Page 1

MSD Servo Drive

Operation Manual

moog

Single-Axis Servo Drive Compact

C2 to C5

2.0 A to 16.0 A

Page 2

moog

C2 C3 C4 C5

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

2

MSDSingle-Axis Servo Drive Compact high-performance drives

The modularity of the MSD Single-Axis Servo Drive Compact guarantees you optimum

integration into the machine process. Whether in high-speed eld bus communication

with the central multi-axis machine controller or with distributed programmable Motion

Control intelligence in the servo drive, the MSD Single-Axis Servo Drive Compact is a

master o

f both.

MSDSingle-Axis Servo Drive Compact Operation Manual

ID no.: CA97555-001, Rev. 5.3

Date: 04/2018

Applicable as from firmware version:V1.25-01

The German version is the original of this Operation Manual.

We reserve the right to make technical changes.

This Operation Manual has been prepared based on DIN EN 82079-1. The content

was compiled with the greatest care and attention, and based on the latest information

available to us.

We should nevertheless point out that this document cannot always be updated in line

with ongoing technical developments in our products.

Information and specications may be subject to change at any time. For information on

the latest version please visit drives-support@moog.com

Page 3

Table of contents

1 General .................................................................................... 5

1.1 Target group ............................................................................................................. 5

1.2 Prerequisites ............................................................................................................. 5

1.3 Reference documents .............................................................................................. 5

1.4 Order code ............................................................................................................... 6

1.5 Production data ........................................................................................................ 6

1.6 Scope of supply........................................................................................................ 6

1.7 Pictograms ............................................................................................................... 7

1.8 Disclaimer ................................................................................................................. 7

1.9 Disposal ................................................................................................................... 7

1.10 Helpline/Support & Ser vice Center ........................................................................... 7

2 Safety ...................................................................................... 9

2.1 O ve r v ie w .................................................................................................................. 9

2.2 For your safety .......................................................................................................... 9

2.3 General safety instructions and warnings ................................................................10

2.4 Intended use ............................................................................................................ 10

2.4.1 Repair ............................................................................................................ 11

2.5 Usage contrar y to intended use...............................................................................11

2.6 Responsibility ..........................................................................................................11

2.7 Relevant laws, standards and directives applied ..................................................... 11

2.8 Declaration of conformity .........................................................................................12

3 Mechanical installation ........................................................... 13

3.1 Notes for operation ..................................................................................................13

3.2 Wall mounting ..........................................................................................................13

3.2.1 Dimensions of the devices .............................................................................14

3.2.2 Mounting clearances .....................................................................................15

4 Electrical installation ............................................................... 17

4.1 Notes for installation ................................................................................................17

4.2 Layout .....................................................................................................................18

4.3 Connection diagram C2 to C4 .................................................................................20

4.4 Connection diagram C5 ..........................................................................................21

4.5 Effective EMC installation ....................................................................................... 22

4.5.1 Interference immunity of Servo Drives .......................................................... 22

4.5.2 Specimen setup ........................................................................................... 22

4.6 Protective earth conductor connection....................................................................25

4.7 Electrical isolation concept ......................................................................................26

4.8 Connection of the supply voltages ..........................................................................27

4.8.1 Connection of control supply (+24VDC) .......................................................27

4.8.2 Connection of mains supply .........................................................................28

4.8.3 Connected load and mains fuse ................................................................... 29

4.9 Control connections ................................................................................................31

4.9.1 Specication of control connections .............................................................31

4.9.2 Connection of motor brake X13 .................................................................... 32

4.10 Specication, Ethernet interface ............................................................................. 33

4.11 Opt i o n 1 .................................................................................................................. 33

4.12 Option 2 .................................................................................................................. 33

4.13 Encoder connection ............................................................................................... 34

4.13.1 Ready made encoder cables ....................................................................... 34

4.13.2 Resolver connection X6 ................................................................................ 35

4.13.3 Connection for high-resolution encoder ....................................................... 36

4.14 Motor connection ....................................................................................................37

4.14.1 Motor temperature sensor .............................................................................37

4.14.2 Connection of the servo motors ................................................................... 38

4.14.3 Switching in the motor cable ........................................................................ 40

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

3

Page 4

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

4

4.15 Brake chopper connection ..................................................................................... 40

4.15.1 Protection in case of brake chopper fault ..................................................... 40

4.15.2 Design with integrated braking resistor (C3+4+5) ......................................... 40

4.15.3 Connection of an external braking resistor ....................................................42

5 Commissioning ...................................................................... 45

5.1 Notes for operation ................................................................................................. 45

5.2 Initial commissioning .............................................................................................. 45

5.2.1 Switching on control supply ......................................................................... 46

5.2.2 Establishing connection between PC and servo drive .................................... 46

5.2.3 Setting parameters ....................................................................................... 46

5.2.4 Controlling drive using Moog Dri veAD ministr Ator5 ....................................... 46

5.3 Serial commissioning .............................................................................................. 48

5.4 Integrated control unit ............................................................................................. 48

5.4.1 Function of buttons T1 and T2...................................................................... 49

5.4.2 Display .......................................................................................................... 50

5.4.3 Parameter menu (PA).................................................................................... 50

5.4.4 Error numbers .............................................................................................. 50

5.4.5 Ethernet IP address menu (IP) .......................................................................51

5.4.6 Field bus address menu (Fb) .........................................................................52

A Appendix ............................................................................... 59

A.1 Servo drive current loads ........................................................................................ 59

A.2 Technical data MSD Single-Axis Servo Drive Compact .......................................... 62

A.3 Ambient conditions ................................................................................................. 64

A.4 UL certication ....................................................................................................... 65

Glossary ........................................................................................ 67

6 Diagnostics ............................................................................ 55

6.1 Device states .......................................................................................................... 55

6.2 Error indication ....................................................................................................... 55

6.3 Error codes ............................................................................................................. 55

6.4 Helpline/Suppor t&Service .................................................................................... 56

7 Safe Torque Off (STO) ............................................................ 57

Page 5

MSDSingle-Axis Servo Drive Compact Operation Manual

moog

1 General

1.3 Reference documents

The product CD from Moog contains the complete documentation for the related

product series. The documentation for a product series includes the Operation Manual

(hardware description), Device Help (software description) as well as further User

Manuals (e.g. field bus description) and Specifications. They are available in the formats

PDF, HTML or chm.

1.1 Target group

Dear user,

the documentation forms part of the device and contains important information on

operation and service. It is aimed at all persons who undertake mounting, installation,

commissioning and servicing work on the product.

1.2 Prerequisites

Prerequisites for the usage of devices from Moog:

y The documentation on the devices is to be stored so it legible, accessible at all times and for the

entire life of the product.

y Read and ensure you under Date the documentation on your device.

y Qualication: to prevent injury or damage, personnel may only work on the device if they have

electrical engineering qualications.

y Knowledge required:

− National health and safety regulations (e.g. VBG 4 in Germany)

− Mounting, installation, commissioning and operation of the device

Work in other areas, for example transport, storage and disposal is only allowed to be

undertaken by trained personnel.

NOTE

This Operation Manual applies to the MSD Single-Axis Servo Drive Compact

(referred to in the following as the servo drive). This manual does not replace the

Operation Manuals for the MSD Single- and Multi-Axis Servo Drive.

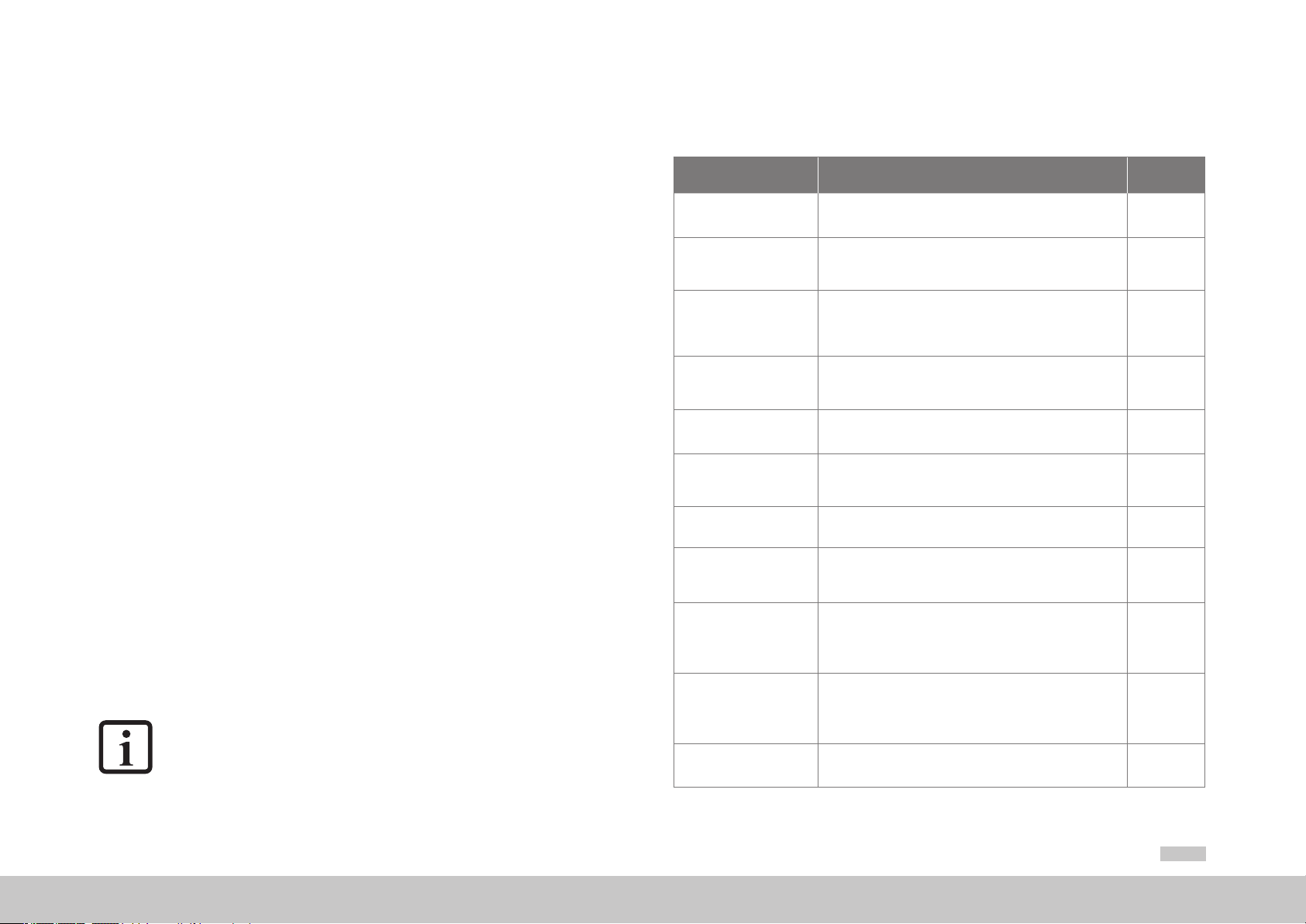

Document Contents

MSD Servo Drive

Single-Axis Servo Drive

Compact - Operation Manual

MSD Servo Drive

AC-AC Servo Drive

Single-Axis System Operation Manual

MSD Servo Drive

DC-AC Servo Drive

Multi-Axis SystemOperation Manual

MSD Power Supply Unit

Multi-Axis SystemOperation Manual

MSD Servo Drive

SERCOS II User Manual

MSD Servo Drive

SERCOS III User Manual

MSD Servo Drive Field bus

systems CANopen/EtherCAT User Manual

MSD Servo Drive

Field bus systems

Profibus/Profine

User Manual

Modular Multi-Axis Servo

Drive System - MSD Ordering Catalog

MSD Servo Drive - Device

Help

Program help

D

riveADminsitrAtor 5

Moog

PC user software

Safety, mechanical installation, electrical installation,

commissioning, diagnostics, specifications certification and

applicable standards, technical data

Safety, mechanical installation, electrical installation,

commissioning, diagnostics, specifications certification and

applicable standards, technical data

Safety, mechanical installation, electrical installation, commissioning,

diagnostics, STO, operation with AC-AC Servo Drive as supply,

planning, application example, specifications certification and

applicable standards, technical data

Safety, mechanical installation, electrical installation, commissioning,

diagnostics, specification certification and applicable standards

technical data

Safety, commissioning, communication phases, parameter interface,

error, warning and status messages, operation modes, weighting,

referencing, touchprobe, parameter lists

Safety, installation and connection, commissioning and configuration

parameterisation, data transmission, scaling and weighting,

functionality, error message and diagnostics, parameter lists

Safety, commissioning, data transmission, operation modes,

referencing, parameters, technical data

Description and configuration of the parameters for the MSD Se vo

Drive on the PROFIBUS/PROFINET field bus syste

Information, notes on ordering, specifications and

technical data on:

MSD Single-Axis Servo Drive Compact, MSD Single-Axis System,

MSD Multi-Axis System, safety technology, communication,

technology, function packages, accessories and motors

Description of the software functionality MSD Servo Drive,

firmware versions

- MSD Single-Axis Servo Drive Compact from V1.30-xx

- MSD Single-Axis System from V3.25-xx

- MSD Multi-Axis System from V3.25-xx

Context-sensitive help for Moog DriveADministrAtor version 5.x

graphic PC user software for initial commissioning and serial

commissioning, operation, diagnostics and project management

ID no.

Format

CA97555-001

PDF

CA65642-001

PDF

CA97554-001

PDF

CA97556-001

PDF

CA65648-001

PDF

CA97557-001

PDF

CA65647-001

CA65645-001

PDF

CDL 29950-en

PDF

CB40859-001

PDF and

HTML

CB19692-001

ID no.:CA97555-001 Date:04/2018

5

Page 6

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

6

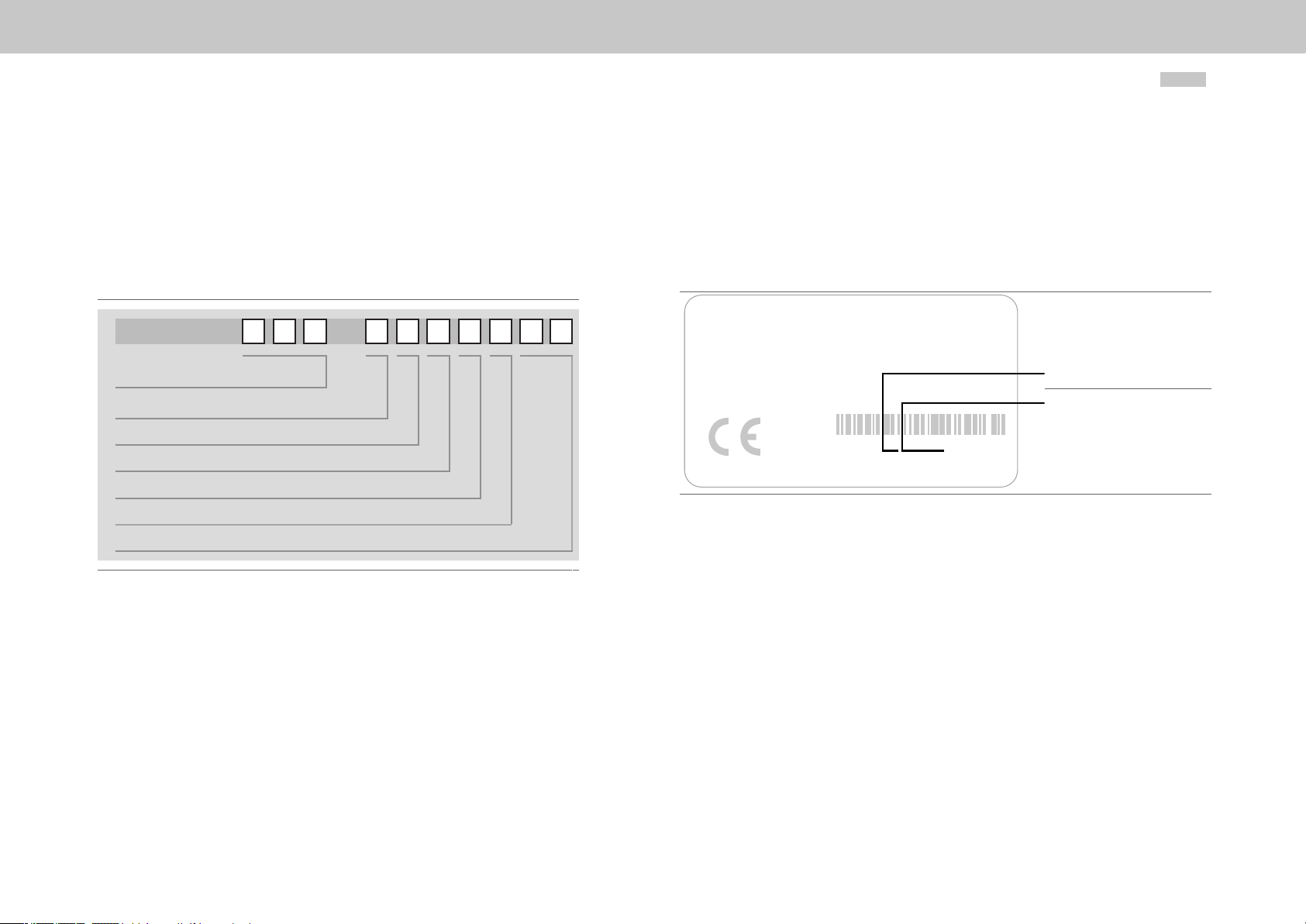

1.4 Order code

The MSD Single-Axis Servo Drive Compact has the article designation

G394-xxx-xxx-xxx. The provides information on the related variant of the supplied

MSD Servo Drive. The signicance of the individual characters of the article designation

is given in the following order code.

You will nd the complete order code with all values in the MSD Ordering Catalog.

G394 -

Rated current

Option 1 (Communication)

Option 2 (Technology)

Option 3 (Safety)

Option 4 (Function package)

Modificatio

Variants

- -

1.5 Production data

On rating plates for the MSD Single-Axis Servo Drive Compact you will nd the serial

number, from which you can identify the date of manufacture based on the following

key. For the location of the rating plate on the servo drive refer to "Figure 4.1 Layout

MSD Single-Axis Servo Drive Compact C2 to C4" and "Figure 4.2 Layout MSD SingleAxis Servo Drive Compact C5".

MOOG

D-71034 Böblingen

www .moog.com/industrial

Made in Germany

Model:: G394-030-210-001

S/N:D116605 Rev. A

In: 230 V AC 3ph, 50/60 Hz

4,0 A

0-230 V AC 3ph, 0-400 Hz

Out:

3,0 A

Year of production

Week of production

ID : JJWWxxxxx

Fig. 1.1 MSD Single-Axis Servo Drive Compact hardware rating plate

1.6 Scope of supply

The scope of supply includes:

y MSD Single-Axis Servo Drive Compact

y Terminal kit for control and power terminals

(depending on device power and variant)

Set with shield connecting plates and xing material

y

Product CD with booklet

y

Page 7

MSDSingle-Axis Servo Drive Compact Operation Manual

moog

1.7 Pictograms

1.10 Helpline/Support & Service Center

The pictograms used in this Operation Manual signify the following for the user:

NOTE

Useful information or reference to other documents.

1.

(digit)

You will nd the pictogram used in this Operation Manual for "General safety instructions and warnings" in chapter "2 Safety".

ACTION TO BE TAKEN

Processing step undertaken by the user or the system.

1.8 Disclaimer

Following the documentation on the devices from Moog GmbH is a prerequisite:

y For safe operation.

y To achieve stated performance features and product characteristics.

Moog GmbH does not accept any liability for injuries, damage or nancial losses that

result from the failure to follow the documentation.

1.9 Disposal

Follow the applicable national regulations! If necessary, dispose of individual parts,

depending on their characteristics and existing national regulations, e.g. as:

y Electrical waste

y Plastic

y Metal

Or engage a certied disposal organisation with scrapping

Our Helpline will help you with fast, specic assistance if you have any technical queries

relating to project planning or commissioning your device.

Address: Moog GmbH

Hanns-Klemm Straße 28

D-71034 Böblingen

The Helpline is available by e-mail, telephone or telefax:

E-Mail: drives-support@moog.com

Phone: +49 7031 622 0

Telefax: +49 7031 622 100

If you need further assistance, our specialists at the Service & Support Center will be

happy to help.

E-Mail: info.germany@moog.com

Phone: +49 7031 622 0

ID no.:CA97555-001 Date:04/2018

7

Page 8

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

8

Page 9

2 Safety

2.1 Overview

Our devices are state-of-the-art and comply with recognised safety regulations,

nevertheless hazards can arise. In this chapter:

y We provide information on residual risks and hazards that can emanate from

our devices on usage as intended.

y We warn about the foreseeable misuse of our devices.

y We refer to the necessary care and measures to be taken to prevent risks.

2.2 For your safety

NOTE

Only install and place in operation your device taking into account the

documentation for the related device family!

Our devices are quick and safe to operate. For your own safety and for the safe

functioning of your device, please be sure to observe the following points:

3.

4.

5.

Protection against magnetic and/or electromagnetic fi lds during

installation and operation.

Persons t ted with heart pacemakers, metallic implants and hearing aids etc. must not be allowed

access to the following areas:

• Areas in the immediate vicinity of electrical equipment!

• Areas in which electronics components and Ser vo Drives are installed,

repaired and operated!

• Areas where motors are installed, repaired and operated!

Motors with permanent magnets pose particular hazards.

During installation observe the following:

• Comply with connection conditions and technical data as per the documentation and the

rating plate!

• Comply with standards and directives on electrical installation, such as cable cross-section,

shielding, etc.!

• Do not touch electronic components and contacts!

Electrostatic discharge can harm people and destroy components!

• Take protection measures and use protective devices as per the applicable regulations

(e.g. IEC/EN60204 or IEC/EN 61800-5-1)!

• Take "device earthing" protection measure!

Ambient conditions

Follow the instructions on the transport, storage and correct operation of the devices stated in

•

the Operation Manual in "A Appendix".

1.

2.

Follow safety instructions for the devices:

Follow all safety instructions and warnings in the entire documentation related to the device series.

Electric drives are dangerous:

• Due to electrical voltages up to 480V AC and up to 800 V DC

• Dangerously high voltages of ≥50V may still be present 10min. after the power is cut

(capacitor charge). So check that electrical power is not present! See also the warning label on

the front panel on the device.

• Rotating parts

• Automatically starting drives.

• Hot components and surfaces

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

9

Page 10

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

10

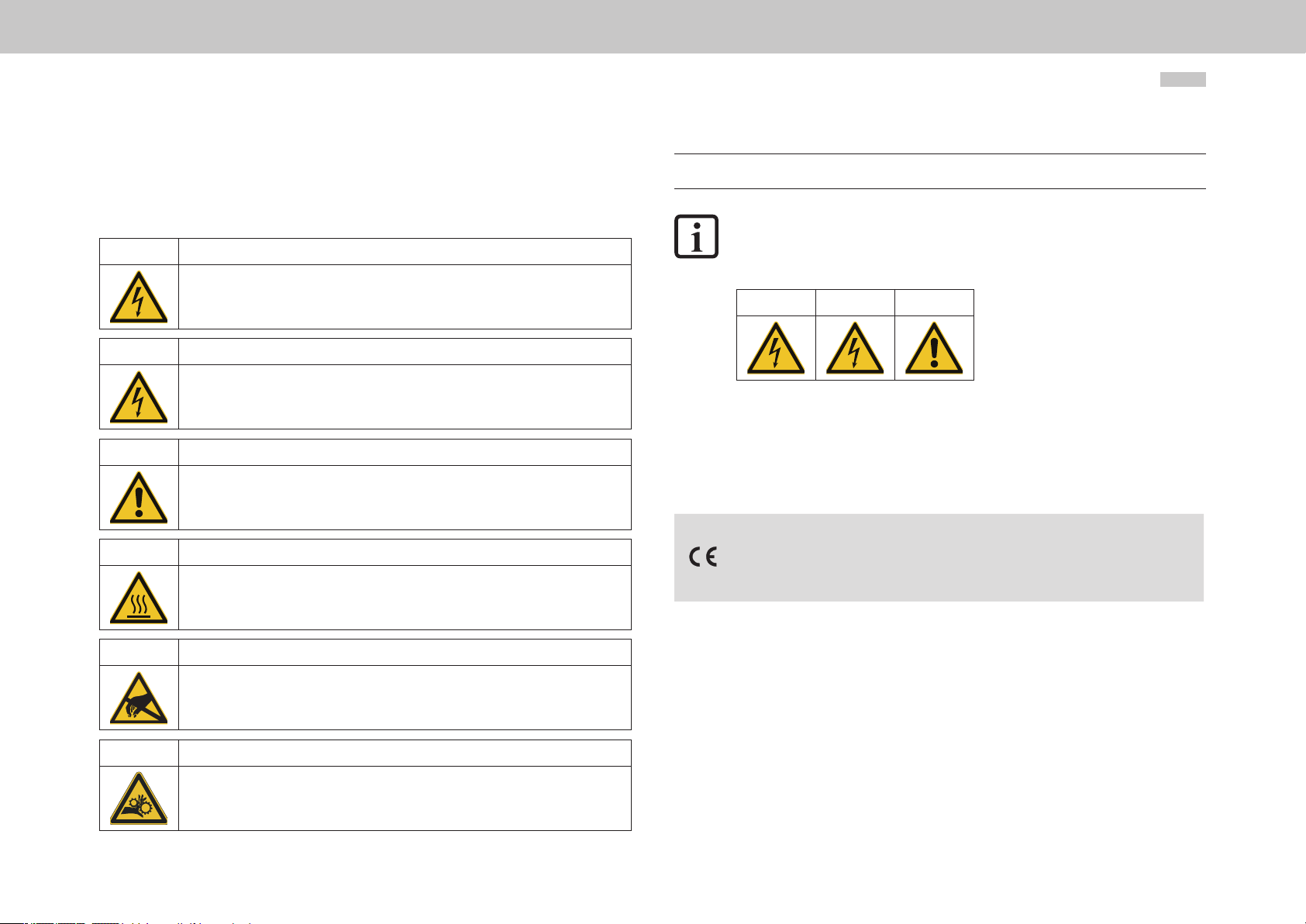

2.3 General safety instructions and warnings

Hazards may emanate from our devices. For this reason it is imperative you follow the

safety instructions and warnings in this document.

DANGER! Risk of injury due to electrical power!

• Carelessness will result in serious injuries or death.

Follow safety instructions and warnings in this document and on the device.

WARNING! Risk of injury due to electrical power!

• Carelessness may result in serious injuries or death.

Follow safety instructions and warnings in this document and on the device.

CAUTION! Risk of injury or damage to the device due to incorrect operation!

• Carelessness may result in minor injuries or

damage.

Follow safety instructions and warnings in this document and on the device.

WARNING! Risk of injury due to hot surfaces and components!

• Carelessness may result in serious burns.

Electronic components may become hot during operation!

Follow safety instructions and warnings in this document and on the device!

Caution! Damage due to electrostatic discharge!

• Electrostatic discharge can destroy components.

Do not touch electronic components and contacts!

Follow safety instructions and warnings in this document and on the device!

DANGER! Risk of injury due to rotating par ts on the motor!

• Carelessness will result in serious injuries or death.

Follow safety instructions and warnings in this document.

Pay attention to special safety instructions and warnings that are given here in the document

before a specic action and that warn the user about a specic hazard!

NOTE:

The pictograms may also be used on their own with the signal word, e.g.

in the connection diagrams, however they have the same function as in the

complete warning.

DANGER WARNING CAUTION

2.4 Intended use

Our devices are components intended for stationary electrical systems and machines in

the industrial and commercial sector.

The devices in the product range MSD Single-Axis Servo Drive Compact conform to the

Machinery Directive 2006/42/EC

Tested and certied in accordance with applicable standards (see declaration of conformity

in chap. 2.8).

When installed in machines it is prohibited to start-up intended operation until it has

been ascertained that the completed machine fully complies with the provisions of

the Machinery Directive (2006/42/EC); compliance with IEC/EN60204 is mandatory.

Starting up intended operation is only permitted on compliance with the EMC Directive

2014/30/EU.

The devices full the demands of the harmonised product standard IEC/EN61800-5-1.

You will find information on the installation of your device in chapter "3 Mechanical

installation".

Page 11

2.4 .1 Repair

Only have repairs undertaken by authorised repair shops. Unauthorised opening and

incorrect intervention could lead to death, physical injury or material damage. The

warranty provided by Moog would thereby be rendered void.

2.5 Usage contrary to intended use

Our devices are:

y Not intended for installation in vehicles. Deployment of the device in non-

stationary equipment is classed as non-standard ambient conditions, and is

permissible only by special agreement.

y Not intended for installation in environments with harmful oils, acids, gases,

vapours, dusts, radiation etc.

y Not approved for usage in special applications (e.g. in potentially explosive

atmospheres or areas in which there is a risk of re).

y Not approved for usage outside a cabinet

y Not approved for the generation of high-frequency onboard

networks for which the device is not designed

2.6 Responsibility

Pay attention to the topic of “Electrical equipment of machines” in IEC/EN60204-1:

2006 “Safety of machinery”. The safety requirements on electrical machines dened

there are intended to protect personnel and machinery or systems.

The emergency stop function (as per IEC/EN 60204) shuts down the supply of power

to a machine, which results in the drives coasting down in an uncontrolled manner. To

avert hazards, check whether it is appropriate:

− To keep individual drives in operation

− To initiate specic safety procedures

− To incorporate a Safe Torque Off function (Safe Torque Off: movement stop

by "switching off the electrical supply" - STO)

2.7 Relevant laws, standards and directives applied

For information on the laws, Dateards and directives applied by Moog, refer to the

declaration of conformity.

NOTE:

Depending on the specic application for the devices, other laws, standards

and directives with provisions on "Safety" may apply. If necessary, contact

the machine or system manufacturer.

Electronic devices are fundamentally not fail-safe. The installer and/or operator of a

complete machine or system is responsible for ensuring:

y That the drive is rendered safe if the device fails

y The safety of personnel and machinery

y The complete machine is in correct working order

For the risk assessment on the complete machine or system according to

y

EN ISO 12100 (formerly EN ISO 14121) and EN ISO 13849-1

(formerly DIN EN 954-1)

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

11

Page 12

moog

ID no.:CA97555-001 Date:04/2018

2.8 Declaration of conformity

MSDSingle-Axis Servo Drive Compact Operation Manual

12

Page 13

3 Mechanical installation

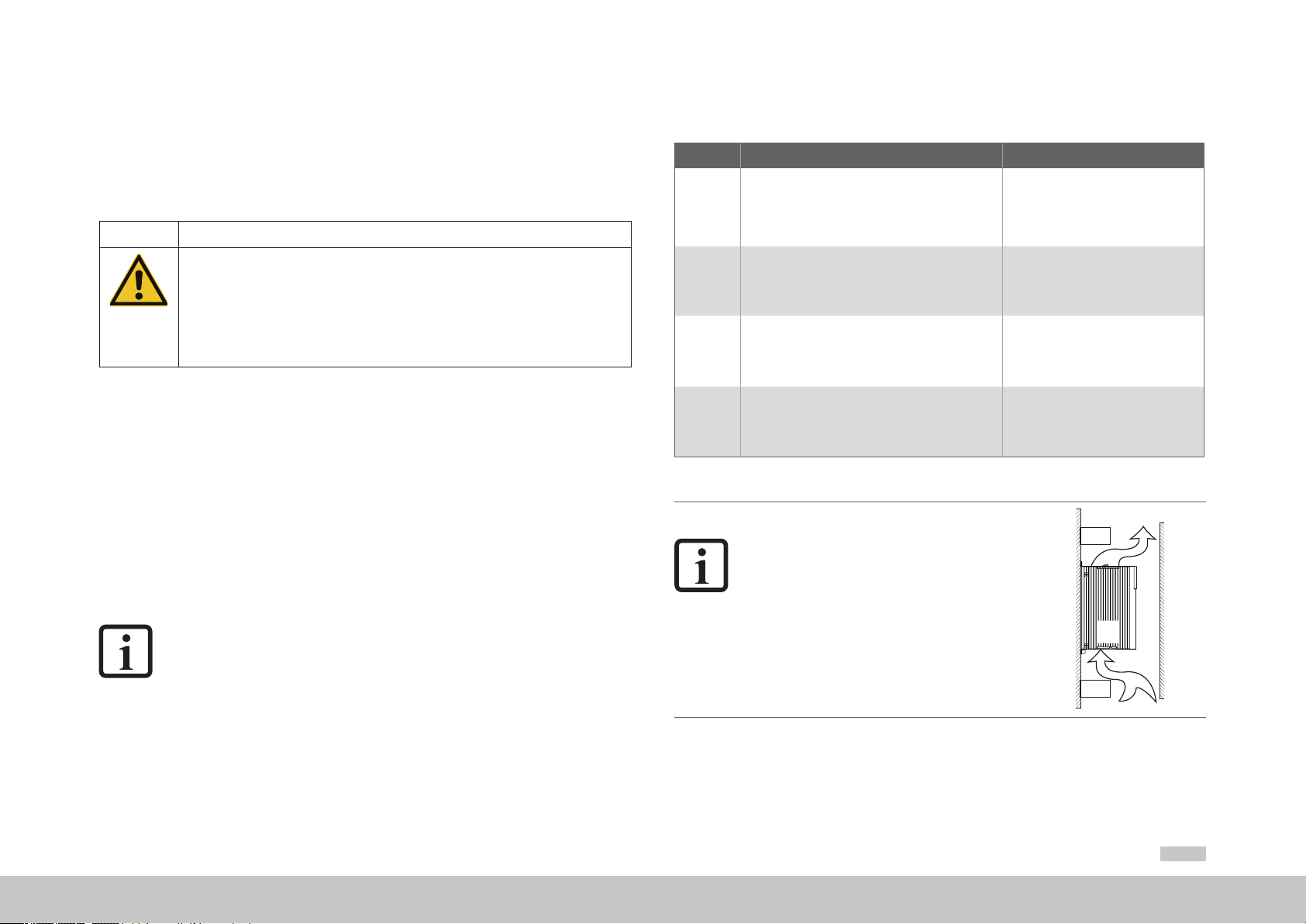

3.2 Wall mounting

Step Action Comment

3.1 Notes for operation

CAUTION Damage to the device due to incorrect installation conditions!

The device may be destroyed

For this reason

• Moisture must not be allowed to enter the device

• There must not be any aggressive or conductive substances in the ambient air

• Foreign bodies such as drilling chips, screws, washers etc. must not be allowed to enter

the device

• The ventilation openings must not covered

Note the following points:

y Cooling air must be able to ow through the device without restriction.

y For mounting in switch cabinets with convection (= heat loss is discharged to the outside via the

cabinet walls), always t an internal air circulation fan.

y The backing plate must be well-earthed.

y The device is designed only for vertical installation in switch cabinets. The switch cabinet must

as a minimum provide IP4x protection.

y To attain the best result for EMC-compatible installation you should use a chromated or

galvanized backing plate. If backing plates are varnished, remove the coating from the contact

area! The devices themselves have an aluminium back panel.

y Maximum pollution degree 2

NOTE

According to ENISO13849-2 the switch cabinet must have IP54 protection

or higher on using the STO (Safe Torque OFF) safety function.

Further information on environmental conditions can be found in the appendix.

Mark out the position of the tapped holes on the

backing plate.

1.

Cut a thread for each xing screw in the backing plate.

Mount the servo drive vertically on the backing

2.

3.

4.

Table 3.1 Mechanical installation

.

plate

Mount the other components, suchas the mains lter,

mains choke etc., on the backing plate.

Continue with the electrical installation in chapter 3.

NOTE

Forced cooling by external air ow is necessary

for all sizes of the MSD Single-Axis Servo

Drive Compact. The air must be able to ow

unhindered through the device. If a temperature

cut-out occurs, the cooling conditions must be

improved.

Air ow: minimum 1.2 m/s (3.93 ft/s)

Dimensional drawings/hole spacing see

Figure 3.1, Figure 3.2

The thread sur face area will provide you

with good, full-area contact.

Observe the mounting clearances! The

contact area must be bare metal.

The cable between mains lter and servo

drive may be 300mm (11.81in) long.

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

13

Page 14

moog

C1

A1

ID no.:CA97555-001 Date:04/2018

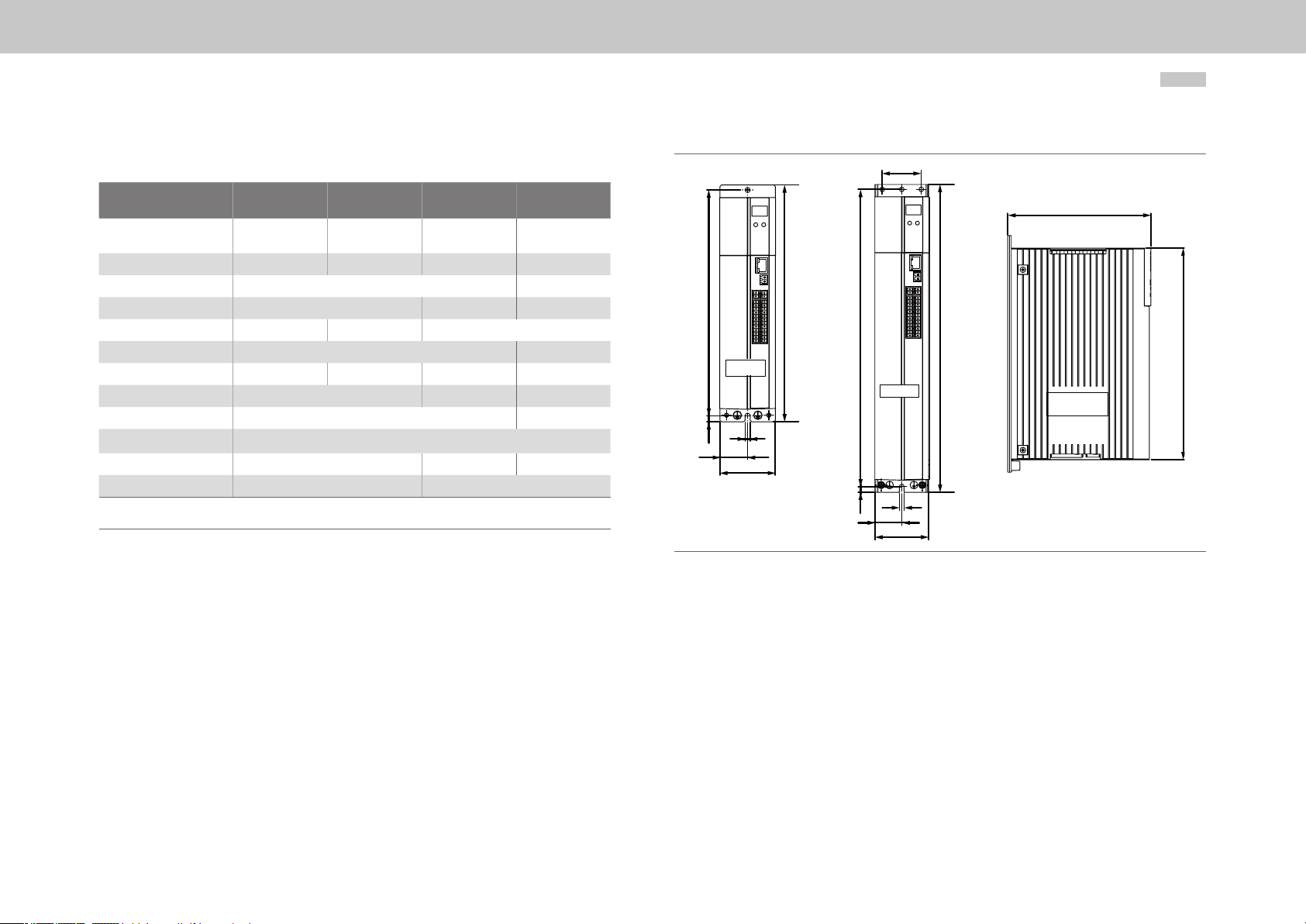

3. 2.1 Dimensions of the devices

MSDSingle-Axis Servo Drive Compact Operation Manual

14

Size C2 C3 C4 C5

MSD Single-Axis Servo

Drive Compact

Weight 1.0 kg (2.2 lb) 1.5 kg (3.3 lb) 2.8 kg (6.2 lb) 5.9 kg (13 lb)

B (width) 55 ( 2.17 ) 90 (3.54)

1)

H (height)

1)

T (depth)

A 27.5 (1. 0 8) 20 (0.79)

A1 - - 40 (1.57) 50 (1. 97)

C 225 (8.86) 30 5 (12.01) 313 (12.32)

C1 5 (0.20) 6 (0. 24)

DØ 4. 8 (0.19)

H1 235 (9.25) 315 (12.40) 324 (12 .76)

Screws 2 x M4 4 x M4

All dimensions in mm (in)

1) without terminals/connections

Table 3.2 MSD Single-A xis Ser vo Drive Compact dimensions - see Figure 3.1 and Figure 3.2

G394-030

G394-020

210 (8.27) 29 0 (11.42 ) 29 1 (11.47)

142 (5.59) 18 9 ( 7. 4 4) 235.5 (9.27)

G394-059

G394-035

G394-080

G394-065

G394-120

G3 9 4 -16 0

C

H1

C

C2 + C3

C4

D

A

B

C1

A

B

Figure 3.1 Dimensional drawing C2, C3, C4

T

H

H1

C2 + C3 + C4

D

Page 15

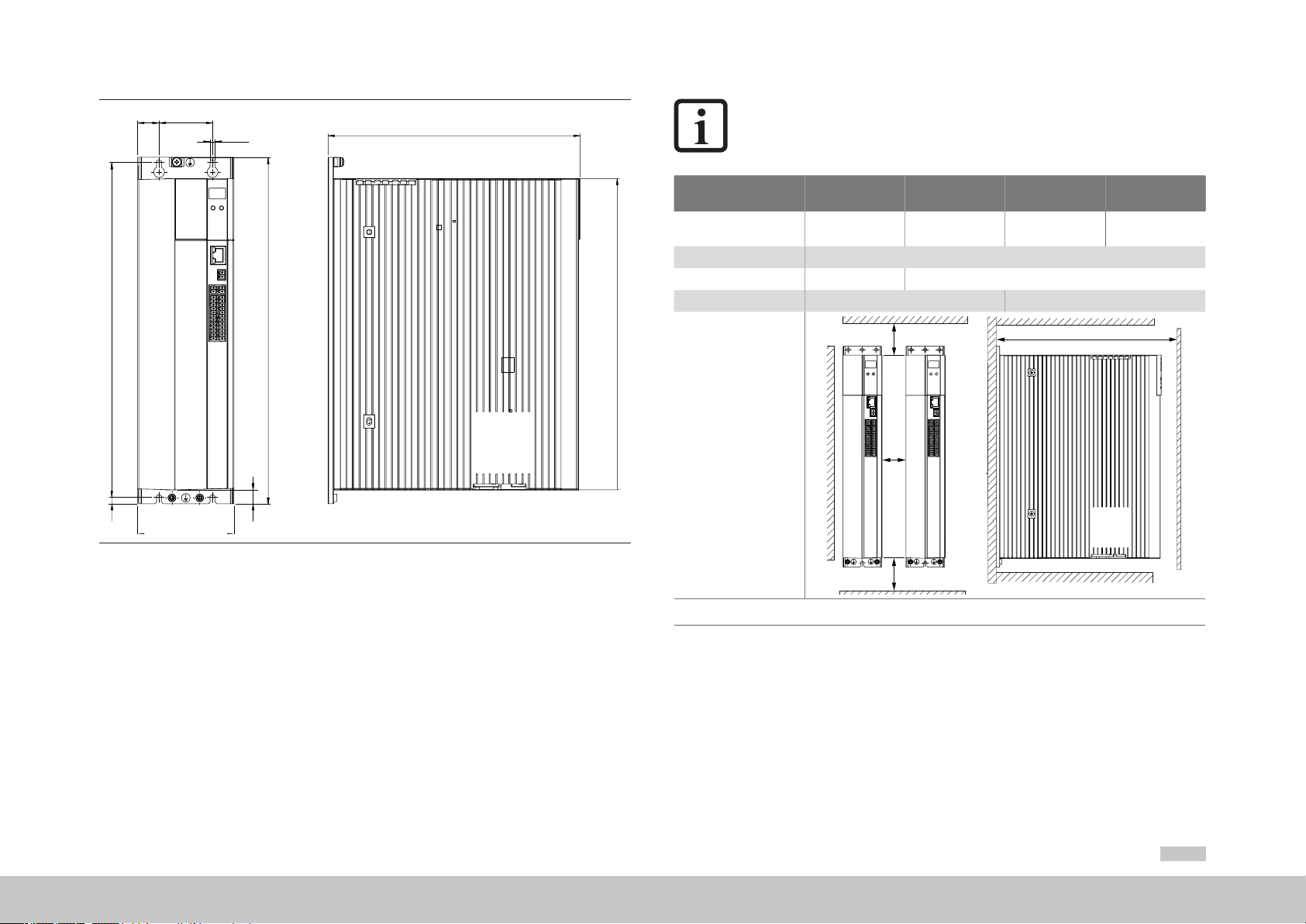

NOTE

A1A

C

D

T

If MSD Single-Axis Servo Drive Compact devices are attached to other

product ranges, corresponding measures must be taken to prevent the

devices affecting each other thermally.

Size C2 C3 C4 C5

H1

MSD Single-Axis Servo

Drive Compact

E Direct butt mounting

1)

F

1)

G

H

Drawing:

Dimensions in mm (in)

G394-030

G394-020

≥100 (3.94) ≥150 ( 5.9 0 )

≥235 (9.25) ≥2 8 0 (11. 0 2)

G394-059

G394-035

G394-080

G394-065

F

E

G394-120

G3 9 4 -16 0

G

C1

Figure 3.2 Dimensional drawing C5

B

H2

F

3.2.2 Mounting clearances

The minimum distances specied in the table apply for devices of the same power.

1) The bend radius of the c onnecti ng cables must be take n into acco unt

Table 3.3 MSD Single-A xis Servo Drive Compact mounting clearances

When butt mounting devices with different drive power you should arrange the devices

according to their power (e.g., viewed from the left, C5-C4-C3-C2). This arrangement

will minimise the thermal interaction.

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

15

Page 16

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

16

Page 17

4 Electrical installation

4.1 Notes for installation

DANGER Risk of injury due to electrical power!

• Carelessness will result in serious injuries or death.

Never wire or disconnect electrical connections while these are live! Always disconnect the power

before working on the device. Dangerously high voltages of ≥50V may still be present 10min.

after the power is cut (capacitor charge). So check that electrical power is not present!

Work on the device must only be carried out after the DC link voltage has dropped below a

residual voltage of 50V (indicated by monitoring LED H1 and to be measured on terminals X1/Land L+).

A dangerous voltage may be present at the device, even if the device does not emit any visual

or audible signals/indications (e.g. with mains voltage applied to terminal X3 and missing control

supply +24 V on X2)!

The following general guidelines apply for the installation of Servo Drives:

y Compliance with the EMC product standard

− Commissioning (i.e. starting intended operation) is only permitted on compliance with the

EMC product standard IEC/EN61800-3. The installer/operator of a machine and/or system

must provide proof of compliance with the protection targets stipulated in the standard.

y Cable type

− Use only shielded mains, motor and signal lines with double copper braiding with 60 to 70%

coverage.

y Cable laying

− Route mains, motor and signal cables separated from one another. If possible, keep a

distance of at least 0.2 m (0.66 ft), otherwise use separators. They should not run in parallel.

If crossovers are unavoidable, they should wherever possible be configured perpendicular (at

a 90° angle).

− Always route the motor cable without interruptions and the shortest way out of the control

cabinet. When using a motor contactor for example, the component should be directly

mounted to the servo drive and the shielding of the motor cable should not be stripped back

too far.

− If possible signal lines should only enter from one side into the switch cabinet.

− Lines of the same electric circuit must be twisted.

− Avoid unnecessary cable lengths and loops.

Earthing measures

y

− Earthing measures of relevance for the servo drive are described in section “4.6 Protective

earth conductor connection”.

y Shielding measures

− Do not strip the cable shields back too far, and lay them with large area connections both on

the component and on the backing plate or on the PE rail (main earth) for the backing plate.

y External components

− Place larger loads near the supply.

− Contactors, relays, solenoid valves (switched inductances) must be wired with suppressors.

The wiring must be directly connected to the respective coil.

− Any switched inductance should be at least 0.2 m (0.66 ft) away from the process controlled

assemblies.

y Additional information can be found in the corresponding connection description.

If you require further detailed information on installation you should consult the Moog Helpline

(see “Commissioning” on page 45).

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

17

Page 18

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

18

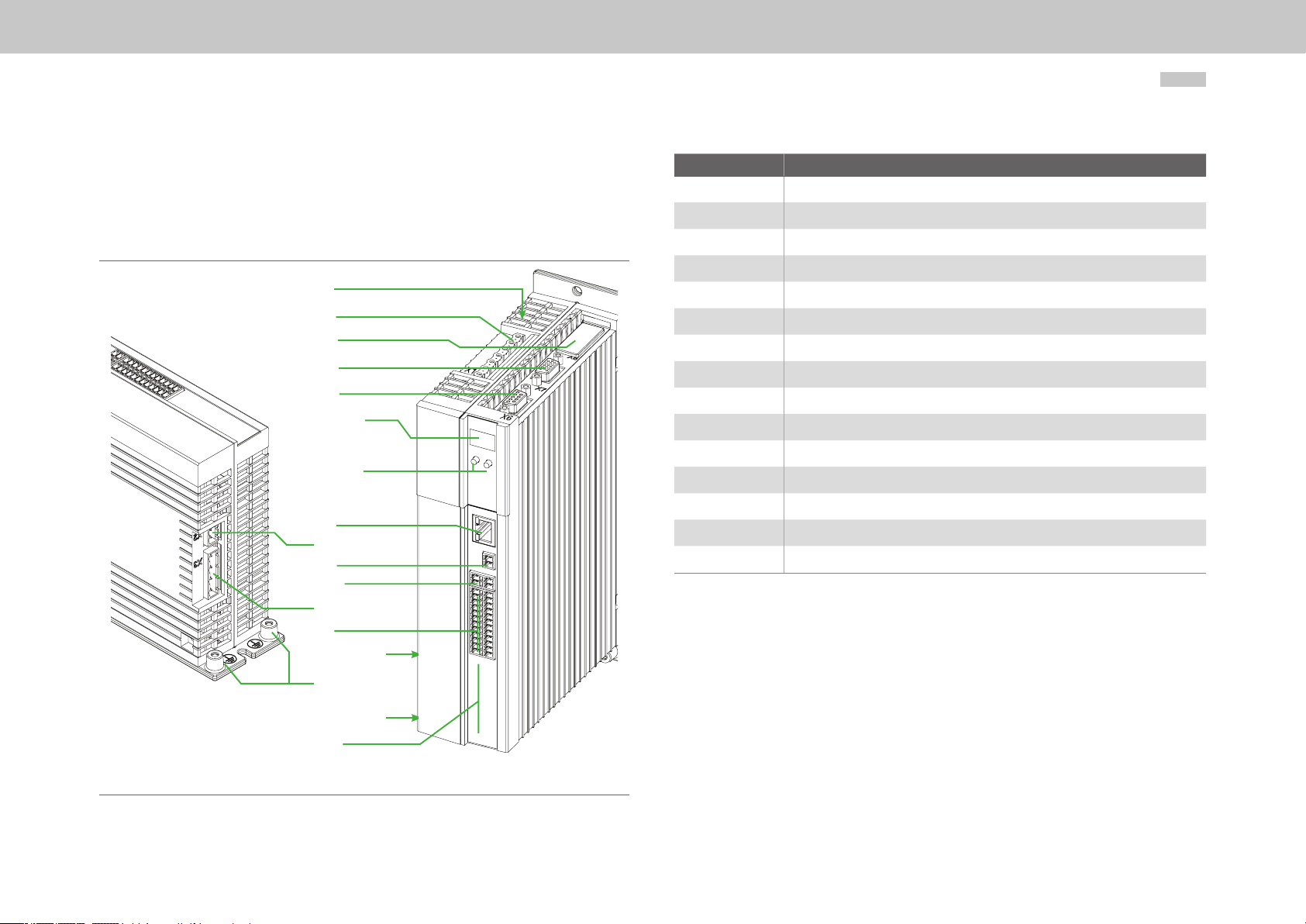

4.2 Layout

The following shows the layout with the corresponding positions of plugs and terminals.

For better orientation we have identified the designations of plugs and terminals with an

abbreviation.

H1

X1

X8

X7

X6

D1, D2

T1, T2

X9

X2

X5

X13

X3

X4

TS-Software

Number Designation

D1, D2 7-segment display

H1 DC link voltage indicator LED (only size C2 to C4)

OP1 Installation space for option 1 (Communication)

T1, T2 Button

X1 Power connections (only size C2 to C4)

X2 Connection for control supply U

X3 AC power connection

PE (bottom) Device protective earth conductor connection

X4 Control terminals

X5 Motor temperature monitoring

X6 Resolver connection

X7 Connection for high-resolution encoder

X8 Option 2 (Technology)

X9 Ethernet interface

X13 Connection for motor brake

Table 4.1 Key to layout MSD Single-Axis Servo Drive Compact C2 to C4

V

PE

TS-Hardware

OP1

Figure 4.1 Layout MSD Single-Axis Servo Drive Compact C2 to C4

Page 19

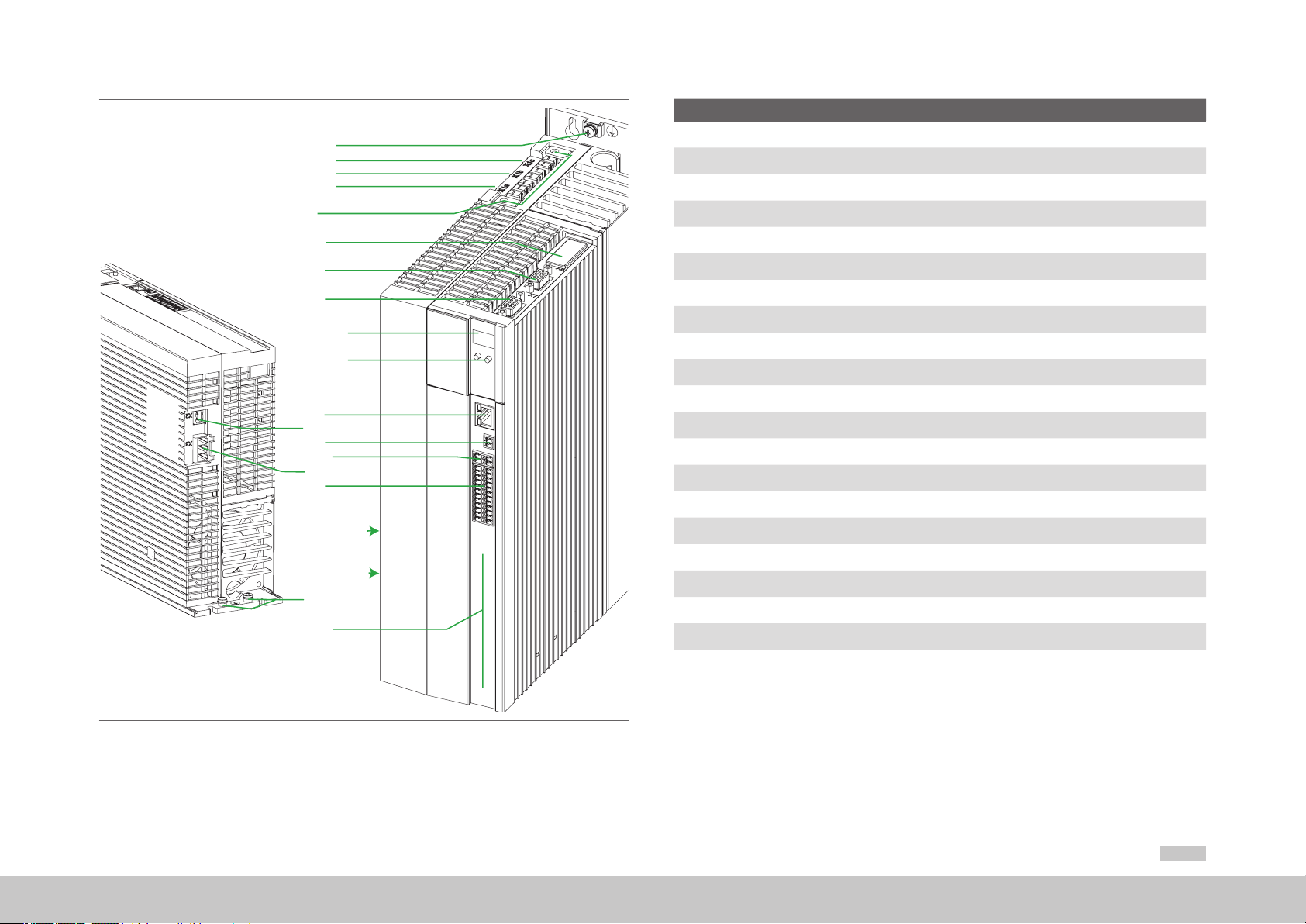

PE

X1.c

X1.b

X1.a

S

Number Designation

D1, D2 7-segment display

OP1 Installation space for option 1 (Communication)

T1, T2 Button

PE (top) Motor PE connection

X8

X7

X6

D1, D2

T1, T2

X9

X2

X5

X13

X3

X4

T. Software

T. Hardware

PE

OP1

X1.a Motor connection (only size C5)

X1.b Measurement of DC link voltage (only size C5)

X1.c Connection for braking resistor (only size C5)

X2 Connection for control supply U

V

X3 AC power connection

PE (bottom) Device protective earth conductor connection

X4 Control terminals

X5 Motor temperature monitoring

X6 Resolver connection

X7 Connection for high-resolution encoder

X8 Option 2 (Technology)

X9 Ethernet interface

X13 Connection for motor brake

S Receptacle for shield plate (see “Detail1: Motor cable C5” on page 23)

T. Software Software rating plate

T. Hardware Hardware rating plate

Table 4.2 Key to layout MSD Single-Axis Servo Drive Compact C5

Figure 4.2 Layout MSD Single-Axis Servo Drive Compact C5

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

19

Page 20

moog

Top view

Bottom view

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

20

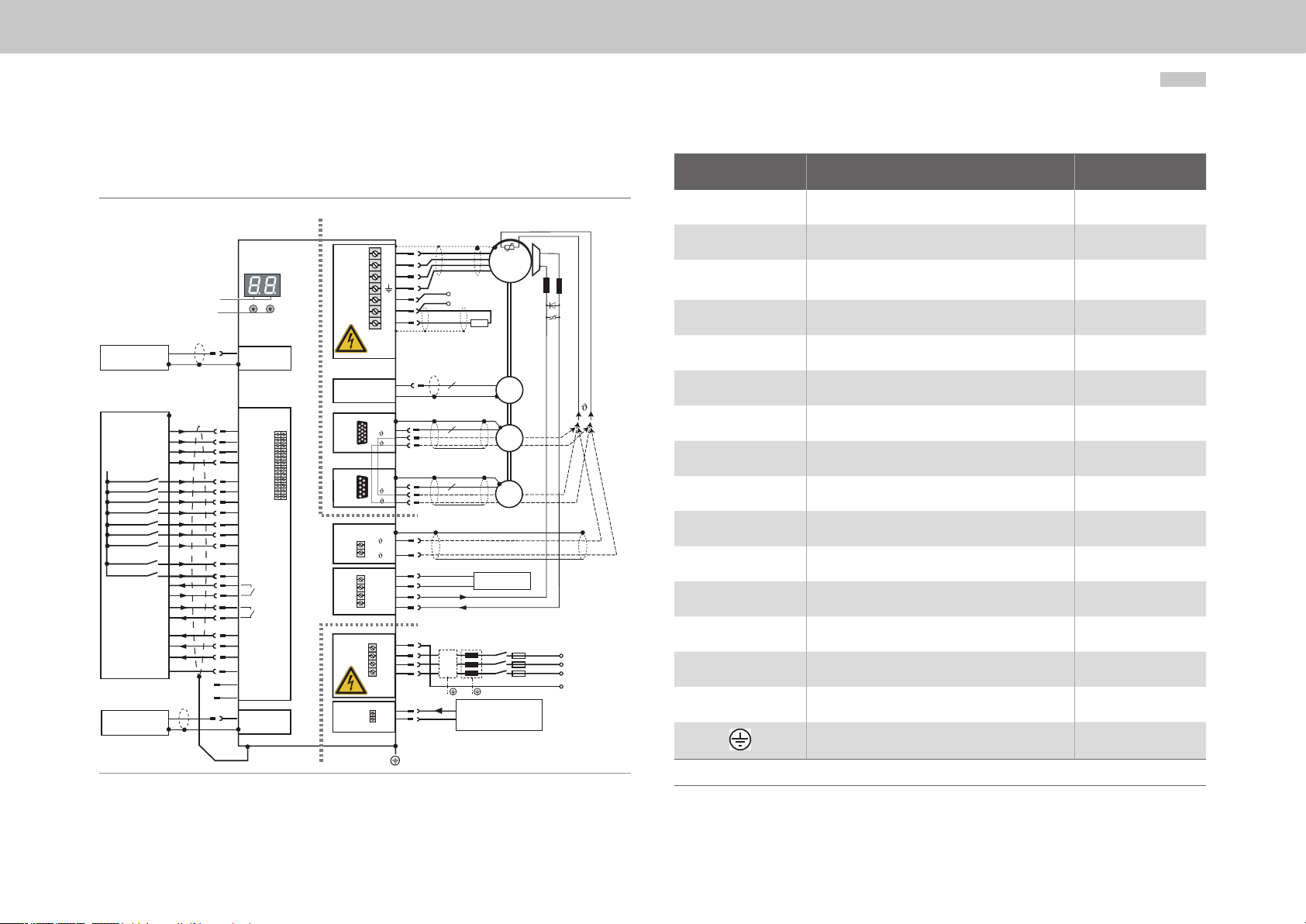

4.3 Connection diagram C2 to C4

1)

Option 2

54321

15 14 13 12 11

10 9876

4321

9876

GND

OSD03

GND

U

V

W

Brake (+)

Brake (-)

Mains 3-phase

FN

DC-link

Braking

resistor

n

n

6

+24 V DC supply for

brake

+24 V DC supply for

control electronic (U

L-

L+

RB

1+

10

9

1-

5

1+

9

1-

+/1

-/2

4

V+

3

2

1

PE

L3

L2

L1

+

+

-

–

D1, D2

T1, T2

Service

interface

Control

Analog set point 1

Analog set point 2

+24 V DC against

E/A-GND

Diagnosis

Relay

Digital0

Digital1

Digital2

E/A-GND

Communication

field buses

STO

Ethernet

3

ISA00+

4

ISA00-

5

ISA01+

6

ISA01-

ISD00

15

ISD01

16

ISD02

17

ISD03

18

ISD04

19

ISD05

20

ISD0621

10

ENPO (STO)

22

ISDSH (STO)

12

RSH

11

23

Relay

24

OSD04

7

OSD00

8

OSD01

9

OSD02

1

DGND

2,14

+24 V (U

13

DGND

Option 1

X9

X4

Front

)

H

1)

Figure 4.3 Connection diagram C2 to C4

X1

Danger!

X8

X7

X6

X5

X13

X3

Danger!

X2

Motor

3

~

Encoder

Resolver

K1

Number Designation Details

D1, D2 7-segment display Page 48

T1, T2 Button Page 48

X1

Connection for motor, braking resistor

and measurement of DC link voltage

Page 38

X2 Connection for control supply Page 27

X3 Connection for AC power supply Page 29

X4 Control terminals Page 31

(-)(+)

X5 Connection for motor temperature monitoring

X6 Connection for resolver

1)

X7 Connection for high-resolution encoder

1)

Page 37

Page 35

1)

Page 36

Option 1 Communication Page 33

PE PE connection Page 25

X8 (Option 2) Technology Page 33

X9 Ethernet interface Page 33

L3

L2

L1

PE

V)

X13 Connection for motor brake

1) Screen connections via separate shield plates

Connection for housing PE conductor

Page 32

Page 23

Page 25

1) NOTE: The temperature sensor for the motor winding can be connected either via the encoder cables (X6 or X7) or to terminal X5.

Table 4.3 Key to connection diagram C2 to C4

Page 21

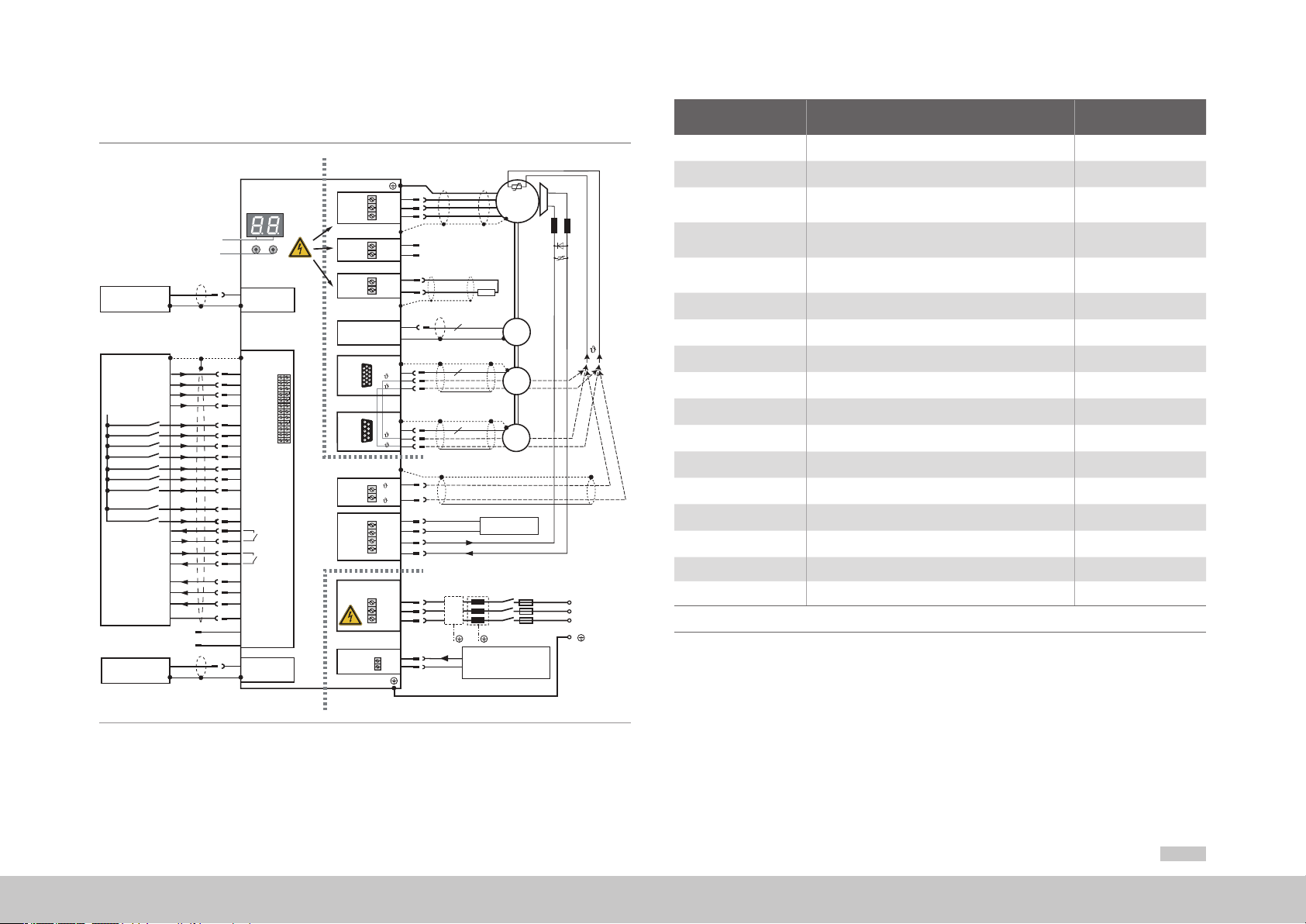

4.4 Connection diagram C5

Top view

U

V

1)

1)

Option 2

54321

15 14 13 12 11

10 9876

4321

9876

1)

GND

OSD03

GND

W

L-

L+

L+

RB

1+

10

9

1-

5

1+

9

1-

+/1

-/2

4

V+

3

2

1

L3

L2

L1

+

+

-

–

Service

interface

Control

Analog set point 1

Analog set point 2

+24 V DC against

E/A-GND

Diagnosis

Relay

Digital0

Digital1

Digital2

E/A-GND

Communication

field buses

STO

D1, D2

T1, T2

Ethernet

1)

3

ISA00+

4

ISA00-

5

ISA01+

6

ISA01-

ISD00

15

ISD01

16

ISD02

17

ISD03

18

ISD04

19

ISD05

20

ISD0621

10

ENPO (STO)

22

ISDSH (STO)

12

RSH

11

23

Relay

24

OSD04

7

OSD00

8

OSD01

9

OSD02

1

DGND

2,14

+24 V (U

13

DGND

Option 1

Danger

X1.b

X1.a

X9

X1.c

X8

X4

X7

X6

X5

Front

X13

X3

Danger

)

H

X2

DC-link

Brake (+)

Brake (-)

Braking

resistor

n

n

6

Mains 3-phase

FN

+24 V DC supply for

control electronic (U

Motor

3

~

Encoder

Resolver

+24 V DC supply for

brake

K1

Number Designation Details

D1, D2 7-segment display Page 48

T1, T2 Button Page 48

X1.a Motor connection Page 37

X1.b Measurement of DC link voltage -

X1.c Connection for braking resistor Page 37

X2 Connection for control supply Page 27

X3 Connection for AC power supply Page 29

(-)(+)

X4 Control terminals Page 31

X5 Connection for motor temperature monitoring

X6 Connection for resolver

1)

X7 Connection for high-resolution encoder

1)

Page 37

Page 35

1)

Page 36

Option 1 Communication Page 33

PE Connection for PE conductor Page 25

X8 (Option 2) Technology Page 33

X9 Ethernet interface Page 33

X13 Connection for motor brake

L3

L2

L1

1) NOTE: The temperature sensor for the motor winding can be connected either via the encoder cables (X6 or X7) or to terminal X5.

1) Screen connections via separate shield plates

Page 32

Page 23

Table 4.4 Key to connection diagram

V)

Bottom view

Figure 4.4 Connection diagram MSD Single-Axis Servo Drive Compact C5

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

21

Page 22

moog

ID no.:CA97555-001 Date:04/2018

4.5 Effective EMC installation

MSDSingle-Axis Servo Drive Compact Operation Manual

22

4.5.1 Interference immunity of Servo Drives

NOTE

This is a restricted availability product in accordance with IEC/EN 61800-3.

This product may cause radio interference in domestic environments; in such

cases the operator may need to take appropriate countermeasures.

External radio frequency interference suppression filters (CB09937-001 to CB09940

001, CB09942-00, for C5 provisional CA71185-001) are available for the Servo Drives.

With the measurement method specified and the exte nal mains filte , these Servo

Drives conform to the EMC product standard IEC/EN 61800-3 for "First environment"

(residential C2) and "Second environment" (industrial C3).

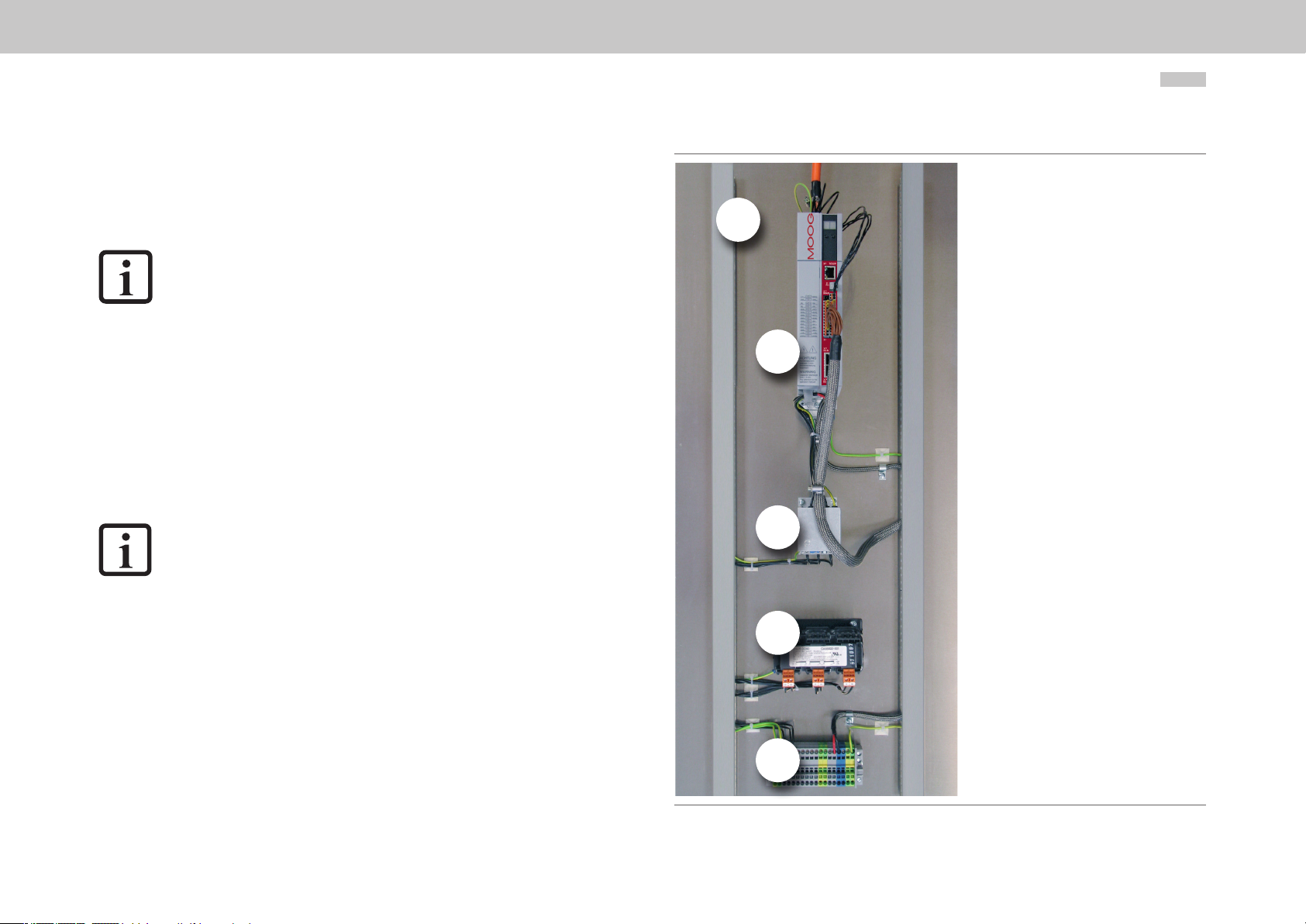

4.5.2 Specimen setup

The specimen setup presented on the following pages is intended to illustrate the key

measures necessary to ensure an effective EMC installation.

NOTE

The specimen setup merely presents a recommendation, and does not

automatically guarantee compliance with applicable EMC directives.

The installer/operator of a machine and/or system must provide proof of

compliance with the protection targets stipulated in the standard.

Overview

A

Detail 1

Detail 2

B

Detail 3

Detail 4

C

D

Figure 4.5 presents an overview of the minimum components required:

Backing plate with cable ducts

A.

B.

MSD Single-Axis Servo Drive Compact

Mains filter

C.

D.

Mains choke

E.

Distributor rail for AC power supply and control supply (+24VDC)

The layout and cabling are based on the requirements in section4.1 The numbered red

arrows refer to four very important detailed notes presented on the following pages.

E

Figure 4.5 Specimen setup - Overview

Page 23

Detail1: Motor cable

Make sure that on devices C2 to C4 the motor connection is connected to terminal (X1)

and on devices C5 to terminal (X1a, X1b, X1c):

y Fasten the shield connection plate supplied (shield plate for C2 to C4 see Figure 4.6, shield plate

for C5 see Figure 4.7) to the top of the device. Ensure the plate is in contact over a large area

with the heat sink on the MSD Single-Axis Servo Drive Compact and with the backing plate. Use

a serrated washer.

Figure 4.6 Shield plate C2 to C4 Figure 4.7 Shield plate C5

y Strip the shielding of the motor cable back only as short as absolutely necessary.

y Connect the motor cable shield over a large area to the shield connection plate using the clamp

supplied.

X1a

X1b

X1c

X1

Figure 4.8 Detail1: Motor cable C2 to C4 Figure 4.9 Detail1: Motor cable C5

NOTE

Ready made motor cables are available for Moog Servo Motors. For details

refer to the MSD Ordering Catalog or to the Servo Motors Ordering Catalog.

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

23

Page 24

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

24

Detail2: Control supply (+24VDC)

At the connection for the control voltage (X2) pay attention to:

y Secure the second of the two shield connection plates supplied to the mount on the bottom of

the unit using the screw. Ensure the plate is in contact over a large area with the heat sink on the

MSD Single-Axis Servo Drive Compact and with the backing plate. Use a serrated washer.

y Pull a shielding sleeve over the control supply cable and strip it back only as short as necessary

before the control supply connection (X2).

y Connect the shielding sleeve on the control supply cable with a large area connection to the

shield connection plate using the clamp supplied.

X2

Detail3: Mains filter and mains connection

At the output of the mains filter and the AC mains connection X3):

y Connect the litz wire on the output of the mains filter directly to the AC mains connection (X3) on

the MSD Single-Axis Servo Drive Compact. The litz wires must not be extended, so the mains

filter should be installed correspondingly close to the MSD Single-Axis Servo Drive Compact. But

be sure to maintain the necessary minimum clearance (see “Table 3.3 MSD Single-Axis Ser

Drive Compact mounting clearances”).

y Fix the litz wire to the shield connection plate using a cable tie as necessary.

y The leakage current of the MSD Single-Axis Servo Drive Compact is >3.5mA. So:

− Connect the protective earth conductor from the output of the mains filter to conne tion (X3)

on the MSD Single-Axis Servo Drive Compact C2 to B4 or to the housing of the

MSD Single-Axis Servo Drive Compact C5 and

− One of the PE connections on the heat sink on the MSD Single-Axis Servo Drive Compact

using a cable of at least the same cross-section to the main earth for the distributor rail.

X3

vo

Figure 4.10 Specimen setup - Detail 2: Control supply

Figure 4.11 Specimen setup - Detail3: Mains lter and mains connection

Page 25

Detail4: Control cables

At the control terminals (X4) of the MSD Single-Axis Servo Drive Compact:

y Strip the shielding of the control cables back only as short as absolutely necessary.

y Connect the shield on the control cables with a large area connection to the shield connection

tab on the mains filter using the clamp supplied If this is not possible, connect the control cable

shield directly to the backing plate with a large area connection directly adjacent to the

MSD Single-Axis Servo Drive Compact.

X4

4.6 Protective earth conductor connection

Step Action

Earth each of the Servo Drives!

Connect the terminal in a star configuration

1.

and with a large area connection to the PE

bar (main earth) in the control cabinet.

Also connect the PE conductor terminals on all other

components, such as mains choke, filte , etc. in a

star configuration and with a large a ea

2.

connection to the PE bar (main earth) in the control

cabinet.

PE mains connection

according to IEC/EN 61800-5-1

For the PE connection the following

applies (as leakage current >3.5mA):

Use protective earth conductors with the

same cross-section as the mains power

cables, though at least 10mm

²

Also comply with local and national

regulations and conditions.

(0.02in²).

Figure 4.12 Specimen setup - Detail4: Control cables

moog

ID no.:CA97555-001 Date:04/2018

U1

V2

U2

V1

U1

V2

U2

W1

W2

W1

V1

W2

PE

Figure 4.13 Star configuration layout for the PE conducto

MSDSingle-Axis Servo Drive Compact Operation Manual

U1

V2

U2

W1

V1

W2

25

Page 26

PE GNDµP

DGND

complexe

not linear

impedance

RC link Polyswitch

GNDµP

GNDµP

GNDµP

X4/15

ISD00

ISD01

I

LIM

X4/21

ISD06

I

LIM

X4/10

ENPO

I

LIM

X4/22

ISDSH

I

LIM

X4/7

OSD00

X4/3

ISA00+

Motor PTC

X4/4

ISA00-

ISD02

ISD03

ISD04

ISD05

A/D

A/D

ISA01+

X4/5

X4/6

ISA01-

X4/14

GNDµP

GNDµP

GNDµP

GNDµP

GNDµP

DGND

DGND

DGND

DGND

DGND

DGND

DGND

DGND

X4/2

ϑ

F1

ϑ

F2

X4/13

DGND

X4/1

ϑ

F3

V

µP

V

µP

V

µP

V

µP

µP

X4/8

OSD01

OSD03

Motor brake

GND

X4/9

OSD02

X5/ϑ +

X5/ϑ −

RSH

X13/2

X13/1

X4/12

X4/11

OSD04

X4/23

X4/24

Ethernet

X9

Resolver

X6

Encoder

X7

PE

U

V

U

V

X2/+

X2/-

U

H

Control

supply

24 V DC

24 V DC

Supply

Brake

GND

X13/3

X13/4

moog

ID no.:CA97555-001 Date:04/2018

4.7 Electrical isolation concept

The control electronics, with their logic (µP), the encoder terminals and the inputs and

outputs, are electrically isolated from the power section (power supply/DC link). All

control terminals are designed as safety extra-low voltage/protective extra-low voltage

(SELV/PELV) circuits and must only be operated with such SELV/PELV voltages, as per

the relevant specification. This p ovides reliable protection against electric shock on the

control side.

A separate control supply, compliant with the requirements of a SELV/PELV, is therefore

needed.

The overview opposite shows the potential references for the individual connections in

detail.

This concept also delivers higher operational safety and reliability of the servo drive.

MSDSingle-Axis Servo Drive Compact Operation Manual

26

Figure 4.14 Electrical isolation concept MSD Single-Axis Servo Drive Compact

SELV = Safety Extra Low Voltage

PELV = Protective Extra Low Voltage

Page 27

4.8 Connection of the supply voltages

X3

L1

X3

L1

Device 1 (e.g. C2) Device 2 (e.g. C2)

The supply of power to the MSD Single-Axis Servo Drive Compact is separate for the

control and power sections. The control supply should always be connected firs , so

that the device parameters can be set with Moog

device set to the correct supply for the power section.

CAUTION! Damage to the device due to incorrect operation!

• Carelessness can cause damage to the device.

Only when the mains voltage has been pre-set in the device firmware and the device has been

restarted (if the mains voltage or switching frequency has been changed) may the mains power

supply for the supply for the power section be activated.

4.8.1 Connection of control supply (+24VDC)

DriveADministrAtor5 and, above all, the

NOTE

Suitable measures must generally be applied to provide adequate cable

protection.

DANGER Risk of injury due to electrical power!

• Carelessness will result in serious injuries or death.

When the mains voltage is switched on at terminal X3 and there is no control supply (+24V DC at

X2), a dangerous voltage is present on the device with no visual signal on the display or acoustic

indication by fan noise. If visible in the installed state, LED H1 (see Figure 4.1) indicates whether

voltage is present on the device. Even if H1 is completely off, X1 must be checked to ensure no

electrical power is present.

NOTE

The start-up current for the supply voltage for the C2 to C5 may be two to

three times the operation current.

X2

+ + +

Figure 4.15 Connection of control supply MSD Single-Axis Servo Drive Compact

maximum 10 A gG

24 V DC ±10 %

external power

supply

next servo drive

Control supply (Specication)

= +24VDC ±10%, stabilised and filtered

• U

V

• I

= 2A (C2 to C5)

Control

supply

Table 4.5 Specification of control supply MSD Single-Axis Servo Drive Compact

X2/+

X2/-

moog

V

• Internal polarity reversal protection

• The power supply unit used must have a safe and reliable isolation against

the mains system acc. to EN50178 or IEC/EN61800-5-1

ID no.:CA97555-001 Date:04/2018

X2

MSDSingle-Axis Servo Drive Compact Operation Manual

27

Page 28

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

28

4.8.2 Connection of mains supply

Procedure:

Step Action Comment

Specify the cable cross-section depending on the maxi-

1.

mum current and ambient temperature.

Wire the servo drive with the mains filte *), maximum cable

2.

length 0.3 m (1.0 ft) (with non-shielded cable)!

Wire the mains choke

3.

(if installed)

Install a mains isolating device K1

4.

(power circuit breaker, contactor, etc.).

Use mains fuses

(duty class gG) to isolate all poles of the servo drive from

5.

the mains supply.

*) optional

DANGER! Risk of injury due to electrical power!

• Carelessness will result in serious injuries or death.

Never wire or disconnect electrical connections while these are live! Always disconnect the power

before working on the device. Dangerously high voltages of ≥50V may still be present 10min.

after the power is cut (capacitor charge). So check that electrical power is not present!

CAUTION!

1) residual current protective device

2) residual current monitor

Risk or injury or damage to the device due to incorrect

earth leakage circuit breaker!

• Carelessness may result in injuries or damage.

If local regulations require the installation of an earth leakage circuit breaker, the following

applies: In case of a fault the servo drive is able to generate DC leakage currents without zero

crossing. Servo Drives therefore must only be operated with (RCDs) 1) type B for AC fault currents,

pulsating or smooth DC fault currents, which are suitable for servo drive operation, see

IEC60755. RCMs 2) can also be used for monitoring purposes.

*)

Cable cross-section according to local

regulations and conditions.

Reduces the distortion (THD) in the system

and prolongs the life of the servo drive.

Do not switch on the power!

For compliance with equipment safety

requirements laid down in IEC/EN61800-

5-1

Note the following points:

Switching the mains power:

y In the event of excessively frequent switching the device protects itself by means of high-

resistance decoupling from the mains. After a rest phase of a few minutes the device is ready to

start once again.

TN and TT system: Operation is permitted if:

y In the case of single-phase devices for 1x230VAC the supply system conforms to the

maximum overvoltage category III as per IEC/EN61800-5-1.

y In the case of three-phase devices with phase conductor voltages 3x230VAC, 3x400VAC,

3x460VAC and 3x480VAC

y The star point of the supply system is earthed and

y The supply system conforms to the maximum overvoltage category III as per IEC/EN61800-5-1

at a system voltage (phase conductor → neutral point) of maximum 277V.

IT system: Operation is not permitted!

y In case of an earth fault the voltage is approx. twice as high. Clearances and creepages to

IEC/EN61800-5-1 are no longer maintained.

Connection of the servo drives via a mains choke is imperative:

y Where the servo drive is used in applications with disturbance variables corresponding to

environment class 3, as per IEC/EN 61000-2-4 and above (harsh industrial environment)

y In the case of single-phase mains supply

y For compliance with IEC/EN61800-3

For further information on permissible current loads, technical data and ambient

conditions please refer to the appendix.

NOTE

Please be aware that the MSD Single-Axis Servo Drive Compact is not

rated for environment class 3. Further measures are essential to achieve

this environment class! For further information please consult your project

engineer.

Page 29

C2 and C3

Mains

1-phase

C2 and C3

4.8.3 Connected load and mains fuse

Mains supply for C2 and C3 devices

2)

Specied mains

fuse, duty class

3)

gG [A]

Servo

Drive

Device rated power

With mains

choke (4% u

)

mains choke

K

1)

[kVA]

Without

Maximum cable cross-section

of the terminal [mm²]

Ferr. with

3)

insul

Ferr. w/o

insul

1x16 maximum

G394-030 1.3 1.6

2.5 2.5

(1-phase)

3x16 maximum

(3-phase)

G394-020 1.5 1.9 3x. 6 maximum

1x16 maximum

G394-059 2.6 3.2

2.5 2.5

(1-phase)

3x16 maximum

(3-phase)

G394-035 2.7 3.3 3x10 maximum

1x20 maximum

G394-080 3.5 4.3

4 4

(1 phase)

3x20 maximum

(3 phase)

G394-065 5.0 6.1 3x16 maximum

G394-120 8.1 10.5

4 6

3 x 32 maximum

G394-160 10.2 13.2 3 x 40 maximum

1) At 3x230VAC or 3x400VAC mains voltage and FT ≥ 8 kHz

The minimum cross-section of the mains power cable depends on the local regulations and conditions, as well as on the rated current of the servo drive.

2)

3) Ferr. with insul. = Ferrule with plastic insulation, Ferr. w/o insul. = Ferrule without plastic insulation

Table 4.6 Connected load and mains fuse

NOTE

Before commissioning, the value of the connected mains voltage must be

set on the servo drive (factory setting = 3x230VAC / 3x400VAC).

X2

+

Mains

Mains

3-phase

L1

L2

L3

K1F1

Figure 4.16 Connection C2 and C3 mains supply 3x230V (G394-030, G394-059) or 3x400V

(G394-020, G394-035) depending on device design

L1

N

Mains

ÿlter

choke

Mains

choke

K1F1

Mains

ÿlter

X3

X2

X3

L1

L2

L3

+

L1

L2

L3

moog

ID no.:CA97555-001 Date:04/2018

Figure 4.17 Connection C2 and C3 mains supply 1x230V) (G394-030, G394-059)

MSDSingle-Axis Servo Drive Compact Operation Manual

29

Page 30

moog

L1

L2

L3

Mains

3-phase

C4

C4

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

30

Mains supply for C4 devices

NOTE

Before commissioning, the value of the connected mains voltage must be

set on the servo drive (factory setting = 3x230VAC / 3x400VAC).

X2

X3

X2

+

L3

L2

L1

+

Mains

3-phase

L3

L2

L1

K1F1

Figure 4.18 Connection of C4 to mains supply 3x230V (G394-080) or 3x400V (G394-065)

depending on device design

Mains

1-phase

Mains

choke

Mains

ÿlter

Mains supply for C5 devices

NOTE:

Before commissioning, the value of the connected mains voltage must be

set on the servo drive (factory setting = 3x400VAC).

Mains

Mains

K1F1

Figure 4.20 Connection of C5 to mains supply 3x400V (G394-120, G394-160) depending on

device design

choke

ÿlter

X2

+

L3

L2

X3

L1

N

L1

K1F1

Figure 4.19 Connection of C4 to mains supply 1x230V (G394-080)

Mains

choke

Mains

ÿlter

X3

L3

L2

L1

CAUTION! Shutdown of the pre-charging!

To protect the servo drive from thermal overload, make sure that the pre-charging of the DC

link is not switched on for more than 2 minutes without the main contactor is active.

The pre-charging of the DC link is not designed for high power consumption during the

operation.

Ignoring of this rule may destroy the device!

Page 31

REL

REL

ISDSH

ISD06

ISD05

ISD04

ISD03

ISD02

ISD01

ISD00

+24V

DGND

RSH

RSH

ENPO

OSD02

OSD01

OSD00

ISA1-

ISA1+

ISA0-

ISA0+

+24V

DGND

X4

4.9 Control connections

4.9.1 Specification of cont ol connections

Step Action Comment

Check whether complete device settings are already

1.

available, i.e. whether the drive has already been

configured

If this is the case, a special control terminal assign-

2.

ment applies.

Please contact your project engineer to obtain the

terminal assignment!

3.

Choose a terminal assignment. Initial commissioning

Wire the control terminals with shielded cables.

4.

The following is imperative: STO request X4/22,

ENPO X4/10 and a start signal (with control via

terminal).

5.

6.

Keep all contacts open (inputs inactive).

Check all connections again! Continue with chapter “5 Commissioning”

Note the following points:

y Always wire the control terminals with shielded cables.

y Lay the control cables separately from the mains power and motor cables.

y A cable type with double copper braiding, with 60 to 70% coverage, must be used for all

shielded connections.

moog

ID no.:CA97555-001 Date:04/2018

Earth the cable shields over a large area at

both ends.

Rigid conductor sizes: 0.2 to 1.5 mm²

(0.0003 to 0.0023 in²)

Flexible conductor sizes:

- Ferrule without plastic sleeve:

0.2 to 1.5 mm² (0.0003 to 0.0023 in²)

- Ferrule with plastic sleeve:

0.2 to 0.75 mm² (0.0003 to 0.0012 in²)

Des. Term. Specication Electrical isolation

Analog inputs

= ±10VDC

• U

ISA0+

ISA0-

ISA1+

ISA1-

X4/3

X4/4

X4/5

X4/6

IN

• Resolution 12bits; R

approx.101kΩ

IN

• Terminal scan cycle in "IP mode" = 125µs, otherwise

= 1ms

• Tolerance: U±1% of the measuring range end value

no

Digital inputs

ISD00

ISD01

ISD02

ISD03

ISD04

ISD05

ISD06

X4/15

X4/16

X4/17

X4/18

X4/19

X4/20

X4/21

ENPO X4/10

• Frequency range <500Hz

• Terminal scan cycle in = 1ms

• Switching level Low/High: ≤4.8V / ≥18V

= +24VDC +20%

• U

IN max

• I

at +24VDC = typ. 3mA

IN

• Frequency range ≤500kHz

• Switching level Low/High: ≤4.8V / ≥18V

• U

= +24VDC +20%

IN max

• I

max at +24VDC = 10mA, RIN approx. 3kΩ

IN max

• Internal signal delay < 2 µs suitable as trigger input for

quickly saving actual position

• Disable restart inhibit (STO)

and enable power stage =

High level

• OSSD support

• 10ms

yes

yes

yes

24

23

22

21

20

19

18

17

16

15

14

13

• Switching level Low/High: ≤4.8V / ≥18V

• U

= +24VDC +20%

IN max

• I

at +24VDC = typ. 3mA

IN

Digital outputs

• No destruction in case of short-circuit (+24VDC ->

OSD00

OSD01

OSD02

X4/7

X4/8

X4/9

DGND), but device may briefly shut down

= 50mA, PLC-compatible

• I

max

• Terminal scan cycle in = 1ms

yes

• High-side driver

Table 4.7 Specification of control connections X4

MSDSingle-Axis Servo Drive Compact Operation Manual

12

11

10

9

8

7

6

5

4

3

2

1

31

Page 32

moog

I

I

REL

REL

ISDSH

ISD06

ISD05

ISD04

ISD03

ISD02

ISD01

ISD00

+24V

DGND

RSH

RSH

ENPO

OSD02

OSD01

OSD00

ISA1-

ISA1+

ISA0-

ISA0+

+24V

DGND

X4

X4/12

X4/11

X4/23

X4/24

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

32

Des. Term. Specication Electrical isolation

STO "Safe Torque Off"

• "Request STO" input = Low level

ISDSH

(STO)

X4/22

• OSSD support

• Switching level Low/High: ≤4.8V / ≥18V

• U

IN max

• I

at +24VDC = typ. 3mA

IN

Diagnostics STO, both cut-off channels

RSH

RSH

active, one NO contact with automatically

X4/11

resetting circuit-breaker (polyswitch)

X4/12

• 25V / 200mAAC, cosϕ = 1

• 30V / 200mADC, cosϕ = 1

Relay outputs

Relay, 1 NO contact

• 25V / 1.0AAC, cosϕ = 1 (AC1)

• 30V / 1.0ADC, cosϕ = 1 (DC1)

• Switching delay approx. 10ms

REL

X4/23

X4/24

• Cycle time 1 ms

Auxiliary voltage

• Auxiliary voltage output (U

control inputs

• U

= UV-∆U (∆U typically approx. 1.2V), no destruction

+24V

X4/2

X4/14

H

in case of short circuit (+24VDC -> DGND), but

device may briefly shut down

• I

= 80mA (per pin) with self-resetting circuit

max

breaker (polyswitch)

Digital ground

DGND

X4/1

Reference ground for +24VDC yes

X4/13

Table 4.7 Specification of control connections X4

= +24VDC +20%

) for feeding the digital

H

yes

yes

yes

4.9.2 Connection of motor brake X13

Connector X13 is intended for connection of a motor brake.

Des. Term. Connection Specication

GND

GND

V+

X13/2

X13/1

X13/3

X13/4

< 2.0 A

BR

Front

X13

OSD03

Motor

3

~

4

24 V DC ext.

V+

supply

3

GND

2

Brake (+)

1

GND

Brake (-)

• Short-circuit proof

• External control supply +24VDC

(I

= 2.1 A) required via X13/3 (GND) and X13/4

IN

(V+)

• U

= UV-∆U` (∆U` typically approx. 1.4 V)

BR

• To actuate a motor holding brake up to

IBR = 2.0A maximum

• Overcurrent causes cyclic shutdown

• Also usable as configurable digital outpu

> 2.0 A

BR

Front

X13

OSD03

Motor

3

~

4

24 V DC ext.

V+

supply

3

GND

2

24 V DC

1

GND

Brake (-)

Brake (+)

• Cable break monitor:

With the brake driver switched on, cable break

is detected at output currents <200mA.

The cable break monitoring can be disabled.

NOTE:

For brakes with higher current requirements (> 2.0 A), a relay must be

provided. The cable break monitoring on X13 is then no longer usable and

must be provided externally.

OSD03

24

12

23

11

22

10

21

9

20

8

19

7

18

6

17

5

16

4

15

3

14

2

13

1

Table 4.8 Specification of the terminal connections X13

Page 33

4.10 Specification, Ethernet interface

4.12 Option 2

The service and diagnostic interface X9 is designed as a TCP/IP Ethernet interface. It

is suitable for connection of a PC for commissioning, service and diagnostics and for

programming of the servo drive.

The following software can communicate with the servo drive via the Ethernet interface:

y Moog DriveADministrAtor5 for commissioning, service and diagnostics on the MSD Single-Axis

Servo Drive Compact

y

CoDeSys 3.x programming system for programming the MSD Single-Axis Servo Drive Compact

in the languages of IEC61131-3. For this purpose a servo drive licence is required.

Specification of interface

y Transfer rate 10/100 Mbits/s BASE

y Line protocol IEEE802.3 compliant

y Connection via standard commercially available crosslink cable, CAT5

4.11 Option 1

Depending on the MSD Single-Axis Servo Drive Compact variant, Option 1 is factoryconfigu ed with various options. Field bus options such as EtherCAT or SERCOS are

available.

You will find all available options in the MSD O dering Catalog. The user manuals for the

respective options provide detailed information on commissioning.

Option 2 can be factory-configu ed with various technology options. Additional or special

encoders can be evaluated here for example.

You will find all available options in the MSD O dering Catalog. The user manuals for the

respective options provide detailed information on commissioning.

moog

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

33

Page 34

moog

r

ID no.:CA97555-001 Date:04/2018

MSDSingle-Axis Servo Drive Compact Operation Manual

34

4.13 Encoder connection

All encoder connections are located on the top of the unit.

Encoder connection for synchronous motors

Please use the ready made motor and encoder cables from Moog to connect the

synchronous motors (see Servo Motors Ordering Catalog).

Assignment of servo

Compare the rating plates of the components. Make absolutely sure you are using the

correct components according to variant A, B or C!

7

X

X

(optional

6

1

X

drive motor-encoder connection

Variant

C

8

X

Variant

)

Variant

A

B

high-resolution encode

high-resolution encoder

NOTE:

Do not split the encoder cable, for example to route the signals via terminals in

the switch cabinet. The knurled screws on the D-Sub connector housing must

be tightly locked!

Motor (with installed encoder) Encoder cable

Variant A

Variant B

Variant C

Table 4.9 Variants of motors, encoder type and encoder cable

With resolver

without further options

Sin/Cos single-/multi-turn encoder

with SSI/EnDat interface

Sin/Cos single-/multi-turn encoder

with HIPERFACE® interface

C08335-013-yyy X6

CA58876-002-yyy X7

CA58877-002-yyy X7

Servo drive

connection

4.13.1 Ready made encoder cables

The specifications can only be assu ed on the usage of Moog system cables.

Encoder cab

Ready m ade cab

Resolver cable

Encoder cable SSI, EnDat CA58876

Encoder cable Hiperface

Encoderystem

Version

Cable l e (m)

C08335

® CA5 8877

013

002

002

- yyy

1)

Resolver

Figure 4.21 Motor/encoder cable assignment

1) yyy sta nd for length in meters; stan dard le ngth; Sta ndardlängen: 1 m (3.28 ft), 5 m (16.40 ft), 10 m (32.80 ft), 15 m (49 ft),

20 m (65 ft), 50 m (164 ft). Furthe r length o n reque st