Page 1

MPT- 90

PAN AND TILT POSITIONER

PRODUCT MANUAL

Page 2

____________________________________________________________________

WARNING

IT IS REQUIRED THAT YOU READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

BY NOT FOLLOWING THE INSTRUCTIONS IN THIS MANUAL MAY RESULT IN DAMAGE

TO THE EQUIPMENT OR OPERATOR

MOOG

Phone: (847) 498-0700

Email: moogs3service@moog.com

LIMITED WARRANTY

Products manufactured by SELLER are warranted at time of shipment to be free from defects in material and workmanship

under normal use and service. This warranty is only applicable to any of SELLER’s products which BUYER returns to

SELLER within one (1) year from the date of initial delivery, and which SELLER determines to be defective within the terms

of this warranty.

Commercial Off-The-Shelf (OTS) products delivered by SELLER are warranted at time of shipment to be free from defects in

material and workmanship under normal use and service. This warranty is only applicable to any of OTS Products delivered

by SELLER which BUYER returns to SELLER within ninety (90) days from the date of initial delivery, and which SELLER

determines to be defective within the terms of this warranty. SELLER's obligations, with respect to such applicable warranty

returns, are limited to repair, replacement, or refund of the purchase price actually paid for the product, at SELLER's sole

option.

SELLER shall bear round-trip shipment costs of defective Items found to be covered by this warranty. Unless otherwise

agreed, the BUYER shall bear any additional costs which SELLER incurs for repair, dismantling, installation, and transport

as a result of the Product being located in a place other than the destination stated in the Contract or, if no destination is

stated, the place of delivery.

Replaced or repaired parts or Products will carry only the unexpired portion of the original warranty as of the date of notice to

SELLER of the warranty defect. Defective Products or parts thereof may be replaced with either new, factory refurbished, or

remanufactured parts. Defective parts, which have been replaced, shall become the SELLER’s property. This warranty does

not extend to any product sold by SELLER which has been subjected to misuse, neglect, accident, improper installation, or a

use for purposes not included or not in accordance with operational maintenance procedures and instructions furnished by

SELLER, or which has been repaired or altered by BUYER or persons other than SELLER or which has been damaged by

secondary causes, including but not limited to, improper voltages, adverse environment conditions, improper signals, or

products which have had their serial number or any part thereof altered, defaced, or removed . Fuses, air filters, desiccants,

and lamps shall be excluded from the provisions of this warranty, and as to these Items no warranty, expressed or implied, is

made by SELLER. SELLER liability does not cover normal wear and tear or deterioration.

THE FOREGOING, WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, INCLUDING, BUT NOT LIMITED TO,

WRITTEN, EXPRESS, IMPLIED OR STATUTORY WARRANTIES.

IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE AND MERCHANTABILITY AND DESIGN

WARRANTIES ARE SPECIFICALLY EXCLUDED AND SHALL NOT APPLY.

SELLER'S OBLIGATIONS AND BUYER'S REMEDIES WITH RESPECT TO DEFECTIVE OR NONCONFORMING

PRODUCTS ARE SOLELY AND EXCLUSIVELY AS STATED HEREIN.

At the time of purchase, the SELLER grants to the BUYER, the option to procure a one or two years warranty extension for

selected custom products at the prices specified in the SELLER’s proposal/contract.

____________________________________________________________________________

MN0090-05 Page 2 of 68 18008

MPT-90 PRODUCT MANUAL

Page 3

____________________________________________________________________

TABLE OF CONTENTS

SECTION OR PAGE

PARAGRAPH TITLE NUMBER

1.0 INTRODUCTION .................................................................................. 6

1.1 SCOPE .................................................................................................................... 6

1.2 CUSTOMER SUPPORT ............................................................................................... 6

1.3 DEFINITIONS, ABBREVIATIONS AND ACRONYMS .......................................... 7

1.4 CONVENTIONS USED IN THIS MANUAL ....................................................................... 8

1.5 SYSTEM DIMENSIONS ............................................................................................... 9

2.0 THEORY OF OPERATION......................................................................... 10

2.1 MODELS ................................................................................................................ 10

2.2 MECHANICAL ......................................................................................................... 10

2.3 POSITION .............................................................................................................. 10

2.4 DRIVE ................................................................................................................... 11

2.5 ELECTRONICS ........................................................................................................ 11

2.6 LIMITS ................................................................................................................... 12

3.0 MPT -90 MODELS ................................................................................ 13

3.1 PAN AND TILT DESCRIPTION ................................................................................... 14

3.1.1 System Input Power – All Models ........................................................................................... 15

3.1.2 IP and Serial Control of Positioner – All Models ..................................................................... 17

3.1.3 Additional Serial Control of Positioner – All Models ............................................................... 18

3.1.4 General Purpose I/O Pass Through & Chassis Ground All Models ....................................... 19

3.1.5 Model 8-PB133, 10/100 Ethernet Ports 1 & 2 ........................................................................ 20

3.1.6 Model 8-PB151, Gigabit Ethernet Base to Port 1 Payload ..................................................... 21

3.1.7 Serial Control Communication to ports ................................................................................... 22

3.1.8 Camera Lens Accommodations .............................................................................................. 23

3.1.9 Video Signal ............................................................................................................................ 24

3.2 MOOG PAN AND TILT CONTROL CIRCUIT BOARD DESCRIPTION ................................. 25

3.2.1 Control Circuit Board Configuration ........................................................................................ 25

3.2.1.1 Circuit Card Access ................................................................................................................. 25

3.2.1.2 PBC Jumper Settings: ............................................................................................................. 29

NOTE All jumper settings, the screened dot is Pin 1. Refer to Figure 10 below. ............................................. 29

3.3 PCB SWITCH SETTINGS ......................................................................................... 32

3.3.1 S2 switch settings for serial communication ports .................................................................. 32

3.3.2 S4 switch settings for serial communication ports .................................................................. 34

_______________________________________________________________________

MN0090-05 Page 3 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 4

____________________________________________________________________

4.0 INSTALLATION ....................................................................................... 35

4.1 UNPACK AND INSPECT ............................................................................................ 35

4.2 QUICK START GUIDE .............................................................................................. 35

4.3 INSTALLATION PROCEDURES - MECHANICAL ............................................................ 35

4.3.1 Site Location ............................................................................................................................ 35

4.3.2 Caution on Mobile Mounting ................................................................................................... 36

4.3.3 MPT-90 Installation ................................................................................................................. 37

4.4 INSTALLATION PROCEDURES – ELECTRICAL ............................................................. 38

4.4.1 Connector installation .............................................................................................................. 38

4.5 MATING RECEPTACLE CONNECTOR WIRING ............................................... 40

4.6 MPT-90 SETUP AND ADJUSTMENT PROCEDURES .................................................... 43

5.0 MOOG PTZ WEB INTERFACE INTERNAL WEB GUI ...................... 44

5.1 CONNECTING THE MPT-90 TO A COMPUTER ................................................ 44

5.2 CONNECTING THE MPT-90 TO A NETWORK .................................................. 46

5.3 MOOG PTZ WEB INTERFACE ........................................................................... 47

6.0 SERVICING / MAINTENANCE ........................................................... 56

6.1 MANUALLY ROTATING THE WORM DRIVE SHAFT (PAN OR TILT) ................................ 56

6.2 INTERNAL ACCESS ................................................................................................. 56

6.3 LIMIT RING (HARD STOP) ADJUSTMENT ................................................................... 57

6.4 DRIVE CHAIN TENSION ADJUSTMENT....................................................................... 60

6.5 PAN AND TILT BEARINGS ........................................................................................ 61

6.6 BACKLASH ............................................................................................................. 61

6.6.1 Backlash Test .......................................................................................................................... 62

6.6.2 Backlash Adjustment ............................................................................................................... 62

7.0 MAINTENANCE & REPAIR ............................................................... 64

7.1 ROUTINE MAINTENANCE ......................................................................................... 64

7.1.1 Fresh Water Wash .................................................................................................................. 64

7.1.2 Inspection Intervals ................................................................................................................. 64

7.1.3 Lubrication ............................................................................................................................... 64

7.1.4 Inspection Items ...................................................................................................................... 65

8.0 FAULT ISOLATION ........................................................................... 66

8.1 INTRODUCTION ...................................................................................................... 66

8.2 MECHANICAL OR ELECTRICAL ................................................................................. 66

8.3 MECHANICAL FAULT ISOLATION ............................................................................... 67

_______________________________________________________________________

MN0090-05 Page 4 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 5

____________________________________________________________________

8.4 ELECTRICAL FAULT ISOLATION ................................................................................ 67

TABLE OF FIGURES

FIGURE TITLE PAGE

Figure 1: Identification Label ................................................................................................ 6

Figure 2: MPT-90 Definitions ............................................................................................... 7

Figure 3: MPT-90 Dimensions ............................................................................................. 9

Figure 4: Feature Comparison Table ................................................................................. 14

Figure 5: Pan & Tilt Unit Major Components ...................................................................... 15

Figure 6: Accessing the Circuit Board ................................................................................ 26

Figure 7: Circuit Board ....................................................................................................... 26

Figure 8: Circuit Board Components I ................................................................................ 27

Figure 9: Circuit Board Components II ............................................................................... 28

Figure 10: Jumper Locations .............................................................................................. 29

Figure 11: PCB Switches ................................................................................................... 32

Figure 12: Mounting Base .................................................................................................. 37

Figure 13: Worm Drive ....................................................................................................... 56

Figure 14: Tilt Limit Ring (Hard Limit) Adjustment.............................................................. 58

Figure 15: Pan Limit Ring (Hard Limit) Adjustment ............................................................ 59

Figure 16: Drive Chain ....................................................................................................... 60

Figure 17: Drive Chain Adjustment .................................................................................... 61

Figure 18: Pan & Tilt Axis Backlash Test & Adjustment ..................................................... 63

Figure 19: AeroShell 64 ..................................................................................................... 65

_______________________________________________________________________

MN0090-05 Page 5 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 6

____________________________________________________________________

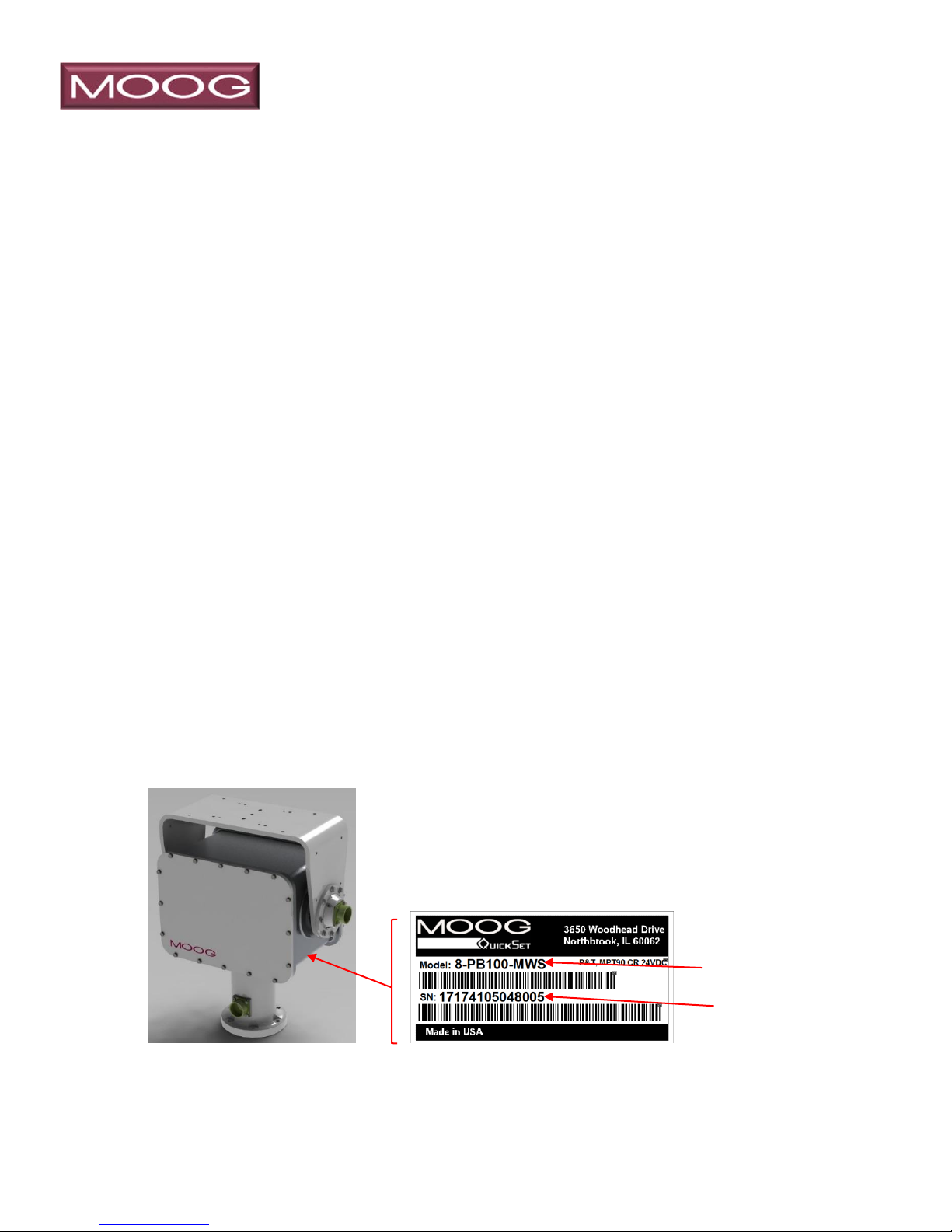

Model Number

Serial Number

1.0 INTRODUCTION

The purpose of this manual is to provide the MPT-90 Moog Pan and Tilt operator with

the required information necessary to install, operate, troubleshoot and maintain, the

MPT-90 to a level approved by the manufacturer, Moog Inc.

1.1 Scope

Read these instructions before installing or operating the MPT-90 Pan and Tilt.

This manual provides basic installation and operation information. In order to use this

document, the reader must have a basic knowledge of Windows-based PC computers

and adequate mechanical ability.

1.2 Customer support

If information beyond the scope of this manual is required, or you require assistance

with the setup, operation, maintenance, and troubleshooting of this product, refer to

this document. If you still have questions, please contact us at:

Moog, Inc.

Sensor and Surveillance Sales and Marketing

Northbrook, IL USA 60062

Telephone: 1-800-247-6563

(847) 498-0700

Email: moogs3service@moog.com

To help us better assist you we recommend that you are at the equipment and ready

with all available details including model & serial number before contacting Moog.

Refer to Figure 1.

Figure 1: Identification Label

The identification label is attached to the underside of the positioner.

_______________________________________________________________________

MN0090-05 Page 6 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 7

____________________________________________________________________

1.3 DEFINITIONS, ABBREVIATIONS AND ACRONYMS

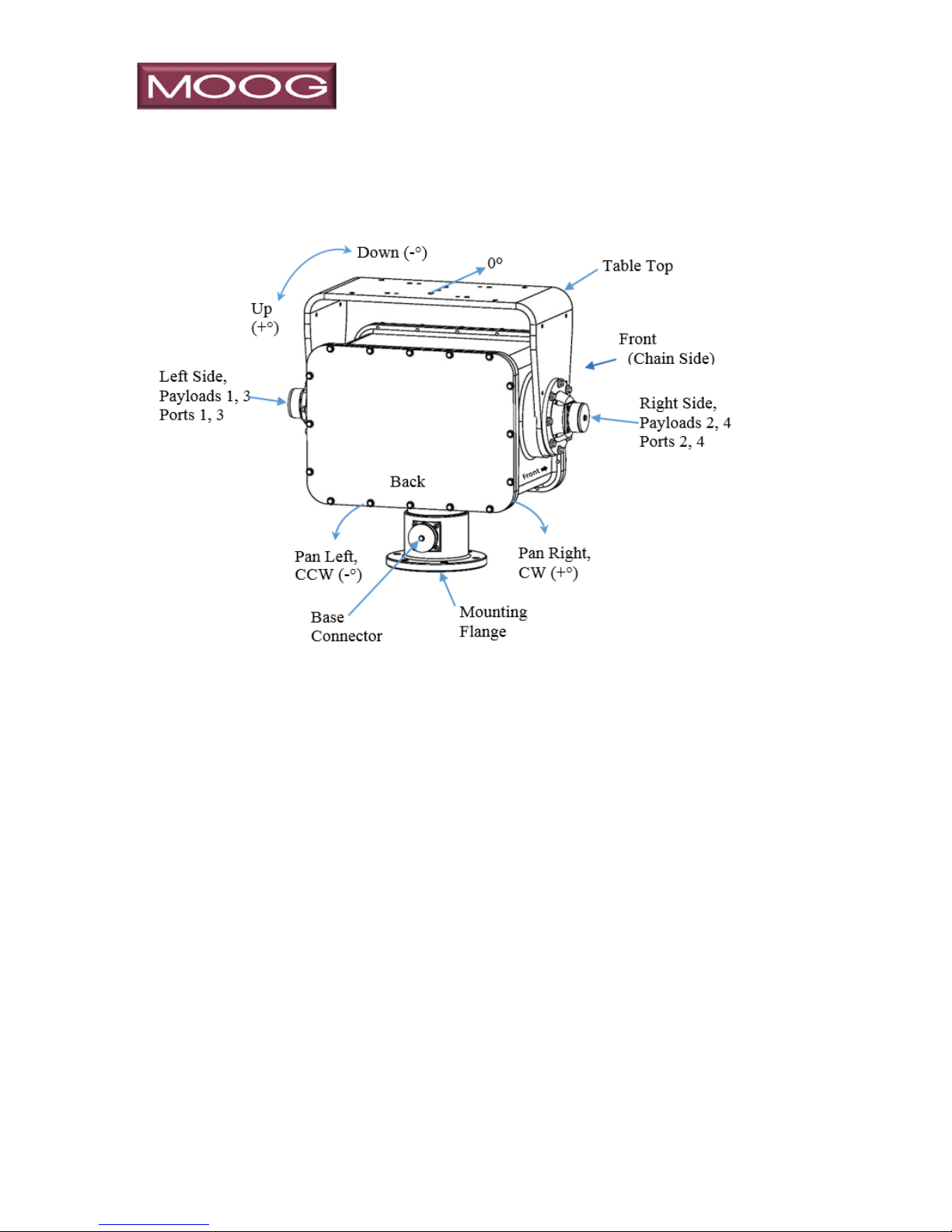

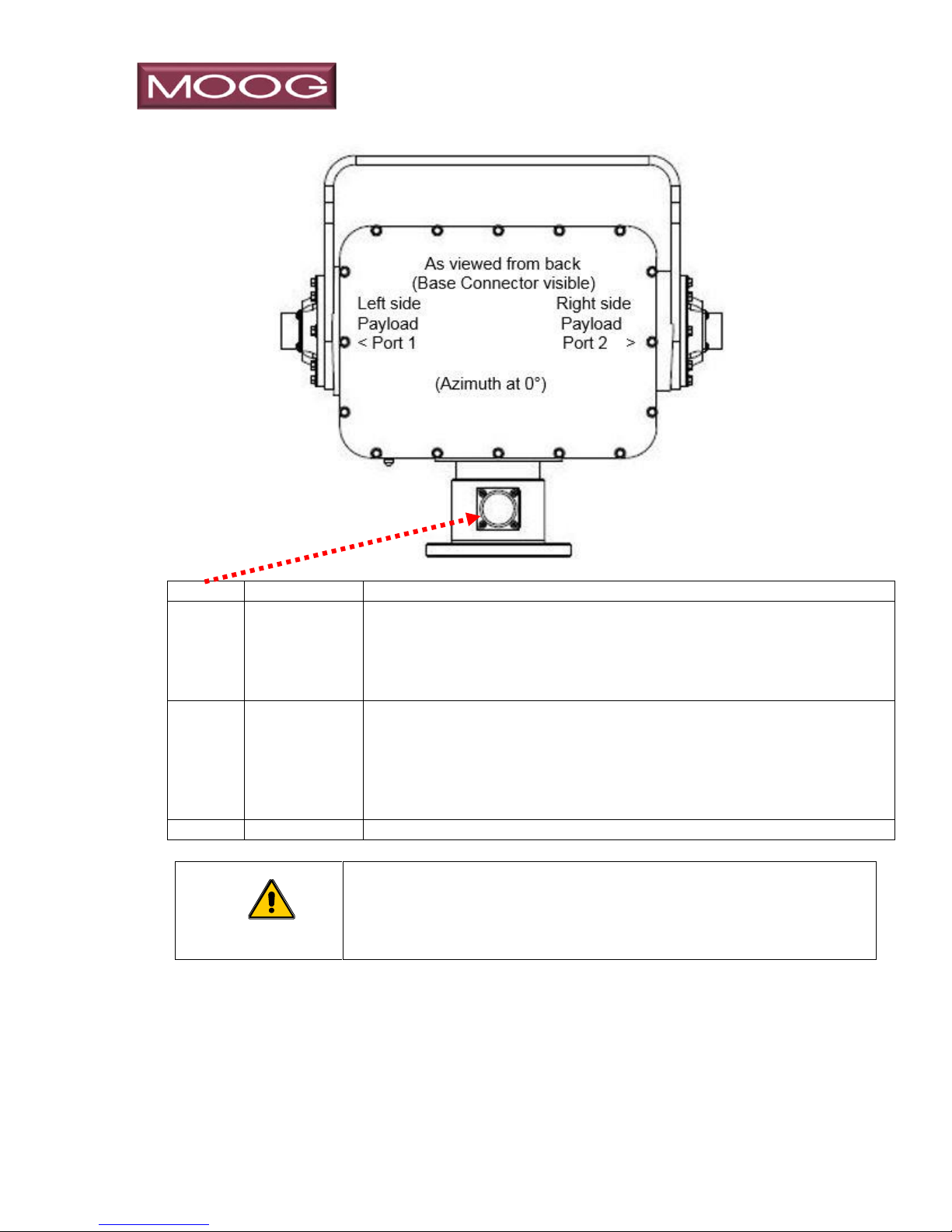

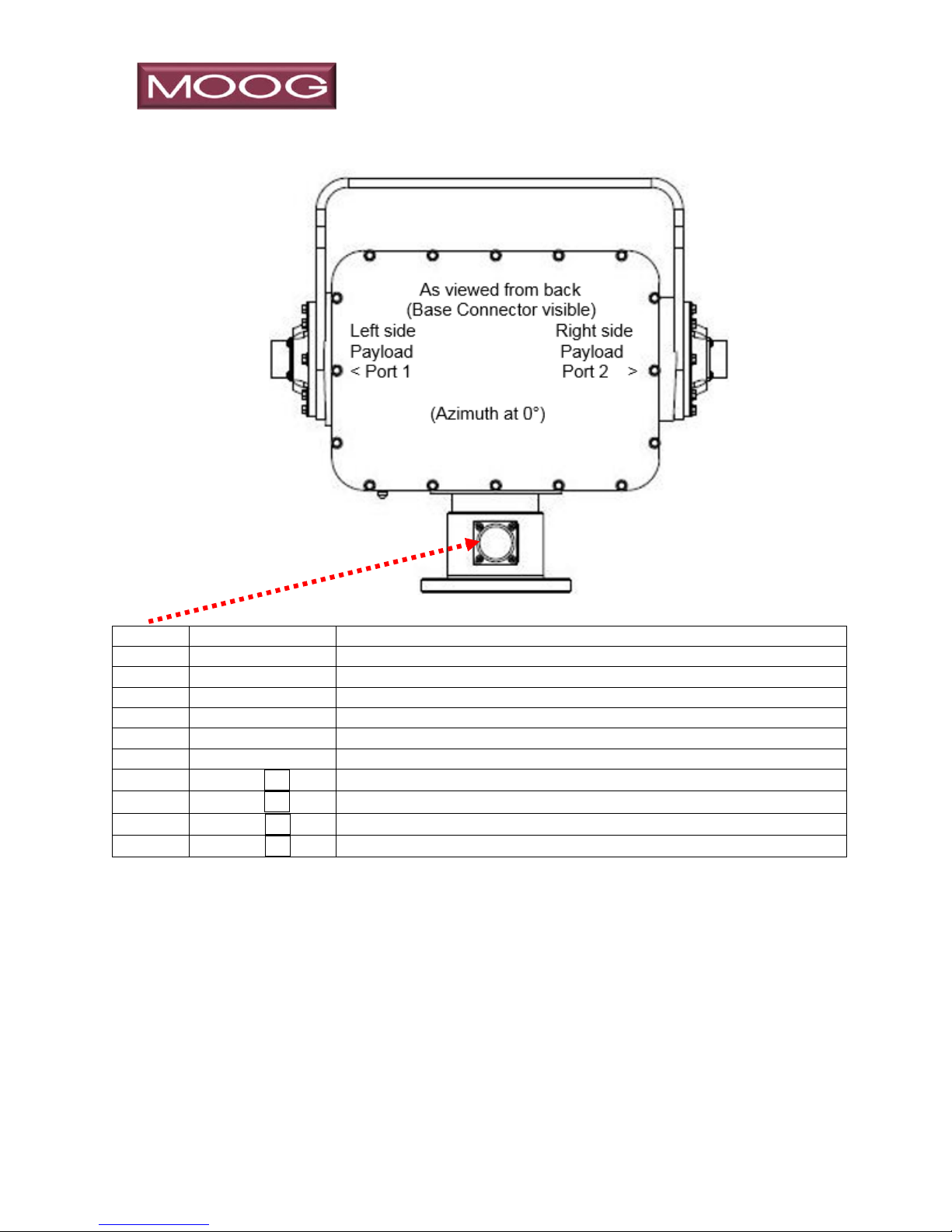

Figure 2: MPT-90 Definitions

Front: the front of the P&T is the side with the Chain Drive under the cover. Most

Moog P&T units have a label on the left side (although shown on right side in

the depiction above) pointing toward the front. Refer to Figure 2.

Zero (0°) Azimuth: typically, the center of azimuth rotation on non-continuous units,

“0° Azimuth” is when the base connector is orientated opposite of the chain

side. When positioned at 0° a cable connected to the base connector would

egress out the “back” of the unit, 180° away from the front.

Left & Right – the left and right side are considered from the perspective of a camera.

With a camera mounted toward the front, an observed video image would

providing the perspective: to “Pan Left”, you would move the positioner

Counter Clock Wise (CCW) as viewed from the top. Moving to the right or

CW increments the degree heading while moving to the left or CCW will

decrement the heading in degrees.

Up & Down – moving upward means the table top is moving toward the rear of the

unit and the indicated position would increment as the elevation increases.

Moving downward would decrement the position in degrees.

_______________________________________________________________________

MN0090-05 Page 7 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 8

____________________________________________________________________

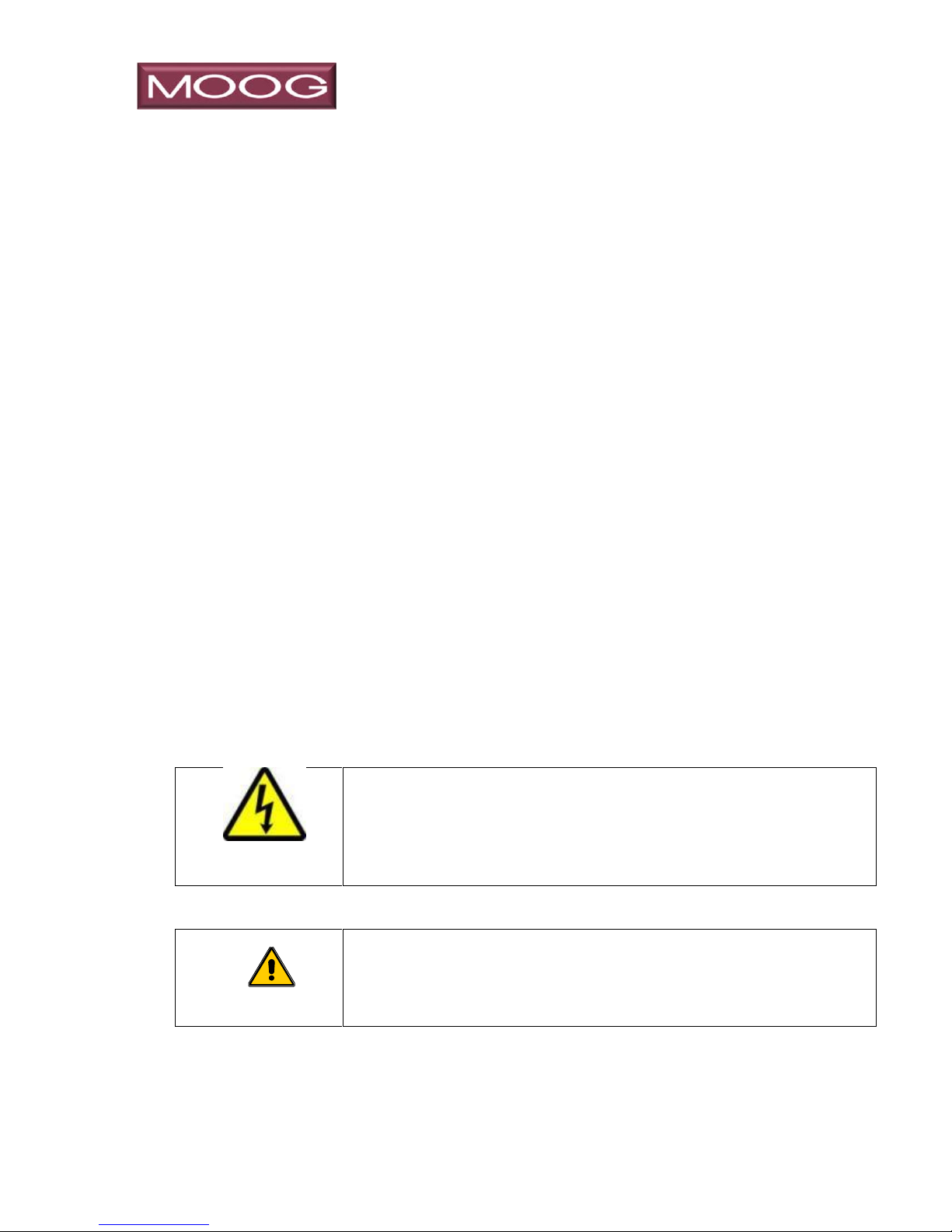

WARNING

IMPROPER USE OF THIS PRODUCT CAN CAUSE SEVERE

BODILY INJURY OR DAMAGE THE EQUIPMENT.

CAUTION

IMPROPER USE OF THIS PRODUCT CAN DAMAGE THE

EQUIPMENT.

Base connector – on base of unit, in a fixed position related to its mounting flange,

egressing out opposite the front at 180°.

The following list of acronyms are used in this manual:

DC Direct Current

EIA Electronic Industry Association

GIG-E Gigabit Ethernet, aka 1000BASE-T

GUI Graphic User Interface

HD-SDI High Definition-Serial Digital Interface

in Inches

I/O Input / Output

lbs. Pounds

mm millimeters

MPT Moog Pan & Tilt

PCB Printed Circuit Board

P & T Pan & Tilt, also known as Positioner

TIA Telecommunications Industry Association

VAC Volts Alternating Current

VDC Volts Direct Current

VRMS Volts Root Mean Square

1.4 Conventions Used in this Manual

Boldface highlights key user interface components. WARNING, CAUTION,

and NOTE highlight statements that identify potential hazards that may occur

if this equipment is not used properly.

NOTE

Notes contain important information about the product or procedure.

_______________________________________________________________________

MN0090-05 Page 8 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 9

____________________________________________________________________

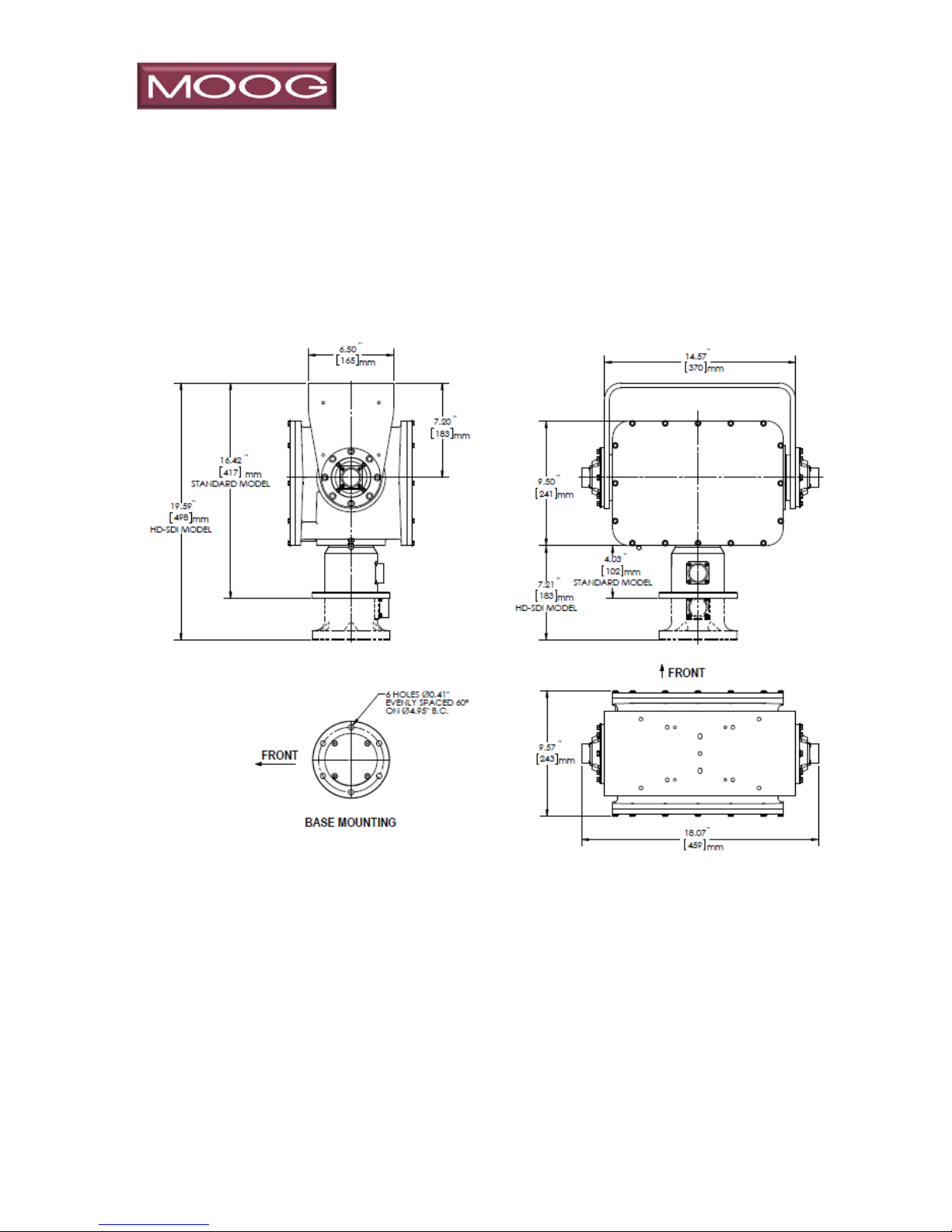

1.5 System Dimensions

Dimensions are per the Figure 3.

Figure 3: MPT-90 Dimensions

This drawing shows the overall dimensions for both the standard base model

and the taller HD-SDI version models.

_______________________________________________________________________

MN0090-05 Page 9 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

NOTE

Page 10

____________________________________________________________________

2.0 THEORY OF OPERATION

2.1 Models

The MPT-90 is available is several Continuous rotation versions or in a NonContinuous configuration. The continuous rotation versions utilize an electrical

slip ring assembly to allow for 360 degrees of pan rotation capability while

providing connectivity to the positioner and payload. Overall connectivity

between the base connector and the payload ports is limited by the number

of conductors in the slip ring, and models vary based on the types of signal

passed through the slip ring.

The Non-Continuous configuration is limited in azimuth rotation, but is factory

default set to 435° of total rotation, with the indicated 0° being the center of

that rotation. The user may set “limit rings” internal to the positioner that will

activate switches to reduce the amount of azimuth travel if desired. Limit rings

are also standard on the tilt mechanism for all models, set at ±90° from the

table top’s horizontal position. Additionally, all units have software adjustable

travel limits.

2.2 Mechanical

Each axis of rotation is rigidly attached to a large 60 tooth helical gear. These

gears are meshed with a worm gear (essentially a 1 tooth gear) that is part of

a steel shaft supported by tapered roller bearings, mounted in an aluminum

“carrier”. The bearings are pre-loaded to prevent lateral play, and the carrier

position is adjustable allowing the worm optimum mesh with helical gear, with

negligible backlash. With the exception of the backlash in the worm drive, the

pan & tilt axis of motion cannot move unless the worm gear is driving it. This

allows the payload to be locked in position even when power is removed.

Mechanical drive mechanisms for Pan and Tilt axis of motion are nearly

identical, with the exception of slight differences in the chain drive sprocket

ratios.

2.3 Position

Position is measured by incremental encoders mounted on-axis to the main

helical gear which read/report actual position inclusive of any system

backlash. Each encoder utilizes an “index” signal that occurs once per

revolution. This index signal is used during the factory installation homing

routine and calibrates the axis of motion 0° azimuth and 0° elevation absolute

position. Position is stored in memory when powered down, allowing the

positioner to know its position when powered up. Since worm gears of this

ratio lock the unit into position, no movement is expected in an unpowered

state, however, each time the axis of motion crosses the index pulse, the unit

will recalibrate position based on the initial homing cycle.

_______________________________________________________________________

MN0090-05 Page 10 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 11

____________________________________________________________________

2.4 Drive

The drive mechanism consists of two 1.8° stepper motors, driven by a 10:1

micro-step motor driver. The motor drivers are provided with DC source

voltage, and enable, direction and pulse signals. 2000 pulses are required for

the motor to turn 1 revolution. Each motor has a 12 tooth sprocket to drive the

worm-carriers via a chain drive. The chain is tensioned with an adjustable

idler, and the chains drive the carriers mentioned above. The pan carrier uses

a 28 tooth sprocket where the tilt uses a 30 tooth sprocket, giving the tilt a

slight increase in ratio reduction.

2.5 Electronics

The controller provides two fundamental types of moves: open loop “jog”

moves where the user specifies direction and velocity, and automated moves

where the controller is managing the move.

Stepper motors require starting at a nominally low speed, and may then be

accelerated by increasing the frequency of the pulse to the motor driver. In jog

mode, the unit will begin a move at a pre-determined speed and accelerate to

the commanded speed. When the jog command is terminated, the pulses

stop quickly decrease in frequency to zero, preventing an abrupt stop.

In automated moves, the microcontroller determines which direction it must

go, then manages the move by controlling acceleration, running at the

commanded speed during the move while monitoring position. The start

speed, acceleration rate and maximum move speed are user adjustable.

When the unit arrives at a pre-determined distance from the commanded

position, a deceleration process begins, slowing the unit to a stop at the

intended destination. User may set the distance from the final destination

where the slow down process starts. These adjustments allow the user to

tailor the motion profile to optimize for the type and size of the payload. For

example, you may wish to position a short range camera system with more

aggressive moves than a satellite dish, due to its size. A more complete

description of adjustments is in the protocol manual.

Additional electronic capabilities provide inner-connections between the

multiple serial ports on the unit, allowing the user to command the positioner

and payloads using various command methods.

_______________________________________________________________________

MN0090-05 Page 11 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 12

____________________________________________________________________

2.6 Limits

Elevation range of motion may be limited in all models both electronically and

mechanically. Additionally, non-continuous rotation models have limit settings

for the azimuth range of motion. “Soft Limits” are software settable, and are

primary method used to limit motion. The P&T units are shipped with the soft

limits set at the maximum range of motion, although the range of motion may

be limited by using the included software. Soft limits should always be set a

minimum of 0.2° beyond any position to be stored as a preset position; the

user should not set a preset position on a soft limit. Please refer to the

MN00307 Moog PTZ Controller Software Manual for instructions on how to

set the soft limits.

Mechanical switches to limit travel (“hard limits”) are provided on the elevation

for continuous rotation models, and on both axis of motion for non-continuous

models. These consist of plastic, moveable, color coded “trip rings” that

trigger a microswitch that tells the microcontroller to stop motion in that

direction, while allowing reverse motion. These should be considered a

secondary method of limiting motion, as there are software limits (“soft limit”)

provided as well. The default setting for the hard limits is slightly beyond the

default soft limit setting at the maximum range of normal motion for the

positioner and the user should not attempt to increase the range of motion

without consultation with the factory. Additionally, it is recommended that hard

limits should always be set at minimum 2° beyond the soft limits. It is not

necessary for the user to adjust the hard limit settings unless they wish to

provide a secondary, redundant method of assuring the unit not travel beyond

the soft limits.

_______________________________________________________________________

MN0090-05 Page 12 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 13

____________________________________________________________________

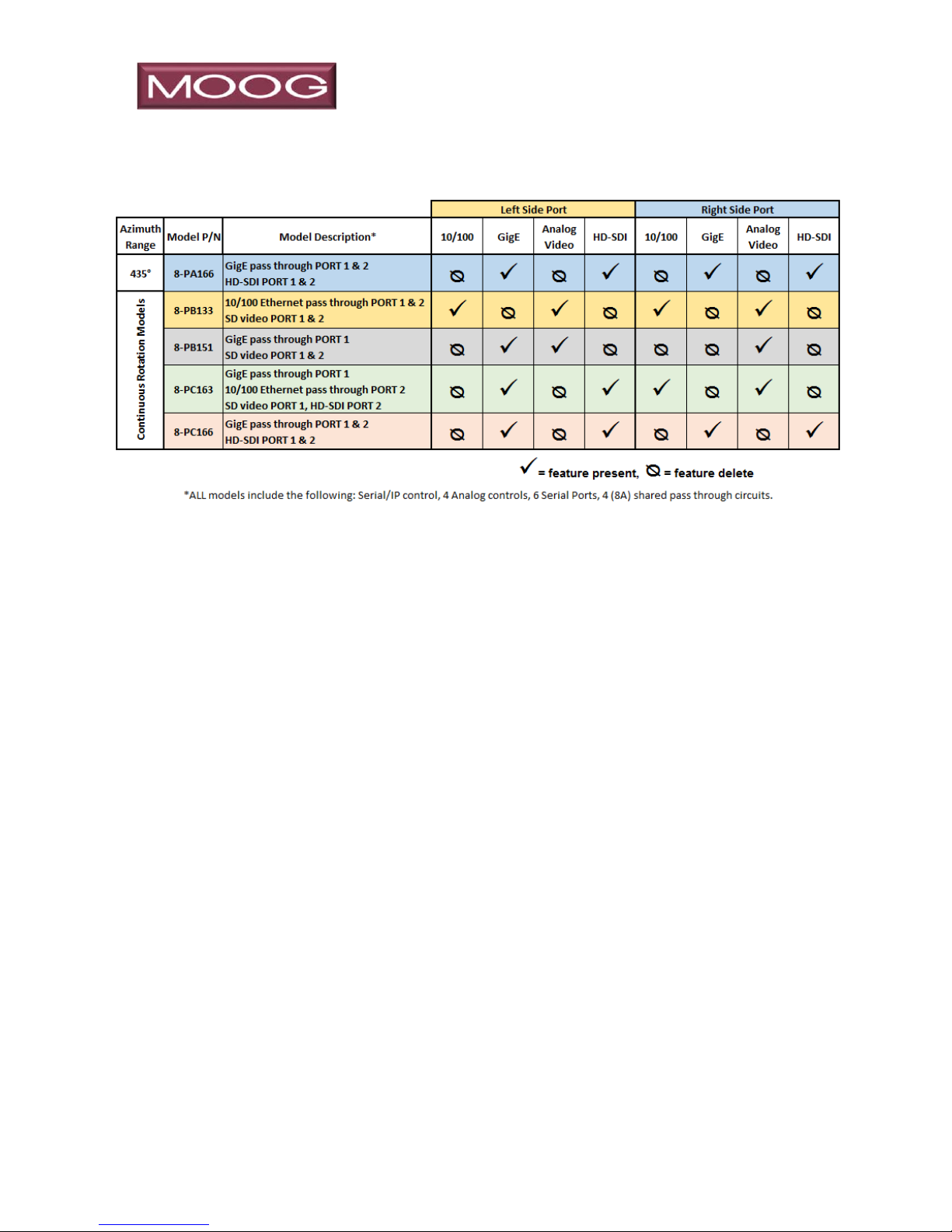

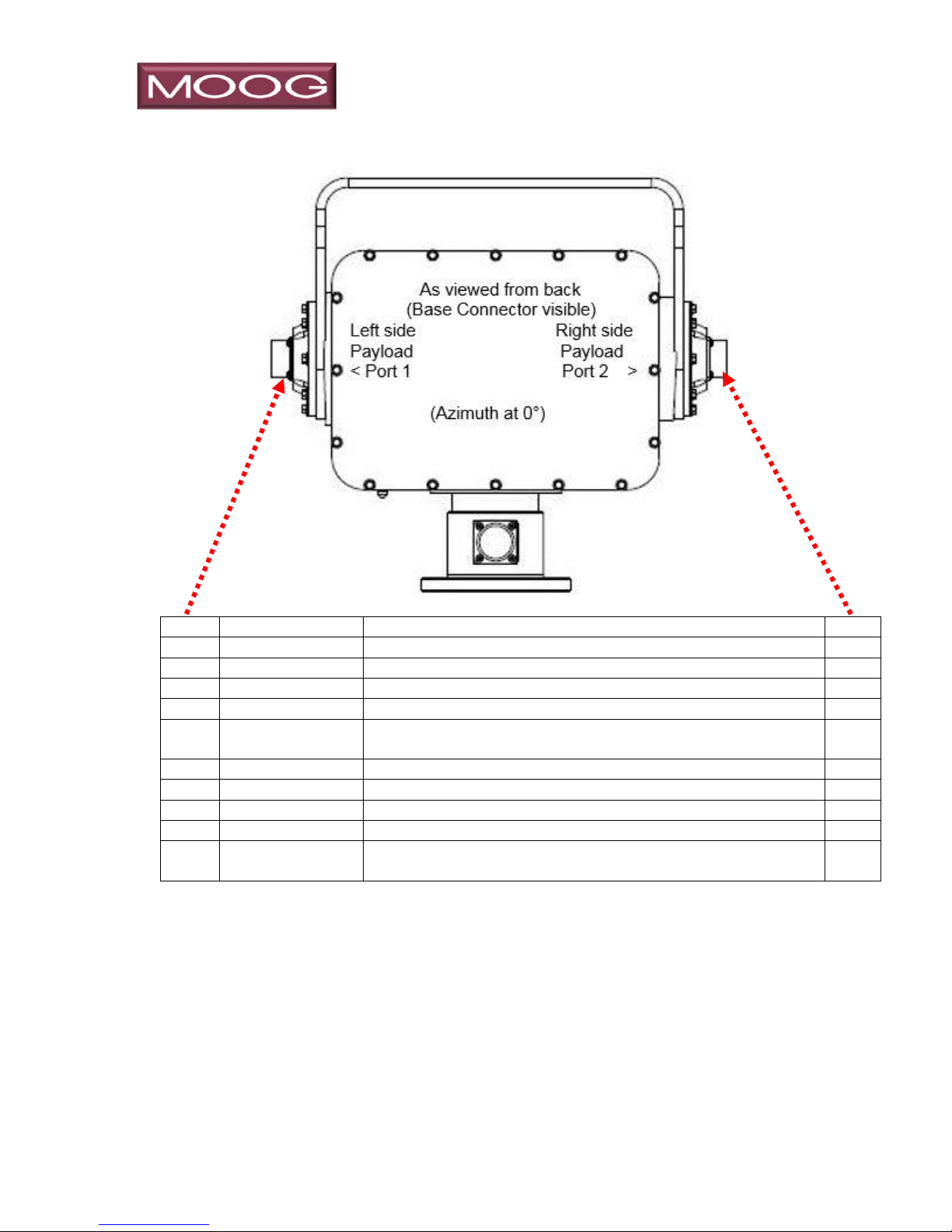

3.0 MPT -90 MODELS

MPT models are designed to have the maximum amount of features and flexibility in

connectivity based on our experience in remote controlled positioners. The MPTs

feature two “Payload Port” connectors (one per side) that allow the user to wire their

payloads to the positioner providing multiple power and control options.

All models provide the following conductivity to EACH of the payload ports:

Four 8-Amp conductors designed for power (up to 210 VDC, 240 VAC) to the

payloads. These conductors are shared between the two payload ports and

the base connector

Two analog (±12 VDC) variable speed drivers designed to drive Zoom and

Focus motors, but may be used for other devices such as low power motors

or lighting.

Two analog inputs, designed to read position potentiometers for Z/F lenses.

These are useful when combining with stored positions to assure consistent

camera framing of objects of interest.

One Auxiliary power source, configurable for 12 or 24 VDC, with on/off

switchable control

One Auxiliary power source, configurable for 5 or 12 VDC, with on/off

switchable control

Three serial ports, providing single ended (RS232) or differential (RS422)

communication between payloads.

Additionally, there are IP and Video signal paths between the base connector

and the payload port. In continuous rotation models, these signals pass through

the integrated slip ring, which creates limitations to the number of signals and

bandwidth that can pass through. The non-continuous rotation model (8PA166) does not have these limitation, and therefore has the higher bandpass

GigE and HD-SDI video connections on each payload port.

Each 10/100 IP signal path requires four conductors, while a GigE IP signal

path requires eight conductors. HD-SDI video requires different wiring and a

higher caliber of slip ring than conventional analog EIA - RS170 video, but not

all budgets can accommodate the higher cost of the HD-SDI slip ring.

For these reasons, several models have been created in various configurations,

and the table below shows the comparisons:

_______________________________________________________________________

MN0090-05 Page 13 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 14

____________________________________________________________________

Figure 4: Feature Comparison Table

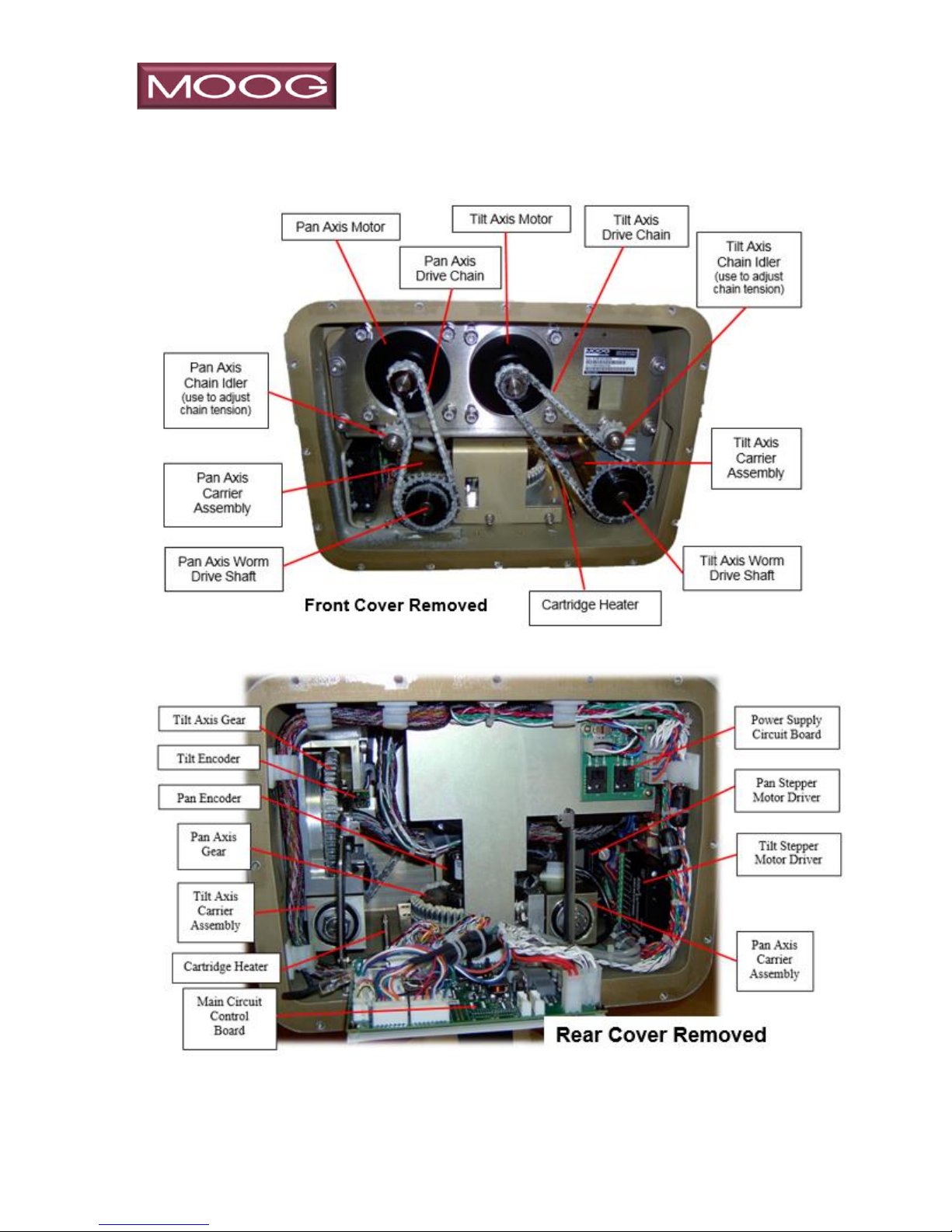

3.1 Pan and Tilt Description

The Pan & Tilt Unit is constructed of aluminum with stainless steel hardware.

The Pan & Tilt Housing (with Access Covers to provide access to the interior)

encloses the Pan & Tilt Motors, Chain & Gear Drive Assemblies, user settable

Limit Rings (hard stops), position encoders, and the main Control Circuit

Board which has multiple configurable options. Please refer to Figure 5 below

for component identification.

_______________________________________________________________________

MN0090-05 Page 14 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 15

____________________________________________________________________

Figure 5: Pan & Tilt Unit Major Components

MPT-90 Wiring Signal Description

3.1.1 System Input Power – All Models

_______________________________________________________________________

MN0090-05 Page 15 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 16

____________________________________________________________________

CAUTION

DO NOT CONNECT TO VOLTAGES HIGHER THAN

28 VDC WITHOUT RECONFIGURING.

Pin #

Signal

Description

45 & 52

System Power

+ (Positive)

Pins 45 & 52 supply positive (+) power to the P&T positioner, as well as

controlled payload power features and heaters. Due to the size of the

contacts, two pins are necessary; connect together external to the

positioner. Power should be between 24 to 28 VDC, and we recommend

an external 15A fuse.

50 & 51

System Power

– (Negative)

Pins 50 & 51 connect return (-) power from the P&T positioner, as well as

controlled payload power and heaters. Due to the size of the contacts, two

pins are necessary; connect together external of the positioner. Power

should be between 24 to 28 VDC. Note this is insulated from chassis

ground, but may be connected to chassis ground external to the positioner

if desired.

53

Chassis GND

Chassis Ground – isolated from power

The positioner is powered by 24-28 VDC, although it may be reconfigured for 28-48

VDC. It is highly recommended that you fuse the + power supply. Verify correct

polarity before applying power. The power of the system is isolated from chassis.

_______________________________________________________________________

MN0090-05 Page 16 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 17

____________________________________________________________________

Pin #

Serial Control

Description

10

Serial Tx+ (TXD)

RS422/485 (or RS232) transmit (configurable)

33

Serial Tx-

RS422/485 transmit

11

Serial Rx+ (RXD)

RS422/485 (or RS232) receive (configurable)

34

Serial Rx-

RS422/485 receive

12

Signal ground

RS422/232, connected to system power negative, isolated from chassis.

Pin #

IP Control

Description

14

TX+_D1 ██

10/100 IP Control White/Orange T568B, typical RJ45 connector

36

TX-_D1 ██

15

RX+_D2 ██

10/100 IP Control White/Green T568B, typical RJ45 connector

37

RX-_D2 ██

10/100 IP Control Green T568B, typical RJ45 connector

3.1.2 IP and Serial Control of Positioner – All Models

Above communication ports may be used for control and settings of positioner and/or

payloads ports. Differential serial communication may be set to full or half duplex,

configurable in settings.

Communication to from base connector to payload ports is supported (see protocol

document).

“Transmit” and “Receive” are from the perspective of the positioner (DCE). Colors

shown for IP signals per EIA/TIA 568B are to aid or reference external wiring to the ports

and do not represent actual color of conductors inside the positioner.

_______________________________________________________________________

MN0090-05 Page 17 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 18

____________________________________________________________________

Pin #

Serial Control

Description

Pin #

16

Serial Tx+ (TXD)

RS422/485 (or RS232) transmit (software configurable)

n/c

33

Serial Tx-

RS422/485 transmit

n/c

11

Serial Rx+ (RXD)

RS422/485 (or RS232) receive (configurable)

n/c

34

Serial Rx-

RS422/485 receive

n/c

12

Signal ground

Serial signal ground, connected to system power negative,

isolated from chassis.

n/c

n/c

Serial Tx+ (TXD)

RS422/485 (or RS232) transmit (software configurable)

16

n/c

Serial Tx-

RS422/485 transmit

33

n/c

Serial Rx+ (RXD)

11

n/c

Serial Rx-

RS422/485 receive

34

n/c

Signal ground

Serial signal ground, connected to system power negative,

isolated from chassis.

12

3.1.3 Additional Serial Control of Positioner – All Models

Additional serial communication ports are provided that allow payload devices to

control the positioner. An example of this may be a camera assembly equipped with

a video encoder.

“Transmit” and “Receive” are from the perspective of the positioner (DCE).

_______________________________________________________________________

MN0090-05 Page 18 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 19

____________________________________________________________________

Left

Pins

Base

Pins

Signal

Description

Right

Pins

46

46

General I/O

User supplied power to payloads. 8A max.

46

47

47

General I/O

User supplied power to payloads. 8A max.

47

48

48

General I/O

User supplied power to payloads. 8A max.

48

49

49

General I/O

User supplied power to payloads. 8A max.

49

53

53

Chassis GND

Chassis Ground.

53

3.1.4 General Purpose I/O Pass Through & Chassis Ground All Models

The General Purpose I/O conductors are typically used for powering devices connected

to Port 1 and/or Port 2. The conductor connected to pins 46 are twisted together with the

conductor connected to pins 49, likewise 47 & 48 are paired. These are conductors

through the slip ring on continuous models, allowing high current (up to 8A continuously)

connections to the payload. Both left and right side ports are connected to the base

allowing a single user supplied power supply to power loads on both sides, assuming

they are of the same voltage. The maximum continuous current rating through the slip

ring is 8 amps, meaning the sum of both the left and right side through any one conductor

is not to exceed 8A. The slip ring is rated up to 210VDC, and may be used for AC current

with a 500 VRMS dielectric strength in all combinations. Chassis Ground is internally

connected to the mechanical chassis of the positioner, and is available on all three

connectors. Chassis ground is not internally connected to any of the General Purpose

I/O ports, but may be connected externally if desired.

_______________________________________________________________________

MN0090-05 Page 19 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 20

____________________________________________________________________

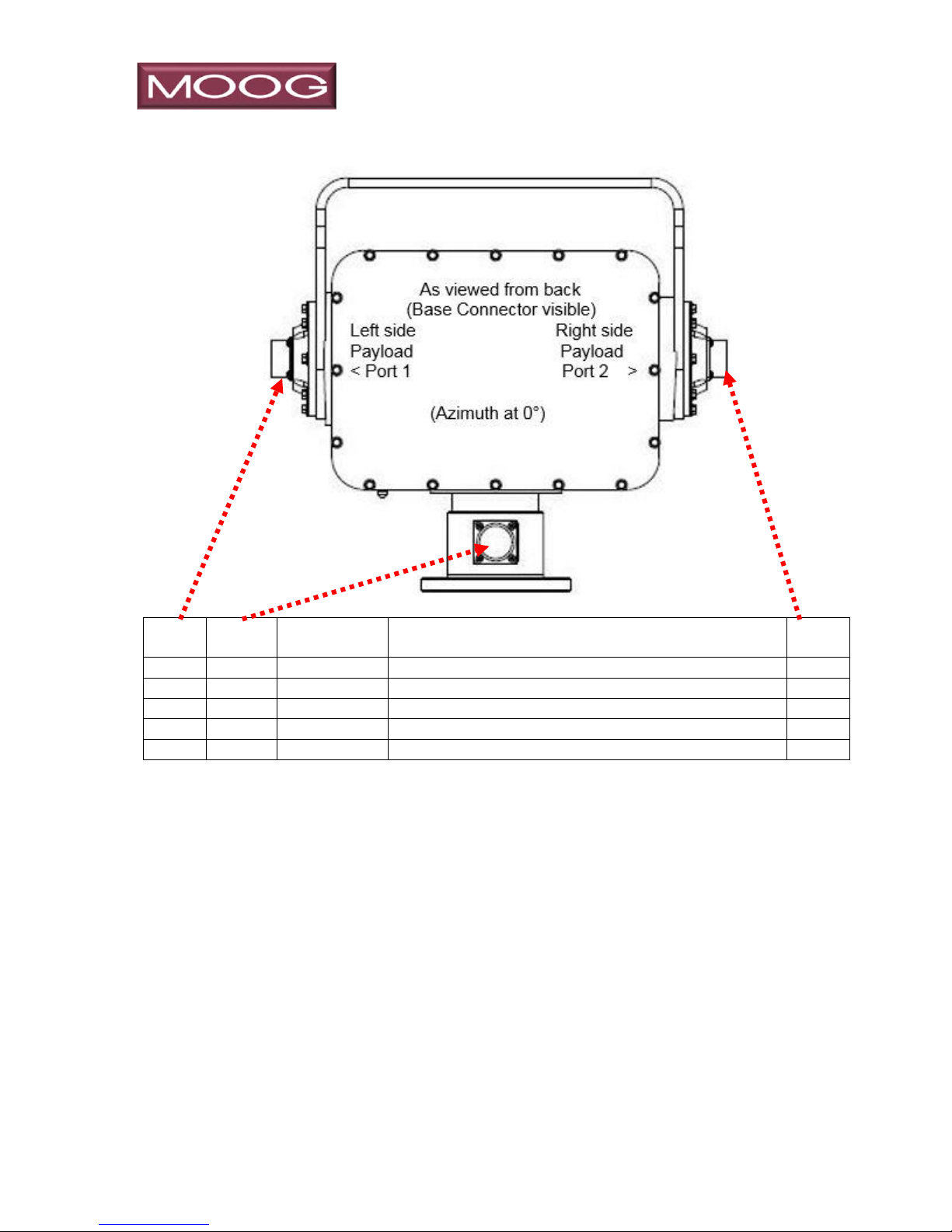

Left

Pins

Base

Pins

Signal

T-568B

Description

Right

Pins

2

2

TX+_D1 ██

Ethernet User 10/100 “A” to port 1

n/c

26

26

TX-_D1 ██

n/c

3

3

RX+_D2 ██

n/c

27

27

RX-_D2 ██

n/c

n/c

20

TX+_D1 ██

Ethernet User 10/100 “C” to port 2

2

n/c

41

TX-_D1 ██

26

n/c

21

RX+_D2 ██

3

n/c

42

RX-_D2 ██

27

3.1.5 Model 8-PB133, 10/100 Ethernet Ports 1 & 2

Typical 10/100 Ethernet connections require 2 sets of Twisted Pair (TP) conductors,

4 conductors total. Gig-E Ethernet connections require 4 sets of TP, a total of 8

conductors. Due to limitations of the conductor availability in the slip ring, the MPT

series allocates 8 conductors between the base connector and the payload ports.

Therefore, these conductors may be configured as two 10/100 Ethernet ports, one

to each side (Model 8-PB133 depicted above) or as a single Gig-E signal path to

either side (See next two pages).

Colors shown for IP signals per EIA/TIA 568B are to aid or reference external wiring

to the ports and do not represent actual color of conductors inside the positioner.

_______________________________________________________________________

MN0090-05 Page 20 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 21

____________________________________________________________________

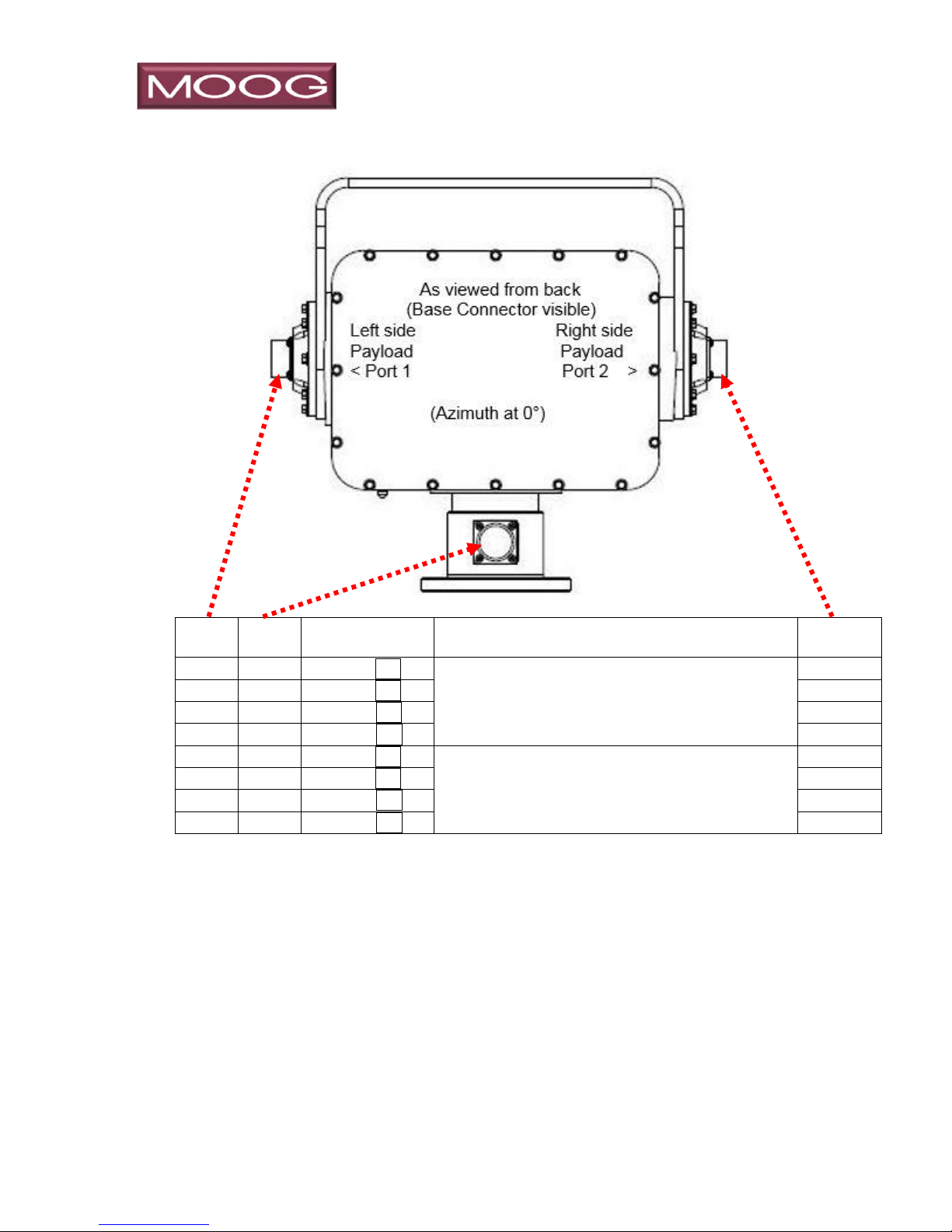

Left

Pins

Base

Pins

Signal

T-568B

Description

Right Pins

2

2

BI_DA+ ██

Ethernet User GigE Base to port 1

n/c

26

26

BI_DA- ██

n/c

3

3

BI_DB+ ██

n/c

27

27

BI_DB- ██

n/c 4 4

BI_DC- ██

n/c

28

28

BI_DC+ ██

n/c 5 5

BI_DD+ ██

n/c

29

29

BI_DD- ██

n/c

3.1.6 Model 8-PB151, Gigabit Ethernet Base to Port 1 Payload

Gig-E Ethernet connections require 4 sets of TP, a total of 8 conductors, so in this

configuration there is a single GigE provision wired to Port 1.

Colors shown for IP signals per EIA/TIA 568B are to aid or reference external wiring

to the ports and do not represent actual color of conductors inside the positioner.

_______________________________________________________________________

MN0090-05 Page 21 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 22

____________________________________________________________________

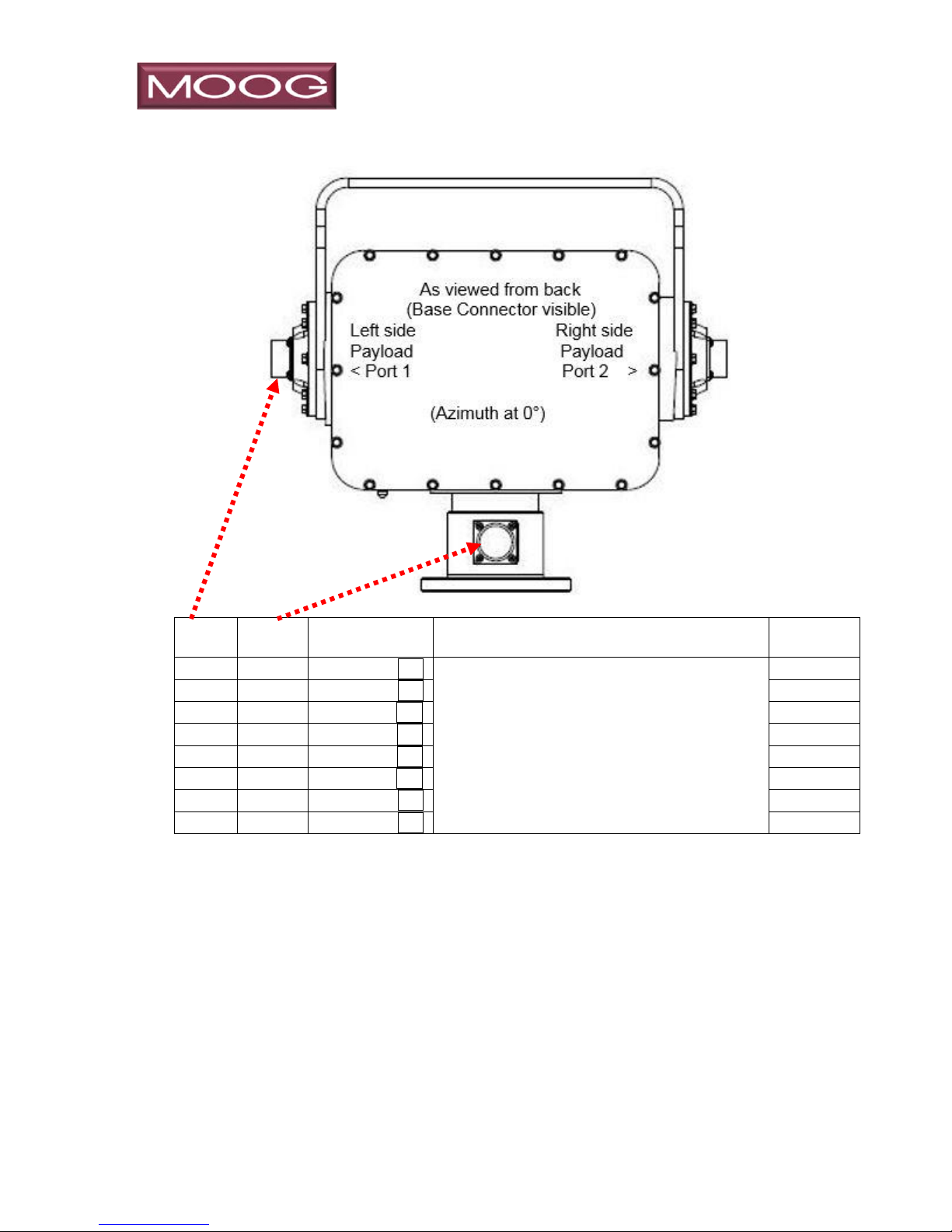

Left

Pins

Signal

Description

Right

Pins

10

Serial Tx+ (Txd)

<Payload 1 control (Left) Payload 2 control (Right)>

10

33

Serial Tx-

<Payload 1 control (Left) Payload 2 control (Right)>

33

11

Serial Rx+ (Rxd)

<Payload 1 control (Left) Payload 2 control (Right)>

11

34

Serial Rx-

<Payload 1 control (Left) Payload 2 control (Right)>

34

12

Signal ground

<Payload 1 control (Left) Payload 2 control (Right)>

12

7

Serial Tx+ (Txd)

<Payload 3 control (Left) Payload 4 control (Right)>

7

31

Serial Tx-

<Payload 3 control (Left) Payload 4 control (Right)>

31

8

Serial Rx+ (Rxd)

<Payload 3 control (Left) Payload 4 control (Right)>

8

32

Serial Rx-

<Payload 3 control (Left) Payload 4 control (Right)>

32

13

Signal ground

<Payload 3 control (Left) Payload 4 control (Right)>

13

3.1.7 Serial Control Communication to ports

These connections connect the control from Moog Main Controller to the payloads.

This provides a method of communicating from the system control signal path to the

payloads via the 62H command as found in the protocol document. The serial ports

may be user configurable as either single ended (RS232) or differential (RS422). All

signal ground wires are connected to the systems negative input power supply.

_______________________________________________________________________

MN0090-05 Page 22 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 23

____________________________________________________________________

Left

Pins

Signal Name

Description

Signal Name

Right

Pins

20

Zoom + (Cam1)

PWM motor drive pair

designed for Zoom Lens Drive

Zoom + (Cam 2)

20

41

Zoom – (Cam 1)

Zoom – (Cam 2)

41

21

Focus + (Cam 1)

PWM motor drive pair

designed for Focus Lens Drive

Focus + (Cam 2)

21

43

Focus – (Cam 1)

Focus – (Cam 2)

43

22

Z/F +3VDC

V source for position feedback

Z/F +3 VDC

22

44

Z/F ground

Return for position feedback

Z/F ground

44

23

Z Position Sense (Cam 1)

Connect to Z position pot wiper

Z Position Sense (Cam 2)

23

44

F Position Sense (Cam 1)

Connect to F position pot wiper

F Position Sense (Cam 2)

44

3.1.8 Camera Lens Accommodations

The positioner controller provides four proportionally controlled, bi-directional PWM

motor drivers suited to drive camera lenses with motorized zoom and focus. Most

of these style lenses also have potentiometers incorporated to provide a relative

sensing of the Z & F position. Use of the Z & F motor drivers with the potentiometer

position feedback to allow stored presets that encompass Az, El, Z & F for easy

camera integration.

Zoom motors should be connected to the Zoom + & Zoom - pins, while Focus

motors should be connected to the Focus + & Focus – pins. Position feedback

potentiometers are typically used as voltage dividers, with the supply voltage (Z/F

+3VDC & Z/F ground) connected across the two potentiometers. The

potentiometers wipers should be connected to the Zoom Position Sense and Focus

Position Sense respectfully.

_______________________________________________________________________

MN0090-05 Page 23 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 24

____________________________________________________________________

Left

Pins

Base

Pins

Description

Right Pins

25

25

Video 1 coaxial

n/c

n/c

30

Video 2 coaxial

30

3.1.9 Video Signal

Signal paths suitable for video run from each of the port connectors (one per

side) to the base. These are suitable for RS170 video signals.

Special connector pins compatible with standard RG179 75Ω coaxial cable

are in the package with the included base and port connectors.

_______________________________________________________________________

MN0090-05 Page 24 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 25

____________________________________________________________________

CAUTION

DO NOT CONNECT TO VOLTAGES HIGHER

THAN 28 VDC WITHOUT RECONFIGURING.

3.2 Moog Pan and Tilt Control Circuit Board Description

Power and communication to control the P&T is provided through the 53-Pin base

connector. The Moog Pan & Tilt microprocessor / circuit control board processes all

communication, position information, and presents it through the communication

buss via the Protocol. The system may be controlled either by a serial or IP

connection.

Power supplied is a minimum 24 VDC providing power to the Control Circuit Board

to control the two (2) stepper motors drivers (1 for Pan Axis and 1 for Tilt Axis), as

well as regulated and unregulated power to the side mounted payload ports. Note

the Positioner may be supplied higher voltages for extended performance if

configured to do so on the Control Circuit Board. DO NOT APPLY MORE THAN 28

VDC to the unit without first configuring the PCB to accept higher voltage.

The Control communication is processed on the control circuit board providing

control and status information on the communication buss. Also connected to main

controller are two incremental position encoders, an optical encoder is used of the

Pan Axis motion and a magnetic encoder is used for the Tilt Axis motion.

The Control Circuit Board is attached vertically to the inside of the Pan & Tilt Housing

and can be accessed by removing the Rear Access Cover. The Control Circuit Board

must be accessed to configure P&T input voltage selection, voltage selection and

method of communication to the payload ports.

The Control Circuit Board has a number of switches and jumpers to allow various

configurations of power and communication options. The following section outlines

PCB configuration to allow various configurations.

3.2.1 Control Circuit Board Configuration

3.2.1.1 Circuit Card Access

1. Remove the sixteen 5/16” hex head bolts holding the rear cover. Place the

cover aside, assuring not to damage the O-Ring gasket, mating surface or

paint. Locate the Ethernet cable on the left side of the board and release the

cable from the connector port. Refer to Figure 6.

_______________________________________________________________________

MN0090-05 Page 25 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 26

____________________________________________________________________

Ethern et Cable

Main Circuit Board

Figure 6: Accessing the Circuit Board

2. Loosen the two #1 Philips head screws at the top of the board; these screws

are retained with a small O-Ring between the PCB and the bracket; turn only

enough to release the bracket. You may need to pull the bracket outward to

allow the board to swing downward. Refer to Figure 7 below.

Figure 7: Circuit Board

3. The PCB has multiple switches and jumpers providing options that are used

for customer configuration. The options are:

Setting input voltage range

Communication settings for primary control of the MPT-90

Communication settings for secondary control of the MPT-90

Communication settings for Payload control

Voltage settings for Port Payload power

Voltage and high-side/low-side switching of Auxiliary Port power

Refer to Figures 7 and 8.

_______________________________________________________________________

MN0090-05 Page 26 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 27

____________________________________________________________________

Figure 8: Circuit Board Components I

_______________________________________________________________________

MN0090-05 Page 27 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 28

____________________________________________________________________

COMM SERIAL

SETTINGS S2

Figure 9: Circuit Board Components II

_______________________________________________________________________

MN0090-05 Page 28 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 29

____________________________________________________________________

Jumper P1, shown

without jumper for clarity

Dot indicates pin 1

3.2.1.2 PBC Jumper Settings:

NOTE

All jumper settings, the screened dot is Pin 1. Refer to Figure 10 below.

3.2.1.2.1 P1 Input Power:

The positioner requires 24 to 28 VDC to operate, with positive current applied

to pins 45 & 52 and power return through pins 50 & 51 of the base connector.

Note that due to current limitations of the pins in the base connector, the user

must apply power to both pairs of pins to assure proper operation. In the event

that two separate power supplies are used, you must connect the two negative

wires (pins 50 & 51) together.

Figure 10: Jumper Locations

The MPT product may be configured to operate on 28-70 VDC by changing

the PCB P1 jumper setting. To reconfigure to operation on voltages higher

than 28 VDC, you must move the jumper on P1 (located in the upper right

corner of the Moog Controller PCB) from the default position of 1-2 to the 2-3

position. The dot screened on the PCB indicates pin 1.

NOTE

The 24 VDC is passed to the payload ports, and is not regulated if the input

power is in the default configuration. If the P&T is configured for higher

voltage usage, the 24 VDC payload power is regulated.

_______________________________________________________________________

MN0090-05 Page 29 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 30

____________________________________________________________________

3.2.1.2.2 P45

P45 is used to select the voltage available on “Aux1 Power” (pin 36 on

Payload Port 1). In the default mode with the jumper on pins 1-2, pin 36 of

Payload Port 1 will have the P&T source voltage (*typically +24 VDC)

available with respect to pin 14. Moving the jumper to pins 2-3 will reduce

this to +12 VDC regulated.

3.2.1.2.3 P48

P48 is used to select the voltage available on “Aux2 Power” (pin 37 on

Payload Port 1). In the default mode with the jumper on pins 1-2, pin 37 of

Payload Port 1 will have the P&T source voltage (*typically +24 VDC)

available with respect to pin 15. Moving the jumper to pins 2-3 will reduce

this to +12 VDC regulated.

3.2.1.2.4 P57

P57 is used to select the voltage available on “Payload 3 (pin 45 of Payload

Port 1). In the default mode with the jumper on pins 1-2, pin 45 of Payload

Port 1 will have +12 VDC regulated power available with respect to pin 50.

Moving the jumper to pins 2-3 will reduce this to +5 VDC regulated.

_______________________________________________________________________

MN0090-05 Page 30 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 31

____________________________________________________________________

3.2.1.2.5 P59

P59 is used to select the voltage available on “Payload 4 (pin 45 of Payload

Port 2). In the default mode with the jumper on pins 1-2, pin 45 of Payload

Port 2 will have +12 VDC regulated power available with respect to pin 50.

Moving the jumper to pins 2-3 will reduce this to +5 VDC regulated.

3.2.1.2.6 P53

P53 is used to reconfigure how Aux 3 (Pins 36 & 14 of Payload 2) power

switching works. In the default mode, the + supply voltage (Pin 36, 12 or 5

VDC configurable) may be switched ON/OFF by the controller.

Reconfiguring P53 allows the – return side (pin 14) to be switched in an “open

collector” configuration. Although useful in some applications, do not use this

if your payload is otherwise connected back to ground.

3.2.1.2.7 P56

P56 is used to reconfigure how Aux 4 (Pins 37 & 15 of Payload 2) power

switching works. In the default mode, the + supply voltage (Pin 37, 12 or 5

VDC configurable) may be switched ON/OFF by the controller.

Reconfiguring P53 allows the – return side (pin 15) to be switched in an “open

collector” configuration. Although useful in some applications, do not use this

if your payload is otherwise connected back to ground.

_______________________________________________________________________

MN0090-05 Page 31 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 32

____________________________________________________________________

3.3 PCB Switch Settings

The PCB has two user configurable eight position switches (Figure 11, S2,

S4) used to configure the serial communication ports. These ports are

typically used to control the positioner, or the payloads attached to the

positioner.

Figure 11: PCB Switches

3.3.1 S2 switch settings for serial communication ports

S2 configures the user control serial ports on the base and payload ports. Set

for the desired serial communication mode. Note that in RS485 mode,

termination should be ON for the last unit in the chain.

BASE PAYLOAD PAYLOAD

CONNECTOR PORT 1 PORT2

RS422 RS232 PINS PINS PINS

Serial Tx+ (TXD) 10 16 16

Serial Tx- 33 38 38

Serial Rx+ (RXD) 11 17 17

Serial Rx- 34 39 39

Signal Ground (Gnd) 12 18 18

_______________________________________________________________________

MN0090-05 Page 32 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 33

____________________________________________________________________

The first three switch positions on S2 configure the serial connection on the

base connector pins in the table above.

S2 switch setting for RS232 at base S2 switch setting for RS 422 at base

S2 switch setting for RS-485 4-wire at base S2 switch setting for RS-485 2-wire at base

The last 3 switch positions on S2 configured the serial connection on Port 1 pins in

the table above:

S2 switch setting for RS232 at port 1 S2 switch setting for RS 422 at port 1

S2 switch setting for RS485 4-wire S2 switch setting for RS485 2-wire

at port 1 at port 1

Switch position 4 should be in the “ON” position to enable the serial connection on

Port 2 pins in the table above. Note that this port may be configured for RS232 or

RS422 via software.

_______________________________________________________________________

MN0090-05 Page 33 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 34

____________________________________________________________________

S4 Switch setting for RS232 at Port 1 S4 Switch setting

S4 Switch setting for RS422 at Port 1 S4 Switch

S2 switch setting to enable port 2 serial.

3.3.2 S4 switch settings for serial communication ports

S4 configures additional serial connections at the payload ports. Set for the desired

serial communication mode. Note that in RS485 mode, termination should be ON

for the last unit in the chain.

PAYLOAD PAYLOAD

PORT 1 PORT 2

RS422 RS232 PINS PINS

Serial Tx+ (TXD) 10 10

Serial Tx- 33 33

Serial Rx+ (RXD) 11 11

Serial Rx- 34 34

Signal Ground Gnd 12 12

_______________________________________________________________________

MN0090-05 Page 34 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 35

____________________________________________________________________

CAUTION

TWO PEOPLE ARE REQUIRED TO MOVE OR LIFT THE

MPT-90, DROPPING IT COULD DAMAGE THE MPT-90

WARNING

THE MPT-90 PRODUCES SIGNIFICANT TORQUE IN BOTH

THE PAN AND TILT MODES THAT CAN CAUSE INJURY IF

YOU ATTEMPT TO STOP IT WITH YOUR HANDS OR BODY

WARNING

DO NOT MOUNT THE MPT-90 (MOBILE OR STATIONARY)

SUCH THAT IT WILL CONTACT POWER LINES. IF THE

MPT-90 DOES CONTACT POWER LINES IT COULD

INJURE THE INSTALLER OR DAMAGE THE MPT-90.

4.0 INSTALLATION

4.1 Unpack and Inspect

Carefully unpack and examine the MPT-90 for signs of physical damage,

particularly dented or broken parts, damage to wire harness, distortion of the

tilt table or covers. If any signs of damage are observed, notify the freight

carrier immediately for a claim. Retain all of the packaging material.

4.2 Quick Start Guide

Upon opening the box containing the MPT-90 refer to the Moog Quick

Start Guide (CC36600) for instructions and for the MPT-90 packing list.

NOTE

One Test Cable, part number CC36117-6 is included in each shipment

regardless of the number of MPT-90 assemblies shipped. It is not

recommended that the Moog supplied test cable be used for a permanent

installation. The test cable should be retained for bench setup and

troubleshooting should it become necessary.

4.3 Installation Procedures - Mechanical

4.3.1 Site Location

Select a mounting location that will provide the desired maximum movement

of the Pan & Tilt angles without coming in contact with or striking any objects

in their sweep paths.

NOTE

An arrow on the side of the Pan & Tilt indicates the direction the front of

the unit is facing.

_______________________________________________________________________

MN0090-05 Page 35 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 36

____________________________________________________________________

Limit Rings (Hard Stops) are provided to limit the degree of travel in the tilt

path. The pan travel is continuous and the tilt travel can be narrowed from

the maximum of 180° (±90° from horizon) to a lesser value.

4.3.2 Caution on Mobile Mounting

When using a Pan & Tilt in mobile applications, transporting an unsupported

system payload can cause mechanical overloading due to the shock and

vibration associated with movement over normal road surfaces.

These forces can be amplified further if travelling off-road, or if the positioner

system is mounted on a moveable platform such as a boom arm or telescopic

mast. In certain conditions, these dynamic forces added to the normal P&T

payload can have a cumulative effect and ultimately cause structural failure of

the positioner.

When designing transportable systems, make sure the payload is secured

during transit to assure that shock and vibration is not transmitted to the tilt

arm or table top by an unsupported load.

_______________________________________________________________________

MN0090-05 Page 36 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 37

____________________________________________________________________

4.3.3 MPT-90 Installation

The Mounting Base (6.0” diameter) is drilled with six (6) .39” diameter

mounting holes on a 5.0” diameter bolt circle. Using the mounting holes,

fasten the base to a stable platform using (recommended) 5/16” high strength

stainless steel bolts, washers, and nuts. Refer to Figure 12.

NOTE

Consideration of wind and ice load factors on the Pan & Tilt Unit, and its

payload, are important when calculating how solid the mounting platform

has to be and the strength required by the mounting bolts.

Figure 12: Mounting Base

1. Place the MPT-90 on the mounting surface. Align the base connector with

the back of the mounting surface and make sure that the pan and tilt is

pointing in the correct direction.

2. Using an alternating pattern insert six (6) 5/16” high strength stainless steel

bolts through the MPT-90 mounting base and mounting surface.

3. Install six (6) washers and nuts on the bolts

4. Torque the nuts to 18-23 ft. lbs.

_______________________________________________________________________

MN0090-05 Page 37 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 38

____________________________________________________________________

CAUTION

CORRECT INSTALLATION OF THE INTERCONNECTING

CABLE TO THE BASE CONNECTOR BETWEEN THE

CONTROLLER AND THE PAN AND TILT UNIT IS REQUIRED

FOR RELIABLE OPERATION OF THE POSITIONING

SYSTEM. CABLES SHOULD BE CONSTRUCTED WITH

CONSIDERATION OF WEATHER CONDITIONS, AND

SEALED AS REQUIRED TO ASSURE TROUBLEFREE

SERVICE. MOOG IS NOT RESPONSIBLE FOR POSITIONER

DAMAGE DUE TO FAULTY CABLING.

4.4 Installation Procedures – Electrical

4.4.1 Connector installation

Included with the positioner are mating plugs and contacts for the base and two side

port connectors. Follow the instructions below to build cables for the installation;

additional instructions may be included with the contacts.

_______________________________________________________________________

MN0090-05 Page 38 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 39

____________________________________________________________________

_______________________________________________________________________

MN0090-05 Page 39 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 40

____________________________________________________________________

4.5 MATING RECEPTACLE CONNECTOR WIRING

The following charts show the signals connected to the various

pins/conductors on the positioner’s connectors. Note that not all models or

variants use all connections, so check with your model number before

constructing wiring harnesses. You may choose to not to use some signals,

and therefore not make connections on your cables. It is recommended that

you use appropriate cabling sealing methods suitable for the environment of

use. This may include potting of the connector, or use of weather sealing

sheathing.

Fundamental power and operational communication is shown on the first

chart below:

_______________________________________________________________________

MN0090-05 Page 40 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 41

____________________________________________________________________

_______________________________________________________________________

MN0090-05 Page 41 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 42

____________________________________________________________________

_______________________________________________________________________

MN0090-05 Page 42 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 43

____________________________________________________________________

CAUTION

PRIOR TO OPERATING THE PAN & TILT UNIT OR ACCESSING

THE INTERIOR, READ AND BECOME FAMILIAR WITH ALL OF

THE SAFETY RECOMMENDATIONS FOUND AT THE

BEGINNING OF THIS MANUAL AND ON ANY SAFETY DECAL

AFFIXED TO THE INSIDE OR OUTSIDE OF THE UNIT.

4.6 MPT-90 Setup and Adjustment procedures

Prior to operating the Pan & Tilt Unit, perform the following Setup &

Adjustment Procedures if necessary:

_______________________________________________________________________

MN0090-05 Page 43 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 44

____________________________________________________________________

5.0 MOOG PTZ WEB INTERFACE INTERNAL WEB GUI

5.1 CONNECTING THE MPT-90 TO A COMPUTER

1) Connect the RJ45 connector labeled “Ethernet Com. to your computer

or Ethernet Switch

2) The MPT-90’s default IP address is 192.168.1.10. Make sure your

computer is on the same subnet; change your private IP address if

necessary.

3) Click or press the

Windows key on

your keyboard and type

“network connections”.

4) Right click on “Local Area Connection” and select “Properties” to open

Local Area Connection Properties. Note that in Windows 8 or 10

naming may be different, such as Ethernet.

_______________________________________________________________________

MN0090-05 Page 44 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 45

____________________________________________________________________

5) Double click on “Internet Protocol Version

4 (TCP/IPv4) to open Internet Protocol

Version 4 (TCP/IPv4) Properties.

6) Within the Internet Protocol Version 4 (TCP/IPv4) Properties panel,

select “Use the following IP address:” and type in the following:

IP address 192.168.1.9 Subnet mask: 255.255.255.0

Default gateway 192.168.1.1 Click OK to save and exit.

7) Open a web browser and type in the IP address of the positioner

(192.168.1.10) into the web browser’s address bar.

NOTE:

Some versions of Microsoft Internet Explorer have issues rendering

HTML5 and will no open the page correctly. Use Google Chrome, or

Mozilla Firefox.

8) The positioner’s web interface should open.

_______________________________________________________________________

MN0090-05 Page 45 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 46

____________________________________________________________________

5.2 CONNECTING THE MPT-90 TO A NETWORK

1) This method is useful if you do not know the IP address assigned to the

positioner.

2) On the Thumb Drive that included this manual is a software utility called

“TI Tiva Board Finder”. Install this software on a computer on the same

network as the positioner.

3) Launch the application (finder.exe) and the IP addresses of all the

positioners on the network will be shown.

4) Open a web browser and type in the IP address of the positioner you

want to connect to into the web browser’s address bar. NOTE: Some

versions of Microsoft Internet Explorer have issues rendering HTML5

and will no open the page correctly. Use Google Chrome, or Mozilla

Firefox.

_______________________________________________________________________

MN0090-05 Page 46 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 47

____________________________________________________________________

5) The positioner’s web interface should open.

5.3 MOOG PTZ WEB INTERFACE

The Moog MPT-90 allows the user to connect and perform fundamental

functions and moves via an IP connection on a network. This is a quick

method to validate proper motion and primary functions.

NAVIGATION BAR - The Navigation Bar is used to select the page of the

Web GUI to select different Web pages. The Navigation Bar appears on all

pages and is used to move from one page to another.

PTZ CONTROL - The default page of the MOOG PTZ WEB INTERFACE is

the PTZ CONTROL page. Positioner movement, current position, setting

presets for both the positioner and payload can be accomplished using this

page.

PTZ CONTROL - The PTZ Control page is used to move the positioner.

_______________________________________________________________________

MN0090-05 Page 47 of 68 18008

MPT-90 PRODUCT MANUAL This document contains U.S. export controlled technical data as regulated by the U.S. Export Administration Regulations 15 CFR Parts 730-774, export, disclosure or transfer contrary to U.S. law is prohibited.

Page 48

____________________________________________________________________

CURRENT POSITION WINDOW: The Current Position window displays

the current position of the P&T in degrees relative to the “0” position. The

Zoom and Focus values represent relative values of the Zoom (pin 23 of

the payload ports) and Focus (pin 44 of the payload ports) designed for

Zoom & Focus potentiometers used in analog camera lenses. Note that

Zoom 1 & Focus 1 are for the Port 1 side and Zoom 2 & Focus 2 are for

the Port 2 side. See CAMERA LENS ACCOMODATIONS section.

JOG BUTTONS WINDOW: The Jog buttons allow you to move the P&T in