Page 1

For the mobile version of this guide, see:

animatics.com/docs/guides-html/c5_dmx/

Page 2

Copyright Notice

©2014-2019, Moog Inc., Animatics.

Moog Animatics Class 5 SmartMotor™ DMX Guide, Rev. C, PN: SC80100004-001.

This manual, as well as the software described in it, is furnished under license and may be

used or copied only in accordance with the terms of such license. The content of this manual is

furnished for informational use only, is subject to change without notice and should not be

construed as a commitment by Moog Inc., Animatics. Moog Inc., Animatics assumes no

responsibility or liability for any errors or inaccuracies that may appear herein.

Except as permitted by such license, no part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

recording, or otherwise, without the prior written permission of Moog Inc., Animatics.

The programs and code samples in this manual are provided for example purposes only. It is

the user's responsibility to decide if a particular code sample or program applies to the

application being developed and to adjust the values to fit that application.

Moog Animatics and the Moog Animatics logo, SmartMotor and the SmartMotor logo,

Combitronic and the Combitronic logo are all trademarks of Moog Inc., Animatics.

Please let us know if you find any errors or omissions in this manual so that we can improve it

for future readers. Such notifications should contain the words "DMX Guide" in the subject line

and be sent by e-mail to: animatics_marcom@moog.com. Thank you in advance for your

contribution.

Contact Us:

Americas - West

Moog Animatics

2581 Leghorn Street

Mountain View, CA 94043

USA

Tel: 1 650-960-4215 Tel: 1 610-328-4000 x3999

Support: 1 (888) 356-0357

Website: www.animatics.com

Email: animatics_sales@moog.com

Americas - East

Moog Animatics

750 West Sproul Road

Springfield, PA 19064

USA

Fax: 1 610-605-6216

Page 3

Table Of Contents

Introduction 5

Purpose 6

Combitronic Technology 6

DMX Overview 8

Safety Information 9

Safety Symbols 9

Other Safety Considerations 9

Motor Sizing 9

Environmental Considerations 9

Machine Safety 10

Documentation and Training 11

Additional Equipment and Considerations 11

Safety Information Resources 11

Additional Documents 13

Related Guides 13

Other Documents 13

Additional Resources 14

DMX Resources 14

Connections, Wiring and Status LEDs 15

Connectors and Pinouts 16

D-Style Motors: Connectors and Pinouts 16

M-Style Motors: Connectors and Pinouts 17

DMX NetworkTopology 17

System Cable Diagram 18

D-Style Multidrop Signal Cable Diagram 19

M-Style Multidrop Signal Cable Diagram 20

Understanding the Status LEDs 21

DMX on the SmartMotor 22

DMXImplementation 23

Data Storage and Usage 23

Example 24

Status Bits 25

End of Packet 25

DMXCommands 27

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 3 of 46

Page 4

Select DMX Channels 27

Special Range Checking 28

Open DMX Channel 28

Close DMX Channel 28

Example Programs 29

Home Against a Hard Stop Example 30

Position Mode Control Example 32

DMX Five Channel Example 35

DMX Packet Test Example 38

Reverse DMXChannel Byte Order Example 40

Troubleshooting 43

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 4 of 46

Page 5

Introduction

Introduction

This chapter provides an overview of the DMX features provided by the Moog Animatics

SmartMotor. It also provides information on safety, and where to find related documents and

additional resources.

Purpose 6

Combitronic Technology 6

DMX Overview 8

Safety Information 9

Safety Symbols 9

Other Safety Considerations 9

Motor Sizing 9

Environmental Considerations 9

Machine Safety 10

Documentation and Training 11

Additional Equipment and Considerations 11

Safety Information Resources 11

Additional Documents 13

Related Guides 13

Other Documents 13

Additional Resources 14

DMX Resources 14

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 5 of 46

Page 6

Purpose

Purpose

This manual explains the Moog Animatics Class 5 SmartMotor™ support for the Digital

MultipleX (DMX) communications protocol. It describes the major concepts that must be

understood to integrate a SmartMotor as a DMX slave device. However, it only minimally

covers the low-level details of the DMX protocol.

NOTE: The Remote Device Management (RDM) bidirectional communication

extension of the DMX protocol is not supported.

The feature set described in this version of the manual refers to firmware in the 5.x.4.y

series, where x = 0, 16, 32, 97 or 98, and y=3 or greater. Versions 5.0.4, 5.16.4, and 5.32.4

are specific to D-style motors, and versions 5.97.4 and 5.98.4 are specific to M-style motors.

Refer to the following lists.

NOTE: The SmartMotor firmware must be one of the listed versions.

For D-style motors:

l

5.0.4.y (where y is 3 or greater)

l

5.16.4.y (where y is 3 or greater)

l

5.32.4.y (where y is 3 or greater)

For M-style motors:

l

5.97.4.y (where y is 3 or greater)

l

5.98.4.y (where y is 3 or greater)

This manual is intended for programmers or system developers who have read and

understand the Engineering Commission of United States Institute for Theatre Technology

(USITT) DMX512-A standard. Therefore, this manual is not a tutorial on that standard or the

DMX protocol. Instead, it should be used to understand the specific implementation details for

the Moog Animatics Class 5 SmartMotor. Additionally, code examples are provided to assist

the programmer with the SmartMotor integration.

The Command Reference section of this manual includes details about the specific DMX

commands available in the SmartMotor through the DMX firmware. For details, see

DMXCommands on page 27.

Combitronic Technology

The most unique feature of the SmartMotor is its ability to communicate with other

SmartMotors and share resources using Moog Animatics’ Combitronic™ technology.

Combitronic is a protocol that operates over a standard CAN interface. It may coexist with

CANopen and other protocols. It requires no single dedicated master to operate. Each

SmartMotor connected to the same network communicates on an equal footing, sharing all

information, and therefore, sharing all processing resources.

While the Combitronic protocol can be used in parallel with a DMX network, there are certain

restrictions:

l

The DMX wiring does not carry the Combitronic signal. Therefore, additional cabling

(available from Moog Animatics) must be used to build the Combitronic network.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 6 of 46

Page 7

Combitronic Technology

l

There is bidirectional, end-to-end connectivity only within the same Combitronic

network of motors. Therefore, one Combitronic network cannot communicate with

another.

When a Combitronic network is used in parallel with a DMXnetwork, you can:

l

Avoid the cost of repeaters.

l

Gain bidirectional, end-to-end connectivity within the Combitronic network of motors.

There are no other motors on the market that can talk to each other on a side bus while

being a slave to the DMX host controller.

l

Compute or synchronize motion between motors within the same Combitronic network.

For example, DMX values (from the host controller) could be used to adjust amplitude

and frequency of SmartMotor Cam tables for an electronic camming or gearing

application that controls the motion pattern of a bank of stage lights.

In short, DMX-equipped SmartMotors retain all the features and benefits of the standard Class

5 SmartMotor, including features like electronic camming, gearing, and Combitronic support.

For additional details, see the Class 5 SmartMotor™ Installation & Startup Guide.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 7 of 46

Page 8

DMX Overview

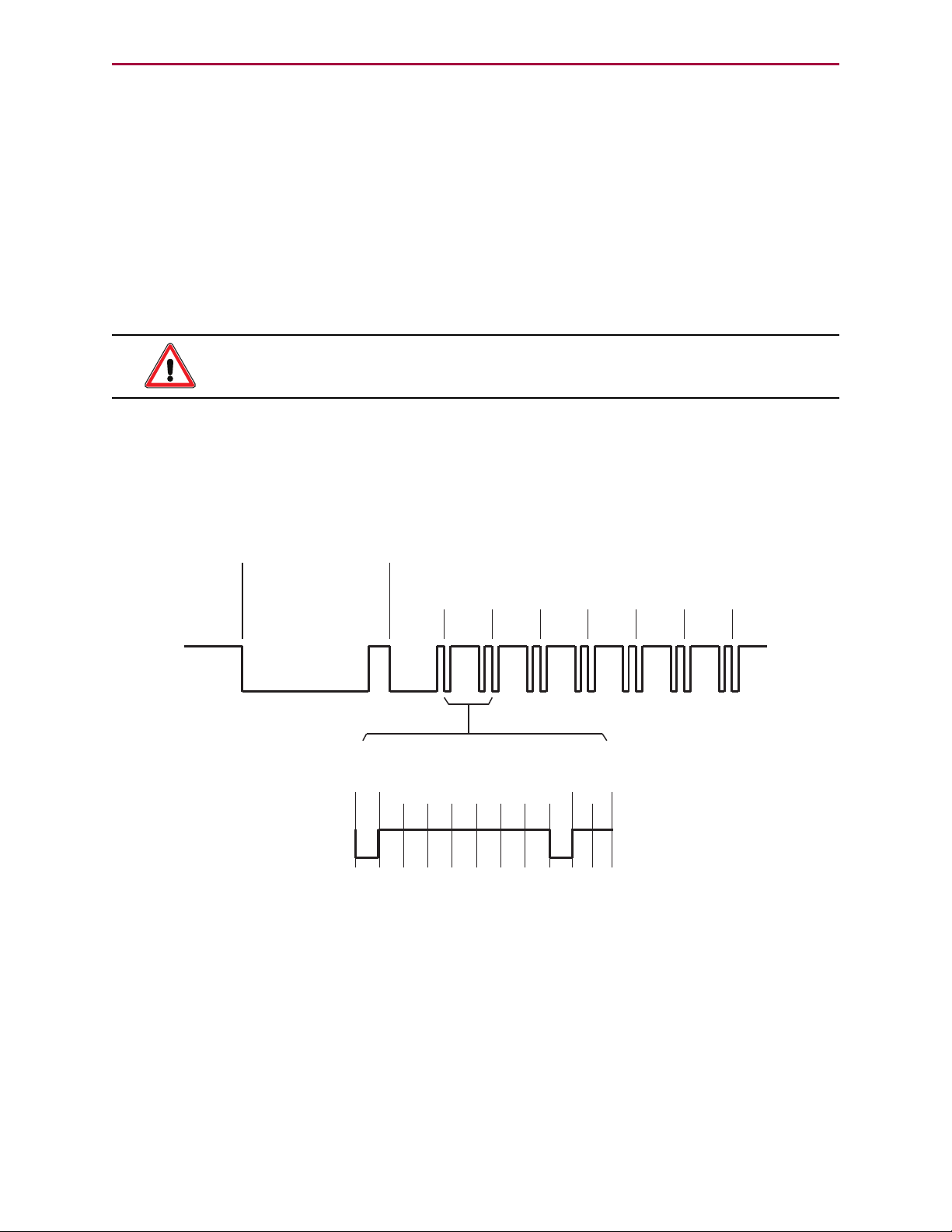

0 1 2 3 4 5 6 7 1 2

Start code and data channels

(11 bits, 4 μs each )

DATA BITS

STOP

BITS

START

BIT

IDLE

START

BREAK

100 μs

(could be as

low as 92 μs)

12

μs

MAB

Start Code in Slot 0

(followed by up to 512 data channels)

SLOT 0

44 μs

SLOT 1

44 μs

SLOT 2

44 μs

SLOT 3

44 μs

SLOT 4

44 μs

SLOT 5

44 μs

SLOT 6

44 μs

DMX Overview

DMX is a standard for digital communications networks that are used to control lighting, stage

effects, dimmers, fog machines and related applications. This control may include positioning

and/or focusing of lights or other objects to aid in visual effects of stage productions or other

live events. As a result, its use is often expanded to the movement or control of curtains,

stage props or other objects that require motion.

DMX, or further expanded as DMX512, is an EIA-485 (RS-485) hardware-based protocol that is

unidirectional in nature — the controller only sends data; it does not receive data. Further, it

has no error checking or checksums that are required for use in hazardous applications.

Therefore, its use must be limited to safe operating environments where failure due to

transmission errors would not cause harm to personnel or equipment.

WARNING: DMX networks must not be used in applications where failure due

to transmission errors would cause harm to personnel or equipment.

DMX512 controllers transmit asynchronous serial data at 250 kilobaud (kBd). The data format

is fixed and begins with a single start bit, eight data bits, and two stop bits with no parity. Up

to 512 8-bit data bytes or "channels" of data may be transmitted to all nodes at once. The data

is ordered serially and typically runs continuously from a DMX master controller. The full data

packet begins with a break, followed by a Mark after Break (MAB), then Slot 0 beginning with

a one-byte Start Code, and that is followed by up to 512 data slots. Refer to the following

figure.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

DMX Data Transmission

Page 8 of 46

Page 9

Safety Information

Safety Information

This section describes the safety symbols and other safety information.

Safety Symbols

The manual may use one or more of the following safety symbols:

WARNING: This symbol indicates a potentially nonlethal mechanical hazard,

where failure to follow the instructions could result in serious injury to the

operator or major damage to the equipment.

CAUTION: This symbol indicates a potentially minor hazard, where failure to

follow the instructions could result in slight injury to the operator or minor

damage to the equipment.

NOTE: Notes are used to emphasize non-safety concepts or related information.

Other Safety Considerations

The Moog Animatics SmartMotors are supplied as components that are intended for use in an

automated machine or system. As such, it is beyond the scope of this manual to attempt to

cover all the safety standards and considerations that are part of the overall machine/system

design and manufacturing safety. Therefore, the following information is intended to be used

only as a general guideline for the machine/system designer.

It is the responsibility of the machine/system designer to perform a thorough "Risk

Assessment" and to ensure that the machine/system and its safeguards comply with the

safety standards specified by the governing authority (for example, ISO, OSHA, UL, etc.) for

the locale where the machine is being installed and operated. For more details, see Machine

Safety on page 10.

Motor Sizing

It is the responsibility of the machine/system designer to select SmartMotors that are

properly sized for the specific application. Undersized motors may: perform poorly, cause

excessive downtime or cause unsafe operating conditions by not being able to handle the

loads placed on them. The System Best Practices document, which is available on the Moog

Animatics website, contains information and equations that can be used for selecting the

appropriate motor for the application.

Replacement motors must have the same specifications and firmware version used in the

approved and validated system. Specification changes or firmware upgrades require the

approval of the system designer and may require another Risk Assessment.

Environmental Considerations

It is the responsibility of the machine/system designer to evaluate the intended operating

environment for dust, high-humidity or presence of water (for example, a food-processing

environment that requires water or steam wash down of equipment), corrosives or chemicals

that may come in contact with the machine, etc. Moog Animatics manufactures specialized

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 9 of 46

Page 10

Machine Safety

IP-rated motors for operating in extreme conditions. For details, see the Moog Animatics

Product Catalog.

Machine Safety

In order to protect personnel from any safety hazards in the machine or system, the

machine/system builder must perform a "Risk Assessment", which is often based on the ISO

13849 standard. The design/implementation of barriers, emergency stop (E-stop)

mechanisms and other safeguards will be driven by the Risk Assessment and the safety

standards specified by the governing authority (for example, ISO, OSHA, UL, etc.) for the

locale where the machine is being installed and operated. The methodology and details of

such an assessment are beyond the scope of this manual. However, there are various sources

of Risk Assessment information available in print and on the internet.

NOTE: The following list is an example of items that would be evaluated when

performing the Risk Assessment. Additional items may be required. The safeguards

must ensure the safety of all personnel who may come in contact with or be in the

vicinity of the machine.

In general, the machine/system safeguards must:

l

Provide a barrier to prevent unauthorized entry or access to the machine or system. The

barrier must be designed so that personnel cannot reach into any identified danger

zones.

l

Position the control panel so that it is outside the barrier area but located for an

unrestricted view of the moving mechanism. The control panel must include an E-stop

mechanism. Buttons that start the machine must be protected from accidental

activation.

l

Provide E-stop mechanisms located at the control panel and at other points around the

perimeter of the barrier that will stop all machine movement when tripped.

l

Provide appropriate sensors and interlocks on gates or other points of entry into the

protected zone that will stop all machine movement when tripped.

l

Ensure that if a portable control/programming device is supplied (for example, a handheld operator/programmer pendant), the device is equipped with an E-stop mechanism.

NOTE: A portable operation/programming device requires many additional

system design considerations and safeguards beyond those listed in this

section. For details, see the safety standards specified by the governing

authority (for example, ISO, OSHA, UL, etc.) for the locale where the

machine is being installed and operated.

l

Prevent contact with moving mechanisms (for example, arms, gears, belts, pulleys,

tooling, etc.).

l

Prevent contact with a part that is thrown from the machine tooling or other parthandling equipment.

l

Prevent contact with any electrical, hydraulic, pneumatic, thermal, chemical or other

hazards that may be present at the machine.

l

Prevent unauthorized access to wiring and power-supply cabinets, electrical boxes, etc.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 10 of 46

Page 11

Documentation and Training

l

Provide a proper control system, program logic and error checking to ensure the safety

of all personnel and equipment (for example, to prevent a run-away condition). The

control system must be designed so that it does not automatically restart the

machine/system after a power failure.

l

Prevent unauthorized access or changes to the control system or software.

Documentation and Training

It is the responsibility of the machine/system designer to provide documentation on safety,

operation, maintenance and programming, along with training for all machine operators,

maintenance technicians, programmers, and other personnel who may have access to the

machine. This documentation must include proper lockout/tagout procedures for maintenance

and programming operations.

It is the responsibility of the operating company to ensure that:

l

All operators, maintenance technicians, programmers and other personnel are tested

and qualified before acquiring access to the machine or system.

l

The above personnel perform their assigned functions in a responsible and safe manner

to comply with the procedures in the supplied documentation and the company safety

practices.

l

The equipment is maintained as described in the documentation and training supplied by

the machine/system designer.

Additional Equipment and Considerations

The Risk Assessment and the operating company's standard safety policies will dictate the

need for additional equipment. In general, it is the responsibility of the operating company to

ensure that:

l

Unauthorized access to the machine is prevented at all times.

l

The personnel are supplied with the proper equipment for the environment and their job

functions, which may include: safety glasses, hearing protection, safety footwear,

smocks or aprons, gloves, hard hats and other protective gear.

l

The work area is equipped with proper safety equipment such as first aid equipment,

fire suppression equipment, emergency eye wash and full-body wash stations, etc.

l

There are no modifications made to the machine or system without proper engineering

evaluation for design, safety, reliability, etc., and a Risk Assessment.

Safety Information Resources

Additional SmartMotor safety information can be found on the Moog Animatics website; open

the file "109_Controls, Warnings and Cautions.pdf" located at:

http://www.animatics.com/support/moog-animatics-catalog.html

OSHA standards information can be found at:

https://www.osha.gov/law-regs.html

ANSI-RIA robotic safety information can be found at:

http://www.robotics.org/robotic-content.cfm/Robotics/Safety-Compliance/id/23

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 11 of 46

Page 12

Safety Information Resources

UL standards information can be found at:

http://ulstandards.ul.com/standards-catalog/

ISOstandards information can be found at:

http://www.iso.org/iso/home/standards.htm

EUstandards information can be found at:

http://ec.europa.eu/growth/single-market/european-standards/harmonisedstandards/index_en.htm

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 12 of 46

Page 13

Additional Documents

Additional Documents

The Moog Animatics website contains additional documents that are related to the information

in this manual. Please refer to the following list.

Related Guides

l

Class 5 SmartMotor™ Installation & Startup Guide

http://www.animatics.com/cl-5-install-startup-guide

l

SmartMotor™ Developer's Guide

http://www.animatics.com/smartmotor-developers-guide

Other Documents

l

SmartMotor™ System Best Practices

http://www.animatics.com/system-best-practices-application-note

l

SmartMotor™ Product Certificate of Conformance

http://www.animatics.com/download/Declaration of Conformity.pdf

l

SmartMotor™ ULCertification

http://www.animatics.com/download/MA_UL_online_listing.pdf

l

SmartMotor Developer's Worksheet

(interactive tools to assist developer: Scale Factor Calculator, Status Words, CAN Port

Status, Serial Port Status, RMODE Decoder and Syntax Error Codes)

http://www.animatics.com/tools

l

Moog Animatics Product Catalog

http://www.animatics.com/support/moog-animatics-catalog.html

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 13 of 46

Page 14

Additional Resources

Additional Resources

The Moog Animatics website contains useful resources such as product information,

documentation, product support and more. Please refer to the following addresses:

l

General company information:

http://www.animatics.com

l

Product information:

http://www.animatics.com/products.html

l

Product support (Downloads, How To videos, Forums, Knowledge Base, and FAQs):

http://www.animatics.com/support.html

l

Sales and distributor information:

http://www.animatics.com/sales-offices.html

l

Application ideas (including videos and sample programs):

http://www.animatics.com/applications.html

DMX Resources

The following equipment and software can be used to test your DMX system:

l

DMX512 Standard:

http://old.usitt.org/DMX512.aspx

l

Lights Up software (open source, GNUlicense):

http://lightsup.sourceforge.net/

l

Enttec Open DMX USB interface:

http://www.enttec.com/?main_menu=Products&pn=70303

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 14 of 46

Page 15

Connections, Wiring and Status LEDs

Connections, Wiring and Status LEDs

This chapter provides information on the SmartMotor connectors, a multidrop cable diagram,

and a description of the SmartMotor status LEDs.

Connectors and Pinouts 16

D-Style Motors: Connectors and Pinouts 16

M-Style Motors: Connectors and Pinouts 17

DMX NetworkTopology 17

System Cable Diagram 18

D-Style Multidrop Signal Cable Diagram 19

M-Style Multidrop Signal Cable Diagram 20

Understanding the Status LEDs 21

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 15 of 46

Page 16

Connectors and Pinouts

PIN

1

2

3

4

5

NC

+V (NC except DeviceNet)

-V (Isolated GND )

CAN-H

CAN-L

DESCRIPTION

5-Pin CAN (female)

1

2

3

4

5

6

7

8

9

10

11

12

I/O-16 GP

I/O-17 GP

I/O-18 GP

I/O-19 GP

I/O-20 GP

I/O-21 GP

I/O-22 GP

I/O-23 GP

I/O-24 GP

I/O-25 GP

+24VDC Input

GND I/O

PIN DESCRIPTION

12-Pin Expanded I/O Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

I/O-0

I/O-1

I/O-2

I/O-3

I/O-4

I/O-5

I/O-6

Encoder A Out

Encoder B Out

RS-232 Transmit

RS-232 Receive

+5VDC Out

Ground

Power Ground

Power

PIN DESCRIPTION

7-Pin Combo D-Sub Power & I/O

A1 A2

1 2

3 4 5

A1

A2

1

2

3

4

5

+20V to +48V DC

Power Ground

I/O-6

+5VDC Out

RS-232 Transmit

RS-232 Receive

RS-232 Ground

PIN DESCRIPTION

15-Pin D-Sub I/O

Trajectory LED

PWR/Servo LED

CAN Fault LED

CAN Status LED

15 14 13 12 11 10 9

8 7 6 5 4 3 2 1

Connectors and Pinouts

D-Style Motors: Connectors and Pinouts

NOTE: DMX support is on RS-485 "COM1"; it uses pins 5 and 6 of the 15-pin D-Sub

I/O connector (see the following figure). Also, see D-Style Multidrop Signal Cable

Diagram on page 19.

The following figure provides a brief overview of the connectors and pinouts available on the

D-style SmartMotors. For details, see the Class 5 SmartMotor™ Installation & Startup Guide.

NOTE: On the SmartMotor, the RS-485 line labeled "A" is the non-inverting line

(D+). This may be different than other systems where "B" is the non-inverting line.

NOTE: The DE power option is recommended. For details, see the Class 5

SmartMotor™ Installation & Startup Guide.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 16 of 46

Page 17

M-Style Motors: Connectors and Pinouts

PIN

1

2

3

4

5

+24VDC Out

I/O-3 or -Limit

GND-Common

I/O-2 or +Limit

I/O-10

DESCRIPTION

LIMIT INPUTS

PIN

1

2

3

4

5

NC

+V (NC except DeviceNet)

-V (Unisolated Ground)

CAN-H

CAN-L

DESCRIPTION

CANOPEN

1

2

3

4

5

6

7

8

9

10

11

12

I/O-0

I/O-1

I/O-4

I/O-5

I/O-6

I/O-7

I/O-8

I/O-9

Not Fault Out

Drive Enable In

+24VDC Out

GND-Common

PIN

I/Os

1

2

3

4

5

6

7

8

GND-Common

RS-485B CH0

RS-485A CH0

ENC A+ (In/Out)

ENC B- (In/Out)

ENC A- (In/Out)

+5VDC Out

ENC B+ (In/Out)

PIN

DESCRIPTION

COMMUNICATION

1

2

3

4

Control Power In 24Vmax

Chassis GND/Earth

GND-Common

Amplifier Power 48Vmax

PIN DESCRIPTION

POWER INPUT

RS-485 serial communication uses a

voltage dierential signal. Appropriate

terminating resistors should be included

on the RS-485 network to ensure reliable

performance.

DESCRIPTION

CANOPEN

RUN LED

12-Pin I/O

4-Pin Power Input

8-Pin

COM Encoder Bus

5-Pin CANopen

(female is standard)

5-Pin

Limit Inputs

CANOPEN

ERROR LED

TRAJECTORY

LED

SERVO-AMPLIFIER

LED

M-Style Motors: Connectors and Pinouts

NOTE: DMX support is on RS-485 "COM0"; it uses pins 2 and 3 of the 8-Pin

COMEncoder Bus connector (see the following figure). Also, see M-Style Multidrop

Signal Cable Diagram on page 20.

The following figure provides a brief overview of the connectors and pinouts available on the

M-style SmartMotors. For details, see the Class 5 SmartMotor™ Installation & Startup Guide.

NOTE: On the SmartMotor, the RS-485 line labeled "A" is the non-inverting line

(D+). This may be different than other systems where "B" is the non-inverting line.

DMX NetworkTopology

As mentioned previously, DMX512 is based on the EIA-485 standard. It comes with all the

limits and requirements of a system based on an RS-485 multi-drop bus. Further, there must

be proper bus termination, as required by the EIA-485 standard. Refer to the following figure.

The EIA-485-A standard for the physical connection allows a length of 1000 feet at 250 kBd.

However, Moog Animatics does not guarantee this distance under all conditions. The user is

responsible for testing and verifying operation in the application environment, including: wire

length, DMX host device, and number of DMX nodes.

At the opposite end from the DMX controller, a 120 Ohm bus terminator must be used (see the

following figure) — this prevents reflected impedance and noise issues that would otherwise

occur.

CAUTION: The 120 Ohm terminator is required at the end of the bus opposite

the DMX controller.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 17 of 46

Page 18

System Cable Diagram

DMX512

Controller

(Master)

OUT

Serial IN/OUT

SmartMotor

(Slave)

120 Ohm

Terminator

Serial IN/OUT

SmartMotor

(Slave)

Serial IN/OUT

SmartMotor

(Slave)

DMX Light Console

SmartMotor

Address: 001

120 Ohm

Terminator

SmartMotor

Address: 002

SmartMotor

Address: 003

SmartMotor

Address: 004

One or more stage props are raised/lowered based on inputs from DMX console

DMX Network Topology

NOTE: Any drops from the main bus should be kept as short as possible, so the

system looks like an "in line" network, as shown in the previous figure.

Each DMX network is called a "universe" and can consist of up to 512 data bytes. If more than

512 data bytes are required, then another universe will be required.

NOTE: Some large DMX controllers (such as an operator console) have multiple

outputs, which allow them to control multiple universes.

For example, the following figure shows a DMX network of SmartMotors being used to

raise/lower one or more stage props based on inputs from the DMX controller. Each motor is

assigned a unique DMX address, so it can be operated from the DMX control console. Also,

note the 120 Ohm terminator, which is required at the end of the bus.

DMXand SmartMotors Controlling Stage Props

System Cable Diagram

As shown in the previous section, DMX networks are most reliable when a straight bus is used.

Common problems with DMX bus wiring are often traced to branches or other configurations.

These often create multipath signal reflections that cause communication errors. Adhere to

the following cabling requirements:

l

The maximum cable length should not exceed 1000 feet at 250 kBd.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 18 of 46

Page 19

D-Style Multidrop Signal Cable Diagram

Motor as Terminating Node

NOTE: A terminating resistor is required at the downstream end of the bus!

I/O Connector

Pin Numbers

Trajectory

LED (Bt)

Power/Servo

LED

120 Ohm Shunt

Shield Drain (optional)

15 14 13 12 11 10 9

8 7 6 5 4 3 2 1

Shield Drain (optional)

Pin 5 “A” (D+)

Pin 6 “B” (D-)

120 Ohm Shunt

15-pin D-sub Male

Terminating Node

15-pin D-sub Male 15-pin D-sub Male 15-pin D-sub Male

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

23456

789

10

11

12

131415

1

23456

789

10

11

12

131415

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Pin 5 “A” (D+)

Pin 6 “B” (D-)

CAUTION: The EIA-485-A standard for the physical connection allows a length

of 1000 feet at 250 kBd. However, Moog Animatics does not guarantee this

distance under all conditions. The user is responsible for testing and verifying

operation in the application environment, including: wire length, DMX host

device, and number of DMX nodes.

l

Each slave must be inline or a short drop from the main bus; do not use branches.

l

Use a 120 Ohm terminator at the downstream end of the bus, which is the end opposite

the DMX512 controller.

CAUTION: The 120 Ohm terminator is required at the downstream end of the

bus.

D-Style Multidrop Signal Cable Diagram

The following figure shows a multidrop signal cable configuration for D-style motors. To

supply power, it is recommended that you use the DE power option. For details, see the Class

5 SmartMotor™ Installation & Startup Guide.

NOTE: DMX support is on RS-485 "COM1"; it uses pins 5 and 6 of the 15-pin D-Sub

I/O connector.

NOTE: On the SmartMotor, the RS-485 line labeled "A" is the non-inverting line

(D+). This may be different than other systems where "B" is the non-inverting line.

D-Style Multidrop Cable Diagram

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 19 of 46

Page 20

M-Style Multidrop Signal Cable Diagram

Motor as Terminating Node

NOTE: A terminating resistor is required at the downstream end of the bus!

120 Ohm Shunt

Shield Drain (optional)

Shield Drain (optional)

Pin 3 “A” (D+)

Pin 2 “B” (D-)

120 Ohm Shunt

Terminating Node

Pin 3 “A” (D+)

Pin 2 “B” (D-)

CANOPEN

RUN LED

4-Pin Power Input

8-Pin

COM Encoder Bus

CANOPEN

ERROR LED

TRAJECTORY

LED

SERVO-AMPLIFIER

LED

M-Style Multidrop Signal Cable Diagram

The following figure shows a multidrop signal cable configuration for M-style motors. Power is

supplied through the separate 4-Pin Power Input connector. For details, see the Class 5

SmartMotor™ Installation & Startup Guide.

NOTE: DMX support is on RS-485 "COM0"; it uses pins 2 and 3 of the 8-Pin

COMEncoder Bus connector.

NOTE: On the SmartMotor, the RS-485 line labeled "A" is the non-inverting line

(D+). This may be different than other systems where "B" is the non-inverting line.

M-Style Multidrop Signal Cable Diagram

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 20 of 46

Page 21

Understanding the Status LEDs

P3 (CANopen option)

LED Status on Power-Up:

• With no program and the travel limits are low:

LED 0 will be solid red indicating the motor is in a fault state due to travel limit fault.

LED 1 will be off.

• With no program and the travel limits are high:

LED 0 will be solid red for 500 milliseconds and then begin flashing green.

LED 1 will be off.

• With a program that only disables travel limits and nothing else:

LED 0 will be solid red for 500 milliseconds and then begin flashing green.

LED 1 will be off.

P1 (Power Input)

LED 0

LED 1

P2 (COM

Encoder Bus)

P3

(I/O Connector)

P4

(Limit Inputs)

P5

(CANopen)

LED 3

LED 2

LED 0: Drive Status Indicator

Off No Power

Solid green Drive On

Flashing green Drive Off

Flashing red Watchdog Fault

Solid red Major Fault

Alt. red/green In Boot Load, Needs Firmware

LED 1: Trajectory Status Indicator

Off Not Busy

Solid green Drive On, Trajectory In Progress

LED 2: CAN Bus Network Fault (Red LED)

Off No Error

Single flash At Least One Error

Exceeded Limit

Double flash Heartbeat or Guard Error

Solid Busy Off State

LED 3: CAN Bus Network Status (Green LED)

Blinking Pre-Operational State

(during boot-up)

Solid Normal Operation

Single Device is in Stopped State

Understanding the Status LEDs

The Status LEDs provide the same functionality for the D-style and M-style (including IPsealed) SmartMotors.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 21 of 46

Page 22

DMX on the SmartMotor

DMX on the SmartMotor

This chapter provides information about DMX operation on the SmartMotor.

DMXImplementation 23

Data Storage and Usage 23

Example 24

Status Bits 25

End of Packet 25

DMXCommands 27

Select DMX Channels 27

Special Range Checking 28

Open DMX Channel 28

Close DMX Channel 28

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 22 of 46

Page 23

DMXImplementation

DMXImplementation

The SmartMotor has the ability to accept DMX512 protocol through the RS-485 port. Flexibility

is maintained by allowing the user to assign and accept multiple slots of incoming DMX

protocol — the starting slot and number of slots may be defined by the user.

DMX data packets are unsigned 8-bit integer data. As a result, and to conform to only positive

integer values, incoming slots of 8-bit data are stored into 16-bit signed array variables in

SmartMotor memory.

SmartMotors have predefined 16-bit array data variables consisting of aw[0] through aw

[101]. Therefore, the SmartMotor is limited to 102 DMX channels. The "aw" stands for "array

word" and is an indexed 16-bit signed integer value. If a slot is assigned to an aw[] array

variable, the value returned will be between 0 and 255. This assures proper sign convention

for all values. It also allows for easier addition and bit shifting to optimize incoming data.

NOTE: The SmartMotor is limited to 102 DMX channels.

The user program must read incoming DMX data in the aw[] registers and perform all actions

from that data, including motion and/or digital outputs.

For example, if you want to control the position of a theater light, you would:

1.

Select an unused DMX controller channel,

2.

Program the base address in the SmartMotor aligned with that particular channel,

3.

Write a program that reads the corresponding array variable in the SmartMotor,

4.

Assign corresponding parameters in the motor, including position, velocity, acceleration

and torque, call out a specific subroutine, and more.

By using the SmartMotor, the entire motion control system requires less cabling and becomes

more compact because no control cabinet is needed. Further, additional axes can be added as

needed.

Data Storage and Usage

Address information for the DMX protocol can be stored in one of the following ways:

l

It can be "hard coded" into the program, or

l

The VST/VLD commands can be used to store/retrieve this information

to/from the desired SmartMotor memory location.

It is up to the system programmer to select the method that works best for the application.

NOTE: Technically, there is no "address" for a DMX slave device. The slave device

sees all (possibly 512 bytes) of the data and decides which part it wants to use.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 23 of 46

Page 24

Example

1 2 3 4 5 ... ... ... ... ... ...

512

1 2 3 4 5 6 ... ... ... ... ...

101

0

DMX network packet

rst

COMCTL(1,3)

COMCTL(4,4)

COMCTL(2,3)

Time

aw[ ] registers

last

Data Transfer from DMX to SmartMotor Array

Data from the DMX packet is stored into the SmartMotor user-variable word array. Even

though the channels are 8-bit data, the 16-bit word locations are used for storage in order to

represent the data as unsigned numbers. When stored as words, the values 0 through 255

appear unsigned. (If the values were presented as bytes, they would appear negative to user

programs when larger than half of the scale.)

Typically, most DMX devices (including the SmartMotor) use a "base channel". The

SmartMotor does that using COMCTL(1,x), where x is the base channel: 1-512.

Example

Settings:

l

Base DMX channel = 5

l

Number of DMX channels = 2

DMX

Channel

1

2

3

4

5 aw[0]

6 aw[1]

7

...

SmartMotor

Variable

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 24 of 46

Page 25

Status Bits

Status Bits

To allow a user program to respond to the conditions of the DMX data stream, several user

bits were implemented in the first user status word. This is accessible for reading as Status

Word 12. See the next table for a description of the bits in Status Word 12.

Note the following:

l

These bits cannot be cleared using ZS or Z(word,bit) commands. See notes in table for

specific usage.

l

All bits in Status Word 12 are cleared when opening the DMX channel. Do not use any of

user status bits 0-15 as a general-purpose user status bits. Use user status bits 16-31

(Status Word 13) if general-purpose user status bits are required.

End of Packet

User bit 2 reports when the end of a packet is received. This allows for better synchronization

among slave devices. Previously, a device reading channel 1 versus a device reading channel

512 could have up to 22 milliseconds of skew if they were depending on user bit 1. User bit 2

would minimize or eliminate this skew.

To use this feature, see the COMCTL(3,value) command. Note that:

l

Bit 2 must be cleared to acknowledge receipt.

l

The system programmer may choose a lower channel for value if the upper channels

are not used or if the DMX master does not send all 512 channels.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 25 of 46

Page 26

End of Packet

The following table provides bit descriptions for Status Word 12:

Status

Word

Bit Description Set By Cleared By

12 0 DMX packets seen within the last second.

Packets may have any start code. They

may or may not be relevant data.

12 1 DMX data received. Set when the last

expected motor channel arrives, not when

the whole packet arrives. For example, if

the channel quantity is set to expect 2

channels, then the flag is set when the

second byte is saved to aw[1].

12 2 COMCTL(3,value) sync on channel

"value", where value is the channel number 1-512; value=512 by default. User bit

2 is set when that channel is received.

Therefore, a full 512 channel packet will

set this bit at the end of the packet.

12 3 - 15 Reserved.

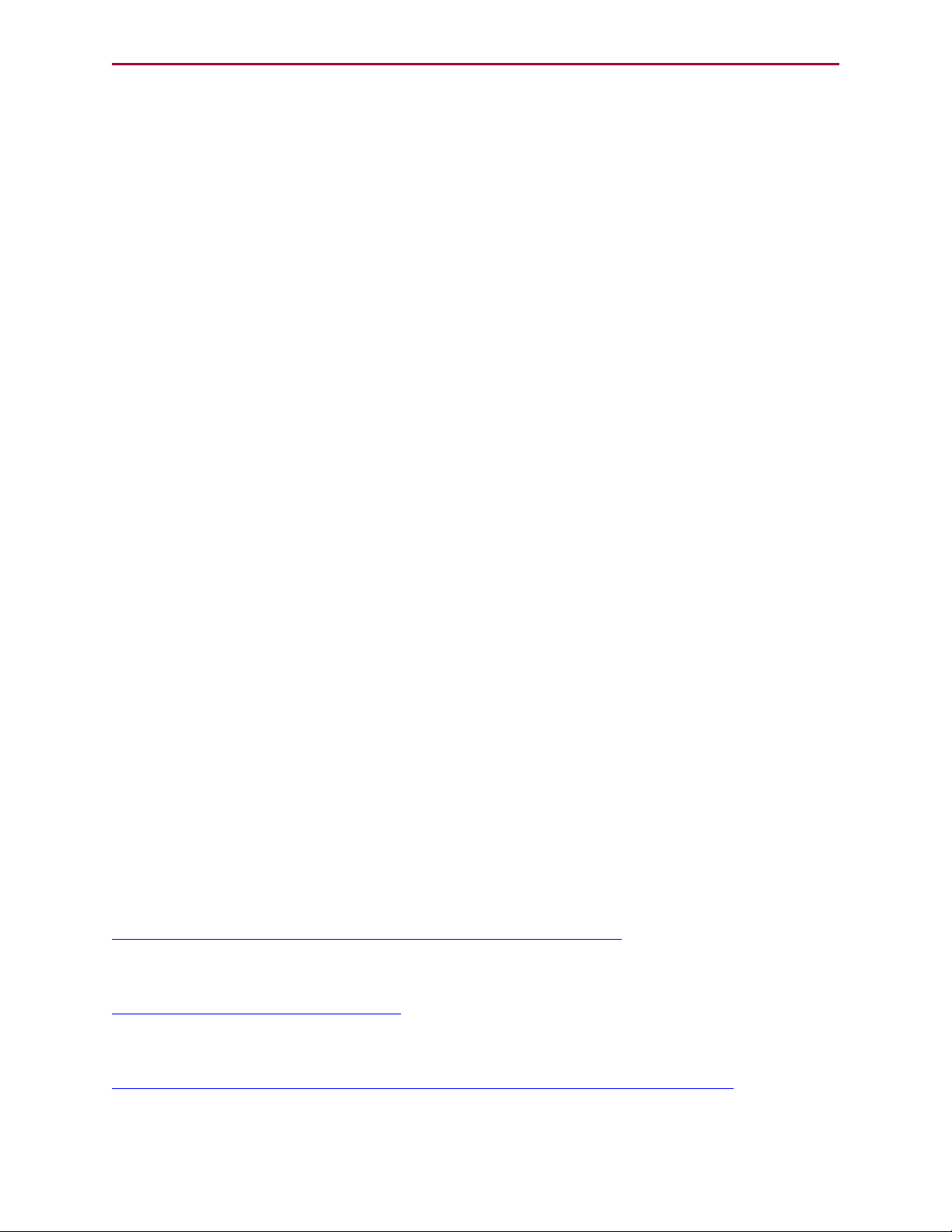

The following diagram shows when each bit is set.

Arrival of any

start code.

Arrival of last

expected

channel.

Set on arrival

of last expected host-capable channel.

Timeout after

1 second of

no valid packets.

User: use

command UR

(1).

User: use

command UR

(2).

DMX Network Packet

Start

code

First

data

Byte: 0 1 2 3 4 5 6 7 … 256 … 511 512

Data configuration:

Selected data

COMCTL(1,3),

COMCTL(2,4)

Status bit B(12,0) Bit set

Status bit B(12,1) Bit

set

Status bit B(12,2),

e.g., when

COMCTL(3,256)

a) Bit set when this byte is complete

Last

data

a

Bit

a

set

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 26 of 46

Page 27

DMXCommands

The following diagram shows how COMCTL(3,value) is useful in applications with multiple

motors.

DMX Network Packet

Start

code

First

data

Byte: 0 1 2 3 4 … 512

Data configuration motor 1:

COMCTL(1,1), COMCTL(2,1)

Data configuration motor 1:

COMCTL(1,2), COMCTL(2,1)

Data configuration motor 1:

COMCTL(1,3), COMCTL(2,1)

Selected

data

Selected

data

Selected

data

Last

data

Data configuration motor 1:

COMCTL(1,4), COMCTL(2,1)

Status bit B(12,2), e.g., when

COMCTL(3,4) in all motors

Selected

data

Bit

a,b,c

set

a) Bit set when this byte is complete.

b) All motors see the bit at the same time.

c) All motors have received their data at this point.

DMXCommands

The following sections describe the DMX-specific commands that are available on the

SmartMotor. The commands are organized by function.

Select DMX Channels

The following commands are used to select the DMX channels:

NOTE: If the input is out of range, these commands will be ignored and issue a

command error. They do not retain any settings between power cycles.

l

COMCTL(1,value) Set base channel [value] (1 through 512); default is 1 at power-up.

l

COMCTL(2,value) Set number of channels [value] to read starting with base channel

(1 through 102); default is 1 at power-up.

l

COMCTL(3,value) Sync on channel, where value is the channel number 1-512; default

is 512 at power-up. User bit 2 is set when that channel is received. Therefore, a full 512

channel packet will set this bit at the end of the packet.

l

COMCTL(4,value) Allows for the selection of the aw[] register where the DMX data

begins loading; default is 0 at power-up. For example, COMCTL(4,10) will start loading

DMX data at aw[10].

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 27 of 46

Page 28

Special Range Checking

Special Range Checking

The following range checks would apply due to a combination of the previously listed

commands:

l

If the value of the base channel + number of channels exceeds 512, then the additional

channels will be ignored.

l

If the value of the aw[] starting channel + number of channels exceeds 102, then the

additional channels will be ignored.

These checks are performed after commands COMCTL(1,value), COMCTL(2,value) and

COMCTL(4,value).

Open DMX Channel

The following commands are used to open a DMX channel:

l

OCHN(DMX,1,N,250000,2,8,D) uses COM1 for D-style motors; by default, DMX on

COM1 is disabled (port closed).

l

OCHN(DMX,0,N,250000,2,8,D) uses COM0 for M-style motors.

Data begins writing into the aw[x] registers as soon as the port is open and valid DMX packets

arrive.

Any other parameters will result in command error, and the state of the port remains

unchanged. DMX specifies these settings: 250 kBd, 8 data bits, 2 stop bits, no parity check.

Close DMX Channel

The following commands are used to close a DMX channel:

l

CCHN(DMX,1) for D-style motors

l

CCHN(DMX,0) for M-style motors

These commands:

l

Stop listening for DMX data

l

Clear flags in Status Word 12

l

Values in the aw[] array are left as is

NOTE: Data in the aw[] array may be only partially updated if the channel closes

at the moment the DMX data is being loaded.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 28 of 46

Page 29

Example Programs

Example Programs

This chapter contains example programs that you can use as a guide for developing your

SmartMotor applications. For more details on SmartMotor programming, see the Class 5

SmartMotor™ Installation & Startup Guide.

NOTE: The programs and code samples in this manual are provided for example

purposes only. It is the user's responsibility to decide if a particular code sample or

program applies to the application being developed and to adjust the values to fit

that application.

Home Against a Hard Stop Example 30

Position Mode Control Example 32

DMX Five Channel Example 35

DMX Packet Test Example 38

Reverse DMXChannel Byte Order Example 40

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 29 of 46

Page 30

Home Against a Hard Stop Example

Home Against a Hard Stop Example

Because the SmartMotor has the capability of lowering its own power level and reading its

position error, it can be programmed to gently feel for the end of travel. This provides a

means to develop a consistent home position subsequent to each power-up.

Machine reliability requires the elimination of potential failure sources. Eliminating a home

switch and its associated cable leverages SmartMotor benefits and improves machine

reliability.

The following program lowers the current limit, moves against a limit, looks for resistance

and then declares and moves to a home position located 100 counts from the hard stop. The

figure following the program illustrates these steps.

MDS 'Using Sine mode commutation

KP=3200 'Increase stiffness from default

KD=10200 'Increase damping from default

F 'Activate new tuning parameters

AMPS=100 'Lower current limit to 10%

VT=-10000 'Set maximum velocity

ADT=100 'Set maximum acceleration

MV 'Set Velocity mode

G 'Start motion

WHILE EA>-100 'Loop while position error is small

LOOP 'Loop back to WHILE

O=-100 'While pressed, declare home offset

S 'Abruptly stop trajectory

MP 'Switch to Position mode

VT=20000 'Set higher maximum velocity

PT=0 'Set target position to be home

G 'Start motion

TWAIT 'Wait for motion to complete

AMPS=1000 'Restore current limit to maximum

END 'End Program

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 30 of 46

Page 31

Home Against a Hard Stop Example

Starng posion

Find home using hard stop

Physical stop -

Posion aer homing

Home oset

Move toward hard stop

1

Bump hard stop

2

Move out to specified count (home value)

3

Set motor posion to zero

4

Homing Against a Hard Stop

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 31 of 46

Page 32

Position Mode Control Example

Position Mode Control Example

The following example is provided to help you understand position mode control through DMX

code. It is recommended to use three DMX channels for maximum position resolution.

However, just one channel may be used.

Also, note that there is a home to hard stop subroutine embedded in this program. It is

important to always home the motor before executing the main DMX code. For more homing

details, see Home Against a Hard Stop Example on page 30.

'==================================================================

'Position Mode Example Code

'==================================================================

ADDR=1 'Set motor serial address as needed.

'This does not affect DMX address.

ECHO 'Set ECHO on, not required for DMX.

EIGN(W,0) 'Disable hardware limit switch checking

'(for demo purposes).

ZS 'Clear any startup errors.

'Variables for DMX control:

b=1 'Set DMX base address (valid address: 1 through 512).

n=3 'Set number of DMX channels to use.

'NOTE:Max that may be summed is 3 or 24-bit position unsigned int.

s=0 'First motor array variable index to use starting with aw[s].

'NOTE: aw[0 thru 101] are available

'NOTE: Data ranges for the value of "n" for number of channels are:

'n=1 0 to 255

'n=2 0 to 65535

'n=3 0 to 16777215

m=1 'Scale factor multiplied by data to give target position.

'NOTE: For 2 or 3 channels (16 or 24-bit position), this should be 1.

'For a single channel with 8 bit positioning, you may need to

'increase "m". Jerky motion may result by using just a single channel

'with only 8-bit resolution

'Configure DMX data usage and motor variable storage:

IF n>3 PRINT("n too large.",#13) END ENDIF

'Limit "n" based on a max of 3 bytes.

IF b>(513-n) PRINT("b too large.",#13) END ENDIF

'Limit "b" based on max data slot.

IF s>(102-n) PRINT("s too large.",#13) END ENDIF

'Limit "s" to max array value.

q=b+n-1 'Last data channel used (will be trigger when data received).

COMCTL(1,b) 'Set base DMX channel to value from CADDR.

COMCTL(2,n) 'Accept one DMX channel of data.

COMCTL(3,q) 'Status word 12 bit 2 will be set to the value 1

'when channel "q" arrives.

COMCTL(4,s) 'Set start of array index storage (good for

'bypassing cam mode dynamic array).

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 32 of 46

Page 33

Position Mode Control Example

OCHN(DMX,1,N,250000,2,8,D) 'Open DMX channel: COM1, no parity,

'250 kBd, 2 stop, 8 data, datamode

GOSUB(100) 'Always run a homing routine before DMX.

'==================================================================

' Set Initial Values

UR(2) 'Clear flag so we know when the end of the next

'data packet arrives.

MP 'Set to Position mode.

ADT=800 'Accel/decel value (adjust as needed).

VT=1500000 'Velocity (adjust as needed).

'===================================================================

' Set up interrupts to linger at higher values:

ITR(0,0,0,0,0) 'Interrupt to catch all motor drive faults.

EITR(0) 'Enable fault interrupt.

ITRE 'Enable global interrupts.

'===================================================================

' Main Program Loop

WHILE 1 'NOTE: This loop constantly polls DMX data and scales.

'it directly to target position.

IF B(12,2)==1 'Check for next data packet.

UR(2) 'Clear flag so we will know when next packet arrives.

nn=n-1

p=0 'Zero data value.

WHILE nn>=0

p=p*256+aw[nn+s] 'Set p variable for next data value.

nn=nn-1

LOOP 'Loop takes 4 milliseconds when using three

'channels (24 bit).

PT=p*m 'Calculate target position.

G 'Start moving to latest trajectory.

ENDIF

LOOP

END 'End of the main program.

'===================================================================

' Fault Routine Code (place here)

C0

END

RETURNI

'===================================================================

' Home Motor

C100 'Set up parameters (edit as required)

rr=-1 'Home direction

vv=10000 'Home speed

aa=1000 'Home accel

ee=100 'Home error limit

tt=3000 'Home torque limit

hh=4000 'Home offset

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 33 of 46

Page 34

Position Mode Control Example

' Home Routine (home to hard stop)

AMPS=512 'Reduce power.

VT=vv*rr 'Set home velocity.

ADT=aa 'Set home accel.

MV 'Set to velocity mode.

ZS 'Clear previous errors.

T=tt*rr 'Preset torque values.

G 'Begin move toward hard stop.

WHILE ABS(EA)<ee LOOP 'Loop while position error is within limit.

MTB 'Mode Torque Break to stop.

MT 'Switch to Torque mode in case bounce off hard stop.

G 'Start motion.

WAIT=50 'Wait 50 milliseconds.

O=hh*rr 'Set origin to home offset.

AMPS=1023 'Set power back to max.

MP PT=0 G TWAIT 'Set motor to zero.

RETURN

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 34 of 46

Page 35

DMX Five Channel Example

DMX Five Channel Example

The following example allows you to use up to five channels. The function of each is shown in

the following table.

Channel Purpose

1st Velocity

2nd Accel/Decel

3rd 8-bit position control

4th + 8 for 16-bit optional position control

5th + 8 more for 24-bit optional position control

In the example code (see below):

"b" sets base DMX channel

"n" sets number of position channels to use (0 through 3)

Also, note that there is a home to hard stop subroutine embedded in this program. It is

important to always home the motor before executing the main DMX code. For more homing

details, see Home Against a Hard Stop Example on page 30.

'==================================================================

'DMXFive Channel Example

'==================================================================

ADDR=1'Set Motor serial address as needed.

'This does not affect DMX address.

ECHO 'Set ECHO on, not required for DMX

EIGN(W,0)'Disable hardware limit switch check (for demo purposes).

ZS 'Clear any startup errors.

'Variables for DMX control

b=1 'Set DMX base address Valid Address: 1 thru 512

n=3 'Set number of DMX channels to use for Position control

'NOTE: Max that may be summed is 3 or 24 bit position unsigned int.

s=0 'First motor array variable index to use starting with aw[s].

'NOTE: aw[0 thru 101] are available

'The main WHILE loop will calculate the binary total value of incoming data.

'NOTE: Data ranges for the value of "n" for number of channels are:

'n=10 to 255

'n=20 to 65535

'n=30 to 16777215

m=1'Scale Factor multiplied by data to give target position.

'NOTE: For 2 or 3 channels (16 or 24-bit position), this should be 1.

'For a single channel with 8-bit positioning, you may need to

'increase "m". Jerky motion may result by using just a single

'channel with only 8-bit resolution.

vvv=2000'Scale factor for velocity target times max of 255

aaa=10'Scale factor for Accel/Decel times max of 255

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 35 of 46

Page 36

DMX Five Channel Example

'Configure DMX data usage and motor variable storage:

IF n>3 PRINT("n too large.",#13) END ENDIF

'Limit "n" based on a max of 3 bytes.

IF b>(513-n) PRINT("b too large.",#13) END ENDIF

'Limit "b" based on max data slot.

IF s>(102-n) PRINT("s too large.",#13) END ENDIF

'Limit "s" to max array value.

q=b+n-1 'Last data channel used (will be trigger when data received).

nnn=n+2

COMCTL(1,b) 'Set base DMX channel to value from CADDR.

COMCTL(2,nnn) 'Accept "n" DMX channels of data.

COMCTL(3,q) 'Status word 12 bit 2 is set to 1 when channel "q"

'arrives.

COMCTL(4,s)'Set start of array index storage (r bypass cam mode

'dynamic array).

OCHN(DMX,1,N,250000,2,8,D)'Open DMX channel: COM1, no parity,

'250 kBd, 2 stop, 8 data, datamode

GOSUB(100) 'Always run a homing routine before DMX.

'===================================================================

'Set Initial Values

UR(2) 'Clear flag so that we know when the end of the next

'data packet arrives.

MP 'Set to Position mode.

ADT=800 'Accel/Decel Value (adjust as needed).

VT=1500000 'Velocity (adjust as needed).

'===================================================================

'Set up interrupts to linger at higher values.

ITR(0,0,0,0,0)'Interrupt to catch all motor drive faults

EITR(0) 'Enable Fault Interrupt

ITRE 'Enable Global interrupts

ss=s+2

'====================================================================

'Main Program Loop

WHILE1'NOTE: This loop constantly polls DMX data and scales it

'directly to target position.

IF B(12,2)==1'Check for next data packet.

UR(2) 'Clear flag so we know when next packet arrives.

nn=n-1

p=0 'Zero data value.

WHILE nn>=0'Byte shifting and summing data.

p=p*256+aw[nn+ss]

nn=nn-1

LOOP 'Loop takes 4 msec when using three

'channels (24 bit).

VT=aw[s]*vvv'Set velocity target off of first channel

'x multiplier.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 36 of 46

Page 37

DMX Five Channel Example

ADT=aw[s+1]*aaa'Set Accel/Decel target off of second channel

'x multiplier.

PT=p*m 'Position target is total for data collected.

G 'Start moving.

ENDIF

LOOP

END ' End of the main program.

'===================================================================

'Fault Routine Code (place here)

C0

END

RETURNI

'====================================================================

' Home Motor

C100 'Set up parameters (edit as required)

rr=-1 'Home direction

vv=10000 'Home speed

aa=1000 'Home accel

ee=100 'Home error limit

tt=3000 'Home torque limit

hh=4000 'Home offset

' Home Routine (home to hard stop)

AMPS=512 'Reduce power.

VT=vv*rr 'Set home velocity.

ADT=aa 'Set home accel.

MV 'Set to velocity mode.

ZS 'Clear previous errors.

T=tt*rr 'Preset torque values.

G 'Begin move toward hard stop.

WHILE ABS(EA)<ee LOOP 'Loop while position error is within limit.

MTB 'Mode Torque Break to stop.

MT 'Switch to Torque mode in case bounce off hard stop.

G 'Start motion.

WAIT=50 'Wait 50 milliseconds.

O=hh*rr 'Set origin to home offset.

AMPS=1023 'Set power back to max.

MP PT=0 G TWAIT 'Set motor to zero.

RETURN

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 37 of 46

Page 38

DMX Packet Test Example

DMX Packet Test Example

The following example will test up to two channels summed together as a single 24-bit data

block. It will provide the time between data packets and the data itself. It is recommended to

use three DMX channels for maximum position resolution.

Also, note that there is a home to hard stop subroutine embedded in this program. It is

important to always home the motor before executing the main DMX code. For more homing

details, see Home Against a Hard Stop Example on page 30.

'==================================================================

'DMXPacket Test Code

'==================================================================

ADDR=1 'Set Motor serial address as needed.

'This does not affect DMX address.

ECHO 'Set ECHO on, not required for DMX.

EIGN(W,0) 'Disable hardware limit switch checking

'(for demo purposes).

ZS 'Clear any startup errors.

'Variables for DMX control

b=1'Set DMX base address Valid Address: 1 thru 512

n=3'Set number of DMX channels to use

'NOTE: max that may be summed is 3 or 24 bit position unsigned int.

s=0'First motor array variable index to use starting with aw[s].

'NOTE: aw[0 thru 101] are available.

'The main WHILE loop calculates binary total value of incoming data.

'NOTE: Data ranges for value of "n" for number of channels are:

'n=10 to 255

'n=20 to 65535

'n=30 to 16777215

'Configure DMX data usage and motor variable storage:

IF n>3 PRINT("n too large.",#13) END ENDIF

'Limit "n" based on a max of 3 bytes.

IF b>(513-n) PRINT("b too large.",#13) END ENDIF

'Limit "b" based on max data slot.

IF s>(102-n) PRINT("s too large.",#13) END ENDIF

'Limit "s" to max array value.

q=b+n-1 'Last data channel used (will be trigger when data received).

COMCTL(1,b)'Set base DMX channel to value from CADDR.

COMCTL(2,n)'Accept 1 DMX channel of data.

COMCTL(3,q)'Status word 12 bit 2 will be set to 1 when

'channel "q" arrives.

COMCTL(4,s)'Set start of array index storage (good for

'bypassing cam mode dynamic array).

OCHN(DMX,1,N,250000,2,8,D)'Open DMX channel: COM1, no parity,

'250 kBd, 2 stop, 8 data, datamode.

'GOSUB(100) 'Always run a homing routine before DMX

'(see other examples)

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 38 of 46

Page 39

DMX Packet Test Example

'===================================================================

'Set Initial Values

UR(2) 'Clear flag so that we know when the end of the next

'data packet arrives.

'===================================================================

'===================================================================

'Main Program Loop

WHILE 1'NOTE: This loop constantly polls DMX data and scales

'it directly to target position.

IF B(12,2)==1'Check for next data packet.

t=CLK-tt't=time in msec since last data packet received.

tt=CLK

UR(2)'Clear flag so we know when next packet arrives.

nn=n-1

p=0 'Zero data value

WHILE nn>=0'Byte-shifting and summing data

p=p*256+aw[nn+s]

nn=nn-1

LOOP 'Loop takes 4 milliseconds when using three

'channels (24 bit).

pp=p'Total for data collected.

ENDIF

LOOP

END 'End of the main program.

'===================================================================

'Fault Routine Code (place here)

C0

END

RETURNI

'===================================================================

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 39 of 46

Page 40

Reverse DMXChannel Byte Order Example

Reverse DMXChannel Byte Order Example

This example reverses the DMX channel byte order, so that the lower DMX channel number is

loaded to a higher byte in the SmartMotor, and vice versa. See the program comments for

more details.

Also, note that there is a home to hard stop subroutine embedded in this program. It is

important to always home the motor before executing the main DMX code. For more homing

details, see Home Against a Hard Stop Example on page 30.

'==================================================================

'Reverse DMX Channel Byte Order Example

'NOTE:

'Normally, for value of "n" (for number of channels), the order is:

'DMX channel 1 (8 bit): n=1, 0 to 255

'DMX channel 2 (8 bit): n=2, 0 to 65535

'DMX channel 3 (8 bit): n=3, 0 to 16777215

'However, this program will reverse the byte order to give:

'DMX channel 1 (8 bit): n=1, 0 to 16777215

'DMX channel 2 (8 bit): n=2, 0 to 65535

'DMX channel 3 (8 bit): n=3, 0 to 255

'==================================================================

ADDR=1 'Set the serial address.

EIGN(W, 0) 'Disable hardware limit switch checking

'(for demo purposes).

ZS 'Clear any startup errors.

'==================================================================

'DMX control for variable settings:

b=1 'Set DMX base address - valid address: 1 thru 512

n=2 'Set the number of DMX channels to use.

'NOTE: max that may be summed is 3 or 24 bit position unsigned int.

s=10 'First motor array variable index to use starting with aw[s].

'NOTE: aw[0 thru 101] are available.

'The main WHILE loop calculates binary total value of incoming data.

m=1 'Scale Factor multiplied by data to give target position.

'NOTE: For 2 or 3 channels (16 or 24-bit position), this should be 1.

'For a single channel with 8-bit positioning, you may need to

'increase "m". Jerky motion may result by using just a single

'channel with only 8-bit resolution.

'==================================================================

'Configure DMX data usage and motor variable storage:

IF n>3 PRINT("n too large.",#13) END ENDIF

'Limit "n" based on a max of 3 bytes.

IF b>(513-n) PRINT("b too large.",#13) END ENDIF

'Limit "b" based on max data slot.

IF s>(102-n) PRINT("s too large.",#13) END ENDIF

'Limit "s" to max array value.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 40 of 46

Page 41

Reverse DMXChannel Byte Order Example

q=b+n-1 'Last data channel used (will be trigger when data received).

COMCTL(1,b) 'Set base DMX channel to value from CADDR.

COMCTL(2,n) 'Accept "n" DMX channels of data.

COMCTL(3,q) 'Status word 12 bit 2 will be set to the value 1

'when channel "q" arrives.

COMCTL(4,s) 'Set start of array index storage (good for bypassing

'cam mode dynamic array).

'==================================================================

' Open DMX ports for communication:

' Note that the command is different in D-STYLE and M-STYLE motors.

OCHN(DMX,1,N,250000,2,8,D) '(D-STYLE motor) Open DMX channel.

'D-STYLE: 250 kBd, 2 stop, 8 data, datamode

'OCHN (DMX, 0, N, 250000,2,8,D) '(M-STYLE motor) Open DMX channel.

'M-STYLE: 250 kBd, 2 stop, 8 data, datamode

'==================================================================

'Home to hard stop:

GOSUB(100) 'C100 = home to hard stop program

'Always run a homing routine before DMX.

'It can be commented out if necessary.

'==================================================================

'Set initial values:

UR(2) 'Clear flag so that we know when the end of the next

'data packet arrives.

MP 'Set to Position mode.

ADT=100 'Accel/Decel value (adjust as needed).

VT=150000 'Velocity (adjust as needed).

'===================================================================

'Set up interrupts:

ITR(0,0,0,0,0) 'Interrupt to catch all motor drive faults.

EITR(0) 'Enable fault interrupt.

ITRE 'Enable global interrupts.

'===================================================================

'Main program loop.

al[10]=0 'Clear any garbage in this temp variable used below.

WHILE 1 'NOTE: This loop constantly polls DMX data and scales it

'directly to target position.

IF B(12,2) == 1 'Check for next data packet.

UR(2) 'Clear flag so we know when next packet arrives.

p=0 'Zero data value.

'=== Reverse Byte Order for DMX Channels (see program header) ====

IF n==2

' 16-bit (unsigned) reverse order:

ab[40]=aw[11]

ab[41]=aw[10]

' (ab[42]=0)

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 41 of 46

Page 42

Reverse DMXChannel Byte Order Example

' (ab[43]=0)

ELSEIF n==3

' 24-bit (unsigned) reverse order:

ab[40]=aw[12]

ab[41]=aw[11]

ab[42]=aw[10]

' (ab[43]=0)

ELSEIF n==4

' 32-bit reverse order:

ab[40]=aw[13]

ab[41]=aw[12]

ab[42]=aw[11]

ab[43]=aw[10]

ENDIF

p=al[10] 'Set p equal to al[10], which covers ab[40]-ab[43]

PT=p*m 'Position target is total for data collected.

G 'Start moving.

ENDIF

LOOP

END 'End main program.

'===================================================================

'Error routine code (place here):

C0

END

RETURNI

'===================================================================

'Home to hard stop:

C100 'Parameter settings (edit as required)

rr=-1 'Homing direction

vv=10000 'Homing speed

aa=1000 'Homing acceleration

ee=100 'Homing error limit

tt=3000 'Homing torque limit

hh=4000 'Homing offset

AMPS=512 'Reduce the motor power. MAX = 1023 (default)

VT=vv*rr 'Set home velocity

ADT=aa 'Set home accel.

MV 'Set to Velocity mode.

ZS 'Clear previous errors.

T=tt*rr 'Preset torque values.

G 'Begin move toward hard stop.

WHILE ABS(EA)<ee LOOP 'Loop while position error is within limit.

MTB 'Mode Torque Break to stop.

MT 'Switch to Torque mode in case of bounce off hard stop.

G 'Start motion.

WAIT=50 'Wait 50 milliseconds.

O=hh*rr 'Set origin to home offset.

AMPS=1023 'Set power back to max.

MP PT=0 G TWAIT 'Set motor to zero.

RETURN

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 42 of 46

Page 43

Troubleshooting

Troubleshooting

The following table provides troubleshooting information for solving common problems. For

additional support resources, see the Moog Animatics Support page at:

http://www.animatics.com/support.html

Issue Cause Solution

Communication and Control Issues

Motor control power

light does not

illuminate.

Motor does not

communicate with

SMI.

Motor disconnects

from SMI

sporadically.

Motor stops

communicating after

power reset, requires

re-detection.

Red PWR SERVO light

illuminated.

Motor is equipped with

the DE option.

Motor has drive power

routed through driveenable pins.

Transmit, receive or

ground pins are not

connected correctly.

Motor program is stuck

in a continuous loop or

is disabling

communications.

COM port buffer settings

are too high.

Poor connection on

serial cable.

Power supply unit (PSU)

brownout.

Motor does not have its

address set in the user

program. NOTE:Serial

addresses are lost when

motor power is off or

reset.

Critical fault. To discover the source of the fault, use

To energize control power, apply 24-48

VDC to pin 15 and ground to pin 14.

Ensure cabling is correct and drive power

is not being delivered through the 15-pin

connector.

Ensure that transmit, receive and ground

are all connected properly to the host PC.

To prevent the program from running on

power up, use the Communications

Lockup Wizard located on theSMI

software Communications menu.

Adjust the COM port buffer settings to

their lowest values.

Check the serial cable connections and/or

replace it.

PSU may be too high-precision and/or

undersized for the application, which

causes it to brown-out during motion.

Make moves less aggressive, increase

PSU size or change to a linear

unregulated power supply.

Use the SADDR or ADDR= command

within the program to set the motor

address.

the Motor View tool located on the SMI

software Tools menu.

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 43 of 46

Page 44

Troubleshooting

Issue Cause Solution

Erratic/no

communication over

RS-485 biasing is

incorrect.

RS-485.

Incorrect signal cable

wiring.

Cable lengths are too

long or incorrect

topology.

Common Faults

Bus voltage fault. Bus voltage is either too

high or too low for

operation.

Overcurrent

occurred.

Motor intermittently

drew more than its

rated level of current.

Does not cease motion.

Excessive

temperature fault.

Motor has exceeded

temperature limit of

85°C. Motor will remain

unresponsive until it

cools down below 80°C.

Excessive position

error.

The motor's

commanded position

and actual position

differ by more than the

user-supplied error

limit.

Historical

positive/negative

hardware limit faults.

A limit switch was

tripped in the past.

Motor does not have

limit switches attached.

Programming and SMI Issues

Several commands

not recognized during

compiling.

SmartMotor not

positioning object at

Compiler default

firmware version set

incorrectly.

Motor not homed before

executing DMX code.

expected location.

SmartMotor not

Varies. Check status bits (see Status Bits on page

responding to DMX

commands.

See EIA-485-A standards. Verify that

shunt is used (see System Cable Diagram

on page 18).

See System Cable Diagram on page 18.

See EIA-485-A standards. See DMX

NetworkTopology on page 17.

Check servo bus voltage. If motor uses

the DE power option, ensure that both

drive and control power are connected.

Consider making motion less abrupt with

softer tuning parameters or acceleration

profiles.

Motor may be undersized or ambient

temperature is too high. Consider adding

heat sinks or forced air cooling to the

system.

Increase error limit, decrease load or

make movement less aggressive.

Clear errors with the ZS command.

Configure the motor to be used without

limit switches by setting their inputs as

general use.

Use the Compiler default firmware

version option in the SMI software

Compile menu to select a default

firmware version closest to the motor's

firmware version. In the SMI software,

view the motor's firmware version by

right-clicking the motor and selecting

Properties.

See Home Against a Hard Stop Example

on page 30.

25). Use Packet Test program (see DMX

Packet Test Example on page 38).

Moog Animatics Class 5 SmartMotor™ DMX Guide,Rev. C

Page 44 of 46

Page 45

Page 46

PN: SC80100004-001

Rev. C

Loading...

Loading...