Page 1

DS2110

DIGITAL CONTROLLER

INSTALLATION & USER’S MANUAL

Document No.: CDS7324 (formerly LSF-0819)

Revision: A

Date: May 2011

INDUSTRIAL CONTROLS DIVISION

Page 2

TABLE OF CONTENTS T/C -1

CHAPTER 1.0 OVERVIEW............................................................................................................. 1-1

1.1 Introduction...................................................................................................................... 1-1

1.2 DS2110 Models................................................................................................................. 1-2

1.3 Environmental Specifications......................................................................................... 1-4

1.4 Design Standards............................................................................................................. 1-5

1.5 Power Ratings Specifications.......................................................................................... 1-6

1.6 General functional specifications................................................................................... 1-9

CHAPTER 2.0 SAFETY & EMC INSTRUCTIONS.......................................................................... 2-1

2.1 General.............................................................................................................................. 2-1

2.2 Safety Regulations............................................................................................................ 2-2

2.3 Electromagnetic Compatibility........................................................................................ 2-12

2.4 UL Requirements ............................................................................................................. 2-22

CHAPTER 3.0 WIRING AND INSTALLATION............................................................................... 3-1

3.1 System Components........................................................................................................ 3-1

3.2 Equipment Mounting........................................................................................................ 3-5

3.3 Pow er Di ssipation ............................................................................................................ 3-15

3.4 DS2110 Connector Terminals ......................................................................................... 3-16

3.5 General System Wiring Guidelines................................................................................. 3-20

3.6 Sequence of Component Wiring Recommendations.................................................... 3-22

3.7 Three Phase AC Mains Power Source Configuration ................................................... 3-23

3.8 24V Backup Connection .................................................................................................. 3-29

3.9 Internal/External Regeneration (Regen) Resistors – Configurations .......................... 3-32

3.10 Motors – Installation ...................................................................................................... 3-36

3.11 DS2110 Control Inputs and Outputs............................................................................. 3-49

3.12 Communication Interface Wiring and Configuration .................................................. 3-54

3.13 Wiring Summary............................................................................................................. 3-55

CHAPTER 4.0 GETTING STARTED.............................................................................................. 4-1

4.1 Introduction...................................................................................................................... 4-1

4.2 Initial Preparation............................................................................................................. 4-1

4.3 Power Supply ................................................................................................................... 4-1

4.4 Installing Windrive ........................................................................................................... 4-2

4.5 Controller Access ............................................................................................................ 4-3

4.6 Motor Selection ................................................................................................................ 4-4

4.7 Regen Resistor Configuration ........................................................................................ 4-6

4.8 Acceleration Limits.......................................................................................................... 4-8

4.9 Parameter Utilities............................................................................................................ 4-9

4.10 Status and Faults ........................................................................................................... 4-10

4.11 High Power Application................................................................................................. 4-11

4.12 Autophasing.................................................................................................................... 4-12

4.13 Torque Mode Enable...................................................................................................... 4-13

4.14 Velocity Mode Enable .................................................................................................... 4-14

4.15 Oscilloscope................................................................................................................... 4-15

4.16 Pow er Down Sequence.................................................................................................. 4-20

TABLE OF CONTENTS

CDS7324

REV. A INSTALLATION & USER’S MANUAL

Page 3

TABLE OF CONTENTS T/C -2

TABLE OF CONTENTS

CHAPTER 5.0 FUNCTIONAL OVERVIEW..................................................................................... 5-1

5.1 Introduction ...................................................................................................................... 5-1

5.2 DS2110 Conventions........................................................................................................ 5-1

5.3 Power Interface Section................................................................................................... 5-2

5.4 Motor Configuration......................................................................................................... 5-8

5.5 Resolver Input .................................................................................................................. 5-13

5.6 Encoder Input................................................................................................................... 5-16

5.7 Commutation Module....................................................................................................... 5-21

5.8 Position Feedback............................................................................................................ 5-24

5.9 Velocity Feedback............................................................................................................ 5-25

5.10 Input and Output Functional Description..................................................................... 5-26

5.11 Control Loops ................................................................................................................. 5-34

5.12 Dri ve Monitoring & Fault Detection .............................................................................. 5-52

5.13 Self Protection................................................................................................................ 5-66

5.14 Parameter Storage ......................................................................................................... 5-67

APPENDIX A – DATA LOGGER.................................................................................................... A-1

APPENDIX B – GUI........................................................................................................................ B-1

B.1 Introduction...................................................................................................................... B-1

B.2 Getting Started/Common Features ................................................................................ B-2

APPENDIX C – RESTART INTERLOCK CIRCUITS...................................................................... C-1

C.1 Intended Application....................................................................................................... C-1

C.2 Restart Interlock Function .............................................................................................. C-2

C.3 Safety Requirements....................................................................................................... C-4

C.4 Restart Interlock Circuit.................................................................................................. C-5

C.5 Restart Interlock Connections........................................................................................ C-7

C.6 Safety Relays – Technical Data...................................................................................... C-9

C.7 Application Example....................................................................................................... C-10

C.8 Checking the Restart Interlock....................................................................................... C-13

C.9 External Consistency Checks ........................................................................................ C-14

C.10 Installation and Routine Test........................................................................................ C-15

APPENDIX D – MEZZANINE CARD INSTALLATION................................................................... D-1

APPENDIX E – ANALOG I/O MEZZANINE CARD........................................................................ E-1

E.1 Introduction...................................................................................................................... E-1

E.2 Overview........................................................................................................................... E-1

E.3 Configurations ................................................................................................................. E-1

E.4 Analog I/O......................................................................................................................... E-2

E.5 SSI Interface..................................................................................................................... E-4

E.6 Simulated Encoder/Resolver .......................................................................................... E-5

E.7 PLC Master – DS2110 Slave Arrangement..................................................................... E-7

E.8 Noise Reduction .............................................................................................................. E-7

CDS7324

REV. A INSTALLATION & USER’S MANUAL

Page 4

TABLE OF CONTENTS T/C -3

TABLE OF CONTENTS

APPENDIX F – DEVICENET™ MEZZANINE CARD...................................................................... F-1

F.1 Connector......................................................................................................................... F-1

F.2 Network Status................................................................................................................. F-1

F.3 Available Objects............................................................................................................. F-1

F.4 MacID and Baud Rate ...................................................................................................... F-2

F.5 Initial Motion Setup.......................................................................................................... F-2

F.6 Fieldbus Scaling Factors................................................................................................. F-2

F.7 Units.................................................................................................................................. F-3

F.8 PARAM UPDATE in.......................................................................................................... F-3

F.9 Implicit I/O......................................................................................................................... F-3

F.10 Parameter List ................................................................................................................ F-4

APPENDIX G – ETHERNET MEZZANINE CARD.......................................................................... G-1

G.1 Introduction ..................................................................................................................... G-1

G.2 Modes of Operation......................................................................................................... G-1

G.3 Changing IP Address for Ethernet Device .................................................................... G-2

G.4 Changing Commands and Status Registers................................................................. G-4

G.5 Allen-Bradley RSLogix Configuration with DS2110 ..................................................... G-6

CDS7324

REV. A INSTALLATION & USER’S MANUAL

Page 5

CHAPTER 1.0 Overview 1-1

1.1 Introduction

This section gives an overview of the available DS2110 models, ratings and general specifications.

Detailed outlines of installation and wiring, functionality, user interfaces and other technical data are

given in subsequent sections.

CAUTION: Repairs or modifications to the product by anyone other than a Moog

authorized repair facility may create unsafe operating conditions and will invalidate

the product warranty.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 6

CHAPTER 1.0 Overview 1-2

1.2 DS2110 Models

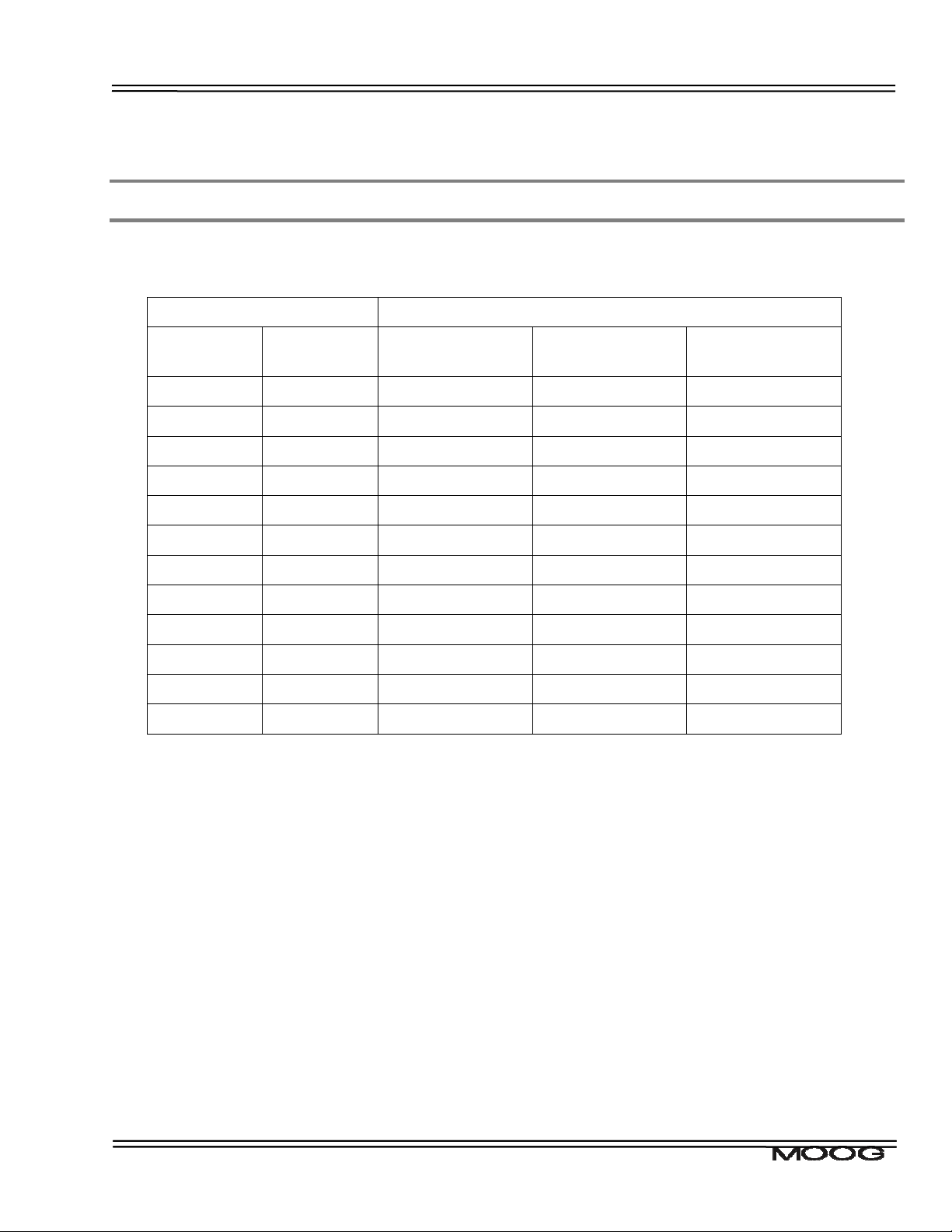

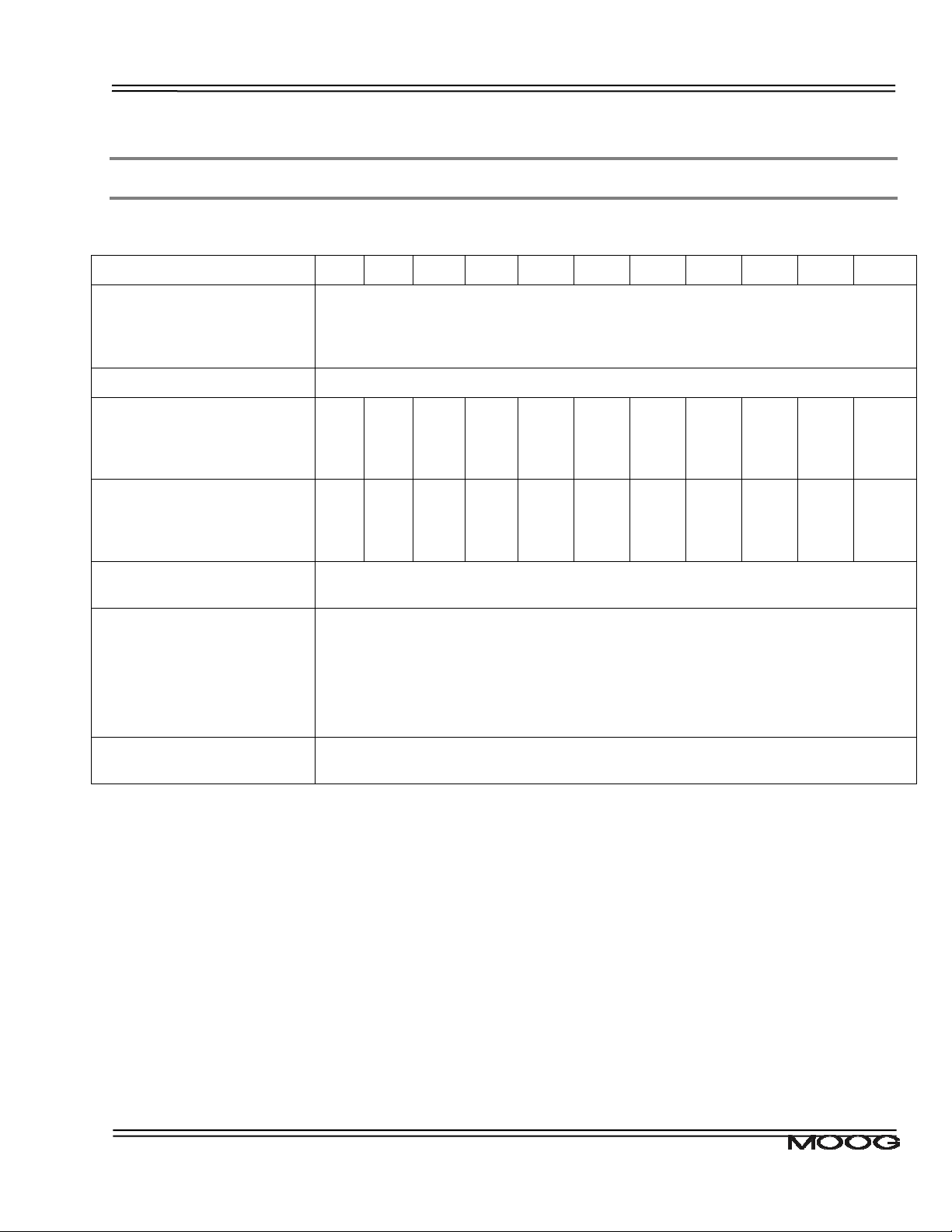

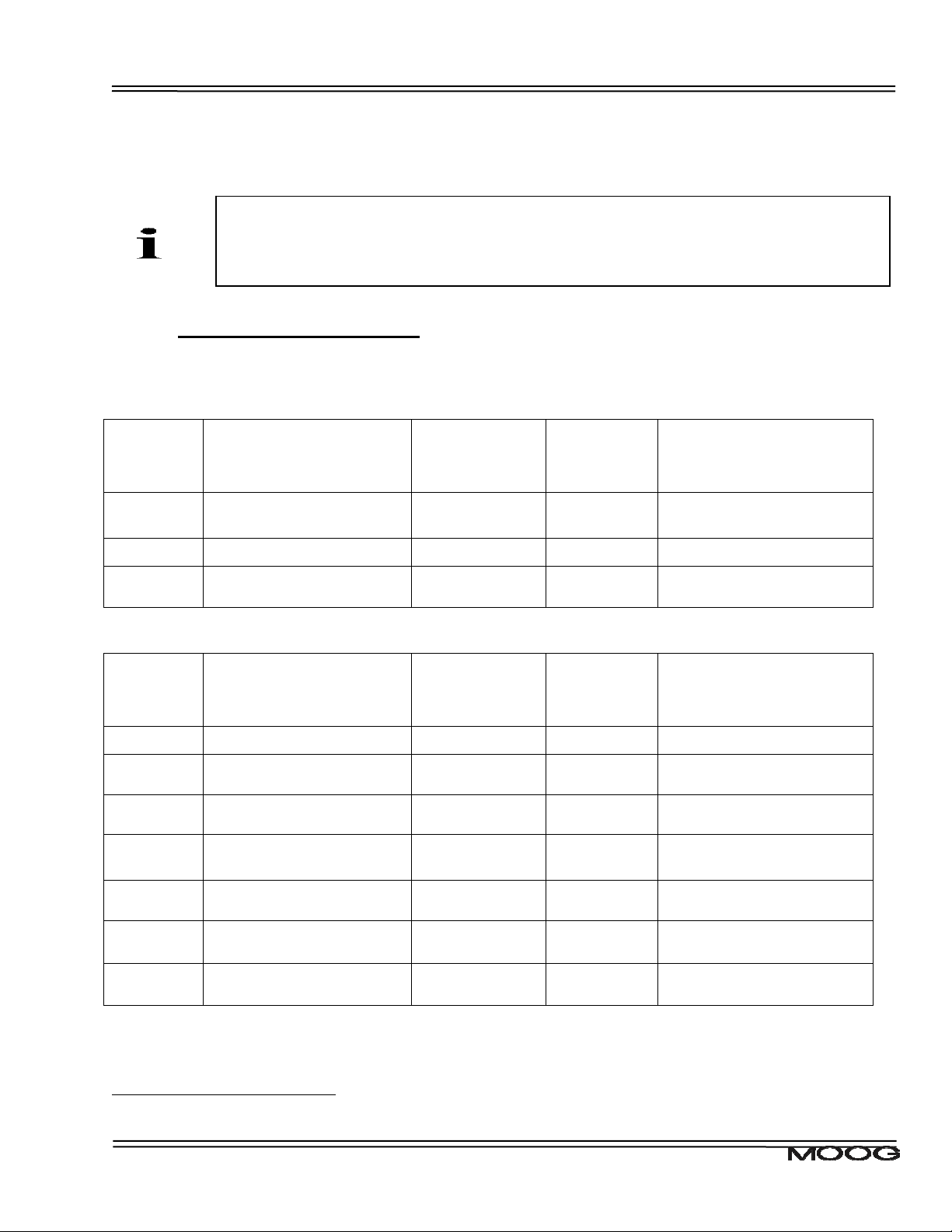

The DS2110 family is available in twelve base models, which cover a range of output current ratings.

DS2110 Base Model Amplifier Current Rating

Code Size Continuous

Maximum (Arms) Peak (A)

(Arms)

G362-x03 µA or A 3 6.4 9

G362-x04 A 4 8.5 12

G362-x06 µA or A 6 16 22

G362-x08 A 8 16 22

G362-010 B 10 29.7 42

G362-014 B 14 29.7 42

G362-020 C 20 31.8 45

G362-025 C 25 49.5 70

G362-030 C 30 63.6 90

G362-050 D 50 99.3 140

G362-060 D 60 127.6 180

G362-100 E 100 212.1 300

Table 1.1 DS2110 Family Models

The DS2110 family uses a 14 character coding system to identify the unique attributes of each model.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 7

CHAPTER 1.0 Overview 1-3

Page Intentionally Blank

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 8

CHAPTER 1.0 Overview 1-4

1.3 Environmental Specifications

DS2110 Electronics

Maximum temperature

Storage: -25 C to 55 C (Class 1K4)

Transport: -25 C to 70 C (Class 2K3)

Surrounding air 0 C to 40 C

Relative humidity: 5 % to 85 %, non-condensing, 1 g/m3 to 25 g/m3, in accordance with

EN50178 class 3k3

Elevation: 1000m (3,300 feet); derate output 2% per 300m (1000 ft) above 1000m

(3300 ft)

Air pressure: 86 kPa to 106 kPa

Type of protection: Components must be installed into an enclosure. The enclosure must

provide at least IP54 per standard EN60529 or equivalent.

Pollution degree: Drive is suitable for installation in a Pollution Degree 2 environment.

Installed position: Vertical only.

Overvoltage protection class: Category 2 per standard VDE0110 / IEC664

Noise: Overall noise depends on the user installation and cabinet.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 9

CHAPTER 1.0 Overview 1-5

1.4 Design Standards

The DS2110 is CE-Marked under the EU's Low Voltage Directive. It has been designed to allow easy

compliance of customer's machines under the EU's EMC Directive (measures as directed in this

manual have to be taken to ensure EMC compliance). It is designed to the UL508C standard. The A

size DS2110 units are UL recognized. The DS2110 A-D sizes are UL listed.

The DS2110 has been designed to the following specific standards:-

IP Code EN 60529:1991

EMC EN 61800-3:1996 , EN 61800-3/A11:2000 (Second Environment)

UL UL508C with reference to UL840

Table 1.2 DS2110 Design Standards

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 10

CHAPTER 1.0 Overview 1-6

1.5 Power Ratings Specifications

Model : G362-x

A.C. Mains Input Range

Minimum

Maximum

Frequency Range

Internal Regeneration Power

Continuous Dissipation

Peak Dissipation @ 230Vac

Peak Dissipation @ 400Vac

External Regeneration Power

Continuous Dissipation

Peak Dissipation @ 230Vac

Peak Dissipation @ 400Vac

Softstart Peak Inrush

Current/Phase

Power Supply Fault Detection

3Amp 6Amp 8Amp 10Amp 14Amp 20Amp 25Amp 30Amp 50Amp 60Amp 100Amp

65Vac (110Vac -40%)

506Vac (440Vac +10%)

50 - 60Hz

150W

50W

1.3Kw

4.8kW

50W

1.2Kw

4.8kW

100W

1.3kW

4.8kW

100W

1.2kW

4.8kW

2.6kW

10.3kW N/A N/A N/A N/A N/A N/A N/A N/A

200W

2.8kW

11.3kW

240W

6.6kW

26.3kW

250W

4.4kW

17.5kW

370W

12.0kW

48.1kW

370W

12.0kW

48.1kW

370W

12.0kW

48.1kW

750W

14.4kW

57.8kW

750W

14.4kW

57.8kW

1kW

37kW

148kW

30Apk

D.C. Bus Overvoltage

D.C. Bus Undervoltage

Bridge Temperature Fault

Amplifier Short Circuit Protection

24V Logic Backup Monitoring

Voltage Discharge after A.C

Mains Removal

Bleed Resistors across high voltage section.

Table 1.3 DS2110 Power Ratings

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 11

CHAPTER 1.0 Overview 1-7

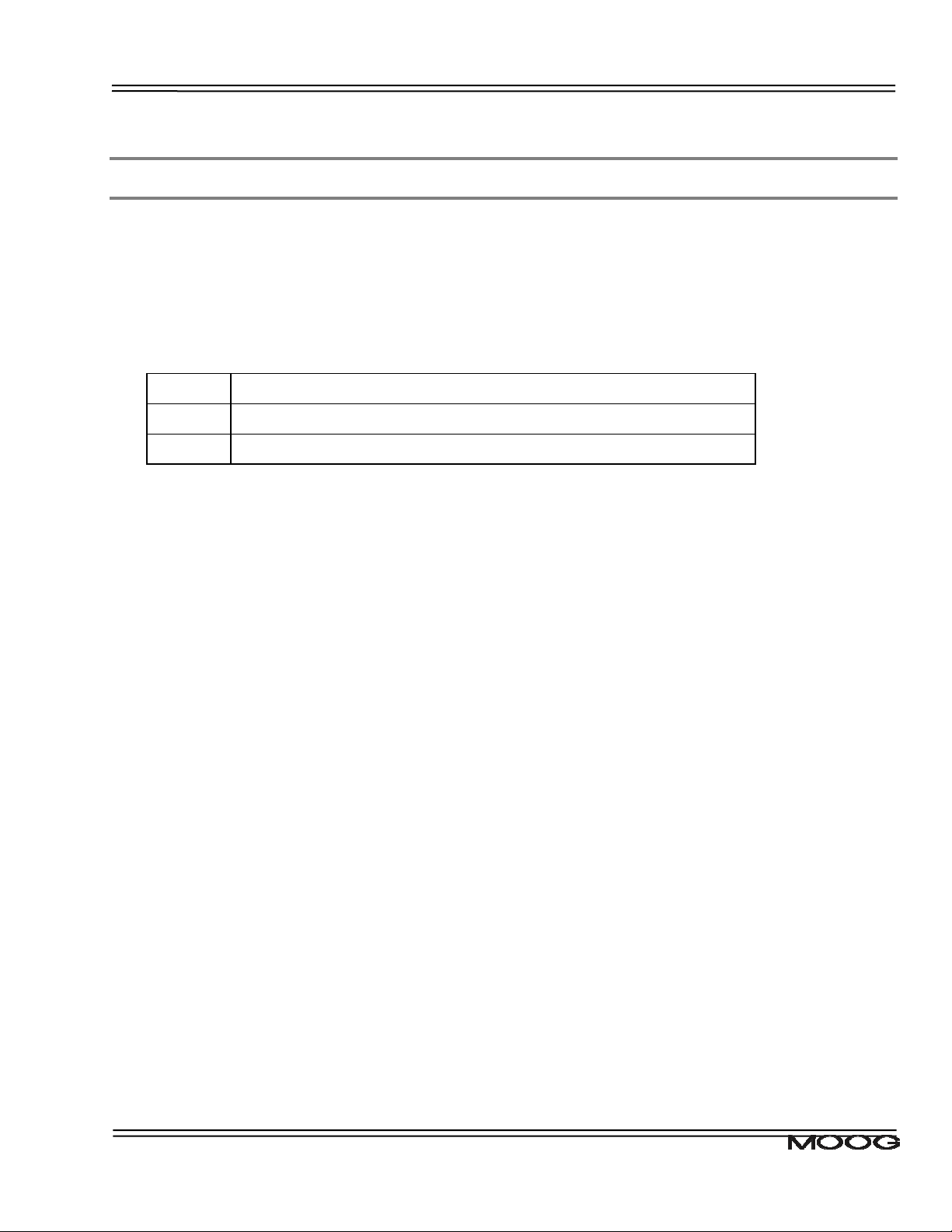

1.5.1 Optional Control Logic Backup Power

D.C. Bus Minimum Voltage

(below which 24Vd.c. Control Logic Backup supply is

needed)

24V Input

Table 1.4 DS2110 Control Logic Backup Power Ratings

An auxiliary 24V d.c. control logic backup supply is

MANDATORY for the –x003 & -x006 variants of the DS2110

product family.

The 24V Backup supply input is intended for use in the

secondary of a Class 2 supply. Alternatively, it should be

additionally fitted with a Listed Current limiting type fuse, rated

3A on the supply input to the device.

170Vd.c. (Generated from rectified 120Va.c.)

24Vd.c.± 10%

2.0A steady state

1.5.2 Power Amplifier

All current ratings are specified in ampere r.m.s. unless otherwise stated.

Power Amplifier Ratings:

G362-x03 3A continuous/9A peak

G362-x04 4A continuous/12A peak

G362-x06 6A continuous/15A peak

G362-x08 8A continuous/22A peak

G362-010 10A continuous/42A peak

G362-014 14A continuous/42A peak

G362-020 20A continuous/45A peak

G362-025 25A continuous/70A peak

G362-030 30A continuous/90A peak

G362-050 50A continuous/ 140A peak

G362-060 60A continuous/ 180A peak

G362-100 100A continuous/ 300A peak

Table 1.5 DS2110 Power Amplifier Ratings

Two levels of thermal protection which limit the peak current and the time for which it is available

protect the DS2110 drives. These are:

• RMS Protection,

• Thermal Foldback.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 12

CHAPTER 1.0 Overview 1-8

1.5.4.1 RMS Protection

The RMS protection acts to limit the current provided to the rated continuous current of the drive. Thus,

a G362-x006 cannot supply, on average, greater than 6Acontinuous RMS to the motor. The current to

the motor is averaged and if it exceeds the RMS rating, the drive limits the current command. If the

controller continuously demands current greater than the drive capability, the RMS protection will limit

the actual current supplied to the drive rating. The time for which peak current can be supplied is

dependent on whether the motor is stalled or running.

1.5.4.2 Thermal Foldback

Thermal foldback is implemented in the DS2110 drives to prevent the junction temperatures of the

amplifier bridge IGBT’s exceeding their maximum rated temperature. The thermal foldback is based on

a measure of the heatsink temperature and the mode in which the drive is operating (motor running or

stalled). As the heatsink temperature increases, the peak current capability of the drive is reduced to

ensure the IGBT die temperature cannot increase above the device maximum rating.

For the DS2110 D size, a simple thermal shutdown is implemented. These drives will report an

overtemperature fault once the measured heatsink temperature exceeds the maximum rating of the

drive.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 13

CHAPTER 1.0 Overview 1-9

1.6 General Functional Specifications

1.6.1 Digital Inputs (J2A)

• 8 Digital Inputs, user configurable

• Digital Input 1 Dedicated to High Power Enable

• All Optically Isolated, 12…36V Input Range.

• 5k input impedance.

STANDARD FUNCTION

High Power Enable Input High Power Enable Input

Auto / Manual Mode See Section 5.9

Torque / Velocity Mode Switch See Section 5.9

Brake Control See Section 5.9

CW Limit Switch See Section 5.9

CCW limit Switch See Section 5.9

Quick Stop See Section 5.9

Controlled Disable See Section 5.9

FIELDBUS OR INTERFACE SPECIFIC

Table 1.6 DS2110 Digital Inputs Overview : Standard Configuration

1.6.2 Digital Outputs (J2B)

• 3 Digital outputs, user configurable

• All outputs are Optically Isolated.

• Nominal ratings of 6V to 32V, 250mA

• Protected for supply range of –40V to 40V

• Short-circuit & reverse polarity protected

• Off-state leakage current <100μA at 0V

Standard Function

Limiting Function

Table 1.7 DS2110 Digital Outputs Overview

Drive Enabled

User defined

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 14

CHAPTER 1.0 Overview 1-10

1.6.3 Standard I/O

Drive Ready (J2C)

Brake Control (J2D)

Motor Position

Feedback Type

(J3/J4)

Communications

Interfaces (J1)

Relay output, contact ratings: 36V, 100mA max.

Closed when drive is ready and has no faults.

2A, 24Vd.c. solid-state high-side drive for motor brake control.

Switched under user control or DS2110 software control

Resolver Encoder Types

• SSI

• Hiperface

• Analogue encoders

• Endat

• NRZ serial

RS232 Interface at 19200Baud

Table 1.8 DS2110 Standard I/O Summary

1.6.4 Variant Specific I/O

Refer to the appendix for details on a specific fieldbus variant.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 15

CHAPTER 1.0 Overview 1-11

Page Intentionally Blank

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 16

p

y

CHAPTER 2.0 Safety & EMC Instructions 2-1

2.1 General

This user’s manual is intended to provide sufficient information on how to install Moog DS2110 electric

motor systems. Section 2.2 covers Safety and System Safeguards. Section 2.3 covers Electromagnetic

Compatibility (EMC). This user’s guide must be read and understood before applying power and

operating the equipment described.

This equipment must be installed and serviced only by duly qualified service personnel. All information

in this manual is directed towards such persons only. Individuals responsible for the installation of the

equipment described in this user’s guide must ensure;

1) only technically qualified individuals are employed to work on the installation,

2) these qualified individuals must have the accompanying documentation available at all times when

working on the installation and are obliged to use this documentation in a consistent manner, and

3) work on, or close to, the installation is prohibited for non-technically qualified individuals

Throughout this user’s guide may be found NOTES, CAUTIONS, and WARNINGS and CECompliance-Required. They are defined as follows:

Required for

CE-Compliance

NOTES are general in nature and are intended to

em

hasise information.

CAUTIONS are to alert personnel to actions that could

cause equipment damage, resulting in the equipment

becoming unsafe.

WARNINGS serve to make personnel aware of potentially

hazardous actions that may result in personal injury or death.

CE-Compliance indicates where a particular application-related

safety or EMC requirement is driven by the need for CECompliance of the DS2110 when installed in the system.

Customers who do not need CE-Compliance on their machinery

ma

choose not to implement these features.

The DS2110 controller contains potentially lethal voltages. Extreme caution shall be observed whenever the

equipment is in operation. Incorrect installation of the motor or the controller may cause damage to the

equipment, serious personal injury or death. Consequently, the instructions in this user’s manual, as well as

national and local rules and safety regulations must be complied with.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 17

CHAPTER 2.0 Safety & EMC Instructions 2-2

2.2 Safety Regulations

1. The DS2110 controller must be disconnected from all power if repair work is to be carried out. Check that the

mains supply has been disconnected and that at least 5 minutes has passed for the A size (6 minutes for AE sizes), to allow for D.C. bus capacitors to discharge, before removing motor and mains connections.

2. Correct protective earthing of the equipment must be established, the user must be protected against supply

voltage, and the motor must be protected against overload in accordance with applicable national and local

regulations.

3. Do not remove the connections for the motor and mains supply while the DS2110 controller is connected to

mains power. Check that the mains supply has been disconnected and that the necessary time has passed

before removing motor and mains connections.

Warning against unintended start

The installation of safety interlocks, additional control and protection devices must be done in accordance with the

relevant local safety requirements. Note that changes made through software can result in the motor starting

suddenly.

This user’s manual assumes that the user has a basic working knowledge of servo-drive products and the system

motion controller. The user should provide the necessary additional training for ALL personnel working within or

around the workcell.

NOTE - These safety precautions are guidelines only and are not claimed to be

comprehensive. The Moog Brushless Technology products described herein, in

conjunction with the system controller, provide the capability for control of remote

devices. Typically, these remote devices move at high speeds and exert considerable

force. Like all mechanical systems and most industrial equipment, they must be treated

with respect by both the machine integrator and user, and the operator.

NOTE - This user’s guide defines “user” as the responsible person or company and

“operator” as a person who starts, stops or monitors workcell operation.

NOTE - This user’s guide should be read by all personnel who operate or who work

within or near the workcell.

Individuals responsible for the installation of the equipment described in this user’s guide

must ensure that only technically qualified service personnel are employed to work on

the installation.

In the context of these safety instructions, skilled technical personnel means people who

are familiar with the product, and have the necessary technical qualifications required for

the performance of their functions.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 18

CHAPTER 2.0 Safety & EMC Instructions 2-3

2.2.1 System Safeguards

a) General Safety Requirements

Users are required to implement safety measures with all equipment, systems and installations into which the

DS2110 Servo-drive are installed. In addition, safeguards must be an integral part of workcell design, installation,

operator training and operator procedures where this equipment is used.

Users are directed to refer to the European Union (EU) Machine Safety

Directive: 98/37/EC and EU Low Voltage Directive 73/23/EEC (as amended by

EU Directive 93/68/EEC) for essential health and safety requirements to be

Required for

CE-Compliance

met. Furthermore the requirements of the EU EMC Directive: 89/336/EEC (as

amended by EU Directive 92/31/EEC and 93/68/EEC) must be met by all

equipment, systems and installations into which the DS2110 Controllers are

installed.

Users are recommended to refer to the latest publications of the European

Union (EU) Commission and to local regulations for further information on the

requirements of these Directives of the EU.

Users are required to ensure that the drive is only connected to supply network

configurations of the following types

• TN Systems including TN-C, TN-S, TN-C-S

• TT Systems.

Required for

CE-Compliance

Connection to IT systems or corner-earthed TN systems is not allowed. Users

should ensure the nature of the supply system is appropriate before connecting

and operating the drive.

b) Specific Safety Requirements

The specific safety measures described below are required to be installed by the user into all equipment, systems

and installations into which the DS2110 Series Controllers are installed.

The user is required to provide safety interlocks to prevent unexpected restart during servicing of the DS2110

Controller and any equipment attached to or driven by these units.

The DS2110 Servo-drives themselves must be installed in enclosures or cabinets that provide a degree of ingress

protection against liquids and objects of at least IP54. These enclosures or cabinets must be accessible to

technically qualified service or maintenance persons only. All external Regen (Regenerative circuit) resistors used

with the DS2110 must be installed in enclosures which provide a degree of ingress protection against liquids and

objects of at least IP22 and which are accessible to technically qualified service or maintenance persons only.

Protection against electric shock must be maintained when installing these resistors.

The equipment may have a continuous leakage current of more than 3.5 mA A.C. or 10 mA D.C. in normal use.

The DS2110 must be permanently and reliably connected to Earth and all conductive parts in the IP54 rated

enclosure or cabinet must be permanently connected to Earth. The impedance between the earth terminal and

any accessible part of the enclosure or cabinet should be less than or equal to 0.1ohm.

A D.C component can occur in the fault current in the event of a fault connection to earth. Only a residual-currentoperated protective device (RCD) of Type B is allowed. When the protection in installations with regard to indirect

contact is achieved by means of an RCD, their appropriate function/combination shall be verified.

All electrical supply wires and cables to this equipment must be installed in wireways (cable routings) which are

smooth and free from sharp edges.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 19

CHAPTER 2.0 Safety & EMC Instructions 2-4

Required for

CE-Compl iance

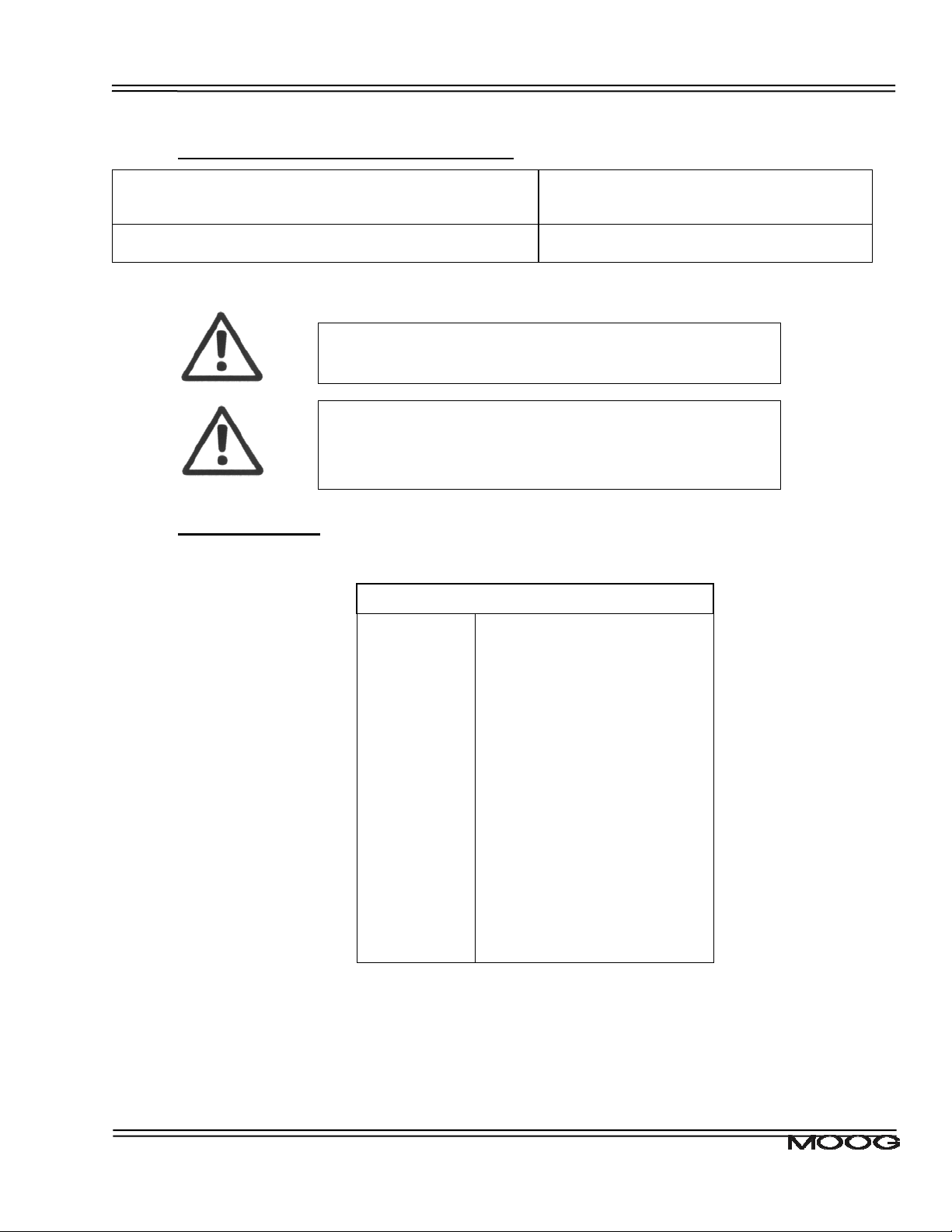

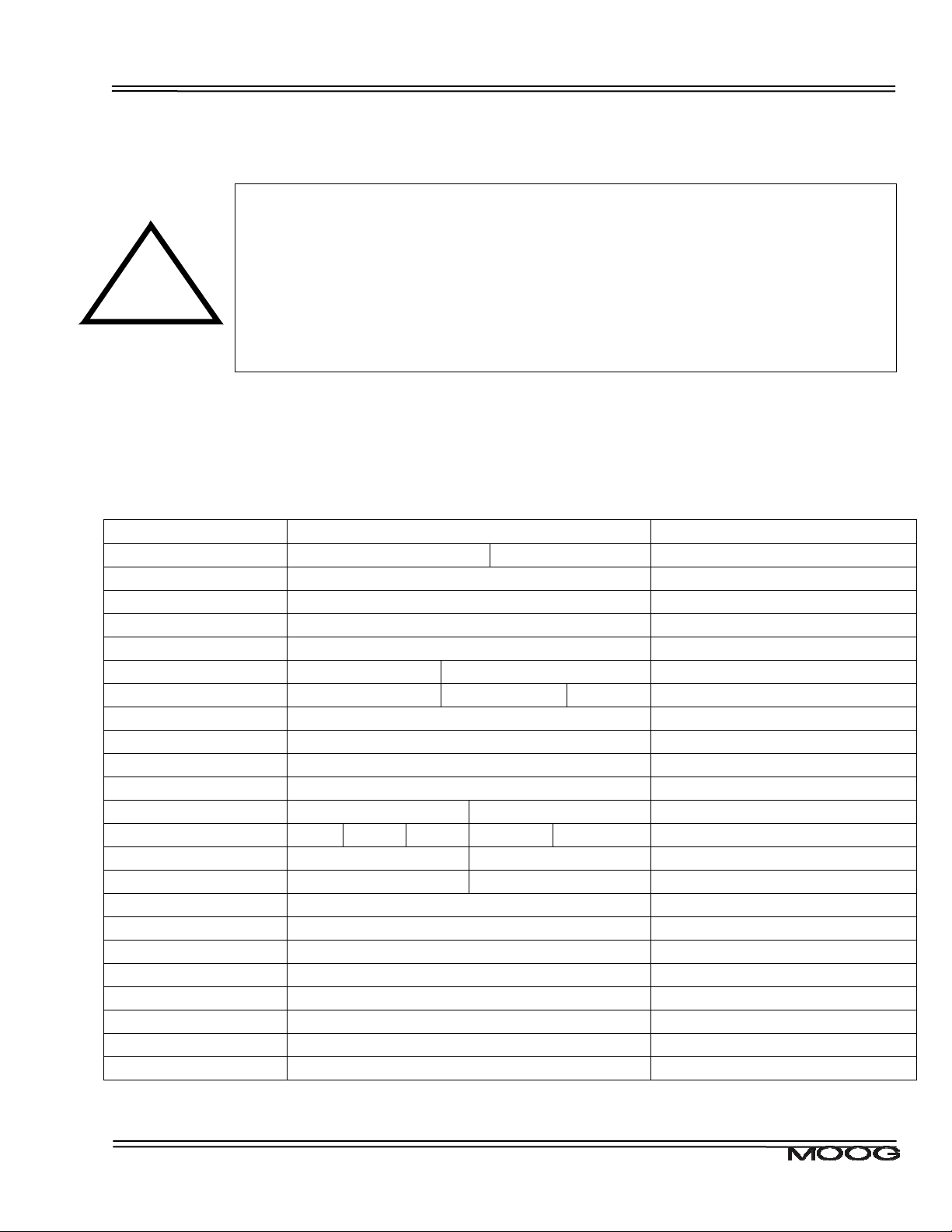

As no fuses are provided inside the drive, the DS2110 must be provided with suitable fusing to protect the drive.

The fuses required for each DS2110 model are detailed in the following table It is recommended to use UL

certified fuses and fuse blocks

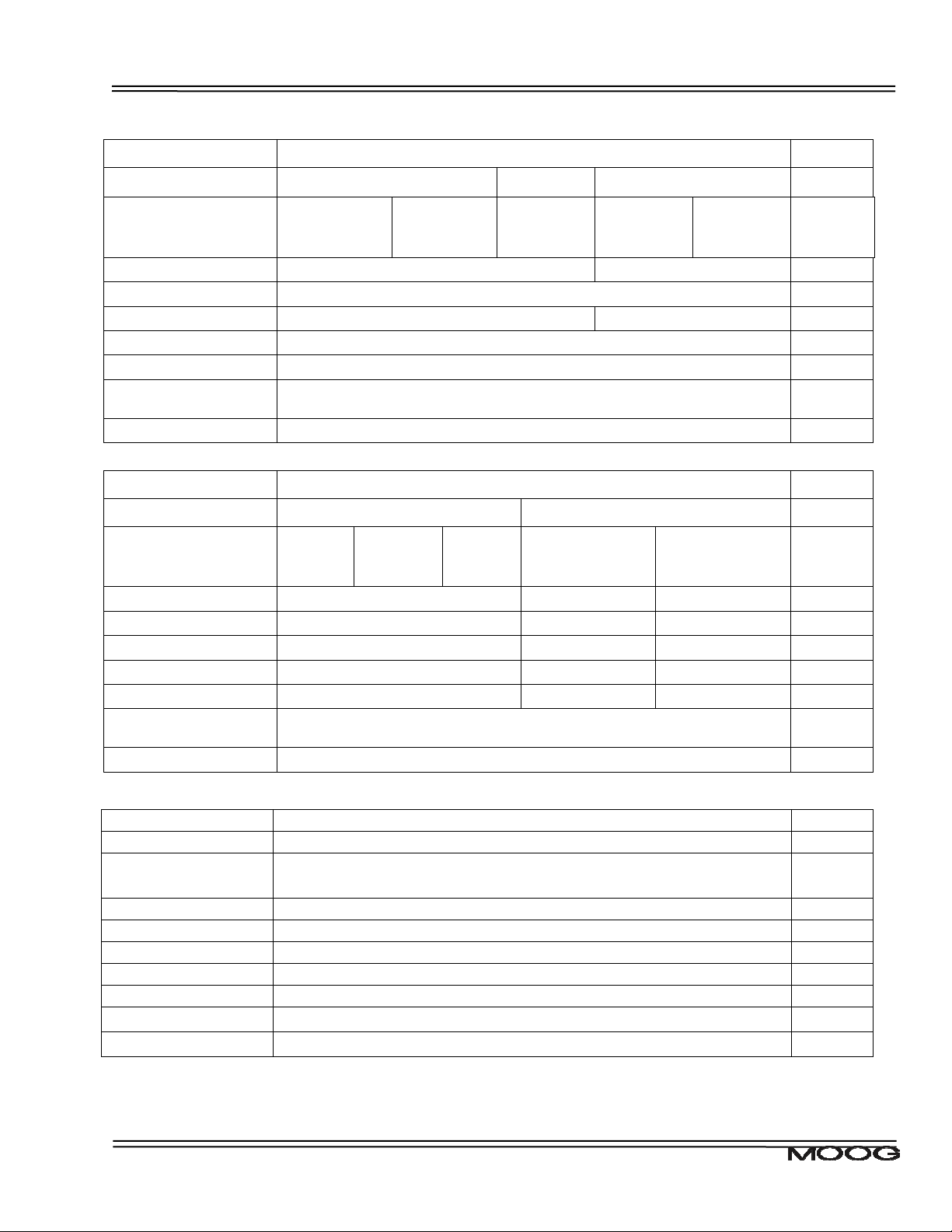

DS2110 Models

Size 3/9 6/22

Short Circuit Rating 5,000 Amps

Power Line Fuse 25A, 660V FWP25-A1F Semiconductor (Cooper Bussmann)

Recovery Resistor Fuse Contact Moog Application Engineering for Advice

24Vdc Aux. Pwr. Fuse 3A, 250V Delayed

DS2110 Models Size A Size B Notes

Size 8/22 10/42 14/42

Short Circuit Rating 5,000 Amps

Power Line Fuse 50-FE 690V Semiconductor (Cooper Bussmann)

Recovery Resistor Fuse Contact Moog Application Engineering for Advice

24Vdc Aux. Pwr. Fuse 3A, 250V Delayed

DS2110 Models Size C Size D Notes

Size 20/45 25/70 30/90 50/140 60/180

Short Circuit Rating 5,000 Amps

Power Line Fuse 100-FE 690V 160-FEE 690V Semiconduct or (Cooper Bussmann)

Recovery Resistor Fuse Contact Moog Application Engineering for Advice

24Vdc Aux. Pwr. Fuse 3A, 250V Delayed

DS2110 Models Size E Notes

Size 100/240

Short Circuit Rating 10,000 Amps

Power Line Fuse 315-FM Semiconductor (Cooper Bussmann)

Recovery Resistor Fuse Contact Moog Application Engineering for Advice

24Vdc Aux. Pwr. Fuse 3A, 250V Delayed

All external d.c. supply voltages used with the DS2110 Series Controllers must be derived from a Safety Extra

Low Voltage (SELV) supply as defined by standard EN60950. Such SELV voltages do not exceed a value of 60

Vd.c. or 42.4 Va.c. peak under normal conditions and are supplied by circuits which are separated from all

hazardous voltage conductors by permitted safety methods such as reinforced insulation.

All external electrical wiring connected to this equipment must be colour coded in accordance with European

Standard EN 60204-1 requirements.

All wires and cables entering and leaving the IP54 rated enclosures or cabinets containing the DS2110 Controllers

and Regen resistor(s) must be protected and anchored in accordance with the requirements of EN 60204-1.

Size μA

Notes

rms

rms

10,000 Amps

rms

rms

rms

Table 1 - Recommended DS2110 Fusing

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 20

CHAPTER 2.0 Safety & EMC Instructions 2-5

2.2.2 Equipment Safety

All persons must observe sound safety practices during the operation and testing of all electrically powered

equipment.

Prior to first use, power should not be applied to the DS2110 Servo-drive until all instructions in the Wiring and

Installation section of this User’s manual have been carried out.

WARNING – In the event of a fuse failure, remove all power, refrain from working on the unit for at least 5minutes

for the A size (6 minutes for the A-E sizes) to allow all internal voltages to decay to a safe level. Remove all fuses

from the system. Determine the source of the failure before re-commencing operation of the drive.

WARNING - DO NOT remove or replace any assemblies, subassemblies or components with primary

power present.

WARNING - Lethal voltages remain present within this equipment when the mains power is removed.

It is recommended to refrain from commencing any servicing, maintenance, repair or upgrading of

this equipment until at least 5 minute for the A size (6 minutes for the A-E sizes) after power

shutdown. It is further recommended to measure the voltage level at all high voltage terminals before

commencing any such activities, to ensure that no lethal voltages are present.

WARNING – The removable plug-in connectors of the DS2110 Servo-Drives are for ease of wiring

installation. These removable plug-in connectors are not suitable for connection or disconnection

under power. All connections must be made with power removed.

WARNING - Repair or internal adjustments to the DS2110 Series Controllers must not be attempted.

All faulty items must be returned to Moog Service Centers for maintenance and repair.

WARNING - Entering the workcell when HIGH POWER or PROGRAM RUNNING indicators are

ON may result in severe injury.

WARNING - The equipment described in this user’s guide operates at voltage levels, which can

exceed 800 volts D.C., and/or 460 volts A.C. These levels are a potential source of severe electrical

shock. DO NOT remove or replace any assemblies, subassemblies or components with the primary

power present. To avoid possible personal injury or equipment damage, always remove power

BEFORE attempting repair or upgrade procedures. Wait at least 5 minutes for the A size (6 minutes

for the A-E sizes) after power shutdown to ensure power supply capacitors have discharged. Then

using a voltmeter, check for safe levels across all high voltage power terminals.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 21

CHAPTER 2.0 Safety & EMC Instructions 2-6

Safeguards should be an integral part of a work cell design, installation, operator training, and operator

procedures. A computer-controlled system may activate remote devices under program control at times not

anticipated by personnel. It is critical that safeguards be in place to prevent personnel from entering the work cell

whenever equipment power is present. Moog highly recommends the use of work cell safety features such as

light curtains, safety gates or safety floor mats to prevent access to the workcell while power is present.

Computer controlled systems have various communication features which may aid the user in constructing

system safeguards, including:

• emergency stop circuitry

• binary input and output lines

• spare system-controlled user lines

The emergency power-off circuitry of a computer-controlled system is generally capable of switching external

power systems, as well as detecting intrusion signals from safety barriers.

All personnel must observe sound safety practices during the operation and testing of all electrically powered

equipment. To avoid injury or damage to equipment, always remove power BEFORE attempting ANY repair or

upgrade activity.

2.2.3 Safety Requirements for Cables

a) Requirements - Conductors and Cables

All cables and conductors used shall be specified as compliant with the requirements of European Standard EN

60204-1 and other known National and International Standards for the environment in which they are installed

and for the voltage and current carried.

Conductors and cables shall be specified and selected so as to be suitable for the operating conditions (e.g.

voltage, current, protection against electric shock, grouping of cables) and external influences (e.g. ambient

temperature, presence of water or corrosive substances, mechanical stress) which can exist.

Required for

CE-Compliance

User's whose machine installations require CECompliance should read this Section.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 22

CHAPTER 2.0 Safety & EMC Instructions 2-7

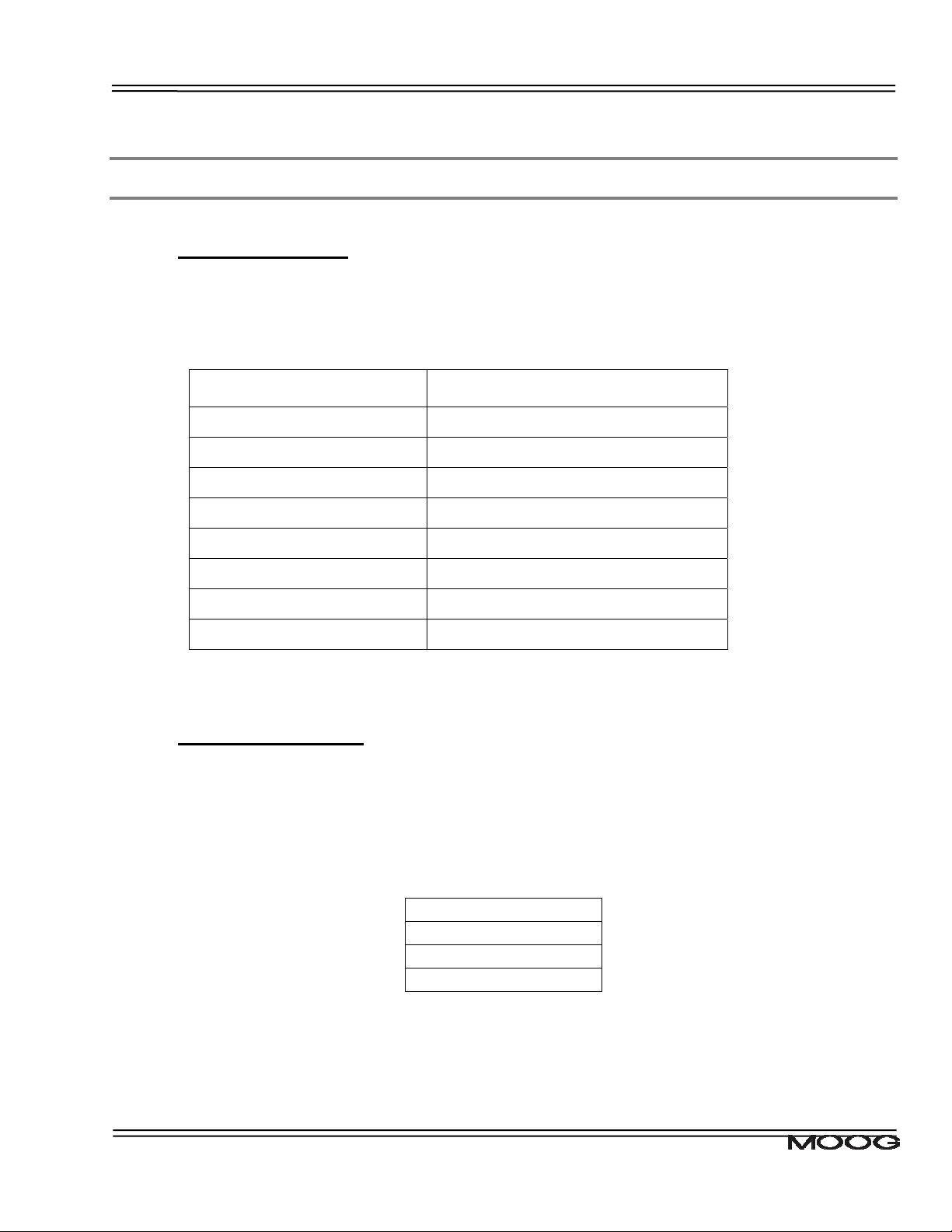

The following table details the recommended cable dimensions for all DS2110 models

Cable 3/9

AWG

(mm

Line Power 3x14 (2.1) 3x12 (3.3)

Protective Bonding Cable 1x 6 (13)

Motor Power Cable 4x14 (2.1) 4x12 (3.31) Shielded

Regen Resistor Cable 2x14 (2.1) Shielded

DC Bus Cable 2x14 (2.1) Shielded

Safety Interlock (If

applicable)

24V Power Cable 2x14 (2.1) Shielded

µA A B

6/22

2

)

AWG

(mm

DS2110 Models Notes

8/22

2

)

AWG

2

(mm

)

2x22 (0.3) Shielded

10/42

AWG (mm2)

14/42

AWG (mm2)

Note: 2x14 (2.08) = Number of conductors x conductor size (AWG = American wire gauge)

DS2110 Models Notes

Cable 20/45

AWG

2

(mm

)

Line Power 3x8 (8.4) 3x 6 (13) 3x 4 (21)

Protective Bonding Cable 1x 6 (13) 1x6 (13) 1x4 (21)

Motor Power Cable 4x8 (8.4) 4x6 (13) 4x4 (21) Shielded

Regen Resistor Cable 2x8 (8.4) 2x 6 (13) 2x4 (21) Shielded

DC Bus Cable 2x8 (8.4) 2x 6 (13) 2x4 (21) Shielded

Safety Interlock (If

applicable)

24V Power Cable 2x14 (2.1) Shielded

C D

25/70

AWG

2

(mm

30/90

AWG

2

)

(mm

)

2x22 (0.3) Shielded

50/140

AWG (mm2)

60/180

AWG (mm2)

Cable 100/240

Line Power 3 x 1 (42)

Protective Bonding Cable 1 x 1 (42)

Motor Power Cable 4 x 1 (42) Shielded

Regen Resistor Cable 2 x 2 (34) Shielded

DC Bus Cable 2 x 1 (42) Shielded

Safety Interlock (If applicable) 2x22 (0.3) Shielded

24V Power Cable 2 x 14 (2.1) Shielded

DS2110 Models Notes

E

AWG (mm2)

Table 2 - DS2110 Cable Dimensions

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 23

CHAPTER 2.0 Safety & EMC Instructions 2-8

Wherever possible, insulated conductors and cables that have flame-retardant properties shall be used.

Where insulated conductors and cables can constitute a fire hazard due to the propagation of a fire or the

emission of toxic or corrosive fumes (e.g. PVC), guidance from the cable supplier should be sought. In particular it

is important to maintain the integrity of circuits having a safety function (e.g. emergency stop) for as long as

possible under these conditions.

The mechanical strength and thickness of the insulation shall be such that the insulation cannot be damaged in

operation or during laying, especially for cables pulled into ducts.

The voltage drops on cables and conductors shall not exceed 5% of the nominal voltage. The current carrying

capacity of the conductors and cables is determined by both:

• the maximum allowable conductor temperature under the highest possible steady state current under normal

conditions; and

• the ultimate allowable short-time conductor temperature under short circuit conditions.

b) Wiring Practices - Connections and routing

All connections, especially those of the protective bonding circuit, shall be secured against accidental loosening.

c) Wiring Practices - Conductor and cable runs

Conductors and cables shall be run from terminal to terminal without splices or intervening j oints

Where it is necessary to connect and disconnect cables and cable assemblies, sufficient extra length shall be

provided for this purpose.

The terminations of multicore cables shall be adequately supported where undue strain can be exerted on the

terminations of the conductors.

Wherever possible, the protective conductor shall be placed close to the associated live conductors in order to

decrease the impedance of the loop.

d) Wiring Practices - Conductors of different circuits

Subject to the constraints for EMC suppression given in this User’s manual, conductors of different circuits may

be laid side by side. They may occupy the same duct (e.g. conduit, cable trunking system) and may be in the

same multicore cable, provided that the arrangement does not impair the proper functioning of the respective

circuits. Where these circuits operate at different voltages, the conductors shall be either separated by suitable

barriers or insulated for the highest voltage to which any conductor within the same duct can be subjected.

Circuits which are not switched off by the supply disconnecting device (circuit breaker) shall be either physically

separated from other wiring or distinguished by color (or both) so that they can be identified as being live when

the supply disconnecting device is in the OFF or OPEN position.

e) Wiring Practices - Identification of conductors

For safety reasons, the color Green or the color Yellow shall not be used where there is a possibility of confusion

with the bicolor combination GREEN-AND-YELLOW.

Color identification using combinations of colors may be used provided there can be no confusion and that

GREEN or YELLOW is not used, except in the bicolor combination GREEN- AND-YELLOW.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 24

CHAPTER 2.0 Safety & EMC Instructions 2-9

f) Wiring Practices - Identification of the protective conductor

The protective conductor shall be readily distinguishable by shape, location, marking or color. When identification

is by color alone, the bicolor combination GREEN-AND-YELLOW shall be used throughout the length of the

conductor. This color identification is strictly reserved for the protective conductor.

For insulated conductors, the bicolor combination GREEN-AND-YELLOW shall be such that on any 15mm length,

one of the colors covers at least 30% and not more than 70% of the surface of the conductor, the other color

covering the remainder of the surface.

Where the protective conductor can be easily identified by its shape, position or construction (e.g. braided

conductor), or where the insulated conductor is not readily accessible, color coding throughout its length is not

necessary. However, the ends or accessible positions shall be clearly identified by the graphical symbol or by the

bicolor combination GREEN-AND-YELLOW.

g) Wiring Practices - Identification of the neutral conductor

Where a circuit includes a neutral conductor identified by color, the color shall be LIGHT BLUE. LIGHT BLUE

shall not be used for identifying any other conductor where confusion is possible.

In the absence of a neutral conductor, a LIGHT BLUE conductor may be used for other purposes except for use

as a protective conductor.

Where identification by color is used, bare conductors used as neutral conductors shall be either colored by a

LIGHT BLUE stripe, 15 mm to 100 mm wide, in each compartment or unit or at each accessible position, or

colored LIGHT BLUE throughout their length.

h) Wiring Practices - Wiring inside enclosures

Panel conductors shall be supported where necessary to keep them in place. Non-metallic channels or conduits

shall be permitted only when made with a flame-retardant insulating material. Where possible earthed shielded

metal cable ducting should be used to minimise EMC noise coupling.

It is recommended that electrical equipment mounted inside the enclosures be designed and constructed in such

a way as to permit modification of the wiring from the front of the enclosure. Where this is not possible and control

devices are connected from the rear of the enclosure, access doors or swing-out panels shall be provid ed.

Connections to devices mounted on doors or to other movable parts shall be made using flexible conductors in

accordance with European standard EN 60204-1, to allow for the frequent movement of the part. The conductors

shall be anchored to the fixed part and the movable part independently of the electrical connections.

Conductors and cables that do not run in ducts shall be adequately supported.

Terminal blocks or attachment plug/socket combinations shall be used for control wiring that extends beyond the

enclosure.

Power cables and cables of measuring circuits may be directly connected to the terminals of the devices for which

the connections were intended.

i) Wiring Practices - Wiring outside enclosures

The means of introduction of cables or ducts with their individual glands, bushings, etc., into an enclosure shall

ensure that the degree of protection is not reduced.

Conductors and their connections external to the electrical equipment IP54 enclosures shall be installed in

suitable ducts (i.e. conduit or cable trunking systems) as described in Section 2.2.4, except for suitably protected

cables, which may be installed without enclosing ducts and with or without the use of open cable trays or cable

support means.

Fittings used with ducts or multi-conductor cable shall be suitable for the physical environ ment.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 25

CHAPTER 2.0 Safety & EMC Instructions 2-10

Flexible conduit or flexible multi-conductor cable shall be used where it is necessary to employ flexible

connections to pendant push-button stations. The weight of pendant stations shall be supported by means other

than the flexible conduit or the flexible multi-conductor cable, except where the conduit or cable is specifically

designed for that purpose.

Flexible conduit or flexible multi-conductor cable shall be used for connections involving small or infrequent

movements. They shall also be permitted to complete the connection to normally stationary motors, to position

switches, and to other externally mounted devices.

Connections to frequently moving parts shall be made with conductors suitable for flexing service in accordance

with European standard EN 60204-1. Flexible cable and flexible conduit shall be so installed as to avoid

excessive flexing and straining particularly at the fittings.

Cables subject to movement shall be supported in such a way that there is no mechanical strain on the

connection points nor any sharp bending. The loop shall have sufficient length to provide for a bending radius of

the cable of at least ten times its outside diameter.

Where cables subject to movement are close to moving parts, precautions shall be taken so that a space of at

least 25mm shall be maintained between the moving parts and the cables. Where this distance is not practicable,

fixed barriers shall be provided between the cables and the moving parts.

The cable sheath shall be resistant to the normal wear which can be expected from movement, and to the effects

of atmospheric contaminants (e.g. oil, water, coolants, dust).

Where flexible conduit is adjacent to moving parts, the construction and supporting means shall prevent damage

to the flexible conduit or cable under all conditions of operation.

Flexible metal conduit shall not be used for rapid or frequent movements, except when specifically designed for

that purpose.

j) Wiring Practices - Ducts, connection and junction boxes

All sharp edges, flash, burrs, rough surfaces, or threads, with which the insulation of the conductors may come in

contact, shall be removed from ducts and fittings. Where necessary, additional protection consisting of a flameretardant, oil-resistant insulating material shall be provided to protect conductor insulatio n.

Ducts and cable trays shall be rigidly supported and positioned at a sufficient distance from the moving parts and

in such a manner so as to minimise the possibility of damage or wear.

Cable trunking systems external to enclosures shall be rigidly supported and clear of all moving or contaminating

portions of the machine or equipment into which they are installed.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 26

CHAPTER 2.0 Safety & EMC Instructions 2-11

2.2.4 EMC requirements for cables

Avoid close parallel routing of signal cables and power cables. Always use the minimum length of cable

necessary and install all cables in a fixed routing.

Data signal cables, motor power and resolver/signal cables, regen resistor cables and power input cables shall

have segregated routings. Where cable routings must intersect, it is recommended that they intersect at an angle

of 90 degrees, to minimise EMC noise coupling.

Required for

CE-Compliance

User's whose machine installations require for

CE-Compliance should read this Section.

Where signal and power cables must run in parallel it is recommended that these cables are separated by at least

20 cm. Where possible cables shall be routed in earthed shielded cable ducting, to minimise electromagnetic

noise coupling.

Use shielded cable to connect the external regen resistor (if installed) to the DS2110. The length of this cable

shall be as short as possible. The shields of these voltage supply cables shall be earthed to Chassis Earth using

the EMC kit or the panel earth bar. Alternatively, if the cable is required to pass through an enclosure panel

earthed to Chassis Earth, the shield may be earthed to the panel by use of a 360 degree metal cable gland.

Cables supplying external d.c. supply voltages to the DS2110 Servo-drive (For example, the 24 Vd.c. supply)

must be as short as possible. The supply wires shall be twisted together or alternatively shielded cable shall be

used.

Cables connecting the d.c. bus from the DS2110 Servo-drives must be as short as possible. Shielded cable shall

be used.

Motor power cables must be shielded with the cable shield securely connected to Chassis Earth at both ends of

the cable. At the DS2110 end of the cable the shield shall be earthed to Chassis Earth using the EMC kit or the

panel earth bar.

Motor resolver/signal cables must be sh ielded with the cable shield securely connected to Chassis Earth at both

ends of the cable.

Signal cables must be shielded with the cable shield securely connected to make a good HF earth bond to

Chassis Earth at both ends of the cable.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 27

CHAPTER 2.0 Safety & EMC Instructions 2-12

2.3 Electromagnetic Compatibility (EMC)

The DS2110 Servo-drive are system components which must be installed in a correct manner to ensure that all

electromagnetic compatibility (EMC) requirements are met. The requirements of European Union (EU) EMC

Directive: 89/336/EEC (as amended by EU Directives 92/31/EEC and 93/68/EEC ) must be met by all equipment,

systems and installations into which the DS2110 Servo-drive are installed.

Required for

CE-Compliance

User's whose machine installations are intended for

CE-Compliance should read this Section.

For further information on the requirements of EU EMC Directive the user is recommended to refer to the latest

publications of the EU Commission and to local regulations.

The DS2110 Servo-drive have been tested for compliance with the requirements of the EU EMC Directive in so

far as they can be regarded as single functional units. The DS2110 have been tested in typical configurations and

it has been found that these configurations meet the essential requirements of the EU EMC Directive. The EMC

standards applied is EN61800-3:

This standard is published by CENELEC, the European Committee for Electrotechnical Standardisation,

Brussels.

2.3.1 Specific Electromagnetic Compatibility (EMC) Requirements:

The EMC measures outlined below are required to be installed by the user into all equipment, systems and

installations into which the DS2110 is installed. Further details are given throughout this User’s Guide.

The DS2110 Servo-drive must be installed by mounting on a panel in a manner that ensures that EMC earthing

requirements are met. (Refer Section 3 of this User’s Guide).

EMC brackets are provided to facilitate earthing of cable shields prior to entering the DS2110. Cable shields must

be bonded to either the panel earthing bar or the EMC brackets.

For safety reasons the DS2110 Servo-drive, and the panel on which they are mounted must be installed in

enclosures or cabinets which provide a degree of ingress protection against liquids and objects of at least IP54.

These enclosures or cabinets must be accessible to technically qualified service or maintenance persons only.

For Electrostatic Discharge (ESD) reasons all service or maintenance persons must ground themselves to the

chassis of the equipment when performing service functions inside the IP54 rated enclosure or cabinet in which

the DS2110 Servo-drive are installed.

All external d.c. supply voltages used with the DS2110 must be supplied from power supplies which are compliant

with the requirements of the EU EMC Directive. All other equipment that is connected to the DS2110 must be

compliant with the EU EMC Directive.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 28

CHAPTER 2.0 Safety & EMC Instructions 2-13

Shielded cable is required to be installed by the user for many external user cable connections to the DS2110.

Details of areas where shielded cable must be installed and details of earthing arrangements which must be

implemented for the shields of such cables are given throughout Section 3 of this User’s Guide.

This equipment intended to be connected to an industrial low-voltage power supply network, or public network,

which does not supply buildings used for domestic purposes (second environment, according to EMC Standards).

If connected to a low-voltage public network that supplies domestic premises (first environment), this product is

expected to cause radio interference in which case supplementary measures may be required.

2.3.2 Recommended EMC Filters

No internal filtering is provided in the DS2110. To ensure EMC compliance an external line filter must be installed.

The recommended filters for the DS2110 are detailed below.

DS2110 µA Size

Moog

Order Code

- Schaffner Fairite Clamp.

Manufacturer Rated Current

Max Voltage Drive Input

(A)

o

@ 50

C (40oC)

- -

Part # 00443164151

Input

24V

dc

(4 Turns in Common Mode)

AT6009 Schaffner FN 258-7/07 7 (8.4) 3x480V 3-phase AC Line Input

- Schaffner FN 350-12/29 12 (13.8) 1x250V

1-phase AC Line Input

(µA 3/11 only)

DS2110 A,B,C,D, E Sizes

Moog

Order Code

Manufacturer Rated Current

Max Voltage Drive Input\Size

(A)

o

@ 50

C (40oC)

AT60171 Schaffner FN2070-3-06 (3) 250V 24Vdc Input

AT6009 Schaffner FN258-7/07 7 (8.4) 3x480V

AT6010 Schaffner FN258-16/07 16 (19.2) 3x480V

3-phase AC Line Input

(Size A)

3-phase AC Line Input

(Size B)

AT6011 Schaffner FN258-30/07 30 (36) 3x480V 3-phase AC Line Input

(Size C)

AT6012 Schaffner FN258-42/07 42 (50.4) 3x480V

AT6013 Schaffner FN258-55/07 55 (66) 3x480V

AT6015 Schaffner FN258-100/35 100 (113) 3x480V

3-phase AC Line Input

(Size D 50/140)

3-phase AC Line Input

(Size D 60/180)

3-phase AC Line Input

(Size D 100/300)

Table 3 - Recommended EMC Filters for DS2110

1

The 24Vdc filter can be used with two DS2110 drives. If more than two DS2110 drives are in use on a machine, a filter

from the same series can be used with a higher current rating.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 29

7

CHAPTER 2.0 Safety & EMC Instructions 2-14

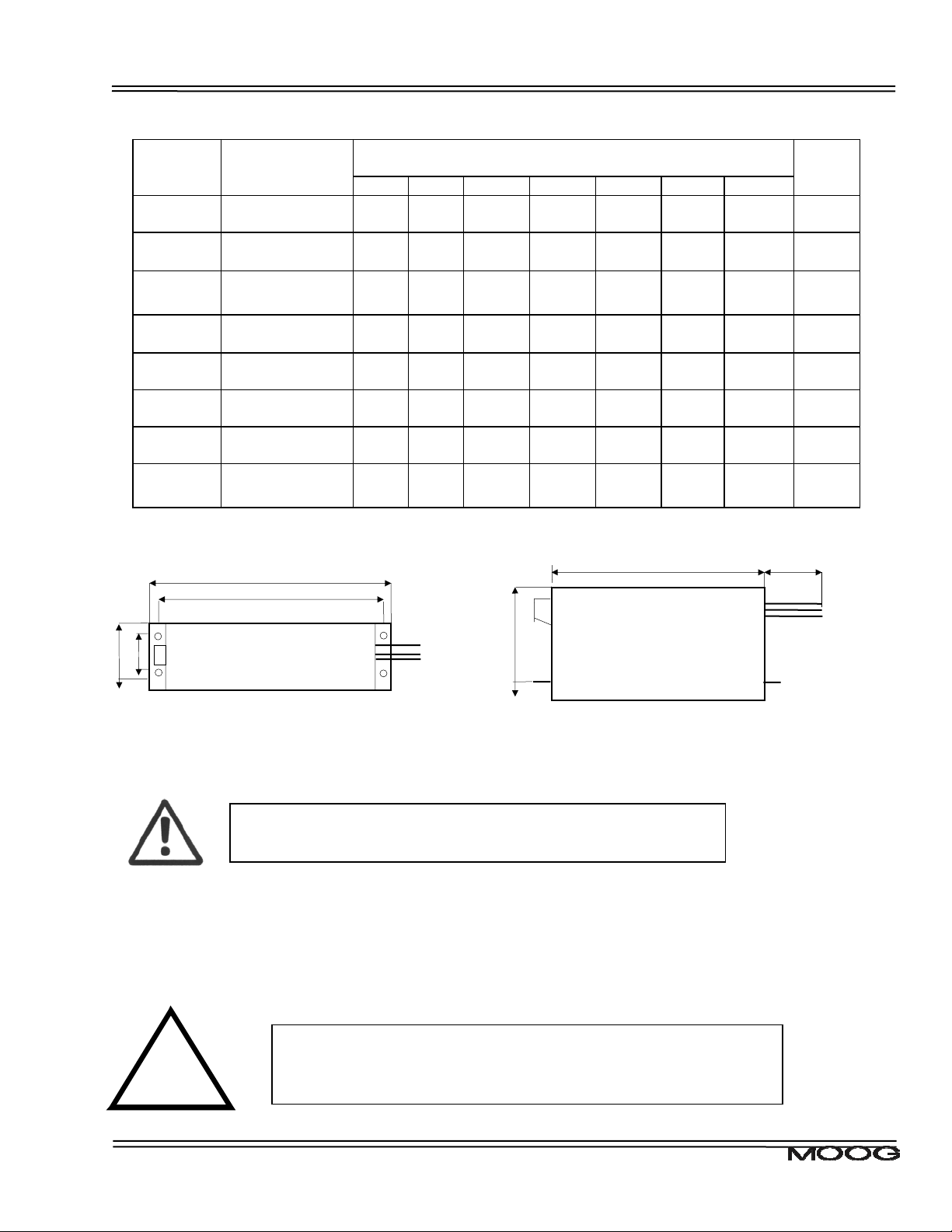

The following table details the mechanical dimensions of the recommended filters.

Moog

Order

Code

AT6017

AT6009

-

AT6010

AT6011

AT6012

AT6013

AT6015

Manufacturer Dimensions

[mm]

Schaffner

FN2070-3-06

Schaffner

FN 258-7/07

Schaffner

FN350-12/29

Schaffner

FN258-16/07

Schaffner

FN258-30/07

Schaffner

FN258-42/07

Schaffner

FN258-55/07

Schaffner

FN258-100/35

L1 L2 L3 L4 L5 L6 L7 [kg]

85 75 54 0 65 40.3 Fast-on 0.25

255 240 50 25

225

±0.8

126

±0.8

99.5 51 105 95 99.5 57

3.5 290 55 30

275±0.8 142±0.

335 320 60 35 305 150 400 1.8

329 314 70 45 300 185 500 2.8

329 314 80 55 300 185 500 3.1

379 364 90 65 350 220

TOP VIEW SIDE VIEW

L1

L2

L5

L4 L3

L6

8

Weight

300 1.1

Terminal

blocks

only

0.9

300 1.7

Terminal

blocks

only

5.5

L

Table 4 - DS2110 Recommended Filters Mechanical Sizing

Caution: A space of at least 60mm (2.4”) must be left around the filter for

air circulation when the cabinet does not have forced ventilation.

The filter must be located as close as possible to the drive input. If the separation between filter and drive

exceeds 30 cm (1’) , then a flat cable (multi-thread copper flat cable) should be used for the RF connection

between filter and drive.

Before mounting the drive and the filter to the cabinet, check that the panel

surface is conductive. If not, remove any paint and/or other insulating

Required for

CE-Comp liance

material before mounting the drive and filter.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 30

CHAPTER 2.0 Safety & EMC Instructions 2-15

EMC filter can produce high leakage currents to ground (Protective Earth). The current levels associated with

individual filters are detailed in the associated filter datasheet.

CAUTION: The filter must be connected to earth before connecting

the supply.

2.3.3 EMC requirements for cables

Requi red for

CE-Compl i ance

User's whose machine installations require for CECompliance should read this Section .

Avoid close parallel routing of signal cables and power cables. Always use the minimum length of cable

necessary and install all cables in a fixed routing.

Data signal cables, motor power and resolver/signal cables, regen resistor cables and power input cables shall

have segregated routings. Where cable routings must intersect, it is recommended that they intersect at an angle

of 90 degrees, to minimise EMC noise coupling.

Where signal and power cables must run in parallel it is recommended that these cables are separated by at least

20 cm. Where possible cables shall be routed in earthed shielded cable ducting, to minimise electromagnetic

noise coupling.

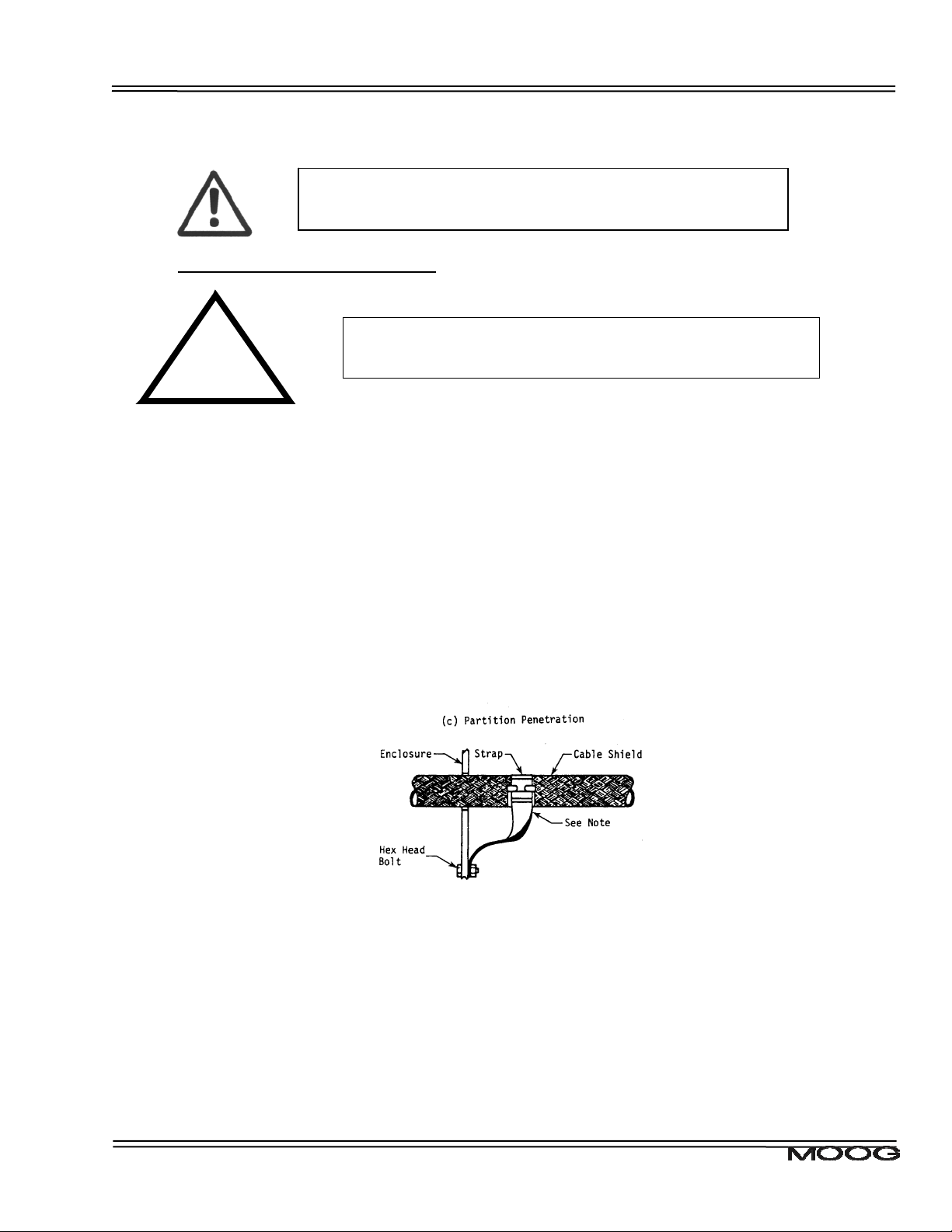

Use shielded cable to connect the external regen resistor (if installed) to the DS2110. The length of this cable

shall be as short as possible. The shields of these voltage supply cables shall be earthed to Chassis Earth using

the EMC kit or the panel earth bar. Alternatively, if the cable is required to pass through an enclosure panel

earthed to Chassis Earth, the shield may be earthed to the panel by use of a 360 degree metal cable gland. If this

is not possible, a copper strap of minimum length should be used. See Figure 1 Partition Crossing.

Figure 1 Partition Crossing

All external Regen (Regenerative circuit) resistors used with the DS2110 must be installed in conductive

enclosures which provide a degree of ingress protection against liquids and objects of at least IP22. Any paint on

the panel or regen resistor enclosure must be removed before the regen resistor enclosure is mounted.

Cables supplying external d.c. supply voltages to the DS2110 Servo-drive (For example, the 24 V

supply) must

d.c.

be as short as possible. The supply wires shall be twisted together or alternatively shielded cable shall be used.

The 24 V

supply should be routed as far from the motor power cable as possible to ensu re EMC compliance.

d.c.

Cables connecting the d.c. bus from the DS2110 Servo-drives must be as short as possible. Shielded cable shall

be used.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 31

CHAPTER 2.0 Safety & EMC Instructions 2-16

Motor power cables MUST be shielded with the cable shield securely connected to Chassis Earth at both ends of

the cable. At the DS2110 end of the cable, the shield shall be earthed to Chassis Earth using the EMC kit or the

panel earth bar. The correct method to earth the shield is shown in Figure 2 Correct Cable Preparation Grounding

of Shield to Chassis.

Figure 2 - Correct Cable Preparation Grounding of Shield to Chassis

Motor resolver/signal cables must be sh ielded with the cable shield securely connected to Chassis Earth at both

ends of the cable.

Signal cables must be shielded with the cable shield securely connected to make a good HF earth bond to

Chassis Earth at both ends of the cable.

Typical cable shield terminations for each of the cables on each DS2110 size are shown in the following figures.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 32

CHAPTER 2.0 Safety & EMC Instructions 2-17

Figure 3 - DS2110 µA Cable Shield Terminations

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 33

CHAPTER 2.0 Safety & EMC Instructions 2-18

Figure 4 - DS2110 A & B Cable Shield Terminations

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 34

CHAPTER 2.0 Safety & EMC Instructions 2-19

Figure 5 - DS2110 C Cable Shield Terminations

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 35

CHAPTER 2.0 Safety & EMC Instructions 2-20

Figure 6 - DS2110 D Cable Shield Terminations

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 36

CHAPTER 2.0 Safety & EMC Instructions 2-21

Figure 7 - DS2110 E Cable Shield Terminations

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 37

CHAPTER 2.0 Safety & EMC Instructions 2-22

2.4 UL Requirements

Detailed below are the specific UL requirements for the DS2110.

2.4.1 Specific UL Requirements

• Usage: The DS2110 shall be used according to the guidelines given in this manual.

• Ratings: The DS2110 shall be used within the ratings specified in the markings on the equipment.

• 24V Logic Supply: The 24V supply is intended for use in the secondary of a Class 2 supply. Alternatively, it

should be additionally fitted with a Listed current limiting fuse, rated 3A on the supply input to the device.

• Surrounding Air Temperature:- “Maximum Surrounding Air Temperature, 40

• Pollution Degree 2 Installation:- The drive must be installed in a Pollution Degree 2 environment.

• Equipment Designation: - Open Type Equipment.

• Short circuit Ratings:-

DS2110 3/9, 6/22, 8/22, 10/42, 14/42, 20/45, 25/70, 30/90, 50/140: “Equipment suitable for use on a

circuit capable of delivering not more than 5000 rms symmetrical Amperes, 460V ac + 10% Maximum”.

DS2110 60/180, 100/240: “Equipment suitable for use on a circuit capable of delivering not more than

10000 rms symmetrical Amperes, 460V ac + 10% Maximum”.

• Branch Circuit Protection. The Branch Circuit Protection for short circuit protection shall be provided in the

end use application by external fuses. Recommended fuses are manufactured by Cooper Bussmann.

DS2110 3/9 & 6/22: Fuse Model No. FWP-25A14F Semiconductor Type Fuses.

DS2110 8/22, 10/42, & 14/42: Fuse Model No. 50FE Semiconductor Type Fuses.

DS2110 20/45, 25/70 30/90: Fuse Model No: 100FE Semiconductor Type Fuses.

DS2110 50/140 & 60/180: Fuse Model No: 160FEE Semiconductor Type Fuses.

DS2110 100/240 : Fuse Model No: 315-FM Semiconductor Type Fuses.

• Wiring. The drive shall be wired with stranded and \ or solid copper (Cu), 60/75

tightening torque for terminal blocks specified in Section 3 of this manual shall be applied. These

requirements do not apply to the control circuit terminals.

• Regeneration Resistor. The regeneration resistor, when external, shall be wired with R/C (AVLV2) rated

wire or shall be insulated with R/C (YDPU2) or R/C (UZCW2) rated insulation.

• Field Wiring. The power connector of the DS2110 A (J6) is not rated as a Field Wiring Terminal. This

connector may only be used as a Factor Wiring Terminal block.

• Over-speed Protection: The DS2110 incorporates a software-based over-speed protection. See ‘Motor

Rating Parameters’ and ‘Velocity Limiting’ in Section 5 of this Manual.

• Motor Overload Protection: The DS2110 does not incorporate an internal motor load protection. The drive is

intended to be used with motors that have integral thermal protection in the form of an NTC or PTC

thermistor. The selections of NTC or PTC and overtemperature fault level are set in software. See ‘Motor

Thermal Parameters’ and ‘Motor Thermal Protection Mechanism’ in Section 5 of this manual.

• Overcurrent Protection: The DS2110 is equipped with internal over current protection. See the ‘Cabling and

Interconnect Protection Scheme’ detailed in Section 5 of this manual.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

o

C”.

o

C conductors only. The

Page 38

CHAPTER 2.0 Safety & EMC Instructions 2-23

Page Intentionally Blank

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 39

CHAPTER 3.0 Wiring and Installation 3-1

This chapter covers the installation, wiring and cabling of the Moog DS2110 Servo-drive series. A pictorial

diagram of a single-axis system, with typical components included, is shown in Figure 3.1. Users are directed to

read Chapter 2, Safety Instructions, before proceeding with wiring and installation.

WARNING - This equipment must be permanently and reliably connected to Earth and all conductive parts

in the IP54 rated enclosure in which the DS2110 Series Servo-drive is installed must be reliably connected

to Protective Earth. A Protective Earth connection must come directly from an approved AC mains

network. Stranded copper-wire is recommended to carry the earth.

3.1 System Components

The following components are required to build a Moog brushless motor digital control system (refer to Figure

3.1). The user supplies all components besides the DS2110, EMC-Brackets, motor and other accessory cabling.

3.1.1 A.C. Mains Power Interface

The DS2110 should be connected to a three-phase AC supply. Operation with a single-phase supply is only

allowed with the G362-x003 and G362-x006 variants of the drive. For single-phase operation, the phase supply

voltage must be limited to 230V and the input power to the drive limited to 1.1kW.

3.1.2 A.C. Input Line Protection

Details of the recommended Line fuses are given in Chapter 2 of this manual. Alternatively an AC mains Circuit

Breaker (Instantaneous Trip Type) can be used as a protective device providing its ratings are equivalent to the

recommended fuses.

After a power loss to the servo-drive, the motor will continue running until its stored energy is dissipated through

friction alone, or will be stopped by a motor-equipped brake if a brake is available.

It is also recommended to install a contactor rated for the DS2110 input between the line fuses and the EMC filter

at the input of the DS2110 (refer to Figure 3.1). This contactor should be controlled directly by user supplied

Emergency Stop Buttons and other series connected safety switches to remove AC input power in any situation

affecting personnel safety.

WARNING - The supply-disconnecting device (circuit breaker) must be switched to the OFF

position before any service or maintenance activity is commenced.

3.1.3 Line Filter Requirements

Details of the recommended line filters for each of the DS2110 variants are given in Chapter 2 of this manual.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 40

CHAPTER 3.0 Wiring and Installation 3-2

Figure 3.1Typical DS2110 System Components (µA Size)

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 41

CHAPTER 3.0 Wiring and Installation 3-3

3.1.4 Serial Set-up Terminal (User-Supplied)

An RS-232 interface should be established for individual servo-drive communications, using a PC. The PC can

run Moog's WinDrive Windows-based user-interface program.

The personal computer using Windrive is a service engineering tool only and

must be installed so that use of the key sequences which allow control of the

machine functions is accessible to authorized, qualified service personnel only.

Required for

CE-Compliance

All such service set-up computers must be CE -marked as compliant with the

EU EMC Directive.

3.1.5 Control-Backup Power Input (User Supplied)

The DS2110 requires a control power source to supply backup-power for the control electronics. This controlbackup power is useful where the user requires that the DS2110 does not lose absolute position data or status

information when AC mains power is removed from the DS2110.

The user is directed to the local Moog sales office or authorised distributor for a recommended list of these control

power source devices.

The G362-x003 &-x006 MUST have a 24Vdc logic backup supply connected for

the drive to operate. No internal high voltage backup is provided on these

smaller models.

The 24V

control power option allows high voltage motor power to be removed from a DS2110 Series Servo-

dc

drive without losing control power.

The acceptable voltage range for this supply is 24V

±10% with a minimum current rating of 2Adc per DS2110

dc

Series Servo-drive connected. A low cost unregulated DC supply is adequate.

Required for

CE-Compliance

NOTE - The 24Vdc power supply must be compliant with the requirements of

the EU EMC Directive. The 24V

output from the power supply must be Safety

dc

Extra Low Voltage (SELV - as defined by European standard EN 60950).

3.1.6 Brushless Servo motors

The DS2110 series Servo-drive is compatible with Moog brushless servomotors.

Normal connection to the motor requires two cables - a power and a signal cable. The power cable provides

three-phase stator power, protective earth and brake connections. The signal cable carries position transducer

feedback signals and motor temperature detection connections.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 42

CHAPTER 3.0 Wiring and Installation 3-4

3.1.6.1 Brushless Motor Brake 24V Power Supply

The motor brake requires a 24V

rated currents of all brakes connected.

supply for release. This should be rated to cover at least twice the sums of the

dc

3.1.7 Heatsinks and Climatic Control

The need for air conditioning will depend on the duty cycle of the system and the surrounding ambient

temperature. The maximum allowable ambient temperature is 40°C (104°F). The humidity range is 5-95% noncondensing.

All DS2110 Servo-drives incorporate internal cooling fans and integral heat sinks. Other than controlling ambient

conditions, additional heat sinking is not required.

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 43

CHAPTER 3.0 Wiring and Installation 3-5

3.2 Equipment Mounting

This section details the mechanical dimensions of the DS2110 chassis, as well as required clearances for cabling

etc. The DS2110 is designed to be panel or cabinet mounted. The DS2110 must be mounted in a vertical

orientation. The DS2110 must be panel mounted within an enclosure or cabinet that provides a degree of ingress

protection against liquids and objects of at least IP54. Such enclosures or cabinets must be accessible to

technically qualified service or maintenance persons only. It is recommended that the cabinet be ventilated using

filtered or conditioned air, free of corrosive or electrically conductive contaminants. The accumulation of dust, dirt,

etc. on the equipment must be avoided. A minimum clearance above and below each of the DS2110 drive sizes is

required. These distances are detailed in Table 3. -1.

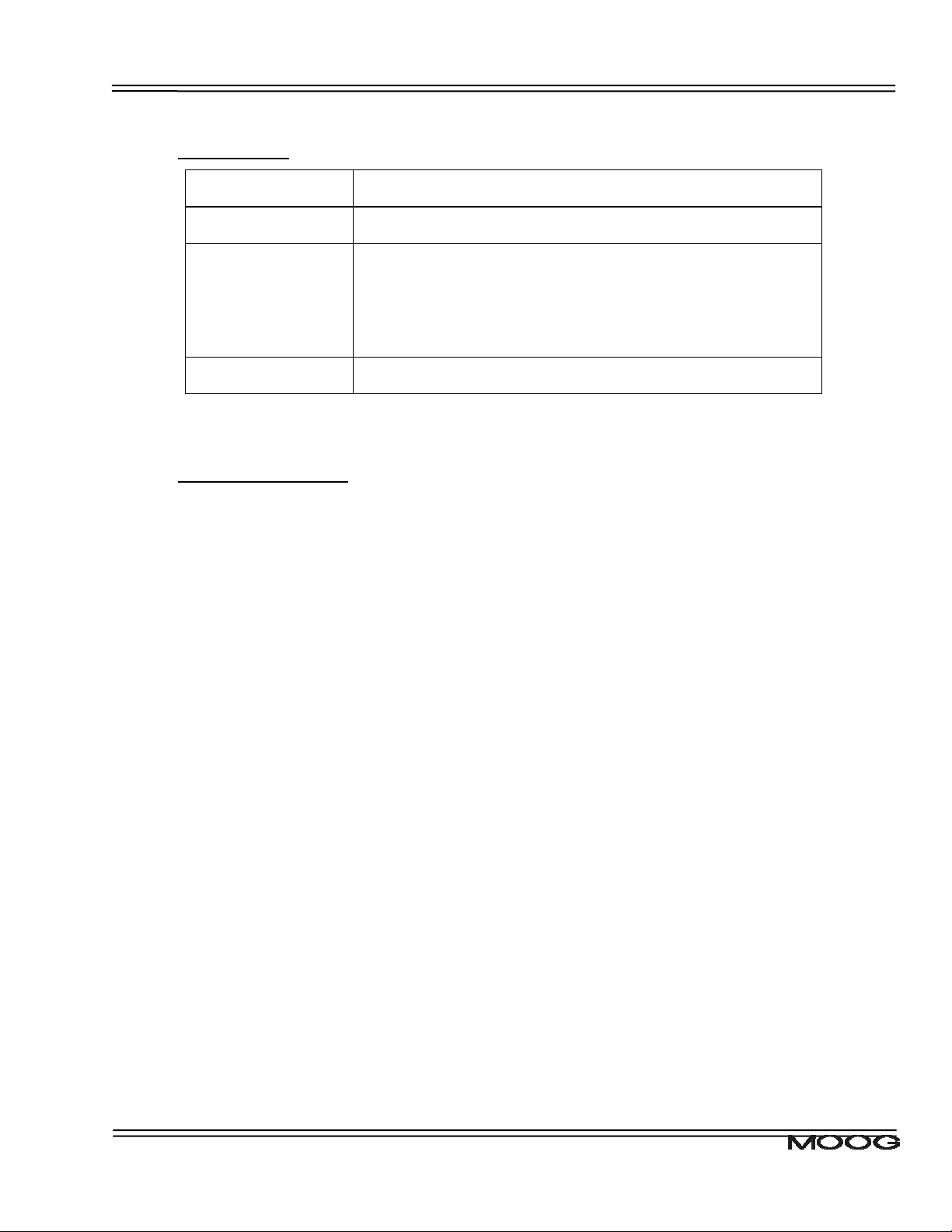

DS2110 Size Minimum Clearance Top

(mm)

µA & A 60 100

B 60 100

C 80 160

D 100 200

E 200 300

Table 3. -1 Minimum Clearance around DS2110 Drives

If any of the DS2110 units are mounted in a closed cabinet, allow 100mm clearance at the front for cable bends.

Minimum Clearance

Bottom (mm)

CDS7324 (FORMERLY LSF-0819)

Rev. A INSTALLATION & USER’S MANUAL

Page 44

CHAPTER 3.0 Wiring and Installation 3-6