Page 1

MOOG

User's Manual

for L180 digital servo drive

Page 2

L180 User's Manual

PAGE 2 of 104 Rev. c 05/01

Page 3

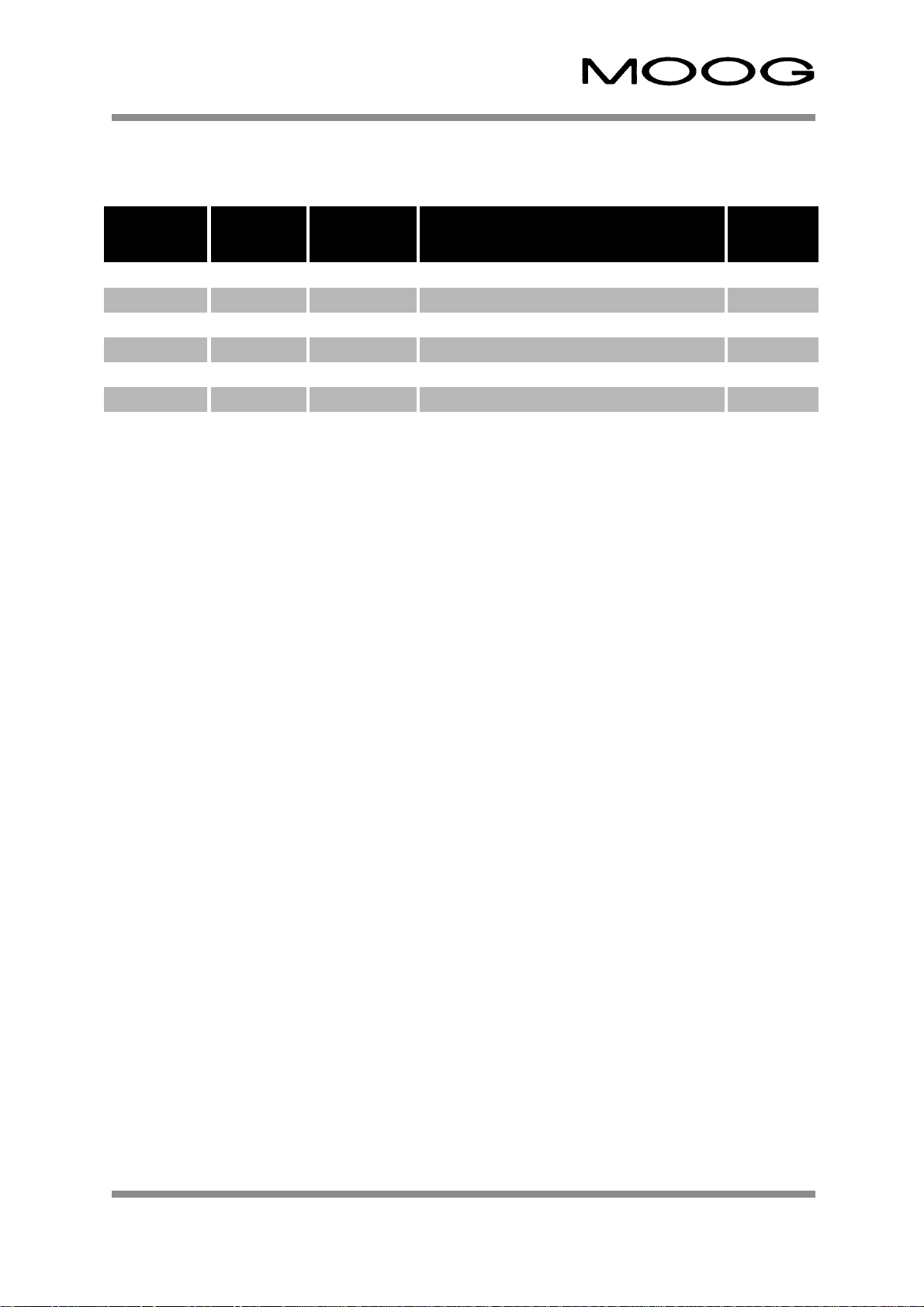

Record of Manual Revision

L180 User's Manual

Revision

Date Author Description Effectivity

Index

a13

b 2nd May 00 Joachim Heinrich Second Release All

c4

th

April. 00 Joachim Heinrich First Release All

th

May 01 Joachim Heinrich Third Release, i nc l udi ng L180GUI 2.0 and firmware A2 All

Copyright Information

=Copyright 2001 MOOG - All rights reserved

The information contained in this document is the property of MOOG GmbH and m ay not be reproduced or transmitted in any

form or by any means, e lectronic, mechanical, photocopying, re cording or otherwise, nor stored in any retrieval system of any

nature without the express written authority of MOOG GmbH.

This manual is periodically revi ewed and revised. T hese instructions have be en written and check ed to the best of our knowledge

and belief. However, M OOG GmbH assumes no responsibility for any errors or omissions in this document. Information in this

manual is subject to change without notice and does not repre s ent a commitment on the part the MOOG Corporation.

Microsoft, Windows NT, Windows 95 and Wi ndows 98 are registered tradema rks of Microsoft Corporation.

Critical evaluation of the manual is we lcomed. Your comments will assist us in future product documentation.

Rev. c 05/01 PAGE 3 of 104

Page 4

L180 User's Manual

TABLE OF CONTENTS

1DESCRIPTION AND TECHNICAL DATA 11

1.1 INTRODUCTION 11

1.1.1 DESCRIPTION 12

1.2 INSTRUCTI O NS TO THE MANUAL 13

1.3 T

1.3.1 DESIGN STANDARDS 14

1.3.2 M

1.3.3 A

1.3.4 G

1.3.5 E

1.3.5.1 D

1.3.5.2 P

1.3.5.3 R

1.3.6 M

1.3.7 D

1.3.8 D

ECHNICAL DATA 14

ODEL NUMBER SELECTION 15

CCESSORIES 16

ENERAL DATA 17

LECTRICAL DATA 18

RIVE RATINGS 18

OWER DISSIPATION 18

EGENERATION POWER 19

ECHANICAL DIMENSIONS 20

RIVE OVERVIEW 21

RIVE NAMEPLATE 22

PAGE 4 of 104 Rev. c 05/01

Page 5

L180 User's Manual

2SAFETY INSTRUCTIONS 23

2.1 QUALIFIED PERSONNEL 23

2.2 M

2.3 I

AIN SAFETY INSTRUCTIONS 24

NFORMATION ON EMC 25

3SERVOMOTORS 27

3.1 MOUNTI NG AND INSTALLATION 27

3.1.1 MOTOR NAMEPLATE 27

3.1.2 M

3.1.3 B

3.1.4 C

3.1.5 R

OTOR INSTALLATION GUIDELINE 28

EARING LOAD CAPACITY 29

OUPLING 32

UNOUT 33

3.2 TECHNICAL MOTOR DATA 34

3.2.1 STANDARDS FOR MOOG MOTORS 34

3.2.2 M

3.2.3 T

3.2.4 T

3.2.5 M

Rev. c 05/01 PAGE 5 of 104

OTOR PERFORMANCE DATA 37

ORQUE SPEED CHARACTERISTIC G400 SERIES MOTORS 39

ORQUE-SPEED-CHARACTERISTICS G300 SERIES MOTORS 43

OTOR BRAKE DATA 45

Page 6

L180 User's Manual

4INSTALLATION 47

4.1 WIRING 47

4.2 C

4.2.1 MOTOR AND POWER CONNECTOR TB1 49

4.2.1.1 TB1

4.2.1.2 A

4.2.2 R

4.2.2.1 A

4.2.3 S

4.2.4 A

4.2.5 E

4.2.6 L

ONNECTOR OVERVIEW 48

POWER CONNECTOR PINOUT 52

CCESSORY POWER PART 52

ESOLVER CONNECTOR J1 54

CCESSORY RESOLVER PARTS 55

ERIAL PORT CONNECTOR J2 56

XIS SIGNALS CONNECTOR J3 57

NCODER SIMULATION CONNECTOR J4 60

OGIC POWER CONNECTOR J5 62

5 L180 GRAPHICAL USER INTERFACE 63

5.1 SYSTEM REQUIREMENTS 63

5.2 GUI I

5.3 S

5.4 U

5.4.1 TOOLBAR 65

5.4.2 Q

PAGE 6 of 104 Rev. c 05/01

NSTALLATION 63

YSTEM INFORMATION 64

SING THE L180GUI 64

UICK START 66

Page 7

L180 User's Manual

5.4.3 GENERAL INSTRUCTIONS 67

5.4.4 S

5.4.5 P

5.4.6 P

5.4.6.1 A

5.4.6.2 E

5.4.6.3 S

5.4.6.4 C

5.4.6.5 M

5.4.7 A

5.4.8 U

5.4.9 S

5.4.10 F

ERIAL LINK 69

ARAMETER FILE DOWNLOAD 69

ARAMETER SETTING 70

DJUST OPTIONS 71

NCODER SIMULATION CONFIGURATION 74

PEED LOOP TUNING 76

URRENT LOOP TUNING 81

OTOR PARAMETERS 83

UTOMATIC COMMAND MODE (FUNCTION GENERATOR)86

PLOAD OF PARAMETER FILES 88

COPE 89

IRMWARE UPGRADE 90

5.4.11 E

5.4.12 P

5.4.13 S

5.4.14 S

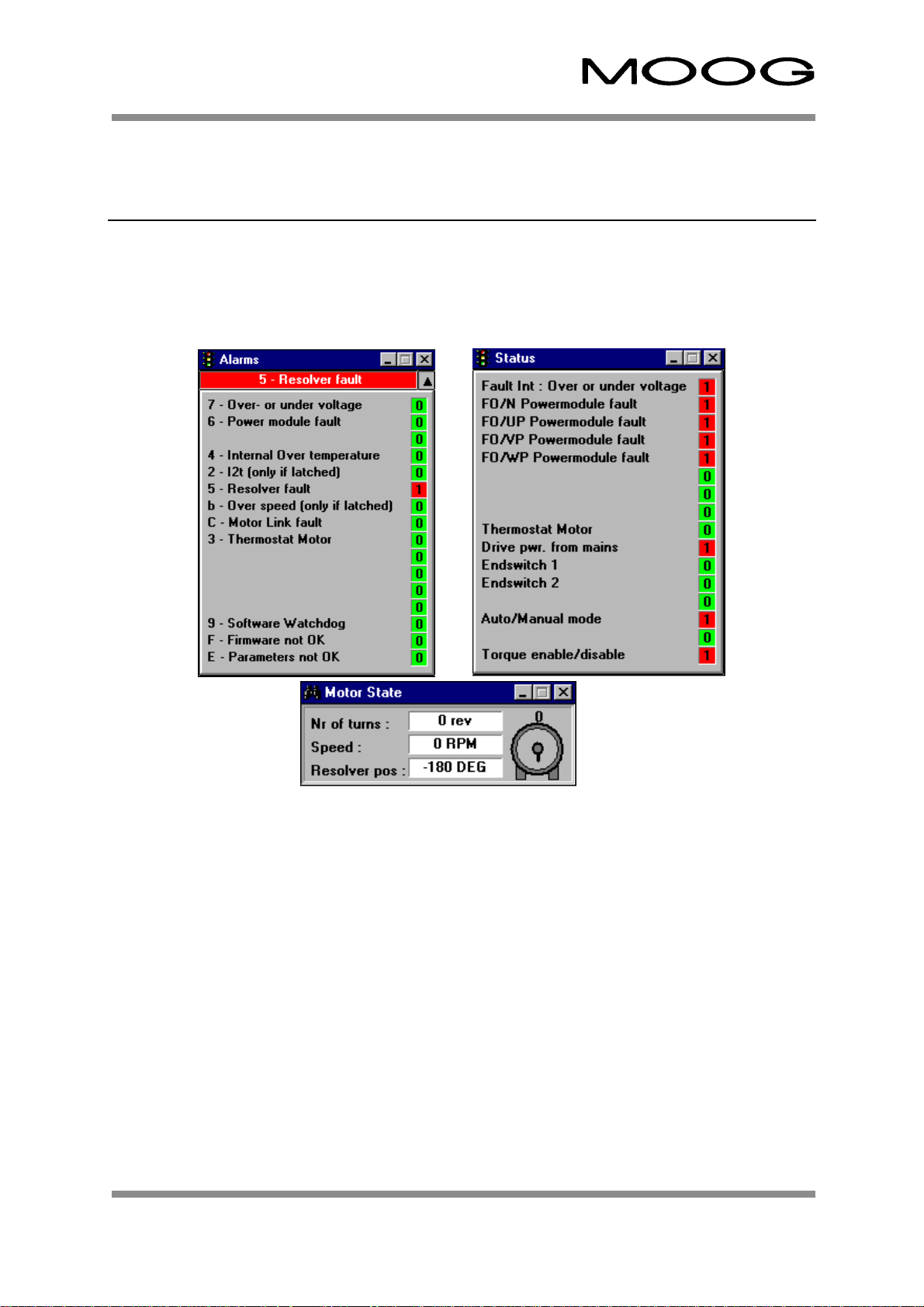

5.4.15 D

DIT PARAMETER FILE 91

RIVILEGED ACCESS 92

OFTWARE DRIVE RESET 92

OFTWARE PREFERENCES 92

RIVE AND MOTOR INDICATIONS 93

Rev. c 05/01 PAGE 7 of 104

Page 8

L180 User's Manual

6SYSTEM DESCRIPTION 95

6.1 SERVO STOP 95

6.2 D

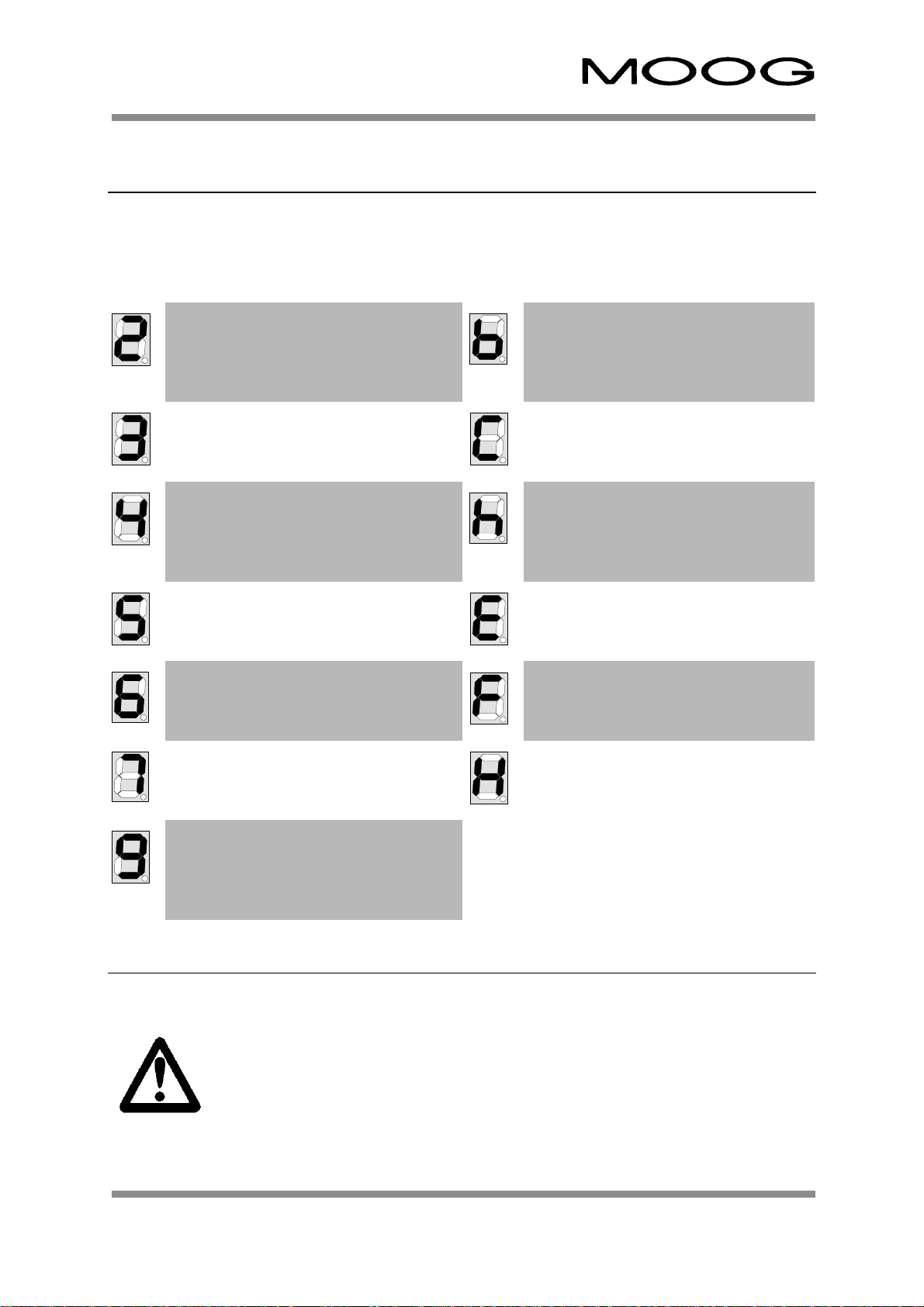

6.2.1 REGULAR INDICATION 96

6.2.2 W

6.2.3 A

6.2.4 A

ISPLAY INDICATION 96

ARNING INDICATION 96

LARM INDICATION 97

LARM HANDLING 97

6.3 TROUBLE SHOOTING GUIDE 98

6.3.1 DRIVE RESET 101

6.3.2 O

THER PROBLEM SOURCES 102

6.4 FAILURE REPORT 103

PAGE 8 of 104 Rev. c 05/01

Page 9

L180 User's Manual

TABLE OF FIGURES

Figure 1: Maximum Regeneration Capability............................................................................................19

Figure 2: Dimensions front and side.........................................................................................................20

Figure 3: Installation and drill plan ...........................................................................................................20

Figure 4: Drive Overview..........................................................................................................................21

Figure 5: Drive Nameplate .......................................................................................................................22

Figure 6: Motor Nameplate (values merely as example)............................................................................27

Figure 7: Radial Load Capacity Gxx2 ........................................................................................................29

Figure 8: Radial Load Capacity Gxx3 ........................................................................................................30

Figure 9: Radial Load Capacity Gxx4 ........................................................................................................30

Figure 10: Radial Load Capacity G4x5......................................................................................................31

Figure 11: Motor Load Coupling..............................................................................................................32

Figure 12: Runout....................................................................................................................................33

Figure 13: Concentricity Figure 14: Perpendicularity ...............................................................................33

Figure 15: Torque-Speed Char. G2L05 Figure 16: Torque-Speed Char. G2L10.......................................39

Figure 17: Torque-Speed Char. G2L20 Figure 18: Torque-Speed Char. G2L40.......................................39

Figure 19: Torque-Speed Char. G3L05 Figure 20: Torque-Speed Char. G3L15.......................................40

Figure 21: Torque-Speed Char. G3L25 Figure 22: Torque-Speed Char. G3L40.......................................40

Figure 23: Torque-Speed Char. G4L05 Figure 24: Torque-Speed Char. G4L10.......................................41

Figure 25: Torque-Speed Char. G4L20 Figure 26: Torque-Speed Char. G4L40.......................................41

Figure 27: Torque-Speed Char. G4L60.....................................................................................................41

Figure 28: Torque-Speed Char. G5L10 Figure 29: Torque-Speed Char. G5L20.......................................42

Figure 30: Torque-Speed Char. G5L30 Figure 31: Torque-Speed Char. G5L50.......................................42

Figure 32: Torque-Speed Char. L2L10 Figure 33: Torque-Speed Char. L2L20 ........................................43

Figure 34: Torque-Speed Char. L3L15 Figure 35: Torque-Speed Char. L3L25 ........................................43

Figure 36: Torque-Speed Char. L4L10 Figure 37: Torque-Speed Char. L4L20 ........................................44

Figure 38:Current/time and torque/time diagrams....................................................................................45

Figure 39: Wiring Overview .....................................................................................................................48

Figure 40: TB1 Wiring..............................................................................................................................50

Figure 41: Multi Axis Wiring ....................................................................................................................51

Figure 42: Resolver wiring, DSUB 9 male cable to J1................................................................................54

Figure 43: Serial link wiring, DSUB9 female cable to J2 and PC.................................................................56

Figure 44: J3 Axis Signals Wiring, DSUB25 male cable to J3 .....................................................................57

Figure 45: Encoder Output, DSUB15 male cable to J4..............................................................................60

Figure 46: Definition of Encoder Signals, viewed from the shaft side........................................................60

Figure 47: J5 Logic Power Wiring, DSUB15 female cable to J5 .................................................................62

Figure 48: Main Window.........................................................................................................................64

Figure 49: Parameters Setting..................................................................................................................66

Figure 50: Warning for ENTER parameters Figure 51: Warning for SAVE parameters..............................67

Figure 52: GUI dialog box features...........................................................................................................68

Figure 53: Setting Serial Port....................................................................................................................69

Figure 54: Parameter Download ..............................................................................................................70

Figure 55: Setting Adjust Options............................................................................................................71

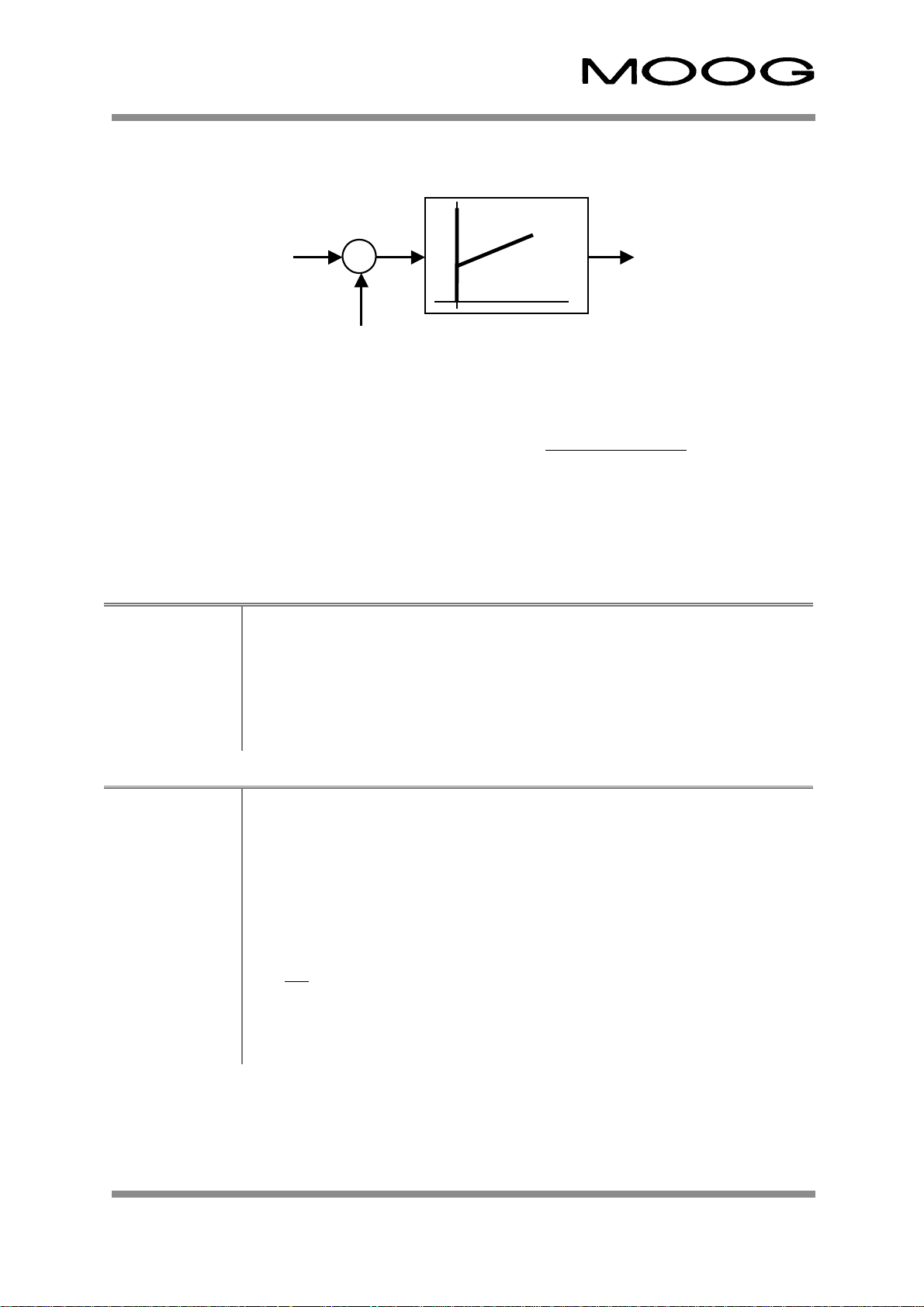

Figure 56: Command Slope .....................................................................................................................73

Figure 57: Encoder Simulation Configuration...........................................................................................74

Figure 58: Encoder Signals.......................................................................................................................76

Figure 59: Adjust Speed Loop Parameters................................................................................................76

Rev. c 05/01 PAGE 9 of 104

Page 10

L180 User's Manual

TABLE OF FIGURES

Figure 60: Speed Loop Regulator.............................................................................................................77

Figure 61: Speed Step, proportional gain.................................................................................................80

Figure 62: Speed Step, integral gain.........................................................................................................80

Figure 63: Adjust Current Loop Parameters..............................................................................................81

Figure 64: Current Loop Regulator...........................................................................................................82

Figure 65: Motor Parameters...................................................................................................................84

Figure 66: Warning during automatic command mode start-up...............................................................86

Figure 67: Automatic command mode.....................................................................................................86

Figure 68: Warning after quit of the automatic command mode..............................................................87

Figure 69: Warning analog command applied..........................................................................................87

Figure 70: Parameter Upload...................................................................................................................88

Figure 71: Notes of parameter files..........................................................................................................88

Figure 72: Scope......................................................................................................................................89

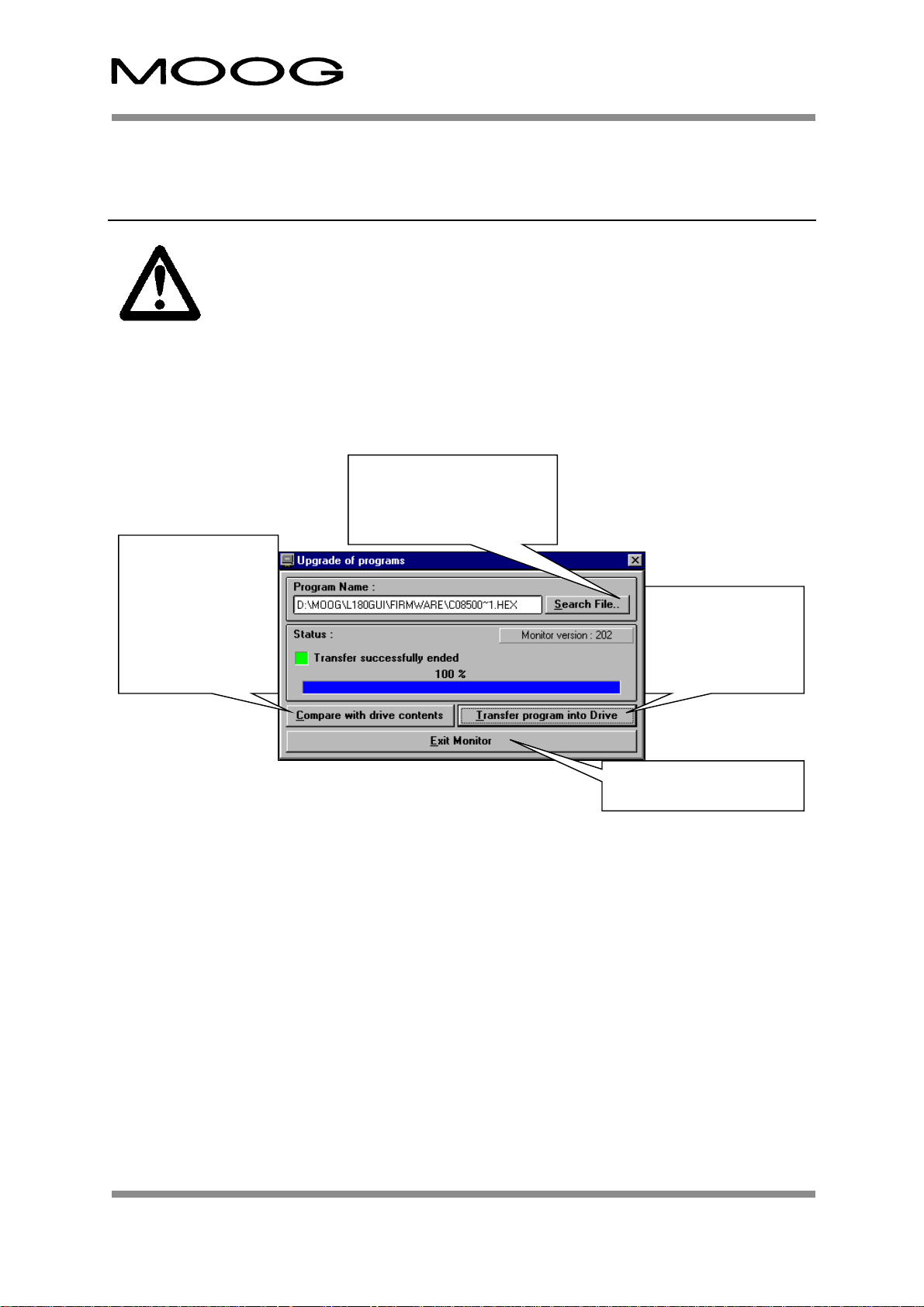

Figure 73: Firmware Upgrade ..................................................................................................................90

Figure 74: Parameter File Editor...............................................................................................................91

Figure 75: Preferences.............................................................................................................................92

Figure 76: Drive GUI Indications...............................................................................................................93

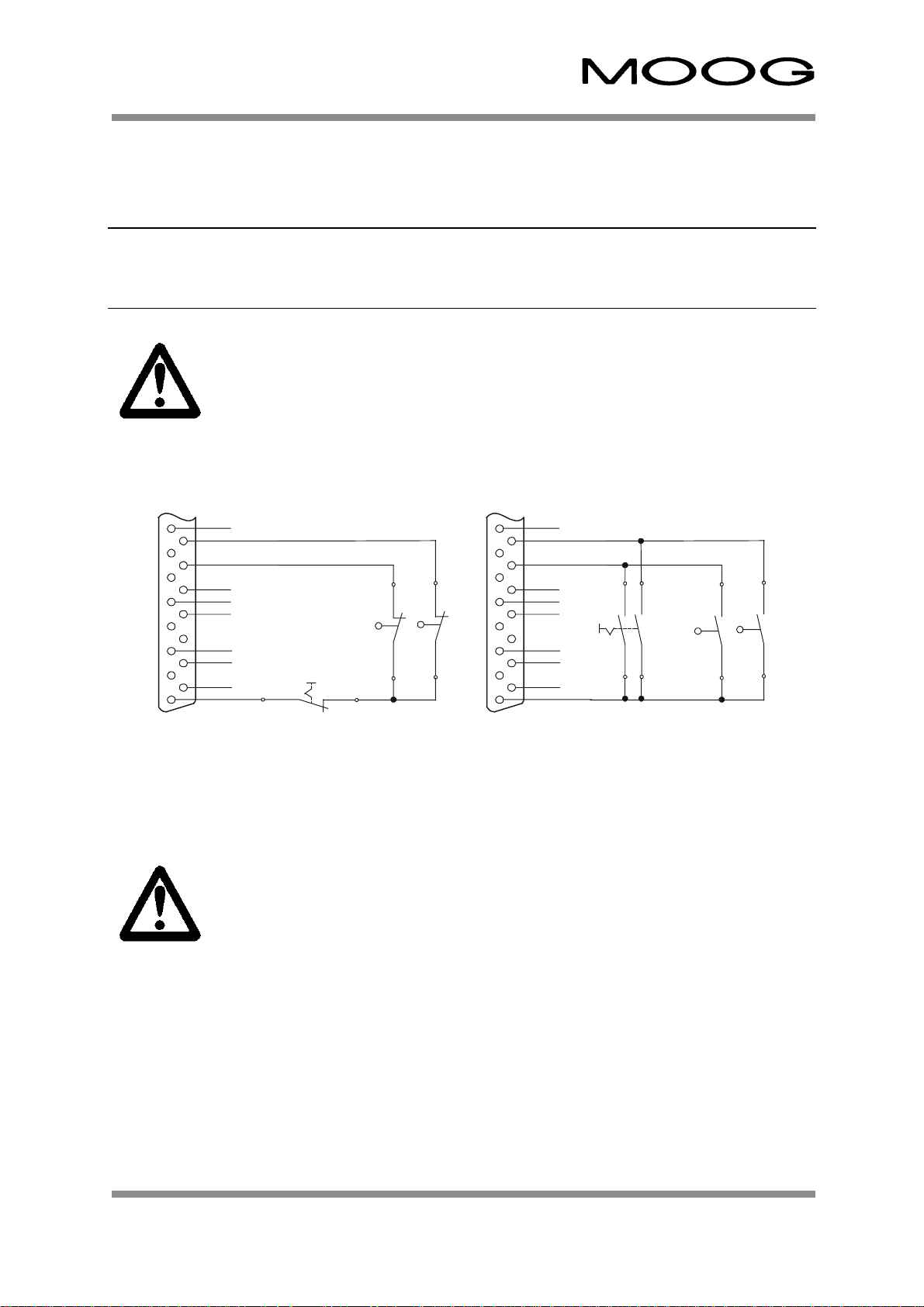

Figure 1: End switch Configuration for servo stop, connector J3 ..............................................................95

Figure 2: Definition of sense of rotation, viewed from the shaft...............................................................96

Figure 79: A1 firmware operation power module Figure 80: A1 firmware Monitoring relay ................98

Figure 81: A2 firmware Monitoring relay Figure 82: A2 firmware operation power module ................99

PAGE 10 of 104 Rev. c 05/01

Page 11

1 Description and Technical Data L180 User's Manual

1 DESCRIPTION AND TECHNICAL DATA

1.1 INTRODUCTION

The L180 servo drive is intended to control MOOG brus hless servo motors. These are 3 phas e

motors with 8 or 12 poles (4 or 6 polepairs) equipped w it h a t w o pole resolver.

The L180 servo drive is fully digital. High-performance torque and speed control fulfill all

requirements for fast response and high control accuracy.

Digital control allows comprehensive diagnostics, motor parameters tuning, data and fault

detection, etc... using a PC based Graphical User Interface (GUI).

Rev. c 05/01 PAGE 11 of 104

Page 12

L180 User's Manual 1 Description and Technical Data

1.1.1 DESCRIPTION

The features of the L180 servo drive are described below:

Power supply

• Single axis unit incorporating regeneration module minimizing wiring and space

requirements.

• 230V three phase or single phase.

• Option: External filters in power source for CE compliance.

• Drive designed according protective extra low voltage standards (PELV). An

autotransformer is sufficient for the main power input.

Power driver

• Galvanic isolation between control and power electronics.

• IGBT output stage.

• Digital PWM current loop providing low ripple motor currents and high motor

efficiency.

Digital controller

• Full-digital servo drive for brushless motor with resolver.

• Easy software download through RS232 serial link.

• Temperature regulated fan-cooling.

• Multi loop control (torque and speed).

• Sinusoidal current output ensures smooth torque and perf or m ance at low speed.

• 7 segment status indicator for diagnostic display.

User's inputs

• ± 10VDC differential analog input for speed or curr ent command.

• RS232 serial port.

• Limit switches for overrun protection in both dire ct ions.

• Optional external 24VDC power supply to the control and interface boards in case of

main power supply interruption.

User's outputs

• Programmable incremental encoder output simulation with resolution from 1 to 2048

ppr (extrapolation), differ ential RS 422 line driver outputs.

• Programmable monitoring relay to indicate ready, alarm or enable status.

Protections

• Power stage protected against short-circuit and over-temperature.

• Motor thermal protection by I²t limitation and thermistor.

• Detection of resolver fault, motor wiring failure.

PAGE 12 of 104

Rev. c 05/01

Page 13

1 Description and Technical Data L180 User's Manual

1.2 INSTRUCTIONS TO THE MANUAL

CE-COMPLIANCE

The symbol on the left indicates where a particular application-related safety

or EMC requirement is driven by the need for CE-Compliance of the L180

when installed in the system. Customers who do not need CE-Compliance

on their machinery may choose not to implement these features.

DANGER

HIGH VOLTAGE

The symbol on the left indicates high voltages which can be extremely

dangerous or lethal if touched and may result in personal injury.

These instructions must be followed.

WARNING

The symbol on the left is used to draw attention to safety instructions

concerning potential damage to the servo drive and motor.

These instructions must be followed.

BEWARE OF HOT PARTS

The symbol on the left indicates hot parts which can be dangerous if

touched and may result in personal injury. These parts must be protected

to prevent contact.

These instructions must be followed.

DELICATE PART

The symbol on the left is used to draw at tention to installation instructions

concerning potential damage to the servo drive and motor. These parts

must be handled with care.

These instructions must be followed.

This user’s manual is written with the intention to supply all necessary information for servo

drive applications. In any case of uncertainty of the drive react ion or m issing inf ormat ion, please

do not hesitate to contact your loca l M OOG applic at ion engineer .

Rev. c 05/01 PAGE 13 of 104

Page 14

L180 User's Manual 1 Description and Technical Data

1.3 TECHNICAL DATA

1.3.1 DESIGN STANDARDS

The low voltage circuits of the L180 drive are designed as protective extra low voltage circuits

(PELV) thus an autotransformer can be used for the main line voltage.

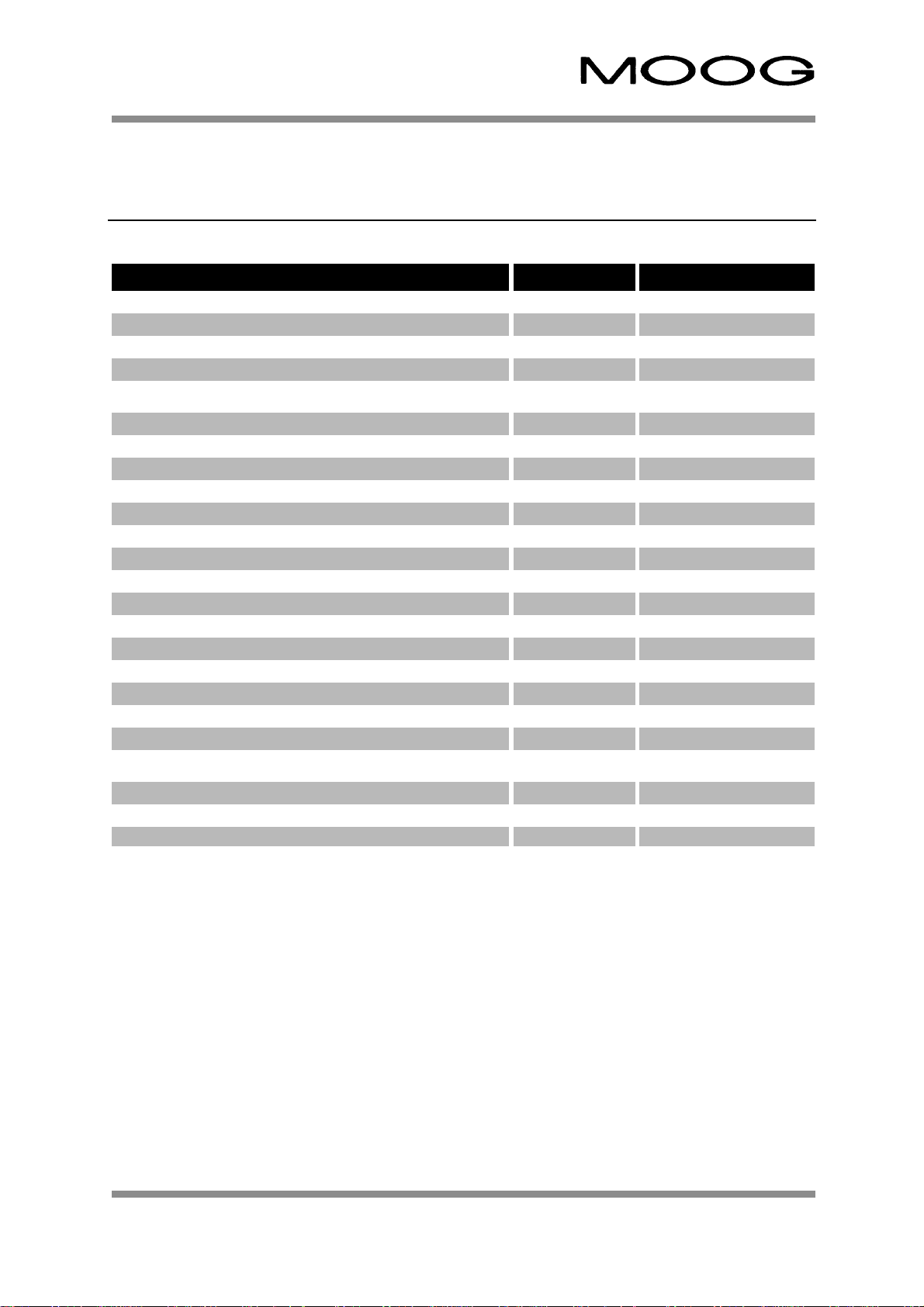

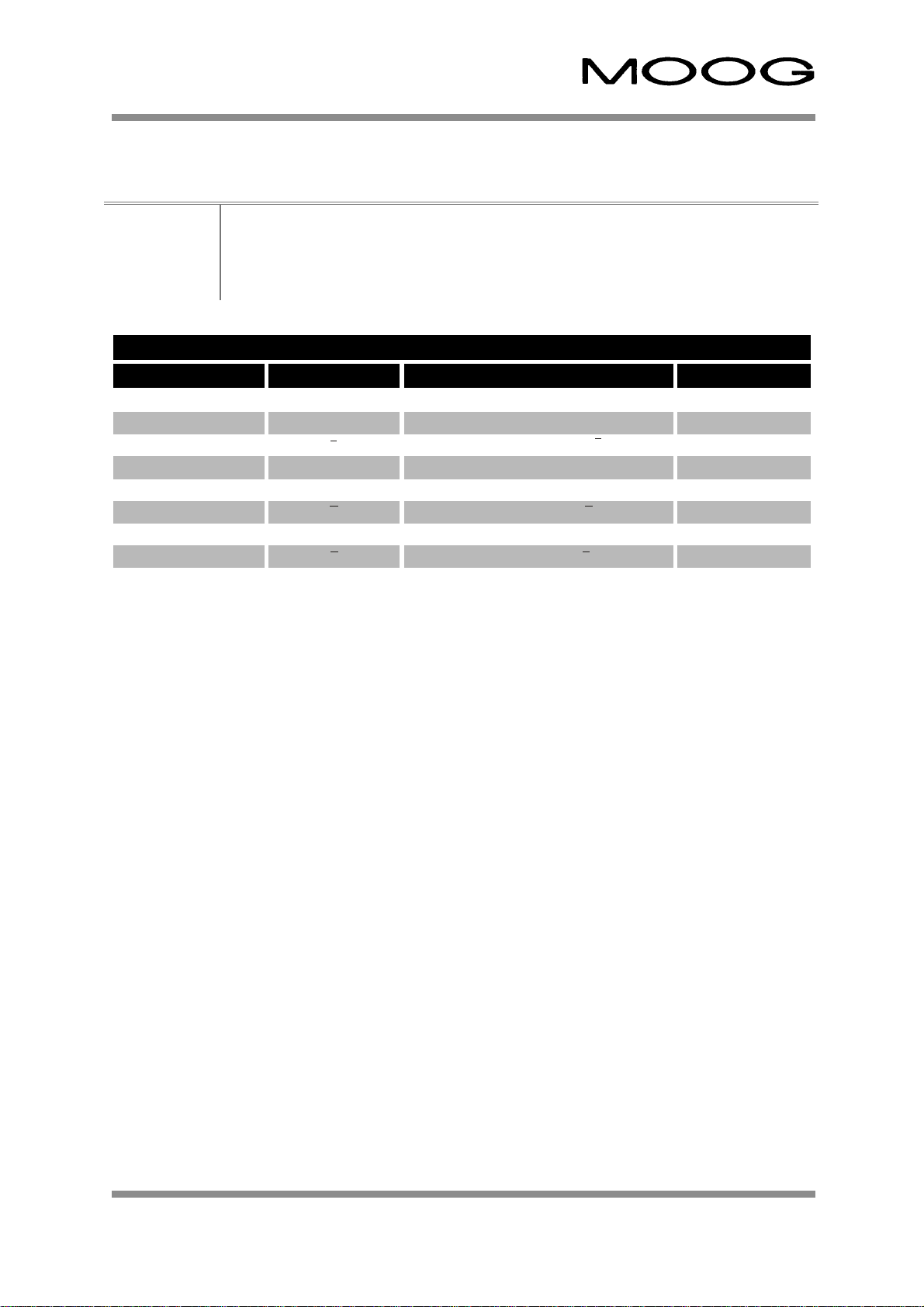

Table 1: Drive Design Standards

Code Year Description

89/366/EEC; 98/13/EEC

IEC 61800-3

EN 50082-2

IEC 61000-4-2

IEC 61000-4-3

IEC 61000-4-4

IEC 61000-4-5

IEC 61000-4-6

EN 50081-2

EN 50081-2 Group 1, Class A, conductive emission requirements (0.15 to 30 MHz)

EN 50081-2 Group 1, Class B, radiated emission requirements (30 to 1000 MHz)

EN 50178

73/23/EEC; 93/68/EEC

1998

1996-06

1995-03

1995

1995

1995

1995

1995

1993-08

1997-10

1993-02

EMC Directive

adjustable speed electrical power drive systems EMC product standard

generic immunity standard

electrostatic discharge immunity test

radiated radio-frequency electromagnetic field immunity test

electrical fast transient, burst immunity test

surge iumminity test

iummunity to conducted disturbances, induced by radio-frequency fields

generic emiss i o n requirements

electronic equipment for use in power installations

low voltage directive

PAGE 14 of 104

Rev. c 05/01

Page 15

1 Description and Technical Data L180 User's Manual

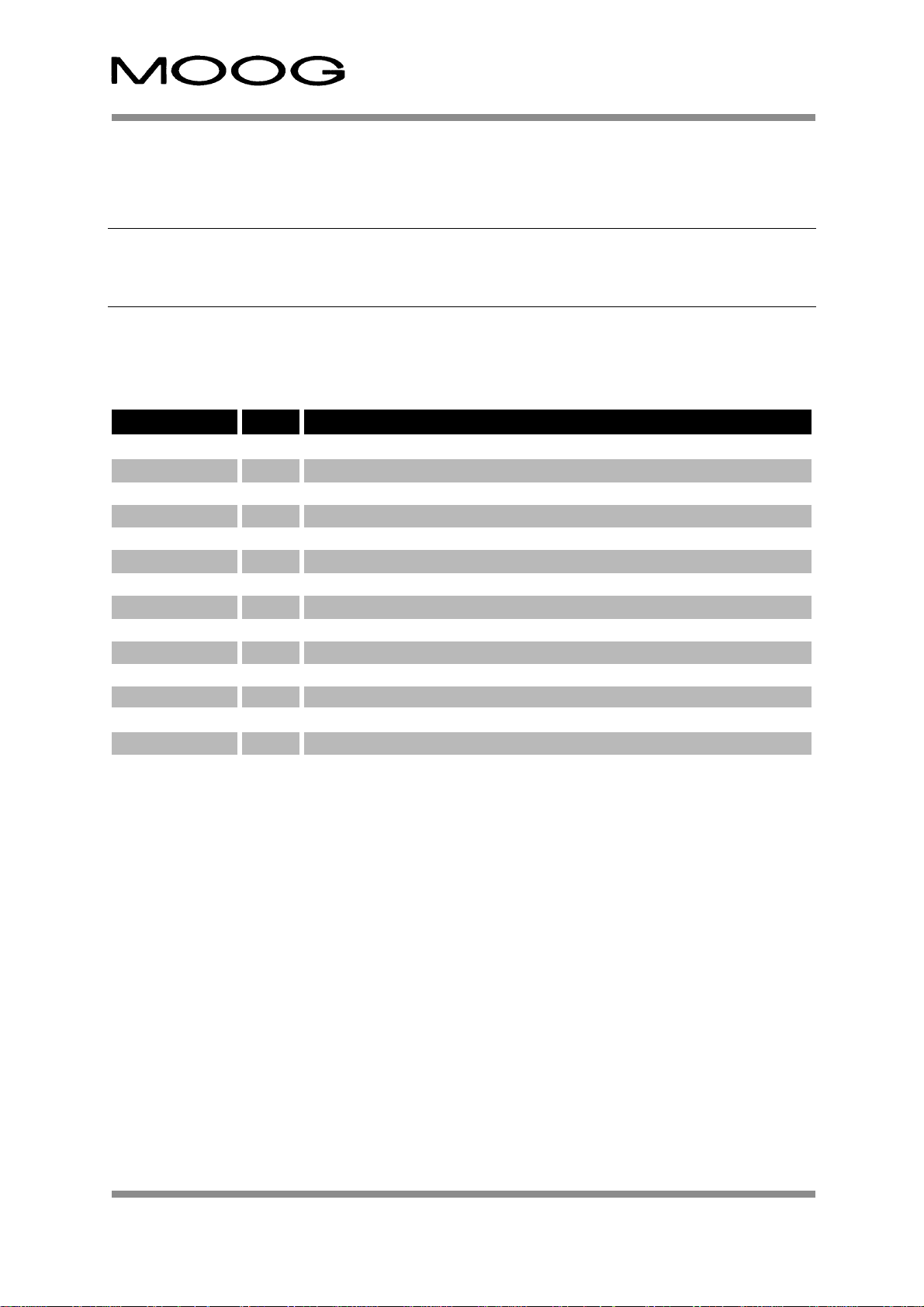

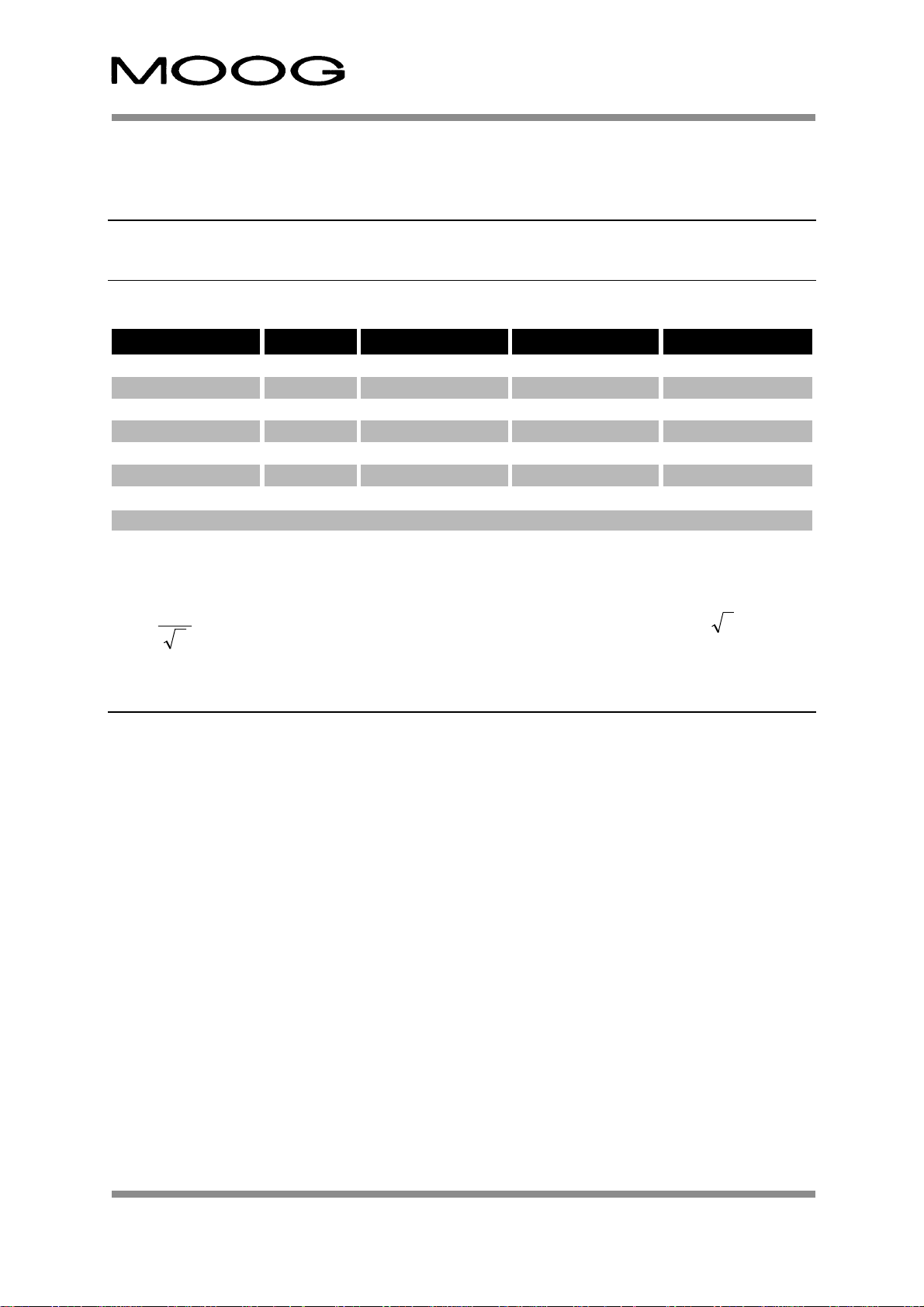

1.3.2 MODEL NUMBER SELECTION

The L180 family uses a 12 character coding system to identify the unique attributes of each

model. The coding system is shown Table 2.

Table 2: Model Number Selection

L180-x10x-xx

PRODUCT

CODE DESCRIPTION

L180 L180 Series

CURRENT RATING

CODE DESCRIPTION

35/10 Arms

4 10/20 Arms

5 15/35 Arms

HARDWARE REVISION

CODE DESCRIPTION

A first release

B second release

FIRMWARE

CODE DESCRIPTION

A ± 10VDC Firmware

FIRMWARE REVISION

CODE DESCRIPTION

1 first release

2 second release

Possible drive model numbers are L180-310A-A1, L180-410A-A1, L180-510A-A1, L180-310AA2, L180-410A-A2, L180-510A-A2, L180-310B-A2, L180- 410B- A2 or L180-510B-A2.

Rev. c 05/01 PAGE 15 of 104

Page 16

L180 User's Manual 1 Description and Technical Data

p

g

g

n

1.3.3 ACCESSORIES

Table 3: Accessories

Part Part Number Length Motor Description

L180 Manual C08476-001 - - L180 User's Manual, english version

L180GUI

Installation Disk

Visual Indication Sticker C08499-001 - - Sticker which explains in short terms the

Raw Power Cable B47890-001 available in

note ➼

Raw Power Cable B47903-001 available in

note ➼

Motor Power Connector A63472-001 - Gxx2, Gxx3, Gxx4 P ower connector for customer

Motor Power Connector C08365-001 - Gxx2, Gxx3, Gxx4 P ower connector for customer

Motor Power Connector B47736-001 - G4x5 Power connec to r for cu sto mer

Motor Power Cable C08336-001-010 10m Gxx2, Gxx3, Gxx4

Motor Power Cable B47915-001-010 10m G4x5

Serial Port RS232 cable C08475-001 5m - Commisioning cable between PC and

Signal Cable C08335-003-010 10m all motors Prefabricated signal cable with mating

Drive matin

Raw signal cable

note ➼

Motor matin

L180 connector kit 1 C53106-001 - - Sol d e r cup kit for use with 10 in

L180 connector kit 2 C53107-001 - - Solder cup kit for use with 12 in

L180 connector kit 3 C53108-001 - - Screw terminal kit for use wi th 12 in

note ➼: consult local sales office

power conn C08474-001 - - Mating power connector for all drives.

signal con

C08478-001

C08478-002

C08336-001-020 20m

B47915-001-020 20m

C08335-003-020 20m

B47885-001

C08485-001 - all motors Signal connector for customer

obsolete - L180 Windows based

Graphical User Interface (L180GUI),

Motor parame te r fi le s

7 segment display indication. Supplied

are part.

drive

customary lengths

customary lengths

available in

customary lengths

with each driv e, s

Gxx2, Gxx3, Gxx4 Shielded cable for customer

configuration

G4x5 Shielded cable for customer

configuration

configuration, smallest version

configuration, easier to assemble

configuration

Prefabricated motor cable with mating

motor connector and ferrule ended leads

Prefabricated motor cable with mating

motor connector and ferrule ended leads

Supplied with each drive, spare part.

all motors Shielded cable for customer

configuration

configuration

clearanc e ca b i net, contains J1, J3 , J4 , J5

mating connector

clearance cabinet, contains J1, J3, J4, J5

mating connector

clearance cabinet, contains J1, J3, J4, J5

mating connector

PAGE 16 of 104

Rev. c 05/01

Page 17

1 Description and Technical Data L180 User's Manual

y

)

p

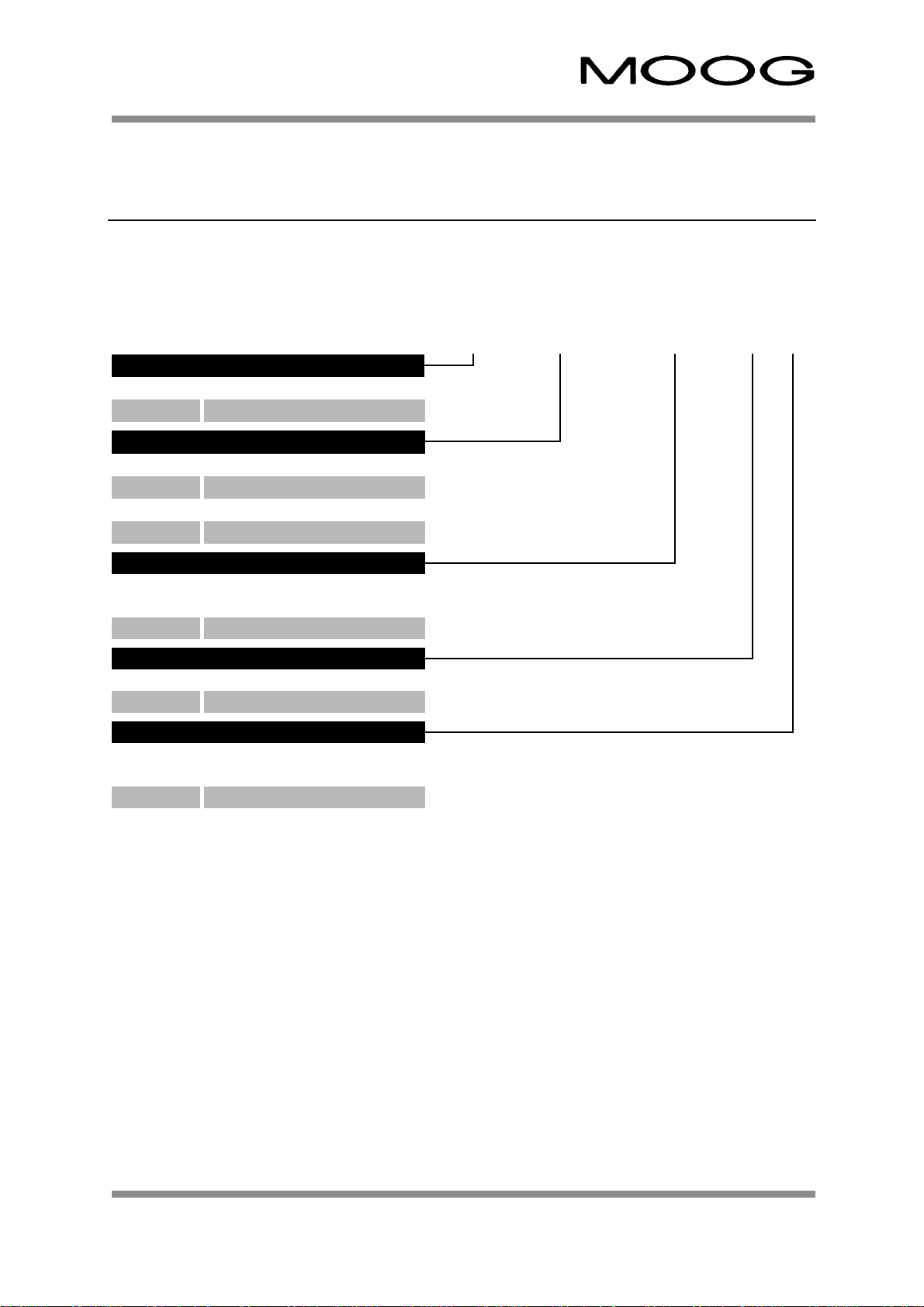

1.3.4 GENERAL DATA

Table 4: General Data

Description Unit L180

Backup Voltage VDC 24 (20 -28)

Supply Voltage line to line , three and single phase VAC 230 +10% -20%

Supply frequency Hz 45 to 65

Operating temperature range ° C 0 to 60

Operating temperature range at full power (from 50°C, reduce output

current b

Storage temperature range °C -20 to +70

PWM chopper frequency kHz 7,5

Differential input reference V + 10 to -10

Continuous regeneration power W 300

Output frequency to motor Hz 0 to 500

Incremental encode r si mulation ppr 1 to 1024 (2048)

Theoretical max. speed for motor with resolver "speed one" rpm 7500

ON-Switching threshold of regene rati on resistor VDC 385

OFF-Switching threshold of regeneration resistor VDC 380

ON-Trip threshold of DC-BUS overvoltage VDC 410

OFF-Trip threshold of DC-BUS ov ervoltage VDC 400

OFF-Trip threshold of DC-BUS undervoltage VDC 230

ON-Trip threshold of DC-BUS undervoltage VDC 220

Baud rate, fixed Bd. 9600

Transmission Full duplex

Serial Link Format

International Protec ti on IP20

Indicative weight kg 3.2

Dimensions (Width,Depth,Height) mm 76.5, 200, 295

2%/°C to 60°C

° C 0 to 50

1 START bit, 8 DAT A bit,

no

arity, 1 STOP bit

Units in VAC are root mean square (rms) values.

Rev. c 05/01 PAGE 17 of 104

Page 18

L180 User's Manual 1 Description and Technical Data

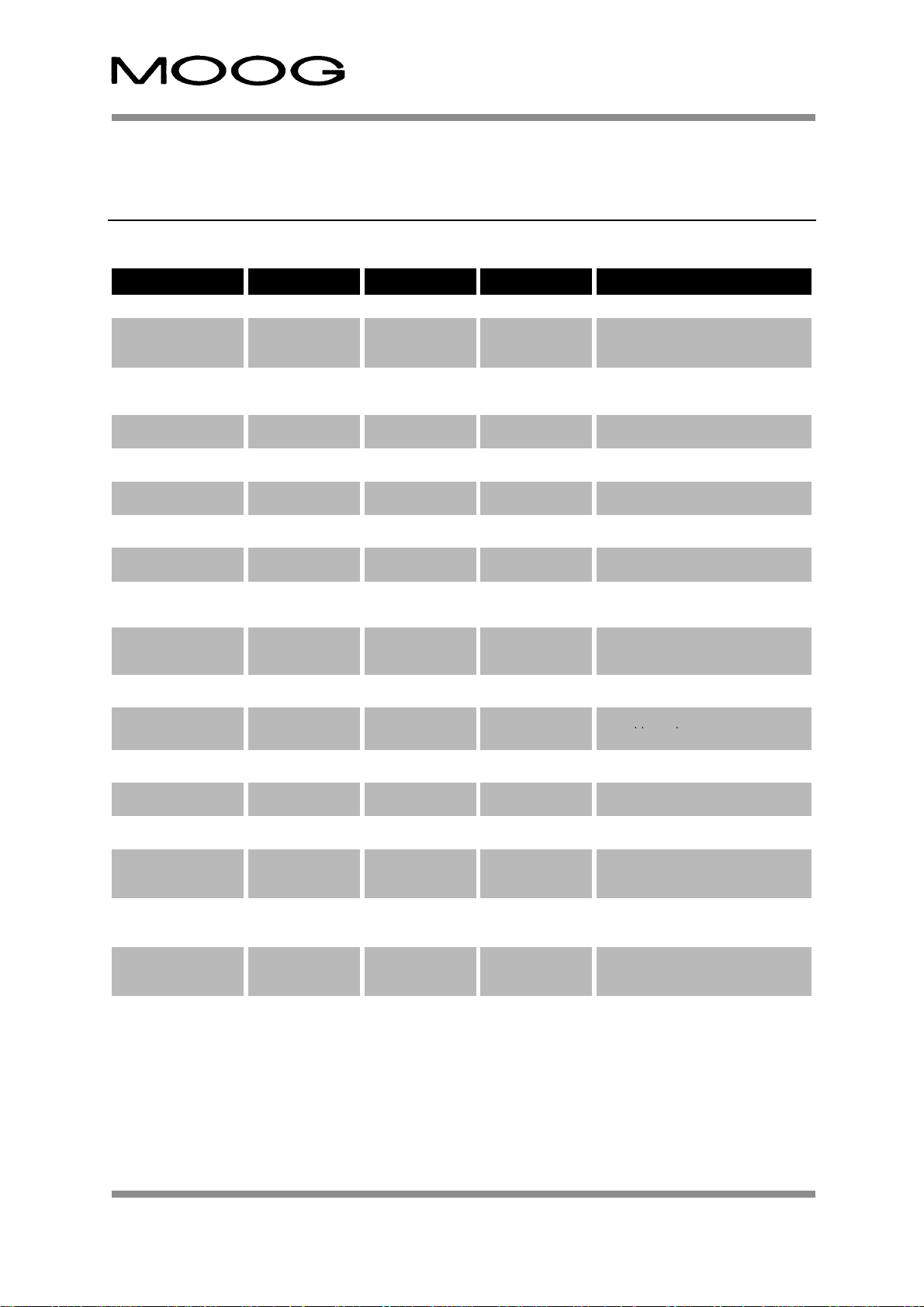

1.3.5 ELECTRICAL DATA

1.3.5.1 DRIVE RATINGS

Table 5: Drive Power Ratings

3~ main line Unit L180-310A L180-410A L180-510A

continuous current Arms 5 10 15

Apeak 7 14 21

maximum current Arms 10 20 36

Apeak142850

continuous power kW 2 4 6

maximum power kW 4 8 14

Single phase operation causes a power reduction to 1/3 of the power rating above

Conversion formula:

I

I =

rms

peak

VU 230=

2

rmsrms

1.3.5.2 POWER DISSIPATION

The power dissipation can be computed with the following formula:

[[[[]

]

]]

P

: total power dissipation in Watt

disp

PIWP ++++++++∗∗∗∗==== 209

brakermsdisp

9: calculation constant in Watt per Arms

I

: continuous current to the motor in Arms

rms

20: power dissipation under no load conditions in Watt

P

: actual regeneration power of the resistor in Wat t

brake

UIP ⋅⋅= 3

rmsrms

PAGE 18 of 104

Rev. c 05/01

Page 19

1 Description and Technical Data L180 User's Manual

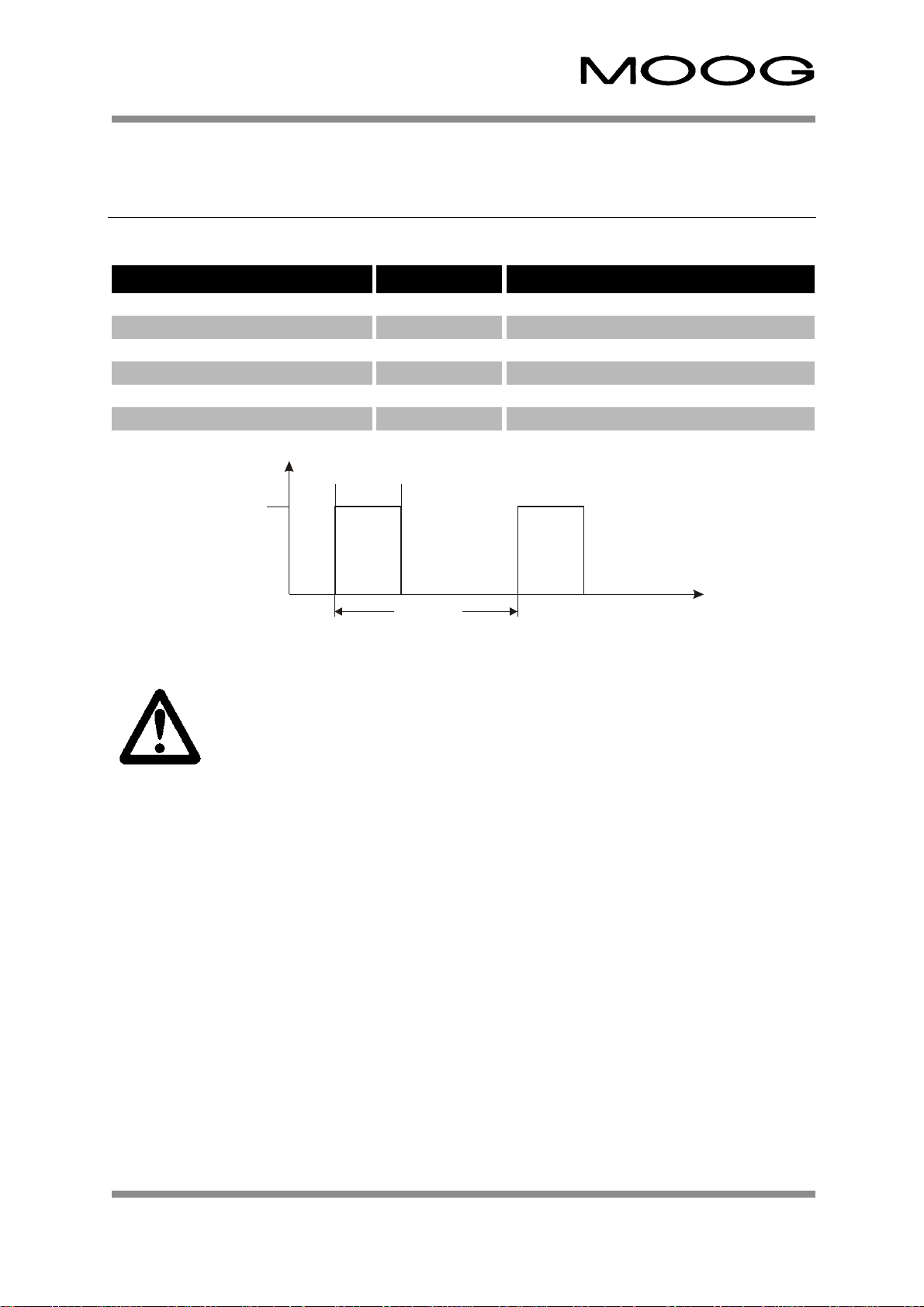

1.3.5.3 REGENERATION POWER

Table 6: Regeneration Power Rating

Regeneration power Unit for all L180 drives

regeneration Resistor Ω 39

maximum regeneration power W 3800

continuous regeneration power W 300

maximum ON-time at max. regen power ms 60

minimum period at max. ON-time s 1

Pmax

ON-time

Figure 1: Maximum Regeneration Capability

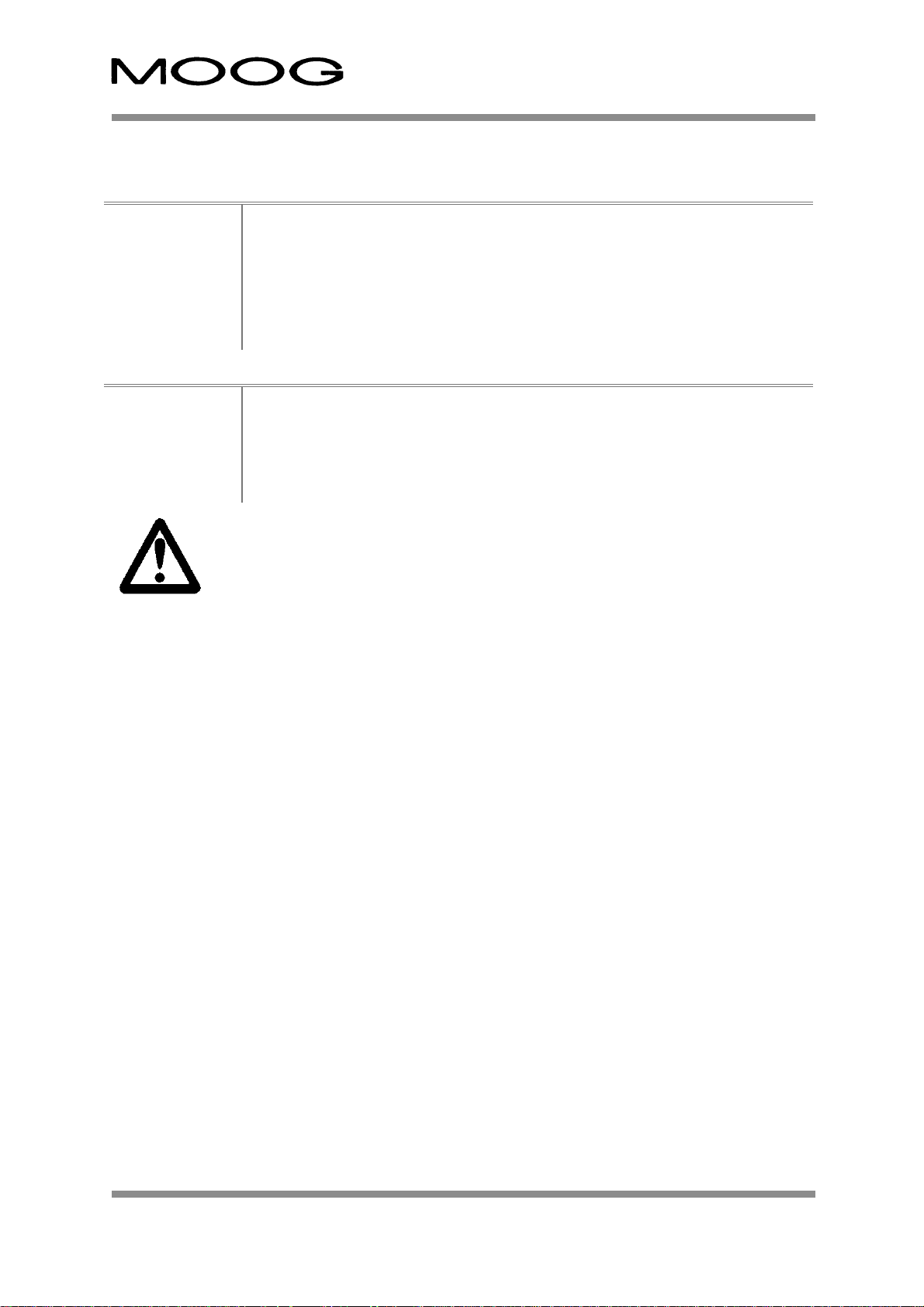

WARNING

The maximum and continuous regeneration power of t he dr ive is limited. An

external regeneration resistor or DC-BUS terminal is not available. The

regeneration power requirements of the application must meet with the

drive capabilities.

If the application regeneration power is above the maximum drive

regeneration power an overvoltage alarm will occur immediately. If the

application regeneration power is above the continuous drive regeneration

power an overheating alarm will occur after a certain period of time. This

time depends on the continuous regeneration power.

period

t

For calculation of regeneration power for your specific application please get

in contact with your local MOOG applicat ion engineer.

Rev. c 05/01 PAGE 19 of 104

Page 20

L180 User's Manual 1 Description and Technical Data

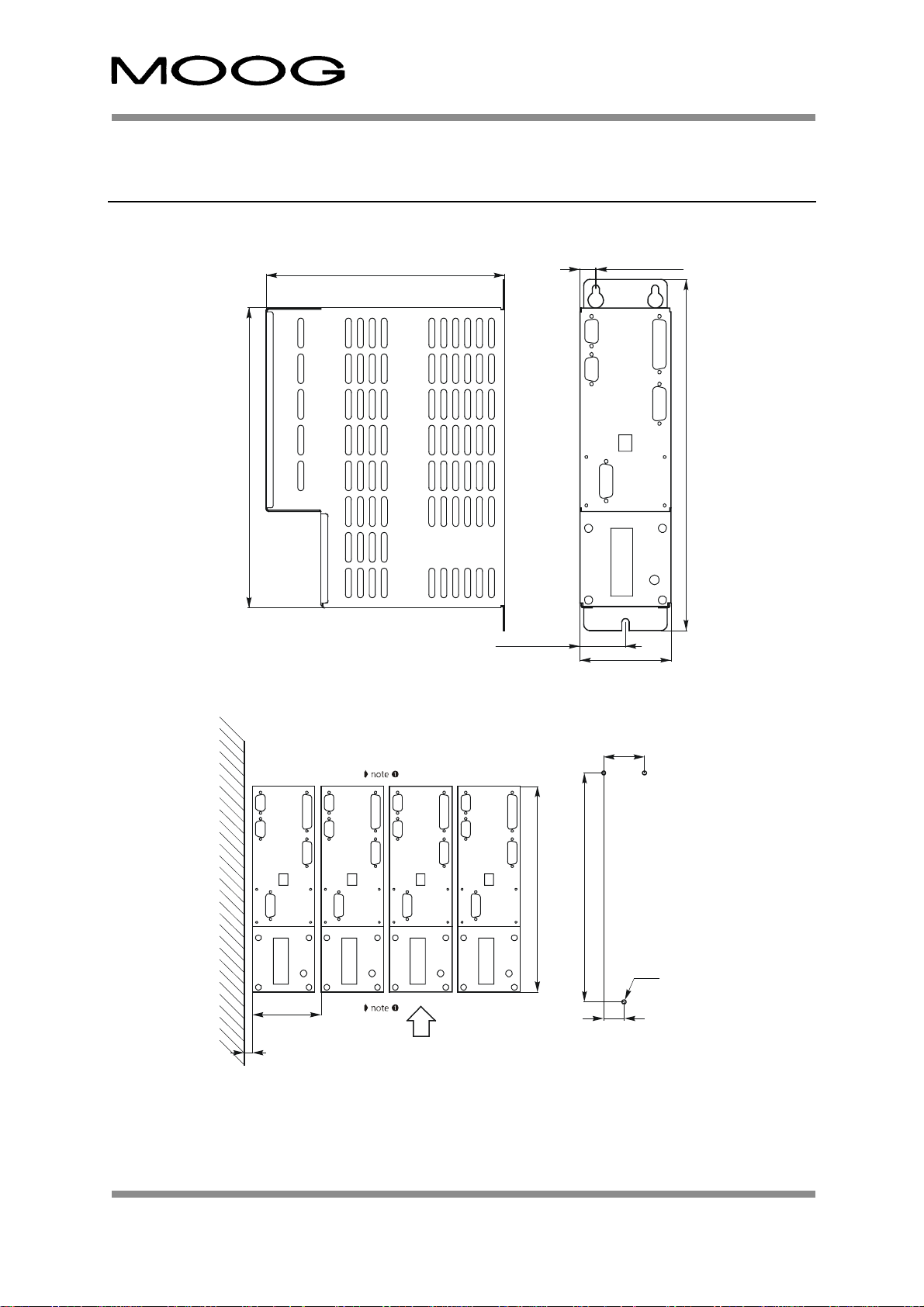

1.3.6 MECHANICAL DIMENSIONS

Dimensions are in millimeter (and inches in br ac ket s ) !

)

3

9

.

9

(

2

.

2

5

2

Figure 2: Dimensions front and side

200 (7.88)

38.25 (1.51)

13.25 (0. 52 2)

MOOG

76.5 (3.01)

)

6

.

1

1

(

5

9

2

DRIVE ARRANGEMENT

MOOG MOOGMOOGMOOG

84 (3.31)

10 (0.394)

AIR FLOW

Figure 3: Installation and drill plan

note ➼: 100 mm (3.94 in) top and bottom clearance re qui red!

50 (1.97)

)

4

)

0

4

.

9

1

.

1

9

(

(

5

5

.

.

0

2

8

5

2

2

3 x 5.5 (0.217)

∅

or M5

25 (0.984)

PAGE 20 of 104

Rev. c 05/01

Page 21

1 Description and Technical Data L180 User's Manual

g

y

y

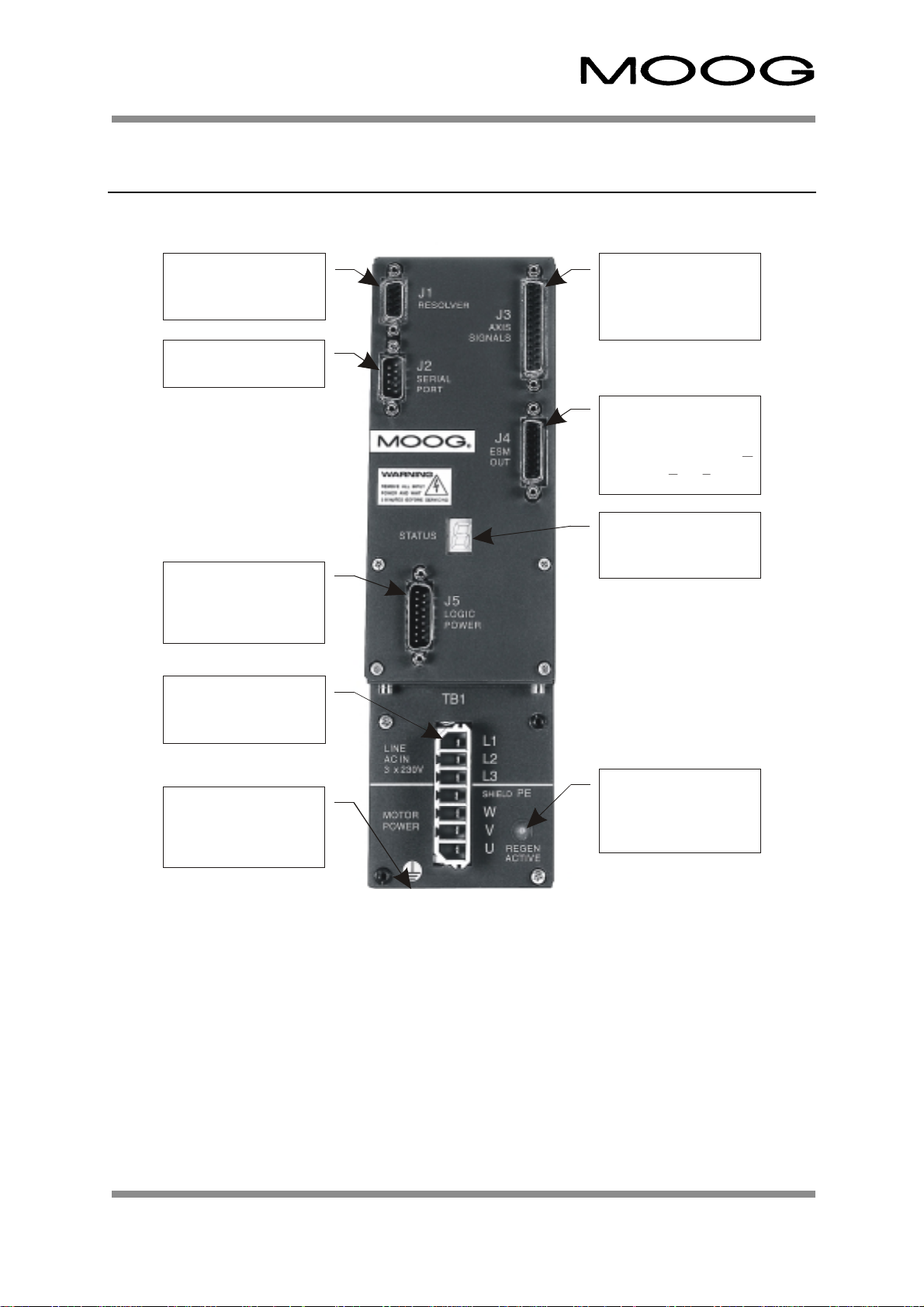

1.3.7 DRIVE OVERVIEW

J1 RESOLVER

Terminal for resolver

cable

J2 SERIAL PORT

RS 232 Interface

J5 LOGIC POWER

24 VDC Power Supply

Input,

±

15 VDC Output

TB1 power connector

Terminal for main lines

and motor cable

J3 AXIS SIGNALS

Analog Input

ital Input/Output

Di

Status Rela

J4 ESM OUT

Differential encoder

output signals from

RS422 line driver, A, ,

seven segment displa

for status information

Contact

B, , Z,

BZ

STATUS

A

REGEN ACTIVE

PROTECTIVE EARTH

Screw terminal for PE

and grounding

(screw not visible)

Figure 4: Drive Overview

Rev. c 05/01 PAGE 21 of 104

red LED , lights up if

motor rege ne rates

energy to drive

Page 22

L180 User's Manual 1 Description and Technical Data

x

1.3.8 DRIVE NAMEPLATE

Please compare received servo drive model listed on nameplate against ordered model. When

contacting MOOG please provide nameplate inform ation.

Model No.

Serial No.

------------- I n p u t ------------- --- O u t p u t ( M o t o r ) ---

Voltage UN[V

Frequency f [Hz]

Line [Phase]

Protection

Detailed informati on see instruction manual

~]

rms

Made in ITALY

MOOG

MOOG

MOOGMOOG

DC Bus Udc[Vdc]

230

Con. CurrentIN[A

50/60

Max. CurrentI

3~/1~

Power PN[kW]

IP 20

Servo drive

ma

~]

rms

[A

~]

rms

Figure 5: Drive Nameplate

The barcode above the nameplate in 3 of 9 style (also called barcode 39) contains the model

and the serial number segregated by a space bar character.

Performance Data

Con. Current continuous output cur r ent to motor

Max. Current maximum output current to motor

Power nominal continuous power to motor

General Data

Voltage Line phase to phase voltage

Frequency line frequency

Line Line number of phases

Serial No. Serial number

Model No. Model number, see table 2

DC BUS internal DC BUS voltage

Standards

Protection Degree of international protection

CE Conformity certificate will be supplied on r eques t

PAGE 22 of 104

Rev. c 05/01

Page 23

2 SAFETY INSTRUCTIONS L180 User's Manual

2 SAFETY INSTRUCTIONS

2.1 QUALIFIED PERSONNEL

WARNING

The components making up the drive system may only be installed and

serviced by qualified personnel. The local regulations for accident

prevention, electronic devices, electric installations and machinery must be

observed.

Unqualified work on the drive components and failure to comply with the warnings contained

in this manual or affixed to the components can be lethal or cause damage t o pr oper t y.

The work permitted within the scope of this manual may consequently only be undertaken by

qualified personnel.

This includes the following people:

•

planning and engineering design personnel familiar with the safety guidelines for

measurement, electronic devices, machinery equipment, electric installations and control

instrumentation,

•

operating personnel who have been instructed with regard to the handling of electronic

devices, machinery equipment, servo drives and who are familiar with the operating

instructions contained in this manual,

•

commissioning and service personnel authorized to start up, ground and mark these

systems in accordance with safety engineering standards. These persons must be qualified

service personnel according to the local regulations.

The design standards offer additional information about the safet y of t he L180 ser v o dr ive.

Rev. c 05/01 PAGE 23 of 104

Page 24

L180 User's Manual 2 SAFETY INSTRUCTIONS

2.2 MAIN SAFETY INSTRUCTIONS

DANGER

HIGH VOLTAGE

The servo drives operate with potentially lethal voltages.

For this reason:

Disconnect the system from the mains supply.

•

Before starting any work on the drive system, it must be disconnected

from the main voltage and secured against inadvertent reconnection by

means of the disconnect switch. Do not remove the plugs for the motor

and mains supply while the L180 servo drive is connected to mains

power.

The servomotor must come to a complete stop.

•

Rotating servomotor can generate potentially lethal volt ages by acting as

generator.

• It is

NOT sufficient to simply disable the drive.

DANGER

HIGH VOLTAGE

The capacitors in the servo drive may s t ill be c har ged.

For this reason:

Note the discharge time of the capacitors.

•

The servo drive contains capacitors which may be charged up to

410 VDC. Wait at least 5 minutes for the capacitors to discharge after

disconnecting the main voltage.

WARNING

The servo drive is designed for use in cabinets and has an IP 20 rating. A

cabinet is recommended which has an IP rating of at least IP54.

PAGE 24 of 104 Rev. c 05/01

Page 25

2 SAFETY INSTRUCTIONS L180 User's Manual

WARNING

BEWARE OF MECHANICAL HAZARDS!

Servomotors can accelerate highly dynamically. They also have enormous

torque. The following points must therefore be observed when starting the

system.

The danger zone of the motor must be cordoned off.

•

The system must feature a safety guard to prevent personnel from

reaching into or entering the danger zone. If the safety syst em is tripped,

the drive system must be disconnected from the main voltage

immediately.

Motor may accelerate inadvertently

•

The motor may accelerate inadvertently due to wiring faults or errors in

the application software. Appropriate safety precautions must be taken

to ensure that neither personnel nor machine components are

endangered in any way.

Coast stop

•

Any failure of the servo drive leads to a coast stop of the motor.

2.3 INFORMATION ON EMC

CE-COMPLIANCE

The information on EMC provided here contains general recommendations

to assist the machine manufacturer when installing L180 components made

by MOOG in finished products which must conform t o the requirements of

EC Directive 89/336/EEC (EMC Directive). Although MOOG has exercised

utmost care in compiling these recommendations, we cannot accept any

liability whatsoever for claims associated with the user's individual

applications. This also applies with regard to non-performance, noncompliance, faults, misunderstandings and mistaken interpretation.

Responsibility for ensuring that every finished product cont aining these components conforms

to the requirements of the EMC Directive rests entirely with the machine manufacturer of the

finished product. MOOG cannot accept any liability what soever for finished products made by

other manufacturers and containing L180 component s f r om MOOG.

Rev. c 05/01 PAGE 25 of 104

Page 26

L180 User's Manual 2 SAFETY INSTRUCTIONS

EMC environment

The L180 components from MOOG are designed for installation in indus trial equipment and for

operation in industrial areas. The L180 components from MOOG have ther efore been test ed in

accordance with the EMC standards, mentioned in the design standards.

Installation of the components

All ground connections between the servo drive cover and the control cabinet must be securely

mounted to guarantee a continuous ground connection. The L180 servo drive is designed for

emission minimization to ensure secure connection between the drive and the baseplate in

conjunction with EMC requirements. The drive has to be connected with prot ect ive eart h on t he

earth stud to ensure proper grounding.

To ensure an optimum EMC shield, the control cabinet should have a continuous ground

connection between all metal panels (frame, side panels, top, baseplate, etc.). A control cabinet

which has been designed to provide an optimum EMC shield can be used for this purpose.

The machine manufacturer must design the system to prevent interference between

subsystems, modules, power supplies, and/or any other component. Furthermore, the complete

system must be designed such that there is no interaction between actual and potential sources

of interference. The machine manufacturer is responsible for taking suitable precautions to

minimize such interference. For example, safe distances must be maintained between

potentially interfering components in addition to the use of proper shielding. The machine

manufacturer is responsible for the design methods used to integrate all system components

together in order to prevent any interference. The machine manufacturer must decide which is

the most efficient method for the complete product .

Where possible, shielded cables with fully shielded connector housings should always be used.

The cable shield must be connected to the connector shields over t he full 360° circumference in

order to ensure a continuous all-round ground connection. All cable connections to the servo

drive must be tightly secured. In particular, all screws in the ground connections of the

connector shields must be securely tightened. To avoid potential interference, power and signal

cables must be routed as far apart as possible in the control cabinet and on the entire finished

product. If power and signal cables must be crossed, t he cables should be crossed perpendicular

to each other to minimize interference. The machine manufacturer of the complete product

must decide which is the most efficient method.

Further details on filtering, grounding and shielding can be f ound in t his m anual.

PAGE 26 of 104 Rev. c 05/01

Page 27

3 SERVOMOTORS L180 User's Manual

3 SERVOMOTORS

A Moog L180 servo drive system consists of a L180 and a Global series servomotor. The Global

series motor nameplate (see Figure 6) lists both the motor model and the motor's electrical

type. The motor electrical type can be used to configure the L180 with the appropriate motor

parameters.

3.1 MOUNTING AND INSTALLATION

3.1.1 MOTOR NAMEPLATE

Please compare received servo motor model listed on nameplate against ordered model. When

contacting MOOG please provide nameplate inform ation.

Figure 6: Motor Nameplate (values merely as example)

General Data

S/N: serial number

Date: production quart er and year

Model: motor model number

Type: electric model, descr iption opt ional br ake

J: rotor inertia

Rtt: terminal to terminal resistance

Ud: bus voltage

Performance Data

: nominal speed (speed at PN)

n

N

: maximum speed

n

max

: nom inal pow er (maximum continuous power)

P

N

: continuous stall torque

M

0

: continuous stall current

I

0

Additional motor data can be found in the motor catalog. Devices without nameplate are not

covered by the manufacturer's warranty and m ust not be put int o operat ion.

Rev. c 05/01 PAGE 27 of 104

Page 28

L180 User's Manual 3 SERVOMOTORS

3.1.2 MOTOR INSTALLATION GUIDELINE

MOOG recommends that hexagon socket head scre ws to DIN 912 8.8 be used to secure the

motor. Assembly is made very much easier by using an Allen key with ball head, particularly in

the cases of motor sizes 2 and 3. The screws used to install these motor sizes must not be more

than 40 mm long.

MOOG motors can become very hot (up to 155°C winding temperature) in operation. Good

heat dissipation must therefore be ensured when installing the motor, i.e. it should be flanged

onto a suitably solid metal part of the machine. Adequat e convection must also be ensured. In

individual cases, the motor must furthermore be protected against contact due to the risk of

burns. Forced cooling (e.g. with fans ) will increase the continuous pow er, while bad convection

may decrease the continuous performance.

Before connecting a coupling to the motor shaft, the shaft must be thoroughly degreased.

When using a degreasing agent, care must be taken to prevent it entering the bearing.

Otherwise the bearings permanent lubrication can no longer be guaranteed. MOOG

recommends the use of a clamp coupling or shrink connection to ensure reliable torque

transmission. An inexpensive and service friendly connection is possible with the slot and key

option (ensure tight slot tolerances).

Impermissibly high axial and radial forces on the shaft can result in motor damage during

installation. The service life of the motor is impaired if the bearing is damaged in any way.

Adjusting the rotor shaft by force can impair the correct functioning of the optional brake to

such an extent that it has little or no braking effect. Excessive pr essure and impact s on the front

end of the shaft and rear housing cover must therefore be avoided under all cir c um st ances.

BEWARE OF HOT PARTS (sticker on servo motor)

In extreme applications, the surface of the servomotor may heat up to more

than 100 °C and can cause skin burns if touched. The servomotor must

therefore be protected to prevent contact.

DELICATE PART (sticker on servo motor)

A hammer must not be used to force the gearing or gearwheel onto the

shaft when installing such parts. The screw thread in the center of the shaft

must be used for this purpose. An extractor supported on the center of the

shaft must be used when dismantling the parts. The permissible axial and

radial forces are in all cases exceeded by the impulses due to hammering.

PAGE 28 of 104 Rev. c 05/01

Page 29

3 SERVOMOTORS L180 User's Manual

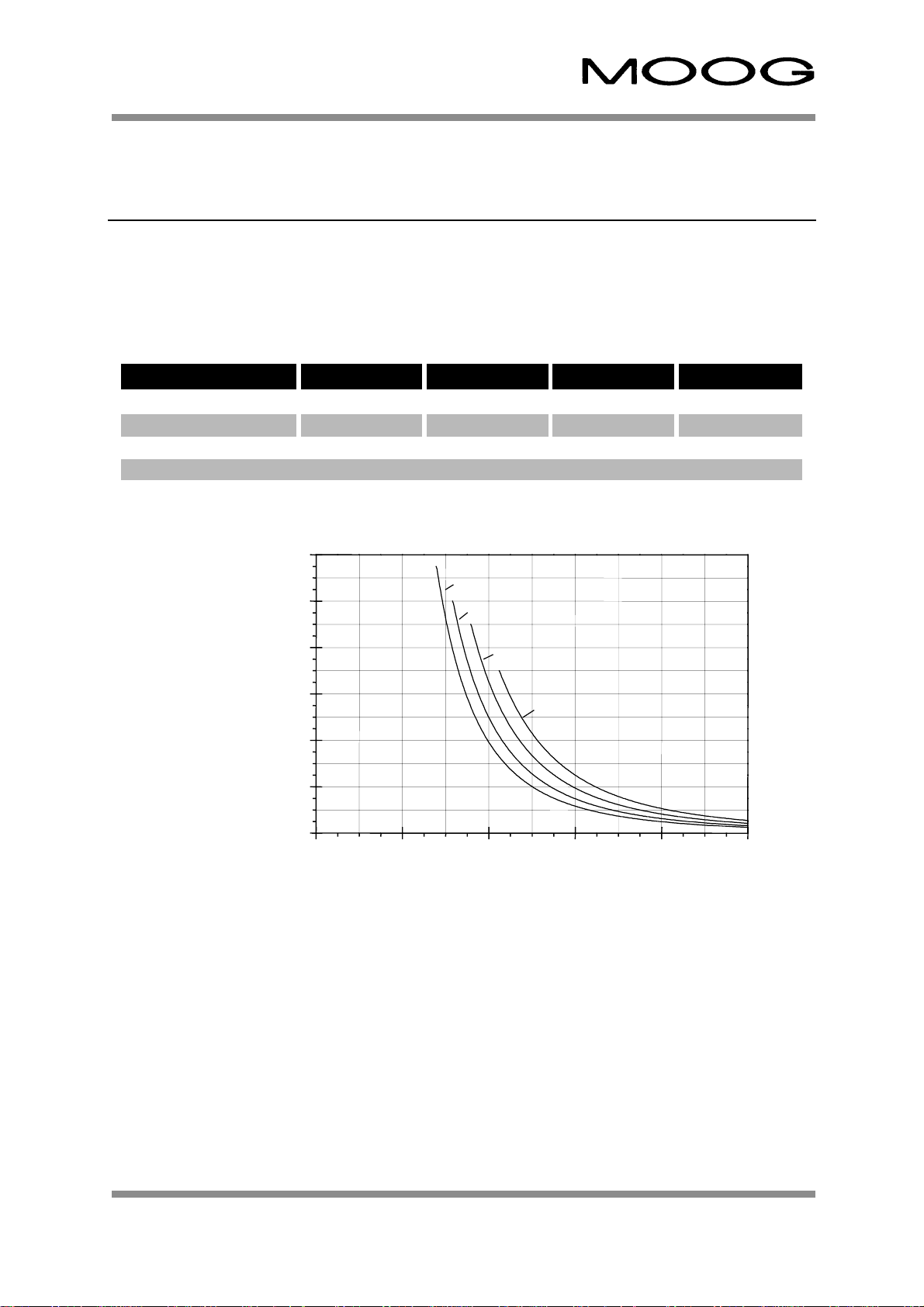

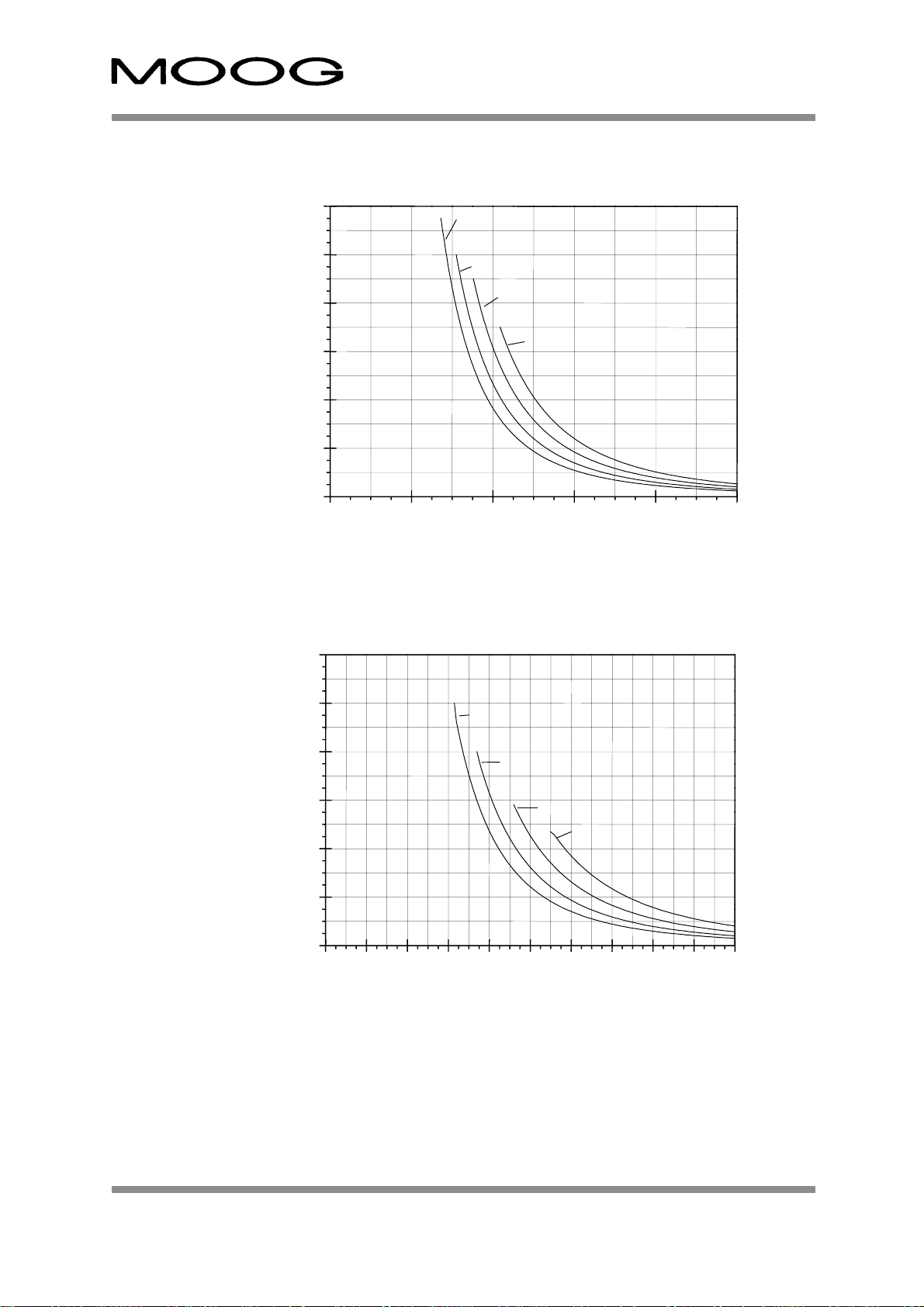

3.1.3 BEARING LOAD CAPACITY

Radial load capacity, shown in Figure 7 to Figure 10, are for a B10 life of 20,000 hours. The

load is applied at shaft extension midpoint. Curves are based on minor axial shaft loads. Consult

factory for other loading conditions. Maximum perm issible axial and radial forces for brushless

MOOG servomotors during inst allat ion r efer to Table 7.

Table 7: Installation Loads

Motor size Gxx2 Gxx3 Gxx4 G4x5

Axial force 150N 150N 300N 400N

Radial force 500N 500N 1000N 1600N

note ➼: During installa ti on. Lower loads apply for the rotating m otor, see catalog.

note ➼

note ➼

Motor Series Gxx2

Speed [rpm]

12000

10000

8000

6000

4000

2000

G4x2-2xx

Gxx2-4xx

Gxx2-6xx

G4x2-8xx

0

0

100 200 300 400 500

Radial Load Capacity [N]

Figure 7: Radial Load Capacity Gxx2

Rev. c 05/01 PAGE 29 of 104

Page 30

L180 User's Manual 3 SERVOMOTORS

Motor Series Gxx3

Speed [rpm]

12000

10000

8000

6000

4000

2000

0

0 100 200 300 400 500

Figure 8: Radial Load Capacity Gxx3

Speed [rpm]

12000

G4x3-2xx

Gxx3-4xx

Gxx3-6xx

G4x3-8xx

Radial Load Capacity [N]

Motor Series Gxx4

10000

8000

6000

4000

2000

0

0 100 200 300 400 500 600 700 800 900 1000

Figure 9: Radial Load Capacity Gxx4

G4x4-2xx

Gxx4-4xx

Gxx4-6xx

G4x4-8xx

Radial Load Capacity [N]

PAGE 30 of 104 Rev. c 05/01

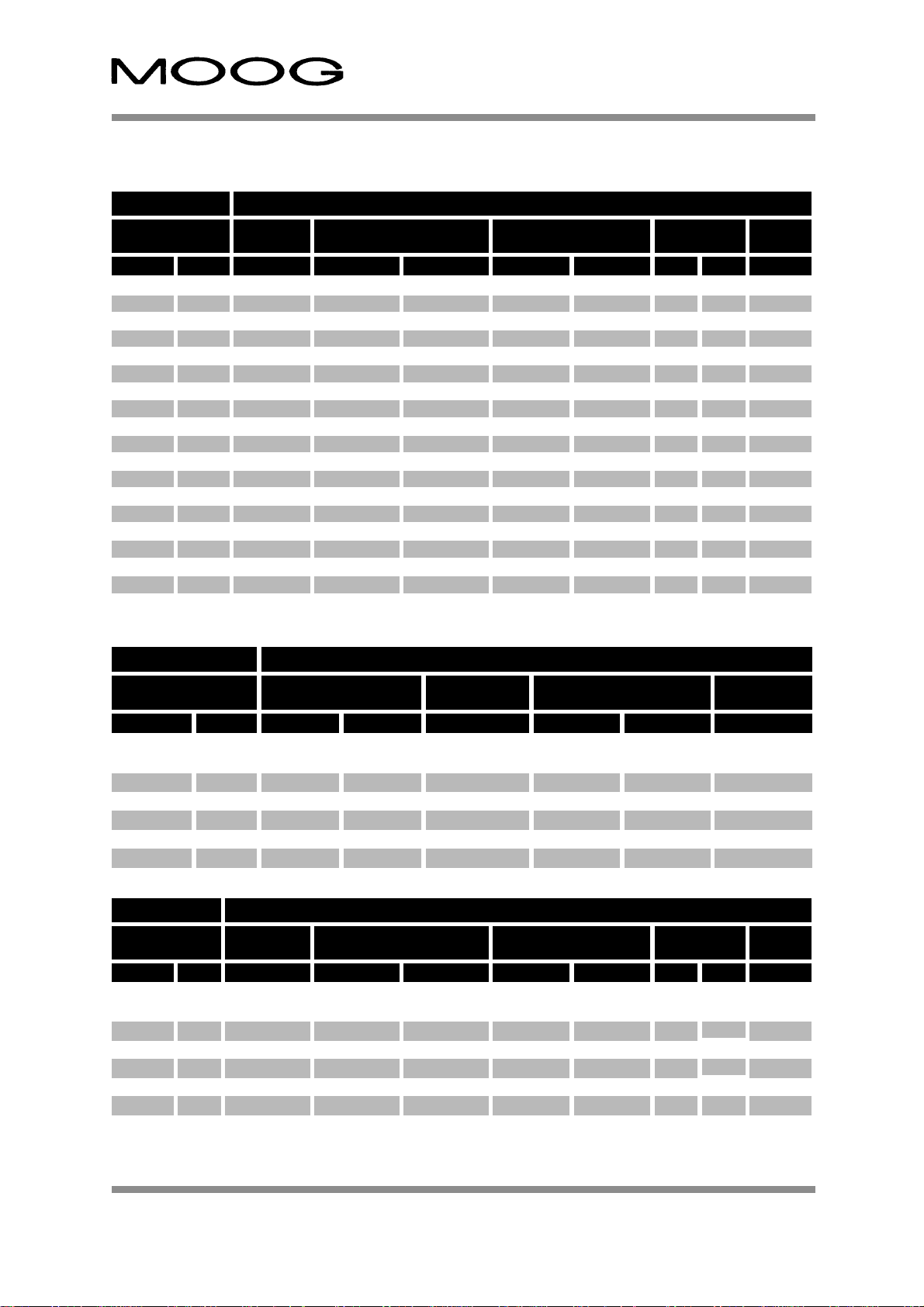

Page 31

3 SERVOMOTORS L180 User's Manual

Motor Series G4x5

Speed [rpm]

8000

7000

6000

5000

4000

3000

2000

1000

0

0 200 400 600 800 1000 1200 1400 1600

Figure 10: Radial Load Capacity G4x5

G4x5-2xx

G4x5-4xx

G4x5-6xx

G4x5-8xx

Radial Load Capacity [N]

Rev. c 05/01 PAGE 31 of 104

Page 32

L180 User's Manual 3 SERVOMOTORS

3.1.4 COUPLING

A flexible coupling offers the advantages of economy, allowance for misalignment, and

reduction of backlash. Flexible disc or bellows style couplings are recomme nded. The couplings

are available for both plain shaft as well as for slot and key configurations. The shaft key should

then be a close clearance or light press fit into the coupling key-way. Refer to Figure 11, for

flexible coupling detail.

WARNING

A rigid coupling should not be used. Normal runouts and eccentricities will

result in damage to motor and/or load shaft and bearings.

Load

Shaft

Key

Motor Shaft

Flexible Coupling

Figure 11: Motor Load Coupling

Key

Double Flexible Coupling Detail

PAGE 32 of 104 Rev. c 05/01

Page 33

3 SERVOMOTORS L180 User's Manual

3.1.5 RUNOUT

The reduced runout provided by MOOG motors allows the attachment of various gear heads.

The precision manufacturing of the motor avoids loads caused by misalignments between

motor and gear heads.

Table 8: Shaft Runout

Diameter of the

Maximum Runout Tolerance

Shaft Extension

øU [mm]

to 10 0.015 0.030

over 10 to 18 0.018 0.035

over 18 to 30 0.021 0.040

over 30 to 50 0.025 0.050

Figure 13: Concentricity Figure 14: Perpendicularity

Class R [mm] Class N [mm]

Figure 12: Runout

Table 9: Flange Concentricity/Perpendicularity

Pilot Diameter of

Mounting Flange

øAK [mm]

to 22 0.025 0.050

over 22 to <40 0.030 0.060

40 to 100 0.040 0.080

over 100 to 230 0.050 0.100

over 230 to 450 0.063 0.125

Rev. c 05/01 PAGE 33 of 104

Maximum Concentricity and

Perpendicularity Tolerance

Class R [mm] Class N [mm]

Page 34

L180 User's Manual 3 SERVOMOTORS

3.2 TECHNICAL MOTOR DATA

3.2.1 STANDARDS FOR MOOG MOTORS

The brushless MOOG Global series servomot ors have been designed, assembled and tested in

conformity with the following standards:

Table 10: Motor design standards

Standard International Europe

Deutschland USA

English

Certified company ISO 9001 EN ISO 9001

Quality systems - model for quality

assurance in design / deve lop m en t ,

production, installation and servicing

Machine guidelines (CE Machine

safety directive)

EMC guidelines (CE-EMC direct i ve) 89/336/EWG,

Low voltage guidelines (CE-Low

voltage directive)

Standard for safety of ele c tri c m otors UL 1004 (1994)

Safety of machinery, electrical

equipment of mach ine s , par t 1:

general requirements

IEC International

Electrotechnical

Commission

ISO 9001 EN ISO 9001 DIN ISO 9001 ISO 9001

89/392/EWG,

91/368/EWG,

93/44/EWG

93/68/EWG,

93/44/EWG

73/23/EWG,

93/68/EWG,

93/44/EWG

IEC 204-1 EN 60204-1 DIN EN 60204-1

EN CENELEC

Europäisches

Komitee für

Elektrotechnische

Normung

89/392/EWG,

91/368/EWG,

93/44/EWG

89/336/EWG,

93/68/EWG,

93/44/EWG

73/23/EWG,

93/68/EWG,

93/44/EWG

DIN / VDE Deutsche

Industrie Norm /

Verband Deutscher

Elektrotechniker

DIN ISO 9001 ISO 9001

89/392/EWG,

91/368/EWG,

93/44/EWG

89/336/EWG,

93/68/EWG,

93/44/EWG

73/23/EWG,

93/68/EWG,

93/44/EWG

VDE 0113-1

NEMA / NEC

National Electric

Code MG.-...

PAGE 34 of 104 Rev. c 05/01

Page 35

3 SERVOMOTORS L180 User's Manual

p

Table 11: Electrical Design Standards

Standard International Europe

English

Rotating electrical machines, Rating

and performance

Rotating electrical machines, Methods

for determing lo sses and efficiency

and performance

Rotating electrical machines,

Classificati on of degrees of protection

rovided by enclosure

Rotating electrical machines, Methods

of cooling (IC-Code)

Rotating electrical machines,

Classifica tion of ty pe s of const ruc tion

and mounting arrangem e nt s (I M

Code)

Rotating electrical machines, Terminal

markings and directions of rotation

Rotating electrical machines, Noise

limits

Insulation coordination for equipment

with low-voltage systems. Part 1:

Principles, requirements and tests

Deutschland USA

IEC I

nternational

E

lectrotechnical

C

ommission

IEC 34-1

IEC 2/915/CDV: 1995

IEC 2G/73/FDIS EN 60034-2 DIN EN 60034-2

IEC 34-5 EN 60034-5 DIN EN 60034-5

IEC 34-6 EN 60034-6 DIN EN 60034-6

IEC 34-7 EN 60034-7 DIN EN 60034-7

IEC 34-8 EN 60034-8 DIN EN 60034-8

IEC 34-9 EN 60034-9 DIN EN 60034-9

IEC 664-1 VDE 0110-1

EN CENELEC

Europäisches Komitee

für Elektrotechnische

N

ormung

EN 60034-1 D I N EN 60034- 1

DIN / VDE D

I

ndustrie Norm /

V

erband Deutscher

E

lektrotechniker

VDE 0530-1

VDE 0530-2

VDE 0530-5

VDE 0530-6

VDE 0530-7

VDE 0530-8

VDE 0530-9

eutsche

NEMA / NEC

Electric Code MG.-...

MG 1-1.65

MG 1-1.25

MG 1-1.26

MG 1-1.25

MG 1-1.26

MG 1-4.03

MG 1-2.61

N/A.

National

Insulation coordina te s f or e qui pm e nt

with low-voltage systems. Part 2:

Partial discharge tests, application

guide

Connectors and plug-a nd- soc k e tdevices, for rate d v o l t ages up to 100 0

V AC, up to 1200 V DC and rated

currents up to 500 A for each pole

IEC 664-2 VDE 0110-2

DIN VDE 0627

Rev. c 05/01 PAGE 35 of 104

Page 36

L180 User's Manual 3 SERVOMOTORS

Table 12: Motor mechanical standards

Standard International Europe

English IEC International

Electrotechnical

Commission

Degrees of protection provided by

enclosure (IP code)

Cylindrical shaft ends for electrical

machines

Mounting flanges for rotati ng

electrical machinery

Dimensions, tolerances and mounting NEMA MG-7

Tolerances of sha f t ext e ns ion run-out

and of mounting flanges for rotat in g

electrical machinery

Mechanical v i bra ti on, ba lance quality

requirements of rigid rot ors,

determination of pe rmi ssible residual

unbalance

Mechanical v i bra ti on, ba lance quality

requirements of rigid rot ors, Ba l a nce

errors

Ball bearings, conr a d typ e , f or

electrical machines, tolerances and

radial clearance

Drive type faste nings without taper

action, parallel keys, keyways, deep

pattern

ISO general purpose metric screw

threads. Part 1 coarse pitch threads in

diameter range 1 mm to 68 mm,

nominal sizes

General tolerances, tolerances for

linear and angula r dim ensions without

individual tole ra nce indications

IEC 529 EN 60529 DIN EN 60529

IEC 72

ISO/R 775-1969

DIN 42948

IEC 72 DIN 42955

ISO 1940-1 DIN ISO 1940-1

ISO 1940-2 DIN ISO 1940-2

DIN 42966

DIN 6885-1

ISO 724 DIN 13-1

ISO 2768-1 EN 22768 DIN ISO 2768-1

EN CENELEC

Europäisches Komitee

für Elektrotechnische

Normung

DIN 748-1 & 3 MG-11...

Deutschland USA

DIN / VDE Deutsche

Industrie Norm /

Verband Deutscher

Elektrotechniker

VDE 0470-1

NEMA / NEC National

Electric Code MG.-...

PAGE 36 of 104 Rev. c 05/01

Page 37

3 SERVOMOTORS L180 User's Manual

3.2.2 MOTOR PERFORMANCE DATA

Operating and ambient conditions for G4xx and G33x motor series:

Temperature for Transport -40 °C to 120°C note Ê

and Storage: -25 °C to 120 °C

Degree of Protection: IP 67 with optional shaft seal or gearbox attached note Ë

(DIN VDE 0470-1, EN 60529, IEC 529)

Ambient temperature in Operation: -25 °C to 50 °C

Runout: Class R (DIN 42955-R, IEC72)

Class N (DIN 42955-N, IEC72)

note Ê: G4xx motor series onl y

note Ë: G33x motor series m ating connector must be attached

Legend:

Motor flanged mounted onto a steel pla te 300 x 300 x 12 mm with the maximum permissible temperature rise of the

winding at 100 K over a still air environment (max. 50 °C)

Á Speed at which the EMF of the motor is equal to the DC-bus voltage

k =

t

M

N

I

N

² = 8.85x10

-4

lb-in-sec

2

1 kg = 2.2 lb 1 kW = 1.341 hp

Â

conversions:

1 Nm = 8.85 lb-in 1 kgcm

note Ê

Table 13: Motor Performance Stall Data G400 series

Motor type

Continuous stall tor que

Model Type Mo [Nm] Mo [lb-in] Io [Arms] Mmax [Nm] Mmax [lb-in] Imax [Arms]

note

G4y2-2xx

G4y2-4xx

G4y2-6xx

G4y2-8xx

G4y3-2xx

G4y3-4xx

G4y3-6xx

G4y3-8xx

G4y4-2xx

G4y4-4xx

G4y4-6xx

G4y4-8xx

G4y4-9xx

G4y5-2xx

G4y5-4xx

G4y5-6xx

G4y5-8xx

note: y = 1 U S versio n ; y = 2 Europe v ersion

G2L05 0.25 2.21 0.65 0.5 4.43 1.9

G2L10 0.50 4.43 1.2 1.4 12.39 3.7

G2L20 0.95 8.41 2.15 2.6 23.01 6.4

G2L40 1.7 15.05 2.85 5 44.25 8.3

G3L05 0.6 5.31 1.6 1.5 13.28 4.6

G3L15 1.65 14.60 3.2 4.7 41.60 10.6

G3L25 2.55 22.57 3.4 8.5 75.23 12.4

G3L40 3.7 32.75 4.2 13 115.05 16.3

G4L05 1.3 11.51 3.1 3.2 28.32 9

G4L10 2.6 23.01 4.8 6.5 57.53 15

G4L20 4.7 41.60 6.7 12.5 110.63 20

G4L40 8.2 72.57 9.2 22 194.70 28

G4L60 11 97.35 9.5 31 274.35 30

G5L10 5.8 51.33 9.5 12.2 107.97 24

G5L20 11.2 99.12 11 25.8 228.33 33

G5L30 16.6 146.91 12.9 40 354.00 38

G5L50 25 221.25 14.8 60 531.00 43

➲

Stall data

Continuous

stall current ➲

Peak stall torque

Peak stall

current

Rev. c 05/01 PAGE 37 of 104

Page 38

L180 User's Manual 3 SERVOMOTORS

Table 14: Motor Performance Miscellaneous Data G400 series

Motor type

Theoret. no

load speed ➳

Model

note

G4y2-2xx G2L05 10200 0.37 3.27 0.09 0.00008 1.0 2.20 8 (4)

G4y2-4xx G2L10 9000 0.42 3.72 0.13 0.00012 1.2 2.64 8 (4)

G4y2-6xx G2L20 7900 0.46 4.07 0.22 0.00019 1.5 3.30 8 (4)

G4y2-8xx G2L40 6300 0.60 5.31 0.41 0.00036 2.3 5.06 8 (4)

G4y3-2xx G3L05 9600 0.40 3.54 0.16 0.00014 1.4 3.08 8 (4)

G4y3-4xx G3L15 7200 0.53 4.69 0.39 0.00035 2.0 4.40 8 (4)

G4y3-6xx G3L25 4900 0.75 6.64 0.62 0.00055 2.6 5.72 8 (4)

G4y3-8xx G3L40 4100 0.90 7.97 0.97 0.00086 3.5 7.70 8 (4)

G4y4-2xx G4L05 8800 0.42 3.72 1.05 0.00093 3.0 6.60 12 (6)

G4y4-4xx G4L10 6900 0.54 4.78 1.55 0.00137 3.6 7.92 12 (6)

G4y4-6xx G4L20 5200 0.70 6.20 2.60 0.00230 4.7 10.34 12 (6)

G4y4-8xx G4L40 4200 0.89 7.88 4.70 0.00416 6.9 15.18 12 (6)

G4y4-9xx G4L60 3300 1.16 10.27 6.80 0.00602 9.1 20.02 12 (6)

G4y5-2xx G5L10 6100 0.61 5.40 4.60 0.00407 7.7 16.94 12 (6)

G4y5-4xx G5L20 3800 1.02 9.03 8.00 0.00708 9.9 21.78 12 (6)

G4y5-6xx G5L30 3000 1.29 11.42 11.50 0.01018 12.1 26.62 12 (6)

G4y5-8xx G5L50 2200 1.69 14.96 18.40 0.01628 16.6 36.52 12 (6)

note: y = 1 US version; y = 2 Europe version

Type Ntheo [rpm] kt [Nm/Arms] kt [lb-in/Arms] J [kgcm²]J [lb-in-sec²] m [kg] m [lb]

Torque constant rotor inertia without brake

Miscellaneous data

Mass without

brake

Poles

(polepairs)

Table 15: Motor Performance Stall Data G300 series

Motor type

Continuo us stall torq ue ➲ Peak stall torque

Model Type Mo [Nm] Mo [lb-in] Io [Arms] Mmax [Nm] Mmax [lb-in] Imax [Arms]

G332-4xx

G332-6xx

G333-4xx

G333-6xx

G334-4xx

G334-6xx

L2L10 0.5 4.43 1.15 1 8.85 2.3

L2L20 0.95 8.41 2 1.9 16.82 4

L3L15 1.6 14.16 3 3.2 28.32 6

L3L25 2.6 23.01 3.3 5.2 46.02 6.6

L4L10 2.5 22.13 4.5 4.7 41.60 9

L4L20 5 44.25 7 9.4 83.19 14

Continuous stall

current ➲

Stall data

Peak stall current

Table 16: Motor Performance Miscellaneous Data G300 series

Motor type

Theoret. no

load speed ➳

Model Type Ntheo [rpm] kt [Nm/Arms] kt [lb-in/Arms] J [kgcm²]J [lb-in-sec²] m [kg] m [lb]

G332-4xx

G332-6xx

G333-4xx

G333-6xx

G334-4xx

G334-6xx

L2L10 9000 0.44 3.89 0.13 0.00012 1.2 2.64 8 (4)

L2L20 7900 0.49 4.34 0.22 0.00019 1.5 3.30 8 (4)

L3L15 7200 0.55 4.87 0.37 0.00033 2 4.40 8 (4)

L3L25 4900 0.8 7.08 0.59 0.00052 2.6 5.72 8 (4)

L4L10 6900 0.58 5.13 1.5 0.00133 3.6 7.92 12 (6)

L4L20 5200 0.76 6.73 2.5 0.00221 4.7 10.34 12 (6)

Torque constant

Miscellaneous data

➴

rotor inertia without brake

Mass without

brake

Poles

(polepairs)

PAGE 38 of 104 Rev. c 05/01

Page 39

3 SERVOMOTORS L180 User's Manual

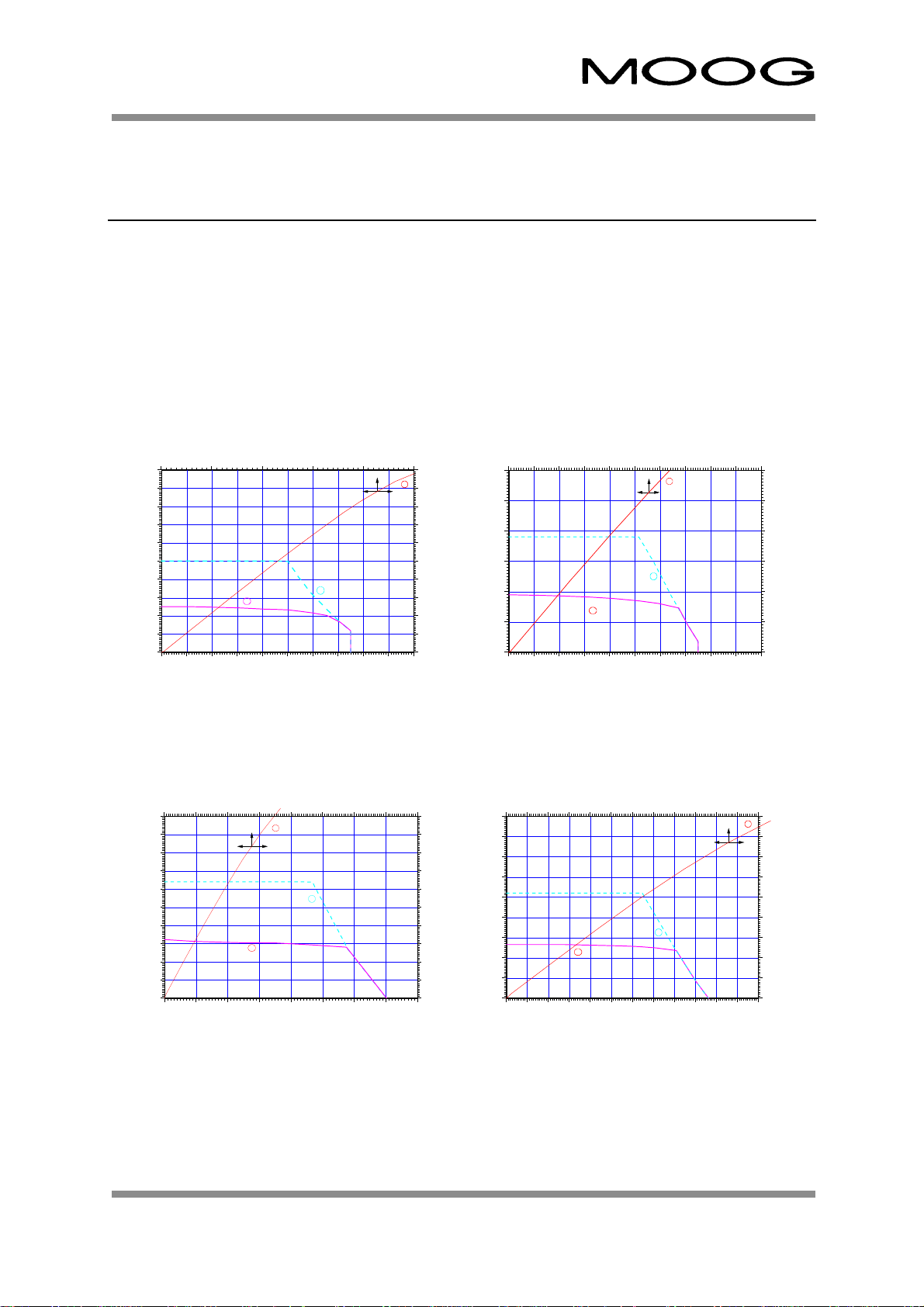

3.2.3 TORQUE SPEED CHARACTERISTIC G400 SERIES MOTORS

Legend:

torque limit for continuous ope rati on (windi ng 100 K abov e a mbie nt, wi th motor mounte d to 300mm x 300m m x 12mm

peak torque at approx. three times continuous stall current with L180 controller (hi gher torque at higher current lev els

kt-line give s torque at current level (top axis)

Drive System L180 - Servomotor G4x2

steel plate)

possible)

G4x2-2xx (G2L05)

0.0 0.5 1.0 1.5 2.0 2.5 3.0

1.0

0.9

0.8

0.7

0.6

0.5

0.4

Torque (Nm)

0.3

0.2

0.1

0.0

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 100001100012000

1

speed (rpm)

Current (Arms)

3

2

8.85

7.96

7.08

6.19

5.31

4.42

3.54

2.65

1.77

0.88

0.00

Torque (lb-in)

G4x2-4xx (G2L10)

012345678910

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

Torque ( Nm)

0.8

0.6

0.4

0.2

0.0

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

1

Current (Arms)

3

2

speed (rpm)

Figure 15: Torque-Speed Char. G2L05 Figure 16: Torque-Speed Char. G2L10

G4x2-6xx (G2L20)

012345678910

5.0

4.5

4.0

3.5

3.0

2.5

2.0

Torque (Nm)

1.5

1.0

0.5

0.0

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

1

speed (rpm)

2

Current (Arms)

3

41.7

37.5

33.3

29.2

25.0

20.8

16.7

12.5

8.3

4.2

0.0

G4x2-8xx (G2L40)

0 2 4 6 8 10 12 14 16

8

7

6

Torque (lb-in)

5

4

3

Torque (Nm)

2

1

1

0

0 1000 2000 3000 4000 5000 6000 7000 8000

Current (Arms)

3

2

speed (rpm)

20.0

18.3

16.7

15.0

13.3

11.7

10.0

8.3

6.7

5.0

3.3

1.7

0.0

66.7

58.3

50.0

41.7

33.3

25.0

16.7

8.3

0.0

Torque (lb-in)

Torque (lb-in)

Figure 17: Torque-Speed Char. G2L20 Figure 18: Torque-Speed Char. G2L40

Rev. c 05/01 PAGE 39 of 104

Page 40

L180 User's Manual 3 SERVOMOTORS

Drive System L180 - Servomotor G4x3

G4x3-2xx (G3L05)

01234567891011

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

Torque (Nm)

0.8

0.6

0.4

0.2

0.0

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000 11000

1

Current (Arms)

3

2

speed (rpm)

20.0

18.3

16.7

15.0

13.3

11.7

10.0

8.3

6.7

5.0

3.3

1.7

0.0

G4x3-4xx (G3L15)

0 3 6 9 12 15 18 21 24

8

7

6

Torque (lb-in)

5

4

3

Torque (Nm)

2

1

0

0 10002000300040005000600070008000

1

speed (rpm)

Current (Arms)

3

2

Figure 19: Torque-Speed Char. G3L05 Figure 20: Torque-Speed Char. G3L15

G4x3-6xx (G3L25)

0 5 10 15 20 25 30

13

12

11

10

9

8

7

6

5

Torque (Nm)

4

3

2

1

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

1

Current (Arms)

3

2

speed (rpm)

115.0

106.2

97.3

88.5

79.6

70.8

61.9

53.1

44.2

35.4

26.5

17.7

8.8

0.0

Torque (lb-in)

G4x3-8xx (G3L40)

0 5 10 15 20 25 30 35 40 45 50

20

18

16

14

12

10

8

Torque (Nm)

6

4

2

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

1

Current (A rms)

2

speed (rpm)

66.7

58.3

50.0

41.7

33.3

25.0

16.7

8.3

0.0

167

150

133

117

100

83

67

50

33

17

0

Torque (lb-in)

Torque (lb-in)

Figure 21: Torque-Speed Char. G3L25 Figure 22: Torque-Speed Char. G3L40

PAGE 40 of 104 Rev. c 05/01

Page 41

3 SERVOMOTORS L180 User's Manual

Drive System L180 - Servomotor G4x4

G4x4-2xx (G4L05)

0 2 4 6 8 1012141618202224

5.0

4.5

4.0

3.5

3.0

2.5

2.0

Torque (Nm)

1.5

1.0

0.5

0.0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

1

Current (Arms)

3

2

speed (rpm)

G4x4-4xx (G4L10)

0 5 10 15 20 25 30

42

38

33

29

Torque (lb-in)

25

21

17

13

8

4

0

10

9

8

7

6

5

4

Torque (Nm)

3

2

1

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

1

speed (rpm)

Current (Arms)

3

2

Figure 23: Torque-Speed Char. G4L05 Figure 24: Torque-Speed Char. G4L10

G4x4-6xx (G4L20)

0 5 10 15 20 25 30 35 40 45 50 55 60

20

18

16

14

12

10

8

Torque (Nm)

6

4

2

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

1

speed (rpm)

Current (Arms)

3

2

G4x4-8xx (G4L40)

167

150

133

117

Torque (lb-in)

100

83

67

50

33

17

0

0 102030405060708090100

40

35

30

25

20

15

Torque (Nm)

10

5

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

1

Current (Arms)

3

2

speed (rpm)

83

75

67

58

Torque (lb-in)

50

42

33

25

17

8

0

333

292

250

208

Torque (lb-in)

167

125

83

42

0

Figure 25: Torque-Speed Char. G4L20 Figure 26: Torque-Speed Char. G4L40

G4x4-9xx (G4L60)

0 1020304050607080

60

55

50

45

40

35

30

25

Torque (Nm)

20

15

10

5

0

0 500 1000 1500 2000 2500 3000 3500 4000

1

speed (rpm)

Current (Arms)

2

3

531

487

442

398

354

Torque (lb-in)

310

265

221

177

133

88

44

0

Figure 27: Torque-Speed Char. G4L60

Rev. c 05/01 PAGE 41 of 104

Page 42

L180 User's Manual 3 SERVOMOTORS

Drive System L180 - Servomotor G4x5

G4x5-2xx (G5L10)

0 10203040506070

20

18

16

14

12

10

8

Torque (Nm)

6

4

2

0

0 1000 2000 3000 4000 5000 6000 7000

1

Current (Arms)

3

2

speed (rpm)

G4x5-4xx (G5L20)

0 102030405060708090

177

159

142

124

Torque (lb-in)

106

88

71

53

35

18

0

35

30

25

20

15

Torque (Nm)

10

5

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500

1

speed (rpm)

Current (Arms)

3

2

Figure 28: Torque-Speed Char. G5L10 Figure 29: Torque-Speed Char. G5L20

G4x5 -6xx (G5L30)

0 1020304050607080

60

55

50

45

40

35

30

25

Torque (Nm)

20

15

10

5

0

0 500 1000 1500 2000 2500 3000 3500 4000

2

1

Current (Arms)

3

speed (rpm)

531

487

442

398

354

310

265

221

177

133

88

44

0

G4x5-8xx (G5L50)

0 102030405060708090100110120

100

90

80

70

Torque (lb-in)

60

50

40

Torqu e (N m)

30

20

10

0

0 200 400 600 800 1000 1200 1400 16001800 2000 2200 2400

2

1

speed (rpm)

Current (Arms)

3

310

265

221

177

133

88

44

0

885

796

708

619

531

442

354

265

177

88

0

Torque (lb-in)

Torqu e (lb -in )

Figure 30: Torque-Speed Char. G5L30 Figure 31: Torque-Speed Char. G5L50

PAGE 42 of 104 Rev. c 05/01

Page 43

3 SERVOMOTORS L180 User's Manual

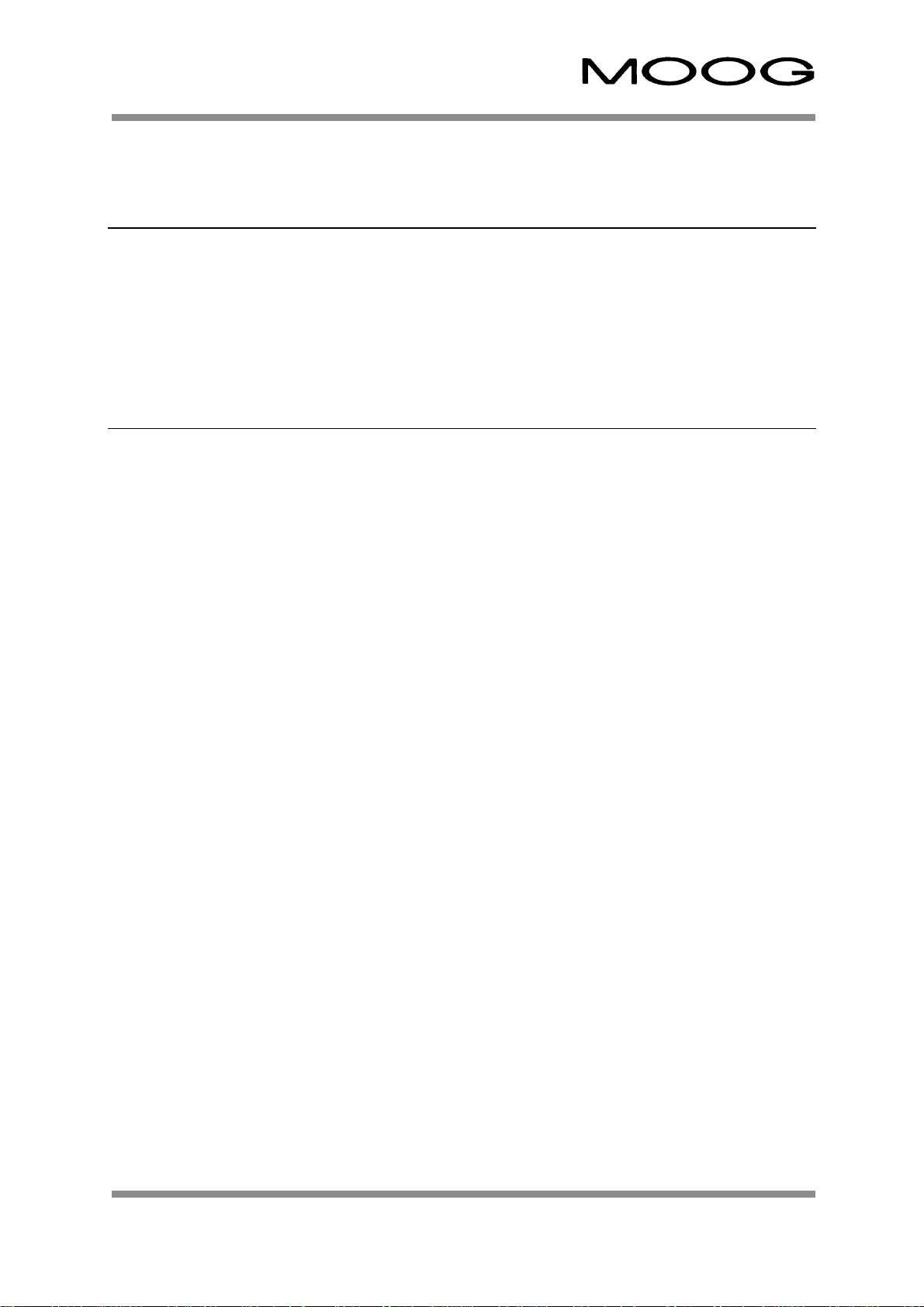

3.2.4 TORQUE-SPEED-CHARACTERISTICS G300 SERIES MOTORS

Legend:

torque limit for continuous ope rati on (windi ng 100 K abov e a mbie nt, wi th motor mounte d to 300mm x 300m m x 12mm

peak torque at approx. two times continuous stall current with L180 controller

kt-line give s torque at current level (top axis)

Drive System L180 - Servomotor G332

steel plate)

G332-4xx (L2L10)

012345

2.0

1.8

1.6

1.4

1.2

1.0

0.8

Torque (Nm)

0.6

0.4

0.2

0.0

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

1

Current (Arms)

3

2

speed (rpm)

2.0

1.8

1.6

1.4

Torque (lb-in)

1.2

1.0

0.8

0.6

0.4

0.2

0.0

G332-6xx (L2L20)

012345678910

3,0

2,5

2,0

1,5

Torque (Nm)

1,0

0,5

0,0

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

1

Current (Arms)

3

2

speed (rpm)

Figure 32: Torque-Speed Char. L2L10 Figure 33: Torque-Speed Char. L2L20

Drive System L180 - Servomotor G333

G333-4xx (L3L15)

03691215182124

5,0

4,5

4,0

3,5

3,0

2,5

2,0

Torque (Nm)

1,5

1,0

0,5

0,0

0 1000 2000 3000 4000 5000 6000 7000 8000

3

1

Current (Arms)

2

speed (rpm)

44,2

39,8

35,4

31,0

26,5

22,1

17,7

13,3

8,8

4,4

0,0

Torque (lb-in)

G333-6xx (L3L25)

0123456789101112

9

8

7

6

5

4

Torque (Nm)

3

2

1

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

1

Current (Arms)

2

speed (rpm)

26,5

22,1

17,7

Torque (lb-in)

13,3

8,8

4,4

0,0

79.6

3

70.8

61.9

53.1

Torque (lb-in)

44.2

35.4

26.5

17.7

8.8

0.0

Figure 34: Torque-Speed Char. L3L15 Figure 35: Torque-Speed Char. L3L25

Rev. c 05/01 PAGE 43 of 104

Page 44

L180 User's Manual 3 SERVOMOTORS

Drive System L180 - Servomotor G334

G334-4xx (L4L10)

0 5 10 15 20 25 30

7

6

5

4

3

Torque (Nm)

2

1

0

0 1000 2000 3000 4000 5000 6000

3

1

Current (Arms)

2

speed (rpm)

62

53

44

Torque (lb-in)

35

27

18

9

0

G334-6xx (L4L20)

0 5 10 15 20 25 30

14

13

12

11

10

9

8

7

6

5

Torque (Nm)

4

3

2

1

0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

1

Current (Arms)

3

2

speed (rpm)

Figure 36: Torque-Speed Char. L4L10 Figure 37: Torque-Speed Char. L4L20

124

115

106

97

88

80

Torque (lb-in)

71

62

53

44

35

27

18

9

0

PAGE 44 of 104 Rev. c 05/01

Page 45

3 SERVOMOTORS L180 User's Manual

3.2.5 MOTOR BRAKE DATA

The following is the specification data for the G4xx motor brakes. Options are specified in the

motor box-car drawing. A regulated DC power supply is recommended.

Table 17: G4xx Motor Brake Data

G4x2

Parameter

Series

Brake

Rated Braking

Holding Torque

Inertia

Rated Voltage [V] 24 +/-15% 24 +/-15% 2 4 +/- 15% 24 +/-15% 24 +/-15% 24 +/-15% 24 +/-15%

Power Consumption

at 20 °C (68 F)

Time to Disengage,

t1

Time to Engage, t 2 [ms] 15 15 15 25 35 35 40

Current at 24 VDC

to release

[Nm] 0.9 1.5 3.0 6.0 15.0 15.0 25.0

[lb-in] 7.97 13.28 26.55 53.10 132.75 132.75 221.25

[kg cm2] 0.02 0.07 0.18 0.54 1.00 1.00 3.6

[lb-in-sec²] 0.00002 0.00006 0.00016 0.00048 0.00089 0.00089 0.00319

[W]11111013191924

[ms] 20 20 20 30 50 50 80

[A] 0.46 0.46 0.42 0.54 0.79 0.79 1.0

G4x3 Series

Brakes

Option 1 Option 2 Option 1 Opti on 2 Opt i on 1 Opt ion 2

G4x4 Series

Brakes

G4x5 Series

Brakes

Figure 38:Current/time and torque/time diagrams

Rev. c 05/01 PAGE 45 of 104

Page 46

L180 User's Manual 3 SERVOMOTORS

PAGE 46 of 104 Rev. c 05/01

Page 47

4 INSTALLATION L180 User's Manual

4 INSTALLATION

This chapter on installation refers to L180 servo drives series. The w iring of the L180 servo dr ive

must be carried out according to the schematics in these instructions. Local wiring regulation

must be observed. Special attention should be paid with respect to wiring rules regarding

ground, earth and neutral. The earth wire to t he drive, motor and housing must be as short as

possible and connected to a common earth point.

4.1 WIRING

The following is a general reminder of the cable requirements for the L180 servo drive series

and related equipment.

Cabling and component wiring is critical in obtaining successful operation of the system. Pay

close attention to specified wiring practice, cabling information, earth and shielding

requirements. Improper wiring can result in electrical noise generation and unstable motor

performance.

Size wire in accordance with standard wiring practice and local codes for amperage and wire

length.

Particular care should be taken when layout of a cabinet is designed. Efforts to separate routing

of signal and power wires should be taken. The following guidelines should be taken into

account:

• Separate signal and power cable for low noise emission

• Minimize of radiated interference by using of shielded signal cables

• Signal cable should cross power cable at an angle of 90°. This reduces field coupling which

causes noise.

All electrical supply wires and cables to this equipment must be installed in conduits (cable

routings) which are smooth and free from sharp edges.

Rev. c 05/01 PAGE 47 of 104

Page 48

L180 User's Manual 4 INSTALLATION

g

y

y

4.2 CONNECTOR OVERVIEW

J1 RESOLVER

Terminal for resolver

cable

J2 SERIAL PORT

RS 232 Interface

J5 LOGIC POWER

24 VDC Power Supply

Input,

±

15 VDC Output

TB1 power connector

Terminal for main lines

and motor cable

J3 AXIS SIGNALS

Analog Input

ital Input/Output

Di

Status Rela

J4 ESM OUT

Differential encoder

output signals from

RS422 line driver, A, ,

seven segment displa

for status information

Contact

B, , Z,

BZ

STATUS

A

REGEN ACTIVE

PROTECTIVE EARTH

Screw terminal for PE

and grounding

(screw not visible)

Figure 39: Wiring Overview

red LED , lights up if

motor rege ne rates

energy to drive

WARNING

The PE terminal of the drive must be permanently connected to the earth

potential. The cross-section of the protective conductor must be at least

4mm² (AWG 10) copper (Cu).

PAGE 48 of 104 Rev. c 05/01

Page 49

4 INSTALLATION L180 User's Manual

4.2.1 MOTOR AND POWER CONNECTOR TB1

The servo drive unit can be operated with either a single-phase or three-phase AC voltage.

Table 18: Main line voltage

Unit Minimum Regular Maximum

Mains frequency

Supply Voltage

Hz 45 50/60 65

VAC 184 230 253

WARNING

A three phase automatic circuit breaker must be used for three phase

operation in order to ensure that all phases are tripped at the same time in

the event of a fault! The wire protection must be taken into account. This

depends on the cross-section of the main line wires. Please refer to your

local regulations for detailed information.

Single phase operation

TB1:L1

TB1:L2

In single phase operation, the voltage between live and neutral is 230 VAC.

The phase line should be connected to TB1:L1 and the neutral line to

TB1:L2. The protective earth conductor must also be connected to the earth

stud on the drive.

Three phase operation

TB1:L1

TB1:L2

TB1:L3

The nominal voltage between the servo drive unit terminals must be equal

to 230 VAC. The phase-to-phase voltage of a normal 3-phase 400 VAC

(440 VAC) mains supply must be stepped down to 230 VAC by means of an

auto or isolation transformer connected to terminal TB1. The protective

earth conductor must be connected to the earth stud on the drive.

Transformer

The selection of the transformer size depends on the ambient conditions,

duty cycle and power requirements of the application. Two or more drives

can be connected to one transformer. The transformer must deliver the

maximum current. In any case of uncertainty do not hesitate to contact your

local application engineer.

Additional Parts for the drive system

Additional fuses for transformer and wiring protection have to be installed

according to the local regulations. The transformer protection should be

clarified with the transformer supplier. Contactors are to be used where

necessary. Examples of contactor use include: emergency stop and on/off

circuits. A main power switch may also be necessary because of local

regulations.

Rev. c 05/01 PAGE 49 of 104

Page 50

L180 User's Manual 4 INSTALLATION

L1

L2

L3

S

W

V

U

SEPARATE

CONTACTOR

/

RELAY

24VDC

POWER

SUPPLY

+

E’

L1’

LINE FILTER

SCHAFFNER

L2’

L3’

SHIELD

WWW

VV

U

-

FN 258

black

black

black

white

black

yello w / green

E

L1

L2

L3

3~ 230 VAC

50/60 Hz

3~ 400 VAC/3~440 VAC

W

1

V

4

U

2

+

5

-

6

G4x5

G4x2

G4x3

G4x4

PROTECTIVE EARTH

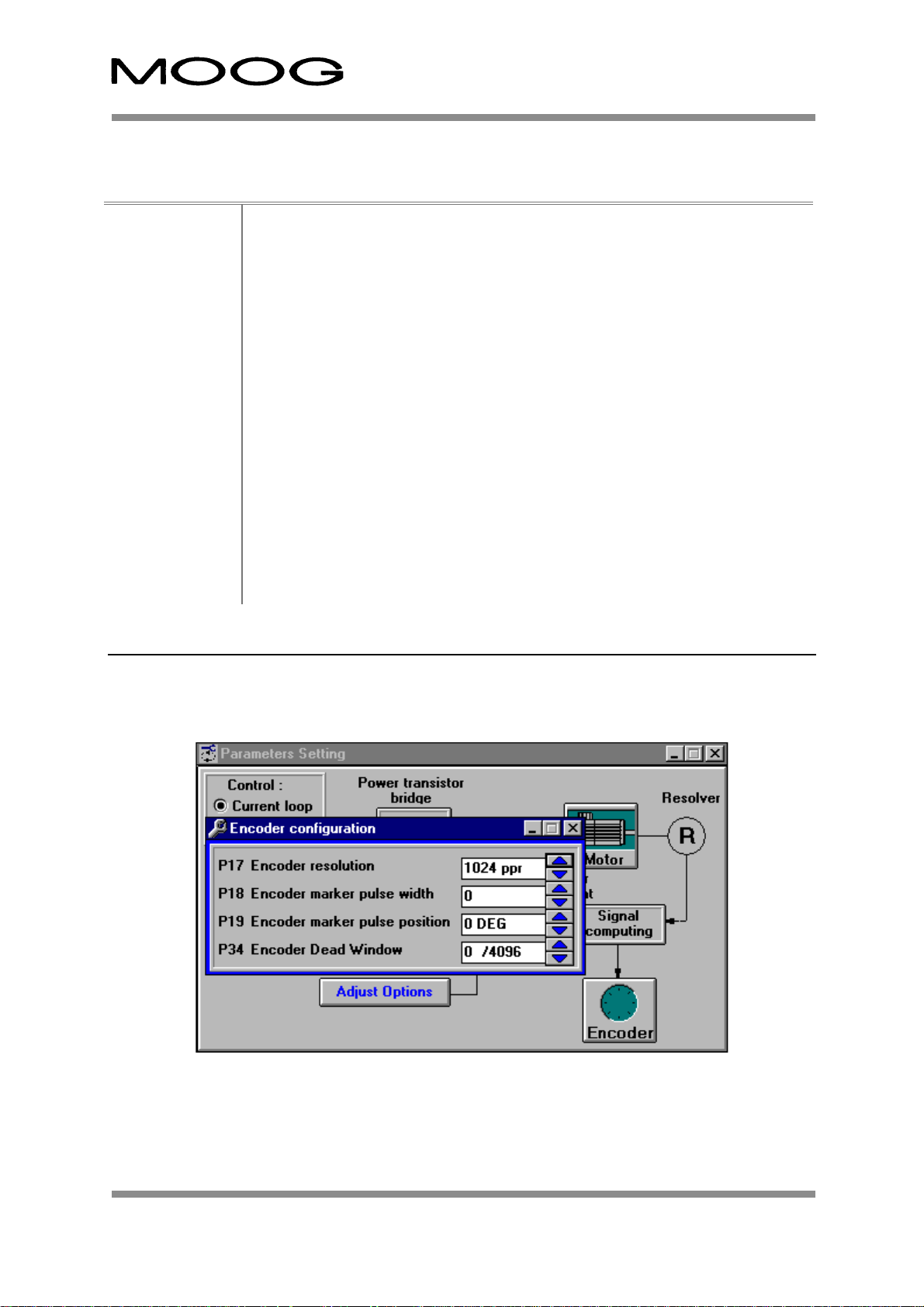

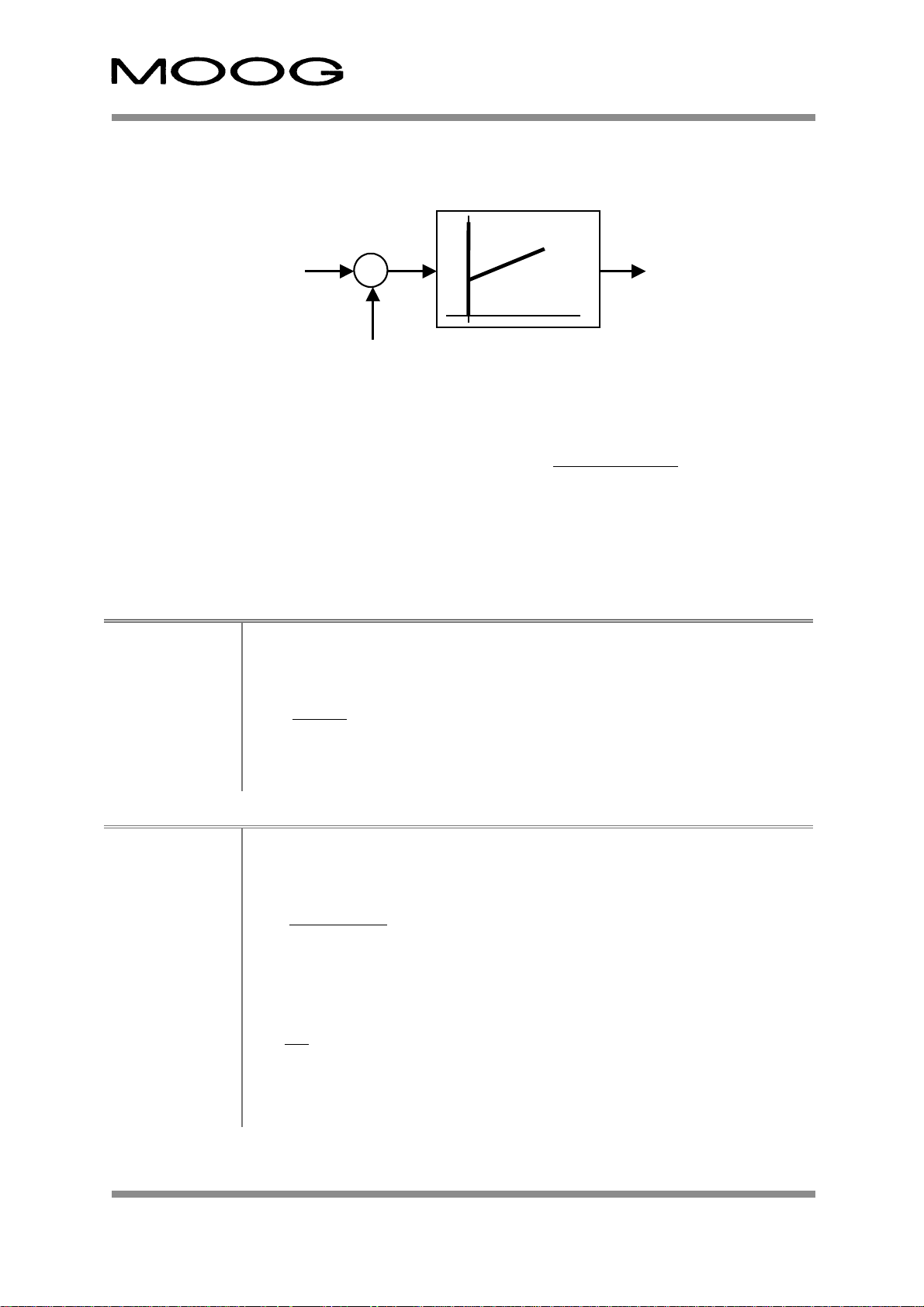

Customer Supplied