Page 1

For the mobile version of this guide, see:

animatics.com/docs/guides-html/c6_pnet/

Class 6 SmartMotor

Technology

Page 2

Copyright Notice

©2012-2019, Moog Inc., Animatics.

Moog Animatics Class 6 SmartMotor™ PROFINET Guide, Rev. D, PN: SC80100007-001.

This manual, as well as the software described in it, is furnished under license and may be

used or copied only in accordance with the terms of such license. The content of this manual is

furnished for informational use only, is subject to change without notice and should not be

construed as a commitment by Moog Inc., Animatics. Moog Inc., Animatics assumes no

responsibility or liability for any errors or inaccuracies that may appear herein.

Except as permitted by such license, no part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

recording, or otherwise, without the prior written permission of Moog Inc., Animatics.

The programs and code samples in this manual are provided for example purposes only. It is

the user's responsibility to decide if a particular code sample or program applies to the

application being developed and to adjust the values to fit that application.

Moog Animatics and the Moog Animatics logo, SmartMotor and the SmartMotor logo,

Combitronic and the Combitronic logo are all trademarks of Moog Inc., Animatics. PROFINET

is a registered trademark of PROFIBUS Nutzerorganisation e.V. Other trademarks are the

property of their respective owners.

Please let us know if you find any errors or omissions in this manual so that we can improve it

for future readers. Such notifications should contain the words "PROFINET Guide" in the

subject line and be sent by e-mail to: animatics_marcom@moog.com. Thank you in advance

for your contribution.

Contact Us:

Americas - West

Moog Animatics

2581 Leghorn Street

Mountain View, CA 94043

USA

Tel: 1 650-960-4215 Tel: 1 610-328-4000 x3999

Support: 1 (888) 356-0357

Website: www.animatics.com

Email: animatics_sales@moog.com

Americas - East

Moog Animatics

750 West Sproul Road

Springfield, PA 19064

USA

Fax: 1 610-605-6216

Page 3

Table of Contents

Introduction 6

Purpose 7

PROFINET Overview 7

Equipment Required 9

Hardware 9

Software 9

Safety Information 10

Safety Symbols 10

Other Safety Considerations 10

Motor Sizing 10

Environmental Considerations 10

Machine Safety 11

Documentation and Training 12

Additional Equipment and Considerations 12

Safety Information Resources 12

Additional Documents 13

Related Guides 13

Other Documents 13

Additional Resources 14

PROFINET and PROFIBUS Resources 14

PROFINET Motor Pinouts, Connections and Status LEDs 15

PROFINET Motor Connectors and Pinouts 16

Cables and Diagram 17

Moog Animatics Industrial Ethernet Cables 17

M-style to M-style Ethernet Cable 17

M-style to RJ45 Ethernet Cable 17

Ethernet Cable Schematic 17

PROFINET Cable Diagram 18

Maximum Cable Length 18

PROFINET Status LEDs 19

PROFINET Configuration 20

Configure Motor with PC 21

User Program Requirements 21

Required Nonvolatile EEPROM Values 21

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 3 of 76

Page 4

Configure PLC with PC 21

Configure SmartMotor to PROFINET 22

PLC Sends Commands to Motor 22

Network Data Format Example 22

PLCMemory 23

Sequence to Set Report Data to Motor Clock 24

PROFINET Communication Example 25

Sample Command Sequences 29

Overview 30

Command and Response Codes 30

Handshaking of Messages 30

Disabling Limits from Preventing Motion 30

Turning the Motor Shaft 30

Disable Limits and Clear Fault Status 31

Commands 31

PLCMemory 31

Disable positive limit, command EIGN(2) 31

Disable negative limit, command EIGN(3) 32

Clear fault status, command ZS 32

Initiate Mode Torque 33

Commands 33

PLCMemory 33

Set torque value, specify the response data 33

Initiate torque mode, command MT 33

Initiate Relative PositionMove 35

Commands 35

PLCMemory 35

Set acceleration value, command ADT=255 35

Set maximum velocity value, command VT=100000 35

Make a relative position move 36

User Program Commands 38

SNAME("string") 39

IPCTL(function,"string") 39

=ETH, RETH 39

ETHCTL(function, value) 42

Program Example 43

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 4 of 76

Page 5

Output and Input Packets 44

Output and Input Packet Format 45

Command (Output) Packet Notes 50

Response (Input) Packet Notes 51

Alternate Communications Channel 52

Reserved Motor Variables 52

Command and Response Codes 53

Command Packet Codes to Motor Commands 54

Extended 16-bit command codes 61

Response Packet Codes to Motor Commands 64

Extended 16-bit response codes 69

Troubleshooting 72

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 5 of 76

Page 6

Introduction

Introduction

This chapter provides information on the purpose and scope of this manual. It also provides

information on safety notation, related documents and additional resources.

Purpose 7

PROFINET Overview 7

Equipment Required 9

Hardware 9

Software 9

Safety Information 10

Safety Symbols 10

Other Safety Considerations 10

Motor Sizing 10

Environmental Considerations 10

Machine Safety 11

Documentation and Training 12

Additional Equipment and Considerations 12

Safety Information Resources 12

Additional Documents 13

Related Guides 13

Other Documents 13

Additional Resources 14

PROFINET and PROFIBUS Resources 14

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 6 of 76

Page 7

Purpose

Purpose

This manual explains the Moog Animatics Class 6 SmartMotor™ support for the PROFINET®

protocol. It describes the major concepts that must be understood to integrate a SmartMotor

slave with a PLC or other PROFINET master. However, it does not cover all the low-level

details of the PROFINET protocol.

NOTE: The feature set described in this version of the manual refers to motor

firmware 6.0.2.25 or later.

This manual is intended for programmers or system developers who understand the use of

PROFINET. (The PROFINET v2.2 specifications are detailed in the following IECpublications:

IEC61158-6-10 Ed2.0, IEC61158-5-10 Ed2.0 and IEC61784-2 Ed2.0.) Therefore, this manual is

not a tutorial on those specifications or the PROFINET protocol. Instead, it should be used to

understand the specific implementation details for the Moog Animatics SmartMotor.

Additionally, examples are provided for the various modes of motion and accessing those

modes through PROFINET to operate the SmartMotor.

The Command and Response Code chapter of this manual includes details about the specific

commands available in the SmartMotor through the PROFINET protocol. The commands

include those required by the specification and those added by Moog Animatics. For details,

see Command and Response Codes on page 53. Also, see User Program Commands on page

38.

In addition to this manual, it is recommended that you visit the PROFINET/PROFIBUS website

(at http://www.profibus.com), where you will find documentation, tutorials, and other useful

resources.

PROFINET Overview

PROFINET is an independent, open fieldbus standard that allows different manufacturers of

automation products to communicate without special interface adjustments. Specifically,

PROFINET, which is optimized for high speed, is designed to communicate between control

systems and distributed I/O at the device level.

Moog Animatics has defined a set of 8-bit command and response codes to be transmitted and

received over PROFINET. For details, see Command Packet Codes to Motor Commands on

page 54. These codes generally correspond to Class 5 and Class 6 SmartMotor™ commands.

To set target position, for example, the "set target position" command code is transmitted

together with the data consisting of the target position value.

The PROFINET SmartMotor is a SmartMotor with the addition of the PROFINET connectors and

interface board, which then accepts commands as a slave over a PROFINET network. In

addition to communicating over PROFINET, SmartMotor commands may be sent through other

communication interfaces of the SmartMotor. Depending on the SmartMotor model, it may

also communicate over RS-232, RS-485 and/or USB.

The Moog Animatics communications profile over PROFINET is intended to integrate well with

a PLC that continuously transmits and receives cyclic data. The command and response codes

achieve this through a handshaking mechanism.

Certain configuration data is held in nonvolatile storage in the SmartMotor. Therefore, the

motor data EEPROM must be correctly initialized before PROFINET operation.

A PROFINET Generic Station Description (GSD) configuration file, which is an XML file (also

referred to as a "GSDML" file), is necessary for the host to configure the PROFINET master

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 7 of 76

Page 8

PROFINET Overview

and to connect to the slave motor. Make sure you obtain the latest version of the file, which is

available from the Moog Animatics website Download Center. For more details, see Software

on page 9.

Document sections include Output and Input data formats (PROFINET cargo), a list of the

Moog Animatics PROFINET command codes explained in terms of the equivalent SmartMotor

commands, and a list of Moog Animatics PROFINET response codes explained in terms of the

equivalent SmartMotor commands.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 8 of 76

Page 9

Equipment Required

Equipment Required

The section describes the required PROFINET hardware and software.

Hardware

The following hardware is required:

l

Moog Animatics PROFINET SmartMotor™

l

Moog Animatics power supply or user-supplied equivalent

l

Moog Animatics RS-485 or USB communications cable that is compatible with the

SmartMotor

l

User-supplied PC with the Microsoft Windows operating system

l

User-supplied PLC with PROFINET master or other PROFINET master

l

Moog Animatics PROFINET cable, or equivalent, to connect the PLC to the SmartMotor's

industrial Ethernet port (for details, see PROFINET Motor Connectors and Pinouts on

page 16)

Software

The following software is required:

l

User-supplied PLC configuration software

l

Moog Animatics SMI software (latest version), which is available on the Moog Animatics

website at:

http://www.animatics.com/support/download-center.html

l

Moog Animatics PROFINET GSDML file, which is available on the Moog Animatics

website at:

http://www.animatics.com/support/download-center.html

NOTE: The PROFINET GSD configuration file name will have the form

"GSDML-Vx.x-MOOG ANIMATICS-SMC06DEV01-date.XML", where 'x.x' is the

version and 'date' is the release date. Make sure you obtain the latest version

of the file.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 9 of 76

Page 10

Safety Information

Safety Information

This section describes the safety symbols and other safety information.

Safety Symbols

The manual may use one or more of the following safety symbols:

WARNING: This symbol indicates a potentially nonlethal mechanical hazard,

where failure to follow the instructions could result in serious injury to the

operator or major damage to the equipment.

CAUTION: This symbol indicates a potentially minor hazard, where failure to

follow the instructions could result in slight injury to the operator or minor

damage to the equipment.

NOTE: Notes are used to emphasize non-safety concepts or related information.

Other Safety Considerations

The Moog Animatics SmartMotors are supplied as components that are intended for use in an

automated machine or system. As such, it is beyond the scope of this manual to attempt to

cover all the safety standards and considerations that are part of the overall machine/system

design and manufacturing safety. Therefore, the following information is intended to be used

only as a general guideline for the machine/system designer.

It is the responsibility of the machine/system designer to perform a thorough "Risk

Assessment" and to ensure that the machine/system and its safeguards comply with the

safety standards specified by the governing authority (for example, ISO, OSHA, UL, etc.) for

the locale where the machine is being installed and operated. For more details, see Machine

Safety on page 11.

Motor Sizing

It is the responsibility of the machine/system designer to select SmartMotors that are

properly sized for the specific application. Undersized motors may: perform poorly, cause

excessive downtime or cause unsafe operating conditions by not being able to handle the

loads placed on them. The System Best Practices document, which is available on the Moog

Animatics website, contains information and equations that can be used for selecting the

appropriate motor for the application.

Replacement motors must have the same specifications and firmware version used in the

approved and validated system. Specification changes or firmware upgrades require the

approval of the system designer and may require another Risk Assessment.

Environmental Considerations

It is the responsibility of the machine/system designer to evaluate the intended operating

environment for dust, high-humidity or presence of water (for example, a food-processing

environment that requires water or steam wash down of equipment), corrosives or chemicals

that may come in contact with the machine, etc. Moog Animatics manufactures specialized

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 10 of 76

Page 11

Machine Safety

IP-rated motors for operating in extreme conditions. For details, see the Moog Animatics

Product Catalog, which is available on the Moog Animatics website.

Machine Safety

In order to protect personnel from any safety hazards in the machine or system, the

machine/system builder must perform a "Risk Assessment", which is often based on the ISO

13849 standard. The design/implementation of barriers, emergency stop (E-stop)

mechanisms and other safeguards will be driven by the Risk Assessment and the safety

standards specified by the governing authority (for example, ISO, OSHA, UL, etc.) for the

locale where the machine is being installed and operated. The methodology and details of

such an assessment are beyond the scope of this manual. However, there are various sources

of Risk Assessment information available in print and on the internet.

NOTE: The following list is an example of items that would be evaluated when

performing the Risk Assessment. Additional items may be required. The safeguards

must ensure the safety of all personnel who may come in contact with or be in the

vicinity of the machine.

In general, the machine/system safeguards must:

l

Provide a barrier to prevent unauthorized entry or access to the machine or system. The

barrier must be designed so that personnel cannot reach into any identified danger

zones.

l

Position the control panel so that it is outside the barrier area but located for an

unrestricted view of the moving mechanism. The control panel must include an E-stop

mechanism. Buttons that start the machine must be protected from accidental

activation.

l

Provide E-stop mechanisms located at the control panel and at other points around the

perimeter of the barrier that will stop all machine movement when tripped.

l

Provide appropriate sensors and interlocks on gates or other points of entry into the

protected zone that will stop all machine movement when tripped.

l

Ensure that if a portable control/programming device is supplied (for example, a handheld operator/programmer pendant), the device is equipped with an E-stop mechanism.

NOTE: A portable operation/programming device requires many additional

system design considerations and safeguards beyond those listed in this

section. For details, see the safety standards specified by the governing

authority (for example, ISO, OSHA, UL, etc.) for the locale where the

machine is being installed and operated.

l

Prevent contact with moving mechanisms (for example, arms, gears, belts, pulleys,

tooling, etc.).

l

Prevent contact with a part that is thrown from the machine tooling or other parthandling equipment.

l

Prevent contact with any electrical, hydraulic, pneumatic, thermal, chemical or other

hazards that may be present at the machine.

l

Prevent unauthorized access to wiring and power-supply cabinets, electrical boxes, etc.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 11 of 76

Page 12

Documentation and Training

l

Provide a proper control system, program logic and error checking to ensure the safety

of all personnel and equipment (for example, to prevent a run-away condition). The

control system must be designed so that it does not automatically restart the

machine/system after a power failure.

l

Prevent unauthorized access or changes to the control system or software.

Documentation and Training

It is the responsibility of the machine/system designer to provide documentation on safety,

operation, maintenance and programming, along with training for all machine operators,

maintenance technicians, programmers, and other personnel who may have access to the

machine. This documentation must include proper lockout/tagout procedures for maintenance

and programming operations.

It is the responsibility of the operating company to ensure that:

l

All operators, maintenance technicians, programmers and other personnel are tested

and qualified before acquiring access to the machine or system.

l

The above personnel perform their assigned functions in a responsible and safe manner

to comply with the procedures in the supplied documentation and the company safety

practices.

l

The equipment is maintained as described in the documentation and training supplied by

the machine/system designer.

Additional Equipment and Considerations

The Risk Assessment and the operating company's standard safety policies will dictate the

need for additional equipment. In general, it is the responsibility of the operating company to

ensure that:

l

Unauthorized access to the machine is prevented at all times.

l

The personnel are supplied with the proper equipment for the environment and their job

functions, which may include: safety glasses, hearing protection, safety footwear,

smocks or aprons, gloves, hard hats and other protective gear.

l

The work area is equipped with proper safety equipment such as first aid equipment,

fire suppression equipment, emergency eye wash and full-body wash stations, etc.

l

There are no modifications made to the machine or system without proper engineering

evaluation for design, safety, reliability, etc., and a Risk Assessment.

Safety Information Resources

Additional SmartMotor safety information can be found on the Moog Animatics website; open

the file "109_Controls, Warnings and Cautions.pdf" located at:

http://www.animatics.com/support/moog-animatics-catalog.html

OSHA standards information can be found at:

https://www.osha.gov/law-regs.html

ANSI-RIA robotic safety information can be found at:

http://www.robotics.org/robotic-content.cfm/Robotics/Safety-Compliance/id/23

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 12 of 76

Page 13

Additional Documents

UL standards information can be found at:

http://ulstandards.ul.com/standards-catalog/

ISOstandards information can be found at:

http://www.iso.org/iso/home/standards.htm

EUstandards information can be found at:

http://ec.europa.eu/growth/single-market/european-standards/harmonisedstandards/index_en.htm

Additional Documents

The Moog Animatics website contains additional documents that are related to the information

in this manual. Please refer to the following list.

Related Guides

l

Class 6 SmartMotor™ Installation & Startup Guide

http://www.animatics.com/cl-6-install-startup-guide

l

Moog Animatics SmartMotor™ Developer's Guide

http://www.animatics.com/smartmotor-developers-guide

Other Documents

l

SmartMotor™ System Best Practices

http://www.animatics.com/system-best-practices-application-note

l

SmartMotor™ Product Certificate of Conformance

http://www.animatics.com/download/Declaration of Conformity.pdf

l

SmartMotor™ ULCertification

http://www.animatics.com/download/MA_UL_online_listing.pdf

l

SmartMotor Developer's Worksheet

(interactive tools to assist developer: Scale Factor Calculator, Status Words, CAN Port

Status, Serial Port Status, RMODE Decoder and Syntax Error Codes)

http://www.animatics.com/tools

l

Moog Animatics Product Catalog, which is available on the Moog Animatics website

http://www.animatics.com/support/moog-animatics-catalog.html

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 13 of 76

Page 14

Additional Resources

Additional Resources

The Moog Animatics website contains useful resources such as product information,

documentation, product support and more. Please refer to the following addresses:

l

General company information:

http://www.animatics.com

l

Product information:

http://www.animatics.com/products.html

l

Product support (Downloads, How To videos, Forums, Knowledge Base, and FAQs):

http://www.animatics.com/support.html

l

Sales and distributor information:

http://www.animatics.com/sales-offices.html

l

Application ideas (including videos and sample programs):

http://www.animatics.com/applications.html

PROFINET and PROFIBUS Resources

PROFINET and PROFIBUS are common standard maintained by PROFIBUS and PROFINET

International (PI):

l PROFIBUS and PROFINET International (PI) website:

http://www.profibus.com/

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 14 of 76

Page 15

PROFINET Motor Pinouts, Connections and Status LEDs

PROFINET Motor Pinouts,

Connections and Status LEDs

The following sections describe the motor pinouts, system connections and the status LEDs.

PROFINET Motor Connectors and Pinouts 16

Cables and Diagram 17

Moog Animatics Industrial Ethernet Cables 17

M-style to M-style Ethernet Cable 17

M-style to RJ45 Ethernet Cable 17

Ethernet Cable Schematic 17

PROFINET Cable Diagram 18

Maximum Cable Length 18

PROFINET Status LEDs 19

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 15 of 76

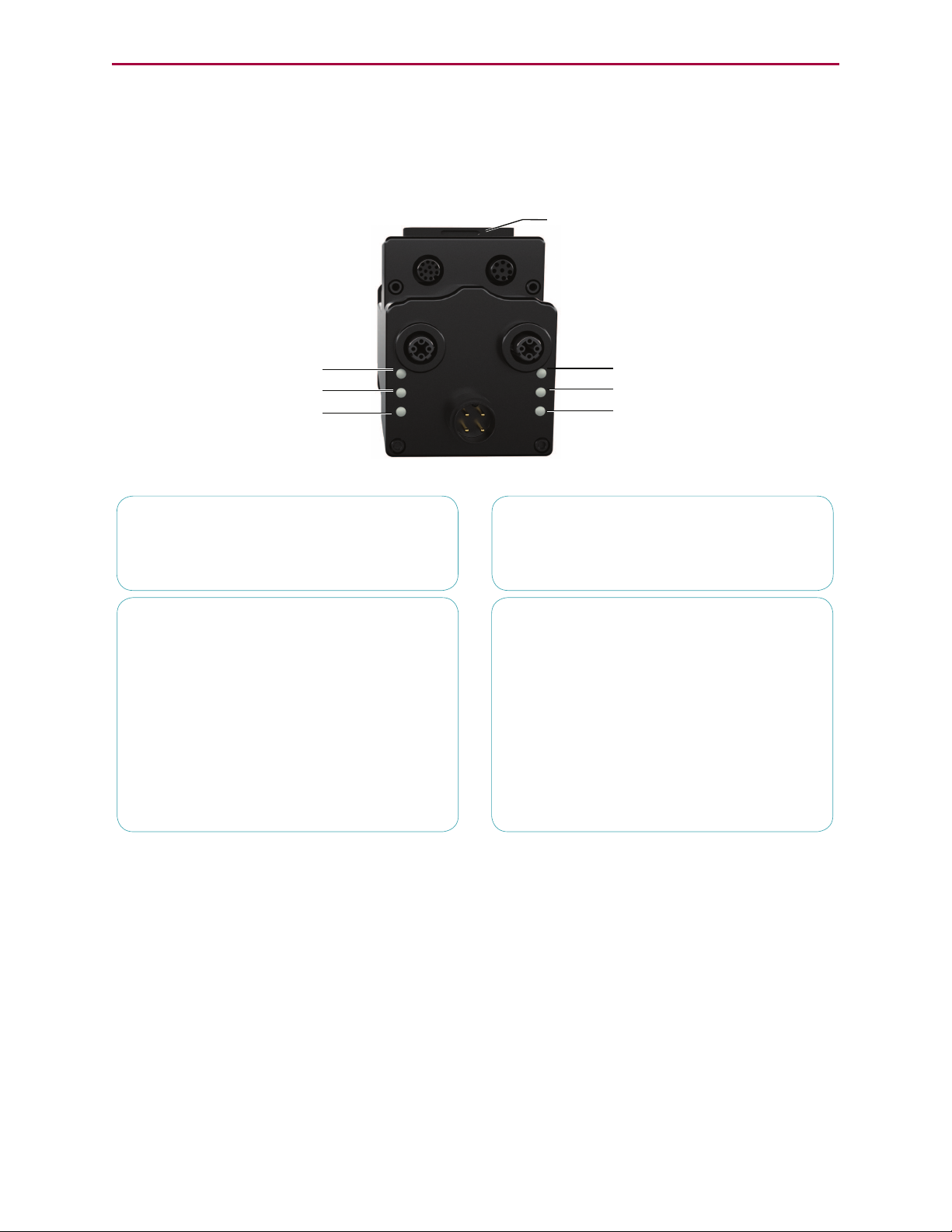

Page 16

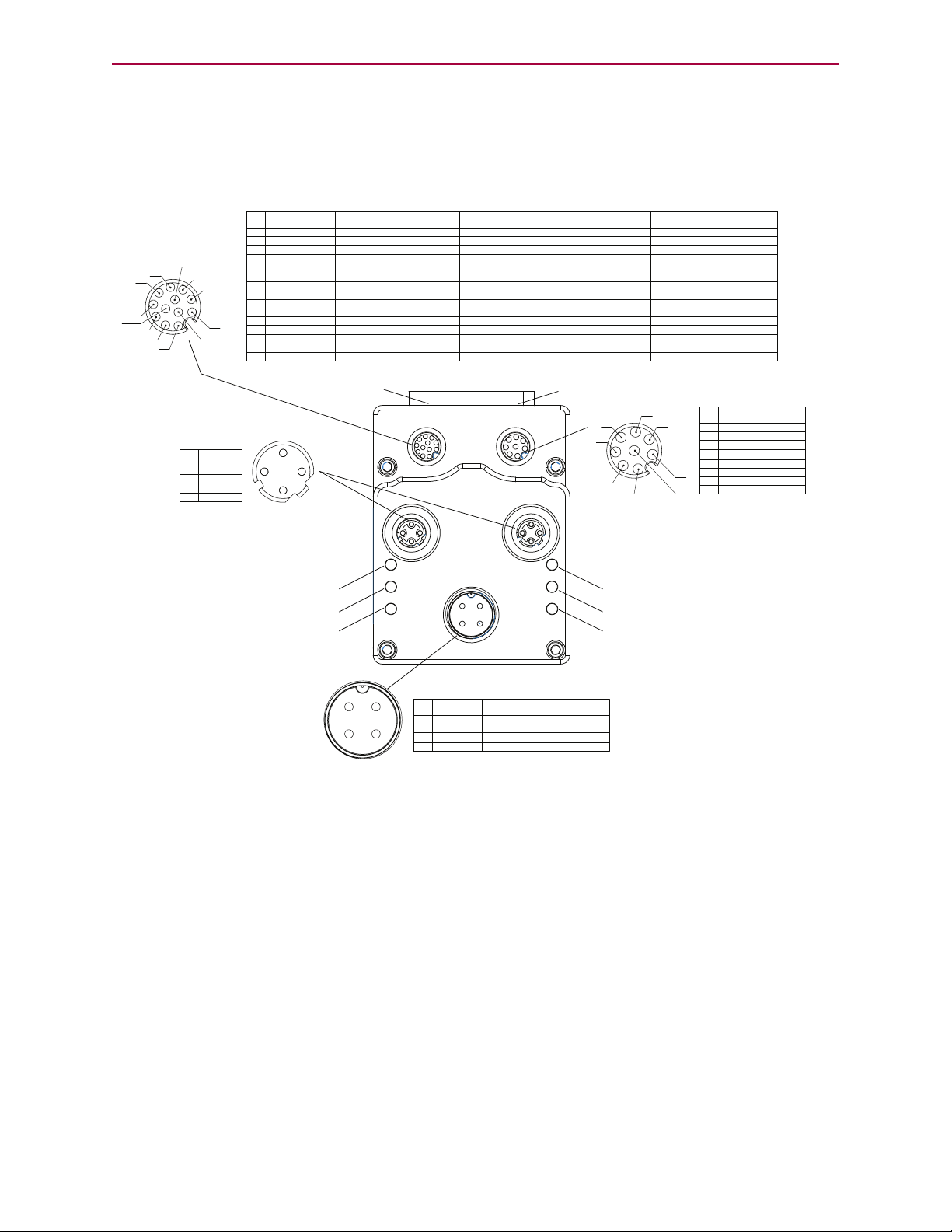

PROFINET Motor Connectors and Pinouts

1

2 3

4

POWER INPUT

PIN

FUNCTION

DESCRIPTION

1

24 VDC

CONTROL I/O POWER

2

EARTH

CHASSIS GROUND

3

GND

MOTOR COMMON GROUND

4

48 VDC

MOTOR POWER

COMMUNICATION

PIN

FUNCTION

1

GND-COMMON

2

RS-485B CH0

3

RS-485A CH0

4

ENC A+ (IN/OUT)

5

ENC B- (IN/OUT)

6

ENC A- (IN/OUT)

7

5 VDC OUT

8

ENC B+

(IN/OUT)

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

11

12

I/Os

PIN

FUNCTION

DEFAULT

1

IN0

GENERAL PURPOSE

2

IN1

GENERAL PURPOSE

3

IN2/POSLIMIT

POSITIVE LIMIT

4

IN3/NEGLIMIT

NEGATIVE LIMIT

5

IN/OUT4

GENERAL PURPOSE

6

IN

/OUT

5

GENERAL PURPOSE

7

IN6

GENERAL PURPOSE

8

IN7-DRVEN

DRIVE ENABLE

9

OUT8/BRAKE

BRAKE OUTPUT

10

OUT9-NOFAULT

NOT FAULT

11

24 VDC OUT*

CONTROL I/O POWER

12

GND

MOTOR COMMON GROUND

INPUT OR OUTPUT

INPUT, DISCRETE OR ANALOG

POSSIBLE (SELECTABLE) FUNCTIONS

INPUT, DISCRETE OR ANALOG

INPUT

INPUT

INPUT/OUTPUT

INPUT/OUTPUT

INPUT

INPUT

OUTPUT

OUTPUT

POWER OUTPUT**

N/A

GENERAL PURPOSE

GENERAL PURPOSE

POSITIVE LIMIT OR GENERAL PURPOSE

NEGATIVE LIMIT OR GENERAL PURPOSE

GENERAL PURPOSE, OR EXTERNAL ENCODER

INDEX CAPTURE

GENERAL PURPOSE, OR INTERNAL ENCODER

INDEX CAPTURE

GENERAL PURPOSE, G COMMAND, OR

HOMING INPUT (ETHERCAT ONLY)

N/A

NOT FAULT

BRAKE OUTPUT OR GENERAL-PURPOSE OUTPUT

DRIVE ENABLE

*NOTE: 2 AMPS MAX **SUPPLIED FROM POWER INPUT PIN 1

CONTROL I/O POWER

RS-485 serial communication uses a

voltage differential signal. Appropriate

terminating resistors should be included

on the RS-485 network to ensure reliable

performance. For details, see the section

Power and RS-485 Com Multidrop.

1

2

3

4

Shield tied to motor

housing

LED 4: PROFINET Link 1 Port LED

LED 2: PROFINET System Fail LED

LED 0: Motor Drive LED

LED 5: PROFINET Link 2 Port LED

LED 3: PROFINET Bus Fail LED

LED 1: Motor Busy LED

USB Port LED

SD Card LED

PIN

FUNCTION

1

+TD

2

+RD

3

-TD

4

-RD

PROFINET

PROFINET Motor Connectors and Pinouts

The following figure provides an overview of the PROFINET connectors and pinouts available

on the Class 6 SmartMotors.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 16 of 76

Page 17

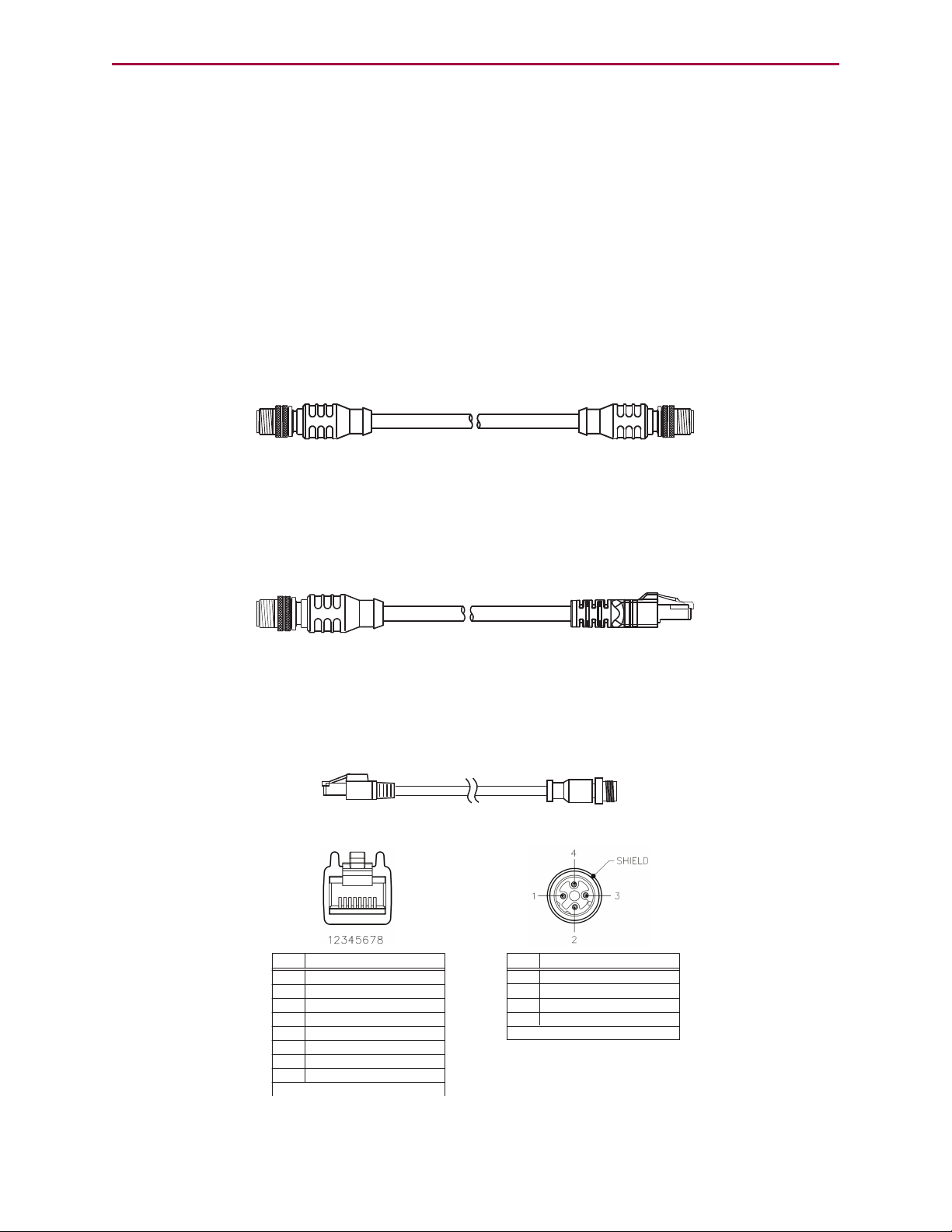

Cables and Diagram

Industrial Ethernet Connector

(Motor end of cable)

PIN

1

2

3

4

+TX

+RX

-TX

-RX

DESCRIPTION

Shield tied to motor housing

RJ45 Connector

(EtherCAT master end of cable)

1

2

3

4

5

6

7

8

+TX

-TX

+RX

No Connection

No Connection

-RX

No Connection

No Connection

PIN

DESCRIPTION

Shield tied to RJ45 connector

Cables and Diagram

This section provides information on Moog Animatics industrial Ethernet cables and a

PROFINET system cable diagram.

Moog Animatics Industrial Ethernet Cables

The following cables are available from Moog Animatics.

M-style to M-style Ethernet Cable

This cable has M12 male threaded connectors at both ends. It is available in 1, 3, 5 and 10

meter lengths. For the standard cable, use part number CBLIP-ETH-MM-xM, where "x"

denotes the cable length. A right-angle version is also available; use part number

CBLIP-ETH-MM-xMRA.

M-style to RJ45 Ethernet Cable

This cable has an M12 male threaded connector at one end, and an RJ45 male connector at the

opposite end. It is available in 1, 3, 5 and 10 meter lengths. For the standard cable, use part

number CBLIP-ETH-MR-xM, where "x" denotes the cable length. A right-angle version is also

available; use part number CBLIP-ETH-MR-xMRA.

Ethernet Cable Schematic

The following figure provides details for creating a custom industrial Ethernet shielded cable.

NOTE: The motor end of the cable requires an industrial Ethernet connector.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 17 of 76

Page 18

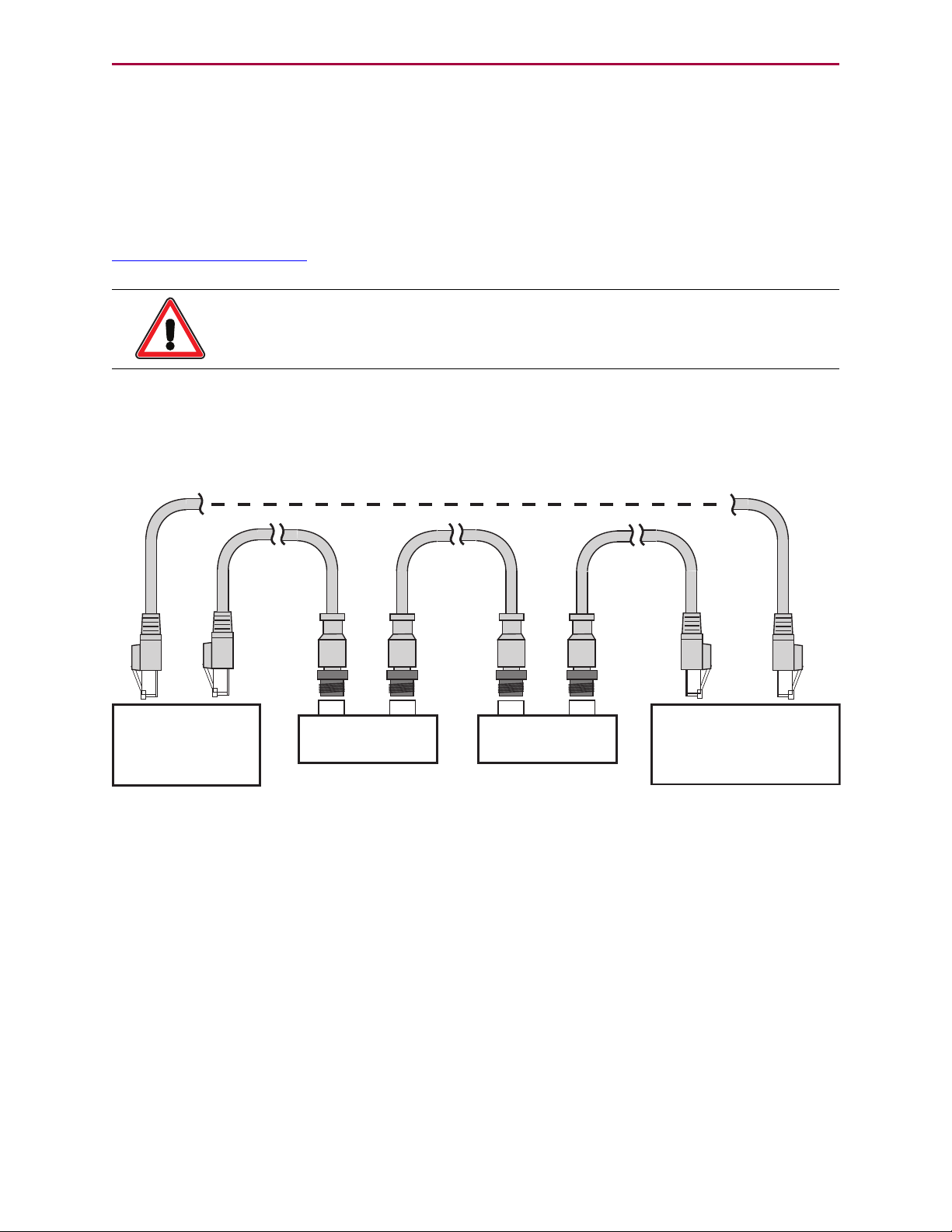

PROFINET Cable Diagram

PROFINET Bus

Other PROFINET device:

- I/O block,

- Servo drive,

- etc.

PROFINET Master

- PC,

- PLC,

- etc.

Moog Animatics

SmartMotor

Moog Animatics

SmartMotor

Optional ring for cable redundancy*

*Ring conguration requires specic PROFINET modes and supporting devices

PROFINET Cable Diagram

PROFINET can support line, tree or star device-connection topology. The supported network

topology and maximum number of devices depends on the selected PROFINET mode and

network class. For example, higher performing modes, like PROFINET IRT, require

specialized equipment. For PROFINET network design and installation details, see the

information available at:

http://www.profinet.com

CAUTION: To minimize the possibility of electromagnetic interference (EMI),

all connections should use shielded Ethernet Category 5 (Cat 5), or better,

cables.

The following diagram shows an example PROFINET network with the SmartMotors daisy

chained to the master device. An optional "ring" configuration can be created if it is supported

by the selected PROFINET mode and network devices.

Maximum Cable Length

For transmission speeds of 100 Megabits/second on shielded Ethernet Cat 5 cable, EtherCAT

and PROFINET allow cable lengths up to 100 meters between network nodes.

NOTE: Unlike other fieldbus protocols, PROFINET does not require terminators at

each end of the network bus.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 18 of 76

Page 19

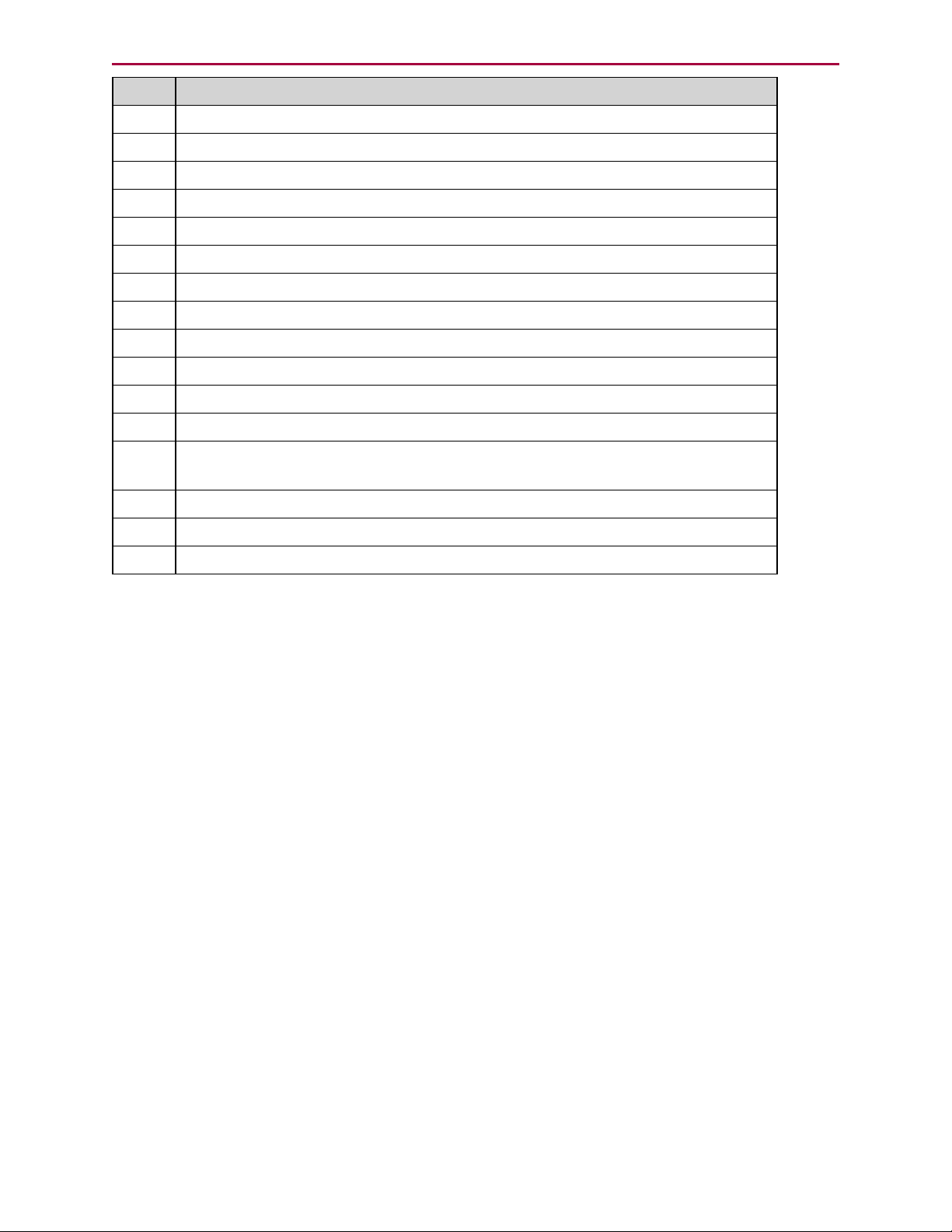

PROFINET Status LEDs

Off No power

Solid green Drive on

Blinking green Drive off, no faults

Triple red flash Watchdog fault

Solid red Faulted or no drive enable input

Off Not busy

Solid green Drive on, trajectory in progress

Flashing # red Flashes fault code* (see below)

when Drive LED is solid red

Refer to the corresponding SmartMotor

fieldbus guide

Refer to the corresponding SmartMotor

fieldbus guide

Refer to the corresponding SmartMotor

fieldbus guide

Refer to the corresponding SmartMotor

fieldbus guide

Under cover:

USB Active LED

SD Card LED (for SD

Card-equipped motors)

LED 4: PROFINET Link 1 Input LED

LED 2: PROFINET System Fail LED

LED 0: Motor Drive LED

LED 5: PROFINET Link 2 Output LED

LED 3: PROFINET Bus Fail LED

LED 1: Motor Busy LED

LED 0: Motor Drive LED LED 1: Motor Busy LED

LED 3: (Network specific) LED

LED 5: Link LED

LED 2: (Network specific) LED

LED 4: Link LED

LED Status on Power-up:

• With no program and the travel limit inputs are low:

LED 0 solid red; motor is in fault state due to travel limit fault

LED 1 off

• With no program and the travel limits are high:

LED 0 solid red for 500 milliseconds then flashing green

LED 1 off

• With a program that only disables travel limits:

LED 0 red for 500 milliseconds then flashing green

LED 1 off

Flash

1

2

3

4

5

6

7

8

9

10

11

Description

NOT Used

Bus Voltage

Over Current

Excessive Temperature

Excessive Position

Velocity Limit

dE/Dt - First derivative of position error is excessive

Hardware Positive Limit Reached

Hardware Negative Limit Reached

Software Positive Travel Limit Reached

Software Negative Travel Limit Reached

LED 1 Fault Codes:

*Busy LED pauses for 2 seconds before flashing the code

Flickering = On/Off in 0.1 sec; Blinking = On/Off in 0.5 sec; Flashing = separated by 1 sec for PROFINET LEDs and 2 sec for Fault Codes

Flashing green Active

Flashing red Suspended

Solid red USB power detected, no

configuration

USB Active LED

Blinking green Busy, do not remove card

Solid green

Card detected

Solid red

Card with no SmartMotor data

SD Card LED (for SD Card-equipped motors)

No card, bad or damaged cardO

PROFINET Status LEDs

This following figure and tables describe the functionality of the PROFINET Status LEDs on the

SmartMotor.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 19 of 76

Page 20

PROFINET Configuration

PROFINET Configuration

The following sections describe how to configure your SmartMotor to communicate over

PROFINET.

Configure Motor with PC 21

User Program Requirements 21

Required Nonvolatile EEPROM Values 21

Configure PLC with PC 21

Configure SmartMotor to PROFINET 22

PLC Sends Commands to Motor 22

Network Data Format Example 22

PLCMemory 23

Sequence to Set Report Data to Motor Clock 24

PROFINET Communication Example 25

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 20 of 76

Page 21

Configure Motor with PC

Configure Motor with PC

Use the following procedure to configure the SmartMotor for communication with the PC.

Refer to the figures in PROFINET Communication Example on page 25.

1.

Connect the SmartMotor to the power supply.

2.

If the motor is already configured, you may skip the balance of this procedure.

3.

Connect the motor to the PC.

4.

Launch the SmartMotor™ Interface (SMI) software, version 2.4.3.6 or later.

User Program Requirements

No user program is specifically required by the Class 6 PROFINET SmartMotor.

Required Nonvolatile EEPROM Values

The nonvolatile settings can be entered using the SMI software’s Terminal window. For details

on using the Terminal window, see the SMI software online help.

After the configuration settings have been entered, cycle the SmartMotor’s power for the new

configuration to take effect.

To change the nonvolatile station name for PROFINET within a user program, see the following

code example:

...

SNAME("mymotor1")

a=ETH(0)

IF(a&2)

Z 'Execute reset if Station Name changed

ENDIF

...

Configure PLC with PC

Use the following procedure to configure the PLC for communication with the PC. Refer to the

figures in PROFINET Communication Example on page 25.

NOTE: You may skip this section if the PLC is already configured.

1.

Using the PLC configuration software running in a PC, load the SmartMotor’s GSDML

(XML) file, set it up as a PROFINET device from the catalog, and define the correct

Station Name. For more details on the GSDML file, seeSoftware on page 9.

2.

Determine the location of the PLC memory to exchange three words (six bytes) of

PROFINET output to the motor and the seven words (fourteen bytes) of input from the

SmartMotor. The GSDML file defines the three output words and seven input words, but

it does not specify where this is located in the PLC memory. That location is determined

by the configuration tools supplied by the PLC manufacturer.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 21 of 76

Page 22

Configure SmartMotor to PROFINET

Configure SmartMotor to PROFINET

Use the following procedure to configure the SmartMotor to PROFINET. Refer to the PROFINET

Status LEDs on page 19.

1.

Verify the corresponding Link LED is ON (green) with possible occasional flashing, which

indicates there is communication traffic.

2.

After connecting the motor, the System Fail LED should go from solid red to flashing

red, which indicates it is waiting for an I/O controller.

3.

After the I/O controller makes a connection, the System Fail LED turns off.

PLC Sends Commands to Motor

Program the PLC or modify by hand the PLC memory areas, as described below, to send the

desired commands over PROFINET and communicate with the motor.

The following are sequences of commands sent, which show all the intermediary PROFINET

packet output data states.

NOTE: Bold characters indicate changes in the PLC memory output buffer and input

buffer values.

Network Data Format Example

Each byte below is represented as two hexadecimal characters. For example, 7A represents

hex 7A or decimal 122.

COMMAND FROM

I/O CONTROLLER

Cmd

Code

00 7A 0000 0000 .......... 00 00 0000 0000 0680 0000 0000 0000

Resp

Code

Data

Cmd

Code

Ack

Resp

Code

Ack

Resp

Data

The following are the SmartMotor’s Status Word response bit definitions (the response shown

above is 0680).

RESPONSE FROM

SMART MOTOR

Status

Word

Measured

Position

Pos

Error

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 22 of 76

Page 23

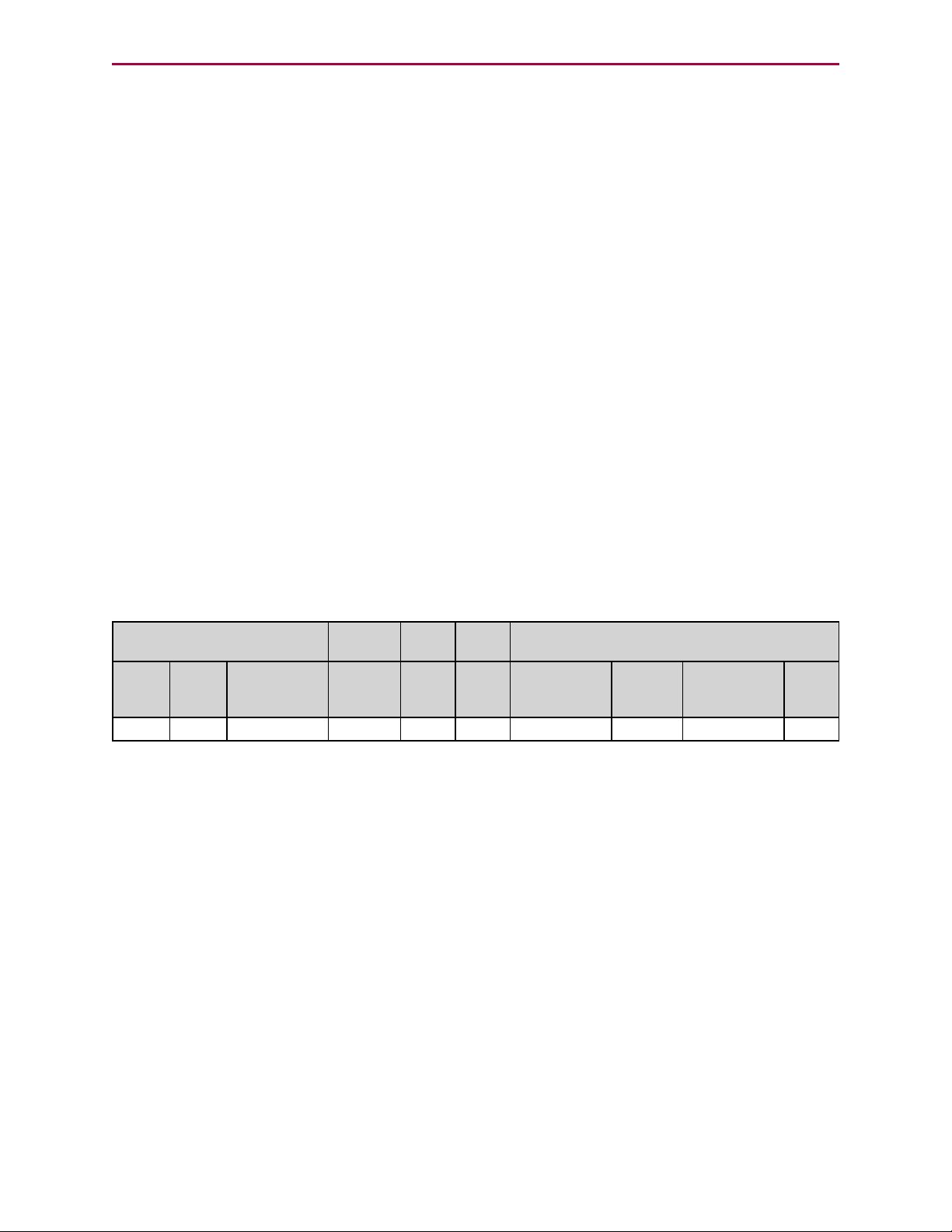

PLCMemory

Bit Description

0 Busy Trajectory

1 Historical + limit (hardware and software limit)

2 Historical - limit (hardware and software limit)

3 Index report available for the rising edge of internal encoder

4 Position wraparound occurred

5 Position error fault

6 Temperature limit fault

7 Drive off

8 Index input active

9 + limit active (hardware and software limit)

10 - limit active (hardware and software limit)

11 Communication error of any type

12 Network user bit, defined by ETHCTL(12,x) command, see User Program

Commands on page 38

13 Command error (includes math and array errors)

14 Peak overcurrent occurred

15 Drive ready

PLCMemory

Each byte below is represented as two hexadecimal characters. For example, 0680 represents

hex 680 or decimal 134.

Output to slave motor: Input from slave motor:

3 two-byte words out 7 two-byte words in

0000 0000 0000 0000 0000 0000 0086 0000 0000 0000

A status word of 0x0680 (which breaks down to the bits 0000 0110 1000 0000) indicates the

servo is off, the left and right limits have been activated, and the drive is not ready.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 23 of 76

Page 24

Sequence to Set Report Data to Motor Clock

Sequence to Set Report Data to Motor Clock

Command

Code

Insert response code 0x7A in the output buffer, which is being transmitted continuously (i.e.,

cyclically) by the master to the slave motor. See Command Packet Codes to Motor Commands

on page 54 to find response code RCLK and its value, hex 7A.

007A 0000 0000 0000 0000 0000 0680 0000 0000 0000

Wait for response code acknowledge in the input buffer, which is being received continuously

(i.e., cyclically) by the master as a response from the slave motor. The clock data begins

being cyclic updates.

007A 0000 0000 007A 0000 03A1 0680 0000 0000 0000

As time goes on, the clock data is updated.

007A 0000 0000 007A 0001 B01A 0680 0000 0000 0000

Response

Code

0x7A RCLK

Data

Command

Motor

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 24 of 76

Page 25

PROFINET Communication Example

PROFINET Communication Example

The following example illustrates PROFINET communications. It sends commands from a PLC

over PROFINET to cause the SmartMotor to continually report its changing clock value to the

PLC. The value is displayed by the PLC registers containing the PROFINET data received from

the motor. It changes as the updated clock value is received.

To create a PROFINET connection to the SmartMotor:

1.

Install the SMI software. For more details, see the Moog Animatics Class 6

SmartMotor™ Installation & Startup Guide.

2.

Connect control power to the 12-pin connector.

a.

Pin 11 is 24 Volt control power.

b.

Pin 12 is Ground or 24 Volt low.

3.

Connect a USBcable from the PC to the USB connector on the SmartMotor. Refer to the

following figure.

USBConnection from PCto SmartMotor

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 25 of 76

Page 26

PROFINET Communication Example

4.

In the SMI software Configuration window, right-click the USB category and select

Detect Motors on USB from the menu.

When detection has completed, Motor 1 will be shown under the USB network.

5.

Double click Motor1 to open the Motor View tool. Click Poll to update the Status.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 26 of 76

Page 27

PROFINET Communication Example

6.

Select the Network tab and then Poll again. Note the default PROFINET name.

7.

Set the station name. Refer to the Terminal window in the following figure.

a.

Execute RETH(0) to get the current Ethernet interface status bit (352 decimal =

160 hex).

b.

Type SNAME("mymotor1") into the Terminal window.

Use the following PROFINET name conventions:

l Characters a-z (lowercase only, uppercase is not permitted)

l Numbers 0-9, but cannot start with a number

l No underscores or other special characters; the hyphen and period are per-

mitted, but not as the first or last character

l No more than 127 characters total or 63 characters as a name component

within the device name (e.g., a character string between two periods); may

be further limited by your configuration software

l Cannot be formatted as an IP address (dotted-decimal notation)

l Cannot begin with the characters "port-nnn-", where "nnn" are three

numeric characters 0-9 (e.g., port-735-)

c.

Execute RETH(0) to get the updated Ethernet interface status bit (354 decimal =

162 hex). After the station name has changed, the status for the report from

RETH(0) should indicate a PROFINET status configuration change on Bit 1 (zero

based). Refer to User Program Commands on page 38.

NOTE: The new station name in the following figure (in the red box)

won't be shown until power is cycled and the motor is redetected. Refer

to the next step.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 27 of 76

Page 28

PROFINET Communication Example

Entering and Verifying the Station Name

8. Cycle motor power to use the new configuration and station name. Refer to the red box

in the previous figure.

9.

Configure your PLC through its serial port using a PC that is running your PLC

configuration software.

a.

Load the motor’s PROFINET GSDML file.

b.

Assign and display the PLC registers associated with the motor’s PROFINET input

and output data.

10.

Connect the PROFINET cable to the PLC and the SmartMotor.

11.

Power cycle the SmartMotor to initialize it with the configured values.

12.

Enter the PROFINET motor response code to report the motor clock in the PLC PROFINET

data registers (i.e., in the "3 words out", the second byte is the motor response code).

a. Using a PC that is running your PLC software, and with your PLC online, enter the

PROFINET response code 122 decimal, x7A hex into the "response code" field.

b.

Watch the clock value being updated in your PLC PROFINET input registers "7

words in", bytes 2-5.

For examples of sending command sequences and communication handshaking, refer to

Sample Command Sequences on page 29.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 28 of 76

Page 29

Sample Command Sequences

Sample Command Sequences

This chapter contains sample PROFINET command sequences.

Overview 30

Command and Response Codes 30

Handshaking of Messages 30

Disabling Limits from Preventing Motion 30

Turning the Motor Shaft 30

Disable Limits and Clear Fault Status 31

Commands 31

PLCMemory 31

Disable positive limit, command EIGN(2) 31

Disable negative limit, command EIGN(3) 32

Clear fault status, command ZS 32

Initiate Mode Torque 33

Commands 33

PLCMemory 33

Set torque value, specify the response data 33

Initiate torque mode, command MT 33

Initiate Relative PositionMove 35

Commands 35

PLCMemory 35

Set acceleration value, command ADT=255 35

Set maximum velocity value, command VT=100000 35

Make a relative position move 36

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 29 of 76

Page 30

Overview

Overview

These sequences illustrate:

l

Disabling limits from preventing motion

l

Turning the shaft in torque mode

l

Moving a relative distance

l

Command and response codes

l

Handshaking of messages

Command and Response Codes

The command and response codes are described in Command Packet Codes to Motor

Commands on page 54 The symbolic command and response codes are listed, along with their

values and the related SmartMotor™ command. See Output and Input Packets on page 44 for

further explanation of how to use the command and response codes.

Handshaking of Messages

Handshaking of output message changes is included in the protocol to ensure coherence in the

packet. See Output and Input Packets on page 44 for an explanation of handshaking.

Disabling Limits from Preventing Motion

At power up, if limit switches are not connected to the motor, the electrical state of the limit

pins will default to indicate that the motor is at the limits. This will prevent motion unless the

limits are disabled and any limit faults are cleared.

These commands may be included in the user program that is downloaded to the motor and

runs at power up. If the user program does not include these commands or the limits are not

held inactive at power-up, before attempting to turn the motor shaft, you must perform the

command sequence described in Disable Limits and Clear Fault Status on page 31.

Turning the Motor Shaft

After disabling the limits and clearing any faults, the shaft may be turned using the following

command sequences:

l

Initiate Mode Torque on page 33

l

Initiate Relative PositionMove on page 35

These sequences are described in following sections.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 30 of 76

Page 31

Disable Limits and Clear Fault Status

Disable Limits and Clear Fault Status

Commands

Command

Code

Response

Code

Data

Resulting

SmartMotor

Command

0x01 0x30 EIGN(2)

0x01 0x33 EIGN(3)

0x01 0x44 ZS

PLCMemory

Output to slave motor: Input from slave motor:

3 words out 7 words in

0000 0000 0000 0000 0000 0000 0680 0000 0000 0000

Cmd

Code

00 7A 0000 0000 .......... 00 00 0000 0000 0680 0000 0000 0000

Resp

Code

Data

Cmd

Code

Ack

Resp

Code

Ack

Resp

Data

Status

Word

Measured

Position

Disable positive limit, command EIGN(2)

Insert command EIGN(2) data = 0x30 in the output buffer, which is being transmitted

continuously (i.e., cyclically) by the master to the slave motor.

Pos

Error

0000 0000 0030 0000 0000 0000 0680 0000 0000 0000

Set command code 0x01 in the output buffer.

0100 0000 0030 0000 0000 0000 0680 0000 0000 0000

Wait for a command code acknowledge in the input buffer, which is being received

continuously (i.e., cyclically) by the master as a response from the slave motor.

0100 0000 0030 0100 0000 0000 0480 0000 0000 0000

The command code acknowledges the motor has received the command.

Clear the command code in the output buffer (handshake) to prepare for the next command.

0000 0000 0030 0100 0000 0000 0480 0000 0000 0000

Wait for acknowledgment of the cleared command code.

0000 0000 0030 0000 0000 0000 0480 0000 0000 0000

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 31 of 76

Page 32

Disable negative limit, command EIGN(3)

Disable negative limit, command EIGN(3)

Insert command EIGN(3) data = 0x33 in the output buffer, which is being transmitted

continuously (i.e., cyclically) by the master to the slave motor.

0000 0000 0033 0000 0000 0000 0480 0000 0000 0000

Set command code 0x01in the output buffer.

0100 0000 0033 0000 0000 0000 0480 0000 0000 0000

Wait for command code acknowledge in the input buffer, which is being received continuously

(i.e., cyclically) by the master as a response from the slave motor.

0100 0000 0033 0100 0000 0000 0080 0000 0000 0000

The command code acknowledges the motor has received the command.

Clear the command code in the output buffer (handshake) to prepare for the next command:

0000 0000 0033 0100 0000 0000 0080 0000 0000 0000

Wait for acknowledgment of the cleared command code.

0000 0000 0033 0000 0000 0000 0080 0000 0000 0000

Clear fault status, command ZS

Insert command ZS data = 0x44 in output buffer, which is being transmitted continuously

(i.e., cyclically) by the master to the slave motor.

0000 0000 0044 0000 0000 0000 0086 0000 0000 0000

Set command code 0x01in the output buffer.

0100 0000 0044 0000 0000 0000 0086 0000 0000 0000

Wait for command code acknowledge in the input buffer, which is being received continuously

(i.e., cyclically) by the master as a response from the slave motor. Fault status is reported

cleared to 0x0080.

0100 0000 0044 0100 0000 0000 0080 0000 0000 0000

The command code acknowledges the motor has received the command.

Clear command code in output buffer (handshake) to prepare for the next command.

0000 0000 0044 0100 0000 0000 0080 0000 0000 0000

Wait for acknowledgment of the cleared command code.

0000 0000 0044 0000 0000 0000 0080 0000 0000 0000

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 32 of 76

Page 33

Initiate Mode Torque

Initiate Mode Torque

Commands

Command

Code

0x94 0xA2 3072 (0x0c00) T=3072

0x01 0xA2 0x21 MT

0x01 0x0C G (begin motion)

Response

Code

Data

RVA (polled motor response)

RVA (polled motor response)

Resulting

SmartMotor

Command

PLCMemory

Output to slave motor: Input from slave motor:

3 words out 7 words in

0000 0000 0000 0000 0000 0000 0080 0000 0000 0000

Set torque value, specify the response data

This will command T=3072 and specify the response data to be the current velocity.

Begin to set torque T=3072 by putting x 00 00 0C 00 in output data.

0000 0000 0C00 0000 0000 0000 0080 0000 0000 0000

Insert command code 0x94 and response code 0xA2.

94A2 0000 0C00 0000 0000 0000 0080 0000 0000 0000

Wait for acknowledge in input buffer:

94A2 0000 0C00 94A2 0000 0000 0080 0000 0000 0000

Now, T=3072 (0x0c00), and the response data value will be velocity. Clear the command code

output buffer (handshake) to prepare for the next command.

00A2 0000 0C00 94A2 0000 0000 0080 0000 0000 0000

Wait for acknowledgment of command code clear in input buffer.

00A2 0000 0C00 00A2 0000 0000 0080 0000 0000 0000

Initiate torque mode, command MT

Insert command 0x21 data to begin torque mode.

00A2 0000 0021 00A2 0000 0000 0080 0000 0000 0000

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 33 of 76

Page 34

Initiate torque mode, command MT

Insert command code 0x01.

01A2 0000 0021 00A2 0000 0000 0080 0000 0000 0000

Wait for command code 1 acknowledgment.

01A2 0000 0021 01A2 0000 0000 0080 0000 0000 0000

Insert command code 0x00.

00A2 0000 0021 01A2 0000 0000 0080 0000 0000 0000

Wait for command code 0 acknowledgment.

00A2 0000 0021 00A2 0000 0000 0080 0000 0000 0000

Insert command 0x0C data to initiate open-loop motion.

00A2 0000 000C 00A2 0000 0000 0080 0000 0000 0000

Insert command code 0x01.

01A2 0000 000C 00A2 0000 0000 0080 0000 0000 0000

When the command is received by the motor, the motor shaft will begin turning if it is not in a

fault state.

Wait for command code acknowledgment in the input buffer.

01A2 0000 000C 01A2 0000 0000 0080 0000 0000 0000

Velocity becomes nonzero, and it is reported as 0x00 14 00 00 in this example. Status

changes are reported as 0x0009 in this example. Position becomes nonzero, and it is reported

as 0x00 00 00 A2 in this example.

01A2 0000 000C 01A2 0014 0000 0009 0000 00A2 0000

Insert command code 0x00 to clear the command code output buffer (handshake) to prepare

for the next command. The position is continually updated. Velocity is a filtered value

measured in:

encoder counts per sample period x 65,536

00A2 0000 000C 01A2 0014 0000 0009 0000 02EE 0000

Wait for the command code clear acknowledge in the input buffer.

00A2 0000 0000 00A2 0014 0000 0009 0000 05DC 0000

Set data to 0.

0000 0000 0000 00A2 0014 0000 0009 0000 05DC 0000

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 34 of 76

Page 35

Initiate Relative PositionMove

Initiate Relative PositionMove

Commands

Command

Code

0x64 255 (0xff) ADT=255

0xA3 100000 VT=100000

0x01 0x1D Change to Mode Position (MP)

0x03 10000 PRT=10000 G

Response

Code

0xA2 RVA (polled motor response)

Data

Resulting

SmartMotor

Command

PLCMemory

Output to slave motor: Input from slave motor:

3 words out 7 words in

0000 0000 0000 0000 0000 0000 0080 0000 0000 0000

Set acceleration value, command ADT=255

Begin to set ADT=255 by putting x00 00 00 FF in output data.

0000 0000 00FF 0000 0000 0000 0080 0000 0000 0000

Insert command code 0x64 and response code 0xA2.

64A2 0000 00FF 0000 0000 0000 0080 0000 0000 0000

Wait for acknowledge in input buffer.

64A2 0000 00FF 64A2 0000 0000 0080 0000 0000 0000

Now, ADT=255, and the response data value will be velocity. Clear the command code output

buffer (handshake) to prepare for the next command.

00A2 0000 00FF 64A2 0000 0000 0080 0000 0000 0000

Wait for acknowledge of command code clear in input buffer.

00A2 0000 00FF 00A2 0000 0000 0080 0000 0000 0000

Set maximum velocity value, command VT=100000

Insert code commanded velocity of VT=100000 = 0x0001 86A0.

00A2 0001 86A0 00A2 0000 0000 0080 0000 0000 0000

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 35 of 76

Page 36

Make a relative position move

Insert command code 0xA3 to set VT=100000.

A3A2 0001 86A0 00A2 0000 0000 0080 0000 0000 0000

Wait for command code acknowledge in the input buffer.

A3A2 0001 86A0 A3A2 0000 0000 0080 0000 0000 0000

Insert command code 0x00.

00A2 0001 86A0 A3A2 0000 0000 0080 0000 0000 0000

Wait for command code acknowledge in the input buffer.

00A2 0001 86A0 00A2 0000 0000 0080 0000 0000 0000

Insert data 0x0000 001D for MP when command is 1.

00A2 0000 001D 00A2 0000 0000 0080 0000 0000 0000

Insert command code 0x01.

01A2 0001 86A0 00A2 0000 0000 0080 0000 0000 0000

Wait for command code acknowledge in the input buffer.

01A2 0001 86A0 01A2 0000 0000 0080 0000 0000 0000

Insert command code 0x00.

00A2 0001 86A0 01A2 0000 0000 0080 0000 0000 0000

Make a relative position move

Insert data for a relative move of 10,000 counts = 0x0000 2710.

00A2 0000 2710 00A2 0000 0000 0080 0000 0000 0000

Insert command code value 0x03.

03A2 0000 2710 00A2 0000 0000 0080 0000 0000 0000

Wait for command code acknowledge in the input buffer.

03A2 0000 2710 03A2 0000 0000 0080 0000 0000 0000

The motor performs its move. While the trajectory is in the slew phase, you will see

something like:

03A2 0000 2710 03A2 0001 86AD 0009 0000 CA23 0011

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 36 of 76

Page 37

which is the following input data:

command code acknowledge 03

response code acknowledge A2

response data current 0001 86AD

velocity (100,000 in slew)

status 0009

Bt = 1

Bi = 1

measured current position 0000 CA23

measured current position error 0011

Make a relative position move

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 37 of 76

Page 38

User Program Commands

User Program Commands

The SmartMotor's EEPROM can store nonvolatile PROFINET information about the network.

For proper PROFINET operation, each SmartMotor must have a unique station name set with

the SNAME instruction. This is can be accomplished: at the PLC over PROFINET; with SMI and

a USB connection over channel 8, or RS-485 on channel 0; with a SmartMotor user program.

NOTE: Nonvolatile memory will be read at power-up or after the Z (reset)

command has been executed.

The following sections list the commands used to operate the motor on a PROFINET network.

SNAME("string") 39

IPCTL(function,"string") 39

=ETH, RETH 39

ETHCTL(function, value) 42

Program Example 43

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 38 of 76

Page 39

SNAME("string")

SNAME("string")

Set PROFINET Station Name

The SNAMEcommand is used to set a unique PROFINET station name. The setting is

nonvolatile. It can use up to 54 characters; the factory default is smc6dev01. It will set the

configuration change bit (Bit 1) returned by the ETH/RETH command (see below) if the Station

Name has changed from the previous value in EEPROM.

Use the following PROFINET name conventions:

l Characters a-z (lowercase only, uppercase is not permitted)

l Numbers 0-9, but cannot start with a number

l No underscores or other special characters; the hyphen and period are permitted, but

not as the first or last character

l No more than 127 characters total or 63 characters as a name component within the

device name (e.g., a character string between two periods); may be further limited by

your configuration software

l Cannot be formatted as an IP address (dotted-decimal notation)

l Cannot begin with the characters "port-nnn-", where "nnn" are three numeric characters

0-9 (e.g., port-735-)

IPCTL(function,"string")

Sets IP address, Mask, or Gateway

The IPCTLcommand is used to set the IPaddress, subnet mask or gateway. The setting is

nonvolatile. This command is not usually needed. Typically, the PLC will handle these settings

during PROFINET network initialization.

The possible function values are:

0: set IP address

1: set Mask

2: set Gateway

The "string" is formatted as an IP address, e.g., IPCTL(0,"192.168.0.10"). By default, these

values are set to 0 (i.e., "0.0.0.0").

=ETH, RETH

Get PROFINET error

The =ETH and RETH commands are used to assign/report errors and certain status

information for the PROFINET bus.

l

Assigned to a program variable: x=ETH(y)

l

As a report: RETH(y)

Refer to the following table for details.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 39 of 76

Page 40

=ETH, RETH

Assignment Report Description

=ETH(0) RETH(0) Gets the PROFINET status bits:

0 Initialization incomplete

Read specific error code from ETH(54);

Contact Moog Animatics

(Confirm SNAME setting if encountering a problem)

1 Configuration change

2 Reserved

3 Network processor failure

Likely due to excessive control power supply noise or ESD

event

4 Reserved

5 Reserved

6 I/O Controller is STOP

7 I/O Controller is RUN

8 I/O Controller aborted cyclic communications

9 Network commanded configuration change

=ETH(5) RETH(5) LFW firmware version as 32-bit integer; e.g., 3.1.0.1 would be a

value 50397185 (0x03010001).

=ETH(6) RETH(6) The current Network Lost program label number. For details, see

ETHCTL(function, value) on page 42.

=ETH(7) RETH(7) Processor type:

-1 Failed

0 Unknown

1 netX 10

2 netX 50

3 netX 51/52

4 netX 100

=ETH(8) RETH(8) Protocol type after successful initialization (Confirm SNAME set-

ting if encountering a problem) See also RETH(19)

0 Not defined

1 PROFINET

2 EtherCAT

3 EtherNet/IP

=ETH(9) RETH(9) The current value assigned to the Network Lost action. For

details, see ETHCTL(function, value) on page 42.

RETH(15) IP address; value is in dotted-decimal format; report only.

RETH(16) Subnet mask; value is in dotted-decimal format; report only.

RETH(17) Gateway; value is in dotted-decimal format; report only.

RETH(18) MAC ID string formatted; report only; e.g., 00:01:02:a9:ff:00

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 40 of 76

Page 41

=ETH, RETH

Assignment Report Description

=ETH(19) RETH(19)

Report the detected LFW ProtocolClass. This gives a wider range

of values than the known and supported protocols listed in ETH

(8). Values designated according to NXF/LFW file loaded into

network processor and too numerous to list here. These are the

values for the supported protocols: (introduced in firmware

6.0.2.41 or later)

0 Not Defined

21 PROFINET

9 EtherCAT

10 Ethernet/IP

... ...

=ETH(30) RETH(30) Gets the present receive I/O data size in bytes

=ETH(31) RETH(31) Gets the present transmit I/O data size in bytes

=ETH(45) RETH(45) IP address as integer; e.g., for an IP address of 192.168.1.3 (C0

A8 01 03 hex), this command reports -1062731517 (it reports as a

32-bit signed value).

=ETH(46) RETH(46) IP subnet mask as integer; e.g., for an IP netmask of 255.255.0.0

(FF FF 00 00 hex), this command reports -65536 (it reports as a

32-bit signed value).

=ETH(47) RETH(47) IP gateway as integer; e.g., for an IP gateway of 192.168.1.1 (C0

A8 01 01 hex), this command reports -1062731519 (it reports as a

32-bit signed value).

=ETH(48) RETH(48) Low 3 bytes of MAC ID (device ID) as integer; e.g., for a MACID

of 00:01:02:a9:ff:00, this command reports 11140864 (00 a9 ff

00 hex).

=ETH(49) RETH(49) High 3 bytes of MAC ID (device ID) as integer; e.g., for a MACID

of 00:01:02:a9:ff:00, this command reports 258 (00 00 01 02

hex).

=ETH(50) RETH(50) Gets the last internal error code

=ETH(51) RETH(51) Gets the last internal error code source

=ETH(54) RETH(54) Gets the Initialization error code; for further information, read

this error when RETH(0) bits 0 or 1 are indicated, or when RETH

(8) returns 0.

The value -1070596029 indicates an invalid SNAMEformat was

used.

=ETH(57) RETH(57) Gets the real-time Ethernet sync correction

=ETH(58) RETH(58) Gets the real-time Ethernet sync count

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 41 of 76

Page 42

ETHCTL(function, value)

ETHCTL(function, value)

Control network features

Commands execute based on the function argument, which controls Ethernet functions. After

issuing an ETHCTL command the Ethernet error codes will be checked to determine the state

of Status Word 2, bit 6 (Ethernet error).

Command Description

ETHCTL(1,TBD)

...

ETHCTL(5,TBD)

ETHCTL(6,<value>)

ETHCTL(7,TBD) Reserved for future use.

ETHCTL(8,TBD) Reserved for future use.

ETHCTL(9,<value>) PROFINET Network Lost Action. This setting is nonvolatile.

Reserved for future use.

User program label number. This setting is nonvolatile.

Program label to jump to if the NET_LOST_LABEL option is chosen

from the NET_LOST_ACTION function.

This function has no effect if the NET_LOST_ACTION is anything other

than NET_LOST_LABEL.

0 Ignore, no action (default setting)

1 Send OFF command to motor

2 Send X command to motor (soft stop)

3 Send S command to motor (immediate stop)

Send GOSUB(x) command, where x is the value of the user

4

program label.

Send GOTO(x) command, where x is the value of the user pro-

5

gram label.

NOTE: Loss of network is an edge-triggered event if I/O Control goes

from RUN to any other state.

ETHCTL(10,x) Allows the position field of 14 byte (7 word) input module to be recon-

figured for alternate data from the motor. See 240, xF0 on page 60.

ETHCTL(11,TBD) Reserved for future use.

ETHCTL(12,<value>) Network user bit set or clear. This is a bit in the status word of the 14

byte (7 word) input module. Also visible in response code 164 "legacy

status word":

0 Clear Bit 12 of SmartMotor I/O Network Bit

1 Set Bit 12 of SmartMotor I/O Network Bit

ETHCTL(45,x) Set IP address as integer; e.g., to set for an IP address of

192.168.1.3 (C0 A8 01 03 hex), x=3232235779; non-volatile.

ETHCTL(46,x) Set IP subnet mask as integer; e.g., to set for an IP netmask of

255.255.0.0 (FF FF 00 00 hex), x=4294901760; non-volatile.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 42 of 76

Page 43

Program Example

Command Description

ETHCTL(47,x) Set IP gateway as integer; e.g., to set for an IP gateway of

192.168.1.1 (C0 A8 01 01 hex), x=3232235777; non-volatile.

ETHCTL(50,<value>) Resets the internal error register: RETH(50); the value argument is

ignored.

ETHCTL(51,<value>) Resets the internal error register: RETH(51); the value argument is

ignored.

ETHCTL(58,<value>) Clears the real-time Ethernet sync count

Program Example

The following code example sets the nonvolatile station name.

SNAME("mymotor1")

a=ETH(0)

IF( a&2 )

Z 'Execute reset if station name changed

ENDIF

'Add rest of program below

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 43 of 76

Page 44

Output and Input Packets

Output and Input Packets

This section describes the PROFINET Output and Input packet format. It also provides notes

for the Command (Output) packets and Response (Input) Packets.

Output and Input Packet Format 45

Command (Output) Packet Notes 50

Response (Input) Packet Notes 51

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 44 of 76

Page 45

Output and Input Packet Format

Output and Input Packet Format

Two options exist for the input/output packet size:

l 3 words (6 bytes) out, 7 words (14 bytes)in

l 12 words (24 bytes) out, 28 words (56 bytes) in

This option is only available with firmware 6.0.2.41 or later, and requires XML (GSDML)

date -20190118 or later. The I/O controller (PLC) will have an interface for loading the

XML file and choosing these options for the input and output packets. Some tools may

provide a drag-and-drop interface for selecting the available modules from the XML file

and placing them into the 2 available slots in the motor.

NOTE: Only the two combinations of specific in/out sizes are allowed. For example,

3 words out cannot be used with 28 words in.

Output (3 Words) Data Format (I/O Controller Command)

Offset

Description Notes

Word Byte

0 0 Command Code

1 Response Code

1 2 Command Data Value (32 bits), big-endian format

3

2 4

5

Input (7 words) Data Format (Motor response)

Offset

Description Notes

Word Byte

0 0 Command Code Acknowledge

1 Response Code Acknowledge

1 2 Response Data Value (32 bits), big-endian format

3

2 4

5

3 6 Status Word (16 bits), big-endian format

7

Affected by

byte / word

swap

parameter

N/A

N/A

Yes

Affected by

byte / word

swap

parameter

N/A

N/A

Yes

Yes

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 45 of 76

Page 46

Output and Input Packet Format

Offset

Description Notes

Word Byte

4 8 Measured Position (32 bits), big-endian format

9

5 10

11

6 12 Position Error (16 bits), big-endian format

13

Command Code: Indicates a command to be issued to the SmartMotor. Also, see Command

Data Value.

Response Code: Indicates additional data to be included in the Response Data Value of the

Input Data.

Command Data Value: Indicates the 32-bit value to be used in conjunction with the

Command Code.

Command Code Acknowledge: Returned in the Input Data to indicate that a Command

Code was processed.

Response Code Acknowledge: Returned in the Input Data to indicate that a Response Code

was processed and that the current Response Data Value corresponds to that Response Code.

NOTE:This field can be configured to report al[0] or af

[0].

Affected by

byte / word

swap

parameter

Yes

Yes

Response Data Value: 32-bit value returned in the Input Data in response to a Response

Code.

Status Word: SmartMotor's current status word (16 bit).

Measured Position: SmartMotor's current measured position value (32-bit); result of RPA

command.

Position Error: SmartMotor’s current commanded trajectory position less the current

measured position.

Extended format: 12 words (24 bytes) out, 28 words (56 bytes) in. This format was created

for the purpose of easier access to reading data cyclically from the motor. Up to 8 response

data items can be read on every cycle, though the first reponse item is required for certain

special items, see notes.

There is still only 1 command code item because most commands require a sequence of

events to operate correctly, and multiple fields could cause conflict.

The command and response codes have been extended to 16-bit values in this extended

format. This allows for a wider set of codes and direct access to variables. See Extended 16bit command codes on page 61, and Extended 16-bit response codes on page 69.

Several pre-set fields have been removed from the extended format: position, status word,

position error. These are still available in the list of response codes (codes 141, 164, 143

respectively), and can be selected by setting those response request codes in the output data.

Position error is a full 32-bit when accessed by this method.

NOTE: The PROFINET SmartMotor supports the byte/word swap parameter as of

firmware 6.0.2.41 or later

Output (12 Words) Data Format (I/O Controller Command)

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 46 of 76

Page 47

Output and Input Packet Format

Offset

Description Notes

Word Byte

0 0 Reserved (write as 0x00)

1 Reserved (write as 0x00)

1 2 Command Data Value (32 bits)

3

2 4

5

3 6 Command code request (16 bits) Yes

7

4 8 Response code 0 request (16 bits)

9

5 10 Response code 1 request (16 bits) 2 Yes

11

6 12 Response code 2 request (16 bits) 2 Yes

13

7 14

15

See note 1: some codes must use of this section

Response code 3 request (16 bits) 2 Yes

4 N/A

4 N/A

1 Yes

Affected by

byte / word

parameter

Yes

swap

8 16 Response code 4 request (16 bits) 2 Yes

17

9 18 Response code 5 request (16 bits) 2 Yes

19

10 20 Response code 6 request (16 bits) 2 Yes

21

11 22 Response code 7 request (16 bits) 2 Yes

23

Input (28 words) Data Format (Motor response)

Offset

Description Notes

Word Byte

0 0 Reserved (reports as 0xFF)

1 Reserved (reports as 0xFF)

1 2 Reserved (ignore, reports as 0)

3

Reserved (ignore, reports as 0) N/A

3 N/A

3 N/A

Affected by

byte / word

N/A

swap

parameter

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 47 of 76

Page 48

Output and Input Packet Format

Offset

Description Notes

Word Byte

2 4

5

3 6

7

4 8

9

5 10

11

6 12

13

7 14 Response code 3 ack (16 bits) 2 Yes

15

8 16 Response code 4 ack (16 bits) 2 Yes

17

Reserved (ignore, reports as 0) N/A

Reserved (ignore, reports as 0) N/A

Command code ack (16 bits) Yes

Response code 0 ack (16 bits)

See note 1: some codes must use of this section

Response code 1 ack (16 bits) 2 Yes

Response code 2 ack (16 bits) 2 Yes

1 Yes

Affected by

byte / word

parameter

swap

9 18 Response code 5 ack (16 bits) 2 Yes

19

10 20 Response code 6 ack (16 bits) 2 Yes

21

11 22 Response code 7 ack (16 bits) 2 Yes

23

12 24 Response data 0 (32 bits)

25

13 26

27

14 28 Response data 1 (32 bits) Yes

29

15 30

31

16 32 Response data 2 (32 bits) Yes

33

17 34

See note 1: some codes must use of this section

Yes

35

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 48 of 76

Page 49

Output and Input Packet Format

Offset

Description Notes

Word Byte

18 36 Response data 3 (32 bits) Yes

37

19 38

39

20 40 Response data 4 (32 bits) Yes

41

21 42

43

22 44 Response data 5 (32 bits) Yes

45

23 46

47

24 48 Response data 6 (32 bits) Yes

49

Affected by

byte / word

parameter

swap

25 50

51

26 52 Response data 7 (32 bits) Yes

53

27 54

55

NOTE: 1) This response request code location is allowed to include attributes

(request codes) 214-225 (special access to variables and EEPROM). It is

recommended to reserve this slot for this type of access. For constantly read

information, like access to variables (using response codes above 255), position,

etc., use response code locations 1-7 instead.

NOTE: 2) This response request code location is not allowed to use attributes

(request codes) 214-225, an error code (255) will result. These request code

locations 1-7 are recommended for information that must be read every cycle, like

a variable, position, velocity, current, etc.

NOTE: 3) These fields report 255 as protection so that the data will be interpreted

as an error if PLC program / controller reads this and attempts to interpret as 14byte input format. It is also helpful for the PLC program / controller to read this

when the 56 byte input mode is intended because it will provide confirmation by

reporting 255. A PLC program could use this as a verification check.

NOTE: 4) You must write 0 to these fields. If any other value is written, then the

remainder of the output packet will be ignored. This is for protection in case the

PLC/Controller is attempting to write in the 6 byte output format but has the 24byte format configured.

Moog Animatics Class 6 PROFINET Guide Rev. D

Page 49 of 76

Page 50

Command (Output) Packet Notes

Command (Output) Packet Notes

The following are notes regarding the Command (Output)Packets:

l

A command is issued to the SmartMotor exactly one time after the Command Code or

Command Data Value changes in the output data. To issue a command:

a.

Set the Command Code to 0.

b.

Wait for Command Code Acknowledge = 0.

c.

Set the Command Data Value to the desired value.

d.

Set the Command Code to the desired command.

e.

Wait for Command Code Acknowledge = Command Code.

l

For <value>, insert the Command Data Value.

l

For the variables <a to zzz>:

l

<a to z> u8VarIndexSet (0-25)

l