Page 1

Silencer

®

Series Brushless Controllers

BDP-Q2-50-10 , BDP-Q2-20-10

2-quadrant speed controller for brushless motors

Instruction Manual

GENERAL

• The BDP-Q2-50-10, BDP-Q2-20-10 controllers are 2-quadrant speed controllers for electronically

commutating three-phase brushless motors with Hall sensors, which are arranged offset at 120

electrical degrees.

• The speed of the motor is preset by means of either an internal or an external potentiometer.

• The maximum constant current can be adjusted via an on-board potentiometer.

• The Direction of rotation of the motor can be preset by means of the Direction control input.

The controller output stage can be activated and deactivated by means of the Disable control input.

• The controller is safeguarded against heat overload by means of an internal thermal cutoff.

• The controller output stage has been constructed using POWER-MOSFET technology, resulting in very

highefciency.

For technical application assistance: 800-577-8685 ext. 3539 • +1-828-837-5115

1995 NC HWY 141, Murphy, NC 28906-6864 • +1-828-837-5115 • Fax +1-828-837-0846

www.moog.com/components • email: mcg@moog.com

Moog Components Group • www.moog.com/components

Moog Components Group

1

1

Page 2

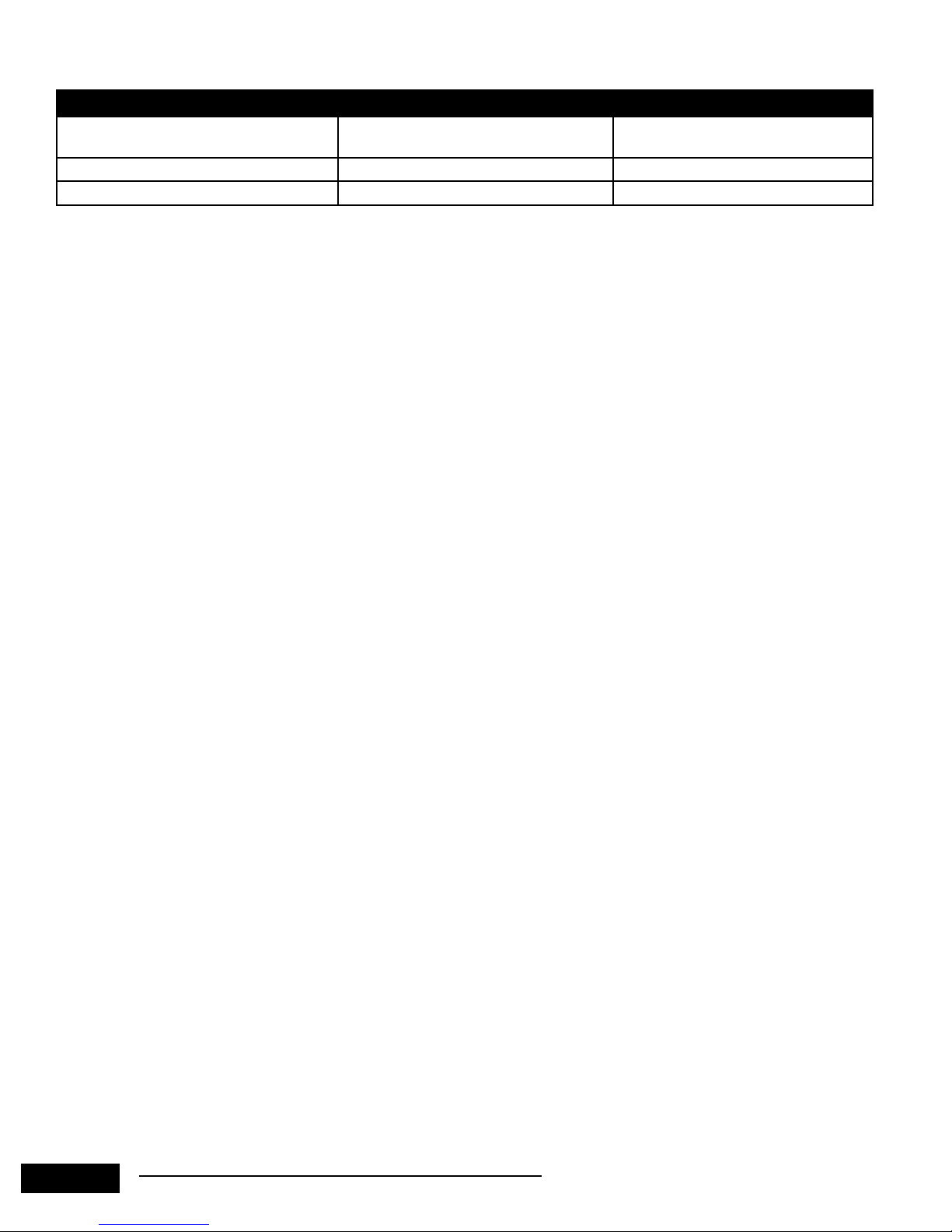

SPECIFICATIONS

ELECTRICAL DATA BDP-Q2-50-10 BDP-Q2-20-10

Operating voltage -+input and Gnd

Residual voltage < 5 %

Maximum constant current (adjustable)*

Supply voltage for Hall sensors

* At higher input voltages, additional heat-sinking may be required for maximum current

20 - 50 VDC

10 A 10 A

6 V / 20 mA

INPUTS

• Direction of rotation – (REV) open collector / TTL / CMOS / switch

• Disable output stage – (DIS) open collector / TTL / CMOS / switch

TEMPERATURE RANGE

Storage -104 to 185°F (-40 to +85°C)

Operation -50 to 113°F (-10 to +45°C)

MOISTURE RANGE

20 to 80% non-condensed

12 - 20 VDC

MECHANICAL DATA

Weight - 4.93 oz (140 g)

Dimensions - (L x W x H) - 2.17 x 3.70 x 1.54 in (55 x 94 x 39 mm)

Mounting - 4 x M3 with a distance between holes of 1.54 x 3.43 in (39 x 87 mm)

Drill Diameter - 4.0 mm - (4) places - M3 screw

ASSEMBLY NOTE

Optimum heat dissipation is achieved by mounting the BDP-Q2-50-10, BDP-Q2-20-10 controller on a heat sink, and

through the use of a thermal conduction paste.

For longer distances between the motor and the control unit, > 12 in (30 cm), shielded cables should be used for the

sensor cable and the motor cable.

SAFETY NOTE

Operatingvoltagesexceedingthespeciedvalues,orreverseconnectionwilldestroythecontrollerandwillvoidthe

product warranty.

Unauthorized opening and improper repairs will put the user in danger and will void the product warranty.

If the controller is brought from a cold environment into the operating environment, there can be condensation. Wait

until the controller has reached the ambient temperature of the operating environment, and is absolutely dry before it

is put into operation.

For technical application assistance: 800-577-8685 ext. 3539 • +1-828-837-5115

2

Moog Components Group • www.moog.com/components

2

Page 3

TERMINATION TABLE

Terminal # Nomenclature Description

1 GND Gnd for Supply Voltage

2 Positive Input Positive Supply Voltage

3 Phase A Motor Phase A

4 Phase C Motor Phase C

5 Phase B Motor Phase B

6 S3 Hall Switch #3

7 S2 Hall Switch #2

8 S1 Hall Switch #1

9 VCC Supply for Hall Switches

10 GND Gnd for Hall Switches

11 DIS Control Input - Disable

12 REV Control Input - Reverse

13 GND Gnd for Dis and Rev

14 SPD Set Value Input for Speed

CONTROL INPUTS

Control inputs 12 (Reverse), 11 (Disable) can be enabled either by an external switch, an open collector transistor, or by means of

TTL / CMOS components. This connection is made to 13 (Gnd).

Control input Input open or high level Input on Gnd or low level

Rev Turning to the right (CW) Turning to the left (CCW)

Dis Controller active Controller inactive

*Note: For positive stopping of the motor it is advisable to use the Disable input rather than setting the speed

potentiometer to zero. Some drift may occur even at zero setting of the speed potentiometer; this will not be the case

when the Disable function is used.

SELECTING MOTOR DIRECTION-OF-ROTATION

Reversing the direction of motor rotation is easily accomplished. Using a switch, relay contact, or simply a jumper wire, connect the

terminal labeled Rev. to the terminal labeled Gnd.

NOTE: Do not reverse motor direction while the motor is rotating. The controller is not designed for instantaneous reversing.

SPEED CONTROL

Motor speed may be controlled via one of the following three methods (see page 4 and 5 for detail instructions):

1. On-Board Speed Potentiometer

2. External Speed Potentiometer – (Recommend 10k – 10 Turn Precision Potentiometer)

3. External Control Voltage

For technical application assistance: 800-577-8685 ext. 3539 • +1-828-837-5115

Moog Components Group • www.moog.com/components

3

3

Page 4

The following is a procedure for using each of the speed control methods mentioned on page 3.

1. On-Board Speed Potentiometer

A. Place a jumper from terminal labeled GND to terminal labeled Spd.

B. Rotate the trimpot labeled Speed fully CW.

C. Rotate the trimpot labeled nmax fully CW.

D. Apply the operating input voltage across + Input and Gnd, being careful to observe polarity.

Do not apply an incremental input voltage, but rather a single step voltage.

E. Motor should now be running at full speed. Measure and record speed.

F. Slowly rotate the nmax trimpot CCW until the motor speed decreases slightly, then slowly rotate the trimpot back CW until

the motor is once again running at full speed (see value recorded in step E).

G. The nmax trimpot is now “tuned” to the motor currently connected to the controller and will not require readjustment unless

a different motor is connected to the controller, or the level of the input voltage is changed.

H. Motor speed may now be varied by using the Speed trimpot.

2. External Speed Potentiometer (optional)

NOTE: See Figure 1 for connection diagram for External Speed Potentiometer.

A. Rotate the External Speed Potentiometer fully CW.

B. Rotate the trimpot labeled Speed fully CCW.

C. Rotate the trimpot labeled nmax fully CW.

D. Apply the operating input voltage across + Input and GND, being careful to observe polarity.

Do not apply an incremental input voltage, but rather a single step voltage.

E. Motor should now be running at full speed. Measure and record speed.

F. Slowly rotate the nmax trimpot CCW until the motor speed decreases slightly, then slowly rotate the trimpot back CW until

the motor is once again running at full speed (see value recorded in step E).

G. The nmax trimpot is now “tuned” to the motor currently connected to the controller and will not require readjustment unless

a different motor is connected to the controller, or the level of the input voltage is changed.

H. Motor speed may now be varied by using the External Speed Potentiometer.

Figure 1

Connection Diagram for External Speed Potentiometer

For technical application assistance: 800-577-8685 ext. 3539 • +1-828-837-5115

4

Moog Components Group • www.moog.com/components

4

Page 5

3. External Voltage Control (Optional)

By applying a DC voltage between 14 (Spd) and 13 (Gnd), the following conditions are observed:

A. 0 to 0.5 volts – speed = 0.

B. 0.5 to 5.0 volts – speed range in control operation.

C. 5.0 to 10.0 volts – no pulse-width-operation-control works in simple commutation mode.

D. Speed potentiometer should be fully CCW.

E. Rotate the trimpot labeled nmax fully CW.

F. Slowly rotate the nmax trimpot CCW until the motor speed decreases slightly, then slowly rotate the trimpot back CW until

the motor is once again running at full speed (see value recorded in step E).

G. The nmax trimpot is now “tuned” to the motor currently connected to the controller and will not require readjustment unless

a different motor is connected to the controller, or the level of the input voltage is changed.

CURRENT LIMITING

Type Max. Left Position Max. Right Position

BDP-Q2-50-10 0 A > 10 A

BDP-Q2-20-10 0 A > 10 A

Note: The controller shuts down automatically when the temperature at the inside of the heat sink exceeds 80°C.

FUSING

Proper overcurrent protection (fusing) is required for the protection of this controller. We recommend a 10 amp , non-time delay fuse.

This fuse should be connected in series with the + Input line going to the controller and should be of a value less than or equal to the

maximum current rating of the controller (Max. Right Position).

Note: Considerations regarding the power supply:

Output voltage: > 12 V and < + input with a residual voltage of < 5%

Output Current: corresponding to the necessary torque and possible reserves for acceleration

Note: Procedure for calculating the necessary minimum supply voltage:

Default: Torque MB [mNm]

Operating speed n

Rated voltage of the motor U

Idling speed with UN n0 [min

[min–1]

B

[V]

N

-1

]

Characteristic curve slope Δn [min

-1

mNm]

ΔM

N

Result: Vcc = *( n

U

0

n

Δn

+ * MB) + 4V

B

ΔM

PUTTING INTO OPERATION

1. Connect motor connections (φA, B, and C).

2. Connect Hall sensors (S1, S2, and S3), as well as the Hall voltage supply (Vcc and Gnd) of Hall sensors.

3. Connect the control inputs according to the requirements (Rev. and Dis.).

4. Connect the supply voltage (+ input and gnd).

5. Set up the speed control for the controller (depending upon which method of speed control is used - see Speed Control).

6. After completion of step #5, speed control is now active.

7. Set the maximum current via the on-board speed potentiometer (current).

For technical application assistance: 800-577-8685 ext. 3539 • +1-828-837-5115

Specicationsandinformationaresubjecttochangewithoutpriornotice.

© 2014 Moog Inc. MS3125, rev. 1 11/16

Moog Components Group • www.moog.com/components

5

5

Loading...

Loading...