Page 1

MOOG MACHINE

CONTROLLER

MC SERIES 600

A modular programmable design

that offers higher precision, maximum

fl exibility and faster cycle times

In the new Moog Machine Controller (MC Series 600), Moog experts have

incorporated over 30 years experience in leading-edge technology into a fl exible

and modular solution for high performance industrial machinery. The hardware is

complemented by the Moog Application Software Suite, a powerful yet easy-touse tool for developing application programs based on CoDeSys, the proven IEC

61131-3 compliant programming system.

The MC Series 600 product family includes CPU, I/O and communications

modules, as well as local and PC-based HMI units. The multitasking Linux-based

real-time operating system guarantees fast reaction and reduced cycle times,

providing effi ciency and productivity enhancements. Analog 16 bit I/O resolution

offers greater precision positioning and higher accuracy.

Designed specifi cally to combine fl exibility with ease of use, MC Series 600

controllers are simple to confi gure and modular in design. While the MC Series

600 is suitable for a wide variety of industrial applications, software templates

for blow and injection molding and the incorporation of integral functions such

as temperature and parison profi le control, make it an ideal choice for plastics

molding applications.

ADVANTAGES

• Higher machine fl exibility thanks to

modular hardware design, easy-to-use

application templates for moulding

control

• Greater precision, faster reaction time

and better accuracy due to leadingleading-edge system design

• Free choice of centralized or

decentralized architectures without

any application software modifi cations

• CoDeSys integrated environment with

special function blocks

• Robust construction suitability for use

in demanding environments

• Availability of Moog application

experts ensures solutions that meet

machines' requirements

APPLICATIONS

• General industrial machine control,

especially where requirements include

fast cycle time, high precision and

maximum fl exibility

WHAT MOVES YOUR WORLD

• Plastics machines

• Special machines

• Packaging machines

• Metal forming machines

Page 2

FEATURES

KEY FEATURES

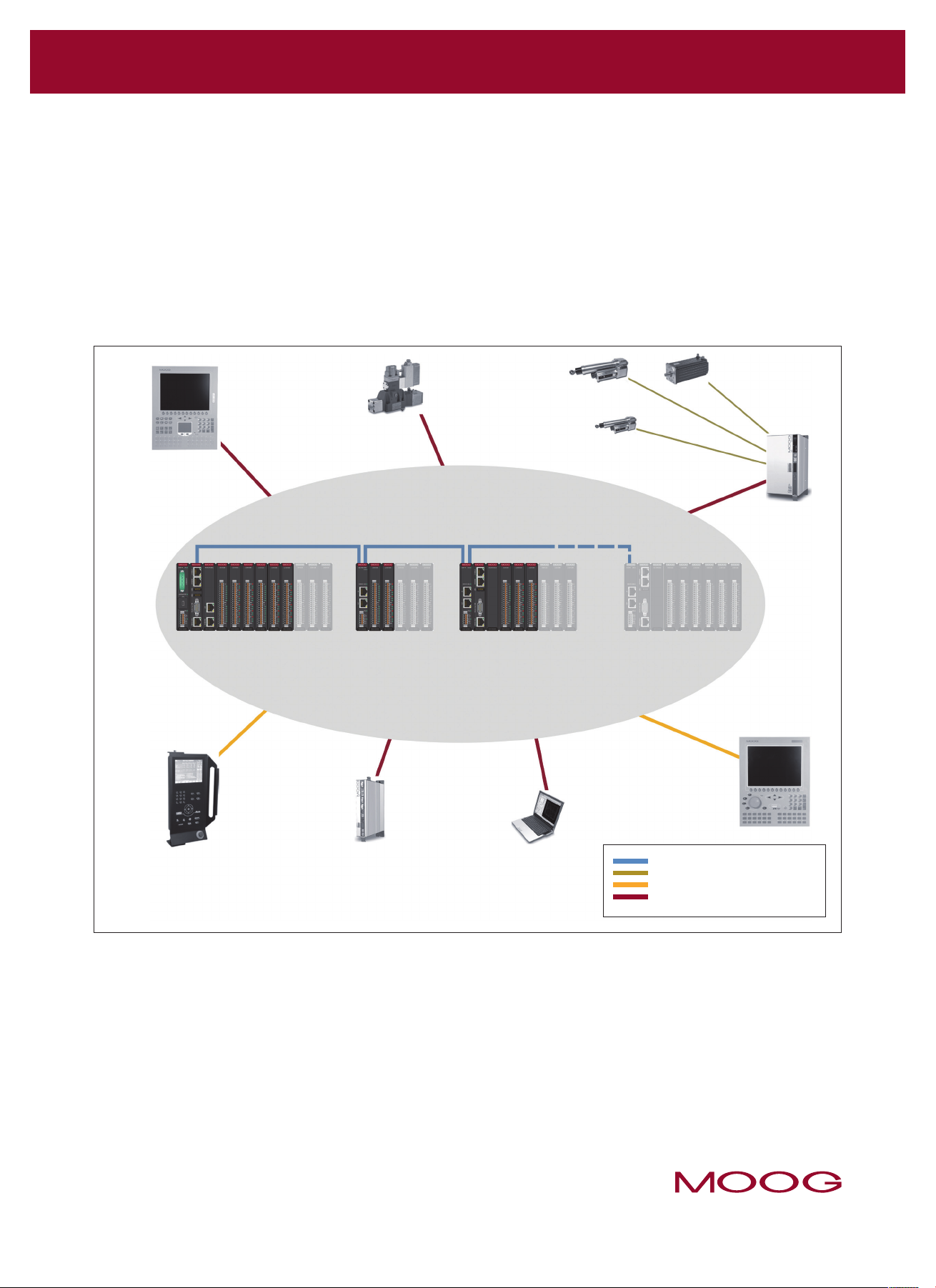

• Distributed architecture with high

performance due to high speed

serialized buses and the ability to

expand easily by adding CPUs with I/O

resources as needed

• Analog functions with high resolution

allow accurate control and positioning

•

Modular design with capacity for up to

2,000 I/O means that the controllers

can be optimally configured to suit

applications of all sizes

Real time Linux-based operating system

•

combines true multitasking with fast

response times and the ability to easily

add PC-like features

• Standardized development environment

that incorporates debugging, simulation,

parameterization and tracing

capabilities makes programming and

testing fast and straightforward

• Use of standard CAT5E cabling, with

segment lengths of up to 50m [164 ft],

for the connection of remote modules

simplifies wiring and reduces installation

costs and time

• Templates library for fast application

software development

• Fuzzy logic temperature control

Moog has offices around the world.

For more information or the office

nearest you, contact us online.

e-mail: info@moog.com

www.moog.com/industrial

Moog is a registered trademark of Moog Inc. and its

subsidiaries. All trademarks as indicated herein are the

property of Moog Inc. and its subsidiaries.

©2010 Moog Inc. All rights reserved. All changes are

reserved.

Moog MC Series 600

RL/September 2010/Id. CDL30068-en

Moog Internal Remote Bus

Power Signal

HMI Communication

Fieldbus

This technical data is based on current available

information and is subject to change at any time

by Moog. Specifications for specific systems or

applications may vary.

Loading...

Loading...