Page 1

MRJ06301 Rev. Orig.

DigiPack

Ⅲ

Parison Wall Thickness Controller

J141-215

INSTALLATION,

MAINTENANCE

AND

USER’S MANUAL

Page 2

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

I

MRJ06301

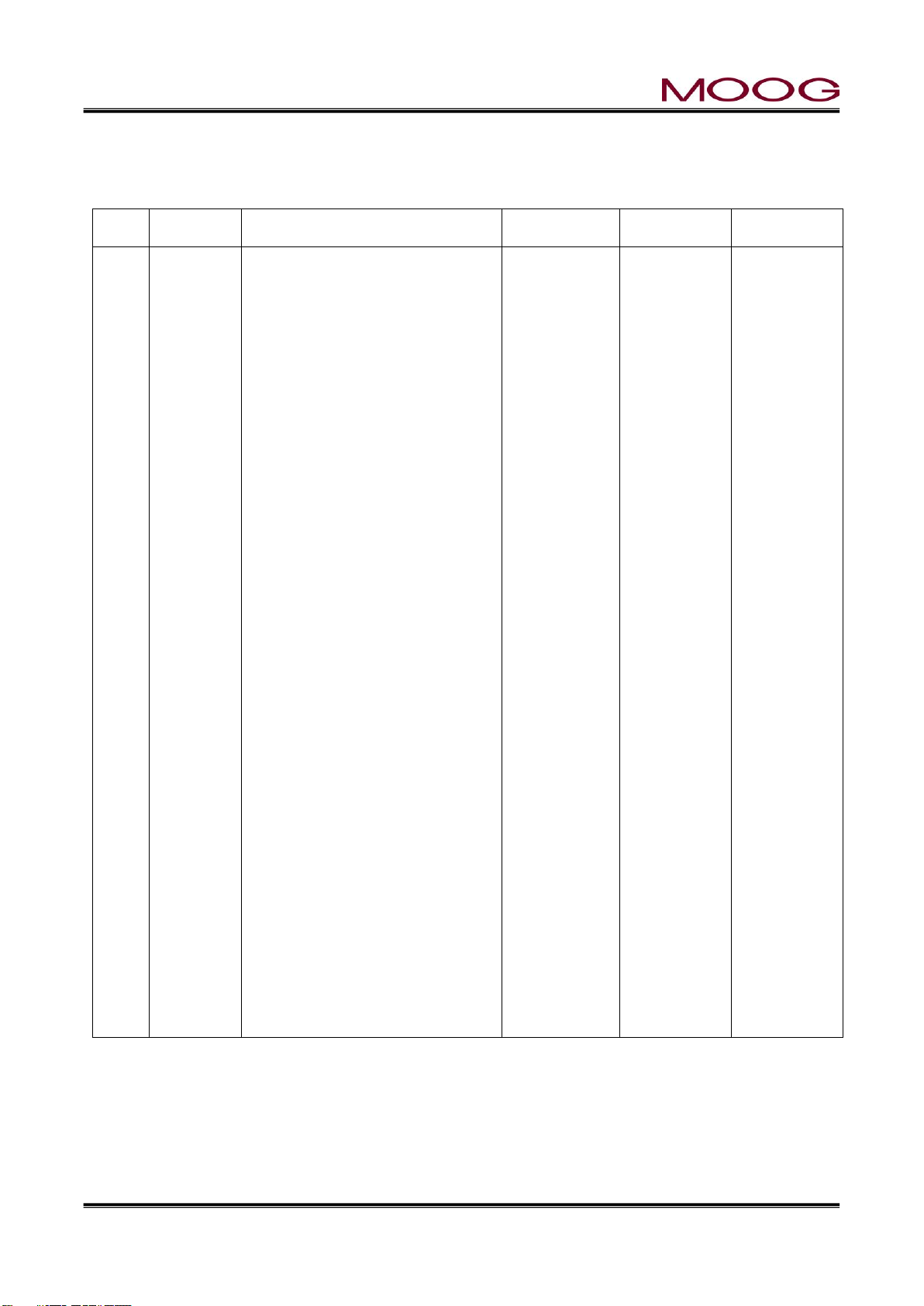

RECORD OF CHANGES

Rev.

Page

Description

Prepared

Checked

Approved

Orig.

New Model Release(EOJ20210)

T. Kouda

15, Mar’19

T.Shimizu

15, Mar ‘19

K.Mashino

29,Mar’19

Page 3

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

II

MRJ06301

MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND

This technical Document contains information that is proprietary to, and is the express property of Moog Inc., or Moog Inc. subsidiaries

except as expressly granted by contract or by operation of law and is restricted to use by only Moog employees and other persons

authorized in writing by Moog or as expressly granted by contract or by operation of law. No portion of this Data/Drawing/Document

shall be reproduced or disclosed or copied or furnished in whole or in part to others or used by others for any purpose whatsoever

except as specifically authorized in writing by Moog Inc.

NOTES TO USERS

(1) Description in this manual is subject to change without any obligation on the part of the Manufac-

turer.

(2) Notice would be appreciated if you find any question, omission or error in this manual.

(3) Disassembly, maintenance or repair, other than in accordance with the instruction herein or other

specific written instruction from MOOG will invalidate MOOG’s obligations under its warranty.

Refer to MOOG warranty for complete previsions thereof.

SAFETY INSTRUCTION

Description in this manual is essential to the safety of life and property, therefore, before operating

this equipment, you should first thoroughly read this manual, and this manual should be kept in accessible for when you have any questions.

WARNING

This symbol with the word “WARNING” is used to call attention to safety instructions

concerning a potential hazard to people. Failure to comply with these safety instructions

can result in serious damage to health and can even prove fatal in extreme cases.

CAUTION

This symbol with the word “CAUTION” is used to call attention to instructions concerning

potential damage to the equipment or to the system as a whole.

NOTE

Notes contain useful information to the operator when starting up and operating the equipment or system.

MOOG JAPAN LTD.

1-8-37 NishiShindo, Hiratsuka, Japan 254-0019

Tel:+81-463-55-7141 Fax:+81-463-54-4709

Page 4

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

III

MRJ06301

EN 61000-6-2:2005

IEC61000-4-2~6

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards

- Immunity for industrial environments

EN61000-6-4:2007+A1:2011

Industrial, scientific and medical equipment - Radio-frequency disturbance characteristics - Limits and methods of measurement

About EMC Standard

1. Safety standard

Notes to certified of EC directive

J141-215 DigiPackⅢ is a device incorporated in customer's equipment (blow molding machine) and we

are conducting EMC test against EC Directive within the scope of embedded equipment, but the J141-215

DigiPackⅢ use by itself is not compatible with the EC Directive.

When customer completes the equipment with J141-215 and use it within Europe or shipment to the area

within European region as the final product, please be sure to check certified of EC Directive by customer

self.

Applicable directive and relative standard.

J141-215 is conducting the EMC test conforming to the EC directive below. It shows directives and related

standards.

EC Directive: EMC Directive 2014/30/EU

Relative Standard:

2. Measures EMC

In order to applicable EMC directive, please takes suitable measure against EMC with a customer's blow

molding machine.

And also, when include J141-215 in apparatus and it is used, please consider wire connection and grounding.

The cable used for each wire connection recommends use of a shielded cable.

A shielded cable should be connected to the terminal of J141-215, and the length of skin wire processing

should be less than 100 mm.

Page 5

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

IV

MRJ06301

TABLE OF CONTENTS

1. DigiPackⅢ Manual, Installation and Maintenance .............................................................................. 1

1-1. CHANGES FROM J141-214A ......................................................................................................... 1

1-2. INTRODUCTION .............................................................................................................................. 2

1-2-1. GENERAL DESCRIPTION.............................................................................................. 2

1-2-2. WHO CAN INSTALL THE DigiPackⅢ ............................................................................. 5

1-2-3. INSTALLATION TIME ..................................................................................................... 6

1-2-4. SOFTWARE UPDATE .................................................................................................... 6

1-2-5. BACKUP BATTERY ........................................................................................................ 7

1-2-6. SCREEN DISPLAY PROTECTION (password) ............................................................... 7

1-2-7. DATA TRANSFER FROM DigiPackⅡ ............................................................................. 7

1-3. DigiPackⅢ SPECIFICATION .......................................................................................................... 8

1-4. CHECK LIST .................................................................................................................................... 9

1-4-1. INSTALLATION CHECK LIST ......................................................................................... 9

1-5. MECHANICAL INSTALLATION ..................................................................................................... 10

1-5-1. GENERAL .....................................................................................................................10

1-5-2. TOOLING ADJUSTMENT .............................................................................................. 11

1-5-3. MOOG DIE GAP TOOLING ACTUATORS .....................................................................12

1-5-4. CYLINDER INSTALLATION ...........................................................................................12

1-5-5. CUSTOMER SUPPLIED CYLINDER REQUIREMENTS ................................................13

1-5-6. TOOLING ADJUSTMENT ..............................................................................................14

1-5-7. ACCUMULATOR POSITION MEASUREMENT .............................................................14

1-5-8. THE IMPORTANCE OF FILTRATION ............................................................................15

1-5-9. FILTER INSTALLATION .................................................................................................15

1-5-10. HYDRAULIC POWER SUPPLY ...................................................................................16

1-5-11. HYDRAULIC POWER SUPPLY START UP INSTRUCTIONS ......................................16

1-5-12. CONTAMINATION CONTROL ..................................................................................... 17

1-6. ELECTRICAL INSTALLATION ....................................................................................................... 18

1-6-1. GENERAL .....................................................................................................................18

1-6-2. REAR CONNECTOR .....................................................................................................18

1-6-3. TB-1, TB-2 WIRING .......................................................................................................19

1-6-4. COMMUNICATION AND SSI SNSOR WIRING..............................................................19

1-6-5. TB-2 I/O CIRCUITRY ................................................................................................ .....25

1-6-6. TB-3: POWER SUPPLY .................................................................................................26

1-6-7. NOISE AND GROUND ISOLATION ...............................................................................26

Page 6

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

V

MRJ06301

1-7. CALIBRATION OF TOUCH SCREEN ........................................................................................... 29

1-8. DigiPackⅢ front panel .................................................................................................................. 30

1-9. TOOLING SYSTEM SETUP .......................................................................................................... 32

1-9-1. GENERAL OF SETUP ................................................................................................ ...32

1-9-2. MACHINE SETTING ......................................................................................................32

1-9-3. SET UP PROCEDURE ..................................................................................................35

2. DigiPackⅢ Manual, User operation .................................................................................................. 43

2-1. INTRODUCTION ............................................................................................................................ 43

2-2. PARISON CONTROL..................................................................................................................... 44

2-2-1. HISTORY .......................................................................................................................44

2-2-2. PARISON PROGRAMMING BENEFITS ........................................................................44

2-2-3. CONTINUOUS EXTRUSION MACHINES .....................................................................44

2-2-4. ACCUMULATOR MACHINES ........................................................................................44

2-2-5. PARISON PROGRAMMING BENEFITS ........................................................................45

2-2-6. WITH ACCUMULATOR BLOW MOLDING MACHINES .................................................46

2-2-7. WITH CONTINUOUS BLOW MOLDING MACHINES ....................................................46

2-2-8. PARISON MOLD ALIGNMENT ......................................................................................47

2-3. MAN MACHINE INTERFACE ........................................................................................................ 48

2-3-1. OPERATOR CONTROL .................................................................................................48

2-3-2. INPUT FUNCTION .........................................................................................................48

2-3-3. FUNCTIONS ..................................................................................................................51

2-3-4. STATE MONITORING AREA .........................................................................................51

2-3-5. EDIT AREA ....................................................................................................................52

2-4. SCREENS OF EDIT AREA ............................................................................................................ 53

2-4-1. EDITING METHOD ........................................................................................................53

2-4-2. F1: Profile Mode ............................................................................................................54

2-4-3. F2: Marker Mode ...........................................................................................................59

2-4-4. F3: File Mode .................................................................................................................61

2-4-5. F4: Monitor Mode ...........................................................................................................65

2-4-6. F5: Data Display Mode ..................................................................................................66

2-4-7. SHIFT→F1: Set Up Mode ..............................................................................................67

2-4-8. SHIFT→F2: Analog monitor ...........................................................................................67

2-4-9. SHIFT→F3: File delete and Backup/Restore .................................................................68

2-4-10. SHIFT→F4: Machine Setup .........................................................................................69

2-4-11. SHIFT→F5: Communication Mode ...............................................................................70

2-5. COMMUNICATION PROTOCOL ................................................................................................... 71

2-5-1. EtherNET COMMUNICATION SPECIFICATION ............................................................71

Page 7

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

VI

MRJ06301

2-5-2. PROFILE .......................................................................................................................71

2-5-3. WAVE ............................................................................................................................73

2-5-4. MONITOR ......................................................................................................................73

2-5-5. INFORMATION DATA ....................................................................................................73

2-5-6. INTERFACE CONTROL ................................................................................................74

2-5-7. OTHER ..........................................................................................................................76

2-5-8. ERROR CODE ..............................................................................................................76

2-5-9. ADC/DAC CHANNEL ................................................................................................ .....76

2-6. PROFILE DATA LIST ..................................................................................................................... 77

2-7. SETTING UP .................................................................................................................................. 78

2-7-1. OBJECTIVE ................................ ................................................................ ...................78

2-7-2. DIE GAP TOOLING SETUP ...........................................................................................78

2-7-3. PRELIMINARY SET UP .................................................................................................79

2-7-4. INITIAL TRIALS .............................................................................................................80

Reference Drawings

CC70353 ---------- Installation

CC70355---------- Customer Wiring

Page 8

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

VII

MRJ06301

Table of Figure

Figure 1-1 DigiPackⅢ appearance - - - - - - Page 2

Figure 1-2 Basic Continuous Blow Molding Machine Control Diagram- - - Page 3

Figure 1-3 Basic Accumulator Machine Control Diagram- - - - Page 4

Figure 1-4 Start up Display - - - - - - - Page 6

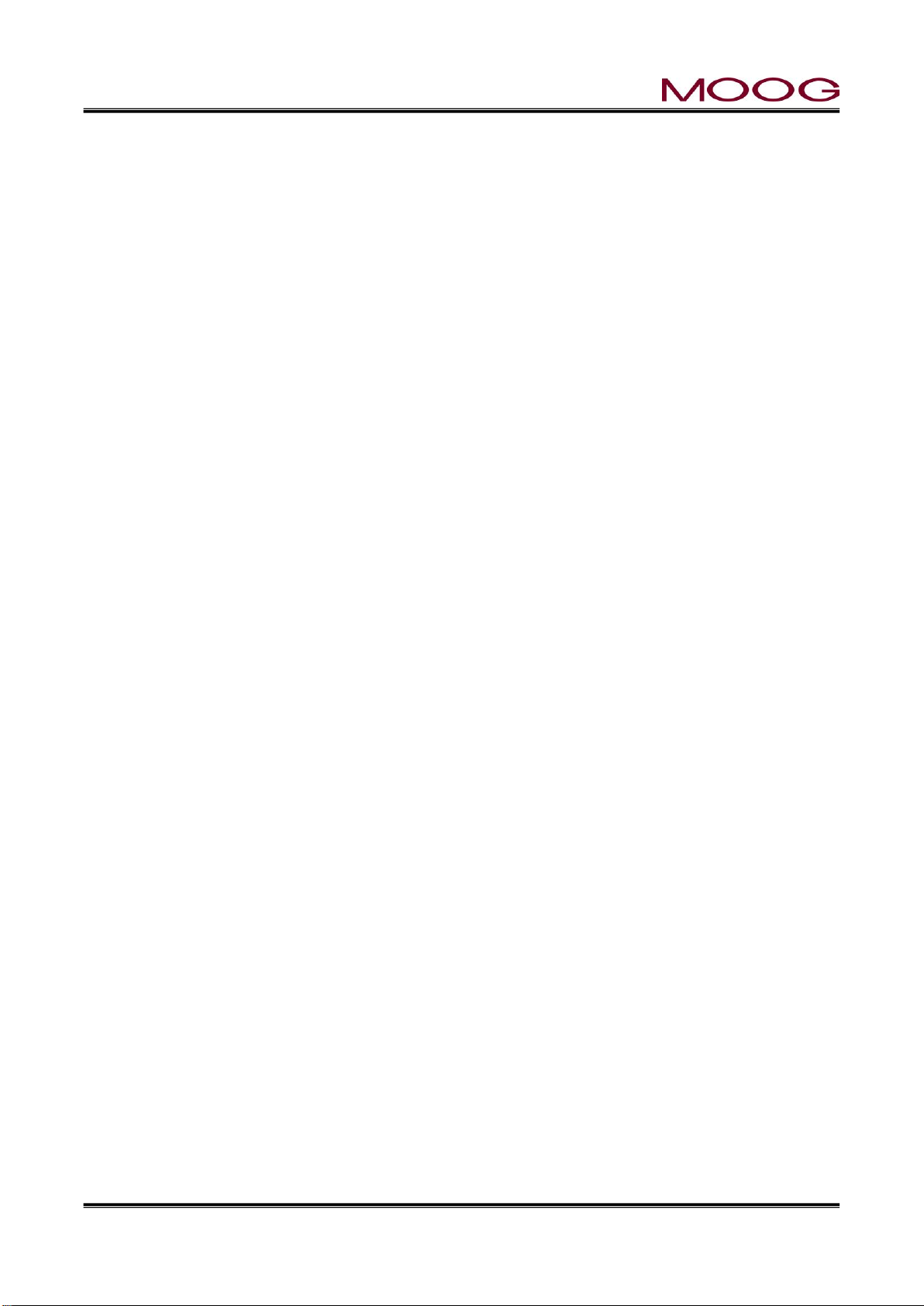

Figure 1-5 Die Gap Tooling Actuator Installation - - - - Page 10

Figure 1-6 Die Gap Tooling Actuator - - - - - - Page 10

Figure 1-7 Actuator – Die Gap Tooling Mechanical Adjustment - - - Page 11

Figure 1-8 Tooling Adjustment Mechanism - - - - - Page 11

Figure 1-9 Typical Cylinder Installation - - - - - Page 12

Figure 1-10 G631-XXX Servovalve - - - - - - Page 13

Figure 1-11 Typical Linear Potentiometer - - - - - Page 14

Figure 1-12 LWHxxx Potentiometer Installation- - - - - Page 14

Figure 1-13 High Pressure Filter - - - - - - Page 15

Figure 1-14 Hydraulic Power Supply - - - - - Page 16

Figure 1-15 Flow Pressure Filter - - - - - - Page 17

Figure 1-16 REAR CONNECTOR - - - - - - Page 18

Figure 1-17 DigiPackⅢ Installation Drawing - - - - - Page 20

Figure 1-18 ServoValve and Transducer Phasing- - - - - Page 21

Figure 1-19 TB-1 Connections - - - - - - Page 21

Figure 1-20 TB-1 Functions - - - - - - Page 22

Figure 1-21 TB-2 Connection - - - - - - Page 23

Figure 1-22 TB-2 Connection - - - - - - Page 23

Figure 1-23 TB-2 Functions - - - - - - Page 24

Figure 1-24 Input use external Power supply - - - - - Page 25

Figure 1-25 Input use internal Power supply - - - - - Page 25

Figure 1-26 Output use external Power supply - - - - Page 25

Figure 1-27 Output use internal Power supply- - - - - Page 25

Figure 1-28 Power supply Connections - - - - - Page 26

Figure 1-29 Accumulator Machine Timing chart - - - - Page 27

Figure 1-30 Continuous Machine Timing chart - - - - Page 28

Figure 1-31 Touch screen Calibration - - - - - Page 29

Figure 1-32 Touch screen calibration display - - - - - Page 29

Figure 1-33 DigiPackⅢ Flont panel - - - - - - Page 30

Figure 1-34 Machine setup display (SHIFT→F4) - - - - Page 33

Figure 1-35 Machine setting Functions - - - - - Page 33

Figure 1-36 Example of profile points change - - - - - Page 34

Figure 1-37 Setup screen - - - - - - - Page 35

Figure 1-38 Die Converge/Diverge Setup- - - - - - Page 35

Figure 1-39 Die Gap Setup - - - - - - - Page 36

Figure 1-40 DCDT Noise Filter - - - - - - Page 36

Figure 1-41 Die Gap Span Setting - - - - - - Page 37

Figure 1-42 Back - - - - - - - - Page 38

Figure 1-43 Gain select - - - - - - - Page 39

Figure 1-44 Gain setting - - - - - - - Page 39

Figure 1-45 Accumulator Setup - - - - - - Page 40

Figure 1-46 EMPTY Accumulator Set Up - - - - - Page 40

Figure 1-47 FULL Accumulator Set Up - - - - - Page 41

Figure 1-48 Extrusion Fixed- - - - - - - Page 41

Figure 1-49 Filling Fixed - - - - - - - Page 41

Figure 1-50 Accumulator setting (Back) - - - - - Page 42

Page 9

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

VIII

MRJ06301

Figure 2-1 DigiPackⅢ appearance - - - - - - Page 43

Figure 2-2 Section of an Un-programmed Parison and the Resulting Container Walls Page 45

Figure 2-3 Section of a Programmed Parison and the Resulting Container Walls - Page 45

Figure 2-4 Poor Vertical Alignment Between the Parison and the Mold - - Page 47

Figure 2-5 Good Vertical Alignment Between the Parison and the Mold. - - Page 47

Figure 2-6 DigiPackⅢ Front panel - - - - - - Page 48

Figure 2-7 Ten key on the screen (1) - - - - - Page 49

Figure 2-8 Ten key on the screen (2) - - - - - Page 49

Figure 2-9 Status indicator - - - - - - - Page 52

Figure 2-10 F1: Profile mode Screen - - - - - Page 53

Figure 2-11 Profile Mode Screen - - - - - - Page 54

Figure 2-12 0%Weight Change - - - - - - Page 56

Figure 2-13 (-)23.3% Weight Change - - - - - Page 56

Figure 2-14 0% Range H - - - - - - - Page 57

Figure 2-15 (+)25.0% Range H Change - - - - - Page 57

Figure 2-16 0% Range L - - - - - - - Page 58

Figure 2-17 (-)20.0% Range L - - - - - - Page 58

Figure 2-18 Marker Mode Screen - - - - - - Page 59

Figure 2-19 Slope Timing - - - - - - - Page 60

Figure 2-20 File Mode Selection Screen - - - - - Page 61

Figure 2-21 Select SAVE - - - - - - - Page 61

Figure 2-22 File Description Data-Page 1 - - - - - Page 62

Figure 2-23 File Description Data-Page 2 - - - - - Page 62

Figure 2-24 File Description Data-Page 3 - - - - - Page 62

Figure 2-25 Edit File name - - - - - - - Page 63

Figure 2-26 Change File Number - - - - - - Page 63

Figure 2-27 Initial Load Screen - - - - - - Page 64

Figure 2-28 File Load - - - - - - - Page 64

Figure 2-29 F4: Monito screen - - - - - - Page 65

Figure 2-30 Data Display Screen A - - - - - - Page 66

Figure 2-31 Data Display Screen B - - - - - - Page 66

Figure 2-32 Data Display Screen C - - - - - - Page 66

Figure 2-33 [SHIFT]→[F1]: Setup Screen - - - - - Page 67

Figure 2-34 [SHIFT]→[F2]: Analog Monitor Screen- - - - - Page 67

Figure 2-35 [SHIFT]→[F3]: File delete and Backup - - - - Page 68

Figure 2-36 File Delete - - - - - - - Page 69

Figure 2-37 [SHIFT]→[F4]: Machine Setup Screen - - - - Page 69

Figure 2-38 [SHIFT]→[F5]: Communication Mode Screen - - - Page 70

Page 10

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

1

MRJ06301

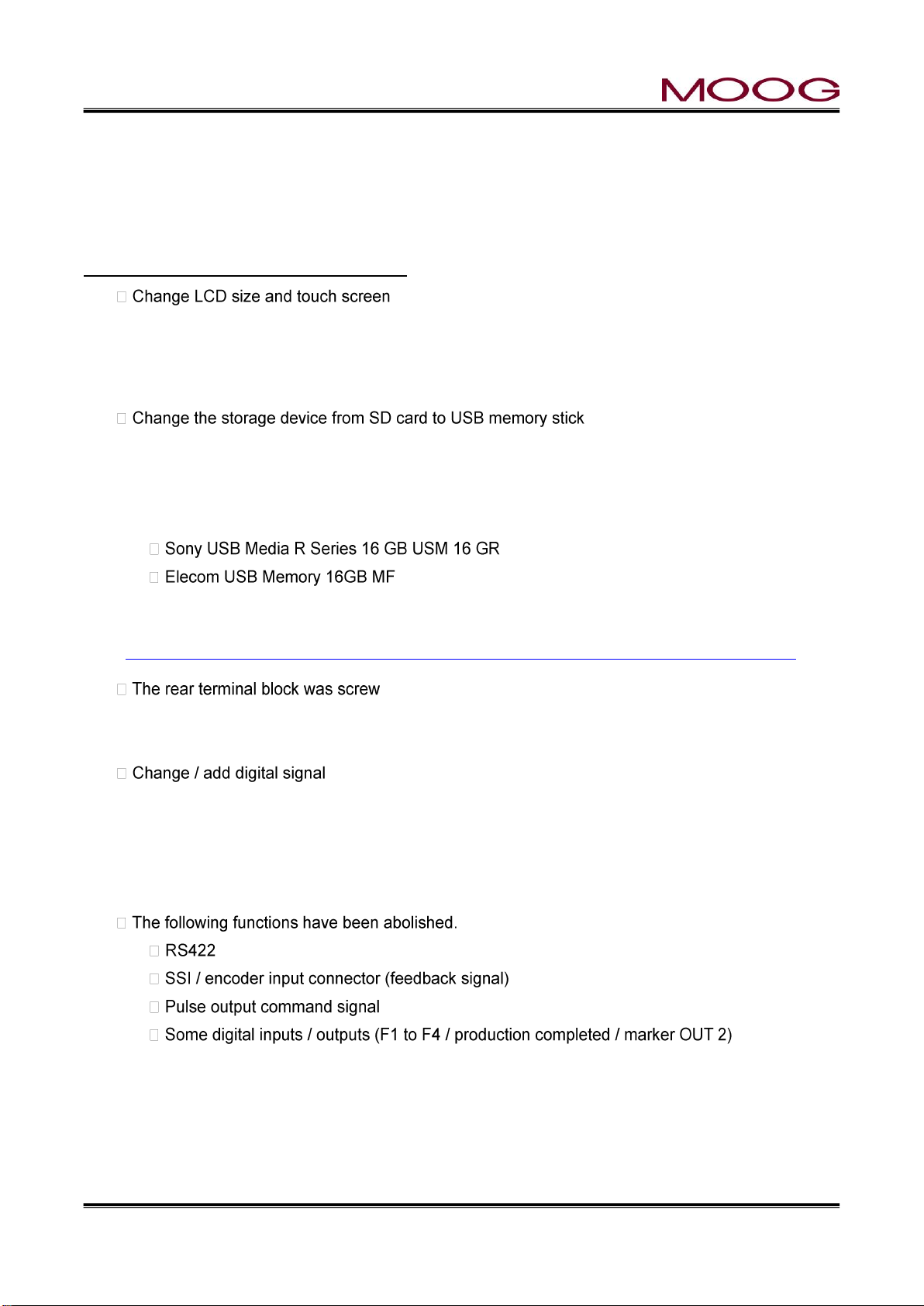

1. DigiPackⅢ Manual, Installation and Maintenance

1-1. CHANGES FROM J141-214A

The basic specifications of DigiPackⅢ (J141-215) are equivalent to conventional J141-214A.

There are the following major differences.

Changed from currnt VGA (480 x 640) to WXGA (1200 x 800) size

In addition, with touch screen conversion, operation by the conventional push button switch and

display by the LED are abolished, and it is changed to operation/display on the screen. (Excluding

rotary knob and power supply confirmation LED)

Considering availability, change the external storage device to USB memory. (It is not attached to

controller)

The following USB memory has been tested for operation. The operation can not be guaranteed

with USB memory other than these model numbers. We recommend that you select the same

model number as below when purchasing.

-HTU3A 16GBK

In addition, other than the above, you can refer to the list of USB memories being used without

problems by customers at the following URL:

https://www.moog.co.jp/products/controllers-software/blow-molding-controllers/digipack3.html

-tightened, and the terminal block was made detachable.

Mounting screw size is M3.5. Please use crimp terminal matching it.

Also, since the terminal block is removable, rewiring is unnecessary when replacing the controller.

Name change: DI 10 Servo OFF → Emergency. This signal is normally(under control) OFF, and

if input is ON, turns OFF the servo output. For details, refer to Figure 1-23 TB-2 Functions .

Signal addition: DI 11 temperature up completion. This signal is normally(under control) OFF, and

if input is ON, turns OFF the servo output. (Please turn ON when the resin is sufficiently warmed

up and it becomes operable.) Please refer to Figure 1-23 TB-2 Functions for details.

serial communication function

For other details, please check this manual in detail.

Page 11

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

2

MRJ06301

1-2. INTRODUCTION

288.00 mm

LCD Touch screen 10.1 (WVGA)

青色画面時 (RGB: 183.221.232)

DigiPackⅢ

Parison Controller

MOOG

0% 25% 50% 75% 100%

100

90

80

70

60

50

40

30

20

10

1

File Name:1234567890123456

Point No.

Die gap

Delay

Auto cycle

72

5.0

1.5

ON

%

sec

Data

Weight

Range H

Range L

* 79.0

0.0

0.0

0.0

%

%

%

%

5

6

Start

Die gap

Continuous

Accumulator

Divergent

Convergent

End of filling

Point out

End of

extrusion

F1 : Profile

F2 : Marker

F3 : File

F4 : Monitor

F5 : Data

Cursor

DEL S hift

X10 Set

2018/1/23 13:35:45

Cycle time 10.0 100% = 25.40

m

m

sec

Figure 1-1 DigiPackⅢ appearance

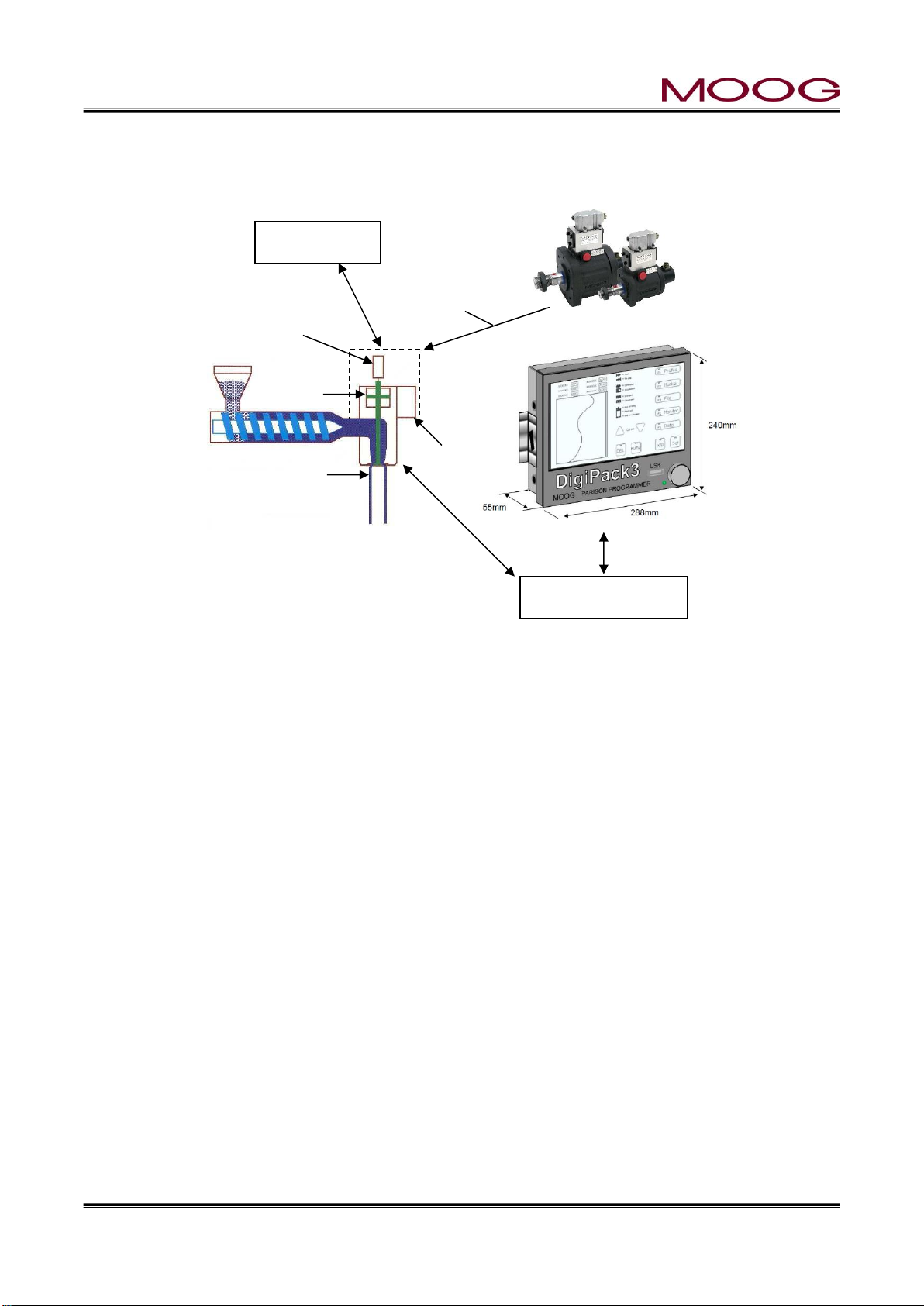

1-2-1. GENERAL DESCRIPTION

The J141-215 DigiPackⅢ is a user friendly, high performance 200 Point Digital Blow Molding Parison

Wall Thickness controller producing lighter, stronger containers at increased production rates.

A properly installed and intelligently used system will deliver higher operating efficiency from your blow

molding machine as a result of faster molding cycles, shorter change over times and reduced scrap.

The DigiPackⅢ adjusts the parison wall thickness by controlling the core position with the core actuator.

The core position can be finely set up to 200 points maximum.

For an accumulator type blow molding machine, set the target core position with reference to the accumulator position. For a continuous blow molding machine, set the target core position based on time.

The core position control system with the above setting consists of four main components: DigiPackⅢ

controller, servo valve, actuator for core and feedback detector for accumulator. The function of each

component is as follows.

Operator using DigiPackⅢ to set the core position (core die gap opening / closing amount) required

DigiPackⅢ also functions as a digital interface with the PLC controller of the blow molding machine

The servo valve adjusts the flow rate to the core actuator according to the flow (spool position) com-

The actuator for the core, the core is fixed to the rod, and the rod (core) moves according to the flow

to obtain a product with the desired wall thickness (usually constant wall thickness). In addition, it

outputs a flow (spool position) command to the servo valve so that the core follows the set core

position.

and provides information such as the end of the program and the point status of sequential programs.

mand from DigiPackⅢ.

rate adjusted by the servo valve. Moving the core changes the gap through which the parison passes

and controls the wall thickness of the parison.

Page 12

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

3

MRJ06301

Hydraulics

Die Gap

PLC Controller

Servovalve

Actuator

DCDT

Core Position

Parison Cutoff Knife

Accumulator feedback detector is used for accumulator type blow molding machine. The DigiPackⅢ

changes the target core position while monitoring the signal from this detector.

1.2.1.1. Continuous blow molding machines

Tooling

Figure 1-2 Basic Continuous Blow Molding Machine Control Diagram

When used with continuous blow molding machines, the DigiPackⅢ controls the parison wall thickness

relative to the machine cycle time. The machine cycle starts when the start signal is input (when the parison

cutting knife disconnects the parison). The cycle time can be determined by the following.

a) Fixed cycle time set by the operator (when [Auto cycle] is OFF)

b) Automatic cycle time set by repeatedly measuring the time between start signals (when [AUTO CY-

CLE] is ON)

When using the fixed cycle time of a), it is necessary for the machine operation time to be negligible for

reasons such as multiple die interlocking, or It is a premise that it is a machine that performs machine

functions such as closing and moving molds within the cycle time

The shape of the parison wall profile is set digitally by the operator. The size of the die gap, measured by

a die gap position transducer, is compared with the operators commanded position as set on the DigiPack

Ⅲ display.

The error between the operators set position and the actual position causes the servovalve to flow oil to

the actuator to reduce the position error to a very small value. This feedback process ensures that the

actual die gap follows the commanded die gap very accurately.

With a continuous blow molding machine, DigiPackⅢ operates / processes as follows.

① The operator sets the core position (core die gap opening / closing amount) necessary to obtain the

desired wall thickness (usually constant wall thickness) product on the DigiPackⅢ controller panel.

② When the start signal switches from OFF to ON, DigiPackⅢ controls the servo valve so that the core

follows the set position according to the cycle time.

③ The servo valve adjusts the flow rate to the core actuator according to the (flow rate) command from

DigiPackⅢ.

Page 13

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

4

MRJ06301

Hydraulics

Die Gap

Actuator

PLC Controller

Servovalve

Actuator

DCDT

Position

Accumulator Push Cylinder

Accumulator

Position

④ By controlling the actuator for the core, control the thickness of the parison at the core die gap portion.

⑤ During ② to ④, DigiPackⅢ functions as a digital interface with the PLC of the blow molding machine

and provides information such as the end of the program and the point status of the program sequentially.

1.2.1.2. Accumurator type molding machines

When used with accumulator machines, the DigiPackⅢ controls the parison wall thickness relative to the

accumulator position as the plastic is being extruded.

As the total quantity or volume of plastic extruded is proportional to the accumulator position, then it follows

that the resulting parison wall thickness at any given point on the length of the container must be related

to the accumulator position. Given that the physical properties of the plastic and its temperature are constant from container to container, then each container’s weight and strength will be consistent.

Tooling

Figure 1-3 Basic Accumulator Machine Control Diagram

A potentiometer measures the accumulator position and controls the vertical axis of the program display.

The operator can also set the accumulator operating stroke, shot size, and accumulator injection comple-

tion position (cushion). In addition, DigiPackⅢ also provides interface signals to the machine's PLC for

these functions. After that, the operation of the accumulator is controlled by the PLC.

With an accumulator type blow molding machine, DigiPackⅢ operates / processes as follows.

① The operator sets the core position (core die gap opening / closing amount) necessary to obtain the

desired wall thickness (usually constant wall thickness) product on the DigiPackⅢ controller panel.

② When the start signal switches from OFF to ON, the DigiPackⅢ controls the servo valve so that the

core follows the set position according to the position of the accumulator.

③ The servo valve adjusts the flow rate to the core actuator according to the (flow rate) command from

DigiPackⅢ.

④ By controlling the actuator for the core, control the thickness of the parison at the core die gap portion.

Page 14

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

5

MRJ06301

⑤ During ② to ④, DigiPackⅢ functions as a digital interface with the PLC of the blow molding machine

and provides information such as the end of the program and the point status of the program sequentially.

Successful performance of the DigiPackⅢ depends a great deal upon how well it is installed on the

machine. By following the instructions contained idatan this manual it will be possible to easily install this

system and obtain many years of trouble free operation.

1-2-2. WHO CAN INSTALL THE DigiPackⅢ

The installation of the DigiPackⅢ control system requires the installer to be familiar with electrical wiring,

hydraulic plumbing and basic metal working. The calibration and start up of the finished system requires

some understanding of the blow molding process and use of test instruments such as a digital voltmeter.

The plumbing, wiring and bracketry should not be difficult. Most molding shop maintenance men who are

familiar with blow molding machines will have little difficulty with the help of this manual.

The system can be satisfactorily calibrated to the machine and started up without assistance or special

equipment by following the instructions in this manual.

Page 15

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

6

MRJ06301

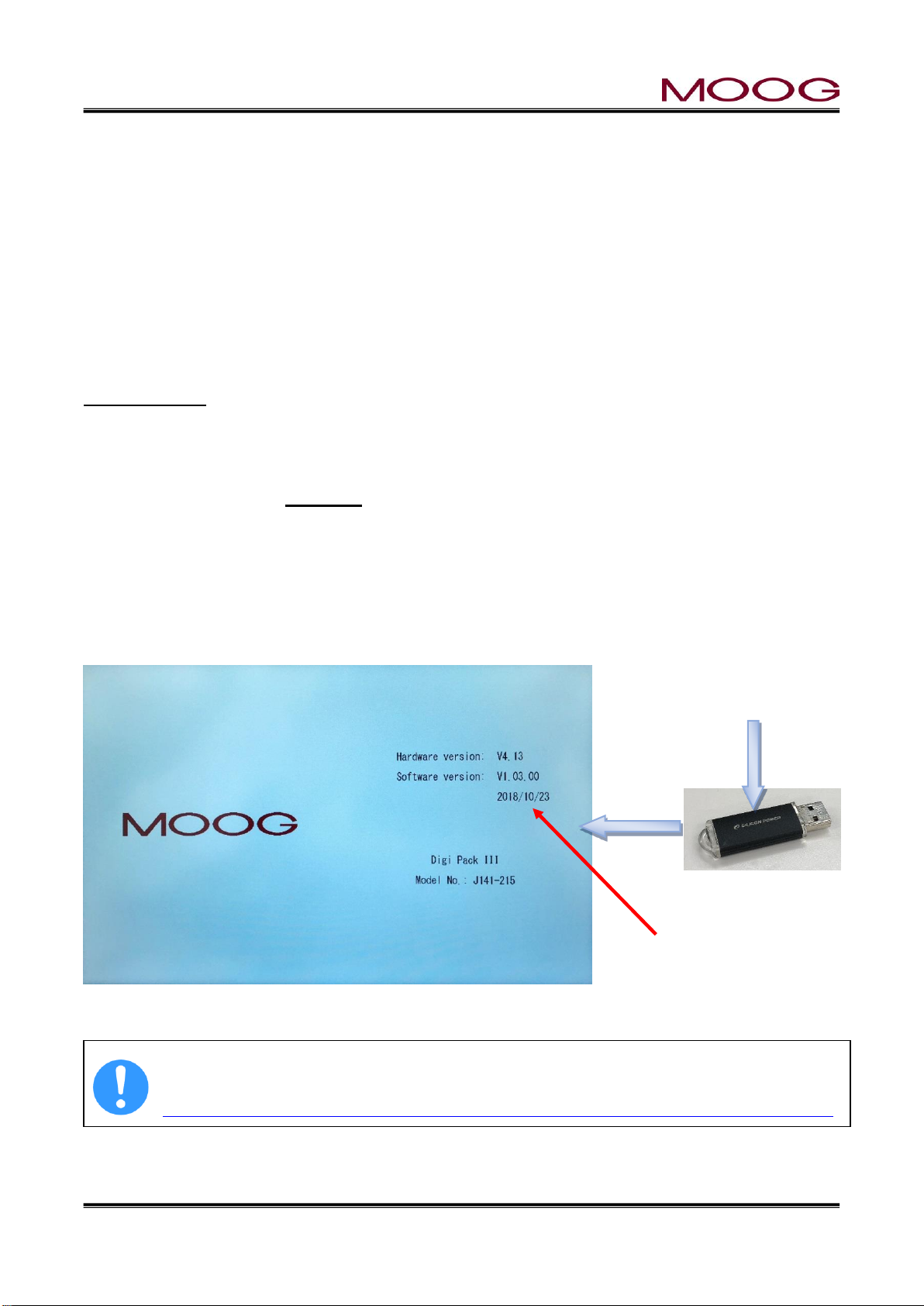

USB memory

Save

DIGIPK3.FMW

Software version

1-2-3. INSTALLATION TIME

The time to install a DigiPackⅢ varies with the type and size of machine, mechanical constraints such

as the location of water lines and auxiliary equipment and the ability of the mechanic doing the installation.

Our experience has shown that typical maintenance men will require about 20 to 30 man hours. Smaller

machines will require less time.

Of this time, the actual machine shut down time can be held to 6 hours or less.

1-2-4. SOFTWARE UPDATE

The software of this controller may be updated if a bug is found or the function is improved. Please check

the software update status (latest version) from the MOOG website below. Also you can download the

update file "DIGIPK3.FMW" from the website. How to update Please refer to the following description.

Update Process

1. Prepare the USB memory and turn off the power of DigiPackⅢ.

2. Save the "DIGIPK3.FWM" file to the USB memory using the computer.

3. Insert the USB memory into the DigiPackⅢ and turn ON the DigiPackⅢ.

4. Turn the rotary knob clockwise while turning on the power.

5. When "Updating firmware ..." appears on the display, the update process is in progress.

※ It takes about 30 seconds to update. If "Failed" is displayed on the screen, or if nothing happens

and screen changed to the startup screen, the upgrade fails. Please try again from process 1. If

"Failed" is inevitably displayed and the upgrade is not successful, there is a possibility that the file

is broken. Please download "DIGIPK3.FWM" again and try update again.

6. Then check the software version in the startup display (Figure 1-4).

7. Turn off the power and remove the USB memory.

Figure 1-4 Start up Display

USB memory is not included with DigiPackⅢ. Refer to section 1-1. for recommended USB.

"DIGIPK3.FWM" can download the latest version from the MOOG website

https://www.moog.co.jp/products/controllers-software/blow-molding-controllers/digipack3.html

Page 16

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

7

MRJ06301

1-2-5. BACKUP BATTERY

Since backup of an internal clock is using the ultra capacitor, there is no necessity for exchange.

Backup time is about three weeks.

A time display may be [----.--.-- --:--] when not turning on electricity the time of the power activation after

purchase, and for a long period of time.

In such a case, please set up the right time on F2 screen. (Reference 2-4-3. )

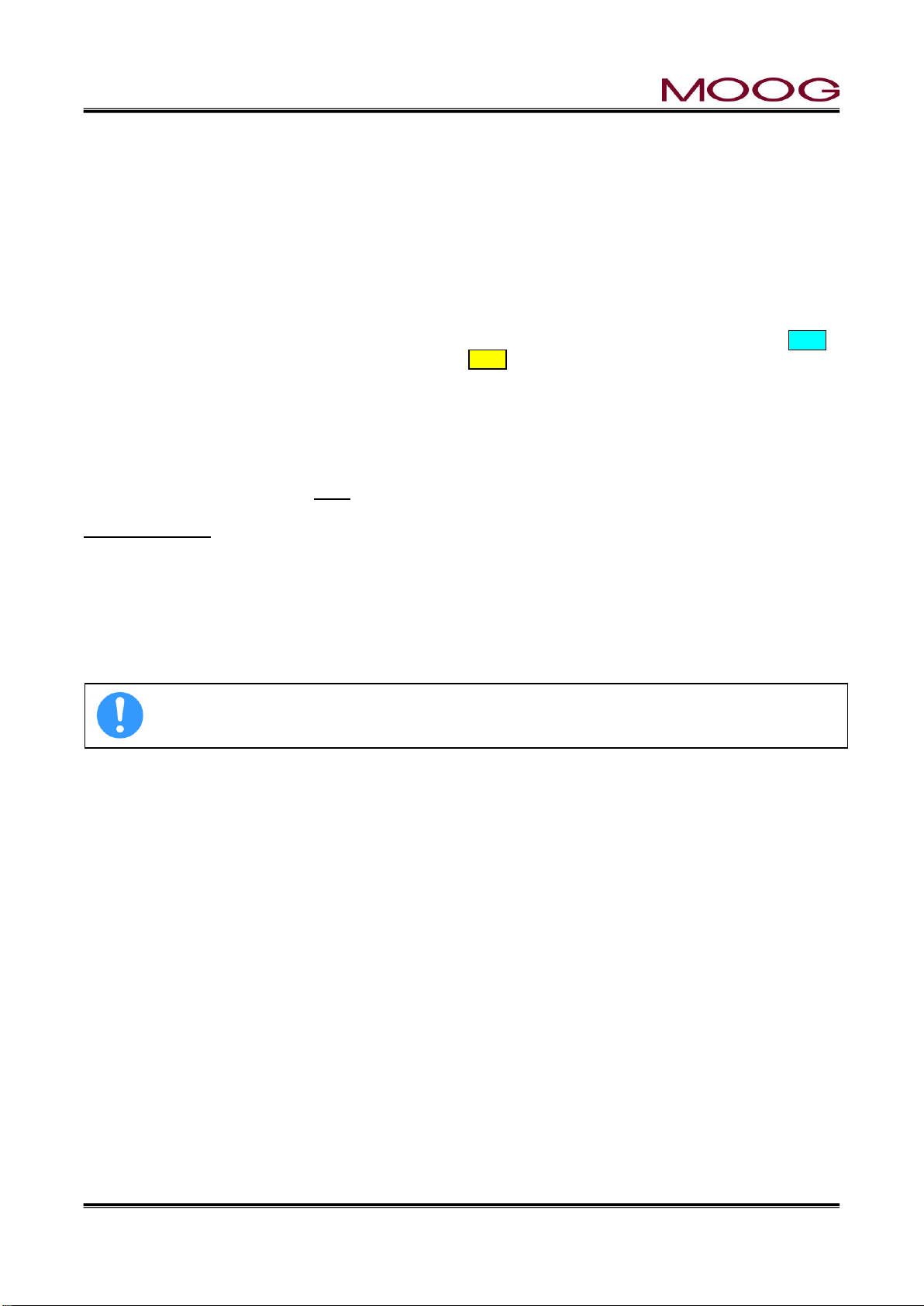

1-2-6. SCREEN DISPLAY PROTECTION (password)

The DigiPackⅢ has two types of screen configurations that the normal operation screen (F1 to F5) and

the setting screen (SHIFT → F1 to F5) for making various settings. Each screen can be distinguished by

the color of the background. The background color of the normal operation screen is light blue " "

The background color of the setting screen is yellow " ". In this controller, the transition to the setting

screen is limited by the password. When entering the setting screen, entering a password enables you to

migrate.

* Once you enter the password, it is not necessary to enter the password until you restart the controller.

Also, if password function is unnecessary, it is possible to invalidate password from SHIFT → F4 screen.

See 1.9.2.1

Password: 6009 (Password is fixed and can not be changed)

Password input

After activating the controller, the password entry screen will be displayed when entering to the setup

screen by first pressing “SHIFT” and then pressed Fx key. Once you enter 4-digit password, you will be

able to switch to the setup screen without entering again the password. This will be retained until you

restart DigiPackⅢ.

In addition, this password can be enabled / disabled on the machine setting screen (SHIFT→ F4) . Refer

to Section 1.9.2.1 Machine Settings for details.

This level change does not indicate any notice on display. Please check the level is correctly

changes or not by press SHIFT→F1, if the level “Low” should not goes to setup display

1-2-7. DATA TRANSFER FROM DigiPackⅡ

The saving data of DigiPackⅡcan be transferred to DigiPackⅢ due to following process.

With the DIgiPackⅡsave the parameters file to SD Card and copy it to USB by using PC. Then, load

parameter file from USB to DigiPackⅢ. (Refer to 2-4-4. for save/load description)

NOTE: New parameter like PURGE/TOOLING is not include.

Page 17

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

8

MRJ06301

1-3. DigiPackⅢ SPECIFICATION

Model Number:

J141-215 DigiPackⅢ.

Function:

Max 200 points Single head blow molding Parison programmer

Application:

Accumulator Based or Continuous Extrusion Blow Molding Machines

can be selected.

Profile Points:

10 to 200,Custom points. And Straight or Spline interpolation can be

selected.

Tooling Type:

Divergent or convergent die gap tooling types can be selected.

Tooling Position Control:

Digital closed loop servo system with a 1m sec update time.

Tooling Position Monitor:

From Tooling Position Actuator’s DCDT 10 VDC.

Accumulator Position Monitor:

From Accumulator Potentiometer 0 to 10 VDC FS.

Programming Inputs:

By Rotaly knob and touch panel switches.

Display:

Color Display (LCD). 10.1 inch(WXGA) touch screen.

English/Japanese/Chinese language selected by Parameter at Setup

screen.

Memory:

100 program profile patterns can be stored in a Flash RAM. And can

be stored in USB memory.

※ Supports standard USB memory, up to 32G. (Refer to 1-1. )

※ Data format: FAT32

Point Marker:

A marker output signal can be set maximum 10 program point.

Other Functions:

Shot Size, Delay, Cushion (for accumulator machines only), die gap,

data saving, profile curve adjustment (Weight and Range H/L), adjustment of the tooling actuator stroke and the accumulator position transducer, backup for the system timer(by capacitor).

Output to Servovalve:

MFB type: ± 10, 20, 50, 100 mA or EFB type: ± 10 VDC

Servovalve Monitor:

± 100% Spool Stroke equals 4-20mA

I/O for Accumulator:

0 to 10 VDC transducer output and 10 V DC transducer excitation.

I/O for Tooling Position:

± 10 VDC DCDT output and ± 10 V DC DCDT excitation.

Common External Input:

Photo Coupler Isolated

Customer Supplied 15 to 24 Vdc @ 10 mA /Channel

24 VDC External Outputs:

Photo MOS Relay

Customer Supplied 15 to 24 Vdc @

100mA /Channel Max.

Accumulator type: End of Extrusion/Filling Relay Contacts:

250Vac @ 1 A/channel MAX.

Communication:

Data transfer with host computer by RS422 and Ethernet

Power Requirements:

24 VDC 0.5A min (MAX 3.0A depend on Servovalve Power required)

No ripple requirement : Max +-10 %

Temperature/Humidity:

0 to 45ºC within 85% relative humidity

IP rating

Front side = IP20, Rear side = IP30

Dimensions:

288 (W) x 240 (H) x 55 (D) mm (not include terminal)

Weight:

3.6 kg

Page 18

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

9

MRJ06301

1-4. CHECK LIST

*The instructions in this section are general installation procedures.

1-4-1. INSTALLATION CHECK LIST

Order parts for installation

Identify component mounting locations and procure the necessary mounting brackets

Install the DigiPackⅢ unit in the blow molding machine or optional enclosure

Mount tooling servoactuator to machine

or Mount servovalve manifold and

or Mount DCDT to tooling actuator

Mount servo actuator pressure filter

Install hydraulic power supply

Install main system filter

Make hydraulic pressure and return connections and flush the hydraulic system,

Mount accumulator position transducer, if required

Install conduit and pull cables for the tooling servoactuator, transducers, filter differential pressure switch

and interface between the DigiPackⅢ control panel and the machine PLC

Check the wiring

Calibrate transducers

Set up the control loop

Connect the actuator to the die gap tooling and adjust the die gap end points.

Page 19

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

10

MRJ06301

Figure 1-5 Die Gap Tooling Actuator Installa-

tion

Figure 1-6 Die Gap Tooling Actuator

Filter

Servovalve

DCDT

Tooling Actuator

1-5. MECHANICAL INSTALLATION

*The instructions in this section are general installation procedures.

1-5-1. GENERAL

Mounting provisions for the tooling servoactuator

should include a stable mounting platform for the

tooling actuator, a filter location which allows the filter

element to be readily replaced and mechanical provisions allowing simple adjustment of the mechanical

relationship between the actuator and the die gap.

Figure 1-5 shows such as a well planned installation.

A tooling servoactuator provides a long lived solution

to the problems caused by high temperatures and

force levels. Low friction seals and strong bearings

insure long term and good tooling die gap positioning

performance. A built in position transducer provides

mechanical isolation from shocks and climbing feet.

A directly manifold servovalve is tightly coupled to the

actuator. Figure 1-6 illustrates a packaged tooling actuator with provisions for pre-blow air.

Figure 1-5 shows a typical tooling actuator installation. A servovalve (upper right) is directly mounted on

a manifold, which in turn is attached to a tooling actuator. Directly below is a DCDT position transducer

measuring the actuator rod and die gap tooling motion. In addition, a high pressure filter mounted directly on the manifold provides clean oil to the servovalve. Tooling adjustment provisions are also shown.

Page 20

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

11

MRJ06301

Figure 1-8 Tooling Adjustment Mechanism

Die Gap

Adjust-

ment

Lock

Figure 1-7 Actuator – Die Gap Tooling Mechanical Adjustment

1-5-2. TOOLING ADJUSTMENT

When a mold change is made, it is often necessary to

change the die gap tooling assembly. Therefore the actuator installation must provide for simple adjustment of the

die gap tooling position relative to the actuator position.

Figure 1-7 shows two possible methods of adjusting the

positional relationship between the tooling actuator and

the die gap tooling’s closed position. Tooling motion stops

may be required to limit the forces on the die gap tooling

when the die and mandrel touch. Figure 1-8 is a typical

installation.

Some actuators with an anti-rotation feature require the nut torque loads on the

anti-rotation device to be limited by absorbing the tightening torque with a

wrench on the actuator rod flats

Tooling stops are required to insure a die gap that cannot close on a continuous molding machine. An

inadvertent closure of the die gap could cause very high pressures in the extruder barrel and extrusion

head and result in their damage and/or failure.

The above comments must be considered for the proper installation of either a Moog supplied die gap

tooling actuator or a customer supplied actuator.

Page 21

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

12

MRJ06301

Core control Actuator (example: J085-139)

Servo Valve(G631-3004B)

DCDT Sensor

The actuator rod extends when the currents of the servo valve pins A, C are positive with respect to the currents of the pins

B, D

Pin A

Pin B

Pin C

Pin D

Pin E

+10V

-10V

+OUT

-OUT

N/A

Pin C becomes positive with respect to pin D

when retracting the actuator

Connector compatible with

MS3106-14S-5S

Servovalve

DCDT Toolong Position Transducer

Tooling Acutuator

The extruder barrel and/or screw can be severely damaged if the die gap closes when the

extruder is running. A mechanical motion stop must be installed which will not allow the die gap

to close.

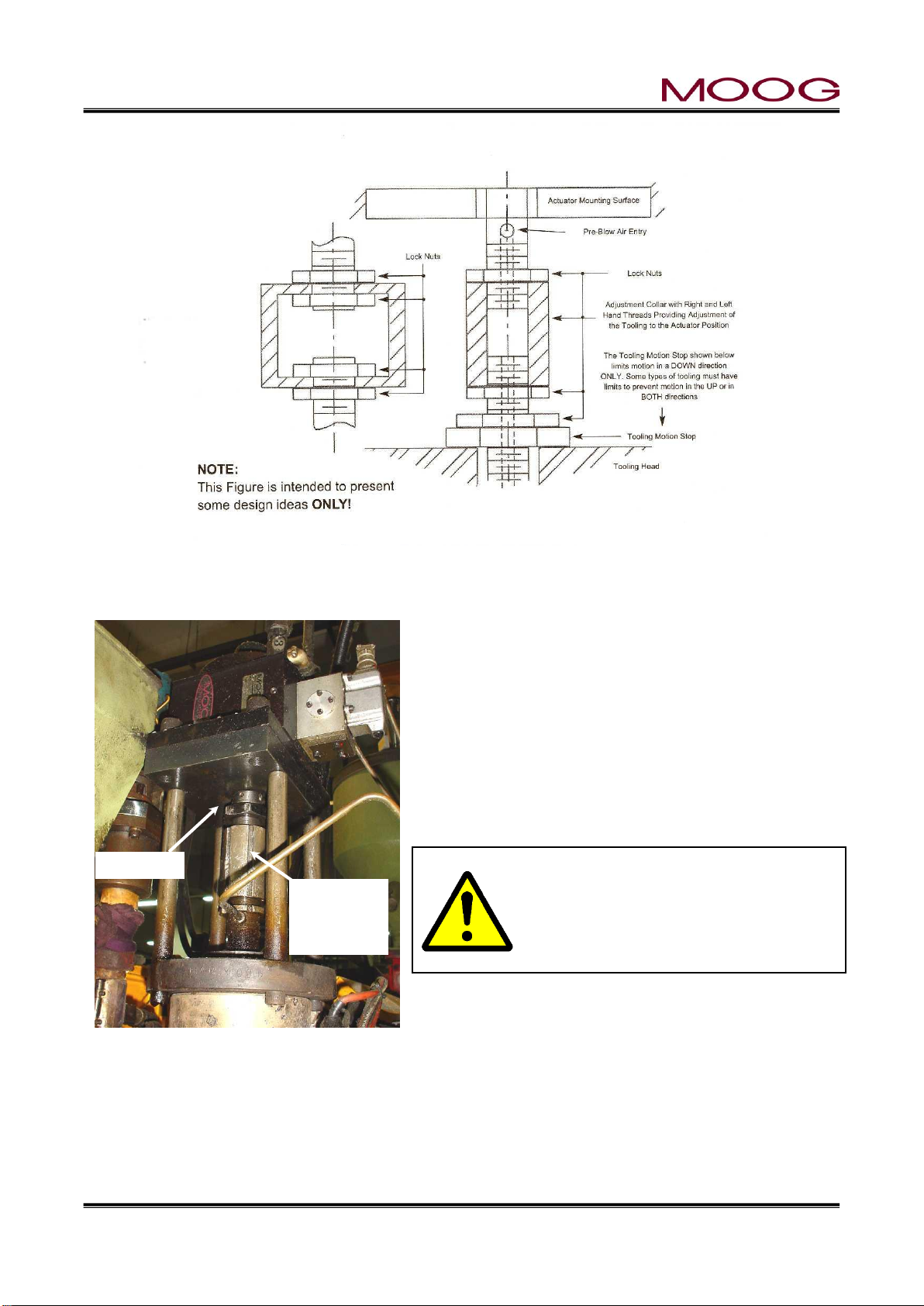

1-5-3. MOOG DIE GAP TOOLING ACTUATORS

The Die Gap Tooling Actuator is designed specifically to control the die gap motion in blow molding extrusion heads. Their design specification includes: Low friction, Long life piston and rod seals. Graphite flake

cast iron rod bearings to absorb potential side loads and high temperatures. Provision for blow air through

the piston rod, and pre adjusted position feedback transducer.

The mounting provisions for a die gap tooling actuator must include: a strong mounting structure, provisions for axial and parallel alignment of the tooling actuation rod (mandrel) with the die gap actuators rod,

provisions to allow the actuator stroke center and the tooling’s effective stroke center to coincide, tooling

motion stops to protect the tooling and/or extruder. Figure 1-6 illustrates a packaged tooling actuator.

1-5-4. CYLINDER INSTALLATION

Figure 1-9 shows an installation example of Moog's die gap core control actuator.

Figure 1-9 Typical Cylinder Installation

Page 22

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

13

MRJ06301

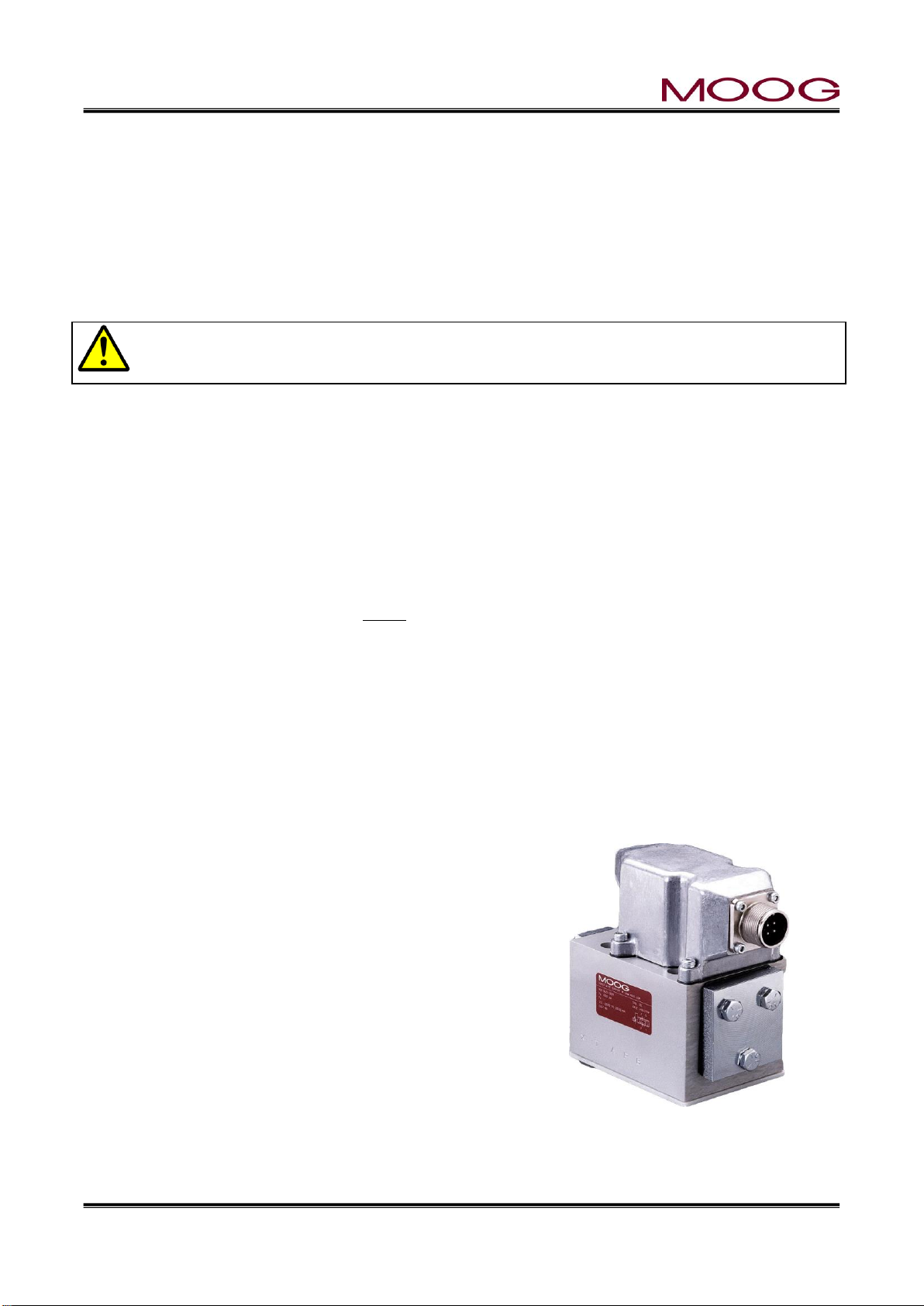

Figure 1-10 G631-XXX Servo-

1-5-5. CUSTOMER SUPPLIED CYLINDER REQUIREMENTS

The customer supplied cylinder is required to control the die gap motion in blow molding extrusion heads.

As such their purchase specification must include: Low friction, long life piston and rod seals; Robust rod

bearings capable of absorbing large potential side loads and high temperatures. A quality cylinder must

be purchased to meet these requirements.

The mounting provisions for the tooling actuator shall include: a strong mounting structure, provisions for

axial and parallel alignment of the tooling actuation rod (mandrel) with the die gap actuators rod, provisions

to allow the actuator stroke center and the tooling’s effective stroke center to coincide, tooling motion stops

to protect the tooling and/or extruder.

Some actuators with an anti-rotation feature require the nut torque loads on the anti-rotation

device to be limited by absorbing the tightening torque with a wrench on the actuator rod flats.

1.5.5.1. MANIFOLD

The manifold must be mounted using as close as possible to the cylinder. Ideal methods are to mount the

manifold directly on the cylinder, sealing the ports with “O” rings or to use tubing between the cylinder and

manifold.

The pressure and return connections should be straight thread fittings using an “O” ring as a seal. Tapered

thread fittings are not encouraged as they tend to leak and when they are torqued up to stop the leak, the

servovalve mounting surface is distorted, causing leakage at the servovalve-manifold seal. Straight thread

fittings using “O” rings do not leak or cause mounting surface distortion.

Should tapered thread fittings be used, ONLY Teflon tape can be used on the tapered threads as a sealant.

The Teflon tape must not cover the last two threads at the smaller diameter portion of the thread. Any other

material will cause eventual contamination problems.

Figure 1-7 shows two possible methods of adjusting the positional relationship between the tooling actuator and the tooling die gap closed position. Tooling motion stops may be required to limit the forces on

the die gap tooling when the die and mandrel touch. “Figure 1-9” is a typical installation.

Tooling motion stops may also be required to insure a die gap opening on a continuous molding machine.

An inadvertent closure of the die gap could cause very high pressures in the extruder barrel and extrusion

head and result in their damage and/or failure. The above comments must be considered for the proper

installation of either a Moog supplied die gap tooling actuator or a customer supplied actuator.

1.5.5.2. SERVOVALE MOUNTING

The servovalve is mounted to a manifold with four mounting

screws and using four “O” rings to seal the Pressure, Return

(Tank), and the two Cylinder hydraulic connections.

The “O” ring seal between the servovalve and manifold depends

upon the servovalve mounting manifold surface flatness to insure

that there are no oil leaks. This surface must be flat within

0.025mm and have a √32 RMS finish.

Two servovalves mounting patterns are available: a Cetop 5, NG

10 or a Ø22,2mm, Moog 76 port circle.

Page 23

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

14

MRJ06301

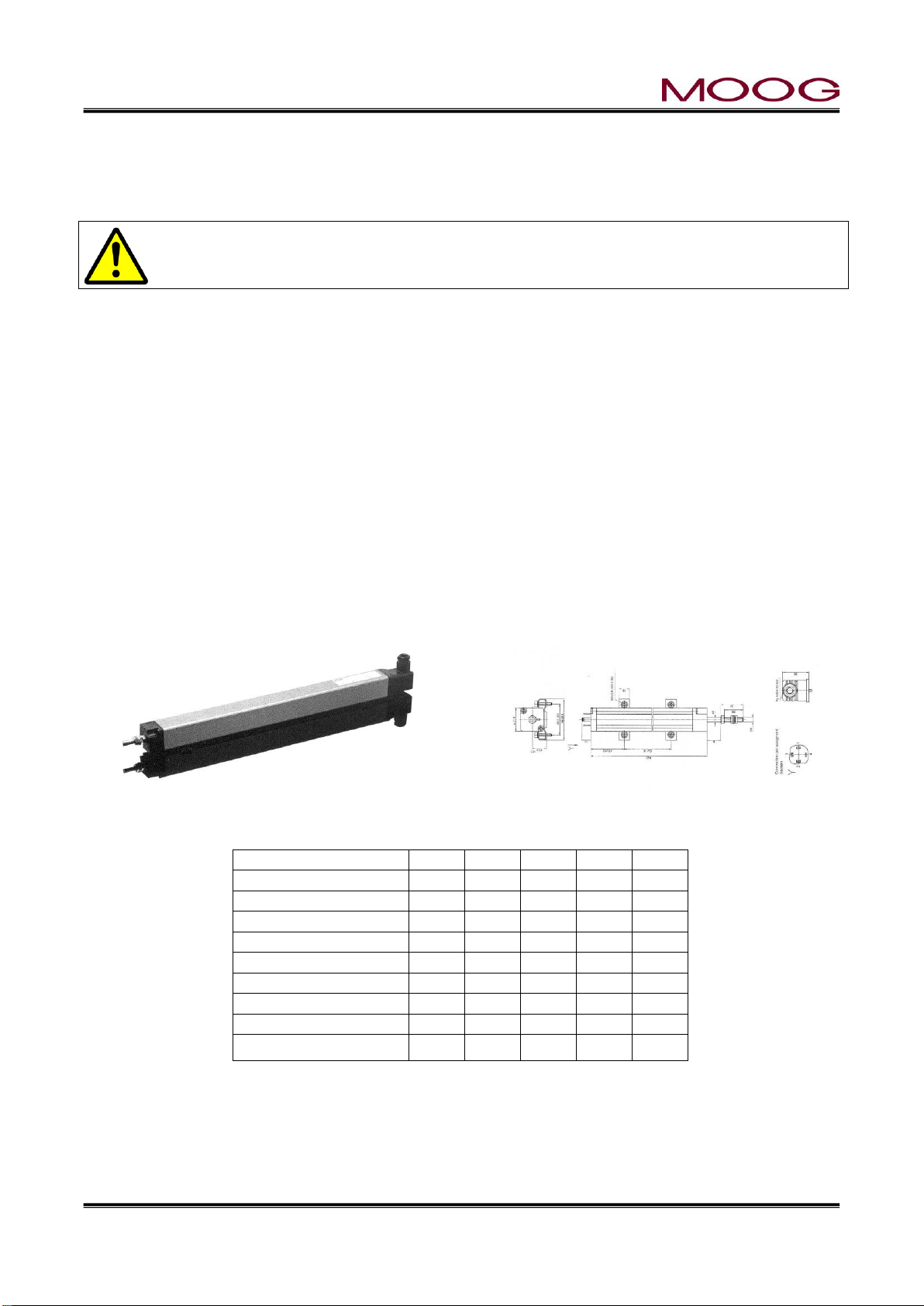

LWH

300

500

750

900

Electrical Data

Rated Stroke

mm

300

500

750

900

Nominal Resistance

Kohm

5 5 10

10

Independent Linearity

%

0.07

0.05

0.05

0.05

Mechanical Data

mm

Mechanical Stroke

B

312

515

769

922

Body Length

A

375

579

833

985

Mounting Feet Spacing

X

280.5

484.5

738.5

890.5

1-5-6. TOOLING ADJUSTMENT

When a mold change is made, it is often necessary to change the die gap tooling assembly. Therefore the

actuator installation must provide for simple adjustment of the die gap tooling position relative to the actuator position.

The extruder barrel and/or screw can be severely damaged if the tooling die gap closes when

the extruder is running. A mechanical motion stop must be installed which will not allow the die

gap to close.

1-5-7. ACCUMULATOR POSITION MEASUREMENT

If the DigiPackⅢ is being installed on a continuous extrusion machine please go to the next section.

Accumulator type blow molding machines require a position transducer to indicate the accumulator posi-

tion. The parison wall thickness pattern can then be programmed with direct reference to the accumulator

stroke of Shot Size.

1.5.7.1. INSTALLATION REQUIREMENTS

The position transducer is required to operate in a high temperature and vibration environment. In addition

the transducer must accommodate some mechanical miss-alignment without reduction of life and linearity.

The part of position sensor allows adjustment for interlocking the movable part of the potentiometer with

the moving of the accumulator. and also has the following functions:

1) An accumulator driven bearing guided structure for the potentiometer drive arm

2) Mounting provisions for the potentiometer on the same bearing guided structure, provisions for

adjustment to insure parallel motion of the potentiometer guide arm and potentiometer drive rod

3) And a rod end bearing between the potentiometer drive rod and the potentiometer guide arm

Figure 1-11 Typical Linear Potentiometer Figure 1-12 LWHxxx Potentiometer Installation

Installation Information

Page 24

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

15

MRJ06301

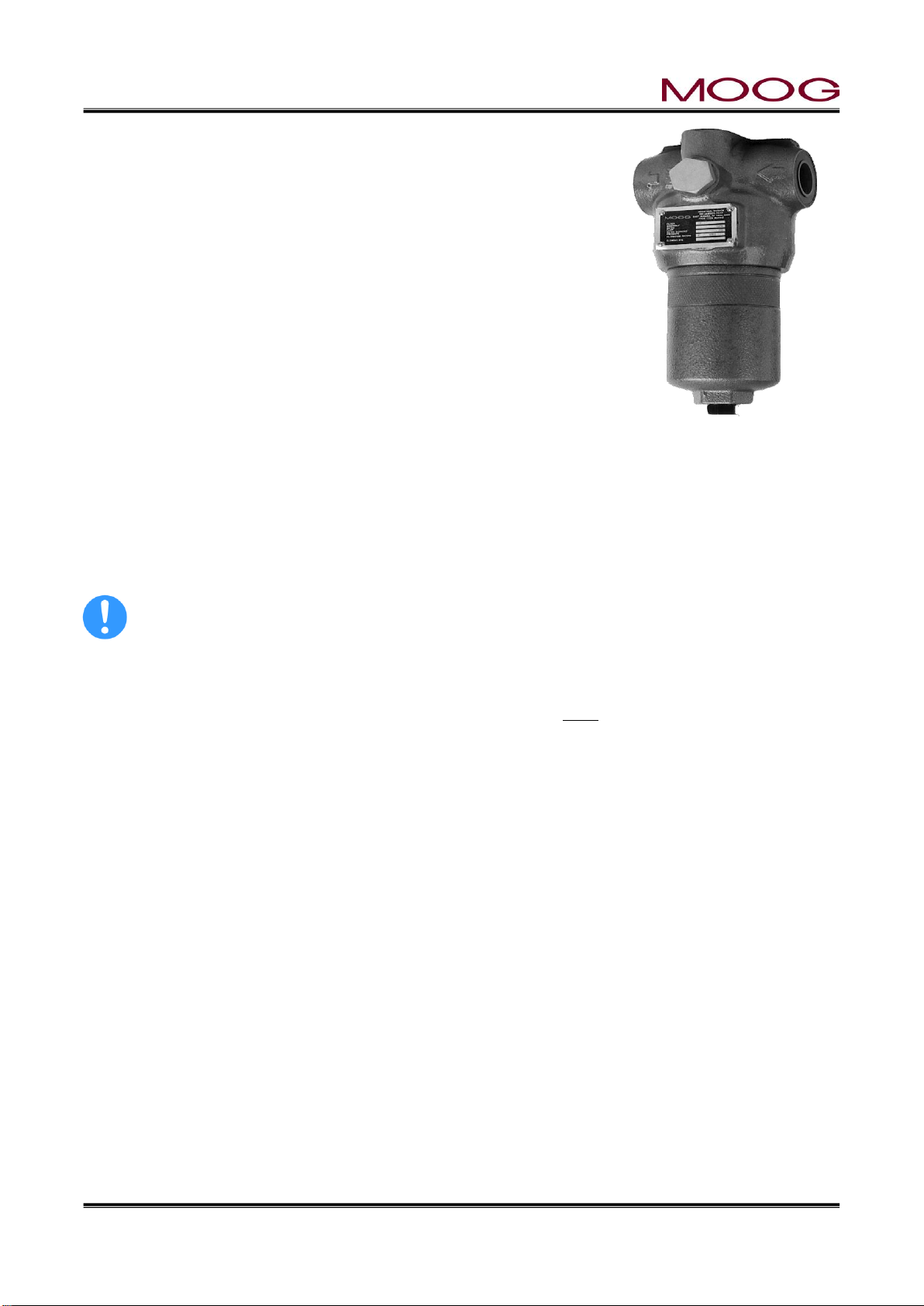

1-5-8. THE IMPORTANCE OF FILTRATION

Figure 1-13 High Pressure Fil-

ter

Adequate contamination control in any hydraulic system is the key to a

highly reliable system. Proper filter placement and selection insures

long term trouble free operation of every hydraulic system component.

There are three essentials:

1) a high pressure filter mounted directly at the tooling actuator

2) a re-circulating circuit providing continuous filtration and

heat removal

3) proper control of the tank breathing and filling operations

to prevent the ingression of contaminant

High pressure filter (β15»75, 15µ absolute) mounted directly with tubing

at the tooling actuator provides protection against particles created by

component failures.

The main contamination protection is provided by oil taken from one

corner of the tank, flowing through the low pressure re-circulating filter

back to the opposite corner of the tank. The re-circulation filter is a low

pressure filter (β3»75, 3µ absolute) with an inexpensive replacement

filter element. The re-circulation also incorporates a heat exchanger to

maintain low oil temperature and insure adequate oil life.

Protection against ingression of contaminant during oil make up and normal breathing is provided with

breather rated at 10µ.

Currently, MOOG does not sell filters. Please purchase directly from the filter manufacturer.

1-5-9. FILTER INSTALLATION

High pressure filter or equivalent, β15>75 rated, high pressure filter must be mounted as close as possible

(50mm to 300mm) to the actuator or servovalve manifold. The location of the filter must allow an easy

access to make a replacement of filter element easy and safety.

Filter Installation Information

The hydraulic connection between the filter and actuator must be tubing. Under no circumstances can

hydraulic hose be used as the hose is a contaminant generator and this contaminant will go directly into

the servovalve, eventually causing contamination problems.

The hydraulic connections used will be a straight thread “O” ring sealed boss into the servoactuator and

high pressure filter with either flared or compression fittings used to connect the tubing to the straight

thread fittings.

The use of tapered thread fittings with pipe dope will cause both contamination and leakage problems.

Teflon tape may be used, but only if applied in such a manner as to keep the edge of the Teflon tape at

least two threads away from the end of the fitting.

Page 25

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

16

MRJ06301

1-5-10. HYDRAULIC POWER SUPPLY

Figure 1-14 Hydraulic Power Supply

The Hydraulic Power Supply provides clean oil to the die gap

tooling actuator at a constant supply pressure. An accumulator

provides the peak flows that may be required. A water heat

exchanger ensures reasonable oil temperatures.

The Hydraulic Power Supply is normally used on first installations when the cleanliness condition of the blow molding machine’s hydraulic power supply is unknown or suspect.

A separate hydraulic power supply provides a reliable source

of clean oil for trouble free long term operation. A bypass filter

allows the oil to be continually cleaned and cooled.

The hydraulic power supply pressure output should be connected directly to the input port of the high pressure filter at

the die gap tooling actuator or the servovalve manifold. The

actuator or manifold return line goes to the hydraulic power

supply return port.

1-5-11. HYDRAULIC POWER SUPPLY START UP INSTRUCTIONS

1) Check for any damage to the hydraulic power supply and its parts.

2) Fill the tank through the breather filter with Shell/Tellus 68 or equivalent fluid.

3) Check the nitrogen gas pressure in the accumulator bladder. The pressure should be 35 bar or 66%

of the maximum system pressure, whichever is higher. Add nitrogen, if necessary.

4) Replace the filter elements with flushing elements. Store the original filter elements in a clean, very

clean plastic bag.

5) Connect the pressure and return lines to and from the tooling actuator assembly

6) Check the motor name plate for the correct line voltages and connect the motor to power. Start the

motor and check that it rotates in the proper direction.

7) Connect cooling water to the heat exchanger. The required water flow rate is 30 1/min at 2-3 bar.

8) Run the hydraulic power supply for at least 6 hours. Vary the flow rate and pressure to thoroughly

flush all chips and dirt into the filters. Monitor for leaks and repair.

9) Replace the flushing filter elements with the elements removed in step 4.

Page 26

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

17

MRJ06301

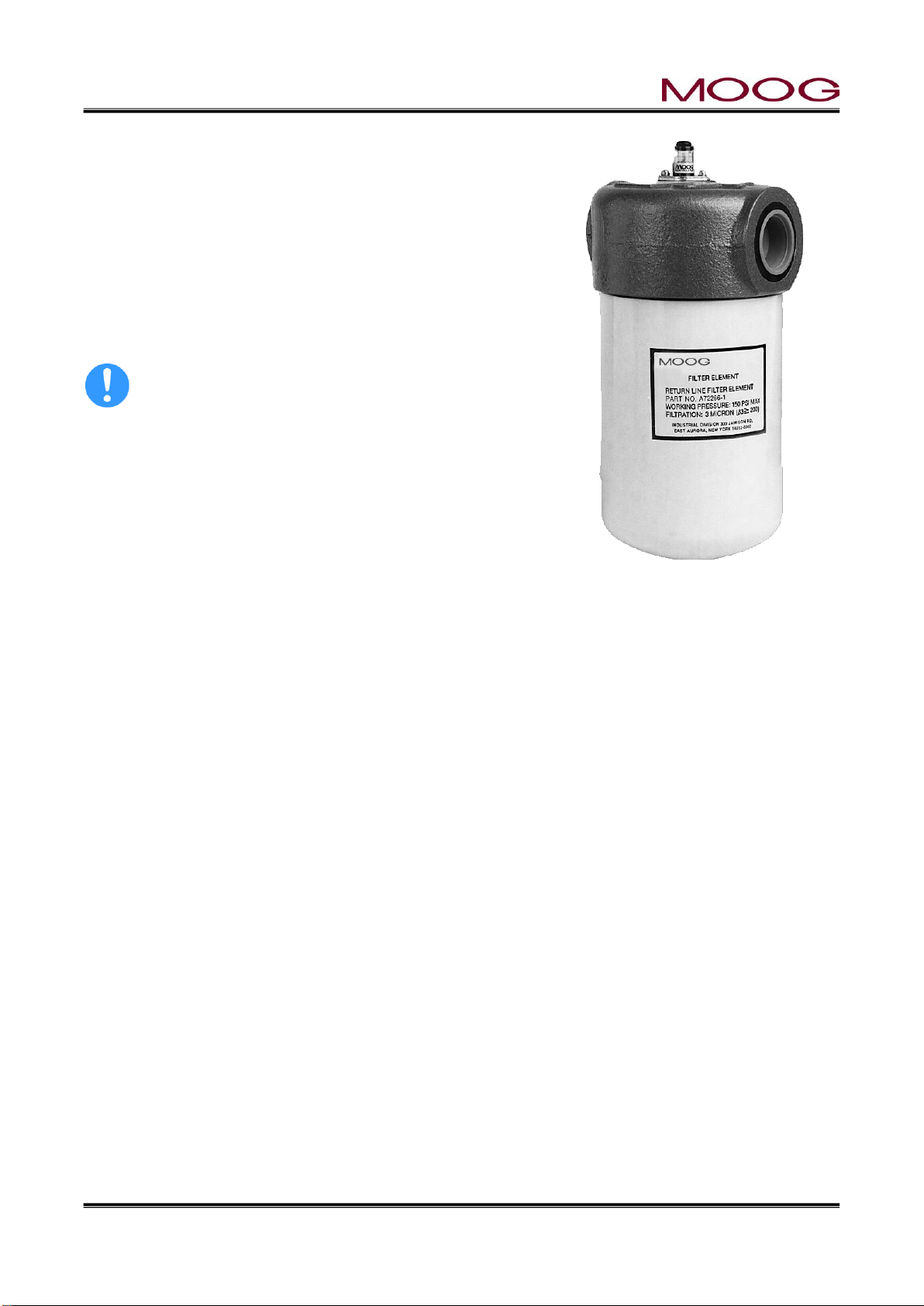

1-5-12. CONTAMINATION CONTROL

Figure 1-15 Flow Pressure Filter

Long term trouble free operation with a minimum of unplanned

down time and adequate oil contamination control are linked very

closely. It is very important to maintain adequate oil cleanliness.

The addition of a system contamination control filter will control

oil contamination levels at minimum expense.

The filter should be located such that the flow through the filter is

relatively constant and at a low pressure. The junction of the return lines from the tooling actuator and the system relief valve is

a suitable location.

Currently, MOOG does not sell filters. Please purchase

directly from the filter manufacturer.

Page 27

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

18

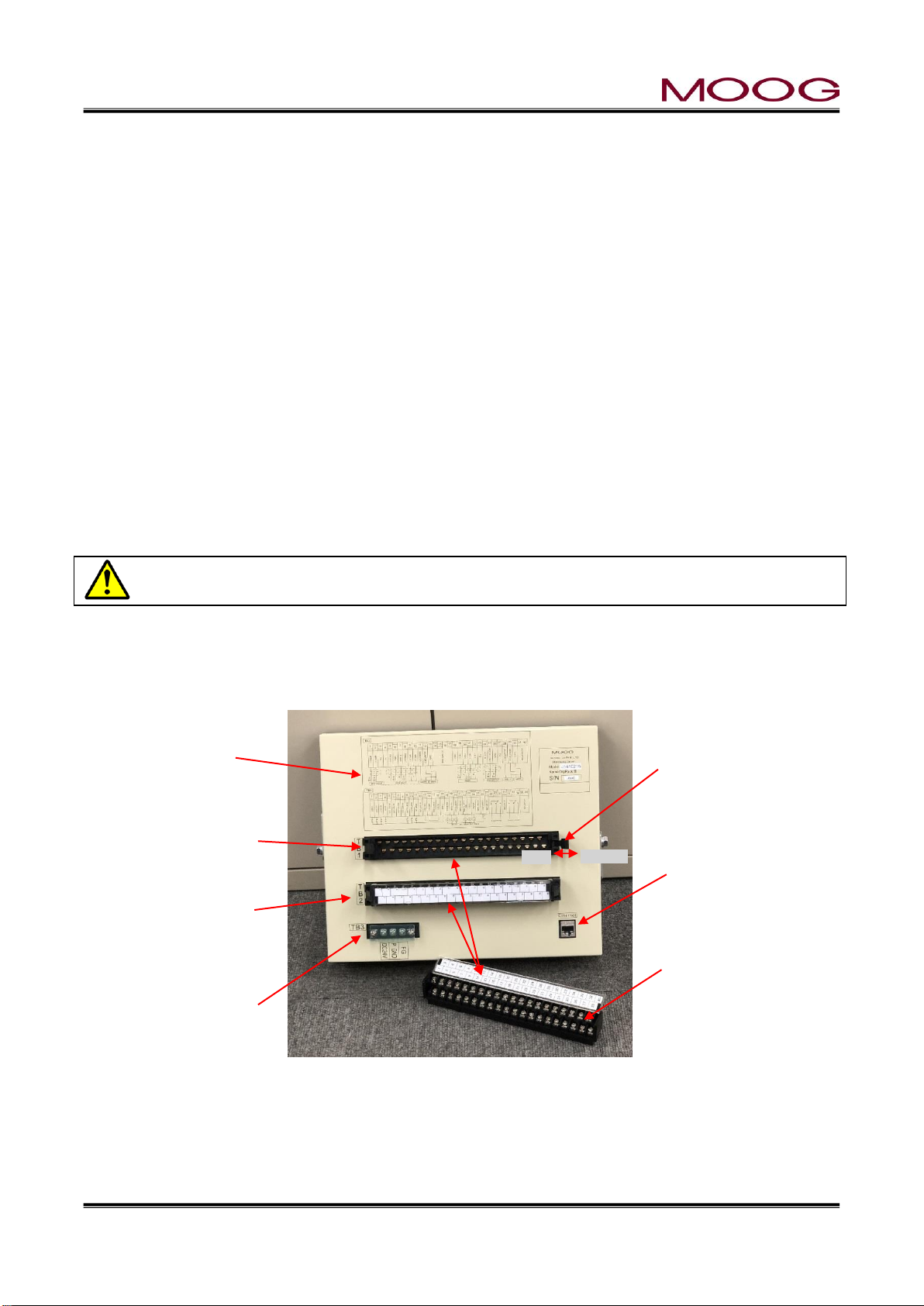

MRJ06301

Lock lever

Please lock securely

when fixing the connector.

TB-3:Power connector

(Screw diameter 3.0 mm,

tightening torque 0.6 Nm)

Reference wiring

diagram

Ethernet Plug

TB-1:Base connector

Connector removal status

(Screw diameter 3.5 mm,

tightening torque 1.0 Nm)

Release

Lock

TB-2 : Connector

installation state

Desorption

1-6. ELECTRICAL INSTALLATION

1-6-1. GENERAL

Electrical installation includes several phases of work:

A) mounting the DigiPackⅢ in a suitable location

B) determining the correct phasing so the servovalve, tooling position transducer and, possibly,

accumulator position transducer may be connected to the DigiPackⅢ

C) determining the blow molding machine interface interaction with the DigiPackⅡand then

wiring the machine-DigiPackⅢ interface

D) connect the DigiPackⅢ to electrical power supply from the stable 24VDC

DigiPackⅢ MOUNTING

The DigiPackⅢ must be mounted in a location free of vibration, with protection from the environment and

most important, located in a position allowing the operator and setup man easy visual and physical access.

It is recommended that the mounting be on a swing out panel allowing easy access to the front and back

sides of the DigiPack3.

Mounting information is shown in “Figure 1-17”. Brackets providing simple panel mounting are included.

All wiring from the DigiPackⅢ must be shielded. The shield is to be grounded to the DigiPackⅢ

ground at the DigiPackⅢ only Any other ground paths may cause damage.

1-6-2. REAR CONNECTOR

The rear connector of DigiPackⅢ can be detached. When installing the connector, secure with the lock

lever. See Figure 1-16.

Figure 1-16 REAR CONNECTOR

Page 28

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

19

MRJ06301

Pin No.

Signal

Connection

1

TD+

2 TD-

3 RD+

4

5

6 RD-

7

8

1-6-3. TB-1, TB-2 WIRING

The wire size for TB-1 and TB-2 are able to use AWG26 - 16(Recommended AWG 19-18, 0.75 mm2),

and required using O type or Y type crimp terminal. (Screw diameter 3.5 mm, tightening torque 1.0 Nm).

TB-1 provides the interface between the DigiPackⅢ and the servovavle, die gap sensor, accumulator

position sensor. TB-1 also provides outputs to optional customer monitors MFB Valve current, EFB spool

monitor, DCDT input voltage, Accumulator voltage, Position command, these signals can be select at

setting display (See 2-4-8. ). A schematic of TB- 1 is shown as “Figure 1-19” and TB-1 functions are

outlined in the table, “Figure 1-20”.

Phasing definitions for the servovalve, die gap position and accumulator position (if used) transducers are

given in “Figure 1-18”.

Some connections to TB-1 are shown in parenthesis, (), in “Figure 1-19”. The parenthesis, (), indicate

alternate connection possibilities result from particular directions of motion or phasing determined during

the design of the mechanical installation. Phasing requires that a defined direction of motion of the tooling

actuator will result from TB-1-1 being negative with respect to TB-1-2; that the output voltage of the die

gap position transducer be positive or negative when the die gap is moving in a specific direction; and that

the accumulator position transducer output voltage direction be defined when the accumulator is ejecting

molten plastic into the die head. Terminal TB-2 is using the external power supply to isolate logic inputs,

“Figure 1-21, Figure 1-22”, TB-2 functions are outlined in “Figure 1-23”.

1-6-4. COMMUNICATION AND SSI SNSOR WIRING

The DigiPackⅢ can be communicate with host computer by Ethernet. The connector is using RJ45

socket type for Ethernet (connector name label “Ethernet”). Please refer to Figure 1-17 for connector

location. And connector pin assign see below list.

Ethernet connector RJ45 socket “Ethernet”

Page 29

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

20

MRJ06301

Figure 1-17 DigiPackⅢ Installation Drawing

Page 30

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

21

MRJ06301

57986104

Figure 1-18 ServoValve and Transducer Phasing Figure 1-19 TB-1 Connections

Page 31

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

22

MRJ06301

Name IN/OUT Function Comments

1 -MFB Signal PinA or D, B to C, MEB Servo valve (MFB) Mechanical Feedback

2 +MFB Signal PinA or D, B to C, MEB Servo valve Connection A to D or D to A allow phase reversal

3 F GND(Cable Shield) Cable Shield ground, MFB Servo valve Do not ground the shield at the servovalve

4 F GND(Cable Shield) Cable Shield ground, EFB Servo valve Do not ground the shield at the servovalve

5 24V DC OUT Pin A, EFB Servo valve (EFB )Electrical Feedback Valve Power. Max 1.5A available

6 GND OUT Pin E or D, EFB Servo valve The polarity is reversed depending on the connection of pin D / E

Connection example

7 P GND Pin B, EFB Servo valve

8 EFB Signal OUT Pin D or E, EFB Servo valve EFB Signal : ±10V OUT

MFB Servo valve

9 Valve Spool(-) Pin C, EFB Servo valve 1 A

10 Valve Spool(+) Pin F, EFB Servo valve 2 D

3 Shield

11 Monitor 1 Monitor Out 1 ±10 V DC OUT. Signal selectable

12 Monitor 2 Monitor Out 2 ±10 V DC OUT. Signal selectable

EFB Servo valve

13 GND Monitor Ground Ground for Monitor 1 and 2 5 A

14 NOT USE 7 B

15 NOT USE 9 C

16 NOT USE 8 D

17 NOT USE 6 E

10 F

18 GND 4 Shield

19 DCDT IN (+) IN Pin C or D : DCDT Feedback signal (+) (DCDT) Parison core position feed back sensor

20 +10V DC OUT Pin A : DCDT Power voltage (+10V) The level of the feedback signal changes depending on the type of DCDT (maximum: ± 10 V)

Core Position (DCDT)

21 DCDT IN (-) IN Pin D or C : DCDT Feedback signal (-) The polarity is reversed depending on the connection of pin C / D 20 A

22 -10V DC OUT Pin B : DCDT Power voltage (-10V) 22 B

23 F GND(Cable Shield) Cable Shield ground, DCDT Do not ground the shield at the Actuator or DCDT 19 C

21 D

24 ACC IN IN Pin 2, Potentiometer (ACC Pot) Accumulator position feed back sensor 23 Shield

25 ACC VLT OUT Pin 1 or 3, Potentiometer Available accumulator type: Internal resistance 1 kΩ or more

26 GND Pin 3 or 1, Potentiometer

ACC Position (POT)

27 F GND(Cable Shield) Cable Shield ground, Accumulator Do not ground the shield at the Accumulator 25 1

24 2

28 Monitor 3 Monitor Out 3 ±10 V DC OUT. Signal selectable 26 3

29 Monitor 4 Monitor Out 4 ±10 V DC OUT. Signal selectable 27 Shield

30 GND Monitor Ground Ground for Monitor 3 and 4

31~40 NOT USE

OUT

OUT

TB-1: Analog I/O Terminals (Moog Production and Transducers)

Term No.

OUT

±10, 20, 50, 100 mA

IN

Spool Signal : 4-20mA

Figure 1-20 TB-1 Functions

Page 32

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

23

MRJ06301

Figure 1-21 TB-2 Connection

with Internal Logic Supply

Figure 1-22 TB-2 Connection

with External Logic Supply

Page 33

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

24

MRJ06301

※ Minimum acceptance time of digital input is 50msec or more

Name IN/OUT Function Comments (Refer Fig1-20, 1-21)

1 IN1 START IN Command for Cycle Start Enable machine cycle start.

2 IN2 DIE GAP IN Command to keep the tooling die gap It is valid at any time by continuous mode. Cycle is stops

at the set Die Gap value until IN1 START Accepted only at injection completion state (END EXT) at ACC mode

3 IN3 REBOOT IN Reboot switch for controller. Not accepted during machine cycle

4 IN4 STOP IN Command for Stop operation Cycle stop, hold at current position

5~8 NOT USE

9 IN9 START SLOPE IN

A command to move the core from the current position to the position of the first point

Maintain position until start after moving completes.

The movement speed is set on the screen. Not accepted during machine cycle

10 IN10 EMERGENCY IN Servo OFF command. (E-Stop)

When it is High, the servo valve signal is stopped.

Because it is an emergency stop, accept at any time

ON = Emergency state

11 IN11 TEMP. OK IN Temperature rise completion confirmation.

When this signal is High, the servo valve signal is stopped.

ON = Temp not rised

12 NOT USE

13 INPUT COM.

14 INPUT COM.

15 NOT USE

16 24V DC

17 P GND

18 END FLG. OUT

ON at End of Filling.

Maintain until it falls below the position of End Filling

With this signal, the filling of the accumulation is stopped

19 END EXT. OUT ON at End of Extrusion. With this signal, the injection of the accumulation is stopped

In Continuous mode: ON until the next start.

※ In the case of Accum mode 1% hysteresis (injection & filling)

In Accumulator mode: ON while the accumulation position is smaller than

the injection completion position

20 MARKER OUT OUT Marker output signal. Output at the specified marker point Pulse width 200 msec

21 NOT USE

22 END ST SLOPE OUT At start slope input, ON at movement completion, maintain until IN1 start input

23 READY OUT Turn on when the start condition is set When this signal is ON, controller can receive the start signal.

※ This is not an interlock. Just inform to the host controller

24 ALARM OUT When both IN10 and IN11 are High and output (OFF=alarm state)

25 NOT USE

26 OUTPUT COM. Common for Digital Output Both Sink/Source support. For details see manual page 25

27 NOT USE

28 EOF Relay COM END OF FILLING Relay Common

29 EOF Relay B END Relay Contact B (NC)

30 EOF Relay A END Relay Contact A (NO)

31 NOT USED

32 EOE Relay COM END OF EXTRUSION Relay Common

33 EOE Relay B END Relay Contact B (NC)

34 EOE Relay A END Relay Contact A (NO)

35~40 NOT USE

Common for Digital Input (Isolation)

Pin 13-14 is internally connected.

Both Sink/Source support. For details see manual page 25

Digital signal power supply for both IN/OUT

Maximum current out : 3.0A

Relay

Relay output、AC250V、Maximum 1A

Relay

Relay output、AC250V、Maximum 1A

TB-2: General I/O Terminals

Term No.

Figure 1-23 TB-2 Functions

Page 34

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

25

MRJ06301

1-6-5. TB-2 I/O CIRCUITRY

Input _________________

Figure 1-24 Input use external Power supply Figure 1-25 Input use internal Power supply

All DigiPackⅢ I/O can be uses both POSITIVE/NEGATVIE LOGIC

DigiPackⅢ can be used external and internal power supply. And provide isolated inputs.

The external power supply has an output 24VDC.

The contacts used must have very low contact resistance over a long life time.

Extreme care is required when wiring to insure that ground loops do not exist. Ground loops can cause

damage to the DigiPackⅢ and other electronic equipment. Ground loops can also cause erratic operation

of the entire blow molding machine.

Output ___________________

Figure 1-26 Output use external Power supply Figure 1-27 Output use internal Power supply

DigiPackⅢ’s output circuits use Photo MOS Relay to provide isolation from the external circuitry.

The maximum voltage and current output to each load terminal (TB-2, 18, 19, 20, 22, 23 and 24) is 24VDC

and 100 mA MAX/each.

Page 35

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

26

MRJ06301

Term No.

Name

Specification

DC24V

Power Supply 24V

24V DC Input 0.5A min – 3.0A max

* Required install Fast blow Fuse.

* No ripple required, Max +-10 %

P GND

Power Supply 0V

0V (for DC 24V)

F GND

Earth

1-6-6. TB-3: POWER SUPPLY

The wire size for TB-3 is able to use AWG17 – 16, 1.75 mm2, and required using O type or Y type crimp

terminal. (Screw diameter 3.0 mm, tightening torque 0.6 Nm).

There is protection that does not break down with reverse wiring, but please be careful because

input of high voltage will damage the circuit.

Figure 1-28 Power supply Connections

1-6-7. NOISE AND GROUND ISOLATION

In any location there is always the potential for electrical noise interference and multiple ground paths.

Electrical noise can cause erratic system operation and is very difficult to find and isolate, ground

loops also cause unexpected operation as well as burn out components. In addition, mains voltage

stability can sometimes be questionable.

An isolation transformer between the mains and DigiPackⅢ can provide some relief from noise,

ground loops and wandering mains.

Page 36

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

27

MRJ06301

Figure 1-29 Accumulator Machine Timing chart

Page 37

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

28

MRJ06301

Figure 1-30 Continuous Machine Timing chart

Page 38

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

29

MRJ06301

1-7. CALIBRATION OF TOUCH SCREEN

Calibration of the touch screen has already been completed at the time of product shipment, so basically

no user setting is necessary. Here is explain that the readjustment method when there is an error in the

calibration of the touch screen by some reasons. (If there is an error in the calibration of the touch screen,

the touch area corresponding to the display button will shift, so it will not react even if you touch the display

button.)

If the readjustment becomes frequently necessary, it seems that some trouble has occurred on

the touch screen. In that case we recommend that you submit it for repair.

Step 1: While DigiPackⅢ powered on, digital signal is continuously input for 3 seconds or longer to TB-

2-8 (this channel displayed as Do not use).

Step 2: DigiPackⅢ will be automatically restarted and the calibration screen as shown in Figure 1-31 will

be displayed. Touch the "Calibration" button. (At this time, since the calibration information is reset,

"Calibration" button can be pressed)

Step 3: Since Figure 1-32 is displayed, touch all the "+" signs surrounded by the red frame square in the

corner. If you press the wrong place to push, the calibration will fail and the screen will stop responding. In that case, please turn on the power again, return to step 1 and try again.

Step 4: If the calibration is successful, display will return to Figure 1-31, Restart the controller and finish.

Figure 1-31 Touch screen Calibration

Figure 1-32 Touch screen calibration display

Page 39

© MOOG 2019

This document is subject to MOOG INTELLECTUAL AND PROPRIETARY INFORMATION LEGEND . The details are on page II.

30

MRJ06301

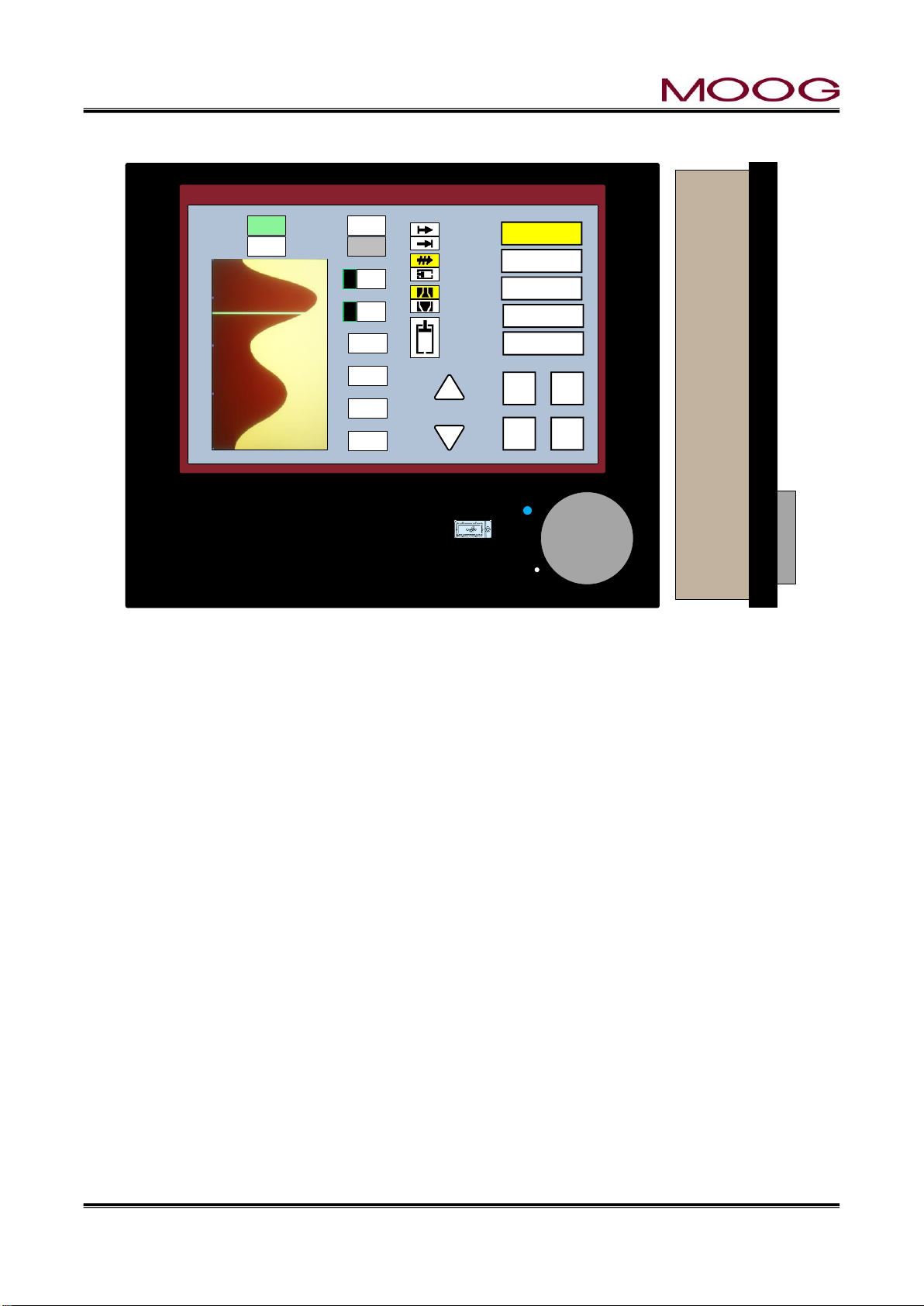

1-8. DigiPackⅢ front panel

288.00 mm

LCD Touch screen 10.1 (WVGA)

青色画面時 (RGB: 183.221.232)

DigiPackⅢ

Parison Controller

MOOG

0% 25% 50% 75% 100%

100

90

80

70

60

50

40

30

20

10

1

File Name:1234567890123456

Point No.

Die gap

Delay

Auto cycle

72

5.0

1.5

ON

%

sec

Data

Weight

Range H

Range L

* 79.0

0.0

0.0

0.0

%

%

%

%

5

6

Start

Die gap

Continuous

Accumulator

Divergent

Convergent

End of filling

Point out

End of

extrusion

F1 : Profile

F2 : Marker

F3 : File

F4 : Monitor

F5 : Data

Cursor

DEL Shift

X10 Set

2018/1/23 13:35:45

Cycle time 10.0 100% = 25.40

m

m

sec

Rotaly Knob

Used to enter the value of various functions. Rotation in a clockwise

X10

Increases the sensitivity of the Rotaly Knob by a factor of 10

SET

Push to set value

DEL

Invalidates the set profile data and changes it to interpolation data.

Rotaly Knob

USB slot

Beep sound speaker

Edit area

Switched by

F1 to F5

Other

Switch

Power LED

State monitoring area

Figure 1-33 DigiPackⅢ Flont panel

OPERATIONS CONTROLS

The operator will setup and monitor the parison wall thickness program using the display switches and

Rotaly knob on the DigiPackⅢ’s front panel, shown in “Figure 1-33”

Beep sound

A beep sounds when parameters and keys in the screen are selected. Also, if an error occurs at startup