Page 1

DS2000

GB-4534

USER'S MANUAL (rev.C)

Page 2

Page 3

INDEX

I.1

INDEX OF REVISIONS

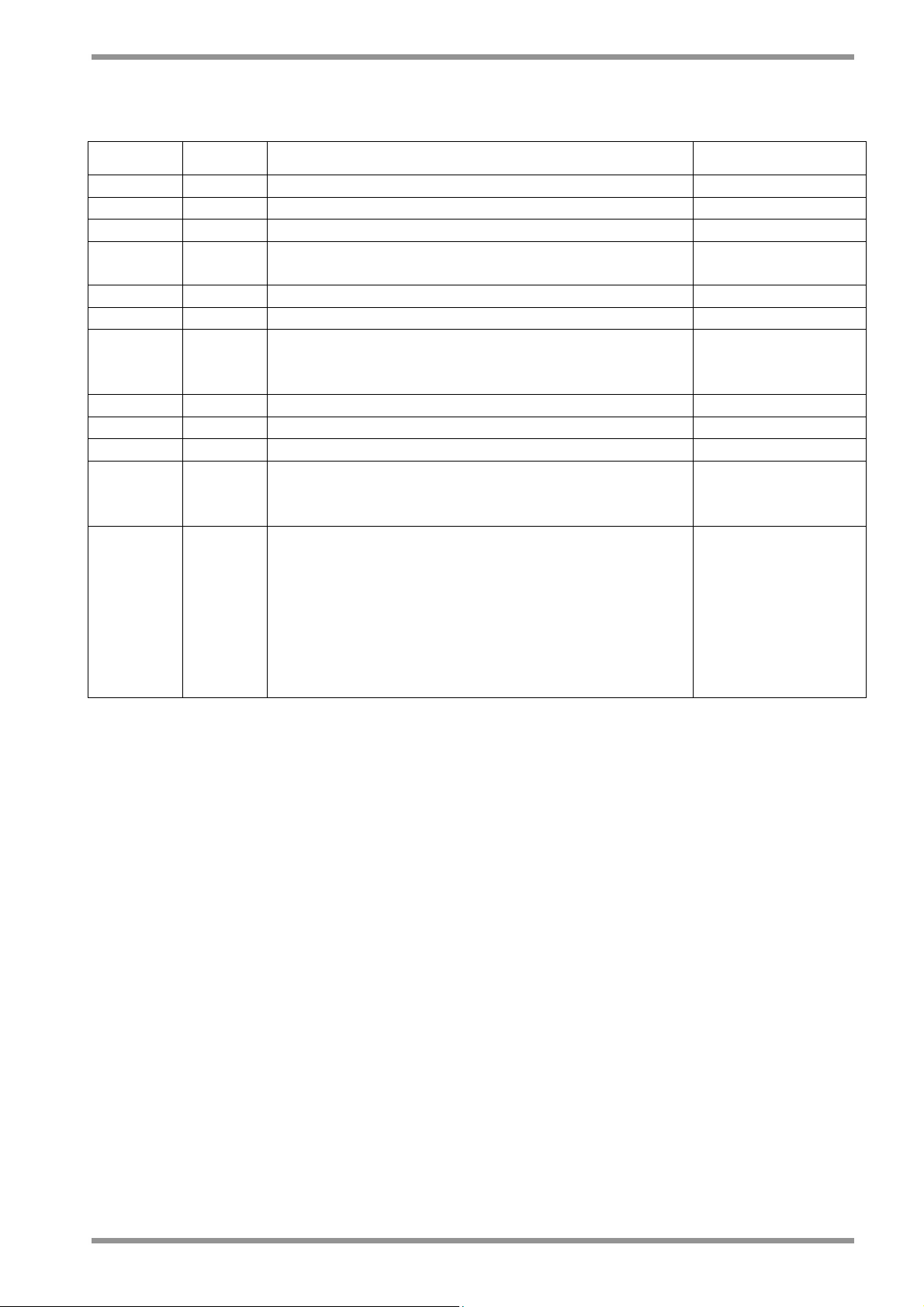

Revision Date Description Updated section

0 Jul 99 Preliminary

1 Dec 99 Initial Release

2 Jan 00 Correct errors

3 Mar 00 Change fuses according UL, correct

miscellaneous errors

4 Jan 01 Changes of control board All

5 May 02 Update on new drives sizes, error correction All

6 Feb 04 Update on new SW release Index,

7 May 04 Update All

8 Jul 04 New UL requirement Table of contents

9 Oct 04 Deleted DSloader section, update All

B Jan 06 New size E, update section 8 – Restart Interlock

Function, update new software releases, correct

miscellaneous errors

C Sep 06 G motor resolver connection, APHAPOS

parameter, update figures Size E, update section

8 – Restart Interlock Function, correct

miscellaneous errors

Section 3-4-7,

Appendix

All

Par. 2.11.2.1,

2.11.3.2, 3.3.4,

6.2.1, 6.2.2, 6.3.1,

6.7.1.5

Fig. 2.4.1, 2.5, 2.6,

2.8, 2.8.1, 2.14,

3.5.1

Section 8

DS2000 USER’S MANUAL (rev.C)

Page 4

I.2

Index

Section 1

Description

Section 2

Wiring and installation

Section 3

Electromagnetic

compatibility (EMC)

INDEX

INDEX OF CONTENTS

Introduction

Using the manual

Accident protection

EC declaration of conformity

EC requirements

UL authorization

UL requirements

ICEPI certificate

Safety requirements

(Restart Interlock Function)

Legal aspects

Introduction

Product range

General features

Technical data

Standard versions codes

Special versions codes

Options

Serial number – Nameplate

Introduction

Dimensions and drilling jig

External fuses

Power dissipation

Soft-start

Recovery circuit

Fans

Reset

Connection cables

AWG/mm2 conversion

Wiring and connectors

Drive starting sequence

Starting sequence times

Dynamic braking

Power off

Mechanical braking

Introduction

European directive (89/336/EEC)

Filters

Wiring and grounding

Recovery resistor

Screening

Safety aspects

I.1

I.2

I.3

I.4

I.5

I.6

I.7

I.8

I.9

I.10

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

3.1

3.2

3.3

3.4

3.5

3.6

3.7

DS2000 USER’S MANUAL (rev.C)

Page 5

Section 4

Starting

Section 5

Component description

Section 6

Commands

Section 7

Troubleshooting

Section 8

Restart interlock circuit

(Optional)

Appendix

INDEX

Introduction

Drive setting up information

First Start-up

Configuration for installation in electrical cabinet

Introduction

High power input section

High power output section

Control section

Introduction

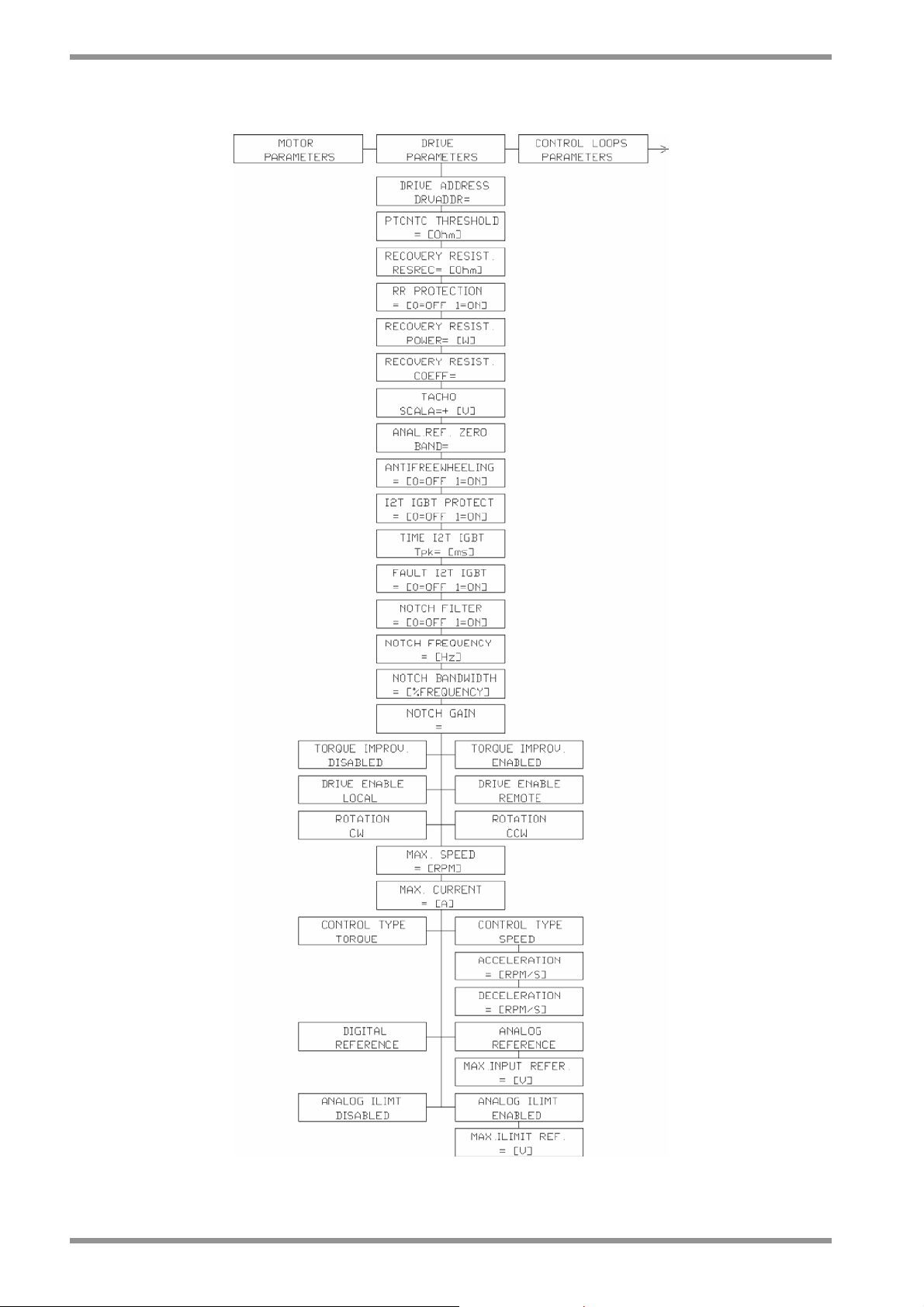

Motor parameters menu

Drive parameters menu

Control loops parameters menu

Drive enable menu

Display variables menu

Utility menu

Keyboard lock menu

Fault detection menu

Introduction

Faults on drive power supply circuit

Faults on drive output section

Faults on feedback section

Control loops troubles

Motor troubles

Recovery resistor troubles

Intended application

Restart interlock function

Safety requirements

Restart interlock circuit

Restart interlock connections

Safety relays – Technical data

Application example

Sequence and procedure using the restart

interlock

Checking the restart interlock

External plausibility tests

Installation and routine test

RIC identification on the nameplate

Appendix A - Motors technical data

Appendix B - FC series technical data

Appendix C - Active software release

Appendix D - Obsolete software release

I.3

4.1

4.2

4.3

4.4

5.1

5.2

5.3

5.4

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

7.1

7.2

7.3

7.4

7.5

7.6

7.7

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

8.10

8.11

8.12

DS2000 USER’S MANUAL (rev.C)

Page 6

I.4

INDEX

I.1 INTRODUCTION

This manual refers to DS 2000 “The Motion Solution” drive, with SW Release 3.20X.

The manuals from 0 to 3 release refers to DS2000 drives and SW release below 2.00X.

The manuals from 4 to 5 release refers to DS2000 “The Motion Solution” drive, with SW

release 3.00X and 3.10X.

New characteristics and added functionalities on DS2000 Software Release 3.200:

• I2T IGBT Protection. This functionality allows to protect IGBT modules from overheating,

due to excessive phase current flowing (particularly at low frequencies or locked rotor).

When the protection activates the drive can be disabled or the current flowing can be

limited. This functionality can be activated or deactivated from menu. Activating this

protection the Notch Filter will be automatically deactivated. I2T IGBT Protection and

NOTCH FILTER cannot be used together.

• Anti-Free-Wheeling (AFW). This functionality allows to have an emergency motor stop in

case of NO POWER, MOTOR OVERHEATING and DRIVE OVERHEATING. The motor

will brake with the deceleration value eventually set in menu. This functionality can be

activated or deactivated from menu.

• Regen Resistor Protection. Some customer applications have shown an intense

continuous utilization of the regen resistor that sometimes ends with its damage or even

breaking. To avoid this problem a new functionality has been developed within the new

DS2000 Firmware Release 3.200: this algorithm estimates the growing of the resistor

temperature and, depending on the manufacturer data (nominal power, maximum power

and time at peak power), protects it from dangerous overheating.

• FAS G Defluxing. This modification improves motor performances at high speed

introducing a defluxing component (sinusoidal current phase shifting) starting from a

speed value and with a maximum angle value to be set in the menu. This functionality can

be activated or deactivated from menu using its related parameter.

• Dead Band on analog reference. A dead Band on analog reference can be introduced

(centered on zero crossing and symmetric in both directions) with an amplitude selected

with the menu. It eliminates possible offsets that can cause slow motor shaft drift

rotations. This functionality can be activated or deactivated from menu using its related

parameter.

• PTC/NTC Selection. PTC/NTC motor thermal sensor can be selected using menu.

• Automatic Current Offset Compensation. This functionality automatically auto-activates

when drive is disabled and it repeats its calculations until the drive is off. When the drive

is enable, the last calculated offset value is memorized and used in current loop. When

the drive is disabled again, this function activates and compensates also possible thermal

drifts.

DS2000 USER’S MANUAL (rev.C)

Page 7

INDEX

I.5

• ENC/OUT Zero Marker Calibration. This functionality is activated through the “ENC/OUT

MARKER CALIBRATION” in the UTILITY menu and shifts the Zero Marker on the electric

turn. It can be useful to align the ENC/OUT Marker with mechanical zero of the machine.

• Digital speed reference parameter saving. Digital speed reference parameter set in

CURRENT LOOP PARAMETERS, SPEED LOOP menu can now be saved.

• Parameter range modification: motor speed and motor Rw.

- Motor speed parameter range has been changed from 300/9999 to 100/9999;

- Motor Rw parameter range has been changed from da 0/30.0 to 0/100.0;

- IOFFS U and V parameter range has been changed from -100/100 to -500/500;

- RECOVERY RESISTOR parameter has been changed from 5/100 to 3/100;

NOTE: this software can be installed on the DS2000 with 3.xxx software version: please

contact Moog service before update the drives.

NOTE: this software is totally compatible with the interface Windrive GUI; with 3.1xx or

previous release use DSLoader interface

.

I.2 USING THE MANUAL

This manual provides the necessary information for a proper installation and use of the

DS2000 servodrive.

The DS2000 was designed to be easily installed; it is not necessary any specific skill

concerning servodrives to start it up.

Anyway, the installer should have basics of electronics/electrotechnics, of servodrives, and of

safety.

The DS 2000 is a digital servodrive, which can be configured via software as a computer,

according to the application requirements.

It is recommended to read carefully the manual before the installation.

After the installation, and before starting up the motor it is also recommended to check all the

system parameters to ensure a correct system configuration.

Particular attention must be used to safety instructions.

DS2000 USER’S MANUAL (rev.C)

Page 8

I.6

INDEX

I.3 ACCIDENT PROTECTION

The safety instructions provided in this Manual are included to prevent injury

to personnel (WARNINGS) or damage to equipment (CAUTIONS).

WARNING: High Voltage. BUS BAR's can have voltage ≥810V

(capacitive voltage). Discharge Time approx. 6 Minutes.

WARNING: High Voltage. The recovery resistor is connected to the BUS BAR’s and can

have voltage ≥810Vdc.

WARNING: do not touch recovery resistor during operation to avoid scalds.

CAUTION: it is recommended to disconnect the drive and the EMC filters to carry out the AC

Voltage Tests of EN 60204-1 (1997), par.19.4, in order to not damage the Y-type capacitors

between phases and ground. Moreover the DC voltage dielectric test required by EN 50178

(1997), product family standard, has been carried out in factory as a routine test. The DC

Insulation Resistance Tests of EN 60204-1 (1997), par.19.3, may be carried out without

disconnecting the drive and the EMC filters.

CAUTION: when required for an emergency stop, opening U2-V2-W2 pins and closing motor

phases to resistors, must be preceded by disabling the axis. The delay time must be at least

30 ms.

CAUTION: in case of repetitive switching on and off, waits 1 minute between off and on.

CAUTION: do not exceed the tightening torque of the table (but see proper data sheets for

the tightening torque of input capacitors and power modules and see section 2 of this manual

for the tightening torque of terminal blocks).

Screw thread

Tightening torque

[Nm] [lb in]

M3 1.00 8.85

M4 3.00 26.55

M5 6.00 53.10

M6 8.00 70.80

M8 20.00 177.00

even after switching off

dc

DS2000 USER’S MANUAL (rev.C)

Page 9

INDEX

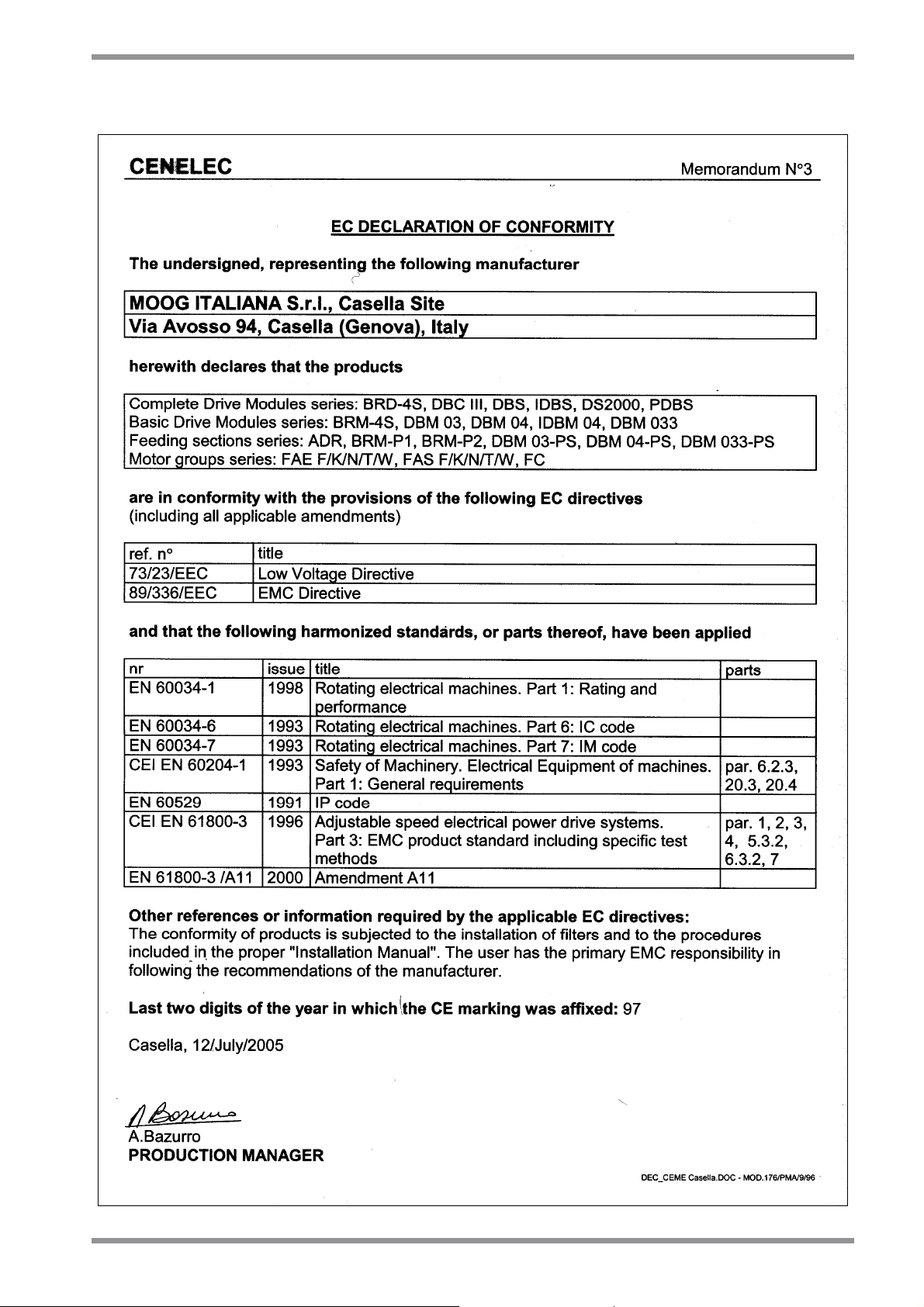

I.4 EC DECLARATION OF CONFORMITY

I.7

DS2000 USER’S MANUAL (rev.C)

Page 10

I.8

INDEX

I.5 EC REQUIREMENTS

Cautionary Marking. See previous page.

Protection against electric shock. Electronic Equipment intended for installation in

closed electrical operating areas kept locked. Where Electronic Equipment requires

manual intervention, 412.2.1 of HD 384.4.41 S2 shall be consulted.

Fixed connection for protection. The equipment may have a continuous leakage

current of more than A.C. 3.5 mA or D.C. 10 mA in normal use and a fixed ground

connection is required for protection.

RCD. When the protection in installations with regard to indirect contact is achieved by

means of an RCD, their appropriate function/combination shall be verified. In any case

only a residual-current-operated protective device (RCD) of Type B is allowed. In fact a

D.C component can occur in the fault current in the event of a fault connection to earth.

Climatic Conditions. Equipment intended to operate within its performance specification

over the range of Class 3K3, as defined in table 1 of EN 60721-3-1, EN 60721-3-2, EN

60721-3-3, EN 60721-3-4, partly modified.

Pollution Degree 2 Installation. The equipment shall be placed in a pollution degree 2

environment, where normally only non-conductive pollution occurs. Occasionally,

however, a temporary conductivity caused by condensation is to be expected, when the

electronic equipment is out of operation.

EMC Requirements. The installer of the equipment is responsible for ensuring

compliance with the EMC standards that apply where the equipment is to be used.

Product conformity is subjected to filters installation and to recommended procedures, as

from section 3 of this manual.

Second Environment (EMC). Equipment intended to be connected to an industrial low-

voltage power supply network, or public network that does not supply buildings used for

domestic purposes (second environment, according to EMC Standards). It is not intended

to be used on a low-voltage public network that supplies domestic premises (first

environment). Radio frequency interference is expected if used on such a network.

Recovery Resistor Cable. Shielding of the recovery resistor cable, provided in kit for test

purposes, is recommended for ensuring compliance with the EMC standards.

Large-Scale Stationary Industrial Tools (WEEE, RoHS). Equipment intended for

installation as part of large-scale stationary industrial tools, covered by the exception of

Annex IA, No.6, of the European Directives 2002/96/EC (WEEE) and 2002/95/EC

(RoHS).

DS2000 USER’S MANUAL (rev.C)

Page 11

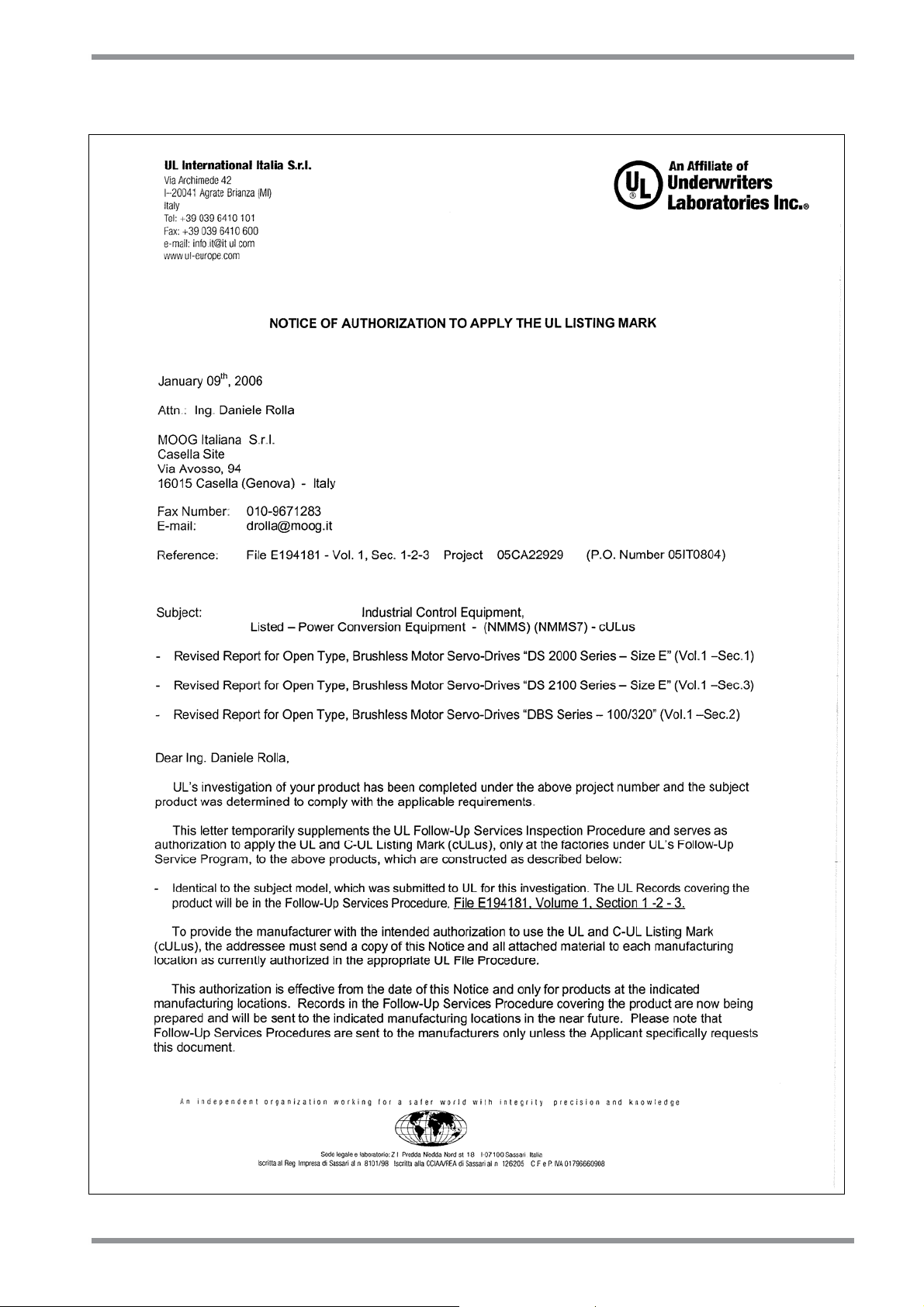

I.6 UL AUTHORIZATION (page 1)

INDEX

I.9

DS2000 USER’S MANUAL (rev.C)

Page 12

I.10

UL AUTHORIZATION (page 2)

INDEX

DS2000 USER’S MANUAL (rev.C)

Page 13

INDEX

I.11

I.7 UL REQUIREMENTS

• These Brushless Servo-Drives shall be assembled with the guidelines specified in this

Manual. Only the configurations with the components tested and described in the UL

Report, file E194181, Vol.1, Sec.1, Issue date 01-21-00 and following Revisions can bear

the Listing Mark.

• These drives shall be used within their ratings, as specified in the marking of the

equipment.

• Cautionary Marking. See Accident Protection page.

• Surrounding Air Temperature. "Maximum Surrounding Air Temperature 40°C". In the

final installation considerations shall be given for the need of repeating Temperature test if

the unit is mounted with a different Surrounding Air conditions.

• Pollution degree 2 Installation. The drive must be placed in a pollution degree 2

Environment.

• Environmental designation. “Open Type Equipment”.

• Short Circuit Ratings.

DS2000 3/9, 4/12, 6/15, 8/22, 14/42, 20/45, 25/70, 35/90, 50/140: “Equipment suitable

for use on a circuit capable of delivering not more than 5000 rms Symmetrical

Amperes, 460 Vac +10% maximum”

DS2000 60/180, 100/300: “Equipment suitable for use on a circuit capable of delivering

not more than 10000 rms Symmetrical Amperes, 460 Vac +10% maximum”

• Branch Circuit Protection. The Branch Circuit Protection for Short Circuit shall be

provided in the end-use applications by external R/C Fuses (JFHR2), manufactured by

Busman Div Cooper (UK) LTD, Semiconductor fuse type, rated 660 Vac, 200 kA A.I.C.,

Mod. No. as follows:

DS2000 3/9, 4/12, 6/15, 8/22, 14/42: Mod. No. 50 FE, rated 50 Amps

DS2000 20/45, 25/70, 35/90: Mod. No. 100 FE, rated 100 Amps

DS2000 50/140, 60/180: Mod. No. 160 FEE, rated 160 Amps

DS2000 100/300: Mod. No, 315-FM, rated 315 Amps

• Overspeed Protection. The Power Conversion Equipment is incorporating an Overspeed

Protection. See MV command in section 6.

• Overvoltage Control. In the equipment the Overvoltage is controlled by a Transient

Suppressive device, with 1500 V Clamping Voltage and min 120 J (10x1000 us or 2 ms)

Energy Handling Capability. See also “Bus not normal” protection in section 6.

• Overload Protection. The equipment does not incorporate internal overload protection

for the motor load. The drive is intended to be used with motors that must have integral

thermal protection through a PTC or NTC. The overtemperature fault of the drive will trip

when the PTC reaches 2 kW or 6.5kW for the NTC. See J4 connector in section 2 of this

manual for wiring.

DS2000 USER’S MANUAL (rev.C)

Page 14

I.12

INDEX

• Over-Current Protection. The drive is provided with a current limiting circuitry. See

ANALOG ILIMIT and I2T commands in section 6.

• Wiring. Wiring shall be made by stranded and/or solid, copper (Cu), 60/75°C (140/167°F)

conductor only, and, for terminal blocks, the tightening torque values specified in section 2

of this manual shall be applied. These requirements do not pertain to control circuit

terminals.

• Wiring of Recovery Resistor. The Dynamic Brake Unit Recovery Resistor, when

external, shall have the connection wiring made with R/C (AVLV2) or insulated with R/C

(YDPU2) or R/C (UZCW2) in the end-use installation.

• Transient Suppression Devices. Input power wiring, only for size A and B, shall be

protected by external Transient Suppression Devices, such as varistors or transient

voltage surge protections, evaluated to the component requirements in UL1449. the

following devices are recommended:

Rating

Drive

A and B

size

Ref.

Code

AS5046

Manufacturer

Littelfuse Inc

Epcos Ohg

S A BC

Components NV

TVSS

Mod. No.

V-575-LA-40-

A

S14-K-550

S20-K-550

2322 595.551

Operating

Voltage

(V

)

ac

575 V

rms

max

550 V

rms

max

550 V

rms

max

550 V

rms

max

Clamping

Voltage

(Vac)

1500

1500

1500

1500

Maximum

Energy (J)

120

(10x1000µs)

120

(2ms)

210

(2ms)

160

(10x1000µs)

Max

Op.

Temp

85°C

85°C

85°C

85°C

Qty

3

DS2000 USER’S MANUAL (rev.C)

Page 15

I.8 ICEPI CERTIFICATE

INDEX

I.13

DS2000 USER’S MANUAL (rev.C)

Page 16

I.14

INDEX

I.9 SAFETY REQUIREMENTS (RESTART INTERLOCK FUNCTION)

• Complete Standstill. The Restart Interlock safety function prevents motor unexpectedly

starting from standstill. This circuit can be used in the “Safe Standstill” machine function.

When the motor is rotating, the switching-on of the Restart Interlock provides an

uncontrolled stop (category 0 according to EN 60204-1:1997). When a controlled stop of

category 1, according to EN 60204-1:1997, is requested, the condition of stopped motor

must be assured. The final machine must be able to stop the motor.

WARNING: The designer must evaluate the machine stopping time during the risk

assessment even in case of failure. The machine can present a dangerous overrun

in case of failure of the drive. Other protective measure are needed to achieve a

safe condition.

• Environmental Conditions. Equipment intended to operate within the following

environmental conditions:

◊ Ambient temperature: 0 to +40°C

◊ EMC immunity: according to EN 61800-3/A11:2000 (Adjustable speed electrical power

drive systems. Part 3: EMC product standard including specific test methods). Second

environment (industrial)

◊ Vibration immunity: 2 to 12Hz, 1.5 mm amplitude (peak); 12 to 200Hz, 1 g acceleration

◊ Shock immunity: 10 g, half sine, 11 ms, according to EN 60721-3-3:1995, Class 3M4

• Enlosure. Electronic Equipment intended for installation in an enclosure providing at least

IP54 protection.

• Pollution Degree 2. The equipment shall be installed in a pollution degree 2 environment,

where normally only non-conductive pollution occurs. Occasionally, however, a temporary

conductivity caused by condensation is to be expected, when the electronic equipment is

out of operation.

WARNING: When the Restart Interlock Circuit is activated, the motor can no longer

generate a torque. Motors which are not automatically clamped when powered

down (e.g. vertical/inclined axes), must be clamped using a mechanical brake

DS2000 USER’S MANUAL (rev.C)

Page 17

INDEX

I.15

I.10 LEGAL ASPECTS

This manual can be used only by final Customers/Users of the Moog product it describes and

only for proper installation purposes.

This manual cannot be reproduced in whole or in part without the prior written consent of

Moog.

No transmission or diffusion of this manual, under electronic, mechanical, or printed form, is

allowed.

Moog issued this manual attempting to ensure a complete information; anyway, Moog shall

not be liable for errors or omissions contained herein and for incidental or consequential

damages due to the above mentioned errors and omissions.

Moog reserves the right to change and update this manual without notice.

This manual has a merely information purpose. There is no obligation for Moog as regard the

correspondence of the product features described in the manual with the features of the real

product purchased by the final Customer/User.

No statement or sentence contained in this manual implies further legal obligations different

from the ones contained in each single sale or supply contract concerning Moog products.

DS2000 USER’S MANUAL (rev.C)

Page 18

I.16

INDEX

THIS PAGE INTENTIONALLY BLANK

DS2000 USER’S MANUAL (rev.C)

Page 19

SECTION ONE – DESCRIPTION

1.1

1. DESCRIPTION

1.1 INTRODUCTION

This section describes the DS2000 drive series, providing information about the coding

system. Such data allow understanding the DS2000 characteristics and makes clear the

necessary concepts to access the following sections.

DS2000 USER’S MANUAL (rev.C)

Page 20

1.2

SECTION ONE – DESCRIPTION

1.2 PRODUCT RANGE

DS2000 is a full digital drive series for permanent magnet synchronous servomotors

(hereinafter: brushless) and for vector control asynchronous servomotors (hereinafter:

asynchronous).

The range is made up of 11 models, corresponding to 3, 4, 6, 8, 14, 20, 25, 30, 50, 60 and

100 A

nominal currents.

rms

The standard transducers provided with the motor are the incremental encoder or the

resolver (with its simulated encoder).

The recovery resistors are placed outside the drive; only the 3, 4, and 6 A models can be

equipped with built-in recovery resistor (optional).

DS2000 drive is provided together with this manual and the Application Notes in the

Appendix of DS2000 user’s manual, for a deep understanding and the best use of the

product.

1.3 GENERAL FEATURES

The DS2000 features provide the automation industry with the best response to the hardest

requirements related to motion control:

FULL DIGITAL:

• Speed and current control loops and many other functions, as the DC BUS status

monitoring, the soft-start and recovery circuit management, and the protections

thresholds detection are carried out through numeric algorithms.

• The digital mode allows a maximum stability related to the aging, the temperature and

the various application cases.

• Settings are carried out through numbers calculated by means of analytic models and

do not depend upon analog calibrations.

FLEXIBLE:

• Any brushless motor can be very well driven by entering a maximum of 8 parameters

which adjust the current loop and identify the motor electromechanical characteristics

(peak current, electromotive force, inductance, resistor, poles number, voltage rating,

speed).

• Any asynchronous motor can be very well driven by vector control, working as a

brushless servomotor; by entering the magnetization current (ID) and the slip gain

(frequency) additional parameters it is possible to use any kind of asynchronous

motor. The other parameters, the ones in connection with the hardware features in

common with brushless motors, remain active.

• The motor transducer can be both a resolver (2 to 24 poles) and an incremental

encoder (1024 to 8192 pulses).

• It is possible to program the device in 2 different languages: Italian and English. The

required language should be specified in the purchase order.

• The power supply voltage range can be from Three-phase 65 Vac to 510 Vac with no

previous setup.

• With power supply voltages lower than 120 Vac Three-phase, it is necessary to supply

a 24 Vdc auxiliary voltage.

DS2000 USER’S MANUAL (rev.C)

Page 21

SECTION ONE – DESCRIPTION

ADVANCED PERFORMANCE:

• The current loop, based on a traditional PI structure, is provided with automatic

compensation algorithms of the EMF and of the KP/KI ratio, as a function of the motor

characteristics.

• Hardware calibrations are not necessary for the current loop, but they are necessary

for parameters setting.

• Current loops are closed at 10kHz.

• The speed loop is closed at 5kHz.

• Additional phase advance is provided.

1.4 TECHNICAL DATA

1.4.1 ELECTRICAL AND MECHANICAL SPECIFICATIONS

Three-phase input voltage rating: 230V

Min/max Three-phase input voltage

- With 24 V

- Without 24 V

auxiliary input voltage: 65 / 510 Vac (DC-BUS: 80 / 720 Vdc)

dc

auxiliary input voltage: 120 / 510 Vac (DC-BUS: 150 / 720 Vdc)

dc

Auxiliary voltage: 24 V

Configurable analog references: 3.2 to 10 V

Max dynamic with encoder: 200 Hz

Switching frequency: 10 kHz

Speed adjustment: 0 to 9999 rpm

Anti-resonance low-pass filter: 20 to 800 Hz

Filter on reference: 1 to 800 Hz

Notch filter (programmable): 50 to 1500 Hz

Output current

Model

Nominal

(A

)

rms

3/9 3 6.4 9 4.5 A

4/12 4 8.5 12 4.5 A

6/15 6 10.6 15 4.5 A

8/22 8 15.6 22 4.5 A

14/42 14 29.7 42 6 B

20/45 20 31.8 45 10 C

25/70 25 49.5 70 10 C

30/90 30 63.6 90 10 C

50/140 50 99.0 140 23 D

60/180 60 127.3 180 23 D

100/300 100 212.7 300 40 E

Tab. 1.0 – Mechanical and electrical characteristics

to 460Vac ±10%, 50/60 Hz

ac

±10% , 1.5A

dc

dc

Max

(A

rms

)

Peak

(A)

Mass

(kg)

Size

1.3

DS2000 USER’S MANUAL (rev.C)

Page 22

1.4

SECTION ONE – DESCRIPTION

1.4.2 CLIMATIC CONDITIONS

1.4.2.1 AMBIENT TEMPERATURE

0°C to +40°C (exceeding EN 60204-1:1997, par.4.4.3).

1.4.2.2 AMBIENT HUMIDITY

5% to 85% with no condensation and no formation of ice (according to EN 50178:1997,

weather protected site).

1.4.2.3 ALTITUDE

The electrical equipment is able to operating correctly at altitudes up to 1000m above sea

level (according to EN 60204-1:1997, par.4.4.5)

1.4.2.4 TRANSPORTATION AND STORAGE

The electrical equipment withstands the effects of transportation and storage

temperatures within a range of –25°C to +55°C and for short periods not exceeding 24 h

at up to +70°C (according to EN 60204-1:1997, par.4.5).

1.4.2.5 POLLUTION

The equipment has been designed according to pollution degree 2, where normally only

non-conductive pollution occurs. Occasionally, however, a temporary conductivity caused

by condensation is to be expected, when the electronic equipment is out of operation.

1.4.3 OTHER MECHANICAL SPECIFICATIONS

1.4.3.1 IMMUNITY TO MECHANICAL VIBRATION

0.075mm amplitude from 10 Hz to 57 Hz, 1g acceleration from 57 Hz to 150 Hz

(according to EN 50178:1997 and to IEC 68-2-6:1995, Fc test).

DS2000 USER’S MANUAL (rev.C)

Page 23

SECTION ONE – DESCRIPTION

1.4.4 INTERFACES

• Analog

Speed (or current) reference differential input: 0 +/- 10V (adjustable scale)

Auxiliary input voltage: 24Vdc ±10%

Output Voltage: 15Vdc

Analog output (configurable)

Tachometric signal (adjustable scale)

Peak current limit (trough adjustable analog signal)

Motor temperature (trough PTC or NTC)

Resolver interface

Sine Encoder Interface (optional)

• Digital

RS485 full-duplex serial link

Encoder input (incremental)

Encoder output (incremental)

Reset

Drive OK output

Drive enable input (torque)

Reference enable input (speed)

CAN BUS (optional)

1.4.5 PROTECTIONS

• Motor over temperature

• Drive over temperature

• Input voltage out of tolerance

• Encoder or resolver signal missed

• Encoder or resolver faulty connections

• Axis short circuit (motor and recovery resistor output)

• Recovery resistor missed (overvoltage)

• Recovery resistor overload (software selectable)

• Over speed in torque mode control (if speed is 12% above max set value).

• IGBT over temperature (software selectable)

• Anti-free-wheeling (software selectable)

• Safety – Restart interlock function (optional).

1.5

DS2000 USER’S MANUAL (rev.C)

Page 24

1.6

SECTION ONE – DESCRIPTION

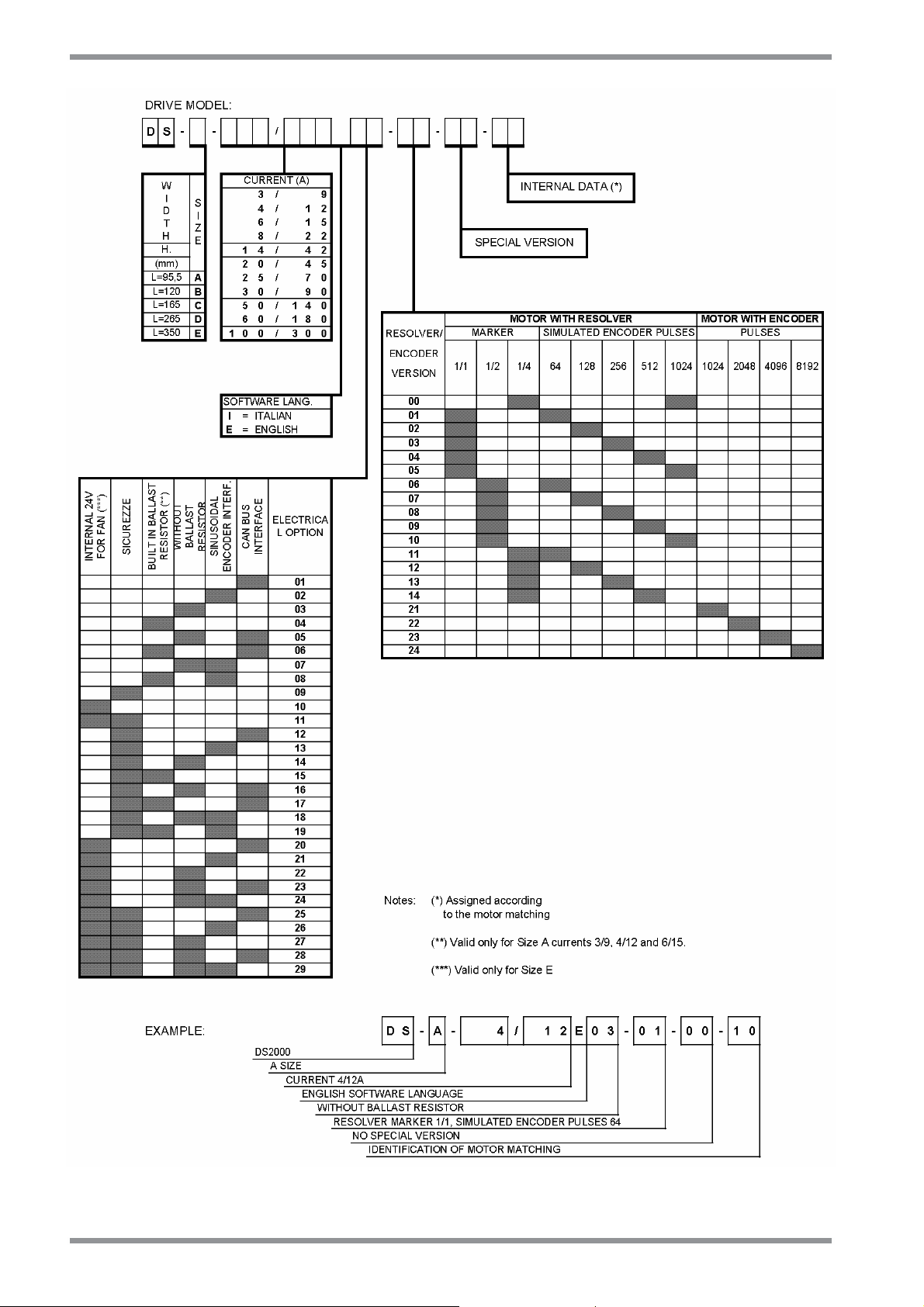

1.5 STANDARD VERSIONS CODES

DS2000 drives are marked by a code identifying both the current supplied by the Model and

the eventual internal recovery resistor.

Codes correspond to:

• Standard Italian software drives

• 6 poles resolver (transformation ratio:0. 29), ¼ marker configured, 1024 simulated

encoder pulses

• External recovery resistor, provided with the drive together with mating connectors.

The following table summarizes the drive codes:

Model

Code Type

CZ1000C0A 3/9 A

CZ1001C0A 4/12 A

CZ1002C0A 6/15 A

CZ1003C0A 8/22 A

CZ1008C0A 14/42 B

CZ1005C0A 20/45 C

CZ1006C0A 25/70 C

CZ1007C0A 30/90 C

CZ1009C0A 50/140 D

CZ1010C0A 60/180 D

CZ1011C0A 100/300 E

Size

Tab. 1.1 – Standard versions codes

Besides the coding in Tab. 1.1, a new coding formed by a descriptive code has been

introduced, which univocally and directly identifies a drive and its configuration.

Fig. 1.1 shows the new codifications .

DS2000 USER’S MANUAL (rev.C)

Page 25

SECTION ONE – DESCRIPTION

1.7

1.6 SPECIAL VERSIONS CODES

For a limited braking power dissipation application, special versions of 3/9, 4/12, and 6/15

Size drives have been realized with built-in recovery resistor. Their codes are different, but all

the other features and the operation remain the same.

Codes correspond to:

• Standard Italian software drives

• 6 poles resolver (transformation ratio:0. 29), ¼ marker configured, 1024 simulated

encoder pulses

• Mating connectors provided with the drive

The following table summarizes the drive codes:

Model

Code Type

CZ1100C0A 3/9 A

CZ1101C0A 4/12 A

CZ1102C0A 6/15 A

Size

Tab. 1.2 – Special versions codes

Additional informations can be found in Section 2 and Section 5.

DS2000 USER’S MANUAL (rev.C)

Page 26

1.8

SECTION ONE – DESCRIPTION

Fig. 1.1 – Table of DS2000 codification

DS2000 USER’S MANUAL (rev.C)

Page 27

SECTION ONE – DESCRIPTION

1.9

1.7 OPTIONS

Optional devices can be built-in or separately supplied.

Built-in drive devices are:

• CAN BUS interface on speed reference (SW Release 4.X00)

• Safety – Restart interlock function

• 24V fans internal power supply (only size E)

Separately supplied devices are:

• RS232/422/485 Converter (Moog code CZ5200)

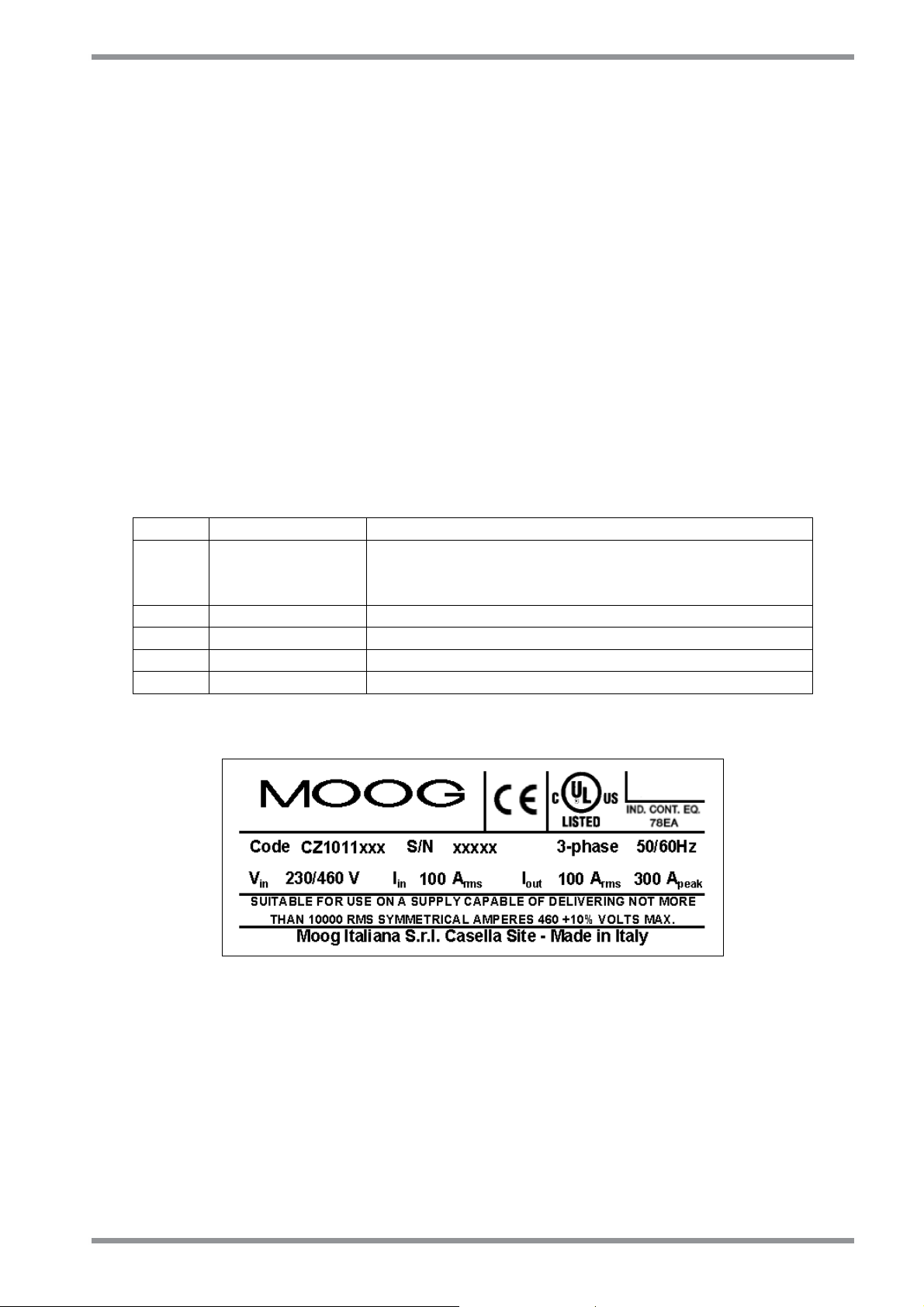

1.8 SERIAL NUMBER – NAMEPLATE

Each drive is provided with a serial number identifying the Model, any eventual option and

the manufacturing date. This number is a useful tool to verify, through the Moog Database,

the original software and firmware revision.

Using these data it is possible to carefully support the final Customers. It is recommended to

take note of the serial number, which is present on each drive, before shipment.

CODE: CZxxxxYYz Product code

S/N: AASSNNNNYYA Serial number, where

AA= year, SS= week, NNNN= progressive number,

YYA= option (C0A= standard version)

Vin: xxx V Input voltage rating

Iin: xxx Arms Nominal effective input current

Iout: xxx Arms Nominal effective output current

Iout: xxx Apeak Output peak max current

Fig. 1.2 – Nameplate

DS2000 USER’S MANUAL (rev.C)

Page 28

1.10

SECTION ONE – DESCRIPTION

THIS PAGE INTENTIONALLY BLANK

DS2000 USER’S MANUAL (rev.C)

Page 29

SECTION TWO – WIRING AND INSTALLATION

2.1

2. GENERAL INFORMATION

2.1 INTRODUCTION

This section describes the installation, wiring and cabling of the Moog DS2000 servo drive

series. Such information allows the understanding of DS2000 functionality and makes clear

the necessary concepts to access the following sections.

DS2000 USER’S MANUAL (rev.C)

Page 30

2.2

SECTION TWO – WIRING AND INSTALLATION

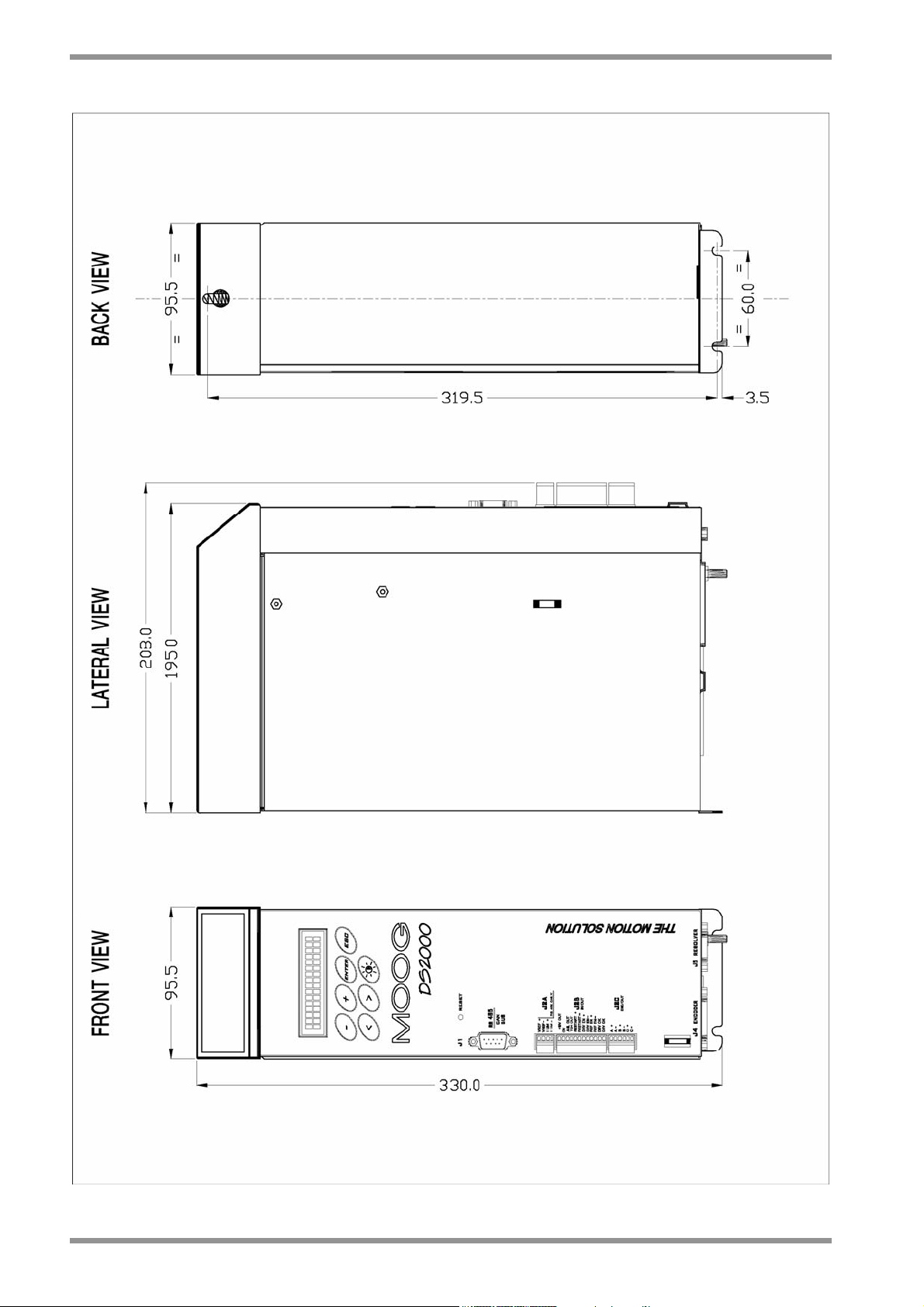

2.2 DIMENSIONS AND DRILLING JIG

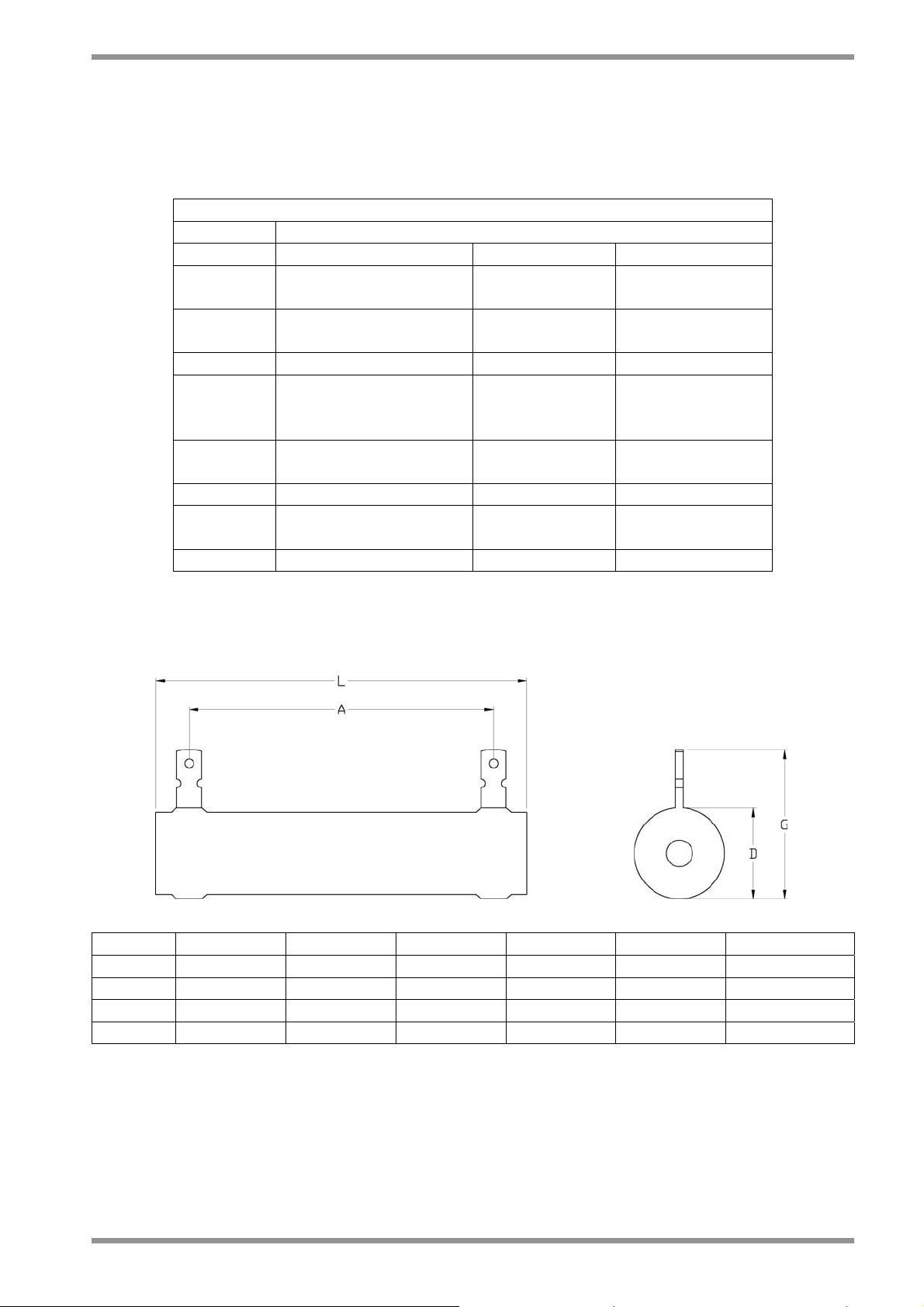

Fig. 2.1 – Size A dimensions and drilling jig (mm)

DS2000 USER’S MANUAL (rev.C)

Page 31

SECTION TWO – WIRING AND INSTALLATION

2.3

Fig. 2.2 – Size B dimensions and drilling jig (mm)

DS2000 USER’S MANUAL (rev.C)

Page 32

2.4

SECTION TWO – WIRING AND INSTALLATION

Fig. 2.3 – Size C dimensions and drilling jig (mm)

DS2000 USER’S MANUAL (rev.C)

Page 33

SECTION TWO – WIRING AND INSTALLATION

2.5

Fig. 2.4 – Size D dimensions and drilling jig (mm)

DS2000 USER’S MANUAL (rev.C)

Page 34

2.6

SECTION TWO – WIRING AND INSTALLATION

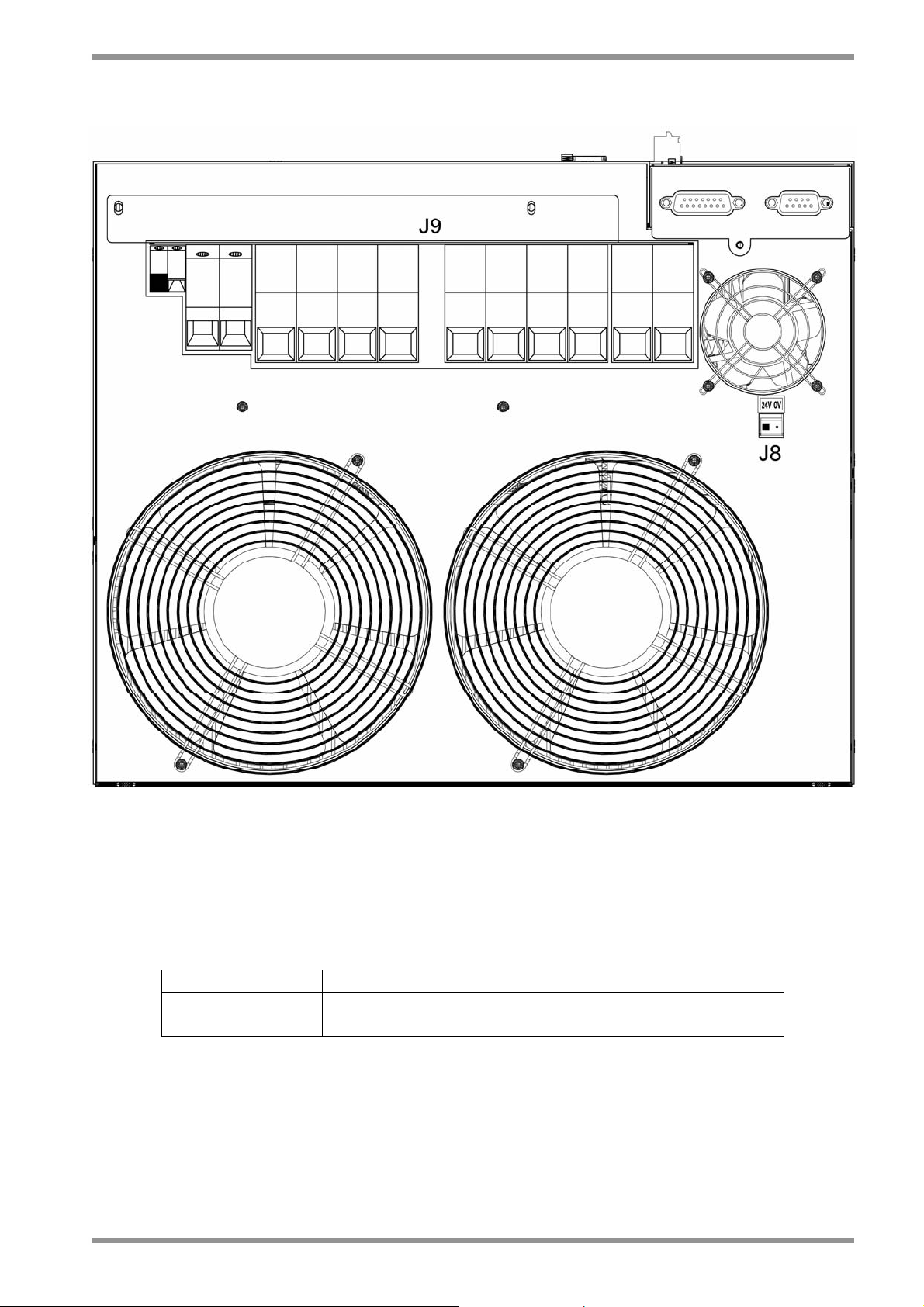

Fig. 2.4.1 – Size E dimensions and drilling jig (mm)

DS2000 USER’S MANUAL (rev.C)

Page 35

SECTION TWO – WIRING AND INSTALLATION

2.7

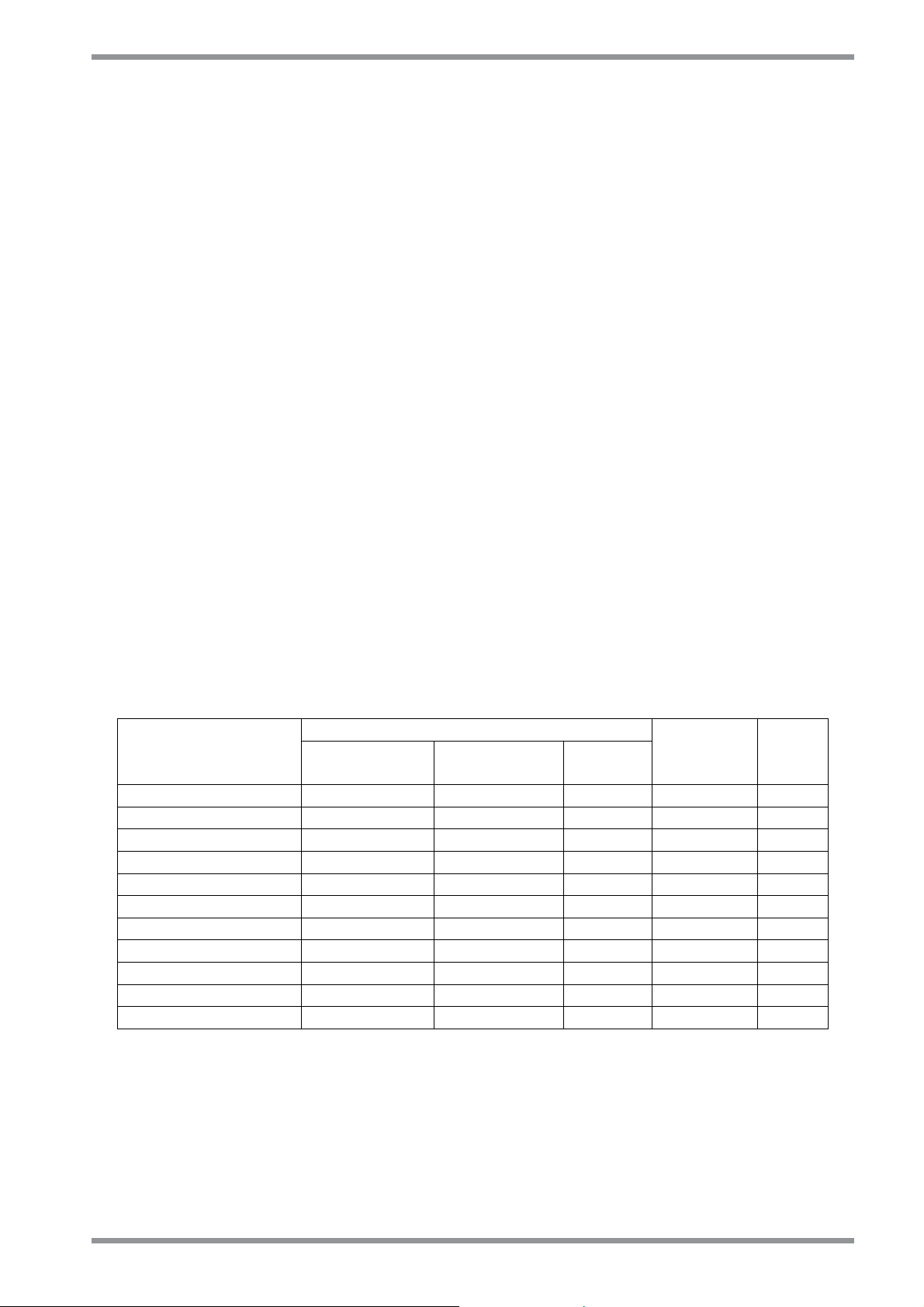

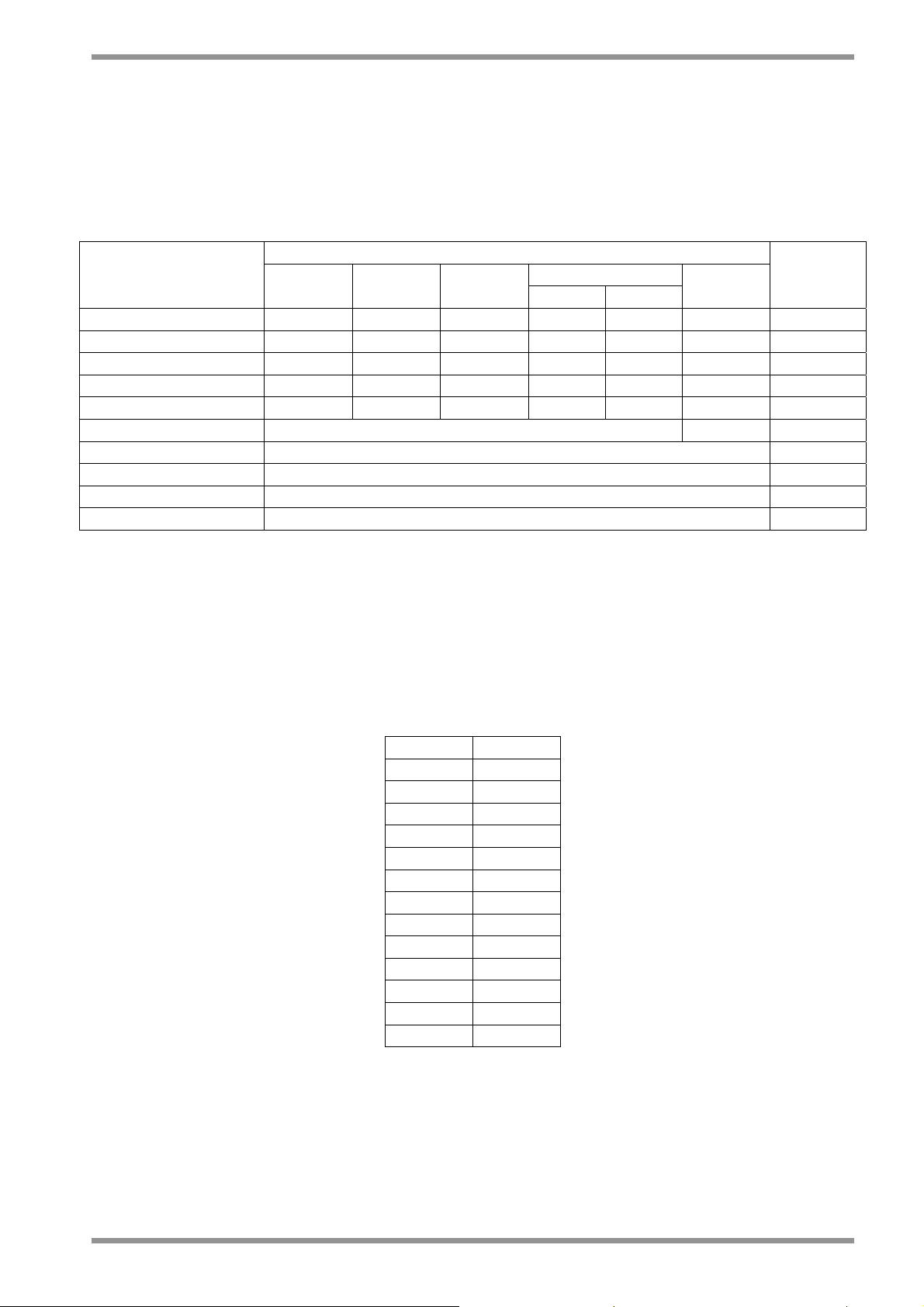

2.3 EXTERNAL FUSES

It is recommended to use the Short Circuit protection in the final application with UL certified

external fuses (cat. JFHR2), manufactured by Bussmann Div. Cooper (UK) Ltd,

semiconductor type, 660 V

As alternate fuses by different manufacturers can be used but UL approved (cat. JFHR2) with

the same data of the fuses shown in table taking care that the Peack-let-trough-current

(A.I.C) and clearing I2T are equal or lower.

3/9 4/12 6/15 8/22 14/42

Short Circuit

Rating

Power line fuse 50 – FE Semiconductor

24 Vdc auxiliary

power supply

fuse

20/45 25/70 30/90 50/140 60/180

Short Circuit

Rating

Power line fuse 100 – FE 160 – FEE Semiconductor

24 Vdc auxiliary

power supply

fuse

, 200 kA symmetrical A.I.C..

ac

DS2000 MODEL

A size B size

5000 rms Amps symmetrical

3A / 250V Delayed

DS2000 MODEL

C size D size

5000 rms Amps

symmetrical

5000 rms

Amps symm.

3A / 250V Delayed

10000 rms

Amps symm.

Notes

Notes

DS2000 MODEL

E size

Notes

100/300

Short Circuit

Rating

10000 rms Amps symmetrical

Power line fuse 315-FM Semiconductor

24 Vdc auxiliary

power supply

3A / 250V Delayed

fuse

Tab. 2.1 – Recommended fuses

DS2000 USER’S MANUAL (rev.C)

Page 36

2.8

SECTION TWO – WIRING AND INSTALLATION

2.4 POWER DISSIPATION

For the thermal sizing of the cabinet in which the drive is installed, it is necessary to refer to

the table. If the application implies continuous braking, it is necessary to add the recovery

resistor power dissipation (use the nominal power if the one required by the application is

unknown).

DS2000 Model Power

3/9 60W

4/12 75W

6/15 90W

8/22 110W

14/42 180W

20/45 250W

25/70 300W

30/90 400W

50/140 650W

60/180 800W

100/300 1200W

Tab. 2.2 – Power dissipation at nominal current

2.5 SOFT-START

The soft-start circuit (current limit at start-up) is included in the drive input stage. Additional

data about the soft-start circuit can be found in the Section 5.

DS2000 USER’S MANUAL (rev.C)

Page 37

SECTION TWO – WIRING AND INSTALLATION

2.9

2.6 RECOVERY CIRCUIT

Standard recovery resistors are in the following table (see Section 5 for additional

informations) :

Dynamic braking unit

DS2000 Standard recovery resistor for 400/460 Vac mains voltage

Model Resistor and power Max Current Max Duty Cycle

3/9

4/12

6/15

8/22

14/42 33Ω/250W (ext.) 22.7A 1.5%

20/45

25/70

30/90

50/140

60/180

100/300 3.9Ω/1000W (ext.) 192.3A 0.7%

3/9

4/12

6/15 56Ω/150W (int.) 13.4A 0.7%

75Ω/100W (ext.) 10A 1.3%

51Ω/200W (ext.) 14.7A 1.8%

12Ω/370W (ext.) 62.5A 0.8%

10Ω/750W (ext.) 75.0A 1.3%

82Ω/150W (int.) 9.1A 1.0%

Tab. 2.3 – Recovery resistor data

Dimensions declared by the supplier are in the following table:

Model 75Ω/100W 51Ω/200W 33Ω/250W 12Ω/370W 10Ω/750W 3.9Ω/1000W

L [mm] 165 ± 2 215 ± 2.5 265 ± 3 265 ± 3 300 ± 5 400 ± 5

A [mm] 150 ± 2 200 ± 2.5 250 ± 3 241 ± 3 270 ± 5 370 ± 5

G [mm] 36 ± 2 46 ± 2 46 ± 2 53 ± 2 88 ± 2 88 ± 2

D [mm] 20.5 ± 1 30.5 ± 1 30.5 ± 1 39 ± 2 76 ± 2 76 ± 2

Tab. 2.4 – Mechanical data of recovery resistor

DS2000 USER’S MANUAL (rev.C)

Page 38

2.10

SECTION TWO – WIRING AND INSTALLATION

2.7 FANS

DS2000 ventilation is provided by one or more fans mounted over the drive and under only

for size E. The fans input power is internally supplied except for size E (option “internal 24V”)

CAUTION: A free air circulation must be ensured for a proper operation as per the following

table..

DS2000

Size

Minimum Clearence Top

(mm)

Minimum Clearence Bottom

(mm)

A 60 100

B 60 100

C 80 160

D 100 200

E 200 300

Tab. 2.5A – Minimum Clearence around DS2000 Drives

2.8 RESET OR RESTART BUTTON

The reset (restart) button is on the drive front panel. It allows the digital control card reinitialization as well as the protections reset.

DS2000 USER’S MANUAL (rev.C)

Page 39

SECTION TWO – WIRING AND INSTALLATION

2.11

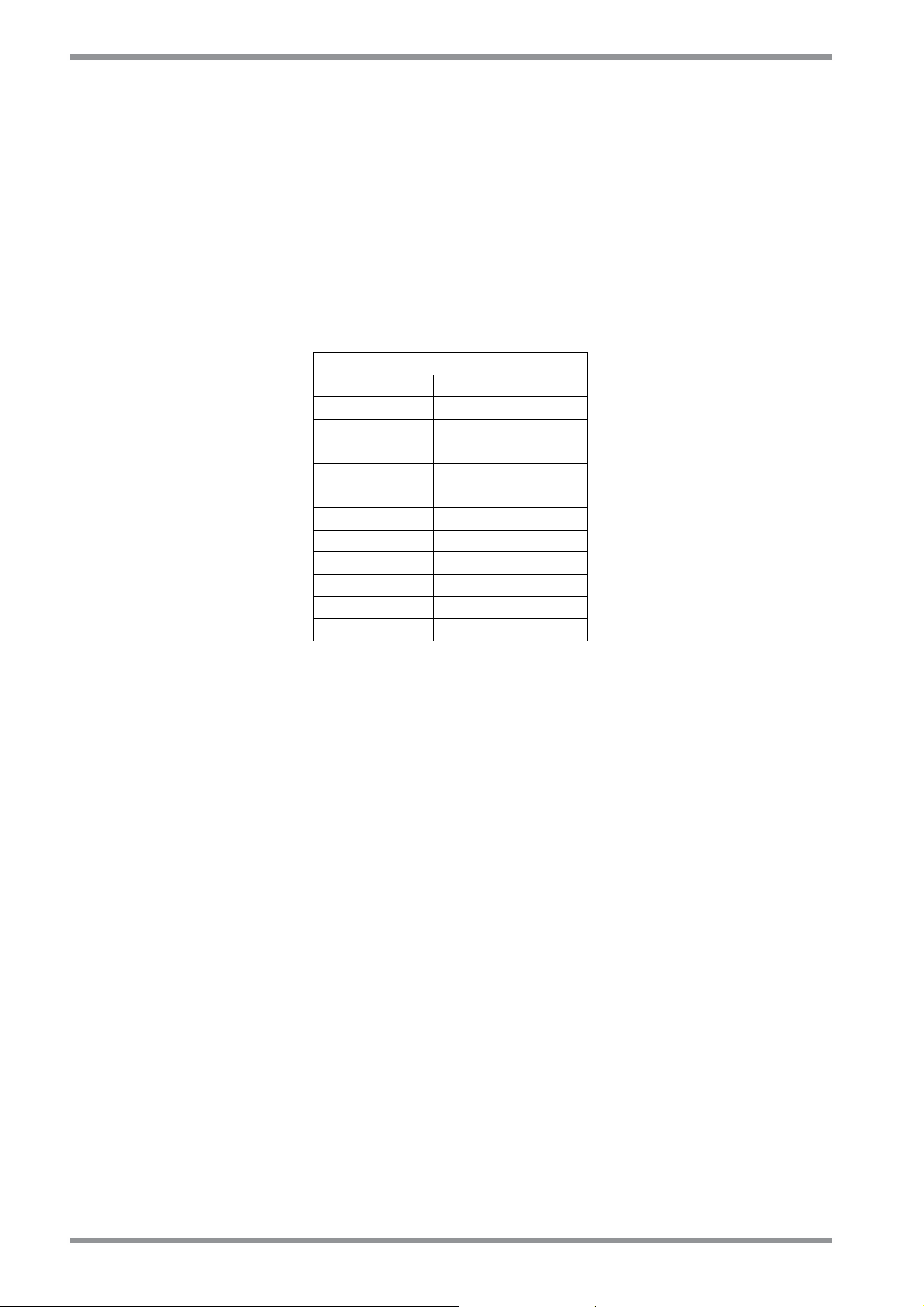

2.9 CONNECTION CABLES

Connection cables must have precise electric characteristics in order to ensure a proper

operation of the servosystem. It is recommended to use copper (Cu) cables, 75°C, UL

certified, according to the cross sections indicated in the table 2.5. The following table shows

the cables specification for each single function.

DS2000 MODEL

Cable

A

Size

B

Size

C

Size

D Size

50/140 60/180

E

Size

Line power 14 AWG 12 AWG 8 AWG 6 AWG 4 AWG 1 AWG

Protective bonding 6 AWG 6 AWG 6 AWG 6 AWG 4 AWG 1 AWG

Motor power cable 14 AWG 12 AWG 8 AWG 6 AWG 4 AWG 1 AWG Shielded

DC BUS (+/-AT) 14 AWG 12 AWG 8 AWG 6 AWG 4 AWG 1 AWG Shielded

Recovery resistor 14 AWG 12 AWG 8 AWG 6 AWG 4 AWG 2 AWG Shielded

24V fans cable 14 AWG Shielded

Restart Interlock 22 AWG Shielded

24V power supply 14 AWG Shielded

Motor encoder 22/20 AWG Shielded

Motor resolver 22/20 AWG Shielded

Notes

Tab. 2.6 – Wiring size

CAUTION: To connect more than one drive through the DC BUS (+/-HV), please ask the

Service Center.

2.10 AWG/mm2 CONVERSION

AWG mm

22 0.3

20 0.5

18 0.8

16 1.3

14 2.1

12 3.3

10 5.3

8 8.4

6 13

4 21

3 27

2 34

1 42

2

Tab. 2.7 – AWG/mm2 conversion

DS2000 USER’S MANUAL (rev.C)

Page 40

2.12

SECTION TWO – WIRING AND INSTALLATION

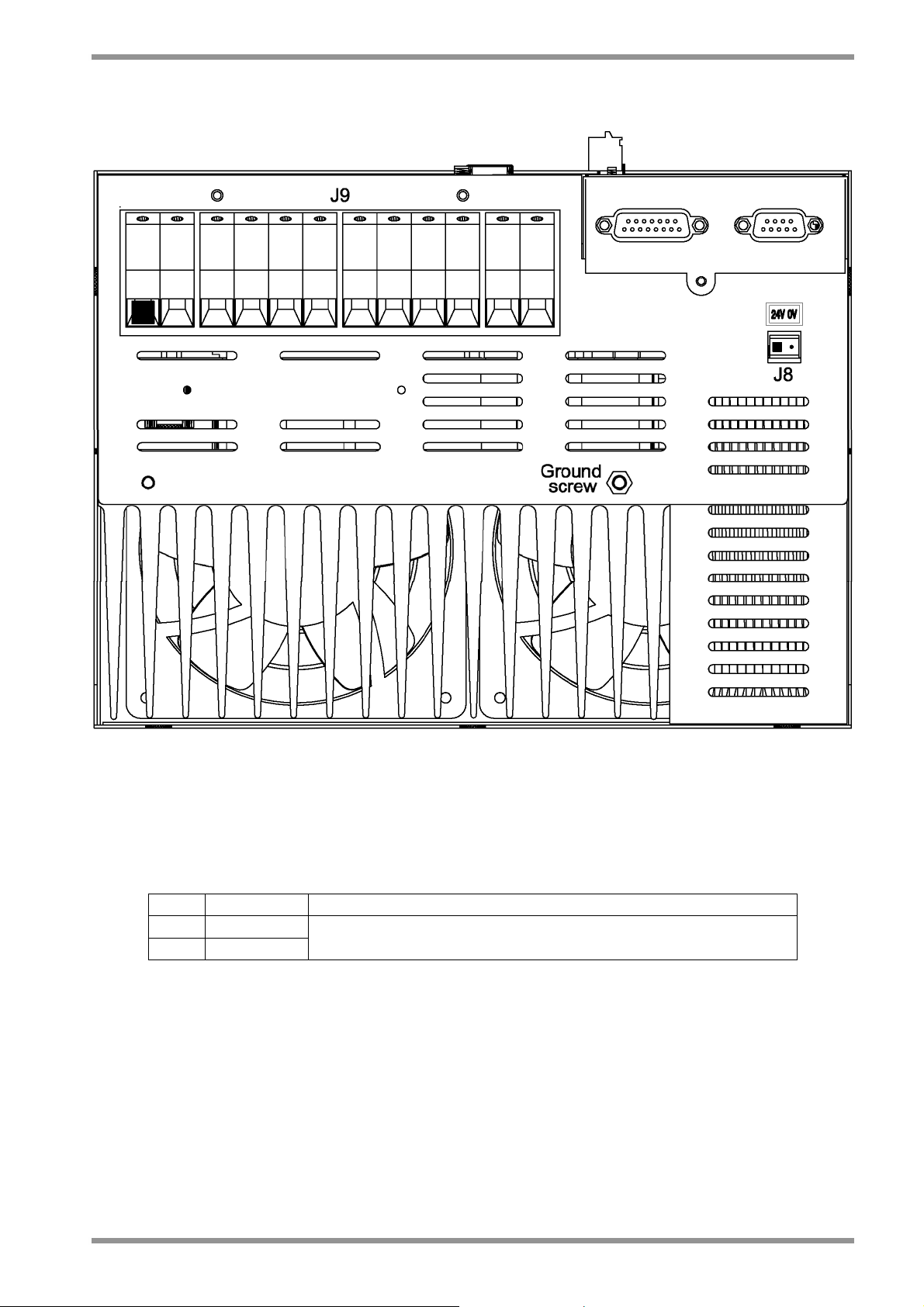

2.11 WIRING AND CONNECTORS

NOTE: Moog DS2000 drives are equipped with all the necessary connectors for a proper

operation. It is not necessary to indicate the connectors, or the recovery resistor in the

purchase order. All of them are included in the drive code.

All the drives (except D size and E size) are equipped with plug-in connectors to ensure a

quick connection of the drive to the switchboard and for Service activities (if applicable).

2.11.1 POWER CONNECTORS

Connectors differ according to the different drive sizes: please, refer to the following

descriptions and tables to detect the corresponding pin configuration; power connectors

bear a pinout label which makes pin detection easier.

2.11.1.1 SIZE A and B POWER CONNECTOR

Note: Pin 1 is marked with the symbol “■”

Fig. 2.5 – Size A and B power connector

• J6 connector

- Mating connector: female. 12 pins, supplied with the drive, model Tyco 1-282960-2 or

1-796981-2 (Moog code AK4987).

Wire stripping: 7 mm. Tightening torque: 0.5Nm.

Pos. Name Function

1 ■ -AT - DC BUS AT

2 RR (+AT) External recovery resistor and +AT of DC BUS

3 RR External recovery resistor

4 U1 Phase "L1", three-phase voltage input 230/460Vac ±10%

5 V1 Phase "L2", three-phase voltage input 230/460Vac ±10%

6 W1 Phase "L3", three-phase voltage input 230/460Vac ±10%

7 GND Motor ground (see also Ground screw)

8 W2 Phase "W2", motor three-phase output

9 V2 Phase "V2", motor three-phase output

10 U2 Phase "U2", motor three-phase output

11 +24V

12 0V (24)

Auxiliary voltage inputs 24 Vdc ±10%, 2A

(pin 12 is connected to drive logic 0)

Tab. 2.8 – J6 connector, size A and B

DS2000 USER’S MANUAL (rev.C)

Page 41

SECTION TWO – WIRING AND INSTALLATION

• Ground screw

Use a lug for M5 screw.

Pos. Name Function

Ground screw GND Equipotential protection circuit.

Tab. 2.9 – Ground screw, size A and B

NOTE: In an especially noisy environment (from an electromagnetic point of view) it can

be useful to connect the motor ground (pin 7 of J6 connector) to the ground screw.

2.13

DS2000 USER’S MANUAL (rev.C)

Page 42

2.14

SECTION TWO – WIRING AND INSTALLATION

2.11.1.2 SIZE C POWER CONNECTOR

Note: Pin 1 is marked with the symbol “■”

Fig. 2.6 – Size C power connector

• J6 connector

- Mating connector: female, 5 pins, crimp, supplied with the drive, model Molex 42816 0512 (Moog code AK4991).

Pos. Name Function

1 ■ W1 Phase "L3", three-phase voltage input 230/460Vac ±10%

2 V1 Phase "L2", three-phase voltage input 230/460Vac ±10%

3 U1 Phase "L1", three-phase voltage input 230/460Vac ±10%

4 RR (+ATP) External recovery resistor and +HV of DC BUS

5 RR External recovery resistor

Tab. 2.10 – J6 input power connector, size C

DS2000 USER’S MANUAL (rev.C)

Page 43

SECTION TWO – WIRING AND INSTALLATION

• J7 connector

- Mating connector: female, 4 pins, crimp, supplied with the drive, model Molex 42816 0412 (Moog code AK4990).

Pos. Name Function

1 ■ U2 Phase "U2", motor three-phase output

2 V2 Phase "V2", motor three-phase output

3 W2 Phase "W2", motor three-phase output

4 GND Motor ground (see also Ground screw)

Tab. 2.11 – J7 output motor power connector, size C

• J8 connector

- Mating connector: female, 2 pins, supplied with the drive, model Wago 231-102/026 000 (Moog code AK4967).

Pos. Name Function

1 ■ +24V

2 0V (24V)

Auxiliary voltage inputs 24 V

±10%, 2A

dc

(pin 2 is connected to drive logic 0)

2.15

Tab. 2.12 – J8 auxiliary input power supply connector, size C

• J9 connector

- Mating connector: female, 2 pins, crimp, supplied with the drive, model Molex 42816 0212 (Moog code AK4989).

Pos. Name Function

1 ■ -AT

2 +AT

DC BUS (see Application Engineer for details)

Tab. 2.13 – J9 DC BUS output connector, size C

• Ground screw

Use a lug for M5 screw.

Pos. Name Function

Ground screw GND Equipotential protection circuit.

Tab. 2.14 – Ground screw, size C

NOTE: In an especially noisy environment (from an electromagnetic point of view) it can

be useful to connect the motor ground (pin 4 of J7 connector) to the ground screw.

DS2000 USER’S MANUAL (rev.C)

Page 44

2.16

SECTION TWO – WIRING AND INSTALLATION

• WIRING NOTES FOR J6, J7, J9 CONNECTORS (SIZE C)

The relevant contacts (Molex type 42815-0031) are supplied together with J6, J7, and J9

mating connectors for C size DS2000 drives. These contacts are sized for an 8 AWG (8.4

mm2) cable with a 10 mm wire stripping. It is recommended the use of a Molex crimping

tool type 63814-0000, or Molex type 63811-1500, or equivalent. The crimping does not

affect the insulating plastic tubing. As an alternative it is possible to sold the contacts,

taking care of folding the contact wings.

After the crimping (or soldering), the contact must be inserted into the Mating connector

following the proper direction and must be kept in position by the TPA (Terminal Position

Assurance) jumper, according to Fig. 2.7.

Fig. 2.7 – Fixing Molex connectors

DS2000 USER’S MANUAL (rev.C)

Page 45

SECTION TWO – WIRING AND INSTALLATION

2.11.1.3 SIZE D POWER CONNECTOR

2.17

Note: Pin 1 is marked with the symbol “■”

Fig. 2.8 – Size D power connector

• J8 connector

- Mating connector: female, 2 pins, supplied with the drive, model Wago 231-102/026 000 (Moog code AK4967).

Pos. Name Function

1 ■ +24V

2 0V (24V)

Auxiliary voltage inputs 24 V

±10%, 2A

dc

(pin 2 is connected to drive logic 0)

Tab. 2.14D – J8 auxiliary input power supply connector, size D

DS2000 USER’S MANUAL (rev.C)

Page 46

2.18

SECTION TWO – WIRING AND INSTALLATION

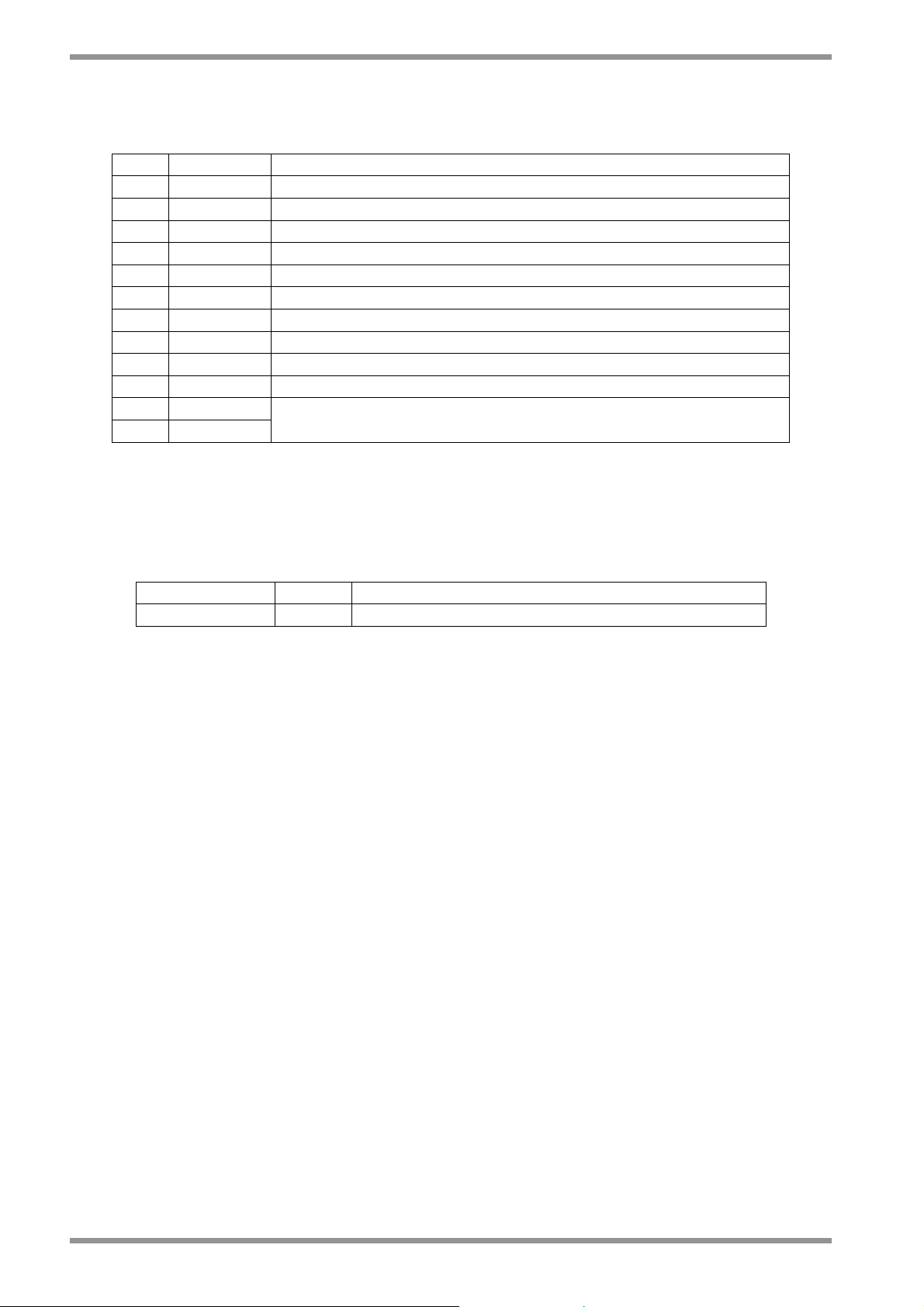

• J9 Terminal block

- Pos.1 to 12 Phoenix - HDFK16: Wire stripping: 16 mm. Tightening torque: 2 Nm.

Pos. Name Function

1 ■ RR External recovery resistor

2 RR (+AT) External recovery resistor and +HV of DC BUS

3 GND Housing ground

4 U1 Phase "L1", three-phase voltage input 230/460Vac ±10%

5 V1 Phase "L2", three-phase voltage input 230/460Vac ±10%

6 W1 Phase "L3", three-phase voltage input 230/460Vac ±10%

7 U2 Phase "U2", motor three-phase output

8 V2 Phase "V2", motor three-phase output

9 W2 Phase "W2", motor three-phase output

10 GND Motor ground

11 +AT

12 -AT

DC BUS (see Application Engineer for details)

Tab. 2.15D – J9 power connector, size D

• Ground screw

Use a lug for M5 screw.

Pos. Name Function

Ground screw GND Equipotential protection circuit.

Tab. 2.16D – Ground screw, size D

NOTE: In an especially noisy environment (from an electromagnetic point of view) it can

be useful to connect the motor ground (terminal 10 of J9 connector) to the ground screw.

DS2000 USER’S MANUAL (rev.C)

Page 47

SECTION TWO – WIRING AND INSTALLATION

2.11.1.3.1 SIZE E POWER CONNECTOR

2.19

Note: Pin 1 is marked with the symbol “■”

Fig. 2.8.1 – Size E power connector

• J8 connector

- Mating connector: female, 2 pins, supplied with the drive, model Wago 231-102/026 000 (Moog code AK4967).

Pos. Name Function

1 ■ +24V

2 0V (24V)

Auxiliary voltage inputs 24 Vdc ±10%, 2A

(pin 2 is connected to drive logic 0)

Tab. 2.14E – J8 auxiliary input power supply connector, size E

DS2000 USER’S MANUAL (rev.C)

Page 48

2.20

SECTION TWO – WIRING AND INSTALLATION

• J9 Terminal block

- Pos. 1,2 Phoenix – HDFK4 : Wire stripping: 9 mm. Tightening torque: 0.7 Nm.

- Pos. 3,4 Phoenix – HDFK25 : Wire stripping: 19 mm. Tightening torque: 4 Nm.

- Pos. 5 to 14 Phoenix – HDFK50 : Wire stripping: 24 mm. Tightening torque: 8 Nm.

Pos. Name Function

1 ■ 24V fans

2 0V fans

Voltage inputs 24V

fans ±10%, 2A

dc

3 RR External recovery resistor

4 RR (+AT) External recovery resistor and +HV of DC BUS

5 GND Housing ground

6 U1 Phase "L1", three-phase voltage input 230/460Vac ±10%

7 V1 Phase "L2", three-phase voltage input 230/460Vac ±10%

8 W1 Phase "L3", three-phase voltage input 230/460Vac ±10%

9 GND Motor ground

10 U2 Phase "U2", motor three-phase output

11 V2 Phase "V2", motor three-phase output

12 W2 Phase "W2", motor three-phase output

13 +AT

14 -AT

DC BUS (see Application Engineer for details)

Tab. 2.15E – J9 power connector, size E

2.11.1.4 POWER WIRING NOTES

It is recommended to use motor phases wiring with low capacitance (max 500 pF/m).

CAUTION: do not parallel power connection cables to achieve requested section: this will

increase the capacitance value at levels that may irreversibly damage the drive. If the

value of capacitance of motor and cables, seen from drive output, exceeds 30 nF it is

necessary to verify with Moog technicians the need of an adequate choke in series.

DS2000 MOTOR

U

V

W

GND

Grounding of shield

via connector clamp

(or RF connection to

metallic PG gland in

case of terminal board)

Grounding of shield

via connector clamp

U2

V2

W2

GND

Fig. 2.9 – Three phase motor supply wiring

DS2000 USER’S MANUAL (rev.C)

Page 49

SECTION TWO – WIRING AND INSTALLATION

2.11.2 CONTROL CONNECTORS

The connectors are common to all drives sizes and are all located on the control card.

2.21

Drive control panel – Frontal view Drive control panel – bottom view

Note: Pin 1 is marked with the symbol “■”

Fig. 2.10 – Control card connectors

DS2000 USER’S MANUAL (rev.C)

Page 50

2.22

SECTION TWO – WIRING AND INSTALLATION

2.11.2.1 RS485 SERIAL LINK (CAN BUS OPTION) (J1)

RS485 serial interface signals are available on the J1 connector. Up to 63 drives can be

connected through the RS 485 serial link (see Section 6 for additional data).

Please contact Service Center if more than 4 (up to 63) drives must be connected.

As an alternative to the serial interface, the J1 connector can contain the CAN BUS serial

interface with the same external connector. For Can Option make reference to the

applicative Can Open manual.

• Mating connector: female, Sub-D 9 pos. (Moog code AK4751)

Pos. Name Function

1 ■ RX+ RX+ (RS485)

2 N.C. Not Connected

3 TX+ TX+ (RS485)

4 N.C. Not Connected

5 N.C. Not Connected

6 RX- RX- (RS485)

7 0V Digital 0V

8 TX- TX- (RS485)

9 N.C. Not Connected

Tab. 2.16 – J1 RS485 serial link

DS2000 USER’S MANUAL (rev.C)

Page 51

SECTION TWO – WIRING AND INSTALLATION

2.11.2.2 INPUT REFERENCES CONNECTOR (J2A)

Analog references (speed and current limit references) are available on the J2A

connector. The conductors are fastened by insertion, opening the connector using a

screwdriver.

• Mating connector: insertion type, 4 poles (Moog code AK4714).

Pos. Name Function

Differential, non-inverted input of speed or torque reference signal (0÷

1 ■

V

Ref

±10V, corresponding to 0÷ ±Max input reference). The end of scale is

+

adjustable via software from ±3.2 to ±10V in steps of 0.1V

2

V

Ref

Differential, inverted input of speed or torque reference signal

-

Differential, non-inverted input of analog current limit (0÷ ±10V,

3

I

limit

corresponding to 0÷ 100%Max set current). The end of scale is adjust-able

+

via software from ±3.2 to ±10V in steps of 0.1V

4

I

limit

Differential, inverted input of analog current limit

-

2.23

Tab. 2.17 – J2A input references connector

CNC-PLC

OUT+

OUT-

Housing

GND

DIFFERENTIAL SIGNALS

CNC-PLC

OUT+

GND_0V

GND

DS2000

1_J2A_V

2_J2A_V

Housing

2_J2B_0V

DS2000

1_J2A_V

2_J2A_V

HousingHousing

2_J2B_0V

Ref

Ref

Ref

Ref

+

-

+

-

SINGLE ENDED SIGNALS

NOTE: J2A and J2B are two different (separate) connectors.

NOTE: shields of cables must be 360° clamped to the cabinet wall

Fig. 2.11 – Example of connections

DS2000 USER’S MANUAL (rev.C)

Page 52

2.24

K

V

SECTION TWO – WIRING AND INSTALLATION

2.11.2.3 DRIVE ENABLE CONNECTOR (J2B)

Drive enable, Drive OK signals, Tacho out, Analog out, and Reference enable are

available on the J2B connector. The conductors are fastened by insertion, opening the

connector using a screwdriver.

• Mating connector: insertion type, 12 pin (Moog code AK4722).

Pos. Name Function

1 ■ +15V OUT +15Vdc output, max 100 mA

2 0V Logic Zero

3 ANL OUT Configurable output (see Analog out configuration)

Tachometric signal output

4 TCH OUT

(0 ÷ ±10V, corresponding to 0 ÷ ± Max speed rpm). The end of scale

is adjustable via software from ±5 to ±10V in steps of 0.1V

5 RESTART+

Opto-insulated Reset input (15 ÷24 Vdc/12mA)

By means of a > 20 ms duration pulse the re-initialization of the

6 RESTART-

7 DRV EN+

8 DRV EN-

9 REF EN+

digital control card and the protections reset are carried out

Opto-insulated Drive Enable input (15 ÷ 24 Vdc/12mA)

When signal is missing the drive does not supply current

Opto-insulated Reference Enable input (15 ÷ 24 V

/12mA)

dc

When signal is missing the motor is in standstill position, at zero

10 REF EN-

speed if in speed control mode, it has zero torque if in torque control

mode. This input can be used for emergency braking

11 DRV OK

Drive OK outputs. Contact closed (24Vdc relays, max 100 mA)

indicates that Drive is OK.

It is recommended to logically connect the DRIVE OK isolated output

12 DRV OK

presence to the power contactor, so that the power supply is disabled

in case of fault

CNC-PLC

+24V

DRIVE O

Tab. 2.18 – J2B drive enable connector

WITH EXTERNAL 24Vdc POWER SUPPLY

24V POWER

SUPPLY

0

DS2000

RST.+

RST.-

DRV. EN.+

DRV. EN.-

REF. EN.+

REF. EN.-

DRV OK

DRV OK

Fig. 2.12 – Example of wiring

WITH INTERNAL ALIMENTATION

DS2000

+15V

0V

RST.+

RST.-

DRV. EN.+

DRV. EN.-

REF. EN.+

REF. EN.-

DS2000 USER’S MANUAL (rev.C)

Page 53

SECTION TWO – WIRING AND INSTALLATION

2.11.2.4 ENCODER OUTPUT CONNECTOR (J2C)

Encoder simulated output are available on the J2C connector. The conductors are

fastened by insertion, opening the connector using a screwdriver.

• Mating connector: insertion type, 6 pin (Moog code AK4716).

Pos. Name Function

1 ■ A+ Encoder output: A channel

2 A- Encoder output: A channel denied

3 B+ Encoder output: B channel

4 B- Encoder output: B channel denied

5 C+ Encoder output: C channel

6 C- Encoder output: C channel denied

Tab. 2.19 – J2C encoder output connector

2.25

DS2000 USER’S MANUAL (rev.C)

Page 54

2.26

SECTION TWO – WIRING AND INSTALLATION

2.11.2.5 ENCODER INPUT CONNECTOR (J4)

NOTES: The motor control encoder is formed by two sections.

• The first one (UVW signals) only generates signals used by the drive to power the

motor phases; this section is defined by the number of motor poles.

• The second one (ABC signals) generates reference signals also available for motion

control through external CNC; the number of pulses in this section is defined according

to final the Customer needs as well as to the application requirements.

All the motor encoder channels and the PTC/NTC for the motor temperature control must

be connected to J4 connector located on the bottom side of the drive. The same

incremental encoder signals are available as output on J2C connector.

The mating encoder connector at drive side is a Sub-D 15 pos., to be soldered (Moog

code AK5221). It is recommended to use a low capacitance, multipolar cable with 22

AWG (0,30 mm2) or 20 AWG (0,50 mm2) conductors, shielded (with 85% min. coverage).

Cable length should not exceed 40 m. It is recommended that the cable and the power

connection cable must be separated through the use of independent duct and by a

distance of 30 cm. It is also recommended not to make intermediate connections on the

encoder cable.

Pos. Name Function

1 ■ +5V +5 Vdc (max 100 mA) output

2 0V Encoder ground and motor PTC/NTC

3 W- Switching signal: W phase denied

4 W+ Switching signal: W phase

5 V+ Switching signal: V phase

6 V- Switching signal: V phase denied

7 A+ A Channel

8 A- A Channel denied

9 C+ C Channel

10 C- C Channel denied

11 U+ Switching signal: U phase

12 U- Switching signal: U phase denied

13 B- B Channel denied

14 B+ B Channel

15 PTC_MOTOR Motor PTC/NTC

Tab. 2.20 – J4 encoder input connector

DS2000 USER’S MANUAL (rev.C)

Page 55

SECTION TWO – WIRING AND INSTALLATION

y

(

)

A

A

V

A

A

2.27

DS2000MOTOR

+5

PTC GND

GND

PTC

+

-

B+

B-

C+

C-

U+

U-

V+

V-

W+

W-

+5V

GND

PTC

+

-

B+

B-

C+

C-

U+

U-

V+

V-

W+

W-

PTC

Shield connected to the

housing by connector clamp

Shield connected to

the housing b

connector shell

Fig. 2.13 – Encoder connections

DS2000 USER’S MANUAL (rev.C)

Page 56

2.28

SECTION TWO – WIRING AND INSTALLATION

2.11.2.5.1 LIMIT SWITCHES CONNECTOR (J4)

When the special software 3.203 is used , the J4 connector becomes the Limit Switches

connector. An option card is needed together with this special software. The encoder cannot

be used as transducer and the ENC/OUT calibration of zero motor function is removed.

See Appendix C for other informations

Pos. Name Function

1 ■ N.C. Not Connected

2 N.C. Not Connected

3 CW LS

Input for CW Limit Switches. Normally connected to +24Vdc.

When the connection to +24Vdc is opened, the CW rotation is disabled.

4 N.C. Not Connected

5 CCW LS

Input for CCW Limit Switches. Normally connected to +24Vdc.

When the connection to +24Vdc is opened, the CCW rotation is disabled.

6 N.C. Not Connected

Input for torque/speed control.

7 Tc/Vc

When connected to +24Vdc the drive is in torque control.

When connected to 0L the drive is in speed control.

8 N.C. Not Connected

9 N.C. Not Connected

10 Common Common input for CW LS, CCW LS and Tc/Vc to be connected to 0L

11 N.C. Not Connected

12 N.C. Not Connected

13 N.C. Not Connected

14 N.C. Not Connected

15 N.C. Not Connected

Tab. 2.20A – J4 Limit Switches connector

DS2000 USER’S MANUAL (rev.C)

Page 57

SECTION TWO – WIRING AND INSTALLATION

2.29

2.11.2.6 RESOLVER CONNECTOR (J5)

All the motor resolver cable and the PTC/NTC for the motor temperature control must be

connected to J5 connector located on the bottom side of the drive.

The mating resolver connector is a male Sub-D 9 pos., to be soldered, provided together

with the drive (Moog code AK5220). It is recommended to use low capacitance, multipolar

cable with 22 AWG (0,30 mm2) or 20 AWG (0,50 mm2) conductors, each pair twisted and

shielded, with an independent overall shield (with 85% min. coverage). Cable length

should not exceed 30 m. It is recommended that the cable and the power connection

cable be separated through the use of independent duct and by a distance of 30 cm. It is

also recommended not to make intermediate connections on the resolver cable.

With the resolver interface it is possible to use the simulated encoder outputs to J2C

connector. The standard pulse of the simulated encoder is 1024 (number of 64, 128, 256

or 512 is selectable via keypad). The standard width of the marker is 90° (width of 180° or

360° is selectable via keypad).

NOTE: DS2000 can be interface with resolvers with the following transformer ratios :

0.23, 0.26, 0.29, 0.47 e 0.50.

The two calibration resistors must have the correct value (the drive is pre-set in factory

in according to the motor, see the trasformation rating in the information sheet-Casella

report- of the drive).

In case of replacement/change of the application, verify the right calibration of DS2000.

If not please ask the Moog Service Center

Pos. Name Function

1 ■ COS+

2 COS-

Differential COS signal non-inverted input amplifier proceeding

from resolver windings.

Differential COS signal inverted input amplifier proceeding from

resolver windings.

3 SHIELD Shield (internally connected to 0V)

4 SEN+

5 SEN-

Differential SEN signal non-inverted input amplifier proceeding

from resolver windings.

Differential SEN signal inverted input amplifier proceeding from

resolver windings.

6 PTC_MOTOR Motor PTC/NTC input

7 10kHz-

10 kHz, 20 V

primary resolver winding.

sinusoidal “denied” output signal for supplying

pp

8 PTC_MOTOR Motor PTC/NTC input

9 10kHz+

10 kHz, 20 V

resolver winding (carrier).

sinusoidal output signal for supplying primary

pp

Tab. 2.21 – J5 resolver connector

DS2000 USER’S MANUAL (rev.C)

Page 58

2.30

SECTION TWO – WIRING AND INSTALLATION

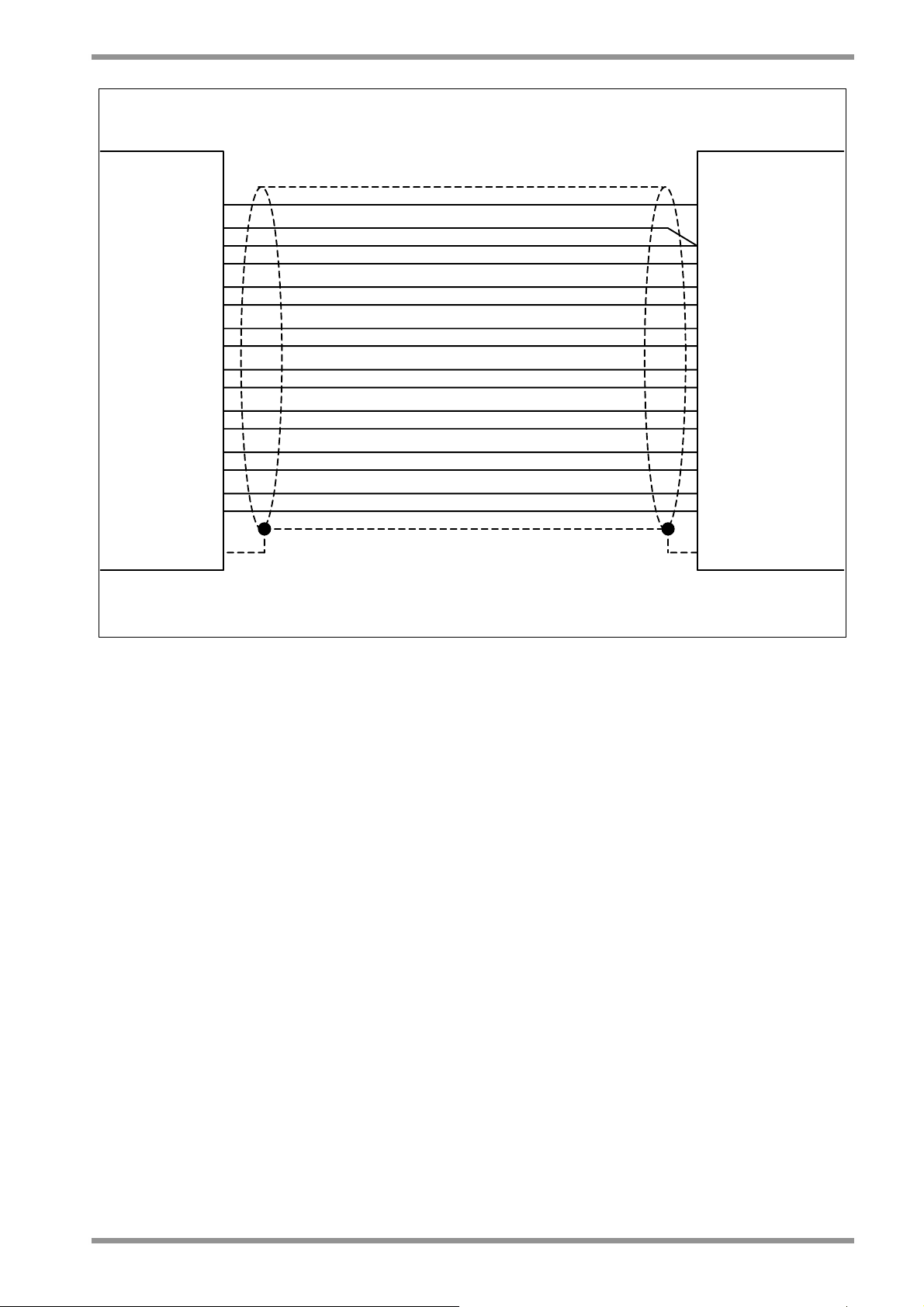

Fig. 2.14 – Resolver connections

DS2000 USER’S MANUAL (rev.C)

Page 59

SECTION TWO – WIRING AND INSTALLATION

2.11.3 MOTOR CONNECTION

2.11.3.1 FAS T/FAS K/FAS N/FAS Y/FAE CONNECTION

MOTOR RESOLVER CONNECTOR

SIGNAL

TYPE

2.31

COS- E 2

COS+ C 1

SHIELD S 3

SEN- H 12

SEN+ G 11

PTC_MOTOR N 8

10kHz- B 7

PTC_MOTOR A 9

10kHz+ D 10

Tab. 2.22 – Resolver connectors

MOTOR ENCODER CONNECTOR

SIGNAL

TYPE

+5V A

0V B and V

W- C

W+ D

V+ E

V- F

A+ G

A- H

C+ J

C- K

U+ L

U- M

B- N

B+ P

PTC_MOTOR R

Tab. 2.23 – Encoder connector

DS2000 USER’S MANUAL (rev.C)

Page 60

2.32

SECTION TWO – WIRING AND INSTALLATION

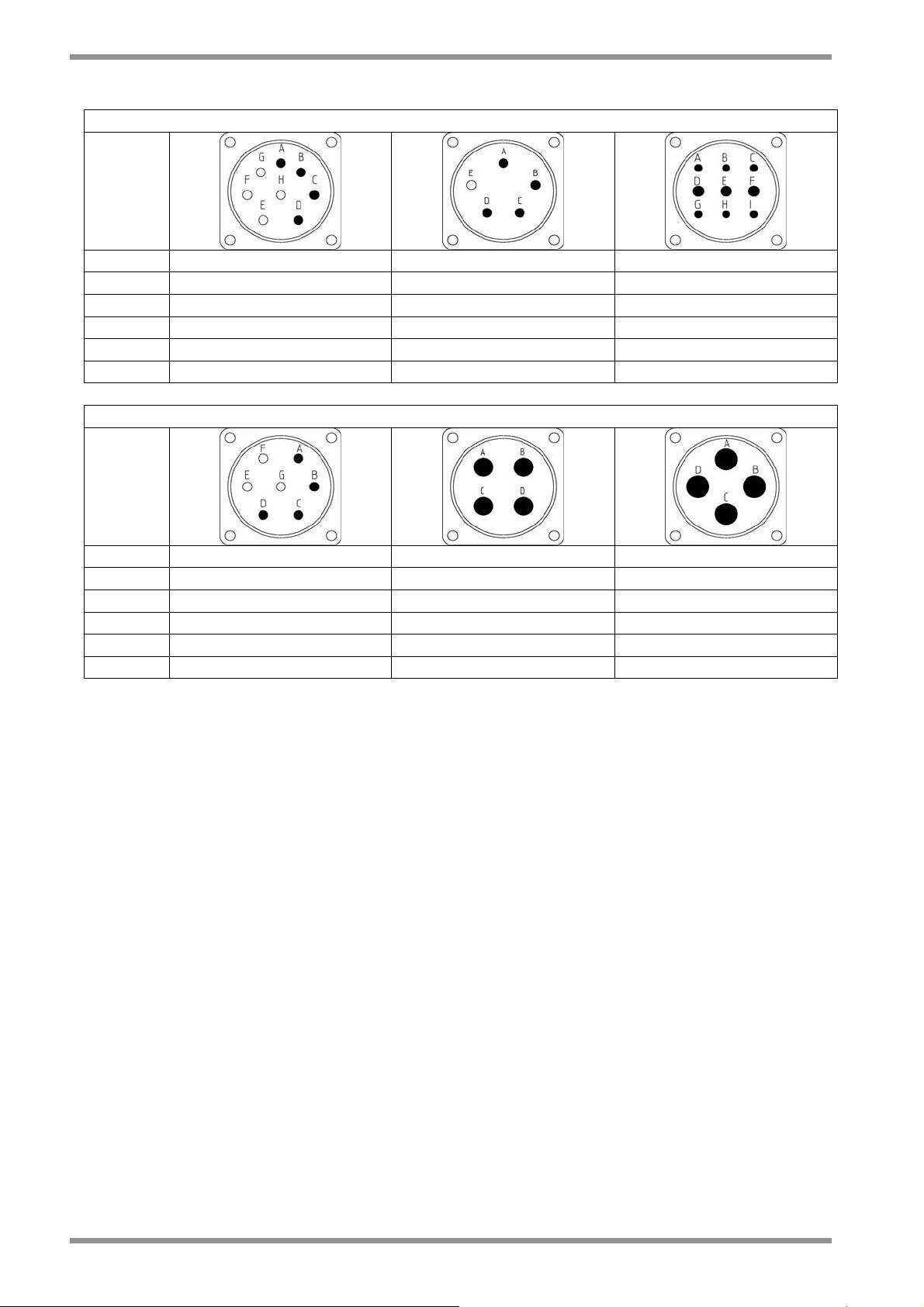

MOTOR POWER CONNECTOR

SIGNAL

TYPE

U A A D

V B B E

W C C F

GND D D G

PTC - - H

PTC - - I

MOTOR POWER CONNECTOR

SIGNAL

TYPE

U A A A

V B B B

W C C C

GND D D D

PTC - - PTC - - -

Tab. 2.24 – Power connectors

DS2000 USER’S MANUAL (rev.C)

Page 61

SECTION TWO – WIRING AND INSTALLATION

2.33

2.11.3.2

G MOTOR CONNECTION

To standardize the resolver connection it is recommended for the new applications to use

the new resolver connection scheme of Tab.2.25A.

RESOLVER CONNECTION

Drive resolver connector

Pin No.

Name Pin name

Motor resolver connector

on G motor

Pin No.

1 ■ COS+ S2 3

2 COS- S4 4

3 SHIELD

4 SEN+ S1 1

5 SEN- S3 2

6 PTC_MOTOR THERM 1 5

7 10kHz- R2 8

8 PTC_MOTOR THERM 2 6

9 10kHz+ R1 7

Tab.2.25A – New resolver connection scheme

The old resolver connection scheme shown in the previous revisions of this Manual and

reprinted in Tab. 2.25B is still valid.

CAUTION: It is recommended not to change the old connections in case of retrofitting

motors or drives.

RESOLVER CONNECTION

Drive resolver connector

Pin No.

Name Pin Name on

Motor resolver connector

G motor

Pin No.

1 ■ COS+ S4 4

2 COS- S2 3

3 SHIELD

4 SEN+ S3 2

5 SEN- S1 1

6 PTC_MOTOR THERM 1 5

7 10kHz- R2 8

8 PTC_MOTOR THERM 2 6

9 10kHz+ R1 7

Tab.2.25B – Old resolver connection scheme

DS2000 USER’S MANUAL (rev.C)

Page 62

2.34

SECTION TWO – WIRING AND INSTALLATION

The ground (pin 3, drive side) has to be connected to the motor connector housing.

Several motor G have as standard a NTC for thermal feedback, the DS2000 can manage

PTC sensor or NTC sensor without any hardware change (see Section 6 for additional

data).

The resolver is looked mechanically: the customer has to perform the AUTOPHASING

with the drive utilities, checking that the value for the APHAPOS parameter is

–209 (±5Units) for 8 poles motor with 2 poles resolver or 45 (±5Units) for 12 poles motor

with 2 poles resolver (see Section 6 for additional informations).

MOTOR POWER CONNECTOR

DS2000

GND GND GND GND

U 2 U U

V 4 V V

W 1 W W

Tab. 2.26 – Power connector

DS2000 USER’S MANUAL (rev.C)

Page 63

SECTION TWO – WIRING AND INSTALLATION

2.35

2.12 DRIVE STARTING SEQUENCE

In order to properly power and enable DS2000 “The Motion Solution” series drives, it is

necessary to follow a start-up sequence, in which the minimum times to fall within are

indicated in order to allow the internal circuits to reach the operating voltage levels and to

make the internal devices ready for enabling.

The chart here below summarizes the start-up sequence and describes the possible reasons

for delays:

• t

Time delay required for the following operations:

1

Switching on of the 24V power supplier and input voltages stabilization

Program loading and logic circuits initialisation

Internal protections check carried out by the internal microprocessor

• t

Reset pulse to allow the reading of reference voltages, as well as the internal offsets

2

initialisation with already stabilized voltages.

Time needed by the drive to allow the program start-up after the reset.

• t

3

• t

Charge time of DC BUS capacitors determined by the soft-start circuit and DC BUS

4

voltage stabilization in order to avoid start-up self induction currents

• t

Time for DRIVE OK acquisition by the control

5

• t

Time to allow the Drive to reach the torque and to check the proper operation of power

6

stages.

The respect of the times indicated in Fig. 2.15 is important to avoid wrong FAULT indications

by the drive.

NOTE: The internal soft-start resistors are sized for a start-up occurring every 60 s. Lower

times cause an excessive stress and can cause the breakdown of such resistors.

DS2000 USER’S MANUAL (rev.C)

Page 64

2.36

SECTION TWO – WIRING AND INSTALLATION

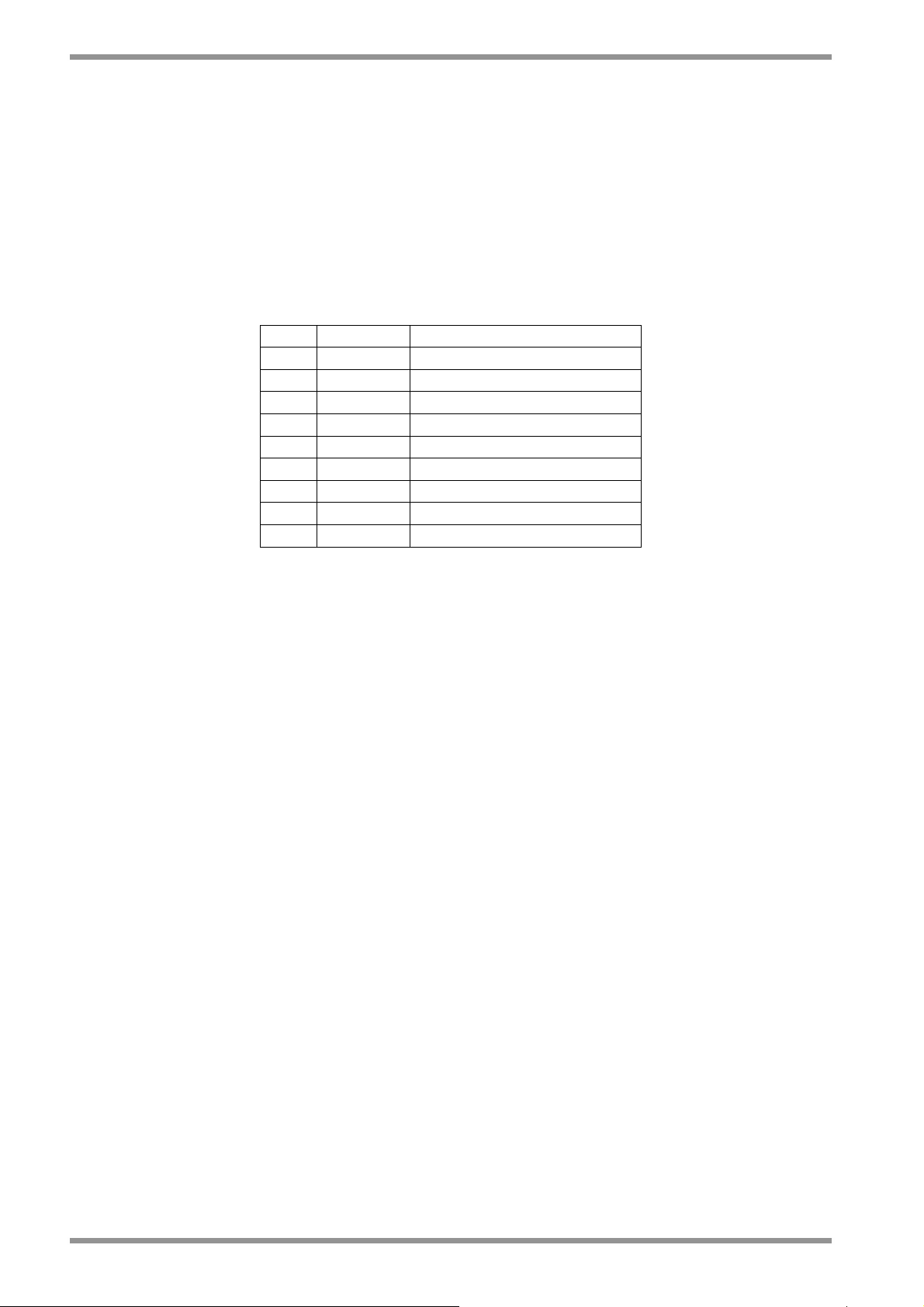

2.13 STARTING SEQUENCE TIMES

t

≥ 3 s, t2 ≥ 100 ms., t3 ≥ 1 s, t4 = 3 s, t5 ≥ 100 ms., t6 ≥ 100 ms.

1

t

1

t

2

t

3

t

4

t

t

5

6

24Vdc

RESET

(restart)

pulse

230/460

V

ac

Three-phase

DRIVE OK

DRIVE

ENABLE

REFERENCE

ENABLE

Fig. 2.15 – Starting sequence times

NOTES:

• Reset pulse generates a complete initialization of the card with all the voltages already

stabilized; this allows a more careful reading of the voltages and a better compensation of

internal offsets.

• In case the auxiliary voltage (24V

) is missing, give the RESET pulse (for a time greater

dc

than 100 ms) after at least 3 seconds from the moment in which the drive is supplied by

three-phase voltage.

• RESET is necessary only after the first drive start-up or, in case of FAULT, to restore the

proper operation of drive.

• DRIVE OK signal depends upon the three-phase voltage presence, in order to allow a

quick and immediate enabling of motor torque.

DS2000 USER’S MANUAL (rev.C)

Page 65

SECTION TWO – WIRING AND INSTALLATION

2.37

2.14 DYNAMIC BRAKING

It is possible to execute a dynamic braking with the help of the motor torque, even in

emergency condition, if the drive is not in FAULT conditions: it is necessary to follow the

sequence times. At braking request, the REFERENCE ENABLE is removed and the motor

brakes with all the available torque.

• t

after 100 ms (this time can be increased in case load inertia is much bigger than motor

1

inertia) the DRIVE ENABLE can be removed

t

= 100 ms

1

Fig. 2.16 – Dynamic braking sequence times

DS2000 USER’S MANUAL (rev.C)

Page 66

2.38

SECTION TWO – WIRING AND INSTALLATION

2.15 POWER OFF

It is necessary to follow the power-off sequence times.

• t

after 100 ms (this time can be increased in case load inertia is much bigger than motor

1

inertia) the DRIVE ENABLE can be removed

• t

Three-phase input voltage release delayed time in order to avoid the undervoltage

2

FAULT.

• t

DC BUS discharge time

3

t

= 100 ms, t2 = 15 ms, t3 = 6 min. (to access the drive).

1

t

1

t

2

t

3

Fig. 2.17 – Power-off sequence times

REFERENCE

ENABLE

DRIVE

ENABLE

230/460

V

ac

Three-phase

DS2000 USER’S MANUAL (rev.C)

Page 67

SECTION TWO – WIRING AND INSTALLATION

2.39

2.16 MECHANICAL BRAKING

The FASTACT series motors have an optional electromagnetic brake with pressure springs

to be supplied with 24 V

CAUTION: the brake must be used only for standing (with motor at standstill). The use of this

brake for dynamic braking seriously damages the brake and reduces the braking torque.

Note 1: t

≥ 300 ms, t2 = application depending, t3 = 100 ms, t4 ≥ 200 ms

1

Note 2: For FASTACT motors, size 3 and size 4, t

t

1

nominal voltage (24 to 26 Vdc) at the motor terminal.

dc

≥ 1000 ms

1

t

t

2

t

3

4

ON

OFF

ON

OFF

RELEASE

CLAMP

0V

0 rpm

DRIVE

ENABLE

24V BRAKE

POWER SUPPLY

BRAKE

REFERENCE

ENABLE

MOTOR

SPEED

Fig. 2.18 – Mechanical braking sequence times

DS2000 USER’S MANUAL (rev.C)

Page 68

2.40

SECTION TWO – WIRING AND INSTALLATION

THIS PAGE INTENTIONALLY BLANK

DS2000 USER’S MANUAL (rev.C)

Page 69

SECTION THREE – ELECTROMAGNETIC COMPATIBILITY (EMC)

3.1

3. ELECTROMAGNETIC COMPATIBILITY (EMC)

3.1 INTRODUCTION

In this section are described the recommended drive installation procedure following EMC

standards. EMC filters are described in the 3.3 par. and the grounding and screening in the

3.4 par. and following. The installer of the drive is responsible for ensuring compliance with

the EMC regulations that apply where the drive is to be used.

3.2 EUROPEAN DIRECTIVE (89/336/EEC)

Compliance with the European Directive 89/336/EEC is required for all electric and electronic

products brought onto the European market after December 31st, 1995.

DS2000 drives meet the following EMC product standard related to the Directive:

EN 61800-3:1996 and EN 61800-3/A11:2000: "Adjustable speed electrical power drive

systems. Part 3: EMC product standard including specific test methods".

Second environment (industrial) compatibility levels.

Tests have been made in an independent test house.

3.3 FILTERS

3.3.1 FILTER TYPES

Trade-mark

Schaffner

FN2070-3-06

Schaffner

FN 258-7/07

Schaffner

FN 258-16/07

Schaffner

FN 258-30/07

Schaffner

FN 258-42/07

Schaffner

FN 258-55/07

Schaffner

FN 258-100/35

Rated current [A]

at 50°C (40°C)

(3) 250 24Vdc input

7 (8.4) 3x480

16 (19.2) 3x480 DS2000 14/42

30 (36) 3x480

42 (50.4) 3x480 DS2000 50/140

55 (66) 3x480 DS2000 60/180

100 (113) 3x480 DS2000 100/300

Max Voltage [Vac]

at 50°C

Drive type / input

DS2000 3/9

DS2000 4/12

DS2000 6/15

DS2000 8/22

DS2000 20/45

DS2000 25/70

DS2000 30/90

Tab. 3.1 – Filter types

DS2000 USER’S MANUAL (rev.C)

Page 70

3.2

SECTION THREE – ELECTROMAGNETIC COMPATIBILITY (EMC)

3.3.2 FILTER SIZING

The filter/drive coupling in the previous table is a standard application coupling. The filter

can be undersized according to the rms input current of the actual application. This should

be done not only because, as a mat-ter of fact, undersizing the filter means less money, but

because the undersized filter provides better performance to EMC.

3.3.3 FILTER DIMENSIONS

Top View

Side View

Trade-mark

Schaffner

FN2070-3-06*

Schaffner

FN 250-6/07*

Schaffner

FN 250-12/07*

Schaffner

FN 258-7/07

Schaffner

FN 258-16/07

Schaffner

FN 258-30/07

Schaffner

FN 258-42/07

Schaffner

FN 258-55/07

Schaffner

FN 258-75/34

Schaffner

FN 258-100/35

L1 L2 L3 L4 L5 L6 L7

85 75 54 0 65 40.3 faston 0.25

85 75 54 0 65 30 300 0.24

85 75 54 0 65 40 300 0.31

255 240 50 25

305 290 55 30

335 320 60 35 305 150 400 1.8

329 314 70 45 300 185 500 2.8

329 314 80 55 300 185 500 3.1

329 314 80 55 300 220

379

±1.5

364

Dimensions [mm]

90

±0.8

65

225

±0.8

275

±0.8

350

±1.2

126

±0.8

142

±0.8

220

±1.5

300 1.1

300 1.7

Terminal

block

Terminal

block

* = the FN2070-3-06 filter have faston at both sides

* = the FN250-6/07 filter have wiring leads (length=300mm) at both sides

* = the FN250-12/07 filter have wiring leads (length=300mm) at both sides

Weight

[kg]

4

5.5

Tab. 3.2 – Filter dimensions

DS2000 USER’S MANUAL (rev.C)

Page 71

SECTION THREE – ELECTROMAGNETIC COMPATIBILITY (EMC)

3.3.4 FILTER INSTALLATION

The filter must be mounted on the same drive panel.

CAUTION: leave a clear space at least 60mm around the filter for air circulation when the

cabinet does not have forced ventilation.

The filter must be connected as close as possible to the cabinet input. If the separation

between filter and drive exceeds around 30 cm (1 ft.) then a shielded cable should be used

for the RF connection between filter and drive.

NOTE: when mounting the drive and the filter to the panel, it is essential that any paint or

other covering material be removed before mounting the drive and the filter.

The maximum torque of mounting screws at terminal block is as follows:

FILTER Max torque

FN 258 - 7/07 0.8 Nm

FN 258 - 16/07 0.8 Nm

FN 258 - 30/07 1.8 Nm

FN 258 - 42/07 1.8 Nm

FN 258 - 55/07 3.0 Nm

FN 258 - 75/34 3.0 Nm

FN 258 - 100/35 4.0 Nm

3.3

Tab. 3.3 – Maximum torque of mounting screws at terminal block

WARNING: the filter can produce high leakage currents (see Filter Data Sheets)

WARNING: the filter must be connected to ground before connecting the supply