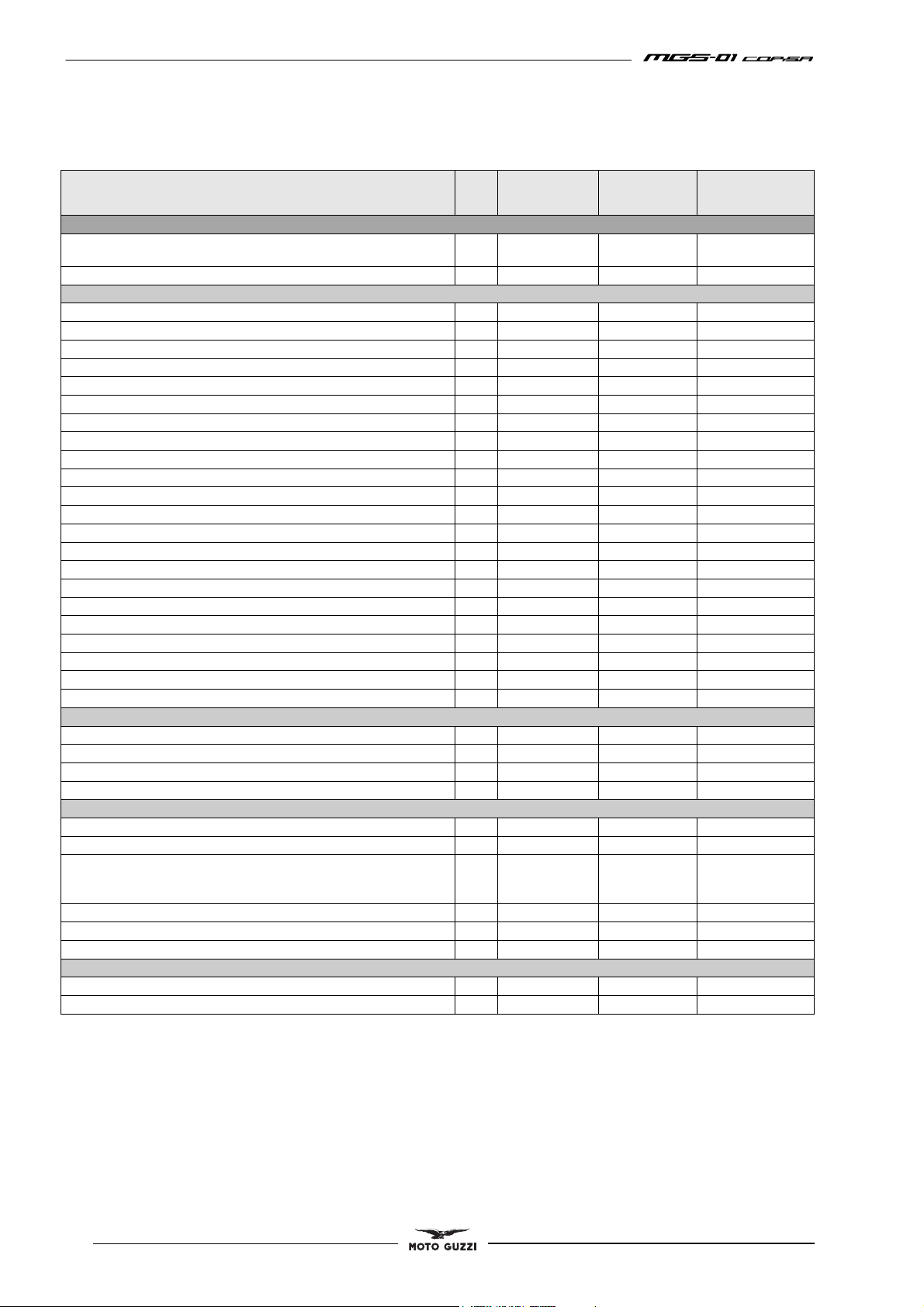

7 TIGHTENING TORQUE SETTINGS

Description Q.ty Measurement

ENGINE

Nuts for head-cylinder linkages, thread lubricated with SAE

85W90 oil

Nut for support securing stud bolt M8 28-32

Spark plugs

Drilled screws securing the head oil delivery hoses M10x1.25 18-20

Head temperature sensor box M10x1.25 12-15 (Loctite 648)

Head temperature sensor M12x1.25 12-15 (Loctite 243)

Screw securing crankshaft flanges M8 25-28 (Loctite 243)

Bolt securing con-rod cap, thread lubricated with SAE 85W90 5/16 UNF 57-62

Screws securing flywheel/crankshaft M8 42-45 (Loctite 243)

Screws securing flywheel crown M6 18-20 (Loctite 243)

Nut securing crankshaft sprocket M25x1.5 120-125

Generator locking nut M16x1.5 60-65

Nut securing shaft pulleys M16x1.5 115-120 (Loctite 243)

Nut securing camshafts pulleys M14x1.5 70-75 (Loctite 243)

Nut securing oil pump gear M8x1 22-25 (Loctite 243)

Oil pressure regulating valve M14x1.5 65-70 (Loctite 648)

Cam housing bushing screw M6 12-15 (Loctite 243)

Screws securing intake manifold lugs M6 12-15 (Loctite 243)

Crank pin plug on crankshaft M24x1.5 20-22 (Loctite 648)

Breather fitting from timing chain area M22x1 30-35 (Loctite 243)

Breather nozzle from heads M10x1 10-12 (Loctite 243)

Nut securing piston coolant nozzles M10x1 10-13 (Loctite 243)

Double screw securing oil nozzle hoses M10x1 10-12

Oil filter 15-20

Oil filter plug 40-45

Stud bolts tightening

Cylinder/head stud bolts on crankcase M10 32-35

Crankcase/gearbox stud bolts M8 28-30

Support/head stud bolts M8 28-30

Stud bolts securing exhaust to head M8 28-30 (Loctite 648)

Gearbox

Primary shaft ring nut on clutch side M25x1.5 100-105 (Loctite 648)

Primary shaft ring nut on cardan joint side M20x1 75-80 (Loctite 648)

Gearbox secondary shaft nut M17x1 90-95

Lower setting bushing (snug only) M20x1.5 10

Setting bushing locking ring nut M20x1.5 50-55

Screw securing linkage under gearbox M10 50-55

Bevel gears

Nut securing sprocket to bevel bearing 190-195

Fastening screws for cardan joint to transmission shaft M8 40-45

M10 32-35

Torque

Nm

Note

(Loctite 648 on

spline and

thread + riveting)

6

Loading...

Loading...